Page 1

User’s

Manual

Model PH100

Panel Mount pH Converter

IM 12B11A01-01E

IM 12B11A01-01E

1st Edition

Page 2

r Introduction

This manual covers the specifications, installation, operation and maintenance of the

panel-mount version of the PH100 pH converter. Please read this before using the PH100.

There are manuals for the related EXA100 series as follows:

Refer to them as required.

Model code Manual Name IM No.

PH100 Panel Mount pH Converter IM 12 B11A01-01E

OR100 Panel Mount ORP Converter IM 12 C11A01-01E

SC100 Panel Mount Conductivity Converter IM 12 D11A01-01E

PH10FP KCl Refillable pH Sensor IM 12 B11C01-01E

PH10RP KCl Replenish-free pH Sensor IM 12 B11C02-01E

OR10FP KCl Refillable ORP Sensor IM 12 C11C01-01E

OR10RP KCl Replenish-free ORP Sensor IM 12 C11C02-01E

SC10XB Conductivity Sensor for SC100 IM 12 D11C01-01E

WTB100 Terminal Box for EXA100 IM 12 B11E01-01E

WF100 Extension Cable for EXA100 IM 12 B11F01-01E

PH10HLD Immersion Holder for EXA100 IM 12 B11D01-01E

PH10HG Guide-pipe Holder for EXA100 IM 12 B11D02-01E

T000.eps

Safety Precautions

IM 12B11A01-01E

1st Edition: Apr. 2003 (YK)

All Rights Reserved, Copyright © 2003, Yokogawa Electric Corporation

IM 12B11A01-01E

i

Page 3

r For the safe use of this equipment

(1) About This Manual

• This manual should be passed on to the end user.

• The contents of this manual are subject to change without prior notice.

• The contents of this manual shall not be reproduced or copied, in part or in whole,

without permission.

• This manual explains the functions contained in this product, but does not warrant that

they will suit the particular purpose of the user.

• Every effort has been made to ensure accuracy in the preparation of this manual.

However, should any errors or omissions come to the attention of the user, please

contact the nearest Yokogawa Electric representative or sales office.

• This manual does not cover the special specifications. This manual may be left

unchanged on any change of specification, construction or parts when the change does

not affect the functions or performance of the product.

• If the product is used in a manner not specified in this manual, the safety of this

product may be impaired.

(2) Safety and Modification Precautions

• Follow the safety precautions in this manual when using the product to ensure protection and safety of personnel, product and system containing the product.

(3) The following safety symbols are used on the product as well as in this manual.

DANGER

This symbol indicates that the operator must follow the instructions laid out in this

manual in order to avoid the risk of personnel injury, electric shock, or fatalities. The

manual describes what special care the operator must exercise to avoid such risk.

WARNING

This symbol indicates that the operator must refer to the instructions in this manual in

order to prevent the instrument (hardware) or software from being damaged, or a system

failure from occurring.

CAUTION

This symbol draws attention to information essential for understanding the operation and

functions.

Tip

This symbol gives information that complements the current topic.

SEE ALSO

This symbol identifies a source to which to refer.

Protective Ground Terminal

Function Ground Terminal (Do not use this terminal as the protective ground

terminal.)

Alternating current

ii

IM 12B11A01-01E

Page 4

r NOTICE and Cautions

• Check specifications

When the instrument arrives, unpack the package with care and check that the

instrument has not been damaged during transportation. In addition, please check that

the specification matches the order, and required accessories are not missing. Specifications can be checked by the model codes on the nameplate. Refer to Chapter 1.2

Specifications for the list of model codes.

• Details on operation parameters

When the PH100 panel mount pH Converter at the user site, it will operate based on

the operation parameters (initial data Table 5.1 to 5.5) set before shipping from the

factory.

Ensure that the initial data is suitable for the operation conditions before conducting

analysis. Where necessary, set the instrument parameters for appropriate operation.

For details of setting data, refer to chapters 4 to 5.

When user changes the operation parameters, it is recommended to note down the

changed setting data.

Safety Precautions

Front Panel of PH100

IM 12B11A01-01E

iii

Page 5

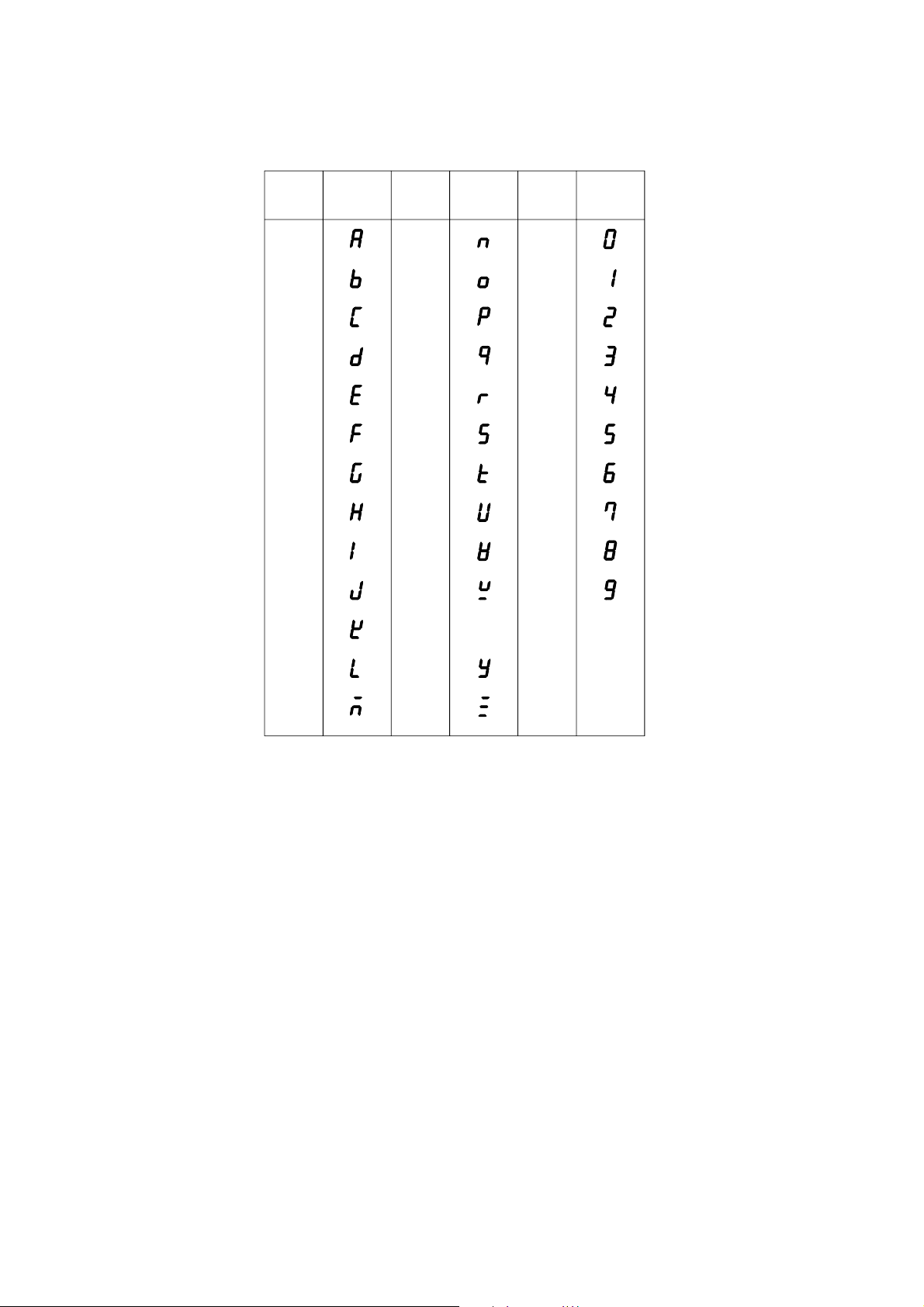

LED Display Symbols

• Alphanumerics are represented as follows on the LED display

Alphanumerics Alphanumerics AlphanumericsLED Display LED Display LED Display

A

B

C

D

E

F

G

H

I

J

K

L

N

O

P

Q

R

S

T

U

V

W

0

1

2

3

4

5

6

7

8

9

X

Y

M

Z

iv

IM 12B11A01-01E

Page 6

r After-sales Warranty

d During the warranty period, for repair under warranty carry or send the product to the

local sales representative or service office. Yokogawa will replace or repair any

damaged parts and return the product to you.

d Before returning a product for repair under warranty, provide us with the model

name and serial number and a description of the problem. Any diagrams or data

explaining the prpoblem would also be appreciated.

d If we replace the product with a new one, we won’t provide you with a repair report.

d Yokogawa warrants the product for the period stated in the pre-purchase quotation.

Yokogawa shall conduct defined warranty service based on its standard. When the

customer site is located outside of the service area, a fee for dispatching the maintenance engineer will be charged to the customer.

d In the following cases, customer will be charged repair fee regardless of warranty

period.

• Failure of components which are out of scope of warranty stated in instruction

manual.

Safety Precautions

• Failure caused by usage of software, hardware or auxiliary equipment, which

Yokogawa Electric did not supply.

• Failure due to improper or insufficient maintenance by user.

• Failure due to modification, misuse or outside-of-specifications operation which

Yokogawa does not authorize.

• Failure due to power supply (voltage, frequency) being outside specifications or

abnormal.

• Failure caused by any usage out of scope of recommended usage.

• Any damage from fire, earthquake, storms and floods, lightning, disturbances, riots,

warfare, radiation and other natural changes.

d Yokogawa does not warrant conformance with the specific application at the user

site. Yokogawa will not bear direct/indirect responsibility for damage due to a specific

application.

d Yokogawa Electric will not bear responsibility when the user configures the product

into systems or resells the product.

d Maintenance service and supplying repair parts will be covered for five years after

the production ends. For repair for this product, please contact the nearest sales office

described in this instruction manual.

IM 12B11A01-01E

v

Page 7

vi

IM 12B11A01-01E

Page 8

Contents

r Introduction ...................................................................................................................... i

r For the safe use of this equipment ................................................................................ ii

r NOTICE and Cautions ..................................................................................................iii

r After-sales Warranty ...................................................................................................... v

1. Overview .....................................................................................................................1-1

1.1 EXA PH100 pH converter .............................................................................. 1-1

1.2 Check the specifications ................................................................................. 1-1

1.3 Features of the EXA PH100 pH converter..................................................... 1-2

1.4 Standard Specifications ................................................................................... 1-2

2. Preparation for Operation ........................................................................................2-1

2.1 Unpacking ....................................................................................................... 2-1

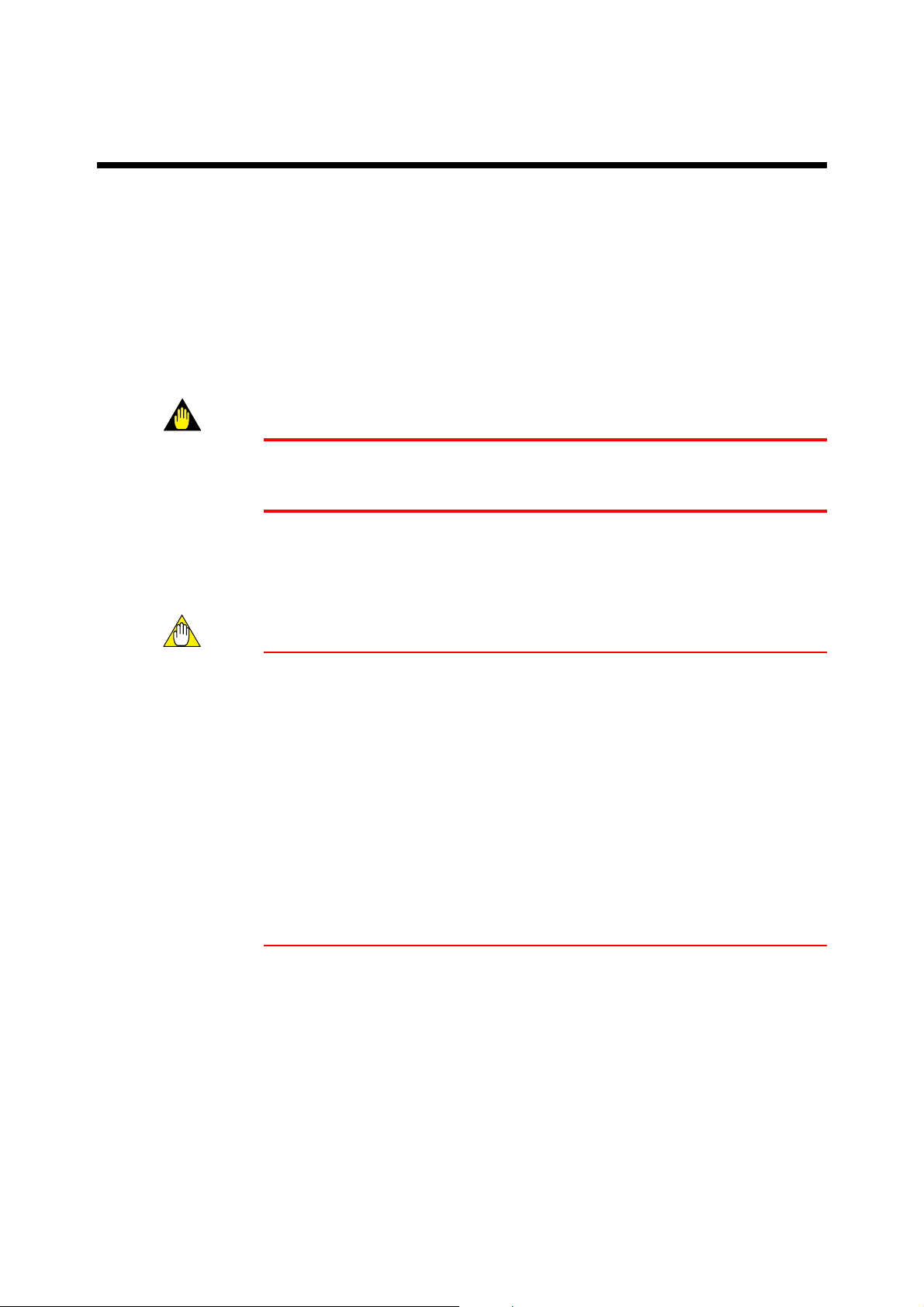

2.2 Choosing an Installation Location .................................................................. 2-1

2.3 External Dimensions ....................................................................................... 2-2

2.4 Panel Cutout Dimensions................................................................................ 2-3

2.5 Mounting ......................................................................................................... 2-4

3. Wiring..........................................................................................................................3-1

3.1 Pulling in Wiring............................................................................................. 3-2

3.2 Noise prevention ............................................................................................. 3-3

3.3 Wiring Terminal Diagram............................................................................... 3-4

3.4 pH detector wiring .......................................................................................... 3-7

3.5 Wiring cable to intermediate terminal box..................................................... 3-9

3.6 Output Signal Cable Wiring ........................................................................... 3-9

3.7 Contact output wiring. .................................................................................... 3-9

3.7.1 Wiring when S1 is used .......................................................................... 3-9

3.7.2 Wiring for S2 (for two-contact-output case) or S2,

S3 and S4 (four-contact output case).................................................... 3-11

3.8 Power and Ground Wiring ............................................................................ 3-12

4. Overview of Operation Panel ................................................................................... 4-1

4.1 Overviews of names and functions of operation panel keys ......................... 4-1

4.2 Key Operation ................................................................................................. 4-2

4.3 Switching display screens ............................................................................... 4-3

4.4 Display screen examples ................................................................................. 4-4

4.4.1 Initial display ........................................................................................... 4-4

4.4.2 Measurement screen ................................................................................ 4-5

4.4.3 Calibration screen .................................................................................... 4-6

4.4.4 Setting screen........................................................................................... 4-7

IM 12B11A01-01E

vii

Page 9

5. Operation .................................................................................................................... 5-1

5.1 Start up ............................................................................................................ 5-1

5.1.1 Check wiring ........................................................................................... 5-1

5.1.2 Start up pH converter .............................................................................. 5-1

5.1.3 Data setting .............................................................................................. 5-1

5.1.4 Temperature Calibration........................................................................ 5-10

5.1.5 Calibration with Standard Liquid.......................................................... 5-10

5.2 Test Operation ............................................................................................... 5-11

5.3 Normal operation .......................................................................................... 5-11

5.4 Stopping and Restarting Operation............................................................... 5-11

6. Calibration with standard solution .......................................................................... 6-1

6.1 Important issues relating to calibration with standard solution ..................... 6-1

6.2 Calculations involved in Calibration with Standard Solution........................ 6-2

6.3 Preparation ....................................................................................................... 6-5

6.4 Auto calibration with standard solution .......................................................... 6-8

6.4.1 Setting parameters for auto calibration ................................................... 6-8

6.4.2 Procedure for auto calibration ................................................................. 6-8

6.5 Manual Calibration with Standard Solution ................................................. 6-12

6.5.1 Manual Calibration Parameter Settings ................................................ 6-12

6.5.2 Procedure for Manual Calibration......................................................... 6-12

6.6 Canceling Calibration .................................................................................... 6-14

6.7 Error during Calibration................................................................................ 6-14

6.7.1 Recovering from an Error ..................................................................... 6-14

6.7.2 Quitting calibration................................................................................ 6-14

7. Maintenance and Cleaning ....................................................................................... 7-1

7.1 Periodic Maintenance...................................................................................... 7-1

7.1.1 Electrode cleaning ................................................................................... 7-1

7.1.2 Calibration with Standard Liquid............................................................ 7-1

7.1.3 Checking the KCl in the Detector........................................................... 7-1

7.2 Preventative Maintenance ............................................................................... 7-2

7.2.1 PH Converter Terminal Isolation ............................................................ 7-2

7.2.2 Check the Display of the pH Converter ................................................. 7-2

8. Troubleshooting .......................................................................................................... 8-1

8.1 Unexpected value displayed

(narrowing down problem to converter or sensor) ........................................ 8-1

8.2 Error Display ................................................................................................... 8-4

8.3 Fixing Error Status .......................................................................................... 8-4

8.3.1 Error 1 pH Measurement Out of Range ................................................ 8-4

8.3.2 Error 2 Temperature Measurement Out of Range................................. 8-4

8.3.3 Error 3 Temperature Sensor Abnormal ................................................. 8-5

8.3.4 Converter Abnormal ................................................................................ 8-5

8.3.5 Calibration Error...................................................................................... 8-5

8.3.6 Asymmetry Potential Abnormal.............................................................. 8-6

8.3.7 Abnormal Slope of sensor emf characteristic ......................................... 8-6

8.3.8 Unstable Sensor Reading ......................................................................... 8-6

Revision Record .................................................................................................................... i

viii

IM 12B11A01-01E

Page 10

1. Overview

1.1 EXA PH100 pH converter

The EXA PH100 pH converter is a panel-mount unit with built-in general-purpose

preamp, large 4-digit LED display for measured value and 4-digit LED display for

settings.

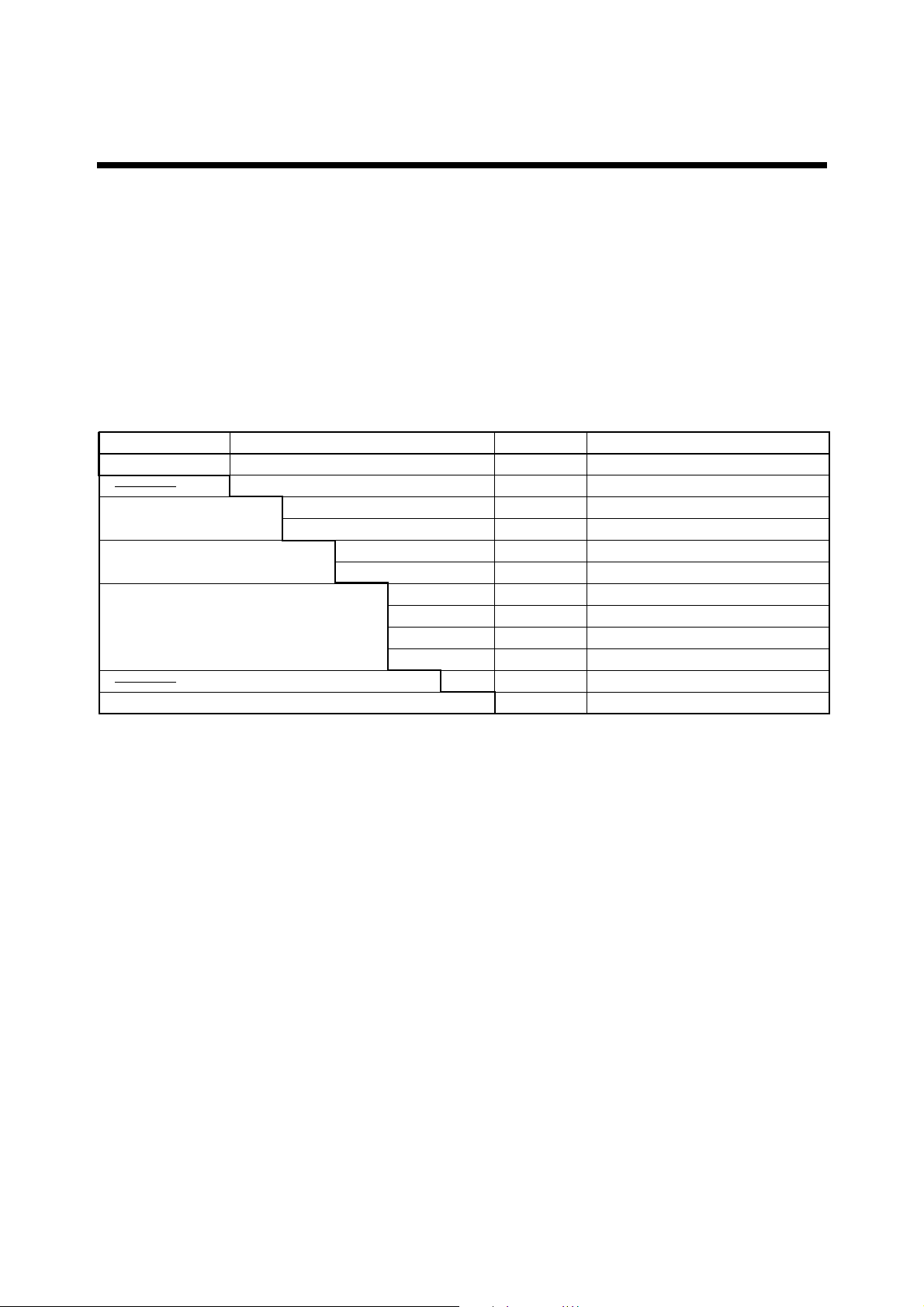

1.2 Check the specifications

The model number and suffix codes are shown below. Check that what you were

supplied is the same as what you ordered.

1. Overview

Model

PH100

Label language

Contact output

Temperature

sensor

Option

Suffix code Option code Description

Panel mounted pH converter

-A

-E

-J

-21

-41

-T1

-T2

-T3

-T4

-NN

Construction

Always -A

English

Japanese

2 contact outputs

4 contact outputs

Pt1000/Pt100

Pt1000/500 Ω

Pt1000/10 kΩ

Pt1000/6.8 kΩ

Always -NN

IP65/65

T1.2E.EPS

IM 12B11A01-01E

1-1

Page 11

1.3 Features of the EXA PH100 pH converter

(1) Large 4-digit display. Both measured pH value and temperature can be displayed at

the same time.

(2) You can easily calibrate the unit with pH4, pH7 or pH9 standard solution.

(3) You can select either two output contacts or four ; and you can select each contact

output type from : high, low, high high, low low, and high high / low low.

(4) Isolated 4 to 20 mA analog output of measured value.

(5) Calibration values and measured values can be read to 0.01 pH, making high accuracy

measurement and calibration possible.

(6) The operation panel is rated for operation in an IP55. IP65 is optional.

(7) 96 mm x 96 mm DIN size panel mount instrument. Depth is 120 mm and weight is

600 g.

(8) Full set of self-diagnostic functions with indication of errors such as measurement

out of range, converter abnormal, calibration-time error.

1.4 Standard Specifications

Measurement : Hydrogen ion concentration (pH) of a solution

Measuring range : -2.00 to 14.00 pH Indication

Display

Display : Digital (LED)

Range : -2.00 to 16.00 pH

Resolution : 0.01 pH (pH reading), 1 8C (temperature reading)

Indication items : pH reading, setting, status, temperature *

*1: Indication “enabled/disabled” selectable

Input signal

pH input range : -2 to 16 pH

pH input impedance : 1012 V or more

Temperature input *2 : Pt1000/Pt100, Pt1000/500 V, Pt1000/10 kV, Pt1000/6.8 kV

*2 : Must be specified when ordering.

Temperature input range : -10 to 110 8C

Transmission signal output

Number of output points : 1 output, pH reading only

Output signal : 4 to 20 mA DC, isolated

Load resistance : 600V or less

Transmission signal range : Configurable within pH-2.0 to pH 16.0 (Detault : pH0.0 to

pH 14.0)

Minimum span : 2 pH

Maintenance output signal : Output hold “enabled/disabled” selectable

Hold output value : Last measured value/preset value (2.0 to 20.8 mA) selectable

Fail output signal : Downscale burnout (2 mA) “enabled/disabled” selectable

1

1-2

IM 12B11A01-01E

Page 12

Contact output

Contact type : Relay contact output

Number of contacts : 2 or 4 outputs (must be specified when ordering)

Contact action : On/Off action

Contact functions : Selectable; High, low, high-high, low-low, high-high/low-low limit

alarms, FAIL

Contact output hysteresis : 0.0 to 4.0 pH (configurable)

Contact output delay time : 0 to 200 seconds (configurable)

Contact rating : When 2 contact outputs specified

S1 : 240 VAC 3A or 30 V DC 3A (resistance load), Form C (NC/NO/COM, 3

terminals)

S2 : 240 VAC 3A or 30 V DC 3A (resistance load), Form A

When 4 contact outputs specified

S1 : 240 VAC 3A or 30 V DC 3A (resistance load), Form C (NC/NO/COM, 3

terminals)

S2, S3, S4 : 240 V AC 3A or 30 V DC 3A (resistanceload), Form A, shared common

Maximum load current on common is 3A.

Contact status:

Table 1.1

Contact

S1 NO-COM Open Open Closed Open Closed Open

NC-COM Closed Closed Open Closed Open Closed

S2 Open Open Closed Open Closed Open

S3 when specified Open Open Closed Open Closed Open

S4 when specified Open Open Closed Open Closed Open

Note: When a contact is activated, the LED on display panel turns on.

Function selected

H, L, HH, LL, HH/LL limit alarms FAIL

Power off

Power on

No alarm Alarm No alarm Alarm

Power off

Power on

Terminal

1

S1

2

COM

3

4

S2

5

S3

6

S4

COM

7

1. Overview

NC

NO

Ambient temperature : -5 to 45 8C

Storage temperature : -25 to 70 8C

Ambient humidity : 10 to 90% RH, non-condensing

Installation altitude : 2000 m or less above sea level

Construction : Front panel : Dust-proof and drip-proof construction IP55,

IP65 (when “/65” option specified)

Materials : ABS resin and polycarbonate

Power supply : Rated voltage 100 to 240 V AC (610%), 50/60 Hz

Power consumption : Max. 9 VA

Weight : Approx. 600g

Dimensions : 96 (W) 3 96 (H) 3 120 (D) mm

Mounting : Panel mount

Panel cutout dimensions : 92 (W) 3 92 (H) mm

Wiring : M3.5 screw terminal

Grounding : grounding resistance 100 V or less

Functional specifications

Asymmetry potential adjustment range : 762 pH

Slope adjustment range : 70 to 110% of theoretical value

Automatic temperature compensation range : -10 to 110 8C, manual temperature

compensation available (setting range : -10 to 110 8C)

Temperature correction function (cable length correction by one-point temperature

calibration)

IM 12B11A01-01E

1-3

Page 13

Calibration function

One touch automatic calibration (one or two point calibration)

Standard solution table : Selectable : JIS • NIST Table (4, 7, 9 pH)

DIN 19267 Table (4, 7, 9 pH)

US Technical Buffer Table (4, 7, 10 pH)

Standard solution temperature range : 0 to 95 8C for JIS • NIST Table

0 to 90 8C for DIN 19267 Table

0 to 60 8C for US Technical Buffer Table

Manual calibration (one or two point calibration at specified setpoint(s))

Self-diagnostics function

FAIL output : pH measurement range failure, temperature measurement range failure,

temperature detection element failure, and converter failure

Detection during calibration, error indication :

Standard solution temperature range failure, asymmetry potential failure,

electromotive force slope failure, stability failure

Converter performance : under normal operating conditions

Linearity : 60.03 pH

Repeatability : 60.02 pH

Transmission output accuracy : 60.3% of span

Sensors connectable with PH100 : PH10FP, PH10RP, PH8EFP, PH8ERP, FU20 (no

ORP measurement available)

Sensors conditionally connectable : PH8ERG, PH8EFG, other companies’ sensors (no

temperature compensation available, manual temperature compensation

required)

Maximum total connection cable length : 50 m (sensor cable length included)

1-4

IM 12B11A01-01E

Page 14

2. Preparation for Operation

2.1 Unpacking

When the instrument arrives, unpack the package with care and check that the instrument has not been damaged during transportation. In addition, please check that the

specification matches the order, and required accessories are not missing.

2.2 Choosing an Installation Location

WARNING

To minimize the danger of shock, the converter should be mounted on the converter

panel before power is applied.

2. Preparation for Operation

When choosing a mounting location: Mounting Cautions

CAUTION

(1) Mount the converter in a location which allows adequate space for access from the

rear for wiring and the like,

(2) Ideally the converter should be on the rear of a panel, so that unauthorized personnel

will not have access to the terminals,

(3) It should be a place with minimal vibration,

(4) It should not be exposed to corrosive gas atmospheres,

(5) Temperature should be near normal (23 8C) with minimal change,

(6) Humidity should be between 10% and 90% RH,

(7) The converter should not be exposed to direct heat radiation,

(8) The converter should not be exposed to strong magnetic fields,

(9) The converter should not be exposed to moisture,

(10) The converter should not be mounted near flammable materials,

(11) The converter should not be exposed to strong UV light.

The case of the converter is made of flammable polycarbonate resin, and the bezel is

flammable ABS resin, so the converter should not be mounted above flammable materials.

IM 12B11A01-01E

If there will be flammable materials in the vicinity, they should be separated from the

converter top, bottom, left and right sides by a clearance of at least 150 mm, and the

converter covered by a plated steel plate at least 1.43 mm thick, or an uncoated steel

plate of thickness 1.6 mm.

2-1

Page 15

150 mm

Fig. 2.1

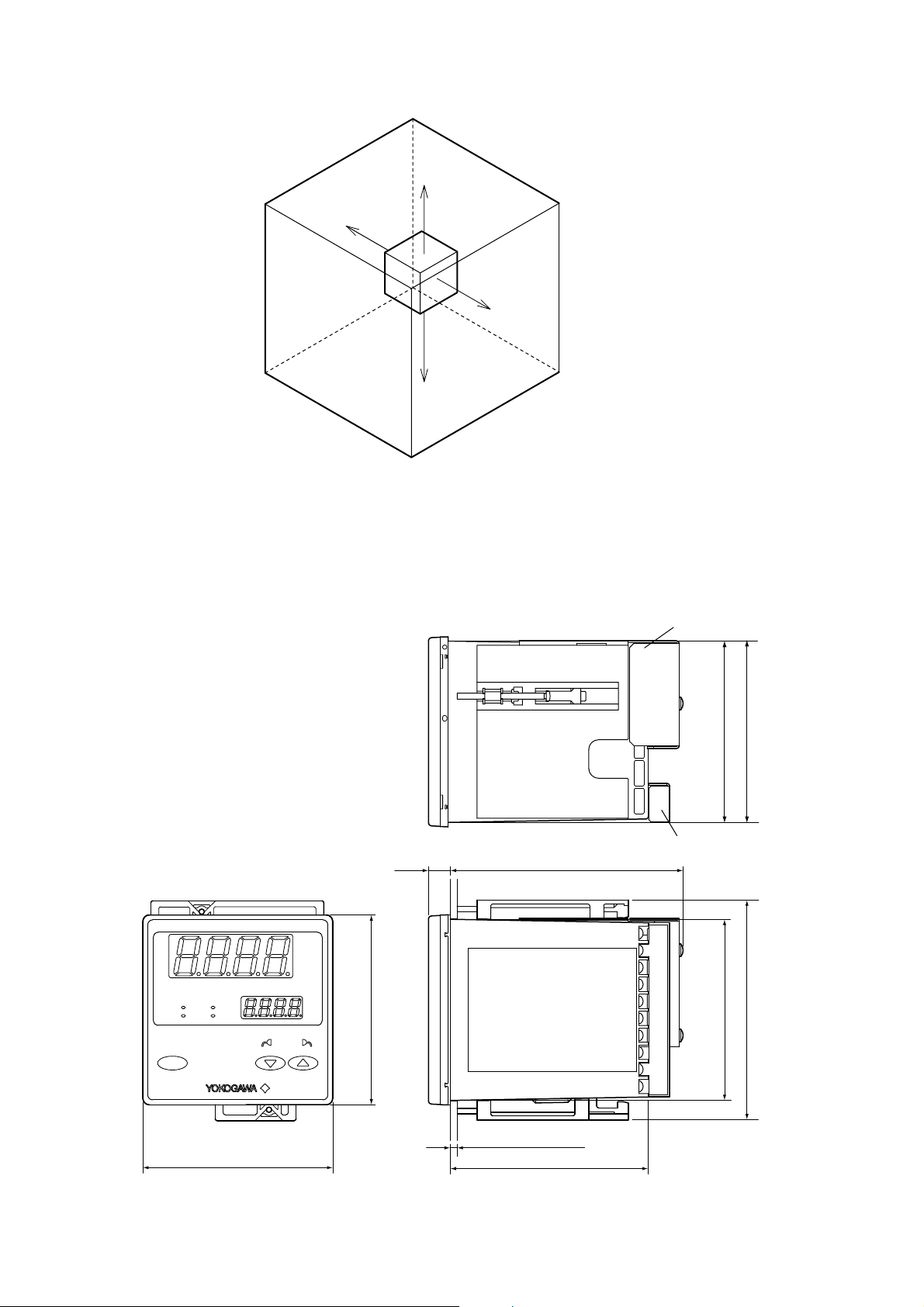

2.3 External Dimensions

• pH Converter

150 mm

150 mm

150 mm

F2.1.EPS

Unit : mm

Shield cover

EXA PH100

pH

S1S2S3

S4

SET CAL MEAS

ENT

CANCEL

96

96

11

118

Panel depth : 1 to 10

100

1-10 4151-60

Terminal cover

91.6

91.6

F003.EPS

92

111

2-2

Fig. 2.2

IM 12B11A01-01E

Page 16

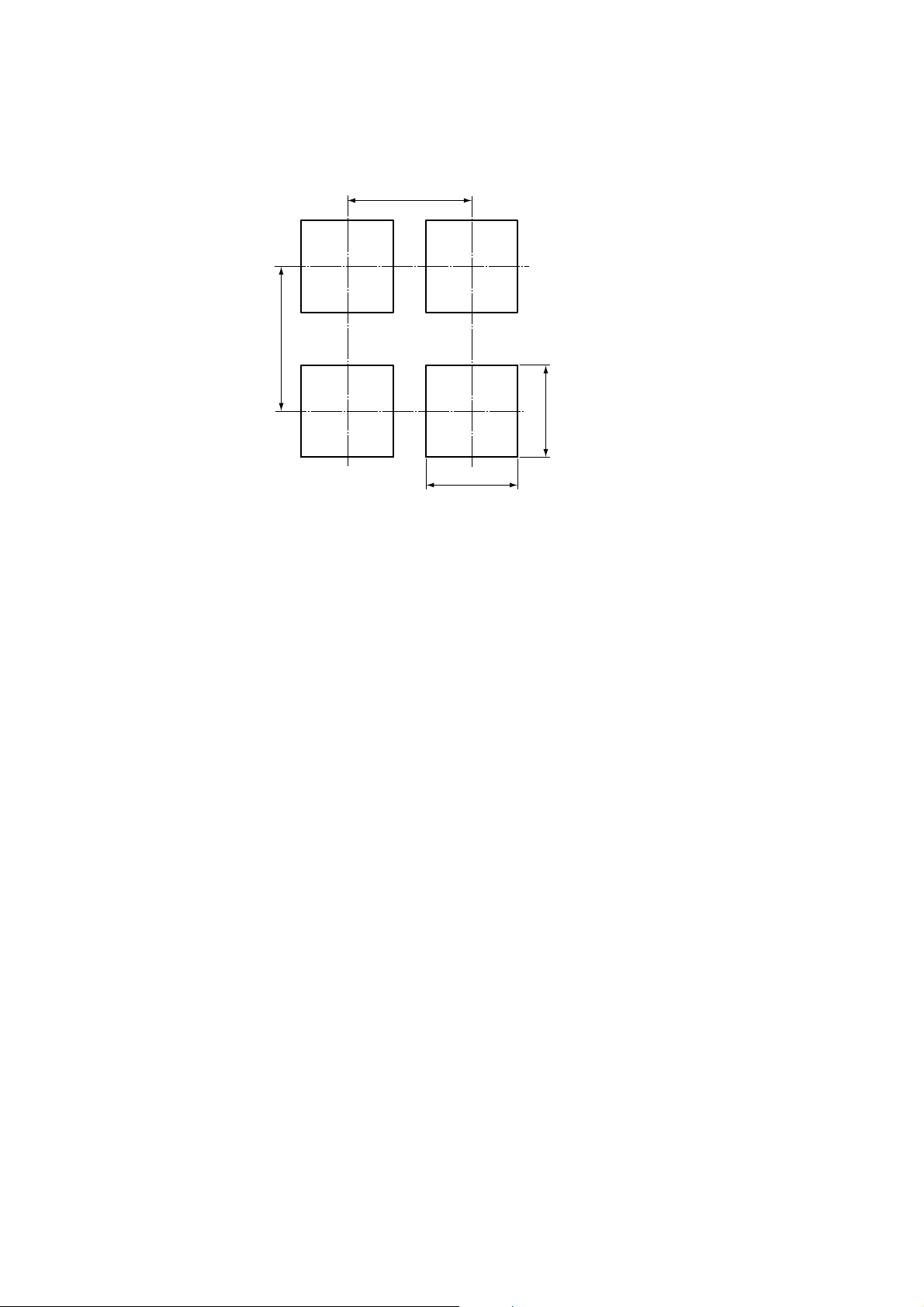

2.4 Panel Cutout Dimensions

2. Preparation for Operation

145 Min.

Fig. 2.3

125 Min.

92

+0.8

0

Unit : mm

+0.8

0

92

IM 12B11A01-01E

2-3

Page 17

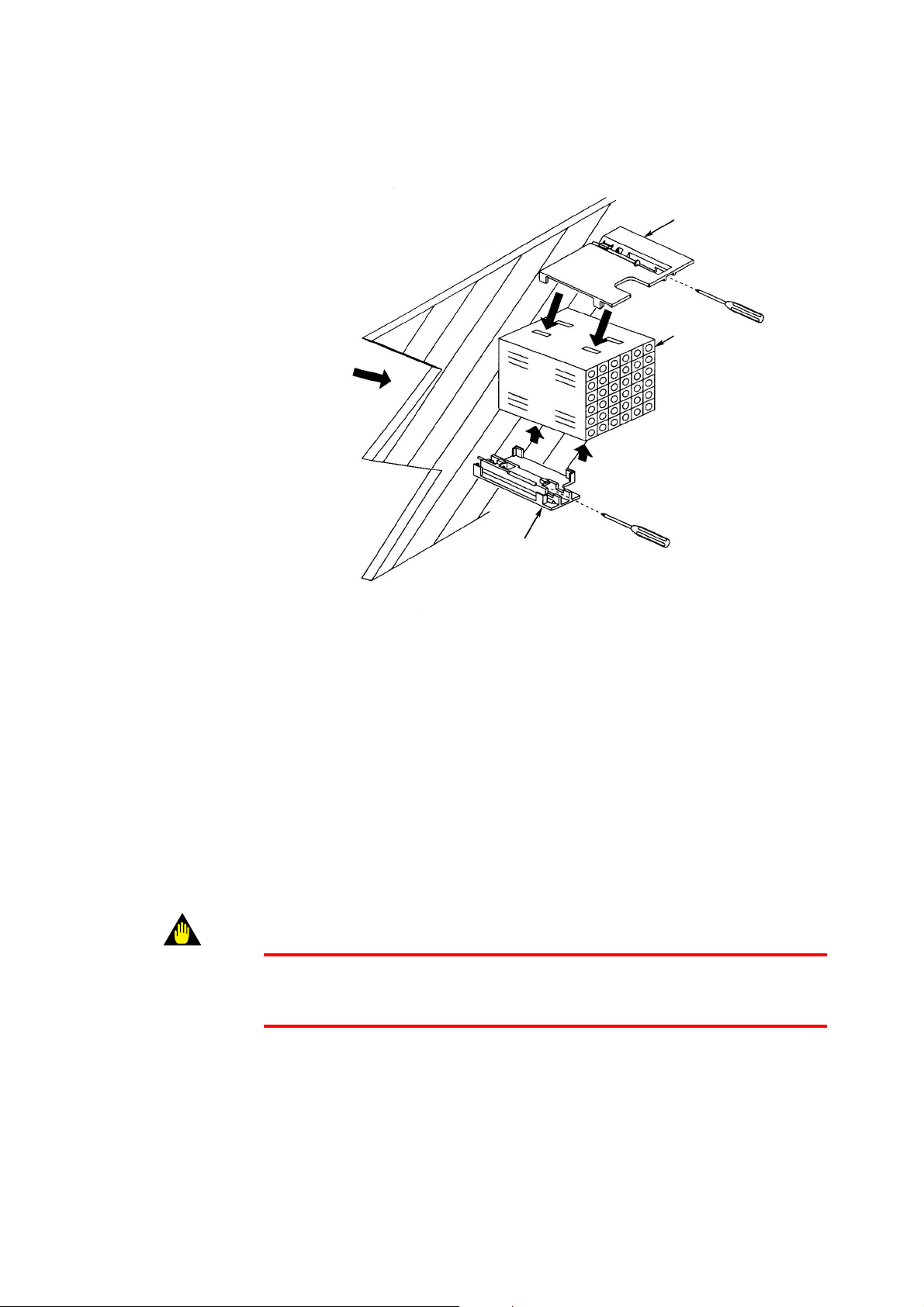

2.5 Mounting

Insert from this

Side of panel

Large brackct (mount at top)

Panel

Terminal board

Insert driver as shown

to tighten bracket

Small bracket (mount at bottom)

Fig. 2.4

Procedure 1

Cut out panel to mount instrument, cut out dimensions are shown on previous page.

Procedure 2

Insert rear of instrument (terminal block side) in panel cutout.

Procedure 3

Mount top and bottom brackets (see figure) to fix instrument to panel.

*When detector output is to be prewired, refer to Sec. 3.4(2)

WARNING

If instrument is a tight fit in cutout, do not force it as case or mounting brackets may be

damaged.

2-4

IM 12B11A01-01E

Page 18

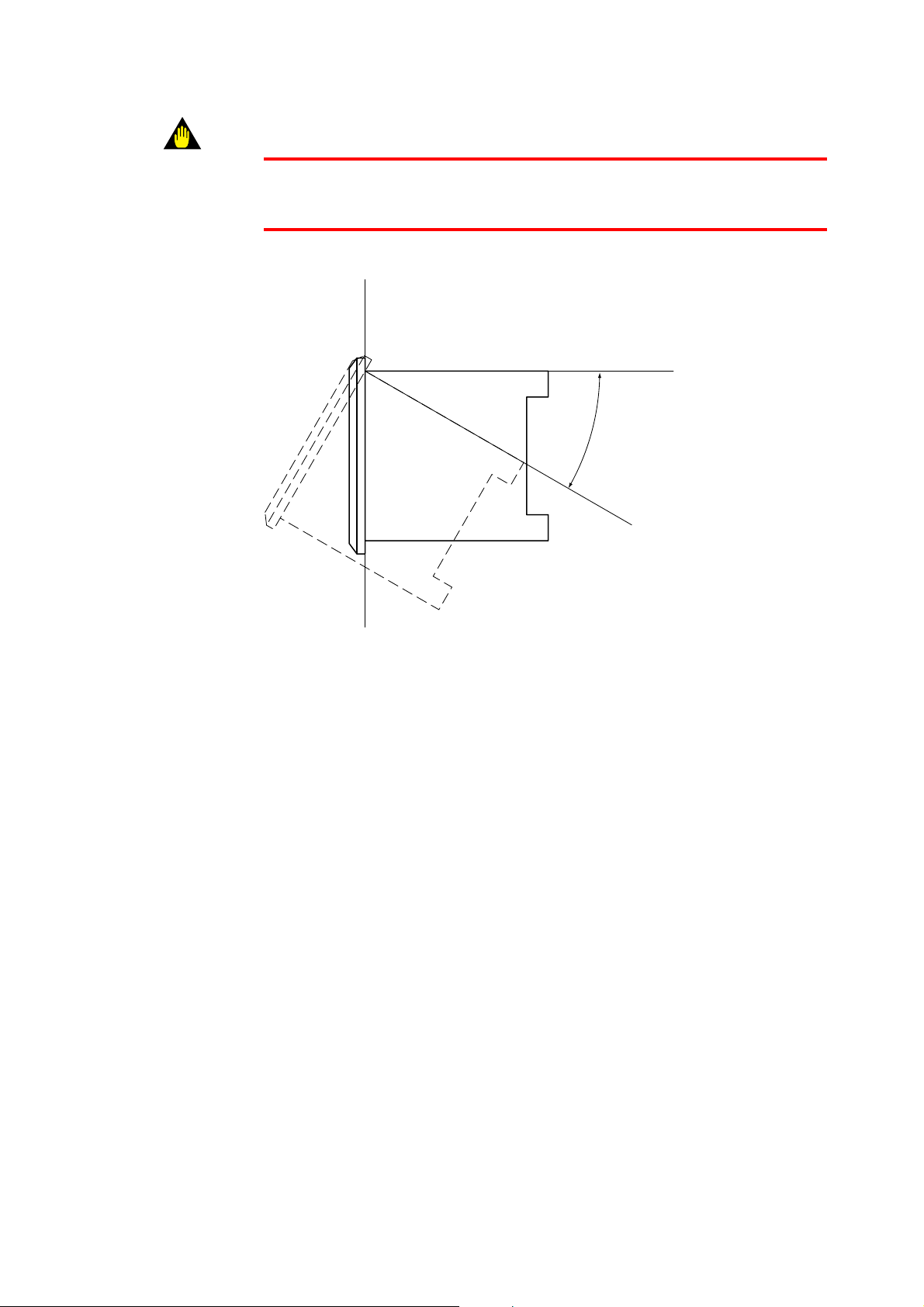

WARNING

The instrument may be installed with the rear inclined at an angle up to 308 below front.

Do not incline with front below rear.

2. Preparation for Operation

Up to 308

Fig. 2.5

F2.5.EPS

IM 12B11A01-01E

2-5

Page 19

2-6

IM 12B11A01-01E

Page 20

3. Wiring

This section explains wiring of the EXA PH100 pH converter.

WARNING

Be sure to turn off power supply, and check with a tester or the like that connected cables

do not have dangerous voltages applied. Do not touch terminals if power may be

applied.

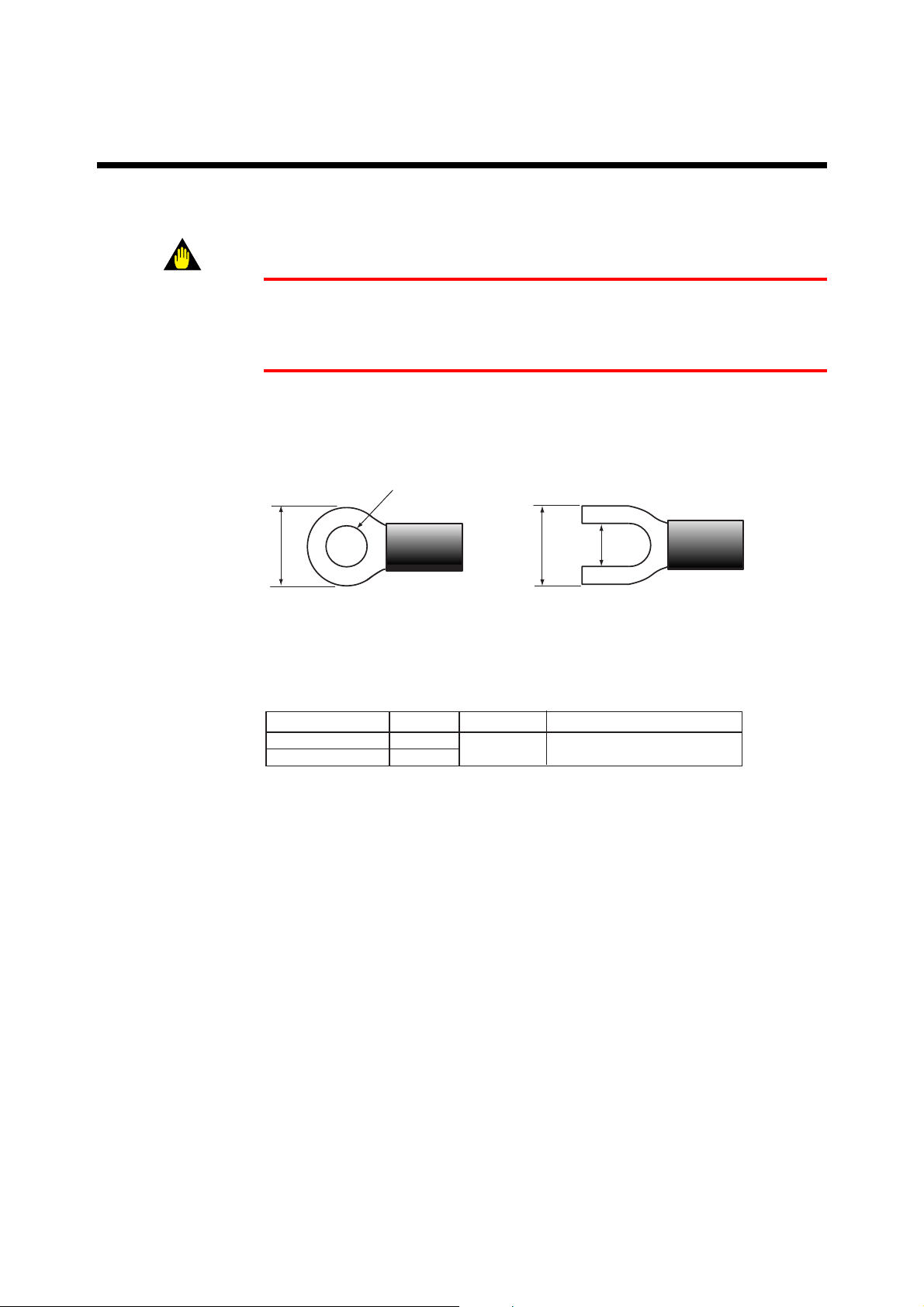

The recommended specifications for wiring terminals are shown below.

Use crimp-on terminals, designed to fit an ISO M3.5 screw, with an insulating sleeve.

3. Wiring

3.7mm\

Up to 7mm

Fig. 3.1

d Recommended terminals

Table 3.1

Maker

Japan AMP Co., Ltd

JST Co., Ltd

model

1.25-YS3A

YD1.25-3.5

For wire size:

0.3~1.65mm

Up to 7mm

3.7mm

Tightening torque

0.8N . m (8 kgf . cm) Up to or Iess

F3.1.EPS

T3.1.EPS

IM 12B11A01-01E

3-1

Page 21

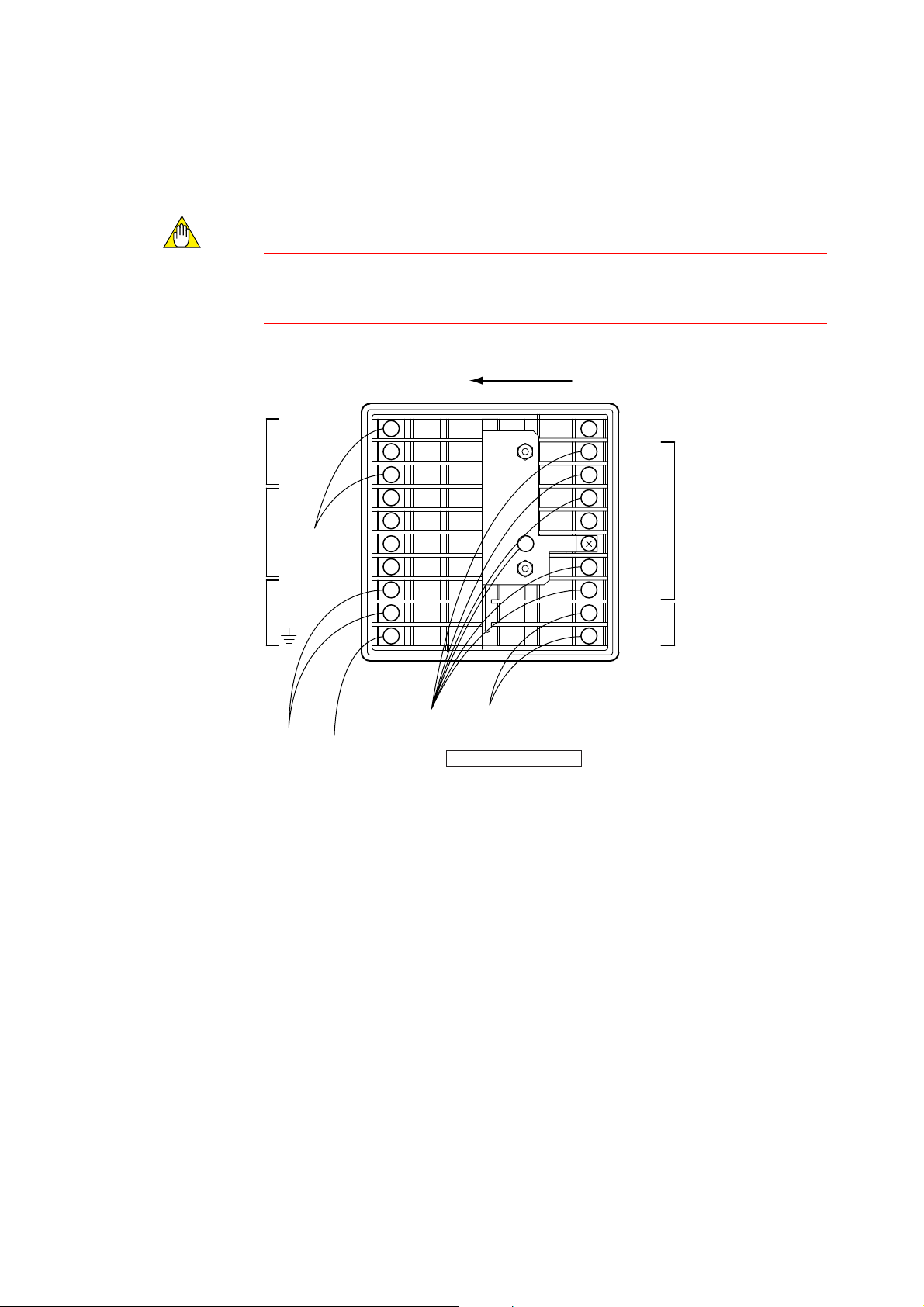

3.1 Pulling in Wiring

When wiring cables to terminals on the rear of the instrument, pull the cables into the

instrument in the direction shown in Fig. 3.2

CAUTION

There’s a terminal wiring diagram on the instrument nameplate on the side of the

instrument.

Pull in cable from left side

Terminal name Terminal name

S1(NC)

S1(NO)

COM1

S2

S3

S4

COM2

L

N

10

1

2

3

4

5

6

7

8

9

16

11

12

13

14

15

17

18

19

20

GE

S

RE

RES

SE

T1

T2

mA (1)

mA (2)

Analog output

cable

Converter rear panel

Power

wiring

Ground

wire

pH sensor

cable

Fig. 3.2 Direction to pull in wiring

F3.2.EPS

3-2

IM 12B11A01-01E

Page 22

3.2 Noise prevention

d Noise sources

The following are typical sources of electrical noise

* Relays and contacts

* Solenoid coil, solenoid valve

* Power lines

* Inductive loads

* Inverters

* Motor commutators

* SCRs used for phase-angle control

* Wireless transmitters

* Welding equipment

* High-voltage ignition systems

d Noise prevention

When wiring, take the following precautions to minimize the effects of noise:

* Keep input circuit wiring as far as possible from power or ground wiring.

* Shielded wires, with single-point grounding, are effective for minimizing pickup of

static electric fields.

* Twisted pair wire is effective in minimizing inductive noise pickup.

3. Wiring

IM 12B11A01-01E

3-3

Page 23

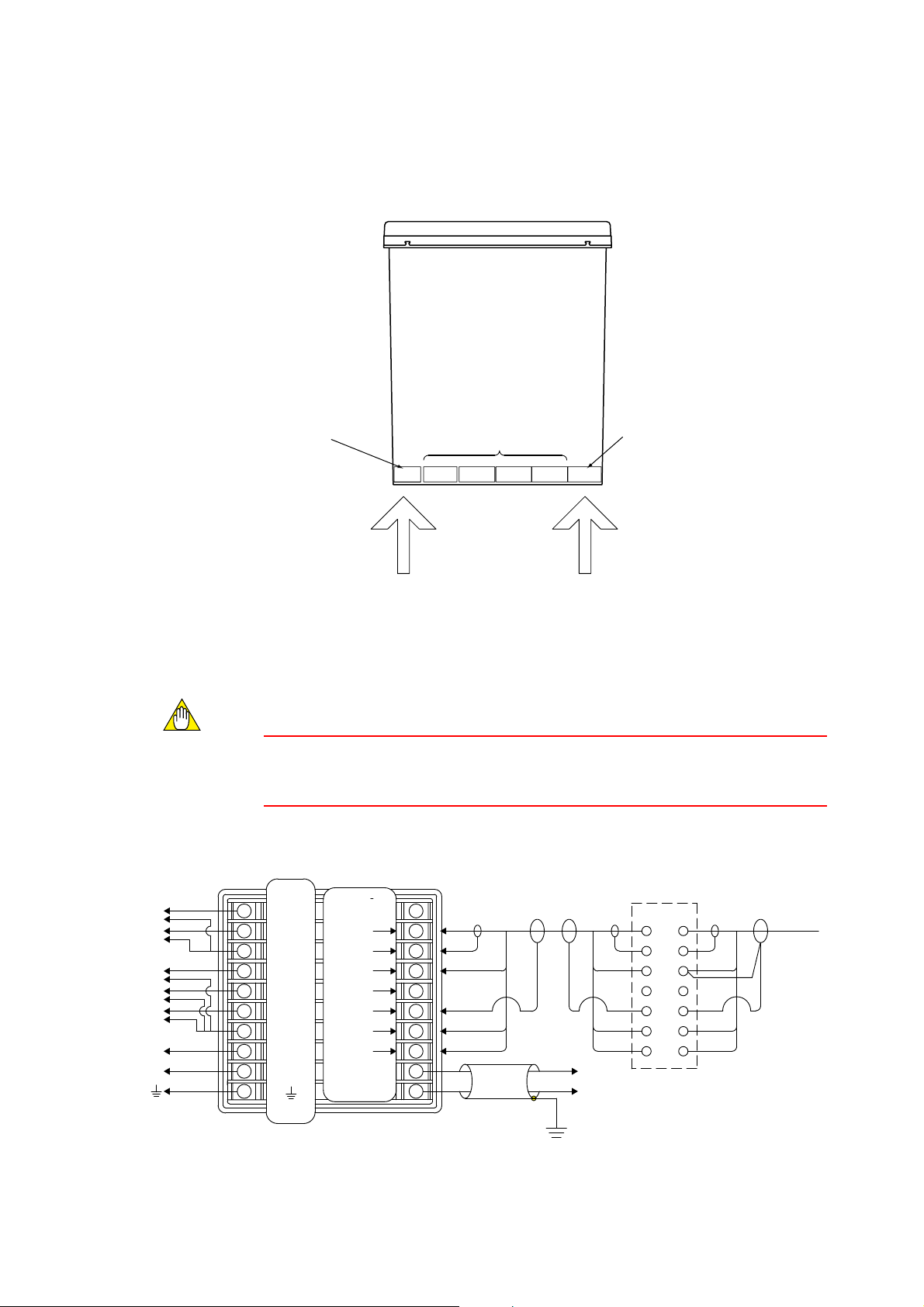

3.3 Wiring Terminal Diagram

There are wiring terminals on the rear of the PH100 converter. Wire to terminals 1 to 10

and terminals 11 to 20 as shown in Fig. 3.3. The terminal block cannot be removed.

Row of terminals

numbered 1 to 10

from top to bottom

Fig. 3.3 Cable wiring position

(1) When intermediate terminal box is used

CAUTION

Terminal size is ISO M3.5. There’s a terminal wiring diagram on the instrument

nameplate on the side of the instrument.

Row of terminals

numbered 11 to 20

Not used

1-10

Contact output and power wiring pH sensor and Analog output cable

31-40 21-30

PH100 Top view

11-2051-61 41-50

from top to bottom

F3.3.EPS

Contact

output 1(NC)

Contact

output 1(NO)

Contact

output 2

Contact

*3)

output 3

Contact

*3)

output 4

Power

supply

L

N

Ground to earth

(grounding resistance

100V or less)

Note : Terminal numbers are indicated on the label side of the converter.

3-4

Converter Rear View

10

1

2

3

4

5

6

7

8

9

Terminal

name

S1(NC)

S1(NO)

COM1

S2

S3

S4

COM2

L

N

Terminal

name

GE

S

RE

RES

SE

T1

T2

mA(1)

mA(2)

11

12

13

14

15

16

17

18

19

20

Extension cable

WF100-PH *2)

Output signal

Shield

Ground to earth (grounding resistance 100V or less)

Fig. 3.4 Wiring diagram when intermediate terminal box is used

Terminal box

WTB100-PH *1)

GE

S

RE

RES

SE

T1

T2

pH sensor

F3.4E.EPS

IM 12B11A01-01E

Page 24

Contact output (NC)

Contact output (NC)

Contact output 2

*3)

Contact output 3

*3)

Contact output 4

Power

supply

Ground to earth

L

N

(grounding resistance

100V or less)

(2) When intermediate terminal box is not used

CAUTION

Terminal size is ISO M3.5. There’s a terminal wiring diagram on the instrument

nameplate on the side of the instrument.

1

2

3

4

5

6

7

8

9

10

Terminal

(contact)

S1(NC)

S1(NO)

COM1

S2

S3

S4

COM2

L

N

Converter rear view

Terminal

name

GE

S

RE

RES

SE

T1

T2

mA (1)

mA (2)

3. Wiring

11

12

13

14

15

16

17

18

19

Output signal

20

Shield

Ground to earth

(grounding resistance 100V or less)

pH Sensor

F3.5.EPS

Fig. 3.5 Wiring diagram when intermediate terminal box is not used

*1) Intermediate terminal box WTB100 is used when pH converter and pH sensor

are far apart.

*2) Extension cable WF100 is used when pH converter and pH sensor are far apart.

*3) When only two contact outputs are specified, contact outputs 3 and 4 (S3 and S4)

are not used. When four contact outputs are used, S3 and S4 share the same

common lead (COM2).

IM 12B11A01-01E

3-5

Page 25

Table 3.2 Terminal wiring example

Terminal no. Signal name Signal description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

S1(NC)

S1(NO)

COM1

S2

S3

S4

COM2

L

N

2

GE

S

RE

RES

SE

T1

Contact output 1 (relay contact) NC

Contact output 1 (relay contact) NO

Contact output 1 (common)

Contact output 2 (relay contact)NO

Contact output 3 (relay contact) NO

Contact output 4 (relay contact) NO

Contact output 2 (common) (shared by S2,S3 & S4)

Power line L

Power line N

Ground

Reserved

Glass electrode input terminal

Glass electrode shield terminal

Reference electrode input terminal

Reference electrode shield terminal

Ground electrode (cable shield) terminal

Temperature input terminal

18

19

20

CAUTION

Figures 3.4 and 3.5 seem to indicate that cable can be pulled in from right hand side, but

in fact cable can only be pulled in from left hand side as described in Sec. 3.1

T2

mA(1)

mA(2)

Temperature input terminal

Analog output terminal (1)

Analog output terminal (2)

T3.2.EPS

3-6

IM 12B11A01-01E

Page 26

3.4 pH detector wiring

This section describes connection of the Model PH10FP KCl Refillable pH sensor or the

Model PH10RP KCl Replenish-free pH sensor to the EXA PH100 pH converter.

CAUTION

For a description of how to connect these sensors via extension cable and intermediate

terminal box, refer to IM 12B11E01-01E for the EXA WTB100 intermediate terminal

box, and refer to IM 12B11F01-01E for the EXA WF100 extension cable.

The procedure for connecting a sensor to the EXA PH100 pH converter is as follows:

(1) Loosen the two holding screws to remove the shielding cover (which covers the

terminals used for connecting a pH detector) from the rear of the EXA PH100 pH

sensor.

(2) Connect the pH sensor (detector) by cable to the terminals. The color coding of the

wires in the cable and the corresponding terminals that they are connected to are

listed below:

3. Wiring

pH converter terminal no. Cable core color code for

1

PH10FP and PH10RP pH sensors

11 Do not use

12 Red (GE)

13 Yellow (S)

14 Brown (RE) two wires

15 Do not use

16 Green (SE)

17 White (T1)

18 Black (T2)

pH converter terminal no. Cable core color code for

2

PH8EFP and PH8ERP pH detectors

11 Do not use

12 Red (GE)

13 Yellow (S)

14 Brown (RE)

15 Do not use

IM 12B11A01-01E

16 Green (SE)

17 White (T1)

18 Black (T2)

CAUTION

When using the PH8EFP or PH8ERP which have pin terminals, be sure to replace the

SE pin terminal with a forked terminal, as if you use the pin terminal is prone to pulling

out, resulting in unreliable measurements.

3-7

Page 27

pH converter terminal no. Cable core color code for

3

CAUTION

When using the PH8EFG or PH8ERG which have pin terminals, be sure to replace the

SE pin terminal with a forked terminal, as if you use the pin terminal is prone to pulling

out, resulting in unreliable measurements. You can’t measure temperature by connecting

… to T1, T2 -- use manual temperature compensation.

PH8EFG and PH8ERG pH detectors

11 Do not use

12 Red (GE)

13 Yellow (S)

14 Brown (RE)

15 Do not use

16 Green (SE)

17 White (T1)

18 Black (T2)

pH converter terminal no. Cable core code for FU20 pH detectors

4

CAUTION

FU20 cable core numbers do not agree with converter terminal numbers, so care is

required.

(3) Use wiring clips to hold the pH sensor cable in place.

(4) Replace the shielding cover removed instep (1) above. Be careful not to pinch the

sensor wiring with the cover when replacing it.

11 Do not use

12 15 (GE)

13 16 (S)

14 13 (RE)

15 Do not use

16 14 (SE)

17 11 (T1)

18 12 (T2)

3-8

IM 12B11A01-01E

Page 28

3.5 Wiring cable to intermediate terminal box

When the EXA PH100 pH converter is separated by a distance from the pH detector,

use the EXA WTB100 terminal box and EXA WF100 extension cable to connect them.

3.6 Output Signal Cable Wiring

DANGER

To minimize the danger of shock, before connecting or disconnecting wires be sure to

confirm that the pH converter power is OFF.

The output signal wiring from the PH100 converter connects to recorders or the like.

Use two-core shielded cable for this wiring.

(1) Connect connecting cable to the terminals. Be sure to use the recommended termi-

nals and be sure that they are the correct size for the cable copper core diameter.

(2) As shown in Figures 3.4 and 3.5 of Section 3.3, ground to earth and ground connec-

tion at one point only.

3. Wiring

3.7 Contact output wiring.

3.7.1 Wiring when S1 is used

A terminal cover is fitted to reduce the risk of electric shock when power is applied.

When connecting contact output wiring, you need to loosen the two cover screws to

remove the cover. After completing the wiring, take care not to forget to replace the

cover.

Load

Load

Fig. 3.6 Relay contact output wiring

* If you want to connect a load which exceeds the contact rating (voltage rating 240 V

AC, current rating 3A resistive load, 30 VDC 3A resistive load) then you need to use

a slave relay.

* If you connect an inductive load like a solenoid valve or slave relay then in parallel

with the contacts you should connect a CR filter (when switching AC) or a diode

(when switching DC), or contact live may be affected.

Terminal no.

NC

1

NO

2

COM

3

F3.6.EPS

IM 12B11A01-01E

3-9

Page 29

WARNING

* Be sure to disconnect power before removing the terminal cover. Since there is the

danger of shock, turn off power and confirm that terminals are not live before wiring.

Under no circumstances should terminals be touched when power is applied.

Recommended CR filters

Table 3.3

Maker Models

MATSUO Electric co.,Ltd

SHIZUKI Electric co.,Ltd

RUBYCON Corporation

• For an DC relay

Instrument

Fig. 3.7

CR UNIT 953, 955 etc.

SKV, SKVB etc.

CR-CFS, CR-U etc.

Relay (coil rating

must not exceed converter contact rating)

T3.3.EPS

External DC source

R

Diode (mount directly on

relay coil terminals or socket)

F3.7.EPS

3-10

• For an AC relay

Instrument

Fig. 3.8

External AC source

R

CR filter (mount directly on

relay coil terminals or socket)

Relay (coil rating

must not exceed con

veter contact rating)

F3.8.EPS

IM 12B11A01-01E

Page 30

3. Wiring

3.7.2 Wiring for S2 (for two-contact-output case) or S2, S3 and S4 (four-contact output case)

A terminal cover is fitted to reduce the risk of electric shock when power is applied.

When connecting contact output wiring, you need to loosen the two cover screws to

remove the cover. After completing the wiring, take care not to forget to replace the

cover.

(1) If you want to connect a load which exceeds the contact rating (voltage rating 240 V

AC, current rating 3A resistive load, 30 VDC 3A resistive load) then you need to use

a slave relay as shown in Sec. 3.7.1.

(2) If switching a very small current, then -- if possible – connecting a bleeder resistor in

parallel with the relay (or the like) that is the load, can improve contact reliability.

(3) If you connect an inductive load like a solenoid valve or slave relay then in parallel

with the contacts you should connect a CR filter (when switching AC) or a diode

(when switching DC), or contact life may be affected. Contact life is typically at

least 10,000 switching operations with a resistive load.

(4) Use the recommended terminals to terminate connecting cables, and make sure that

they are the correct size to match the cable core diameter.

Terminal no.

S2

4

Load

Fig. 3.9

Load

S3

S4

Load

COM

5

6

7

F3.9.EPS

IM 12B11A01-01E

3-11

Page 31

3.8 Power and Ground Wiring

* Power: This wiring should connect a power source of the correct voltage and fre-

quency to the EXA PH100 pH Converter. The power wiring should be heavy vinyl

sheath cable rated at 600V (specifications equivalent to JIS C 3307).

* Ground: Ground to earth (ground resistance 100 ohms or less). Use a sufficiently

heavy cable (cross sectional area of 2 mm2 or greater).

* Use the recommended terminals to terminate connecting cables, and make sure that

they are the correct size to match the cable core diameter.

A terminal cover is fitted to reduce the risk of electric shock when power is applied.

When connecting contact output wiring, you need to loosen the two cover screws to

remove the cover. After completing the wiring, take care not to forget to replace the

cover.

WARNING

* Be sure to disconnect power before removing the terminal cover. Since there is the

danger of shock, turn off power and confirm that terminals are not live before wiring.

Under no circumstances should terminals be touched when power is applied.

CAUTION

The EXA PH100 pH converter does not have a power switch built in. You should add

an on-off switch with two poles (to disconnect both sides of the power line).

3-12

IM 12B11A01-01E

Page 32

WARNING

Any errors in power and ground wiring may damage the converter. Before applying

power to the converter, be sure to check the wiring.

EXA PH100 pH converter

Terminal no.

1

2

3

4

5

6

1

S1(NC)

S1(NO)

COM1

S2

S3

S4

~

10

3. Wiring

Power

Fig. 3.10

Switch (provided by user)

Power wiring

10

COM2

7

L

8

N

9

F3.10.EPS

IM 12B11A01-01E

3-13

Page 33

3-14

IM 12B11A01-01E

Page 34

4. Overview of Operation Panel

4. Overview of Operation Panel

4.1 Overviews of names and functions of operation panel

keys

1

Measured value display

4-digit display

When measuring: pH value is displayed

When measuring or calibrating: numerical

data and alphanumerics

Set/Ent key

m key. key

4

Status display

Four LEDs (When 2 contact outputs specified : two LEDs)

*Display contact output status (lit when operated)

Fig. 4.1

2

Auxiliary display

4-digit display

When measuring: temperature display

(selectable)

When setting: parameters

3

Keypad area

Three keys:

*SET/ENT key

* m key

* . key

F4.1.EPS

IM 12B11A01-01E

4-1

Page 35

4.2 Key Operation

On the EXA PH100 front panel there are three keys for screen/mode switching and data

entry.

CANCEL

(A) (B) (C)

SET CAL MEAS

ENT

key

F4.2.EPF

Fig. 4.2 Layout of three keys on front panel

Main uses of these keys are as follows:

(A) SET/ENT key: used to confirm mode changes and data settings

* From the measurement panel, if you press it continuously for at least three seconds

then the data setting screen is displayed.

SET

Press for 3 sec. and

ENT

Fig. 4.3

(B) ( ) key: Use to select different menu item or reduce data setting value.

* Pressing this key for at least three seconds switches to the calibration screen.

SET (data entry screen) is displayed.

F4.3.EPS

CAL

Press for 3 sec. and CAL

(calibration screen) is displayed.

F4.4.EPS

Fig. 4.4

(C) ( ) key: Use to select different menu item or increase data setting value.

* Pressing this key for at least three seconds from calibration or data setting top

screen switches back to the measurement screen.

MEAS

Press for 3 sec. and MEAS

(measurement screen) is displayed.

F4.5.EPS

Fig. 4.5

(B) + (C) Pressing both ( ) and ( )) screen simultaneously cancels operations

4-2

IM 12B11A01-01E

Page 36

4.3 Switching display screens

EXA PH100 has three menu screens: measurement, calibration and data setting screens.

The screen transition diagram is shown below.

Power ON

Initial display (4?4?1)

4. Overview of Operation Panel

Measurement screen

Press SET/ENT key

for three seconds

Data setting screen

Fig. 4.6

(4?4?2)

(4?4?4)

Press ( ) key for 3 seconds

Press ( ) key for 3 seconds

Press ( ) key for 3 sec.

Calibration screen

(4?4?3)

F4.6.EPS

IM 12B11A01-01E

4-3

Page 37

4.4 Display screen examples

4.4.1 Initial display

Display when converter is normal.

(1) All LEDs are lit when converter is powered on.

Fig. 4.7 All LEDs lit

(2) Then all LEDs turn off.

4-4

Fig. 4.8 All LEDs off

IM 12B11A01-01E

Page 38

(3) Measurement screen is displayed

4. Overview of Operation Panel

Fig. 4.9 Measurement screen with temperature display

4.4.2 Measurement screen

1) Measurement screen

* Measurement display: Displays pH value.

Decimal point is fixed; two digits below the decimal point.

* Auxiliary display:

When temperature display functions are provided, the temperature and units (C

for 8C, F for 8F) are displayed. When temperature display functions are not

provided, nothing is displayed. (The initial setting is for no temperature display).

pH display - up to 2 digits below decimal point

When temperature display is provided

IM 12B11A01-01E

F4.7.EPS

Fig. 4.10

4-5

Page 39

4.4.3 Calibration screen

(1) From Measurement screen

Press ( ) key for 3 sec. to transfer to Calibration screen

Press for at less 3 sec.

Fig. 4.11 Measurement screen

(2) Calibration screen

4-6

Fig. 4.12 Calibration screen (for Autocalibration case)

Press ( ) for at less 3 sec. to return to Measurement screen

IM 12B11A01-01E

Page 40

4.4.4 Setting screen

4. Overview of Operation Panel

(1) Measurement screen display

Press SET/ENT screen for at least 3 sec. to transfer to Setting screen.

Press for at less 3 sec.

Fig. 4.13 Measurement screen

(2) Setting screen

IM 12B11A01-01E

Fig. 4.14 Setting screen

Press ( ) for at less 3 sec. to return to Measurement screen

4-7

Page 41

4-8

IM 12B11A01-01E

Page 42

5. Operation

5.1 Start up

5.1.1 Check wiring

Check that all wiring is correct (refer to Sec. 3.3)

5.1.2 Start up pH converter

Apply power (100 to 240V AC 6 10% 50/60Hz) to EXA PH100 pH converter.

5.1.3 Data setting

Set the following parameters -- (1) analog output parameter, (2) calibration parameters,

(3) alarm settings, and (4) other parameters -- in the order listed, to enable desired

operation for process pH control:

(1) Analog output parameters

This screen is for user setting of analog-output-related settings

5. Operation

(2) Calibration parameters

This screen is for user setting of calibration-related settings

(3) Alarm parameters

This screen is for user setting of alarm-related settings

(4) Other parameters

This screen is for user setting of parameter settings other than (1) to (3) above.

Note

See Sec. 4 “Overview of Operation Manual” and table of LED display symbols in

preface to this manual.

IM 12B11A01-01E

5-1

Page 43

(1) Analog output parameter setting screen (Ao.PA displayed at top of screen)

This screen is for user setting of analog-output-related settings. A list of menu

options on this screen is shown below:

Table 5.1

Name Parameter Setting range Initial value Note

Ao.PA Menu Title NA (not applicable) NA

RL

Range low

limit

22.0 ~ 16.0pH

0.0pH

High & low at

least pH2 apart

RH

M.HLd

H.Ao

F.HLd

Range high

limit

Hold during

Maintenance

Hold output

setting

Hold if

abnormal

22.0 ~ 16.0pH

0 : No Hold

1 : Hold

2 : Set value

2.0 ~ 20.8mA

0 : No Hold

1 : Burn out down scale (2mA)

14.0pH

1 : Hold

2.0

1 : Burn out down scale (2mA)

High & low at

least pH2 apart

T5.1E.EPS

5-2

IM 12B11A01-01E

Page 44

OR100EXA

mV

S1S2S3

S4

SET

ENT

CANCEL

MEASCAL

Measurement screen

5. Operation

Example flow chart for analog output parameter setting is shown below

Press mkey

for 3 esc

Low range limit

High range limit

Press SET/ENT

for 3 sec.

S1S2S3

EXA OR100

S4

Ao.PA flashing

mV

Analog output parameter setting screen

SET/ENT key

Change value with m and . keys

EXA OR100

S1S2S3

mV

S4

SET/ENT key

Change value with m and . keys

EXA OR100

S1S2S3

mV

S4

SET/ENT key

S1S2S3

S1S2S3

EXA OR100

S4

EXA OR100

S4

mV

SET/ENT key

rewrites data

mV

SET/ENT key

rewrites data

S1S2S3

Hold during

maintenance

S1S2S3

Hold output

setting

S1S2S3

Hold if

abnormal

Change value with m and . keys

EXA OR100

mV

S4

SET/ENT key

Change value with m and . keys

EXA OR100

mV

S4

SET/ENT key

Change value with m and . keys

EXA OR100

mV

S4

SET/ENT key

S1S2S3

S1S2S3

S1S2S3

EXA OR100

S4

EXA OR100

S4

EXA OR100

S4

mV

SET/ENT key

rewrites data

mV

SET/ENT key

rewrites data

mV

SET/ENT key

rewrites data

Fig. 5.1 Example flow chart for analog output parameter setting

* Note: To cancel, press both ( ) and ( ) simultaneously.

F5.1.EPS

IM 12B11A01-01E

5-3

Page 45

Hame

(2) Calibration parameter setting screen (CAL displayed at top of screen)

This screen is for user setting of calibration-related settings. A list of menu options

on this screen is shown below:

Table 5.2

Parameter Setting range Initial value Note

CAL Menu Title

CL.md Calibration

CL.Po Calibration

CL.2P

CL.1P

CL.tb

method

points

Two-point CAL

std. liquid

One-point CAL

std. liquid

Std. liquid

cal.table

NA (not applicable)

0 : Autocalibration

1 : Manual calibration

0 : One-point

1 : Two-point calibration

0 : pH7, pH4

1 : pH9, pH7 (US: pH 10, pH7)

2 : pH9, pH4 (US: pH 10, pH4)

0 : pH7

1 : pH4

2 : pH9 (US: pH 10)

0 : JIS, NIST

1 : US

2 : DIN

NA

0 : Autocalibration

1 : Two-point calibration

0 : pH7, pH4

0 : pH7

0 : JIS, NIST

T5.2.EPS

5-4

IM 12B11A01-01E

Page 46

Example flow chart for calibration parameter setting is shown below

pH

EXA PH100

S1S2S3

S4

pH

EXA PH100

ENT

S1S2S3

S4

SET CAL MEAS

CANCEL

pH

EXA PH100

S1S2S3

S4

pH

EXA PH100

S1S2S3

S4

pH

EXA PH100

S1S2S3

S4

pH

EXA PH100

S1S2S3

S4

pH

EXA PH100

S1S2S3

S4

pH

EXA PH100

S1S2S3

S4

S4S3S2

S1

PH100EXA

pH

pH

EXA PH100

S1S2S3

S4

pH

EXA PH100

S1S2S3

S4

pH

EXA PH100

S1S2S3

S4

pH

EXA PH100

S1S2S3

S4

F5.2.EPS

Measurement screen

Perss m key

for 3sec.

Press SET/ENT

for 3 sec.

Perss m key

for 3sec.

Perss . key Perss m key

CAL flashing

Calibration parameter setting screen

SET/ENT key

Change value with m and . keys

SET/ENT key

SET/ENT key

CAL method

setting

CAL points

setting

SET/ENT key

rewrites data

Change value with m and . keys

Change value with m and . keys

SET/ENT key

rewrites data

SET/ENT key

Std. liquid

for 2- point CAL

Change value with m and . keys

Std. liquid

for 1- point CAL SET/ENT key

SET/ENT key

rewrites data

Change value with m and . keys

Table type

for Std.liquid CAL SET/ENT key

SET/ENT key

rewrites data

SET/ENT key

rewrites data

5. Operation

IM 12B11A01-01E

Fig. 5.2 Example flow chart for calibration parameter setting

* Note: To cancel, press both ( ) and ( ) simultaneously.

5-5

Page 47

(3) Alarm parameter setting screen (Alrm displayed at top of screen)

This screen is for user setting of alarm data. A list of menu options on this screen is

shown below:

Table 5.3

Hame Parameter Setting range Initial value Note

Alrm top menu NA (not applicable) NA

S1 S1 0: high limit alarm

HY1

dLY1 S1 delay time 0-200 seconds 0

S2 S2

HY2

dLY2

S3

HY3 S3 hysteresis 0.0-4.0 pH 0.1 pH

dLY3 S3 delay time 0-200 seconds 0

S4 S4 0: high limit alarm

HY4 S4 hysteresis 0.0-4.0 pH

dLY4 S4 delay time 0-200 seconds 0

H.A

S1 hysteresis 0.0-4.0 pH 0.1 pH

S2 hysteresis 0.0-4.0 pH

S2 delay time

S3

high limit alarm

1: low limit alarm

2: high high limit alarm

4: high high limit/low low limited alarm

5: abnormal

0: high limit alarm

1: low limit alarm

2: high high limit alarm

4: high high limit/low low limited alarm

5: abnormal

0-200 seconds 0

0: high limit alarm

1: low limit alarm

2: high high limit alarm

4: high high limit/low low limited alarm

5: abnormal

1: low limit alarm

2: high high limit alarm

3: low low limit alarm

4: high high limit/low low limited alarm

5: abnormal

-2.0-16.0pH

0: high limit alarm

1: low limit alarm

0.1 pH

2: high high limit alarm when suffix

3: low low limit alarm

0.1 pH

14.0pH

code is -21,

S3 does not

appear

when suffix

code is -21,

HY3 does not

appear

when suffix

code is -21,

dLY3 does not

appear

when suffix

code is -21,

S4 does not

appear

when suffix

code is -21,

HY4 does not

appear

when suffix

code is -21,

dLY4 does not

appear

L.A

HH.A high high limit alarm

LL.A low low limit alarm

low limit alarm 0.0 pH

5-6

-2.0-16.0pH

-2.0-16.0pH

-2.0-16.0pH

14.0pH

0.0 pH

T5.3.EPS

IM 12B11A01-01E

Page 48

Example flow chart for setting alarm parameters is shown below

EXA PH100

S1S2S3

SET CAL MEAS

ENT

Measurement screen

pH

S4

CANCEL

5. Operation

Press m key

for 3 sec.

Press m key

for 3 sec.

Press . key

for 2 times.

S1 hysteresis

S1 delay time

S2 hysteresis

S2 delay time

S3 hysteresis

Press SET/ENT key

for 3 sec.

EXA PH100

pH

S1S2S3

S4

Press m key

for 2 times.

PH100EXA

pH

S1

S4S3S2

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

S1

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

S2

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1

S2S3S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

S3

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

SET/ENT key

Ao.PA flashing

ALrm flashing

Alarm parameter setting screen

EXA PH100

S1

S2S3S4

SET/ENT key

rewrites data

EXA PH100

S1S2S3

S4

SET/ENT key

rewrites data

EXA PH100

S1S2S3

S4

SET/ENT key

rewrites data

EXA PH100

S1S2S3

S4

SET/ENT key

rewrites data

EXA PH100

S1

S2S3S4

SET/ENT key

rewrites data

EXA PH100

S1S2S3

S4

SET/ENT key

rewrites data

EXA PH100

S1S2S3

S4

SET/ENT key

rewrites data

EXA PH100

S1

S2S3S4

SET/ENT key

rewrites data

Change value with m and . keys

S3 delay time

S4

S4 hysteresis

EXA PH100

pH

S1S2S3

S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1

S2S3S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1

S2S3S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1S2S3

S4

SET/ENT key

Change value with m and . keys

EXA PH100

pH

S1

S2S3S4

SET/ENT key

pH

pH

pH

pH

S4 delay time

pH

High limit alarm

pH

Low limit alarm

pH

High high limit alarm

pH

Low low limit alarm

EXA PH100

S1S2S3

S4

EXA PH100

S1S2S3

S4

EXA PH100

S1

S2S3S4

EXA PH100

S1S2S3

S4

EXA PH100

S1

S2S3S4

EXA PH100

S1S2S3

S4

EXA PH100

S1

S2S3S4

EXA PH100

S1

S2S3S4

pH

SET/ENT key

rewrites data

pH

SET/ENT key

rewrites data

pH

SET/ENT key

rewrites data

pH

SET/ENT key

rewrites data

pH

SET/ENT key

rewrites data

pH

SET/ENT key

rewrites data

pH

SET/ENT key

rewrites data

pH

SET/ENT key

rewrites data

IM 12B11A01-01E

F5.3.EPS

Fig. 5.3 Example flow chart for setting alarm parameters when four contacts

output specified

Note: To cancel, press both ( ) and ( ) simultaneously.

5-7

Page 49

(4) Other parameter setting screen (otHr displayed at top of screen)

This screen is for user setting of parameters for other measurements. A list of menu

options on this screen is shown below

Table 5.4

Name Parameter Setting range Initial value Note

otHr

dsP.t

UnIt

t.SnS

SEL.t

SEt.t

t.CAl

Menu Title

temperature in display

Temperature unit

RTD type

temperature compensation

temperature setting

temperature calibration

(1-point calibration)

NA (not applicable) NA

0: OFF

1: ON

0: 8C

1: 8F

0: Pt1000

1: Other

0: automatic (temperature sensor)

1: manual (setting)

-10.0~110.08C

(14.0~230.08F)

-15.0~115.08C

(5.0~239.08F)

0: OFF

0: 8C

0: Pt1000

0: automatic (temperature sensor)

25.08C

(77.08F)

For reference.

temperature is displayed when this

parameteris displayed.

The temperature is not updated

automatically

Other depends on the

suffix code

Effective when

SEL.t is 1

Please input the actual

temperature of the

measurement liquid

Effective when SEL.t

is 0.

d.InS

InSP menu display

fliag setting

0: no display

1: display

0: no display Alwaus set 0

When the power is turned

off, the setting become

0

T5.4.EPS

5-8

IM 12B11A01-01E

Page 50

EXA PH100

S1S2S3

S4

SET CAL MEAS

ENT

CANCEL

Measurement screen

5. Operation

Example flow chart for setting other measurement parameters is shown below

pH

Press m key

for 3 sec.

Press m key

for 3 sec.

Press . key

for 3 times

S1S2S3

S1S2S3

S1

Temperature display setting

S1

Temperature unit setting

S1

Temperature RTD type setting

EXA PH100

S4

EXA PH100

S4

SET/ENT key

PH100EXA

S4S3S2

SET/ENT key

PH100EXA

S4S3S2

SET/ENT key

PH100EXA

S4S3S2

SET/ENT key

Press SET/ENT

for 3 sec.

pH

Ao.PA flashing

Press m key

for 3 times.

otHr flashing

pH

Other parameter setting screen

Change value with m and . keys

pH

Change value with m and . keys

pH

Change value with m and . keys

pH

Change value with m and . keys

PH100EXA

S4S3S2

SET/ENT key

rewrites data

pH

Temperature

compensation

S1

PH100EXA

S4S3S2

pH

SET/ENT key

rewrites data

Temperature setting

S1

PH100EXA

S4S3S2

pH

SET/ENT key

rewrites data

Temperature

calibration

InSP menu dispisplay

on/off Flag setting

S1

PH100EXA

S1

pH

S4S3S2

SET/ENT key

Change value with m and . keys

PH100EXA

S1

pH

S4S3S2

SET/ENT key

Change value with m and . keys

PH100EXA

S1

pH

S4S3S2

SET/ENT key

Change value with m and . keys

PH100EXA

S1

pH

S4S3S2

PH100EXA

S4S3S2

pH

SET/ENT key

rewrites data

S1

PH100EXA

S4S3S2

pH

SET/ENT key

rewrites data

S1

PH100EXA

S4S3S2

pH

SET/ENT key

rewrites data

S1

PH100EXA

S1

pH

S4S3S2

SET/ENT key

SET/ENT key

rewrites data

IM 12B11A01-01E

F5.4.EPS

Fig. 5.4 Example flow chart for setting other measurement parameters

Note: To cancel, press both ( ) and ( ) simultaneously.

5-9

Page 51

5.1.4 Temperature Calibration

The EXA PH100 PH converter is used with a pH sensor, and the resistance of the

cabling between them will vary depending on the length of the cable. When Yokogawa’s

PH10FP or PH10RP are used, the cable length is selectable – it may be any of 3 m, 5 m,

or 10 m. When the WTB100 intermediate terminal box is used with the special WF100

extension cable, the cable length may be increased up to 50 m. For accurate temperature

compensation, one time temperature calibration (to compensate for the resistance of the

cable between converter and detector) after installation is recom- mended.

Procedure for Temperature Compensation

Temperature compensation should be performed with the measured solution as near as

possible to the normal temperature of measurement. To minimize temperature change

during measurement, you should prepare at least 4 liters of solution. You also need a

thermometer to measure the temperature of the solution. Temperature calibration uses

the t.CL (Temperature Calibration) setting screen described in Section 5.1.3 (4) Other

Parameters.

The pH detector (immersed up to the liquid junction) and thermometer should be placed

in the solution to be used for temperature calibration. For best accuracy, leave the

detector until its temperature has stabilized (this usually takes about two minutes) before

reading the thermometer, setting that temperature into the conductivity converter, and

calibrating.

Temperature calibration can be performed in the range -15˚C to +115˚C, and the

compensation value (pH detector measured temperature minus thermometer measured

temperature) should be within the range -20˚C to +5˚C.

5.1.5 Calibration with Standard Liquid

The emf of the glass electrode varies a little between electrodes. Before stareting normal

operation, calibrate with standard solution.

The emf of the electrode will also vary if it gets dirty or as the electrode ages, so

recalibration needs to be performed periodically at frequent enough intervals to keep

error within rated tolerance.

The procedure for calibration with standard liquid is described in Sec. 6.

5-10

IM 12B11A01-01E

Page 52

5.2 Test Operation

To check if operation of the EXA PH100 pH converter is normal, monitor it in test

operation mode for a while.

5.3 Normal operation

From the parameter setting screen, press the ( ) key for at least 3 seconds to return to

the measurement screen.

Apart from when changing settings or calibrating with standard solution, during normal

operation there should be no need for operating this machine.

If an error message is displayed or the output scales out, refer to Sec. 8 for troubleshooting. please make the cause be clear by following the on and treat immediately.

Also, please be sure to perform the daily checks and maintenance described in Sec. 7 in

order to maintain reliable operation.

5.4 Stopping and Restarting Operation

5. Operation

After changing settings, be sure to wait at least 2 seconds before turning off the power.

In other cases, no special precautions are required.

To stop operation, simply turn off the power supply.

To restart operation, simply restore power and parameter values remain the same as

before the power failed.

IM 12B11A01-01E

5-11

Page 53

5-12

IM 12B11A01-01E

Page 54

6. Calibration with standard solution

6. Calibration with standard solution

The emf characteristics of pH electrodes vary between electrodes, and vary with electrode aging The variability of pH detectors that are used only for short periods can be

particularly high. The variability of pH detectors that are used only occasionally for

short periods can be particularly high. So there is a need for electronic circuitry to

perform automatic compensation of pH.

Calibration with standard solution involves measuring the pH of standard solution of

known pH, and adjusting the pH meter to show the correct pH value.

Calibration with standard solution of the EXA PH100 pH converter can be either

automatic calibration using standard solutions of two predetermined pH values chosen

from pH 4, 7, and 9 (JIS), and manual calibration using arbitrary standard solution.

6.1 Important issues relating to calibration with standard

solution

Standard solution/

temperature 8C

pH4

pH7

pH9

(1) Be careful to use the standard solution marked with the correct pH.

If the pH standard solution has deteriorated and its pH changed, calibration will not

be accurate.

Note: when automatic calibration is used, choose two standard solutions from those

(pH4, pH7and pH9) shown in Table 6.1.

(2) If the temperature of the standard solution is changing, the measured pH value will

not stabilize. At calibration time, keep the standard solution at constant temperature.

(3) During auto calibration, do not touch ENT or ( ), ( ) keys as calibration values

may be affected.

Table 6.1 JIS Z8802 standard solution

0 5 10 15 20 25 30 35 40 45 50 55 60 70 80 90 95

4.01

4.01

4.00

4.00

4.00

4.01

4.01

4.02

4.03

4.04

4.06

4.08

4.10

4.12

4.16

4.20

6.98

6.95

6.92

6.90

6.88

6.86

6.85

6.84

6.84

6.83

6.83

6.84

6.84

6.85

6.86

6.88

9.46

9.39

9.33

9.27

9.22

9.18

9.14

9.10

9.07

9.04

9.01

8.99

8.96

8.93

8.89

8.85

4.23

6.89

8.83

T6.1.EPS

IM 12B11A01-01E

6-1

Page 55

6.2 Calculations involved in Calibration with Standard

Solution

(1) When performing auto one-point calibration of the EXA PH100 pH converter using

one type of standard solution, use one of the standard solutions (pH4, pH7 or pH9)

and adjust the asymmetry potential so that the calibration curve passes through the

calibration point (see Fig. 6.1).

Calibration curve

pH0

Calibration point for

one-point calibration at pH7

Calibration curve

+mV

-mV

Theoretical value

pH7, 0mV

pH14

Asymmetry potential

Calibration point for

one-point calibration at pH4

pH0

+mV

-mV

Theoretical value

pH7, 0mV

pH14

Asymmetry potential

Fig. 6.1

*) When you measure the pH of solutions that have nearly the same pH as a standard

solution, you can use auto one-point calibration, a simple method of calibration that

gives sufficient accuracy in this case.

2) When using two kinds of standard solution for two-point automatic calibration of the

EXA PH100 pH converter, choose two standard solutions pH4, pH7 or pH9 and

adjust the asymmetry potential and slope so that the calibration curve passes through

the first and second calibration points (Fig. 6.2)

Second calibration point (pH4)

F6.1.EPS

Second calibration point (pH4)

m

pH0

First calibration point (pH7)

Fig. 6.2

+mV

-mV

Theoretical value

pH7, 0mV

pH14

Asymmetry potential

Calibration curve (slope)

F6.2.EPS

6-2

IM 12B11A01-01E

Page 56

6. Calibration with standard solution

3) When using one kind of standard solution for manual calibration of the EXA PH100

pH converter, choose any of the standard solutions and draw the calibration curve

through the calibration point (Fig. 6.3).

calibration curve

+mV

Theoretical value

pH7, 0mV

Theoretical value

calibration point when using arbitrary standard liquid

Fig. 6.3

CAUTION

Calibration point represents the electrode emf corresponding to the pH value of the

standard solution used.

pH0

-mV

pH14

Asymmetry potential

F6.3.EPS

IM 12B11A01-01E

6-3

Page 57

4) When using two kinds of standard solution for manual calibration of the EXA PH100

pH converter, choose two arbitrary standard solutions and adjust the asymmetry

potential and slope so that the calibration chart passes through the first and second

calibration points (Fig. 6.4)

CAUTION

It will need more than a pH difference of at least 2 between pH values of the two kinds

of standard solution.

Second calibration point

+mV

Theoretical value

pH7, 0mV

pH0

Fig. 6.4

pH14

asymmetry potential

first calibration point

-mV

calibration curve (slope)

F6.4.eps

6-4

IM 12B11A01-01E

Page 58

6.3 Preparation

(1) Selection the calibration method

* On the calibration parameter setting screen, select the calibration method: automatic

calibration or manual calibration.

* On the calibration parameter setting screen, select one-point calibration or two-point

calibration. Usually, we recommend two-point calibration.

1) Two-point calibration

Select combination of standard solutions from the following:

* pH7 and pH4

pH9 (pH10*) and pH7

pH9 (pH10*) and pH4

*: if US technical standard solution table selected.

2) One-point calibration

Select standard solution from the following:

pH7

pH4

pH9 (pH10*)

*: if US technical standard solution table selected

* On the calibration parameter setting screen, select the kind of standard solution

calibration table from JIS • NIST standard solution table, US technical standard table,

or DIN standard solution table.

6. Calibration with standard solution

IM 12B11A01-01E

6-5

Page 59

Press m key

for 3 sec.

Press m key

for 3 sec.

Example flow chart for setting of auto calibration (two-point calibration) at pH9 and pH7,

using JIS standard calibration table.

PH100EXA

S1

S4S3S2

ENT

Measurement screen

PH100EXA

S1

S4S3S2

pH

CANCEL

MEASCALSET

Press SET/ENT

for 3 sec.

pH

Ao.PA flashing

m key key

EXA PH100

S1S2S3

S4

Calibreation screen

S1

Calibration method setting

S4S3S2

S1

S4S3S2

Calibration points

m

CAL flashing

pH

SET/ENT key

PH100EXA

Meaning of the parameter

Auto calibration: 0 (initial value)

pH

Manual calibration: 1

SET/ENT key

PH100EXA

*Meaning of the parameter

One-point calibration: 0

pH

Two-point calibration: 1(initial value)

Change value with m and . keys

PH100EXA

pH

S1

S4S3S2

Two-point calibration with standard solution

SET/ENT key

rewrites data

PH100EXA

pH

S1