User ’s

Manual

PG400

Pulse Generator for Clean Unit

IM 19C01B05-01EN

IM 19C01B05-01EN

1st Edition

u Introduction

Thank you for purchasing the PG400 Pulse Generator for Clean Unit.

This Instructor’s Manual contains all essential information for the user to make full use of PG400.

Used in combination with an ultrasonic oscillator, the PG400 composes an ultrasonic cleaning

device, supplying the operating power to the oscillator via cabling.

The ultrasonic oscillator combined with PG400 is a piezoelectric ceramic-type vibrator mainly

composed of lead zirconate titanate.

The ultrasonic oscillator is built into sensor holders and detectors of the following instruments.

PH8HS, PH8HF:

TB820D: Right Angle Scattered Light Turbidity Analyzer

TB810D *: Scattered Light Turbidity Analyzer

TB750G: Right Angle Scattered Light Turbidimeter

TB700G *: Scattered Light Turbidimeter

* : TB810D and TB700G are sold only in Japan.

For further information on the holders and detectors/sensors, refer to the respective

specications.

An exclusive User’s Manual might be attached to the products whose sux codes or option

codes contain the code “Z” (made to customers’ specications). Please read it along with this

manual.

sensor holders with ultrasonic cleane

2

r

For PG400 General Specications, read GS 19C01B05-01EN.

You can download the latest documents from our website.

https://www.yokogawa.com/an/pg400/

n Notes on Handling User’s Manuals

• Please hand over the user’s manuals to your end users so that they can keep the user’s

manuals on hand for convenient reference.

• Please read the information thoroughly before using the product.

• The purpose of these user’s manuals is not to warrant that the product is well suited to any

particular purpose but rather to describe the functional details of the product.

• No part of the user’s manuals may be transferred or reproduced without prior written

consent from YOKOGAWA.

• YOKOGAWA reserves the right to make improvements in the user’s manuals and product at

any time, without notice or obligation.

• If you have any questions, or you nd mistakes or omissions in the user’s manuals, please

contact our sales representative or your local distributor.

n Trademark Notices

All other company and product names mentioned in this user’s manual are trademarks or

registered trademarks of their respective companies.

We do not use TM or ® mark to indicate those trademarks or registered trademarks in this user’s

manual.

n Product Disposal

The instrument should be disposed of in accordance with local and national legislation/

regulations.

Media No. IM 19C01B05-01EN 1st Edition : Feb. 2021 (YK)

All Rights Reserved Copyright © 2021, Yokogawa Electric Corporation

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

u Safety Precautions

WARNING

Installation and wiring

The PG400 should only be used with equipment that meets the relevant IEC, American or

Canadian standards. Yokogawa accepts no responsibility for the misuse of this unit.

Don’t install “general purpose type” instruments in the hazardous area.

Do not use an abrasive or organic solvent in cleaning the instrument.

Electrostatic discharge

The PG400 contains devices that can be damaged by electrostatic discharge. When servicing this

equipment, please observe proper procedures to prevent such damage. Replacement components

should be shipped in conductive packaging. Repair work should be done at grounded workstations

using grounded soldering irons and wrist straps to avoid electrostatic discharge.

CAUTION

The Instrument is packed carefully with shock absorbing materials, nevertheless, the instrument

may be damaged or broken if subjected to strong shock, such as if the instrument is dropped.

Handle with care.

This instrument is EN61326-1 Class A product, and it is designed for use in the industrial

environment. Please use this instrument in the industrial environment only. When you open the

front cover, make sure the screws are completely out of the screw holes, and then open the front

cover slowly in order not to damage the threaded parts on the housing. If the threaded parts are

damaged and the screws cannot be tightened, the waterproof performance will deteriorate.

3

n Safety,Protection,andModicationoftheProduct

• In order to protect the system controlled by the product and the product itself and ensure

safe operation, observe the safety precautions described in this user’s manual. We assume

no liability for safety if users fail to observe these instructions when operating the product.

• If this instrument is used in a manner not specied in this user’s manual, the protection

provided by this instrument may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for

the product itself, prepare it separately.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter

simply referred to as YOKOGAWA) when replacing parts or consumables.

• Modication of the product is strictly prohibited.

• The following safety symbols are used on the product as well as in this manual.

WARNING

This symbol indicates that an operator must follow the instructions laid out in this manual in order

to avoid the risks, for the human body, of injury, electric shock, or fatalities. The manual describes

what special care the operator must take to avoid such risks.

CAUTION

This symbol indicates that the operator must refer to the instructions in this manual in order to

prevent the instrument (hardware) or software from being damaged, or a system failure from

occurring.

CAUTION

This symbol gives information essential for understanding the operations and functions.

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

NOTE

This symbol indicates information that complements the present topic.

This symbol indicates Protective Ground Terminal.

n Warning and Disclaimer

The product is provided on an “as is” basis. YOKOGAWA shall have neither liability nor

responsibility to any person or entity with respect to any direct or indirect loss or damage arising

from using the product or any defect of the product that YOKOGAWA can not predict in advance.

u Compliant Standards

Safety: UL 61010-1

CAN/CSA-C22.2 No.61010-1

EN 61010-1

GB30439

Installation altitude: 2000 m or less

Category based on IEC 61010: II (Note 1)

Pollution degree based on IEC 61010: 2 (Note 2)

Note 1: Installation category, called over-voltage category,species impulse withstand voltage.

Category II is energy-consuming equipment to be supplied from the xed installation.

Note 2: Pollution degree indicates the degree of existence of solid, liquid, gas or other inclusions which may reduce

dielectric strength. Degree 2 is the normal indoor environment.

EMC: EN 61326-1 Class A,Table 2 (For use in industrial locations)

EN61000-3-2

EN61000-3-3

RCM: EN 61326-1 Class A,Table 2

Korea Electromagnetic Conformity Standard Class A

A급 기기 (업무용 방송통신기자재)

이 기기는 업무용(A급) 전자파적합기기로서 판매자 또는

사용자는 이 점을 주의하시기 바라며, 가정외의 지역에서

Information of the WEEE Directive

This product is purposely designed to be used in a large scale xed installations only and,

RoHS: EN IEC 63000

REACH: Regulation EC 1907/2006

사용하는 것을 목적으로 합니다.

therefore, is out of scope of the WEEE Directive. The WEEE Directive does not apply.

The WEEE Directive is only valid in the EU

4

한국 전자파적합성 기준

u CE marking products

n Authorized Representative in EEA

The Authorized Representative for this product in EEA is Yokogawa Europe B.V. (Euroweg 2,

3825 HD Amersfoort, The Netherlands).

n IdenticationTag

This manual and the identication tag attached on packing box are essential parts of the product.

Keep them together in a safe place for future reference.

n Users

This product is designed to be used by a person with specialized knowledge.

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

n Information of the WEEE Directive

This product is purposely designed to be used in a large scale xed installations only and,

therefore, is out of scope of the WEEE Directive. The WEEE Directive does not apply.

This product should be disposed in accordance with local and national legislation/regulations.

The WEEE Directive is only valid in the EU.

5

u

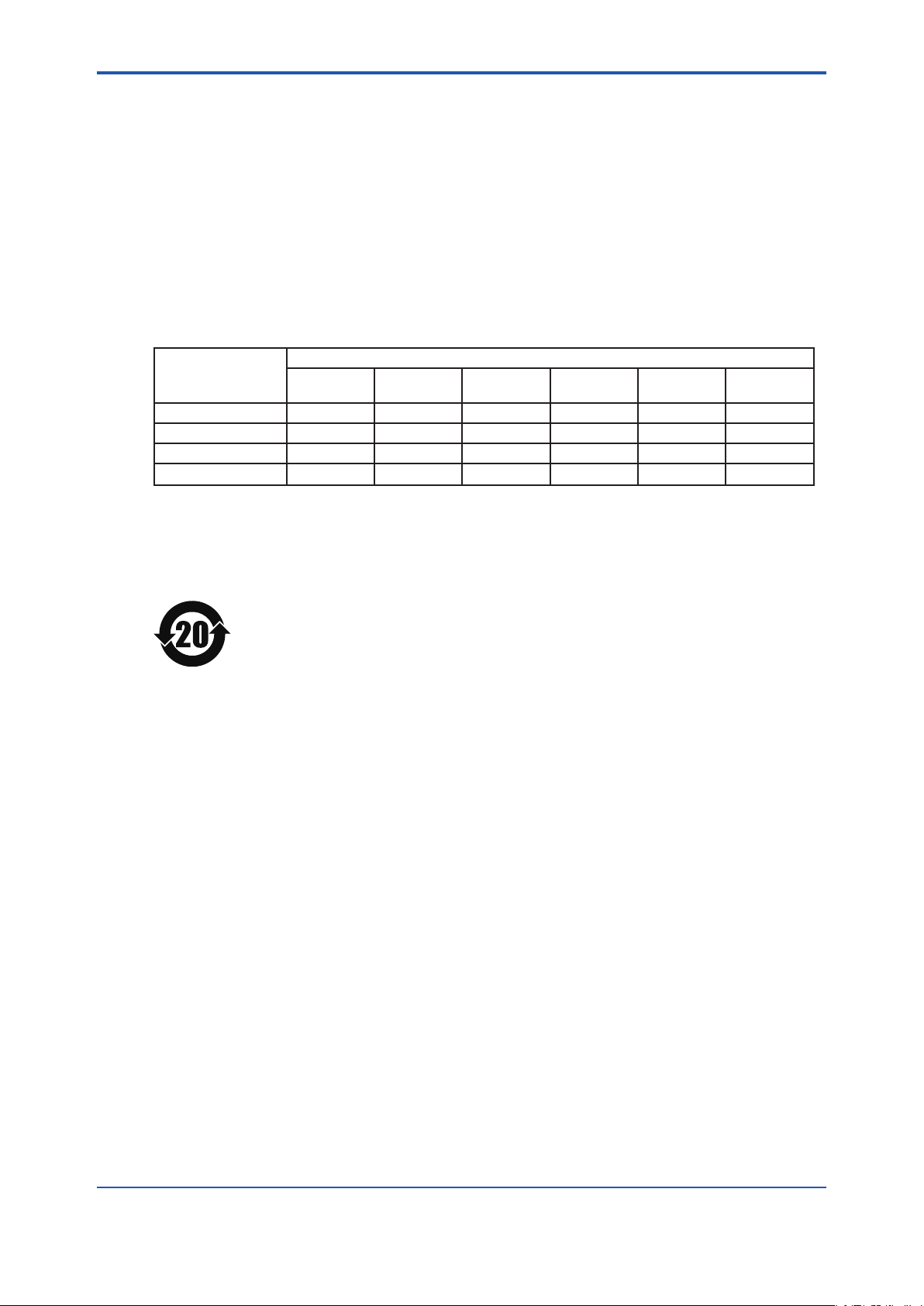

Control of Pollution Caused by the Product

This is an explanation for the product based on “Control of Pollution caused by Electronic

Information Products” in the People’s Republic of China.

产品中有害物质的名称及含量

有害物质

部件名称

外壳(金属) × × × × ○ ○

外壳(塑料) × × × × ○ ○

印刷电路板组件 × × × × ○ ○

电缆 ○ ○ ○ ○ ○ ○

○: 表示该有害物质在该部件中所有均质材料中的含有量都在GB/T26572所规定的限量要求以下。

×: 表示该有害物质至少在该部件的某一均质材料中的含有量超出GB/T26572所规定的限量要求。

环保使用期限: 这个标志是基于SJ/T11364,在中国(不包括台湾,香港,澳门)贩售的电子电

器产品所适用的环保使用期限。

只要遵守产品上关于安全及使用上的注意事项,从制造之日起计算在该年限

内,不会发生制品内的有害物质外泄,突然变异,对环境或人体以及财产产生

重大影响的情况。

(注) 该年限是《环境保护使用期限》,不是产品的保质期限。

铅

(Pb)

汞

(Hg)

镉

(Cd)

六价铬

(Cr (VI))

多溴联苯

(PBB)

另外,关于替换部件的推荐替换周期,请阅读使用说明书。

多溴二苯醚

(PBDE)

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

1. Overview

Upon delivery, unpack the instrument carefully and inspect it to ensure that it was not damaged

during shipment. If damage is found, retain the original packing materials (including the outer

box) and then immediately notify the carrier and the relevant Yokogawa sales oce.

Verify the items on the name plate including Model, Sux code, axed to the left side of the

instrument, are correct and same as your order. Check whether all accessories are supplied.

n GeneralSpecications

See the latest PG400 specications GS 19C01B05-01EN.

6

n Model&SuxCodes

Model Suxcode

PG400 ······························ ··············· Pulse generator for clean unit

Power supply

Housing

(*1)

Type -AB

Output -PU

— -00 ··············· Always -00

Country (*5) -N

Assembled in stanchion -NN

Option /UM

*1: For high anti-corrosion coating, urethane coating and epoxy coating which is for alkali resistance are applied.

*2: “-AJ” is recommended for use in Japan.

*3: Oscillator cables are supplied with PH8HS or PH8HF when a code for ultrasonic cleaning is specied.

*4: When connecting to TB820D or TB810D with “-NN”, a dedicated oscillator cable is required separately.

*5: When using in Japan, be sure to select “-J”

*6: Select “-TU”. In addition, order a TB810D with the specic sux code for ultrasonic cleaning. /UM, /U, /U1, /PM,/PM1, /

*7: Universal mounting kit includes the pipe, wall mounting bracket (/U) and panel mounting bracket (/PM).

-A ···············

-B

-D

-AD

-AG

-AJ

-TU

-J

When replacing from a PUS400G, use the existing cable.

Refer to the “Oscillator cable” table.

When connecting to TB810D with “-ST”, an arrangement of the oscillator cable is not required.

When connecting to a TB700G or TB750G (when replacing from a TUS400G), use the existing cable. Also, since the

existing cable is not compatible with the safety standards, select “-AJ” or “-AG”.

H6, /H7 cannot be selected.

-ST

Option code

···············

···············

···············

···············

···············

···············

···············

···············

···············

···············

···············

···············

/U

/U1

/PM

/PM1

/H6

/H7

/SCT

/CB

/CD

/CF

Description

AC power supply

Aluminum alloy cast + urethane coating

Aluminum alloy cast + high anti-corrosion coating

General purpose for CE, China standard

General purpose for CSA

General purpose for KC, RCM

General purpose (*2)

for PH8HS,PH8HF (*3)

for TB820D,TB810D TB750G,TB700G (*4)

Global except Japan

Japan

Not assembled in stanchion

Assembled in stanchion (*6)

Universal mounting kit (stainless steel) (*7)

Pipe and wall mounting hardware (stainless steel)

Wall mounting hardware for replace (from PUS400G/TUS400G)

Panel mounting hardware (stainless steel)

Panel mounting hardware for replace (from PUS400G/TUS400G)

Hood, stainless steel

Hood, stainless steel + urethane coating

Stainless steel tag plate

Conduit adapter (G1/2 x 2 pcs)

Conduit adapter (1/2NPT x 2 pcs)

Conduit adapter (M20 x 1.5 x 2 pcs)

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

Accessories

Name Q’ ty Remarks

Cable gland 3 pieces

1 rubber plug is attached.(Part No. of the set K8008EN)

Plate 1 piece For cable gland connection (Part No. K8008ET)

Option Mounting bracket 1 set Option / UM, /U, /U1, /PM, /PM1

Hood 1 set Option /H6, /H7

Stainless steel tag plate 1 set Option /SCT, tag plate, wire.

Tag plate 1 sheet Other than /SCT, TAG No.is specied

Conduit adapter setting 1 set (2 pack/1 set) Option /CB, /CD, /CF

User’s Manual 1 book (This manual)

Oscillator cable

Required for connection to TB820D, TB810D.

Part No. Cable Length

K8008AW 1 m

K8008AX 5 m

K8008AY 10 m

K8008AZ 15 m

Option parts

Rubber plug K9703ZN for cable gland

Fuse A1109EF 250V/1.0A (minimum 5 pcs)

Conduit

adapter

Hardware Pipe and wall mounting

Hood Stainless steel K9698WK same as Option code /H6

Name Part No. Remarks

G1/2 K8008GF for Option code /CB

1/2NPT K8008GG for Option code /CD

M20×1.5 K8008GH for Option code /CF

K9703SS same as Option code /U

hardware

Panel mounting hardware K9703ZD same as Option code /PM

Wall mounting hardware for

K8008GN same as Option code /U1

replace

Panel mounting hardware

K8008GA same as Option code /PM1

for replace

Stainless steel with

K9698WL same as Option code /H7

urethane coating

7

n Names and description

LED Display

Front cover

Front view

Figure 1 PG400 Parts names

Power cable inlet Oscillator cable inlet

Ground terminal

Fuse case

Protect cover

POWER LED

OUTPUT LED

Volume

OUTPUT switch

(Not used)

Plate

When Front cover is open

Shield terminal (S)

Power terminal (L, N)

When Front cover is open and Protect cover is removed.

Output terminal (U1, U2, U3)

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

n Dimensions

8

165

For power supply

165

40

For Oscillator cable

(not used)

146 9

137

Unit: mm

80

80

4-M6 depth 8

137

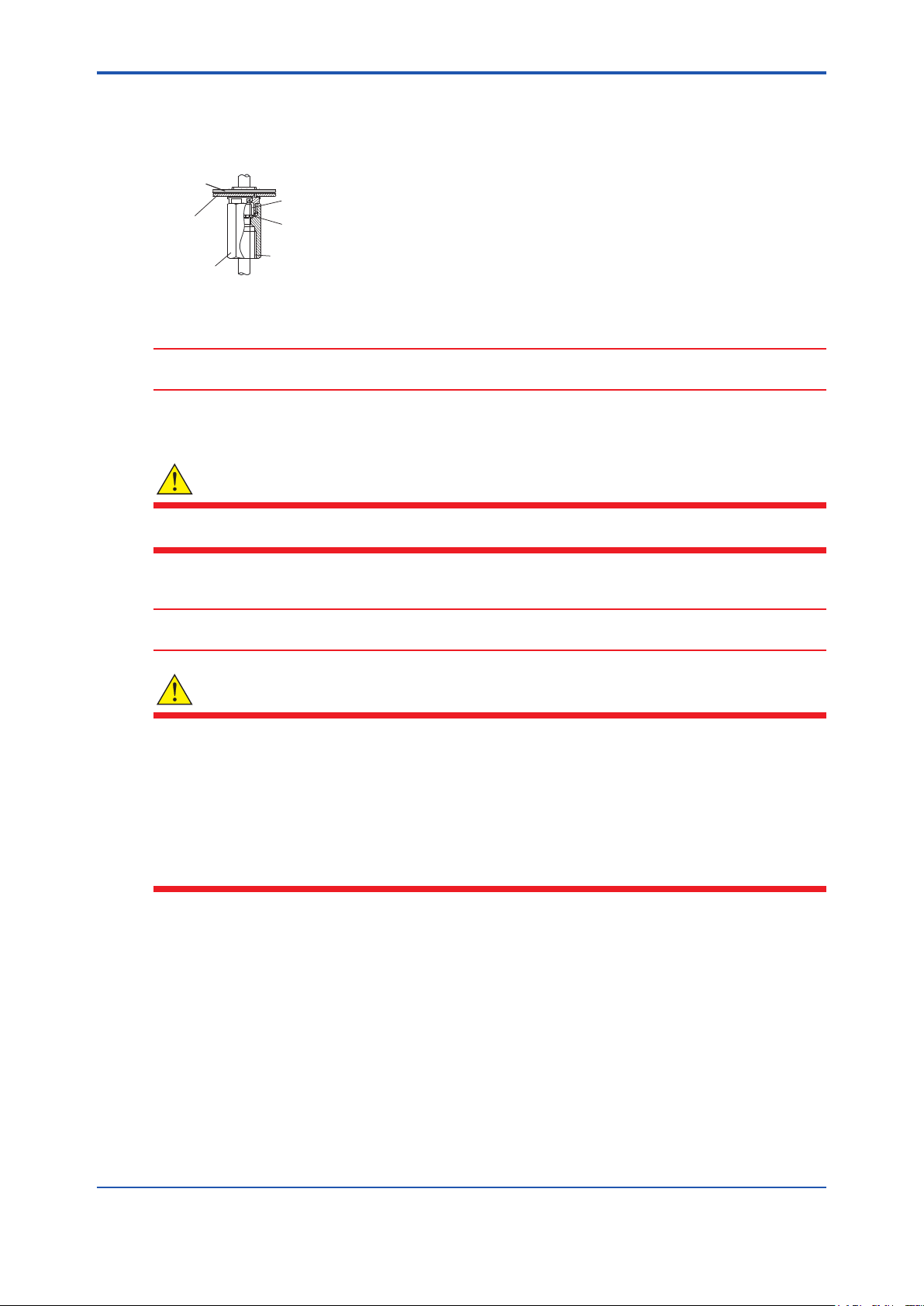

l Conduit Adapter (Option code: /CB, /CD, /CF)

Unit: mm(inch)

Case

Plate

Approx.

55(2.2")

Adapter

49

(1.93")

Packing

Tab

G1/2 female thread (/CB)

1/2 NPT female thread (/CD)

M20x1.5 (/CF)

l Stainless steel hood (Option code: /H6, /H7)

199

184

165

165

220

9

57

72

Unit: mm

(50)

(70)

(100)

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

(Note)

The universal mounting kit (/UM) contains the pipe and wall mounting hardware (/U) and the panel mounting hardware (/PM).

l Panel mounting hardware (Option code: /PM, /UM)

1 to 12

9

Unit: mm

Panel thickness

2-M5 length 35

4-M6 *

121

+1

0

138

138

+1

0

100

185

Spacing panel cutout

178

l

Panel mounting hardware for replace (from PUS400G/TUS400G) (Option code: /PM1)

*: Tighten the four screws to a torque of 2 N•m.

Unit: mm

195

+1.1

156

0

121

+1.1

0

138

173

121

Panel cutout dimensions

180

Part for

replacement

138

180

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

l Wall mounting hardware (Option code: /U, /UM)

10

165

168

4-M6 *

13

165

234.5

For wall mounting

3-ø10 holes

200

50

15

70

*: Tighten the four screws to a torque of 2 N•m.

l

Wall mounting hardware for replace (from PUS400G/TUS400G) (Option code: /U1)

4-M6 *

Unit: mm

100

Unit: mm

185

42

15

For wall mounting

3-ø10 holes

70

100

*: Tighten the four screws to a torque of 2 N•m.

l Pipe mounting hardware (Option code: /U, /UM)

155

50 184.5

Pipe mounting (Horizontal)

*: Tighten the four screws to a torque of 2 N•m.

(209)

Pipe mounting (Vertical)

Pipe 50A

(ø60.5)

4-M6 *

M8 U-bolt

200

165

100

Unit: mm

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

2. Installation and Wiring

This chapter describes wiring and installation.

2.1 Installation

The PG400 is weatherproof and can be installed both indoors and outdoors. It should, however,

be installed as close as possible to the holders for pH meters or turbidity detectors. Avoid long

cable runs of oscillator cables between the instrument and detectors.

Select an installation site where the ambient temperature and humidity are within the limits of the

instrument specications as below. If the instrument is installed outdoors and exposed to direct

sunlight, a sun shade hood should be used.

Ambient Operating Temperature: -15 to +55 ºC

Storage Temperature: -30 to +70 ºC

Humidity: 10 to 90% RH at 40ºC (Non-condensing)

Select an installation site that meets the following conditions.

• Mechanical vibrations and shocks are negligible.

• No relay switch and power switch are installed close to the converter.

• There is space for cable connection beneath the cable glands.

• Not exposed to direct sunlight or severe weather conditions.

• Maintenance is possible.

• No corrosive atmosphere.

The PG400 has following mounting possibilities. See Dimensions for information on the hardware

for mounting.

• Panel mounting using optional mounting hardware (/PM or /UM)

• Wall mounting using optional mounting hardware (/U or /UM)

• Pipe mounting using optional mounting hardware (/U or /UM) on a horizontal or vertical

pipes (Nominal size: 50A)

When replacing PUS400G or TUS400G with PG400, you can continue to use the existing panel

holes or installation holes by using the hardware for replacement.

• Panel mounting using optional mounting hardware (/PM1)

• Wall mounting using optional mounting hardware (/U1)

The universal mounting kit (/UM) contains the pipe and wall mounting hardware (/U) and the

panel mounting hardware (/PM). Some can be left unused.

11

2.2 Wiring

Loosen the screws at the four corners of the front cover and open the front cover to the left.

For replacement, screws (Part No. K9699PL : M5 screw + spring) are required.

Before you remove the protect cover to wire output terminals and power cable, be sure to shut down

the power supply.

Do not allow cables to cover the LED light.

WARNING

Always place the protect cover over the terminals to avoid electric shock.

CAUTION

To install the front cover, tighten each screw evenly until every four of them is completely

fastened. For example turn each screw in two times and repeat it until all of the screws are

evenly tightened up.

Do not use an electric screwdriver with high revolutions such as 1000 rpm. The revolutions

of the electric screwdriver should be less than 400 rpm.

Tighten the four front cover screws to the torque of 1.5 to 1.6 N·m. for complying with IP66 or Type4X)

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

2.2.1 Removing/Installation protect cover

The protect cover (Part No. K8008EF) covers high-voltage power supply terminals and output terminals.

WARNING

To ensure your safety, before you remove the protect cover, be sure to shut down the power

supply and wait for 15 seconds after LED light turns o.

To remove the protect cover, loosen the two screws at Δ (triangle) (Figure 2, left). Pull out the

protect cover by holding the marked point :○ (circle) (Figure 2, left). Do not lose the setscrews for

the cover.

To install the protect cover, hold the marked point :○ (circle) (Figure 2, right) and push the top of

the protect cover along with the shaded part (Figure2, right).

Protect cover

12

Figure 2 Protect cover

2.2.2 Installation cable gland

Follow the next procedure to install the supplied cable gland. (Figure 3)

The supplied cable glands are for cables with an outside diameter of 6 to 12 mm (0.24 to 0.47 inches).

(1) Push the plate along with the metal plate to help indicate the position.

(2) Conrm that the cable gland has gasket and washer attached. Screw lightly the three cable

glands from the bottom of the case while keeping the setscrews settled properly.

(3) Tighten the cable glands to the torque of 2 N•m.

Unused cable entry holes must be sealed with cable glands including the supplied rubber plugs.

CAUTION

● Be careful not to be injured by the sharp hole edges on the housing.

● Tighten the cable glands to the torque of 2 N•m. (rating IP66 or higher)

Power cable inlet

Plate

Washer

Oscillator cable inlet

(unused)

Plate for positioning

Gasket

Cable gland

Figure 3 Cable glands

Rubber plug

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

l Conduit adapter

When protecting the cable with a conduit, use an adapter. (option codes: /CB, /CD, /CF)

Apply the supplied cable gland for adapter (white) to the holes which conduit adapters connect to

instead of using supplied-accessory cable gland (dark gray). Caps of cable glands are not used.

Plate

Case

Adapter

Figure 4 Conduit adapter (option)

Packing

Tab

G1/2 female thread (/CB)

1/2 NPT female thread (/CD)

M20x1.5 (/CF)

CAUTION

When using a cable conduit, use a exible conduit to avoid stress on the conduit adapter.

The excessive stress on the conduit adapter may damage the housing.

2.2.3 Wiring power supply

WARNING

13

Use wiring cables with heat resistance above 75°C.

For power supply, wire cables with a ammability rating of UL 2556 VW-1 or equivalent.

CAUTION

Turn o power supply to PG400 before wiring. Power rating must comply with PG400

specication. Power voltage must match with the one indicated on the name plate.

WARNING

● You must install external power supply switch or circuit breaker for power supply.

● The external power supply switch or a circuit breaker must comply with a current rating of

5A, IEC60947-1 or IEC60947-3.

● Yokogawa recommend installing the external power supply switch, circuit breaker and

PG400 all in the same location.

● Install the external power supply switch or circuit breaker to the place where operators

access easily. To alert users, put a label on the external power switch.

● Wire cables of power supply or contact output securely with cable rack, conduit and vinyl

band. Unplugged cables are dangerous and may cause an electric shock.

Some regions where the instrument is used may require the installation of an external circuit

breaker.

When TB810D or TB820 supplies power, no installation of an external circuit breaker is needed.

To prepare for wiring cables, open the front cover and remove the protect cover so that you can

access terminals easily.

The size of power supply cable is 2.0 mm2 (14 AWG) or larger. Use the crimp terminals of 7.2 mm

or less width. The terminals use M4 screw.

l Power supply

Connect cables to the power terminals L, N. See Figure 1. Use crimp terminals.(ring or fork type)

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

l Grounding

WARNING

Use the protective earth conductors whose minimum size of the cross-sectional area is 0.75 mm2.

For CSA compliance (Type: -AD), use ones with cross-section area of 0.75 mm2 to 2.1 mm2.

CAUTION

Connect PG400 to ground (Class D ground: 100 ohm or less) for interference avoidance and

safety reasons.

Use ground cables with larger cross - sectional area. Connect the ground cable to the internal/

external grounding terminal. (Figure 5) Use ring terminals for wiring terminals.

14

(M4 screw) (M4 screw)

Figure5 External(rear)grounding,Internalgrounding

2.2.4 Wiring to output terminal

The type of oscillator cables to connect to output terminals or shield terminals varies depending

on the instrument to connect.

l -PU (Connect to PH8HS, PH8HF)

Wire the oscillator cable to terminal U1, U2, and S. Oscillator cables are supplied to PH8HS or

PH8HF with ultrasonic cleaning specied. The terminal U3 is not used.

l -TU (Connect to TB810D, TB820D/TB700G, TB750G)

When connecting to TB810D or TB820D, wire the oscillator cable to terminal U1, U2 and S. You

need to purchase the oscillator cable separately.

When connecting to TB700G or TB750G, wire the oscillator cable to terminal U1, U2, U3 and

S.You can continue to use the existing oscillator cables.

To connect to TB810D- with -ST, or for its replacement, use the cable as shown in note *4 on

“Model and Sux Codes” table.

3. Operation

After every wiring completes and the cover is installed, turn on the power and conrm the green

POWER LED is lit. To start the cleaning, turn on the output switch inside the instrument and

conrm the red OUTPUT LED is lit. Make an adjustment of ultrasonic power then shut the front

cover.

WARNING

To avoid electric shock, do not insert thin or exible wires or the like from the opening of the

instrument.

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

CAUTION

● When the oscillator does not contact uid, turn o the output switch to avoid damages to

instrument.

● Tighten the four front cover screws to the torque of 1.5 to 1.6 N·m.

n Adjusting ultrasonic power

In ultrasonic cleaning, cavitation caused by the application of ultrasonic waves contributes to the

cleaning eect. The more cavities are produced, the more the cleaning eect is enhanced.

In turbidity measurement using an optical system or pH measurement, however, measured

values are more largely inuenced with increase in the number of cavities produced.

PG400 can adjust the ultrasonic power so that the inuence on measurements is controlled to

within an allowable range and provide the most ecient cleaning.

Adjusting the ultrasonic power is recommended, when using for the rst-time, replacing the

ultrasonic oscillator, or changing the process ow rate.

l Adjusting Procedure

Adjust the ultrasonic power by turning the volume adjuster. Adjust it so that the measurement

dierence of turbidity detector or pH sensor can fall within an allowable range between when the

ultrasonic cleeaning is on and o.

(1) Turn OFF the output switch of PG400. Then, feed a sample water into the turbidity detector

or pH sensor at the same ow rate as in a steady-state operation. Actuate the turbidimeter

or pH analyzer.

Note: Even if the ultrasonic power is the same, the inuence of ultrasonic waves on measured values varies depending

on the properties (velocity of ow and amount of suspended solids) of uid in the sample cell.

(2) Keep the output switch turned OFF. Wait until the turbidity or pH measurement becomes

stable then record the measurement value.

(3) Turn ON the output switch of PG400. Wait until the turbidity or pH measurement becomes

stable then record the measurement value.

(4) Compare the result from (2) and (3). If the dierence between the two measurement

is within an allowable range, the adjustment is complete. If not, you need to adjust the

ultrasonic power. Insert a athead screwdriver into the slot of the volume adjuster and turn it

counterclockwise to reduce the ultrasonic power. (Figure.3.1) Then, return to (3).

Note:In case the power seems to have lowered excessively, turn it clockwise to increase the power.

Then, return to (3).

15

4. Maintenance

The PG400 requires very little periodic maintenance, except to make sure the front window is

kept clean in order to permit a clear view of the LED.

If the window becomes soiled, clean it using a soft damp cloth or soft tissue. To deal with more

stubborn stains, a neutral detergent may be used.

When you must open the front cover and/or remove cable glands, make sure that the seals

are clean and correctly tted when the unit is re-assembled in order to maintain the housing’s

weatherproof integrity against water and water vapor.

CAUTION

Never use harsh chemicals or solvents. If the window does become heavily stained or scratched,

parts replacement might be required.

Contact Yokogawa service when replacing the front cover. Part numbers are

coating), or K8008DF (Code of Housing “-D”, High anti-corrosion coating).

K8008DC (Code of Housing “-B”, Urethane

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

<PG400 Pulse Generator for Clean Unit>

Check sometimes whether POWER LED, OUTPUT LED is lit. If they are not lit on, refer to the

following procedure.

● POWERLEDiso.

PG400 is protected by fuse which provides overcurrent protection of inner circuit.

POWER LED is o because the fuse may be blown out. To replace the fuse with a new

one(A1109EF), shut o the power supply rst then remove the protect cover. If the POWER

LED stays o even after the fuse is replaced, contact Yokogawa service center. For

replacement, use the fuse with a rating specied on page 7 the table “Option parts”.

WARNING

Fuse replacement should be performed only by a qualied service personnel.

● OUTPUTLEDiso.

If OUTPUT LED is o, even when POWER LED is lit on and the output switch is on, contact

Yokogawa service.

n Nocleaningeectbyultrasoniccleaning

Ultrasonic cleaning is considered to be working eectively, when no visible contamination is

found on the surface of glass electrode/junction of pH sensors, or the window of ultrasonic

oscillator of turbidity detectors. However, if you found no or little eect even after the cleaning-

power adjustment, the possible reasons would be as follows.

● Ultrasonicoscillatorerror

Check whether there is a hole made by a surface corrosion of the oscillator. If there is the

corrosion and uid enters the instrument, other parts may need to be replaced.

● Oscillatorcableerror

Shut o the power supply then check whether there is wire disconnection or short circuit.

16

NOTE

Adhesive substances in sample may aect the junction of the ultrasonic oscillator. The

contamination of the wetted surface, especially on the surface of the vibrating part should be

removed. The contamination may impair the cleaning eect. If the sample contains adhesive

contaminants, keep the surface from the xation of contaminations when the operation is

paused. Refer to each detector’s user’s manual for cleaning those contaminants including

chemicals or substances which ultrasonic cleaning may not be eective to.

Revision Record

Feb. 2021/1st Edition

Newly published

Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo 180-8750, JAPAN

http://www.yokogawa.com/

IM 19C01B05-01EN 1st Edition : Feb. 18, 2021-00

Loading...

Loading...