Page 1

GS200

DC Voltage/Current Source

IM GS210-01EN

3rd Edition

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and

services.

Please allow us to serve you best by completing the product registration

form accessible from our homepage.

http://tmi.yokogawa.com/

PIM 103-03E

Page 3

Notes

Trademarks

Thank you for purchasing the GS200 DC voltage/current source.

This user’s manual explains the features, operating procedures, and handling

precautions of the GS200. To ensure correct use, please read this manual thoroughly

before beginning operation. Keep this manual in a safe place for quick reference in the

event a question arises.

• The contents of this manual are subject to change without prior notice as a result

of continuing improvements to the instrument’s performance and functionality. The

figures given in this manual may differ from those that actually appear on your screen.

•

Every effort has been made in the preparation of this manual t

o ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without

YOKOGA

• The TCP/IP

WA’s permission is strictly prohibited.

software of this product and the document concerning the TCP/IP

software have been developed/created by YOKOGAWA based on the BSD Networking

Software, Release 1 that has been licensed from University of California.

• Microsoft, Internet Explorer, MS-DOS, Windows, and Windows XP are either

registered trademarks or trademarks of Microsoft Corporation in the United States

and/or other countries.

•

Adobe and Acrobat are trademarks of

• In this manual, the TM and

® symbols do not accompany their respective registered

Adobe Systems Incorporated.

trademark or trademark names.

• Other company and product names are registered trademarks or trademarks of their

respective holders.

Revisions

• 1st Edition : December 2009

• 2nd Edition: July 2012

• 3rd Edition: September 2013

3rd Edition: September 2013 (YMI)

All Rights Reserved, Copyright ©2009, Yokogawa Electric Corporation

All Rights Reserved, Copyright ©2012, Yokogawa Meters & Instruments Corporation

IM GS210-01EN

i

Page 4

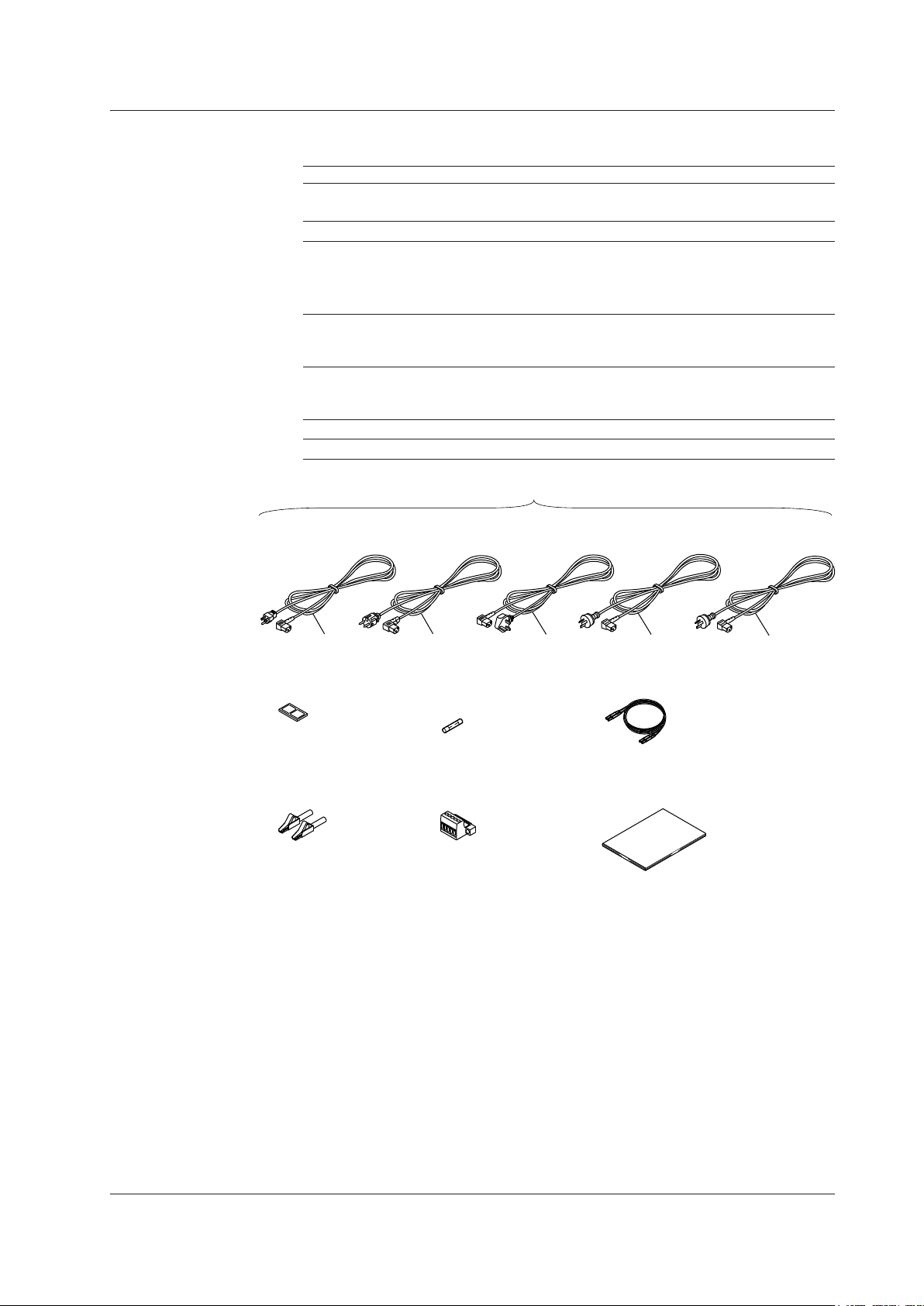

Checking the Contents of the Package

MODEL

SUFFIX

Made in Japan

NO

MODEL

SUFFIX

Made in Japan

NO

After receiving the product and opening the package, check the items described below.

If the wrong items have been delivered, if items are missing, or if there is a problem with

the appearance of the items, contact your nearest YOKOGAWA dealer.

GS200

Check that the model name and suffix code given on the name plate on the side panel

are the same as those on your order.

MODEL and SUFFIX Codes

Model Suffix Code Description

GS210 DC voltage/current source (front panel output terminals)

GS211 DC voltage/current source (rear panel output terminals)

Supply voltage -1 100 VAC, 50/60 Hz

-4 120 VAC, 50/60 Hz

-7 230 VAC, 50/60 Hz

Power cord

[Maximum rated voltage: 125 V; Maximum rated current: 7A]

-F VDE Standard Power Cord (Part No.: A1009WD)

[Maximum rated voltage: 250 V; Maximum rated current: 10 A]

-Q BS Standard Power Cord (Part No.: A1054WD)

[Maximum rated voltage: 250 V; Maximum rated current: 10 A]

-R AS Standard Power Cord (Part No.: A1024WD)

[Maximum rated voltage: 250 V; Maximum rated current: 10 A]

-H GB Standard Power Cord (Part No.: A1064WD)

[Maximum rated voltage: 250 V; Maximum rated current: 10 A]

Options /MON Voltage and current monitoring

/C10 Ethernet interface

1

-D UL/CSA Standard Power Cord (Part No.: A1006WD)

1 Make sure that the attached power cord meets the designated standards of the country and

area that you are using it in.

NO. (Instrument Number)

When contacting the dealer from which you purchased the instrument, please tell them

the instrument number.

ii

IM GS210-01EN

Page 5

Standard Accessories

Rubber feet

A9088ZM

User’s manual (this manual)

IMGS210-01EN

Measurement lead

2

758933

Alligator clip adaptor set

2

758922

Spare power supply fuse

A1109EF or A1108EF

Terminal plug

3

A2006JT

UL, CSA Standard

A1006WD

VDE Standard

A1009WD

BS Standard

A1054WD

AS Standard

A1024WD

D

F

R

Q

One of these power cords1 is supplied according to the suffix code.

H

GB Standard

A1064WD

The standard accessories below are supplied with the instrument.

Name Model or Part No. Quantity Note

Power cord

page

Rubber feet A9088ZM 1 Two rubber feet in one set.

Spare power supply fuse

Power cord suffix code

-1 or -4

-7 A1108EF 1 250 V, 0.5 A, time lag.

Measurement lead 758933 1 set Safety terminal cable. Red and black, 1

Only included wi

Alligator clip adapter 758922 1 set Safety terminal-to-alligator clip adapter.

Only included wi

Terminal plug A2006JT 1 Only included with the GS211.

User’s manual IMGS210-01EN 1 This manual.

Checking the Contents of the Package

1

See the previous 1

A1109EF 1 250 V, 1 A, time lag.

pc each.

th the GS210.

Red and black, 1 pc each.

th the GS210.

IM GS210-01EN

1 Make sure that the attached power cord meets the designated standards of the country and

area that you are using it in.

2 Only included with the GS210.

3 Only included with the GS211.

iii

Page 6

Checking the Contents of the Package

Optional Accessories (Sold separately)

The optional accessories below are available for purchase separately.

Name Model or Minimum Note

Part No. Q’ty.

Measurement lead 758933 1 Safety terminal cable. Length: 1 m.

Red and black, 1 pc. each.

Measurement lead 758917 1 Safety terminal cable. Length: 0.75 m.

Red and black, 1 pc. each.

Banana plug set 758919 1 set

Small alligator clip adapter 758922

Large alligator clip adapter 758929

Fork terminal adapter 758921

Conversion adapter 758924

Conversion adapter 751512 1 Banana plug-to-binding post adapter.

BNC cable 366924 1 BNC-BNC, length: 1 m.

BNC cable 366925 1 BNC-BNC, length: 2 m.

Safety terminal adapter 758923 1 set Spring clamp type. Red and black, 1

Safety terminal adapter 758931

Terminal plug

Synchronous operation cable 758960

A2006JT 1 For use with the GS211 rear panel

4 mm plug/φ4 mm socket adapter. Red

φ

and black, 1 pc. each.

1 set Safety terminal-to-alligator clip adapter.

Red and black, 1 pc each.

1 set Safety terminal-to-alligator clip adapter.

Red and black, 1 pc each.

1 set Safety terminal-to-fork terminal adapter.

Red and black, 1 pc each.

1 BNC-to-safety terminal adapter.

pc. each.

1 set Screw-in type. Red and black, 1 pc.

each.

terminals.

1 RJ-11 cable, 6 pins, length: 1 m.

iv

IM GS210-01EN

Page 7

Safety Precautions

This instrument is an IEC safety class I instrument (provided with a terminal for protective

earth grounding).

The general safety precautions described herein must be observed during all phases

of operation. If the instrument is used in a manner not specified in this manual, the

protection provided by the instrument may be impaired. Yokogawa Electric Corporation

assumes no liability for the customer’s failure to comply with these requirements.

The following symbols are used on this instrument.

Warning: handle with care. Refer to the user’s manual or service manual.

This symbol appears on dangerous locations on the instrument which require

special instructions for proper handling or use. The same symbol appears in the

corresponding place in the manual to identify those instructions.

Ground (earth) or functional ground terminal (do not use this terminal as a

protective ground terminal).

Alternating current

ON (power)

OFF (power)

In-position of a bi-stable push control

Out-position of a bi-stable push control

Be sure to comply with the precautions below. Not complying might result in

injury or death.

WARNING

Use the Instrument Only for Its Intended Purpose

The GS200 is a generator that can generate DC voltage and current. Do not use

this instrument for anything other than as a DC voltage and current generator.

Check the Physical Appearance

Do not use the instrument if there is a problem with its physical appearance.

Use the Correct Power Supply

Before connecting the power cord, ensure that the source voltage matches the

rated supply voltage of the instrument and that it is within the maximum rated

voltage of the provided power cord.

IM GS210-01EN

Use the Correct Power Cord and Plug

To prevent the possibility of electric shock or fire, be sure to use the power cord

supplied by YOKOGAWA. The main power plug must be plugged into an outlet with

a protective earth terminal. Do not disable this protection by using an extension

cord without protective earth grounding. Additionally, do not use the power cord

supplied with this instrument with another instrument.

v

Page 8

Safety Precautions

Do not use the power cord in a bundled condition. If you use a power plug with

foreign substance on it, insulation may be compromised by humidity or other

factors and may cause a fire. Clean the power plug regularly.

Connect the Protective Grounding Terminal

Be sure to connect the protective earth to prevent electric shock before turning ON

the power. The power cord that comes with the instrument is a three-prong type

power cord. Connect the power cord to a properly grounded three-prong outlet.

Do Not Impair the Protective Grounding

Never cut off the internal or external protective earth wire or disconnect the wiring

of the protective earth terminal. Doing so poses a potential shock hazard.

Do Not Operate with Defective Protective Grounding or Fuse

Do not operate the instrument if the protective earth or fuse might be defective.

Also, make sure to check them before operation.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gasses or vapors.

Operation in such an environment constitutes a safety hazard.

Do Not Remove the Covers or Disassemble or Alter the Instrument

Only qualified YOKOGAWA personnel may remove the covers and disassemble or

alter the instrument. The inside of the instrument is dangerous because parts of it

have high voltages.

Ground the Instrument before Making External Connections

Securely connect the protective grounding before connecting to the item under

measurement or to an external control unit.

If you are going to touch the circuit, make sure to turn OFF the circuit and check

that no voltage is present.

Measurement Category

The measurement category of the GS200 signal input terminals is Other (O). Do

not use it to measure the main power supply or for Measurement Categories II, III,

and IV.

Installation Location

•

This instrument is designed to be used indoors. Do not install or use it outdoors.

Install the instrument so that you can immediately remove the power cord if an

•

abnormal or dangerous condition occurs.

CAUTION

Operating Environment Limitations

This product is a Class A (for industrial environment) product. Operation of this

product in a residential area may cause radio interference in which case the user is

required to correct the interference.

vi

IM GS210-01EN

Page 9

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE), Directive 2002/96/EC

(This directive is valid only in the EU.)

This product complies with the WEEE Directive (2002/96/EC) marking

requirement. This marking indicates that you must not discard this electrical/

electronic product in domestic household waste.

Product Category

With reference to the equipment types in the WEEE directive

product is classified as a “Monitoring and Control instrumentation” product.

Annex 1, this

Do not dispose

contact your local Yokogawa Europe B. V. office.

in domestic household waste. When disposing products in the EU,

New EU Battery Directive

New EU Battery Directive, DIRECTIVE 2006/66/EC

(This directive is valid only in the EU.)

Batteries are included in this product.

out and collected as ordained in ANNEX II in DIRECTIVE 2006/66/EC.

Battery type

Lithium battery

You cannot replace batteries by yourself. When you need to replace batteries,

contact your local Yokogawa Europe B.V.office.

This marking indicates they shall be sorted

IM GS210-01EN

vii

Page 10

Symbols and Notations Used in This Manual

Safety Markings

The following markings are used in this manual.

Improper handling or use can lead to injury to the user or damage

to the instrument. This symbol appears on the instrument to indicate

that the user must refer to the user’s manual for special instructions.

The same symbol appears in the corresponding place in the user’

s manual to identify those instructions. In the manual, the symbol is

used in conjunction with the word

“

WARNING” or “CAUTION.”

WARNING

CAUTION

Calls attention to information that is important for proper operation of

Note

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

Calls attention to actions or conditions that could cause light injury to

the user or damage to the instrument or user’s data, and precautions

that can be taken to prevent such occurrences.

the instrument.

Notations Used in the Procedural Explanations

On pages that describe the operating procedures in chapters 3 through 15 and the

appendix, the following symbols are used to distinguish the procedures from their

explanations.

Procedure

Explanation

Carry out the procedure according to the step numbers. All

procedures are written under the assumption that you are starting

operation at the beginning of the procedure, so you may not need

to carry out all the steps in a procedure when you are changing the

settings.

This section describes the setup items and the limitations regarding

the procedures. It may not give a detailed explanation of the feature.

For a detailed explanation of the feature, see chapter 2.

<<Corresponding Command Mnemonic>>

Indicates a communication command that corresponds to the feature described on the

procedural explanation page.

Characters and Terminology Used in Procedural Explanations

Keys

Bold characters used in the procedural explanations indicate characters that are marked

on the panel keys.

NUM LOCK + or

This means the following: press the NUM LOCK key to make it illuminate, and then press

the

or key. When the instrument is in this state, you can use the and keys to

directly access the items that are marked above and below these keys (numbers 0 to 9,

period, and BS).

viii

IM GS210-01EN

Page 11

Contents

3

2

1

4

5

6

7

8

9

10

11

12

13

14

15

App

Index

Checking the Contents of the Package.............................................................................................ii

Safety Precautions ............................................................................................................................v

Waste Electrical and Electronic Equipment .................................................................................... vii

New EU Battery Directive ...............................................................................................................vii

Symbols and Notations Used in This Manual ................................................................................ viii

Chapter 1 Component Names and Functions

1.1 Front Panel ....................................................................................................................... 1-1

1.2 Rear Panel ....................................................................................................................... 1-2

1.3 Display Mode and Displayed Contents ............................................................................ 1-3

1.4 Keys

................................................................................................................................. 1-5

Chapter 2 Features

2.1 SystemConguration ....................................................................................................... 2-1

ProductFeaturesandSystemConguration ................................................................ 2-1

2.2 Source Feature and Measurement Feature (Monitoring fe

2.3 Source .............................................................................................................................. 2-6

Source Range ...............................................................................................................

Source Function ............................................................................................................

Source Action ................................................................................................................

Output ON/OFF .............................................................................................................

DUT Protection Using Limiters ...................................................................................... 2-8

Local Sense and Remote Sense .................................................................................. 2-9

Guard Terminal Feature .............................................................................................. 2-10

2.4

Programs

Program Feature .......................................................................................................

Program Interval Time ..................................................................................................2-11

Program Slope Time ....................................................................................................2-11

Repeating Programs ................................................................................................... 2-12

Program Triggers ......................................................................................................

Program Files ..............................................................................................................

Executing Programs .................................................................................................... 2-14

2.5 Measurement (Monitoring feature; /MON option) ........................................................... 2-16

Measurement Function and Measurement Range ......................................................

Measurement ON/OFF ............................................................................................... 2-16

Measurement Operation ............................................................................................. 2-16

Measurement Delay .................................................................................................... 2-17

Highly Accurate Measurement and High-Speed Measurement .................................. 2-17

NULL Computation ...................................................................................................... 2-17

Store/Recall (Statistical Computation Value Display).................................................. 2-18

2.6

riggering ....................................................................................................................... 2-20

T

Overview ......................................................................................................

Program Triggers ........................................................................................................

Measurement Triggers (/MON option) ........................................................................ 2-21

Trigger Block Diagram ................................................................................................ 2-22

Trigger Output ......................................................................................................

Trigger Hold ................................................................................................................

Sampling Error ............................................................................................................

.........................................................................................................................2-11

ature; /MON option) ............... 2-3

2-6

2-7

2-7

2-8

2-11

...

2-12

..

2-13

2-16

.......

2-20

2-20

2-23

2-23

2-23

...............

IM GS210-01EN

ix

Page 12

Contents

2.7 Synchronization .............................................................................................................. 2-24

Synchronization ..........................................................................................................

External I/O .................................................................................................................

2.8 Other Features ............................................................................................................... 2-25

USB Storage Feature .................................................................................................. 2-25

USB Communication (USB-TMC command control) .................................................. 2-26

Ethernet Communications (/C10 option) ..................................................................... 2-27

GP-IB Communications .............................................................................................. 2-27

Saving, Loading, and Deleting Setup Data ................................................................. 2-27

Selecting the Settings Applied at Power-On ............................................................... 2-27

Chapter 3 Instrument Preparation and Common Operations

3.1 Handling Precautions ....................................................................................................... 3-1

3.2 Installation ........................................................................................................................ 3-3

3.3 Connecting the Power Supply .......................................................................................... 3-6

3.4 Turning the Power Switch On and Off .............................................................................. 3-7

3.5 Wiring Precautions ........................................................................................................... 3-8

3.6 Wiring the GS211 Rear Panel Terminal Plug .................................................................... 3-9

3.7 Setting the Date,

Time, and the Time Difference from GMT (Greenwich Mean Time) ... 3-10

Chapter 4 Common Settings

4.1 Basic Key Operations and How to Enter Values .............................................................. 4-1

4.2 Selecting the Wiring System (Remote Sense or Local Sense) ........................................ 4-3

4.3 Setting the Guard Terminal ............................................................................................... 4-5

4.4 USB Storage Feature ......................................................................................................

2-24

2-24

. 4-7

Chapter 5 Source

5.1 Setting the Source Function ............................................................................................. 5-1

5.2 Setting the Source Range ................................................................................................ 5-2

5.3 Setting the Source Level .................................................................................................. 5-3

5.4 Setting the Limiter ......................................................................................................

5.5 T

urning the Output On and Off ......................................................................................... 5-5

Chapter 6 Programs

6.1 Turning Program Repetition Mode On and Off ................................................................. 6-1

6.2 Setting the Program Interval Time .................................................................................... 6-2

6.3 Setting the Program Slope

6.4 Setting the Program

6.5 Creating and Editing Programs ........................................................................................ 6-5

6.6 Saving and Loading Programs ......................................................................................... 6-8

6.7 Executing Programs ......................................................................................................

Trigger (/MON option) ...................................................................... 6-4

Chapter 7 Measurement (Option)

7.1 Turning Measurement On and Off .................................................................................... 7-1

7.2 Setting the Integration Time ............................................................................................. 7-2

7.3 Setting the Measurement Delay ....................................................................................... 7-3

7.4 Selecting the Measurement

7.5 Setting the Measurement

7.6 T

7.7 Zero Calibration (Zero reference measurement) .............................................................. 7-7

7.8 Storing Measured Results ................................................................................................ 7-8

7.9 Performing Statistical Computations on Measured V

urning the NULL Computation On and Off ..................................................................... 7-6

...... 5-4

Time ...................................................................................... 6-3

. 6-12

Trigger ................................................................................. 7-4

Timer ....................................................................................... 7-5

alues (Recall) ............................... 7-10

x

IM GS210-01EN

Page 13

Contents

3

2

1

4

5

6

7

8

9

10

11

12

13

14

15

App

Index

Chapter 8 Synchronous Operation

8.1 Synchronous Operation Using the BNC I/O Terminals (IN and OUT) .............................. 8-1

8.2 Using the RJ-11 Connectors (SYNC IN and SYNC OUT) to Perform Synchronous

Operation ..........................................................................................................................

8-4

Chapter 9 Other Features

9.1 Initializing Setup Data ....................................................................................................... 9-1

9.2 Saving, Loading, and Deleting Setup Data ...................................................................... 9-2

9.3 Selecting the Settings

9.4 Selecting the Display Brightness,

Sound On and Off

9.5 Selecting the CSV File Format ......................................................................................... 9-6

9.6 Error Log Display .......................................................................................................

Applied at Power-On ..................................................................... 9-4

Turning the Display Off, and Turning the Beep

............................................................................................................. 9-5

....... 9-7

Chapter 10 USB Interface

10.1 USBInterfaceFeaturesandSpecications .................................................................... 10-1

10.2 Setting the USB Interface Mode ..................................................................................... 10-2

10.3 V

iewing the VISA Setup Information............................................................................... 10-3

Chapter 11 Ethernet Interface (Option)

11.1 EthernetInterfaceFeaturesandSpecications ..............................................................11-1

11.2 Connecting to a Network .................................................................................................11-2

11.3

11.4

11.5

ConguringNetworkSettings(TCP/IP) ...........................................................................11-3

Viewing the Network Settings ..........................................................................................11-6

Web Server Feature ........................................................................................................11-7

Chapter 12 GP-IB Interface

12.1 GP-IBInterfaceFeaturesandSpecications ................................................................. 12-1

12.2 Connecting the GP-IB Cable .......................................................................................... 12-2

12.3 Setting the GP-IB

12.4 7651-Compatible Mode .................................................................................................. 12-4

12.5 Responses to Interface Messages ................................................................................. 12-5

12.6 About the IEEE 488.2-1992 Standard ............................................................................ 12-7

Address and Command Mode ........................................................... 12-3

Chapter 13 Communication Commands

13.1 Program Format ............................................................................................................. 13-1

13.1.1 Symbols Used in the Syntax ............................................................................ 13-1

13.1.2 Messages ........................................................................................................ 13-1

13.1.3 Commands ...................................................................................................... 13-3

13.1.4 Responses ....................................................................................................... 13-5

13.1.5 Data

13.2 Commands ......................................................................................................

13.2.1 List of Commands ............................................................................................ 13-7

13.2.2 Output Commands (OUTPut group) .............................................................. 13-10

13.2.3 Source Commands (SOURce group) .............................................................13-1

13.2.4 Program Commands (PROGram group) ....................................................... 13-13

13.2.5 Measurement Commands (SENSe group) .................................................... 13-15

13.2.6 Measured V

groups)

13.2.7 Store/Recall Commands (TRACe group) ...................................................... 13-18

13.2.8 External I/O Commands (ROUT

13.2.9 System Commands (SYST

................................................................................................................. 13-5

alue Read Commands (INITiate, FETCh, READ, and MEASure

........................................................................................................... 13-17

............... 13-7

1

e group) ....................................................... 13-20

em group) ............................................................ 13-21

IM GS210-01EN

xi

Page 14

Contents

13.2.10 Status Commands (STATus group) ............................................................... 13-23

13.2.11 Common Commands ..................................................................................... 13-24

13.3 Status Reports

13.3.1 Status Reports

13.3.2 Status Byte

13.3.3 Standard Event Register................................................................................

13.3.4 Extended Event Register ............................................................................... 13-30

13.3.5 Output Queue and Error Queue .................................................................... 13-31

.............................................................................................................. 13-26

............................................................................................... 13-26

.................................................................................................... 13-28

Chapter 14 Troubleshooting and Maintenance

14.1 Troubleshooting .............................................................................................................. 14-1

14.2 Error Code Descriptions and Corrective Actions ............................................................ 14-3

14.3 Self-T

14.4 V

14.5 Updating the System Firmware ...................................................................................... 14-9

14.6 Changing the Power Fuse .............................................................................................14-11

14.7 Recommended Replacement Parts and Maintenance ................................................. 14-12

est ......................................................................................................................... 14-6

iewing the Product Information..................................................................................... 14-8

Chapter 15 Specications

15.1 Source Section ............................................................................................................... 15-1

15.2 Measurement Section (On models with the /MON option) ............................................. 15-3

15.3 Features

15.4 External I/O Section (BNC (IN/OUT) and I/O for synchronous operation

(SYNC IN/OUT))

15.5 Interface

15.6 General

15.7 External Dimensions ...................................................................................................... 15-8

......................................................................................................................... 15-3

.............................................................................................................

......................................................................................................................... 15-5

Specications ................................................................................................... 15-6

13-29

15-4

Appendix

Index

Appendix 1 Factory Default Settings .....................................................................................App-1

Appendix 2 Block Diagram ....................................................................................................App-2

xii

IM GS210-01EN

Page 15

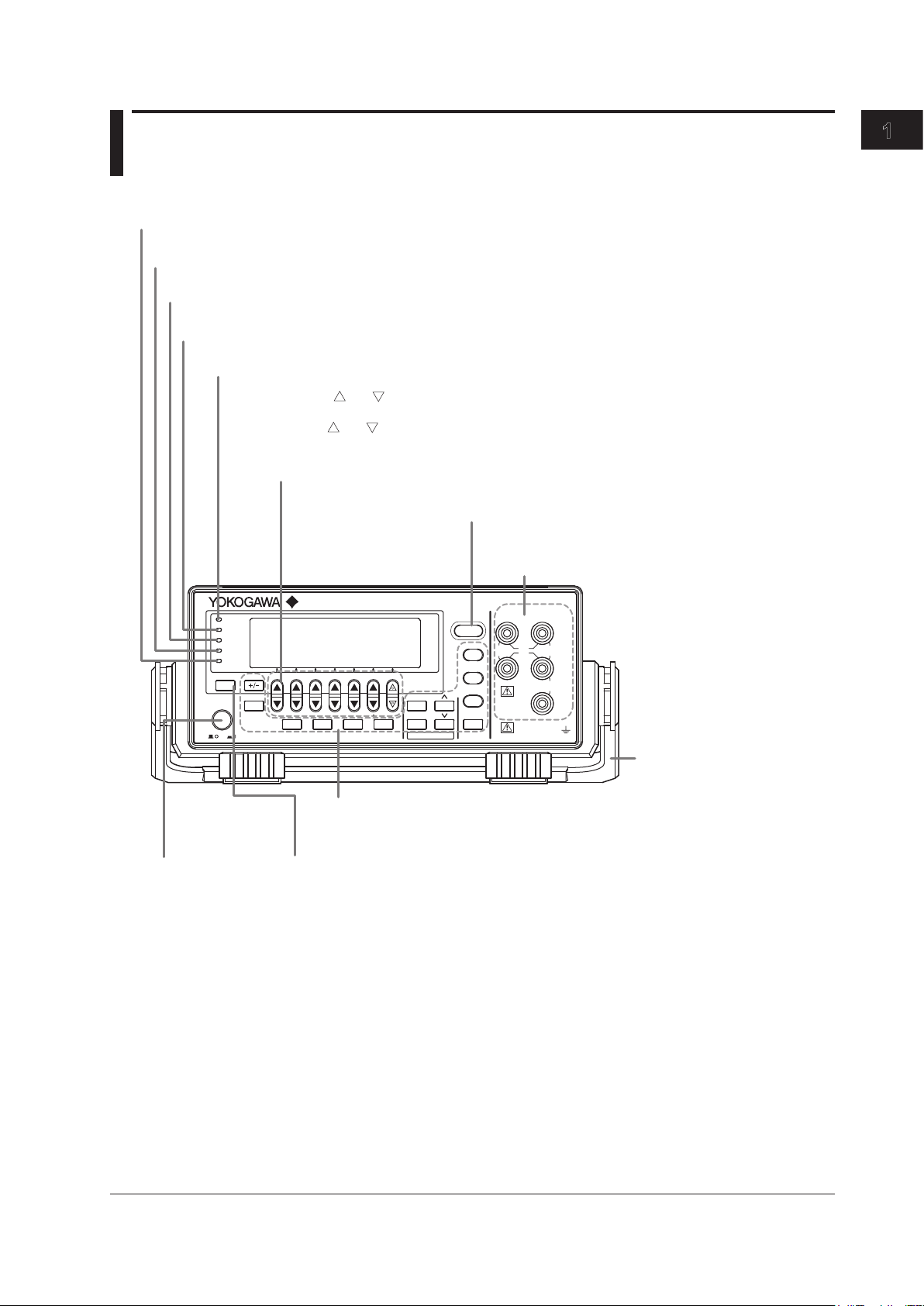

1

GS200

DC VOLTAGE/CURRENT SOURCE

SAMPLE

ERROR

REPEAT

STORE

REMOTE

ERROR

LOCAL

ESC

POWER

NUM

LOCK

1 2 3 4 5BSRANGE

6 7 8 9 0

UTILITY

SETUP

LIMIT

MEASURE

PROGRAM

END

DEL

HOLD

STEP

RUN

PROGRAM

OUTPUT

V

mV

mA

SRQ

ENTER

SENSE OUTPUT

32V

MAX

0.5V

MAX

32V

200mA

MAX

Hi

Lo

42V

10mA

PEAK

G

G TERM 250 V PEAK TO

Power switch

→ Section 3.4

Handle

Used to carry the GS200.

→ Section 3.2

Output terminals (only on the GS210)

Used to connect the included measurement leads.

→ Sections 3.5, 4.2, and 4.3

Soft keys, and

keys, and the keypad

• Use the soft keys to select items on the soft key menus that appear during configuration.

• Use the and keys to increase and decrease each digit of the displayed value during numeric

input.

• Use the keypad to specify a value directly during numeric input.

→ Section 4.1

ESC (LOCAL) key

Switches the display or clears a soft key menu → Section 4.1

Setup and execution keys

These keys are used to change settings or execute operations.

Press a setup key to show the respective setup item. → Sections 1.4 and 4.1

Remote indicator

Illuminates when the GS200 is in remote mode (controlled through communications) → Section 12.1

Store indicator

Illuminates when store mode is turned on → Section 7.8

Sampling error indicator

Illuminates when a sampling error occurs in a program or measurement trigger → Sections 6.4 and 7.4

Repeat indicator

Illuminates when the program’s repeat mode is turned on → Section 6.1

Output control key

Press to turn the source on and off. → Section 5.5

Error indicator

Illuminates when there are errors in the error log → Section 14.2

Chapter 1 Component Names and Functions

1.1 Front Panel

Component Names and Functions

IM GS210-01EN

1-1

Page 16

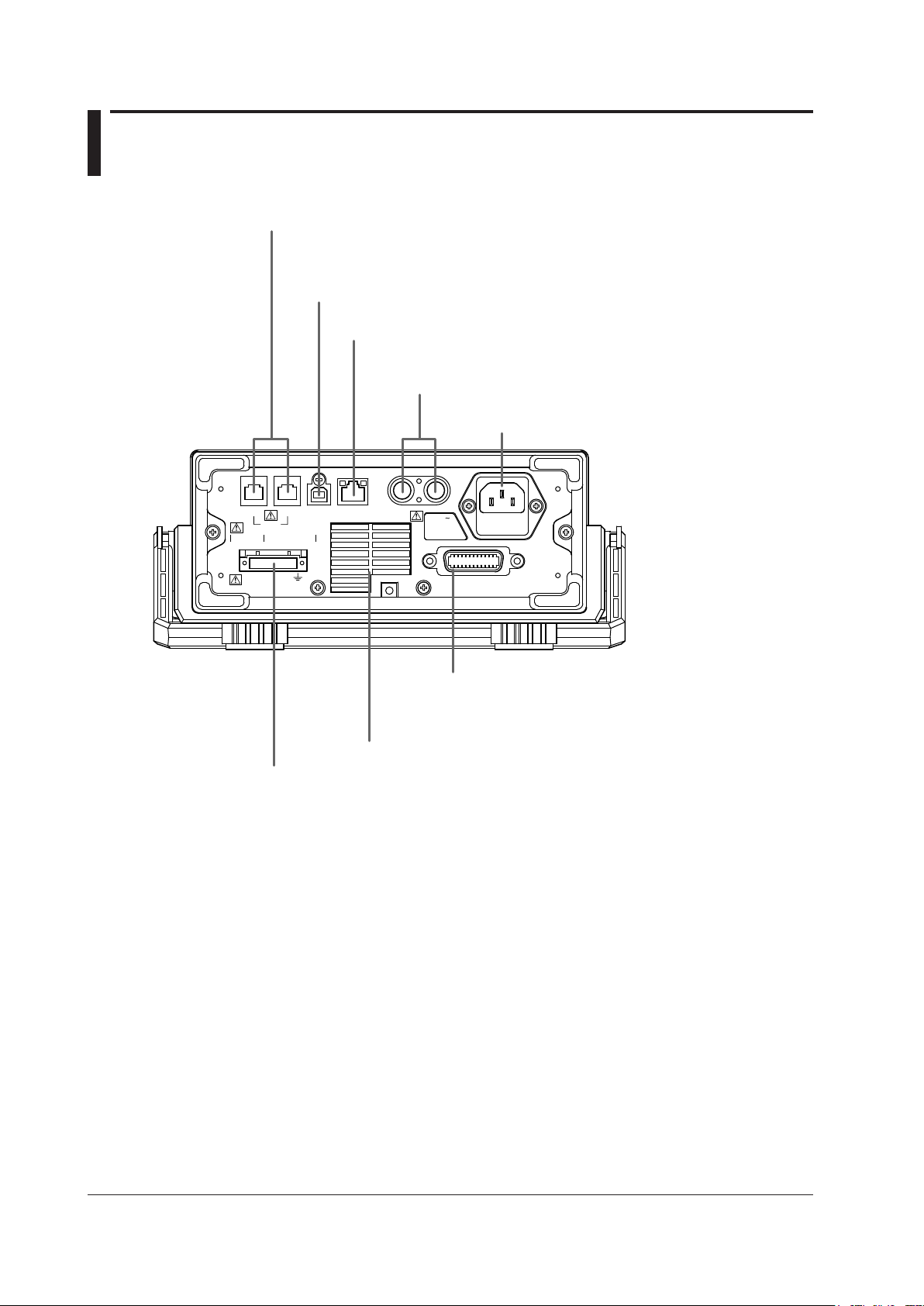

1.2 Rear Panel

LINK

ACT

ETHERNET

100BASE-TX

IN

OUT USB

SYNC

IN

OUT

100V AC

80 VA MAX

50/60 Hz

FUSE 250 V T 1A

GP-IB(IEEE 488

)

Cooling fan → Section 3.2

USB port

Used to connect the GS200 to a PC that has a USB interface and to access the GS200

as USB storage or to control the GS200 through USB-TMC commands.

→ Sections 4.4 and 10.2

I/O terminals for synchronous operation

Used to connect multiple GS200s and perform synchronous operation. → Section 8.2

Ethernet port

Used to connect the GS200 to a network. → Section 11.2

BNC I/O terminals

Used to receive and transmit trigger, output state, and source

change completion signals. → Section 8.1

Power inlet

Connects to a power supply → Section 3.3

GP-IB connector

Used when controlling the GS200 with commands

through the GP-IB interface. → Section 12.2

Output terminal (only on the GS211)

Used to connect the DUT cable. → Sections 3.5, 3.6, 4.2, and 4.3

*

1-2

IM GS210-01EN

* Only on models with the Ethernet option (/C10).

Page 17

1

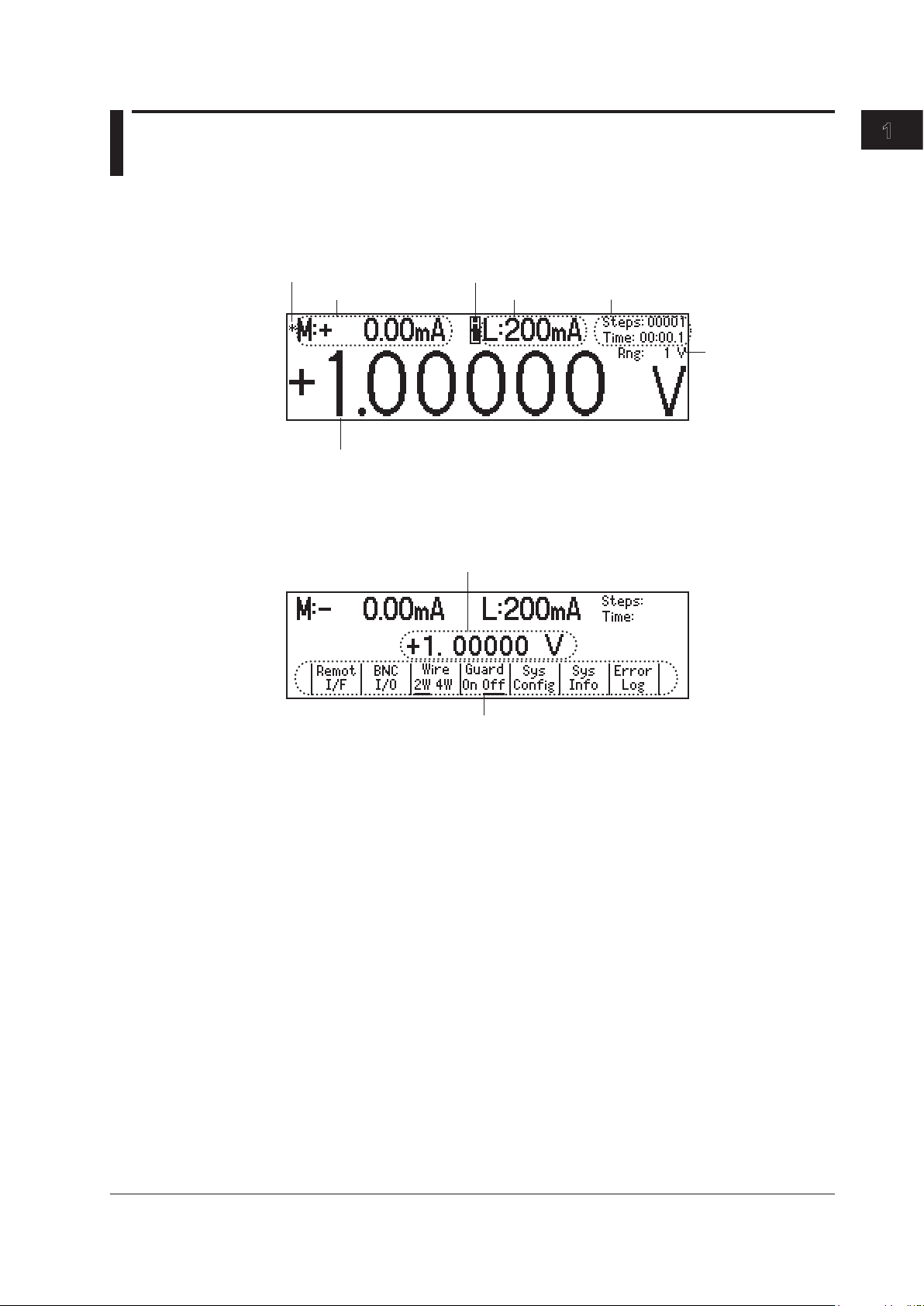

1.3 Display Mode and Displayed Contents

Limiter indicators

H: High limiter

L: Low limiter

Limit

Measured value

1

Source level

Source range

Program execution status

Measurement sample

indicator

1

Source level

Menu items

Display Mode

Main Screen

1 This is displayed on models with the monitoring (/MON) option.

Menu Screen

Component Names and Functions

Displayed Contents

Source Level

The source level that is being produced is displayed here.

Measurement Sample Indicator (On models with the /MON option)

During measurement, an asterisk illuminates. When the measurement completes, the

asterisk turns off. If you are performing sequential measurements that have a short

integration time, the asterisk illuminates and turns off once every 100 ms.

Measured Value (On models with the /MON option)

When the source function is set to voltage, this displays the measured current. When the

source function is set to current, this displays the measured voltage. When there is no

measured value, “-------” is displayed. When the source range is set to 10 mV or 100 mV,

you cannot use the measurement (monitoring) feature. In these situations, the message

“Cannot measure in mV source range” is displayed. When the measurement feature is

turned off, “Off” is displayed.

On models without the monitoring (/MON) option, nothing is displayed in the measured

value area.

IM GS210-01EN

1-3

Page 18

1-4

IM GS210-01EN

1.3 Display Mode and Displayed Contents

Limits

When the source function is set to voltage, this displays the current limit. When the

source function is set to current, this displays the voltage limit. When the source range

is set to 10 mV or 100 mV, the limit is fixed to 200 mA (you cannot change this value). In

these situations, “------mA” is displayed for the limit.

Note

In voltage source mode’s 10 mV and 100 mV ranges, the output resistance is approximately 2

. Therefore, these ranges are not suitable when the GS200 is connected to a load that allows

Ω

current to flow (a low-impedance load). Connect a load that allows as little current to flow as

possible (a high-impedance load).

Limiter Indicators

•

is displayed when the high limiter is activated.

•

is displayed when the low limiter is activated.

Program Execution Status

When a program is running, the following items are displayed.

•

Steps:

• Time: The remaining interval time (minutes:seconds.tenths of seconds).

The step number that is currently being executed.

Source Range

The source range that is currently in use is displayed here.

Page 19

1

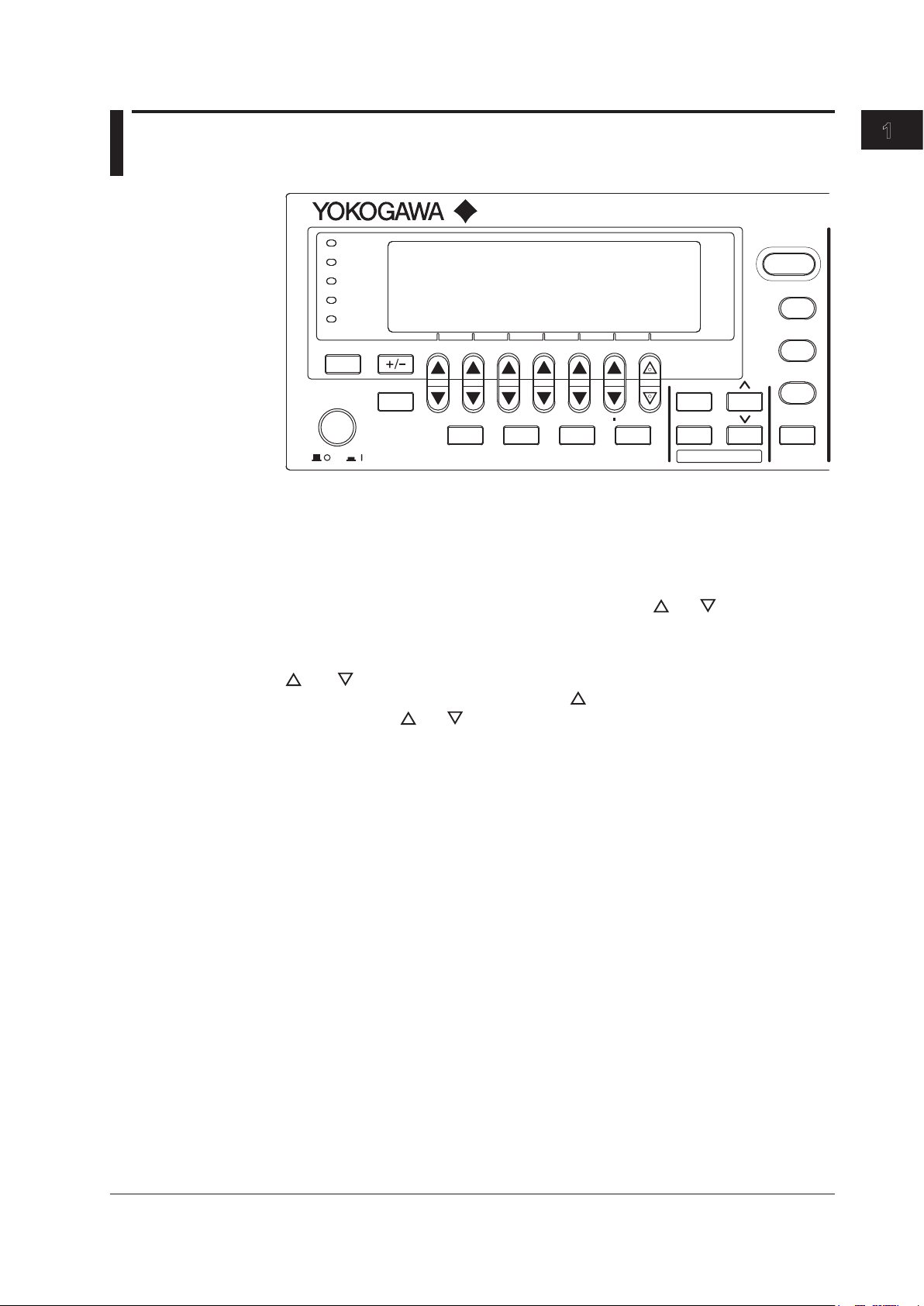

1.4 Keys

GS200

DC VOLTAGE/CURRENT SOURCE

SAMPLE

ERROR

REPEAT

STORE

REMOTE

ERROR

LOCAL

ESC

POWER

NUM

LOCK

1 2 3 4 5

BS

RANGE

6 7 8 9 0

UTILITY

SETUP

LIMIT

MEASURE

PROGRAM

END

DEL

HOLD

STEP

RUN

PROGRAM

OUTPUT

V

mV

mA

SRQ

ENTER

General-Purpose Keys

+/- Key (Section 4.1)

This key is used when you enter numeric values or change a value’s sign.

NUM LOCK Key (Section 4.1)

When you press the NUM LOCK key, the NUM LOCK key’s indicator illuminates, and the

GS200 enters keypad mode. In this mode, you can use the

access the items that are marked above and below these keys (numbers 0 to 9, period,

and BS).

and keys to directly

Component Names and Functions

and Keys (Section 4.1)

When a soft key menu is displayed, press the keys to make selections and perform

actions. Press the

mode.

ENTER Key (Section 4.1)

When the GS200 is in keypad mode, press this key to enter the setting that you have

specified.

ESC (LOCAL) Key (Section 4.1)

When a menu is displayed, press this key to display the previous menu (to move up one

level in the menu hierarchy). If you press this key when you are entering a value with

the GS200 in up/down key mode, the GS200 returns to one screen before the numeric

value input screen. When the GS200 is displaying the top menu, you can press this key

to switch between the top menu and the main screen. This is also the LOCAL key. When

the GS200 is in remote mode, you can press this key to return it to local mode.

and keys to enter values in up/down key mode and keypad

IM GS210-01EN

1-5

Page 20

1-6

IM GS210-01EN

1.4 Keys

Source Keys

V Key (Sections 5.2 and 5.3)

If you press this key when the GS200 is in up/down key mode and is displaying the main

screen, the source function is set to voltage, and the source range is set to 1 V. If you

press this key when the GS200 is in keypad mode and is displaying the main screen, the

voltage source level that you specified is fixed, the source function is set to voltage, and

the source range is set to the most appropriate range greater than or equal to the 1 V

range.

mV Key (Sections 5.2 and 5.3)

If you press this key when the GS200 is in up/down key mode and is displaying the

main screen, the source function is set to voltage, and the source range is set to 10 mV

(the circuit that produces the 10 mV range uses the voltage divider). If you press this

key when the GS200 is in keypad mode and is displaying the main screen, the voltage

source level that you specified is fixed, the source function is set to voltage, and the

source range is set to the most appropriate range.

mA Key (Sections 5.2 and 5.3)

If you press this key when the GS200 is in upd/down key mode and is displaying the

main screen, the source function is set to current and the source range is set to 1 mA. If

you press this key when the GS200 is in keypad mode and is displaying the main screen,

the current source level that you specified is fixed, the source function is set to current,

and the source range is set to the most appropriate range.

RANGE Keys (Section 5.2)

Press these keys to change the source range. Press the

range by one. Press the

displayed, you can use the

range continuously by holding these keys down.

Depending on the operation menu, these keys may be used to scroll the screen. In these

situations, you can scroll the screen by holding these keys down.

key to decrease the source range by one. When a menu is

key as a menu selection soft key. You cannot change the

key to increase the source

LIMIT Key (Section 5.4)

Press this key to display the limit input screen. If you press this key in keypad mode

when you are entering a limit, the limit that you specified is discarded, and the GS200

returns to the main screen.

OUTPUT Key (Section 5.5)

Output turns on and off each time that you press the OUTPUT key. When output is

turned on, this key illuminates in red. When output is turned off, this key turns off. When

you turn output on, the display switches to the main screen.

Page 21

1

Program Keys

PROGRAM Key (Chapter 6)

Press this key to display the program menu. If you press this key while you are editing a

program, program editing finishes.

RUN Key (Section 6.7)

Press this key to execute the program from its first step.

STEP Key (Section 6.7)

Press this key to execute just one of the program’s steps.

HOLD Key (Section 6.7)

Press this key to pause the program that is running. If you press this key while the

program execution is paused, the program resumes executing.

If you execute a program by pressing the RUN, STEP, or HOLD key, the display switches

to the main screen.

Measurement (Monitoring) Key (Option)

MEASURE Key (Chapter 7)

Press this key to display the measurement setup menu. On models without the

monitoring (/MON) option, if you press the MEASURE key, “Not Available” appears.

1.4 Keys

Component Names and Functions

Setup Information Key

SETUP Key (Sections 9.1, 9.2, and 9.3)

Press this key to list setup files and display the SETUP menu.

Communication, System Setup, and Other Keys

UTILITY Key

Press this key to display the UTILITY menu. Use the UTILITY menu to access the

following settings and features:

• Communication settings (section 4.4 and chapters 10, 1

• Terminal settings (sections 4.2, 4.3, and 8.1).

• System settings (section 3.7, 4.4, and 15.5 and chapter 9).

• Self-test (section 15.3).

• Product information (section 15.4).

• Error log (section 9.6).

1, and 12).

IM GS210-01EN

1-7

Page 22

Chapter 2

2

1

Features

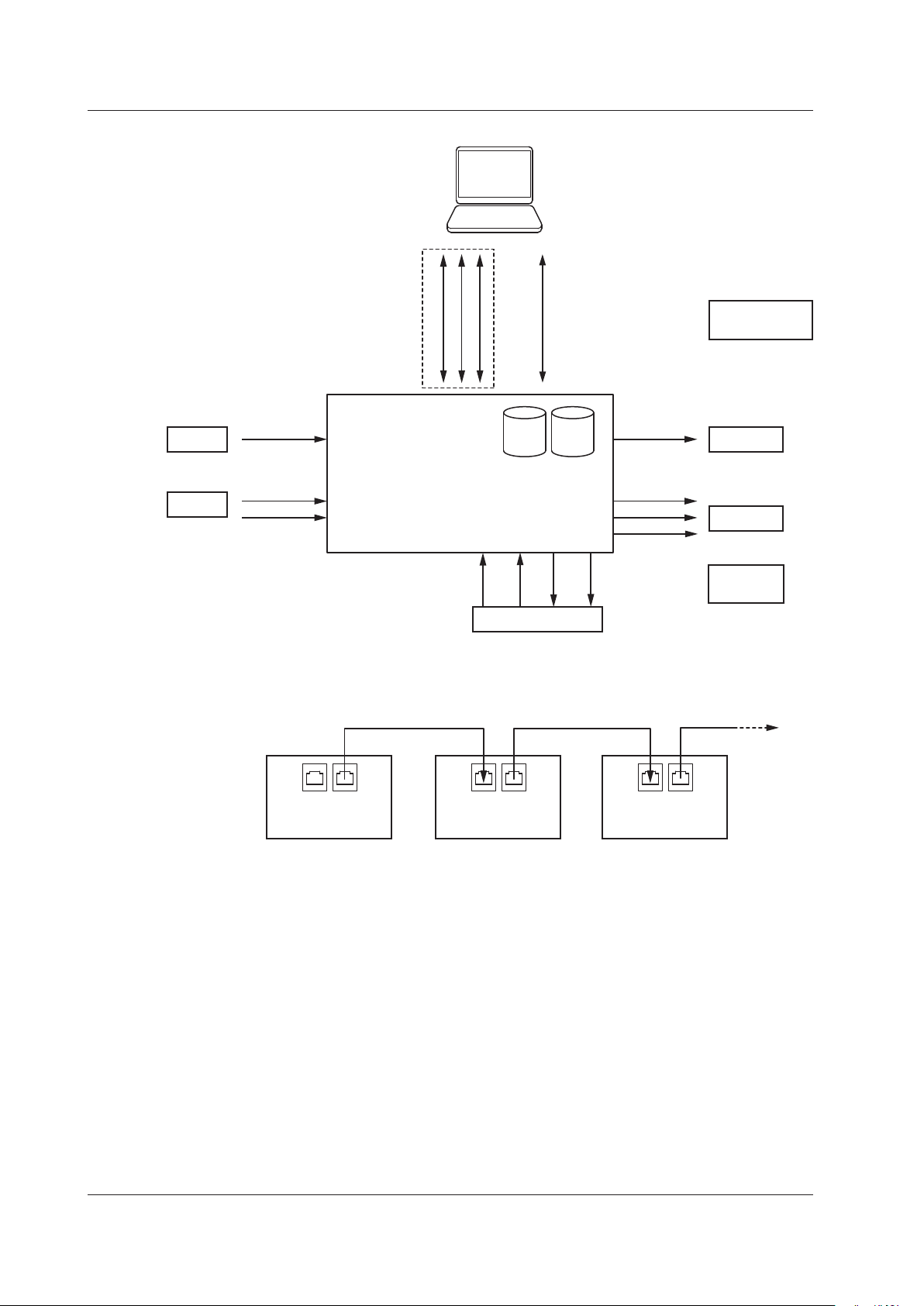

2.1 System Configuration

Product Features and System Configuration

GS200 Features

• The GS200 uses dual D/A conversion to produce voltage and current with high

accuracy and resolution. It can produce stable current or voltage whether it is used for

a short or long period of time and maintains superb linearity over all the ranges. You

can also use the GS200 to produce voltage and current that has low noise.

•

The GS200 can perform four-quadrant operation by operating

current sink in the range of ±32 V and ±200 mA.

• The GS200 has an optional voltage and current measurement

feature). The GS200 can measure current in voltage source mode and measure

voltage in current source mode. The display resolution is 4½ digits.

• By using the program feature, you can specify up to 10000 ste

controls the generation of voltage or current. You can also generate ramp waveforms

by using the slope setting.

• Y

ou can use the external I/O BNC connector on the rear panel to control multiple

GS200s or other measuring instruments by synchronizing them to actions such as the

source action and the output action.

• The I/O terminals for synchronous operation (SYNC IN/OUT) o

be connected in a daisy chain to allow synchronization of output control and triggers.

This increases the number of channels that can be controlled.

• The GS200 has a built-in 4 MB non-volatile storage disk (GS2

various settings and a 16 MB volatile storage disk (GS200RAM) for storing data such

as measurement results. If you use USB to connect the GS200 to a PC, you can

access these storage disks as the PC’s external drives. Because settings and results

are saved to general text files or .CSV files, you can use software such as a text editor

or a general-purpose spreadsheet application to edit these files or use them to display

graphs on your PC.

In addition to the storage feature, the USB interface can be us

control by way of the USB-TMC protocol. Furthermore, command control can be

performed by way of other communication interfaces such as GP-IB, and Ethernet

(VXI-1

1 protocol/7655 command socket).

Y

ou can also use the Ethernet interface to access the GS200’

FTP (the FTP server feature) and to display the GS200’s information and control

it from a Web browser by accessing the GS200 through HTTP (the HTTP server

feature).

Features

as a current source or a

feature (monitoring

ps, each of which

f multiple GS200s can

00ROM) for storing

ed to perform command

s internal disks through

IM GS210-01EN

2-1

Page 23

GP-IB

USB

(

USB-TMC

)

Ether

(

VXI-11

)

GS200

RAM

GS200

ROM

Internal storage

High

GS200

Low

TRIG

OUTPUT

TRIG

OUTPUT

Use the USB storage

feature to connect the

GS200 to a PC as the

PC’s external disk.

PC

Command

control

Communication

line

SYNC OUT

Analog

I/O

SYNC IN

OUTPUT

High Low

SENSE

DUT

BNC OUT

BNC IN

TRIG

OUTPUT

TRIG

OUTPUT

READY

READY

GS200 GS200 GS200

SYNC

IN OUT

SYNC

IN OUT

SYNC

IN OUT

2.1 System Configuration

2-2

IM GS210-01EN

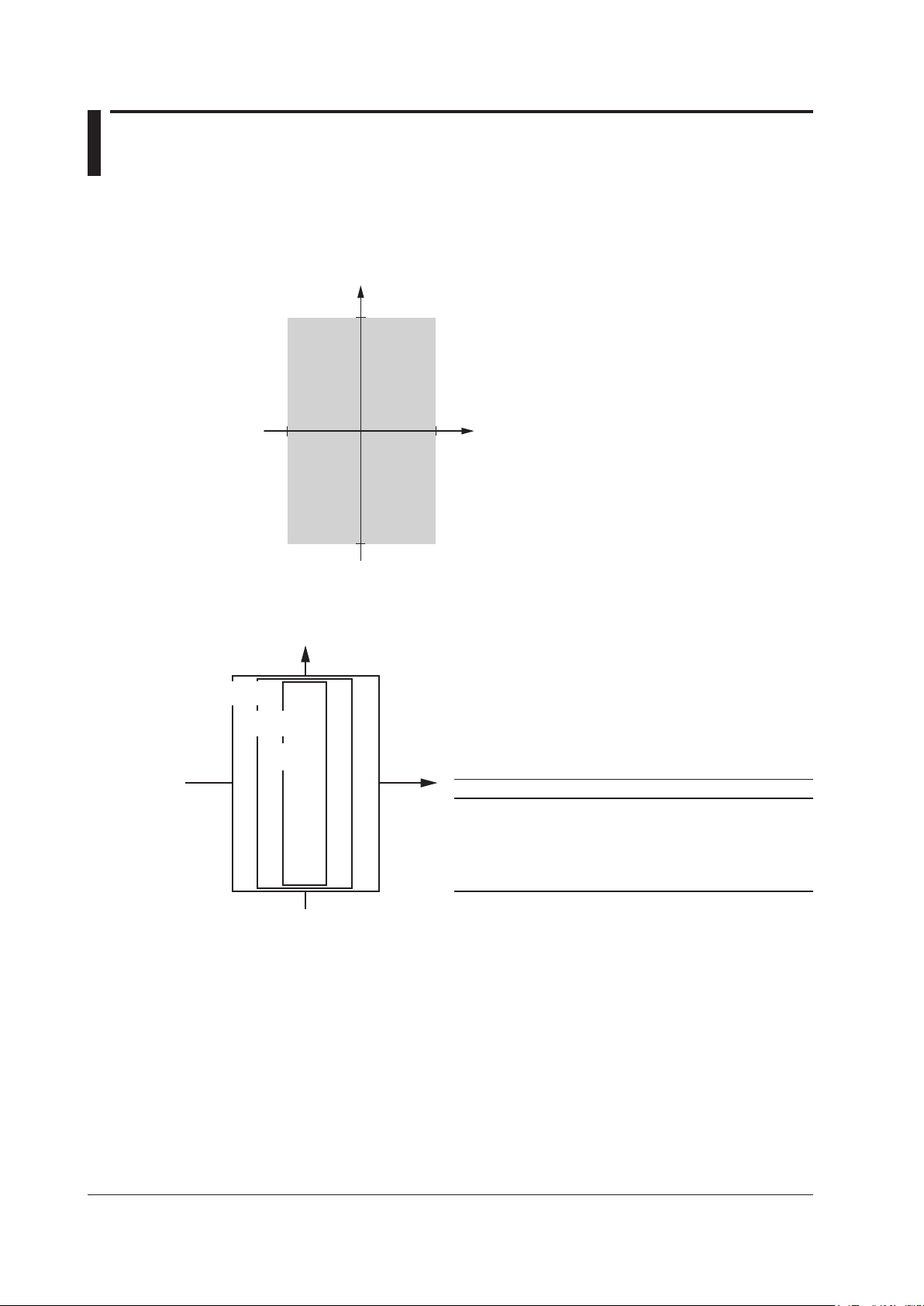

System Configuration Diagram

Synchronous Operation by Connecting the I/O Terminals for Synchronous

Operation (SYNC IN/OUT)

Page 24

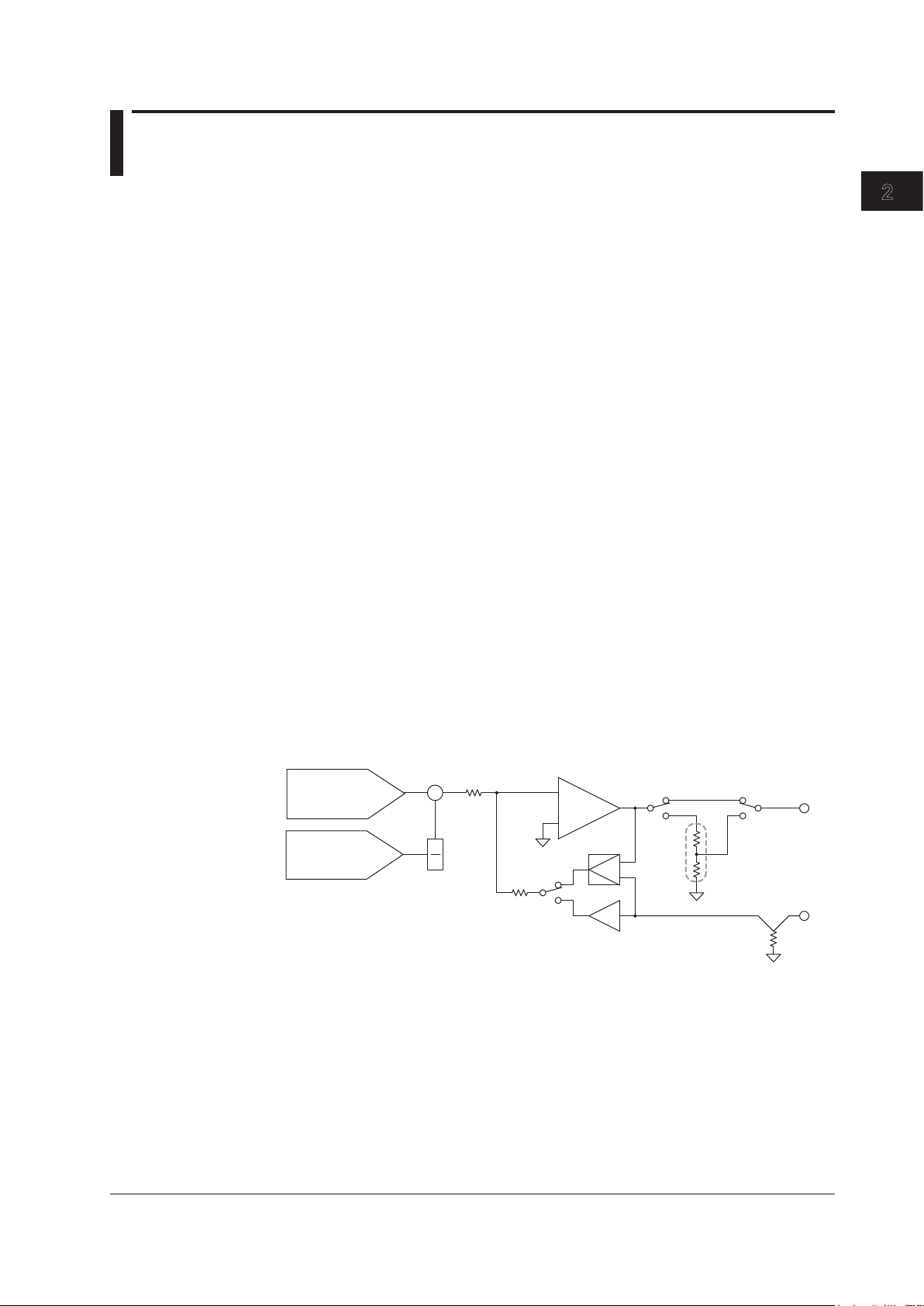

2.2 Source Feature and Measurement Feature

+

-

+

-

1

n

+

V, mA V, mA

mV mV

V, mV

mA

Voltage divider

Power amplifier

Dual D/A converter

Hi

Lo

Shunt resistor

Most

significant bits

D/A

Least

significant bits

D/A

2

1

(Monitoring feature; /MON option)

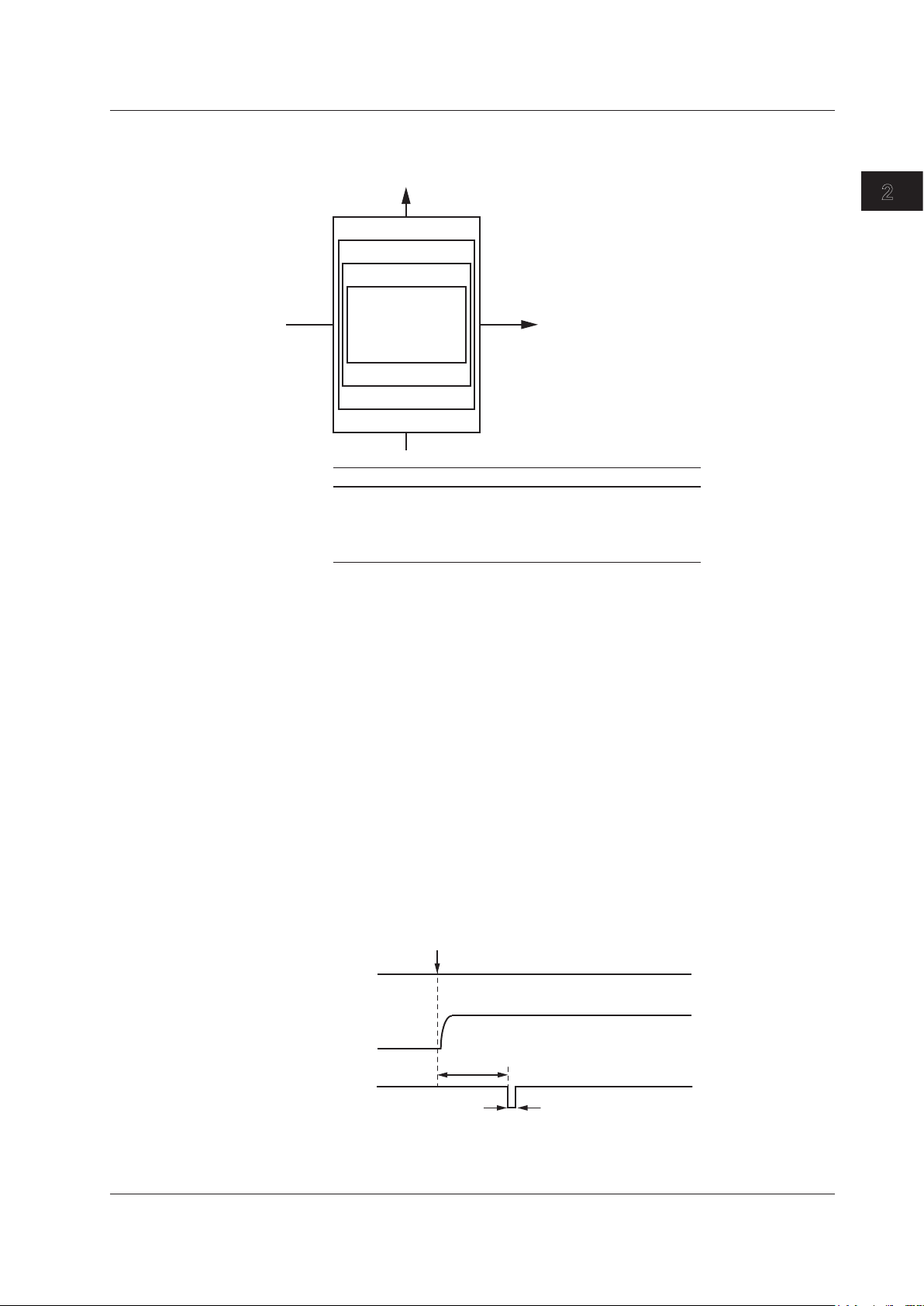

This section explains the basic features of the GS200: the source feature and the

measurement feature (monitoring feature).

Generating Voltage and Current

The GS200 uses dual D/A conversion and a highly accurate power amplifier. This

enables you to set the voltage and current at a resolution of 5½ digits.

Voltage Source

The GS200 has 10 mV, 100 mV, 1 V, 10 V, and 30 V ranges. You can specify and

generate a positive or negative voltage of up to 32 V.

Current Source

The GS200 has 1 mA, 10 mA, 100 mA, and 200 mA ranges. You can specify and

generate a positive or negative current of up to 200 mA.

The 1 V, 10 V, and 30 V voltage source ranges enable you to generate a positive or

negative output current of up to 200 mA with a low output resistance. These ranges are

well-suited to situations such as the evaluation of devices that require current.

When you select the 10 mV or 100 mV range, the GS200 uses a voltage divider that

consists of a pair of resistors. This enables you to use the GS200 to generate low

voltages at resolutions as low as 100 nV or as a 3 μVp-p*, low-noise voltage signal

source. These ranges are well-suited to providing simulated signals to instruments such

as sensors.

In current source mode, you can generate a positive or negative output voltage of 30 V

on all of the current ranges. Current source mode is well-suited to evaluating the charge/

discharge characteristics of rechargeable batteries and other devices.

* 10 mV range, DC to 10 Hz

Features

IM GS210-01EN

2-3

Page 25

200 mA

–32 V 32 V

–200 mA

Current

Voltage

Source

Sink

Sink

Source

Voltage

source

GS200

Load

Source Operation Example

I

Current

source

GS200

Battery

Sink Operation Example

I

2.2 Source Feature and Measurement Feature (Monitoring feature; /MON option)

2-4

IM GS210-01EN

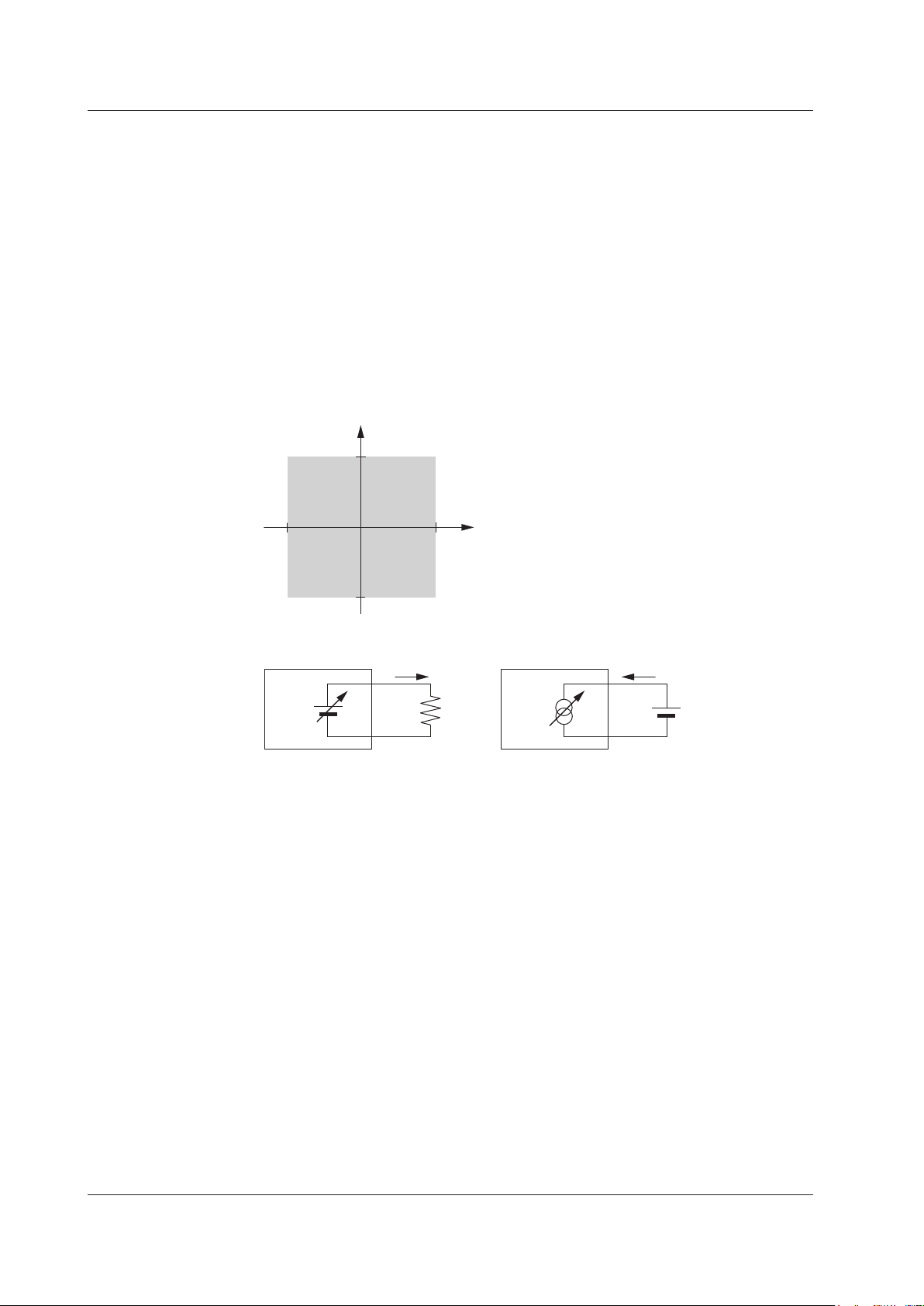

Source and Sink Operations

The GS200 can perform four-quadrant operation by operating as a current source or a

current sink in the range of ±32 V and ±200 mA.

During sink operation, the GS200 operates in the same quadrants as it does during

source operation, so you can use it not just as a true constant voltage source but also as

a highly accurate electronic load.

V

oltage ranges:

1 V, 10 V, and 30 V

Maximum output current: ±200 mA (at 1 V, 10 V, and 30 V ranges)

Current ranges: 1 mA, 10 mA, 100 mA, and 200 mA

Maximum output voltage: ±30 V

Voltage and Current Generation Region

Bipolar Output

Because the GS200 inverts the signal polarity and produces the signal without the use

of a mechanical contact, no abnormal voltage (or current) is generated when the polarity

is inverted. Therefore, the GS200 can generate continuous, variable output ranging

from the maximum negative value to the maximum positive value. This is effective when

you want to invert the polarity to generate program output or evaluate zero-crossing

comparators. Additionally, when you change settings within the same range, glitches are

not generated.

Page 26

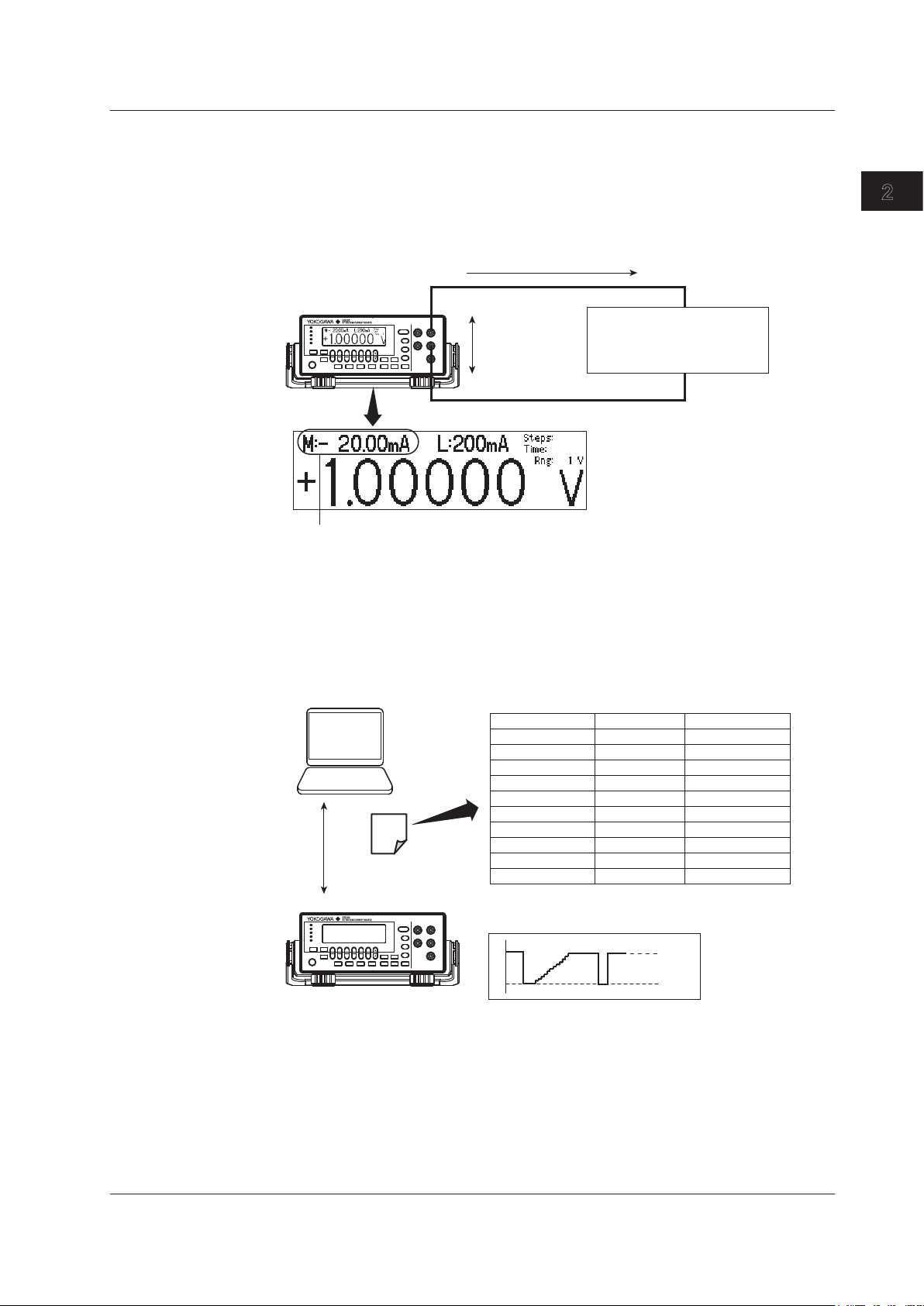

The monitoring feature can be used to:

• Check that current is flowing.

• Check and inspect current consumption.

• Log fluctuations in the load current.

• Record V-I characteristics.

DUT

• Resistance

• Diodes and transistors

• Other electronic parts

Load current measurement

GS200

Vcc application

Edit the output pattern on a spreadsheet, and copy

the data to the internal memory.

GS200

USB

PC

Program file

(CSV format)

Up to 10000 steps

Source Value (V)

1.00

1.01

1.02

1.03

1.04

1.05

1.06

1.07

1.08

1.09

Source Range

10

10

10

10

10

10

10

10

10

10

Source Function

V

V

V

V

V

V

V

V

V

V

2

1

2.2 Source Feature and Measurement Feature (Monitoring feature; /MON option)

Voltage and Current Measurement Feature (Monitoring feature; /MON option)

The GS200 can measure voltage or current while it generates voltage or current. In

voltage source mode, you can measure current with a display resolution of 4½ digits. In

current source mode, you can measure voltage with a display resolution of 4½ digits. You

can use the store feature to save the measured value together with the source value to

the internal RAM disk.

Features

Using up to 10000 Steps to Program the Output

IM GS210-01EN

You can use the program feature to specify up to 10000 output steps. You can edit

programs from the GS200 or create program files in CSV format on a PC and use the

USB storage feature to load the files on the GS200.

For details on programs, see section 2.4, “Programs.”

2-5

Page 27

2.3 Source

200 mA

–32 V 32 V

–200 mA

Current

Voltage

V

I

30 V/200 mA

range

10 V/200 mA

range

1 V/200 mA

range

Range Source Range Resolution Max. Load Current

10 mV ±12.0000 mV 100 nV --------

*

100 mV ±120.000 mV 1 µV --------

*

1 V ±1.20000 V 10 µV ±200 mA

10 V ±12.0000 V 100 µV ±200 mA

30 V ±32.000 V 1 mV ±200 mA

2-6

IM GS210-01EN

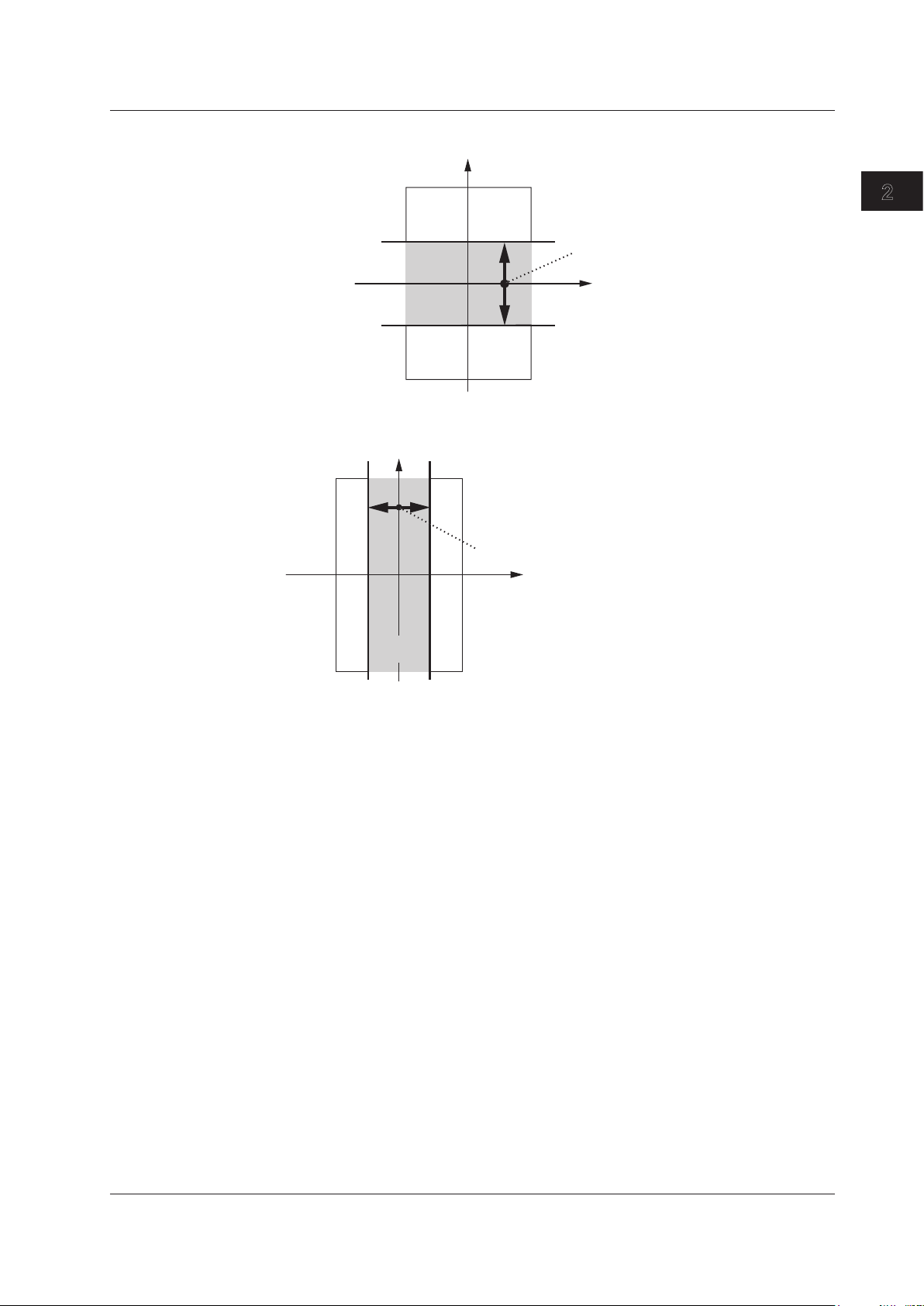

Source Range

Source Range

The following figure indicates the range that the GS200 can generate.

Voltage Source Range (See section 5.2 for the procedure)

The following voltage source ranges are available.

* In voltage source mode’s 10 mV and 100 mV ranges, because the GS200 uses a voltage

divider, the output resistance is approximately 2 Ω. Therefore, these ranges are not suitable

when the GS200 is connected to a load that allows current to flow (a low-impedance

load). Depending on the load current, the output voltage may decrease. Also, four-terminal

connection does not function for these voltage ranges. You must use the two-terminal

connection instead. Connect a high-impedance load, a load that is sufficiently larger than the

output resistance.

Page 28

V

I

100 mA/30 V range

10 mA/30 V range

1 mA/30 V range

Range Source Range Resolution Max. Load Current

1 mA ±1.20000 mA 10 nA ±30 V

10 mA ±12.0000 mA 100 nA ±30 V

100 mA ±120.000 mA 1 µA ±30 V

200 mA ±200.000 mA 1 µA ±30 V

200 mA/30 V range

Source setting change caused by front panel

operation or communication command control

Trigger busy

(TrigBusy)

Source change

completion

(Ready)

Source level

Previous

setting

Next setting

10 ms

10 µs

2

1

2.3 Source

Current Source Range (See section 5.2 for the procedure)

The following current source ranges are available.

Features

Source Function (See section 5.1 for the procedure)

Source Action

The source function can be set to either voltage (V or mV) or current (mA).

Voltage (V): Operates as a constant voltage source. The current limiter is enabled.

Voltage (mV): Operates as a voltage source that uses a voltage divider.

Current (A): Operates as a constant current source. The voltage limiter is enabled.

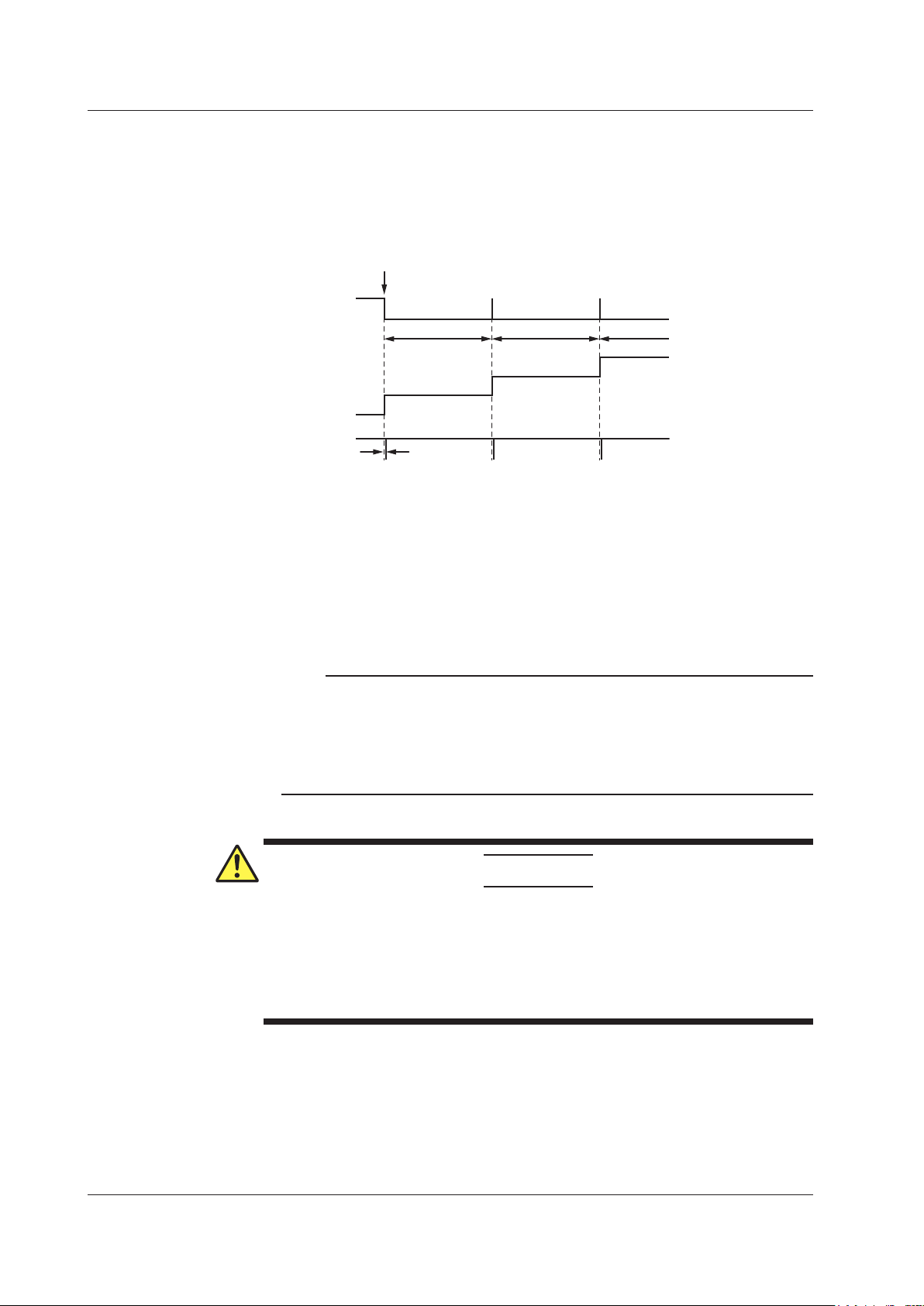

Source action refers to the setting of the source level and the way that the source level

changes to the new value. In source actions, various control signals change as shown

below.

During DC Source Operation (When a program is not running)

The actual source level will change at the time the setting change is instructed from a

panel operation or communication command. The source change completion (Ready)

signal, which is a low-level pulse signal with a width of 10 μs, is generated 10 ms after

the source level changes. Additionally, the trigger busy (TrigBusy) signal, which indicates

the program execution status, remains at high level and does not change.

IM GS210-01EN

2-7

Page 29

RUN key

Trigger busy

(TrigBusy)

Source change

completion

(Ready)

Source level

Ti

Ti

Ti: Program interval time

10 ms

2.3 Source

2-8

IM GS210-01EN

During Program Execution

When you execute a program, the trigger busy signal is set to low level, and the source

level changes. The source change completion (Ready) signal, which is a low-level pulse

signal, is generated 10 ms after the source level changes. When each program interval

time completes, the trigger busy signal is set to high level. The program proceeds from

step to step by repeating this pattern.

Output ON/OFF (See section 5.5 for the procedure)

There are two output modes: OFF or ON.

OFF: The output is disconnected, and the specified source level is not generated. In

this mode, program and measurement functions are disabled.

The output is connected, and the specified source level is generated. In this

ON:

mode, program and measurement functions are enabled.

Note

A mechanical relay operates when the GS200 switches between output on and output off. Note

the following points when using the GS200.

• It takes approximately 20 ms for the relay to stabilize.

• As the number of on/off operations increases, effects begin to appear such as the relay

taking longer to stabilize. Though dependent on the load, the electrical life of the relay is

around 100,000 operations.

DUT Protection Using Limiters (See section 5.4 for the procedure)

CAUTION

If a current source that exceeds the current limiter setting is connected in voltage

source mode; if a voltage source that exceeds the voltage limiter setting is

connected in current source mode; or if a load that exceeds the source range listed

above is connected, an abnormal load is detected, and the output is turned off (the

output trips). Do not connect these types of loads to the GS200. Doing so may

damage the instrument.

Voltage Limiter and Current Limiter

If a limiter is set, an additional limit can be placed within the source range. This limit can

prevent damage to the connected device due to overcurrent or overvoltage. In voltage

source mode, the current limiter is enabled. In current source mode, the voltage limiter is

enabled.

Page 30

I

V

Source voltage level

High limit value

Low limit value

Operating

range

I

V

High limit value

Low limit value

Operating

range

Source current level

2

1

2.3 Source

Limiter Operation in Voltage Source Mode

Features

Limiter Operation in Current Source Mode

A limiter has an operating range which is defined by a positive value and a negative

value in relation to 0. The positive value is the high limit. The negative value is the low

limit.

If the high limiter is activated, the high limiter indicator (H) is displayed. If the low limiter is

activated, the low limiter indicator (L) is displayed.

Tripping the Output

If the GS200’s output exceeds the high limiter or falls below the low limiter, the output

is automatically turned off. If this occurs, the error indicator illuminates, and the event is

written to the error log.

Local Sense and Remote Sense (See section 4.2 for the procedure)

Two wiring systems, 2W (two-terminal connection or local sense) and 4W (four-terminal

connection or remote sense) are available. In voltage source mode, when the current

flowing through the load becomes large, the voltage drop in the lead wire can no longer

be ignored. If this occurs, you can select the four-terminal connection and connect the

SENSE terminal near the DUT so that the voltage at the connected location is adjusted

to the specified voltage. This alleviates the effects from lead wire resistance, and the

desired voltage can be applied to the DUT.

IM GS210-01EN

2-9

Page 31

2.3 Source

2-10

IM GS210-01EN

Guard Terminal Feature (See section 4.3 for the procedure)

If the GS200 and the DUT are far apart or if the GS200 shares its power source with

electric motors, common mode noise may be superimposed on the power source signal

supplied to the DUT. If common mode noise is superimposed on the signal between the

GS200’s Hi and Lo terminals, the noise current enters the internal source circuit from

the output terminals and changes the generated signal. To reduce this effect, a shield

for the source circuit is connected to the guard terminal of the GS200. If you connect the

noise source to the guard terminal, the noise current passes through the guard and is

grounded, bypassing the internal source circuit. This reduces the amount of noise that

enters the circuit from the connected power source. Use the guard terminal when a large

amount of common mode noise is superimposed on the power source signal.

Page 32

2.4 Programs

1 V

4 V

2 V

1 V

5 V

7 V

Ti

Ti: Program interval time

Ti

Ti

Ti

Ti

Ti

Program slope time

Next step’s source level – current step’s source level

2

1

Program Feature (See section 6.1 for the procedure)

The program feature enables you generate the source data pattern that you specified

as a program in advance. Each step in the program is executed in order, and each step

has a fixed execution time. You can also set the slope time, so you can generate step

responses, ramp responses, and various waveforms such as triangular waveforms.

To create and load programs you can:

•

Create and edit programs from the GS200 screen.

•

Create programs on a PC, save them to the GS200’s internal memory (GS200ROM)

as program files in CSV format, and load them from the internal disk.

Source data that programs can contain:

• The source level.

•

The source range.

• The source function.

Programs can contain up to 10000 steps. If the number of steps exceeds 10000, only the

first 10000 steps are loaded.

Program Interval Time (See section 6.2 for the procedure)

The program interval time specifies the execution interval for each step in the program.

Features

Program Slope Time (See section 6.3 for the procedure)

The program slope time specifies the amount of time that the GS200 takes to linearly

change (increase or decrease) the current step’s source level to the next step’s source

level from the beginning of the step. The slope of this linear line is calculated as follows:

IM GS210-01EN

2-11

Page 33

Ts: Program slope time

Ti: Program interval time

* The TrigBusy signal’s state transitions shown here assume that the program

trigger is set to Norm.

Ti

Ti

Ts < Ti

Ti

Ti

Ts = 0

Ti

Ti

Ts > Ti

Ti

Ti

Ts = Ti

Ts

Ts

RUN key

TrigBusy

Ready

TrigBusy

Ready

RUN key

RUN key RUN key

2.4 Programs

2-12

IM GS210-01EN

When Ts is greater than Ti, the situation shown in the bottom right section of the figure

above occurs, so be sure to make Ts less than or equal to Ti.

Repeating Programs (See section 6.1 for the procedure)

If you specify to repeat programs, after the last step in a program finishes, the first step in

the program begins executing.

Program Triggers (See section 6.4 for the procedure)

Depending on the program trigger setting, there are the following two types of program

operation.

When Program Triggers Are Set to Normal (Norm)

You can use the RUN, STEP, and HOLD keys and external triggers to control the

program execution.

RUN key: Executes the program from step 1.

STEP

HOLD key: Pauses the program execution or resumes execution of a paused program.

The program interval time specifies the execution interval for each step in the program.

When Program Triggers Are Set to Measurement End (M.End; only on

models with the /MON option)

The program executes the source and measurement operations of each step in the

minimum time required. The RUN, STEP, and HOLD keys and external triggers are

disabled. Additionally, the program interval setting is ignored.

key: Executes only one program step.

Page 34

Program Files

1 V

4 V

2 V

1 V

5 V

7 V

1,10,V

4,10,V

2,10,V

1,10,V

5,10,V

7,10,V

Program file

Source level, source range, source function

Ti

Ti: Program interval time

Ti

Ti

Ti

Ti

Ti

2

1

2.4 Programs

You can use the USB storage feature (see page 2-22) to store programs in the

PROGRAM folder in the GS200’s non-volatile disk (GS200ROM).

Prgm01.csv and Prgm02.csv that are stored in the PROGRAM folder when the GS200

is sent from the factory or when you format its disk are program file samples. You can

check the contents of program files on the display.

Program File Contents (See section 6.5 for the procedure)

Program files are text files that have been created and edited in spreadsheet applications

or text editors. Each file contains multiple lines, and each line represents one step in the

program.

Features

Line

A line is a string of text that is delimited with line-feed codes (LF or CR+LF). Each line

defines the following items (from left to right).

•

The source level:

Defined with an integer or a real number. Examples: 1, 0.485,

–12E–3

• The source range:

Defined with an integer or a real number. Examples: The same

as the examples given above.

• The source function:

Defined with a character (V or I).

Make the program file a .CSV file by using a separator (choose either a comma or

a semicolon) to separate each item. You can also include white space (space or tab

characters) before and after each item.

You can omit the source range and source function. If any items are omitted, the same

item from the previous step is used. If the source function is not defined in the program’s

first step, the source function that the GS200 was using when the program file was

loaded is used. If the source range is not defined in the program’s first step, the source

range is set to the most appropriate range for the source level that is defined in the

program’s first step.

Comments

You can include comments in program files. A comment consists of any text between “//”

and a line-feed code or the end of the file. The GS200 ignores comments when it loads

program files.

IM GS210-01EN

2-13

Page 35

Ts: Program slope time

Ti: Program interval time

Ti

Ti

RUN key

TrigBusy

Ready

HOLD key STEP key

HOLD key

Ts Ts Ts Ts

Ti Ti

Executing Paused

Step

execution

Paused Executing

End

Step

completion

State

Key

0 V

1 V

2 V

3 V

The low pulse that indicates source change completion (Ready) is generated 10 ms after Ts elapses.

2.4 Programs

2-14

IM GS210-01EN

Executing Programs (See section 6.7 for the procedure)

Operations When the Program Trigger Is Set to Norm

You can use the RUN, STEP, and HOLD keys and external triggers to control the

program execution. The program interval time specifies the execution interval for each

step in the program.

When you press the HOLD or STEP key, the trigger busy (TrigBusy) and source change

completion (Ready) signals change as shown in the following example.

Program Setup Example

Step 1: 1 V

Step 2: 2 V

Step 3: 3 V

Program Conditions

•

Repeat mode is of

• Program interval time is 5 s.

• Program slope time is 3 s.

f.

HOLD and STEP

When you press the HOLD key to pause program execution, the paused step is said

to be in the “mid-execution” state. If you press the STEP key while the GS200 is in this

state, the current step that was in the mid-execution state is re-executed. When this step

completes, the GS200 pauses the program again. If, on the other hand, you press the

HOLD key while the GS200 is in this state, the GS200 continues program execution from

the point that it was paused in the step that was in the mid-execution state.

For example, assume that we have a program that begins at 0 V and ends at 10 V. Each

step specifies an increase of 1 V, and a step is executed each second. Now assume that

we execute the program and press HOLD when 4 V has been generated for only 0.5

seconds.

•

If the STEP

The GS200 does not generate 5 V as specified by the next step, but rather generates

4 V for 1 second as specified by the step that was in the mid-execution state, and then

pauses execution again. If you press the STEP key once more, 5 V is generated for 1

Key Is Pressed

second, and then the program execution is paused again.

Page 36

Ts: Program slope time

M.End

TrigBusy

Ready

Ts

M.End

Ts

The low pulse that indicates source change completion (Ready) is generated

10 ms after Ts elapses.

2.4 Programs

2

1

• If the HOLD Key Is Pressed

The GS200 generates 4 V for the remaining 0.5 seconds as specified by the step

that was in the mid-execution state, generates 5 V for 1 second, and then continues

executing the rest of the program.

Operations When the Program Trigger Is Set to M.End (/MON option)

When measurement completes, the GS200 proceeds to the next step in the program and

changes the source level. If you set the program trigger to measurement end (M.End),

and the measurement trigger to source change completion (Ready), the program

executes the source and measurement operations of each step in the minimum time

required.

The RUN, STEP, and HOLD keys and external triggers are disabled. Additionally, the

program interval setting is ignored.

Changes to the Control Signals

The trigger busy (TrigBusy) and source change completion (Ready) signals change as

shown in the following example.

Features

IM GS210-01EN

2-15

Page 37

2.5 Measurement (Monitoring feature; /MON

Measurement

trigger

Measurement

delay

Displays the measured value

Stores to the storage

memory

NULL

computation

Integration time

and software

processing time

Measurement

Zero reference

measurement

Integration time

and software

processing time

Only when the NULL computation

is turned on

2-16

IM GS210-01EN

option)

Measurement Function and Measurement Range

Measurement Function

In voltage source mode, the GS200 measures (monitors) current. In current source

mode, the GS200 measures (monitors) voltage.

Measurement Range

When Measuring Voltage

Range Measurement Range Resolution

30 V ±31.000 V 1 mV

When Measuring Current

Range Measurement Range Resolution

200 mA ±210.00 mA 10

Measurement ON/OFF (See section 7.1 for the procedure)

Measurement OFF (Off)

Measurement is not performed. Select this mode if you only intend to use the GS200

source features.

Measurement ON (On)

Measurement is performed. The measured value is displayed in the upper-left section of

the screen.

A

μ

Note