Page 1

General

Specications

GS 12D08G02-E

Conductivity

Detectors/Sensors

n GENERAL

YOKOGAWA has been supplying superior on-line

analyzers for monitoring or controlling the conductivity

of liquid or solutions.

Now, YOKOGAWA provides the 4-Wire Converter

TM

(FLXA

FLXA

402), the 2-Wire Liquid Analyzer (FLXATM202,

TM

21).

Adapter Mounting

SC8SGSC4AJ

Flow-through Type

YOKOGAWA also provides many kinds of detectors/

sensors for accurately measuring liquid conductivity

when using analyzers.

The combination of YOKOGAWA’s analyzers and

detectors/sensors meets the demanding ultrapurewater

requirements of the growing semiconductor and

pharmacentical markets in addition to traditional water

quality measurements for standard power plant and

chemical applications.

SC210G

Screw-in Type

4-Wire Converter

FLXA402

FLEXA, FLXA, EXA SC are registered trademarks or trademarks of Yokogawa Electric Corporation.

All other company and product names mentioned in this GS are registered trademarks or trademarks of their respective companies.

2-Wire Liquid Analyzer

FLXA21

Refer to GS 12A01A02-01E Refer to GS 12A01A03-01ENRefer to GS 12A01F01-01EN

Yokogawa Electric Corporation

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 Japan

2-Wire Liquid Analyzer

FLXA202

GS 12D08G02-E

©Copyright Dec. 2000

17th Edition Dec. 2019

Page 2

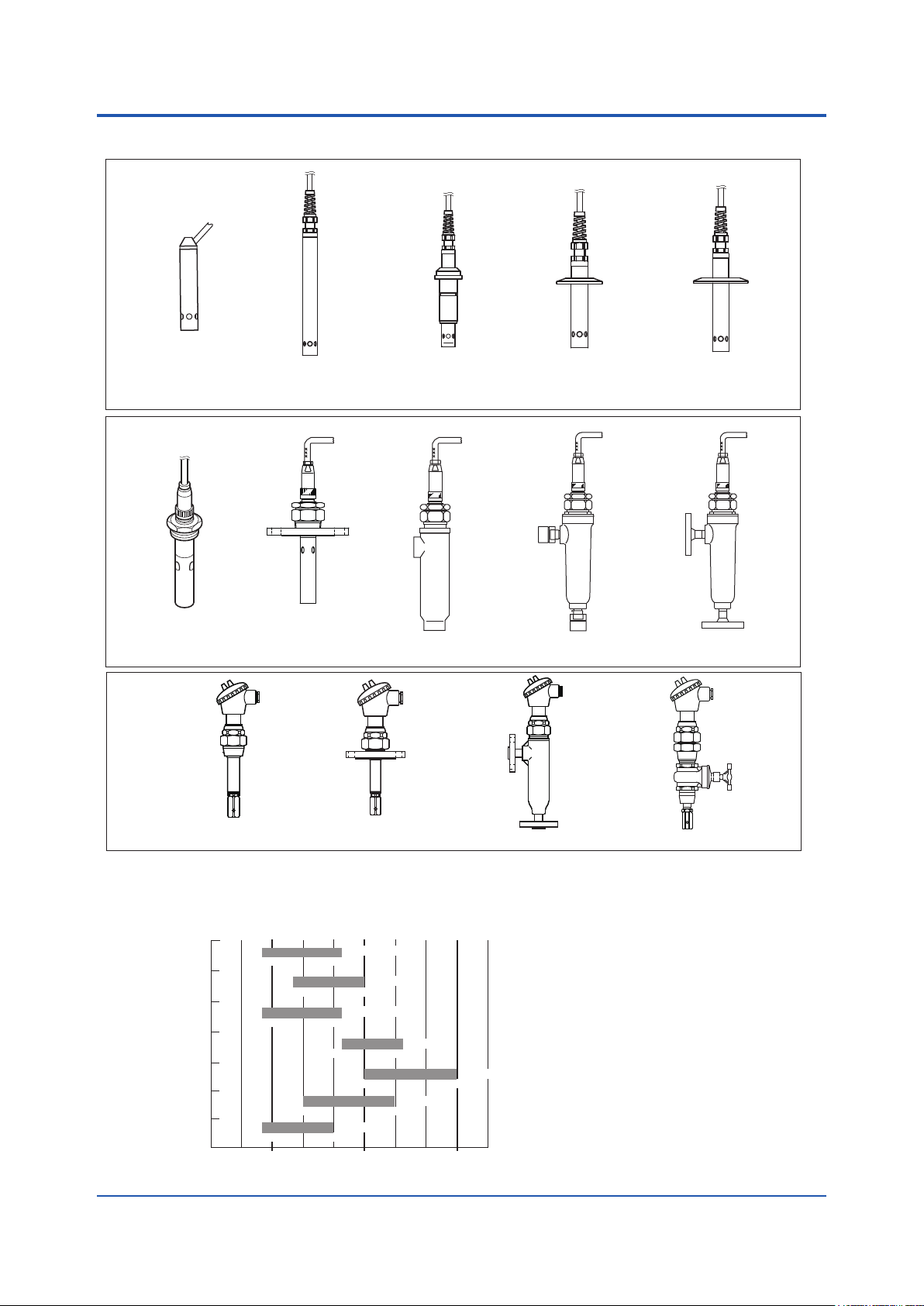

n Models of Conductivity Detectors/Sensors

SC4AJ

-AD-09

Adapter

Mounting Type

(Sensor length: 9 cm)

SC8SG

-

AD-15

Adapter

Mounting Type

(Sensor length: 15 cm)

-SA

Welding

Socket Type

1 or 1.5 inch welding

-SB

Clamp Type

2

--SC

2 inch welding

Clamp Type

Screw-in Type

Flange Type

Flow-through Type

(Screw Jointed)

Chamber Material : SCS14

Flow-through Type

(Screw Jointed)

Chamber Material : PP

SC210G

Screw-in Type

Flange Type

Flow-through Type Screw-in Type with Gate Valve

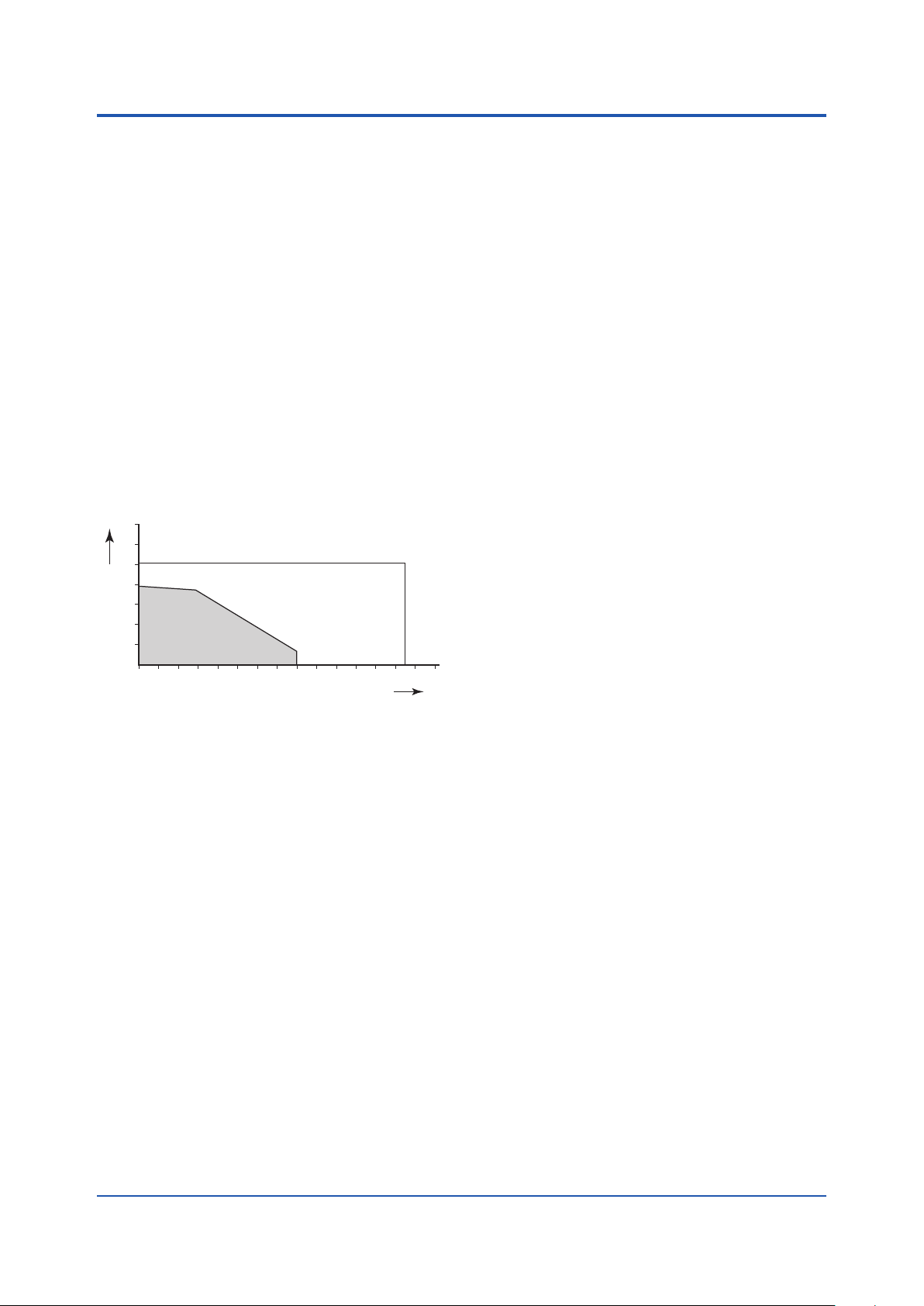

n RANGE OF MEASURING UPPER RANGE LIMIT OF

EACH SENSORS

Sensors

SC4AJ

SC4AJ

SC210G-A, -V

SC210G-B, -W

SC8SG-R61

SC8SG-R42

SC8SG-R31

0.5 µS/cm

5 µS/cm

0.5 µS/cm

10 µS/cm

0.5 µS/cm

1(µS/cm)

(C=0.02 cm-1)

200 µS/cm

(C=0.1 cm-1)

1 mS/cm

(C=0.05 cm-1)

200 µS/cm

200 µS/cm

1 mS/cm

(C=0.01 cm-1)

100 µS/cm

1(mS/cm)

Conductivity

(C=5 cm-1)

20 mS/cm

(C=0.1 cm-1)

10 mS/cm

(C=10 cm-1)

1 S/cm

1(S/cm)

Note

The bar graph at the left shows the range of the

upper range limit of each sensor.

For example, in the case of SC8SG-R61, the

measuring range is from 0-1 mS/cm to 0-1 S/cm.

In measurement in high conductivity range,

polluted solution may aect measured values of

any sensors. C represents cell constant.

Flow-through Type

(Flange Jointed)

F01.ai

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

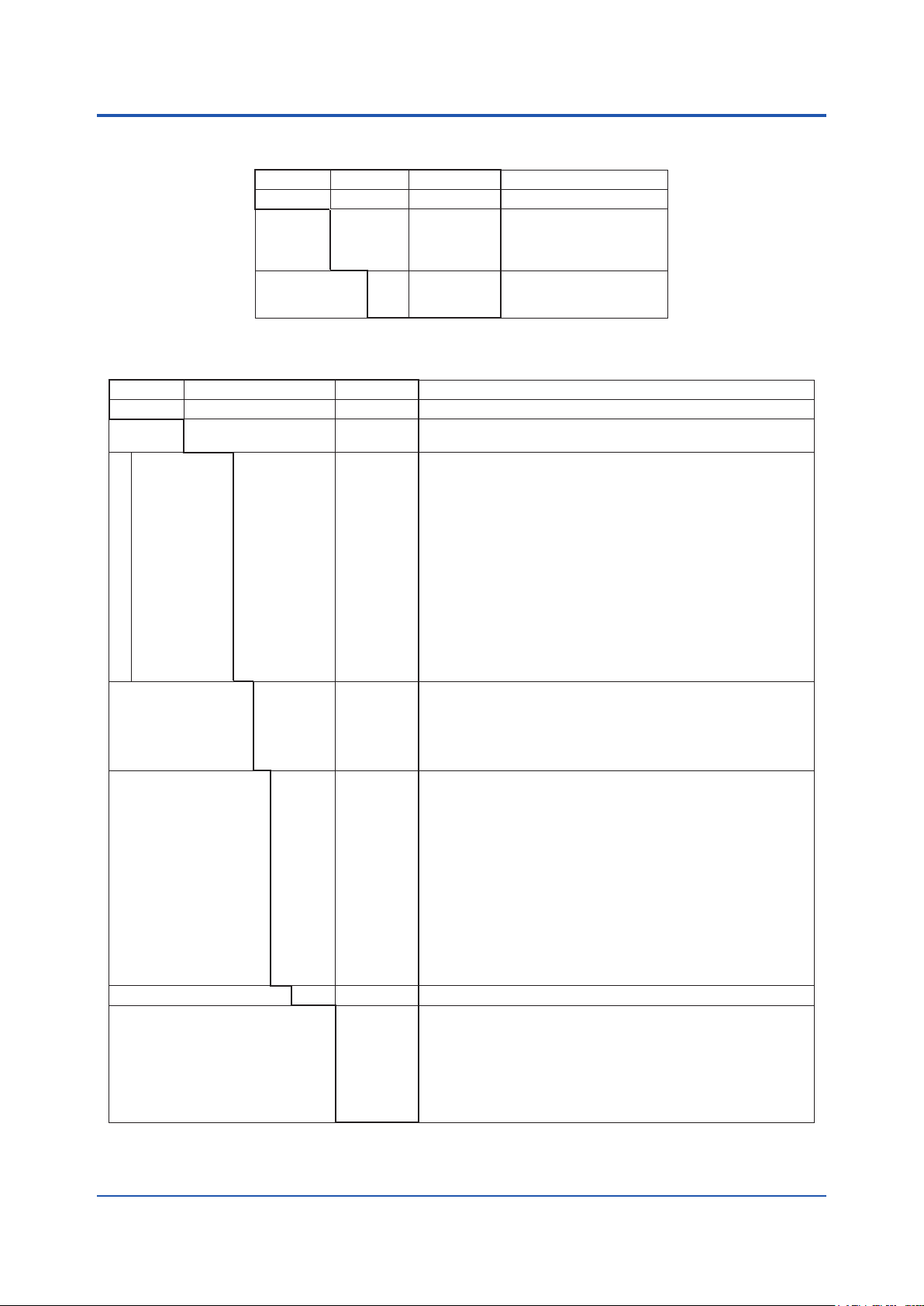

Page 3

3

MPa

F03.ai

n GENERAL SPECIFICATIONS

1. SC4AJ:

Cable with pin terminals (applicable to FLXA202,

Cable with M4 ring terminals (applicable to FLXA202,

Cable with M3 ring terminals (applicable to FLXA402)

Variopin connector (applicable to SA11)

Object of measurement: Conductivity of solutions

Measuring principle: Two-electrode system

Cell constant: 0.02 cm-1, 0.1 cm

Measuring range:

For a cell constant: 0.02 cm

For a cell constant: 0.1 cm

Temperature Range: For electrode, 0 to 110°C

For holder, see Figure 1

Sterilization for electrode:

135°C (275°F), within 30 minutes in

Pressure range : For electrode, 0 to 1 MPa

For holder, see Figure 1

1.2

1.0

0.8

0.6

0.4

0.2

Figure1: The range of tolerance of holders (option:

Sample solution condition:

Temperature sensor: Pt1000

Materials: Stainless steel (316L SS) (for all Fitting-

Mounting adapter: Polyvinylidene diuoride (for /PF

and /RF) or Stainless steel (316

SS), Stainless steel (316L SS)

Weight:

Sensors:

Adapter mounting type

Adapter mounting type

Welding socket type

1 or 1.5 inch welding clamp type

2 inch welding clamp type

FLXA21, FLXA402)

FLXA21)

-1

-1

:

0-0.5 µS/cm to 0-200 µS/cm

-1

:

0-5 µS/cm to 1 mS/cm

Steam Sterilization

SUS316L

PVDF

0 10 20 30 40 50 60 70 80 100 120 140

/PS, /PF, /RS, /RF, /SA1, /SA2, /SB1, /SB2,

/SC1) for temperature and pressure

Although ow rate is not limited in

measurement, air bubbles should not be

mixed in the sample solutions to obtain

correct measured values.

type) or Titanium (only for adapter

mounting type-AD), Fluoro rubber (FKM)

O-ring. EPDM O-ring (for -SA with Variopin)

(SC4AJ-S-AD-09-002-03): approx. 0.3 kg

(SC4AJ-S-AD-15-002-03): approx. 0.4 kg

(SC4AJ-S-SA-NN-002-03): approx. 0.5 kg

(SC4AJ-S-SB-NN-002-03): approx. 0.4 kg

(SC4AJ-S-SC-NN-002-03): approx. 0.5 kg

˚C

Note: There are weight dierences among SC4AJ

sensors. In order to know the more accurate

weight of each type of sensors, please calculate it

from following information. The cable weighs 0.07

kg/m. The SC4AJ with 0.02 cm-1 cell constant is

0.02 kg heavier than the SC4AJ with 0.1 cm-1 cell

constant. 314L SS electrode is 0.04 kg heavier

than Titanium electrode.

Adapters:

3/4NPT stainless steel adapter (/PS):

R3/4 stainless steel adapter (/RS):

3/4NPT PVDF adapter (/PF):

R3/4 PVDF adapter (/RF):

approx. 0.04 kg

approx. 0.04 kg

Straight welding socket (/SA1):

Angle welding socket 15 (/SA2):

Welding clamp 1 inch (/SB1):

approx. 0.3 kg

Welding clamp 1.5 inch (/SB2):

Welding clamp 2 inch (/SC1):

note: Do not submerge the sensor itself in process

water, as the seams between the mold and the

metal of the sensor are not waterproof.

approx. 0.4 kg

approx. 0.1 kg

approx. 0.1 kg

approx. 0.3 kg

approx. 0.3 kg

approx. 0.3 kg

2. SC8SG:

Cable with pin terminals (applicable to FLXA202,

Cable with M4 ring terminals (applicable to FLXA202,

Cable with M3 ring terminals (applicable to FLXA402)

Variopin connector (applicable to SA11)

Object of measurement:

Conductivity of liquids

Measuring Principle: 2-electrode system or

Cell Constants: 0.01 cm-1, 0.1 cm-1, 10 cm-1

(for two-electrode system)

Measuring Ranges: 0-0.5 µS/cm to 0-100 µS/cm

for a cell constant of 0.01 cm-1

0-10 µS/cm to 0-10 mS/cm

for a cell constant of 0.1cm

Temperature Range: 0˚ to 100˚C (130˚C maximum only for

0.01 cm-1 cell constant detectors,

excluding those with polypropylene

chambers)

Pressure: 1000 kPa max. (500 kPa maximum for

de

chambers)

Flow rate of Sample Solution:

No particular limitation applies,

Note: No limitation applies to ow rate (ow velocity)

RTD for Temperature Compensation:

Pt1000 (built into the sensor)

Construction: Direct insertion (in-situ) type or

Rainproof encapsulation

FLXA21, FLXA402)

FLXA21)

4-electrode system

10 cm-1 (for four-electrode system)

0-1 mS/cm to 0-1000 mS/cm

for a cell constant of 10 cm

tectors with polypropylene

although a value of less than 20

L/min. is recommended for ow-

through detectors.

as far as measurement is concerned. However,

when using ow-through detectors, electrodes or

the inner walls of a liquid chamber may be worn

out drastically at higher ow speeds if a measured

solution contains slurry. Air bubbles should not be

mixed in the sample solutions to obtain correct

measured values.

ow-through types.

(equivalent to JIS C0920

Japanese Industrial Standard)

-1

1

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 4

4

Installation :

•Screw-in type: held by the process piping

No particular limitation applies,

•Flange type: held by the process piping

•Flow-through type (polypropylene chamber)

: mounted on a pipe (nominal diameter

of 50 mm ±2 in.)

•Flow-through type (SCS14 chamber)

: held by the process piping

Process Connection: Screw-in, Flange, ow-through

Construction of Wetted Part:

•Sensor-holding base:

316 SS) and Fluoro

Temperature sensor: Thermistor (PB36NTC)

Wet part Materials

•0.01 cm

Stainless steel (

rubber when using screw-in type holder

or the chamber made of stainless steel.

PP and Fluoro rubber when using the

chamber made of PP.

-1,

0.1 cm-1 cell constant, two-electrode

sensor:

Stainless steel (316 SS) and ethylene

chloride triuoride

-1

•10 cm

•10 cm

cell constant, two-electrode sensor:

reinforced epoxy resin and graphite

-1

cell constant, four-electrode sensor:

polyvinylidene diuoride (PVDF), glass

and platinum

•Stem (ow-through type):

SCS14 or polypropylene resin

Weight:

Screw-in type

approx. 0.9 kg (-R31) (excluding the cable)

Flange type

approx. 2.8 kg (-R31) (excluding the cable)

Flow-through type (SCS14 chamber)

approx. 3.1 kg (excluding the cable)

Construction: JIS C0920 watertight (equal to NEMA 4)

Weight:

Flow-through type (SCS14 chamber, anged)

approx. 4.5 kg (excluding the cable)

Flow-through type (polypropylene chamber)

approx. 2.7 kg (excluding the cable)

Flow-through type (polypropylene chamber, anged)

approx. 3.2 kg (excluding the cable)

Cable ; approx. 0.3 kg for 5.5 m length

; approx. 0.5 kg for 10 m length

; approx. 0.9 kg for 20 m length.

● WU41: Dedicated cable for the SC8SG

Cable : Six multicore wire

Diameter: 9.2 mm

Material : Thermoplastic PVC

3. SC210G:

Cable with pin terminals (applicable to FLXA202, FLXA21, FLXA402)

Cable with M4 ring terminals (applicable to FLXA202, FLXA21)

Cable with M3 ring terminals (applicable to FLXA402)

Object of measurement:

Conductivity of solutions

Measuring principle : Two-electrode system

Cell constant : 0.05 cm-1, 5 cm

Measuring range : 0-0.5 µS/cm to 0-200 µS/cm

(Cell constant: 0.05 cm

0-200 µS/cm to 0-20 mS/cm

(Cell constant: 5 cm

-1

-1

)

-1

)

Temperature Range: 0 to 105°C

(chamber material: SCS14)

0 to 100°C

(chamber material: Polypropylene)

Pressure range : 0 to 1 MPa

(chamber material: SCS14)

0 to 500 kPa

(chamber material: Polypropylene)

n Compliance with the simple ap

requirements

SC210G and SC4AJ meet the simple apparatus

requirements dened in the following standards.

Use the sensors under the conditions of use required

by the standards.

Applicable standards:

ANSI/ISA-60079-11 (2014)

ANSI/ISA-60079-0 (2009)

CAN/CSA-C22.2 NO. 60079-11:14

CAN/CSA-C22.2 NO. 60079-0:11

방호장치 의무안전인증 고시

GB 3836.4-2010

Flow rate of Sample Solution:

although a value of less than 20

L/min. is recommended for ow-

through detectors.

Note: No limitation applies to ow rate (ow velocity)

as far as measurement is concerned. However,

when using ow-through detectors, electrodes or

the inner walls of a liquid chamber may be worn

out drastically at higher ow speeds if a measured

solution contains slurry. Air bubbles should not be

mixed in the sample solutions to obtain correct

measured values.

SC210G-A: For sensor, Stainless steel (316 SS),

Fluoro rubber (FKM) (O-ring) and

Polytriuorochloroethylene For body,

Stainless steel (316 SS), polypropylene

and Fluoro rubber (FKM) (O-ring)

SC210G-B: For sensor, Platinum, glass and Fluoro

rubber (FKM) (O-ring)

For body, Stainless

steel (316 SS), polypropylene and

Fluoro rubber (FKM) (O-ring)

Flange (Flange type): Stainless steel (316 SS)

Flow-through type holder: SCS14 or polypropylene

resin, Fluororubber(FKM)

(O-ring)

Gate valve: SCS13A, Stainless steel (304 SS),

Stainless steel (316 SS Hard chrome

plating), Expanded graphite, PTFE

Screw-in type

approx. 2.1 kg (-L015) (excluding the cable)

Flange type

approx. 4.3 kg (-L015) (excluding the cable)

Flow-through type (SCS14 chamber)

approx. 3.7 kg (excluding the cable)

Flow-through type (SCS14 chamber, anged)

approx. 5.0 kg (excluding the cable)

Flow-through type (polypropylene chamber)

approx. 3.1 kg (excluding the cable)

Flow-through type (polypropylene chamber, anged)

approx. 3.3 kg (excluding the cable)

With gate valve

approx. 3.9 kg (excluding the cable)

Cable ; approx. 0.9 kg for 3 m length

; approx. 1.5 kg for 5 m length

; approx. 3.0 kg for 10 m length

; approx. 1.5 kg for 15 m length

; approx. 6.0 kg for 20 m length.

paratus

Note: TIIS certied types cannot be connected.

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 5

Conditions of use:

(1) Use in combination with an internally isolated analyzer, or use with, an analyzer in combination with isolated

barrier.

The FLXA202/FLXA21 is internally isolated.

(2) Upper limit of the process temperature.

The upper limit of process temperature is indicated below when the sensor is used in combination with a

YOKOGAWA analyzer.

For FLXA202/FLXA21, model and sux code below is available.

FLXA21-D-□-D-◊-C1-○-A-N-LA-N-NN

□: can be any value.

◊: must be EA, CD, CH, or EG.

○: must be NN or C1.

Any option code is available.

FLXA202-D-□-D-◊-C1-○-A-N-LA-N-NN

□: can be any value.

◊: must be CD, CH, or CG.

○: must be NN or C1.

Any option code is available.

Upper limit of process temperature on the SC210G

Analyzer used in combination FLXA202/FLXA21

Ambient temperature Ta

40°C 60°C

Temperature class

T6 30 30

T5 95 (*1) 35

T4 105 45

T3 105 65

T2 105 105

T1 105 105

*1: Care about upper limit 100°C of temperature class T5 should be taken.

5

Upper limit of process temperature on the SC4AJ

Analyzer used in combination FLXA202/FLXA21

Ambient temperature Ta

40°C 60°C

Temperature class

T6 49 49

T5 95 (*1) 64

T4 110 99

T3 110 11 0

T2 110 11 0

T1 110 11 0

*1: Care about upper limit 100°C of temperature class T5 should be taken.

Other warnings are provided in the user’s manual.

■ Applicableanalyzerwithvariousdetectors

Detector SC4AJ SC8SG SC210G

Type of terminals Pin Ring M4 Ring M3 Pin Ring M4 Ring M3 Pin Ring M4 Ring M3

Analyzer: FLXA402 (*) Yes N.A. Yes Ye s N.A. Ye s Ye s N.A. Ye s

Analyzer: FLXA202 (*), FLXA21 Yes Ye s N.A. Yes Yes N.A. Ye s Yes N.A.

*: FLXA402 or FLXA202 when connected to a SA11 can be connected with sensors equipped with Variopin connector.

(SC4A..-VS, SC42-�V, SX42..�V, SC4AJ..-VS, SC8SG..-VS)

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Jan. 12, 2021-02

Page 6

n MODEL AND SUFFIX CODES

1. SC4AJ

Model SuxCode Option Code Description

SC4AJ

Material -T

Fitting type -AD

Sensor length -09

Cell constant -002

Cable length -03

Temperature sensor -T1

Option For AD only /PS

*1: When you select Fitting type -SA, place an order on the SC4AJ with Option code /SA1 or /SA2.

*2: When you select Fitting type -SB, place an order on the SC4AJ with Option code /SB1 or /SB2 (including seal ring),

When you select Fitting type -SC, place an order on the SC4AJ with Option code /SC1 (including seal ring).

*3: Washing treatment of wet part with alcohol.

*4: Used for connection to FLXA202, FLXA21.

*5: Used for connection to FLXA402, SC450G.

*6: Used for connection with SA11. Sensor length -09 is not selectable.

........................................................... ........................

.......................

-S

-SA

-SB

-SC

-15

-NN

-010

-05

-10

-15

-20

-X1

-X2

-X3

-X4

-X5

-Y1

-Y2

-Y3

-Y4

-Y5

-VS

For SA only /SA1

For SB only /SB1

For SC only /SC1 Welding clamp 2 inch 316L SS

Oil prohibit /DG1 Oil-prohibited use (*3)

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

/PF

/RS

/RF

/SA2

/SB2

Conductivity sensor

Titanium (Only for -AD)

316L SS

Adapter mounting type

Welding socket type (*1)

1 or 1.5 inch welding clamp type (*2)

2 inch welding clamp type (*2)

9 cm (Code for -AD)

15 cm (Code for -AD)

xed length (Code for -SA, -SB, -SC)

-1

0.02 cm

-1

0.1 cm

3 m (pin terminals)

5 m (pin terminals)

10 m (pin terminals)

15 m (pin terminals)

20 m (pin terminals)

3 m (M4 ring terminals) (*4)

5 m (M4 ring terminals) (*4)

10 m (M4 ring terminals) (*4)

15 m (M4 ring terminals) (*4)

20 m (M4 ring terminals) (*4)

3 m (M3 ring terminals) (*4)

5 m (M3 ring terminals) (*4)

10 m (M3 ring terminals) (*4)

15 m (M3 ring terminals) (*4)

20 m (M3 ring terminals) (*4)

Variopin connector (*6)

Pt1000

3/4NPT adapter 316 SS

3/4NPT adapter PVDF

R3/4 adapter 316 SS

R3/4 adapter PVDF

Straight welding socket 316L SS

Angled welding socket 15° 316L SS

Welding clamp 1 inch 316L SS

Welding clamp 1.5 inch 316L SS

6

Spare parts for SC4AJ

Parts No. Description

K9670MA

K9675VY

K9670MK

K9670MP

K9670MT

K9670MU

K9670MV

K9670MW

K9670MD

K9670ME

K9670MB

K9670MC

K9670ML

K9670MQ

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

O-ring for -SA (excluding -VS)

O-ring set for -SA (for -VS)

Seal rings for /SB1 or /SB2

Seal rings for /SC1

3/4 NPT Stainless steel adapter for -AD

3/4 NPT PVDF Adapter for -AD

R3/4 Stainless steel adapter for -AD

R3/4 PVDF Adapter for -AD

Angled welding socket and mounting nut for -SA

Staight welding socket for -SA

Angled welding socket for -SA

Straight welding socket for -SA

Welding clamp 1 or 1.5 inch for -SB

Welding clamp 2 inch for -SC

Page 7

2. SC8SG

Model SuxCode

SC8SG

Measuring

range

............................................. ...............

-R31

-R42

-R61

Electrode

-T

conguration

-F

Screw-in type

-100

-101

-102

Flange type

-206

-207

-208

Flow-through type

(*3)

Construction

-302

-312

-303

-313

-304

-314

-305

-315

Cable length -P1

-P2

-P3

-F1

-F2

-F3

-X1

-X2

-X3

-Y1

-Y2

-Y3

-VS

Style code *A

Option /PS

*1: Electrode conguration -F cannot be selected when -R31 or -R42 is selected.

When -R61 is selected, 2-electrode system -T is normally used, however, for process where detectors are susceptible to

contamination, a 4-electrode system -F should be used.

*2: If a welding socket (K9208BK) needs to be ordered beforehand, either place a separate order or prepare one by referring to

the extemal view later in this brochure.

*3: No chamber is equipped with a mounting hardware. Please place an order on the SC8SG with option code /PS or /SS

when you select ow-through model.

The PP chamber can have cracks or splits unless it is supported by a mounting hardware.

*4: Used for connection to FLXA202, FLXA21.

*5: Used for connection to FLXA402, SC450G.

*6: Used for connection with SA11. SC8SG-R61-T ( Measuring range: -R61 with Electrode conguration -T) is not selectable.

Spare Parts for SC8SG

Option

Code

..............

..............

..............

..............

..............

..............

..............

.............

.............

.............

.............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

..............

.............

..............

/SS

Description

Conductivity detector

Low range; cell constant: 0.01 cm

Medium range; cell constant: 0.1 cm

High range; cell constant: 10 cm

2-electrode system (for both 0.01 cm-1, 0.1 cm

-1

-1

-1

-1,

10cm-1 cell constants)

- for general measurements

4-electrode system (for 10 cm-1 cell constant only)

- for countermeasures against polarization due to contamination (*1)

with welding socket (*2)

without welding soket(a welding socket [K9208BK] should be ordered separately)

R1-1/2 material: SCS14

JIS 10 K 50 RF Flange

ANSI Class 150 2 RF ange (with serration)

JPI Class 150 2 RF ange

Rc1/2 female threaded; chamber material: SCS14

Rc1/2 female threaded; chamber material: PP

1/2NPT female threaded; chamber material: SCS14

1/2NPT female threaded; chamber material: PP

JIS 10K 15 RF ange; chamber material: SCS14

JIS 10K 15 FF ange; chamber material: PP

ANSI Class150 1/2 RF ange with serration; chamber material: SCS14

ANSI Class150 1/2 FF ange; chamber material: PP

5.5 m (special cable supplied with detector) (pin terminals)

10 m (special cable supplied with detector) (pin terminals)

20 m (special cable supplied with detector) (pin terminals)

5.5 m (special cable supplied with detector) (fork terminal)

10 m (special cable supplied with detector) (fork terminal)

20 m (special cable supplied with detector) (fork terminal)

5.5 m (special cable supplied with detector) (M4 ring terminal) (*4)

10 m (special cable supplied with detector) (M4 ring terminal) (*4)

20 m (special cable supplied with detector) (M4 ring terminal) (*4)

5.5 m (special cable supplied with detector) (M3 ring terminal) (*5)

10 m (special cable supplied with detector) (M3 ring terminal) (*5)

20 m (special cable supplied with detector) (M3 ring terminal) (*5)

Variopin connector (*6)

Style A

Stainless Steel

Stainless Steel

Mounting hardware (for PP chamber)

Mounting hardware (for SCS14 chamber)

7

Parts No. Description

K9208BA 0.01 cm

K9208BB 0.1 cm

K9208BC 10 cm

K9208BD 10 cm

K9208BV 0.01 cm

K9208BY 0.1 cm

K9208BZ 10 cm

-1

cell constant, two-electrode sensor

-1

cell constant, two-electrode sensor

-1

cell constant, two-electrode sensor

-1

cell constant, four-electrode sensor

-1

cell constant, two-electrode sensor, Variopin connector

-1

cell constant, two-electrode sensor, Variopin connector

-1

cell constant, four-electrode sensor, Variopin connecto

K9208BK Welding socket for screw-in model

G9303EB O-ring

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 8

WU41

This cable can be purchased additionaly. SC8SG is supplied with cables of selected length.

Model Suxcode Option code Description

WU41

Cable end -F

Cable length -05

*1: Used for connection to FLXA202, FLXA21.

*2: Used for connection to FLXA402, SC450G

..................... ..........................

.........................

-10

-20

.........................

.........................

.........................

.........................

.........................

.........................

-P

-X

-Y

Dedicated Cable for SC8SG

fork terminals

pin terminals

M4 ring terminals (*1)

M3 ring terminals (*2)

5.5 m

10 m

20 m

3. SC210G

Model SuxCode Option Code Description

SC210G

Measuring

range

Screw-in type

Flange type

Flow-through

type (*1)

Construction

With gate valve

Sensor length -L015

Cable length -03

Style code *A

Option /SCT

*1: The model is not equipped with a mounting brackets, place an order on the SC210G with option code /PS or /SS when you

*2: Only for Screw-in type and Flange type

........................................... .......................

-A

-B

-100

-103

-206

-207

-208

-302

-312

-303

-313

-304

-314

-305

-315

-306

-402

-403

-L030

-L050

-L100

-L150

-L200

-05

-10

-15

-20

-AA

-BB

-CC

-DD

-EE

-Y1

-Y2

-Y3

-Y4

-Y5

select ow-through model. The PP chamber material can have cracks or splits unless it is not supported by a mounting

hardware.

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

......................

/ANSI

/PF

/PS

/SS

/X1

/DG1

/MCT

Conductivity detector

Low range; cell constant: 0.05 cm

Medium range; cell constant: 5 cm

R1-1/2 male

1-1/2NPT male

JIS 10K 50 RF ange

ANSI Class150 2 RF ange (with serration)

JPI Class150 2 RF ange

Rc1/2 female, chamber material: SCS14

Rc1/2 female, chamber material: PP

1/2NPT female, chamber material: SCS14

1/2NPT female, chamber material: PP

JIS 10K 15 RF ange, chamber material: SCS14

JIS 10K 15 FF ange, chamber material: PP

ANSI Class150 1/2 RF ange with serration, chamber material: SCS14

ANSI Class150 1/2 FF ange, chamber material: PP

JPI Class150 1/2 RF ange, chamber material: SCS14

R1-1/4 male

1-1/4NPT male

150 mm (Standard)

300 mm (*2)

500 mm (*2)

1000 mm (*2)

1500 mm (*2)

2000 mm (*2)

3 m (M4 ring terminals) (*3)

5 m (M4 ring terminals) (*3)

10 m (M4 ring terminals) (*3)

15 m (M4 ring terminals) (*3)

20 m (M4 ring terminals) (*3)

3 m (pin terminals)

5 m (pin terminals)

10 m (pin terminals)

15 m (pin terminals)

20 m (pin terminals)

3 m (M3 ring terminals) (*4)

5 m (M3 ring terminals) (*4)

10 m (M3 ring terminals) (*4)

15 m (M3 ring terminals) (*4)

20 m (M3 ring terminals) (*4)

Style A

Stainless steel tag plate

With ANSI connection adaptor (*5)

DAI-ELperfrow (peruoro-elastomer) specication (*6)

SUS mounting hardware (for PP construction)

SUS mounting hardware (for SCS14 construction)

Epoxy-coated (baked)

Oil-prohibited use (Degrease cleaning treatment) (except for the type with gate valve)

Material Certicate (*7) (except for gate valve)

-1

-1

8

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 9

*3: Used for connection to FLXA202, FLXA21.

*4: Used for connection to FLXA402, SC450G.

*5: Adaptor for cable inlet (carbon steel)

*6: Materials for O-ring of electrode assembly and chamber seal become peruoro-elastomer. But, in construction -402 and

-403, the sealing part of gate valve doesn’t become the elastomer.

*7: Additional lead time is required.

Spare Parts for SC210G

Name Part No. Remarks

-1

Electrode Assembly (*1)

(for SC210G-A)

Electrode Assembly (*2)

(for SC210G-A with gate valve)

Electrode Assembly (*1)

(for SC210G-B)

Electrode Assembly (*2)

(for SC210G-B with gate valve)

Cable K9315QA

O-ring K9050AT

*1: For the electrode assembly for oil-prohibited use (/DG1) and/or with material certicate (/MCT), please contact Yokogawa.

*2: For the electrode assembly with material certicate (/MCT), please contact Yokogawa.

K9208EA

K9208EB

K9208EC

K9208ED

K9208EE

K9208EF

K9315NA

K9315NB

K9315NC

K9315ND

K9315NE

K9315NF

K9208KA

K9315NN

K9208JH

K9208JF

K9208JB

K9208JC

K9208JD

K9208JE

K9208JJ

K9315NH

K9315NJ

K9315NK

K9315NL

K9315NM

K9208MA

K9315NP

K9315QB

K9315QC

K9315QF

K9315QG

K9315QR

K9315QS

K9315QT

K9315QU

K9315QV

K9315QJ

K9315QK

K9315QL

K9315QM

K9315QQ

K9050MR

K9319RN

150 mm (C=0.05cm

500 mm (C=0.05cm-1)

1000 mm (C=0.05cm-1)

1500 mm (C=0.05cm-1)

2000 mm (C=0.05cm-1)

300 mm (C=0.05cm-1)

150 mm (C=0.05cm-1) with peruoro-elastomer

300 mm (C=0.05cm-1) with peruoro-elastomer

500 mm (C=0.05cm-1) with peruoro-elastomer

1000 mm (C=0.05cm-1) with peruoro-elastomer

1500 mm (C=0.05cm-1) with peruoro-elastomer

2000 mm (C=0.05cm-1) with peruoro-elastomer

-1

(C=0.05cm

(C=0.05cm-1) with peruoro-elastomer

150 mm (C=5cm

300 mm (C=5cm-1)

500 mm (C=5cm-1)

1000 mm (C=5cm-1)

1500 mm (C=5cm-1)

2000 mm (C=5cm-1)

150 mm (C=5cm-1) with peruoro-elastomer

300 mm (C=5cm-1) with peruoro-elastomer

500 mm (C=5cm-1) with peruoro-elastomer

1000 mm (C=5cm-1) with peruoro-elastomer

1500 mm (C=5cm-1) with peruoro-elastomer

2000 mm (C=5cm-1) with peruoro-elastomer

(C=5cm

(C=5cm-1) with peruoro-elastomer

3 m (M4 ring terminals, SC210G...-03)

5 m (M4 ring terminals, SC210G...-05)

10 m (M4 ring terminals, SC210G...-10)

15 m (M4 ring terminals, SC210G...-15)

20 m (M4 ring terminals, SC210G...-20)

3 m (pin terminals)

5 m (pin terminals)

10 m (pin terminals)

15 m (pin terminals)

20 m (pin terminals)

3 m (M3 ring terminals)

5 m (M3 ring terminals)

10 m (M3 ring terminals)

15 m (M3 ring terminals)

20 m (M3 ring terminals)

Fluoro-rubber (FKM) O-ring (for screw-in type, ange type and ow-through type)

Fluoro-rubber (FKM) O-ring (for gate valve type)

Peruoro-elastomer O-ring (for all types)

)

-1

)

)

-1

)

9

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Jul. 10, 2020-01

Page 10

n DIMENSIONS

1. SC4AJ

˂Adapter mounting type˃

SC4AJ-p-AD-09

Sensor length: 09 (9 cm)

10

ø19.1

Cable length (3m, 5m, 10m, 15m, 20m)

SC4AJ-p-AD-15

Sensor length: 15 (15 cm)

ø19.1

90

Approx. 350

152

Pin-type Ring-type

57.6

Variopin connector

Unit: mm

Unit: mm

Cable length (3m, 5m, 10m, 15m, 20m)

Approx. 350

Pin-type Ring-type

●Option: Adaptermountingtype(-AD) /PS(StainlessSteel) /PF(PVDF)

/RS (Stainless Steel) /RF (PVDF)

Unit: mm

Approx. 49

3/4NPT or R3/4

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 11

˂Welding socket type˃

SC4AJ-p-SA-NN

11

ø24.9

ø19.1

ø33.8

ø38

ø24.9

ø19.1

ø33.8

ø38

Cable length (3m, 5m, 10m, 15m, 20m)

95

95

Approx. 185

Approx. 350

●Option: Weldingsockettype(-SA)

Unit: mm

Variopin connector

189

O-ring

Pin-type Ring-type

Straight welding socket: /SA1 Angled welding socket: /SA2

51

8.5

55

ø42

Socket

thickness

(56.3)

(43.5)

8.5

Socket

ø42

Unit: mm

15°

thickness

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 12

˂Weldingclamptype˃

SC4AJ-p-SB-NN

ø19.1

ø50.5

12

Unit: mm

Variopin connector

70

ø19.1

ø50.5

70

Cable length (3m, 5m, 10m, 15m, 20m)

Approx. 350

●Option: Weldingclamptype(-SB)

Welding clamp 1 inch: /SB1 Welding clamp 1.5 inch: /SB2

12.7

158

Approx. 160

12.7

Pin type

Ring type

Unit: mm

ø25.4

ø38.1

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Jan. 15, 2021-03

Page 13

Sensor SC4AJ-p-SC-NN

13

Unit: mm

ø64

ø25

ø64

ø19.1

ø19.1

80

80

Cable length (3m, 5m, 10m, 15m, 20m)

Approx. 350

167.3

Approx. 170

Variopin connector

Pin type

Ring type

●Option: Weldingclamptype(-SC)

Welding clamp 2 inch: /SC1

12.7

ø50.8

Unit: mm

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 14

2. SC8SG

˂Screw-in type˃ Only the dierence between SC8SG-R □□-□-100 and SC8SG-R□□-□-101 is whether or not having a welding

socket. SC8SG-R □□-□-100 has a welding socket but SC8SG-R□□-□-101 does not.

14

SC8SG-R31-T-100 (Low range)

Electrode with 0.01cm

Two-electrode system

Locknuts

(M48x2)

45

Variopin connector

Outlet for

measured solution

SC8SG-R42-T-100 (Medium range)

Electrode with 0.1cm

Two-electrode system

Locknuts

(M48x2)

45

Variopin connector

Outlet for

measured solution

SC8SG-R61-T-100 (High range)

Electrode with 10cm

Two-electrode system

Welding

socket

Welding

socket

-1

Cell constant

95

95

ø30

-1

Cell constant

42

ø30

-1

Cell constant

Approx. 78

192

192

156

156

Approx. 78

138

102

Unit: mm

Pin terminals

Fork terminals

Ring terminals

Unit: mm

Pin terminals

Fork terminals

Ring terminals

Unit: mm

SC8SG-R61-F-100 (High range)

Electrode with 10cm

Four-electrode system

45

Variopin connector

measured solution

Locknuts

(M48x2)

Welding

socket

Outlet for

-1

Cell constant

133

26

ø29

Approx. 78

222

186

Welding socket

Parts No: K9208BK (Material: 316SS)

C1

C1

Note: If you make the welding socket for screw-in type,

refer to the above drawing.

ø55

ø42

ø45

ø50±0.2

22

3

27

3

(5)

Unit: mm

Pin terminals

Fork terminals

Ring terminals

Unit : mm

Locknuts

(M48x2)

Welding

socket

Outlet for

measured solution

125

ø30

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Approx. 78

185

Pin terminals

Fork terminals

221

Ring terminals

Page 15

15

SC8SG-R31-T-102 (Low range)

Electrode with 0.01cm

-1

Cell constant

Two-electrode system

Locknuts

(M48x2)

45

R1-1/2

Variopin connector

Outlet for

measured solution

95

ø30

SC8SG-R42-T-102 (Medium range)

Electrode with 0.1cm

-1

Cell constant

Two-electrode system

Locknuts

(M48x2)

45

Approx. 78

192

Approx. 78

Unit: mm

Pin terminals

Fork terminals

Ring terminals

Unit: mm

Pin terminals

SC8SG-R61-F-102 (High range)

Electrode with 10cm

-1

Cell constant

Four-electrode system

Locknuts

(M48x2)

45

R1-1/2

Variopin connector

Outlet for

measured solution

133

26

Unit: mm

Pin terminals

Approx. 78

Fork terminals

222

Ring terminals

ø29

Variopin connector

R1-1/2

Outlet for

measured solution

42

SC8SG-R61-T-102 (High range)

Electrode with 10cm

-1

Cell constant

Two-electrode system

Locknuts

(M48x2)

R1-1/2

Outlet for

measured solution

125

Fork terminals

138

Ring terminals

ø30

Unit: mm

Pin terminals

Approx. 78

Fork terminals

221

Ring terminals

ø30

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 16

˂Flange type>

16

Unit: mmSC8SG-R□□-□-20□

Variopin

connector

45

Locknuts

(M48×2)

øC

øD

Flange

138

H3

125

øC øD t

120

155

120.7

152.4

120.6

152

ø30

16

19.1

19.5

221

H3

133

<Insertion length>

øh

H1

19

127

19.1

124

20

123.5

26

H2

74

71

70.5

4-øh holes

191

t

H2

H1

95

SC8SG-R31-T SC8SG-R42-T SC8SG-R61-T SC8SG-R61-F

<Flange>

SC8SG - R□□ - □ - 206 - □□ *A

SC8SG - R□□ - □ - 207 - □□ *A

SC8SG - R□□ - □ - 208 - □□ *A

Outlet for

measured

solution

ø30

Model and Code

42

ø30

Flange rating

JIS 10K 50 RF

ANSI Class150 2 RF

JPI Class150 2 RF

Note: ANSI flange with serrations

Pin terminals

Approx. 78

Fork terminals

222

Ring terminals

ø29

H3

157

154

153.5

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 17

˂Flow-throughtype˃

SC8SG-Rpp-p-302,

SC8SG-Rpp-p-303,

Screw connection (Chamber Material: SCS14)

Unit: mm

Variopin

connector

Pin terminals

●Option: Mounting hardware (-SS)

SCS14 Chamber

20

Approx.102

17

Unit : mm

45

Outlet

Rc1/2 or

1/2NPT(F)

Locknuts

42

172

Approx. ø58

Approx. 78

Fork terminals

260

Ring terminals

Inlet

Rc1/2 or

1/2NPT(F)

SC8SG-Rpp-p-304,

SC8SG-Rpp-p-305,

Flange connection (Chamber Material: SCS14)

Unit: mm

Variopin

connector

45

Locknuts

Approx. 78

Pin terminals

70

100

55

82

203

50A pipe

293

52

95

34.91515.71211.2

Fork terminals

Ring terminals

4-øh holes

øC

øD

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

øG

t

205

Flange rating øGøC øh t

JIS 10K 15 RF

ANSI Class150 1/2 RF

(with serretion)

75

70

60.5

øD

88.9

Page 18

SC8SG-Rpp-p-312, SC8SG-Rpp-p-313,

Screw connection (Chamber Material: PP) + Option (Mounting hardware (/PS)

Variopin

connector

18

Unit: mm

Pin terminals

45

203

47

Approx. 78

100

305

1/2NPT

Outlet

217

Rc1/2

40

87 99

170

Rc1/2

1/2NPT

Inlet

/PS

Mounting

hardware

SC8SG-Rpp-p-314, SC8SG-Rpp-p-315,

Flange connection (Chamber Material: PP) + Option (Mounting hardware (/PS) )

Variopin

connector

Pin terminals

Fork terminals

Ring terminals

JIS 50A pipe

53

Unit: mm

45

203

47

Approx. 78

4-ø15 holes

øC

øD

303

100

215

/PS

12

85 99

Mounting

hardware

Fork terminals

Ring terminals

JIS 50A pipe

98

Flange rating

JIS 10K 15 FF

ANSI Class150 1/2 FF7060.59588.9

øDøC

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 19

● WU41 for SC8SG

19

Unit : mm

64.5

ø 29

15

16

11

12

PG9

Cable lengh:

14

13

Earth

3. SC210G

● SC210GDetector-converter connectioncable(accessory)

Black

T2

Red

White

Brown

To detector

T1

C1

C2

Approx. 75 Approx. 80

ø10.5

L

(3, 5, 10, 15, 20 m)

Approx. 100

5.5 m, 10 m, 20 m

Fork terminal

To converter

Ring terminal

Green

White

Yellow

Brown

Black

Red

Green

White

Yellow

Brown

Black

Red

Pin terminal

White

Brown

Green

Yellow

Black

Red

F22.ai

13

14

15

Ring terminals

16

12

11

13

14

15

Pin terminals

16

12

11

Unit: mm

● Option: WithANSIconnectionadaptor (/ANSI)

45

26

1/2NPT

ø15

G1/2

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Unit: mm

Page 20

˂Screw-intype˃

SC210G-p-100, SC210G-p-103

20

Clearance for maintenance access

H+60

A : Mounting

screw

ø30

91

Approx.

H+184

H

26

SC210G-A, -VSC210G-B, -W

˂FlangeType˃

SC210G-p-206, SC210G-p-207, SC210G-p-208

Clearance for maintenance access

H+50

91

82

28

G1/2

Cable inlet

Gage

diameter

Approx.

H+10

< Mounting screw >

Model and Code A

SC210G - □ - 100

SC210G - □ - 103

< Sensor length >

Model and Code

SC210G - □ - 10□ - L015 - □ □ *A

SC210G - □ - 10□ - L030 - □ □ *A

SC210G - □ - 10□ - L050 - □ □ *A

SC210G - □ - 10□ - L100 - □ □ *A

SC210G - □ - 10□ - L150 - □ □ *A

SC210G - □ - 10□ - L200 - □ □ *A

82

Unit : mm

R 1-1/2

1-1/2 NPT

H

150

300

500

1000

1500

2000

Unit: mm

G1/2

Approx.

4 -øh holes

øC

øD

ø30

<Flange> <Sensor length>

Model and code

SC210G - □ - 206 -L □ □ □ - □ □ * A

SC210G - □ - 207 -L □ □ □ - □ □ * A

SC210G - □ - 208 -L □ □ □ - □ □ * A

Note : ANSI flange with serrations.

26

SC210G-ASC210G-B

JIS 10K 50 RF

ANSI Class150 2 RF

JPI Class150 2 RF

H+172

t

Flange rating

28

øC øD øht

120

155

120.7

152.4

120.6

152

19.1

19.5

16

Cable inlet

Approx.H

19

19.1

20

SC210G - □ - 20□ - L015 - □ □ * A

SC210G - □ - 20□ - L030 - □ □ * A

SC210G - □ - 20□ - L050 - □ □ * A

SC210G - □ - 20□ - L100 - □ □ * A

SC210G - □ - 20□ - L150 - □ □ * A

SC210G - □ - 20□ - L200 - □ □ * A

HModel and code

162

312

512

1012

1512

2012

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 21

21

˂Flow-throughtype˃

SC210G-p-302, SC210G-p-303 *1

Screw connection (Chamber Material: SCS14)

Clearance for maintenance access

210

Outlet

Rc1/2 or

1/2NPT

91

Approx.

374

42

172

ø58

Inlet

Rc1/2 or

1/2NPT

*1: Refer to p17 for Dimension and Fitting of Option

(Mounting hardware (/SS)).

Unit: mm

82

G 1/2

Cable inlet

SC210G-p-312, SC210G-p-313

Screw connection (Chamber Material: PP)

Clearance for maintenance access

210

58

/PS

Mounting

hardware

99

91

40

Approx.

47

Rc1/2

1/2NPT

1/2NPT

Approx.

372

Outlet

170

B

82

Inlet

Unit: mm

G1/2

Cable inletRc1/2

100

JIS 50A pipe

SC210G-p-304, SC210G-p-305

SC210G-p-306 *1

Flange connection (Chamber Material: SCS14)

Clearance for maintenance access

210

91

t

øD øC

75

Approx.

409

205

ØCFlange rating

JIS 10K 15 RF

ANSI Class150 1/2 RF

JPI Class150 1/2 RF

70 1295 15

88.9

60.5

60.3 10.989 16

Note: ANSI flange is serration.

*1: Refer to p17 for Dimension and Fitting of Option

(Mounting hardware (/SS)).

82

ø58

Inlet

tØD Øh

11.2

Unit: mm

G 1/2

Cable inlet

Outlet

4-øh holes

15.7

SC210G-p-314, SC210G-p-315

Flange connection (Chamber Material: PP)

Clearance for maintenance access

210

/PS

Mounting

hardware

98

91

Approx.

t

øC øD

85

99

Flange rating

JIS 10K 15 FF

ANSI Class150 1/2 FF

419

Outlet

215

JIS 50A pipe

ØC ØD

70 95

60.5 88.9

t

12

12

Unit: mm

82

G 1/2

Cable inlet

100

4-øh holes

Inlet

Øh

15

15

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 22

˂Withgatevalve˃

SC210G-p-402, SC210G-p-403

SC210G-A (Low range)

Clearance for maintenance access

210

91

Approx.

264

123

82

Unit : mm

G1/2

Cable inlet

SC210G-B (Medium range)

Clearance for maintenance access

225

91

22

Unit : mm

82

G1/2

Cable inlet

Approx.

410

Mounting screw

R1-1/4 or

1-1/4NPT

Gage diameter

Approx.

89

28

n WIRING DIAGRAM

SC4AJ Conductivity Sensor

(two-electrode system)

Applicable Analyzer:

FLXA402, SC450G, FLXA202, FLXA21

Approx.

155

26

11

12

13

14

15

16

Temperature

Electrode

Mounting screw

R1-1/4 or

1-1/4NPT

SC8SG Conductivity Detector

(two-electrode system, four-electrode system)

Applicable Analyzer:

FLXA402, SC450G, FLXA202, FLXA21

123

Gage diameter

Approx.

Approx.

133

199

ø30

11

Temperature

12

13

14

Electrode

15

16

11

Temperature

12

13

14

Electrode

15

16

F33.ai

SC210G Conductivity Detector

(two-electrode system)

Applicable Analyzer:

FLXA402, SC450G, FLXA202, FLXA21

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition Dec. 20, 2019-00

Page 23

n TABLE OF CORROSION-RESISTANT MATERIALS

Note: This table shows corrosion resistances against each specied chemical only. If two or more kinds of chemical are mixed in

a sample, the properties may be dierent from those shown in this table.

Very suitable

Suitable

Slightly unsuitable

r

Í

Unusable

Hydrochloric acid 5 20

Hypohlorous acid 10 20

Nitric acid 10 20

Sulfuric acid

Inorganic acids

Phosphoric acid

Ammonia water 15 80

Caustic potash

Caustic soda

Alkali

Potassium carbonate 5 b

Sodium carbonate

Zinc chloride

Aluminum chloride

Ammonium chloride

Potassium chloride sat. 60 sat. 60 sat. 60

Calcium chloride sat. 80

Chlorides

Ferric chloride 20 40

Sodium chloride 20% + C12

(saturated) (Electrolyte)

Sea water 24

Ammonium sulfate 5 60 20 b

Potassium sulfatc 10 b 10 b 10 b

Sulfates

Sodium sulfate

Ammonium nitrate 20 b 20 b 20 b

Ni-

Sodium nitrate 50 b 50 b 50 b

trates

Sodium sulte 20 b 20 b

Hydrogen peroxide 10 30 10 30 10 30

Sodium hypochlorite 10 90

Potassium bichromate 10 b

Alcohol 96 70 100 b

Others

Acetic acid

Phenol

Aromatic solvent

(Note) b: Shows temperatures up to the boiling point. PVDF: Polyvinylidene diuoride

Holder material Electrode material

Polypropylene 316 SS

80

40

80

3 20

3 100

30 60

30 100

15 100

20 80

20 100

sat. 100 25 b 25 b 25 b

35 40

sat. 100

60

100

Good corrosion

resistance against

all salts normally

used

20 80

100 70 100 70

100 20 95 30

100 20

5 30

14 30

10 30 10 30

5 30

5 100

15 30

5 b

r

10 b

28 65

10 b

25 b

20 30

20 b

35 b

20 b

25 25

25 25

25 b

25 b

30 b

90

24

sat. 30

20 b 20 b 20 b

2 60 to 90

100 25

Í

Example of Description

Concentration Temperature Judgement

% ˚C

Epoxyresin PVDF

Í

5 30

10 60

Í

15 30

25 60

5 20

Í

10 60

5 30

25 100

10 b

28 65

10 60

25 b

20 60

20 b

5 b

35 b

r

20 60

Í

Í

r

25 20

25 b 25 b

Í

30 60

100

Í

90

r

60

20 b

sat. 30

Í

2 60 to 90

10 20

80 60

10 60

100 20

100 20

Í

Í

Í

Í

Í

Í

Í

Í

Í

Í

Í

Í

5 30

1 b

20 40

10 100

5 30

5 100

5 30

5 60

10 b

28 65

10 b

25 b

20 30

20 b

5 b

35 b

20 b

10 b

25 b

25 b

30 b

90

24

20 b

sat. 30

15 30

10 b

80 100

10 100

100 20

100

Í

Í

Í

O-ring material

Fluoro-rubber (FKM)

Strong acid

Weak acid

Strong alkali

Weak alkali

23

Seal

Í

r

CAUTION

Select the material of wetted parts with careful consideration of process characteristics. Inappropriate

selection may cause leakage of process fluids, which greatly affects facilities. Considerable care must be

taken particularly in the case of strongly corrosive process fluid such as hydrochloric acid, sulfuric acid,

hydrogen sulfide, and sodium hypochlorite. If you have any questions about the wetted part construction

of the product, be sure to contact Yokogawa.

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition

Dec. 20, 2019-00

Page 24

24

ConductivityDetectors/SensorsInquirySpecications

Thank you for inquiry about YOKOGAWA Conductivity Detector/Sensor. Please check () the appropriate box () and

write down the relevant information in the underlined blanks.

1. General Items

Name of your company :

Person in charge : Belongs to: (Phone No.: )

Name of plant :

Measuring point :

Purpose of use : Indication Record Alarm Control

Power supply : V AC, Hz

2. Measuring Conditions

(1) Liquid temperature : to , Normal [˚C]

(2) Liquid pressure : to , Normal [kPa]

(3) Flow rate : to , Normal [L/min.]

(4) Flow speed : to , Normal [m/s]

(5) Slurry or fouling components: No Yes

(6) Name of measuring liquid :

(7) Component of measuring liquid :

(8) Others :

3. Installing Location

(1) Ambient temperature :

(2) Installing location : Outdoors Indoors

(3) Others :

4. SpecicationRequirements

(1) Measuring Range :

(2) Transmission output : 4 to 20 mA DC 0 to 20 mA DC

(3) Detector/Sensor : SC4AJ 2-electrode system (0.02 cm-1) 2-electrode system (0.1 cm-1)

SC8SG 2-electrode system (0.01 cm-1) 2-electrode system (0.1 cm-1)

2-electrode system (10 cm-1) 4-electrode system (10 cm-1)

SC210G 2-electrode system (0.05 cm-1) 2-electrode system (5 cm-1)

(4) Mounting type : SC4AJ Adapter mounting Welding socket Welding clamp

SC8SG Screw-in Flange Flow-through

SC210G Screw-in Flange Flow-through

Screw-in with gate valve

(5) Cable length : SC4AJ 3 m 5 m 10 m 15 m 20 m

none (SA11)

SC8SG 5.5 m 10 m 20 m none (SA11)

SC210G 3 m 5 m 10 m 15 m 20 m

(6) Others :

All Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation GS 12D08G02-E 17th Edition

Subject to change without notice

Dec. 20, 2019-00

Loading...

Loading...