Yokogawa FX1002 Installation Manual

name plate

4

5

WARNING

CAUTION

WARNING

CAUTION

Installation

Guide

IM 04L21B01-03EN

Model FX1002/FX1004/FX1006

/FX1008/FX1010/FX1012

FX1000 Paperless Recorder

Safety Precautions and

Installation Guide

Introduction

Thank you for purchasing the FX1002, FX1004, FX1006, FX1008, FX1010, or FX1012 Paperless

Recorder (hereafter referred to as “FX” or “FX1000”.). This manual describes the safty precautions

and installation and wiring procedures of the FX1000.

To ensure correct use, please read this manual and the manuals below thoroughly before

beginning operation. For the product specications, see the general specications.

Paper Manual

Manual Title Manual No.

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder Safety Precautions and Installation Guide

Installing the FXA120 DAQSTANDARD

FX1000 Mode Transition Diagram

Setting Mode / Basic Setting Mode Maps (This manual)

IM 04L21B01-03EN

Electronic Manuals

You can download these manuals from the following web page. You will need Adobe Reader 7 or

later (latest version recommended) by Adobe Systems.

http://www.yokogawa.com/ns/fx1000/im/

Manual Title Manual No.

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder User’s Manual

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder First Step Guide

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder Safety Precautions and Installation Guide

Installing the FXA120 DAQSTANDARD

FX1000 Mode Transition Diagram

Setting Mode / Basic Setting Mode Maps

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder Communication Interface (/C2, /C3, and /C7)

FXA120 DAQSTANDARD for FX1000 Data Viewer IM 04L21B01-63EN

FXA120 DAQSTANDARD for FX1000 Hardware Configurator IM 04L21B01-64EN

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder Usage Precautions

IM 04L21B01-01EN

IM 04L21B01-02EN

IM 04L21B01-03EN

IM 04L21B01-17EN

IM 04L21B01-91EN

General Specications (GS)

General Specifications Name General Specifications No.

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder

* The last two characters of the manual number and the general specications number indicate

the language in which the manuals or general specications are written.

GS 04L21B0-02EN

About the Usage of Open Source Software

MD5

The following products uses MD5 source code.

In accordance with the MD5 license agreement, the copyright notice, redistribution conditions, and

license are listed below.

FX1002, FX1004, FX1006, FX1008, FX1010, FX1012

• RSA Data Security’s MD5 License

RSA Data Security, Inc., MD5 message-digest algorithm

Copyright (C) 1991-2, RSA Data Security, Inc. Created 1991. All rights reserved.

License to copy and use this software is granted provided that it is identified as the “RSA Data

Security, Inc. MD5 Message-Digest Algorithm” in all material mentioning or referencing this

software or this function.

License is also granted to make and use derivative works provided that such works are identified

as “derived from the RSA Data Security, Inc. MD5 Message-Digest Algorithm” in all material

mentioning or referencing the derived work.

RSA Data Security, Inc. makes no representations concerning either the merchantability of this

software or the suitability of this software for any particular purpose. It is provided “as is” without

express or implied warranty of any kind.

These notices must be retained in any copies of any part of this documentation and/or software.

The Authorised Representative for this product in the EEA is:

Yokogawa Europe B.V.

Euroweg 2, 3825 HD Amersfoort,The Netherlands

Model and Sux Codes

A name plate is located on the top panel of the FX. Check that the model name and sux code

given on the name plate match those on your order.

8th Edition : Jun. 2020

*

*

*

Model

code

FX1002

FX1004

FX1006 6ch, Shortest measurement interval:1s

FX1008 8ch, Shortest measurement interval:1s

FX1010

FX1012

External

storage

medium

slot

Language -2

Withstanding voltage

between measuring

input terminals

Options /A1 Alarm output 2 points (C-contact)

Suffix code

-0 Without CF card slot/SD card slot and medium

-4 With CF card slot and medium

-7 With SD card slot and medium

Optional

code

-H 1000 VAC(50/60 Hz), 1 min

-L 400 VAC(50/60 Hz), 1 min

/A2 Alarm output 4 points (C-contact)

/A3 Alarm output 6 points (C-contact)

/A4A Alarm output 12 points (A-contact)

/C2 RS-232 interface

/C3 RS-422A/485 interface

/C7 Ethernet interface

/F1 FAIL/Status output

/M1

/N2 3 leg isolated RTD

/N3F Extended input type (without Pt1000)

/P1 24 VDC/AC power supply

/R1 Remote control 8 points

/TPS2 24VDC transmitter power supply (2 loops)

/TPS4 24VDC transmitter power suply (4 loops)

/USB1 USB interface (1 port)

/PM1 Pulse input 3 points, Remote control 5 points (including

/CC1 Calibration correction function

/LG1 Log scale

/PWR1 Power monitor (1 A input, including Mathmatical

/PWR5 Power monitor (5 A input, including Mathmatical

/S# Customized product; details in IM FX1K-S#E

Description

2ch, Shortest measurement interval:125ms

4ch, Shortest measurement interval:125ms

10ch, Shortest measurement interval:1s

12ch, Shortest measurement interval:1s

English/German/French/Italian/ Spanish/ Portuguese/

Russian/ Korean

deg F and DST

*1*10

*1

*1*3

*2

*2

*3

Mathematical functions (including Report functions)

Mathematical functions)

functions)

functions)

*4

*9*10

*10*11

*1*3

*5

*6*10

*7

*8

(Note)

*12

Note: To load data, the FX must be equipped with a communication interface (/C2, /

C3 or /C7 option) or the USB interface (/USB1 option.)

*1 Any combination of /A1, /A2, /A3, and /A4A cannot be specied together.

*2 /C2 and /C3 cannot be specied together.

*3 /A3 or /A4A cannot be specied together with /F1.

*4 /N2 cannot be specied for FX1002 or FX1004.

*5 If /R1 is specied, /A4A, /TPS2, /TPS4, /PM1, /PWR1, or /PWR5 cannot be specied.

*6 If /TPS2 is specied, /TPS4, /A2, /A3, /A4A, /F1, /R1, or /PM1 cannot be specied.

*7 If /TPS4 is specied, /TPS2, /A1, /A2, /A3, /A4A, /F1, /R1, or /PM1 cannot be specied.

*8 If /PM1 is specied, /A4A, /M1, /R1, /TPS2, /TPS4, /PWR1, or /PWR5 cannot be specied.

*9 If /PWR1 is specified, /A3, /A4A, /F1, /R1, /PM1, /M1, or /PWR5 cannot be

specied.

*10 /TPS2, /PWR1, and /A1 cannot be specied together. /TPS2, /PWR5, and /A1

cannot be specied together.

*11 If /PWR5 is specied, /A3, /A4A, /F1, /R1, /PM1, /M1, or /PWR1 cannot be specied.

*12 Contact your supplier in case your instrument has option /S# (where ‘#’ is a

number), and you are not in the possession of IM FX1K-S#E.

Standard Accessories

The standard accessories below are supplied with the instrument. Check that all

contents are present and undamaged.

1

2

3

No. Name Model Qty. Notes

1 Mounting brackets B8730BU 2 For panel mounting

2 Rubber packing for dust and water protection - 1 For single-unit

3 Model FX1002/FX1004/FX1006/FX1008/

FX1010/FX1012

FX1000 Paperless Recorder Safety Precautions

and Installation Guide

Installing the FXA120 DAQSTANDARD

FX1000 Mode Transition Diagram

Setting Mode / Basic Setting Mode Maps

4 CF card

5 SD card

*1 On FXs that have a CF card slot (sux code -4.)

CF card capacity is subject to change.

*2 On FXs that have a SD card slot (sux code -7.)

SD card capacity is subject to change.

*3 For optional accessories (Sold Separately), see the IM 04L21B01-02EN.

*1

*2

IM 04L21B01-

03EN

772093 1 512 MB

773001 1 1 GB

mounting

1 A3 size

Softoware (FXA120 DAQSTANDARD for FX1000), Label

Please download the software and the label data from the following web page.

http://www.yokogawa.com/ns/fx1000/soft/

Item Description

Software FXA120 DAQSTANDARD for FX1000

Consists of the Data Viewer and the Hardware Configurator.

Label Labels to Attach to the FX1000 Operation Cover

Download the label data (Excel file). Print the label that you want to use.

Label size: 19 ± 0.3 mm tall and 90 ± 0.3 mm wide

File name: IM04L21B01-81Z1.xls

1. Safety Precautions

The following safety symbols are used on the product and in this manual.

Calls attention to actions or conditions that could cause serious

or fatal injury to the user, and indicates precautions that should be

taken to prevent such occurrences.

Calls attention to actions or conditions that could cause injury to

the user or damage to the instrument or property and indicates precautions that should be taken to prevent such occurrences.

“Handle with care.” To avoid injury and damage to

the instrument, the operator must refer to the

explanation in the manual.

Protective ground terminal

Note

Identies important information required to operate the instrument.

Safety Precautions

n

• This instrument conforms to IEC safety class I (provided with terminal for protective grounding), Overvoltage Category II or I

ment Category II (CAT II)

*1 II: Applied to standard power supply(100-240 VAC), I: Applied to /P1 option (24 VDC/AC)

*2 Measurement Category II (CAT II) applies to measuring circuits connected to low voltage

installation, and electrical instruments supplied with power from fixed equipment such as

electric switchboards.

• This instrument is an EN61326-1 (EMC standard) class A instrument (for use in

commercial, industrial, or business environments). The inuence rate (judgment condition A) in the immunity test environment is within ±15 % of the range or ±10 mV.

• The general safety precautions described here must be observed during all phases

of operation. If the FX is used in a manner not described in this manual, the FX

safety features may be impaired. Yokogawa Electric Corporation assumes no liability for the customer’s failure to comply with these requirements.

• The FX is designed for indoor use.

About User’s Manual

n

• Please pass user’s manuals to the end user. We also ask you to store manuals in

a safe place.

• Read user’s manuals thoroughly and have a clear understanding of the product

before operation.

• User’s manuals explain the functions of the product. It does not guarantee that the

product will suit a particular purpose of the user.

Precautions Related to the Protection, Safety, and Alteration of the Product

n

• For the protection and safe use of the product and the system in which this product

is incorporated, be sure to follow the instructions and precautions on safety that are

stated in this manual whenever you handle the product. Take special note that if you

handle the product in a manner that violates these instructions, the protection functionality of the product may be damaged or impaired. In such cases, YOKOGAWA does

not guarantee the quality, performance, function, and safety of product.

When installing protection and/or safety circuits such as lightning protection devices

•

and equipment for the product and control system or designing or installing separate

protection and/or safety circuits for fool-proof design and fail-safe design of the pro

cesses and lines that use the product and the control system, the user should implement these using additional devices and equipment.

•

If you are replacing parts or consumable items of the product, make sure to use parts

specied by YOKOGAWA.

This product is not designed or manufactured to be used in critical applications that di-

•

rectly aect or threaten human lives. Such applications include nuclear power equipment,

using radioactivity, railway facilities, aviation equipment, air navigation facilities,

devices

aviation facilities, and medical equipment. If so used, it is the user’s responsibility to include in the system additional equipment and devices that ensure personnel safety.

• Do not modify this product.

*2

.

Alternating current

Direct current

*1

, Pollution Degree 2, and Measure-

-

Use the Correct Power Supply

l

Ensure that the source voltage matches the voltage of the power

supply before turning ON the power.

Connect the Protective Grounding Terminal

l

Make sure to connect the protective grounding to prevent

electric shock before turning ON the power.

Do Not Impair the Protective Grounding

l

Never cut off the internal or external protective grounding wire

or disconnect the wiring of the protective grounding terminal.

Doing so invalidates the protective functions of the instrument

and poses a potential shock hazard.

Do Not Operate with Defective Protective Grounding

l

Do not operate the instrument if the protective grounding might

be defective. Also, make sure to check them before operation.

Do Not Operate in an Explosive Atmosphere

l

Do not operate the instrument in the presence of flammable

liquids or vapors. Operation in such an environment constitutes

a safety hazard. Prolonged use in a highly dense corrosive gas

S, SOx, etc.) will cause a malfunction.

(H

2

Do Not Remove Covers

l

The cover should be removed by YOKOGAWA’s qualified

personnel only. Opening the cover is dangerous, because some

areas inside the instrument have high voltages.

Ground the Instrument before Making External Connections

l

Connect the protective grounding before connecting to the item

under measurement or control unit.

Damage to the Protection

l

Operating the instrument in a manner not described in this

manual may damage the instrument’s protection.

This instrument is a Class A product. Operation of this instrument in a

residential area may cause radio interference, in which case the user is

required to take appropriate measures to correct the interference.

Exemption from Responsibility

n

• YOKOGAWA makes no warranties regarding the product except those stated in

the WARRANTY that is provided separately.

• YOKOGAWA assumes no liability to any party for any loss or damage, direct or

indirect, caused by the user or any unpredictable defect of the product.

2. Installation

Installation Location

n

Install the FX indoors in an environment that meets the following conditions:

• Instrumentation Panel

The FX is designed to be installed in an instrumentation panel.

• Well-Ventilated Location

To prevent overheating, install the FX in a well-ventilated location. For the panel

cut dimensions when arranging multiple FXs, see “External Dimensions and Panel

Cutout Dimensions.” When other instruments are installed next to the FX, follow

the panel cut dimensions to provide adequate space around the FX.

• Minimal Mechanical Vibrations

Install the FX in a location that has minimal mechanical vibrations. Installing the FX

in a location that is subject to large levels of mechanical vibration will not only put

added stress on its components, it may also impede ordinary measurement.

• Level Location

Install the FX in a level location so that it is not slanted to the left or the right (how-

ever, the FX can be inclined up to 30 degrees backward for panel mounting).

• Ambient temperature range between 0 to 50°C

• Ambient humidity between 20 to 80%RH (However, less than moisture content

of 40°C 80% RH at 40°C or more), No condensation should be present.

• Altitude 2000 m or less

Note

Condensation may form when moving the FX from an environment whose temperature or

humidity is low to an environment whose temperature or humidity is high, or when there

is a sudden change in temperature. Temperature or humidity changes may also result in

thermocouple measurement errors. In these kinds of circumstances, let the FX adjust to

the new environment for at least an hour before using it.

Do not install the FX in the following places.

• Outdoors

• In Direct Sunlight or Near Heat Sources

Install the FX in a place that is near room temperature (23°C) and that is not sub-

ject to large temperature uctuations. Placing the FX in direct sunlight or near heat

sources can cause adverse eects on the internal circuitry.

• Where an Excessive Amount of Soot, Steam, Moisture, Dust, or Corrosive

Gases Are Present

Soot, steam, moisture, dust, and corrosive gases will adversely affect the FX.

Avoid installing the FX in such locations.

• Near Strong Magnetic Field Sources

Do not bring magnets or instruments that produce electromagnetic elds close to the

FX. Operating the FX near strong magnetic elds can cause measurement errors.

• Where the Display Is Dicult to See

The FX uses an LCD screen, so it is dicult to view the display from an extreme

angle. Install the FX so that the user can view the display directly from the front.

IM 04L21B01-03EN page 1/4

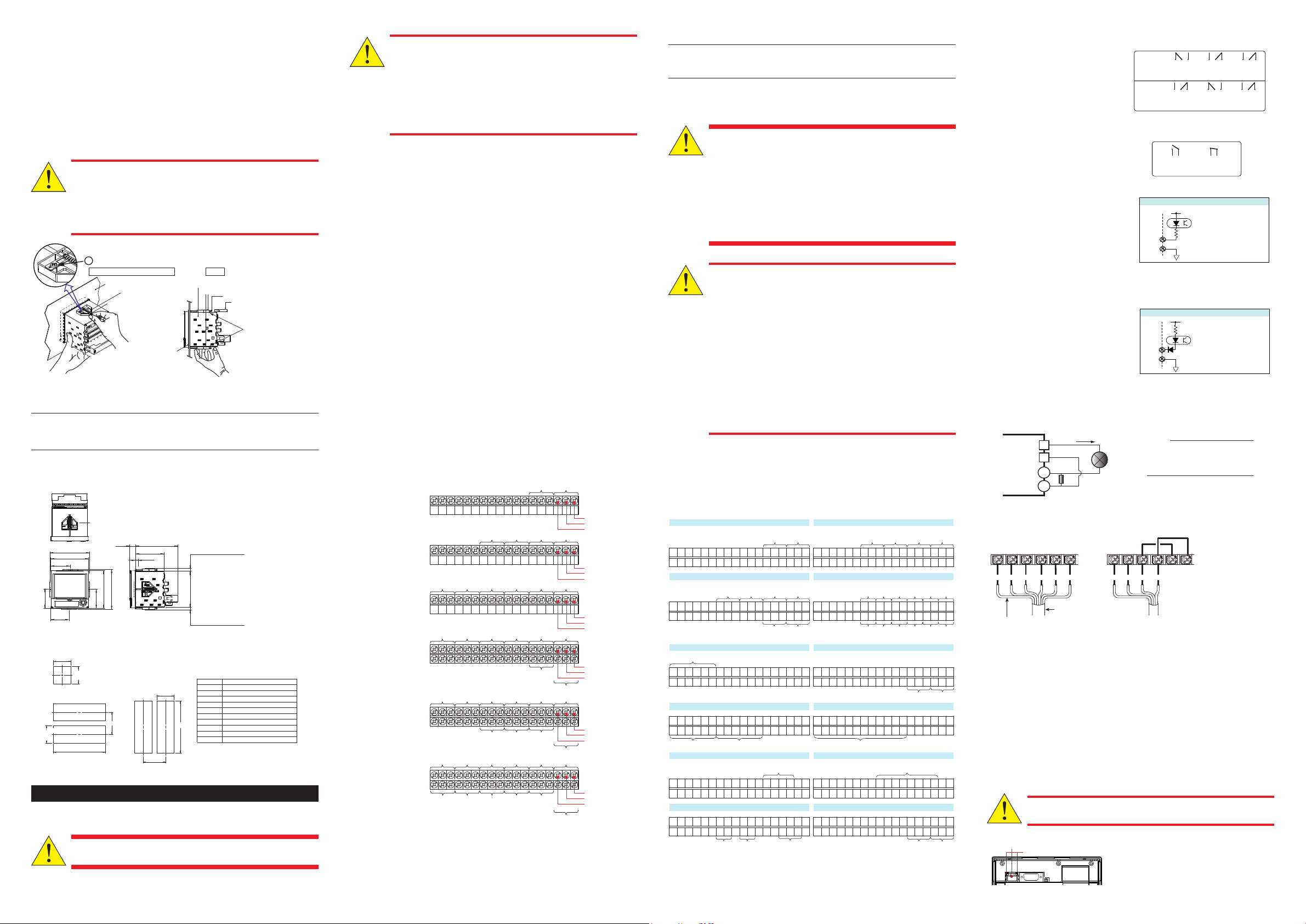

Installation Procedure

CAUTION

136.5

+0.4

0

External dimensions

WARNING

CAUTION

Input terminal block

of the FX1002

Input terminal block

of the FX1004

Input terminal block

of the FX1006

Input terminal block

of the FX1008

Input terminal block

of the FX1010

Input terminal block

of the FX1012

For TC input, use shielded compensating lead wires for wiring.

For RTD input, lead wire resistance per wire of 10 Ω or less. Make the resistances of

the three wires equal.

For DCA input, example: for 4 to 20 mA input, use a shunt resistor of 250 Ω ± 0.1%.

CH1

CH2

WARNING

CAUTION

Alarm output

input

input

/A1 /A2

status occurs

Output format: Relay contact

Contact rating:

Withstand voltage:

Output format:

Contact rating:

Withstand voltage:

and the ground terminal)

Alarm output

• Transistor input (open collector)

• Relay contact input (voltage-free contact)

and the ground terminal

and the ground terminal

Internal circuit

• Transistor input (open collector)

• Relay contact input (voltage-free contact)

FX

Transmitter

power supply

output terminal

Two-wire system

Electric potential of the shield

Four-wire system

Shielded twisted pair cable. 3 pairs, 24 AWG or more (four wire); 2 pairs,

• Total cable length: Up to 1.2 km

CAUTION

Ethernet port

n

Use a steel panel that is 2 mm to 26 mm thick.

1) Insert the FX through the front of the panel.

Mount the FX to the panel using the included mounting brackets as shown in the gure below.

2)

•

Use two mounting brackets to support the top and bottom or the left and right sides of the

case (remove the stickers that are covering the holes before you attach the brackets).

• Follow the procedure below to mount the FX to the panel.

First, attach the two mounting brackets and temporarily tighten the mounting screws.

•

•

Next, x the FX in place by tightening the mounting screws with the appropriate torque.

When the FX is approximately perpendicular to the panel, press the mounting brackets

so that they are in contact with the case, and fully tighten the mounting screws.

• Tighten the mounting bracket screws until you hear clicks.

Using more than the appropriate torque to tighten the screws

l

can deform the case or damage the brackets.

Be sure not to insert foreign objects or tools into the case

l

through the mounting bracket holes.

Do not touch the screw at the top of the mounting bracket

l

(A). Loosening or tightening this screw may cause the FX to

malfunction.

A

FX case

Panel

Fixed

Mounting bracket

Mounting screw

Torque driver

(Phillips or flat blade)

Attach firmly

Screws temporarily fastened

Panel

Mounting bracket

Mounting screw

Front

Rubber packing for dust

and water protection

(except side-by-side

(In the figure, the mounting brackets are used on the top and bottom of the case.)

mounting)

Note

To achieve sucient dust proong and waterproong, mount the FX in the middle of

the panel cut out. However, do not use the rubber packing if you are mounting two

instruments side by side or one on top of the other.

External Dimensions and Panel Cutout Dimensions

n

Unit: mm (approx. inch)

If not specified, the tolerance is ±3%.

However, in cases of less than 10mm, the tolerance is ±0.3 mm.

If not installing the rubber packing for dust and water protection,

Mounting bracket

161.7 (6.37)

144.0 (5.67)

74.5 (2.93)

72.0 (2.83)

69.5

(2.74)

Panel cut dimensions

Single-unit mounting

137 (5.39)

+ 2 (0.08)

137

0

(5.39)

72.0 (2.83)

+ 2 (0.08)

0

+ 2 (0.08)

0

137

(5.39)

Side-by-side mounting

(horizontally)

+ 2 (0.08)

L

0

3. Wiring

Input Signal Wiring

n

To prevent electric shock while wiring, make sure that the power

supply is turned o.

*1: 20.2 (0.80), *2: 163.7 (6.44), *3: 110.0 (4.33).

(*1) (*2)

22.2 (0.87) 161.7 (6.37)

Panel thickness

144.0 (5.67)

161.7 (6.37)

Side-by side mounting

(vertically; max. 3 units)

MIN 175

(6.89)

108.0 (4.25)

2 to 26

0.08 to 1.02)

(

137 (5.39)

MIN 175

(6.89)

(*3)

±0.3(0.01)

136.5

12.6

+ 2 (0.08)

0

+ 2 (0.08)

L

0

(Dimensions after attaching

the mounting bracket)

12.6 (0.50)

(5.37)

(Dimensions after attaching

the mounting bracket)

(0.50)

+ 2 (0.08)

0

L

Units

2

282 (11.10)

3

426 (16.77)

4

5

714 (28.11)

6

858 (33.78)

7

1002 (39.45)

8

1146 (45.12)

9

1290 (50.79)

10

1434 (56.46)

n

(144 × n) – 6 [(5.67 × n) – 0.24]

in mm (approx. inches)

570 (22.44)

Applying a strong tension to the input and output signal cables

l

connected to the FX may damage the cables or the FX terminals.

To avoid applying tension directly to the terminals, fix all cables

to the rear of the mounting panel.

To prevent fire, use signal cables with a temperature rating of 80°C or more.

l

Do not apply voltages that exceed the following values to the

l

input terminals. Doing so may damage the FX.

• Maximum input voltage: ±60 VDC

• Maximum common mode voltage: ±60 VDC (under

measurement category II conditions)

Precautions to Be Taken While Wiring

Take the following precautions when wiring the input signal cables.

When using a screw terminal, we recommend that you use a crimp-on lug with an

insulation sleeve (designed for 3 mm screws).

Take measures to prevent noise from entering the measurement circuit.

Move the measurement circuit away from the power cable (power circuit) and ground circuit.

•

• Ideally, the object being measured should not generate noise. However, if this is

unavoidable, isolate the measurement circuit from the object. Also, ground the object being measured.

• Shielded wires should be used to minimize the noise caused by electrostatic induction. Connect the shield to the ground terminal of the FX as necessary (make sure

you are not grounding at two points).

• To minimize noise caused by electromagnetic induction, twist the measurement

circuit wires at short, equal intervals.

• Make sure to earth ground the protective ground terminal through minimum resis-

tance (less than 100 Ω).

Do not allow static electricity to be applied to the terminals.

• When wiring the terminals, remove static electricity so that static electricity is not applied.

• If static electricity or similar high-voltage transient noise is applied to the signal

line, the system may break.

When using internal reference junction compensation on the thermocouple input,

take measures to stabilize the temperature at the input terminal.

• Always use the terminal cover.

• Do not use thick wires which may cause large heat dissipation (we recommend a

cross sectional area of 0.5 mm

2

or less).

• Make sure that the ambient temperature remains reasonably stable. Large tem-

perature uctuations can occur if a nearby fan turns on or o.

Connecting the input wires in parallel with other devices can cause signal degradation,

aecting all connected devices. If you need to make a parallel connection, then

• Turn the burnout detection function o.

• Ground the instruments to the same point.

• Do not turn other instruments on or o during operation. This can have adverse effects on the other instruments.

• RTDs cannot be wired in parallel.

+/A

–/B

CH1

CH1

CH1

CH7

CH1

CH7

CH1

CH7

/b

+/A

–/B

/b

+/A

–/B

/b

+/A

–/B

/b

+/A

–/B

/b

+/A

–/B

/b

CH2CH3CH4

CH2CH3CH4CH5CH6

CH2

CH3CH4CH5CH6

CH8

CH2

CH3CH4CH5CH6

CH8

CH9CH10

CH2

CH3CH4CH5CH6

CH8

CH9CH10CH11CH12

Note

RTD input terminals A and B are isolated on each channel. Terminal b is shorted

internally across all channels. However, terminal b is also isolated on each channel

on models with the /N2 option (3 leg isolated RTD).

Optional Terminal Wiring

n

To prevent electric shock while wiring, make sure that the power

l

supply is turned off.

If a voltage of more than 30 VAC or 60 VDC is to be applied to the

l

output terminals, use ring-tongue crimp-on lugs with insulation

sleeves on all terminals to prevent the signal cables from

slipping out when the screws become loose. Furthermore, use

double-insulated cables (dielectric strength of 3000 VAC or more)

for the signal cables on which a voltage of 30 VAC or 60 VDC

or more is to be applied. For all other signal cables, use basic

insulated cables (dielectric strength of 1500 VAC). To prevent

electric shock, attach the terminal cover after wiring and make

sure not to touch the terminals.

Use the following circuit voltages for the connection to the alarm/

l

FAIL/status output terminal.

• When the connection is to Mains Circuits (primary power

supply circuits): 150 V or less

• When the connection is to circuits derived from Mains

Circuits (secondary power supply circuits): 250 V or less

(Keep the Mains Circuit voltage at 300 V or less, and use

an isolation transformer.)

To prevent fire, use signal cables with a temperature rating of 70°C or more.

l

Applying a strong tension to the input and output signal cables

l

connected to the FX may damage the cables or the FX terminals.

To avoid applying tension directly to the terminals, fix all cables

to the rear of the mounting panel.

Do not short the transmitter power supply output terminal or apply

l

external voltage to it. Doing so may damage the instrument.

When using the transmitter power supply output terminal, do not

l

use current that is equal to or greater than the maximum output

current (25 mADC). Doing so may damage the instrument.

Precautions to Be Taken While Wiring

We recommend that you use crimp-on lugs (designed for 3 mm screws) with

insulation sleeves to connect to the optional terminals.

The following figures show the terminal positions for each option when only that

option is installed. Even if you have installed a number of options, the individual

terminal positions of the options do not change (except for the case where you have

installed both the /TPS2 and /A1 options; in this case, the /A1 terminal positions are

dierent).

01

02

C

C

NC

NC

NO

NO

/A3 /A4A

01

02

03

04 010203040506

C

C

C

C

NC

NC

NO

NO

NO

RS-422A/485

FG SG

SDB SDARDB RDA

L H L H L H 4 23 1 C5 8 7 6 4 23 1 C5

Pulse input

Remote control input

Transmitter power supply output

/PWR1, /PWR5

3S 1L 1S P1P2P33L

Current

NO

/C3

/PM1

/TPS2

NC

NC

NO

C

C

NC

NC

NO

0506

Alarm output

Remote control input

+- +- +- +-+- +-

/A1 when installed in the FX with a /TPS2

Voltage inputCurrent

Alarm outputAlarm output

02

03

04

C

C

C

NC

NO

NO

NO

NO

/F1

/R1

/TPS4

Transmitter power supply output

NC

NO

Alarm outputAlarm output

Alarm output

NO

NO

FAIL

NC

0809101112

C

NC

C

NC

01

C

NO

07

C

NO

Memory

end

C

NO

0102

NC

CNOCNOCNOCNOCNOC

CNOCNOCNOCNOCNOC

NC

NC

Alarm Output Terminal (/A1, /A2, and /A3), FAIL Output Terminal and Memory

•

End Output Terminal (/F1)

250 VAC (50/60 Hz)/3 A,

250 VDC/0.1 A (load resistance)

1600 VAC (50/60 Hz) for one

minute (between output

terminals and the ground

terminal)

Alarm Output Terminal (/A4A)

•

Remote Control Input Terminal (/R1)

•

Contact open at 200 Ω or less

Contact closed at 100 kΩ or greater

On voltage: 0.5 V or less (30 mADC)

Leakage current when turned off: 0.25 mA or less

•

Pulse Input Terminal (/PM1)

Contact open at 200 Ω or less

Contact closed at 100 kΩ or greater

On voltage: 0.5 V or less (30 mADC)

Leakage current when turned off: 0.25 mA or less

•

24 VDC Transmitter Power Supply Output Terminal (/TPS2, /TPS4)

Relay contact

250 VAC (50/60 Hz)/3 A,

250 VDC/0.1 A (load resistance)

1600 VAC (50/60 Hz) for one

minute (between output terminals

FAIL output

(/F1)

Other output

(/F1)

NO C NC

During normal

operation

NO C NC NO C NC NO C NC

During normal

NO C

During normal

operation

operation

NO C NC

When a failure

occurs

When the

specified

NO C

When the specified

status occurs

NO C NC

When power

is turned off

When power

is turned off

Internal circuit

5 V

Input format:

Photocoupler isolation

1 to 8

C

Withstand voltage: 1000 VDC for one minute

H

L

Withstand voltage: 1000 VDC for one minute

Shared common (C)

Allowable input voltage:

5 VDC

between input terminals

5 V

Input format:

Photocoupler isolation

Shared common (L)

Allowable input voltage:

30 VDC

between input terminals

Connect the FX to the transmitter as shown below.

Current

+

–

+

Input terminal

•

Serial Communication Interface (/C2)

–

Shunt resistor: 250 Ω

Transmitter

Note

To reduce noise, use a shielded

cable for wiring. Connect the

shield to the ground terminal of

the FX.

9-pin D-sub RS-232 connector

•

Serial Communication Interface (/C3)

FG SG SDB SDA RDB RDA

FG SG SDB SDA RDB RDA

Shield

FG (Frame Ground) Case ground of the FX

SG (Signal Ground) Signal ground

SDB (Send Data B) Send data B (+)

SDA (Send Data A) Send data A (–)

RDB (Received Data B) Receive data B (+)

RDA (Received Data A) Receive data A (–)

Recommended length of stripped wire: 9 mm.

Recommended tightening torque: 0.4 to 0.5 N•m

Cable

There are two types of cables available: the four-wire cable and the two-wire cable, which is used only

for the Modbus protocol.

The cable must meet the following specifications.

• Type:

• Characteristic impedance: 100Ω

• Capacitance: 50 pF/m

24 AWG or more (two wires).

• Connecting to the USB Port (/USB1)

The USB port complies with USB revision 1.1. The USB port is installed on the FX’s front panel.

• Connecting to the Ethernet Port (/C7)

Do not connect an Ethernet cable whose plug does not comply with

FCC specications. If you do, the FX may malfunction.

Indicators

IM 04L21B01-03EN page 2/4

Loading...

Loading...