Page 1

User’s

Manual

FSA120 (EJXMVToolTM)

EJX-MV Configuration DTM

IM 01C25R51-01E

okogawa Electric Corporation

IM 01C25R51-01E

4th Edition

Page 2

FSA120 (EJXMVT oolTM)

EJX-MV Configuration DTM

IM 01C25R51-01E 4th Edition

CONTENTS

1. Introduction ............................................................................................ 1-1

1.1 About This Manual .......................................................................................... 1-1

1.1.1 Trademarks....................................................................................... 1-2

1.1.2 Environmental Condition................................................................... 1-2

TM

1.2 Software License Agreement for EJXMVTool

1.2.1 Grant of License ............................................................................... 1-3

1.2.2 Restriction ........................................................................................ 1-3

1.2.3 Copyright/Ownership ........................................................................ 1-4

1.2.4 No W arr anty / Limitation of Liability ................................................... 1-4

1.2.5 Term and Termination ....................................................................... 1-4

1.2.6 General Provisions ........................................................................... 1-5

1.2.7 DIPPR .............................................................................................. 1-5

..............................................................................

Toc-1<Int> <Ind> <Rev>

1-3

2. General.................................................................................................... 2-1

3. Functional Specification ........................................................................ 3-1

3.1 PC .................................................................................................................... 3-1

3.1.1 Hardware Operating Environment..................................................... 3-1

3.1.2 Software Operating Environment ..................................................... 3-1

3.2 Field Communication...................................................................................... 3-2

3.3 Model to be Connected................................................................................... 3-2

3.4 Outline of FSA120 ........................................................................................... 3-3

3.4.1 Components ..................................................................................... 3-3

3.4.2 EJX910 HART/FF DTM and EJXMVTool .......................................... 3-4

3.5 FSA120 DTM Function Detail ......................................................................... 3-5

3.5.1 Transmitter Management.................................................................. 3-5

3.5.2 Flow P arameter Management (Flow Configuration Wizard)............... 3-6

3.5.3 Flow P arameter Management (Obtain Flo w Coefficient) ................... 3-6

3.5.4 Primary Devices Supported in Auto Compensation Mode ................. 3-7

3.5.5 Density Compensation in Auto Compensation Mode ........................ 3-8

4. Preparation ............................................................................................. 4-1

4.1 PC .................................................................................................................... 4-1

4.1.1 Setting Items after Installing Windows............................................... 4-1

4.2 Installation Procedure .................................................................................... 4-3

4.2.1 EJXMVTool online manual ................................................................ 4-3

Media No. IM 01C25R51-01E 4th Edition :Feb. 29, 2008 (YK)

All Rights Reserved Copyright © 2006, Yokogaw a Electric Corporation

IM 01C25R51-01E

Page 3

<Int> <Ind> <Rev>

Toc-2

4.2.2 Uninstall FSA210.............................................................................. 4-3

4.2.3 For FieldMate Users ......................................................................... 4-3

4.2.4 Installations of FieldMate and Device Files........................................ 4-4

4.2.5 EJX MVTool additional resource installation...................................... 4-5

4.2.6 How to confirm Version Number of DTM ........................................... 4-8

4.3 Uninstallation .................................................................................................. 4-9

4.4 Initial Setting (HART communication) ......................................................... 4-10

4.4.1 HART Communication Modem ....................................................... 4-10

4.4.2 COM port........................................................................................ 4-10

4.4.3 Wiring ............................................................................................. 4-12

4.4.4 Communication setting (HART comm unication).............................. 4-12

4.5 Initial Setting (FF Communication) .............................................................. 4-13

4.5.1 EJX910A ........................................................................................ 4-13

4.5.2 Install NI-FBUS Card ...................................................................... 4-13

4.5.3 NI-FBUS Setting (Interface Configur ation Utility)............................. 4-14

4.5.4 Start NI-FBUS Communications Manager ...................................... 4-16

4.5.5 Connect the EJX910A to the power supply ..................................... 4-16

4.5.6 Connect the NI-FBUS card to the EJX910A .................................... 4-16

4.6 Start FDT frame application ......................................................................... 4-17

4.6.1 Update DTM Browser ..................................................................... 4-17

4.6.2 Start FieldMate ............................................................................... 4-18

4.6.3 Start EJX910 DTM.......................................................................... 4-20

4.6.4 Save DTM Inf omation ..................................................................... 4-21

4.6.5 Exit FieldMate and DTM Works....................................................... 4-22

4.7 EJXMVT ool Activ ation .................................................................................. 4-22

4.7.1 How to Activate............................................................................... 4-22

5. Operational Flow..................................................................................... 5-1

6. Display Specification .............................................................................. 6-1

6.1 Transmitter Management................................................................................ 6-3

6.1.1 Connect / Disconnect........................................................................ 6-3

6.1.2 Par ameter......................................................................................... 6-5

6.1.3 Upload from Device / Do wnload to De vice......................................... 6-7

6.1.4 Print................................................................................................ 6-10

6.1.5 Properties....................................................................................... 6-10

6.1.6 Additional functions......................................................................... 6-11

6.2 Flow P arameters Management..................................................................... 6-12

6.2.1 Initialize .......................................................................................... 6-12

6.2.2 Import ............................................................................................. 6-13

6.2.3 Export............................................................................................. 6-14

6.2.4 Report ............................................................................................ 6-15

6.2.5 Help................................................................................................ 6-16

All Rights Reserved Copyright © 2006, Yokoga wa Electric Corporation

IM 01C25R51-01E

Page 4

Toc-3<Int> <Ind> <Rev>

6.3 Flow Configuration Wizar d

(Auto Compensation Mode) ......................................................................... 6-17

6.3.1 Flow Configuration Mode................................................................ 6-17

6.3.2 Primary Device and Pipe Setup ...................................................... 6-18

6.3.3 Fluid Setup ..................................................................................... 6-20

6.3.4 Natural Gas Setup .......................................................................... 6-23

6.3.5 Fluid Operating Range Setup.......................................................... 6-28

6.3.6 Fluid Physical Property Setup ......................................................... 6-31

6.3.7 Apply Flow Configuration ................................................................ 6-33

6.4 Flow Configuration Wizar d (Basic Mode) .................................................... 6-33

6.4.1 Flow Configuration Mode................................................................ 6-33

6.4.2 Basic Mode Setup........................................................................... 6-34

6.4.3 Apply Flow Configuration ................................................................ 6-37

6.5 Obtain Flow Coefficient ................................................................................ 6-37

7. File Format .............................................................................................. 7-1

7.1 Configuration file ............................................................................................ 7-1

7.2 Other files ........................................................................................................ 7-2

8. Error Message......................................................................................... 8-1

8.1 Error Message ................................................................................................. 8-1

Appendix A........................................................................................................A-1

REVISION RECORD

IM 01C25R51-01E

Page 5

Blank Page

Page 6

<Toc> <Ind> <1. Introduction>

1. Introduction

This User’s Manual giv es instructions on FSA120 EJX-MV Configuration DTM

“EJXMVTool”.

This software is to be used to setup the EJX910A Multivariable Transmitter; therefore , it is

indispensable for users to read, understand and f ollow the instructions on all the f ollowing

user’s manual bef ore actually starting the operation.

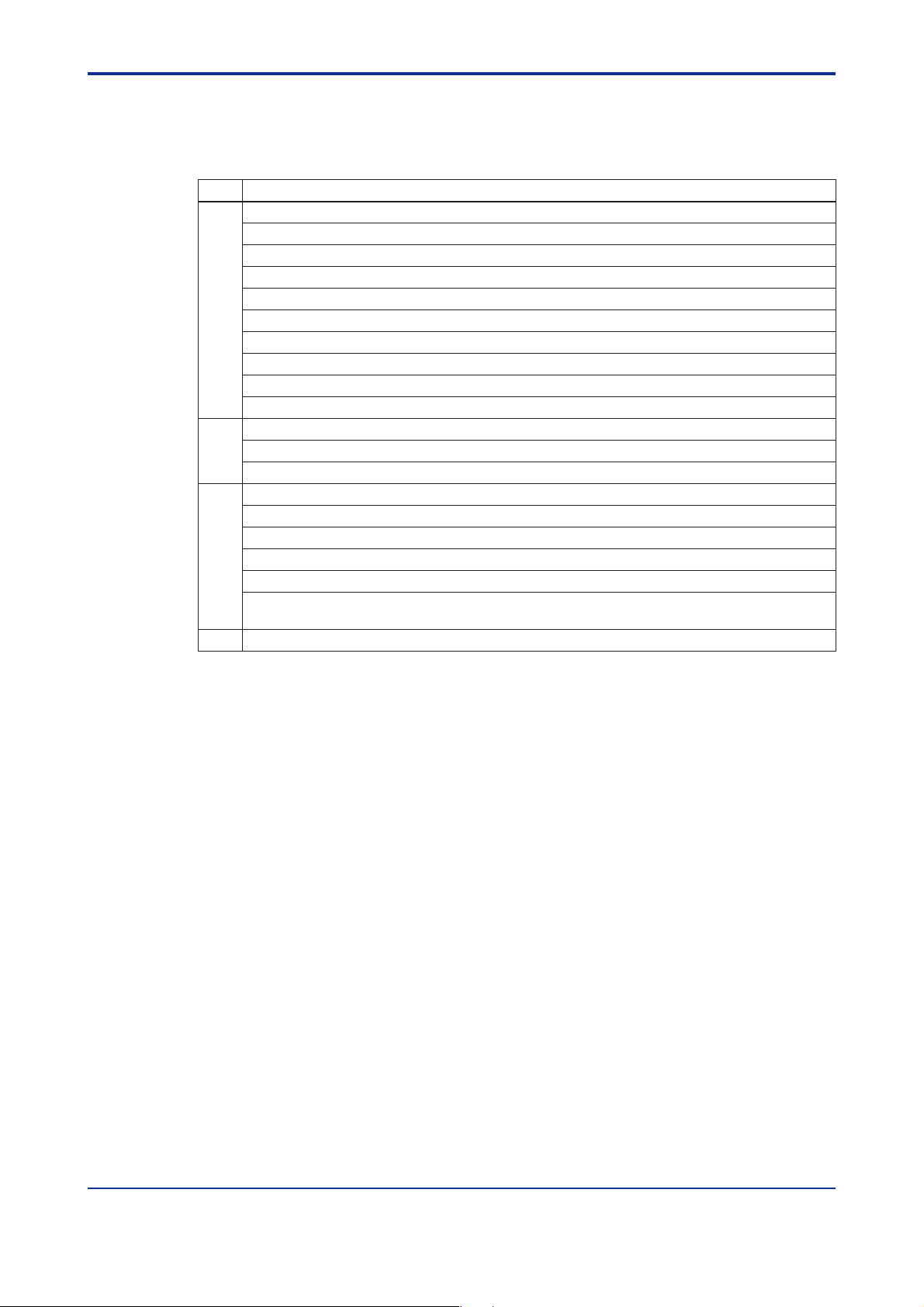

Table 1.1 List of User’ s Manual

IM No. Title

IM 01C25R01-01E EJX910A Multivariable Transmitter Hardware

Manual

IM 01C25R02-01E EJX910A HART Communication

IM 01C25R03-01E EJX910A Fieldbus Communication

IM 01C25R51-01E FSA120 EJX-MV Configuration DTM

In this manual, Following abbre viation ma y be used,

FF for FOUND ATION Fieldbus

Installation, wiring, and maintenance.

Operation manual for HART

communication type.

Operation manual for Foundation Fieldbus

communication type.

This manual. Operation manual of FSA120.

Contents

1-1

T0101E.EPS

1.1 About This Manual

• This manual should be delivered to the end user.

• The inf ormation contained in this manual is subject to change without prior notice.

• The inf ormation contained in this manual, in whole or part, shall not be transcribed or

copied without YOKOGA W A’s written permission.

• In no case does this manual guarantee the merchantability of the tr ansmitter or the

software or its adaptability to a specific client needs.

• If any question arises or errors are f ound, or if any inf ormation is missing from this

manual, please inform the nearest Y okoga wa sales office.

• Changes to specifications, structure, and components used ma y not lead to the re vision

of this manual unless such changes affect the function and perf ormance of the products.

• The operation of the EJX910DTM and EJXMVTool described in this manual is the

operation for the use with FieldMate Basic. For the detailed installation and operation of

FieldMate and additional functions availab le on FieldMate Advance , please ref er to the

FieldMate User’s man ual.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, ma y result in minor or

moderate injury . It ma y also be used to alert against unsafe practices .

All Rights Reserved Copyright © 2006, Yokogaw a Electric Corporation IM 01C25R51-01E

Page 7

<T oc> <Ind> <1. Introduction>

IMPORTANT

Indicates that operating the hardware or software in this manner ma y damage it or lead to

system failure.

NOTE

Draws attention to information essential f or understanding the operation and f eatures.

1.1.1 Trademarks

•Microsoft and Windows are trademarks or registered trademarks of Microsoft

Corporation in the US and other countries.

• Adobe, Adobe Acrobat, and Adobe Reader are tr ademarks or registered trademarks of

Adobe Systems Incorporated in the US and other countries.

1-2

•Pentium is a registered trademark of Intel Corporation.

• IBM PC/AT is a registered trademark of International Business Machines Corp.

• HAR T is a registered trademark of HART Comm unication F oundation.

•MACT ek is a registered tr ademark of MACTek Corporation.

• AIChE, DIPPR (Design Institute f or Ph ysical Properties) is a registered trademark of

American Institute of Chemical Engineers.

• NI-FBUS is a tr ademark of National Instruments Corporation.

• Other compan y/organization and/or product names are registered trade marks of their

respective holders.

• In this document, the TM and ® marks may not be sho wn ne xt to the registered

trademarks or trademarks of their respective companies.

1.1.2 Envir onmental Condition

Operation

Temperature: 0 to 40 °C

Humidity: 20 to 80 % (No de w condensation)

Storage

Temperature: -10 to 50 °C

Humidity: 20 to 80 % (No de w condensation)

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 8

<Toc> <Ind> <1. Introduction>

1-3

1.2 Software License Agreement for EJXMVTool

License Agreement on EJX-MV Configuration DTM (EJXMVTool DTM) for Multivariable

Transmitter

IMPORTANT - PLEASE READ THIS AGREEMENT CAREFULLY :

BY INSTALLING, COPYING OTHERWISE USING THE ENCLOSED SOFTWARE PROD-

UCT AS IDENTIFIED ABOVE, YOU A GREE T O BE BOUND BY THE TERMS AND CONDITIONS OF THIS SOFTW ARE LICENSE A GREEMENT (“A GREEMENT”). IF YOU DO

NOT AGREE TO THE TERMS OF THIS A GREEMENT, DO NOT INSTALL, COPY OR USE

THE SOFTWARE PRODUCT AND PR OMPTLY RETURN IT T O THE PLACE OF PURCHASE.

1.2.1 Grant of License

(1) Subject to the terms and conditions of this Agreement, Yokogawa Electric Corporation

(“Licensor”) hereby grants to you (“Licensee”) a non-e xclusiv e and non-transf erab le

right to use the enclosed software product EJXMVTool as identified above and associated materials and documentation in printed or electronic format (Collectively “Licensed Software”), in consideration of full payment b y Licensee to the Licensor of the

license fee separately agreed upon by Licensor or its distrib utor .

(2) Licensee shall have the right to use the Licensed Software in the operating en viron-

ment identified by the Licensor , either (a) to the extent specified in the specifications

as agreed upon by both parties, or (b) if not specified, for a single user on single

computer.

TM

(3) Licensee may use the Licensed Software solely f or its own internal data processing

operations. Use of the Licensed Softw are for any purpose other than those as e xpressly specified in the documentation provided by Licensor shall be prohibited. An y

result or damage arising out of the use of licensed software shall be at Licensee’s o wn

risk and responsibility .

(4) No copies of the Licensed Software shall be made without Licensor’ s prior written

consent.

(5) The Licensed Software may contain software which Licensor is licensed from third

parties (“Third Party Software”). Licensee agrees to use the Third Party Software in

accordance with the terms and conditions as set forth by licensors of such Third P arty

Software and agrees to be bound thereby.

(6) In no event shall Licensee mak e any use of the Licensed Softw are for an y other

purposes or in any other manner than those stipulated hereunder.

(7) Licensee agrees to use any Third P arty Software solely as runtime use software which

shall be used solely as part of and with the integrated Licensed Software, and shall

not make any further use of Third P arty Software for any other purposes or in any

other manner.

1.2.2 Restriction

Licensee shall not: (a) remov e any marks or notices of the Licensed Softw are identification,

intellectual property rights like trademark and copyright notice, or other notices or restrictions from the Licensed Software; (b) tr ansfer, sell, assign, sublicense or otherwise convey

the Licensed Software to any third party without Licensor’s prior written consent; nor (c)

cause, permit or attempt the reverse engineering, disassembly, decompilation, translation

or adaptation of the Licensed Software. Any tr ansfer of the Licensed Softw are is subject to

Licensor’s transf er policies and f ees.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 9

<T oc> <Ind> <1. Introduction>

1.2.3 Copyright/Owner ship

The Licensed Software, including but not limited to an y technology, algorithm, know-how,

process and others contained therein, is the proprietary property and may include trade

secret of Licensor or a third party who grants to Licensor the right of sub-licensing and is

protected by copyright and other intellectual property laws and treaties. Licensee acquires

only right to use the Licensed Software and does not acquire any rights, expressed or

implied, in the Licensed Software or media containing the Licensed Software other than

those specified in this Agreement. Licensor shall at all times retain all rights, titles, and

interests, including intellectual property rights, in the Licensed Software and such media.

The Licensee may not disclose or divulge the af oresaid trade secret to any other individual

or entity than the Licensee's personnel who reasonably need to know and the Licensee.

1.2.4 No W arranty / Limitation of Liability

(1) THE LICENSED SOFTWARE SHALL BE PR O VIDED TO LICENSEE ON AN "AS IS"

BASIS. UNLESS O THER WISE EXPRESSLY PRO VIDED BY LICENSOR, LICENSOR AND THE SUPPLIERS WHO PROVIDE OR LICENSE PART OF THE LICENSED SOFTW ARE T O LICENSOR ("SUPPLIERS") HEREBY EXPRESSLY

DISCLAIM ANY AND ALL IMPLIED WARRANTIES OF ANY KIND WHA TSOEVER,

INCLUDING WITHOUT LIMITATION W ARRANTY OF UNINTERR UPTED OR ERROR-FREE OPERATION, SATISFACT OR Y Q U ALITY, NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE, AND SHALL NOT

BE LIABLE TO LICENSEE FOR ANY DAMA GE OR LOSS CA USED BY USE OR

INABILITY TO USE OF THE LICENSED SOFTW ARE. LICENSOR AND SUPPLIERS

DISCLAIM ANY AND ALL LIABILITY AND WILL HAVE NO LIABILITY FOR VIOLATION, MISAPPROPRIATION OR INFRINGEMENT OF INTELLECTUAL PROPER TY

RIGHTS OF ANY THIRD PARTY.

1-4

(2) IN NO EVENT SHALL LICENSOR AND SUPPLIERS BE LIABLE, WHETHER IN

CONTRACT, T ORT OR O THER WISE AND WHETHER OR NOT LICENSOR AND

SUPPLIERS HA VE BEEN AD VISED OF THE POSSIBILITY OF SUCH LOSS OR

DAMAGE, FOR ANY LOSS OR DAMAGE INCLUDING CONSEQUENTIAL, INCIDENTAL, INDIRECT OR EXEMPLARY DAMA GES, LOSS OF PR OFITS , LOSS OF

REVENUE, LOSS OF BUSINESS OR GOODWILL, LOSS OF DATA OR LOSS OF

AVAILABILITY.

(3) THIS SECTION 1.2.4 STA TES THE ENTIRE WARRANTY AND LIABILITY OF LI-

CENSOR AND SUPPLIERS IN CONNECTION WITH THE LICENSED SOFTWARE.

THIS PARAGRAPH 4 ALLOCATES RISKS UNDER THIS A GREEMENT BETWEEN

LICENSEE AND LICENSOR/SUPPLIERS AND COMPRISES FUNDAMENTAL

ELEMENTS OF THIS LICENSE. LICENSOR’S PRICING OF THE LICENSED SOFTWARE REFLECTS THIS ALLOCATION OF RISKS AND LIMIT ATION OF LIABILITY.

(4) LICENSEE SHALL INDEMNIFY, DEFEND AND HOLD LICENSOR AND SUPPLIERS

FROM ANY CLAIMS, DEMANDS , LIABILITIES, LOSSES , D AMA GES, JUDGMENTS

OR SETTLEMENTS, INCLUDING ALL REASONABLE COSTS AND EXPENSES

RELATED THERETO INCLUDING ATTORNEY’S FEES, DIRECTLY OR INDIRECTLY

RESULTING FROM ANY CLAIM MADE OR PO TENTIAL CLAIM BY A THIRD PARTY

AGAINST LICENSOR OR SUPPLIERS ARISING OUT OF ANY A CT OR USE OF

LICENSED SOFTWARE BY LICENSEE.

1.2.5 T erm and T ermination

(1) This Agreement shall become effectiv e when the Licensee installs, copies or other-

wise uses the Licensed Software and remain in full force until and terminate when (a)

Licensor terminates this Agreement according to this 1.2.5 (2); or (b) the Licensee

ceases to use the Licensed Product, whichever comes earlier.

(2) Licensor shall have the right to immediately terminate this Agreement without any

notice to Licensee, if Licensee breaches any of the terms and conditions hereof.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 10

<Toc> <Ind> <1. Introduction>

(3) Upon termination of this Agreement, Licensee shall immediately , in accordance with

instructions by Licensor, return all copies of the Licensed Software in its possession to

Licensor or its designee and erase all copies of the Licensed Software installed in any

computer hereunder.

(4) The license fee paid by the Licensee to the Licensor in consideration of the use of the

Licensed Software hereunder shall be non-refundable unless otherwise e xpressly

provided herein.

(5) The provisions of the 1.2.3 and 6 shall survive after termination of this Agreement.

1.2.6 General Provisions

(1) This Agreement shall be governed by and construed in accordance with the laws of

Japan. All disputes , controv ersies or differences which ma y arise between the parties

hereto, out of or in relation to or in connection with this Agreement shall be finally

settled by arbitration in Tokyo, Japan in accordance with the Commercial Arbitr ation

Rules of the Japan Commercial Arbitration Association. The award rendered by the

arbitrator(s) shall be final and binding upon the parties hereto.

(2) This Agreement shall supersede any prior representations, discussions, undertakings,

communications or advertising with respect to the Licensed Software.

(3) If any part of this Agreement is found void or unenf orceab le under any la ws or regula-

tions and Licensor deems it is not reasonable to license without such void or unenforceable part, Licensor is entitled to modify the terms of this Agreement or terminate

this Agreement at its option without owing any liability to Licensee.

(4) Licensee agrees that the Licensed Software shall not be shipped, transf erred or

exported to any country or used in any manner prohibited by any e xport administration

laws, restrictions or regulations or regulations of Japan, the United States and other

countries that may be applicable to the Licenced Software.

1-5

1.2.7 DIPPR

(1) Licensed Software may include a database dev eloped by the Design Insti-

(2) THE BYU-TPL WILL USE REASONABLE EFFORTS DESIGNED T O

(3) LICENSEE ACKNOWLEDGES THE ABO VE 1.2.7 (1) AND (2) AND

tute for Ph ysical Property Data (DIPPR®) which is a branch of the sponsored

research projects of the American Institute of Chemical Engineers (AIChE®).

VERIFY THAT THE D ATA CONT AINED IN THE D ATABASE HAS BEEN

SELECTED ON THE BASIS OF SOUND SCIENTIFIC JUDGMENT. HO W EVER, NEITHER THE BYU-TPL NOR AICHE® MAKE ANY W ARRANTIES

TO THAT EFFECT. THE D ATABASE IS PRO VIDED “AS IS” WITHOUT

WARRANTY OF ANY KIND. BYU-TPL DISCLAIMS ALL W ARRANTIES ,

EITHER EXPRESS OR IMPLIED , INCLUDING BUT NO T LIMITED T O

WARRANTIES OF MERCHANT ABILITY AND FITNESS FOR A PARTICULAR PURPOSE. NEITHER THE BYU-TPL NOR AICHE® SHALL BE LIABLE FOR ANY DAMA GES , LOSS OF PROPER TY OR PROFITS, OR

CONSEQUENTIAL, EXEMPLARY OR SPECIAL DAMAGES THAT MAY

RESULT FROM ERRORS OR OMISSIONS IN THE D ATABASE EVEN IF

AD VISED OF THE POSSIBILITY OF SUCH D AMA GES.

AGREES NO T TO MAKE ANY CLAIMS OR DEMANDS AGAINST LICENSOR, BYU-TPL NOR AICHE® WITH RESPECT TO DIPPR® AS STATED IN

1.2.4 (4).

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 11

Blank Page

Page 12

<Toc> <Ind> <2. General >

2. General

EJXMVTool is a PC tool that is used to set the flow parameters of EJX910A multivariable

transmitters.

EJXMVTool consists of Flow Configuration Wizard and Obtain Flow Coefficient.

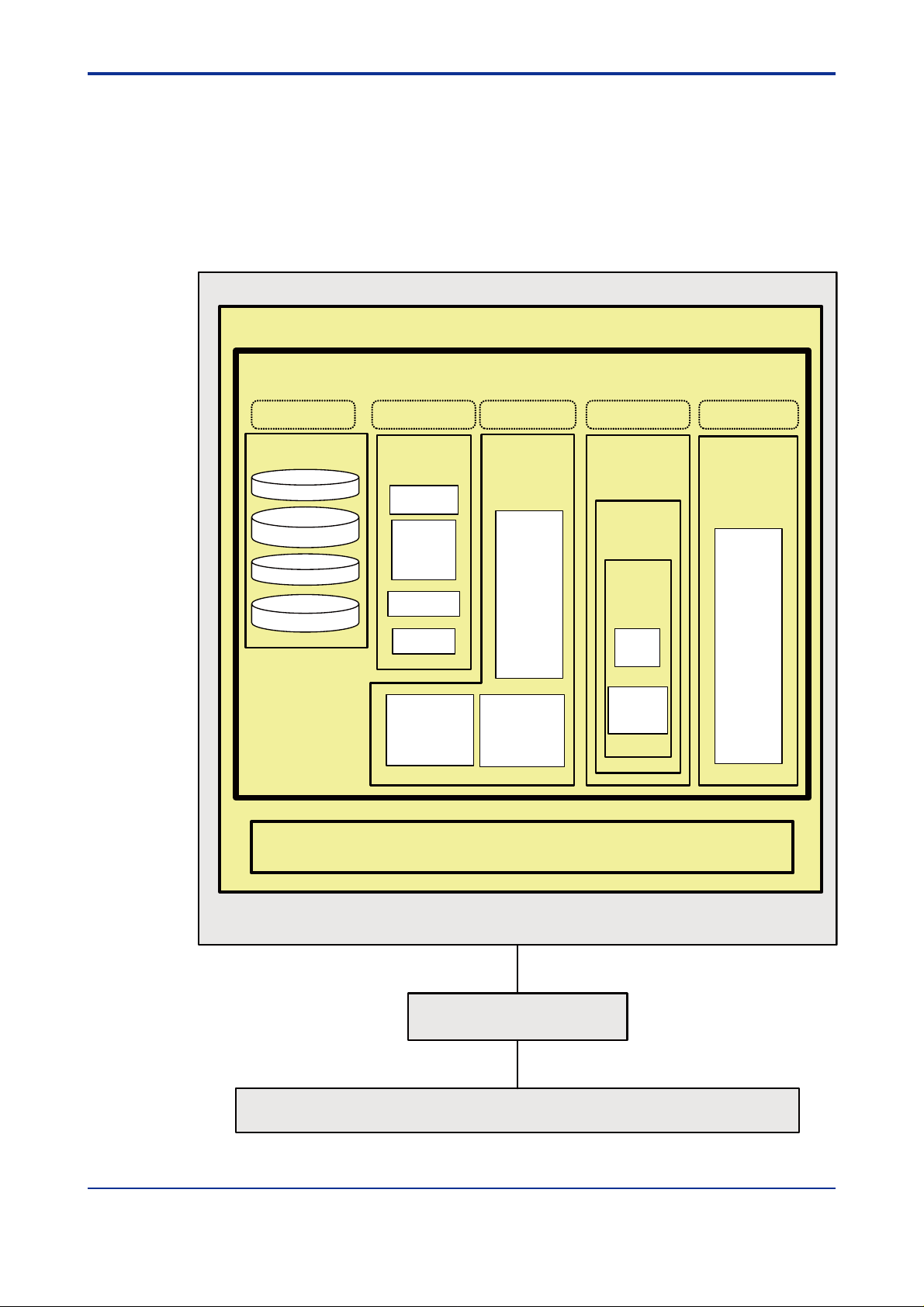

The following chart shows a configuration consisting of a note PC, communication interf ace

and EJX910A multivariable transmitter .

Frame Application

EJX-MV Configuration DTM

2-1

EJXMVTool DTM

This area requires license

Database

Operating conditions

Primary element

information

Fluid information

Phisical property

database

EJXMVTool DTM

This area requires license

Flow

Configuration

Wizard

Dialog editor

Calculation

of flow

parameters

for EJX910

File

Management

Report

Upload

from

transmitter

Comm DTM

EJX910 HART DTM

EJX910 FF DTM

Transmitter

Management

(Offline

parameters)

Dialog

Editor

Monitoring

Process

Value

Tag

Range

Unit

Damping

Lowcut

Adjustment

Download

to

transmitter

EJXMVTool DTM

This area requires license

Flow

Parameter

Management

Obtain Flow

Coefficient

Dialog

Editor

Sensor

mode

Simulation

mode

EJX910 HART DTM

EJX910 FF DTM

Transmitter

Management

(Online

parameters)

Dialog

Editor

Monitoring

Process

Value

Tag

Range

Unit

Damping

Lowcut

Adjustment

Notebook PC

PCMCIA I/F / Serial Port

FF-H1 /HART Communications

NI PCMCIA F-BUS

/HART modem

FF-H1 /HART Communications

Multivariable Transmitter

(EJX910A)

F0201.EPS

Figure 2.1 Functional diagram

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 13

Blank Page

Page 14

<Toc> <Ind> <3. Function Specification>

3. Functional Specification

3.1 PC

3.1.1 Hardware Operating En vir onment

Condition for the FieldMate is included.

Machine: IBM PC/AT-compatible

CPU: P entium3 1 GHz or faster

Main memory: 1 GB or more

Hard disk drive: 8 GB or more

CD-ROM drive: Windows XP compatib le

Display: 1024 768 or better resolution recommended 16 bit colors or better

For HART comm unication: Serial port (RS232C or USB)

OUNDATION Fieldbus communication: Either PCMCIA card slot or PCI slot

For F

3-1

3.1.2 Software Operating Envir onment

IMPORTANT

When using FOUNDATION Fieldbus DTM, login Windo ws as an Administrator or a user with

an administrative authority.

Microsoft Windows XP Prof essional SP2 (English)

Following software is necessary to be installed in your computer .

Common

Adobe Reader

FDT Frame application conf orming to FDT Interface Specification Version 1.2

The frame application which is already tested with FSA120 and proper operation is

confirmed; FieldMate

For HART Communication

Communication DTM for HAR T Modem conformed FDT Interf ace Specification Version 1.2

Follo wing Communication DTM has been tested with FSA120 and compatibility is

confirmed; HART Comm unication DTM included in FieldMate

OUNDATION Fieldbus Comm unication

For F

(included in FieldMate)

NI-FBUS Communications Manager

Communication DTM for PCMCIA-FBUS or PCI-FB US conf orming to FDT version 1.2

Follo wing Communication DTM has been tested with FSA120 and compatibility is

confirmed; F

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

OUNDATION Fieldbus communication DTM included in FieldMate.

Page 15

<T oc> <Ind> <3. Function Specification>

NOTE

Install the following software which is contained in CD if y ou don’t hav e them in y our computer. Refer to section 4.2 for procedures.

1)Adobe Reader

2)FieldMate

• FDT Frame application

• HART communication DTM

• FF communication DTM

3)Device Files

• FJX910 HART DTM (included in Yokogawa DTM Library HART)

• FJX910 FF DTM (included in Yokogawa DTM Libr ary FF)

IMPORTANT

3-2

If you already hav e FSA210 Mass Flow Configuration Softw are installed in your computer,

Uninstall FSA210 to avoid the competition of COM POR T.

3.2 Field Communication

1)HART communication

Recommended HART modem: USB HART Interf ace (Yokogawa P arts Number F9197UB)

OUNDATION Fieldbus communication

2)F

Recommended: NI-FBUS:National Instrument’ s PCMCIA-FB US or PCI-FBUS NI-FBUS

3.0 or later

3.3 Model to be Connected

EJX910A Multivariable Transmitter

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 16

<Toc> <Ind> <3. Function Specification>

3.4 Outline of FSA120

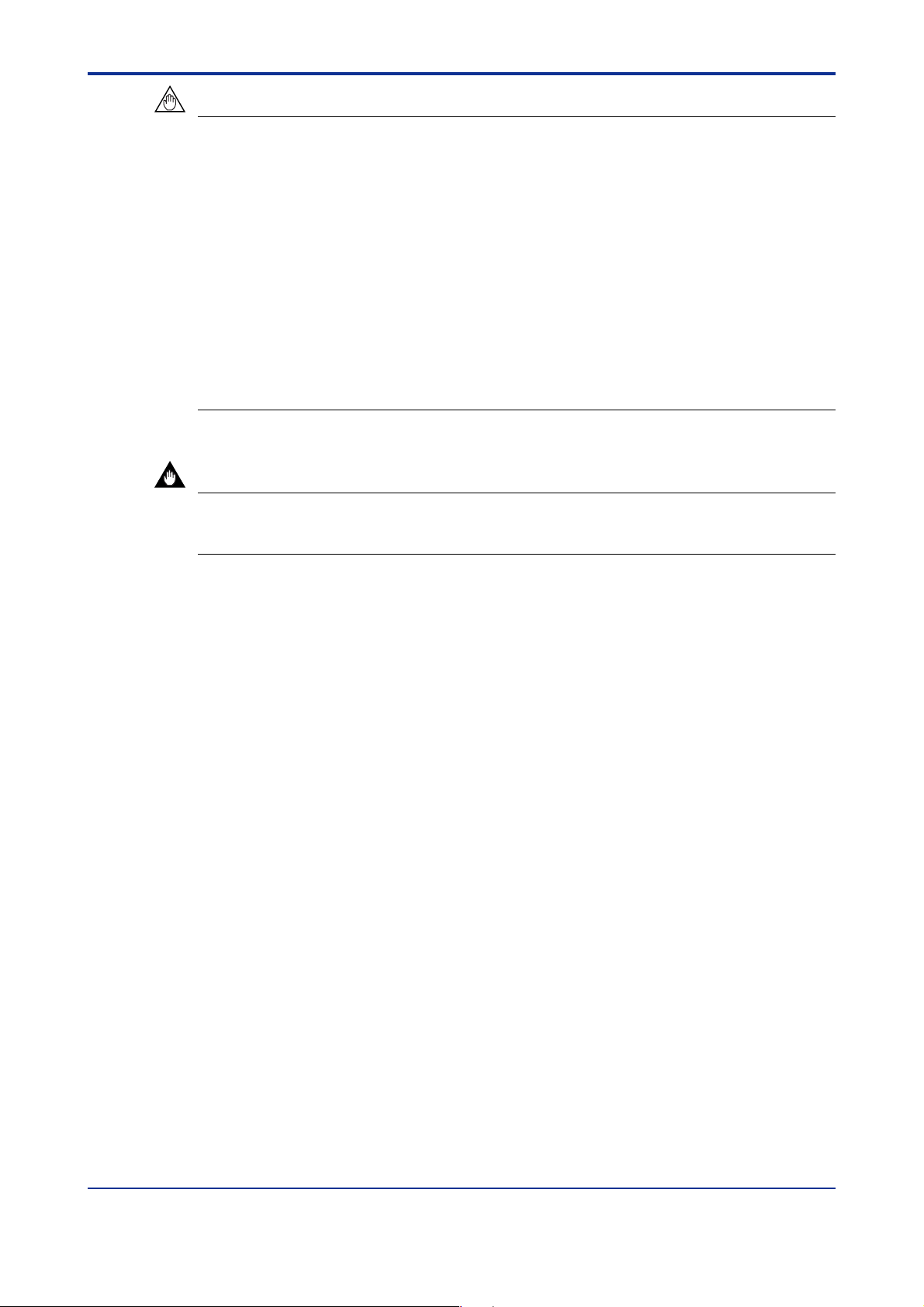

3.4.1 Components

Following picture sho ws the items included in the FSA120 package.

3-3

Disk

FieldMate

Disk

Yokogawa

EJXMVTool

additional

resource

Figure 3.1 Components of FSA120

User license

sheet

(FieldMate)

User license

sheet

(EJXMVTool)

F0301E.EPS

Disk

Device Files

Each disk contains the following software.

[FieldMate disk]

•FieldMate

[Device Files disk]

•Yokogawa DTM Library HART

(Includes EJX910 HART DTM, EJXMVTool source program and HART DTMs of other

YOKOGAW A products.)

•Yokogawa DTM Libr ary FF

(Includes EJX910 FF DTM, EJXMVTool source program and FF DTMs of other

YOKOGAW A products.)

[Yokogawa MVTool additional resource disk]

• Programs necessary to activate EJXMVTool

• User's manual of EJXMVTool (in pdf format)

FieldMate is Yokogawa's FDT fr ame application and bundled in FSA120. Device Files

contains YOKOGA W A DTM library which include EJX910 HART/FF DTM(f or transmitter

management) and EJXMVTool DTM (for flow parameter management).

Yokogawa MVTool additional resource disk contains the programs necessary for

EJXMVTool.

To use the full part of FSA120, it is necessary to correctly install a frame application

(FieldMate), libraries, and the programs in the additional resource disk into your computer .

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 17

<T oc> <Ind> <3. Function Specification>

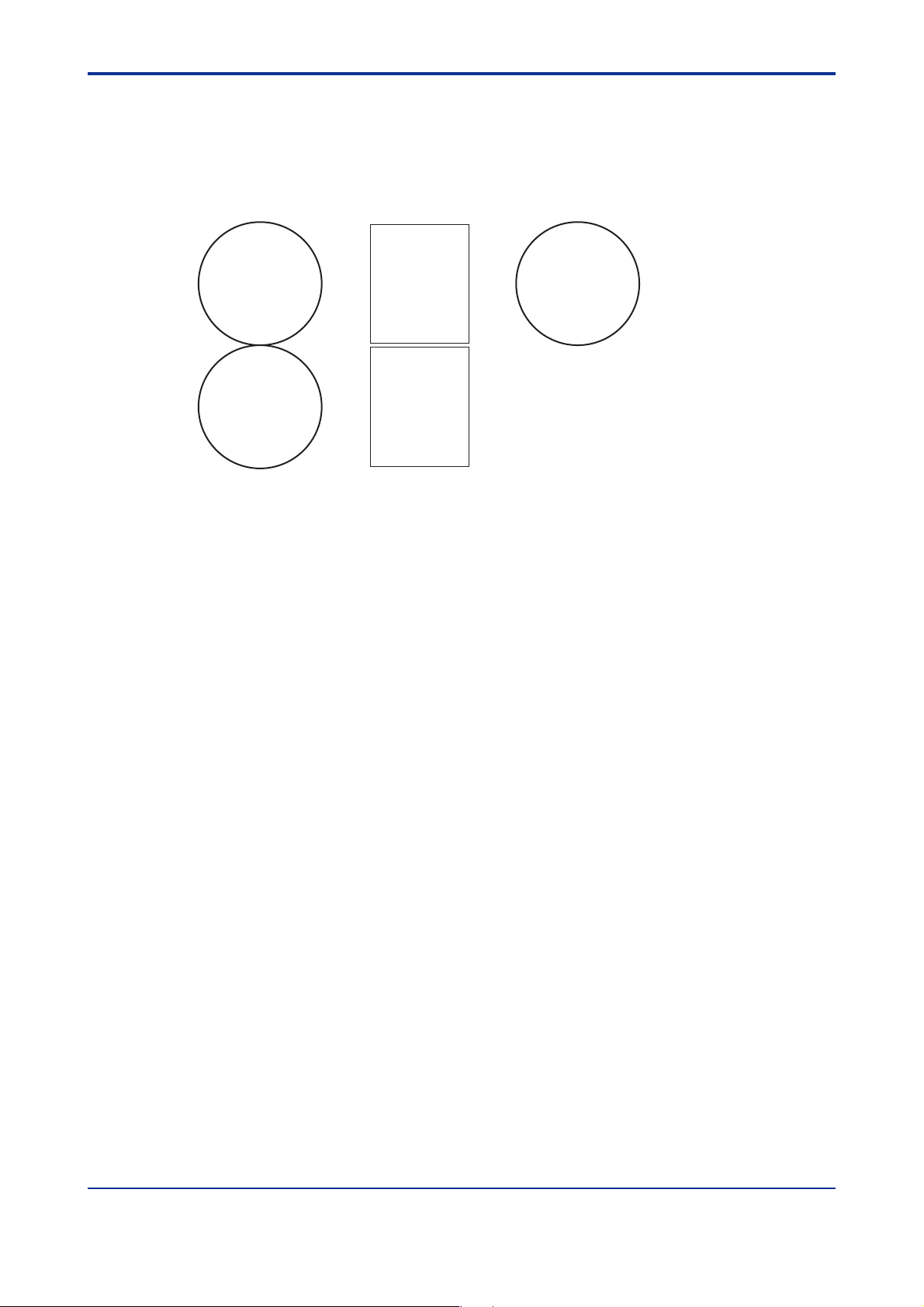

3.4.2 EJX910 HART/FF DTM and EJXMVTool

EJX910 HART/FF DTM and EJXMVTool consist of the following programs.

Table 3.1 Function of EJXMVT ool (f or HART comm unication)

Program Function

EJX910HART DTM

EJX

MVTool

Flow

Configuration

Wizard

Obtain Flow

Coefficient

Database

Transmitter

Management

Flow

Parameter

Management

Flow

Parameter

Management

Database - Necessary* Physical property

* Online Parameter

* Offline Parameter

* Downloads to or uploads

from the transmitter

parameters for the

EJX910A.(Auto

compensation mode,

Basic mode)

* File management

* Report function

retrieval

database used for flow

parameter calculation.

<DTMInstDrive>

\Program

Files\Yokogawa

\DTMs

<DTMInstDrive>

\Program

Files\Yokogawa

\DTMs

\EJXMVTool

Startup method

Execute from

the frame

application

Execute from

the EJX910

HART DTM

Execute from

the EJX910

HART DTM

3-4

Entry of LicenseContens Install location

Not

necessary

Necessary* Configuration of flow

Necessary* Flow coefficient

T0301-1E.EPS

Table 3.2 Function of EJXMVT ool (f or FF comm unication)

Program Function

EJX910FF DTM

EJX

MVTool

Flow

Configuration

Wizard

Obtain Flow

Coefficient

Database

Transmitter

Management

Flow

Parameter

Management

Flow

Parameter

Management

Database - Necessary* Physical property

* Online Parameter

* Offline Parameter

* Downloads to or uploads

from the transmitter

parameters for the

EJX910A. (Auto

compensation mode,

Basic mode)

* File management

* Report function

retrieval

database used for flow

parameter calculation.

<DTMInstDrive>

\Program

Files\Yokogawa

\DTMs

<DTMInstDrive>

\Program

Files\Yokogawa

\DTMs\EJXMVTo

olFF

Startup method

Execute from

the frame

application

Execute from

the EJX910

FF DTM

Execute from

the EJX910

FF DTM

Entry of LicenseContens Install location

Not

necessary

Necessary* Configuration of flow

Necessary* Flow coefficient

T0301-2E.EPS

Each program can be started in the following wa y.

>Execute EJX910 HART DTM or EJX910 FF DTM on the frame application.

(Not necessary to enter a license for EJXMVTool)

>Execute the Flow Configuration Wizard /Obtain Flo w Coefficient on the EJX910 HAR T or

FF DTM (Necessary to enter your license for EJXMVTool.)

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 18

<Toc> <Ind> <3. Function Specification>

3.5 FSA120 DTM Function Detail

3.5.1 T ransmitter Mana gement

Transmitter management function is supported by EJX910 HART DTM and EJX910 FF

DTM.

EJX910FF DTM supports the following blocks in the EJX910: Resource Block, Sensor

Transducer Block, Flow Transducer Block, LCD Transducer bloc k, and AI function blocks .

Parameters of other function blocks should be set and changed by other Fieldbus

configurators.

• Setting of Node Address and tag is not supported.

• Scheduling is not supported.

NOTE

Setting of Node Address and PD Tag and scheduling are not supported by FSA120. Use

general purpose Fieldbus setting tool to set these items. After using setting tool, finish the

program before starting FSA120.

3-5

(1) Online Parameter

The Transmitter General parameters of the device can be edited directly in online

status.

(Process value monitoring, Tag, Range, Unit, Damping, Lowcut, Indicator displa y,

Maintenance, Adjustment, Status information display)

(2) Offline Parameter

The Transmitter General parameters of the device can be edited and stored in offline

database.

(Process value monitoring, Tag, Range, Unit, Damping, Lowcut, Indicator displa y,

Maintenance, Adjustment, Status information display)

(3) Downloads to or uploads from the transmitter

The Transmitter Flow and General P arameters stored in offline database are

downloaded the to device .

The parameters of the device is uploaded from the de vice and stored in offline

database.

Transmitter General Parameters:

HART or F

HART handheld terminal or Fieldbus Configuration Tool. e.g. range, damping, etc.

User Flow Parameters:

The parameters which users input on EJXMVTool for flow configuration.

OUNDATION Fieldbus parameters of the de vice, which can be modified with using

This parameters are used to generate flow appro ximation and not downloaded to the

device.

Transmitter Flow Parameters:

The parameters which EJXMVTool calculates and generates with using the User Flow

Parameters and are downloaded to the device.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 19

<T oc> <Ind> <3. Function Specification>

3.5.2 Flow P arameter Management (Flow Configuration Wizard)

This function is supported by EJXMVTool DTM.

(1) Auto compensation mode

Configuration of the fluid physical properties and primary element for the EJX910A

can be performed using a dialog window . Refer to section 6.3.

(2) Basic mode

Flow operation and density compensation are perf ormed conventionally, with the flow

factors being input manually. Ref er to section 6.4.

(3) File management

xmv file: Import / export User Flow parameters

Import / export Transmitter Flow parameters.

prm file: Import HART Transmitter General parameters

(only for FSA210 user)

(4) Report function

Export user flow parameters in CSV file format.

3.5.3 Flow P arameter Management (Obtain Flow Coefficient)

3-6

This function is supported by EJXMVTool.

Flow coefficient retrieval

The flow coefficient can be obtained from the transmitter (input selection: sensor data

or simulated data).

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 20

<Toc> <Ind> <3. Function Specification>

3.5.4 Primary Devices Supported in Auto Compensation Mode

This function is supported by EJXMVT ool DTM.

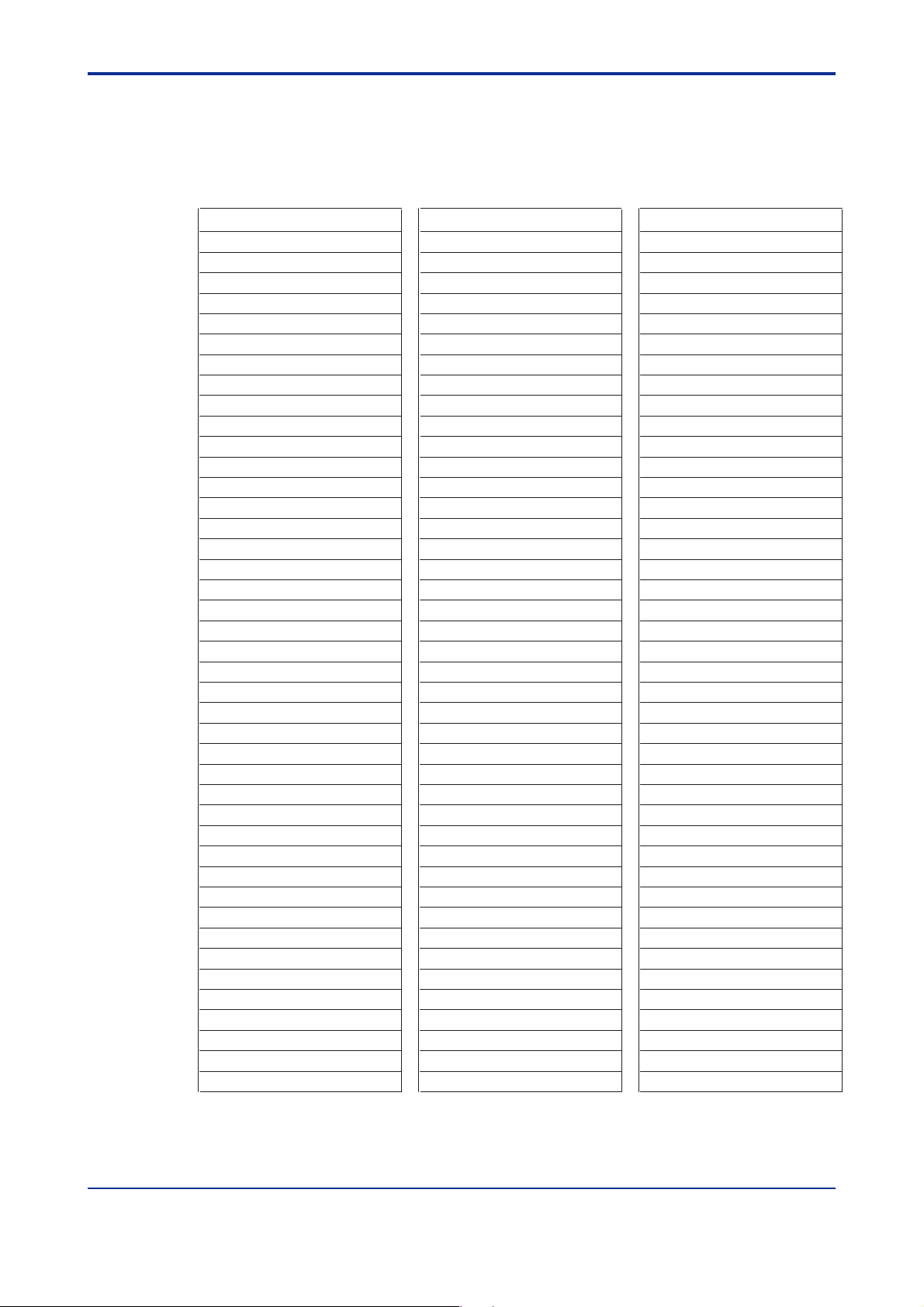

Table 3.3 Supported primary devices

Type

Orifice

Nozzle

Venturi

FIX

Orifice Corner Taps [ISO5167-1 1991]

Orifice Corner Taps [ISO5167-2 2003]

Orifice Corner Taps [ASME MFC-3M 1989]

Orifice Flange Taps [ISO5167-1 1991]

Orifice Flange Taps [ISO5167-2 2003]

Orifice Flange Taps [ASME MFC-3M 1989]

Orifice Flange Taps [AGA No.3 1992]

Orifice D and D/2 Taps [ISO5167-1 1991]

Orifice D and D/2 Taps [ISO5167-2 2003]

Orifice D and D/2 Taps [ASME MFC-3M 1989]

ISA1932 nozzle [ISO5167-1 1991/ ISO5167-3 2003]

Long radius nozzle [ISO5167-1 1991/ ISO5167-3 2003]

ASME FLOW NOZZLES [ASME MFC-3M 1989]

Venturi nozzle [ISO5167-1 1991/ ISO5167-3 2003]

Classical Venturi tube “as cast” convergent section [ISO5167-1 1991/ ISO5167-4 2003]

ASME Venturi Tubes With a rough Cast or Fabricated Convergent [ASME MFC-3M 1989]

Classical Venturi tube with a machined convergent section [ISO5167-1 1991/ ISO5167-4 2003]

ASME Venturi Tubes With a machined convergent section [ASME MFC-3M 1989]

Classical Venturi tube with a rough-welded sheet-iron convergent section

[ISO5167-1 1991/ ISO5167-4 2003]

Fixed Mode (Sets the discharge coefficient and gas expansion factor to a fixed value)

Primary Device

T0302E.EPS

3-7

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 21

<T oc> <Ind> <3. Function Specification>

3.5.5 Density Compensation in Auto Compensation Mode

This function is supported by EJXMVTool DTM.

(1) Density compensation using physical properties database

Table 3.4 Supported physical properties database

Fluid name Fluid name Fluid name

Acetic Acid Hydrogen Chloride Phosphoric Acid

Acetone Hydrogen Cyanide Propadiene

Acetonitrile Hydrogen Peroxide Propane

Acetylene Hydrogen Sulfide Propylene

Acrylonitrile Isobutane Pyrene

Air Isobutene Styrene

Allyl Alcohol Isobutylbenzene Sulfur Dioxide

Ammonia Isopentane Toluene

Argon Isoprene Trichloroethylene

Benzaldehyde Isopropanol Trichlorofluoromethane

Benzene m-chloronitrobenzene Vinyl Acetate

Benzoic Acid m-dichlorobenzene Vinyl Chloride

Benz Alcohol Methane Vinyl Cyclohexene

Biphenyl Methanol Water

Bromine Methyl Acrylate 1-Butene

Carbon Dioxide Methyl Ethyl Ketone 1-Decene

Carbon Monoxide Methyl Vinyl ether 1-Decanal

Carbon Tetrachloride Monochlorobenzene 1-Decanol

Chlorine n-Butane 1-Dodecene

Chlorodifluoromethane n-Butanol 1-Dodecanol

Chloroprene n-Butyraldehyde 1-Heptanol

Chlorotrifluoroethylene n-Butyronitrile 1-Heptene

Citric Acid n-Decane 1-Hexene

Cycloheptane n-Dodecane 1-Hexadecanol

Cyclohexane n-Heptadecane 1-Octanol

Cyclopentane n-Heptane 1-Octene

Cyclopentene n-Hexane 1-Nonanal

Cyclopropane n-nonane 1-Nonanol

Dichlorodifluoromethane n-Octane 1-Pentadecanol

Divinyl Ether n-Pentane 1-Pentanol

Ethane Neon 1-Pentene

Ethanol Neopentane 1-Undecanol

Ethylamine Nitric Acid 1,1,2,2-Tetrafluoroethane

Ethylbenzene Nitric Oxide 1,1,2-Trichloroethane

Ethylene Nitrobenzene 1,2,4-Trichlorobenzene

Ethylene Glycol Nitroethane 1,2-Butadiene

Ethylene Oxide Nitrogen 1,3-Butadiene

Fluorene Nitromethane 1,3,5-Trichlorobenzene

Furan Nitrous Oxide 1,4-Dioxane

Helium-4 Oxygen 1,4-Hexadiene

Hydrazine Pentafluoroethane 2-Methyl-1-Pentene

Hydrogen Phenol

Source:

DIPPR

This Physical Property Database from American Institute of Chemical Engineers

(AIChE

®

Project No .801 Database 2003 Edition

®

)

2,2-Dimethylbutane

3-8

T0303E.EPS

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 22

<Toc> <Ind> <3. Function Specification>

NOTE

The DIPPR recommends an air temperature no higher than –25°C and cannot guarantee results if this temperature limit is exceeded.

(2) Density compensation using standard steam tables

IAPWS-IF97 W ater and Steam (1997)

IAPWS-IF97: IAPWS Industrial F ormulation 1997

IAPWS: The International Association for the Properties of W ater and Steam

(3) Density compensation using standard.

Natural gas:

AGA8.

Compressibility Factors of Natural Gas and Other Related Hydrocarbon Gases

American Gas Association (AGA)

Transmission Measurement Committee Report No.8 Second Edition, Nov ember

1992

3-9

Detail Characterization Method

Gross Characterization Method 1

Gross Characterization Method 2

ISO 12213:1997 First edition 1997-12-01

Part 2: molar-composition analysis

Part 3: ph ysical properties

(4) Custom fluid density and viscosity compensation

Numerical value user input for physical properties (density, viscosity, etc.)

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 23

Blank Page

Page 24

<Toc> <Ind> <4. Preparation>

4. Preparation

4.1 PC

To ensure that EJXMVTool functions properly, please make sure your PC meets the

requirements stated in the section ‘3.1 PC’.

All application must be finished.

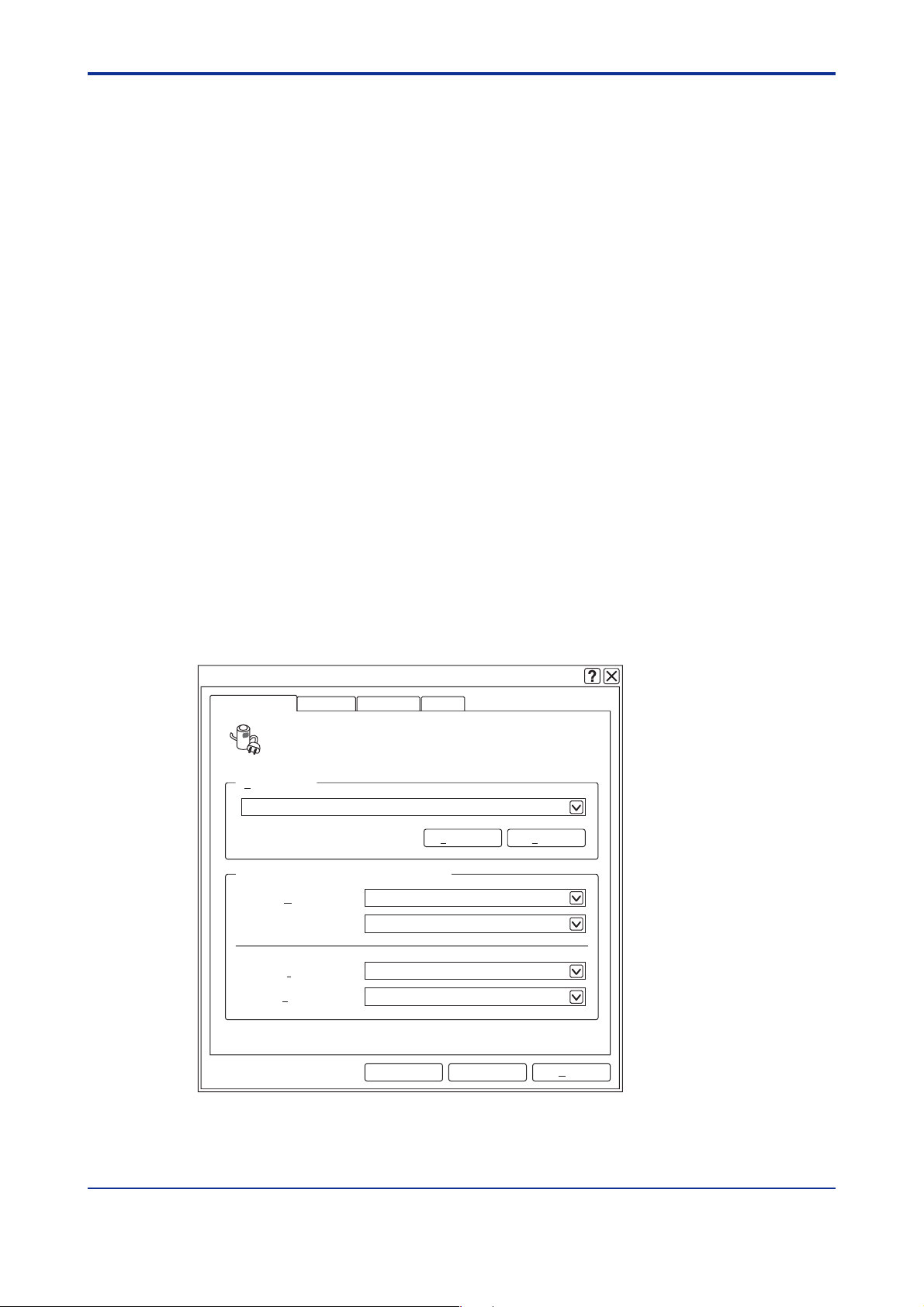

4.1.1 Setting Items after Installing Windo ws

Before installing EJXMVTool to Windows environment, the f ollo wing settings are recommended.

•Power Options

It is recommended to set System Standby to [Nev er]. Setting procedure is as f ollows .

Login Windows XP as administrator , and then choose [Start] - [Control P anel] [PowerOptions] to open [Power Options Properties] dialog box. Confirm the settings on this

dialog box are the same as follows .

4-1

•Power Schemes Tab

System standby and System hibernates are recommended to be set as follows;

Turn off hard disk: Nev er

System standby: Ne v er

System hibernates: Nev er

Power Options Properties

HibernateAdvancedPower Schemes

Select the power scheme with the most apropriate settings for

this computer. Note that changing the settings below will modify

the selected scheme.

Power schemes

Home/Office Desk

Setting for Home/Office Desk power scheme

NeverTurn off monitor:

NeverTurn off hard disks:

NeverSystem standby:

NeverSystem hibernates:

UPS

DeleteSave As...

CancelOK

Figure 4.1 Power Sc hemes Tab

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Apply

F0401E.EPS

Page 25

<T oc> <Ind> <4. Preparation>

• Adv anced T ab

Some PC keyboards hav e a sleep b utton. It is recommended to disab le this b utton.

When press the sleep button on my computer: No action

Figure 4.2 Advanced T ab

• Hibernate T ab

Do not check the option [Enable hibernation].

Power Options Properties

4-2

HibernateAdvancedPower Schemes

When you computer hibernates, it stores whatever it has in

memory on your hard disk and then shuts down. When your

computer comes out of hibernation, it returns its previous state.

Hibernate

Enable hibernation

Disk space for hibernation

Free disk space: 22,057 MB

Disk space required to hibernate: 256 MB

Figure 4.3 Hibernate Tab

UPS

CancelOK

Apply

F0403E.EPS

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 26

<Toc> <Ind> <4. Preparation>

4.2 Installation Procedure

4.2.1 EJXMVT ool online man ual

The pdf format Manual for EJXMVTool is located at <Yokogawa MVTool Additional resource

disk>: \EJXMVTool_Manual.pdf.

If Adobe Reader is not on your PC, install it.

This may be done by doub le clicking on < FieldMate CDROM>:

\READER\ENGLISH\AdbeRdr80_en_US.ex e in Windo ws Explorer.

(<CDROM> is the CD-ROM drive of your computer.)

4.2.2 Uninstall FSA210

This procedures are only applicable for the users of FSA210 Mass Flow Configur ation

Software.

If FSA210 is existing on your PC , uninstall it to av oid the competition with FieldMate.

To uninstall all the program of FSA210, take the following three steps.

(1) Uninstall a field communication server

Execute <FieldInstDrive>: \PRM\Prog ram\PRMUninstall.e x e

4-3

Double-click the filename in Windows Explorer .

<FieldInstDrive> is the drive on which field communication server is installed.

<FieldInstDrive> is the drive where the PRM directory is located.

The default drive is the same drive on which Windo ws is installed.

(2) Uninstall the EJXMVTool program with the Add or Remove Programs function of the

Windows Control Panel. Select EJXMVT ool and click [Change/Remov e].

(3) Uninstall Exaopc

Use the Add or Remove Progr ams function of the Windows Control P anel to uninstall

Exaopc. Select Exaopc and clic k [Change/Remov e].

Follow the instruction to reboot the computer .

NOTE

Refer to Appendix A for the detailed procedures of uninstalling FSA210.

4.2.3 For FieldMate Users

If you already hav e FieldMate installed in your computer , which satisfies the oper ating

requirement of FSA120, you may need to skip the installation of FieldMate. Please see the

followings.

NOTE

If FieldMate installed in your PC is older version and does not satisfy the working condition

of FSA120, it is necessary to install FieldMate which satisfies the requirement.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 27

<T oc> <Ind> <4. Preparation>

1)If you have FieldMate Basic installed on your PC , and...

• if y ou ha ve purchased FSA120 with FieldMate Basic;

check the version of FieldMate which is installed on y our PC .

On the other hand, the version of the bundled FieldMate is sho wn on the disk.

If the version is low er than that of the bundled FieldMate , install the bundled

FIeldMate.

If the version is equiv alent or higher , install Additional Resource Disk alone.

• if y ou ha ve purchased FSA120 with FieldMate Adv ance;

install the bundled FieldMate Advance and Additional Resource Disk.

2)If you have FieldMate Advance installed on y our PC, and...

• if y ou ha ve purchased FSA120 with FieldMate Basic;

check the version of FieldMate which is installed on y our PC .

On the other hand, the version of the bundled Fieldmate is sho wn on the disk.

If the version is low er than that oh the bundled FieldMate, install the b undled

FieldMate Basic after uninstalling the previous v ersion of FieldMate Advance .

If the version is equiv alent or higher , install Additional Resource Disk alone.

4-4

• if y ou ha ve purchased FSA120 with FieldMate Adv ance;

check the version of FieldMate which is installed on y our PC .

On the other hand, the version of the bundled FieldMate is sho wn on the disk.

If the version is low er than that of the bundled FieldMate , install the bundled

FIeldMate.

if the version is equivalent or higher, install Additional Resource Disk alone.

4.2.4 Installations of FieldMate and Device Files

For the installations of FieldMate and De vice Files, please f ollow the procedures described

in the User’s manual “FieldMate Versatile Device Management Wizard Getting Started” (IM

01R01A04-01E) included in the FSA120 package.

•Yokogawa HART/FF DTM library

Automatically installed during the installation of FieldMate.

• Related program installation(f or F

For the operation of EJX910 FF DTM, "NI-FBUS Comm unications Manager" must be

installed.

NOTE

OUNDATION Fieldbus communication)

For the installation procedures of FieldMate, ref er to the user’ s man ual of FieldMate.

When installing FieldMate, log-in the Windo ws as an Administrator or an user with an

administrative authority.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 28

<Toc> <Ind> <4. Preparation>

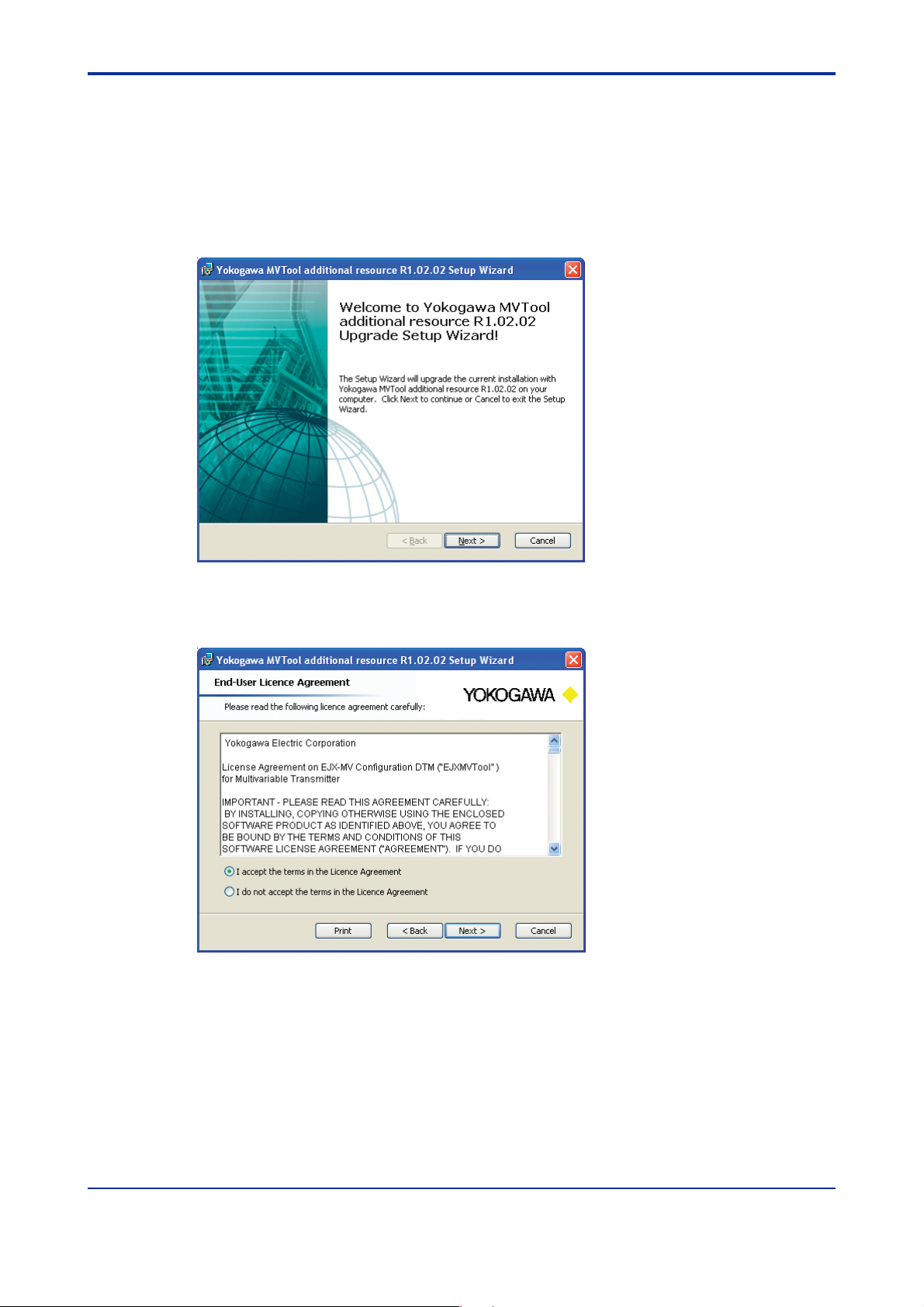

4.2.5 EJX MVT ool additional resour ce installation

Execute <CDROM>: \ Resource \ setup .e x e

Double-click the file name in Windows Explorer, and the EJXMVTool installation prog ram

will be started.

(<CDROM> is the CD-ROM drive of your computer.)

(1) Click [Next].

4-5

Figure 4.6a W elcome screen

(2) Select [I accept ...] and click [Next].

Figure 4.6b License agreement screen

F0405E.EPS

F0406E.EPS

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 29

<T oc> <Ind> <4. Preparation>

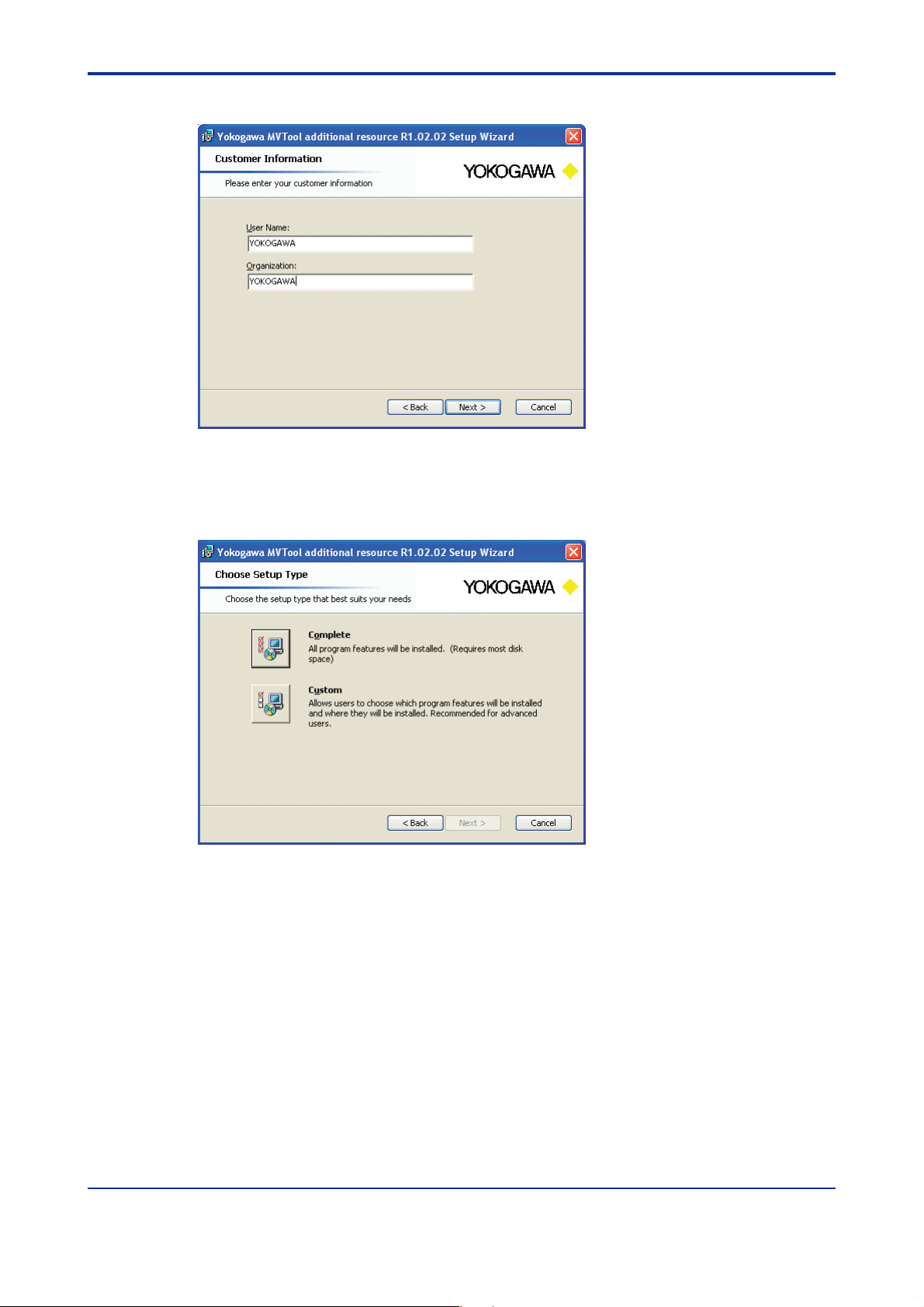

(3) Input “User Name”,“Organization” and Clic k [Next].

F0407E.EPS

Figure 4.6c Customer Information Screen

(4) Select [Complete] or [Custom].

4-6

Complete setup is recommended.

Figure 4.6d Choose Setup Type

F0408E.EPS

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 30

<Toc> <Ind> <4. Preparation>

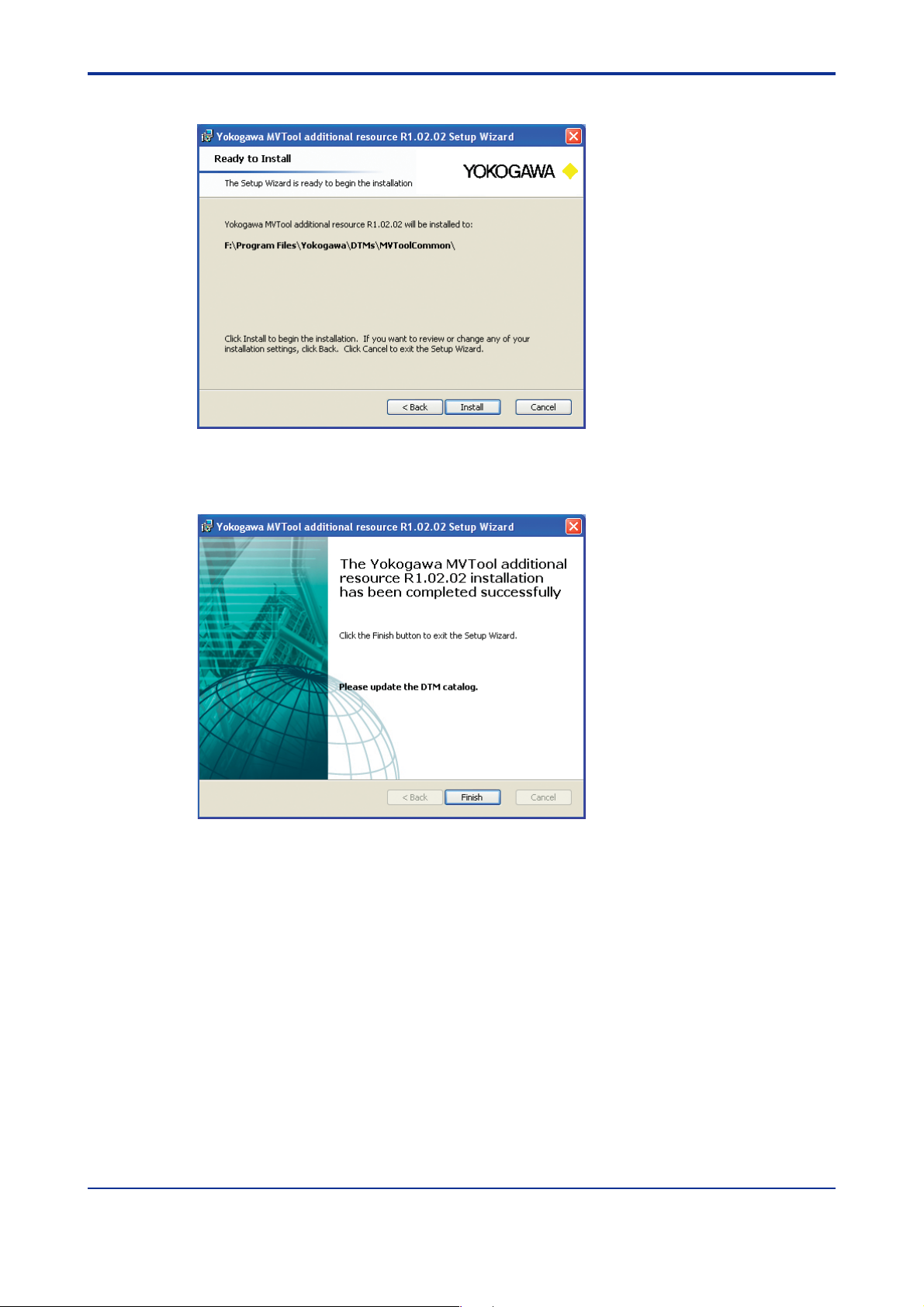

(5) Click [Install].

F0409E.EPS

Figure 4.6e Ready to install screen

(6) Click [Finish].

4-7

F0410E.EPS

Figure 4.6f Finish Setup screen

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 31

<T oc> <Ind> <4. Preparation>

4.2.6 How to confirm V ersion Number of DTM

1)Y ok oga wa HAR T/ FF DTM library

The version number is display ed on the “Add / remov e program” screen of Windo ws

Control Panel. (See figure 4.7.)

Version number

F0411E.EPS

Figure 4.7 V ersion Number of DTM Library

4-8

2)EJXMVT ool DTM

The version number is display ed on the HELP screen of Flow Configur ation Wizard or

Obtain Flow Coefficient.

Refer to 6.2.5 or 6.5.

3)MVT ool additional resource (Release number of FSA120)

The version number is display ed on the “Add / remov e program” screen of Windo ws

Control Panel. (See figure 4.8.)

4) EJX910DTM

Refer to 4.6.3 ‘Start EJX910DTM’.

F0412E.EPS

Figure 4.8 V ersion No. of Y okoga wa MVTool Addirional Resource

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 32

<Toc> <Ind> <4. Preparation>

4.3 Uninstallation

(1) FieldMate

Refer to User's manual IM01R01A01-00E.

(2) MVTool Additional Resouce

Use the Add or Remove Progr ams function of the Windows Control P anel.

Select Yokoga wa MVTool additional resouce Rx.xx.xx and click [Remove].

4-9

Figure 4.9 Remove Yokoga wa MVTool Additional Resource

F0413E.EPS

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 33

<T oc> <Ind> <4. Preparation>

4.4 Initial Setting (HART comm unication)

4.4.1 HART Communication Modem

Connect the HART communication modem to the PC’ s COM port.

NOTE

Either a serial (RS232C) or USB port may be used.

4.4.2 COM port

Find out which COM port the modem will be connected to.

Select the Start menu. Right click [My Computer] and select [Properties].

4-10

F0414E.EPS

Figure 4.10a Windo ws Properties

Click [Hardware] and select [Device Manager]

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 34

<Toc> <Ind> <4. Preparation>

F0415E.EPS

Figure 4.10b Hardware pr opoerties

4-11

Click [Ports (COM & LPT)] to find out the port number.

Figure 4.10c COM port number

F0416E.EPS

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 35

<T oc> <Ind> <4. Preparation>

4.4.3 Wiring

Figure 4.11 Connection of HART instruments

NOTE

When RTD is not connected to EJX910A, the setting is possible though alarm 03 is displayed on the indicator.

4-12

F0417E.EPS

4.4.4 Communication setting (HAR T communication)

This subsection describes the procedures to change the communication related setting of

FieldMate. Please try these procedures after you start FieldMate and if you e xperience that

communication is not correctly established. Please ref er to 4.6.2.

(1) Communication port setting on FieldMate

1. Clic k the [Tool] --> [HART Modem Configuration..] at FieldMate window .

2. Select com port number .

3. Clic k the [OK] b utton.

F0433E.EPS

Figure 4.12 HART Modem configuration

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 36

<Toc> <Ind> <4. Preparation>

Select COM port number.

F0434E.EPS

Figure 4.13 COM port

Please refer to FieldMate User's manual for details .

(2) Communication address setting on FieldMate

In FieldMate, the default setting of maximum scan v alue of communication address is “0”.

If the transmitter’s address is other than “0”, FieldMate cannot distinguish the tr ansmitter .

Therefore, the setting should be changed to the correct v alue.

1. Clic k the [Tool] --> [HART Modem Configuration..] at FieldMate window .

2. Select address number.

4-13

3. Clic k the [OK] b utton.

Maximum value of communication

Addressfor scaning

F0435E.EPS

Figure 4.14 Address Setting

Please refer to FieldMate for detail.

4.5 Initial Setting (FF Communication)

4.5.1 EJX910A

Address and Tags (PD Tag and VFD Tag) must be set in the EJX910A.

IMPORTANT

FSA120 does not support address setting. Use general purpose Fieldbus setting tool for

setting an address and tags. After using gener al purpose Fieldbus setting tool, e xit from

the program before starting EJX910 FF DTM. Please also refer to 4.7.1 FF comm unication

(Node Address).

4.5.2 Install NI-FBUS Card

Install the NI-FBUS card on PC.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 37

<T oc> <Ind> <4. Preparation>

4.5.3 NI-FBUS Setting (Interface Configuration Utility)

Please define the NI-FBUS setting as follows .

IMPORTANT

Activate the program as an Administrator or user with an Administr ative authority.

(1) Activate the program

On PC, click the f ollo wing order and activate the prog ram

Click [Start] --> [All Programs] --> [National Instrument] --> [NI-FBUS] --> [Interface

Configuration Utility]

4-14

Figure 4.15a Starting NI-FBUS Utility

(2) Select the port

On the screen shown up , select “Port0" and press “Edit”.

Figure 4.15b NI-FBUS Interface Config Screen

F0418E.EPS

F0419E.EPS

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 38

<Toc> <Ind> <4. Preparation>

(3) Setting(if Link Master Device e xits in the segment)

After that, on the screen shown up, select the items indicated as belo w .

F0420E.EPS

Figure 4.15c NI-FBUS H1 Port Properties (1)

Device Address: Select [Visitor]

4-15

Device Type : Select [Basic Device]

Usage : Select [NI-FBUS]

CAUTION

Do not set the NI-FBUS card to Link Master Device in the Fieldbus segment where other

host may exist.

Setting may cause disturbance of control.

(4) Setting (if no Link Master Device exists in the segment)

After that, on the screen shown up, select the items indicated as belo w .

F0421E.EPS

Figure 4.15d NI-FBUS H1 Port Properties (2)

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 39

<T oc> <Ind> <4. Preparation>

Device Address: Select [Visitor]

Device Type : Select [Link Master De vice]

Usage : Select [NI-FBUS]

4.5.4 Start NI-FBUS Communications Manager

Please Start the NI-FBUS Communications Manager as follows.

Click [Start] --> [All Programs] --> [National Instrument] --> [NI-FBUS] -->

[NI-FBUS Communications Manager].

F0422E.EPS

Figure 4.15e Starting NI-FBUS

IMPORTANT

4-16

When running the program, log-in the Windows as an Administr ator or an user with an

administrative authority.

4.5.5 Connect the EJX910A to the power supply

Please refer to User’ s manual IM 01C25 R03-01E “EJX910A Fieldbus Comm unication.”

4.5.6 Connect the NI-FBUS card to the EJX910A

CAUTION

FSA120 is the software tool which is purposed for the setup and maintenance. Do not try

connecting it to the EJX910A which is under actual operation in the process. Bef ore connecting NI-FBUS card to the segment, make sure that the process which is controlled by

the segment is off-lined.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 40

<Toc> <Ind> <4. Preparation>

NI-FBUS Card

4-17

Terminator

FF Device

+

-

Across the FF device.

*

Figure 4.16 Connection example for FF

*

Terminator

Loop Power

Supply

+

-

F0423E.EPS

4.6 Start FDT frame application

This section describes the operation of DTM with using FieldMate.

For the detailed operation of FieldMate , refer to User's man ual of FieldMate.

IMPORTANT

When running the program, log-in the Windows as an Administr ator or an user with an

administrative authority.

4.6.1 Update DTM Browser

After new DTM is installed, click “DTM Bro wser”, so as to confirm that the designated DTM

is correctly installed.

Click [Start] --> [All Programs] --> [Y OK OGA W A FieldMate] --> [Tool] --> [DTM browser]

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 41

<T oc> <Ind> <4. Preparation>

4.6.2 Start FieldMate

Starting FieldMate by following operation.

(1) Click [Start] --> [All Programs] --> [Y OKOGAWA FieldMate] --> [FieldMate]

4-18

Figure 4.17a Start FieldMate

F0424E.EPS

(2) Default Scan Segment is to select the communication protocol of the segment to be

scanned on startup. Select [HAR T] or [FF-H1] and clic k [OK].

Figure 4.17b Select HART/FF

F0425E.EPS

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 42

<Toc> <Ind> <4. Preparation>

(3) FieldMate Segment Vie wer window.

Open Segment View er on FieldMate.

A device icon appears on the window if it is successful to connect to FieldMate. If not, “No

device found” message is sho wn on the window .

If a connected device icon does not appear , check that initial setting f or comm unication is

correctly done. Ref er to section 4.4 for HAR T and 4.5 f or FF.

4-19

Figure 4.17c Segment Vie wer

F0426E.EPS

NOTE

How to confirm EJX910DTM version number.

Click [Action]--> [Select DTM] to select the target de vice.

Confirm version number .

F0428-02E.EPS

Figure 4. 17d Confirm Version of EJX910DTM

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 43

<T oc> <Ind> <4. Preparation>

F0428-03E.EPS

Figure 4. 17e Version Number of EJX910 DTM

4.6.3 Start EJX910 DTM

(1) Start DTM Works

Select the icon of the target device for configur ation in the window.

Click the [Action] --> [Assign DTM]

4-20

Figure 4.18 Start DTM Works

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

F0427E.EPS

Page 44

<Toc> <Ind> <4. Preparation>

(2) Online Parameter windo w appears.

It may takes about one minute to open Online P arameter windo w .

F0428E.EPS

Figure 4. 19 Online P arameter Window

4-21

4.6.4 Save DTM Infomation

If “Sav e to file” is perf ormed, a device parameter snapshot is sav ed to an e xternal file-.dfs

file, which includes the following parameters .

• User Flow parameters

• Transmitter Flow parameters

• Transmitter General parameters

For a file f ormat of .dfs, refer to “File F ormat” of section 7.

This command is enabled while communication with a device is disconnected.

1. Clic k the [Device] --> [Disconnect] at DTM Works window.

2. Clic k the [File] --> [Sav e to file] at DTM W orks window .

3. Clic k the [OK] b utton.

Figure 4.20 Confirmation Message in Saving .dfs file

F0429E.EPS

4. Sav e .dfs file in the computer .

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 45

<T oc> <Ind> <4. Preparation>

NOTE

• .dfs file is not compatible among diff erent communication.

• .dfs file is not compatible among diff erent fr ame applications.

4.6.5 Exit FieldMate and DTM Works

DTM W orks and FieldMate are ended by closing each window.

1. Clic k the [File] --> [Exit] at DTM W orks window .

2. Clic k the [File] --> [Exit] at FieldMate window.

4.7 EJXMVT ool Activ ation

4.7.1 How to Activate

Start EJX910DTM. (see 4.6.3)

4-22

> Start DTM Works.

> Select [Device] --> [Additional Functions] --> [Flow Configuration Wizard]

• The f ollowing screen appears only when this prog ram is run for the first time .

Figure 4.21 EJXMVTool Activ ation Screen

Enter the EJXMVTool license number, and Click [Check and Sav e].

F0430E.EPS

NOTE

You must enter whole license number includeing ‘-’ .

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 46

<Toc> <Ind> <4. Preparation>

4-23

Figure 4.22 Software License Form

F0431E.EPS

Once the license number is confirmed, Flow Configuration Wizard screen belo w appears.

F0432E.EPS

Figure 4.23 T op Menu Screen of Flow Configuration Wizard

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 47

Blank Page

Page 48

<Toc> <Ind> <5. Operation Specification for EJX910A Configuration>

5. Operational Flow

Following is an e xample of configuration procedures using A uto Compensation Mode .

(A) New Configur ation (e xample f or using FieldMate project file)

(B) Configure with e xisting Configuration File (dfs file)

(C) Configure with existing Configuration File (example for using XMV file)

(D) Configure with existing Configuration File (import:XMV file, PRM file,export:dfs file)

(A) New Configur ation (Example of using Auto Compensation Mode)

5-1

Upload

parameters

1

from the

device

Perform

2

Flow

Configuration

Download

parameters

3

to the device

Confirm

flow

4

coefficient

Save

settings to

5

.dfs file

FieldMate

Menu

Assign DTM

DTM Works

Menu

Device

Device

Device

Device

Device

File

Sub MenuStep Sub Menu Procedure Description

Online Parameter

screen is opened

ParameterDevice

Upload from

1)

device

Additional

Functions

Download

to device

Additional

functions

Disconnect

Save to

file…

2)

Offline

Parameter

Flow

Configuration

Wizard

Obtain Flow

Coefficient

Initialize menu

Flow Configuration

Mode

Primary Element and

Pipe Setup

Fluid type Setup

Fluid Operating

Range Setup

Fluid Physical

Property Setup

Export -> XMV menu

Report

Apply

Open Offline Parameter

window.

Upload T ransmitter Flow

parameters and Transmitter

General parameters.

Edit T ransmitter General

parameters and Apply Offline

Database

Initialization(Needed only if

configuration has been done

before)

Edit User Flow parameters.

Select Auto Compensation

Mode

Export User Flow parameters

and Transmitter Flow parameters

Export the User flow parameters

in CSV file format.

Apply T ransmitter Flow

parameters to Offline Database

Download T ransmitter Flow

parameters and Transmitter

General parameters.

You can check th flow

coefficient. The v alue is sa v ed in

a log file: “Flo wCoeffLog”.

Goes offline

Save the XXXXXX.dfs

User Flow parameters,

Transmitter Flow parameters

and T ransmitter General

parameters.

T0501E.EPS

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 49

<T oc> <Ind> <5. Operation Specification for EJX910A Configuration>

1)Before starting operation, execute ‘Upload from de vice’, so that the general par ameters

of the transmitter in the offline database are synchronized with the device . Upload data

from the transmitter does not include User Flow Par ameters.

*: User Flow P arameters consist of primary device information, fluid information and

operating condition.

2)Executing ‘Download to de vice’ will write both Transmitter Flow Parameters and Transmit-

ter General Parameters into the de vice. Before executing ‘Download to device’, e x ecute

‘Upload from device’, so as to make the general par ameters of the transmitter in the

offline database synchronized with the device.

Download data to the transmitter does not include User Flow P arameters.

(B) Configure with e xisting configuration file (dfs file)

5-2

Step

Open Offline

1

Parameter

window.

Open .dfs file

and download

2

parameters

to the device

Confirm

flow

3

coefficient

FieldMate

Menu

Assign DTM

DTM Works

Menu

File

Device

Device

Device

Sub Menu Sub Menu Procedure Description

Online Parameter

screen is opened

DisconnectDevice

ParameterDevice

Load from

file…

Download

to device

Additional

functions

Disconnect

Offline

Parameter

1)

Obtain Flow

Coefficient

Goes offline

Open Offline Parameter

window.

Load the XXXXXX.dfs

User Flow parameters,

Transmitter Flow parameters

and T ransmitter General

parameters.

Edit T ransmitter General

parameters and Apply to

Offline Database

Goes onlineConnectDevice

Download T ransmitter Flow

parameters and Transmitter

General parameters.

You can check th flow coefficient.

The value is saved in a log file:

“FlowCoeffLog”.

Goes offline

T0502E.EPS

1)Before starting operation, execute ‘Upload from de vice’, so that the general par ameters

of the transmitter in the offline database are synchronized with the device. Upload data

from the transmitter does not include User Flow P arameters.

*: User Flow P arameters consist of primary device information, fluid inf ormation and

operating condition.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 50

<Toc> <Ind> <5. Operation Specification for EJX910A Configuration>

(C) Configure with existing Configuration File (XMV file)

5-3

Step

Upload

parameters

1

from the

device

Import Xmv

file and modify

2

flow

configuration

Download

3

parameters

Confirm

flow

4

coefficient

FieldMate

Menu

Assign DTM

DTM Works

Menu

Device

Device

Device

Device

Device

Sub Menu Sub Menu Procedure Description

Online Parameter

screen is opened

ParameterDevice

Upload from

1)

device

Additional

functions

Download

to device

Additional

functions

Disconnect

2)

Offline

Parameter

Flow

Configuration

Wizard

Obtain Flow

Coefficient

Import ->Import XMV

Flow Configuration

Mode

Primary Element and

Pipe setup

Fluid type setup

Fluid Operating

Range setup

Fluid Physical

property setup

Apply

Open Offline Parameter

window.

Upload T ransmitter Flow

parameters and Transmitter

General parameters.

Edit T ransmitter General

parameters and Apply to

Offline Database

Specify the target Flow Config

file “XXXXXX.xmv”

Import User Flow parameters,

Transmitter Flow parameters.

Confirm User Flow parameters.

Apply T ransmitter Flow

parameters to Offline Database

Download T ransmitter Flow

parameters and Transmitter

General parameters.

You can check th flow coefficient.

The value is saved in a log file:

“FlowCoeffLog”.

Goes offline

T0503E.EPS

1) Before starting operation, execute ‘Upload from device’, so that the gener al parameters

of the transmitter in the offline database are synchronized with the de vice.

Upload data from the transmitter does not include User Flow P arameters .*

*: User Flow Par ameters consist of primary device information, fluid information and

operating condition.

2) Executing ‘Download to de vice’ will write both Transmitter Flow P arameters and Transmit-

ter General Par ameters into the de vice. Bef ore e x ecuting ‘Download to device’, e xecute

‘Upload from device’, so as to make the general par ameters of the transmitter in the

offline database synchronized with the device.

Download data to transmitter does not include User Flow P ar ameters.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 51

<T oc> <Ind> <5. Operation Specification for EJX910A Configuration>

(D) Configure with existing Configuration File (import:XMV and PRM file,export:dfs file)

Applicable only f or FSA210 user .

5-4

Step

Upload

parameters

1

from the

device

Import existing

file and

cofirm/modify

2

flow

configuration

Download

3

parameters

Confirm

flow

4

coefficient

Save

parameters

5

to .dfs file

FieldMate

Menu

Assign DTM

DTM Works

Menu

Device

Device

Device

Device

Device

File

Sub Menu Sub Menu Procedure Description

Online Parameter is

open

ParameterDevice

Upload from

1)

device

Additional

functions

Download

to device

Additional

functions

Disconnect

Save to

file…

2)

Offline

Parameter

Flow

Configuration

Wizard

Obtain Flow

Coefficient

Import ->Import XMV

Import ->Import PRM

(HARTonly)

Flow Configuration

Mode

Primary Element and

Pipe setup

Fluid type setup

Fluid Operating

Range setup

Fluid Physical

property setup

Apply

Open Offline Parameter

window.

Upload T ransmitter Flow

parameters and Transmitter

General parameters.

Specify the target Flow Config

file “XXXXXX.xmv”

Import User Flow parameters,

Transmitter Flow parameters.

“XXXXXX.prm” to be edited.

HART Transmitter General

parameters.(FSA210 user only)

Confirm User Flow parameters.

Apply T ransmitter Flow

parameters to Offline Database

Download T ransmitter Flow

parameters and Transmitter

General parameters.

If required, you can check th flow

coefficient. The value is saved in

a log file: “Flo wCoeffLog”.

Goes offline

Save the XXXXXX.dfs

User Flow parameters,

Transmitter Flow parameters

and T ransmitter General

parameters.

T0504E.EPS

1)Before starting operation, execute ‘Upload from de vice’, so that the general par ameters

of the transmitter in the offline database are synchronized with the device .

Upload data from the transmitter does not include User Flow Par ameters.*

*: User Flow P arameters consist of primary device information, fluid inf ormation and

operating condition.

2)Executing ‘Download to de vice’ will write both Transmitter Flow P arameters and Transmit-

ter General Parameters into the de vice. Before executing ‘Download to device’, execute

‘Upload from device’, so as to make the gener al parameters of the transmitter in the

offline database synchronized with the device.

Download data to transmitter does not include User Flow P arameters.

All Rights Reserved Copyright © 2006, Yokogawa Electric Corporation IM 01C25R51-01E

Page 52

<Toc> <Ind> <6. Displa y Specification >

6. Display Specification

Following sho ws a main items in the menu, e xcluding the items specific to FieldMate.

NOTE

Displayed items ma y slightly diff er according to communication protocol.

(1) Menu and Function (Example of HART)

Connect

Disconnect

Upload from device

Download to device

Parameter

Device

(EJX

Additional

910)

functions

Delete device

Print

Properties

Menu Submenu Functions

Load from a

transmitter.

Store to a transmitter.

Offline Parameter

Online Parameter

Calculate flow

configuration data of a

transmitter.

Initialization (Needed

only if configuration

has been done before)

Flow configuration file

management

Flow configuration

report file

EJXMVTool

Instruction Manual

Version information

Obtain Flow coefficient

from T ransmitter

EJXMVTool

Instruction Manual

Version information

Flow

Configuration

Wizard

Obtain Flow

Coefficient

Initialize

Import

Export