Page 1

Instruction

Manual

Model FF20

Flow fittings

Model FS20

Subassembly flow fittings

IM 12B6K1-01E-E

7th edition

Page 2

1. INTRODUCTION .........................................................................................................1

1-1. General ...............................................................................................................1

1-2. Features ..............................................................................................................1

2. UNPACKING AND CHECKING ..................................................................................1

2-1. Unpacking and inspection ...................................................................................1

2-2. Mounting location ...............................................................................................1

2-3. Specifications ......................................................................................................2

2-3-1. General specifications ..............................................................................2

2-3-2. Functional specifications...........................................................................3

2-4. Model and codes ................................................................................................4

2-4-1. Flow fittings ..............................................................................................4

2-4-2. Subassemblies ......................................................................................... 5

2-5. Dimensions .........................................................................................................6

2-5-1. Fittings .....................................................................................................6

2-5-2. Subassemblies ......................................................................................... 7

3. PIPING AND INSTALLATION .....................................................................................8

3-1. General ...............................................................................................................8

3-2. Piping ..................................................................................................................8

3-2-1. Mounting in a sample line .........................................................................8

3-2-2. Mounting in a shunt line ...........................................................................8

3-2-3. Mounting in a sample line with extra connection for liquid cleanser ..........9

3-3. Installation ...........................................................................................................9

3-3-1. Mounting for fitting ...................................................................................9

3-3-2 Mounting the subassembly .....................................................................10

3-4. Sensor mounting ...............................................................................................10

3-4-1. General ..................................................................................................10

3-4-2. Mounting in a 1-hole design ...................................................................11

3-4-2. Mounting in a 3- and 4-hole design ........................................................11

4. ACCESSORIES..........................................................................................................11

4-1. General .............................................................................................................11

4-2. Mounting kit for BELLOMATIC electrodes .........................................................11

4-3. Mounting kit for sterilisable applicaitons ............................................................12

4-4. Mounting kit for top refillable electrodes ............................................................ 13

4-5. Cleaning systems ..............................................................................................13

4-5-1. General ..................................................................................................13

4-5-2. Selection criteria ..................................................................................... 14

4-5-3. Mechanical cleaning ...............................................................................14

4-5-4. Chemical cleaning ..................................................................................15

4-6. Salt bridge ........................................................................................................16

5. MAINTENANCE .........................................................................................................17

5-1. General .............................................................................................................17

5-2. Cleaning ............................................................................................................17

5-3. Calibration .........................................................................................................18

5-4. Replacing the O-rings .......................................................................................18

6. EXPLODED VIEW ......................................................................................................19

7. SPARE PARTS LIST .................................................................................................21

IM 12B6K1-01E-E

Page 3

1

1. INTRODUCTION

1-1. General

The flow fittings (Model FF20) and their subassemblies (Model FS20) are used to mount

sensor tips in a piping system so that the pH and/or the ORP (Redox) potential of the liquid

flowing through it can be measured.

The flow fittings are for connection between two pipes of the piping system providing a

“flow through” path. From a practical plant aspect (for easy maintenance and calibration)

the mounting place is in a by-pass behind a sample valve. They are supplied with a ring to

hold calibration dish for this cleaning and/or calibration.

The subassemblies should be cemented or welded direct in the piping system or in a

T-piece of it. The subassemblies of stainless steel meet the requirements of DIN 11850

for mounting in sanitary constructions.

1-2. Features

- Wide choice fo construction materials.

- High degree fo standardisation reduces spare holding requirements.

- Direct mounting of sensors with DIN dimensions.

- Liquid earth sensor for stable measurements.

- High pressure and temperature specifications.

- Chemical or brush cleaning (optional in 4-hole fittings).

2. UNPACKING AND CHECKING

2-1. Unpacking and inspection

When you receive the flow fitting (Model FF20) or the subassembly flow fitting (Model FS20)

it is packed in a cardboard box. Open the box and check that the model code is the same

as on the packing list (see §2-3 for the model code). Also check that it is supplied with the

options you ordered. These options are delivered in seperate bags.

If you have any problems or questions, please contact the nearest Yokogawa service center

or sales organisation for assistance.

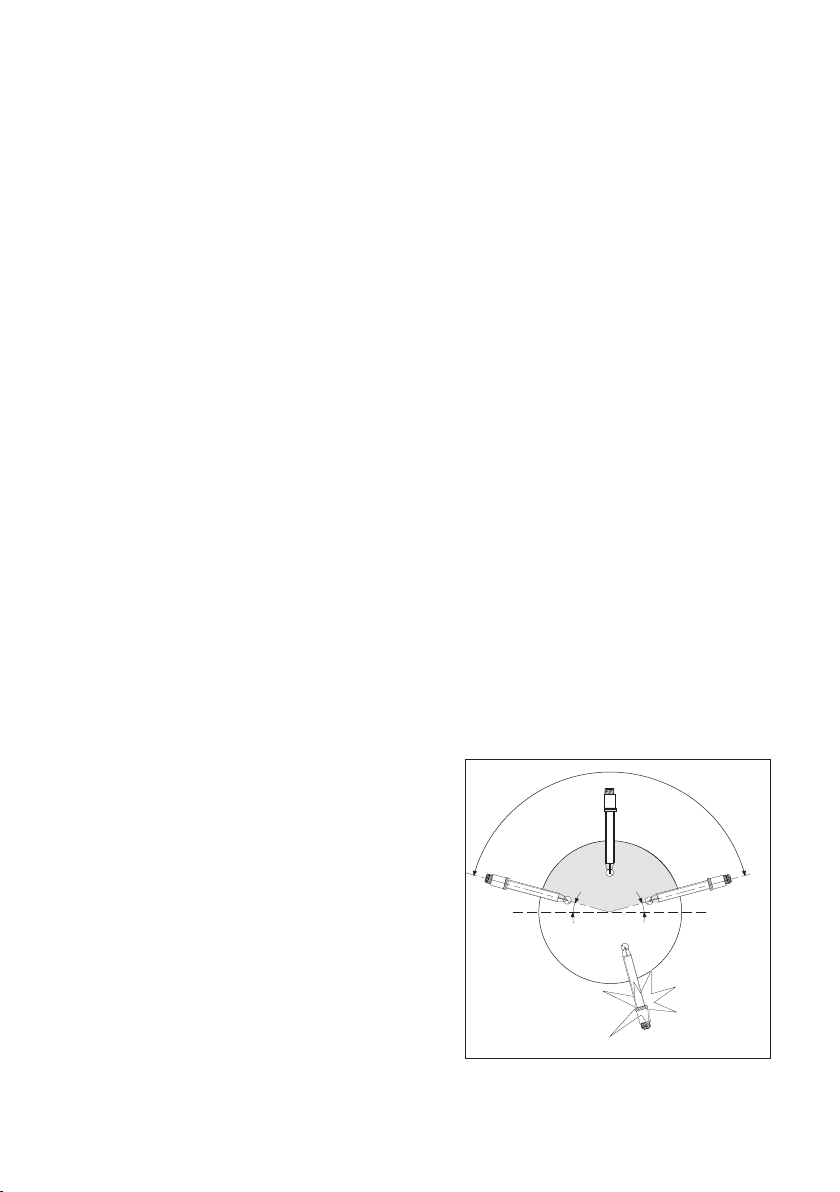

2-2. Mounting location

The flow fitting or subassembly flow fitting

is intended to be used for pH and/or ORP

(Redox) measurement. The location should

be in a bypass of a piping system behind a

GO O D

sample valve. The angle of the fitting with the

horizontal should be less than 15°

(see fig. 2-1).

The pressure and temperature ratings of the

electrode inside the fitting should be noticed

to determine the maximum rating of the

measurement point.

Figure 2-1

GO O D

HO R IZ ON TAL

15 º

15 º

INC OR RE CT

IM 12B6K1-01E-E

Page 4

2

2-3. Specificaitons

2-3-1. General specifications

MATERIALS

- Wetted parts

a. body : refer to model code

b. O-rings : silicon rubber

c. liquid earth sensor

(not in 1-hole subassembly) : titanium (plastic designs) SS AISI 316 (SS designs)

- Non-wetted parts

a. mounting bracket : SS AISI 316 (SS designs) PVC

(plastic designs)

b. electrode mounting sets : Ryton R4

c. holder for calibration dish : SS AISI 316

d. calibration dish : PP

e. retaining nut for electrode holder : SS AISI 304

VOLUME MEASURING VESSEL

- 3-hole design : 130 ml

- 4-hole design : 250 ml

PROCESS CONNECTIONS : 1/2” NPT or flange LAP-joint (DIN or ANSI).

(fittings only) See model code.

NOMINAL PIPE SIZE FOR MOUNTING SUBASSEMBLIES

- 1-hole : DN20

- 3-hole : DN50

- 4-hole : DN80

WEIGHT* : see table:

Tabel 2-1

Material PP SS PVC PVDF

Fitting

1-hole subassembly 0,2 kg 0,1 kg

3-hole subassembly 1,2 kg 0,5 kg

4-hole subassembly 3 kg 1,4 kg

3-hole fitting 1,1 kg 2,2 kg 1,5 kg

4-hole fitting 1,4 kg 6,5 kg 1,8 kg

* The accessories are not included.

IM 12B6K1-01E-E

Page 5

2-3-2. Funcitonal specifications

TEMPERATURE

- min -10 °C

- max depending on material and application (see fig. 2-2)

FLOW RATE (fittings only) : 0,1 to 10 1/min (depending on applicaiton)

PRESSURE

bar

12

10

8

6

4

2

0 10 20 30 40 50 60 70 80 100 120 140 160

Figure 2-2. Pressure/temperature class

PVC

PP

AISI 316

PVDF

3

IM 12B6K1-01E-E

Page 6

4

2-4. Model and codes

2-4-1. Fittings

Model Suffix Option Description

Code Code

FF20 Flow fitting

Material -P Polypropylene (PP)

-S Stainless steel AISI 316 (SS)

-F Polyvinylidenefluoride (PVDF)

Number 22 For PH20

of holes 33 3 electrode mounting holes

43 4 electrode mounting holes

*B Style code B

Options /HCN2 FF20- .22

-Cleaning system /HCN3 FF20- .33

/HCN4 FF20- .43

Options /B For mounting Bellomatic reference electrodes

-Mounting kit

-Flange adapters /FP1 DN15-PN10 PP

(NPT 1/2" male lap joint) /FP2 DN25-PN10 PP

-KCl-reservoir /K Electrolyte tubing (2.5 m) is included.

-Salt bridge /S For liquid which cannot stand contamination

-Certificate /M Material certificate 3.1 according to EN 10204

/R For mounting (top) refillable electrodes

with long glass shaft.

/FP3 1/2" 150 lbs PP

/FP4 1" 150 lbs PP

/FF1 DN15-PN10 PVDF

/FF2 DN25-PN10 PVDF

/FF3 1/2" 150 lbs PVDF

/FF4 1" 150 lbs PVDF

/FS1 DN15-PN10 SS 316

/FS2 DN25-PN10 SS 316

/FS3 1/2" 150 lbs SS 316

/FS4 1" 150 lbs SS 316

with KCl.

for wetted metal parts only

IM 12B6K1-01E-E

Page 7

2-4-2. Subassemblies (flow fittings)

Model Suffix Option Description

Code Code

FS20 Subassembly (Flow fitting)

Material -V Polyvinylchloride (PVC)

-P Polypropylene (PP)

-S Stainless steel AISI 316 (SS)

-F Polyvinylidenefluoride (PVDF)

Number 12 1 electrode mounting holes (only V,S)

of holes 22 For PH20

32 3 electrode mounting holes

43 4 electrode mounting holes (only V,S)

Mounting -WE Welding end: Type, S12, S22,S32, S43

Glue for PVC: Type V12, V22, V32, V43

Heat welding: Type F22, F32, P22, P32

-TP Tapered pipe thread (2"NPT acc. ANSI B.20.1).

(for 2 and 3 holes version, and not in case of

type V22 and V32)

Options /HCN2 FS20- .22

-Cleaningsystem /HCN3 FS20- .32

/HCN4 FS20- .43

Options /B For mounting Bellomatic reference electrodes

-Mounting kit and combined electrodes.

/R For mounting (top) refillable electrodes

with long glass shaft.

-KCl-reservoir /K Electrolyte tubing (2.5 m) is included.

-Salt bridge /S For liquid which cannot stand contamination

with KCl.

-Certificate /M Material certificate 3.1 according to EN 10204

for wetted metal parts only

5

IM 12B6K1-01E-E

Page 8

6

2-5. DIMENSIONS

2-5-1. Flow Fittings

PP/PVDF

FF20-P22

FF20-F22

PP/PVDF

FF20-P33

FF20-F33

Ø71 (2. 80 ")

Ø71 (2.80 ")

1/2" NPT

Ø 9 2

(3.62")

1/2" NPT

1/2" NPT

1/2" NPT

IN

IN

OUT

60 (2. 36")

OUT

60 (2. 36")

Ø 8 (0,31 ")

Ø 90

(3.54")

(3.54 ")

5 (2.1 6")

Ø8 (0.31 ")

Ø 9 0

SS

52 [2.05"]

255 [10.04"]

6,5 (1.43" )

76 (10 .82" )

3

2

71 [2.80"]

½"NPT

Outlet

17.5 [0.69"]

67 [2.64"]

70.3 [2.77"]

5

½" NPT inlet

=

=

76 [2.99]

175 [6.89"]

48 [1.89"]

3x59 [50.35"]

FF20-S22

SS

71 [2.80"]

205 [8.07"]

15 + 3 (8 .46" + 0.12 ")

6,5 (1.4 3 ")

2

3

5 (2. 16")

5

67 [2.64"]

½" NPT inlet

=

=

175 [6.89"]

48 [1.89"]

76 [2.99"]

52 [2.05"]

½"NPT

Outlet

17.5 [0.69"]

FF20-S33

PP/PVDF

Ø90 (3.54")

320 (12. 6")

FF20-P43

FF20-F43

IM 12B6K1-01E-E

230 (9.0 5")

280 (11.02")

1/2"NPT

130 (5.11")

SS

150 (5.90")

1/2"NPT

1/2"NPT

4XØ 12 ( 0.47" )

70 (2 .75")

225 ( 8.86 ")

OUT

Ø90 (3.54")

")

4XØ12 (0.47

OUT

90 (3.54")

20 ( 4.72 ")

90 ( 3.54 ")

1

15 (4.52")

1

1/2"NPT

157 (0.18")

IN

80 (3 .15")

IN

265 (10.43")

Distance wall-outlet: 85 (3.35”)

FF20-S43

Page 9

160 (6.30")

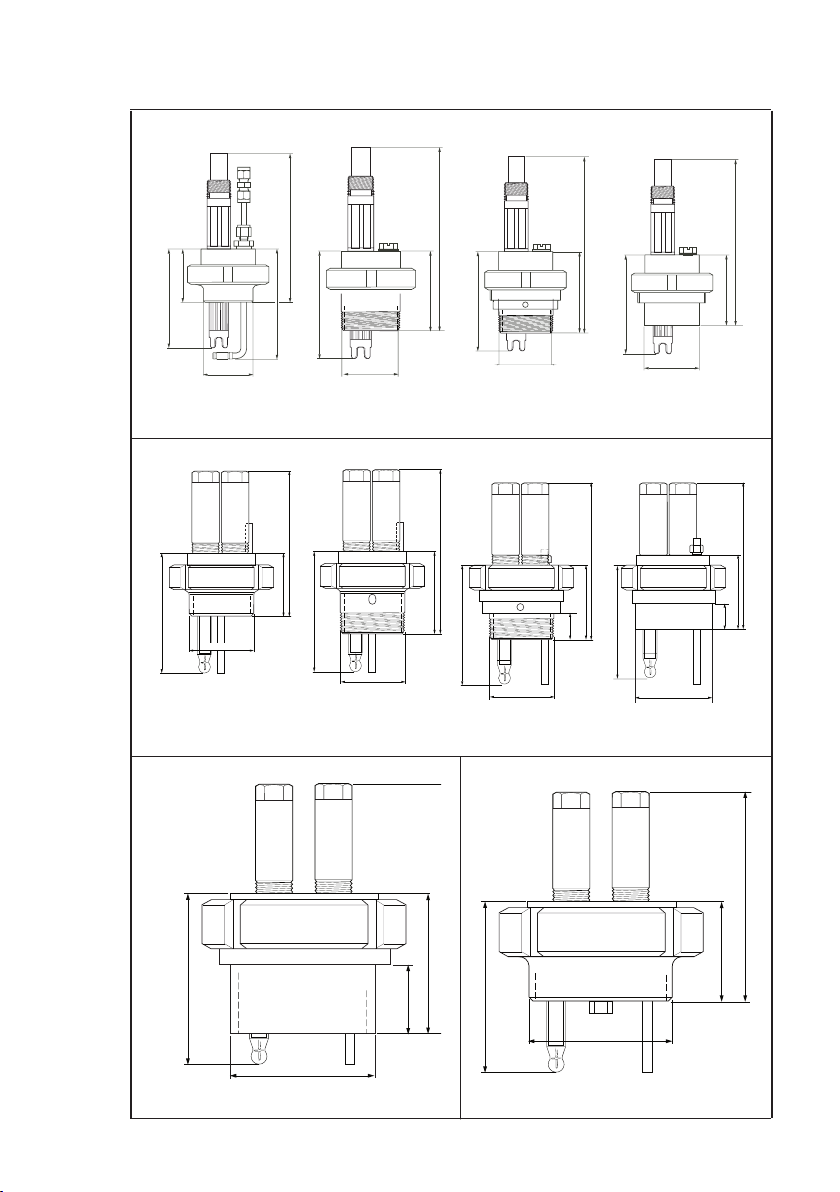

2-5-2. Subassamblies

SS SS PP/PVDF PP/PVC/PVDF

169 (6.65")

60 (2.36")

112 (4.41")

Ø56 (2.20")

124(4.88")

112 (4.41")

2-11,5NPT

ANSI B.20.1

FS20-S22-WE FS20-S22-TP

190(7.48")

82(3.23")

112(4.41")

2-11.5 NPT

ANSI

FS20-P22-TP

FS20-F22-TP

200(7.87")

92(3.62")

112 (4.41")

B.21.1

SS SS PP/PVDF PP/PVC/PVDF

124 (4.88")

53 (2.08")

105 (4.13")

Ø 56 (2.20")

105 (4.13")

2-11,5 NPT

ANSI B.20.1

FS20-S32-WE FS20-S32-TP

PVC

146 (5.75")

75 (2.95")

105 (4.13")

FS20-P32-TP

FS20-F32-TP

2-11,5 NPT

ANSI B.20.1

138 (5.43")

70 (2.75")

27

105

SS

Ø 63 (2.48")

FS20-P22-WE

FS20-V22-WE

FS20-F22-WE

Ø 63 (2.48")

FS20-P32-WE

FS20-V32-WE

FS20-F32-WE

189(7,44")

81.5(3.21")

136 (5.35")

66 (2.60")

26 (1.02")

105 (4.13")

89 (3.50")

45 (1.77")

106 (4.17")

Ø 88 (3 .46")

Ø 90 (3 .54")

FS20-V43-WE FS20-S43-WE

IM 12B6K1-01E-E

129 (5.08")

58 (2.28")

Page 10

8

12B6K1-41

MOUNTING IN A

SHUNT LINE

12B6K1-40

MOUNTING IN A

SAMPLE LINE

3. PIPING AND INSTALLATION

3-1. General

It is important that, whatever method of mounting is used, the point of measurment is

truly representative of the entrie solution. Avoid an area where the measurement varies

significantly or the flow can be interrupted (the sensors must always be immersed in the

process liquid). The recommended type of fitting or subassembly will depend on pressure,

temperature, kind of liquid, pollution, etc. Check whether the specifications of the fitting/

subassembly and electrodes fulfil the maximum occuring process conditions. The fitting/

suassembly has several options and optional connection possibilities. Check that you

received the correct size and type.

3-2. Piping

3-2-1. Mounting in a sample line

Part of the process liquid is tapped off to

PROCESS PIPING

the flow fitting or subassembly (see fig. 3-1)

DRAIN

.

Figure 3-1

3-2-2. Mounting in a shunt line

By means of restrictor in the main line a small flow of the process liquid is lead through

the flow fitting or subassembly via the shunt line (see fig. 3-2). The pressure in the fitting or

subassembly is controlled by means of two valves.

RESTRICTOR

P1

PROCESS PIPING

P2

P2 < P1

Figure 3-2

IM 12B6K1-01E-E

Page 11

3-2-3. Mounting in a sample line with extra connection for buffer liquid/cleanser

12B6K1-42

MOUNTING IN A

SAMPLE LINE

+CONNECT. FOR

BUFFER...

12B6K1-44

MOUNTING THE FITTING

12B6K1-43

MOUNTING THE FITTING

12B6K1-45

LOCKING SCREWS

The sample line has an extra input for cleaning or calibration (see fig. 3-3).

PROCESS PIPING

9

buffer

liquid

cleaner

Figure 3-3

3-3. Installation

3-3-1. Mounting the fitting

Install the fitting at a convenient location for maintenance and calibration.

Ensure that there is some place at the top of the fitting (approx. 20 cm) for mounting or

replacing the electrodes.

Mounting the fitting in a piping system is shown in fig. 3-4.

Refer to §2-4 for dimensional drawings.

DRAIN

Figure 3-4 Figure 3-5

NOTE: The process connection (liquid outlet) can be turned from right to left.

1. The plastic fittings have locking screws for the holder of the calibration dish

(see fig. 3-5). These screws must be loosened before turning.

2. The liquid outlet of the stainless steel fittings can be turned after loosening from the

mounting bracket (see exploded view at the end of this manual).

IM 12B6K1-01E-E

Page 12

10

3-3-2. Mounting the subassembly

The subassembly can be cemented or welded directly in a piping system or in a T-piece of

it. Install the subassembly at a convenient location for maintenance and calibration.

Ensure that there is some place at the top of the fitting (approx. 20 cm) for mounting or

replacing electrodes.

Fig. 3-6 shows some mounting examples. Select the mounting position so that the sensors

are immersed in the process liquid during measurement.

(Model WU20) should be used (see fig. 3-7).

GLUE

GLUE

GLUE

3-hole (DN50)

4-hole (DN80)

PVC

Figure 3-6

3-4. Sensor mounting

3-4-1. General

For stable measurement the glass- and the reference electrode should be mounted in the

holes nearest to the earth connection.

When mounting sensors of Yokogawa in a fitting or subassembly the electrode cables

(Model WU20) should be used (see fig. 3-7).

screening

TRIAX-cable (model WU20-LT) for combined electrode

colour

marker

Cable nut

10 cm

COAX-cable (model WU20-PC) for single electrode

colour

marker

colour

colour

outer

marker

inner

marker

screening

core red

white

core red

blue

Figure 3-7

IM 12B6K1-01E-E

Cable nut

10 cm

screen

blue

Page 13

3-4-2. Mounting in a 1-hole design

12B6K1-21

1-HOLE MOUNTING

12B6K1-22

MOUNTING IN A 3- AND

4-HOLE DESIGN

Unscrew the electrode mounting set and fix the

cable and electrode as shown in fig. 3-8.

3-4-3. Mounting in a 3- and 4-hole design

Unscrew the nut from the top end of the fitting

or subassembly. Fix the electrodes and cables

as shown in fig. 3-9.

Note: In the holes for placing the electrodes are

blanking plugs (stoppers). These plugs

can be placed in unused holes after

pushing the two O-rings over the bottom

end.

ATTENTION

To prevent fouling of the contact new

Yokogawa electrodes are delivered with a cap.

It is recommended to remove the cap just

before fixing the cable.

ENSURE THAT THERE IS NO MOISTURE OR

DUST IN THE PLUG

Figure 3-8 Figure 3-9

11

4. ACCESSORIES

4-1. General

For mounting the non-DIN sized sensors in the

fittings and subassemblies Yokogawa added a

range of accessories to the program of fittings

which can be indespensable tools for optional

measuring tools (the specifications of the

accessories are on seperate sheets, see GS

12B6J1-E-E).

See the chapters below for mounting the

accessories.

4-2. Mounting kit for BELLOMATIC

electrodes (Model FP20-S13)

Using this mounting kit a BELLOMATIC

electrode of Yokogawa can be fixed in a fitting

or subassembly (see fig. 4-1).

This mounting kit can also be used for fixing

combined electrodes.

Figure 4-1

Electrode

Ring

Ring

O-rings

(11 X 3)

IM 12B6K1-01E-E

Page 14

12

RECOMMENDED ELECTRODES1)

TYPE DESCRIPTION

SR20-AC32 Reference electrode

SC29-PTC542) Combined redox/ref. electrode

1

) For specifications of the electrodes see GS 12B6J1

2

) Atmospheric conditions only

PARTS AND ACCESSORIES

ORDER NR. DESCRIPTION

K1500HC Set rubber ring (10x)

K1500GE Set O-rings (5x) for BELLOMATIC electrode

K1500GF

K1520VA

K1500GG

K1520VN

250 ml KCI-solution (1 m.)

250 ml KCI-solution (3,3 m.)

250 ml KCI-solution (1 m.) thickend

250 ml KCI-solution, (3,3 m.) thickend

4-3. Mounting kit for sterilisable

applications (Model FP20-S14)

To assure sterilisable applications and a

constant flow of electrolyte this mounting kit

can be used for fixing combined electrodes

with a large KCI-reservoir (see fig. 4-2).

For pressurising the system there is a 1/8”

nipple for connecting to each standard

pump. The pressure inside the holder may

never exceed the specifications of the

electrodes. See GS 12B6J1 for these

specifications.

Tape

ELECTRODES TO BE USED1)

TYPE DESCRIPTION

SC21-AAC54 Combined pH/ref.

electrode

O-rings

(K1500GS)

SC29-PTC54 Combined redox/ref.

electrode

1) For specifications see general

specifications sheet GS 12B6J1.

PARTS AND ACCESSORIES

ORDER NR. DESCRIPTION

K1500GS Set O-rings

K1520VN 250 ml KCI-solution,

(3,3 m.) thickend

Figure 4-2

IM 12B6K1-01E-E

Electrode

O-rings (11x3)

(K1500BZ)

Page 15

4-4. Mounting kit for refillable ref.

KCI-reservoire

(K1500FU)

Silicone tubing

(K1500GA)

O-rings

(11 x 3

(K1500BZ)

)

electrodes

This mounting kit replaces the standard

electrode mouting set so that elctrodes of

Yokogawa with a long glass shaft can be fixed

in the fitting or subassembly (see fig. 4-3). This

mounting kit may be used as process pressure

up to 3 bar. Higher pressure ratings require

the standard mounting set for electrodes with

DIN dimensions or, alternately a salt bridge

(see §4-5). The refillable electrodes can be

connected to a KCI-reservoir via a silicone

tubing (see fig. 4-3). The pressure on the KCIsolution and consequently, the liquid outlet

can be increased by mounting the reservoir

above the fitting or subassembly. This prevents

penetration of the process liquid into the

electrode.

Note: The pressure on the KCI-solution must

exceed the liquid pressure. Figure 4-3

In §7 you will find the spareparts

4-5. Cleaning systems

4-5-1. General

The standardised design of the fittings and subassemblies makes it possible to mount

cleaning systems directly. The 4-hole types are especially designed for these applications.

13

Three different types of cleaning systems are available (see fig. 4-4):

- mechanical cleaning (electrically or mechanically driven)

- chemical cleaning

Detailed specifications of the cleaning systems are on seperate sheets

(see GS 12B6V1-E-E).

Figure 4-4

brush cleaning

chemical cleaning

IM 12B6K1-01E-E

Page 16

14

12B6K1-39

SELECTION CRITERIA

K1547PP

O-rings

(11x3)

K1500BZ

4-5-2. Selection criteria

cleaning system mechanical chemical acoustical

brush acid base emulsifier ultra sonic

Applications:

oils fats x x

resins (wood, pulp) x x

emulsions of latex x

fibers (paper, textile) x

crystalline precipations

(carbonates) x xx x

amorpheus precipations x xx x

4-5-3. Mechanical cleaning

The brush of this cleaning system periodically strikes along the sensitive glass membrane

of the electrode, so that this part is wiped frequently preventing sediment formation on it.

Electrically or pneumatically versions are available.

Electrically driven brush cleaning (Model FC20-VE). Figure 4-5 shows the mounting.

PARTS AND ACCESSORIES

ORDER NR. DESCRIPTION

WU20-PC Cable (to be used as a

K1520NG Brush holder

K1520NB Brush

supply cable for the motor)

K1520NF Motor unit

Figure 4-5

IM 12B6K1-01E-E

Motor

O-rings (11x 3

(K1500BZ)

Brush holder

)

Cable

WU20

Page 17

Pneumatically driven brush cleaning

12B6K1-27

PNEUMATICAL CLEANING

(Model FC20-VP)

CONTROL

UNIT

PARTS AND ACCESSORIES

ORDER NR. DESCRIPTION

K1520NA Tubing (ø4 mm)

TUBING

K1520NA

K1520NG Brush holder

K1520NB Brush

K1520NG Protection hose

K1520NH Piston

K1520NJ Control unit

PISTON

O-RING (11x 3)

BRUSH HOLDER

Figure 4-6 Example FC20-VP

4-5-4. Chemical cleaning HCN.

The chemical cleaning system is effective in

processes where deposits can be removed

by a suitable solvent. Good cleaning effects

can be obtained from periodically spraying of

an electrode. EXA has a built-in wash timer

with programmable washtime, interval time

and relaxation time for automatic cleaning

of the electrodes, preventing pollution of

the pH sensitive parts. After washing, it is

possible to check the response time of the

electrodes. A built-in (no return) nozzle in

the spray unit prevents penetration of the

process liquid in the cleaning system. The

standardised dimensions allow mounting in

O-rings

(11x3)

K1500BZ

all flow-, insertion- and immersion fittings of

Yokogawa as well as back-end mounting

on the 4-in-one pH/Redox electrodes, like

FU20.

PROTECTION

HOSE

K1520NC

15

Features

• The EXA analyzer has a built-in timer and

HOLD circuit.

• Built-in (no return) nozzle to prevent

penetration of the process liquid into the

cleaning system.

Figure 4-7 Example HCN4

K1547PP

(spare tubing, EPDM)

IM 12B6K1-01E-E

Page 18

16

Specifications

Materials

Nozzle : Hastelloy

O-rings : EPDM rubber

Mounting set : Stainless steel

Tubing : 1/4” (OD Ø) Nylon tubing

Process cond. : Max. 1 MPa (10 bar) at 100 ºC

Mounting

K1547PA : /HCN2, 2-hole flow-, insertion fitting (PH20)

K1547PA : /HCN3, 3-hole flow-, insertion-, immersion fitting

K1547PB : /HCN4, 4-hole flow-, insertion-, immersion fitting

K1547PJ : /HCNF, back-end mounting on FU20/PH20

4-5. Salt bridge

(Model SB20-VP, VC and VS)

This reference electrode/salt bridge

combination allows pH and ORP(Redox)

measurement with the normal electrodes in

those cases when:

a. excessive contamination of the ceramic

flow diaphragm is expected

- the flow of the reference liquid

through the diaphragm is increased

by pressurising the container.

Consequently, the contamination rate will

decrease.

b. the process to be measured cannot stand

the contamination with KCl

- the salt bridge can be filled with several

electrolytes.

c. measurements have to be performed at

pressures up to 10 bar and temperatures

up to 100 °C

- the container with reference liquid can

be pressurised.

FLOW TUBE (A)

Material : glass

Flow diaphragm : ceramic, PTFE or sleeve

Connector : Ryton R4

TUBING (B)

Material : nylon

Diameter : 1/4” o.d.

Length : 2 mtr.

CONTAINER (C)

Container : PVC, PVC (transparent)

Electrode

mounting set : Ryton R4

“O” ring : silicone

Figure 4-8

65

C

Ø 17

Ø 12

Figure 4-9

A

Reference

Electrode

B

Ø 1/4”

39

120

Ø 75

166

Ø 75

IM 12B6K1-01E-E

Page 19

17

Connection : nylon

Weight : approx. 300 g.

Mounting : wall mounting (support with hole for screw M5)

Temperature/

pressure ratio : max. 200 kPa (2 bar) at 100°C

Notes:

1. The dimensions of the flow tube equal to those of standard electrodes

2. The standard reference electrodes can be mounted in the container

3. To observe the electrolyte level, the container is made of PVC.

For mounting instructions see fig. 4-9

PARTS AND ACCESSORIES

ORDER NR. DESCRIPTION

K1500BW Flow tube with ceramic diaphragm

K1500EE Flow tube with PTFE diaphragm

K1500EF Flow tube with sleeve diaphragm

K1520VA Electrolyte 3.3M KCl (250 ml)

K1520VN Thickened electrolyte 3.3M KCl (250 ml)

K1500GF Electrolyte 1M KCl (250 ml)

K1500GG Thickened electrolyte 1M KCl (250 ml)

5. MAINTENANCE

5-1 General

Before the electrodes can be serviced, the electrode holder should be physically separated

from the process. The fittings can be changed from the measuring position in the

maintenance position by following the reversed procedures described in §4.

5-2. Cleaning

Cleaning the fitting

When process liquid contains slurry which intends to settle in the fitting regularly, the

electrode holder must be removed for cleaning.

Cleaning the electrodes

When the sensitivity of the electrode has decreased or the response has slowed down,

the electrode should be cleaned. The 3- and 4-hole fittings are provided with a calibration

ring with a set of beakers. The electrode holder complete with electrodes and liquid earth

sensor can be placed on the ring for cleaning.

If cleaning with hot water is not sufficient, more aggressive water based agents should be

used.

- Deposits of limes, hydroxides or carbonates can be removed by immersing the electrode

in a solution containing diluted hydrochloric acid. Afterwards rinse the electrode with

water.

- Deposits of oil and fat can be removed with hot water in conjunction with a detergent.

When the results are unsatisfactory a mild (carbonate based) abrasive can be used.

- Protein (albuminous) deposits should be removed with a protein enzymatic solution. For

instance a solution containing 8.5 ml concentrated hydrochloric acid and 10 gr pepsin in

1 litre water.

IM 12B6K1-01E-E

Page 20

18

ATTENTION

Avoid using non-polar solvents like tri-chloro ethylene, toluene or hexane. Even cleaning

with ethanol or acetone is not recommended. These solvents will break up the gel-layer on

the glass bulb and afterwards needs to remain soaked in water for at least 12 hours before

functioning normal. The PTFE diaphragm of the combined electrode can sometimes be

regenerated by putting it in hot (60 to 80 °C) 1 molar Potassium chloride (KCl) solution and

letting it cool to room temperature. After cleaning the probe is re-inserted into the process

by following the reverse procedure (see §3-5).

5-3. Calibration

It is recommended to start calibration with clean electrodes. Always calibrate new

electrodes. With the electrodes connected to the transmitter a calibration can take place.

Check the appropriate chapters in the instruction manual of the pH transmitter for details.

General procedure for calibration

To calibrate a pH transmitter two buffer solutions with known pH value are required. It is

recommended that one buffer solution has a value near pH 7.

Depending on the liquid to be measured the second buffer solution should either be in the

acidic or base area. Normally the buffers pH 4.01 or 9.22 are used.

Generally the procedure for calibration is as follows:

- Clean the electrodes

- Rinse the electrodes

- Immerse the electrodes in the first buffer solution (pH 7)

- Adjust the asymmetry setting of the transmitter for reading a known value

- Rinse the electrodes

- Immerse the electrodes in the second buffer (pH 4 or pH 9)

- Adjust the slope setting of the transmitter for reading a known value

- Rinse the electrodes.

During calibration the temperature compensation should be active. It is advised top

calibrate with buffer solutions at a temperature near the process temperature.

5-4. Replacing the O-rings

The exploded view (see §6) shows the position of the sealing O-rings. The O-rings used

in the wetted part are made of silicone rubber, which has superior resistance to corrosion

suitable for use with most process liquids.

Usually no periodical inspection is necessary. To prevent trouble, replace the O-ring seal

periodically, e.g. every year.

IM 12B6K1-01E-E

Page 21

6. EXPLODED VIEW

12B6K1-31

ASSEMBLED FLOW

FF20-.33

12B6K1-32

ASSEMBLED FLOW

FF20-.43

12B6K1-33_New

ASSEMBLED FLOW

FF20-S33

12B6K1-34

ASSEMBLED FLOW

FF20-S43

19

FF20-.33

FF20-P22

FF20-F22

FF20-S33

FF20-.43

FF20-S22

FF20-S43

IM 12B6K1-01E-E

Page 22

20

12B6K1-21

1-HOLE MOUNTING

12B6K1-35

SUBASSY FLOW

FS20-.33

12B6K1-36

SUBASSY FLOW

FS20-.43

12B6K1-37

SUBASSY

FS20-S33

12B6K1-38

SUBASSY FLOW

FS20-S43

FS20-.12

FS20-S22

FS20-P22

FS20-F22

FS20-V22

FS20-S32 FS20-S43

FS20-.43FS20-.32

IM 12B6K1-01E-E

Page 23

SPARE PARTS

Accesoires

Part no. Description

K1500FU KCl reservoir PVC for F*20

SB20 Salt bridge

K1500BX Grommet for watertight cable input in PG 16 gland

(3 electrodes cables and liquid earth cable)

K1500BY Mounting kit for (top) refillable electrodes

K1547PA Complete hastelloy cleaning system /HCN2 and /HCN3

K1547PB Complete hastelloy cleaning system /HCN4

K1521AD Flange adapter /FS3

K1521AE Flange adapter /FF3

K1521AF Flange adapter /FP3

K1521AG Flange adapter /FS4

K1521AH Flange adapter /FF4

K1521AJ Flange adapter /FP4

K1521AK Flange adapter /FS1

K1521AL Flange adapter /FF1

K1521AM Flange adapter /FP1

K1521AN Flange adapter /FS2

K1521AP Flange adapter /FF2

K1521AQ Flange adapter /FP2

Consumable Parts

Part no. Description

K1520BA Buffer Solution Starters Kit: (3x 500 ml) Solutions pH 4.01 / 6.87 / 9.18

K1520BB Buffer Solution (3x 500 ml) pH 1.68

K1520BC Buffer Solution (3x 500 ml) pH 4.01

K1520BD Buffer Solution (3x 500 ml) pH 6.87

K1520BE Buffer Solution (3x 500 ml) pH 9.18

K1500GF 250 ml. KCl-solution (1 M)

K1520VA 250 ml. KCl-solution (3.3 M)

K1500GG 250 ml. KCl-solution (1 M), thickened

K1520VN 250 ml. KCl-solution (3.3 M), thickened

21

Cables

Part no. Description

K1500FV Liquid earth cable (10 m)

K1500DU Liquid earth cable (25 m)

WU20-PC02 COAX-cable (2 m) for single electrode

WU20-PC05 COAX-cable (5.5 m) for single electrode

WU20-PC10 COAX-cable (10 m) for single electrode

WU20-PC15 COAX-cable (15 m) for single electrode

WU20-PC20 COAX-cable (20 m) for single electrode

WU20-PC25 COAX-cable (25 m) for single electrode

WU20-LT02 TRIAX-cable (2 m) for combined electrode

WU20-LT05 TRIAX-cable (5.5 m) for combined electrode

WU20-LT10 TRIAX-cable (10 m) for combined electrode

WU20-LT15 TRIAX-cable (15 m) for combined electrode

WU20-LT20 TRIAX-cable (20 m) for combined electrode

WU20-LT25 TRIAX-cable (25 m) for combined electrode

IM 12B6K1-01E-E

Page 24

22

Spare parts FF20

Part no. Description

K1500BV O-rings EPDM 11x3 (6 Pcs.)

K1500BW Flow tube for SB20-VC

K1500BY Option /R for F*20.. (82850747)

K1500BZ O-rings Viton 11x3 (6Pcs)51250

K1500DU Liquid earth cable 25m

K1500DW Set of 12 cable nuts for WU20

K1500DX 5 m tubing for SB20

K1500DZ Nut SS, FF/S20-3* + ISC40FF/S

K1500EK O-rings viton 6.07x1.78 (5x2)

K1500EQ O-ring set EPDM FF20-S22

K1500ER O-ring set Viton FF20-S22

K1500ES O-ring set EPDM FF20P&F33

K1500ET O-ring set Viton FF20P&F33

K1500EU O-ring set EPDM FF20-S33

K1500EV O-ring set Viton FF20-S33

K1500EW O-ring set EPDM FF20P&F43

K1500EX O-ring set Viton FF20P&F43

K1500EY O-ring set EPDM FF20-S43

K1500EZ O-ring set Viton FF20-S43

K1500FK O-ring set Viton FF20P&F22

K1500FL O-ring set standard FF20P&F22

K1500FM O-ring set FF20-S22

K1500FU KCl reservoir PVC for F*20

K1500FV Liquid earth cable 10m

K1500GA 5 m tube for KCl reservoir

K1500GN O-ring set FF/FS20 3-hole SS

K1500GP O-ring set FF/FS20 3-hole P/F

K1500GR O-rings silicon 11x3 8pcs

K1500GT O-ring set silicon. FF20-.4.

K1500GZ Earthpin assy for F*20 non-S

K1500HA Calibr. dish for FF20-*33 (50)

K1500HB Calibr. dish for FF20-*43 (50)

K1500HD O-rings silicon 11x3 50pcs

K1511DP O-rings viton 21.9x2.62 (5x2)

K1520CE Spare 3-hole holder PP

K1520CF Spare 3-hole holder PVDF

K1521AD Flange adapter /FS3

K1521AE Flange adapter /FF3

K1521AF Flange adapter /FP3

K1521AG Flange adapter /FS4

K1521AH Flange adapter /FF4

K1521AJ Flange adapter /FP4

K1521AK Flange adapter /FS1

K1521AL Flange adapter /FF1

IM 12B6K1-01E-E

Page 25

K1521AM Flange adapter /FP1

K1521AN Flange adapter /FS2

K1521AP Flange adapter /FF2

K1521AQ Flange adapter /FP2

K1547PA Hast. cleaning unit HCN2/3

K1547PB Hast. cleaning unit HCN4

K1547PF Nozzle and mounting HCN2/3/F

K1547PG Nozzle and mounting HCN4

K1547PH 10 m Nylon Tube and mounting

K1547PP Spare Part EPDM spraying valves

23

IM 12B6K1-01E-E

Page 26

24

IM 12B6K1-01E-E

Page 27

25

IM 12B6K1-01E-E

Page 28

YOKOGAWA ELECTRIC CORPORATION

World Headquarters

9-32, Nakacho 2-chome, Musashino-shi

Tokyo 180-8750

Japan

www.yokogawa.com

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

USA

www.yokogawa.com/us

YOKOGAWA EUROPE BV

Euroweg 2

3825 HD AMERSFOORT

The Netherlands

www.yokogawa.com/eu

YOKOGAWA ELECTRIC ASIA Pte. LTD.

5 Bedok South Road

Singapore 469270

Singapore

www.yokogawa.com/sg

YOKOGAWA CHINA CO. LTD.

3F Tower D Cartelo Crocodile Building

No.568 West Tianshan Road Changing District

Shanghai, China

www.yokogawa.com/cn

YOKOGAWA MIDDLE EAST B.S.C.(c)

P.O. Box 10070, Manama

Building 577, Road 2516, Busaiteen 225

Muharraq, Bahrain

www.yokogawa.com/bh

Yokogawa has an extensive sales and

distribution network.

Please refer to the European website

(www.yokogawa.com/eu) to contact your

nearest representative.

IM 12B6K1-01E-E

Subject to change without notice Printed in The Netherlands, 07-113 (A) I

Copyright ©

Loading...

Loading...