Page 1

User's

Manual

1

Thank you for purchasing the JUXTA Signal Conditioner.

Please read through this manual before use for correct handling.

Network Solutions Business Division

2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 Japan

Phone: +81-422-52-7179 Facsimile: +81-422-52-6619

IM 77J08R05-01E

1st Edition Jan.2007 (YK)

CAUTIONARY NOTES FOR SAFE USE OF THE

PRODUCT

This User’s Manual should be carefully read before installing and

operating the product. The following symbol is used on the prod-

uct and in this manual to ensure safe usage.

Th is symbol is d is pl ay ed on the product w he n i t is

necessary to refer to the User's Manual for information

on personal and i ns tr ument sa fe ty. This s ymbol is

displayed in the User's Manual to indicate precautions

to a vo id d an ger to the opera to r, su ch as an el ectric

shock.

The following symbols are used only in this manual.

NOTE

D r a w s a t t e nt io n t o es s e n t ia l i n f o r ma ti on f o r

understanding the operations and/or functions of the

product.

CHECKING PRODUCT SPECIFICATIONS AND

PACKAGE

(1) Checking the Model and Product Specications

Check that the model and specifications indicated on the

nameplate attached to the main unit are as ordered.

(2) Packaged Items

Check that the package contains the following items:

FR5A or FR5V: 1

Mounting block: 2

Tag number and range label : 1 each

Mounting screw (M4 x 0.7): 2

User’s Manual (this manual : IM 77J08R05-01E)

GENERAL

The FR5A/FR5V is a compact, front terminal connection and

free range type RTD converter that is connected to an IEC/JIS-

standard resistance temperature detector (RTD) to convert tem-

perature signals into isolated DC current or DC voltage signals.

Selection of input type, I/O range setting, burnout setting,

output adjustment, I/O monitoring, and loop back test can be

made using the op tional Parameter Setting Tool (VJ77) or

Handy Terminal (JHT200).

MODEL AND SUFFIX CODES

Model Sufx codes Description

FR5A -

*C /RTD Converter

FR5V (Free Range Type)

Input -1 Pt100 (IPTS-68:JIS'89)

-2 JPt100 (JIS'89)

-3 Pt50 (JIS'81)

-4 Pt100 (ITS-90)

-0 Custom order

Output A 4 to 20 mA DC FR5A

B 2 to 10 mA DC

C 1 to 5 mA DC

D

0 to 20 mA DC

E 0 to 16 mA DC

F 0 to 10 mA DC

G 0 to 1mA DC

Z (Custom order)

Direct current signals

1 0 to 10 mV DC FR5V

2 0 to 100 mV DC

3 0 to 1 V DC

4 0 to 10 V DC

5 0 to 5 V DC

6 1 to 5 V DC

7 -10 to 10 V DC

0 (Custom order)

Direct voltage signals

Style code *C Style C

Burnout /BU Up

/BD Down

/BN None

Temperature unit /DF Fahrenheit (°F) display function

Models FR5A, FR5V

RTD Converter

(Free Range Type)

Page 2

2

IM 77J08R05-01E 1st Edition 2007.01.15-00

1. MOUNTING METHOD

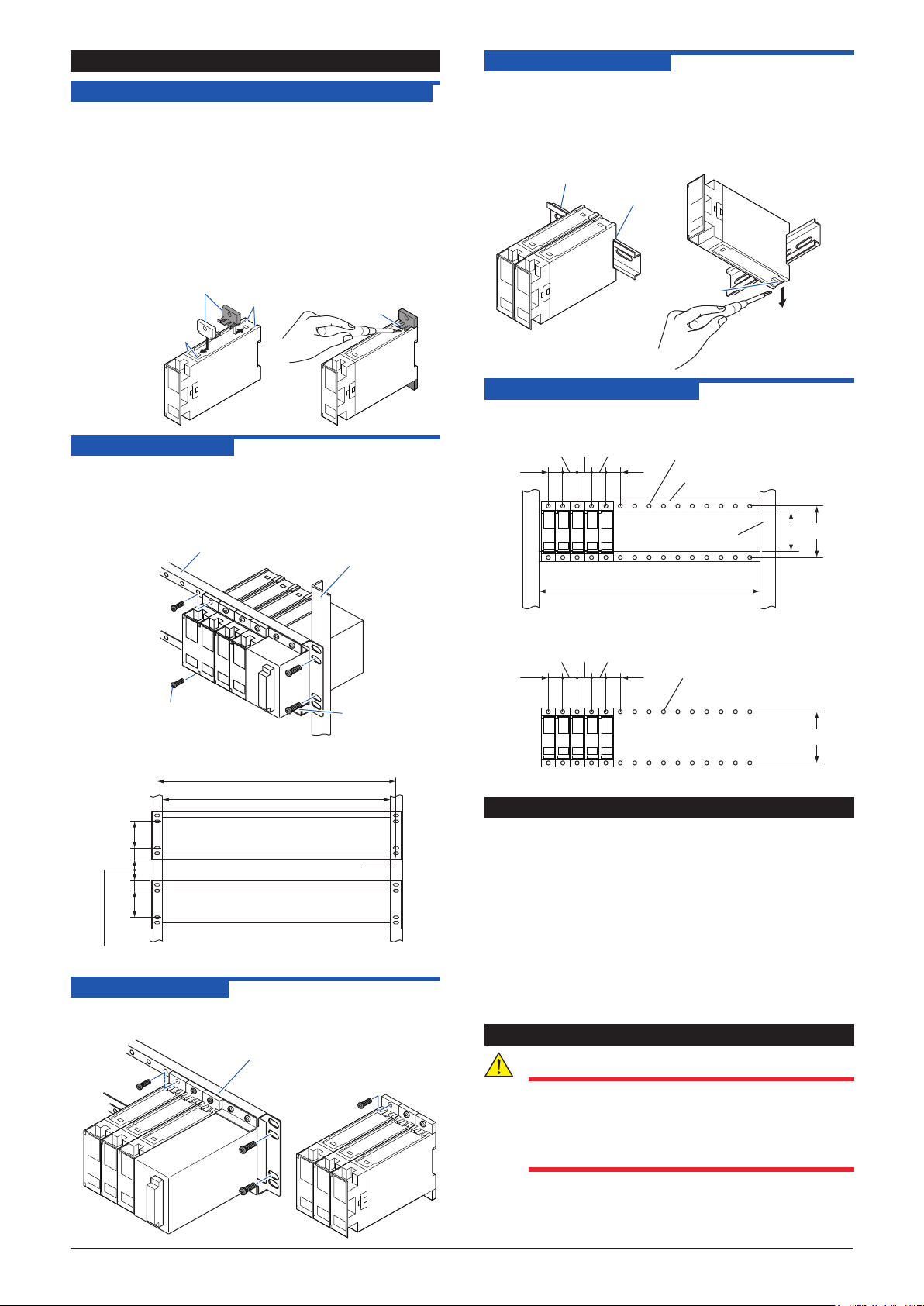

1.1 Installing/Uninstalling the Mounting Block

The mo unting block is neces sary for rack mountin g or wall

mounting.

Installing the mounting block

Fit the mounting block into the grooves of the converter,

and slide it in the direction of an arrow as shown below-

left.

Uninstalling the mounting block

Lift the stopper using a slotted screw-driver as shown

below-right, and pull the mounting block to remove it.

Groove

(Rack mounting)

Groove (Wall mounting)

Stopper

Mounting block

1.2 Rack Mounting

Take the FRK panel and install it on a mounting angle as shown

below.

Th is m ethod is sui table for hig h densit y mounti ng o f the

converters on a 19-inch rack panel.

Mounting angle

Mounting angle

Mounting Dimensions

450±1

465±1

M5 screw

(4 places)

Supplied spacer(50) or Wiring space(30 to 60)

FRK panel

Mounting screw (M4x0.7)

(2 screws in the package)

50

25

25

50

Unit: mm

1.3 Wall Mounting

Mount the converter onto the FRK panel as shown below or

mount it directly on the wall.

FRK panel

1.4 DIN Rail Mounting

Place the converter so that the DIN rail ts into the upper part of

the DIN-rail groove at the rear of the socket, and fasten the socket

using the slide lock located underneath the socket.

To remove the converter, pull down the slide lock using a slotted

screw-driver.

Slide lock

DIN rail

DIN rail groove

1.5 Mounting Dimensions

Mounting angle

M4×0.7 Mounting screw

Support

24.524.5

24.5

24.5 24.5

Angle Mounting Dimensions

n×24.5+2

M4×0.7 Mounting screw

Unit: mm

73 90

24.524.5

24.5 24.5 24.5

Wall Mounting Dimensions

90

2. INSTALLATION LOCATION

Avoid the following environments for installation locations:

Areas with vibration, corrosive gases, dust, water, oil, solvents,

direct sunlight, radiation, a strong electric eld, and/or a strong

magnetic eld, altitude of more than 2000m above sea level.

If there is any risk of a surge being induced into the power line

and/or signal lines due to lightning or other factors, a dedicated

lightning arrester should be used as protection for both this

converter and a eld-installed device.

Operating temperature/humidity range: 0 to 50C/5 to 90%RH

(no condensation)

3. EXTERNAL WIRING

WARNING

Be sure to turn OFF the power supply before wiring to

avoid the risk of electric shock. Use a tester or similar

device to ensure that no power is being supplied to a

cable to be connected

.

Page 3

3

IM 77J08R05-01E 1st Edition 2007.01.15-00

M4 screw terminals are provided for the connection of external

signals. Attach a crimp-on lug to each wire for connection to the

terminals.

●Recommended cables: A nominal cross-sectional area of 0.5

mm2 or thicker for signal cables, and that of 1.25 mm2 or thicker

for power cables.

Wiring Diagram

1

2 3

4 5

6 7

3

2

6

7

4

5

1

A

+

−

Input (RTD)

Output

Power Supply

B

B

+

−

NOTE

●The power line and input/output signal lines should

be installed away from n oise-generating s ources.

Otherwise accuracy cannot be guaranteed.

●The wiri ng r esist ance of input terminals and

should be the same.

●Adhe r e s t r i c tly to the spec i f i c a tions to av o i d

overheating or damage. Before turning on the power,

ensure the following:

(a ) P ow er su pply voltage and input si gn al va lu e

applied to the product should meet the required

specications.

(b) The external wiring to the terminals and wiring to

ground are as specications.

●Do no t o p erat e t h e p rod u c t i n the pr e s ence o f

ammable or explosive gases or vapors.

●The product is sensitive to static electricity; exercise

ca re whe n i n o per at ion . B ef ore yo u o per at e t he

pr od uc t, to uc h a nearby metal part to di sc ha rg e

static electricity.

Power Supply and Isolation

Power supply voltage: 24V DC ±10% (ripple: less than 5% p-p)

Current consumption: FR5A 65mA, FR5V 50mA

Insulation resistance: 100M Ω at 500V DC between input, output

and power supply mutually.

Withstand voltage: 1500V AC/minute between input-output,

input-power supply

500V AC/minute between output-power supply

4. SETTING PARAMETERS

The parameters are set as you specied in your order. Refer

to the following to change the default settings.

Set the parameters using a PC (VJ77 Parameter Setting Tool)

or the Handy Terminal. Refer to "5. List of Parameters" in this

manual and the User’s Manual for VJ77 PC-based Parameters

Setting Tool (IM 77J01J77-01E) or the User’s Manual for JHT200

Ha nd y Terminal (IM JF 81 -0 2E ). Parameters are sh ow n in

brackets "[ ]".

Connection of Setting Tools

VJ77 Dedicated adapter (E9789HA)

[Provided with VJ77]

PC with VJ77 installed

Dedicated cable (E9786WK)

[Provided with VJ77]

*Be sure to use the VJ77 of version R1.05 or later.

JHT200

Handy Terminal

JUXTA communication cable

3 pin connector (F9182ED)

[Provided with VJ77 and JHT200]

Setting RTD Type

S e t the R T D type to be co n n e c t e d to th e input in

[B05: TYPE].

Display Type of input Measuring

range

Measuring

span

PT Pt100

(IPTS-68:JIS'89)

-200 to 660°C

10°C

or more

JPT JPt100 (JIS'89) -200 to 10°C

PT100-90 Pt100 (ITS-90:JIS'97) -200 to 850°C

PT50 Pt50 (JIS'81) -200 to 649°C

JPt100 (JIS'89): R0=100Ω, R100/R0=1.3916

Pt100 (IPTS-68): R0=100Ω, R100/R0=1.3850

Pt100 (ITS-90): R0=100Ω, R100/R0=1.3851

Setting Temperature Unit

Set the temperature unit of the input range in [B09: UNIT]

NOTE

Do not set the "-----" as the temperature unit, even if it

is displayed during the setting.

Otherwise it may cause the malfunction or damage.

Setting Input Range

Set the zero percent value of input range in [B10: ZERO], and

the span of input range in [B11: SPAN].

Setting Burnout Action

Set the burnout action in [B12: BURN OUT]

Set "OFF", "UP", or "DOWN."

NOTE

Input adjustment should be applied when the setting

of input range, burnout action direction or input wiring

has been changed.

Page 4

4

IM 77J08R05-01E 1st Edition 2007.01.15-00

5. LIST OF PARAMETERS

Parameter Display Items

A DISPLAY Display

A01 INPUT Input value

A02 OUTPUT Output value

A03 STATUS Status (*1)

A04 REV NO Revision number

B SET Setting

B01 TAG NO.1 Tag number 1

B02 TAG NO.2 Tag number 2

B03 COMMENT1 Comment 1

B04 COMMENT2 Comment 2

B05 TYPE Input type

B09 UNIT Unit

B10 ZERO Zero (0% of input range)

B11 SPAN Span (Input span)

B12 BURN OUT Burnout

C ADJUST Adjustment

C01 OUT 0% Output 0% adjustment

C02 OUT 100% Output 100% adjustment

C04 ZERO ADJ Input zero adjustment

C05 SPAN ADJ Input span adjustment

*1: This “STATUS” is for the customer’s engineer to check the history.

6. MAINTENANCE

The product starts running immediately when the power is turned

on; however, it needs 10 to 15 minutes of warm-up before it

meets the specied performance.

6.1 Calibration Apparatus

A 6-dial variable resistor (Yokogawa Meters & Instruments

Corporation 279301 or equivalent)

A digital multimeter (Yokogawa 7561 or equivalent)

A precision resistor of 250 Ω ±0.01%, 1W

A setting tool for adjustment (Refer to "4. Setting Parameters"

in this manual.

6.2 Calibration Procedure

1. Connect the instruments as shown below.

1

2 3

4 5

6 7

3

2

6

7

4

5

1

A

B

B

6-dial

variable resistor

Setting tool

Output

Input

24V DC

Ro

Ro: 250Ω precision resistor for

current output

DMM

Power Supply

2 Use the 6- dial vari able resi stor and appl y the res istance

equivalent to 0, 25, 50, 75, and 100% of the measuring range

to the converter.

3. Verify that the corresponding output voltages are 0, 25, 50, 75,

and 100% respectively and within the specied accuracy rating.

(Ro is used for current output.)

Use the setting tool (VJ77 Parameter Setting Tool or JHT200

Handy Terminal) to adjust the input/output signals.

Input Adjustment Procedure

(1) Input the value equivalent to 0% value of the input range

to the converter.

(2) Read the parameter [C04: ZERO ADJ] and check the

input value.

(3) Select “INC” or “DEC” in the parameter [C04: ZERO

ADJ] to adjust.

INC: Increase (Adjusts the increased value of the input

[resistance] value)

DEC: Decrease (Adjusts the decreased value of the

input [resistance] value)

RST: Reset of the adjustment value

(4) Input the value equivalent to 100% value of the input

range to the converter.

(5) Read the parameter [C05: SPAN ADJ] and check the

input value.

(6) Adjust the span in the same way as (3).

Output Adjustment Procedure

When adjusting 0% value of output:

(1) Set the adjustment value 0% in the parameter [C01:

OUT 0%].

•The value equivalent to 0% of the output range will be

output, irrespective of the input.

(2) Check the output value via digital multimeter, and adjust

it in the parameter [C01: OUT 0%].

•If it slips out to the (+) side, set (−) value equivalent

to slipout; if it slips out to the (−) side, set (+) value

equivalent to slipout for adjusting the output value to

0%.

*: The 100% value of output can be adjusted by the

same operation as the above in [C02:OUT100%]

For adjustment using a setting tool, refer to the User’s Manual for

each setting tool and “5. List of Parameters” in this manual.

User’s Manual for VJ77 [Document No.: IM 77J01J77-01E];

however, use the VJ77 of version R1.05 or later.

User’s Manual for JHT200 [Document No.: IM JF81-02E]

Loading...

Loading...