Page 1

User ’s

Manual

Model FLXA402

4-Wire Converter

Installation and Wiring

(Introduction and General Description)

IM 12A01F01-02EN

IM 12A01F01-02EN

7th Edition

Page 2

u Introduction

Thank you for purchasing the FLXATM402 4-Wire Converter.

This Instructor’s Manual contains all essential information for the user to make full use of

FLXA402.

Please read the following respective documents before installing and using the FLXA402.

The related documents are listed as follows.

General Specications

Contents Document number Note

FLXA402 4-Wire Converter

“EN” in the document number is the language code.

User’s Manual

Contents Document number Note

FLXA402 4-Wire Converter

Start-up and Safety Precautions

FLXA402 4-Wire Converter

Installation and Wiring

FLXA402 4-Wire Converter

Operation of Converter

FLXA402 4-Wire Converter

Operation of pH/ORP

FLXA402 4-Wire Converter

Operation of SC

FLXA402 4-Wire Converter

Operation of ISC

FLXA402 4-Wire Converter

Operation of DO

“EN” in the document number is the language code.

An exclusive User’s Manual might be attached to the products whose sux codes or option

codes contain the code “Z” (made to customers’ specications). Please read it along with this

manual.

i

GS 12A01F01-01EN Online manual

IM 12A01F01-01EN Attached to the product (printed manual)

IM 12A01F01-02EN Online manual (This manual)

IM 12A01F01-03EN Online manual

IM 12A01F02-01EN Online manual

IM 12A01F03-01EN Online manual

IM 12A01F04-01EN Online manual

IM 12A01F05-01EN Online manual

Technical Information

Contents Document number Note

FLXA402 4-Wire Converter

HART communication

FLXA402 4-Wire Converter

MODBUS communication

“EN” in the document number is the language code.

TI 12A01F01-61EN Online manual

TI 12A01F01-62EN Online manual

You can download the latest documents from our website. Scan QR code.

http://www.yokogawa.com/an/xa402/download/

Media No. IM 12A01F01-02EN 7th Edition : Nov. 2020 (YK)

All Rights Reserved Copyright © 2018, Yokogawa Electric Corporation

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 3

n Notes on Handling User’s Manuals

• Please hand over the user’s manuals to your end users so that they can keep the user’s

manuals on hand for convenient reference.

• Please read the information thoroughly before using the product.

• The purpose of these user’s manuals is not to warrant that the product is well suited to any

particular purpose but rather to describe the functional details of the product.

• No part of the user’s manuals may be transferred or reproduced without prior written

consent from YOKOGAWA.

• YOKOGAWA reserves the right to make improvements in the user’s manuals and product at

any time, without notice or obligation.

• If you have any questions, or you nd mistakes or omissions in the user’s manuals, please

contact our sales representative or your local distributor.

n Drawing Conventions

Some drawings may be partially emphasized, simplied, or omitted, for the convenience of

description.

Some screen images depicted in the user’s manual may have dierent display positions or

character types (e.g., the upper / lower case). Also note that some of the images contained in this

user’s manual are display examples.

ii

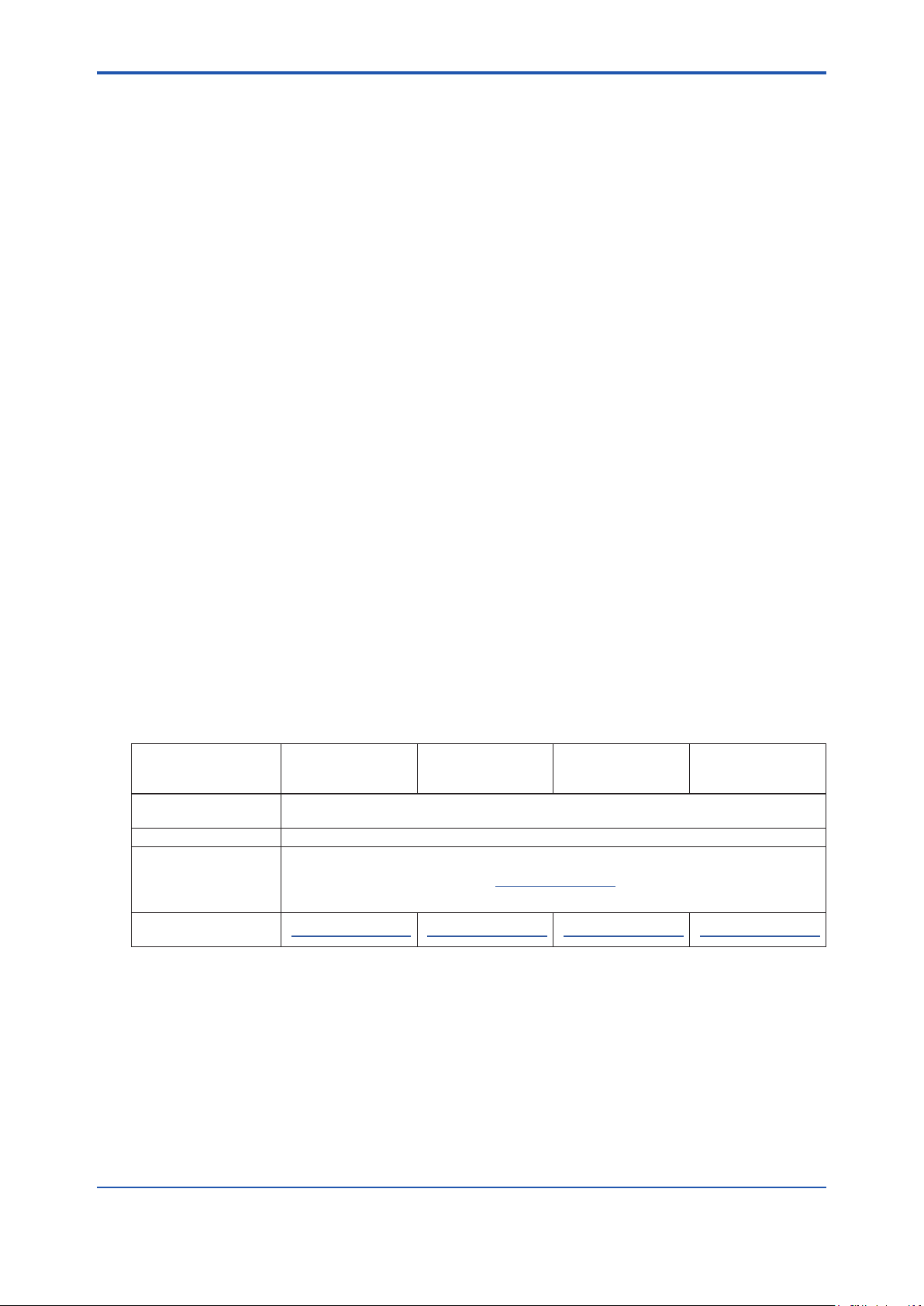

n Composition of this User’s Manual

FLXA402, a modular-designed converter, is a multi- parameter instrument oering a wide

range of measurement choices; such as: pH/ORP (oxidation-reduction potential), Resistivity/

Conductivity (SC), Inductive conductivity (ISC), Dissolved Oxygen (DO) – with the respective

sensor module.

This user’s manual contains general description and precautions of the instrument.

The table below shows user’s manuals to read concerning the instrument’s operation,

conguration, or calibration, which vary depending on its installation, wiring, and specication of

each instrument.

Contents

Introduction and

general description

Wiring and installation IM 12A01F01-02EN (this manual)

Converter operation

(Setting, Calibration)

Maintenance,

Troubleshooting

Sensor operation

(Setting, Calibration)

pH/ORP

SENCOM

IM 12A01F02-01EN IM 12A01F03-01EN IM 12A01F04-01EN IM 12A01F05-01EN

TM

SA

Contacting

conductivity (SC)

SENCOM SA

IM 12A01F01-02EN (this manual)

IM 12A01F01-03EN

n Trademark Acknowledgments

Inductive

conductivity (ISC)

Dissolved oxygen

(DO)

• FLEXA, FLXA, SENCOM and FieldMate are trademarks or registered trademarks of

Yokogawa Electric Corporation.

• All other company and product names mentioned in this user’s manual are trademarks or

registered trademarks of their respective companies.

• We do not use TM or ® mark to indicate those trademarks or registered trademarks in this

user’s manual.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 4

u Regulatory Compliance for Radio

and Telecommunication

l FCC Approval

FCC CAUTION

Changes or modications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own

expense.

This transmitter must not be co-located or operated in conjunction with any other antenna or

transmitter.

iii

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment and meets the FCC radio frequency (RF) Exposure Guidelines. This equipment has

very low levels of RF energy that it deemed to comply without maximum permissive exposure

evaluation (MPE).

l IC Approval

This Class A digital apparatus complies with Canadian ICES003.

Cet appareil numerique de la classe A est conforme a la norme NMB-003 du Canada.

This device complies with Industry Canada’s applicable license-exempt RSSs. Operation is

subject to the following two conditions:

(1) this device may not cause interference; and

(2) this device must accept any interference, including interference that may cause undesired

operation of the device.

Le présent appareil est conforme aux CNR d’ Industrie Canada applicables aux appareils radio

exempts de licence.

L’exploitation est autorisée aux deux conditions suivantes:

(1) l’appareil ne doit pas produire de brouillage;

(2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d’en compromettre le fonctionnement.

This equipment complies with IC radiation exposure limits set forth for an uncontrolled

environment and meets RSS-102 of the IC radio frequency (RF) Exposure rules. This equipment

has very low levels of RF energy that it deemed to comply without maximum permissive

exposure evaluation (MPE). [*But it is desirable that it should be installed and operated keeping

the radiator at least 20cm or more away from person’s body.]

Cet équipement est conforme aux limites d’exposition aux rayonnements énoncées pour un

environnement non contrôlé et respecte les règles d’exposition aux fréquences radioélectriques

(RF) CNR-102 de l’IC. Cet équipement émet une énergie RF très faible qui est considérée

comme conforme sans évaluation de l’exposition maximale autorisée (MPE).

[*Cependant, il est souhaitable qu’il devrait être installé et utilisé en gardant une distance de 20

cm ou plus entre le radiateur et le corps human.]

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 5

l RE Directive

When FLXA402 contains Bluetooth communication, FLXA402 is built in compliance with

requirements of RE Directive:

We, Yokogawa Electric Corporation hereby declare that this equipment, FLXA402 is in

compliance with the essential requirements and other relevant provisions of Directive 2014/53/

EU. The full text of the EU declaration of conformity is available at the following internet address:

http://www.yokogawa.com/an/xa402/download/

l Singapore IMDA Approval

FLXA402 complies with IMDA Standards.

iv

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 6

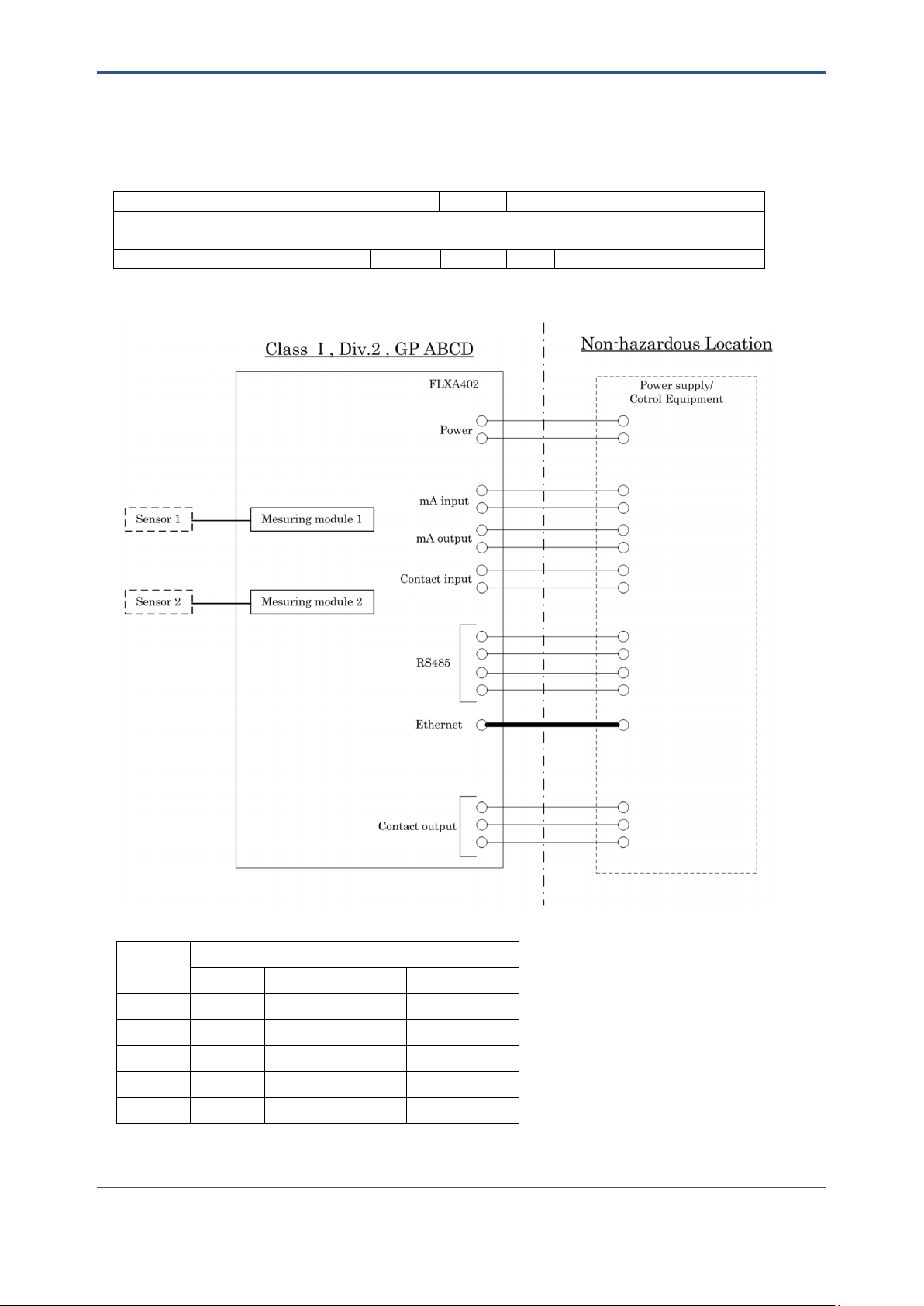

u Control Drawings

n FM Nonincendive

v

Title

Control drawing

No.

NFM038-A81

Yokogawa Electric Corporation

Page

01

Model

Revision

FLXA402

0

Date

2018-06-29

Measuring Module 1, 2 NIFW parameter

Type of Measuring Module

PH SC ISC SENCOM SA

Uo 11.76V 11.76V 11.76V

5.36V

Io 116.5mA 116.5mA 60.6mA 106.16mA

Po 0.3424W 0.3424W 0.178W

0.1423W

Co 4µF 4µF 4µF 31µF

Lo 4.5mH 4.5mH 19mH

0.45mH

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 7

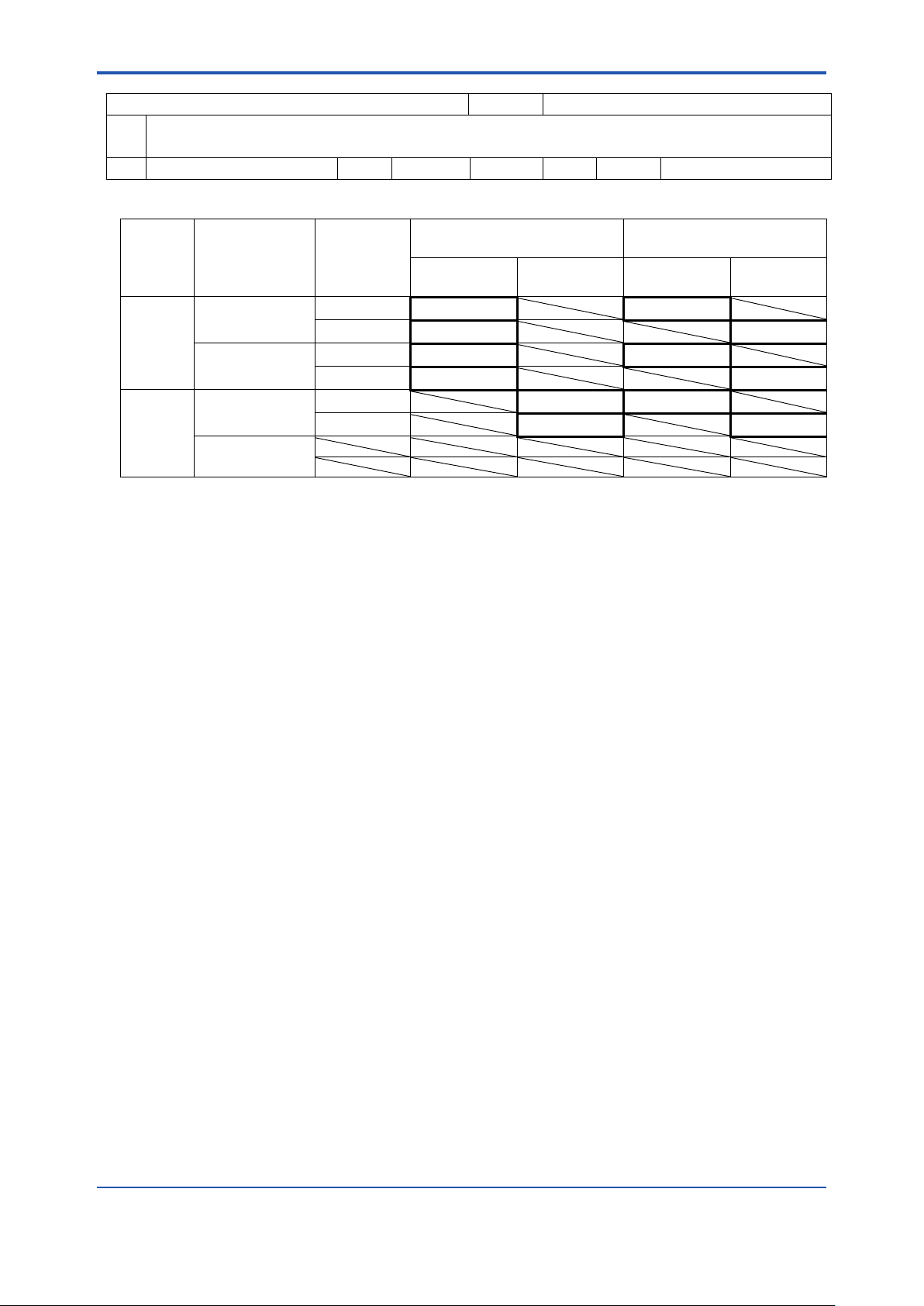

vi

Temp.

Power supply

Number of

Ambient Temperature

Switch capacity

-

20 to

-

20

to

✓

✓

✓

✓

✓

✓

✓

✓

✓ ✓

✓

✓

Model

Revision

0

Date

FLXA402

2018-06-29

Title

Control drawing

No.

NFM038-A81

Yokogawa Electric Corporation

Page

02

Spec. restriction

class

T4

T6

AC version

100-240V AC

DC version

12-24V DC

AC version

100-120V AC

mA

Output

2

4

2

4

2

4

+55°C

of Contact Output

+40°C

MAX. 5A MAX. 4A

DC version

N/A

Notes:

1. No revision to this drawing without prior approval of FM.

2. Installation must be in accordance with the National Electrical Code (NFPA 70), ANSI/ISA-

RP12.06.01 and relevant local codes.

3. When installed in Division 2, Sensor 1 and Sensor 2 may be simple apparatus or nonincendive

field wiring apparatus meeting the conditions below, or alternatively, they may be equipment

suitable for Division 2 respectively, if a suitable wiring method other than nonincendive field

wiring is employed.

Ui ≥ Uo

Ii ≥ Io

Pi ≥ Po

Ci ≤ Co − Ccable

Li ≤ Lo − Lcable

4. WARNING-EXPLOSION HAZAERD. DO NOT OPEN WHILE THE EQUIPMENT IS

ENERGIZED OR WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT.

5. WARNING-EXPLOSION HAZAERD. DO NOT REMOVE OR REPLACE THE FUSE WHILE

THE EQUIPMENT IS ENERGIZED OR WHEN AN EXPLOSIVE ATMOSPHERE IS

PRESENT.

6. WARNING-SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

DIVISION 2.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 8

Model FLXA402

4-Wire Converter

Installation and Wiring (Introduction and General Description)

IM 12A01F01-02EN 7th Edition

CONTENTS

u Introduction ....................................................................................................i

Regulatory Compliance for Radio and Telecommunication ..................iii

u

Control Drawings .........................................................................................v

u

1. INTRODUCTION AND GENERAL DESCRIPTION .................................. 1-1

1.1 Instrument check .............................................................................................. 1-2

1.2 Name and description ...................................................................................... 1-6

1.3 Specication ...................................................................................................... 1-8

1.4 Model & Sux Codes ....................................................................................... 1-9

1.5 Dimensions ...................................................................................................... 1-10

Toc-1

2. WIRING AND INSTALLATION .................................................................. 2-1

2.1 Installation site .................................................................................................. 2-1

2.2 Mounting methods ............................................................................................ 2-2

2.3 Removing the shield cover .............................................................................. 2-3

2.4 Installing the cable glands ............................................................................... 2-4

2.5 Wiring ................................................................................................................. 2-6

2.5.1 Wiring the power supply ..................................................................... 2-7

2.5.2 Wiring relay module (Contact outputs) ............................................ 2-10

2.5.3 Wiring network cables ...................................................................... 2-12

2.5.4 Wiring IO module ............................................................................. 2-13

2.6 Sensor wiring .................................................................................................. 2-15

2.6.1 Wiring the pH/ORP sensor .............................................................. 2-18

2.6.2 Wiring the conductivity (SC) sensor ................................................. 2-20

2.6.3 Wiring the inductive conductivity (ISC) sensor ................................ 2-21

2.6.4 Wiring the dissolved oxygen (DO) sensor ....................................... 2-22

2.6.5 Wiring digital sensors ....................................................................... 2-23

2.6.6 Wiring sensors with SENCOM SA ................................................... 2-24

Customer Maintenance Parts List.......................................CMPL 12A01F01-01EN

Revision Record

.......................................................................................................i

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 9

Blank Page

Page 10

<1. INTRODUCTION AND GENERAL DESCRIPTION>

1. INTRODUCTION AND GENERAL DESCRIPTION

The FLXA402 can work with the existing analog sensors*1 (pH/ORP, conductivity, inductive

conductivity, and dissolved oxygen).

The FLXA402 can additionally work with the SA11 SENCOM

sensors to provide measurements with digital sensors and multiple sensor connections

5 sensors.

For the transfer of diagnostic data and other device information to a host system, the FLXA402

supports the HART and MODBUS protocols. This solution also facilitates connection to the cloud

and the construction of an Industrial IoT (IIoT) environment, for improved eld maintenance.

For further information, see GS 12A01F01-01EN.

This manual describes how to use the FLXA402 with Yokogawa’s or other companies’ sensors.

Please read carefully this manual and the instruction manuals relevant to those sensors you use

before using this instrument.

*1: Analog sensors here represent sensors , PH8E�P, SC4AJ, ISC40GJ, DO30G etc., which are connectable when Model and

Sux codes -P1, -C1, -C5, -D1 are specied in 1st or 2nd input. However, when Type is “-DD” (NI for FM), -D1 (DO) cannot be

selected.

*2: When -S5 on 1st input is specied, up to 4 pH or SC sensors equipped with SA11 can be connected with a connection to BA11

Junction Box. However, when Type is -DD (NI for FM), -S5 (SENCOM SA) cannot be selected. (1st/2nd input)

TM

Smart Adapter and its dedicated

*2

of up to

1-1

IM 12A01F02-02EN 7th Edition : Nov. 30, 2020-00

Page 11

<1. INTRODUCTION AND GENERAL DESCRIPTION>

1.1 Instrument check

Upon delivery, unpack the instrument carefully and inspect it to ensure that it was not damaged

during shipment. If damage is found, retain the original packing materials (including the outer

box) and then immediately notify the carrier and the relevant Yokogawa sales oce.

n Checking the model and sux code

Make sure the model and sux code on the nameplate axed to the left side of the housing.

Refer to

Apply correct power identied on the nameplate to the unit.

1.4 Model & Sux Codes

-A-AB-P1-P1-A2-NR

-N-N-N-NN/U/H6

1-2

Figure 1.1 Example of nameplate (FLXA402)

You nd the model, style, and serial number of the product inside of the front panel, but no

description of the power supply.

n Mark position of FM nonincendive

When selecting the nonincendive model (sux code Type : -DD), make sure the FM nonincedive

information on the standard nameplate axed to the right side of the housing.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 12

<1. INTRODUCTION AND GENERAL DESCRIPTION>

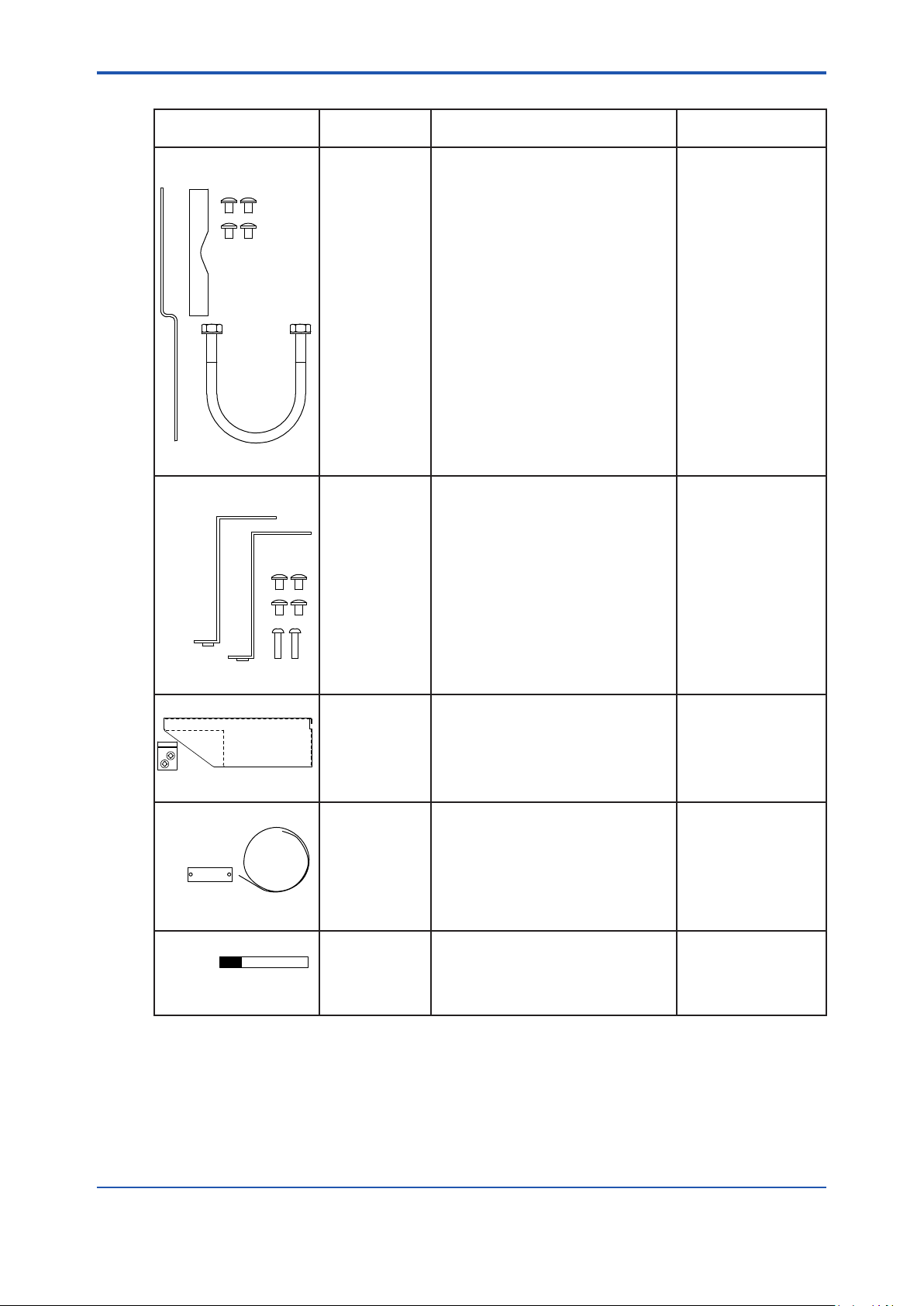

n Spare parts

Spare parts are supplied by Yokogawa with the product. Make sure items in Table 1.1 are

included.

Table 1.1 Spare parts

1-3

Product Name Model and sux

Cable glands

Grommet set

Grommet

code

all others except

the one below

digital

communication: -E

(Modbus TCP/IP)

1st input: -P1(pH/

ORP)

2nd input: -P1(pH/

ORP)

1st input: ,

-S5(SENCOM SA)

2nd input:

-S5(SENCOM SA)

Quantity Remark

Cable gland (M20x1.5): 8 pcs

Rubber plug attachment : 5 pcs

Cable gland (M20x1.5): 7 pcs

Ethernet cable gland (black): 1 piece

Rubber plug attachment (black): 5 pcs

1set

1set

1 piece

1 piece

Jumper

Start-up Manual

IM 12A01F01-01EN

1st input: -P1(pH/

ORP)

2nd input: -P1(pH/

ORP)

digital

communication:

-R (Modbus

RTU(RS-485))

All 1 book

2 pcs

2 pcs

1 piece For terminating

resistor

IM 12A01F02-02EN 7th Edition : Nov. 30, 2020-00

Page 13

<1. INTRODUCTION AND GENERAL DESCRIPTION>

Table 1.2 Options (option code)

1-4

Product Name Model and

sux code

Pipe and wall mounting

hardware

Panel mounting

hardware

Option code: /

UM, /U

Option code:

/UM, /PM

Quantity Remark

1 set For /UM, bracket for /U

and /PM,one of each,

are supplied.

1 set

Hood

Stainless steel tag plate

Tag plate

TAG NO.

Option code:

/H6, /H7

Option code:

/SCT

when other

than /SCT is

specied with a

print order of tag

plate number.

1 set

1 set Stainless steel tag plate

wire

User-specied tag

number is printed.

1 piece User-specied tag

number is printed.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 14

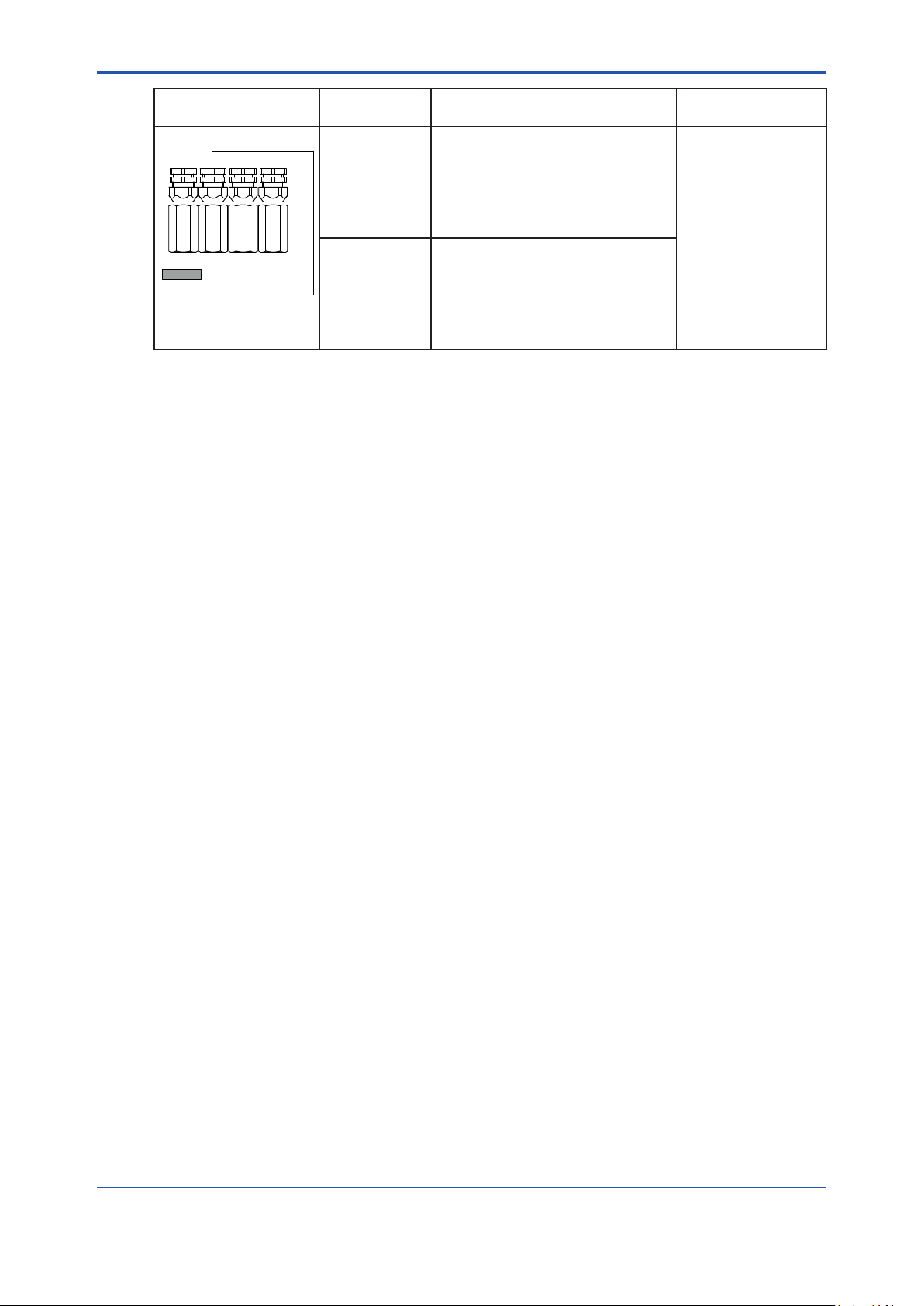

<1. INTRODUCTION AND GENERAL DESCRIPTION>

1-5

Product Name Model and

Conduit adapter

sux code

Option code:

/CB4, /CD4, /

CF4

/CB6, /CD6, /

CF6

Adapter: 4 pcs

Cable gland for adapter: 4 pcs

Rubber plug attachment : 1 piece

Adapter: 3 pcs

Cable gland for adapter: 3 pcs

Ethernet adapter: 1 piece

Ethernet cable gland (black): 1 piece

Rubber plug attachment 1 piece

Quantity Remark

Parts to be purchased separately are not listed here. For information on accessories to be

purchased separately, see 1-10 l

Conduit adapter (need to be purchased additionally)

IM 12A01F02-02EN 7th Edition : Nov. 30, 2020-00

Page 15

<1. INTRODUCTION AND GENERAL DESCRIPTION>

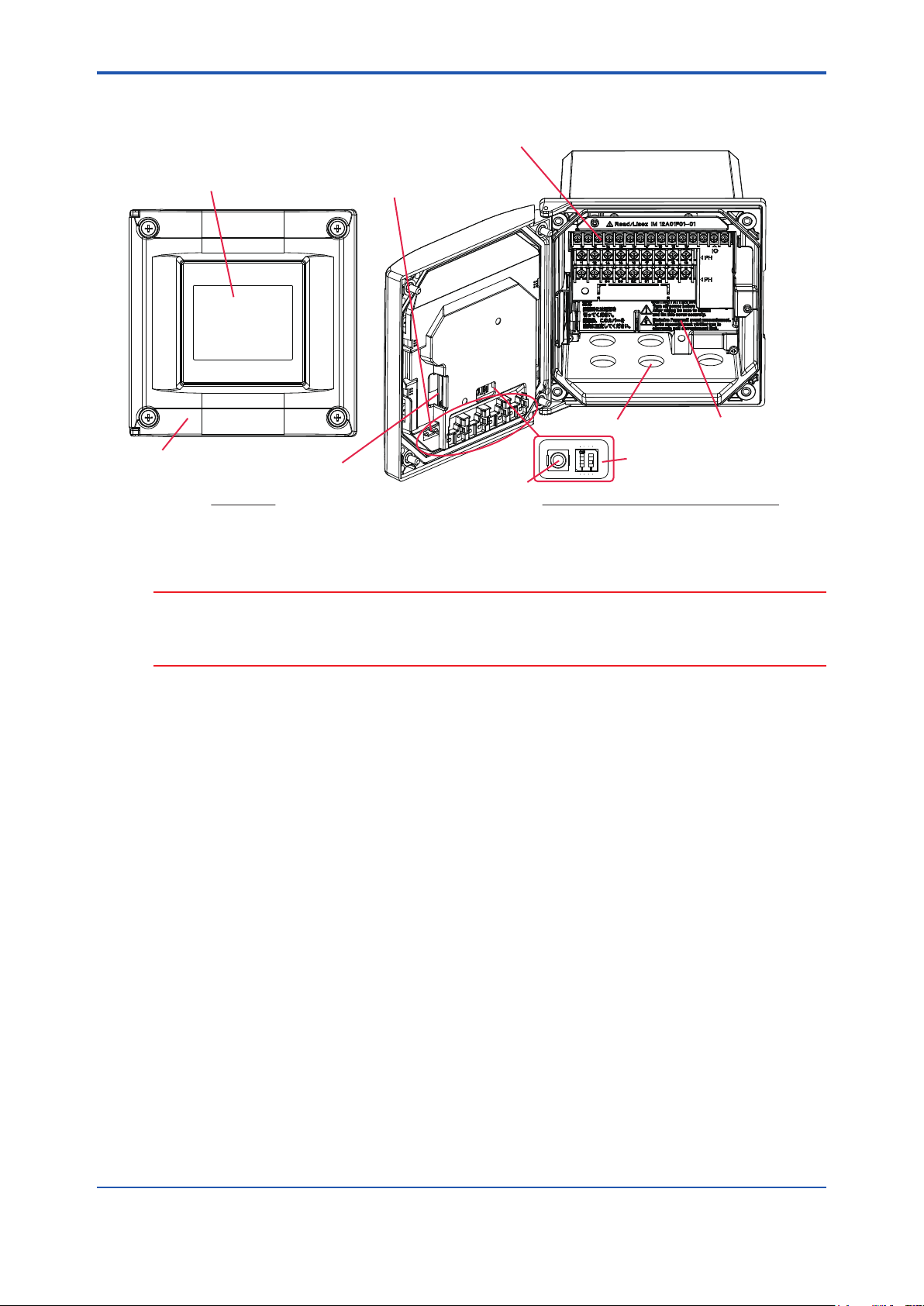

1.2 Name and description

1-6

Jumper holder

(provided only for

LCD display

Front panel

Front view

Figure 1.2 FLXA402 Parts names and descriptions

pH measurement)

Reboot switch

(Do not use it)

CAUTION

Module

Cable entry holes

Slide switch

(for HART only)

Front view with the front panel opened

Terminal block

for power supply

Slide switch 1 is for HART. See the technical information TI 12A01F01-61EN for the technical

information.

Do not switch ON the Slide switch 2. Do not press reboot switch, either.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 16

<1. INTRODUCTION AND GENERAL DESCRIPTION>

FLXA 402 is a module-designed converter, assigning each function to separate module. The

gure below shows how modules are installed, although modules to use are dierent according

to specication.

IO module

1-7

1st sensor module

2nd sensor module

Communication module

Relay module

power terminal

ground terminal

fuse case

*2

*1

*1

*3

*1: Model and Sux Code specied for 1st/2nd sensor module denes what is printed on the

shield cover, next to the sensor module. Figure 1.3 shows an example of selecting -P1 for

both modules. The following list shows what is printed according to MS code.

-P1: PH

-C1: SC

-C5: ISC

-D1: DO

-D5: DIGITAL SENSOR (cannot select for 2nd sensor module)

-S5: SENCOM SA

-NN: (selectable for only 2nd input. No 2nd sensor module. )

*2: An example when -R (Modbus RTU) is specied.

The next gure shows an example when -E (Modbus TCP/IP) is specied.

Modbus TCP/IP

(Ethernet)

Figure 1.3 FLXA 402 Module installation (example, without shield cover)

*3: An example when -WR (Contact outputs) for Contact Outputs is specied.

IM 12A01F02-02EN 7th Edition : Nov. 30, 2020-00

Page 17

<1. INTRODUCTION AND GENERAL DESCRIPTION>

l Jumper and Jumper holder

When you don’t need the jumpers, store them in the jumper holders located inside of the front

panel, to prevent them from being lost.

You can put jumpers anywhere among 5 holders (1A and 4Bs) as Figure 1.4.

A has a guide hole. B has clicks on both side of each holder.

A Bclicks

Figure 1.4 Jumper holders

1.3 Specication

See the latest specication. GS 12A01F01-01EN

1-8

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 18

<1. INTRODUCTION AND GENERAL DESCRIPTION>

1.4 Model & Sux Codes

Model Sux code

FLXA402 ······································································· ················· 4-Wire Converter

Power

supply-A-D

Housing

(*1)

Type -AB

1st input (*9) -P1

2nd input (*9)

mA Output/Input -A2

Contact Outputs -WR

Bluetooth -N

Digital Communication -N

Country (*4) -N

— -NN ················· Always -NN

Option Mounting hardware

Notes:

*1. Urethane coating is for acid resistance. For high anti-corrosion coating, urethane coating and epoxy coating which is for alkali

*2. On 1st input, with a connection to BA11 Junction Box, up to 4 sensors equipped with SA11 can be connected except when

*3. On 2nd input, only 1 sensor equipped with SA11 can be connected.

*4. Select only “-J” if you use the converter in Japan. Only SI unit (International System of Units) applies.

*5. Universal mounting kit contains pipe, wall mounting hardware (/U) and panel mounting hardware (/PM).

*6. Available only when “-E” (Modbus TCP/IP) via digital communication is selected.

*7 There are 8 cable entry holes. Check the table below. If you need, purchase the adapters additionally to comply with

Required No.of cable

*: Conduit exclusively for Ethernet

*8 When selecting Type “-DD” (Nonincendive for FM), “-D1” “-D5” on 1st/2nd input are not available.

*9

-B

-D

-AD

-AG

-AJ

-DD

-C1

-C5

-D1

-D5

-S5

-NN

-P1

-C1

-C5

-D1

-S5

-A4

-NR

-B

-E

-R

-J

Conduit adapter (*7)

resistance are applied.

Type “-DD” (NI for FM) is selected. When Type “-DD” (NI for FM) is selected, only 1 sensor equipped with SA11 can be

connected. BA11 cannot be used.

requirements in the specication.

Spec. Power

Code All All -NN

entry holes

When selecting “-S5” as 1st/2nd input, select SA11 “-CD” (IS for FM-US, FM-Canada). Please check Control Drawing about the other conditions.

When you select both 1st and 2nd inputs, prepare a sensor for each input. If you do not connect the sensor, an alarm will occur.

1 1 0 1 1 2 2 0 0 1* 1

1st

input

Tag plate

2nd input

others

Option code

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

·················

················

·················

·················

················

················

/UM

/U

/PM

Hood

/H6

/H7

/SCT

/CB4

/CD4

/CF4

/CB6

/CD6

/CF6

mA output/input Contact Outputs Digital Communication

the

-A2 -A4 -WR -NR -N -E -R

AC version

DC version

Aluminum alloy cast + urethane coating

Aluminum alloy cast + high anti-corrosion coating

General purpose for CE, RCM, China standard

General purpose for CSA

General purpose for KC

General purpose

NI for FM (*8)

pH/ORP (PH)

Conductivity (SC)

Inductive conductivity (ISC)

Dissolved oxygen (DO)

Digital sensor (DO70G)

SENCOM SA (*2)

Without input

pH/ORP (PH)

Conductivity (SC)

Inductive conductivity (ISC)

Dissolved oxygen (DO)

SENCOM SA (*3)

2 x 4-20 mA Output + 1 x Contact Input (mA1 output:

with HART)

4 x 4-20 mA Output + 2 x Contact Input + 1 x 4-20 mA

Input (mA1 output: with HART)

Contact outputs

Without Contact outputs

Without Bluetooth

Bluetooth

Without Digital communication

Modbus TCP/IP

Modbus RTU (RS-485)

Global except Japan

Japan

Universal mounting kit (*5)

Pipe and wall mounting hardware

Panel mounting hardware

Hood, stainless steel

Hood, stainless steel + urethane coating

Stainless steel tag plate

G1/2 x 4 pcs

1/2NPT x 4 pcs

M20 x 1.5 x 4 pcs

G1/2 x 3 pcs + G 1/2 for Ethernet x 1 pcs (*6)

1/2NPT x 3 pcs + 1/2 NPT for Ethernet x 1 pcs (*6)

M20 x 1.5 x 3 pcs + M20 for Ethernet x 1 pcs (*6)

Description

IM 12A01F02-02EN 7th Edition : Nov. 30, 2020-00

1-9

Page 19

<1. INTRODUCTION AND GENERAL DESCRIPTION>

l Conduit adapter (need to be purchased additionally)

1-10

Type

G 1/2

(Cable gland for adapter + adapter)

1/2 NPT

(Cable gland for adapter + adapter)

M 20 x 1.5

(Cable gland for adapter + adapter)

Parts

number

K9703WF 4 set for Option code /CB

K9703WG 4set for Option code /CD□

K9703WH 4 set for Option code /CF□

Quantity Remark

l Optional parts

Name

Mounting

hardware

Sun shade hood Stainless K9698WK 1 set same as Option code /H6

Rubber plug attachment K9334CN 1 pcs for Cable gland

Fuse A1633EF 1 pcs 250V/2.5A (minimum 5 pcs)

SD card A1005NL 1 pcs 2 GB industrial SD card (with power failure

for pipe, wall mounting

(stainless)

for panel mounting

(stainless)

stainless + urethane K9698WL 1 set same as Option code /H7

Parts

number

K9703SS 1 set same as Option code /U

K9703ZD 1 set same as Option code /PM

Quantity Remark

recovery)

Customers can provide the cards with spec.:

Storage capacity:

128 MB or greater

Type: SD, SDHC

NOTE

SD cards are supplied by users if necessary. For further information, see 5.1 in IM 12A01F01-

03EN.

1.5 Dimensions

See the latest General Specication: .GS 12A01F01-01EN.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 20

<2. WIRING AND INSTALLATION>

2. WIRING AND INSTALLATION

Install the cable glands on FLXA402 before wiring. The cable glands are included inside the

product package.

2.1 Installation site

The FLXA402 is weatherproof and can be installed both indoors and outdoors. It should,

however, be installed as close as possible to the sensor to avoid long cable runs between the

instrument and sensor.

Select an installation site where the ambient temperature and humidity are within the limits of the

instrument specications as below. If the instrument is installed outdoors and exposed to direct

sunlight, a sun shade hood should be used.

Ambient Operating Temperature: -20 to +55 ºC

Storage Temperature: -30 to +70 ºC

Humidity: 10 to 90% RH at 40ºC (Non-condensing)

Select an installation site that meets the following conditions.

• Mechanical vibrations and shocks are negligible.

• No relay switch and power switch are installed close to the converter.

• There is space for cable connection beneath the cable glands.

• Not exposed to direct sunlight or severe weather conditions.

• Maintenance is possible.

• No corrosive atmosphere.

2-1

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 21

<2. WIRING AND INSTALLATION>

2.2 Mounting methods

See 1.5 Dimensions for information on the hardware for mounting.

The FLXA402 has various mounting possibilities.(Figure.2.1)

• Panel mounting using optional mounting hardware (/PM or /UM)

• Wall mounting using optional mounting hardware (/U or /UM)

• Pipe mounting using optional mounting hardware (/U or /UM) on a horizontal or vertical

pipes (Nominal size: 50A)

The universal mounting kit (/UM) contains the pipe and wall mounting hardware (/U) and the

panel mounting hardware (/PM). Some can be left unused.

2-2

Panel mounting

Bracket mounting screws*

Bracket

* Tighten the four screws to a torque of 2 N·m.

Wall mounting

Bracket mounting screws*

Wall

Wall mounting holes (x3)

Note: The wall on which the

analyzer is mounted

should be strong enough

to bear the weight of

more than 8kg.

Pipe mounting

Bracket mounting screws*

Panel

Fixing screws (x2)

+1

138

0

0

+1

138

185

Spacing panel cutout

Note: The attached hardware is the same

as that for the pipe mounting.

Only the bracket is used for the

wall mounting.

M8 bolt (not supplied)

Prepare bolts of the same

length as the mounting hole.

Bracket

* Tighten the four screws to a torque of 2 N·m.

Note: For a sun shade hood (option),

use the upper two bracket

mounting screws to fix it.

Unit: mm

195

Bracket

Bracket for piping

U-bolt

Washers (x2)

Stanchion (50A pipe)

* Tighten the four screws to a torque of 2 N·m.

Figure 2.1 Three types of mounting with the optional mounting hardware

Note: Horizontal pipe mounting is

possible by turning the bracket

90 degrees.

Nuts (x2)

When you change the mounting type, you can order mounting hardware optionally. For further

information see l

Optional parts

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 22

<2. WIRING AND INSTALLATION>

2.3 Removing the shield cover

The shield cover covers high-voltage power supply terminals and relay modules.

CAUTION

To ensure your safety, be sure to shut down the power supply before you remove the shield

cover.

Open the front panel and remove the shield cover. After removing the shield cover, install the

cable glands.

To remove the shield cover, loosen the 2 screws at Δ (triangle). Pull out the shield cover by

holding the marked point :○ (circle) (Figure 2.2).

NOTE

Be careful not to lose the shield cover screws.

DO NOT REMOVE

these screws.

2-3

screws

Figure 2.2 Shield cover

shield cover

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 23

<2. WIRING AND INSTALLATION>

2.4 Installing the cable glands

The supplied cable glands are for cables with an outside diameter of 6 to 12 mm (0.24 to 0.47

inches). Unused cable entry holes must be sealed with cable glands including the supplied

rubber close up plugs.

When the sux code for Digital Communication code is -E (Modbus TCP/IP), apply cable glands

(black) for Ethernet to the holes on the modules for communication.

For installing conduit adapters, apply Conduit adapter set (need to be purchased additionally,

see

l Conduit adapter (need to be purchased additionally) l Conduit adapter (need to be

purchased additionally) and follow the instruction shown on Figure 2.5.

For IO module

For COM module

2-4

For sensor modules

For relay module

Figure 2.3 Cable gland conguration

For power supply

CAUTION

Be careful not to be injured by the sharp hole edges on the housing.

Case

O-ring

Cable gland

Seal packing

Cable gland

cap

Close up plug

(rubber)

Figure 2.4 Cable glands

CAUTION

To install cable glands, tighten it with torque of 2 N•m.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 24

<2. WIRING AND INSTALLATION>

l Conduit adapter

When protecting the cable with a conduit, use an adapter. (option codes: /CB4, /CD4, /CF4, /

CB6/ CD6 /, /CF6)

CAUTION

There are 8 holes for cable connection. Apply the cable gland of supplied accessories (darkgrayed cable glands) to the holes which no conduit adapters connect to.

Apply the supplied cable gland for adapter (white) to the holes which conduit adapters connect to

instead of using supplied-accessory cable gland (dark gray). (Figure 2.5)

Caps of cable glands are not used.

For Ethernet wiring, use Cable gland for Ethernet (black) and Conduit adapter for Ethernet

(punched with a letter “E”).

Case Case

2-5

Cable gland

for adapter

Adapter

G1/2 (/CB4, /CB6)

1/2NPT (/CD4, /CD6)

M20x1.5 (/CF4, /CF6)

Figure 2.5 Conduit adapter (option)

Cable gland

for Ethenet

Adapter

for Ethernet

G1/2 (/CB6)

1/2NPT (/CD6)

M20x1.5 (/CF6)

CAUTION

When using a cable conduit, use a exible conduit to avoid stress on the conduit adapter.

The excessive stress on the conduit adapter may damage the housing.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 25

<2. WIRING AND INSTALLATION>

2.5 Wiring

Wire in the following steps. (Figure 1.3) (Each parenthesis shows the section number to see.)

1: Power supply terminals (See 2.5.1)

2: Relay module (2.5.2)

3: Communication module (2.5.3)

4: 2nd sensor module (2.6)

5: 1st sensor module (2.6)

6: IO module (2.5.4)

1st and 2nd order shown above are reversible. When wiring be sure to remove the shield cover.

After the wiring, screw up the shield cover.

WARNING

Use wiring cables with heat resistance above 75 °C, waterproof rating IP66 or higher.

Four front panel screws should be tightened to the following torque; 1.5 to 1.6 N·m.

For power supply, wire cables with a ammability rating of UL 2556 VW-1 or equivalent.

2-6

WARNING

Always place the shield cover over the power supply and contact terminals for interference

avoidance and safety reasons.

CAUTION

Turn o power supply to FLXA402 before wiring cables.

CAUTION

After wiring of power supply or contact output is completed, put on the shield cover. (see section

2.3)

NOTE

Grounding of shielded cable

The shielded cables are very eective for noise-rejection, but the grounding of the shielded

cables varies depending on the conditions of use.

One side grounding, which grounds only one end of the shield to FLXA402, requires longer

cables and is eective for noise reduction when there is a potential dierence of grounds

between the FLXA402 and the connected device on the other side.

If there is no potential dierence between the FLXA402 and the device on the other side, it may

be more eective to connect to the ground on both sides.

It may also be eective to connect a capacitor in series to one ground while both sids being

grounded.

However, it is assumed that sensors are used with one side grounding. Therefore, be careful not

to use those sensors with both sides grounded.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 26

<2. WIRING AND INSTALLATION>

2.5.1 Wiring the power supply

CAUTION

Turn o power supply to FLXA402 before wiring. Power rating must comply with FLXA402

specication. Power voltage must match with the one indicated on the name plate.

WARNING

● You must install external power supply switch or circuit breaker for power supply.

● The external power supply switch or a circuit breaker must comply with a current rating of 5A

or IEC60947-1 or IEC60947-3

●

Yokogawa recommend installing the external power supply switch, circuit breaker and

FLXA402 converter all in the same location.

●

Install the external power supply switch or circuit breaker to the place where operators

access easily. To alert users, put a label on the external power switch.

●

Wire cables of power supply, contact output securely with cable rack, conduit and vinyl

band. Unplugged cables are dangerous and may cause an electric shock.

2-7

To prepare for wiring cables, open the front panel and remove the shield cover so that you can

access terminals easily.

The cable size of terminals is 2.5 mm

terminals.

2

in cross-sectional area or AWG14. Use the solderless

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 27

<2. WIRING AND INSTALLATION>

n Wiring the power supply

Select AC (-A) or DC (-D) power supply wiring.

l AC power supply

Match the terminal block code “L” “N” with those of the cables.

See Figure 2.8 on grounding. Use cables of rated voltage 300 V AC or greater.

Figure 2.6 AC power supply

2-8

l DC power supply

Match the terminal block code “+” “-” with those of the cables.

Use Conductors with a cross sectional area of 1.25 mm2 or greater,

Cables with an outer diameter of 6 to 12 mm,

Cables with rated voltage 30 V AC or greater.

Figure 2.7 DC power supply

n Grounding

CAUTION

Connect FLXA402 to ground. (Class D ground: 100 ohm or less) for interference avoidance and

safety reasons.

Use ground cables with larger cross - sectional area. Fix the cable on the rear side of FLXA402

outer case or connect the grounding cable to the terminal of the power module inside. See Figure

2.8.

Use ring terminals for wiring terminals.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 28

<2. WIRING AND INSTALLATION>

WARNING

Use the protective earth conductors whose minimum size of the cross-sectional area is 0.75 mm2.

For CSA compliance (Type: -AD), use ones with cross-section area of 0.75 mm2 to 2.1 mm2.

(M4 screw)

(M4 screw)

Figure2.8 External grounding (rear side), internal grounding

2-9

NOTE

● FLXA402 on AC power supply requires the protective grounding.

● The converter on DC power supply does not require the protective grounding but it does

function grounding.

● It has the same type of case as the converter on AC power supply, therefore you see the

symbol of protective grounding . Recognize the symbol as function ground terminal.

● When selecting Type “-DD” (Nonincendive for FM), please check the condition of Control

Drawings.

CAUTION

Put the shield cover back in place after the wiring of power supply terminal and contact output

terminals, if the converter has a relay module, are completed.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 29

<2. WIRING AND INSTALLATION>

2.5.2 Wiring relay module (Contact outputs)

Contact conguration of FLXA402 is the Single Pole Double Throw SPDT relay, which allows

signals to be used as digital output to controller or PLC etc.

Use multi-core cables for contact output signals.

Those screws of contact terminals are all M3 with washer.

2-10

Terminal

number

32 S1(NC) Contact S1 Normally Close

31 S1(C) Contact S1 Common

33 S1(NO) Contact S1 Normally Open

42 S2(NC) COntact S2 Normally Close

41 S2(C) Contact S2 Common

43 S2(NO) Contact S2 Normally Open

52 S3(NC) Contact S3 Normally Close

51 S3(C) Contact S3 Common

53 S3(NO) Contact S3 Normally Open

72 S4(NO) Contact S4 Normally Open

71 S4(C) Contact S4 Common

73 S4(NC) Contact S4 Normally Close

Figure 2.9 Relay module contacts

Contact

terminals

Description

FLXA402 has 4 contact outputs, which allows conguration to adjust to operation. Contact S4 is

fail safe contact. See IM-Converter operation

IM 12A01F01-03EN Section 4.4.

There are 2 cable inlets. Take a suitable one to run wiring with good structure. Be sure to plug

unused cable gland with a supplied rubber close up plug.

NOTE

When selecting Type “-DD” (Nonincendive for FM), please check the condition of Control

Drawings.

l Alarm (Process Alarm monitoring)

Contact outputs an alarm when a measurement exceeds or falls below the permissible range.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 30

<2. WIRING AND INSTALLATION>

l Error

Contact outputs Error, “Fault” or “Problem”. Internal function of electric circuit alerts some errors

automatically. You can dene “Fault” or “Problem” for general errors. See IM-Converter operation

IM 12A01F01-03EN Section 4.7

Contact for Error must connect to alarm related components including alarm lamp, alarm bell,

indicators.

The table below shows the relay operation. Go to Main screen and tap

status. See IM 12A01F01-03EN 2.2 Main screen.

to display contact

2-11

Contact

terminals

S1, S2, S3

S4

Normal operation

when power on

NO

C

NC

NO

C

NC

Alarm on when

power on

NO

C

NC

NO

C

NC

Power o

NO

C

NC

NO

C

NC

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 31

<2. WIRING AND INSTALLATION>

2.5.3 Wiring network cables

FLXA402 provides two types of wired digital network, Ethernet (Modbus TCP/IP) or RS-485

(Modbus RTU).

Use shielded cable to avoid deteriorated performance caused by EMI disturbance or radiation

eects on electric devices.

n RS-485 cabling

Sux code -R is specied, i.e. (Modbus RTU (RS-485)) of digital communication.

All screws for the network module terminals are M3 with washers.

2-12

Terminal

number

94 SHILD Shield

93 GND Signal ground

92 B- data-negative

91 A+ data-positive

95 Term

Figure 2.10 Network module terminal

terminal

name

Application

terminal for termination resistor (110

Ω)

Use multi-core shielded cable whose core wire is twisted pair. Connect them to terminal 94.

According to your network environment, terminate the network by using the built-in termination

resistors with a value of 110 Ω.

Jumper terminals 91 and 95 with each other with a supplied jumper. (Figure 2.11) The jumper

terminates signals inside the module. In this case, the screw of terminal 91 is tightened with the

signal cable and the jumper all together.

Figure 2.11 How to terminate RS-485 connection

NOTE

If you don’t need the termination, keep the jumper in the jumper holder attached to the back of

the front panel to avoid losing it. (Figure 1.4)

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 32

<2. WIRING AND INSTALLATION>

n Ethernet cabling

Sux code-E is specied. (Modbus TCP/IP) Figure 2.12 shows the positions of RJ45.

Use STP shield cable of category 5 or greater to the RJ45 connector.

You can apply both straight and crossover cable for Ethernet cabling.

Modbus TCP/IP

(Ethernet)

Figure 2.12 Network module (Ethernet) connector

NOTE

Use cable gland or adapters (option) for Ethernet.

2.5.4 Wiring IO module

First complete the sensor wiring. (Read 2.6)

Wire for mA input, mA output, contact input. Wiring for mA input may not be necessary according

to the specication.

2-13

n Wiring mA output

FLXA402 transmits 4-20 mA analog signals with maximum load of 600 Ω to peripherals including

a control system or recorders. IO module has mA output function.

Be sure to use shielded cables for output signal cables, and connect shield to terminal 63 (or

89*).

*: When mA I/O is “-A4”, the terminal 89 is used for mA input and cannot be used for output.

Use cables of rating 30 V AC or greater.

For wiring, use shielded multi-core cables.

Screws for IO module are all M3 with washers.

Terminal

number

61 mA1+ 4-20 mA output 1+(with HART)

62 mA1- 4-20 mA output 1-

65 mA2+ 4-20 mA output 2+

66 mA2- 4-20 mA output 2-

81 mA3+ 4-20 mA output 3+ *1

82 mA3- 4-20 mA output 3- *1

85 mA4+ 4-20 mA output 4+ *1

86 mA4- 4-20 mA output 4- *1

63 SHILD Shield

89 SHILD Shield

*1 only when mA output is -A4 in the Sux Codes.

Figure 2.13 IO module terminal assignment

Contact

terminals

Description

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 33

<2. WIRING AND INSTALLATION>

n mA input

This describes a wiring when the sux code for mA Output/Input is -A4.

FLXA 402 receives 4-20 mA analog signals inputs of pressure compensation for DO sensors, or

of temperature compensation for pH, SC, ISC, DO sensors.

Use shielded cable for input signal cable and connect the shield to terminal 89. Rated voltage

of cable is 30 V AC or greater. For wiring use multicore shielded cable. Screws for IO module

terminals are all M3 with washers.

2-14

Terminal

number

87 AI+ 4-20 mA input +

88 AI-- 4-20 mA input-

89 SHILD Shield

Figure 2.14 IO module terminal assignment

n Contact input

IO module contains contact input function which is for starting WASH CYCLE or changing

RANGE of 4-20 mA output.

For input signal cable, use shielded cables. Connect the shield to terminal 63.

All screws are M3 with washers.

Terminal

number

21 Dl1 Contact input 1

22 COM Contact input common

24 DI2 Contacct input 2*1

63 SHILD Shield

*1 when mA IO code -A4 is selected

Figure 2.15 IO module terminal assignment

Contact

terminals

Contact

terminals

Description

Description

When all wiring is complete, close the FLXA402 front cover, and turn the power on.

Check that the screen displays normally.

CAUTION

To install the front panel, tighten each screw evenly until every four of them is completely

fastened. For example turn each screw in two times and repeat it until all of the screws are evenly

tightened up

Do not use an electric screwdriver with high revolutions such as 1000 rpm. The revolutions of the

electric screwdriver should be less than 400 rpm.

Four front panel screws should be tightened to the following torque; 1.5 to 1.6 N•m

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 34

<2. WIRING AND INSTALLATION>

2.6 Sensor wiring

The FLXA402 can be used with a wide range of commercially available sensor types, both from

Yokogawa and other manufacturers.

Terminal screw size is M3, and torque of screw up is 0.6 N•m.

Pin terminal, ring terminal and spade terminal can be used.

Pin terminal: pin diameter: max. 1.9 mm

Ring and fork (spade) terminal: width: max. 7.8 mm

For details on the sensors, refer to the respective instruction manuals of the sensors.

NOTE

When the second input is used, the upper-level module is for the rst input. Be careful not to

make a mistake when wiring the modules.

If the second input is available, wire the second module in the lower level rst.

There are two cable entry holes. Both can be used.

When the second input s not available, be sure to plug holes of unused cable gland with the

supplied rubber close up plug.

The table below shows the section of this IM describing the wiring of rst/second input according

to the sux code.

2-15

Sux code Input Section

-P1 pH/ORP PH) 2.6.1

-C1 Conductivity (SC) 2.6.2

-C5 Inductive conductivity

(ISC)

-D1 Dissolved oxygen (DO) 2.6.4

-D5 Digital sensor 2.6.5

-S5 SENCOM SA 2.6.6

2.6.3

CAUTION

It is assumed that sensors are used with one side grounding. Therefore, be careful not to use

those sensors with both sides grounded.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 35

<2. WIRING AND INSTALLATION>

n Wiring of YOKOGAWA sensors

2-16

FLXA402 Terminals

Sensor

DO30G DO 11 12 13 14 15 16 Fixed Cable

FU20/

PH20/

FU24

FU20/

PH20/

FU24

FU20/

PH20/

FU24

FU20-VP/

FU24-VP

FU20-VP/

FU24-VP

FU20-VP/

FU24-VP

ISC40 ISC 11 12 13 14 15 16 Fixed Cable

PR20/

PR10

SC21 pH Blue

SC24V pH E F C H A B D VP8-DC

SC25V pH E F B D A Yes No VP6-SC

SC29-PTG

SC29-PTP ORP Blue

SC42 SC 11 12 13 14 15 16 WU40 cable

SC4A SC 11 12 13 14 15 16 Fixed Cable

SM21/

SR20/

SM60

SM29/

SR20

SX42 SC Brown Brown

Measurement

pH, pH &

ORP, rH

ORP 11 12 13 14 Ye s Ye s 13/14 Fixed Cable

pH Comp.

ORP

pH, pH &

ORP, rH

ORP E F B D Yes Ye s 13/14 VP6-SC

pH Comp.

ORP

pH 11 12 13 14 15 16 Ye s No Fixed Cable

pH Comp.

ORP

pH

ORP

*1: The jumper cables to short are attached to the product.

*2: Jumper cables to short are supplied by users.

11 12 13 14 15 16 17 18/13 19/15

Sensor cable marking (or color) Jumper *1

11 12 13 14 15 16 Yes No Fixed Cable

11 12 15 14 16 No Ye s 13/14 Fixed Cable

E F B D A Yes No VP6-SC

E F A D No Yes 13/14 VP6-SC

Green:

Red

Green:

Blue

Red

Yellow:

Red

Yellow:

Red

Yellow:

Green

Liquid

Earth

Liquid

Earth

Liquid

Earth

Black

Black

Red

Blue

Red

Red:

Red

Red:

Red

Red

Red:

Blue

Red:

Blue

(White)

(White)

(White)

Yellow:

Blue

Yellow:

Blue

No No WU20 Triax

Yes Yes WU20 Triax

Yes No

Yes Yes

Short *2

FLXA402

/FLXA21

Terminals

13/14

and

15/16

Remark

WU20 Triax

WU20 Color

Coded Coax

WU20 Color

Coded Coax

Sensor

Wiring

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 36

<2. WIRING AND INSTALLATION>

n Wiring of HAMILTON sensors

2-17

Sensor

CHEMTRODE

CHEMTRODE-

ORP

CHEMTRODE-

VP

CLARITRODE

CLARITRODE-

VP

CONDCUELL SC

CONDCUELL-

VP

EASYFERM pH Blue Red

EASYFERM-

VP

INCHTRODE pH E F B D A Yes No VP6-SC

MECOTRODE

MECOTRODE-

VP

OXYFERM-

VP/

OXYGOLD

OXYSENS DO

pHEASY pH E F B D A B Yes No

POLILYTE pH Blue Red

POLILYTE-

VP

POLILYTE

PLUS-VP

*1: The jumper cables to short are attached to the product.

*2: Jumper cables to short are supplied by users.

Measure-

ment

pH Blue Red

ORP Yes Yes 13/14

pH E F B A Yes No 13/14 VP6-SC

pH Blue Red

pH E F B A Yes No VP6-SC

SC Blue

pH E F B A Yes No 13/14 VP6-SC

pH Blue Red

pH E F B A Yes No VP8-DC

DO White Green

pH White Green Red Blue

pH White Green Red Blue

11 12 13 14 15 16 17 18 18/13 19/15

Sensor cable marking (or color) Jumper *1

White/

Yellow

Blue Green Pink

Grey

Yellow

Black

Blue Black Clear

FLXA402 Terminals

Brown Yellow

Grey

Clear

Clear

Grey

Shield

Black

Shield

Green/

Yellow

Black/

Black/

(White)

(White)

(White)

(White)

Black Red

Brown

(White)

Yes No 13/14

Yes No 13/14

Yes No 13/14

Yes No 13/14

Yes No

Yes No

Yes No

Short *2

FLXA402

/FLXA21

Terminals

Remark

WU20D

Cable

WU20D

Cable

Fixed

Cable

Hamilton

VP Cable

WU20D

Cable

WU20D

Cable

Hamilton

VP Cable

Fixed

Cable

WU20D

Cable

Hamilton

VP Cable

Hamilton

VP Cable

Color coding of Variopin cables

Cable PIN A B C D E F G H

Hamilton VP6-SC

Hamilton VP8-DC

WU20-V-S VP6-SC Clear Brown Black Yellow Red Blue

WU20-V-D VP8-DC

Black/

Clear

Black/

Clear

Brown

Core

Red Grey Blue White Green

Black

Shield

Brown

Shield

Red/

Clear

White

Cored

Red

Shield

White

Shield

White Green Yellow Brown

Red Blue Yellow

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 37

<2. WIRING AND INSTALLATION>

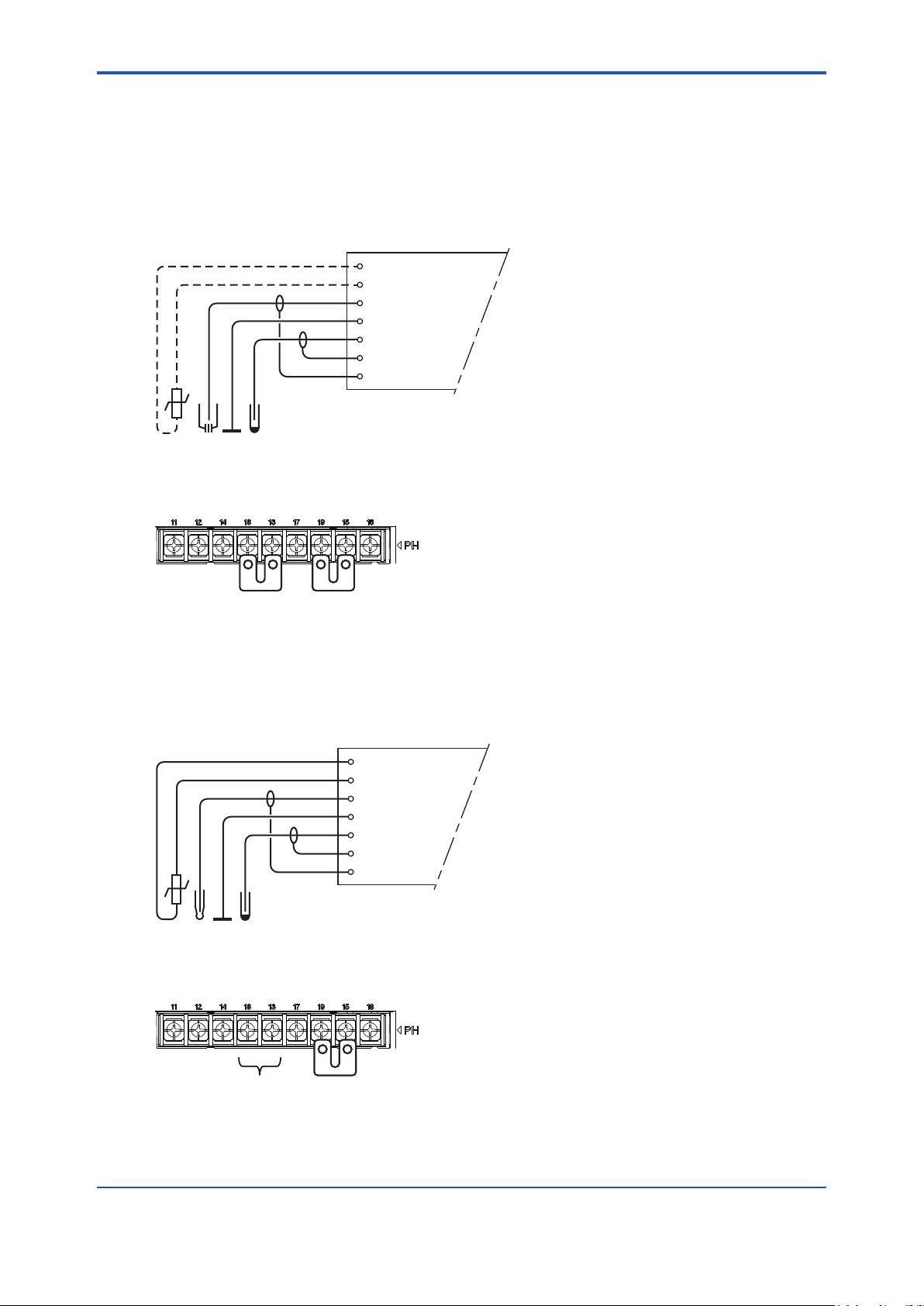

2.6.1 Wiring the pH/ORP sensor

n pH Measurement

Conventional pH sensors are connected to the module as follows:

FLXA402

11 Temperature

12 Temperature

13 Reference

14 Solution ground

15 Glass (measure)

16 Shield

17 Shield

REFTC PHLiquid

Earth

In addition to the wiring of the sensor, insure that a jumper for low-impedance sensor inputs

is installed. Two jumpers are supplied with each module. Keep unused jumpers in the jumper

holder to avoid losing them.

• pH Glass Electrode is a high impedance sensor input

• Standard reference electrodes and an ORP/REDOX electrode are low impedance sensor

inputs

• Special electrodes using 2 glass sensors (example: Pfaudler, SC24V) do not need jumpers.

2-18

Terminals 15-19 are identied as input 1 (High Impedance) and terminals 13-18 are dened as

input 2 (Low Impedance). For conventional pH sensors, the jumper is placed as illustrated:

Input 2

Glass sensor on Input 1

Reference sensor on Input 2

Input 1

Store jumpers that you do not use in the jumper holder.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 38

<2. WIRING AND INSTALLATION>

n ORP Measurement

The ORP measurement uses the same sensor input module as the pH measurement. It is not

uncommon to measure ORP as process variable and a pH Glass electrode as reference. This is

the case with rH measurement and with pH compensated ORP measurement.

Conventional ORP sensors are connected to the module as follows:

FLXA402

11 Temperature

12 Temperature

13 Reference

14 Solution ground

15 Metal (measure)

16 Shield

17 Shield

2-19

REFTC Liquid

Earth

ORP

For conventional ORP sensors, the jumpers are placed as illustrated:

Input 2 Input 1

Metal sensor on Input 1

Normal reference on Input 2.

pH Compensated ORP sensors are connected to the module as follows:

FLXA402

11 Temperature

12 Temperature

13 Glass

14 Solution ground

15 Metal

16 Shield

17 Shield

PHTC ORPLiquid

Earth

For pH Compensated ORP sensors, the jumper is placed as illustrated:

Input 2

Metal sensor on Input 1

pH glass (as reference) on Input 2

Input 1

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 39

<2. WIRING AND INSTALLATION>

NOTE

The special grommet is intended to be used to seal the multiple cables from the Yokogawa ow

ttings such as FF20.

The designated cables are WU20 sensor cables, which are approximately 5 mm (0.2”) in

diameter, and K1500FV liquid earth cables, which are approximately 2.5 mm (0.1”) in diameter.

For sensor systems using a single cable, like the FU20/FU24 and the PR10, PD20, PF20 and

PS20, the standard gland will accommodate the cable adequately. Single cables between

approximately 6 mm and 12 mm (0.24” and 0.47”) can be sealed properly with these glands and

the standard tule.

Remove

standard packing

2-20

Grommet set

Figure 2.13 Grommet set use

Sensor

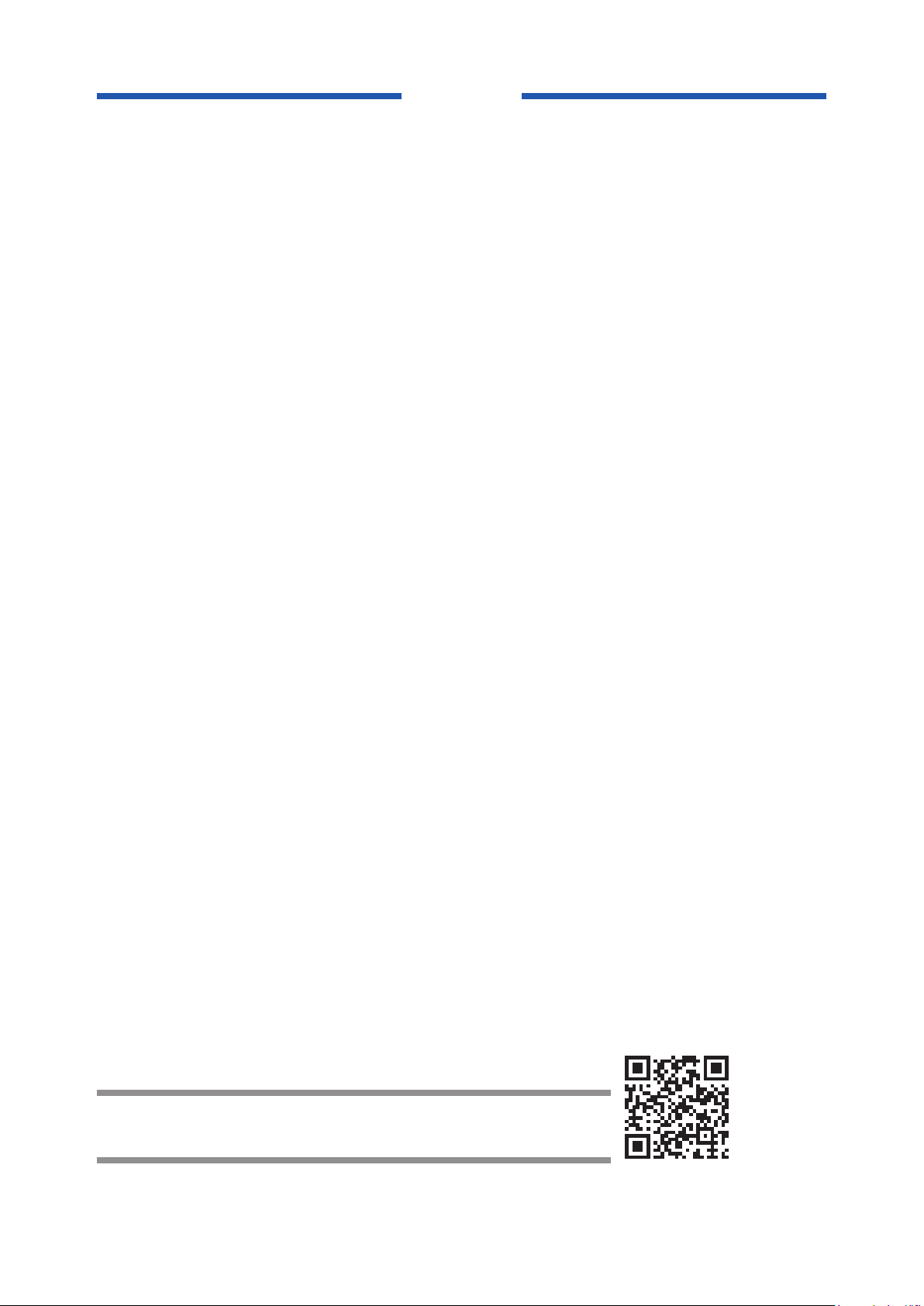

2.6.2 Wiring the conductivity (SC) sensor

Contacting Conductivity, SC, sensors are connected to the module as follows:

FLXA402

11 +

Temp

-

12

V-

13

i-

14

15

V+

16

i+

The above diagram shows wiring for 4-electrode conductivity sensors, such as SC42-SP34

large bore series. For 2-electrode conductivity sensors, such as SC42-SP36 small bore series,

jumpers must be installed between terminals 13-14 and between terminals 15-16, as shown in

the diagram below.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 40

<2. WIRING AND INSTALLATION>

FLXA402

11 +

Temp

-

12

V-

13

i-

14

15

V+

16

i+

2.6.3 Wiring the inductive conductivity (ISC) sensor

ISC40 sensors are connected to the module as follows:

FLXA402

11 +-Temp

12

Receive coil

13

shield

17

14

Sensor shield

(internal)

2-21

Drive coil

15

shield

16

The sensors are supplied with integral cables and each individual wire is marked with the

corresponding terminal numbers.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 41

<2. WIRING AND INSTALLATION>

2.6.4 Wiring the dissolved oxygen (DO) sensor

The input module for DO measurement is suitable for dierent types of DO sensors:

i. Galvanic sensors like model DO30G

ii. Polarographic sensors like HAMILTON’S Oxyferm and Oxygold

The connection is as follows:

FLXA402

TC +

11

TC -

12

16

15

+ anode galvanic

- cathode galvanic

13

+ anode polarographic

18

14

shield

- cathode polarographic

17

2-22

The DO30G sensor comes with integral cable and the wires are labeled with the corresponding

terminal numbers.

NOTE

When Type is “-DD” (Nonincendive for FM), -D1 (DO) cannot be selected.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 42

<2. WIRING AND INSTALLATION>

2.6.5 Wiring digital sensors

When sux code -D5 (digital sensors) for 1st input is specied.

Be sure to nd the label “DIGITAL SENSOR” beside the terminals.

Screws are all M3 with washers.

Figure 2.27 Digital sensor module terminal assignment

FLXA402

terminal number

Exclusive cable

Black

Transparent

Transparent

Red

Green

White

Yellow

Brown

Green and Yellow

10

13

11

12

14

*

*

12V

GND

*

*

A+

BSHLD

2-23

* Cables with * are not used. Connect

them to any terminal of somewhere between 15 to 18.

DO70G

Figure 2.28 Wiring digital sensors

For Digital sensor (-D5), see the dedicated Instruction Manual for it.

FLXA402 detects the sensor connected and displays an alarm if the sensors are not connected.

CAUTION

Turn o the power to FLXA402 when pulling o cables from the digital sensors, or connecting the

digital sensors to cables which are already wired to FLXA402.

NOTE

When Type is “-DD” (Nonincendive for FM), -D5 (Digital Sensor) cannot be selected.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 43

<2. WIRING AND INSTALLATION>

2.6.6 Wiring sensors with SENCOM SA

When sux code -S5 (SENCOM SA) for 1st or 2nd input is specied.

The next gure shows a wiring with WU11, which connects to SENCOM SA.

Be sure to nd the label “SENCOM SA” beside the terminals. Screws are all M3 with washers.

Figure 2.29 SENCOM module terminal assignment

SHLD

82

86

83

84

87

Signal ground

GND

Data (negative)

B-

Data (positive)

A+

Power supply

V5

for SENCOM SA

BA11

WU11

cable

SA11

SA11

WE10

Extension cable

*2

WU11 cable

SA11

Sensor

2-24

Sensor

Sensor

Multiple

connection

Figure 2.30 Wiring SENCOM SA

*1:

Multi sensor connection: 1st sensor module can connect up to 4 sensors equipped with SA11 SENCOM SA, via BA11 junction box.

Note: When selecting Type “-DD” (NI for FM), Multi sensor connection cannot be used. Only one sensor can connect.

*2: WE10 is an extension cable stretching between SA11 and sensors. WE10 is universal to connections if needed.

*1

Connect a SA11 SENCOM Smart adapter to a sensor. Connect SA11 to FLXA 402 via WU11

SENCOM cable.

Read each exclusive user’s manual for information on SA11 Smart Adapter, WU11

Interconnection/Extension Cable for SENCOM Products, WE10 extension cable, BA11 Active

Junction Box.

Because WU11 cables are thin, rst remove the cable gland’s standard packing and apply the

supplied grommet instead.

Grommet

Remove the standard packing.

Sensor

FLXA402 acknowledges the connection of sensors, if not, FLXA402 alerts an error.

NOTE

When Type is “-DD” (Nonincendive for FM), -S5 (SENCOM SA) cannot be selected.

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 44

Customer

Maintenance

Parts List

FLXA402

4-Wire Converter

3 2

14

1

15 16

17

18

4

5

6

7

9

12

8

10

Item

Part No.

1 K9703SA 1 Shield plate assembly 10 — – Sun shade hood set

2 — – Cover assembly K9698WK 1 Stainless steel (option code: /H6)

K9699QK 1 Urethane coating K9698WL 1 Stainless steel with urethane

K9699QM 1 High anti-corrosion coating 11 K9703ZM 2 Jumper set (for pH, RS485), 5 pcs

3 K9699PP 1

Qty

Hinge pin assembly (Hinge pin + spring)

Description

11

Item

Part No.

12 K9676BY 1 Grommet set (only for pH)

Qty

Description

coating (option code: /H7)

13

4 — – Cable gland set 13 K9676CL 1 Grommet (only for SENCOM SA)

K9703PC 1 Cable gland x8 + Rubber plug x5 14 K9699PL 5 Screw assembly (M5 screw + spring)

K9703PE 1 Cable gland x7 + for Ethernet x1 +

5 K9334CN 1 Rubber plug (for auxiliary component) K9704QB 1

6 — – Adapter set for conduit work (Conduit

K9703WF 1 G1/2 x 4 sets 16 — – Sensor module assembly, QIC sheet

K9703WG 1 1/2NPT x 4 sets

K9703WH 1 M20x1.5 x 4 sets

K9703WJ 1 G1/2 x 3 sets + for Ethernet x1 set

K9703WK 1

K9703WL 1

7 K9703ZD 1 Panel mouting set (option code: /PM)

8 K9703ZL 2

9 K9703SS 1 Pipe and wall mounting set (option

Rubber plug x5

adapter + Cable gland)

1/2NPT x 3 sets + for Ethernet x1 set

M20x1.5 x 3 sets + for Ethernet x1 set

Screw set (for panel mount), 2 pcs 17 — – Communication module assembly,

code: /U)

All Rights Reserved. Copyright © 2019 Yokogawa Electric Corporation.

Subject to change without notice.

15 — – IOmodule assembly, QIC sheet is

K9704QC 1 mA Output/Input: -A4

(See Table 1)

(See Table 1)

(See Table 1)

(See Table 1)

(See Table 1)

(See Table 1)

K9704PB 1 Digital Communication:

K9704PC 1 Digital Communication:

18 A1633EF 1 Fuse

included.

mA Output/Input: -A2

is included.

1 1st/2nd input: -P1 (pH/ORP (PH))

1

1st/2nd input: C1 (Conductivity (SC))

1 1st/2nd input: -C5 (Inductive

conductivity (ISC))

1 1st/2nd input: -D1 (Dissolved

oxygen (DO))

1 1st input: -D5 (Digital sensor)

1 1st/2nd input: -S5 (SENCOM SA)

QIC sheet is included.

-E (Modbus TCP/IP)

-R (Modbus RTU (RS-485))

CMPL 12A01F01-01EN

1st Edition: Apr. 2019 (YK)

4th Edition: Nov. 2020 (YK)

Page 45

2

Table 1 Item 1; Sensor module assembly, QIC sheet is included.

Type code

Module

pH/ORP K9704EB

SC K9704FB

ISC K9704GB

DO K9704HB ―

Digital sensor K9704SC ―

SENCOM SA *2 K9704SB K9704SA

*1: If you like to replace sensor modules within explosion proof model (Type -DD (NI for FM)) for maintenance, please

consult us.

*2: Module for general purpose can not be used for Type -DD (NI for FM).

Note: The part numbers in Table 1 are modules with QIC. Sensor module number in the Table 2 shows each model number

printed on the QIC. However, you can not order with the sensor module number in Table 2.

-AB, -AD, -AG, -AJ, -AQ, -AR

(General purpose)

-DD

(NI for FM) *1

Table 2 Sensor module number (reference)

Sensor module assembly Sensor module number Sensor module assembly Sensor module number

K9704EB K9704ED K9704SC K9704SG

K9704FB K9704FD K9704SB K9704SF

K9704GB K9704GD K9704SA K9704SE

K9704HB K9704HD

4th Edition: Nov. 2020 (YK)

CMPL 12A01F01-01EN

Page 46

Revision Record

l Manual Title : Model FLXA402 4-Wire Converter Installation and Wiring

(Introduction and General Description)

l Manual No. : IM 12A01F01-02EN

Nov. 2020/7th Edition

Corrections (page 2-9)

Revised CMPL 12A01F01-01EN.

Sep. 2020/6th Edition

Added notes (pages 1-9, 2-24)

Revised CMPL 12A01F01-01EN.

July 2019/5th Edition

Revised CMPL 12A01F01-01EN.

July 2019/4th Edition

Added SENCOM SA for SC (pages ii, 1-1)

Other modication (page 2-6)

Corrections (page 2-16)

Apr. 2019/3rd Edition

Added Control Drawings (pages v, vi)

Modied (pages. 1-1, 1-2, 1-9, 2-9, 2-10, 2-22, 2-23, 2-24)

Customer Maintenance Parts List was newly released.(CMPL 12A01F01-01EN)

i

Feb. 2019/2nd Edition

Modied Model & Sux Codes. (pages. 1-7, 1-9)

Nov. 2018/1st Edition

Newly published

IM 12A01F01-02EN 7th Edition : Nov. 30, 2020-00

Page 47

Blank Page

Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo 180-8750, JAPAN

http://www.yokogawa.com/

Loading...

Loading...