Page 1

Instruction

Models FD30 / PB30

Manual

Fittings for the DO30G

IM 12J6K4-E-E

5th edition

Page 2

2

3

Table of contents

1. Introduction ..............................................................................................................3

2. Unpacking and checking ........................................................................................3

3. Warranty and service ...............................................................................................3

4. Genral specifications ...............................................................................................4

4-1. Model FD30 Immersion Fitting .............................................................................4

4.2 Model PB30 Floating Ball Fitting ..........................................................................5

5 Installation ................................................................................................................6

5.1 General................................................................................................................6

5.2 Assembling and mounting of the immersion fitting...............................................6

5.2.1 Checklist ..................................................................................................6

5.2.2 Preparing the immersion fitting .................................................................7

5.2.3 Mounting the sensor in the immersion fitting ............................................7

5.2.4 Mounting the sensor cleaner (/JC option) .................................................7

5.3 Installing the floating ball fitting ............................................................................8

5.3.1 Checklist ..................................................................................................8

5.3.2 Installation ................................................................................................8

5.3.3 Assembling the floating ball fitting (ref to Figure 4)....................................8

6 Spare parts ...............................................................................................................9

6.1 Model FD30V27 Immersion Fitting .......................................................................9

6.2 Sensor Cleaner (/JC option) ................................................................................9

6.3 Model PB30 Floating Ball Fitting ..........................................................................9

7 Dimensions .............................................................................................................10

1. Introduction

To support the Yokogawa Model DO30G sensor for measuring dissolved Oxygen, two types

of sensor holders are offered; an immersion fitting (Model FD30V27) and a floating ball fitting

(Model PB30). Both fittings are intended for mounting the DO30G in a tank, measuring

either on the surface or sub-surface of the process liquid.

The type of sensor holder, as well as the point of installation, should be selected to allow

measurement in a location where the measurement truly represents the entire solution.

Avoid areas where the measurement value varies significantly e.g. stagnant corners. Select a

place where the sensor is always immersed in the process liquid.

Properties of the sensor holders are:

Model FD30V70

• Sub-surface measurement of dissolved Oxygen

• Available in different pipe-lengths – i.e. 40mm outer diameter

• Available with a metric to inch adapter – i.e. 40 to 42mm outer diameter (standard 1¼“

pipe)

• Standard equipped with membrane check-facility

• Available in flanged and non-flanged version

• Optional Jet Cleaning (/JC Option) for avoiding fouling of the membrane

• Optional Mounting Set (/MS1 Option) for convenient mounting)

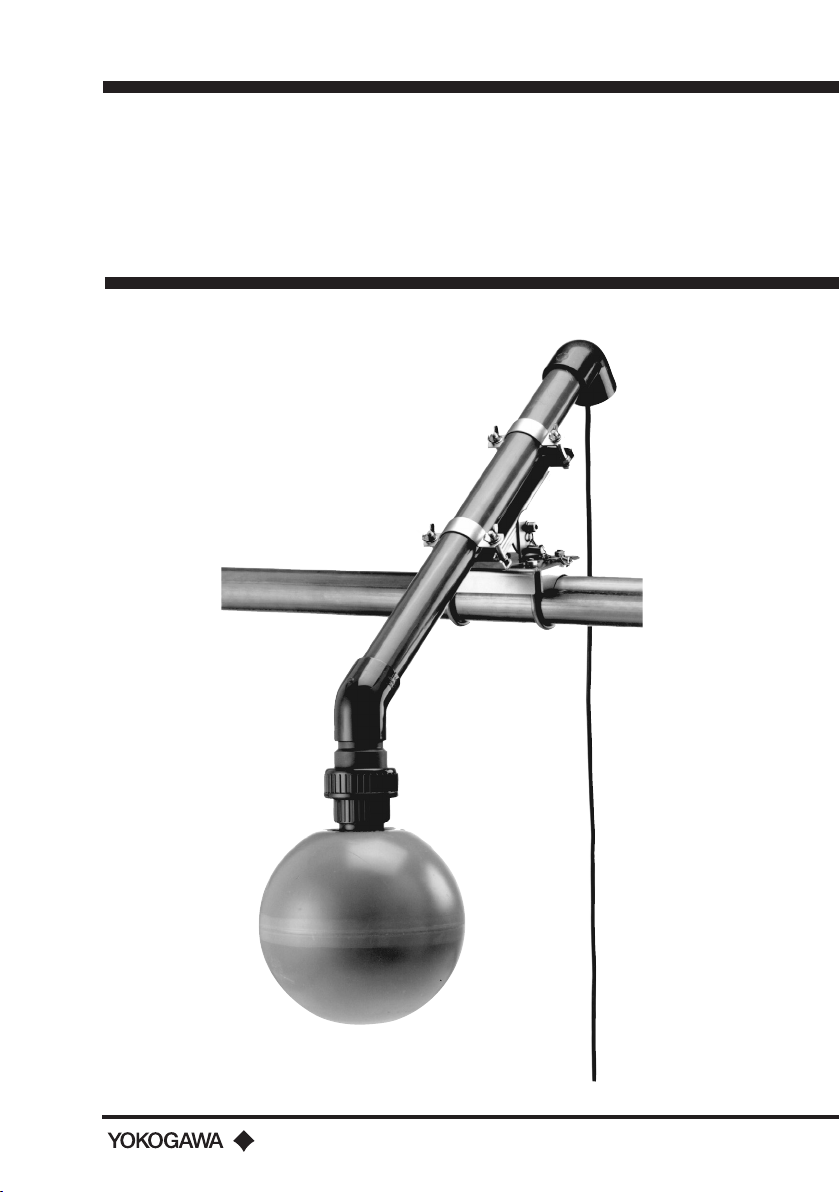

Model PB30

• Designed for minimal user maintenance

• Good flow of sample at the membrane due to wave action and constant ball movement

• Constant measurement depth

• Standard equipped with membrane check-facility

• Shipped including a winch mounting mechanism

IM 12J6K4-E-E

2. Unpacking and checking

Upon receipt of the goods, carefully inspect the shipping package for any evidence of

damage. If the carton is damaged, notify the shipping agent and the sales organizationv

immediately.

If the shipping package is not damaged, remove the products and parts. Confirm that

all items shown on the packing list are available and that the package does not contain

any parts or accessories hidden between the shock absorbing fillers. Notify the sales

organization if items are missing.

3. Warranty and service

Products and parts are warranted to be free from defects in workmanship and material

under normal use and service for a period of typically twelve months from the date of

shipment by manufacturer. The sales organization has the possibility to deviate from this

typical warranty period and the actual terms and conditions as specified in the sales order

must be consulted. Damage caused by wear and tear, inadequate maintenance, corrosion

and attack by chemical processes are excluded from this warranty coverage.

IM 12J6K4-E-E

Page 3

4

5

All defective goods need to be sent to the service of the sales organization for repair or

replacement and the returned material should be accompanied by a letter of transmittal,

which should include the following information:

• Part number, Model code and Serial number

• Date and number of sales order

• Length of time of service and type of service

• Description of the faulty operation of the device and the circumstances of the failure

• Pressure, temperature, process composition and all other process conditions or

environmental circumstances which are related to the installation and possibly failure of the

device

• Statement as to whether warranty or non-warranty service is requested

• Complete shipping and billing instructions for return of material and name, phone number

of contact person that can be approached for further information.

The returned goods that have been in contact with process fluids must be detoxified and

disinfected prior to shipment for the health and safety of our employees. Material Safety

Data sheets must be included for all components of the processes in which the sensors/

fittings have been used. The shipping address where to the goods have to be returned is

specified on the original sales order or on the back page of this manual.

4. General specifications

4.1 Model FD30 Immersion Fitting

Wetted materials

- Body & flange : Polyvinylchloride (PVC)

- O-rings : Silicone rubber

- Blanking plug : Ryton R4 (remove before use!)

- Conductive bushing : Brass

Temperature

- Minimum : -10 °C

- Maximum : +50 °C

Pressure : 2 bar max.

Immersion length : 0.5 to 2.0 m (10 cm steps) When ordered as a

subassembly (pipe length 00), a tube with PVC

cement will be delivered with the holder

Weight

- Without flange : 1.35 kg + 0.2 kg per 0.5 meter

- With flange : 0.5 kg extra

Options

- Sensor/cable : See DO30G

- Flexible conduit : PVC and Nylon

Option /PH5 : 5 meter protection hose

Option /PH10 : 10 meter protection hose

- Jet cleaner (Option /JC) : Materials: PVC, Nylon, PVDF and PTFE

Temperature: as FD30

Pressure: as FD30

Immersion length: nominal + 4 cm

- Mounting set (Option /MS1) : Material; Galvanized steel

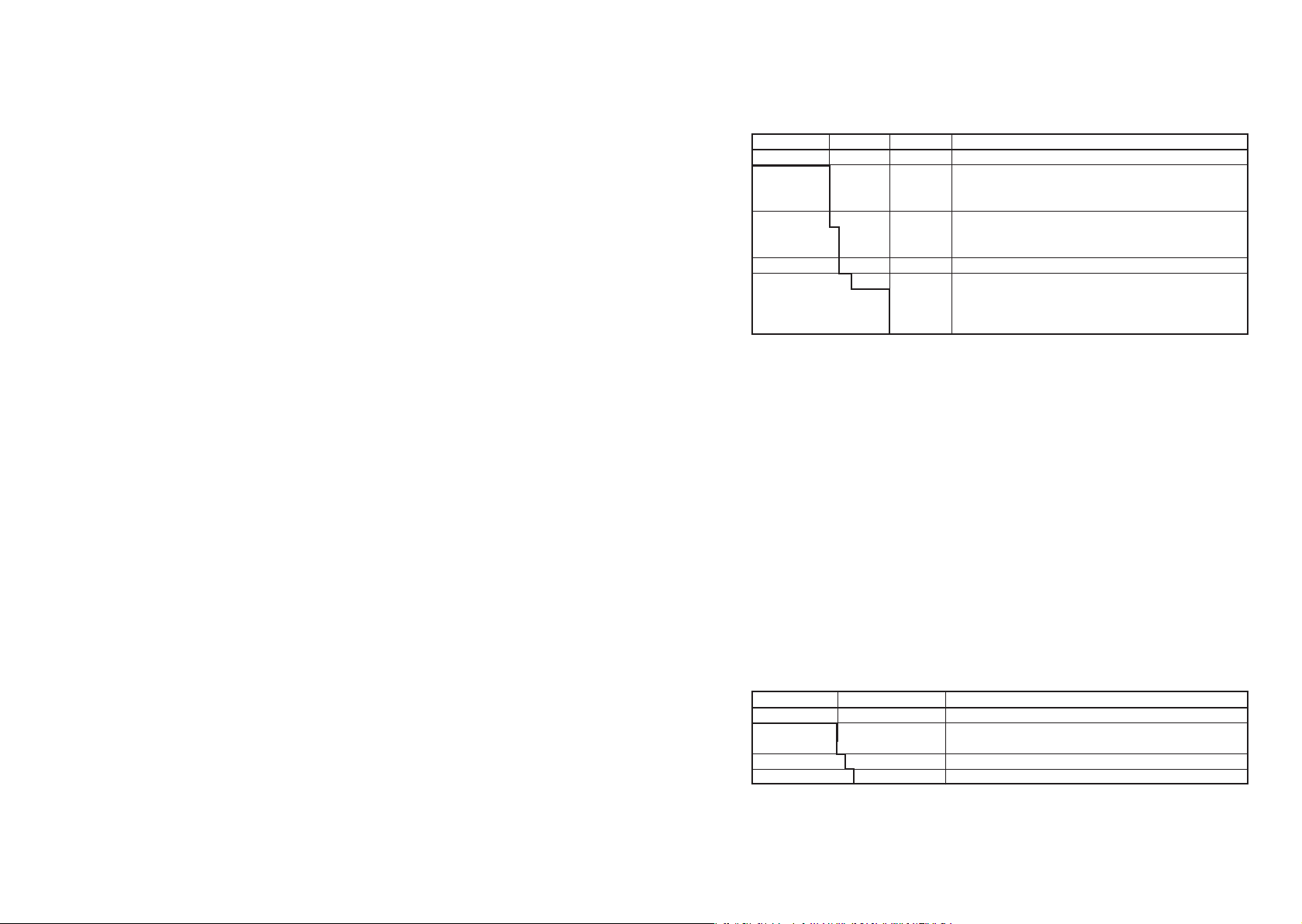

Model and Suffix code

Immersion Fitting

Model Suffix Option Description

FD30V27 Immersion Fitting PVC

Immersion -00 Pipe supplied by user

length -xx Between 0.5 and 2.0

(in steps of 0.1m) Example: 06 = 0.6 m

Mounting -FN No flange

flange -F1 DIN DN50 PN10

-F2 ANSI 2” 150 lbs

*A Style A

Protection hose /PH5 5 meter

/PH10 10 mtr

Jet Cleaner /JC *

Mounting set /MS1 *

* Not available with flanged versions.

4.2 Model PB30 Floating Ball Fitting

Wetted materials : High impact polystyrene, PVC & Brass

Temperature : 0-40 °C

Mounting bracket : Galvanized steel, for rail, or surface mounting

Sensor/cable : See DO30G

Shipping details

- Weight : 12.5 kg Approx.

- Package size : 490 x 320 x 340 mm

- Main support arm : 2.5 m

Model and Suffix Codes

Floating Ball

Model Suffix Code Description

PB30 Floating Ball Fitting

Pipe length -00 Pipe supplied by user

-25 2.5 meter

Sensor type -SNN No sensor

Cable length -00 No cable

IM 12J6K4-E-E

IM 12J6K4-E-E

Page 4

6

7

5. Installation

5.1 General

It is important to have the point of measurement in a location that is representing the

process composition. Check whether the specifications of the sensor/fitting/holder fulfill

the maximum occurring process conditions. Install the fitting in a place where it can be

maintained and calibrated safely and easily. After installation of the sensor it may need

several hours to stabilize readings. Stabilization can take up to 24 hours.

ATTENTION

Do not insert the fitting/holder into the process without the sensor mounted, to

avoid the cable leads becoming wet.

5.2 Assembling and mounting of the immersion fitting

5.2.1 Checklist

The FD30V27-xx-FN fittings will be delivered completely assembled. Flanges (suffix code -F1

or -F2) and options will be delivered separately. The FD30V27-00 version will be delivered in

parts excluding the pipe (see Figure 1). The holder piece (3) and the top piece (1a/b) have

an internal diameter suitable for both 40 mm and 11/4" customer's pipe. The jet cleaning

(option /JC) will be delivered as indicated in Figure 2.

2

11

1a

10

3

6

7

Top piece (1a/b)

• Pigtail (2)

Holder piece (3)

1b

• Screw piece (4)

5

• Conductive bu shing (5)

• “O”-ring (6)

• Stopper (7)

8

• “O”-ring (8)

Tube PVC adhesive (9)

4

Instruction manual (10)

Flange (if specified) (11)

9

Figure 2

5.2.2 Preparing the immersion fitting

Prepare the immersion fitting by unscrewing

the screw piece (4) from the bottom of the

fitting. Remove the stopper (7), which can

be discarded, and the conductive bushing

(5). The screw piece will be used to fix the

DO sensor in the fitting. When a flexible

conduit (protecting hose) will be used,

the pigtail part (2) can also be discarded.

When an immersion fitting with cleaner

is used the cleaning cage will be used to

fix the DO-sensor. In that case the screw

piece can also be discarded. In case of

a FD30V27-00 version the top piece and

the holder piece should be mounted on

the customers pipe using the supplied

adhesive. Ensure that the sealing will be

watertight.

5.2.3 Mounting the sensor in the

immersion fitting

Pull the sensor cable through the O-ring

into the fitting and through the pigtail (see

Figure 3). In case a flexible conduit will

be used please remove the pigtail and

follow the instructions delivered with the

protecting hose option. Push the O-ring

over the cable assembly until it lies on the

knurled ring. Plug the cable assembly into

the sensor body, if this was not performed

before. Secure the cable assembly with the

knurled ring. Place the sensor in the fitting

and put the bushing (essential for sensor

diagnostics) around the sensor as far as

it will go. Then screw the screw piece, or

the cleaning cage, in again. This will fix the

sensor in place by compressing the O-ring.

Tighten the pigtail at the top of the fitting.

Figure 1

IM 12J6K4-E-E

IM 12J6K4-E-E

Page 5

8

9

5.2.4 Mounting the sensor cleaner (/JC

option)

• After fixing the sensor with the cleaning

cage it is possible to screw the cleaner

tubing on the cage using the swage

lock coupling material provided with the

cleaner.

• It is recommended to fix the tubing to the

holder using tie wraps.

• Keep some flexible length of tubing for

ease of maintenance.

The cleaner can be used for both water and

air. It is recommended to use a solenoid

valve of the normally closed type with

matching connections. The solenoid valve

can be switched with the wash contact of

the EXA DO-converter.

5.3 Installing the floating ball fitting

5.3.1 Checklist

The floating ball fitting with sensor for

Dissolved Oxygen will be delivered in parts

and has to be assembled before it can

be used. Check if all standard parts are

delivered, see Figure 4. Please note that

items (4), (5) and (2 + 6) are optional and, if

not specified with the order, these parts will

not be delivered. The position ring (9) will

only be received when PB30-00. is ordered.

This part is only needed when 11/2" pipe

will be used in stead of 50 mm.

Figure 3

5.3.2 Installation

Mount the floating ball not exactly vertical, but under a slight angle, so that air bubbles do

not 'stick' or adhere to the membrane.

5.3.3 Assembling the floating ball fitting (ref to Figure 4)

• Attach the mounting bracket (1) to wall or pipe; clamps are already fixed to the bracket.

• Install the main support arm (2) (in case of PB30-00... the customers pipe), in the

mounting bracket (1) and adjust its length to the desired length.

• Use the supplied adhesive (7) to stick the lower support to the main support arm (2).

When a 11/2" pipe is used, the position ring (10) must be mounted in between them to

compensate for the difference.

• Attach (not for PB30-00...) the 90° elbow (6) to the upper end of the main support arm

and cement it with adhesive (7).

• Guide the cable assembly (4) through the main support arm.

• Position the complete sensor (4+5) in the lower support.

• Place the lower support (3) into the ball (8) by screwing the fixing nut hand-tight.

• Connect the leads of the cable to the EXA DO converter.

6

7

2

1

9

3

10

4

7

8

Figure 4

6. Spare parts

6.1 Model FD30V27 Immersion Fitting

Item Description Spare part no

6 5 x O-ring K1500FX

8 5 x O-ring K1500FY

6.2 Sensor Cleaner (/JC option)

Item Description Spare part no

1 5 x O-ring 37.7 X 2.6 for mounting sensor in fitting K1500FY

2 Holder

3+4 Nozzle parts K1500AZ

7 10m tubing (1/4 “) for jet cleaner K1530UL

3,4,6 Spray nozzle for jet cleaner K1530UK

6.3 Model PB30 Floating Ball Fitting

Item Description Spare part no

1 Mounting bracket K1530DQ

2 Main support arm

3 Lower support arm with O-ring K1530QA

4 DO30G sensor See DO30G

6 Elbow 90º

7 Tube PVC adhesive

8 Floating ball assembly with O-ring K1530SA

9 Position ring

10 O-ring 25.3 x 3.2 Viton 70º shore K1500AV (5x)

IM 12J6K4-E-E

IM 12J6K4-E-E

Page 6

10

10

11

11

Dimensions

Figure 5: FD30 Figure 6: FD30 with flange

78 (3.07)

125 (4.92)

168 (6.60)

18 (0.70)

Ø 100 (3.94)

Ø 40 (1.57)

L

18 (0.70)

Figure 7: Option /MS1

Fill piece

Figure 8: PB30 rail mounting

Guide pipe

Ø 48,6 x 600

(Ø1.9 x 24")

Min: 110 (4.35")

Max: 515 (20")

2-inch Stanchion

(Vertical)

Ø 50 (1.97)

IM 12J6K4-E-E

IM 12J6K4-E-E

70 (2.80)

90 (3.54)

Ø 40 (1.57)

Ø 50 (1.97)

70 (2.80)

L

90 (3.54)

pipe/rail

mounting

DN 50 (2.00)

2570 ± 50 (100 ± 2)

Ø 50

(1.97)

230 (9.06)

344 (13.54)

IM 12J6K4-E-E

IM 12J6K4-E-E

Page 7

Figure 9: wall mounting

70 (2.75)

111 (4.37)

121 (4.76)

164 (6.45)

YOKOGAWA HEADQUARTERS

9-32, Nakacho 2-chome,

Musashinoshi

Tokyo 180

Japan

Tel. (81)-422-52-5535

Fax (81)-422-55-1202

E-mail: webinfo@mls.yokogawa.co.jp

www.yokogawa.com

YOKOGAWA EUROPE B.V.

Euroweg 2

3825 HD AMERSFOORT

The Netherlands

Tel. +31-88-4641 000

Fax +31-33-4641 111

E-mail: info@nl.yokogawa.com

www.yokogawa.com/eu

Ø 9 (.35)

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

United States

Tel. (1)-770-253-7000

Fax (1)-770-251-2088

E-mail: info@yca.com

www.yca.com

YOKOGAWA ELECTRIC ASIA Pte. Ltd.

5 Bedok South Road

Singapore 469270

Singapore

Tel. (65)-241-9933

Fax (65)-241-2606

E-mail: webinfo@yas.com.sg

www.yokogawa.com.sg

Yokogawa has an

extensive sales and

distribution network.

Please refer to the

European website

(www.yokogawa.com/eu)

to contact your nearest

representative.

YOKOGAWA

IM 12J6K4-E-E 05-811 (A) I

Subject to change without notice Printed in The Netherlands

Copyright ©

Loading...

Loading...