Page 1

Instruction

Manual

Model FD20

Immersion Fittings

pH/ORP

YOKOGAWA

IM 12B6K2-01E-E

7th edition

Page 2

TABLE OF CONTENTS

1. INTRODUCTION ......................................................................................................... 2

2. SPECIFICATIONS .......................................................................................................3

2-1. General specifications ............................................................................................ 3

2-2. Functional specifications ........................................................................................ 3

2-3. Model and codes ...................................................................................................4

2-4. External dimensions ..............................................................................................5

3. INSTALLATION ..........................................................................................................6

3-1. Selecting the installation site .................................................................................. 6

3-2. Installation .............................................................................................................. 6

3-3. Cables and sensor mounting ................................................................................. 7

4. MOUNTING OF ACCESSORIES .............................................................................. 11

4-1. Mounting kit (FP20-S13) ...................................................................................... 11

4-2. Mounting kit (order nr. 82850747) ........................................................................ 12

4-3. Cleaning systems ................................................................................................. 12

4-4. Salt bridge ...........................................................................................................15

4-5. Protection hoses .................................................................................................. 15

5. MAINTENANCE AND INSPECTION ........................................................................ 16

6. SPARE PARTS ..........................................................................................................16

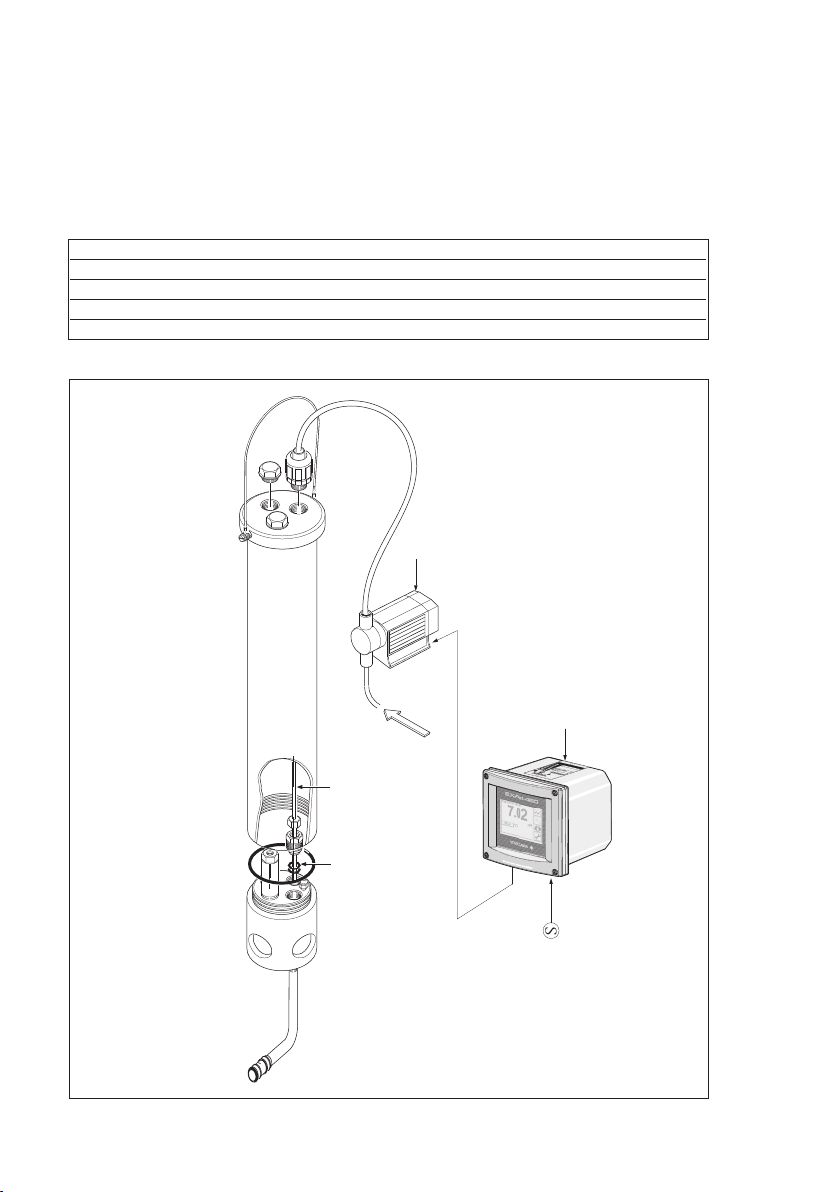

1. INTRODUCTION

The model FD20 immersion fittings are used to submerge sensor tips so that the pH and/or

ORP (redox) potential of liquids in open vessels, tanks, drains etc. can be measured.

The fittings are available for mounting of either:

- one electrode

- three electrodes

- four electrodes or alternatively three electrodes and a cleaning system.

Features

• Designed for either pH or ORP measurements in tanks open vessels and drains.

• “Hoisting cable” for easy maintenance.

• Pre-selected immersion length.

• Wide choice of construction materials.

• Flange mounting.

• High degree of standardisation reduces spare holding requirements.

• Liquid earth pin for stable measurements.

• Chemical or brush cleaning systems as an option.

Page 3

2. SPECIFICATIONS

2-1. General specifications

Materials

- wetted parts

A. body (refer to model code) : polyproplylene (PP)

stainless steel AISI 316 (SS)

polyvinylchloride (PVC)

polyvinylidenefluoride (PVDF)

B. O-rings : silicone rubber

C. liquid earth sensor : titanium (PP and PVDF design)

(not in 1-hole fitting) stainless steel AISI 316 (SS design)

- electrode mounting sets : Ryton R 4

- “hoisting eye” : stainless steel cable (twisted)

Weight* : see tabel 1

Table 1

Material PVC PP SS PVDF

Fitting

1-hole fitting 0,4 kg

3-hole fitting 2 kg 5,3 kg 2,5 kg

4-hole fitting 4,5 kg 6,4 kg 5,5 kg

* The accessories are not included. The noted weights are at an immersion length of 1 m.

3

Mounting : by means of the “hoisting eye” or flange

mounting

2-2. Functional specifications

Temperature

- min. : -10°C

- max. : depending on material and application (see

figure 2-1)

Immersion length (in dm) : between 0,5 and 2,0 m

Pressure : see figure 2-1

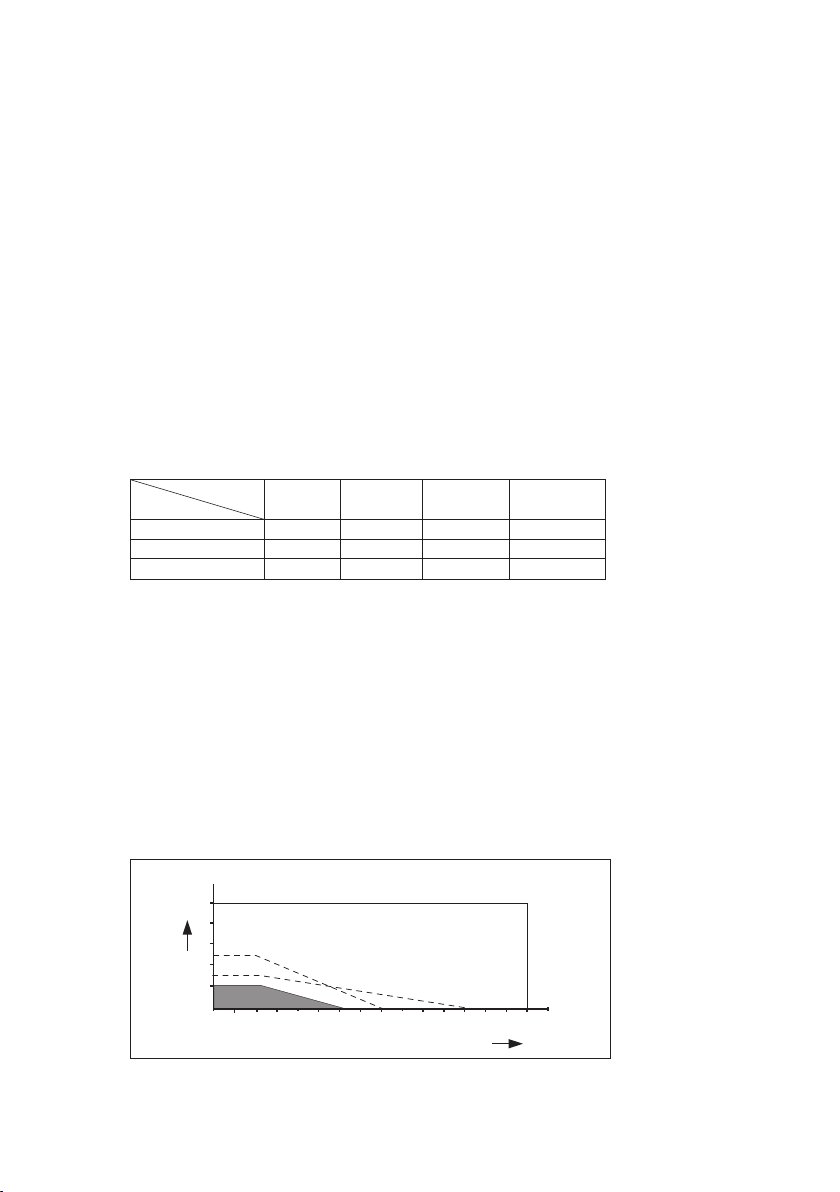

Pressure/temperature class (figure 1)

10

BAR

8

6

PP

4

PVDF

2

0 20 40 60 80 100 120 140 160

PVC

SS

ºC

Fig. 2-1. Pressure/temperature class

IM12B6K2-01E-E

Page 4

4

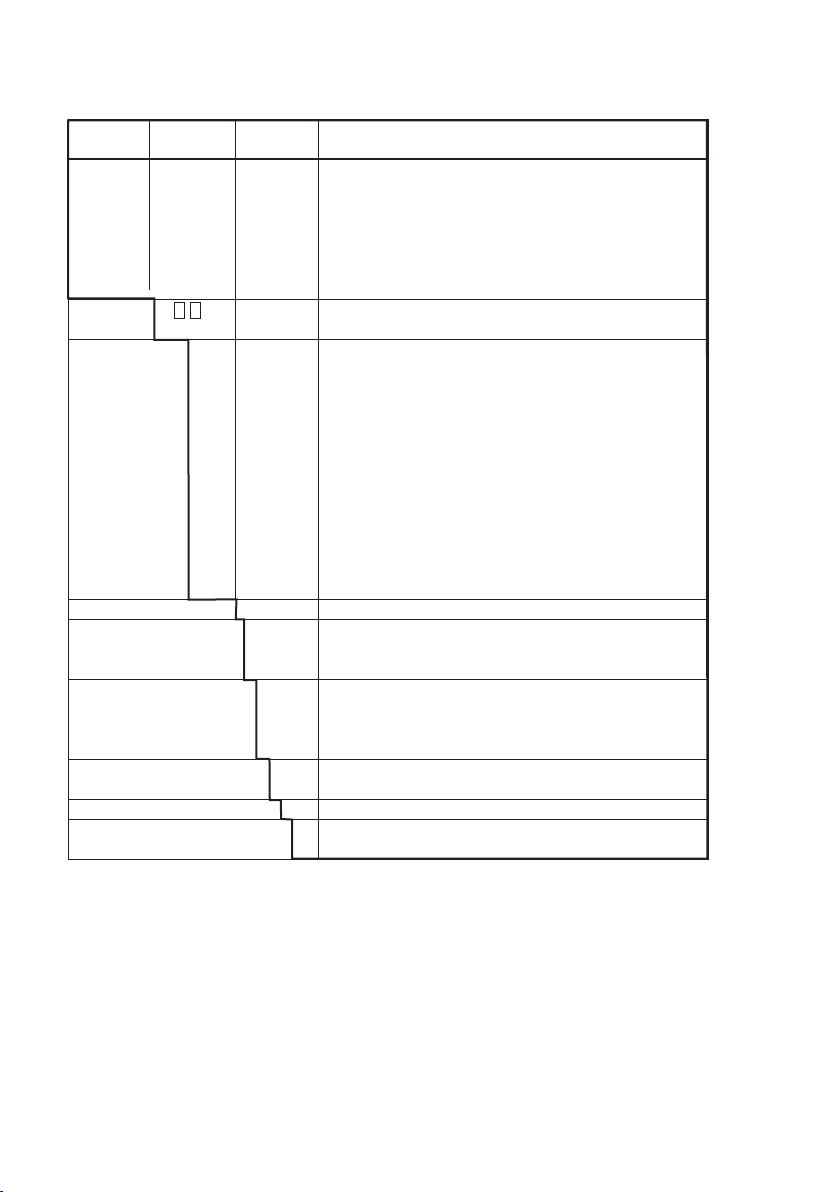

2-3. Model and codes

Model Suffix Option Description

Code Code Code

FD20F37 Immersion fitting, PVDF, 3 electrode mounting holes

FD20F47 Immersion fitting, PVDF, 4 electrode mounting holes

FD20P37 Immersion fitting, PP, 3 electrode mounting holes

FD20P47 Immersion fitting, PP, 4 electrode mounting holes

FD20S37 Immersion fitting, SS, 3 electrode mounting holes

FD20S47 Immersion fitting, SS, 4 electrode mounting holes

FD20V18(1 Immersion fitting, PVC, 1 electrode mounting holes

Immersion - Between 5 and 20 (in dm)

length(2 example 06=0.6 m.

Flange(3 -NF No flange

(Working -F1 Flange DN32 for 1 hole fitting

pressure -F2 Flange DN80 for 3 hole fitting PP

not more than -F3 Flange DN80 for 3 hole fitting PVDF

3 bar) -F4 Flange DN80 for 3 hole fitting SS

-F5 Flange DN125 for 4 hole fitting PP

-F6 Flange DN125 for 4 hole fitting PVDF

-F7 Flange DN100 for 4 hole fitting SS

-S1 Flange ANSI 11/4” 150Lbs for 1 hole fitting PVC

-S2 Flange ANSI 3” 150Lbs for 3 hole fitting PP

-S3 Flange ANSI 3” 150Lbs for 3 hole fitting PVDF

-S4 Flange ANSI 4” 150Lbs for 3 hole fitting SS

-S7 Flange ANSI 4” 150Lbs for 4 hole fitting SS

*A Style A

Options

Protectionhose /PH5 For 5,5 m cable

installation kit /PH10 For 10 m cable

Mounting kit /R For mounting (top) refillable electrodes with al long

glass shaft

/B For mounting Bellomatic reference and combined

electrodes

KCL reservoir(4 /K Electrode tubing is included (2,5 m)

(only in combintaion with /R)

Salt bridge /S For liquid which cannot stand contamination with KCL

Certificate /M 3.1 according EN-10-024 (DIN 50049 3.1)

for wetted metal parts

1. PVC is available in a 1-hole design only.

2. The immersion length of stainless steel fittings with a flange will be shortened by 35 mm

(refer to dimensional drawings).

3. Configuration of hole (see dimensional drawings 2-4). Working pressure not more than 3

bar. For higher pressure ratings please contact your local Sales Department of Yokogawa.

4. In combination with /R option only.

Notes:

a. Options are supplied with the fitting.

b. The available length of the electrode cables between fitting and converter or connection

box is cable length minus immersion length (L).

IM 12B6K2-01E-E

Page 5

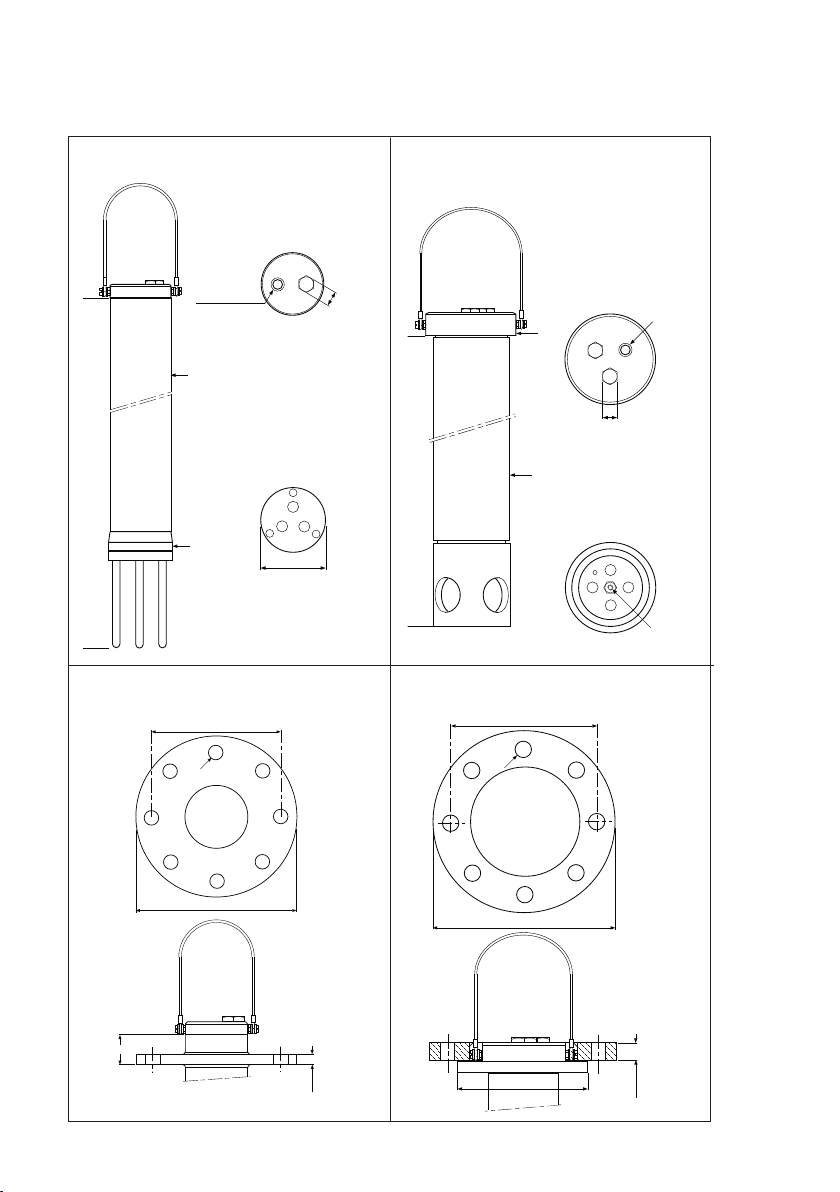

2-4. External dimensions

ø 30

ø 25

ø 40

L

ISO 228/2-G1/2

5

1-hole PVC

3-hole PP and PVDF

Flange Flange

ø D

ø dg

ø90

ISO 228/2-G 1/2

(2x)

ø75

ø k

dg

27

ø k

b

ø D

b

ø 125

IM12B6K2-01E-E

Page 6

6

ø130

ø110

27

M8

ISO 228/2-G1/2 (3x)

3-hole SS

ISO 228/2-G 1/2

2x

ø76

ø80

27

80

4-hole PP and PVDF

Flange Flange

ø k

ø k

35

IM 12B6K2-01E-E

dg

ø D

dg

ø D

b

ø 188

b

L

Page 7

7

L

ø 88

ISO 228/2-G 1/2

(3x)

27

M8

ø 100

35

b

ø D

ø k

4-hole SS

Flange

dg

L D k dg b

FD20-V18-..-NF 5-20dm

FD20-V18-..-F1 5-20dm 120 90 14 26

FD20-V18-..-S1 5-20dm 120 90 16 26

FD20-P37-..-NF 5-20dm

FD20-F37-..-NF 5-20dm

FD20-P37-..-F2 5-20dm 200 160 18 20

FD20-F37-..-F3 5-20dm 200 160 18 20

FD20-P37-..-S2 5-20dm 190 152.4 20 18

FD20-F37-..-S3 5-20dm 190 152,4 20 18

FD20-S37-..-NF 5-20dm

FD20-S37-..-F4 5-20dm 200 160 18 10

FD20-S37-..-S4 5-20dm 228,6 190,5 19 23,8

FD20-P47-..-NF 5-20dm

FD20-F47-..-NF 5-20dm

FD20-P47-..-F5 5-20dm 250 210 18 25

FD20-F47-..-F6 5-20dm 250 210 18 25

FD20-S47-..-NF 5-20dm

FD20-S47-..-F7 5-20dm 220 180 18 10

FD20-S47-..-S7 5-20dm 228,6 190,5 19 23,8

unit in mm

IM12B6K2-01E-E

Page 8

8

3. INSTALLATION

3-1. Selecting the installation site

It is important that, whatever method of

mounting is used, the point of measurement is

truly representative for the entire solution.

- Avoid an area where the measurement value

varies significantly.

- Ensure that the sensors are always immersed

in the process liquid (not dry).

GO OD

GO OD

HOR IZO NTAL

15 º

15 º

- When selecting the installation site, first check

that the liquid temperature and pressure

meets the sensors and fittings requirements.

- If the fitting is used in a tank with stirrer

or agitator, or if it is placed in a fast flowing

process, care must be taken that it

Fig. 3-1. Mounting position of sensors

INC ORR ECT

is adequately supported to prevent any

movement.

- Install the fitting in a site where it can be easily maintained.

The mounting position of the sensors must be within the area as shown in figure 3-1.

3-2. Installation

Before installing the immersion fitting, check that all parts and accessories were supplied by

Yokogawa.

Ensure that there is enough spare around to withdraw the fitting for calibration and maintenance.

3-2-1. “Hoisting eye” type mounting

On top of each fitting is a “hoisting eye” to withdraw from the process.

3-2-2. Flange mounting fitting

If ordered, the immersion fittings are supplied with a flange for fixing in a tank. The flange is

connected to the fitting as shown in the dimensional drawings. These drawings also show

the configuration of holes.

The max. pressure is 3 bar. For higher pressure ratings and other types of flanges please

contact your local Sales Department of Yokogawa.

Table 2. Flanges being used as a standard

Type Material TypePP Material DN Thickness

fitting fitting flange flange flange

1-hole PVC glue-flange PVC 32

3-hole SS weld-flange SS 80 10 mm

4-hole SS weld-flange SS 100 10 mm

3-hole PP collar-bush + PP + 80

lap-joint flange PP (steal inlay)

4-hole PP collar-bush + PP + 125

lap-joint flange PP (steal inlay)

3-hole PVDF collar-bush + PVDF + 80

lap-joint flange PP (steal inlay)

4-hole PVDF collar-bush + PVDF + 125

lap-joint flange PP (steal inlay)

IM 12B6K2-01E-E

Page 9

9

10 cm

colour

marker

colour

marker

outer

screening

white

core red

inner

screening

blue

Cable nut

3-3. Cables and sensor mounting

Before mounting a sensor and/or accessory

the cables must be passed through the

fitting. When mounting Yokogawa sensors

the electrode cables, model WU20(D),

should be used (see figure 3-2). Length 1,

2, 51/2, 10, 15, 20 or 25 m.

Model code Suffix code Description

WU20(D) Electrode cable

Type -PC COAX

-LT TRIAX

Length in mm 01 1 mtr

02 2 mtr

05 51/2 mtr

10 10 mtr

3-3-1. 1-Hole fitting

Unscrew the protector from the lower end

and the nut with glands from the top end of

15 15 mtr

20 20 mtr

25 25 mtr

the fitting. Mount the cable and sensor as

shown in figure 3-3.

Type WU20-PC Type WU20-LT

Cable nut

Cable nut

10 cm

10 cm

colour

marker

colour

marker

COAX

screen

blue

Fig. 3-2. Electrode cables

colour

marker

core

red

TRIAX

inner

screening

blue

core red

colour

marker

outer

screening

white

IM12B6K2-01E-E

Page 10

10

10 cm

colour

marker

colour

marker

outer

screening

white

inner

screening

blue

Cable nut

Type WU20D-PC

Cable nut

10 cm

screen

blue

COAX

colour

marker

colour

marker

O-rings

(11x3)

core

red

Type WU20D-LT

Cable nut

10 cm

colour

marker

colour

marker

TRIAX

inner

screening

blue

core red

outer

screening

white

Attention:

Ensure that the cable has slack remaining

in the fitting so that sensor replacement is

simplified. To prevent damage of the O-rings

the nut and glands must be screwed

HAND-TIGHT to the fitting. Prepare the

sensor to be used in accordance with the

directions for use. After that mounting can

be made as shown in fig. 3-3.

Attention:

To prevent fouling of the contacts, it is

recommended to screw the electrode

cable on the electrode as soon as possible.

Ensure that there is no moisture or dust in

the connection sensor-cable.

Electrode cable model WU20

Fig. 3-3. Mounting a cable and sensor

in a 1-hole fitting

IM 12B6K2-01E-E

Page 11

11

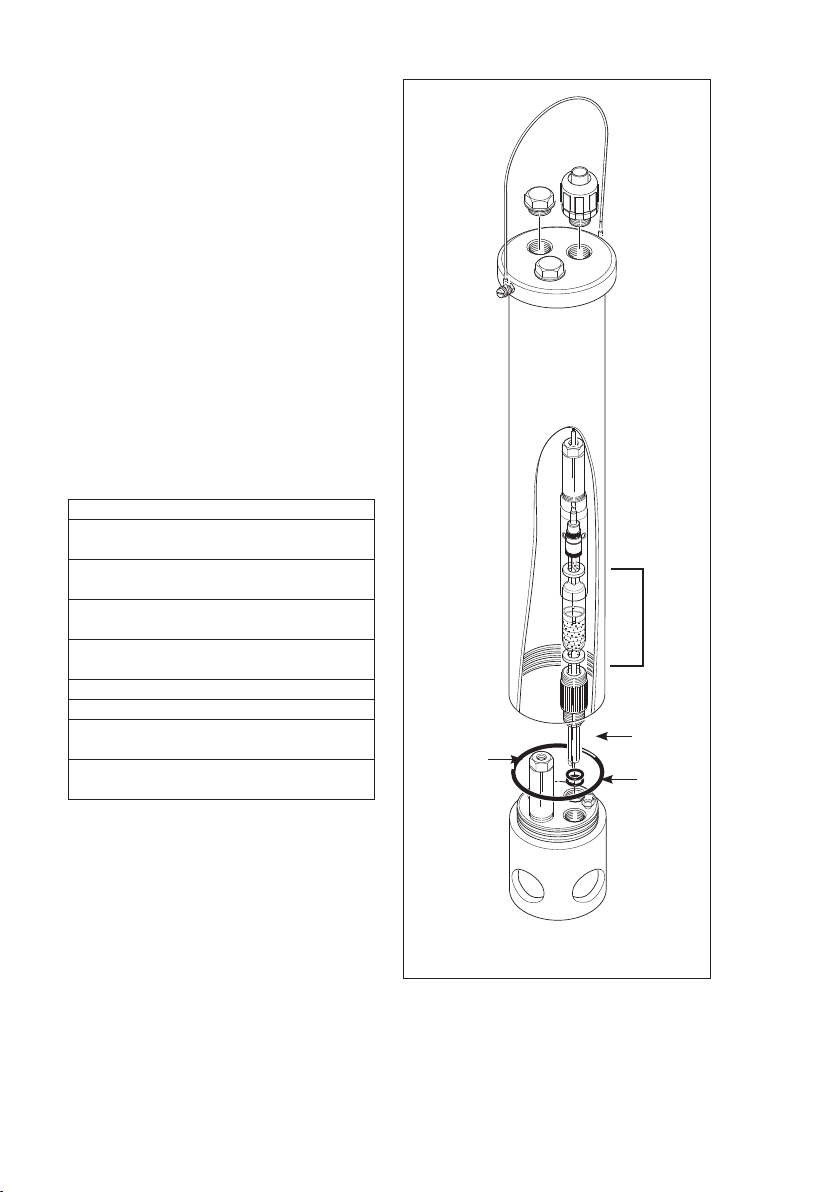

3-3-2. 3-Hole and 4-hole fitting

Unscrew the protector complete with

electrode holder from the lower end of the

fitting (see figure 3-3).

Unscrew the cap of an electrode mouting

set. Pass the electrode cable through this

cap and after that through the fitting.

Mount the other electrode cables in a

similar manner. Pass the electrode cables

and the liquid earth cable through a hose

connection, which is delivered with the

fitting in a plastic pocket.

Attention:

Ensure that the cables have slack remaining

in the fitting. The plug of the electrode cable

must be ± 15 cm out of the lower end so

that torsion will be avoided and

sensor mounting is simplified.

Before screwing the hose connection into

place HAND-TIGHT, some glue must be put

to the screw end (see figure 3-4).

Prepare the sensors to be used in

accordance with the directions for use and

mount them in the fitting as shown in fig.

3-4. For stable measurements the glass

and reference electrode should be mounted

in the holes nearest to the earth connection.

As delivered the O-rings (2x) for water-tight

sealing in the mounting holes are on the

blanking plugs. These plugs are for unused

holes.

To prevent fouling of the contacts, it is

recommended to screw the electrode cable

on the electrode as soon as possible.

ENSURE THAT THERE IS NO MOISTURE

OR DUST IN THE CONNECTION CABLEELECTRODE.

Liquid earth

cable

Protection

hose

Glue

Electrode cable

model WU20(D)

Electrode

O-rings

(11x3)

Attention:

To have slack remaining in the fitting the

protector complete with electrode holder

should be turned to the left before fixing

HAND-TIGHT to the fitting.

Fig. 3-4. Mounting cables and sensors

in 3-hole and 4-hole fittings

IM12B6K2-01E-E

Page 12

12

4. MOUNTING OF ACCESSORIES

4-1. Mounting kit (FP20-S13(D))

Using this mounting kit a SR20(D)-AC32

reference electrode of Yokogawa can be

mounted in a fitting (see figure 4-1.).

For atmospheric conditions the mounting kit

can be used also for combined electrodes,

types SC29-PTC54.

Electrodes to be used*

Order nr. Description

SR20(D)-AC32 Reference electrode

SC29-PTC54 Combined redox/reference

electrode

* For specifications of the electrodes see

seperate sheets.

Parts and accessories

Order nr. Description

FP20-S13 Mounting kit for SR20-AC32

(10x)

FP20-S13D Mounting kit for

SR20(D)-AC32 (10x)

K1500HC Rubber rings for FP20-S13

(10x)

K1500GE O-rings for SR20D-AC32

electrode (5x)

K1500GF 250 ml, KCI-solution (1 m)

K1500VA 250 ml, KCI-solution (3,3 m)

K1500GG 250 ml, KCI-solution (1 m)

thickened

K1520VN 250 ml, KCI-solution

(3,3 m) thickened

Ring

K1500HC

Bellomatic

electrode

K1500BZ

IM 12B6K2-01E-E

Fig. 4-1. Mounting of a BELLOMATIC

electrode

Page 13

4-2. Mounting kit (order nr. K1500BY)

This mounting kit replaces the standard

electrode mounting set so that Yokogawa

refillable electrodes with a long glass shaft

can be mounted in a fitting.

The mounting set may be used at process

pressures up to 3 bar. Higher pressure

ratings require the standard mounting set

and consequently, electrodes with DINdimensions.

Figure 4-2 shows the mounting.

Note:

The pressure on the KCI-solution must

always exceed the liquid pressure.

The refillable electrodes can be connected

to a KCI-reservoir via a silicone tubing

(see figure 4-2). The pressure on the

KCI-solution and consequently, the liquid

outlet of the electrode can be increased by

mounting the reservoir on top of the fitting.

This prevents penetration of the process

liquid into the electrode.

Electrode to be used*

Order nr. Description

SR20-AC52 Reference electrode

SR20-AS52 Reference electrode

SC21-AGC52 Combined pH/ref. electrode

SC21-ASC52 Combined pH/ref. electrode

* For specifications see seperate sheets.

Parts and accessories

Order nr. Description

K1500BY Mounting kit

K1500FZ O-ring for mounting kit

K1500GF 250 ml, KCI-solution (1 m.)

K1500GG 250 ml, KCI-solution (1m.),

thickend

KCI-Reservoir

K1500FU

Silicone tubing

K1500GA

13

Electrode

O-Rings

K1500BZ

Fig. 4-2. Mounting of refillable electrodes

with a long glass shaft

IM12B6K2-01E-E

Page 14

14

4-3. Cleaning systems

The standardised design of fittings makes it

possible to mount cleaning systems directly.

The 4-hole types are especially designed for

these applications.

The Yokogawa program includes two

different types of cleaning systems

(see figure 4-3):

- brush cleaning

(electrically or pneumatically driven)

- chemical cleaning

Fig. 4-3a. Brush Cleaning Fig. 4-3b. Chemical Cleaning

4-3-1. Selection criteria

Cleaning system Mechanical Chemical

Applications with Brush Acid Base

Oils, fats

Resins (wood, pulp) X

Emulsions of latex X

Fibers (paper, textile) X

Crystaline precipations (carbonates) X XX

Amorpheus precipations (hydroxides) X XX

IM 12B6K2-01E-E

Page 15

15

4-3-2. Brush cleaning

The brush of this cleaning system wipes

across the glass membrane of the

Motor

K1520NF

Cable

model

WU20(D)

O-rings (11x3)

(K1500BZ)

Brush holder

K1520NG

Control unit

electrode every 30 seconds. Electrically or

pneumatically driven versions are available.

Figures 4-4a and 4-4b show the mounting.

Protection hose

K1520NC

Tubing

K1520NA

Control unit

Piston unit

K1520NH

O-rings (11x3)

Brush holder

K1520NG

Fig. 4-4a. Mounting a brush cleaning

(electrically driven) FC20-VE

Fig. 4-4b. Mounting a brush cleaning

(pneumatically driven) FC20-VP

Parts and accessories

Order nr. Description

FC20-VE Brush cleaning (electrically driven)

WU20-PC Electrode cable (to be used as a supply cable for the motor)

Length: 1, 3, 5, 10, 15, 20 or 25 m.

FC20-VP Brush cleaning (pneumatic driven)

K1520NB Brush

K1520NA Tubing (ø 4 mm) for FC20-VP for connection between piston and supply unit

* Detailed specifications are on seperate sheets.

IM12B6K2-01E-E

Page 16

16

4-3-3. Chemical cleaning

The chemical cleaning system is based on periodically spraying of a cleanser on to the

glass membrane of the electrode. The cleanser to be used, the cleaning frequency, etc. are

highly dependent on the liquid to be measured. The cleaning period and frequency can be

adjusted on a control unit. The mounting procedure is shown in figure 4-5.

Parts and accessories

Order nr. Description

K1520FK Tubing ø1/4” for chemical cleaning (1 m)

K1547PA Complete chemical cleaning system HCN2, HCN3 for 2-hole and 3-hole fittings

K1547PB Complete chemical cleaning system HCN4, for 4-hole fittings

K1547PP EPDM spraying valve nozzle 5 sets (for all HCN- chemical cleaning systems)

* Detailed specifications are on seperate sheets.

PUMP

(type dependent on application)

Spray unit HCN

Fig. 4-5. Mounting a spray unit

IM 12B6K2-01E-E

TUBE

O-RINGS

(11 x 3)

Control unit

Page 17

4-4. Salt bridge

This reference electrode/salt bridge

combination allows the measurement of

pH and ORP (Redox) potentials with normal

electrodes in those cases when:

A. excessive contamination of the flow

diaphragm is expected. The flow of the

reference liquid through the diaphragm is

increased by pressurising the container.

Consequently, the contamination rate will

decrease.

B. the process to be measured cannot

stand contamination with KCI. The

salt bridge can be filled with several

electrolytes, e.g. KNO3.

C. measurement has to be performed at

pressures up to 10 bar and temperatures

up to 100 °C. As the container with

reference liquid can be pressurised.

FLOW TUBE (A)

Material : glass

Flow diaphragm : ceramic, PTFE or sleeve

Connector : Ryton R4

TUBING (B)

Material : nylon

Diameter : 1/4” o.d.

Length : 2 mtr.

CONTAINER (C)

Container : PVC, PVC (transparent)

Mounting set : Ryton R4

O-ring : silicone

Connection : nylon

Weight : approx. 300 g.

Mounting : wall mounting (support

with hole for screw M5)

Temperature/

pressure ratio : max. 200 kPa

(2 bar) at 100°C

Parts and accessories

Order nr. Description

SB20-VC Salt bridge with ceramic junction

SB20-VP Salt bridge with porous PTFE

junction

SB20-VS Salt bridge with glass sleeve

junction

K1500DX 5m tubing for SB20

K1500BW flow tube for SB20-VC

K1500EE flow tube for SB20-VP

K1500EF flow tube for SB20-VS

17

REFERENCE

ELECTRODE

Fig. 4-6. Mounting the salt bridge

Note: The reference electrode must be

ordered seperately.

4-5. Protection hose installation kit

The protection hose installation kit is for

protection of electrode cable and/or tubing

between fitting and converter, connecting

box, supply unit, etc. The hoses can be

mounted directly to the hose connections(s)

on top of each fitting. Clamps for fixing are

part of the installation kit.

Parts and accessories

Order nr. Description

K1500DN Protection hose kit 3 m

K1500DP Protection hose kit 5,5 m

K1500DQ Protection hose kit 10 m

K1500DR Protection hose kit 15 m

K1500DS Protection hose kit 20 m

IM12B6K2-01E-E

Page 18

18

5. MAINTENANCE AND INSPECTION

5-1. Cleaning and fitting

Usally no cleaning is necessary.

5-2. Inspection of the O-ring seal

The O-ring seal used in the wetted parts of the fitting is made of silicone rubber which has

superior resistance to corrosion and is suitable for use with most process liquids.

Usually no periodically inspection is necessary. To prevent trouble, replace the O-ring seal

periodically, e.g. every year.

Note: For chemical resistance of the used material refer to General Specifications sheet

GS 12B6K2-01E-E.

6. SPARE PARTS

Order nr. Description

K1500GR O-rings (11x3) for electrode mounting (8 pieces)

K1500FU Set O-rings for 3-hole fitting (PP and PVDF)

K1500FB (viton) Set O-rings for 3-hole fitting (PP and PVDF)

K1500FA (EPDM) Set O-rings for 3-hole fitting (PP and PVDF)

K1500GV Set O-rings for 4-hole fitting (PP and PVDF)

K1500FF (viton) Set O-rings for 4-hole fitting (PP and PVDF)

K1500FE (EPDM) Set O-rings for 4-hole fitting (PP and PVDF)

K1500GW Set O-rings for 3-hole fitting (SS)

K1500FD (viton) Set O-rings for 3-hole fitting (SS)

K1500FC (EPDM) Set O-rings for 3-hole fitting (SS)

K1500GX Set O-rings for 4-hole fitting (SS)

K1500FH (viton) Set O-rings for 4-hole fitting (SS)

K1500FG (EPDM) Set O-rings for 4-hole fitting (SS)

K1500DQ 10 m protection hose and glands

K1500DP 5,5 m protection hose and glands

FP20-R12 Electrode mounting set (Ryton R4) (1x)

FP20-R12M Mounting set (Ryton R4) (12x)

FP20-S12 Electrode mounting set (SS)

K1500FV Liquid earth cable (10 m)

K1500DU Liquid earth cable (25 m)

K1500FU KCI-reservoir

WU20-PC01 COAX-cable (1 m) for single electrode

WU20-PC02 COAX-cable (2 m) for single electrode

WU20-PC05 COAX-cable (5,5 m) for single electrode

WU20-PC10 COAX-cable (10 m) for single electrode

WU20-PC15 COAX-cable (15 m) for single electrode

WU20-PC20 COAX-cable (20 m) for single electrode

WU20-PC25 COAX-cable (25 m) for single electrode

WU20-LT01 TRIAX-cable (1 m) for combined electrode

WU20-LT02 TRIAX-cable (2 m) for combined electrode

WU20-LT05 TRIAX-cable (5,5 m) for combined electrode

WU20-LT10 TRIAX-cable (10 m) for combined electrode

WU20-LT15 TRIAX-cable (15 m) for combined electrode

WU20-LT20 TRIAX-cable (20 m) for combined electrode

WU20-LT25 TRIAX-cable (25 m) for combined electrode

IM 12B6K2-01E-E

Page 19

1-Hole PVC

Note

This fitting has no liquid earth connection

19

3-Hole PP and PVDF 4-Hole PP and PVDF 3-Hole SS 4-Hole SS

IM12B6K2-01E-E

Page 20

YOKOGAWA ELECTRIC CORPORATION

World Headquarters

9-32, Nakacho 2-chome, Musashino-shi

Tokyo 180-8750

Japan

www.yokogawa.com

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

USA

www.yokogawa.com/us

YOKOGAWA EUROPE BV

Euroweg 2

3825 HD AMERSFOORT

The Netherlands

www.yokogawa.com/eu

YOKOGAWA ELECTRIC ASIA Pte. LTD.

5 Bedok South Road

Singapore 469270

Singapore

www.yokogawa.com/sg

YOKOGAWA CHINA CO. LTD.

3F Tower D Cartelo Crocodile Building

No.568 West Tianshan Road Changing District

Shanghai, China

www.yokogawa.com/cn

YOKOGAWA MIDDLE EAST B.S.C.(c)

P.O. Box 10070, Manama

Building 577, Road 2516, Busaiteen 225

Muharraq, Bahrain

www.yokogawa.com/bh

Yokogawa has an extensive sales and

distribution network.

Please refer to the European website

(www.yokogawa.com/eu) to contact your

nearest representative.

IM 12B6K2-01E-E

Subject to change without notice Printed in The Netherlands, 07-1008 (A) I

Copyright ©

Loading...

Loading...