Page 1

User ’s

TM

Manual

Model FC500G

Free Available Chlorine

Analyzer

(Non-Reagent Type)

IM 12F5A2-01E

IM 12F5A2-01E

5th Edition

Page 2

Introduction

This user’s manual describes the specications, installation, operation, maintenance, and

troubleshooting for Model FC500G Free Available Chlorine Analyzer. Read this manual

thoroughly to understand the contents before operating the equipment.

n Notes on Hardware

l Appearance and Accessories

Check the following when you receive the product:

• Appearance

• Standard accessories

Contact our sales representative or your local distributor if the product’s coating has come o, it

has been damaged, or there is shortage of required accessories.

l Model and Sux Codes

The name plate on the product contains the model and sux codes. Compare them with those in

the general specication to make sure the product is the correct one. If you have any questions,

contact our sales representative or your local distributor.

i

Media No. IM 12F5A2-01E 5th Edition : July 2018 (YK)

All Rights Reserved Copyright © 2007, Yokogawa Electric Corporation

IM 12F5A2-01E

Page 3

ii

Safety Precautions

Safety, Protection, and Modication of the Product

n

• In order to protect the system controlled by the product and the product itself and ensure

safe operation, observe the safety precautions described in this user’s manual. We assume

no liability for safety if users fail to observe these instructions when operating the product.

• If this instrument is used in a manner not specified in this user’s manual, the protection

provided by this instrument may be impaired.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter simply

referred to as YOKOGAWA) when replacing parts or consumables.

• Modication of the product is strictly prohibited.

Signal Words

n

The following words are used in this manual.

CAUTION

This symbol gives information essential for understanding the operations and functions.

NOTE

This symbol indicates information that complements the present topic.

Notes on Handling User’s Manuals

n

• Please hand over the user’s manuals to your end users so that they can keep the user’s

manuals on hand for convenient reference.

• Please read the information thoroughly before using the product.

• The purpose of these user’s manuals is not to warrant that the product is well suited to any

particular purpose but rather to describe the functional details of the product.

• No part of the user’s manuals may be transferred or reproduced without prior written

consent from YOKOGAWA.

• YOKOGAWA reserves the right to make improvements in the user’s manuals and product at

any time, without notice or obligation.

• If you have any questions, or you nd mistakes or omissions in the user’s manuals, please

contact our sales representative or your local distributor.

Warning and Disclaimer

n

The product is provided on an “as is” basis. YOKOGAWA shall have neither liability nor

responsibility to any person or entity with respect to any direct or indirect loss or damage arising

from using the product or any defect of the product that YOKOGAWA can not predict in advance.

n Trademark Acknowledgments

• EXA FC is a trademark of Yokogawa Electric Corporation.

• All other company and product names mentioned in this user’s manual are trademarks or

registered trademarks of their respective companies.

• We do not use TM or ® mark to indicate those trademarks or registered trademarks in this

user’s manual.

IM 12F5A2-01E

Page 4

After-sales Warranty

n Do not modify the product.

n During the warranty period, for repair under warranty consult the local sales

representative or service oce. Yokogawa will replace or repair any damaged

parts. Before consulting for repair under warranty, provide us with the model

name and serial number and a description of the problem. Any diagrams or

data explaining the problem would also be appreciated.

l If we replace the product with a new one, we won’t provide you with a repair report.

l Yokogawa warrants the product for the period stated in the pre-purchase quotation

Yokogawa shall conduct dened warranty service based on its standard. When the

customer site is located outside of the service area, a fee for dispatching the maintenance

engineer will be charged to the customer.

n In the following cases, customer will be charged repair fee regardless of

warranty period.

• Failure of components which are out of scope of warranty stated in instruction manual.

• Failure caused by usage of software, hardware or auxiliary equipment, which Yokogawa

Electric did not supply.

• Failure due to improper or insucient maintenance by user.

• Failure due to modication, misuse or outside-of-specications operation which Yokogawa

does not authorize.

• Failure due to power supply (voltage, frequency) being outside specications or abnormal.

• Failure caused by any usage out of scope of recommended usage.

• Any damage from re, earthquake, storms and oods, lightning, disturbances, riots, warfare,

radiation and other natural changes.

iii

n Yokogawa does not warrant conformance with the specic application at the

user site. Yokogawa will not bear direct/indirect responsibility for damage due

to a specic application.

n Yokogawa Electric will not bear responsibility when the user congures the

product into systems or resells the product.

n Maintenance service and supplying repair parts will be covered for ve years

after the production ends. For repair for this product, please contact the

nearest sales oce described in this instruction manual.

IM 12F5A2-01E

Page 5

Blank Page

Page 6

Model FC500G

Free Available Chlorine Analyzer

(Non-Reagent Type)

IM 12F5A2-01E 5th Edition

CONTENTS

Introduction ..........................................................................................................i

Safety Precautions .......................................................................................ii

1. OVERVIEW ................................................................................................ 1-1

1.1 Standard Specications ................................................................................... 1-2

1.2 Model and Sux Codes ...................................................................................1-4

1.3 External Dimensions ........................................................................................1-5

1.4 Measuring Principle .......................................................................................... 1-6

2. COMPONENTS AND FUNCTIONS .......................................................... 2-1

2.1 Detector .............................................................................................................. 2-1

2.2 Converter ........................................................................................................... 2-2

Toc-1

3.

INSTALLATION, PIPING, AND WIRING ....................................................3-1

3.1 Installation ......................................................................................................... 3-1

3.1.1 Location .............................................................................................. 3-1

3.1.2 Mounting ............................................................................................ 3-2

3.2 Piping ................................................................................................................. 3-2

3.2.1 Sample Water Piping ......................................................................... 3-2

3.2.2 Air Purge Piping ................................................................................. 3-2

3.3 Wiring ................................................................................................................. 3-3

3.3.1 Wiring for Power Supply and Grounding ........................................... 3-3

3.3.2 Analog Output Wiring ......................................................................... 3-3

4. OPERATION .............................................................................................. 4-1

4.1 Preparation for Operation ................................................................................ 4-1

4.1.1 Inspection of Piping and Wiring Status .............................................. 4-1

4.1.2 Fill with Glass Beads for Electrode Polishing .................................... 4-1

4.1.3 Measuring Range Setting .................................................................. 4-2

4.1.4 Setting of “Applied Voltage Compensation/Applied Voltage Fixation’’ Se-

lection Jumper .................................................................................... 4-3

4.2 Start-Up .............................................................................................................. 4-4

4.2.1 Supplying Sample Water ................................................................... 4-4

4.2.2 Conrmation of “Power Supply Voltage” and “Measuring Range” Selec-

tion Jumpers Setting Status ............................................................... 4-4

4.2.3 Supplying Power ................................................................................ 4-5

4.2.4 Operation Check ................................................................................ 4-5

4.2.5 Calibration .......................................................................................... 4-5

4.3 Steady State Operation .................................................................................... 4-5

IM 12F5A2-01E

Page 7

Toc-2

5. CALIBRATION ........................................................................................... 5-1

5.1 Zero Calibration ................................................................................................. 5-1

5.1.1 Zero Calibration Procedure Using the Open Input Circuit Method .... 5-1

5.1.2 Zero Calibration Procedure Using Chlorine-Free Water Method ......5-1

5.2 Span Calibration ............................................................................................... 5-2

5.2.1 Span Calibration Procedure Using the Sampling Method ................. 5-2

5.2.2 Span Calibration Procedure Using Standard Solution Method ......... 5-2

6. INSPECTION AND MAINTENANCE ........................................................ 6-1

6.1 Mechanical System ........................................................................................... 6-1

6.1.1 Indicator Electrode Polishing ............................................................. 6-1

6.1.2 Glass Beads and Measuring Tank Cleaning ..................................... 6-2

6.1.3 Brush and Slip Ring Checking ........................................................... 6-3

6.2 Electrical System .............................................................................................. 6-5

6.2.1 Span Calibration ................................................................................ 6-5

6.2.2 Converter Checking ...........................................................................6-5

6.2.3 Fuse Replacement .............................................................................6-5

7. TROUBLESHOOTING .............................................................................. 7-1

8. AUXILIARIES AND CONSUMABLES ...................................................... 8-1

8.1 Auxiliaries and Consumables List .................................................................. 8-1

8.2 Auxiliaries and Consumables ......................................................................... 8-1

8.2.1 Polisher (Part number: K9088PE) ..................................................... 8-1

8.2.2 Glass Beads (Part number: K9332ZJ)............................................... 8-1

8.2.3 Indicator Electrode (Part number: K9332MB) ................................... 8-1

8.2.4 Grease (Part number: K9044FX) .......................................................8-1

8.2.5 Counter Electrode (Part number: K9332MK) .................................... 8-1

8.2.6 Brush and Slip Ring (Part number: K9332JX, K9332JZ) .................. 8-2

Customer Maintenance Parts List .......................................... CMPL 12F5A2-01E

Revision Information ...............................................................................................i

IM 12F5A2-01E

Page 8

<1. OVERVIEW>

1. OVERVIEW

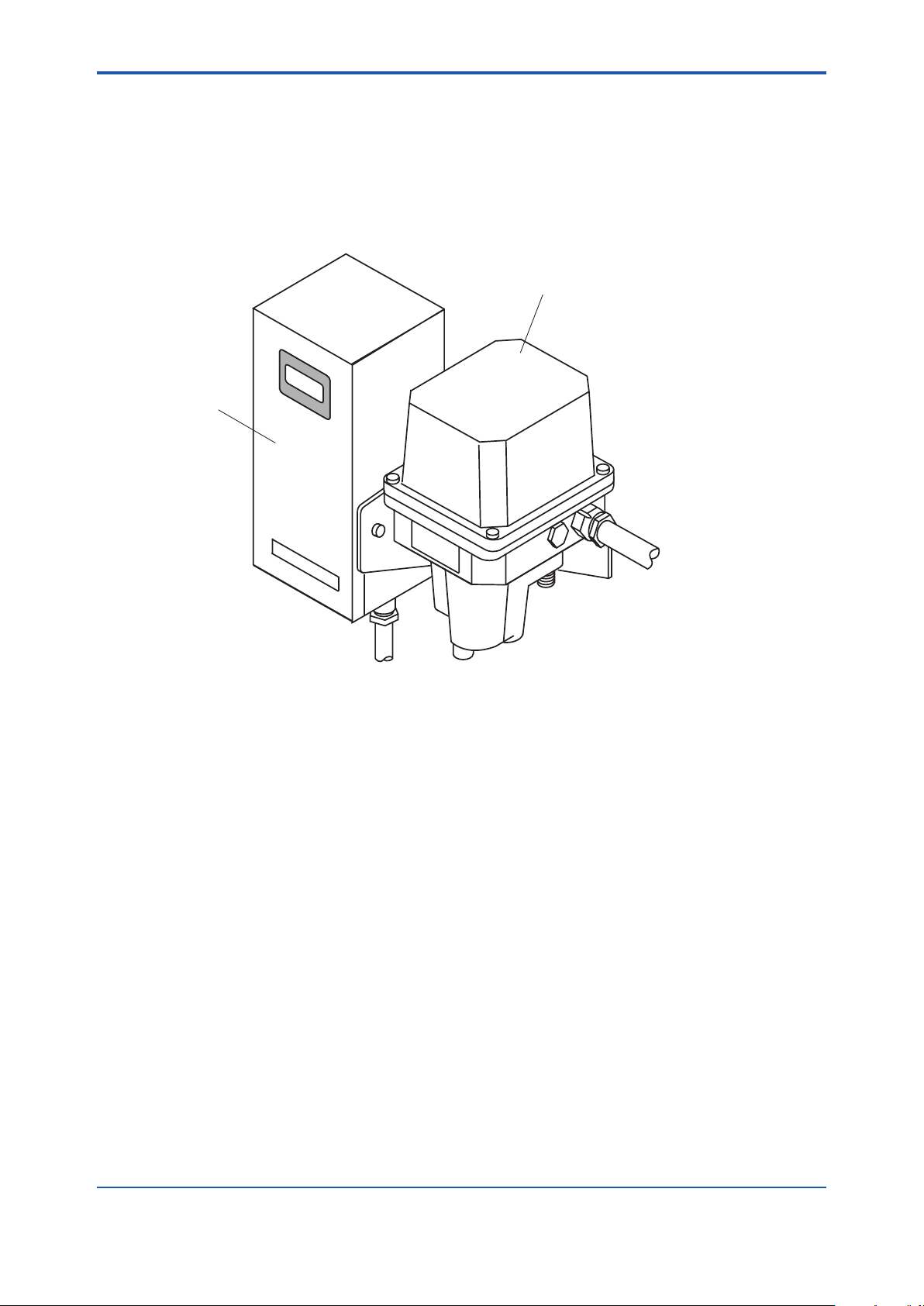

Model FC500G Free Available Chlorine Analyzer (Non-Reagent Type) is used for continuous

measurement of free available chlorine in tap water distribution. This analyzer consists of a

detector and a converter as shown in Figure 1.1.

This chapter describes the FC500G free available chlorine analyzer specications and its

measuring principle.

Detector

Converter

1-1

Figure 1.1 Appearance of Model FC500G Free Available Chlorine Analyzer

IM 12F5A2-01E

Page 9

<1. OVERVIEW>

1-2

1.1 Standard Specications

Measured Object: Free available chlorine contained in tap water

Measuring System: Polarographic method using rotating electrode

Measuring Ranges: 0 to 1 / 0 to 2 / 0 to 3 mg/L (Model FC500G-1)

0 to 5 / 0 to 10 mg/L (Model FC500G-5) (Air purge is necessary.)

Indication: Digital (3 1/2 LCD)

Output Signal: 4 to 20 mA DC (Load resistance: Maximum 500 Ω)

Operating pH Range of Sample Solution:

pH 6.5 to 7.5: For measured liquids whose pH exceeds the above limits,

error increases (refer to the following gure).

Sample Solution:

Temperature: 0 to 40°C (temperature compensation range 5 to 35°C).

Pressure: 1 to 30 kPa (for without VALVE)

1 to 150 kPa (with VALVE)

Flow Rate: 0.1 to 2.5 L/min (at tank inlet)

Conductivity: 100 to 300 μS/cm

SS (Suspended Solid): 10 mg/L or less

Air Purging (for only 0 to 5 / 0 to 10 mg/L Range)

Supply Air Pressure: About 50 to 140 kPa

Air Consumption: About 5 L/min

Electrode:

Indicator Electrode: Rotating gold electrode

Counter Electrode: Silver electrode (with Pt 1000 installed)

Electrode Cleaning: Glass beads used for cleaning

Wetted Part Materials:

Measuring Tank: Acrylic resin (molding)

Piping: Flexible PVC and PE

Color: Muncell 5Y7/1

Finish: Baked polyurethane resin coating

Mounting: On the wall or 2 inch pipe (OD 60.5 mm)

Ambient Temperature: -5 to 50°C

Power Supply: 100 or 110 V AC; or 200 or 220 V AC as per order ±10%, 50 or 60 Hz

Power Consumption: Approximately 15 VA (100 or 110 V), 20 VA (200 or 220 V)

Weight: Approximately 6.5 kg

EMC Regulatory Arrangement in Australia and New Zealand (RCM)

EN 55011 Class A, Group 1

IM 12F5A2-01E

Characteristics:

Reproducibility: 2% of full scale

Linearity: ±5% of full scale

Stability: Zero Drift: Within ±1% of full scale/month

Span Drift: Maximum -10% of full scale/month

Page 10

<1. OVERVIEW>

Indicated value (mg/l)

Response Time: Approximately 2 minutes (time required to obtain a value within 90% of

nal value)

Ambient Temperature Inuence:

±0.5% of full scale/10°C

Power Voltage Fluctuation Inuence:

±0.5% of full scale/10% of rated voltage

Sample Solution Temperature Compensation Error:

±3% of full scale/5 to 35°C

1.0

pH6.5 pH7.5

1-3

0.5

0

3 4 5 6 7 8 9 10

Figure 1.2 Sensitivity characteristics of diusion current by pH value

Figure 1.3 Sensitivity characteristics of diusion current by conductivity

Note: If conductivity exceeds 300 μS/cm, default value of applied voltage should be changed.

Operating range

pH

n Accessories

Fuse (1 A) .........................4 pcs.

Glass Beads .....................1 (2 bags)

Allen Wrench ....................2 pcs.

Screwdriver (at blade) ...1 pc.

Polishing Powder ..............1 bottle

IM 12F5A2-01E

Page 11

<1. OVERVIEW>

1-4

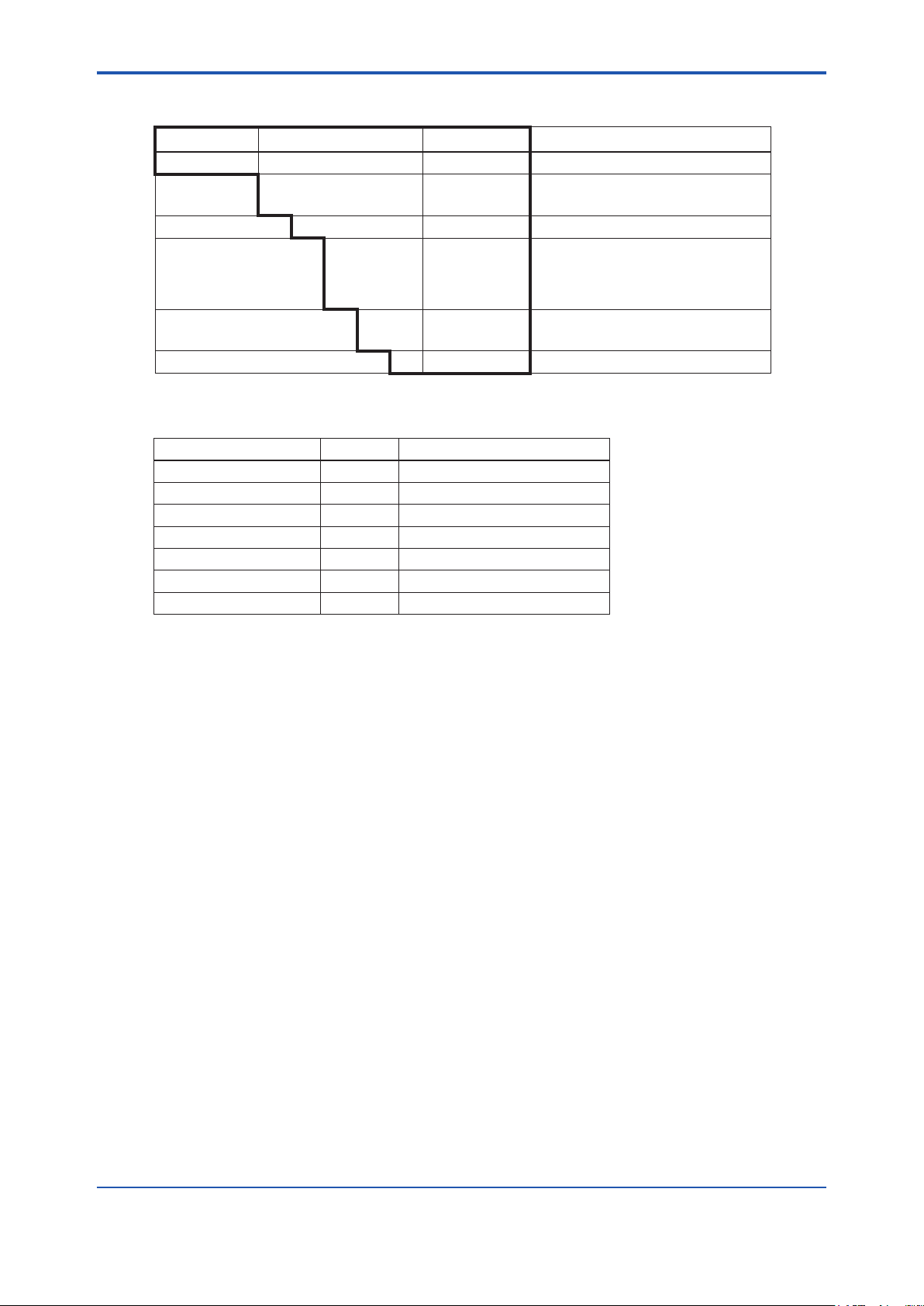

1.2 Model and Sux Codes

Model Sux Code Option Code Description

FC500G ���������������������������������� ���������������������� Free Available Chlorine Analyzer

Range

Output signal 1 ���������������������� 4 to 20 mA DC

Power

Inlet valve

Language -E ���������������������� English

n Spare Parts

Indicator Electrode K9332MB Rotating Electrore

Counter Electrode K9332MK Reference Electrode

Glass Beads K9332ZJ Washing Indicator Electrode (2 bags)

Polishing Powder K9088PE Polishing Indicator Electrode

Brush K9332JX

Slip Ring K9332JZ

Grease K9044FX

-1

-5

3

4

5

6

0

1

Name Parts No. Note

����������������������

����������������������

����������������������

����������������������

����������������������

����������������������

����������������������

����������������������

0 to 1 / 0 to 2 / 0 to 3 mg/L Switchable

0 to 5 / 0 to 10 mg/L Switchable

100 V ±10%, 50/60 Hz

110 V ±10%, 50/60 Hz

200 V ±10%, 50/60 Hz

220 V ±10%, 50/60 Hz

Without Valve

With Valve

IM 12F5A2-01E

Page 12

<1. OVERVIEW>

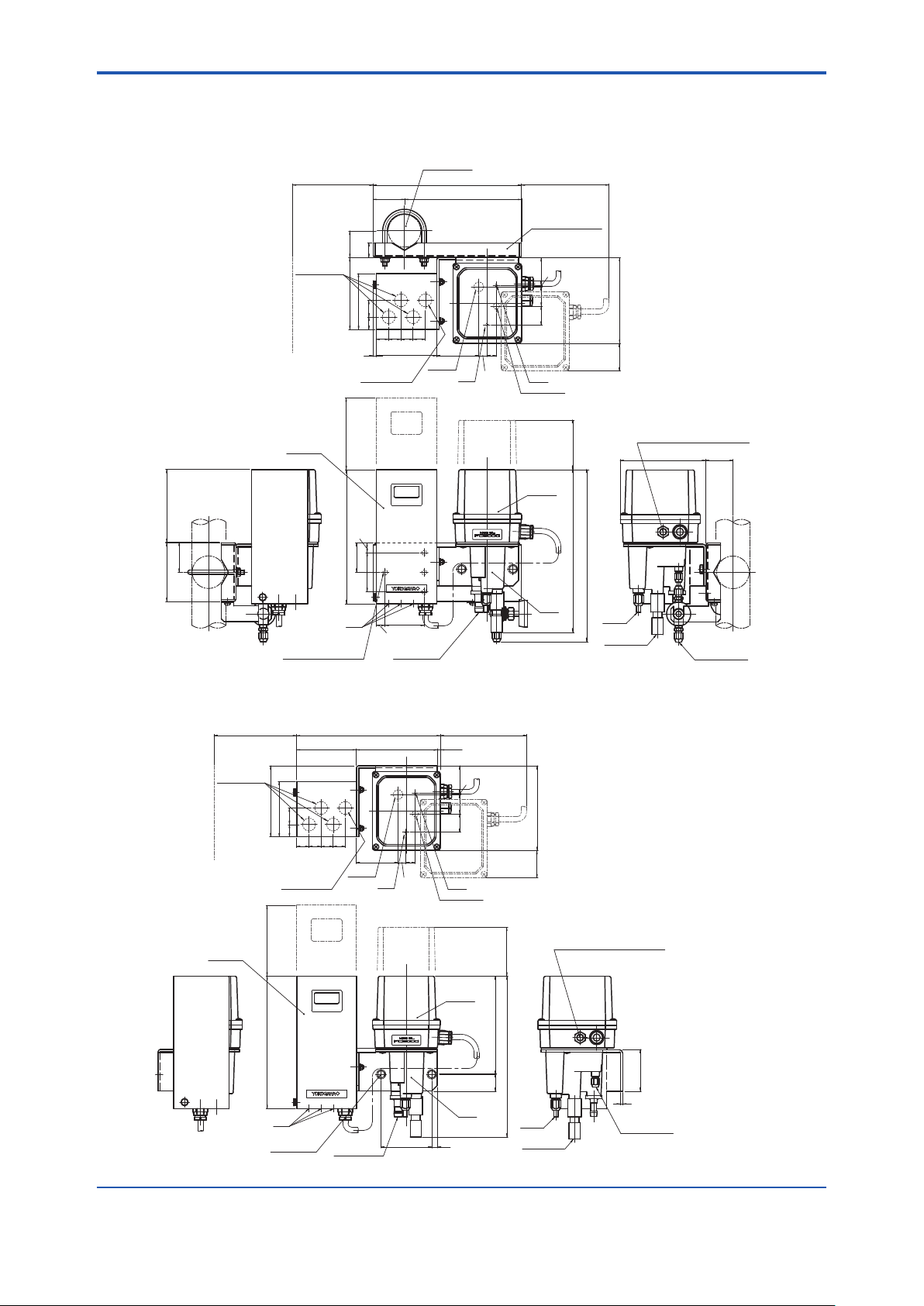

1.3 External Dimensions

(1) With Inlet Valve (FC500G-¨¨¨1-E)

1-5

105 131

52.5

Approx.150

Wiring inlet

3-Ø23 holes

Converter

4-Ø8.5 holes

for mounting

(U-bolt on bracket)

Approx.250

240

Cap

100

128.5 48

3022 26

22

5.5

Cable gland

space

Maintenance

17.5

52.5

70

(22)

22 22

108

0.50

mg/l

70

21

Outlet

Ø12 Nipple

2-inch pipe (Ø60.5)

265

(209)56

76

Cap

17.3

13.7

Outlet

Maintenance spaceMaintenance space

Approx.160

Mounting bracket

2.8

49.2

35

33.4

Inlet

Drain cock

Approx.

Driving

Box

Tub

150

space

Maintenance

295

310

154

50

Approx.

space

Maintenance

Purge air inlet

1/4-18 NPT

(for only FC500G-5-E)

Insert

Drain cock

Unit: mm

(48)(154)

Inlet

Ø6/Ø4 Union

(2) Without Inlet Valve (FC500G-¨¨¨0-E)

17.3

92

Maintenance spaceMaintenance space

Approx.160

2.8

49.2

35

33.4

Inlet

Drain cock

Driving

Box

Tub

10

Approx.150

Wiring inlet

3-Ø23 holes

Converter

100

128.5

3022

22

Cable gland

space

Approx.250

Maintenance

240

Cap

2-Ø8.5 holes

for mounting

22 22

0.50

(22)

Outlet

mg/l

Outlet

Ø12 Nipple

260

76

Cap

146.5 (5.5)108

13.7

150

Approx.

17830

295

154

50

Approx.

space

Maintenance

Purge air inlet

1/4-18 NPT

(for only FC500G-5-E)

space

Maintenance

Insert

Drain cock

Unit: mm

75

4

Inlet

Ø6/Ø4 Union

Figure 1.4 Model FC500G Free Available Chlorine Analyzer External Dimensions

IM 12F5A2-01E

Page 13

<1. OVERVIEW>

1-6

1.4 Measuring Principle

The FC500G free available chlorine analyzer (non-reagent type) is used for measuring

concentration of free available chlorine present in sample water, such as chlorine (Cl2)

hypochlorous acid (HClO), and hypochlorite ion (ClO-).

The measuring principle of this analyzer is analysis determination using the rotating electrode

polarographic method. Free available chlorine concentration is determined by measuring the

current (diusion current) which ows when free available chlorine is subjected to electrolytic

reduction by applying a voltage (applied voltage) between the indicator electrode (rotating

electrode) and the counter electrode. The applied voltage is set in a region where concentration

polarization occurs (plateau region) in polarography. In the plateau region, the diusion current

does not change even if the applied voltage changes.

In measurement practice, since the plateau region changes with free available chlorine

concentration, the applied voltage is compensated so that measurement can always be

performed in the plateau region. Also, since the diusion current is aected by the sample water

temperature, temperature is compensated using a temperature sensor (Pt1000Ω) incorporated in

the counter electrode.

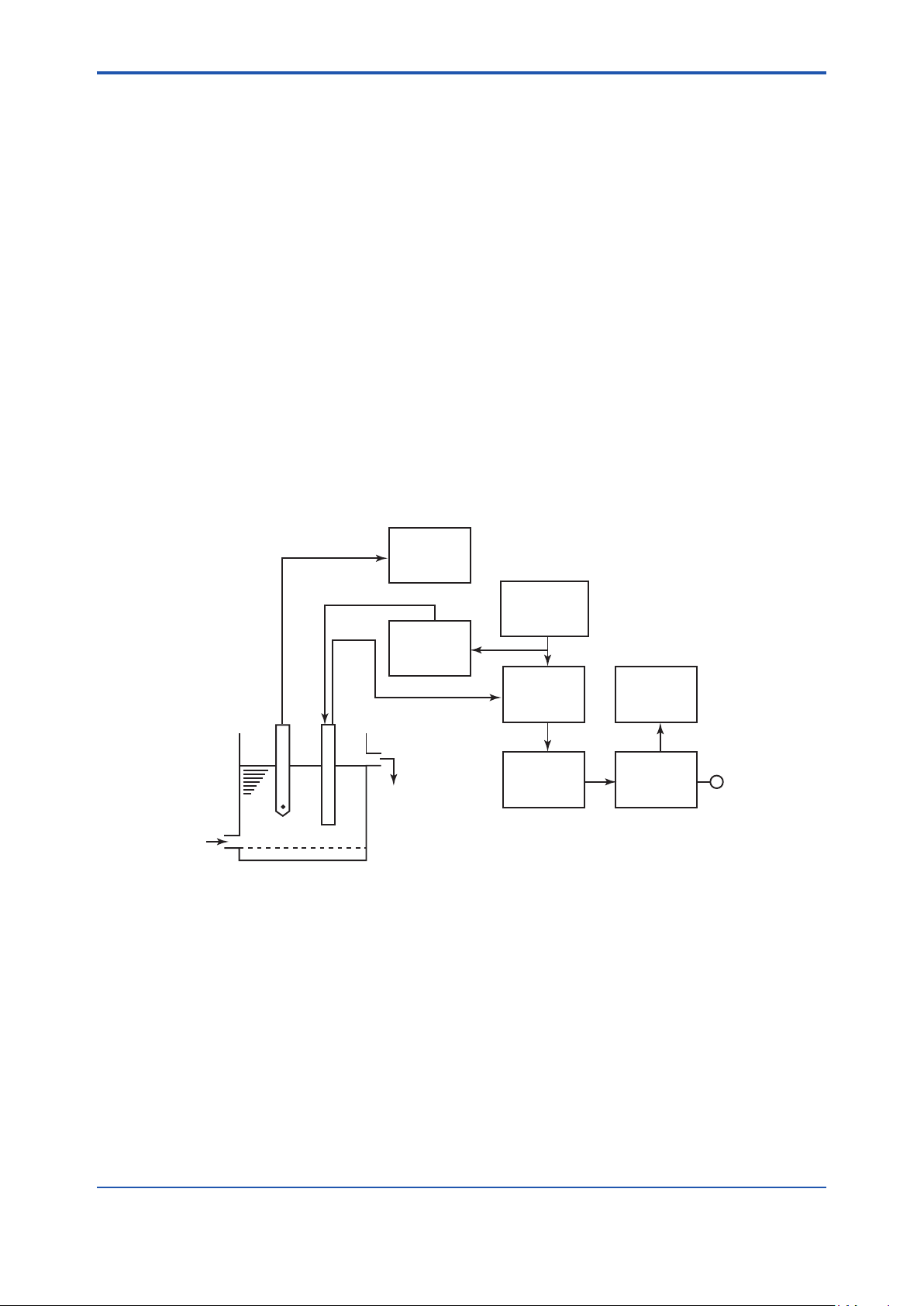

Figure 1.5 shows the block diagram for the FC500G free available chlorine analyzer (nonreagent type) operation. The analyzer determines the free available chlorine concentration by

applying an applied voltage corresponding to the diusion current between the indicator and

counter electrodes and by applying temperature compensation to the diusion current.

First stage

amplifier

Applied voltage

compensating

pulse circuiut

Drain

Measuring

tank

Temperature

signal

Free available

chlorine

detecting circuit

Temperature

compensation

circuit

PWM circuit

isolator

Free available

chlorine/

conductivity

display

Voltage-current

conversion

circuit

Sample

water

Indicator

electrode

Diffusion current

Applied voltage

Counter

electrode

(Pt 1000Ω)

Figure 1.5 Block Diagram for FC500G Free Available Chlorine Analyzer Operation

4 to 20 mA DC

output

F1-5.ai

IM 12F5A2-01E

Page 14

<2. COMPONENT NAMES AND FUNCTIONS>

2. COMPONENTS AND FUNCTIONS

2.1 Detector

Teflon (PTFE) ring

2-1

Beads case

Measuring tank

Electrode assembly

Measuring tank

Indicator electrode

(rotating elecrtrode)

Glass beads

Polishes the totating indicator

electrode to hold indicator

electrode in a clean state.

Cell motor

A motor for rotaing the

indicator electrode at a

constant speed.

Air purge piping connection port

(for FC500G-5)

Sample inlet

Counter electrode

(Pt1000Ω sensor

incorporated)

Indicator electrode

(rotating elecrtrode)

Drain cock

If loosened, this cock drains the

liquid in the measuring tank.

Figure 2.1 Component Names and Functions of the Detector

F2-1.ai

IM 12F5A2-01E

Page 15

<2. COMPONENT NAMES AND FUNCTIONS>

2-2

2.2 Converter

Figure 2.2 shows the converter component names and their functions.

Figure 2.2 is a gure with the cover removed. Measuring range selection should be performed in

this state.

Converter cover

Display (liquid crystal)

Measuring range

setting switch

Sets a measuring

range.

Measuring range

selecting jumper

Applied voltage

compemsation/fixation

selection jumper

Fastener

The terminal cover

should be attached

or detached with

this fastener grip

pulled out.

Terminal cover

MEAS / CHECK selection switch

For converter checking,

select CHECK position.

mg/l

POWER

MEAS.

CHECK

SPAN

+

ME RE T1

-

G

T2

ON

OFF

L2

L1

G

C2

G

SG

C1

FUSE

1A

Zero calibrator

Operated when

zero is to be

calibrated.

(To be operated

with the

terminal cover

removed.)

Power supply

voltage selection

jumper

Power switch

Fuse

External wiring

connection terminals

Span calibrator

Operated when span

is to be calibrated.

Figure 2.2 Converter Component Names and Their Functions

NOTE

The measuring range selection jumper and the power supply voltage selection jumper are

shipped with these set based on the desired specications.

The specications cannot be changed by jumper selection.

IM 12F5A2-01E

Page 16

<3. INSTALLATION, PIPING, AND WIRING>

3-1

3.

INSTALLATION, PIPING, AND WIRING

This chapter describes procedures for the FC500G free available chlorine analyzer installation,

piping, and wiring.

3.1 Installation

3.1.1 Location

Install the FC500G free available chlorine analyzer (non-reagent type) in a location which meets

the following conditions:

● Free from rain water such as an indoor location or in a cabinet

● Low vibration

● No exposure to direct sunshine

● Little dust

● Absence of corrosive gas

● Easy maintenance

Figure 3.1 shows maintenance spaces.

Approx.150

265

Maintenance spaceMaintenance space

Approx.160

Unit: mm

154

50

space

Approx.

Maintenance

space

Approx.250

Maintenance

0.50

mg/l

240

Figure 3.1 Maintenance Spaces for the FC500G Free Available Chlorine Analyzer

150

Approx.

310

space

Maintenance

IM 12F5A2-01E

Page 17

<3. INSTALLATION, PIPING, AND WIRING>

3-2

3.1.2 Mounting

Mount the FC500G free available chlorine analyzer (non-reagent type) on a wall surface. For

mounting holes, see section 1.3.

3.2 Piping

3.2.1 Sample Water Piping

Connect a 6 mm OD X 4 mm ID polyethylene tube to the sample water inlet. Set the sample

water pressure at the sample water inlet to 1 to 30 kPa (ow rate: 0.1 to 2.5 l/min).

Note: If a sample water inlet valve is used, set the pressure at the valve inlet to 10 to 150 kPa.

Connect a hose of 12 mm lD to the sample outlet. Make piping so that no drain stagnates in the

hose.

3.2.2 Air Purge Piping

Make the air purge piping only when the FC500G-5 free available chlorine analyzer is used.

The air purge piping connecting port (1/8 NPT female) is located at the electrode assembly.

Exercise care in piping because the electrode assembly must be removed in implementing

inspection or maintenance (see Figure 3.2).

Electrode

assembly

Measuring

tank

Detector

Pressure regulator

6 mm OD X 4 mm ID

polyyethylene tube

Figure 3.2 Air Purge Piping

Inspection or

maintenance

Air supply

IM 12F5A2-01E

Page 18

<3. INSTALLATION, PIPING, AND WIRING>

3.3 Wiring

Make wiring for power supply and output signal. Figure 3.3 shows the symbols on the converter

terminals and the types of wiring to be connected.

Terminal board TM1 (M4 screw)

TM1

+

- G G L1 L2 ME RE T1 T2 SG G C1 C2

3-3

500Ω or less

4 to 20 mA DC

output

Note: Make grounding to earth (grounding resistance 100 Ω or less).

Figure 3.3 Symbols on the Converter Terminals and the Types of Wiring to be Connected

Ground

to earth

(Exclusively used cable: already wired)

Power

supply

Detector signal

F3-3.ai

3.3.1 Wiring for Power Supply and Grounding

Use a three-conductor cable of 9 to 12 mm OD, each conductor having a cross section of 1 mm2

or more.

Make grounding to earth (grounding resistance 100 Ω or less).

3.3.2 Analog Output Wiring

Use a two-conductor shielded cable of 9 to 12 mm OD, each conductor having cross section of

0.5 mm2 or more. The shield should be connected to terminal ‘‘G”.

IM 12F5A2-01E

Page 19

Blank Page

Page 20

<4. OPERATION>

F4-1.ai

4. OPERATION

This chapter chiey describes the preliminary work to be performed prior to putting into operation.

4.1 Preparation for Operation

4.1.1 Inspection of Piping and Wiring Status

Conrm that wiring and piping are made properly.

4.1.2 Fill with Glass Beads for Electrode Polishing

Put glass beads (accessories) for cleaning the indicator (rotating) electrode into the beads case

in the measuring tank in the following procedure:

(1) As shown in Figure 4.1, mount the electrode assembly to the holding stud. The electrode

assembly is xed to the measuring tank assembly using two screws.

In doing this, exercise care so that the indicator (rotating) electrode and the counter

electrode are not struck by the measuring tank. Also, do not touch the surface of the

indicator electrode with the ngers.

In maintenance position

4-1

Electrode

assembly

Measuring

tank

Fixing screws

(2 pcs.)

Holding stud

Figure 4.1 Removal of Electrode Assembly

(2) Remove the beads case from the measuring tank. The new glass beads are normally lled

up to the bottommost notch of the beads case when the indicator electrode is inserted.

Taking care that glass beads do not drop from the beads case. Mount the beads case so

that its slits face the counter electrode.

Slits

Beads case

Counter electrode

(reference electrode)

Glass beads

Rubber packing

Figure 4.2 Amount of Glass Beads to be Put into the Beads Case

The bottommost notch

of the beads case

Indicator electrode

(rotating electrode)

Beads case

Glass beads

F4-2.ai

IM 12F5A2-01E

Page 21

<4. OPERATION>

4-2

(3) Return the electrode assembly to the measuring tank and tightly secure it using the xing

screws.

4.1.3 Measuring Range Setting

Select the measuring range using the setting switch. Set it as shown in Table 4.1. Operate the

setting switch using a small at blade screwdriver.

Table 4.1 Switch Setting Corresponding to Measuring Range

Model

FC500G-1

FC500G-5

1 2 3 4

ON

OFF

S3

Measuring

range

0 to 1 mg/l

0 to 2 mg/l

0 to 3 mg/l

0 to 5 mg/l

0 to 10 mg/l

J5 jumper

see Figure 4.5

DIP switch position

1 2 3 4

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

ON

OFF

ON

Figure 4.4 Measuring Range Setting Switch

IM 12F5A2-01E

Page 22

<4. OPERATION>

NOTE

For the FC500G-1, measuring ranges of 0 to 5 and 0 to 10 mg/l cannot be used. For the

FC500G-5, measuring ranges of 0 to 1, 0 to 2, and 0 to 3 mg/l cannot be used.

4.1.4 Setting of “Applied Voltage Compensation/Applied Voltage Fixation’’ Selection Jumper

The applied voltage can be xed to a denite value without applied voltage compensation. When

the applied voltage compensation/applied voltage xation transfer jumper shown in Figure 4.5 is

set to the side B (lower), the applied voltage is xed to the starting voltage value.

4-3

Side A

Applied voltage

compensation

J5

J5

Side B

Figure 4.5 “Applied Voltage Compensation/Applied Voltage Fixation” Selection Jumper

Applied voltage

fixation

J5

F4-5.ai

NOTE

If conductivity exceeds 300 μS/cm, applied voltage should be changed to xation.

IM 12F5A2-01E

Page 23

<4. OPERATION>

4-4

4.2 Start-Up

4.2.1 Supplying Sample Water

<Sample inlet valve is not provided>

Conrm that the sample water pressure is within the range of 1 to 30 kPa and supply sample

water at the ow rate of 0.1 to 2.5 l/min. After supplying sample water, conrm that the sample

water level does not contact the top of the measuring tank.

<Sample inlet valve is provided>

First, fully close the sample inlet valve. Then, supply sample water at the pressure of 10 to 150

kPa. After supplying sample water, open the sample inlet valve so that the sample water ow rate

is 0.1 to 2.5 l/min.

4.2.2 Conrmation of “Power Supply Voltage” and

“Measuring Range” Selection Jumpers Setting Status

If power supply specication for the free available chlorine analyzer (non-reagent type) used is

the 100 V system, conrm that the “power supply voltage” selection jumper is set as shown in

Figure 4.6 (1).

If the power supply specication is the 200 V system, conrm that the jumper is set as shown in

Figure 4.6 (2).

J1

J2

J1

J2

J4

200 V 100 V

S1

Figure 4.6 “Power Supply Voltage” Selection Jumper

200 V 100 V

J1

J2

200 V 100 V

100 V System

200 V System

(1)

(2)

IM 12F5A2-01E

Page 24

<4. OPERATION>

If the FC500G-1 free available chlorine analyzer is used, conrm that the “measuring range”

selection jumper is set as shown in Figure 4.7 (1).

For the FC500G-5 free available chlorine analyzer, conrm that the jumper is set as shown in

Figure 4.7 (2).

(1)

FC500G-1

Side A

Measuring range

0 to 3 mg/l

4-5

(2)

FC500G-5

Figure 4.7 ‘‘Measuring Range” Selection Jumper

Side B

Measuring range

0 to 10 mg/l

4.2.3 Supplying Power

Arrange a power supply whose voltage and frequency conrm to the specications. Conrm that

the fuse holder cap in the converter is tight and then turn ON the power switch.

4.2.4 Operation Check

Conrm that a measured value is displayed in the display.

Also, visually conrm that there is no irregularity or signicant deection when the indicator

electrode revolves.

4.2.5 Calibration

Implement zero and span calibration referring to chapter 5.

4.3 Steady State Operation

There is no need for special action during analyzer operation except for executing inspection and

maintenance described in chapter 6. If a failure occurs, dispose of it referring to chapter 7.

IM 12F5A2-01E

Page 25

Blank Page

Page 26

<5. CALIBRATION>

5. CALIBRATION

Perform zero and span calibration when the analyzer is to be initially started up and also when

re-operated after prolonged shutdown.

During operation, perform span calibration periodically (approx. once a month). When span is to

be calibrated, rst polish the indicator electrode (see subsection 6.1.1) and then perform runningin operation for approx. one hour.

Zero calibration is virtually unnecessary during operation if it is performed once at start-up. However, merely conrm periodically that the zero point is correct during operation.

5.1 Zero Calibration

There are two methods for calibrating zero: the “open input circuit method” using which the

calibration is performed by pulling up the rotating and counter electrodes from the sample water

and the “chlorine-free water method” using water free from chlorine (e.g., water ltered through

activated carbon). Normally calibrate zero using the “open input circuit method”. However, if free

available chlorine of low concentration is always to be measured (e.g., approx. 0.1 mg/l), use the

“chlorine-free water method” for zero calibration.

5.1.1 Zero Calibration Procedure Using the Open Input

5-1

Circuit Method

(1) Remove the electrode assembly from the measuring tank with the indicator electrode ro-

tated and x it to the holding studs. (Remove the electrode assembly by loosening the two

xing screws.)

It is not necessary to stop the sample water.

(2) After display of the free available chlorine concentration has stabilized, perform zero calibra-

tion. First, remove the terminal cover.

Next, slowly turn the zero calibrator (potentiometer) using the attached at blade screwdriv-

er to adjust display to zero.

(3) Mount the terminal cover. Return the electrode assembly to the measuring tank and tightly

x the assembly using the two xing screws.

5.1.2 Zero Calibration Procedure Using Chlorine-Free Water Method

(1) Prepare two to three litre of chlorine-free water (prepared by adding 10 ml/l of pH 7 buer

solution and 50 mg/l of NaCl to puried water).

(2) Stop supply of sample water and wait until the sample water level in the measuring tank

decreases to below the sample water inlet. Then disengage the sample water inlet piping.

(3) Introduce the chlorine-free water into the measuring tank.

Connect a tube to the sample water inlet and pour the chlorine-free water contained in a

suitable vessel into the measuring tank by utilizing a head from the inlet. If a pump is used

for supply, use a ow rate of 100 ml/min or more.

(4) After the free available chlorine concentration display has stabilized, perform zero calibra-

tion. First, remove the terminal cover.

Next, slowly turn the zero calibrator (potentiometer) using an attached at blade screwdriver

to adjust display to zero.

(5) Mount the terminal cover. Also stop supply of the chlorine-free water.

After the solution level in the measuring tank decreases to below the sample water inlet,

remove the tube and restore the sample water piping connection.

Supply sample water.

IM 12F5A2-01E

Page 27

<5. CALIBRATION>

5-2

5.2 Span Calibration

There are two span Calibration methods: “sampling method’’ using which calibration is performed

based on the manually analyzed free available chlorine concentration of sample water, and the

“standard solution method” which allows calibration using a standard calibration solution having a

free available chlorine concentration of approximately 80 % of the measuring range.

Calibrate the analyzer span using the “sampling method’’ unless the chlorine concentration of

sample water is near zero. (Span calibration can be performed without removing the terminal

cover).

Note: Before performing span calibration, conrm that the electrode does not remain exposed to

the air as after zero calibration, and the electrode rotates normally in the measuring tank.

5.2.1 Span Calibration Procedure Using the Sampling Method

(1) Conrm that the free available chlorine concentration in the sample water is stable by ob-

serving displayed values.

(2) Sample the sample water by loosening the drain cock at the bottom of the measuring tank.

When sampling the sample water, exercise care so that the tip of the counter electrode is

not exposed to air above the level of the sample water.

(3) Quickly measure the free available chlorine concentration of the sampled sample water, us-

ing a manual analysis such as amperometric titration (AT method).

(4) Slowly turn the span calibrator (potentiometer) using the attached at blade screwdriver to

adjust display to the manually analyzed value.

5.2.2 Span Calibration Procedure Using Standard Solution Method

(1) Prepare diluting solution which is obtained by adding 10 ml/l of pH 7 buer solution and 50

mg/l of NaCl to puried water (sample water can also be used instead of puried water).

(2) Prepare 2 to 3 liter of the standard solution conditioned to a free available chlorine concen-

tration of approximately 80 % of the measuring range. To obtain this solution, dilute commercially available sodium hypochlorite (NaClO) solution using the diluting solution prepared in

step (1).

(3) Stop supply of sample water and wait until the sample water level in the measuring tank

decreases to below the sample water inlet. Then disengage the sample water inlet piping.

(4) Introduce the standard solution into the measuring tank.

Connect a tube to the sample water inlet and pour the solution contained in a suitable vessel

into the measuring tank by utilizing a head from the inlet. If a pump is used for supply, use a

ow rate of 100 ml/min or more.

(5) After the free available chlorine concentration display has stabilized, loosen the drain cock

to sample the standard solution.

In sampling the solution, exercise care so that the tip of the counter electrode is not exposed

to air above the level of the solution.

IM 12F5A2-01E

(6) Quickly measure the free available chlorine concentration of the sampled sample water, us-

ing a manual analysis such as amperometric titration (AT method).

(7) Slowly turn the span calibrator (potentiometer) using the attached at blade screwdriver to

adjust display to the manually analyzed value.

(8) Stop supply of the standard solution.

After the solution level in the measuring tank decreases to below the sample water inlet,

remove the tube and restore the sample water piping connection.

Supply sample water.

Page 28

<6. INSPECTION AND MAINTENANCE>

6. INSPECTION AND MAINTENANCE

To continue good operating status, perform inspections and maintenance as shown in Table 6.1.

Determine the implementation cycle in accordance with the individual operation conditions. Table

6.1 is a guide for the implementation cycle.

Table 6.1 Inspection and Maintenance Items and Implementation Cycle

Inspection and maintenance item Implementation cycle

Indicator electrode polishing Once/month

Glass beads cleaning Once/three months

Measuring tank cleaning Once/three months

Inspection or brush and slip ring Once/three months

Calibration Once/month

Converter checking Once/month

Fuse replacement Once/year

6.1 Mechanical System

6-1

6.1.1 Indicator Electrode Polishing

Indicator electrode contamination inuences the measured values. Accordingly, the indicator

electrode (rotating electrode) is always rotated to polish its surface using glass beads.

However, the surface very gradually becomes contaminated with time elapse. Thus, periodically

polish the electrode surface using a polisher (alumina).

Polish the electrode surface using the following procedure:

(1) Remove the converter cover and turn OFF the converter power switch.

(2) Remove the electrode assembly from the measuring tank and x it to the holding stud. It is

not necessary to stop the sample water.

(3) Remove the electrode assembly cover.

(4) Insert an Allen wrench (accessories) into the hole on the side of the rotating shaft below the

drive belt and manually x the shaft. Remove the indicator electrode by turning it counterclockwise. Do not touch the rotating shaft brush, slip ring, or the indicator electrode surface.

(5) Apply polisher (alumina) attached as an accessory to a wet gauze and carefully polish the

electrode surface until all contamination is completely removed. After polishing, wash o the

polisher using clean water. Once the surface is clean, it will wet uniformly without repelling

water.

Electrode surface

Figure 6.1 Indicator (Rotating) Electrode

(6) Similar to electrode removal, insert an Allen wrench into the hole and manually x the

rotating shaft so that it does not turn. Fully screw in the indicator electrode (turn clockwise).

F6-1.ai

IM 12F5A2-01E

Page 29

<6. INSPECTION AND MAINTENANCE>

6-2

CAUTION

Do not touch the rotating shaft brush, slip ring, or the indicator electrode surface.

(7) Mount the electrode assembly cover and restore the electrode assembly in the measuring

tank. Tightly secure the assembly using the two xing screws.

(8) Turn the converter power switch ON and conrm that the indicator electrode revolves

normally. Also conrm that the concentration display presents an approximately proper

value.

(9) Mount the converter cover.

In addition, after the electrode is polished, perform running-in operation for one hour or

longer. Then, calibrate span without fail.

Note: Polish the electrode surface (gold electrode) by following the instructions below when it has become corrugated or deformed

from the original shape (about 3 mm in diameter).

Polish the electrode surface with sandpaper (about #600) until the surface becomes nally rounded. Then, polish it with

sandpaper (about #2000), and lastly with polishing powder (alumina). Make sure the electrode surface is clean and then install

the indicator electrode. Reduce the amount of ceramic beads if the electrode has deformed greatly. The ceramic beads should

be lled up to 5 mm under the bottommost notch of the beads case when the indicator electrode is inserted.

6.1.2 Glass Beads and Measuring Tank Cleaning

If the glass beads are contaminated, cleaning eect deteriorates. Periodically clean the glass

beads and the measuring tank.

The procedure follows:

(1) Turn OFF the converter power switch. Stop sample water supply.

(2) Remove the two xing screws of the electrode assembly and secure the assembly to the

holding studs.

(3) Remove the beads case from the measuring tank with the rubber packing attached. In this

case, exercise care so as not to drop glass beads into the measuring tank.

(4) Clean the inside of the measuring tank using a brush with detergent on it. Use dilute

hydrochloric acid if manganese or iron adheres. Do not use organic solvent.

After cleaning, completely wash out the detergent (or acid) using clean water or sample

water.

(5) Move the glass beads to another vessel and clean them using dilute hydrochloric acid.

After that, completely wash out the acid using clean water or sample water. For the beads

case and rubber packing, remove dirt using detergent or dilute hydrochloric acid. After that,

completely wash out the detergent or acid using clean water or sample water.

(6) Set the beads case to the rubber packing and load the cleaned glass beads in the case.

If the beads have obviously become smaller in size (much smaller than a diameter of 1.7

to 2.3 mm), replace them with new ones. Glass beads are worn in long-term use, thereby

reducing the ability of polishing indicator electrode.

For optimum polishing, the new glass beads are normally lled up to the bottommost notch

of the beads case when the indicator electrode is inserted (See Figure 4.2). The polishing

ability cannot be recovered by replenishing the beads only by volume reduced by wear.

(7) Restore the beads case and rubber packing in the measuring tank.

(8) Restore the electrode assembly to the measuring tank and secure it using the two xing

screws.

(9) Supply sample water. Turn ON the converter power switch. Conrm that the indicator

electrode normally revolves and the concentration display presents approx. the proper

value. Finally, mount the converter cover.

The cleaning eect of the glass beads deteriorates owing to abrasion of the beads

themselves over prolonged use. Recommended practice is to replace the beads once or

twice a year.

IM 12F5A2-01E

Page 30

<6. INSPECTION AND MAINTENANCE>

6.1.3 Brush and Slip Ring Checking

CAUTION

Do not touch the brush except when replacement is performed.

When the electrode assembly cover is removed for polishing the indicator electrode or for other

purposes, visually check the slip ring on the rotating shaft and the brush contacting the slip ring

for abrasion.

Further, measure resistance at the contact every six months. On revolving the indicator

electrode, measure the resistance between the brush-securing screws and the part of the

rotating shaft under the slip ring using a multi-meter. A resistance of 500 Ω or less is acceptable.

6-3

Deive shaft

Belt

Slip ring

Rotating shaft

Contact-pressure

adjusting screw

Electrode assembly

Clamp

Holder

Counter

(reference) electrode

Indicator

(rotating) electrode

Figure 6.2 Indicator (Rotating) Electrode

Pulleys

Brush

Base

Brush-securing screws

Lock screw

Gear head

Cell motor

F6-2.ai

If the resistance exceeds 500 Ω, clean the slip ring using an cotton applicator soaked with alcohol

with the indicator electrode rotated.

After cleaning, re-measure the resistance and conrm that the resistance is 500 Ω or less. If the

resistance does not decrease below 500 Ω or if abnormalities such as slip ring wear or brush

wear and bending are detected, the slip ring and/or the brush must be replaced.

The following is the replacement procedure: However, in principle, replacement should be

entrusted to Yokogawa service personnel.

(1) Turn OFF the converter power switch.

(2) Remove the electrode assembly cover. Remove the brush. The brush is secured using two

securing screws (one of them also serves for the wiring terminal).

(3) Remove both pulleys of the drive shaft (motor shaft) and the rotating shaft (indicator

electrode mounting shaft) together with the belt. Remove the drive shaft pulley by loosening

two set screws using an Allen wrench of nominal 1.5 mm (accessory). Remove the rotating

shaft pulley by loosening the screw at the tip of the shaft using a at blade screwdriver, with

an Allen wrench of nominal 2 mm (accessory) inserted in the hole of the rotating shaft for

preventing revolution.

(4) Draw out the slip ring from the rotating shaft and introduce a new slip ring.

IM 12F5A2-01E

Page 31

<6. INSPECTION AND MAINTENANCE>

6-4

(5) Mount the two pulleys and the belt in the reverse procedure.

Note: If the belt is replaced, perform the procedure described in the following steps (6) and (7) without fail.

(6) Loosen the four mounting screws of the (acrylic) holder that secures the rotating shaft. Set a

spring balance to the hole under the rotating shaft slip ring and pull the shaft in the direction

of applying tension to the belt.

(7) Fix the holder. Tighten the holder-securing screws with a tension set at 0.4 kgf.

(8) Mount the brush. Fit the brush hole above the right brush-securing screw in with the

positioning pin on the mounting bracket and tighten the two brush-securing screws.

(Exercise care so as not to bend the brush tip.)

Conrm that the brush contactor contacts the slip ring and that the brush does not touch the

pulley. Adjust the contact-pressure of the brush contact or in the following procedure:

● Loosen the two securing screws of the brush-mounting bracket.

● Loosen the lock screw to the right of the contact-pressure adjusting screw.

● Move the brush-mounting bracket toward you to once separate the brush contactor from the

slip ring.

● Screw in the contact-pressure adjusting screw and then further screw in by three and a half

turns from the position where the brush contactor just contacts the slip ring. The contact of

the contactor to the slip ring should be judged by the resistance change on a multi-meter

connected between the brush and slip ring.

● Tighten the lock screw. Also tighten the brush-mounting bracket securing screws.

(9) Turn ON the converter power switch. Conrm that the driving and rotating shafts revolve

smoothly. Visually conrm that there is no irregularity at the contact part of the brush and the

slip ring.

(10) Measure the resistance value again between the brush and the slip ring and conrm that it is

500 Ω or less.

(11) Mount the electrode assembly cover.

(12) Conrm that the concentration displays present the proper values and then mount the

converter cover.

IM 12F5A2-01E

Page 32

<6. INSPECTION AND MAINTENANCE>

6.2 Electrical System

6.2.1 Span Calibration

Perform span calibration at the rate of once every one or two weeks during the initial operation

start period and check the sensitivity changes owing to indicator electrode contamination or the

like to establish a reference for determining the calibration period. After the calibration period

is determined, perform span calibration in an appropriate interval using the above period as a

guide. When the indicator electrode is polished, perform span calibration without fail.

6.2.2 Converter Checking

Check the converter periodically.

The converter check function means to check the converter circuit operation.

Converter checks can be performed using switch operations. Placing the MEAS./CHECK

selector switch in the “CHECK” position transfers the converter input (current input and

temperature input) from connection to the detector to connection to the simulated input. When

the converter is normal, the free available chlorine concentration display indicates 0.90 to 1.10

mg/l regardless of the measuring range. In this case, the analog output is sent out in the range

shown in Table 6.2 corresponding to the measuring range setting.

6-5

Table 6.2 Analog Output in Checking

Measuring range Output current Approximate position

0 to 1 mg/l 18.4 to 21.6 mA Approx. 100 % point of full scale

0 to 2 mg/l 11.2 to 12.8 mA Approx. 50 % point of full scale

0 to 3 mg/l 8.8 to 9.9 mA Approx. 33 % point of full scale

6.2.3 Fuse Replacement

For preventive maintenance, it is recommended to replace the power supply fuse once a year.

The fuse rating is 250 V, 1 A.

Power Supply Fuse

Figure 6.3 Power Supply Fuse

Cap

FUSE

Remove the cap by

turning it in the

direction of the arrow.

IM 12F5A2-01E

Page 33

Blank Page

Page 34

<7. TROUBLESHOOTING>

7. TROUBLESHOOTING

If any operation abnormality appears, take measures using the following procedures.

Abnormalities Cause Countermeasures

No indication 1. The fuse is blown.

Indication shows

hunting.

Abnormal chlorine

concentration

displayed.

Abnormal analog

output

The indicator

electrode does

not revolve or

irregularly rotates.

Sample water

leakage

2. Converter connector poor contact

1. Poor contact in the indicator

(rotating) electrode mounting

position

1. Poor contact of the electrode

terminals with connecting

leadwires

2. Miss-wiring of leadwires to be

connected to electrode terminals

3. Poor continuity between the

indicator (rotating) electrode and

the contactor

4. Deterioration of RTD insulation

5. Sample water ow rate is out of

range (0.1 to 2.5 l/min).

6. Calibrated value deviation

7. Electrical circuit failure

1. The load resistance is larger than

500 Ω.

2. Electrical circuit failure

1. The belt is broken.

2. The motor fails.

3. The rotating shaft bearing has

corroded.

1. Drain cock is inadvertently not

closed.

2. Piping joint loosened.

1. Replace the fuse.

2. Once turn OFF power and re-engage the

relevant connector.

1. Coat conductive grease (auxiliary).

1. Correctly connect leadwires to the counter

electrode terminals (RE, T1, T2) and the

indicator electrode terminals (ME).

2. Check the leadwire symbols and correctly

connect the leadwires.

3. Clean the brush and the slip ring.

a. Adjust the brush contact pressure and

remove wear debris from the slip ring (see

subsection 8.2.6).

b. Replace the brush and slip ring (see sub-

section 6.1.3).

4. Disconnect leadwires to the counter electrode terminals T1 and T2, and check that

the resistance across terminals T1 and T2

is approx. 1 kΩ at room temperature and

the resistance across the terminals RE and

T1 (or T2) is 1 MΩ or more. If these are not

satised, replace the counter electrode.

5. Adjust the ow rate. (Adjust so that

sample water just overows the weir in the

measuring tank.)

6. Perform zero and span calibration.

7. Place the MEAS./CHECK selector switch

in CHECK position and check if the

display indicates 0.9 to1.1 mg/l. lf it is not

satised,contact Yokogawa.

1. Adjust the load resistance to 500 Ω or less.

2. Contact Yokogawa.

1. Replace the belt.

2. Replace the motor.

3. Replace the bearing.

1. Re-tighten the drain cock.

2. Re-tighten the piping joint ttings.

7-1

IM 12F5A2-01E

Page 35

Blank Page

Page 36

<8. AUXILIARIES AND CONSUMABLES>

8. AUXILIARIES AND CONSUMABLES

8.1 Auxiliaries and Consumables List

Table 8.1 shows auxiliaries and consumables.

Table 8.1 Auxiliaries and Consumables

Item Part number Remarks

Indicator electrode K9332MB Rotating gold electrode

Counter electrode K9332MK Reference elctrode

Glass beads K9332ZJ

Polishing powder K9088PE

Brush K9332JX Paired with slip ring

Slip ring K9332JZ Paired with brush

Grease K9044FX

Fuse (1 A) A1109EF 250 V, 1 A

Washing indicator electrode

(2 bags)

Polishing Indicator electrode

alumina, 30 g

One bottle 3 ml, for continuity stabilization at

the base of indicator electrode

8-1

8.2 Auxiliaries and Consumables

8.2.1 Polisher (Part number: K9088PE)

This is used for polishing the indicator electrode surface.

8.2.2 Glass Beads (Part number: K9332ZJ)

The cleaning capability of glass beads in prolonged use deteriorates owing to abrasion. Normally,

replace the beads once or twice a year.

8.2.3 Indicator Electrode (Part number: K9332MB)

The electrode is gradually abraded by cleaning using glass beads. Generally, the electrode can

be used for around three or four years. However, it is recommended that one spare electrode

should be stored for unforeseen accident.

8.2.4 Grease (Part number: K9044FX)

The grease is applied to stabilize continuity at the mounting base part (screw connection) when

the indicator electrode is replaced. Apply the grease to the indicator electrode screw thread

referring to the procedure manual attached to the auxiliaries.

8.2.5 Counter Electrode (Part number: K9332MK)

Not subject to any abrasion, this electrode can be used for a prolonged period. However, it is

recommended to store one electrode as a spare.

IM 12F5A2-01E

Page 37

<8. AUXILIARIES AND CONSUMABLES>

8-2

8.2.6 Brush and Slip Ring (Part number: K9332JX, K9332JZ)

Normally, two years are considered the replacement interval. Replacement of both items as a

pair should be performed.

CAUTION

Do not touch the brush except when replacement is performed.

l Procedures for adjusting the brush contact pressure and removing wear

debris from the slip ring

Wear debris generated from the sliding action of the slip ring and brush (generated largely at the

beginning), may enter between the slip ring and the brush, thereby temporarily increasing the

contact resistance. This may cause a drop in readings. When this phenomenon occurs, polish

and clean the surface of the slip ring to prevent the generation of wear debris and the ingress

of wear debris generated into a space between the slip ring and the brush, and furthermore

increase the contact pressure of the brush to the slip ring surface.

(1) Polishing and cleaning the surface of the slip ring

With the FC500G being powered, press sandpaper (#2000) on the rotating slip ring. Then,

press a cotton swab soaked in alcohol on the rotating slip ring to wipe o debris.

(2) Increasing the brush contact pressure

Turn o power to the FC500G. Loosen the lock screw next to the contact pressure adjusting

screw and then the 2 xing screws for the brush mounting bracket. Turn the contact

pressure adjusting screw in 1/2 turn.

Tighten the lock screws and bracket xing screws. Make sure that the brush does not come

in contact with the pulleys and does not come o the slip ring. Then turn on the power.

IM 12F5A2-01E

Page 38

Customer

Maintenance

Parts List

Model FC500G

Free Available Chlorine Analyzer

( Non-Reagent Type)

18

17

1

33

16

19

Item Part No. Qty Description

1 1

2

3 1 Cover

31

4 1 Display Assembly

5 Y9620NU

Case Assembly

1

Knob

2 M6320 Bolt

2

13

6 A1109EF

7 1 Protector Assembly

1 Fuse (1A)

8 1 Plate

9 1 Bracket Assembly

11

32

15

12

14

3

24

10

5

4

9

30

29

8

25

10 1 Main Board Assembly

11 K9332ZJ 1 Beads

12 K9332KZ 1 Packing

20

13

21

K9332KX

14

K9332MB 1 Indicator Electrode

15

K9044FX 1 Conductive Grease

K9332MK 1 Counter Electrode

16

1 Beads Case

17 Y9416LU 4 M4316 Bolt

18 1 Cover

19

K9332LK 1 Gasket

20

22

21 K9332KL 1 Measuring Cell

22

Y9114XB 1 O-Ring

K9334UN 1 Connector

23

23

24

Y9110XB 1 O-Ring

25

K9332KR 1 Drain Cock Assembly

2 Post

26 1 Bracket Assembly

27 Y9520LU

2 M5320 Bolt

28 Y9601BU 2 M6 Nut

29 L9831KL 1 Nut

30 K9332KP 1 Cap

26

31 K9332JX 1 Brush Assembly

32 K9332JZ

1 Slip Ring

33 L9804UK 1 Belt

6

7

Yokogawa Electric Corporation

28

All Rights Reserved, Copyright © 1993, Yokogawa Electric Corporation.

Subject to change without notice.

27

CMPL 12F05A02-01E

2nd Edition : Apr. 2001 (YK)

Page 39

Page 40

Revision Information

l Title : Model FC500G Free Available Chlorine Analyzer (Non-Reagent Type)

l Manual No. : IM 12F5A2-01E

July 2018/5th Edition

Revision according to the suppliment

Added EMC(Australia and New Zealand) (p.1-2)

Note (p.6-2)

Revised description (p.3-3)

Aug. 2012/4th Edition Page layout changed

All page layout changed by the standard template; p.1-5, Deletion of conductivity measurement in

subsection 1.4 Measuring Principle; p.2-2, Deletion of some conductivity measurement description in

Figure 2.2; p.3-3, Deletion of subsection 3.3.3 Contact Output Wiring (this function doesn’t exist); p.42, Deletion of subsection 4.1.3 Setting of Display (Free Available Chlorine or Conductivity) Selection

Jumper; p.4-6, Deletion of subsection 4.3.1 “Out-of-Sample Detection” Contact Signal Output;

p.7-1, Deletion of “conductivity display shows abnormality”, and “Abnomal out-of sample detection”

in chapter 7. TROUBLESHOOTING table; p.8-1, Some revision of subsection 8.1 Auxiliaries and

Consumables List (P/N of fuse changed).

Oct. 2009/3rd Edition Editted by InDesign

Change the package of glass beads (p.1-3)

i

Apr. 2008/2nd Edition

Everything is reviewed.

Mar. 1993/1st Edition

Newly published.

Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo 180-8750, JAPAN

http://www.yokogawa.com/

IM 12F5A2-01E

Page 41

Blank Page

Loading...

Loading...