Page 1

Technical

Information

Range-free Multi-controller

FA-M3 R Overview

TI 34M6A01-01E

2000.5 2nd Edition

Page 2

This document is based on the version of FA-M3 R as of May 2000.

For details about the current version of FA-M3 R, please contact your

nearest distributor or agency.

Page 3

CONTENTS

Introduction to FA-M3 ………………..………………………………………………………... 1

FA-M3 Features ……………………………………………………………………………… ..... 2

Ultra-fast Processing Speed………..………………………………………………………... 3

Comparison with Competitors……..……………………………………………………….... 4

Compact Size. ……………………..………………………………………………………….. 5

Universal Range.……………………..……………………………………………………...... 6

Multiple CPUs .………………………………………………………………………………....7

Sequence CPU Modules.…………………………………………………………………....8

(F3SP05-0P, F3SP21-0N, F3SP28-3N, F3SP38-6N, F3SP53-4H, F3SP58-6H, F3FP36-3N)

BASIC CPU Modules……………………………………………………………………….. 9

(F3BP20-0N, F3BP30-0N)

Easy Real-time Processing with BASIC ………………………………………………… 10

Program Development Tools

FA-M3 Programming Tool WideField

Ladder Programming Tool Designed for Engineers………………………………. 11

Object Ladder…………………………………………………………………………. 12

Program Component…………………………………………………………………. 13

Index View…………………………………………………………………………….. 14

Collective Change of I/O Positions ………………………………………………… 15

Logical Design by Tag Name……………………………………………………….. 16

Group Tag Name……………………………………………………………………... 17

Advantages of Windows Environment……………………………………………... 18

Flexible Operability …………………………………………………………………...19

Sophisticated Debugging Functions………………………………………………... 20

Enriched Help…………………………………………………………………………. 21

BASIC Programming Tool M3 for Windows………………………………………………. 22

Outstanding Maintenance Support Functions ……………………………………………. 23

Remote OME …………………………… ……………………………………… …………. 24

Remote OME via Ethernet ………………………………………………………………...25

Remote OME Using Commercially-available Modem …………………………………. 27

System Log ……………………………………………………………………………….... 28

User log …………………………………………………………………………………….. 29

Sampling Traces…………………………………………………………………………….30

Analog Input/Output Modules ……………………………………………………………….31

(F3AD04-0N, F3AD08-1N, F3DA02-0N, F3DA04-1N, F3DA08-5N)

Temperature Control Modules ……………………………………………………………... 32

(F3CT04-0N, F3CT04-1N, F3CR04-0N, F3CR04-1N, F3CV04-1N)

Positioning Modules for Controlling Every Type of Motor ……………………………... 33

F3NC11-0N and F3NC12-0N Advanced model Positioning Modules

with Positioning Pulse Output ………………………………………………………..34

F3NC51-0N and F3NC52-0N Positioning Modules with Analog Voltage Output…….35

TI 34M6A01-01E I

Page 4

Applications of Personal Computer Link Interface………………………………………...36

(Connection with personal computer/Display)

Personal Computer Link Modules ………..…………………………………………………37

(F3LC11-1N, F3LC11-2N)

Personal Computer Link via Programming Port……………………………………………38

(F3SP05-0P, F3SP21-0N, F3SP28-3N, F3SP38-6N, F3SP53-4H, F3SP58-6H)

Ethernet Interface Module………..……………..……………………………………………39

(F3LE01-5T)

FA Link H Module ………..……………..………..…………………………………………..40

(F3LP02-0N)

Fiber-optic FA Link H Module………..……………..………………………………………..41

(F3LP12-0N)

UT Link Module………..……………..………..……..……………………………………….42

(F3LC51-2N)

Multi-Link Module ………..……………..……..……..……………………………………….43

(F3LC21-1N)

GP-IB Communication Module ………..……………..………..……. .…………………….44

(F3GB01-0N)

RS-232-C and RS-422/485 Communication Modules (1) ………….. …………………..45

(F3RZ81-0N, F3RZ91-0N)

RS-232-C and RS-422 Communication Modules (2) ………..……………………………46

(F3RS22-0N, F3RS41-0N)

FA-M3 Value………..……………..……..……..………..……………………………………47

(F3SC21-1N)

Fiber-optic FA-bus Module………..………………..………………………………………..48

(F3LR01-0N)

Fiber-optic FA-bus Type 2 Module………...……..………………… ……… ………………49

(F3LR02-0N)

DeviceNet Interface Module………..……………..…………………………………………50

(F3LD01-0N)

24 V DC Power Supply Module………..……………..……………………………………..51

(F3PU26-0N)

Market Standard Connectors………..……………..……………………………………......52

TI 34M6A01-01E II

Page 5

P

P

L

L

C

C

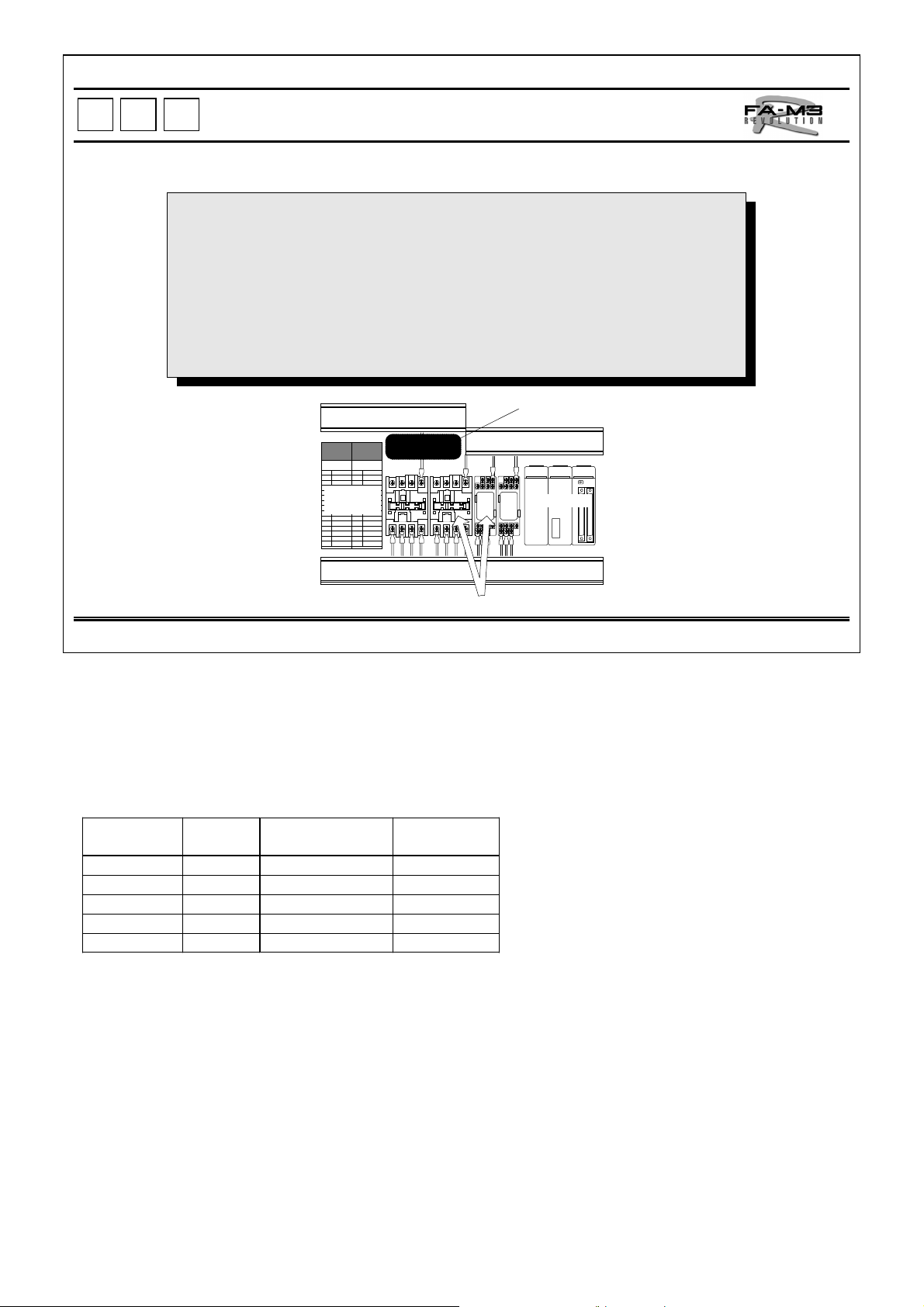

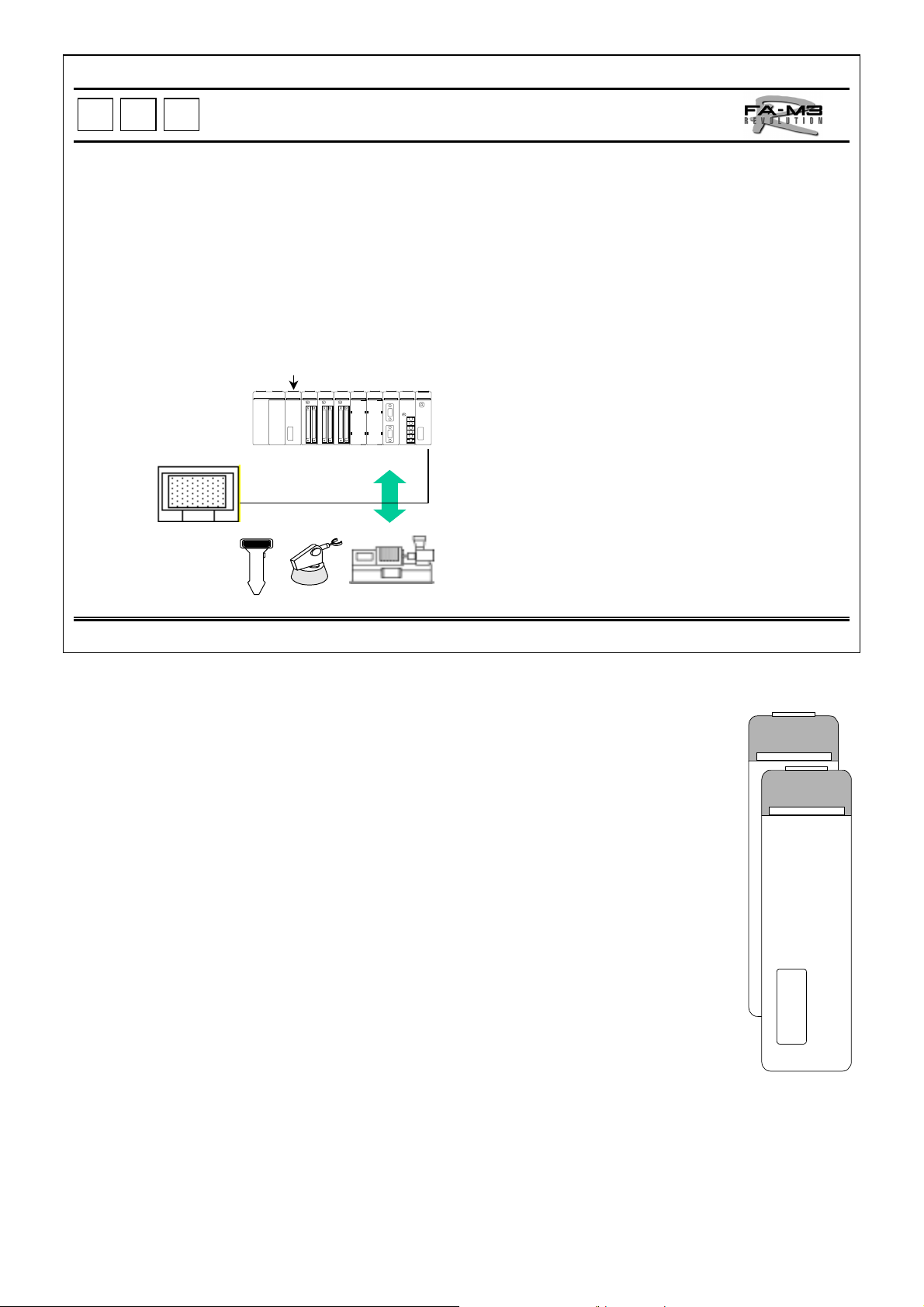

Introduction to FA-M3

From EVOLUTION to REVOLUTION

The FA-M3 has rebor ned as the FA-M3 R,

to revolutionize the users' equipment.

for Revolution!

FA-M3 R is a new generic name for FA-M3 controllers containing one or

more of the brand new, ultra-fast four CPU modules.

FA-M3 R can simply be called the

FA-M3 R and FA-M3 have upward compatibility.

The design concept was to increase the speed of the FA-M3. The new high-

speed Instruction-Process-Response-Scan, or High-speed IPRS, in the FA-M3 R

was designed to achieve this objective.

Extensive studies were conducted to meet every requirement including ultra-high-

speed control, steady dispersion-free control and improved networking functions

including link control. The FA-M3 R is Yokogawa's ideal controller for nextgeneration equipment, delivering even greater accuracy and productivity.

"

M3R".

TI 34M6A01-01E

Instruction

Process

Scan

High speed

Response

1

Page 6

P

P

L

L

C

C

FA-M3 R Features

Ultra-fast Processing Speed

20K steps of ladder program scanned per millisecond

Minimum scan time of 200 µs

Sensor control function with constant scan from 200 µs

Quick response from input to output

Quick response time 100 µs to an interrupt signal

Ultra-compact Size

The compact, 147 (W) x 100 (H) x 88 (D) mm size

handles 192 points.

Universal I/O Range

Can control up to 8, 192 points and contain devices of up

to 310K words per system.

Capabilities of a high-end PLC at the cost of a low- or

mid-range PLC

In case of 1000-2000 I/O points, the list price becomes

one third to a hal f against other vendor’s PLC

* I ndicates the performance when running a program that contains basic instructions and application instructions in average ratios; does not guara ntee that all

the user's program wi ll run at this speed.

** Acronym of rem ot e Operation Maintenance and Engineering proposed by Yokogawa Electric Corporation.

Outstanding Maintenance Support Functions

*

Remote OME**function using public phone line and Ethernet

Diagnostic based on error log and user log

Diagnostic based on sampling trace

Common I/O mod ule spares for all system regardless of I/O

range

Multi-CPU

Tasks can be divided by multiple ladder CPUs

Data processi ng by the BASIC CPU

PC applications run by the AT-compatible CPU

FA-M3 Programming Tool WideField

Object ladder, a new programming method succeedin g to

structured programming

Blocks and macros can be code d independently, t hus

drastically increasing reusability.

Increased efficiency of reuse with improved visibility

Easy data exchange wit h W i ndows- bas ed appli c ati ons

BASIC Programming Tool M3 for Windows

Convenient BASIC program development under the Windows

environment

The FA-M3 R outclasses the capabilities of today's PLCs and offers the

functionality, performance, a choice of languages and expandability

provided by a microcomputer board.

No more tedious quality control of huge variety of boards or

discontinuation of parts - the user can concentrate on adding value to

equipment.

TI 34M6A01-01E

2

Page 7

P

P

L

L

C

C

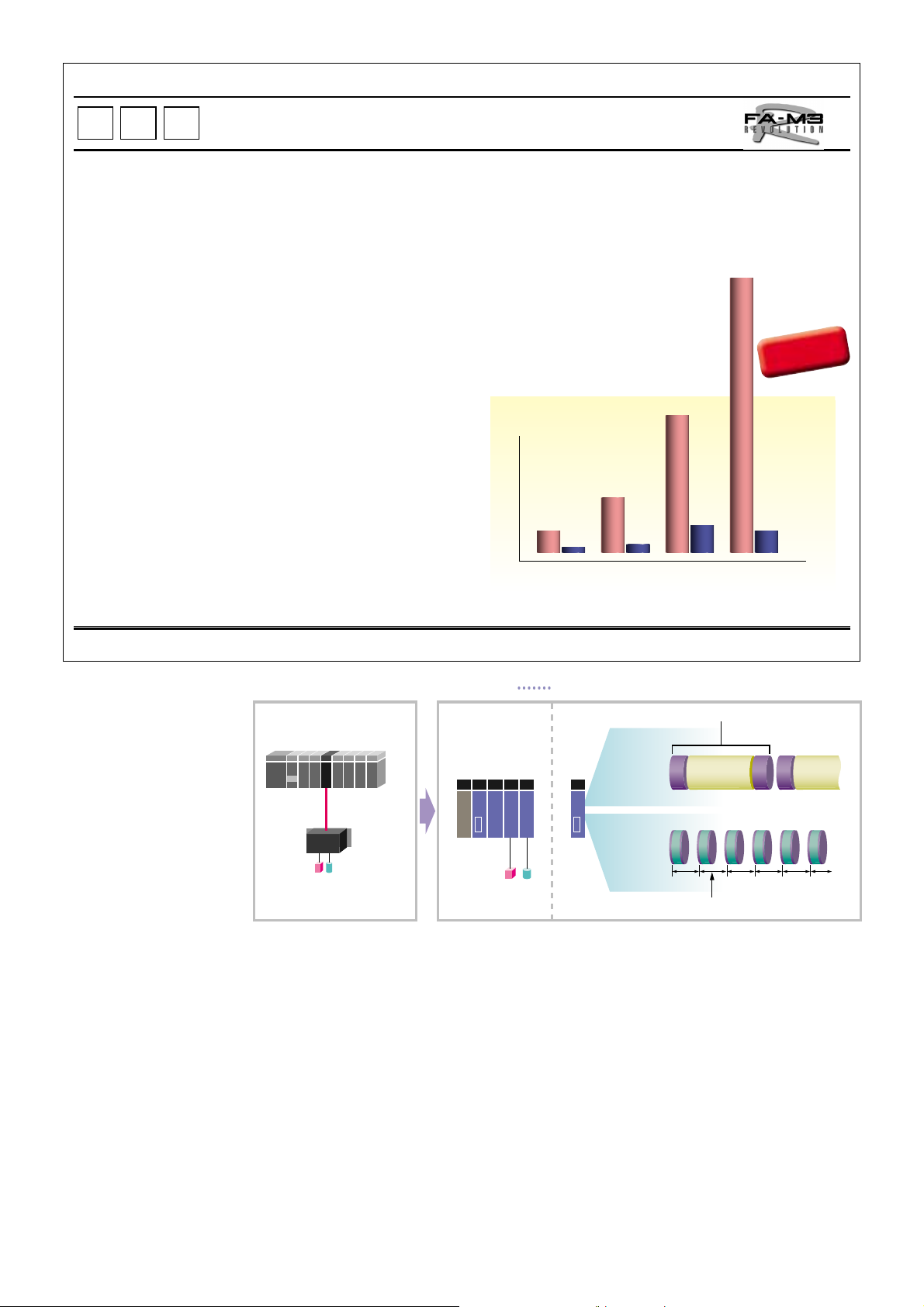

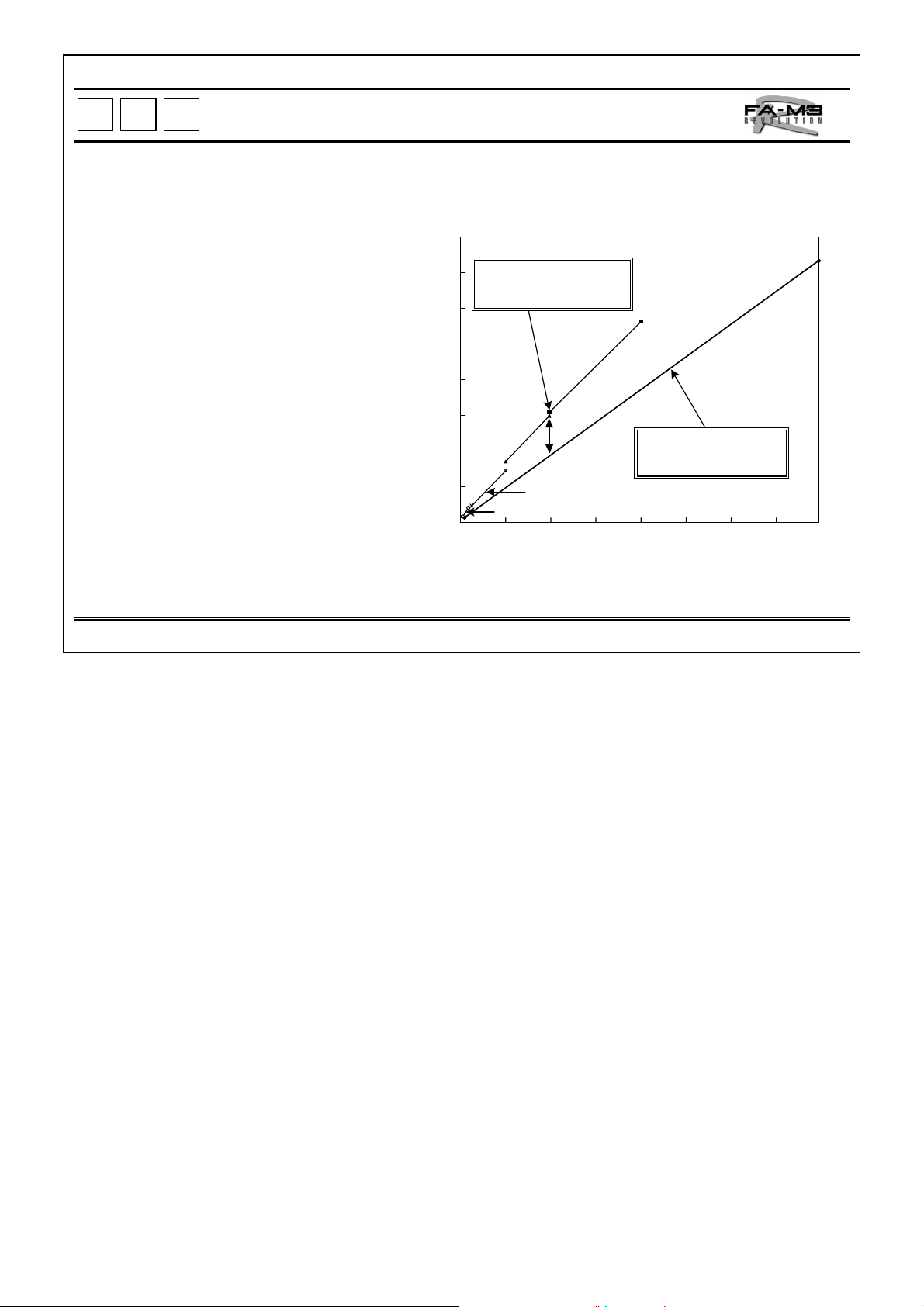

Ultra-fast Processing Speed

World's fastest processing speed realized by triple processors.

20K steps of ladder program scanned per milli second.

Minimum scan time of 200 µs.

The FA-M3 R del ivers high-speed in all aspects, running a 20K st eps of program in on e

millisecond (ratio of application instructions used: 50%). Actual applications for to day's

functionally-enhanced equipme nt contain a larger ratio of application instructions. For

such applicati ons, the FA-M3 R achieves at leas t ten times the performance of the

former CPU modules for the FA-M3.

The graph on the right shows examples of perform ance improvement s.

4

Average number of

Instruction executed

Molding

machine

* In comparison to the former CPU module of Yok ogawa with the actual applications

9.8

Sorting

machine

Application Type

*

10.8

max.10 times

faster*

4.1

F3SP58

F3SP35

Picking

machine

1: Compared whith Our Conventional CPU

Cleaning

machine

1

● With conventional PLC

PLC/

sensor controller

Sensor actuator

Quick response from in put to outp ut

• Ultra-quick response time: 100 µs

F3XD08-6F, F3XD16-3F, F3XD32-3F/4F,

F3XD64-3F/4F (with 32 input points)

• Ultra-quick response to input: 10 µs

F3XD16-3H (when used with the F3SP28,

F3SP38, F3SP53 or F3SP58)

• Output shutoff function added:

F3YD64-3F, F3WD64-3F/4F (with 32 output

points)

● With FA-M3 R

Sensor Control Function

The number of PLC units can be reduced since two ladder programs

can be executed by one CPU module.

1 scan

Main scan

High-speed

constant

scan

constant scan : Min. 200 µs

• One CPU can carry out a high-speed constant

scan (from 200 µs) independently besides the

normal scan.

• The same CPU also achieves a quick

response.

Faster Response to Interrupt Signal

• DC input module allows quick response of 100

µs to an interrupt input

• Swift response to a change in input level to

implement instantaneous high-speed control

TI 34M6A01-01E

3

Page 8

P

P

L

L

C

C

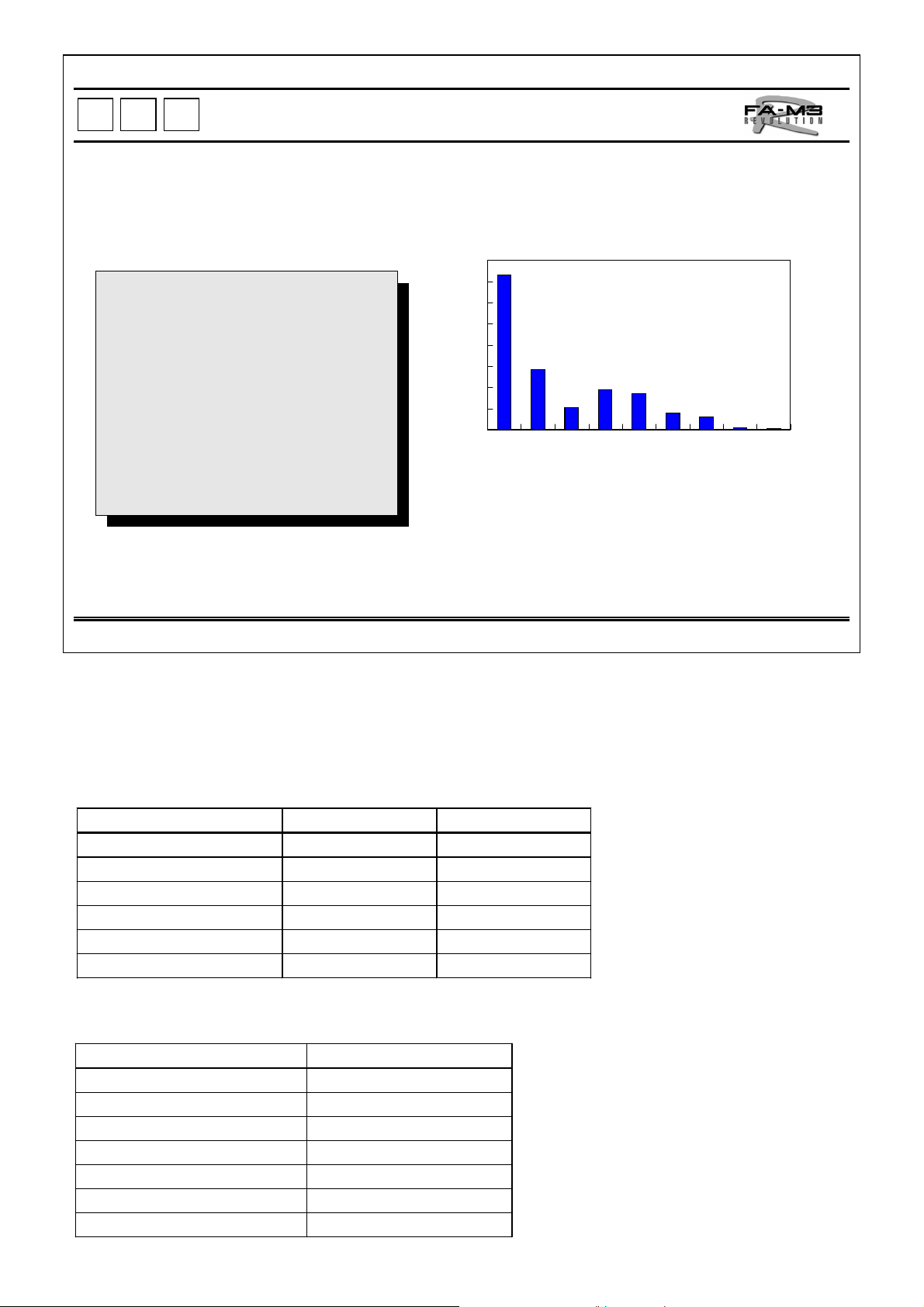

Comparison with Competitors

Due to the ultra-fast pro c es sin g speed, there's no nee d to

consider the processing time when programming.

Why is high-speed processing necessary?

To carry out complicated calculations (with

•

application instructions) quickly

To stabilize mechanical control of higher

•

speed for higher productivity

To allow human-interface and diagnostic

•

programs to be enhanced, thus providing an

easier interface for the operator

To reduce unstable actions during each scan

•

time by network servicing

* Execute d i nstructions mea ns t he aver age number of inst r uct i o ns executed in 1 µsby PLC.

Ultra-fast Execution of Instructions

Executed*

16.00

14.00

12.00

10.00

8.00

6.00

4.00

2.00

0.00

Comparison of Processing speed

14.50

5.62

3.80

3.54

1.52

Model of

Model of

Model of

company A

company A

company B

SP53/58

1.83

SP21

SP28/38

High-speed PLC CPU

Price: 200,000 to

550,000 yen

1.33

0.04

0.02

Model of

Model of

General PLC CPU

Price: 60,000 to

200,000 yen

company A

company B

Model of

company B

Basic instruction: Min. 0.0175 µs

Application instruction: Min 0.070 µs

Comparison with Yokogawa's Former CPU Module for Basic

Instructions

Instruction New SP53 Former SP35

LD, AND, OR 17.5 to 35 ns 90 ns

Timer 175 ns 360 ns

Transfer 70 ns 180 ns

Comparison 70 ns 180 ns

Addition, subt raction 105 ns 270 ns

Logic operator 105 ns 270 ns

Comparison with Yokogawa's Former CPU Module for Application

Instructions

Instruction SP58 vs. SP35

Transfer between file registers 74.1 times faster

Index modification (LD) 10.7 times faster

Index modification (MOV) 30.4 times faster

Read/write 6.4 times faster

Timer update 6.7 times faster

BMOV/BSET 12.8 times faster

FOR-NEXT 7.7 times faster

TI 34M6A01-01E

4

Page 9

P

P

L

L

C

C

Compact Size

Postcard-size Controller

Why does a controller need to be smaller?

• To provide ample room for additional modules

• To allow installation of the controllers without affecting the machine design and

safety of the user factory (al lowing per s pe c tive facilities)

• To help standardize control panels

• To reduce the size of the control panel to be min imized regardless of t he

controller scale

• To reduce costs

Duct

Other

manufacturer's

PLC

Duct

Relays, conductors, etc.

Design concept: PLC is a subs ti tu te for relays

The FA-M3 R is packaged into the size of usual relays and conductors, and is designed for ins tallation in the

same row with those inside a panel, thus allowing effective internal design of the panel.

Dimensions

Base

Module

F3BU04-0N 4 100 x 147 88.5

F3BU06-0N 6 100 x 205 88.5

F3BU09-0N 9 100 x 322 88.5

F3BU13-0N 13 100 x 439 88.5

F3BU16-0N 16 100 x 537 88.5

* Dimensions of a base module with I /O modules installed in it (excluding c onnectors and terminals bl ocks )

Slots

Mounting

Dimensions

(mm)

Depth of

Module

*

(mm)

Waste space

Duct

FA-M3 R

TI 34M6A01-01E

5

Page 10

P

P

L

L

C

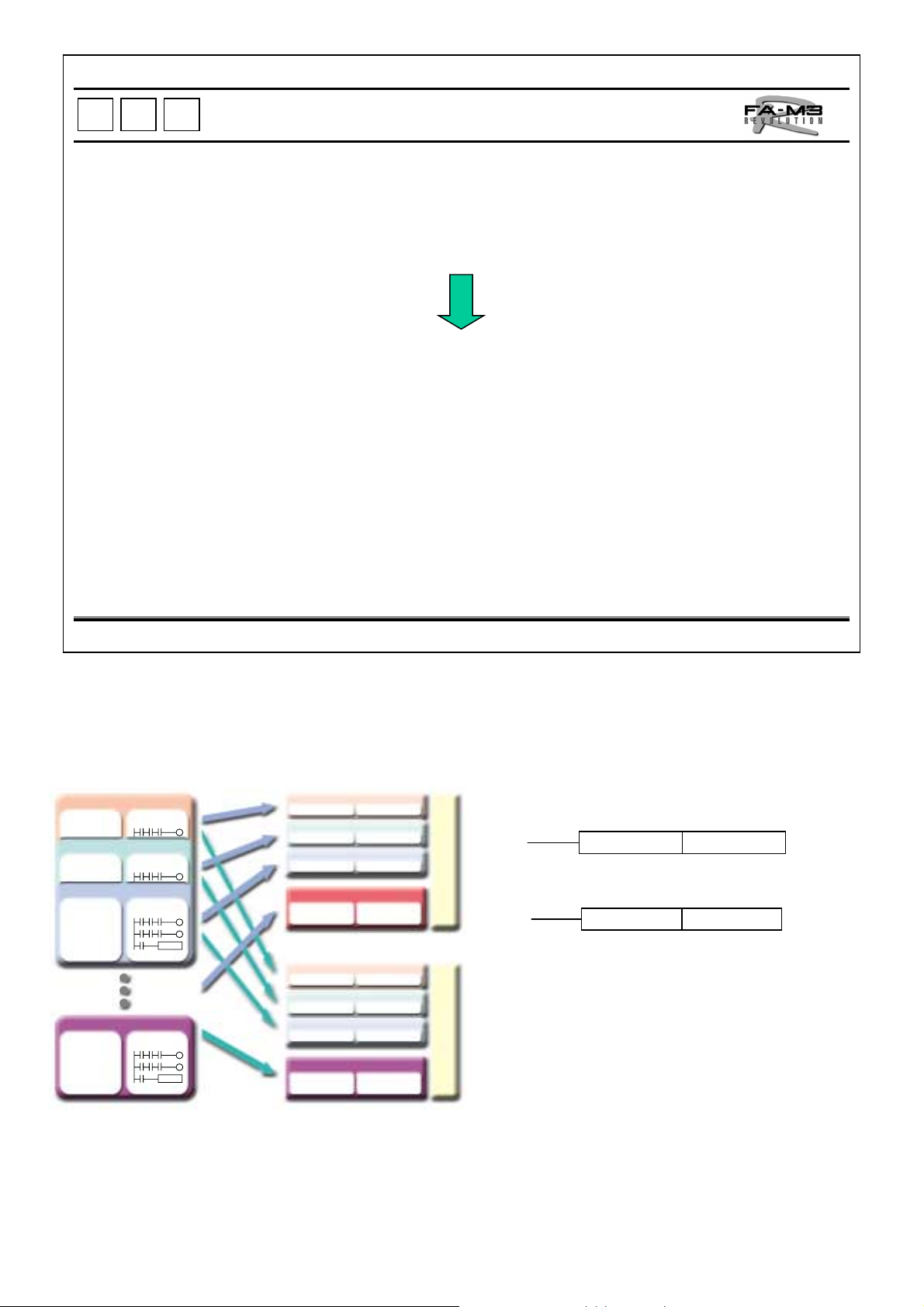

C

Universal Range

Whatever the number of I/O points, one PLC covers all.

•Higher functionality than high-end PLC,

yet more reasonable cheaper than

low-end PLC

•Only one model covers a broad range

of I/O points, from small to large

•High expandability independent of

scale

•Common modules and parts eliminates

need for diverse spares.

800

FA-M3 R costs only twothirds of competitors' for

2048 points.

FA-M3R

Other manufacturers'

ultra-high-end PLCs

Other

manufacturers'

high-end PLCs

Other manufacturers' mid-range PLCs

0

Other manufacturers' low-end PLCs

0 1024 2048 3072 4096 5120 6144 7168 8192

One model of FA-M3 R

covers the entire range

of I/O points.

Price (yen)

700

600

500

400

300

200

100

I/O Points

Flexible Combination of Diverse Types of I/O Modules

• Offered with various types of I/O modules as used in high-end PLCs

• Simple access to advanced I/O modules

Number of I/O Points

• 4 to 288 analog inputs

• 2 to 288 analog outputs

• 1 to 288 axes for positioning

• 4 to 144 pulse inputs

• 1 to 36 serial communication ports (F3RZ1, F3RS41)

• 2 to 72 serial communication ports (F3RS22)

• 1 to 8 GP-IB communication ports

Note: Shown above are the maximum numbers of points and ports when the corresponding modules are inst al l ed for the maximum

numbers independentl y, and do not mean that all these maximums are available at the same time for the same controller. The

maximum number for each item depends on the combination of modules actually installed.

TI 34M6A01-01E

6

Page 11

P

P

L

L

C

C

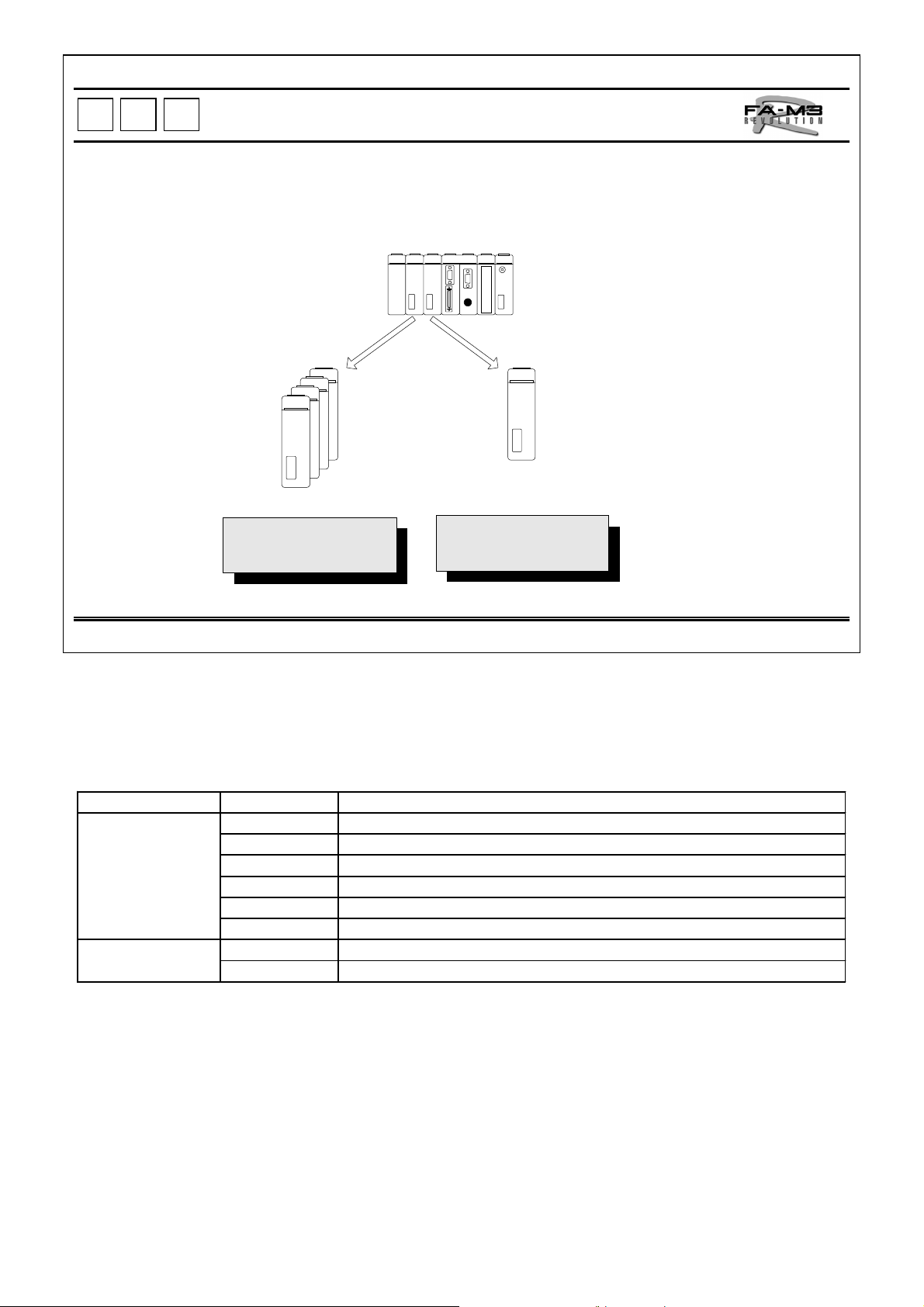

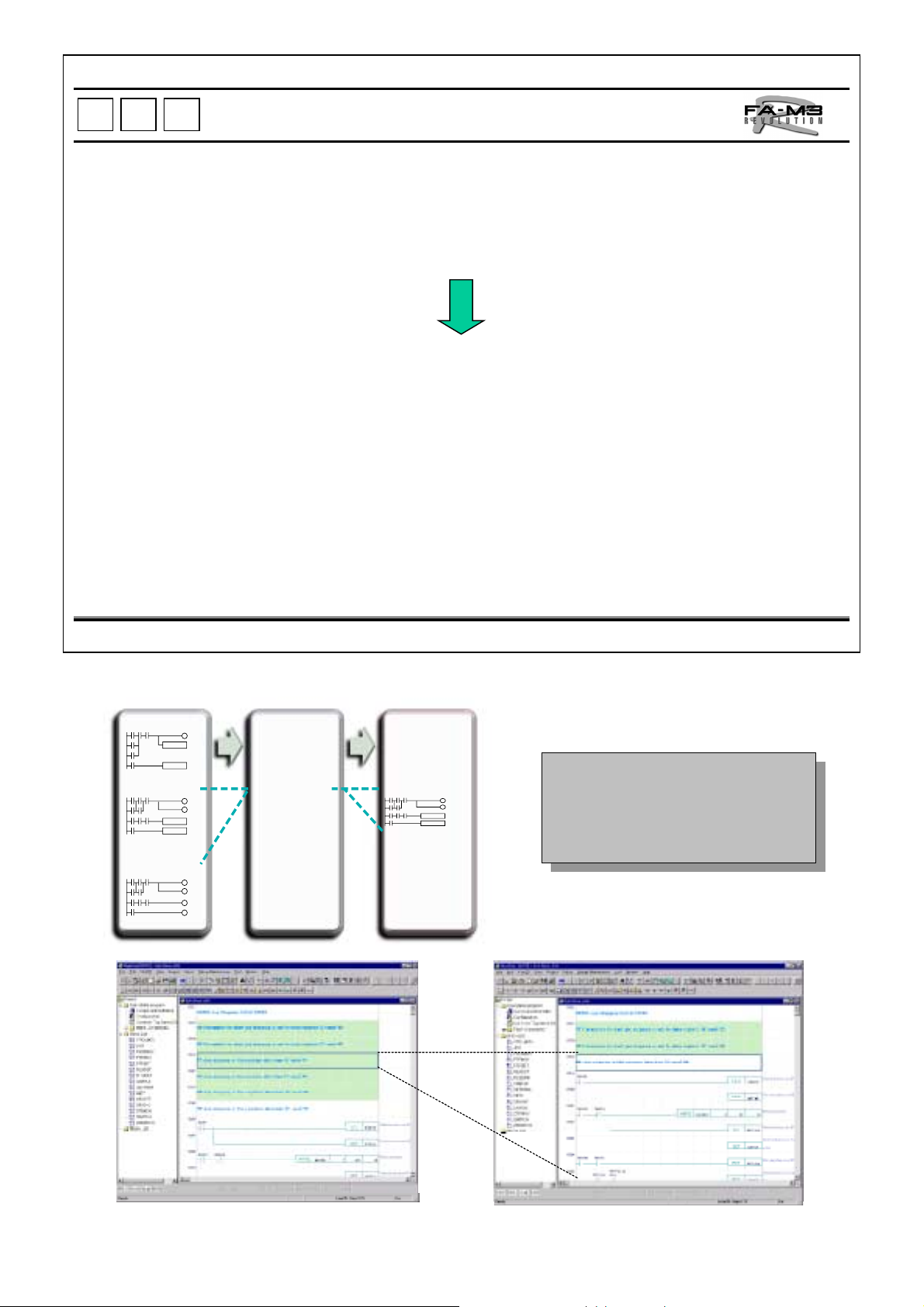

Multiple CPUs

•Use any programming language you like.

•Use the optimum language for your applicatio ns.

•Combine languages freely .

Up to 4 CPU modules can be combined.

Ultra-high-speed

processing

Sequence CPU BASIC CPU

Up to 4 ladder programs

can be run, allowing task

to be shared.

• Mechanical engineers may prefer a ladder diagram, while production engineers may prefer BASIC.

Æ

The FA-M3 R allows the programming language to be chosen freely.

• Sequence CPUs are good for tasks requiring high-speed proc essing, a BASIC CPU for floating-point and

character calculations.

Æ

You can select CPUs to meet your application requirements.

Real-time BASIC programs

can be run.

Communication and

text processing

(character handling)

* Only one BASIC CPU mod ule can be installed per controller.

*

Module Model Specifications

Sequence CPU F3S P 21-0N

modul e F3SP28-3N

F3SP38-6N

F3SP53-4H

F3SP58-6H

F3FP36-3N

BA SI C CPU F3BP20-0N

modul e F3BP30-0N

• Any CPU can directly access I/O modules.

• Different types of CPU modules can exchange data with each other.

•Without additional module(s), the above mentioned CPU module can achieve function of

a controller.

Str uc tured ladder languge, 10K steps, 0. 18 µs/basic instr uc tion

Object ladder language 30K steps, 0.045 µs/basic instruction

Object ladder language 120K steps, 0.045 µs/basic instruct ion

Object ladder language 56K steps, 0.0175 µs/basic instruction

Object ladder language 120K steps, 0.0175 µs/basic instruct ion

Ladder and SF C language, 40K steps, 0. 09 µs/c ont ac t or c oil instruct ion

YM-BASI C/ FA language, 120KB

YM -B ASI C/ F A language, 510KB

TI 34M6A01-01E

7

Page 12

P

P

L

L

C

C

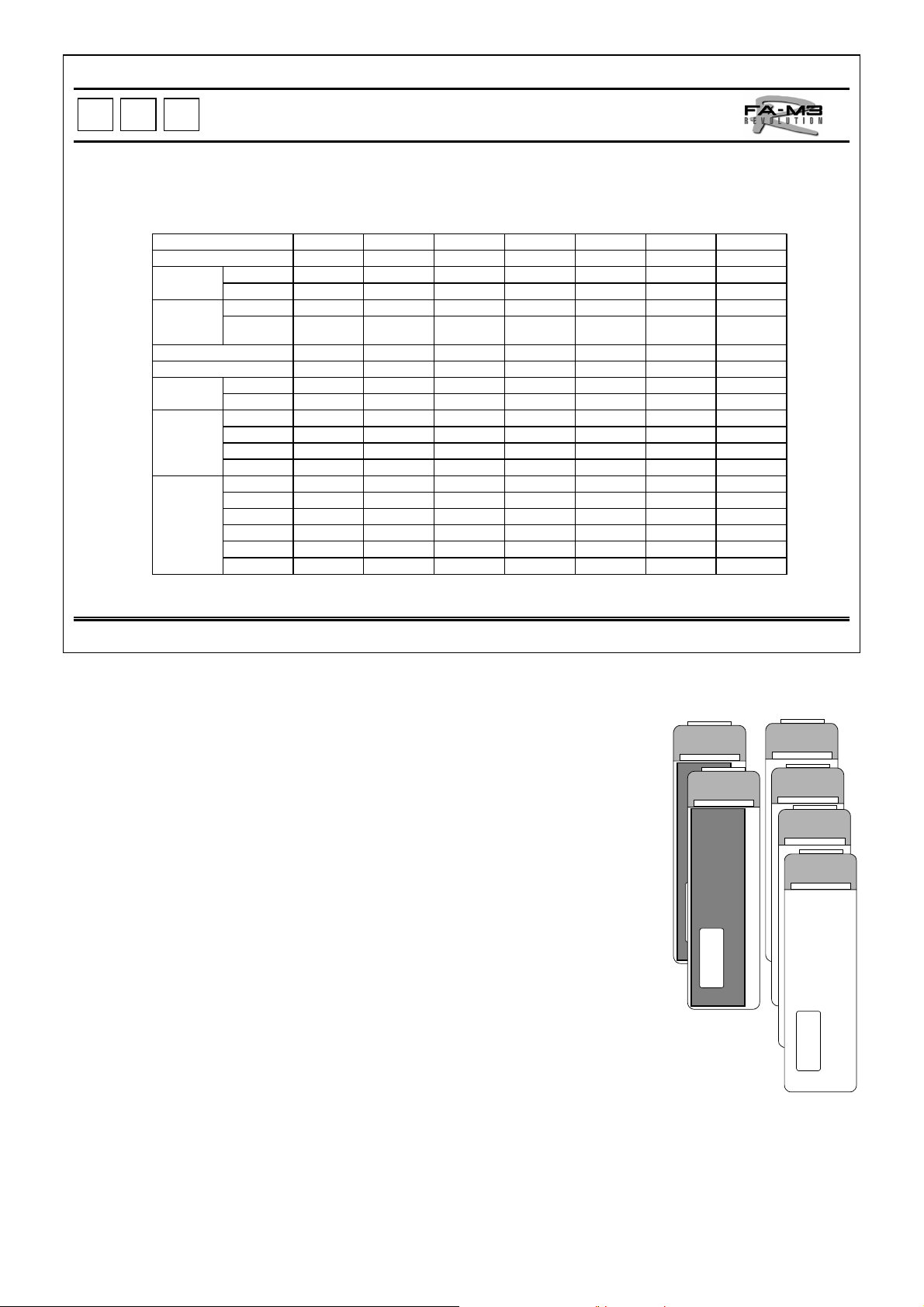

Sequence CPU Modules

Larger Program Capacity, Device Capacity and

Variety of Instructions than for High- end PLCs

Seven modules to meet various needs.

Number of i nputs / output s 2,048 2,048 4,096 8,192, 4,096 8,192 4,096

Number ofBasic 252533333333 8

instructions Application 227 227 312 312 312 312 59

Processing

speed per

instruction

Program capacit y (st eps ) 5K 10K 30K 120K 56K 120K 40K*

Number of program blocks 32 32 1,024 1,024 1,024 1,024 1,024**

Devices Timers*** 512 512 2,048 3,072 2,048 3,072 2,048

Relays Internal 4,096 4,096 16,384 32,768 16,384 32,768 8,192

Registers Data 5,120 5,120 16,384 32,768 16,384 32,768 5,120

Item

Basi c (µs) 0.18–0.36 0.18–0.36 0.045–0.18 0.045–0.18 0.0175– 0.07 0.0175– 0.07 0.09–0.18

Application

(µs)

Counters*** 512 512 2,048 3,072 2,048 3,072 2,048

Shared — 2,048 2,048 2,048 2,048 2,048 4,096

Link 2,048 2,048 8,192 16,384 8,192 16,384 8,192

Special 2,048 2,048 9,884 9,884 9,884 9,884 9,984

File — — 32,768 262,144 32,768 262,144 27,648

Link 2,048 2,048 8,192 16,384 8,192 16,384 8,192

Special 512 512 1,024 1,024 1,024 1,024 512

Index 32 32 256 256 256 256 —

Shared — 1,024 1,024 1,024 1,024 1,024 4,096

F3SP05 F3SP21 F3SP28 F3SP38 F3SP53 F3SP58 F3FP36

Min. 0. 36 Min. 0. 36 Min. 0.18 Min. 0.18 Min. 0.07 Min. 0.07 Min. 0.18

* Capacity in steps of lad der program

** Capacity in steps of sequence function chart (SFC)

*** T ot a l numb er of tim er s a nd co u nter s

F3SP05-0P, F 3SP21- 0N, F3SP 28 -3N, F 3 SP38-6 N, F3SP5 3- 4 H, F3SP58 -6H an d

F3FP36-3N Sequence CPU Modules

• High-speed execution of instructions easily handles high-speed processing and response.

(Scan time of 1 ms for a 20K step program when us ing an F3SP53 or F3SP58)

• Sensor control function enables quick scan (input Æ program execution Æ output)

besides normal scan . This allows to have stable input/output response of 400 µs (200 µs

x 2). (when using an F3SP28, F3SP38, F3SP53 or F3SP58).

• Inheriting the structured programming, object ladder programmingis adopted as a

dramatically upgraded programming language that facilitates program development and

modification (for the F3SP28, F3SP38, F3SP53 or F3SP58).

• User-defined macro instructions can be created and registered.

• Enriched functions, such as forced set/reset that are not affected by the results of

program computations as well as a scan operati on, fac ilit ate progra m debugg ing and

modification.

• The PROGRAMMER port (connection port for programming tool) supports a personal

computer link, allowing linkage to upper-level computers and display units without a

personal computer link module (at maximum baud rate of 115K bps for the F3SP28,

F3SP38, F3SP53 or F3SP58).

• Programs and data can be stored in an optional ROM pack, which is useful when

performing program replacement and making many copies of the same program on site.

• Protect function is provided to prevent programs from being read and copied by

unauthorized persons.

RDY

RUN

ALM

ERR

SP53-4H

CPU

RDY

RUN

ALM

ERR

SP58-6H

CPU

PROGR

AMMER

PROGR

PROGRAMMER

AMMER

PROGRAMME R

F3SP53-4H

F3SP58-6H

RDY

RUN

ALM

ERR

SP21-0N

CPU

RDY

RUN

ALM

ERR

SP28-3N

CPU

RDY

RUN

ALM

ERR

SP38-6N

RDY

RUN

ALM

PROGRAMMER

ERR

FP36-3N

PROGRAMMER

PROGRAMMER

PROGRAMMER

F3SP21-0N

F3SP28-3N

F3SP38-6N

F3FP36-3N

CPU

CPU

Note: The F3FP36-3N is used for both SFC and ladder pro grams (ladder program s only is availabl e), and supports

neither index modific ation, scan operation, person al computer link, user log, ROM pack nor program security.

TI 34M6A01-01E

8

Page 13

P

P

L

L

C

C

BASIC CPU Modules

YM-BASIC/FA, th e world's fastest BASIC

•

Incorporates YM-BASIC/FA, a BASIC language for real-time control used in proven Yokogawa

YEWMAC500 computer for factory automation.

•

Realizes a BASIC program-based controller (no need for a sequence CPU module).

•

Can directly access inputs and outputs.

Direct I/O access without a sequence CPU enables field data to be read and written at high speed.

(16 I/O points can be accessed within 5.2 ms.)

F3BP20-0N

F3BP30-0N

TOP77RT/TOP72S

FA-M3 R

•

Ideal for high-level computations

•

Simplifies character and array computations.

•

Dedicated interpreter realizes high-speed

processing.

Real-time control of field

F3BP20-0N and F3BP30-0N BASIC Modules

• Useful for communication tasks or high-level computations that are not easily controlled by

a ladder program.

• Can configure as a BASIC controller since a BASIC CPU module alone can be used

without a sequence CPU module.

• When installed in slots 2 to 4, BASIC CPU modules work as add-on BASIC CPU modules

for a sequence CPU module.

• Can directly access input and output modules.

• Can exchange data with ladder programs and synchronize with ladder programs by using

events.

• Allows structured programming using subprograms.

• Can access common data with a personal computer link module (can also connect a

display unit and access data via Ethernet or modem).

• The PROGRAMMER port (connection port for programming tool) provided with each

BASIC CPU module allows programming for each CPU.

RDY

RUN

ALM

ERR

BP20-0N

CPU

RDY

RUN

ALM

ERR

BP30-0N

PROGRAMMER

PROGRAMMER

CPU

• Programs can be developed and debugged on a personal computer.

• By installing an optional ROM pack, programs and common data can be saved and the

programs in the ROM pack can be run. The ROM pack is useful when performing

program replacement and making many copies of the same program on site.

TI 34M6A01-01E

F3BP20-0N

F3BP30-0N

9

Page 14

P

P

L

L

C

C

Easy Real-time Processing with BASIC

A statement to start an interrupt routine needs only one line.

F3BP20-0N and F3BP30-0N

FA-M3 R

F3BP20-0N

F3BP30-0N

YM-BASIC/FA

Barcode Remote ID

100 ON INT 2 , 5 GOSUB WARI@

110 !

120 LOOP@

130

.

Main routine

.

.

140 GOTO LOOP@

150 !

160 WARI@

170 !

180 ENTER xxxxx

190 OUTPUT xxxxx

200 RETURN

210 !

220 STOP

230 END

YM-BASIC/FA, real-time BASIC

Data input

Data output

Interrupt st atement

Interrupt routine

Barcode reader

• On-line real-time processing

- Supports extensive interrupt methods to enable immediate response of a BASIC program to external events.

- Facilitates development of on-line real-time programs.

• Modular program structure

- Can use subprograms.

- Variables, line numbers and labels in the main and individual subprograms independently, thus it simplifies

development and program maintenance, and improving program reusability.

- The main program and subprograms can be developed separately, and assembled together by using the

APPEND command later.

• Combination with sequence programs

- Variables used in a BASIC program can be combined with shared registers by a common variable

statement, thus it facilitates data exchange with sequence CPU module. Synchronization with sequence

CPU modules can also be achieved by using SIGNAL, ON SEQEVT, ENTER and OUTPUT statements.

- Device values in CPU modules can be read and written by using ENTER and OUTPUT statements.

• I/O support

- Can access various communication modules such as serial communication modules, various digital I/O

modules, and various analog I/O modules by using ENTER statements for input and OUTPUT statements

for output.

TI 34M6A01-01E

10

Page 15

P

P

L

L

C

C

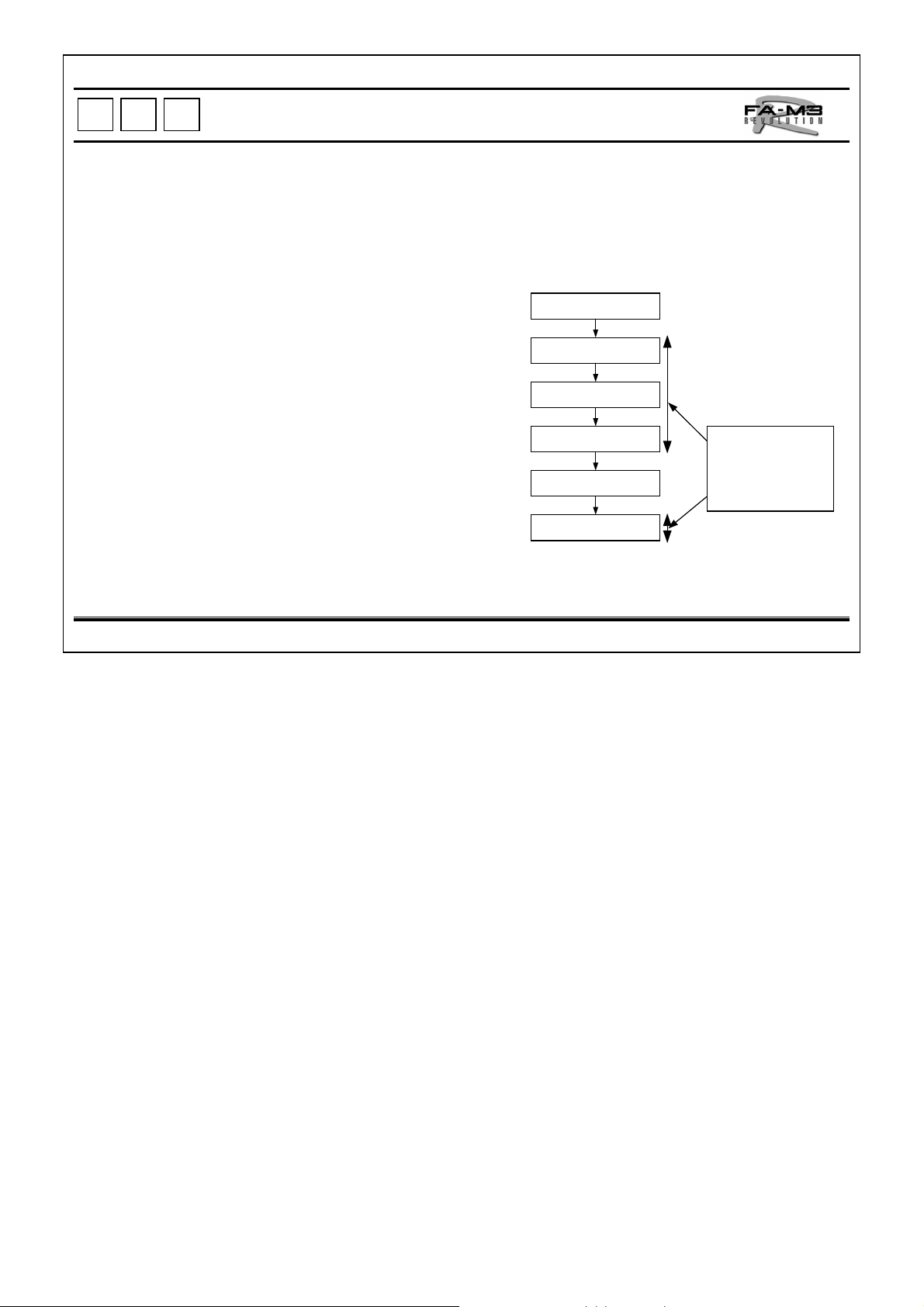

Ladder Programming Tool Designed for Engineers

Ultimate pr og ram reusability.

WideField dramatically reduces Total Cost of Ownership

by customization of each machine.

FA-M3 Programming Tool WideField

Object ladder Enriched help

Program Component Remote OME*

Index view System log*

Collective change of I/O positions User log*

Logical design by tag name Sampling traces*

Group tag name Ethernet connection*

Advantages of Windows environment Modem connection*

Flexible operability

Sophisticat ed debugging functions

* See the respective pages of these excellent maintenance functions for det ails.

System Design

Program Design

Programming

Debugging

Running

Maintenance*

WideField great ly

reduces the time

required for these

processes.

FA-M3 Programming Tool WideField (SF610-E3W)

WideField solves all issues facing user program development. It offers extensive features for greatly

increasing the efficiency of program development, such as the clarification of the component structure of

programs, improved visibility, under the familiar Windows environment.

z

Product concept:

• Customized program design

• Operability

• Reusability

• Link with other applications

• Visibility

• Ease of debugging and maintenance

• Concurrent development by multiple engineers

• Improved software quality

• Shorter development period

z

WideField is ready to go simply by installing it in your PC.

z

WideField can be run under Windows 95, Windows 98 or Windows NT 4.0.

TI 34M6A01-01E

11

Page 16

P

P

The FA-M3 Programming Tool WideField is a revolutionary application for programming object

An object ladder is a new concept of developing programs. The object in which a piece of program

An object ladder is highly reusable. When customizing an existing machine control program for a

C

L

C

L

ladder succeeding to structured ladder programming and created with new concept.

and the related devices are assembled for each functional unit called a block. The blocks are then

assembled together to form the entire ladder program. Each block can thus be functionally

independent, which improves productivity and program maintainability compared to structured

programming*.

particular user, the details of each block need not be checked; blocks are simply added or replaced.

Object Ladder

1990

Structured

programming

Conventional ladder

programming

2000

Object ladder

programming

*

Structured programming.

Yokogawa Electric Corporation in 1989, in which an increasingly

complexed ladder program is divided into parts for individual functional

units so that developers can easily understan d t he program framework,

and improved productivity and program maintainability. As these

advantages became recognized in the 1990's, structured programming

grew rapidly. Other PLC manufacturers rolled out product s based on the

same concept, and structured program m ing is now t he de facto standard

in PLCs.

A programming method proposed by

TI 34M6A01-01E

12

Page 17

P

P

L

L

C

C

Program Component

Independence of Blocks and Macros for Enhancing Drastical Reusabi lity.

Blocks and macros are pieces of program and use common devices as their data. Thus,

devices need to be assigned uniquely not to doubly used in different blocks and macros.

By using the concept of local devices in each block and macro, devices can be handled

independently in each block and macro.

Different macros and blocks can have a local device having the same name since

different physical addresses will be assigned to those local devices, thus device conflict

can be avoided

.

Programs and local devices can be handled as sets so that they can be reused easily as

parts.

Basic Blocks

Block A

Local

devices

Block B

Local

devices

Block C

Local

devices

-Reylay

-Register

-Timer

-Counter

Block Z

Local

devices

-Reylay

-Register

-Timer

-Counter

Program

Program

Program

Program

Standard configuration

Block A

Local devices

Block B

Local devices

Block C

Local devices

Block D

Local

devices

Optional

Block A

Local devices

Block B

Local devices

Block C

Local devices

Block Z

Local

devices

Program

Program

Program

Program

configuration

Program

Program

Program

Program

Address Indication

z

Global devices

Local device

Global device

Global devices

MOV /D1

MOV D1

• Local devices and global devices can be used

as different devices.

• When reusing a block, device addresses need

not to be changed.

• When local devices need to be added in a block,

no change to other blocks is needed.

TI 34M6A01-01E

13

Page 18

P

P

L

L

C

C

Index View

Increased Efficiency of Reuse with Improved Visibility.

A ladder program is coded as a long strip of diagram, which makes it difficult to grasp the

overall flow.

The entire program structure can be grasped.

You can hide and show each circuit block under the circuit comment (just like expanding

and collapsing the tree) to grasp the entire program structure and go to the corresponding

parts.

Programs written long ago or written by other engineer can be easily modified.

Index View

♦Supply of materials

♦Preparatory neating

♦Flacks coating

♦Formalting

♦Idling

•

•

•

♦Supply of materials

♦

Preparatory neating

♦Flacks coating

♦Coating

♦Fixing heating

♦Cleaning

♦Cooting

♦Unloading

•

•

•

♦Diagnosis

♦Power off

♦Formalting

♦Idring

•

•

•

♦Supply of materials

♦Preparatory neating

♦Flacks coating

♦Coating

♦Fixing heating

♦Cleaning

♦Cooting

♦Unloading

♦Diagnosis

♦Power off

Debugging after grasping

Debugging after grasping

the overall flow

the overall flow

Collapsed View of Circuit Expanded View of Circuit

TI 34M6A01-01E

14

Page 19

P

P

L

L

C

C

Collective Change of I/O P osi ti on s

Whenever the I/O m od ule allocation is changed,

the I/O addresses in the program can be changed instantly.

Before change

After change

Addition of

Addition of

I/O Modules

I/O Modules

Before change

After change

Deletion of

Deletion of

I/O Modules

I/O Modules

z When a standard machine control program is customized and I/O modules need to

be added or their position changed, the I/O addresses in the program can be

collectively changed accordingl y for each slot.

TI 34M6A01-01E

15

Page 20

P

P

C

L

C

L

A name suggesting the corresponding action can be assigned to each device to increase

maintainability.

Arbitrary names for individual devices can be used in the programming before the terminal

assignment is decided. The ability to separately determine the logical design and physical

design (i.e., program design and terminal assignment) greatly reduces the engineering

period.

Wiring changes can be accomplished be changing the tag definitions.

Use of tag names helps standardize circuits and enables programs to be reused with ease.

Logical Design by Tag Name

X00021

I00015

X00023

z Tag names can be set easily (see the figure below right);

however, even if the tag names have not yet been set ladder

diagrams can be edited using tag names.

Even when the terminal assignment has not yet been

Æ

decided, programs can be developed using signal

names.

z Tag names should be up to 8 characters long and begin with 2

alphanumeric characters.

X00022 I00015

Y00056

Conventional PLCs require

terminal addresses.

START

LOCK

SWITCH

The FA-M3 R allows you to write in

logical addresses (tag names).

KEEP LOCK

ABOUT

TI 34M6A01-01E

16

Page 21

P

P

L

L

C

C

Group Tag Name

Sets of names can be named to enable data sets to be managed under group names

System Configuration

Multi-axis positioning control

C

C

H

H

2

1

CH1

• Intuitive understanding by group presentation

• Intuitive understanding by group presentation

• Efficient programming by group handling of data

• Efficient programming by group handling of data

CH2

M M M M

C

C

H

H

3

3

CH3

CH8

Group Name Settings

Group name

PCH1

Signal Name Address

START Y00233

STOP Y00234

ERROR X00201

PAUSE Y00235

Programming

AUTO1

NO_ERR Pch1.START

AUTO2 NO_ERR READY2

AUTO3

READY1

Pch2.START

START Pch1

TI 34M6A01-01E

17

Page 22

P

P

L

L

C

C

Advantages of Windows Environment

Effortless da ta exchange with Windows-based applications.

Support for versatile Windows technologies such as OLE.

Tag name definitions set on a Microsoft Excel sheet can be imported into

WideField.

Data in WideField, such as a ladder diagram, can be utilized for the As Built

Drawings.

A Engineering Document can be easily created.

Note: The As Buil t Drawings and Engineering Document indicat e documents prepared using a Windows-

based application.

Practical use of Microsoft Excel

Tag name definitions can be copied and pasted not only

between Excel and WideField but also to engineering

documents.

Signal

Definitions

MS-Excel

As Built Drawings and other

engineering documents can be

easily prepared as Microsoft

Word documents using copy and

paste.

TI 34M6A01-01E

18

Page 23

P

P

L

L

C

C

Flexible Operability

Ladder diagrams can be modified like editing a document with a word processor.

Programming problems are minimized and operability maximized.

Program modification and monitoring can be done simultaneously by

opening multiple windows.

Both mouse and key operations are supported.

Connection lines can be dawn and deleted by dragging.

Shortcut menus displayed by right-clicking provide quick access to

commands valid for that screen region or selection.

A range of a ladder diagram can be copied and pasted between different

programs.

From a list of search results, a desired point can be retrieved.

All instructions can be entered by typing characters, and automatically

converted to the corresponding device on the screen.

You can select a device type from the I/O configuration and monitor the

statuses of the correspondin g devices.

File structure can

be viewed while

programming.

Intuitive operations with

buttons having symbolic

labels.

Comments and

diagram portions can

be colored differently

for visual

identification.

TI 34M6A01-01E

Example of Window Display

CPU running status can

be checked at all times.

19

Page 24

P

P

L

L

C

C

Sophisticate d Debugging Functions

Ladder diagrams can be modified while they are running.

User-oriented debugging functions assist program development and modification.

The log of CPU-detected errors can be viewed as the System Log, and the

trend of the system running status can be managed as the User Log.

Multiple parts of a diagram can be changed at once and modified parts can

be reverted at once, all while online.

Monitoring and debugging can be done via multiple personal computers

concurrently.

Fast scrolling quickly brings onto the screen in which the part of the diagram

you want to monitor.

Monitored data values can be displayed as deci m al, hexadecimal, binary,

character or floating-point values as you choose.

Security protection can be set for each program.

Choosing a device type, and

monitoring, setting and resetting

device values.

TI 34M6A01-01E

Example of Device Monitor

20

Page 25

P

P

L

L

C

C

Enriched Help

A description, operands and examples of action are shown for each instruction.

The appropriate help for each situation can be called.

Details on how to use an instruction and its act i on can be referenced.

An outline of a function and how to use it can be referen ced.

Potential causes and countermeasures for an error can be referenced.

Items can be looked up by entering a key word.

The help for an instruction can be called by choo sing the instruction from a

list of instructions.

Easy key operations

in the field.

A description, operands and

examples of action are shown for an

instruction.

Example of Help

CPU running

status can be

checked at all

times.

TI 34M6A01-01E

21

Page 26

P

P

L

L

C

C

BASIC Programming Too l M3 for Windows

Convenient BASIC program development under Windows environment.

Features:

Runs under Windows 95, Windows 98 or Windows NT.

Sophisticated debugging functions:

•

On-line program modification

•

Variable data trace

•

Break actions

•

Step run

CPU self-diagnostics:

•

•

Ref Check of various CPU settings and shared data

settings erence to CPU error log

Help:

•

Online help for functions, statements and commands

•

Help for errors and countermeasures

BASIC Programming Tool M3 for Windows (SF560)

BASIC Programming Tool M3 for Windows (SF560) is a Windows-based application for programming and

debugging applications for the BASIC CPU modules (F3BP20/30) as well as for setting up those CPU modules.

SF560 can perform all engineering, including programming, debugging and maintenance.

TI 34M6A01-01E

22

Page 27

P

P

C

L

C

L

Supports remote OME* via Ethernet or Public Phone Line with modem.

Allows the operation status to be checked and failures to be analyzed with

reference to the Error Log and User Log.

Allows complex failures and rare failures to be analyzed using the sampling t race

function.

Allows modules to be replaced easily even when installed inside a panel or

machine because they are detachable from the front.

Reduces maintenance and spare parts because part s can be stocked in common

for all systems regardless of scale. Maintenance parts no longer need to be

stocked separately for each system scale or model.

Outstanding Maintenance Support Function s

* Acronym of remote Operation Maintenance and Engineering proposed by Yokogawa Electric Corporation.

z

The memory backup batteries for all CPU modules are maintenance-free and have a shelflife of at least 10 years and a service life of at least 30 years under normal operating conditions

(ambient temperature of 30, and operating time of 12 hours/day)

TI 34M6A01-01E

23

Page 28

P

P

C

L

C

L

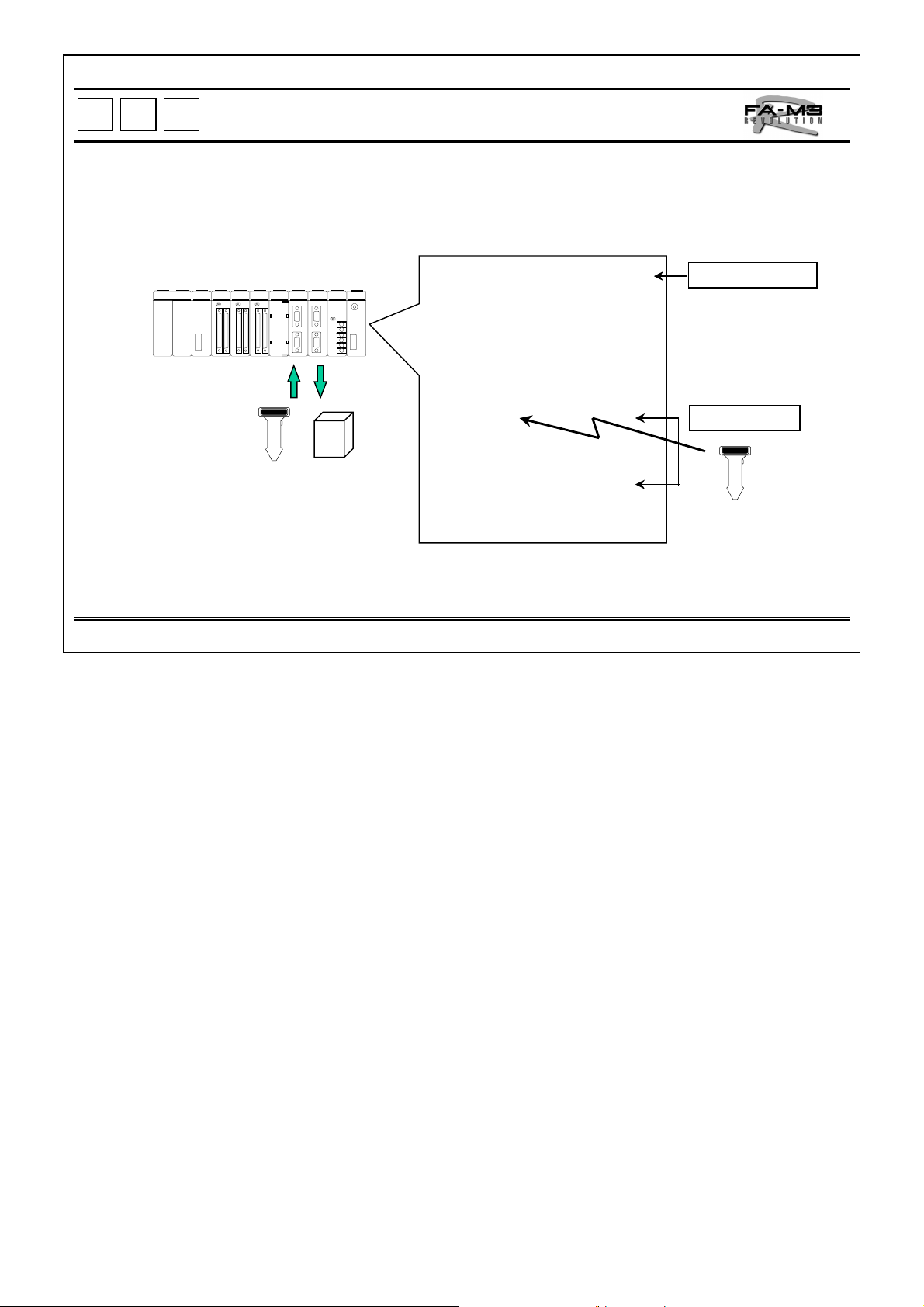

The FA-M3 R supports remote equipment maintenance, called "Remote OME. "

Remote OME involves performing the following remotely:

z O

peration: Operation and monitoring

z

M

aintenance: Troubleshooting

z E

ngineering: Program modification and debugging

Remote OME is achieved:

(1) Over a local area network via Ethernet, whereby OME requests are connected using a readily

available dial-up router to a public phone line

(2) Over public phone lines via a modem connected to the Programming port

Remote OME

z

For an FA-M3 R incorporated in a system, the following can be done from a personal computer at a distant

place:

• Machine maintenance and inspections using the device monitoring and diagnostics functions

• Check of machine operating statuses by monitoring the FA-M3 R's devices online, and machine

operation test by changing the device values

• Troubleshooting and failure analyses for machine using the FA-M3 R's diagnostics functions, namely,

such as to the error log, user log and sampling traces

• Improvement of machine operation by adding, modifying and debugging a ladder diagram.

z

There are two methods of remote OME:

• Via Ethernet ( remote maintenance camera is available)

• Via public telephone lines

TI 34M6A01-01E

24

Page 29

P

P

L

L

C

C

Remote OME via Ethernet

The FA-M3 R is the world's first* PLC that supports remote maintenance of multiple pieces of

machines installed in distant locations, via Ethernet. Using a remote maintenance camera,

remote maintenance can be performed while actually monitoring the equipment.

The following can be performed remotely with the standard features of WideField:

z Editing/loading/saving programs, monitoring ladder diagrams, monitoring devices,

monitoring operation statuses and reading various data. The personal computer

link feature can also be used.

z System log, user log and sampling traces that fully support remote OME

Ethernet

Public telephone line / ISDN (Integrated Services Digital Network)

Ethernet

z

Remote OME via Ethernet

• By connecting all the FA-M3 R controllers

incorporated in equipment at a plant, via

Ethernet all the machine statuses can be

viewed from a personal computer in an

office or control room.

• All functions of WideField can be used for

the FA-M3 R controllers remotely.

• Monitoring and data modification of one

FA-M3 R controller can be performed

simultaneously from multiple personal

computers via Ethernet.

EthernetEthernet

* Programs cannot be developed or modified with any

other manufacturer's PLC. An F3LE01-5T Ethernet

interface module and a personal computer r unning

Windows 95 or Windows NT are required.

Electrical Equipment Room /

Factory

Ethernet

FA-M3 R

Ethernet

Interface Module

Ethernet

D1 1234

D2 5678

D5 1927

Ethernet

Office

D1 1234

D2 5678

D3 9876

D4 1357

However, WideField cannot run

simultaneously on two or more

computers on the network.

TI 34M6A01-01E

Mechanical Equipment Room /

Factory

Camera

Ethernet

Machine A Machine B

D1 1234

D2 5678

D5 1927

Control Room /

Maintenance Facility

25

Page 30

z

Remote OME via Ethernet and Dial-up Router

Factory / Plant Engineering Dept. / Headquarters

Operating status

monitoring, program

modofication, program

start/stop, and error log

reading

F3LE0

FA-M3 R

1-5T

Remote maintenance

camera

FA-M3 RFA-M3 R

Ethernet

Dial-up router

Public

phone

Line

Windows-based

Dial-up router

PC

DOS-based

PC

Ethernet

• Remote OME is made available in various facilities at plants via Ethernet. Moreover, by using a public

phone line with dial-up routers as shown in the figure above, remote OME of equipment from

headquarters is possible through the FA-M3 R controllers connected to the Ethernet network inside

respective plants, even if they are located abroad.

z

Remote Maintenance Camera*

• Ethernet is fast enough to transmit large amounts of data such as images and sounds. By installing a

network camera and sound interface, you can perform remote OME while monitoring live images of the

equipment status captured by the camera.

Features of the remote maintenance camera:

• Nothing else needed for connection to Ethernet, as

web sever capabilities are built in.

• The captured image can be viewed using general

browsers including Netscape Navigator and Internet

Explorer.

• Manufactured by Axis Communications.

Image Viewing via Ethernet

Network Camera for

Remote Maintenance

AXIS 200 + Camera Server

The AXIS 200 full-color, digital network

camera and the Camera Server from

AXIS Communications bring you a realtime view of the remote location.

TI 34M6A01-01E

26

Page 31

P

P

L

L

C

C

Remote OME Using Commercially-available Modem

An FA-M3 R installed in a distant location can be

maintain ed via a public te lephone line.

The following can be performed remotely with the standard features of WideField:

Editing/loading/saving programs, monitoring ladder diagrams, monitoring devices, monitoring operation

statuses, viewing system log, reading various data, and more.

Programming, debugging,

and other data

reading using WideField

Modem

Modem

Public phone line

For connection, you need to do the following:

z

Modem for the personal computer

• Set the communications protocol (baud rate, data length, etc.) using AT commands.

z

FA-M3 programming Tool WideField.

• Set up the modem connection:

Æ

Tool

z

FA-M3 R

• In the configuration settings, set the CPU communication port as follows:

- 9600 bps without parity check

- Use the personal computer link

The program in which the above configuration is set up needs to be downloaded in advance. When downloading

a program via a public telephone line, make sure that the program configuration is set as above

z

Modem for the FA-M3 R

• Switch on the automatic terminal mode.

• Set the communications protocol using

AT commands.

Setup Environment ÆSetup Communication.

.

TI 34M6A01-01E

27

Page 32

P

P

L

L

C

C

System Log

Status changes, failures and errors during operation of

an FA-M3 R can be re corded.

z The system log lists the date, time and message of each event to allow you to grasp the past

operation log and analyze changes in the system status and the results of program failures.

z The information displayed as the system log can also be printed and saved to a file, which can

then be opened and printed later.

Date and Time Message Detail Block Instruction/

Code Name Slot No.

11/07/1999 15:12:15 Startup Completed 01-00

10/29/1999 15:11:03 Power Off 03-00

10/29/1999 15:10:50 I/O Check Error 24-01 ACT3 00013N

10/29/1999 15:09:20 I/O Check Error 24-01 ACT3 00013N

10/29/1999 15:08:05 I/O Check Error 24-01 ACT3 00013N

10/29/1999 15:07:55 I/O Check Error 24-01 ACT3 00013N

10/29/1999 15:07:20 I/O Check Error 24-01 ACT3 00013N

10/29/1999 15:06:22 I/O Check Error 24-01 ACT3 00013N

10/29/1999 15:05:33 I/O Check Error 24-01 ACT3 00013N

10/29/1999 14:04:45 Subunit Communication Error 06-00 SLOT=1607

10/29/1999 12:43:51 I/O Check Error 24-02 READST 00012N

z

Display

System status changes (power-on/off), failures and

errors occurring in the past are displayed in

chronological order with the latest event at the top.

A maximum of 70 to 150 of such events (the number

depends on the contents of the event data) can be

stored. When the stored event data reaches the

storage capacity, the latest event data overwrites the

oldest event data.

z

Printout

The displayed log can be printed in the same format.

z

Storage and retrieval

The displayed log can be saved to a file and the

saved file can be opened.

Note: The system log can be monitored from a

remote location via Ethernet.

Example of System Log

TI 34M6A01-01E

28

Page 33

P

P

L

L

C

C

User log

Alarms, events and errors for equipment and

machines (controlled by an FA-M3 R) occurring during operation can be logged.

z In addition to the system log, user-defined messages can be recorded (for up to 64 messages per CPU)

as the user log.

z The user log lists the date, time and message of each event to allow you to grasp the past operation log

and analyze changes in the system status and the results of improper equipment/machine operations.

z The information displayed as the user log can also be printed and saved to a file, which can then be

opened and printed later.

Date and Time Message No./Para met er /Mes s age Te xt

09/28/1999 11:59:09 main= 18 sub= 1 Heater Failure

09/28/1999 10:34:48 main= 14 sub= 1 Run Out Of Material

09/28/1999 08:30:32 main= 1 sub= 1 Machine Start

09/27/1999 17:34:27 main= 2 sub= 1 Machine Stop

09/27/1999 17:05:40 main= 6 sub= 1 Lot End

09/27/1999 17:00:10 main= 4 sub= 1 Product Departure

09/27/1999 16:05:32 main= 40 sub= 5 Alarm On

09/27/1999 15:59:58 main= 12 sub= 1 Limiter Off

09/27/1999 15:57:24 main= 11 sub= 1 Limiter On

09/27/1999 08:55:32 main= 3 sub= 1 Product Entry

09/27/1999 08:45:40 main= 5 sub= 1 Lot End

09/27/1999 08:30:51 main= 1 sub= 1 Machine Start

Define messages in the dialog box shown right, and carry out

ULOG instructions in the ladder diagram. Then, the specified main

code, subcode, and the time and date of occurrence for each will be

stored in the user log data storage area. You can also send user

log information to other equipment by using the ULOGR instruction.

z

Other related instructions and devices

•

UCLR instruction: Clears the user log

•

Z105 register: Special register for the number of

user log messages to be stored

z

Display

User log messages occurring in the past are

displayed in chronological order with the latest event

at the top.

Up to 64 messages corresponding to the main codes

can be stored per CPU. W hen the stored message

data reaches the storage capacity, the latest message

data overwrites the oldest message data.

z

Printout

The displayed log can be printed in the same format.

z

Storage and retrieval

The displayed log can be saved to a file and the saved

file can be opened.

.

Note: The user log can be m oni tored from a remote location via

Ethernet or a public phone line.

TI 34M6A01-01E

29

Page 34

P

P

z You can trace device values while running a program.

z You can also record device values before the trigger condition is established.

z You can use sampling traces not only while debugging but also during operation for troubleshooting

z Use of the sampling trace function does not affect the scan time.

z Sampling traces are very useful for capturing phenomena that seldom occur, such as once a week or

C

L

C

L

and failure analyses (no other manufacturer's PLC provides this function

month.

Sampling Traces

).

Specifications

Number of sampling points: 16 relays / 4

registers.

Sampling timing:

Whenever a TRC instruction i s carried out

•

At specified intervals (10 to 2000 ms)

•

• At the end of every 1 to 1000 scan

intervals

Number of traces : 1024

Trigger condit ion:

Specified relay

•

Data matching f or the specif ied device

•

By configuring the trigger condition with the ladder program, you

can attain traces of the values of the desired devices when

complicated conditions including status transitions are met.

Sampling traces can be attained without affecting the scan time of

the ladder program.

Non-conformities occurring at irregular times can be

Æ

detected.

There are two setting methods:

z

Add the setting in the configuration of the user program.

•

Make settings at any time you want during operation.

•

Display

z

Sampling traces can be displayed in a time chart format

together with the relay statuses and register values

sampled.

Settings in configuration prior to runtim e

z

You can make sampling trace settings previously in the

configuration so that sampling traces are obtained during

normal operation.

* The sampling trace function is available in the SP25 and SP35.

Making Sampling Trace Settings

Settings on demand

z

You can make sampling trace settings at any time you

want.

Storage and retrieval

z

The obtained sampling traces can be saved to a file and the

saved file can be opened.

TI 34M6A01-01E

30

Page 35

P

P

L

L

C

C

High-speed Conversion, High Precision and High Noise Tolerance

Combined with a high-speed CPU module, high-speed analog input and output control system

can be built.

(1) Analog Input Modules

F3AD04-0N: 4 analog inputs

F3AD08-1N: 8 analog inputs

• Input signal range: -10 to 10 V DC, 0 to 5 V DC, 1 to 5 V DC

• Accuracy : 0.2% of full scan (at 23 ºC ± 2 ºC) or 0.5% of full scan (at 0 to 55ºC)

• Conversion period: 1 ms/channel

• Other features: Filtering, scaling and channel skip functions as well as a noise-resistant conversion

system

(2) Analog Output Modules

F3DA02-0N: 2 analog outputs

F3DA04-1N: 4 analog outputs

F3DA08-5N: 8 analog outputs (voltage output only)

• Output signal range: -10 to 10 V DC or 4 to 20 mA DC

• Accuracy : 0.2% of full scan (at 23 ºC ± 2 ºC) or 0.5% of full scan (at 0 to 55ºC)

• Conversion period: 2 ms (fixed) for F3DA02-0N, 4 ms (fixed) for F3DA04-1N and F3DA08-5N

• Other features: Output upon error occurrence

Analog Input/Outp ut M od ule s

F3DA02-0N: Holds the output levels.

F3DA04-1N: Holds the output le vels or sets to t he preset level , as specified.

F3DA08-5N: Holds the output le vels or sets to t he preset level , as specified.

For all five types of modules, the module's internal circuit is isolated by photocouplers from the field.

z Channe l skip

In analog input modules, A/D conversion for unused channels can be stopped, and data is not updated

for a channel specified to be skipped. This speeds up t he conversion period for all channels.

The conversion period is expressed as: 1 ms × num ber of channels used

RDY

ALM

AD04-0N ADC

+

IN1

-

SHIELD

+

IN2

-

+

IN3

-

SHIELD

+

IN4

-

RDY

ALM

AD08-1N ADC

+

IN1

+

IN2

+

IN3

+

IN4

-

SHIELD

AG

+

IN5

+

IN6

+

IN7

+

IN8

-

DA02-0N

V+

V-

OUT1

I+

I-

V+

V-

OUT2

I+

I-

+

-

RDY

ALM

DAC

RDY

ALM

DA04-1N DAC

+

V

-

OUT1

+

V

-

+

V

-

OUT2

+

V

-

+

V

-

OUT3

+

V

-

+

V

-

OUT4

+

V

-

RDY

ALM

DA08-5N ADC

+

OUT1

+

OUT2

+

OUT3

+

OUT4

-

OUT5

+

+

OUT6

+

OUT7

+

OUT8

-

TI 34M6A01-01E

F3AD04-0N F3AD08-1N F3DA02-0N F3DA04-1N F3DA08-5N

31

Page 36

P

P

L

L

C

C

Temperature Control Modules

Four Temperature Controllers in One Compact FA-M 3 R Module

Wide range of temperature controller module lineups for all types of inputs and outputs.

Selectable speed of control span according to the application requirement: 500 ms/4 channels,

250 ms/2 channels, 125 ms/channel

Auto/manual mode switching useful for sequence maintenance at machine startup.

PID control for heating/cooling

Overshoot protection feature

Cascade control using multiple channels

Input Type Output Type

Modu le

name

Temperature

control and

monitoring

PID control F3CV04 -1N

Model

F3CT04

F3CR04

-0N

-1N

-0N

-1N

Time-

TC/mV

444

4 444

RTD

Pt100Ω

444

4 444

DC Voltage

4444

proportional

Open

Collector

Time-

proportional

Voltage

Pulse

4-20 mA

Continuous

F3CT04-0N and F3CT04-1N Temperature Control and Monitoring

Modules for Thermocouple input

z One module can control and monitor up to 4 thermocouples or 4 mv

input loops.

z Provided with the multi-range input system, the input ranges of all 4

channels can be set by a rotary switch.

z T he universal control output system enables the output type for each

channel to be selected between time-proportional PID output (open

collector or voltage pulse) and continuous PID output (4-20 mA).

However, a continuous PID output is only available on the F3CT041N module.

z Can be used as a heating/cooling controller, though a different

output module is required for the cooling output.

z Multi loop contr o l using multip le channels, such as cascade control,

can be performed using ladder and BASIC programs.

z Loop-back feature facilitates system debugging.

z Auto tuning function as well as overshoot suppression function,

which uses fuzzy logic and is called the "SUPER" function, are

provided as standard for optimum control.

RDY

ALM

ERR

CT04-1N

INPUT

50 60Hz

F3CT04-1N

IN4

IN3

V

+

·

TC

-

IN2

IN1

V

+

·

TC

-

OUT

COM

TC/PID

4

3

2

1

TI 34M6A01-01E

32

Page 37

P

P

L

L

Positioning Modu les for Controlling Every Type of Motor

C

C

Module Features

z

Open-loop control

z

Good controllability

F3NC11

F3NC12

• Max. 6 ms high speed startup time

• On-route action, control mode switching by an external trigger signal

• Biaxial arc interpolation; acceleration/deceleration method: trapezoidal drive

• Position control, velocity control, switching over between position and velocity

control

z

Open-loop control

z

F3YP04

F3YP08

F3NC51

F3NC52

Control of up to 8 axes (up to 288 axes p er system)

• Max. 6 ms high speed startup time

• Acceleration/deceleration method : trapezoidal drive

z

Closed-loop control

z

Good controllability

• Max. 6 ms high speed startup time

• On-route action, control mode switching by an external triggter signal

• Biaxial arc interpolation; acceleration/deceleration method: trapezoidal drive

• Position control, velocity control, switching over between position and velocity

control

z

F3DA

Velocity control in co mbina tion with an inverter

Applicable

Moter

Pulse

moter

Servomotor

DD motor

Induction motor

z Open-loop control (F3NC11-0N, F3NC12-0N, F3YP04-0N and F3YP08-0N)

According to the instructions sent

from a CPU module, the positioning

FA-M3 R

module computes the positioning

command values and output them as

pulse trains.

CPU

Module

Positioning Data

Velocity Data

Positioning

Module

Pulse Train

z Closed-loop control (F3NC51-0N and F3NC52-0N)

According to the instructions sent

from a CPU module, the positioning

FA-M3 R

module performs the position servo

computation based on the position

feedback signal input from the

external position sensor, and outputs

the velocity command as an analog

voltage signal.

CPU

Module

Positioning D a ta

Velocity Data

Positioning

Module

Positioning

Servo

Computation

Analog

Voltage

Servo Driver

Positioning

Servo

Computation

Velocity and Position

Servo Driver

Velocity

Servo

Computation

Velocity

Servo

Computation

Feedback

Drive Current

En-

coder

Encoder Output

Drivie Current

En-

coder

Servomotor

Servomotor

TI 34M6A01-01E

Position Feedback

Velocity

Feedback

Encoder Output

33

Page 38

F3NC11-0N and F3NC12-0N Advanced model Positioning Modules with Positioning Pulse Output

For motor control on either 1 or 2 axes per module. Best suited to position-

instructed servomotors and servo drivers as well as pulse motors and drivers.

B S Y

1 2 3 4

NC11-0N

Max. 6 ms high speed response to activate the output pulse.

A variety of actions are available, including on-route action and control mode

switching by an external trigger signal.

Various changes are possible during movement such as:

• Velocity change

• Target position change

• Target position change associated with a change in direction of action

Capable of switching the control mode from velocity control to position control

and vice versa

Biaxial arc interpolation is possible.

Multiaxial linear interpolation is possible.

RDY

POSIT

RDY

A X 1 A X 2

B S Y B S Y

1 2 3 4 1 2 3 4

NC12-0N

POSIT

Both line-driver and open-collector pulse outputs are available. The maximum

output pulse rate is as high as 250 kpps (when using a line driver).

F3NC52-0N

FA-M3

Example of Multiaxial

Interpolation

Driver

F3NC11-0N F3NC12-0N

F3YP04-0N and F3YP08-0N Positioning Modules with Multi-channel Pulse

Output

For motor control on either 4 or 8 axes per module. Best suited to

position-instructed servomotors and servo drivers as well as pulse

motors and drivers.

Max. 6 ms high speed response to activate the output pulse.

Multiaxial linear interpolation is possible.

Line-driver pulse outputs (differential signals conforming to RS-422) at

the output pulse rate of as high as 250 kpps.

TI 34M6A01-01E

RDY

ERR

YP04-0N

POSIT

RDY

ERR

YP08-0N

POSIT

F3YP04-0N F3YP08-0N

34

Page 39

F3NC51-0N and F3NC52-0N Positioning Modules with Analog Voltage Output

z For motor control on either 1 or 2 axes per module. Outputs the velocity

command value to srevomoters and servo drivers based on the feedback

signal from an external position sensor (encoder).

z Max. 6 ms high speed response to activate the output pulse

z Applicable to various encoders:

• Incremental encoders, including:

General-purpose two-phase rotary encoders

• Absolute encoders, including:

Yaskawa Electric serial absolute encoder

Sanyo Denki serial absolute encoders and their compatibles

z Motor control at a maximum speed of 2 Mpps in quad-speed mode

• Can control a motor axis of 8000 pulses/rotation at 12000 rpm

(corresponding to 1.6 Mpps).

z A variety of available functions include:

• Switching between velocity control and position control, target position

changes, linear interpolation, arc interpolation and on-route action

z Trapezoidal, two-line segment and three-step S-shaped drives are available

in both the acceleration and deceleration modes.

• No mechanical shock to transported goods

• No mechanical stress to machines

RDY

ERR1

NC51-0N

POSIT

RDY

ERR1

ERR2

NC52-0N

POSIT

F3NC51-0N F3NC52-0N

Comparison of Positioning Modules

Item F3NC11/F3NC12 F3NC51/F3NC52 F3YP04/F3YP08

Axes/module 1 or 2 1 or 2 4 or 8

Axes/system 36 or 72 36 or 72 144 or 288

Control method Open-loop control Feedback control Open-loop control

Control output

Control mode

Interpolation

Position command -8,388,608 to 8,388,608 pulses -134,217,728 to 134,217,727 pulses

Velocity command 0.1 to 249,750 pulses/s 0.1 to 2,000,000 pulses/s 0.1 to 250,000pulses/s

Functions

Acceleration and

deceleration method

Acceleration and

deceleration time

RS-422A-compliant differential pulse output

or open collector pulse output

Position control

Velocity control

Position-velocity control switching

Axis-by-axis independent interpolation

Multiaxial linear interpolation

Biaxial arc interpolation

On-route action

Change in target position during movement

Change in velocity during movement

Trapezoidal

0 to 32,767 ms set individually for

acceleration and deceleration

-10 to 10 V DC

Position control

Velocity control

Position-velocity control switching

Axis-by-axis independent interpolation

Multiaxial linear interpolation

Biaxial arc interpolation

On-route action

Change in target position during movement

Change in velocity during movement

Absolute and relative position designations

Axis feed by manual pulser

Trapezoidal, two-line segment,

three-line segment

0 to 32,767 ms set individually for

acceleration and deceleration

RS-422A-compliant

differential pulse output

Position control

-

-134,217,728 to 134,217,727

pulses

Absolute and relative

position designations

Trapezoidal

0 to 32,767 ms set

individually for acceleration

and deceleration

TI 34M6A01-01E

35

Page 40

P

P

L

L

C

C

Applications of Personal Computer Link Interface

The personal computer link:

(1) Is a communication link that is dedicated for the FA-M3 R and allows the device data within

sequence CPUs to be read or written from other equipment (personal computers, display units,

etc.) without intervention of a sequence program, and also allows a sequence program to notify

events.

(2) Allows you to select the network hardware specification from RS-232-C, RS-422, and Ethernet as

required.

(3) Allows use of display units from various manufacturers that support the FA-M3 R-specific personal

computer link protocol.

PC/YEWMAC PC/Workstation

Communication Specification Module Name

RS-232-C

RS-422/485 F3LC11-2F

Ethernet F3LE01-5T

* The PROGRAMM ER por t on the C PU m odul e is used.

(F3SP05/21/28/38/53/58)

F3LC11-1

F3LC12-1F

F3SP-*

RS-232-C

RS-232-C

RS-232-C

RS-422

Display unit Display unit

Enthernet

PC/YEWMAC

Public phone line

Modem

Modules that support personal computer link commands:

F3LC11-N personal computer link module

F3LC12-1F personal computer link module

F3SP- sequence CPU module

F3LE01-1N Ethernet interface module

Differences in personal computer link between Ethernet interface module and other modules:

All modules support ASCII-coded commands and responses, but only the Ethernet interface module supports

binary-coded commands and responses. Note that the Ethernet interface module uses different header and

termination codes in ASCII mode from those of other modules.

TI 34M6A01-01E

36

Page 41

P

P

L

L

C

C

Personal Computer Link Modules

A personal computer link module provides the FA-M3 R with the personal computer

link feature via RS-232-C or RS-422/485.

The built-in communications protocol allows connections to be made to other equipment that

supports the same protocol without requiring any program, and facilitates system configuration.

A personal computer link module is typically used to connect display units.

F3LC11-2NF3LC11-1N

FA-M3 R

RS-422/485

RS-232-C

PC, Display Unit, etc.

Display Units, etc.

F3LC11-1, F3LC11-2N and F3LC12-1F Personal Computer Link Modules

Read/Write all devices in sequence CPU modules

Read/Write common variables in the BASIC CPU module

User program for data transmission not needed

Direct connection to a display unit having a programmable controller interface

Run/Stop a sequence CPU module remotely

Load/Save a sequence program

Read sequence program information such as program names, program size

and block names, as well as error logs and user logs

RDY

LC11-1N

C LINK

RDY

LC11-2N

TERMINATOR

2- 4-WIRE

OFF

SD A

SD B

RD A

RD B

SG

SHIELD

C LINK

STATION

NO.

TI 34M6A01-01E

F3LC11-1N

(RS-232C)

F3LC11-2N

(RS-422/485)

37

Page 42

P

P

C

L

C

L

A personal computer or display unit can be connected to the programming port of a

sequence CPU module, providing an instant and low-cost personal computer link.

Personal Computer Link via Programming Port

Display Unit

F3SP-

RS-232-C

FA-M3 R

The same commands are used for personal computer link modules are sequence CPU modules.

Note: The following cables are available for connection from Yokogawa.

Model: KM11-2T, -3T or -4T

Specification: D-sub 9-pin female; approx. 3, 5, or 10 meters long, respectively

Model : KM10C-0C

Specification : D-sub 9-pin female; approx. 0.5 meter long

Note: For details, see the General Specifications, FA-M3 CPU Port Cables (GS 34M6C 91-01E).

TI 34M6A01-01E

38

Page 43

P

P

L

L

C

C

Ethernet Interface Module

The Ethernet interface module enables the FA-M3 R's data to be accessed via Ethernet as one

style of personal computer link. Using this Module, the FA-M3 R's data can be accessed

directly from personal computers and workstations, thus allowing an information system and

control system to be directly linked.

*Remote OME (see pages 29 to 32) is possible from a personal computer using WideField.

Personal Computer

FA-M3 Programming

Tool WideField

Personal Computer and Workstation

Ethernet

FA-M3 R

F3LE01-5T

F3LE01-5T Ethernet Interface Module

The Ethernet interface module provides an IEEE802.3-compliant network connection port

(10Base5/10Base-T), and performs the same functions as those performed by personal

computer link modules (n:n communication) via serial communication.

Remote OME

You can create and modify programs using WideField from a personal computer on the

same network.

Information

System

Control

System

LE01-5T

RDY

SND

RCV

ERR

ETHER

T

Personal Computer Link (access through another node)

Through a node, yon can:

• Monitor and write devices in sequence CPUs from another node on the same network.

• Download, upload, start and stop programs.

• Read/write common variables in the BASIC CPU module.

None of these requires a user program for communication. Both binary-coded and ASCIIcoded commands and responses are supported, allowing for high-speed data transmission.

Event transmission (access to another nodes)

The Ethernet module enables events to be transmitted to another nodes on the same

network.

Note: 10B ase-T requires no external power sup pl y.

When a 10Base5 network is used and the connected Et hernet device requires power to be supplied to its AUI

connector, a 12 V DC power supply must be connected to t he Ethernet module.

TI 34M6A01-01E

AUI

+

-

F3LE01-5T

39

Page 44

P

P

L

L

C

C

FA Link H Module

High-speed data transmission between FA-M3 R controllers for data

sharing

(4 times faster than the conventional FA link)

F3LP02-0N

Item Specification

Link relays

Link registers

Transmission

speed

Maximum

transmission

distance

Transmission

media

Transmission Speed vs. Transmission Dist ance

Transmission speed

Maximum transmission

distance

Up to 8192

Up to 8192

Max. 1.25 Mbps

(can be selected from 125 Kbps,250 Kbps,625 Kbps,

and 1.25 Mbps)

1 km, 500 m, 200 m or 100 m depending on

the transmission sp ee d

Shieded twist-pair cable

(up to 2048 per link)

(up to 2048 per link)

.

125

Kbps

1 km 500 m 200 m 100 m

F3LP02-0N FA Link H Module

Conventional FA Link

(F3LP01-0N)

250 Kbps

(see the ta ble below).

250

Kbps

625

Kbps

1.25

Mbps

FA-M3 R

FA-M3 R

FA Link H

(F3LP02-0N)

1.25 Mbps

F3LP02-0N

F3LP02-0N

FA Link H

(max. 1.25 Mbps, max. 1 km,

connecting max. 32 stations)

FA link H is a high-speed network for data exchange between FA-M3 R controllers. Up to 32

stations, where one station corresponds to one FA link H module, can be linked together for

data sharing.

z Up to 8 FA link H modules can be installed in an FA-M3 R main unit (for the SP28, SP38,

SP53 or SP58; up to 2 modules for the SP21) to allow data links to be structured

hierarchically.