Page 1

User’s

Manual

Positioning Modules

(with Multi-channel Pulse Output)

Model: F3YP04-0N, F3YP08-0N

IM 34M6H55-01E

Yokogawa Electric Corporation

IM 34M6H55-01E

3rd Edition

Page 2

Applicable Product

● Range-free Multi-controller FA-M3

Model : F3YP04-0N, F3YP08-0N

Name: Positioning Module (with Multi-Channel Pulse Output)

The document number and document model code for this manual are given below:

Refer to the document number in all communications; also refer to the document number or

the document model code when purchasing additional copies of this manual.

Document No. : IM 34M6H55-01E

Document Model Code : DOCIM

i

Media No. IM 346H55-01E (CD) 3rd Edition : Apr, 2002 (YK)

All Right Reserved Copyright © 1999, Yokogawa Electric Corporation

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 3

Important

About This Manual

- This Manual should be passed on to the end user.

- Before using the controller, read this manual thoroughly to have a clear understanding

of the controller.

- This manual explains the functions of this product, but there is no guarantee that they

will suit the particular purpose of the user.

- Under absolutely no circumstances may the contents of this manual be transcribed or

copied, in part or in whole, without permission.

- The contents of this manual are subject to change without prior notice.

- Every effort has been made to ensure accuracy in the preparation of this manual.

However, should any errors or omissions come to the attention of the user, please

contact the nearest Yokogawa Electric representative or sales office.

Safety Precautions when Using/Maintaining the Product

ii

- The following safety symbols are used on the product as well as in this manual.

CAUTION

Danger. This symbol on the product indicates that the operator must follow the

instructions laid out in this instruction manual to avoid the risk of personnel injuries,

fatalities, or damage to the instrument. Where indicated by this symbol, the manual

describes what special care the operator must exercise to prevent electrical shock or

other dangers that may result in injury or the loss of life.

Protective Ground Terminal. Before using the instrument, be sure to ground this

terminal.

Function Ground Terminal. Before using the instrument, be sure to ground this

terminal.

Alternating current. Indicates alternating current.

Direct current. Indicates direct current.

The following symbols are used only in the instruction manual.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 4

WARNING

Indicates a “Warning”.

Draws attention to information essential to prevent hardware damage, software damage

or system failure.

CAUTION

Indicates a “Caution”

Draws attention to information essential to the understanding of operation and functions.

TIP

Indicates a “TIP”

Gives information that complements the present topic.

SEE ALSO

Indicates a SEE ALSO reference.

Identifies a source to which to refer.

iii

- For the protection and safe use of the product and the system controlled by it, be sure

to follow the instructions and precautions on safety stated in this manual whenever

handling the product. Take special note that if you handle the product in a manner

other than prescribed in these instructions, the protection feature of the product may

be damaged or impaired. In such cases, Yokogawa cannot guarantee the quality,

performance, function or safety of the product.

- When installing protection and/or safety circuits such as thunderbolt protection devices and equipment for the product and control system as well as designing or

installing separate protection and/or safety circuits for fool-proof design and fail-safe

design of processes and lines using the product and the system controlled by it, the

user should implement it using devices and equipment, additional to this product.

- If component parts or consumable are to be replaced, be sure to use parts specified

by the company.

- This product is not designed or manufactured to be used in critical applications which

directly affect or threaten human lives and safety — such as nuclear power equipment,

devices using radioactivity, railway facilities, aviation equipment, air navigation facilities, aviation facilities or medical equipment. If so used, it is the user’s responsibility to

include in the system additional equipment and devices that ensure personnel safety.

- Do not attempt to modify the product.

Exemption from Responsibility

- Yokogawa Electric Corporation (hereinafter simply referred to as Yokogawa Electric)

makes no warranties regarding the product except those stated in the WARRANTY

that is provided separately.

- Yokogawa Electric assumes no liability to any party for any loss or damage, direct or

indirect, caused by the use or any unpredictable defect of the product.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 5

Software Supplied by the Company

- Yokogawa Electric makes no other warranties expressed or implied except as provided in its warranty clause for software supplied by the company.

- Use the software with one computer only. You must purchase another copy of the

software for use with each additional computer.

- Copying the software for any purposes other than backup is strictly prohibited.

- Store the original media, such as floppy disks, that contain the software in a safe

place.

- Reverse engineering, such as decompiling of the software, is strictly prohibited.

- No portion of the software supplied by Yokogawa Electric may be transferred, exchanged, or sublet or leased for use by any third party without prior permission by

Yokogawa Electric.

iv

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 6

General Requirements for Using the FA-M3

● Avoid installing the FA-M3 in the following locations:

- Where the instrument will be exposed to direct sunlight, or where the operating temperature exceeds the range 0°C to 55°C (0°F to 131°F).

- Where the relative humidity is outside the range 10 to 90%, or where sudden temperature changes may occur and cause condensation.

- Where corrosive or flammable gases are present.

- Where the instrument will be exposed to direct mechanical vibration or shock.

- Where the instrument may be exposed to extreme levels of radioactivity.

● Use the correct types of wire for external wiring:

- Use copper wire with temperature ratings greater than 75°C.

● Securely tighten screws:

- Securely tighten module mounting screws and terminal screws to avoid problems

such as faulty operation.

v

- Tighten terminal block screws with the correct tightening torque as given in this

manual.

● Securely lock connecting cables:

- Securely lock the connectors of cables, and check them thoroughly before turning on

the power.

● Interlock with emergency-stop circuitry using external relays:

- Equipment incorporating the FA-M3 must be furnished with emergency-stop circuitry

that uses external relays. This circuitry should be set up to interlock correctly with

controller status (stop/run).

● Ground for low impedance:

- For safety reasons, connect the [FG] grounding terminal to a Japanese Industrial

Standards (JIS) Class D Ground

Ground). For compliance to CE Marking, use cables such as twisted cables which can

ensure low impedance even at high frequencies for grounding.

*1 Japanese Industrial Standard (JIS) class D Ground means grounding resistance of 100Ω max.

*1

(Japanese Industrial Standards (JIS) Class 3

● Configure and route cables with noise control considerations:

- Perform installation and wiring that segregates system parts that may likely become

noise sources and system parts that are susceptible to noise. Segregation can be

achieved by measures such as segregating by distance, installing a filter or segregating the grounding system.

● Configure for CE Marking Conformance:

- For compliance to CE Marking, perform installation and cable routing according

to the description on compliance to CE Marking in the “Hardware Manual”

(IM34M6C11-01E).

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 7

● Keep spare parts on hand:

- Stock up on maintenance parts including spare modules, in advance.

● Discharge static electricity before operating the system:

- Because static charge can accumulate in dry conditions, first touch grounded metal to

discharge any static electricity before touching the system.

● Never use solvents such as paint thinner for cleaning:

- Gently clean the surfaces of the FA-M3 with a cloth that has been soaked in water or a

neutral detergent and wringed.

- Do not use volatile solvents such as benzine or paint thinner or chemicals for cleaning,

as they may cause deformity, discoloration, or malfunctioning.

● Avoid storing the FA-M3 in places with high temperature or humidity:

- Since the CPU module has a built-in battery, avoid storage in places with high

temperature or humidity.

- Since the service life of the battery is drastically reduced by exposure to high

temperatures, take special care (storage temperature should be from –20

- There is a built-in lithium battery in a CPU module and temperature control module

which serves as backup power supply for programs, device information and

configuration information. The service life of this battery is more than 10 years in

standby mode at room temperature. Take note that the service life of the battery may

be shortened when installed or stored at locations of extreme low or high

temperatures. Therefore, we recommend that modules with built-in batteries be stored

at room temperature.

°C to 75°C).

vi

● Always turn off the power before installing or removing modules:

- Failing to turn off the power supply when installing or removing modules, may result in

damage.

● Do not touch components in the module:

- In some modules you can remove the right-side cover and install ROM packs or

change switch settings. While doing this, do not touch any components on the printedcircuit board, otherwise components may be damaged and modules may fail to work.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 8

Introduction

■ Overview of the Manual

This user’s manual, “Positioning Module with Multi-channel Pulse Output,” explains the

specifications and provides information necessary for operation of the positioning modules,

F3YP04-0N and F3YP08-0N, used with an FA-M3 controller.

Before using the modules, read this manual thoroughly to have a clear understanding for

proper operation. Keep this manual on hand for future reference.

■ Other Manuals

Refer to the following manuals.

● For sequence CPU functions:

- Sequence CPU Modules - Functions (for F3SP21, F3SP25 and F3SP35)

(IM 34M6P12-02E)

- Sequence CPU Modules - Functions (for F3SP28, F3SP38, F3SP53 and F3SP58)

(IM 34M6P13-01E)

vii

● For sequence CPU instructions:

- Sequence CPU Modules - Instructions (IM 34M6P12-03E)

● For creating programs using ladders:

- FA-M3 Programming Tool WideField (IM 34M6Q14-01E)

- FA-M3 Programming Tool WideField - Application (IM 34M6Q14-02E)

● For the FA-M3 specifications and configurations*1, installation and

wiring, maintenance, and module installation limits for the whole system:

- Hardware Manual (IM 34M6C11-01E)

*1: Refer to the relevant product manuals for specifications except for power supply modules, base modules, input/

output modules, cables and terminal units.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 9

Copyrights and Trademarks

■ Copyrights

Copyrights of the programs and online manual included in this CD-ROM belong to

Yokogawa Electric Corporation.

This online manual may be printed but PDF security settings have been made to prevent

alteration of its contents.

This online manual may only be printed and used for the sole purpose of operating this

product. When using a printed copy of the online manual, pay attention to possible inconsistencies with the latest version of the online manual. Ensure that the edition agrees with

the latest CD-ROM version.

Copying, passing, selling or distribution (including transferring over computer networks) of

the contents of the online manual, in part or in whole, to any third party, is strictly prohibited.

Registering or recording onto video tapes and other media is also prohibited without expressed permission of Yokogawa Electric Corporation.

■ Trademarks

viii

The trade names and company names referred to in this manual are either trademarks or

registered trademarks of their respective companies.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 10

FA-M3

Positioning Module

(with Multi-channel Pulse Output)

IM 34M6H55-01E 3rd Edition

CONTENTS

Applicable Product ............................................................................................... i

Important ...............................................................................................................ii

Introduction......................................................................................................... vii

Copyrights and Trademarks .............................................................................. viii

1. Overview ................................................................................................. 1-1

2. Specifications ......................................................................................... 2-1

2.1 General Specifications ................................................................................... 2-1

2.2 Operating Environment .................................................................................. 2-2

2.3 Model and Suffix Codes.................................................................................. 2-2

2.4 Components and Functions ........................................................................... 2-3

2.5 External Dimensions ...................................................................................... 2-4

2.6 Terminal Assignments and Connections ...................................................... 2-5

2.7 Applicable External Interface Connectors..................................................... 2-6

Toc-1

3. Function Overview.................................................................................. 3-1

3.1 Positioning Operation..................................................................................... 3-2

3.2 Jog Stepping ................................................................................................... 3-3

3.3 Contact Inputs ................................................................................................. 3-3

3.4 Z-phase Encoder Input ................................................................................... 3-3

3.5 Origin Search .................................................................................................. 3-4

3.6 Deviation Pulse Clear Signal Output.............................................................. 3-6

3.7 Linear-Interpolated Operation ........................................................................ 3-6

4. Parameters .............................................................................................. 4-1

4.1 Parameters ...................................................................................................... 4-1

4.1.1 Entry Parameters.............................................................................. 4-4

4.1.2 Command Parameters ...................................................................... 4-4

4.2 Parameters Required for Each Command ..................................................... 4-5

4.3 Descriptions of Parameters............................................................................ 4-6

4.3.1 Entry Parameters.............................................................................. 4-6

4.3.2 Command Parameters ...................................................................... 4-7

4.4 Examples of Setting Entry Parameters .......................................................... 4-9

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 11

Toc-2

5. Status ...................................................................................................... 5-1

5.1 List of Status ................................................................................................... 5-2

5.2 Description of Status ...................................................................................... 5-3

6. Input/Output Relays................................................................................ 6-1

6.1 Output Relays.................................................................................................. 6-1

6.2 Input Relays .................................................................................................... 6-2

7. Accessing Modules ................................................................................ 7-1

7.1 Accessing from the Sequence CPU ............................................................... 7-1

7.1.1 Reading the Module Status ............................................................... 7-2

7.1.2 Set Parameter .................................................................................. 7-3

7.1.3 Error Reset ....................................................................................... 7-5

7.1.4 Jog Stepping .................................................................................... 7-7

7.1.5 Using Origin Search .......................................................................... 7-9

7.1.6 Set Current Position ........................................................................ 7-12

7.1.7 Positioning Operation ...................................................................... 7-14

7.1.8 Request to Decelerate and Stop ..................................................... 7-16

7.1.9 Request to Stop Immediately .......................................................... 7-18

7.2 Accessing from BASIC CPU......................................................................... 7-20

7.2.1 Reading the Module Status ............................................................. 7-21

7.2.2 Set Parameter ................................................................................ 7-22

7.2.3 Error Reset ..................................................................................... 7-23

7.2.4 Jog Stepping .................................................................................. 7-24

7.2.5 Origin Search ................................................................................. 7-25

7.2.6 Set Current Position ........................................................................ 7-27

7.2.7 Positioning Operation ...................................................................... 7-28

7.2.8 Request to Decelerate and Stop ..................................................... 7-29

7.2.9 Request to Stop Immediately .......................................................... 7-30

8. Errors and Troubleshooting.................................................................... 8-1

8.1 Troubleshooting Flow ..................................................................................... 8-1

8.2 Error Codes ..................................................................................................... 8-2

9. External Contact Signals ........................................................................ 9-1

9.1 Pulse Output ................................................................................................... 9-1

9.2 External Contact Input .................................................................................... 9-2

9.3 Encoder Z-phase Input ................................................................................... 9-3

9.4 Deviation Pulse Clear Signal Output.............................................................. 9-4

10. Examples of Connections to Servo Drivers......................................... 10-1

10.1 Example of Connection to Oriental Motor Driver ........................................ 10-2

10.2 Example of Connection to YASKAWA Electric ∑II-Series Driver ................ 10-3

10.3 Example of Connection to Sanyo Denki PZ Series Driver ......................... 10-4

Revision Information ............................................................................................ i

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 12

1. Overview

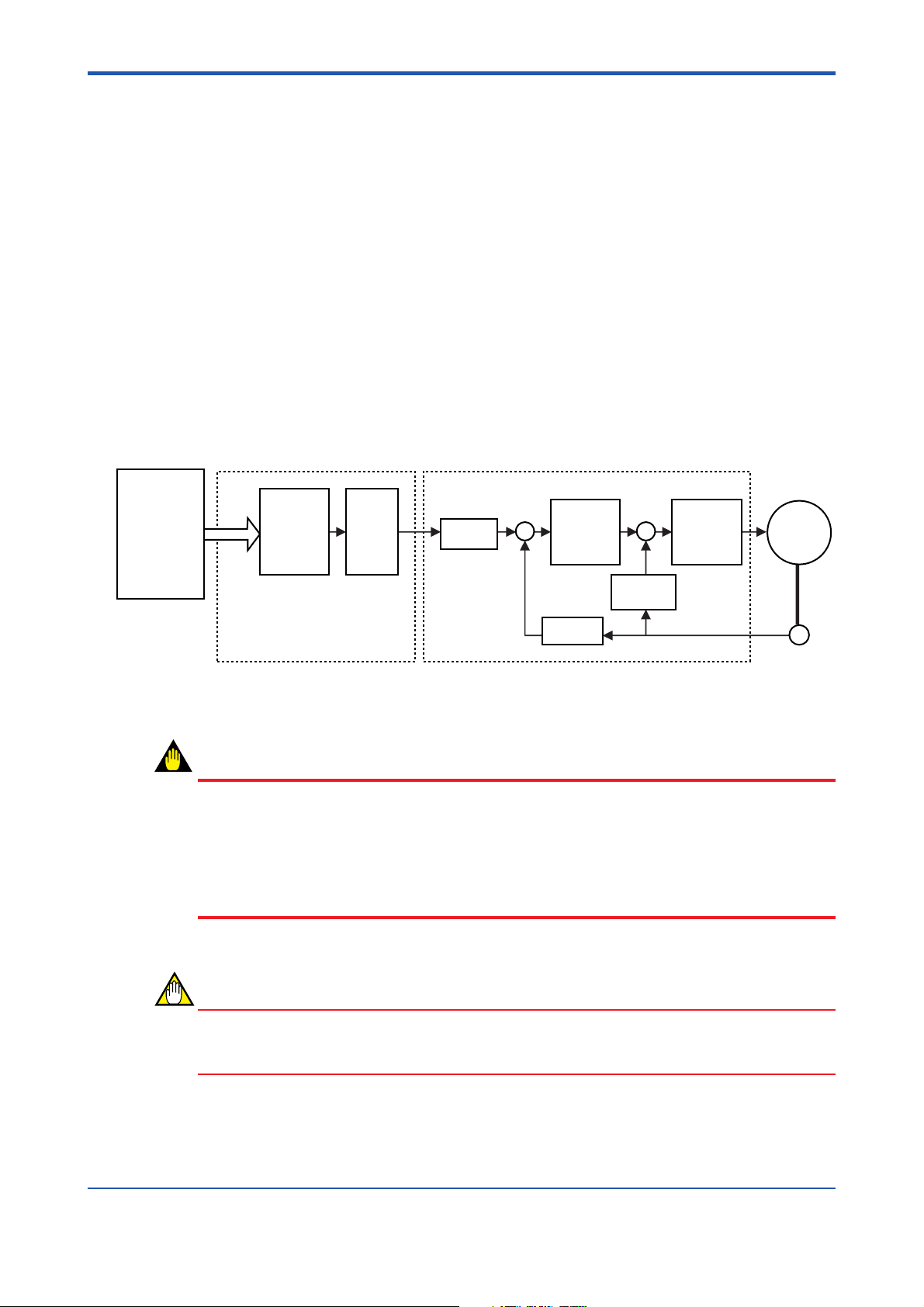

Models F3YP04-0N-and F3YP08-0N are advanced positioning modules (hereinafter

referred to as the modules or positioning modules) used to control servo drivers and

thereby the speed and position of pulse-driven motors. Driven by commands from the CPU

module of the FA-M3 controller, the positioning module generates paths for positioning and

outputs positioning command values in the form of pulse trains.

One module alone can control different types of motors/drivers. It can control up to 4 (the

F3YP04-0N module) or up to 8 (the F3YP08-0N module) pulse motors or servo motors.

When in use, the positioning modules are attached to the base module of an FA-M3 controller.

Features

- Compared with the original positioning module, which allows up to 2 controlled axes

per slot, this module allows up to 8 controlled axes from one slot.

- With a short startup time (6 ms maximum), it can come into action quickly and operate

in synchronization with peripheral equipment.

1-1

High-end

CPU module

Positioning module

Path

generation

Figure 1.1 Operating Principle of Positioning Module (with Multi-channel Pulse Output)

Pulse

Output

Counter

Servo driver

Position

controller

Counter

Speed

detector

Speed

controller

Motor

Encoder

F0101.EPS

WARNING

In order to ensure safety if the positioning module or servo driver fails or if any of the signal

lines is disconnected, be SURE to take necessary safety measures in your system design.

Such measures should include automatically shutting down the power to a motor if the

motor runs in excess of the specified normal operating limits. An external emergency stop

circuit should be built in to shut down the power to the motor and to stop it immediately if

the motor operates in an unexpected manner due to machine fault or misoperation.

CAUTION

When controlling a servo motor with the positioning module, choose a position-control

servo driver. Velocity-control and torque-control servo drivers do not meet this application.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 13

Blank Page

Page 14

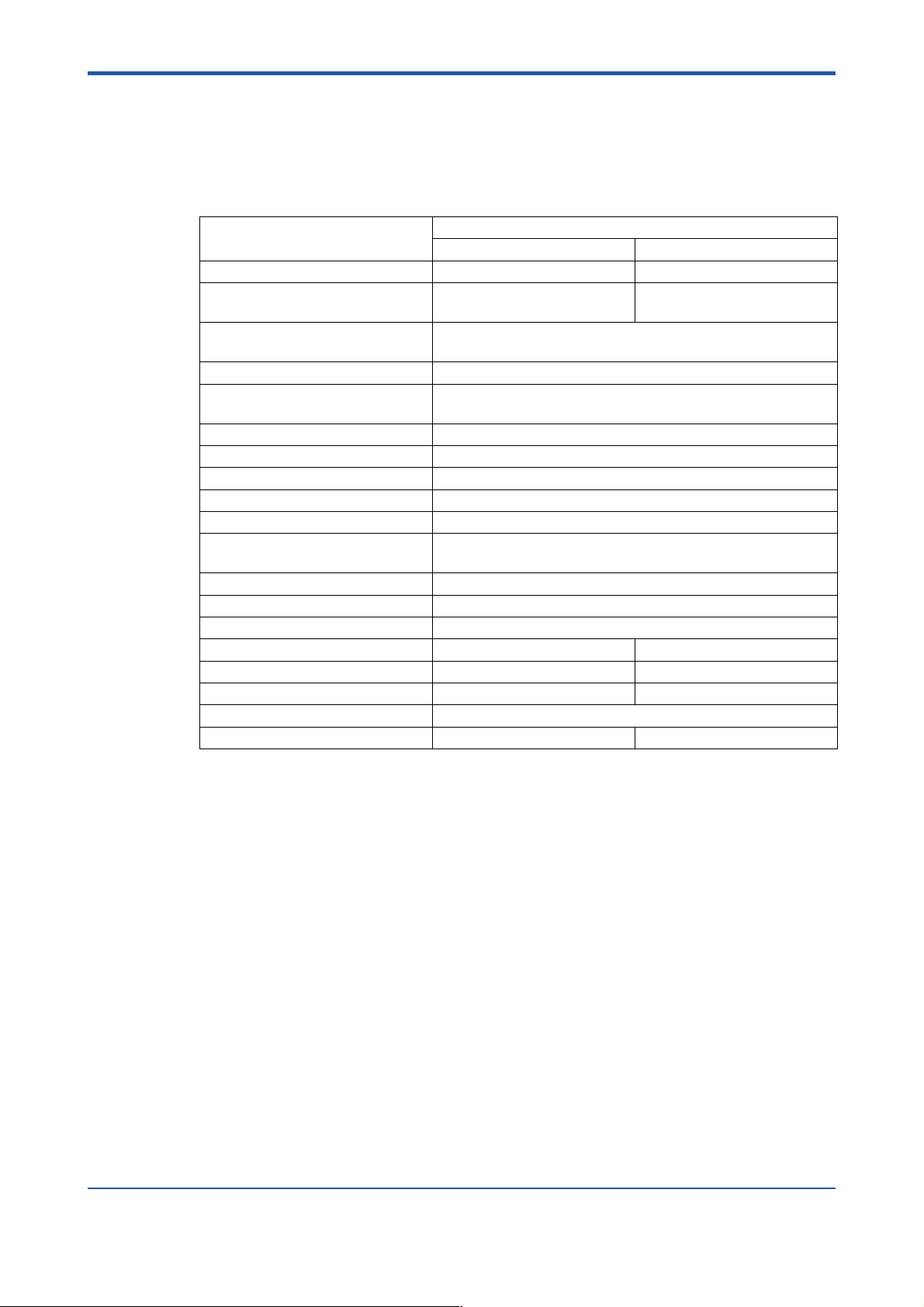

2. Specifications

2.1 General Specifications

2-1

Item

Number of controlled axes

Number of axes controlled

simultaneously

Pulse output method

Maximum velocity

Acceleration/deceleration method

Acceleration/deceleration time

Command pulse range

Command velocity

Origin position search method

Origin position search velocity

External contact input

External contact output

Data backup

Startup time

Current consumption

External power supply

External wiring

External dimensions

Weight

Note: Not including protrusions (see the external dimension diagram for more details).

F3YP04-0N Module F3YP08-0N Module

48

48

RS422A-conformed differential output

Clockwise/counterclockwise rotation pulse output for each axis

250,000 pps

Automatic-trapezoidal acceleration/deceleration

User-definable for start-up speed

0 to 32767 ms (separate for acceleration/deceleration)

–134,217,728 to 134,217,727

0.1 to 250,000 pps

User-definable using a combination of external contact inputs

User-definable using a command speed range

Positive direction limit input, negative direction limit input, origin

position input, Z-phase input

Deviation pulse clear signal

By CPU module

6 ms max.

300 mA 350 mA

5 V DC ±5%, 350 mA 5 V DC ±5%, 700 mA

48-pin connector (one unit) 48-pin connector (two units)

28.9 (W) × 100 (H) × 83.2 (D) (mm)

110 g 130 g

Specifications

(Note)

TC0201.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 15

2.2 Operating Environment

There are no restrictions on the CPU modules with which the positioning modules can be

used.

2.3 Model and Suffix Codes

Model Suffix Code Style Code Option Code Remarks

F3YP04 -0N . . . . . . 4-axis, multi-channel pulse output

F3YP08 -0N . . . . . . 8-axis, multi-channel pulse output

2-2

Maximum 250,000 pps

Maximum 250,000 pps

TC0203.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 16

2.4 Components and Functions

● F3YYP04-0N (4-axis module)

2-3

YP04-0N

RDY

ERR

POSIT

RDY indicator:

Lit when the internal circuitry is functioning normally.

ERR indicator:

Lit if an error occurs.

For details, refer to Section 8.2, “Error Codes.”

Connector for axes 1 to 4 (48P)

Connects to external I/O devices such as servo motors and limits switches.

● F3YP08-0N modules (8-axis module)

YP08-0N

RDY

ERR

POSIT

RDY indicator:

Lit when the internal circuitry is functioning normally.

ERR indicator:

Lit if an error occurs.

For details, refer to Section 8.2, “Error Codes.”

Connector for axes 1 to 4 (48P)

Connector for axes 5 to 8 (48P)

Connects to external I/O devices such as servo motors and limit switches.

FC0204.EPS

Even though the ERR LED lights up, normal axes other than the error axis can still be

operated.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 17

2.5 External Dimensions

2-4

Unit: mm

83.2 28.9

External Dimension Diagram for F3YP04-0N Module

1.3

2

100

FC0205.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 18

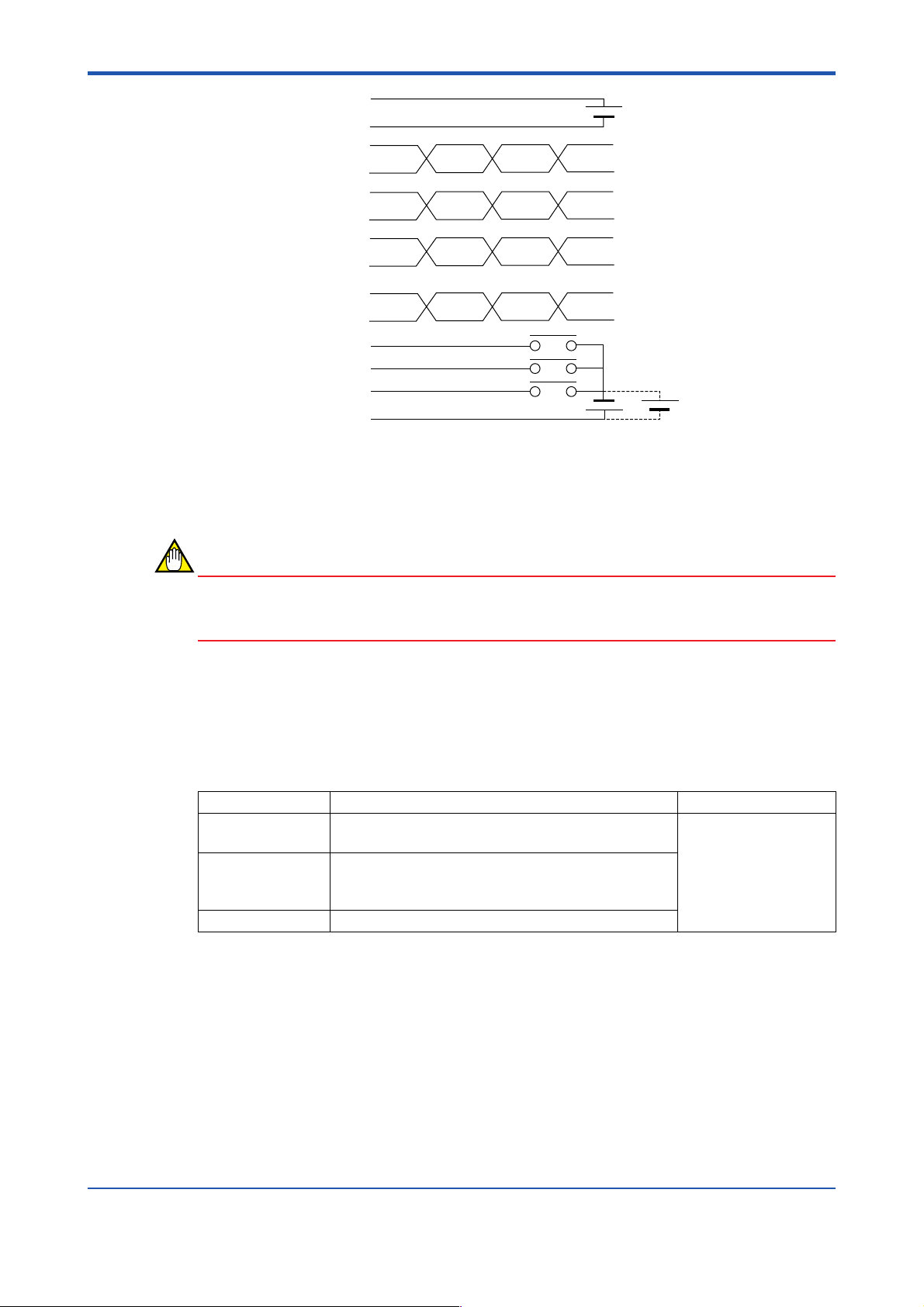

2.6 Terminal Assignments and Connections

2-5

RDY

ERR

YP04-0N

24b Axis 4 Z-phase – 24a Axis 2 Z-phase input –

23b Axis 4 Z-phase input + 23a Axis 2 Z-phase input +

22b Axis 4 clockwise pulse + 22a Axis 2 clockwise pulse +

21b Axis 4 clockwise pulse – 21a Axis 2 clockwise pulse –

20b Axis 4

19b Axis 4

18b Axis 4 deviation pulse clear 18a Axis 2 deviation pulse clear

17b Axis 4

16b Axis 3 Z-phase input – 16a Axis 1 Z-phase input –

15b Axis 3 Z-phase input + 15a Axis 1 Z-phase input +

14b Axis 3 clockwise pulse + 14a Axis 1 clockwise pulse +

13b Axis 3 clockwise pulse – 13a Axis 1 clockwise pulse –

12b Axis 3

11b Axis 3

10b Axis 3 deviation pulse clear 10a Axis 1 deviation pulse clear

9b Axis 3

8b External power 5Vin 8a External power 5Vin (GND)

7b Axis 4 origin input 7a Bi-axis origin input

6b Axis 4

5b Axis 4

4b Axis 3 origin input 4a Axis 1 origin input

3b Axis 3

2b Axis 3

1b Contact input common 1a Contact input common

counterclockwise pulse +

counterclockwise pulse –

deviation pulse clear (GND)

counterclockwise pulse +

counterclockwise pulse –

deviation pulse clear (GND)

positive-direction limit input

negative-direction limit input

positive-direction limit input

negative-direction limit input

20a Axis 2

19a Axis 2

17a Axis 2

12a Axis 1

11a Axis 1

9a Axis 1

6a Axis 2

5a Axis 2

3a Axis 1

2a Axis 1

POSIT

counterclockwise pulse +

counterclockwise pulse –

deviation pulse clear (GND)

counterclockwise pulse +

counterclockwise pulse –

deviation pulse clear (GND)

positive-direction limit input

negative-direction limit input

positive-direction limit input

negative-direction limit input

RDY

ERR

YP08-0N

POSIT

24b Axis 8 Z-phase input – 24a Axis 5 Z-phase input –

23b Axis 8 Z-phase input + 23a Axis 5 Z-phase input +

22b Axis 8 clockwise pulse + 22a Axis 5 clockwise pulse +

21b Axis 8 clockwise pulse – 21a Axis 5 clockwise pulse –

20b Axis 8

19b Axis 8

18b Axis 8 deviation pulse 18a Axis 6 deviation pulse clear

17b Axis 8

16b Axis 7 Z-phase input – 16a Axis 5 Z-phase input –

15b Axis 7 Z-phase input + 15a Axis 5 Z-phase input +

14b Axis 7 clockwise pulse + 14a Axis 5 clockwise pulse +

13b Axis 7 clockwise pulse – 13a Axis 5 clockwise pulse –

12b Axis 7

11b Axis 7

10b Axis 7 deviation pulse clear 10a Axis 5 deviation pulse clear

9b Axis 7

8b External power 5Vin 8a External power 5 Vin (GND)

7b Axis 8 origin input 7a Axis 6 origin input

6b Axis 8

5b Axis 8

4b Axis 7 origin input 4a Axis 5 origin input

3b Axis 7

2b Axis 7

1b Contact input common 1a Contact input common

counterclockwise pulse +

counterclockwise pulse –

deviation pulse clear (GND)

counterclockwise pulse +

counterclockwise pulse –

deviation pulse clear (GND)

positive-direction limit input

negative-direction limit input

positive-direction limit input

negative-direction limit input

20a Axis 5

19a Axis 5

17a Axis 6

12a Axis 5

11a Axis 5

9a Axis 5

6a Axis 6

5a Axis 6

3a Axis 5

2a Axis 5

counterclockwise pulse +

counterclockwise pulse –

deviation pulse clear (GND)

counterclockwise pulse +

counterclockwise pulse –

deviation pulse clear (GND)

positive-direction limit input

negative-direction limit input

positive-direction limit input

negative-direction limit input

FC0206_1.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 19

2-6

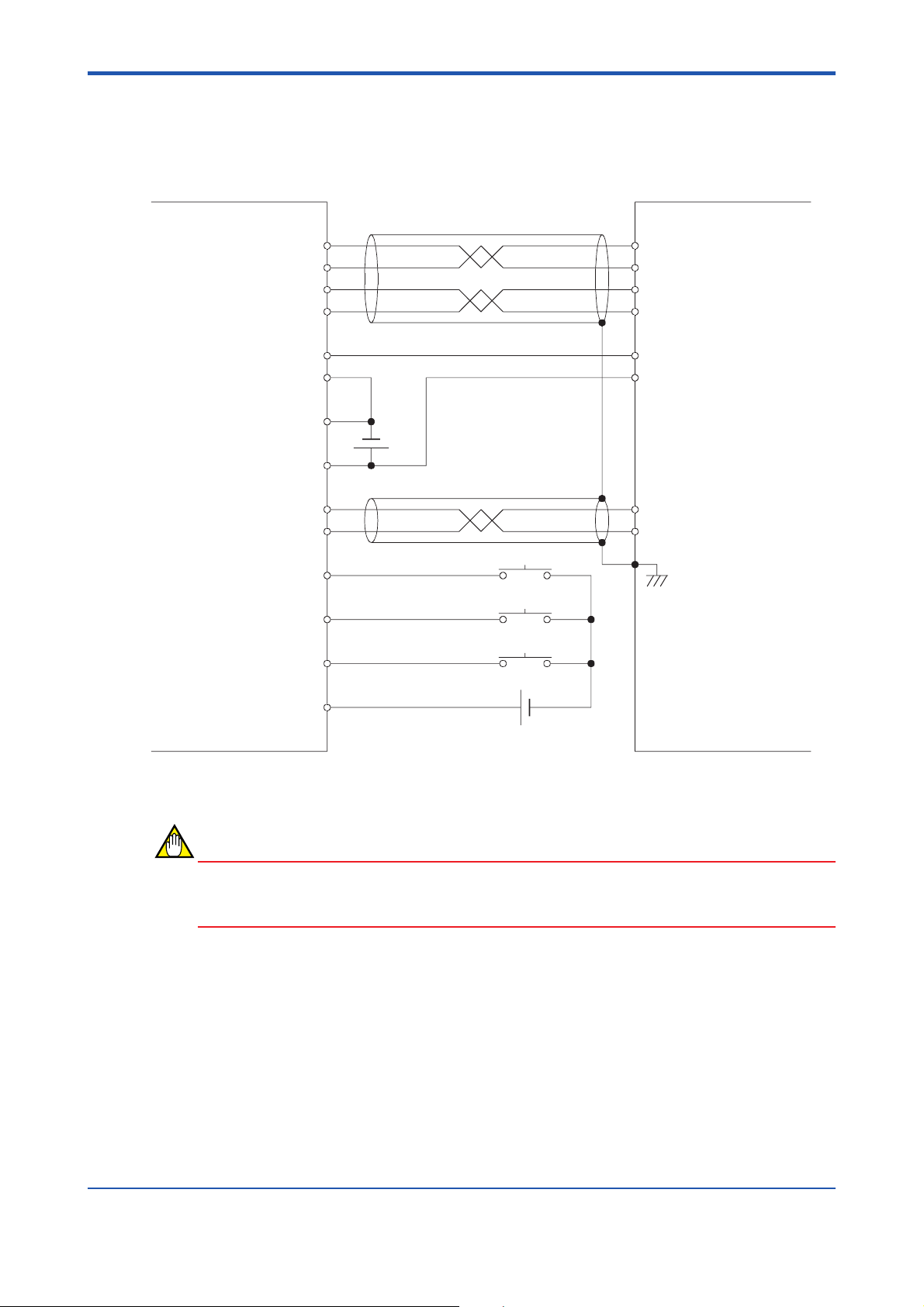

External power 5Vin

External power 5Vin (GND)

Clockwise pulse –

Clockwise pulse +

Counterclockwise pulse –

Counterclockwise pulse +

Deviation pulse clear

Deviation pulse clear (GND)

Z-phase input –

Z-phase input +

Origin input

Positive-direction limit input

Negative-direction limit input

Contact input common

+

5 V DC

–

24 V DC

FC0206_2.EPS

Contact input common and the external power supply 5Vin/GND are common to all axes

(they are connected through the internal circuitry even between different connector

terminals). Other signals are independent for each axis.

CAUTION

Be sure to connect the external power supply (5 V DC) with the correct polarity. The internal

circuitry may be damaged if it is connected incorrectly.

For details on the external connection signals, please refer to Chapter 9, “External Connection Signals.”

2.7 Applicable External Interface Connectors

Connection Applicable Connector Remarks

Soldered FCN-361J048-AU connector

FCN-360C048-B connector cover (Fujitsu Limited)

Crimp-on FCN-363J048 housing

FCN-363J-AU contacts

FCN-360C048-B connector cover (Fujitsu Limited)

Pressure-welded FCN-367J048-AU/F connector (Fujitsu Limited)

Purchase the desired

connector kit

separately.

TC0207.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 20

3. Function Overview

This chapter explains the major functions of the positioning modules. For details on how to

use each function, see Chapter 7. Table 3.1 summarizes the functions discussed in this

chapter.

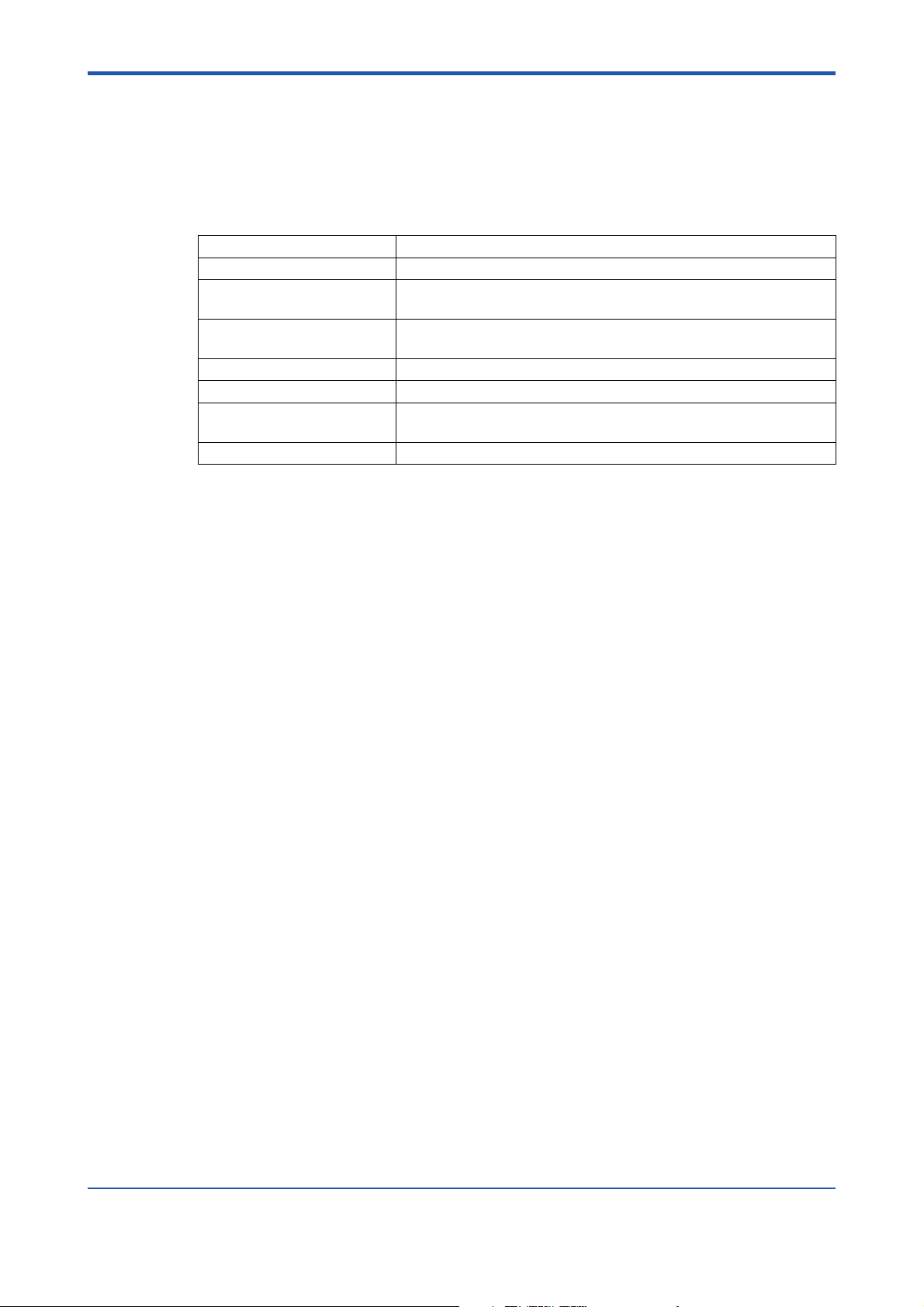

Table 3. Major Functions

Function Description

Positioning operation Carries out normal positioning.

Jog stepping Allows a motor to be rotated manually, for example, during position

teaching.

Contact input Inputs external contact signals such as a limit-switch signal or an

ORIGIN input signal.

Z-phase encoder input Inputs a Z-phase encoder signal used to search for the origin.

Origin-search operation Searches for the origin using an external contact input.

Deviation pulse clear signal Outputs a deviation pulse clear signal when an origin position search

is completed.

Linear-interpolated operation Carries out a multi-axial linear-interpolated operation.

3-1

T0301.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 21

3.1 Positioning Operation

To initiate the positioning operation:

- first write the target velocity, target position, acceleration time, deceleration time and

other necessary parameters from the CPU module,

- Set the command code to 0,

- change the state of the output relay defined as “Execute Command” from off to on.

When the positioning operation is completed, the input relay defined as “End of Positioning”

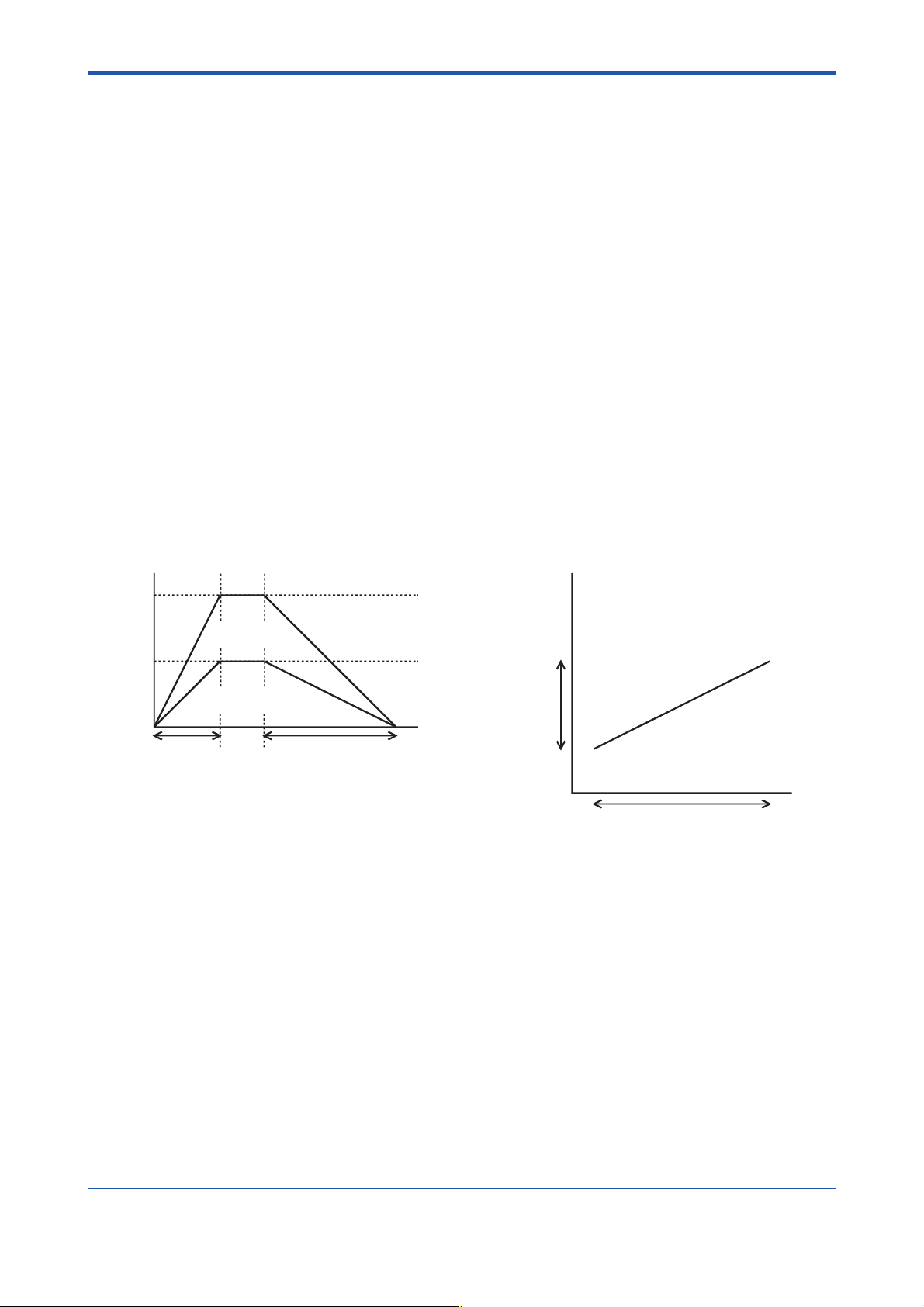

turns on. The trace of the acceleration/deceleration curve is trapezoidal, and the acceleration/deceleration times are set separately.

3-2

Velocity

Acceleration

time

Velocity

Tr av e l

Target velocity

Deceleration time

Time

Tr av e l

Acceleration

time

Deceleration time

Target velocity

Actual velocity reached

Time

Actual acceleration/deceration times

F0301.EPS

Figure 3.1 Velocity and Acceleration/Deceleration Times in Trapezoidal and Trigonometric Drives

Position

Position-command

pulse count

End of positioning

Delay before target

position is reached

Motor position

Time

F0302.EPS

Figure 3.2 Comparison Between the Theoretical and Actual Behaviors of a Servo Motor in

Position Control

Velocity

Target velocity

Starting velocity

Time

Acceleration time Deceleration time

F0303.EPS

Figure 3.3 Acceleration/Deceleration Times Where Starting Velocity Is Set

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 22

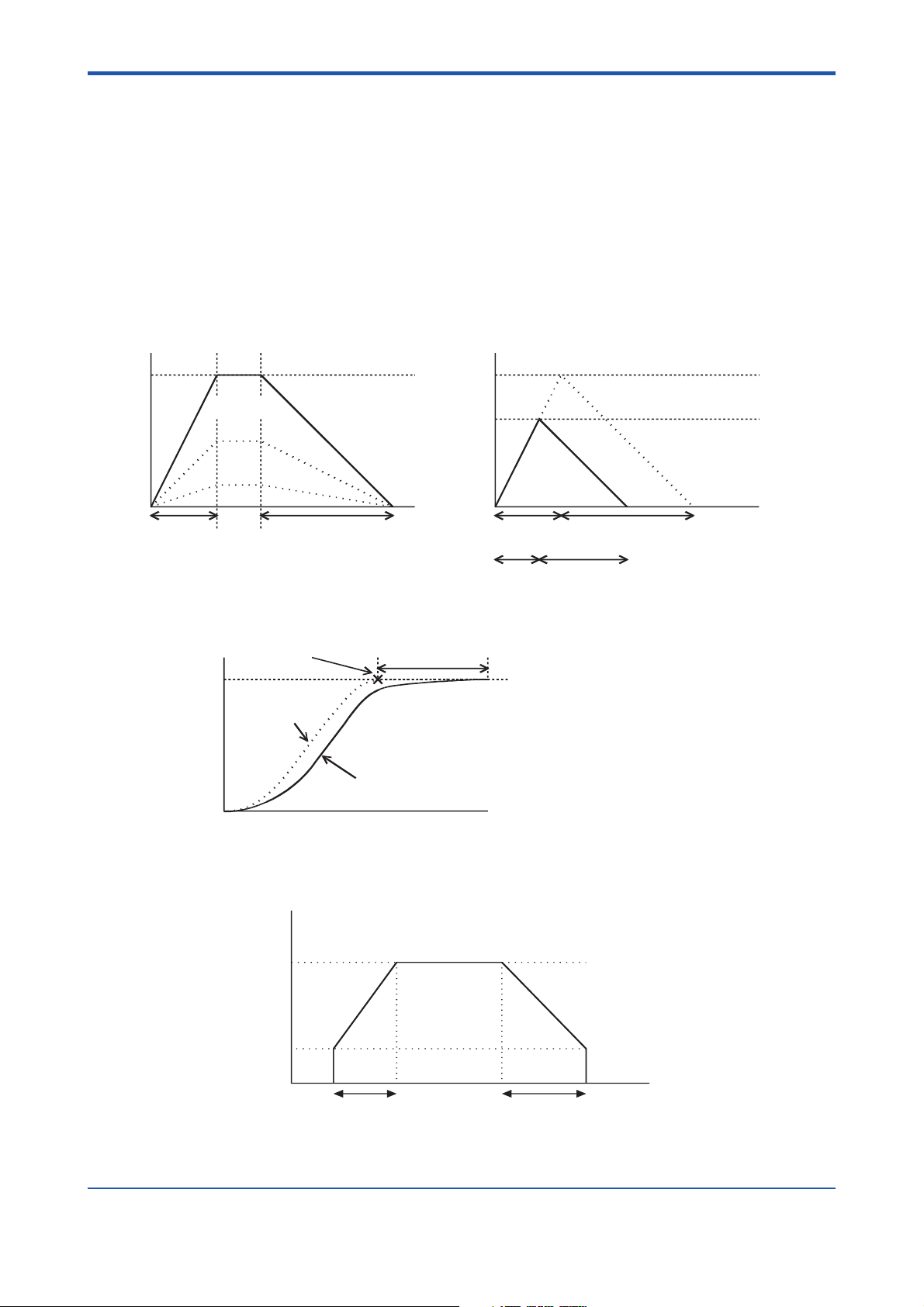

3.2 Jog Stepping

j

To carry out jog stepping:

- first write the target velocity, acceleration time, deceleration time and other necessary

parameters from the CPU module, and then

- change the state of the output relay labeled “Positive-direction jog stepping” or “Nega-

tive-direction jog stepping” from off to on.

To quit the jog-stepping operation, turn the output relay off.

During jog stepping, errors in the positive-direction limit value or negative-direction limit

value are not detected. (No error occurs).

Velocity

Start

Positive-direction

og stepping

Figure 3.4 Jog-stepping Operation (Positive Direction)

3-3

End

Time

F0304.EPS

3.3 Contact Inputs

The positioning module has three external contact inputs defined as “POSITIVEDIRECTION LIMIT,” “NEGATIVE-DIRECTION LIMIT,” and “ORIGIN” for each axis.

You can read the state of each contact input using an application program. In addition, you

can set the polarity of each contact input separately.

3.4 Z-phase Encoder Input

For improved repeatability in origin searches, you can use Z-phase encoder input. You can

read the state of the encoder input the same way you read the states of a contact input.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 23

3.5 Origin Search

To start an origin search:

- first write the velocity set point, the direction of the origin search, the origin search

mode (operation on detecting an external contact input), Z-phase edge selection, and

other necessary parameters,

- set the command code to 2,

- change the state of the output relay defined as “Execute Command” from off to on

If the positioning module detects a change in the state of a preset external contact input

after the start of the origin search operation, the module either stops the motor or checks

the Z-phase, depending on the setting of the origin search mode.

When checking the Z-phase, once the module detects the preset Z-phase pulse count, it

immediately stops the motor. The position where the motor stops is defined as the origin

(position “0”). At that point, it outputs the deviation pulse clear signal according to the time

specified in the deviation pulse clear time parameter. When the Z-phase pulse count is set

to 0, it does not output a deviation pulse clear signal.

There is an application where an origin search is carried out at two different speeds or a

change is made to the direction of rotation while checking for an external contact input

during the origin search. In such a case, split the origin search process into several cycles

while varying the parameters for each cycle, and then do the search. This strategy enables

you to customize your origin-search operation to follow your desired search patterns.

3-4

Please refer to the following page for information on the origin search mode.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

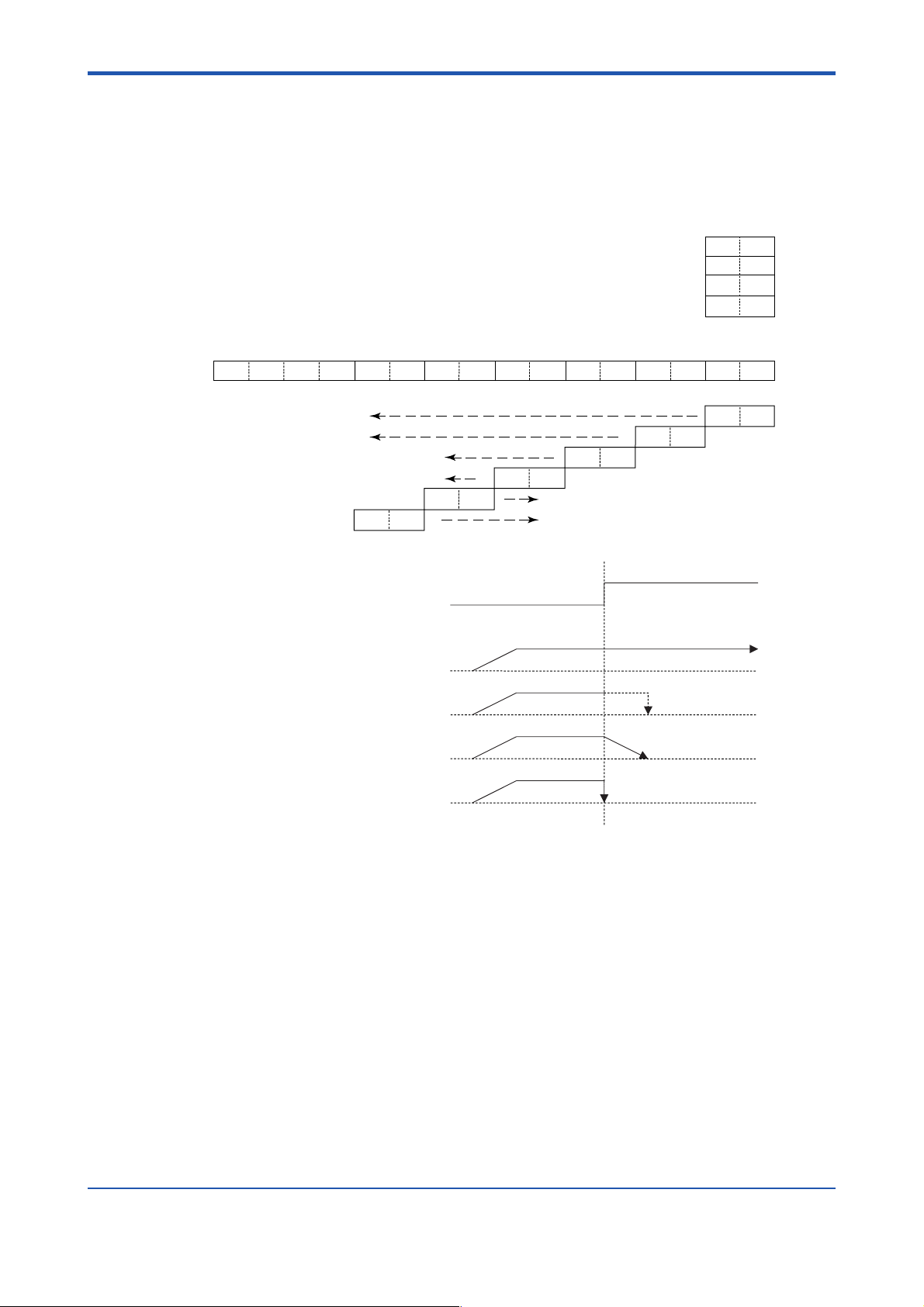

Page 24

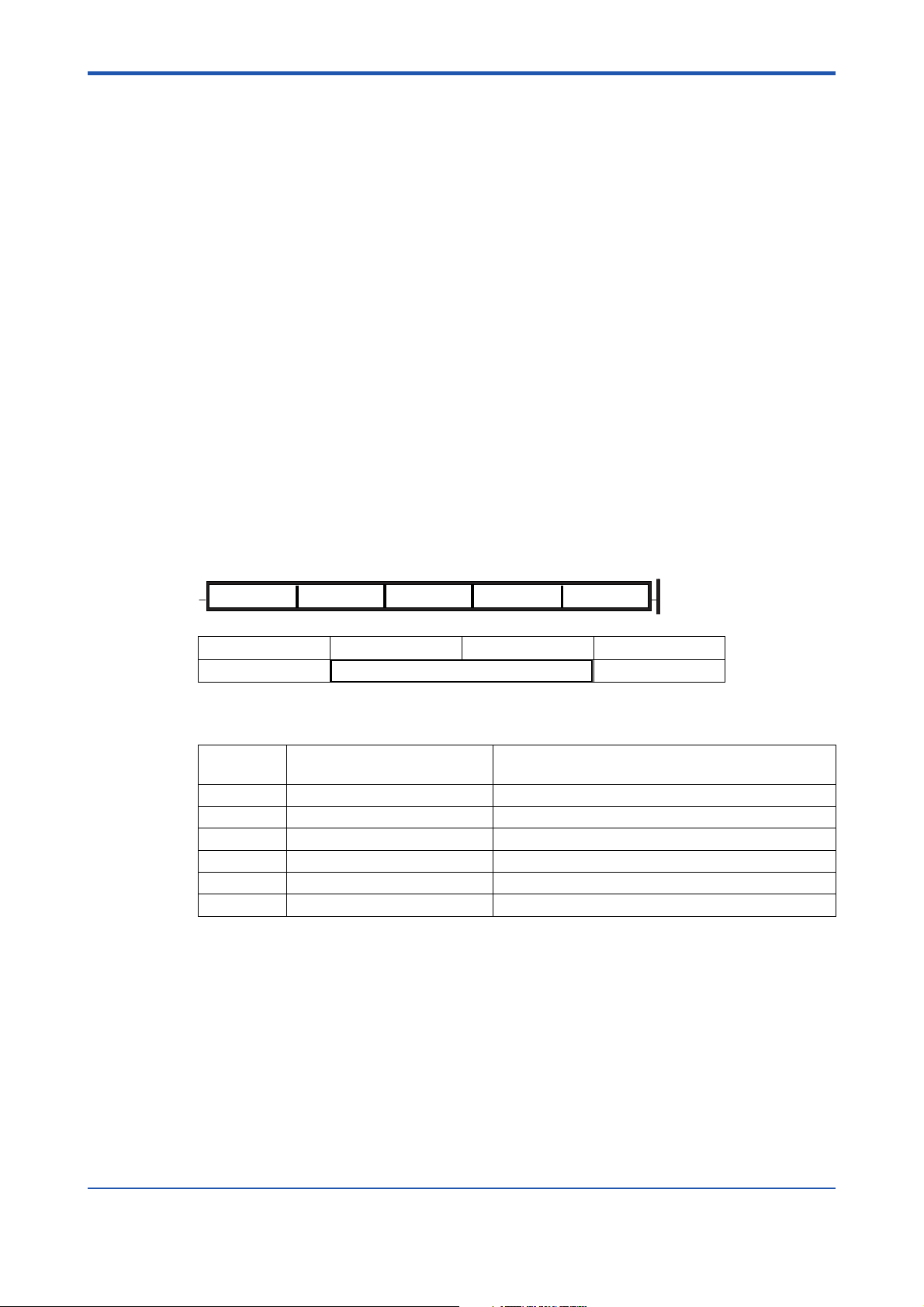

■ Details on Origin Search Mode

Sets the operation of each contact input when an edge is detected using bit combinations.

Four 2-bit combinations can be set for each rising/falling edge of an external contact input.

Bits 12 to 15 are fixed at 0.

If all bits are 0, it shifts to a Z-phase search after the start of the origin search.

3-5

Ignore (error and stop at the rising edge of the limit input in the direction of operation)

Shift to Z-phase

Decelerate and stop

Immediate stop

0000

Fall in origin input

Rise in origin input

Fall in positive-direction limit input

Rise in positive-direction limit input

For rise in contact input

When “ignore” is specified

NU0NU1

NU0NU1

ND0ND1

ND0ND1

PU0PU1

PU0PU1

Fall in negative-direction limit input

Rise in negative-direction limit input

PD0PD1

PD0PD1

OU0OU1

OU0OU1

0

0

0

1

1

0

1

1

0123456789101112131415

OD0OD1

OD0OD1

When a “Z-phase search” is specified

When the “decelerate and stop” is specified

When “stop immediately” is specified

Figure 3.5 Origin Search Operation

Stop when Z-phase is detected

F0305.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 25

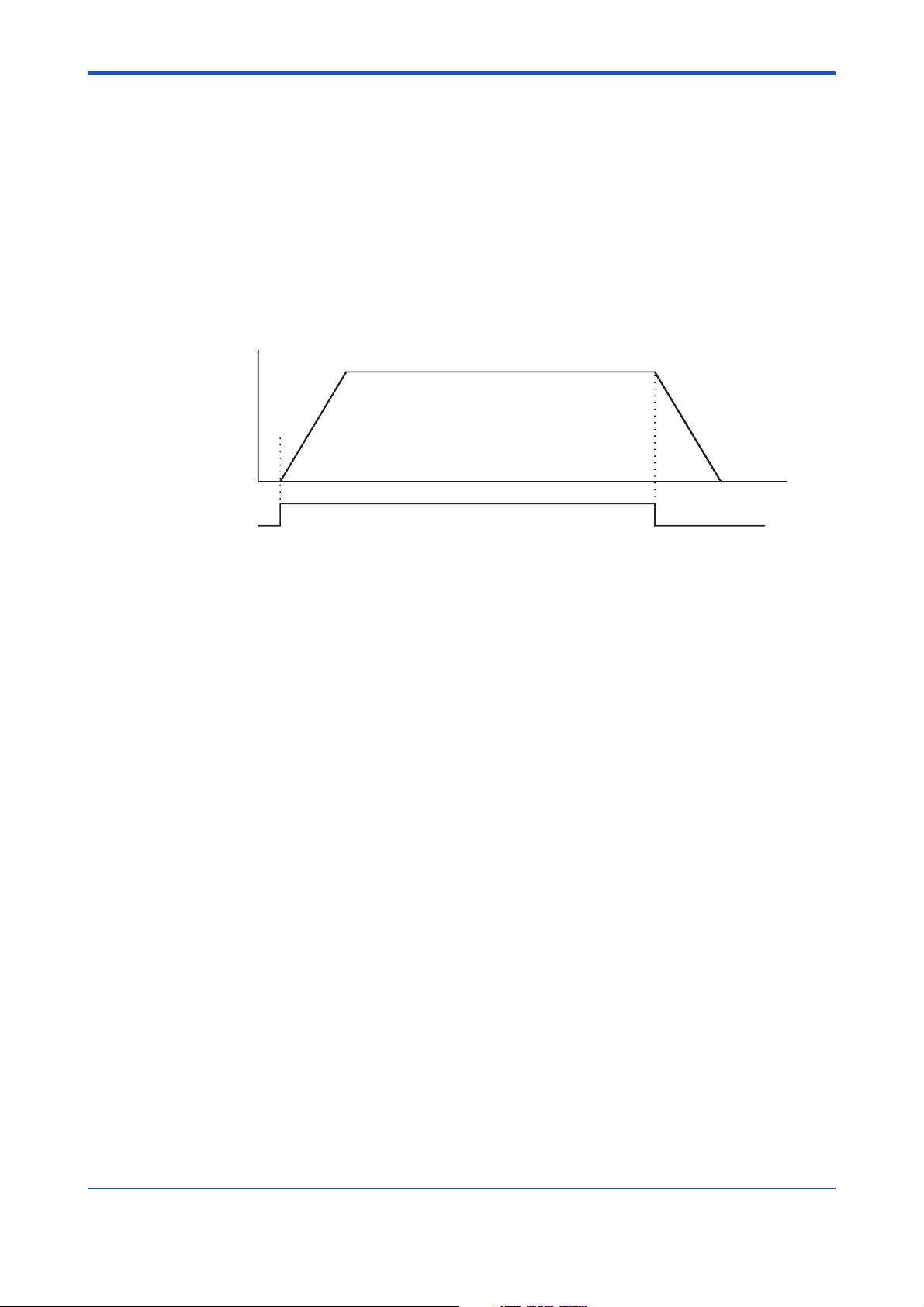

3.6 Deviation Pulse Clear Signal Output

In an origin search using a servo driver, this outputs a deviation pulse clear signal at the

end of the origin search to the servo driver. It is connected to the deviation pulse clear

signal input of the servo driver.

The time period to output the deviation pulse clear signal is set in a parameter.

When the Z-phase pulse count is set to 0, a deviation pulse clear signal is not output.

3.7 Linear-Interpolated Operation

To carry out a linear-interpolated operation:

- first write the target velocity, target position, acceleration time, deceleration time and

other necessary parameters for each axis from the CPU module,

- Set the command code to “0,”

- change the state of the output relay defined as “Execute Command” from off to on for

all axes simultaneously. When the positioning operation for each axis is completed, the

input relay defined as “End of Positioning” for each axis turns on.

In this operation, set the same acceleration and deceleration times to all axes concerned.

Calculate and set the ratio between the target velocities of the two axes so that it equals the

ratio between the travels of the two axes.

3-6

Velocity

Acceleration time

Figure 3.6 Multi-axial Linear-interpolated Operation (Example of Biaxial Application)

X-axis travel

Y-axis travel

Y-axis

X-axis target velocity

Y-axis target velocity

Y-axis

travel

Time

Deceleration time

X-axis

X-axis travel

F0306.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 26

4. Parameters

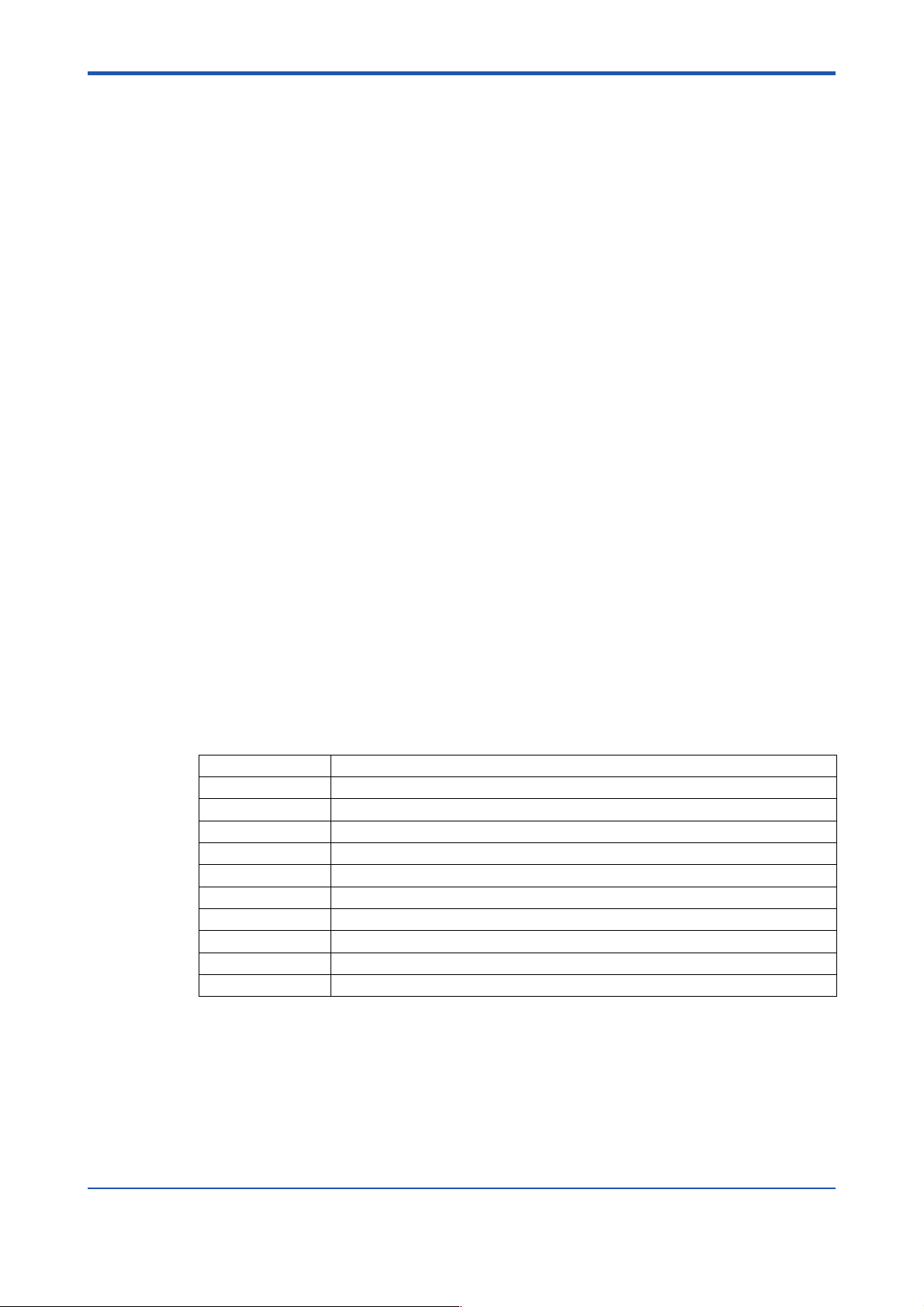

4.1 Parameters

Among the parameters listed in Tables 4.2 and 4.3, the ones with two data position numbers are 2 word data. The data item with the smaller number is the low-order word, and the

one with the larger number is the high-order word.

Data position numbers are three-digit numbers and the leading * symbol is the value of

(axis number - 1). The values from the first axis to the eighth axis are 0 to 7 respectively.

Data position numbers each correspond to a word. The WRITE and READ instructions

used to access from a sequence program must be on a word-basis. Long-word-based

instructions cause unexpected results. You should also use word-based instructions when

you access from BASIC programs.

In speed-related data, data whose setting units are [(1/65536) pulses/ms] are fixed point

data with 1-word integers (16 bits) and 1-word fractions (16 bits). The data item with the

smaller number is the low-order word, and the one with the larger number is the high-order

word.

4-1

■ Fixed-point data

The higher digits for the integer part of the binary data are sequentially defined as 1, 2, 4 ...

in value, and the lower digits for the fraction part are defined as 1/2, 1/4, 1/8, and so forth in

value. If both the integer and the fraction parts consist of 16 bits, the least significant bit for

the fraction part is 1/65536, which means that it is 32-bit (long-word) data whose setting

unit is 1/65536. Negative numbers are expressed as complements of 2 like ordinary binary

data.

Table 4.1

Bit 31(MSB) 30 ... 17 16 15 14 ... 1 0(LSB)

Value sign bit 16384 ... 2 1 1/2 1/4 ... 1/32768 1/65536

(Example of fixed point data)

When setting 123.45 [pulse/s] (=123450 [pulses/s]),

123.45x65536 = 8090419.2 [(1/65536) pulses/ms]

Thus, we should set 8090419 as long-word data. The high-order word of this data is 123

because 8090419 ÷ 65536 = 123. The low-order word is the remainder, i.e., 29491.

High-order word Low-order word

T0401.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 27

4-2

(Reference)

Example of a sequence program which converts data in [pulses/s] into data to be set for a

positioning module ([(1/65536) pulses/ms])

Let D0001 (long-word data) be the original data ([pulses/s]).

(1) Divide D0001 by 1000 (long-word division) and put the result into D0011. In this case,

since the maximum value of D0001 is 250000 (250000 pps) and it is positive, the

maximum value of the result is 250 and, thus, the high-order word (D0012) is always 0.

The low-order word of the result of the division (D0011) is the high-order word (the

integer which is 16 bits long) of the value ([(1/65536) pulses/ms]) to be set in the

positioning module.

The remainder is put into D0013 (the low-order word) and D0014 (the high-order

word). Since the maximum value of the remainder is 999 because the divisor is 1000,

the high-order word of the remainder (D0014) is always 0.

(2) Multiply the remainder by 65536 and divide it again by 1000. A useful trick here is this:

the remainder is in D0013 and D0012 is 0; thus, if D0012 is treated as long-word data,

its value is already the result of multiplying of the remainder by 65536. Therefore, in

order to divide the result of multiplying the remainder by 65536 by 1000, it is only

necessary to divide D0012 by 1000 (long-word division). Put the result of this division

into D0021.

D0012 (long word) is 999*65536 at most; dividing by 1000 is 65470 at most and the

high-order word (D0022) always becomes 0. Thus, D0021 is a low-order word (the

fraction of 16 bits) of data [(1/65536) pulses/ms] to be set in the positioning module

and the remainder is truncated.

(3) Combine the results of D0011 and D0021 into long-word data ([(1/65536) pulses/ms]).

To do this, it is only necessary to do long-word division twice and transfer the resulting

high-order and low-order words to D0032 and D0031, respectively. D0011-D0014 and

D0021-D0024 are work areas.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 28

(1) Long-word division

D0011 = D0001 ÷ 1000

FC0401_1.EPS

Computation results

D0014 D0013 D0012 D0011

0

Remainder

0

High-order of set data

(2) Long-word division

D0021 = D0012 ÷ 1000

FC0401_2.EPS

Computation results

D0024 D0023 D0022 D0021

0

Remainder

0

Low-order of set data

(3) Data transfer

4-3

TC0401_1.EPS

TC0401_2.EPS

MOV D0011 D0032

MOV D0021 D0031

FC0401_3.EPS

Computation results

D0032

High-order set data

D0031

Low-order set data

TC0401_3.EPS

In the case of 123450 [pulses/s]

(1) D0011 = 123450/1000 (long-word division)

D0014 D0013 D0012 D0011

0 450

0 123

29491200 (= 450 × 65536)

TC0401_4.EPS

(2) D0021 = 29491200/1000 (long-word division)

D0014 D0013 D0012 D0011

0 200 0 29491

TC0401_5.EPS

From the results, the high-order word of the long-word data ([(1/65536) pulses/ms]) to

be set in the positioning module is 123, and the low-order word is 29491.

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 29

4.1.1 Entry Parameters

Entry parameters are usually set only once after turning the power on. You can set them by

writing from the CPU module and then executing the Set Parameter command. Be sure to

set all the parameters.

When the power supply is cut off, entry parameters are cleared and it is necessary to set

the parameters again.

Table 4.2 Entry parameters

4-4

Data Position

Number

01 Contact Input Polarity 0 to 7

*

02/*03 Positive-direction Limit Value –134217728 to 134217727 [pulses]

*

04/*05 Negative-direction Limit Value –134217728 to positive-direction limit value-1 [pulses]

*

is the value of (axis number - 1). The values from the first axis to the eighth axis are 0 to 7 respectively.

*

Parameter Range of values

4.1.2 Command Parameters

These are parameters to be set when executing a command. It is necessary to write all the

required parameters when executing a command.

Table 4.3 Command Parameters

Data Position

Number

11 Command Code 0 to 5

*

12 Target Position Mode 0: absolute position; 1: relative position

*

13/*14 Target Position Negative-direction limit value to positive-direction

*

15/*16 Target Velocity 1 to 16384000 [(1/65536) pulses/ms]

*

17 Acceleration Time 0 to 32767 [ms]

*

18 Deceleration Time 0 to 32767 [ms]

*

19/*20 Start Up Velocity 0 to set velocity [(1/65536) pulses/ms]

*

21 Origin Search Mode 0 to 4095

*

22 Origin Search Direction 0: Negative Direction; 1: Positive Direction

*

23 Z-phase Edge Selection 0: OFF→ON edge; 1: ON→OFF edge

*

24 Z-phase Search Count 0 to 32767 [times]

*

25/*26 Z-phase Search Range 0 to 134217727/Z-phase search count [pulses]

*

27 Deviation Pulse Clear Time 0 to 32767 [ms]

*

is the value of (axis number - 1). The values from the first axis to the eight axis are 0 to 7 respectively.

*

Parameter Range of values

T0402.EPS

limit value [pulse]

T0403.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 30

4-5

●

●

●

●

4.2 Parameters Required for Each Command

To execute a command for the positioning module from the CPU module, it is necessary to

write all the required parameters in advance.

The table below shows the required parameters for each command.

The Set Parameter command is not included in this table because it changes all the entry

parameters.

Table 4.4 Parameters Required for Each Command

Command (output relay)

Positivedirection

Jog

Data

Position

Number

11 Command code ●●— ●●— ●

*

12 Target position mode ● —— ————

*

13/*14 Target position ● —— ● ———

*

15/*16 Target velocity ●●●————

*

17 Acceleration time ●●●————

*

18 Deceleration time ●●●————

*

19/*20 Starting velocity ●●●————

*

21 Origin search mode — ● —————

*

22 Origin search direction — ● — ————

*

23 Z-phase edge selection —

*

24 Z-phase search count —

*

25/*26 Z-phase search range —

*

27

*

Parameter

Deviation pluse clear time

is the value of (axis number - 1). The values from the first axis to the eighth axis are 0 to 7 respectively.

*

● : Required parameters.

: Parameters that are required or not depending on the values of the other parameters.

—: Non-required parameters (have no effect on the operation of the commands if used).

Start

Positioning

Command

—

Origin

Search

Command

Stepping

Command

Negative-

direction

Jog

Stepping

Command

—————

—————

—————

—————

Set

Current

Position

Command

Decelerate

& Step

Command

Stop

Immediately

Command

Error

Reset

Command

T0404.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 31

4.3 Descriptions of Parameters

4.3.1 Entry Parameters

When the power is switched on, all entry parameters are cleared. Set all entry parameters

using the Set Parameter command in an application program. When a set parameter value

is invalid, an Error Notification input relay is set, and a setting error in the entry parameter

results. When this happens, execute Error Reset and execute the Set Parameter command

again with valid values.

Table 4.5 Entry parameters

Parameter

Type

(Data Position

Number)

What the set

parameter does

Data Range Remarks

4-6

Contact input

polarity

(

01)

*

Positivedirection limit

value

(

02/*03)

*

Negativedirection limit

value

(

04/*05)

*

Defines the logic of

the external

contact input.

Sets the operation

limit position in the

positive direction

as the number of

pulses from the

origin.

Sets the operation

limit position in the

negative direction

as the number of

pulses from the

origin.

Specified for each contact

input as a bit. “0” indicates an

“a” contact and “1” indicates a

“b” contact.

Bit 0: Negative-direction limit

input

Bit 1: Positive-direction limit

input

Bit 2: Origin position input

–134217728 to 134217727

[pulses]

–134217728 to Positivedirection limit value-1 [pulses]

An “a” contact input is an input

which is effective when a signal

input exists, and a “b” contact

input is an input which is

effective without a signal input .

For example, a “limit input of ‘b’

contact” detects the limit when

there is no signal input, but

does not detect the limit when a

signal input exists.

If an origin search is not

executed, then the position at

the moment when the main

switch is turned on is defined as

the origin. If you start the

system after setting a target

position beyond this range, an

error results and the motor does

not start.

Detection of the limit values is

not performed during an origin

search or jog stepping. (An

error does not occur.)

T0405.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 32

4.3.2 Command Parameters

Table 4.6 Command Parameters

Parameter

Type

(Data Position

Number)

What the set

parameter does

4-7

Data Range Remarks

Command

Code

(

11)

*

Target

Position

Mode

(

12)

*

Target

Position

(

13/*14)

*

Target

Velocity

(

15/*16)

*

Acceleration

Time

(

17)

*

Deceleration

Time

(

18)

*

Starting

Velocity

(

19/*20)

*

Sets the command type

for the command

execution using the

Execute Command Relay.

Sets the types of Target

positions

Sets the target position for

the positioning operation,

or the current position.

Sets the operation velocity

in position control, origin

position search and jog

stepping.

Sets the time it takes to

reach the target velocity

from the Starting velocity.

Sets the time from the

target velocity to

Decelerate and Stop.

This is the starting velocity

of the operation at the

start of the positioning

operation and the velocity

just before stopping at the

end of Positioning.

0: Start Positioning command

1: Decelerate-and-Stop

command

2: Origin Search command

3: Set Parameter command

4: Set Current Position

command

5: Error Reset command

0:Absolute position,

1:Relative position

Negative-direction limit value

to Positive-direction limit

value [pulse]

1 to 16384000 [(1/65536)

pulses/ms]

0 to 32767 [ms]

0 to 32767 [ms]

0 to target velocity [(1/65536)

pulses/ms]

If the value of the target velocity specified

is smaller than the Starting velocity, an

error occurs.

When using a pulse motor and

accelerating from the velocity [0],

resonance may occur resulting in out of

phase at the low velocity portion during

acceleration. (The situation is the same

for deceleration). Set a velocity faster

than the resonance point to prevent this

from happening. However, you should

take note that too large a setting may

cause the moter to be out of phase at

startup or stop because of impact.

When using a servo motor, it is normally

set to [0].

Origin-search

Mode

(

21)

*

Origin-search

Direction

(

22)

*

Sets the motion of the

motor for each contact

input after detecting the

edges of each contact

input during an origin

search using bit patterns.

Sets the motor rotation

direction during an origin

search.

0 to 4095

0: Negative -direction,

1: Positive-direction

For details, refer to Section 3.5, “Originsearch Operation.”

T0406_1.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 33

Parameter

Type

(Data Position

Number)

What the set

parameter does

4-8

Data Range Remarks

Z-phase

Edge

Selection

(

23)

*

Z-phase

Search Count

(

24)

*

Z-phase

Search

Range

(

25/*26)

*

Deviation

Pulse Clear

Time

(

27)

*

Sets the Z-phase edge

direction when detecting

the Z-phase during an

origin search.

Sets the number of Zphase pulses to be

counted during origin

search fefore an origin

can be established.

Error occurs if a Z-phase

cannot be detected even

after the search exceeds

the Z-phase search range.

Sets the output time of the

deviation pulse clear

signal when the origin

search ends because of a

Z-phase detection.

0: OFF→ON edge

1: ON→OFF edge

0 to 32767 [times]

0 to 134217727/Z-phase

search count [pulses]

0 to 32767 [ms]

This parameter is used to prevent

continued operation when a Z-phase

cannot be detected because of a Z-phase

signal disconnection, etc. Usually, this is

set close to the number of pulses between

two Z-phase pulses.

T0406_2.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 34

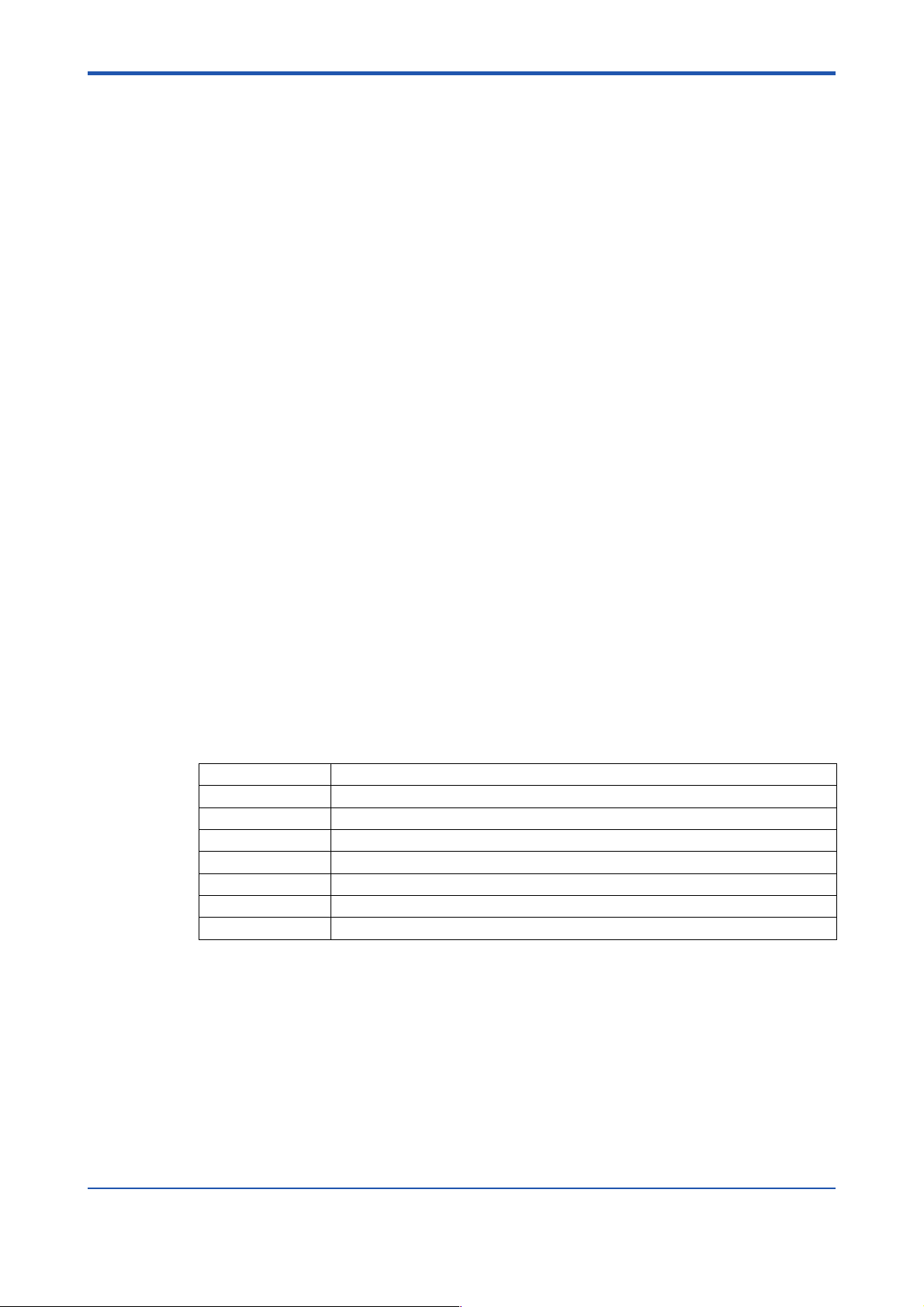

4.4 Examples of Setting Entry Parameters

The following examples show the minimum settings of entry parameters for controlling the

motor using the positioning module. The underlined values are set.

■ The motor used

Rated rotating speed: 3000 rpm

Encoder pulse count: 1 rotation: 8192 pulses

CAUTION

You can set/change the ratio of the command pulses and encoder pulses on the servo

driver side. In these cases, the parameters set in the positioning module must match the

setting of the servo driver. So calculate the values of the entry parameters after confirming

the setting of the servo driver.

4-9

■ Mechanism

Direct shaft drive using ball screw

Ball screw pitch: 5 mm/rot

Operation Range: –500 mm to +1000 mm

Maximum speed: 6000 mm/min (100 mm/s)

Contact Input: Positive/Negative-direction limit input (“b” contact), origin (“a” contact)

■ Calculation of entry parameters

- Contact input polarity

Positive-direction limit value ( “b” contact), Negative-direction limit input ( “b” contact),

Origin ( “a” contact) →

- Positive-direction limit value

1000 (mm) ÷ 5 (mm/rot) × 8192 (pulses/rot) =

- Negative-direction limit value

–500 (mm) ÷ 5 (mm/rot) × 8192 (pulses/rot) =

Negative-direction limit

$0003

1638400 (pulses)

–819200 (pulses)

Positive-direction limitOrigin Negative Positive

500 mm 1000 mm

Figure 4.1 Direct Shaft Drive Using Ball Screw

F0401.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 35

Blank Page

Page 36

5. Status

Statuses are the data which the CPU module reads from the positioning module. You can

check the state of the positioning module using these statuses and input relays.

CAUTION

When the CPU module reads 2-word data from the positioning module, the high-order

word/low-order word of 2-word data is not guaranteed to be concurrent due to a conflict

between the reading timing of the CPU module and the data update period of the positioning module.

In reading from the sequence CPU, to ensure that the high-order word and low-order word

of 2-word data are concurrent, use the READ command to read the data twice consecutively and verify that the data read are the same in both instances. In this situation, if the

HRD command is used, data concurrency cannot be guaranteed even if you confirm that

the data are the same.

In reading from the BASIC CPU, concurrency is not guaranteed because the time required

to read 2-word data is longer than the data update period of the positioning module.

5-1

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 37

5.1 List of Status

In Table 5.1, the statuses listed with 2 data position numbers are 2-word data. The data item

with the smaller number is the low-order word, and the one with the larger number is the

high-order word.

5-2

The data position number consists of three digits, the leading

is the value of (axis num-

*

ber-1). Insert the values 0 to 7 for axes 1 to 8 respectively.

Data position numbers are specified for each word. The READ instruction used for access

from a sequence program must be on a word basis. Long-word-based instructions cause

unexpected results.

Use word-wise instructions also when accessing from a BASIC program.

Speed-related data, data with a setting unit [(1/65536) pulses/ms], are fixed-point data with

a 1-word (16 bits) integer and a 1-word (16 bits) fraction. The data with the smaller number

is the low-order word, and the one with the larger number is the high-order word. For more

information on fixed-point data, refer to the description of fixed point data in Section 4.1,

“Parameters.”

(Reference)

To convert data in [(1/65536) pulses/ms] units into data in [pulses/sec] units, multiply the

data by 1000 in a long Operation Result word operation, ignore the lowest-order word and

the highest-order word and use the second and the third words as long-word data.

(Example)

Let D0001 be long-word data in [(1/65536) pulses/ms] units. The operation is as follows.

D0011 = D0001

D0014 D0013 D0012 D0011

0

Resulting long word [pulses/ms] Truncated Portion

*

1000

FC0501.EPS

TC0501.EPS

Table 5.1 Statuses

Data Position

Number

51/*52 Target Position Status –134217728 to 134217727 [pulses]

*

53/*54 Current Position Status –134217728 to 134217727 [pulses]

*

55/*56 Current Velocity Status 0 to 16384000 [(1/65536) pulses/ms]

*

57 Contact Input Status States of contact inputs

*

58 Error Status Error information when an error occurs

*

59 Origin Search Status Status related to an origin search

*

is the value of (Axis number - 1). The values of axis1 to axis 8 are 0 to 7, respectively.

*

Status Range of values

T0501.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 38

5.2 Description of Status

Table 5.2 Statuses

5-3

Data Position

Number

51/*52 Target Position Status

*

53/*54 Current Position

*

55/*56 Current Velocity

*

57 Contact Input Status Reads the state of the external contact input and the

*

58 Error Status Reads the error code when an error occurs. It is

*

[pulses]

Status [pulses]

Status [(1/65536)

pulses/ms]

Status Data Contents

Reads the operation target position during a positioning

operation. The target position which is set at the start of the

positioning is stored as the operation target position.

This represents the current position of the positioning

module output. Therefore, it is not the actual motor position

when the servomotor is used.

Reads the current velocity status, which is the current

velocity of the output pulse of the positioning module.

Therefore, it is not the actual velocity of the motor when the

servomotor is used. Regardless of the direction of the

motor’s rotation, the value is zero or positive.

encoder Z-phase input. The state of each contact is stored

as 1 bit (0: off; 1: on). When a contact is specified as an “a”

contact, it is represented by “1” if the contact is closed.

When a contact is specified as a “b” contact, it is

represented by “1” if the contact is opened.

bit 0: negative-direction limit input

bit 1: positive-direction limit input

bit 2: origin input

bit 3: encoder Z-phase input

meaningless if the relay labeled “Error Notification” is off.

For details, refer to Section 8.2, “Error Codes.”

59 Origin Search Status Reads the status during an origin search and at the end of

*

is the value of (axis number - 1). The values of axis 1 to 8 are 0 to 7, respectively.

*

an origin search.

0: On power-up or when at normal end of the origin search

1: Stops when the input edge of “Stop immediately” or

“Decelerate and Stop” command setting is detected.

2: Stopped by a “Stop immediately” or “Decelerate and

Stop” command.

3: Stopped by an error

4: During a Z-phase search

5: Before a Z-phase search

T0502.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 39

Blank Page

Page 40

6. Input/Output Relays

The positioning module has 32 output relays and 32 input relays as the interface to the

FA-M3 CPU module. For details on each input/output relay, refer to Chapter 7, “Accessing

Modules.”

CAUTION

In the F3YP04-0N, NEVER set the output relays related to axes 5 to 8 (Y49 to

Y64).

Further, input relays related to axes 5 to 8 (X17 to X32) are meaningless.

6.1 Output Relays

Table 6.1 Output Relays

6-1

Output

relay

number

Y33 Axis 1 Execute Command Y49 Axis 5 Execute Command

Y34 Axis 1 Stop Immediately Y50 Axis 5 Stop Immediately

Y35 Axis 1 Positive-direction Jog Stepping Y51 Axis 5 Positive-direction Jog Stepping

Y36 Axis 1 Negative-direction Jog Stepping Y52 Axis 5 Negative-direction Jog Stepping

Y37 Axis 2 Execute Command Y53 Axis 6 Execute Command

Y38 Axis 2 Stop Immediately Y54 Axis 6 Stop Immediately

Y39 Axis 2 Positive-direction Jog Stepping Y55 Axis 6 Positive-direction Jog Stepping

Y40 Axis 2 Negative-direction Jog Stepping Y56 Axis 6 Negative-direction Jog Stepping

Y41 Axis 3 Execute Command Y57 Axis 7 Execute Command

Y42 Axis 3 Stop Immediately Y58 Axis 7 Stop Immediately

Y43 Axis 3 Positive-direction Jog Stepping Y59 Axis 7 Positive-direction Jog Stepping

Y44 Axis 3 Negative-direction Jog Stepping Y60 Axis 7 Negative-direction Jog Stepping

Y45 Axis 4 Execute Command Y61 Axis 8 Execute Command

Y46 Axis 4 Stop Immediately Y62 Axis 8 Stop Immediately

Y47 Axis 4 Positive-direction Jog Stepping Y63 Axis 8 Positive-direction Jog Stepping

Y48 Axis 4 Negative-direction Jog Stepping Y64 Axis 8 Negative-direction Jog Stepping

(Note) Insert into the empty boxes above () the number of the FA-M3 slot where this module is installed.

Operation when ON

Output

relay

number

Operation when ON

T0601.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 41

6.2 Input Relays

Table 6.2 Input Relays

6-2

Input

relay

number

X01 Axis 1 Execute Command ACK X17 Axis 5 Execute Command ACK

X02 Axis 1 Stop Immediately ACK X18 Axis 5 Stop Immediately ACK

X03 Axis 1 Error Notification X19 Axis 5 Error Notification

X04 Axis 1 End of Positioning X20 Axis 5 End of Positioning

X05 Axis 2 Execute Command ACK X21 Axis 6 Execute Command ACK

X06 Axis 2 Stop Immediately ACK X22 Axis 6 Stop Immediately ACK

X07 Axis 2 Error Notification X23 Axis 6 Error Notification

X08 Axis 2 End of Positioning X24 Axis 6 End of Positioning

X09 Axis 3 Execute Command ACK X25 Axis 7 Execute Command ACK

X10 Axis 3 Stop Immediately ACK X26 Axis 7 Stop Immediately ACK

X11 Axis 3 Error Notification X27 Axis 7 Error Notification

X12 Axis 3 End of Positioning X28 Axis 7 End of Positioning

X13 Axis 4 Execute Command ACK X29 Axis 8 Execute Command ACK

X14 Axis 4 Stop Immediately ACK X30 Axis 8 Stop Immediately ACK

X15 Axis 4 Error Notification X31 Axis 8 Error Notification

X16 Axis 4 End of Positioning X32 Axis 8 End of Positioning

(Note) Insert into the empty boxes above () the number of the FA-M3 slot where this module is installed.

Operation when ON

Input

relay

number

Operation when ON

T0602.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 42

7. Accessing Modules

In the program examples shown in this chapter, the positioning module is installed in the

4th slot (slot #004) of the main unit; when only one axis is used in these examples, it will be

axis 1.

7.1 Accessing from the Sequence CPU

The following are the instructions to access from the sequence CPU with the ladder sequence program. The details for each instruction are explained in the “Sequence CPU

Instruction Manual — Instructions” (IM34M6P12-03E).

■ Reading/Writing Parameters and Statuses

The instructions should be in word units. Long-word unit instructions cannot be used.

• Special Module Read Instruction (READ Instruction)

kDn1SLREAD

FC0701_1.EPS

SL: number of slot where the module is installed

7-1

n1: first data position number for reading data

D: first device to store the read data

k: number of data (in word units) to be read

• Special Module Write Instruction (WRITE Instruction)

kn2SLSWRITE

FC0701_2.EPS

S: device in which to store the write data

SL: number of slot where the module is installed

n2: first data position number for the write data

k: number of data (in word unit) to be written

• Special Module High-Speed Read Instruction (HRD Instruction)

kDn1SLHRD

FC0701_3.EPS

SL: number of slot where the module is installed

n1: first data position number for reading data

D: first device in which to store the read data

k: number of data (in word units) to be read

• Special Module High-Speed Write Instruction (HWR Instruction)

kn2SLSHWR

FC0701_4.EPS

S: device in which to store the write data

SL: number of slot where the module is installed

n2: first data position number for the write data

k: number of data (in word units) to be written

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 43

7.1.1 Reading the Module Status

This section explains how to read the status of the positioning module.

Item to Note

- The status of the positioning module can be read at any time. Take care when reading

the long-word data. Refer to Chapter 5, “Statuses.”

Program Example

In the example below, all of the statuses are read at the same time using a READ instruction.

● Major devices used

D0051/D0052 Read the target position status

D0053/D0054 Read the current position status

D0055/D0056 Read the current velocity status

D0057 Read the contact input status

D0058 Read the error status

D0059 Read the origin search status

D0121/D0122 Current Velocity [pulses/s]

D0131 to D0134 (Computation Work Area)

I00001 to I00016 Bit Data of Contact Input

7-2

TC070101.EPS

(0001)

(0002)

00001

(0003)

(0004)

(0005)

Module Status Reading Program

M0033

READ 5149

D0131 D0055

Figure 7.1 Module Status Reading Program

Status Read

D0051

Contact Input

MOV

=

MOV

D0057

D0132

I00001

*

1000

D0121

Expansion

Change Current

Velocity

Pulses/s

F0701.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 44

7.1.2 Set Parameter

This sets the entry parameters.

Items to Note

- This command is accepted only if both of the following conditions are satisfied: (1) the

positioning module is in the End of Positioning status and (2) no other commands are

being executed. If these conditions are not satisfied, then the command will be ignored.

- An error cannot be reset with the Error Reset command if the error occurs with the Set

Parameter command (error code 2uuu). Run the Set Parameter command again

with proper data.

Procedure:

1) Write setting parameters and command codes on the positioning module with the

WRITE command.

2) Set the Execute Command output relay.

3) Reset the Execute Command output relay after confirming that the Execute Command

ACK input relay is set. If there is an entry parameter setting error, the Execute Command ACK input relay is not set, but the Error Notification input relay is set. In this

case, reset the Execute Command output relay, and then go back and repeat from

step 1.

7-3

4) Check that the Execute Command ACK is reset.

Program Example:

In this example, parameters are set in the data register in advance. All entry parameters will

be written at once with the WRITE instruction.

● Major devices used

D0001 Contact Input Polarity

D0002/D0003 Positive-direction Limit Value

D0004/D0005 Negative-direction Limit Value

Y00433 Execute Command (Output Relay)

X00433 Execute Command ACK (Input Relay)

I00099 Command Execution Prohibit Condition (set elsewhere)

I00101 Request to Execute Command

I00102 Request to Execute Command (Rising Edge)

I00103 Waiting for Command ACK

I00104 Executing Command

I00105 Forced Reset of Set Parameter

TC070102.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 45

7-4

(0001)

(0002)

00001

(0003)

00003

(0004)

(0005)

(0006)

(0007)

(0008)

00015

(0009)

(0010)

00024

Parameter Setting Program

I00101

I00102 I00099

I00103 Y00433 X00401

I00105

I00104 I00103 X00401

Figure 7.2 Parameter Setting Program

DIFU

WRITE D0001 4 1 5

WRITE 43111

SET

SET

SET

RST

RST

RST

I00102

Y00433

I00103

I00104

Y00433

I00103

I00104

F0702.EPS

I00101

I00102

I00103

I00104

Y00433

X00401

F0703.EPS

Figure 7.3 Parameter Setting Program Time Chart

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 46

7.1.3 Error Reset

This resets the error status of the positioning module.

Item to Note:

- The positioning module ignores any commands other than the Error Reset command

and Set Parameter command in an error status (i.e. the status where the Error Notification input relay is set). So be sure to execute the Error Reset command in an error

status. However, if an error occurs because of an entry parameter setting error (error

code 2) in the Set Parameter command, the error cannot be reset using the

Error Reset command. Refer to Section 7.1.2, “Parameter.”

Procedures:

1) Write the command code on the positioning module with the WRITE instruction.

2) Set the Execute Command output relay.

3) Check that the Error Notification relay is reset. Then reset the Execute Command

output relay.

7-5

Program Example:

This example assumes that the Error Reset operation is done manually. All output relays of

the positioning module are reset at the time of the Error Reset operation. The error code

remains until the completion of Error Reset.

● Major devices used

X00433 Execute Command (Output Relay)

Y00401 Execute Command ACK (Input Relay)

X00403 Error Notification (Input Relay)

I00111 Request to Reset Error (Manually Operated Signal)

I00112 Request to Reset Error (Rising Edge)

I00113 Request to Reset Error (Falling Edge)

D0201 Error Code Storage Device

TC070103.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 47

7-6

(0001)

(0002)

00001

(0003)

(0004)

00006

(0005)

(0006)

(0007)

(0008)

(0009)

(0010)

(0011)

00022

Error Reset Program

I00111

I00112 X00403

I00114

Y00433 X00401

DIFU

DIFD I00113

READ 58 D0201 1

WRITE 45

4

RST

RST

RST

SET

SET

RST

I00112

11

Y00434

Y00435

Y00436

Y00433

I00114

Y00433

1

(0012)

I00113

Figure 7.4 Error Reset Program

I00111

I00112

I00113

Y00433

X00401

X00403

Figure 7.5 Error Reset Program Time Chart

F0705.EPS

RST

I00114

F0704.EPS

IM 34M6H55-01E 3rd Edition : Apr 1, 2002-00

Page 48

7.1.4 Jog Stepping

When the Positive- (Negative-) direction Jog Stepping output relay is on, the motor rotates

in the positive (negative) direction.

Items to Note:

- This command is accepted only if all of the following conditions are satisfied: (1) it is

not in an error state, (2) it is in the End of Positioning status and (3) no other command

is being executed. Otherwise, it is ignored.