Page 1

L-nSERIES

SGDH

DeviceNet

USER1S'

MODEL:

JUSP-NS310

INTERFACE

MANUAL

UNIT

'

..

/

i

~i

/

YASKAWA

MANUAL NO; SIE-C718-7

Page 2

/

"

Page 3

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precau-

tions provided

ucts

or

to related equipment and systems.

&

WARNING

Safety

in

this

manual

Indicates precautions that, if not heeded, could possibly result in loss

serious injury.

can

result

in

serious

or

possibly even

fatal

injury

or

damage

Infonnation

to

the

prod-

of

life

or

&

Caution

Indicates precautions that, if not heeded, could result in relatively serious

injury, damage to the product,

or

faulty operation.

or

minor

©Yaskawa,

All rights reserved. No part

or

by any means, mechanical, electronic, photocopying, recording,

Yaskawa. No patent liability

Yaskawa

/

change without notice. Every precaution has been taken

sumes no responsibility for errors

information contained in this publication.

2000

of

this publication may

is

assumed with respect to the use

is

constantly striving to improve its high-quality products, the information contained in this manual is subject to

or

omissions. Neither

be

reproduced, stored in a retrieval system, or transmitted,

or

otherwise, without the prior written permission

of

the information contained herein. Moreover, because

in

the preparation

is

any liability assumed for damages resulting from the use

iii

of

this manual. Nevertheless, Yaskawa as-

in

any form,

of

of

the

Page 4

Visual Aids

The

following aids are used to indicate certain types of information

for

easier reference.

/

",EXAMPLE~

(.1

INFO

I>

I

IMPORTANT

II.

T.EI~s

Indicates application examples.

Indicates supplemental information.

I Indicates important information that should be memorized

1 • Explains difficult

to

understand terms and terms that have not been explained before.

/

..

/

iv

Page 5

Visual

Aids

Overview

Using

This

OVERVIEW

..................••....•........••.............

....

, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual

.......................•.......•.......

OVERVIEW

, . .

iv

xi

xii

TABLE OF CONTENTS

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Checking Products and Part Names

1.1

Checking Products on Delivery

1.2

Product Part Names

1.3

Mounijng the NS310

2

Installation....................................

2.1

Storage Conditions

2.2 Installation Site

2.3 Orientation . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . 2 - 3

2.4

Installation...............

3 Connectors

3.1

Connecting to Peripheral Devices

3.2

SERVOPACK Internal Block Diagrams. . . . . . . . . . . . . . . . . . . . . 3 - 5

3.3

VO

Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

3.4 Connections for DeviceNet Communications 3 -

4 Parameter Settings

4.1

Parameter Outline

.....................................

............

....................................

Unit................................

.....................................

............

__

.. " ___

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

...... _ .. .. .. ..

............

......................................

........

__

............

'.

. . . . . . . . . . . . . . 1 - 2

.. .. .. .. ..

. . . . . . . . . . . . . . . . . 3 - 2

........ _ .. ..

. 3 - 1

. 4 - 1

4.2 Parameters Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

4.3 Parameter Details

......................................

vii

1 - 1

1 - 4

1 - 5

2 - 1

2 - 2

11

4 - 2

4 -

11

5 DevlceNet Communications

5.1

Specifications and Configuration

5.2 DeviceNet Communications Setting Switches. . . . . . . . . . . . . . . 5 - 4

5.3 Command/Response

5.4 Commands from the Host

5.5 Program FUnction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 24

Changing Parameters and Command Blocks

5.6

6

SG

DH

Parameters

6.1

Parameters and Standard Settings for NS310

Settings According to Equipment Characteristics

6.2

6.3 Settings According to Host

6.4

Setting

Up

the SERVOPACK

/

6.5 Setting Stop Functions

6.6 Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 17

6.7

Digital Operator

v

Format.

........ _ .. . ..

.................................

........................................

....

___

........

..........................

. .

..

. . . . . . .

..

. .

Controller. . . . . . . . . . . . . . . . . . . . . . . 5 - 15

...............

.. .. ..

Units.........

Controller . . . . . . . . . . . . . . . . . . . . . . 6 - 6

.............................

..

. . . . .

..

.. .. ..

............

___

..

..

. . . . 5 - 7

. 6 - 1

.

5 - 1

5 - 3

5 - 34

6 - 2

6 - 4

6 - B

6

-12

6 -

21

Page 6

7 Using the NSxxx Setup Tool

7.1

Connection and Installation

7.2

How

to

Use

......................................

..............................

.................

..

. 7 • 1

......

/

7 - 2

7-3

8 Ratings, Specifications, and

B.1

Ratings and Specifications

8.2 Dimensional Drawings

9

Troubleshooting...............................

9:

1 Troubleshooting Problems

9.2 Troubleshooting Problems

Alann

9.3

9.4

A DevieeNet Object Model

Display Table

Waming

Displays

B DeviceNet Attributes

C Alarm

and

Warning Codes

.................................

..............................

......................

..

.....

Dimensions.

.......

. . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

with

Alarm Displays

with

No Alarm

...

.. .. .. ..

.'..............................

..............

. . . . . . . 8 • 1

, . 8 - 3

.............

~jsplay

..

...........

. . . . . . . 9 -

..

. .

..

. . . . .

..

. . . . 9 -

.. . .. ..

..

.. . ..

.. ..

. . . . . . . . . . . . . . . . . C - 1

9 • 1

9 - 2

9 - 19

21

24

A-I

B-1

/

vi

Page 7

TABLE

OF CONlENTS

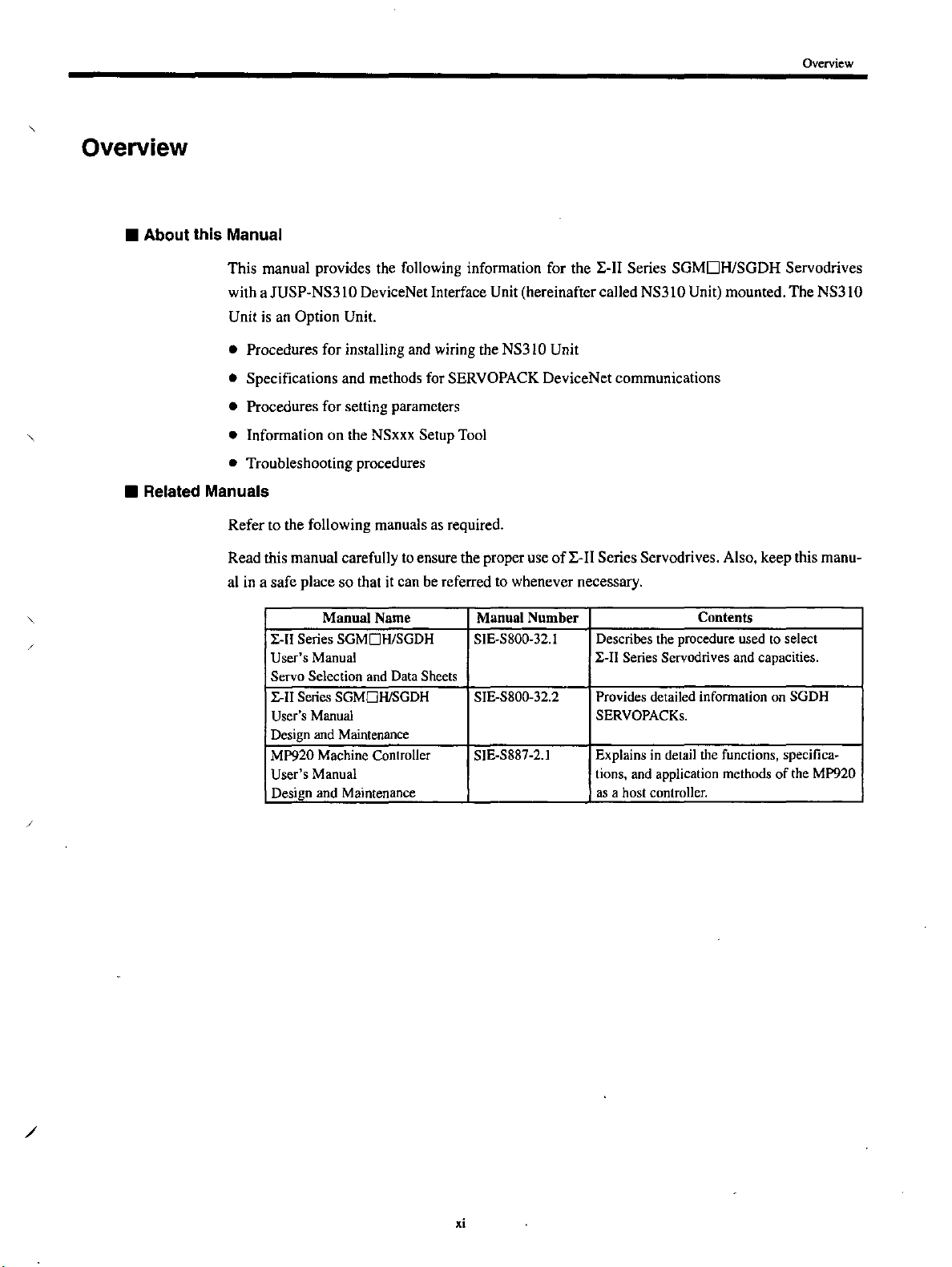

TABLE OF CONTENTS

Visual Aids

.....................................................

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Using This Manual

1 Checking Products and Part Names .

1.1

Checking Products

1.2 Product Part Names

1.3 Mounting the NS310

2 Installation .

2.1

Storage Conditions. . .

2.2 Installation Site

..............................................

...................

on

Delivery

.............................

........................................

Unit...................................

..........................................

.. . .. ..

............................................

. . . .

..

. . . . .

..

. . . . .

.. . ..

..

. . . . . . 2 - 2

2.3 Orientation

2.4 Installation

3 Connectors .

.........................................

iv

xii

1 - 1

1 - 2

1 - 4

1 - 5

2 - 1

2 - 2

2-3

2-4

3 - 1

3.1

Connecting to Peripheral Devices

3.1.1 Single·phase (100 V or 200

3.1.2 Three·phase 200 V Main Circuit Specifications. . . . . . . .

V)

Main

3.2 SERVOPACK Internal Block Diagrams

/

3.3 1/0 Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

3.3.1 Connection Example of

3.3.2

I/O Signals Connector

3.3.3 I/O Signal Names

3.3.4 Interface Circuits. . . . .

1/0

Signal Connector (CN1)

(CN

1)

...........................................

and

Functions. . . . . . .

..

. . .

..

. . . . . . . . . . . . .

3.4 Connections for DeviceNet Communications . .

3.4.1 DeviceNet Communications Connection Example

3.4.2 DeviceNet Communications Connectors (CN6)

3.4.3 Precautions for Wiring DeviceNet

3.4.4 Grounding

4 Parameter Settings

4.1

Parameter Outline

4.1.1

/

What Are Parameters?

4.1.2 Parameter Types

4.1.3 Editing Parameters. . .

4.1.4 Effective Timing

...........................................................

...................................

..........................................

...............................................

.....................................................

..

. . . . . . . . . . . . . . .

......................................................

...........................

Circui1

Specifications. . . .

.......................

..

. . . . . . .

..

. . . . .

...........................

Cables. . . . . . . .

..

. .

..

. .

.. ..

..

..

. . . . . . . . . . . . . . . . . . 3 • 4

.......................

..

. . . . .

..

. . . . .

..

..

. . . . . .

.. .. ..

,.

. .

...

....

.........................

..

. . . . . . . .

.. . .. ..

.. .. ..

. .

..

. . .

..

3 - 2

. . .

...

. .

3·3

3 - 5

3 • 6

3 • 7

. . . .

..

. .

3·8

. . .

..

. . . 3 • 9

..

. . 3 -

. . . . . . . . . 3 • 15

11

3 •

11

3 • 13

3 • 18

4 - 1

4 - 2

4·2

.

4 • 2

. . . . . . . . 4 • 3

4 • 4

vii

Page 8

4.2 Parameters

4.2.1

Unit Parameters

4.2.2 Homing Parameters

4.2.3 Machine System and Peripheral Device Parameters

4.2.4 Speed, Acceleration, and Deceleration Parameters

4.2.5 Positioning Parameters

'Tables

.....................................................

..................................

.....................

:

...............

......................

.......................

'

...........................

4·5

/

4-5

.

4-5

.

4-7

.

4-8

.

4 -

10

.

4.3 Parameter Details

4.3.1

Unit Parameters

4.3.2 Homing

4.3.3 Machine System and Peripheral Device Parameters

4.3.4

Speed, Acceleration,

Positioning Parameters

4.3.5

Parameters

5 DeviceNet Communications

5.1

Specifications

5.1.1

Specifications

5.1.2 Control Configuration

.........................................

.....................................................

... : ...............................................

and

Deceleration Parameters

.....................

:

1

..... ; .....................

and

Configuration

.......................................................

......................

.....

. '

:

5.2 DeviceNet Communications Setting Switches

5.2.1

Rotary Switch Settings for Setting' Node Address

5.2.2 Rotary Switch Settings for Setting Baud Rate

5.2.3 LED Indicators

5.3 Command/Response Format .

5.3.1

Command Format.

5.3.2 Command Data Specifications

5.3.3 Response Format

......................................................

.............................

........... .-.......................................

.........................

.........................

","

:

.......................

.......................

..........................

......................

............

'.'

............

...............

.........................

.'

.......................

:

................

..........................

..

.

4

·11

4 -

11

.

4

-14

.

4

-18

.

4

-24

.

4

-35

.

5 • 1

5·3

.

5-3

.

5-3

.

5·4

.

5-4

.

5-5

.

5-5

.

5·7

5-7

.

5-9

.

5 -

.

11

/

5.4 Commands from the Host Controller

5.4.1

Positioning

5.4.2 Continuous Rotary Operation

5.4.3 Homing

5.4.4 Hard

5.4.5 Deceleration and Stop Operation

5.4.6 Emergency Stop Operation

5.4.7 Hardware Limit Operation

5.4.8 Software Limit Operation

5.5 Program Function .

5.5.1

Outline

5.5.2 Command Blocks

5.5.3 Command Block Links

5.6 Changing Parameters

5.6.1

DeviceNet Data Management

5.6.2 Editing Parameters

5.6.3 Editing Command

5.6.4 Organizing Data

...........................................

..........................................

...............

Stop Operation

."

.............................................

...............

..................

.............

...................

:

.................................

............ : ..........................

'.'

...................

.............................................................

.....................................................

................................................

and

Command Blocks

.........................................

...................................................

Blocks

.....................................................

..................

viii

..

1

•••• ; •••••••••••••••••

,'

..............

:

..........................

..............................

:

..........................

:

.....................

................

."

..........................

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5

·15

5 -

15

5

-16

5 - 18

5

-20

5 -

21

21

5 5 -

22

5 - 23

5·24

5

-24

5 -

26

5 -

32

·34

5

5 -

34

5 - 35

5

-37

37

5 -

Page 9

6

SGDH

6.1

Parameters and Standard Settings for NS310 Units

6.1.1

6.1.2 Standard Settings for

Parameters

Parameters

....................................

..........................................................

CN1

I/O

Signals.

. . . . .

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

TABLE

...........

OF

CONTENTS

6 - 1

6 - 2

6 - 2

6.2 Settings According to Equipment Characteristics .

6.2.1

Switching Servomotor Rotation Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

6.2.2 Stop Mode Selection

6.3 Settings According to Host Controller

6.4 Setting Up the SERVOPACK

6.4.1

Parameters

6.4.2 Input Circuit Signal Allocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Output Circuit Signal Allocation

6.4.3

..........................................................

6.5 Setting Stop Functions

6.5.1

Using the Dynamic Brake

6.5.2 Using the Holding Brake

6.6 Absolute Encoders

6.6.1

Selecting

6.6.2

Absolute Encoder Setup

Multiturn Limit Setting

6.6.3

an

Absolute Encoder

6.7 Digital Operator

6.7.1

Connecting the Digital

6.7.2 Limitations

6.7.3 Panel Operator Indicators

in

Using a Hand-held Digital

at

Servo

OFF.

. . . . . . . .

..

. . . . . . .

.......................

................................

.........................................

.....................................

..............................................

....................................

.........................................

.........................................

...............................................

.................................................

............................................

Operator.........................................

Operator........

..................................

__

..

. . . . . . . . .

..................

','

. . . . . . . . . 6 - 4

..

. . . . . . . 6 - 4

,..........

..

. . .

..

. . . 6 -

6 - 6

6 - 8

6 - 8

6 - 9

6 - 12

6 - 12

6 - 13

6 - 17

6 - 17

6 - 18

6 - 18

6 -

21

6 -

21

6 -

21

21

7 Using the NSxxx Setup

7.1

Connection and Installation.

7.1.1

Connecting the NS310 Unit

7.1.2 Software Installation. . . . . .

7.2 How to Use

7.2.1 Screen Configuration at Startup. . . . .

7.2.2 Functions Configuration. . . . . . . .

................................................

8 Ratings, Specifications,

8.1

Ratings and Specifications

8.2 Dimensional Drawings. .

8.2.1

NS310 Unit

9 Troubleshooting

9.1

Troubleshooting Problems with Alarm Displays

9.2 Troubleshooting Problems

..........................................................

...........

Tool

............................................

...

...........................

.. .. . ..

. . .

..

...

and

. . . . . . . .

. . . . . . . .

.. ..

. . . . . . . .

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

. . .

..

. . .

..

..

. . . . . . . .

Dimensions

..

. .

. . . . . . . . . . . . . . . . . .

..

.................................

.. ..

. . . . .

..

. . . . .

.. .. ..

...........................

with

No Alarm

Display............

.. . ..

.. ..

..

. .

..

. . .

..

. . .

..

...............

. .

.. .. .. ..

..............

..

7 - 1

. . 7 - 2

7 - 2

7 - 3

..

. . 7 - 3

. . . 7 - 5

8 - 1

8 - 2

..

8 - 3

8 - 3

9 - 1

9 - 2

9

-19

/

9.3 Alarm Display Table

9.4 Warning Displays

........................................

..........................................

9 -

21

9 - 24

ix

Page 10

A DeviceNet Object Model

............................

/

, A - 1

B DeviceNet Attributes

B.l

Identity Object (OxOl)

B.2 Message Router Object

B.3 DeviceNet Object

B.4

Assembly Object

B.5 Connection Object

B.6 Position

B.7 Position

B.8

Block

B.9 Command Block Object

B.l0

Control Parameter Object

B.ll

SERVOPACK Parameter Object

Controller Supervisor Object

Controller Object

Sequencer Object

(Ox03)

(Ox04)

(Ox05)

...•.....•..

.•..............

(Ox02)

..............

..........••........••..•.........•.

(Ox26)

(Ox27)

........

....•.... : ..

(Ox25)

...••............•..•.......•

............•.................

(Ox64)

(Ox66)·.....

, . . . . . . . . . . . . . . . . .

>

....•.........

:......................

.'......................

:.

. . . • .

..

(Ox24)

.....

-...

...........................

....

. . . . . . . . . • . • • . . . . . . . . B - 9

. . . . . . . • . . • .

..

B-1

,......

. • . • • . • . • . . . . . B - 6

, . • • . . . . . . . . . B - 8

•. . ..

B-2

B-3

B - 4

B - 5

B - 12

B - 13

B

-14

B - 18

/

C Alarm and Warning

C.l

Alarm Codes

.......•.•.......••.........•....•.••••......•

Codes.

. . . • . . .

..

. . . . • . . . . . . . . . .

..

C - 1

C - 2

x

Page 11

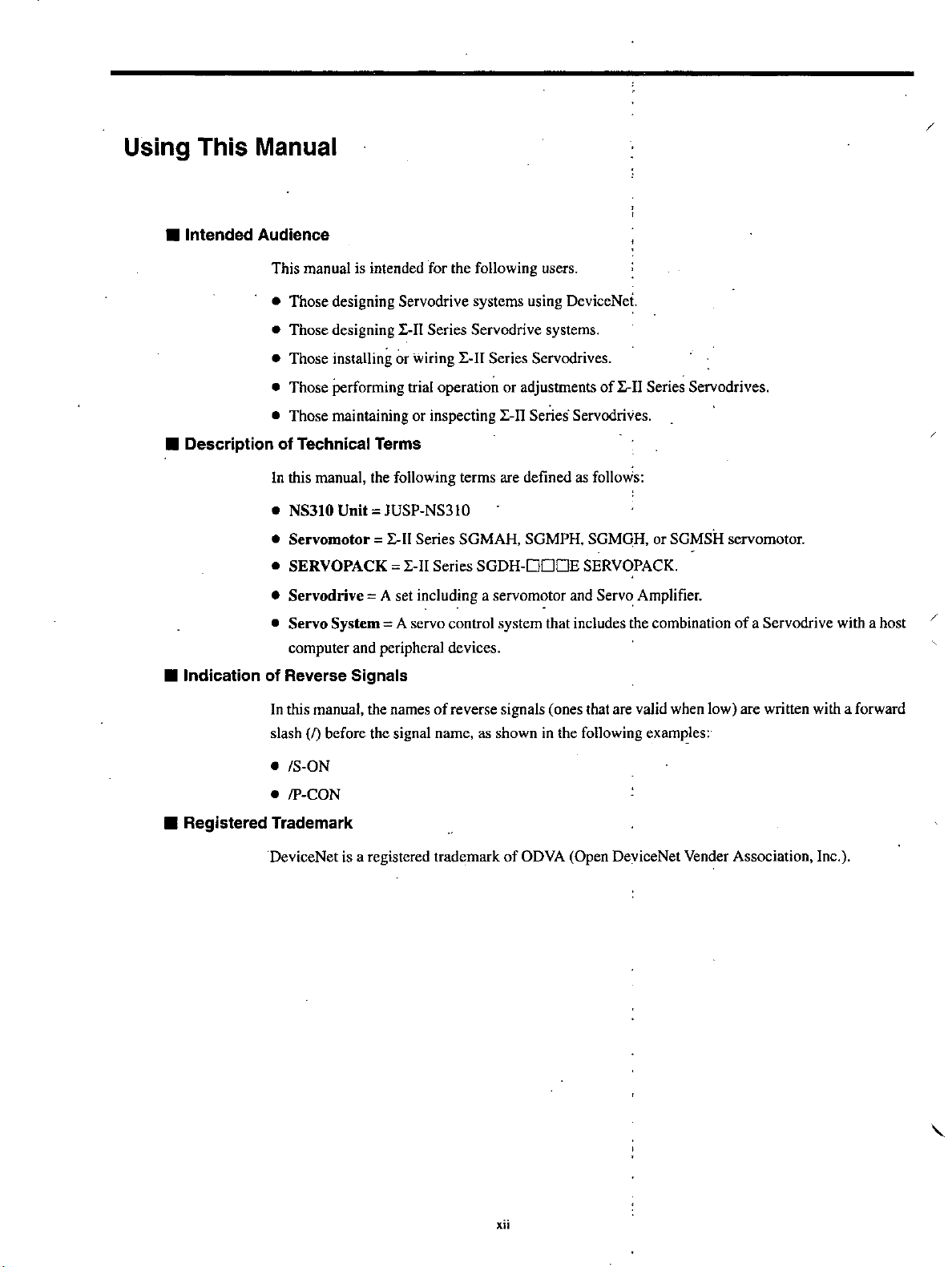

Overview

• About this Manual

Overview

This manual provides the following information for the

with a

Unit is an Option Unit.

Procedures for installing and wiring the NS3

•

Specifications and methods for SERVOPACK DeviceNet communications

•

• Procedures

• Information on the NSxxx Setup Tool

• Troubleshooting

• Related Manuals

Refer to the following manuals as required.

Read this manual carefully to ensure the proper use

in

a safe place so that it can be referred to whenever necessary.

al

I:-II Series

SGMDHlSGDH

Servodrives

JUSP-NS31O DeviceNet Interface Unit (hereinafter called NS3 10 Unit) mounted. The NS3 10

10

Unit

for

setting

parameters

procedures

ofI:-I1 Series Servodrives. Also, keep this manu-

Manual

L-II Series SGMOHlSGDH

User's

Manual

Servo

Selection

L-II Series SGMOHlSGDH SIE-S800-32.2

User's

Manual

Design

and

MP920

Machine

User's

Manual

Design

and

Name

and

Data

Maintenance

Controller

Maintenance

Sheets

Manual

SIE-S800-32.1

SIE-S887-2.1

Number

Describes

1;-11

Series

Provides

SERVOPACKs.

Explains

tions.

as

a

host

detailed

in

and

controller.

Contents

the

procedure

Servodrives

information

detail

the

application

used

and

capacities.

functions,

methods

to

select

on

SGDH

specifica-

of

the

MP920

/

xi

Page 12

Using This Manual

• Intended Audience

This manual is intended for the following users.

• Those designing Servodrive systems using DeviceNei.

• Those designing 1:-II Series Servodrive systems.

• Those instaIJing or wiring 1:-II Series Servodrives.

/

• Those Performing trial operation or adjustments

• Those maintaining or inspecting

• Description

of

Technical Terms

In

this manual, the following terms are defined as follows:

• NS310

•

Servomotor

•

SERVOPACK = 1:-11

•

Servodrive

Unit

• Servo System = A servo control system that includes the combination

computer and peripheral devices.

• Indication

of

Reverse Signals

In this manual, the names

(f) before the signal name, as shown in the following examples:

slash

• IS-ON

• /P-CON

• Registered Trademark

of

1:-11

Series Servodrives.

1:-11

Series Servodrives.

= JUSP-NS31O

= 1:-II Series

SGMAH,

Series

SGDH-DDDE

SGMPH, SGMGH, or SGMSH servomotor.

SERVOPACK.

= A set including a servomotor and Servo Amplifier.

of

reverse signals (ones that are valid when low) are written with a forward

of

a Servodrive with a host

DeviceNet

is a registered trademark

of

ODVA (Open DeviceNet Vender Association, Inc.).

xii

Page 13

Safety Precautions

The following precautions are for checking products upon delivery, installation, wiring, operation,

maintenance

• Checking Products upon Delivery

and

inspections.

& CAUTION

Safety

Precautions

•

Installation

• Wiring

• Always use the servomotor and SERVOPACK in one

Not

doing

so

may

cause

fire

or

malfunction.

of

the specified combinations.

& CAUTION

• Never use the products in an environment subject to water, corrosive gases, inflammable gases,

or combustibles.

Doing

so

may

result

in

electric

shock

or

fire.

& WARNING

• Connect the SERVOPACK ground terminal effectively to a system grounding conductor or

(100

II

grounding electrode

Improper

grounding

may

or less).

result

in

electric

shock

& CAUTION

or

fire.

•

Do

not connect a three-phase power supply to SERVOPACK U,

Doing

sO

may

result

in

injury

or

fire.

• Securely fasten the power supply terminal screws and motor output terminal screws.

Not

doing

so

may

result

in

fire.

V,

or W output terminals.

/

xiii

Page 14

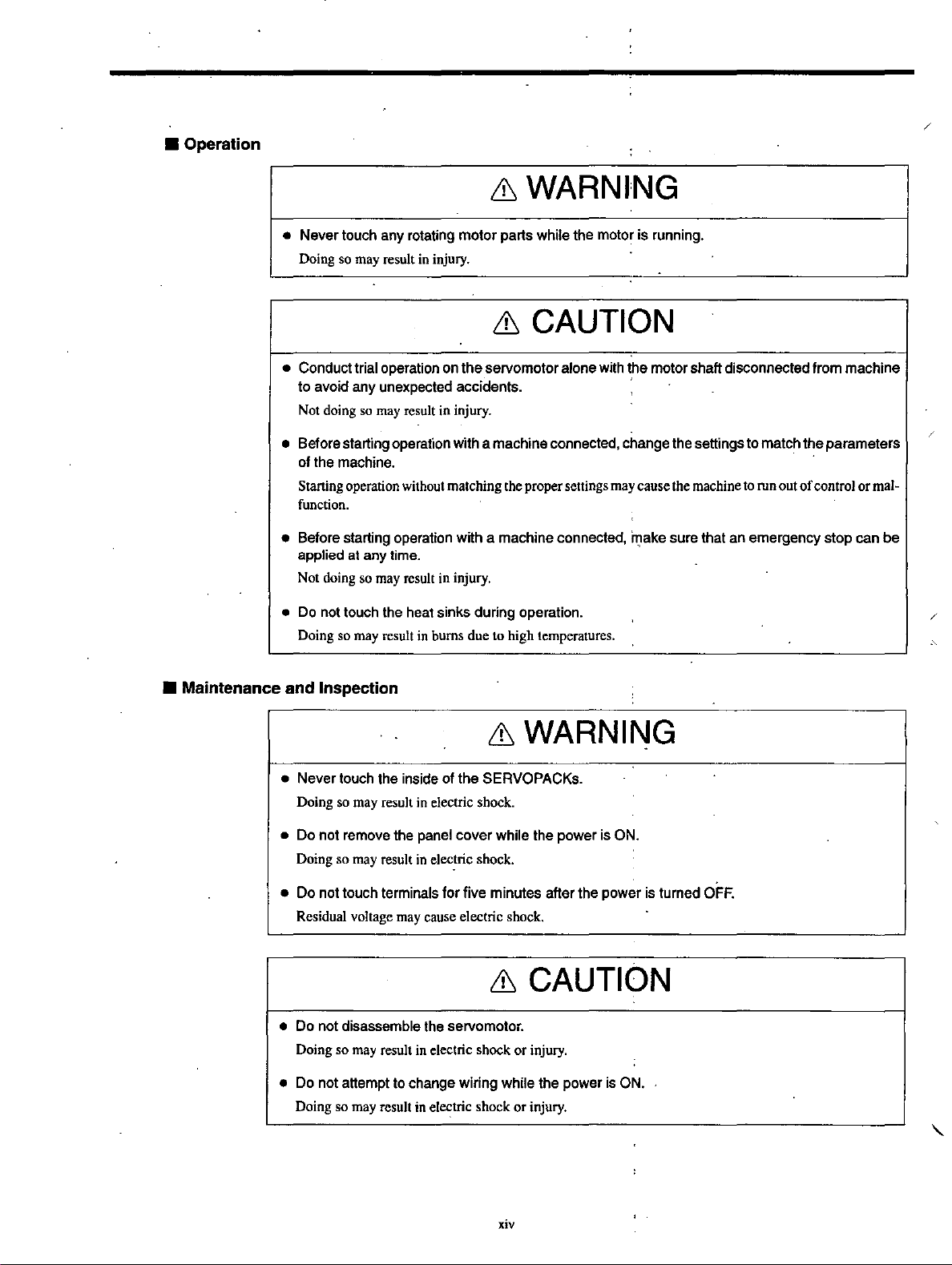

• Operation

/

& WARNING

• Maintenance

• Never touch any rotating

Doing so

may

result

in

motor

injury.

parts while the motor is running.

& CAUTION

• Conduct trial operation on

to

avoid any unexpected accidents. .

Not

doing

so

may

result

• Before starting operation with a machine connected, change the settings

of the machine.

Starting

function.

• Before starting operation with a machine connected,

applied at any time.

Not

•

Do

Doing

and

operation

doing

so

may

not

touch

the

so

may

result

Inspection

without

result

heat

in

bums

the

servomotor alone with the motor shaft disconnected from machine

in

injury.

matching

in

injury.

sinks

during

due

the

operation.

to

high

proper

settings

temperatures

may

.

cause

",ake

the

machine

sure that

an

to

match

the

parameters

to

run

out

of

control

or

emergency stop can

mal-

be

& WARNING

• Never touch the inside of

Doing

so

may

result

• Do not remove the panel cover while the power is ON.

Doing

so

may

result

• Do not touch terminals for five minutes after the power is turned OFF.

Residual

voltage

may

in

electric

in

electric

cause

the

SERVOPACKs.

shock.

shock.

electric

shock.

& CAUTION

• Do not disassemble the servomotor.

Doing so

• Do not attempt to change wiring while the power is ON.

Doing

so

may

may

result

result

in

electric shock

in

ele~tric

shock

or

or

injury.

injury.

xiv

Page 15

• General Precautions

Safety Precautions

Note

•

The

drawings

guards. Always replace the cover or protective guard as specified first, and then operate the

products

• The drawings presented in this manual are typical examples and may not match the product you

received.

• This manual is subject to change due to product improvement, specification modification, and

manual improvement. When this manual is revised, the manual code is updated and the new

manual is published as a next edition. The edition number appears on the front and back covers.

•

If

tive or one

• Yaskawa will not take responsibility for the results

uct. Yaskawa shall not be liable for any damages or troubles resulting from unauthorized modifi-

cation.

in

accordance

the manual must

of

the offices listed on the back

the

following

presented

in

this

with

the

manual.

be

ordered due to loss or damage, inform your nearest Yaskawa representa·

manual

to

ensure

are

of

this manual.

safe

sometimes

of

unauthorized modifications

application.

shown

without

covers

or

protective

of

this prod-

/

xv

Page 16

/

Page 17

Checking Products and Part Names

This chapter describes the procedure for checking l:-II Series products and

NS3l

the

1.1

1.2

1.3

0 Unit upon delivery.

Checking

Product

Mounting

Products

Part

the

It

Names

NS310

also describes the names

on

Delivery

.........

..................

Unit

of

product parts.

.

.

1 - 2

1 - 4

1 - 5

/

I

·1

Page 18

Checking Products and Part Names

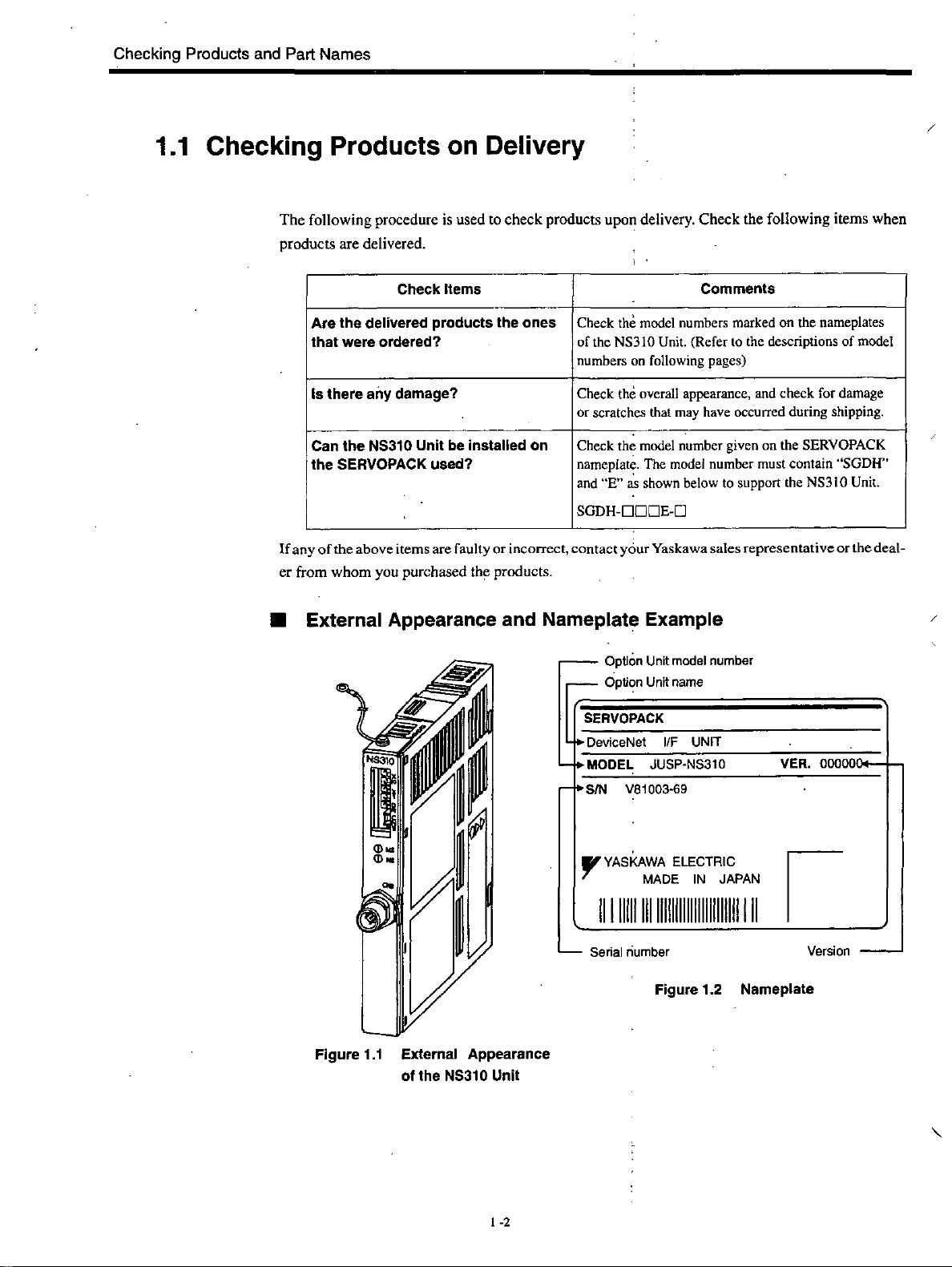

1.1 Checking Products

The

following procedure is used to

products are delivered.

on

Delivery

check

products upon delivery.

Check

the following items when

/

Check Items

Are the delivered products the ones

that were ordered?

Is

there any damage?

Can the

the SERVOPACK used?

If

any

of

er

from

NS310

Unit

be

the

above

items

are

faulty

whom

you purchased the products.

installed on

or

incorrect,

Check

the

model numbers marked on the nameplates

NS310

of the

numbers on following pages)

Check the overall appearance, and

or

scratches that may have occurred during shipping.

Check the

nameplate. The model number must contain

and

SGDH-DDDE-D

contact

model

"E"

~s

shown below to support

your Yaskawa

Comments

Unit.

(Refer to

number given

sales

• External Appearance and Nameplate Example

r--

pon

_

Opti~n

SERVOPACK

"OeviceNet

• MODEL

•

SIN

mmoenumer

Unit

name

I/F

JUSP-NS310

V81003·69

UNIT

the

descriptions of model

check

for damage

on

the

SERVOPACK

the

NS310

representative

VER.

00000

"SGDH"

Unit.

or

the

deal-

Figure

1.1

External Appearance

NS310

of the

Unit

1·2

"YASKAWA

111111111111111111111111111111111111

Senal

-

ELECTRIC

MADE

number

IN

JAPAN

Figure 1.2 Nameplate

I

Version

-

Page 19

• Model Number

NS310 Unit

1.1

JUSP - NS31 0

Checking

Products

on

Delivery

SERVOPACK

Type

NS31:

peripheral device

01

device:

DeviceNet

Interface

~

Unit

~

L

Design

Revision Order

/

1·3

Page 20

Checking Products and Part Names

1.2 Product Part Names

The following diagram illustrates the part names of theNS310 Unit.

Ground

wire:

Conect

to

SERVOPACK.

the

terminal

ma'rked

"G~

on

the

~

SGDH

'L_-

Rotary switches

Used

to

Rotary Switch (SW3):

Used

to

set

set

(SWt,

the

DeviceNet

the

baud

SW2):

rate

node

for

DeviceNet.

address.

"6iMtl-l--- Connector for RS-232C communications (CN11):

Used

to

communicate

LEO

(MS):

Module

LED (NS): Network Status LED indicator

Connector

Micro

for

Connector

with

Status

DeyiceNet

for

DeviceNet

the

NSxxx

Setup

LED

indicator

communications

Communications.

Tool.

(eN6):

Figure 1.3 NS310 Unit

1-4

Page 21

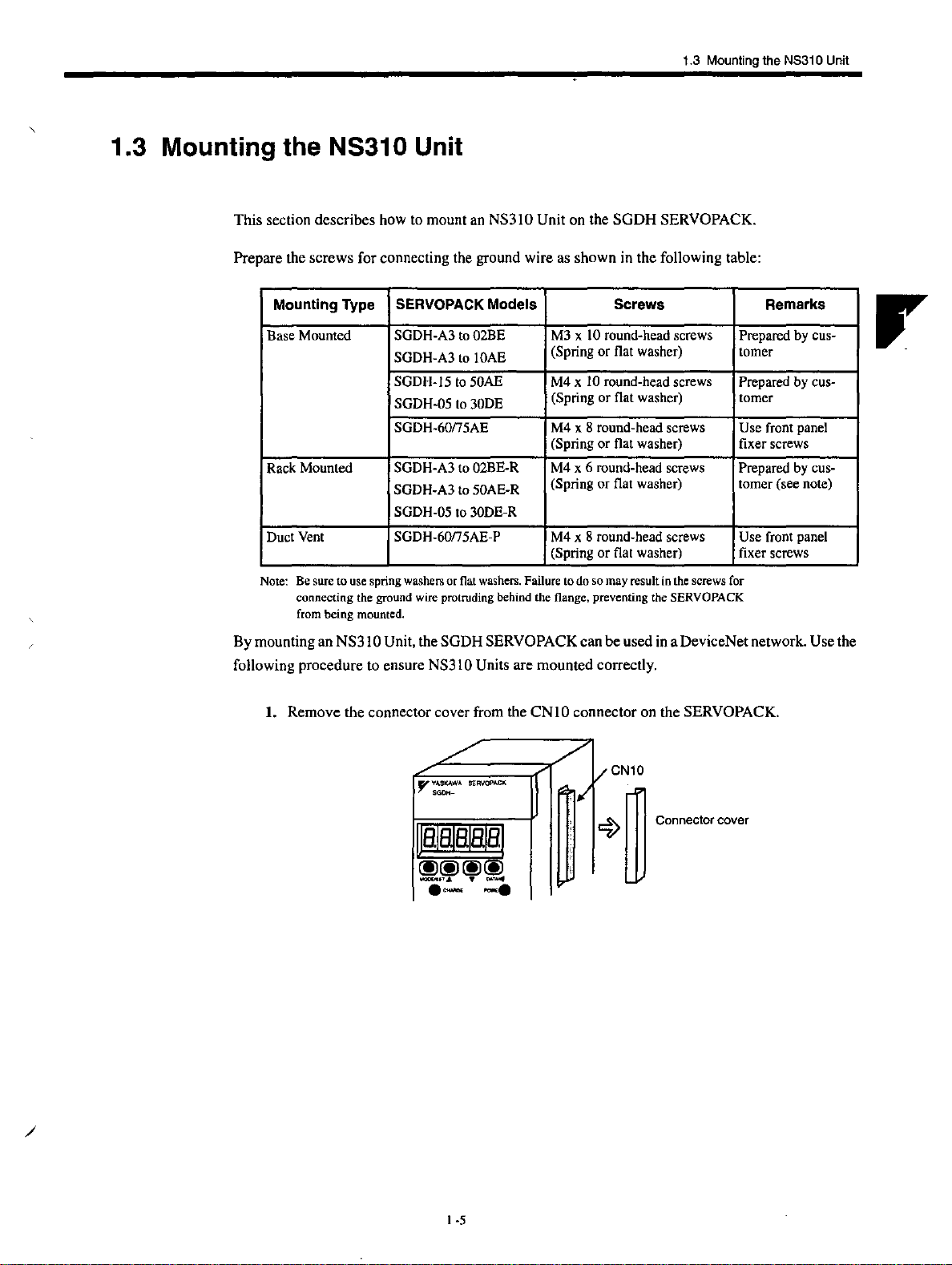

1.3 Mounting the NS310 Unit

1.3 Mounting the NS31 0 Unit

This section

Prepare the

describes

screws

Mounting Type SERVOPACK Models Screws Remarks

Base Mounted SGDH-A3

Rack

Mounted

Duct

Vent

how to mount an NS310 Unit on the

for connecting the ground wire as

to

02BE

SGDH-A3

SGDH-15

SGDH-05

to

to

to

lOAE

50AE

30DE

SGDH-60mAE

M3 x 10

(Spring or flat washer)

M4 x 10

(Spring or flat washer) torner

M4

(Spring

SGDH-A3

SGDH-A3

SGDH-05

SGDH-60mAE-p

to

02BE-R

to

50AE-R

to

30DE-R

M4

(Spring

M4

SOOH

shown

in the following table:

round-head

round-head

x 8

round-head

or

flat

washer)

x 6

round-head

or

flat

washer)

x 8

round-head

SERVOPACK.

screws

screws

screws

screws

Prepared by cus-

temer (see note)

screws Use

(Spring or flat washer)

Note:

Be

sure

to

use

spring

washers

or

flat

washers.

Failure

to

do

so

may

result

in

the

screws

for

By

mounting an

following

connecting

from

procedure

the

ground

wire

being

mounted.

NS310

Unit, the

SODH

to ensure NS310 Units are

protruding

behind

SERVOPACK can

the

flange. preventing

mounted

the

SERVOPACK

be

used in a DeviceNet network. Use the

correctly.

Prepared

by

ellS-

tomer

Prepared by cus-

Use

front

panel

fixer screws

front

panel

fixer

screws

1.

Remove

the connector cover from the

CNIO

connector on the SERVOPACK.

/

t

-5

Page 22

Checking Products

a,nd

Part Names

2.

Mount the NS310 Unit on the SERVOPACK.

SERVO

.,.,--.

7

SGDH-

PACK

Connector

I

o.

o.

/

-

3.

For grounding, connect a ground wire

SERVOPACK.

~alBJaalal

~~~~

~

. .

""

'"

POM.'.

30 W to

-<3"

~_

Illi"lIIlD

l/JJ

...

For

SERVOPACK

./

·,.Y~~

•

__

~

-.

of

5.0

kW

"

\//

~

a

Cl!;l!;lCl1l

0

, '

the NS31 0 Unit to the point marked

"""\JIIiI,,/

'-"'"

~

,.",-

Ground

.

wire

-%

"G"

on the

For

SERVOPACK

1-6

6.0

kW

to

7.5

kW

Page 23

1.3

Mounting

the

NS31 0 Unit

When the

in

NS31

the

following diagram.

0 Unit

has

been

mounted correctly. the SERVOPACK will appear

as

shown

/

1

-7

Page 24

Page 25

Installation

This chapter describes precautions for

The

SODH SERVOPACKs are base-mounted servo amplifiers. Incorrect

installation will cause problems. Always observe the installation precautions shown in this chapter.

2.1

Storage

2.2

Installation

2.3

Orientation

Installation

2.4

Conditions

Site

.......................

...........................

...........................

~I1

Series product installation.

...................

2-2

.

2-2

.

2-3

.

2-4

.

/

2

-I

Page 26

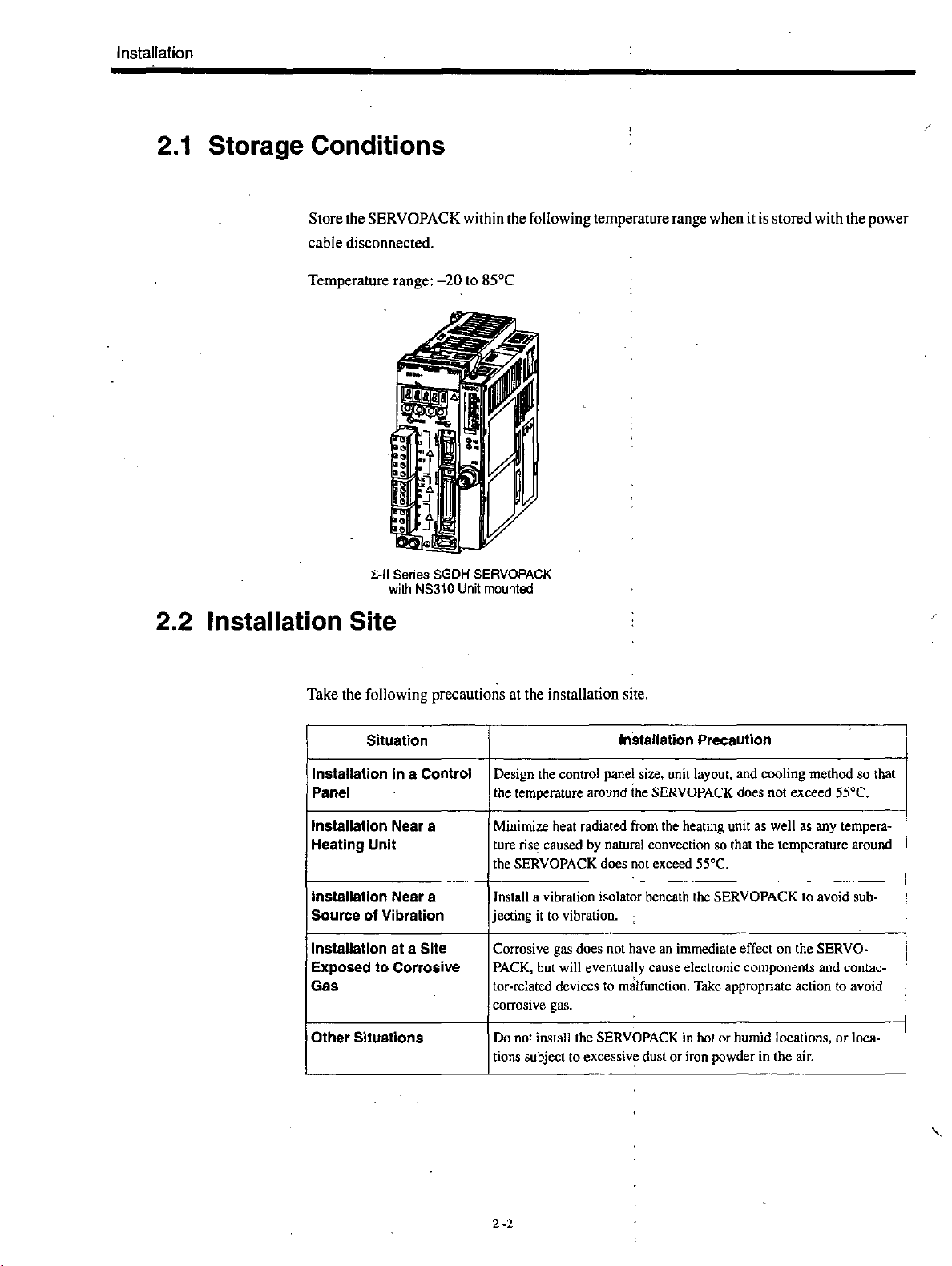

Installation

2.1

Storage

Conditions

Store the SERVOPACK within the following temperature range when it is stored with the power

cable disconnected.

Temperature range:

l:-II Series SGDH SERVOPACK

with

-20

NS310

to 85°C

Unit

mounted

2.2 Installation Site

Take the following precautions at the installation site.

Situation

Installation In a Control

Panel

Installation Near a Minimize heat radiated from the heating unit as well as any tempera-

Heating Unit

Installation Near a

Source

Installation at a Site Corrosive gas does not have an immediate effect

Exposed

Gas

Other Situations

of

Vibration jeeting

to

Corrosive

Installation Precaution

Design the control panel size. unit layout, and cooling method so that

the temperature around

ture

ris~

caused by natural convection so that the temperature around

the SERVOPACK does not exceed 55

Install a vibration isolator beneath the SERVOPACK to avoid sub-

it

to vibration.

PACK, but will eventually cause electronic components and contactor-related devices to malfunction. Take appropriate action to avoid

corrosive gas.

Do not install the SERVOPACK in hot or humid locations,

tions subject to

the

SERVOPACK does not exceed 55°C.

excessiv~

dust

or

'C.

on

the SERVO·

iron powder in the air.

or

loca-

2-2

Page 27

2.3 Orientation

2.3

Orientation

Install the SERVOPACK perpendicular to the wall as shown in the figure.

must

be

oriented this way because it is designed to be cooled by natural convectiori

fan.

Secure the SERVOPACK using2 to 4 mounting holes.

VOPACK

capacity.

The

number

of

holes depends

t t

Wall

Ventilation

The

SERVOPACK

on

or

cooling

the SER-

r

/

2 ·3

Page 28

Installation

2.4 Installation

Follow the procedure below to install multiple SERVOPACKs side by side in a control panel.

50 mm (1.97 in) min.

30 mm (1.18 in) min. 10 mm (0.39 in) min.

50 mm (1.97 in) min.

• SERVOPACK Orientation

Install the SERVOPACK perpendicularto the wall so that the front panel (containing connectors)

faces outward.

• COOling

As shown in the figure above, provide sufficient

by

cooling

fans

or

natural

convection.

sp~ce

around each SERVOPACK for cooling

• Side-by-side Installation

When installing SERVOPACKs side by side as shown in the figure above, provide

(0.39 in) between and at least

ing fans above the

perature inside the control panel.

SERVOPACKs to avoid excessive temperature rise and to maintain even tem-

• Environmental Conditions in the

50

mm

(1.97 in) above and below each SERVOPACK. Install cool-

CO!'!trol

Panel

at

least 10

mm

Oto

• Ambient Temperature:

Humidity:

•

• Vibration:

• Condensation and Freezing: None

• Ambient Temperature for Long-tenn Reliability;

2-4

55°C

90% or less

2

4.9mJs

max.

45°C

Page 29

•

jM

fiii*5MMW

fipM;

#

""*EM

Connectors

This chapter describes the procedure used to connect I:-II Series products

to peripheral devices when an

amples

3.1

of

I/O signal connections.

Connecting to Peripheral Devices

3.1.1 Single-phase (100 V or 200

Main Circuit Specifications

3.1.2 Three-phase

3.2 SERVOPACK Internal Block Diagrams

3.3

110

Signals

3.3.1 Connection Example of I/O Signal Connector

I/O Signals Connector (CN1)

3.3.2

3.3.3

110

3.3.4 Interface Circuits

...........................

(CN1)

....................................

Signal

3.4 Connections for DeviceNet Communications

NS310 Unit

is

mounted and gives typical ex-

.......

V)

..................

200 V Main Circuit Specifications

.................

Names

and Functions

..........

. . . . . . . . . . . . . . . . . . 3 - 9

..............

..

.

.

..

.

.

.

.

3-2

3-3

3-4

3-5

3-6

3-6

3-7

3 - 8

3 -

11

3.4.1 DeviceNet Communications Conneclion Example

3.4.2 DeviceNet Communications Connectors (CN6)

3.4.3 Precautions for Wiring DeviceNet Cables

3.4.4 Grounding

/

3 -I

.................................

......

..

3 -

11

3

-13

.

3 - 14

.

3 - 18

Page 30

Connectors

·3.1

Connecting to Peripheral Devices

This section provides examples

It

also briefly explains how to connect each peripheral device.

of

standard

1:-11

Series product connections to peripheral devices.

3 -2

Page 31

3.1

Connecting to Peripheral Devices

3.1.1

Molded-case Circuit

Breaker

00

Single-phase (100 V

(MCCB)

P<otect,

th,

line

by

overcurrent

detected.

pow·

shuttIng

OFF

er

o the circuit

When

is

&1

Noise

Filter

Used

to eliminate external noise

Irom the power line.

or

Power

supply

Single-phase 200

R • T

""[I;IJ'IPIV

200

VAC

,

,

I

:

I

I

I

I

I

I

I

I

V)

Main Circuit Specifications

Can

Host

be connected to

~mlffi

MEMOCON

(Manufactured by

Digital Operator (See note.)

~~~;n

Personal Computer (See note.)

,

,

,

,

,

,

,

,

,

,

,

GL1201130,

Yaskawa)

DeviceNet

Master.

MP920

JUSP·QP02A·2

Allows

the

user

parameters

tion

display operation or

alarm

Communication

possible

al

computer.

or

references

status.

with a person-

to

opera-

and

is

set

to

also

~

Cable model:

Magnetic Contactor

HI

S'""

Turns

the

servo

ON

and

OFF.

fIj

Power Supply for Brake

Used

brake.

/

Install a surge

suppressor

magnetic conlac-

tor.

lor a servomotor

on

tna

with

a

I I

,---

--- ---

Regenerative Resistor

Connect

-:

to

capacity

:;~~:~::'~;:':t.:~".:,::;:::;::

terminals

81

and

is

insuflicienl.

---:----

---

Regenerative

- _ (option)

resistor

--

--

--- ---

---

Note Used for maintenance. Be sure to coordinate

operation from these devices with controls exerted

by the host controller.

JZSP-CMS01

Encoder

Cable

Encoder

Connector

to 03

3 ·3

Page 32

Connectors

3.1.2 Three-phase 200 V Main Circuit Specifications

3.1.2 Three-phase 200 V Main Circuit Specifications

Breaker (MCCB)

o the circuit

00

Circuit

P,otect, the

9f

line

by

when

overcurrent

is

detected.

pow-

shutting

OFF

r!J

Noise Filter

Used

to

eliminate external

from the power line.

Magnetic Contactor

noise

Noise

Power supply

Three-phase

filter

0

Host

: Controller

Can be connected

to

DeviceNet Master.

~el~o~ij~,U1

MEMOCON

,

,

,

,

,

,

,

200

VAC

T

,

,

,

,

,

,

,

,

..

I

I

I

I

I

I

I

I

(Manufactured

Digital

Personal

Cable model: JZSP·CMS01

Gl1201130, MP920

by

Operator

JUSP·OP02A·2

Allows

parameters or operation references and

display operallon

alarm status .

Communication is

posSible with

al

computer.

Computer

Yaskawa)

(See note.)

the

user

(See

-s

to

03

to

set

to

or

a

~~::::

ON

;'";,'~ta;;It,-;;;;

IJ

Power Su'pply

Used for a

brake.

If

the

capacity

the

tive

For SERVQPACKs

eldemal

and

SERVOPACKs.)

of

wire

between

resistor

to

terminals 81 and

regenerative resistor between terminals

82. (There

is

to'

servomotor

the internal regenerative resistor

tanninsls

82

with

a capacity

no

terminal 83

seriO

and

OFF

~~

II,.

I

for

Brake

with a

II

1:_----_

is

kW

or

higher,

Bl

insufficient,

and

83

and connect an external regenera-

82.

of

6.0

on

these '

----

connect

remove

---

--

. Encoder

Cable

Encoder

Connector

--

--

-- --

--

Note U sed for maintenance. Be sure to coordinate

--

--

---

operation from these devices with controls

by the host controller.

exerted

3-4

Page 33

3.2 SERVOPACK Internal Block Diagrams

The

following sections show an internal block diagram for the SERVOPACK with an NS3 10 Unit.

30 to 400 W 200·V and 30 to 200 W 100·V Models

Single-phase

200

to

230

v:;:

(5ot60Hz)

~--

...,.,

'"

3.2 SERVOPACK Internal Block Diagrams

AC

servomotor

~r;~I~~~~~'~

L.. _ _ Open

(iII'l

D'

, ,

'"------------------------.

during

servo

alarm

Master node

24·V

communications

power

supply

'!'

0------------

,

,

,

.w

,

,

,

...

"N

,

ASIC

(PWM control)

,

I

,

I

,

I

,

L

__

_

Analog

momlor

output

,..-_

,

I

,

I

,

I

,

I

,

L

! I

for

....!:e~sion

DeviceNet

communications

DC to DC

converter

____________________________

-c~~~:~:c::::::f=::::::::~;~:'~'-

::

Digital Operator!

su-

personal

_________

interface

computer

CPU

(position

calculations)

and

speed

--c===;:=====;;!;-

CPU

(position

command

arithmetic

etc.)

commands,

interpretation,

processing,

~,

--'

51Mb"

...

Saud

...

No.

Sequence

va

!.

.

/

3

-S

Page 34

Connectors

3.3.1

Connection Example of

3.3 1/0 Signals

110

Signal Connector (CN1)

This section describes 110 signals for the SERVOPACK with the NS3l 0 Unit.

3.3.1

Connection Example of

The following diagram shows a typical example

Backup

batte~

2.8

to

4.5

V·

+24

Not

used

Forward run prohibited

(Prohibited when OFF)

Reverse run prohibited

(Prohibited when OFF)

Not

used

Home position

Emergency

signal

stop signal

1/0

Signal Coimector (CN1)

of

110

signal connections.

SGDH

SERVOPACK

CNI

BAT

~'--'Tr:

::r

V"'l

~~

+

IP----,+'21

~BAT

-

+24VIN 47

~~-}---~~:::-~

__

~4~1~_~

40

22

3.3kQ

:+-~~1

__

:~t_:~\i

~~~P~-o~T!-,f4~2~_+-_-4:~t_:~{j

I-o~

ZERO

EMSTOP

'-<"";==:::"'F~----i":-!..

*

1.

:P

*

2.

When using an absolute encoder, connect a backup battery only

battery connected to the eNS.

* .3. Make signal allocations using parameters. (Refer to 6.1.2 Standard

CNI/IO

45

~

46

represents twisted-pair wires.

Signals.)

-(";'Ji

:-t

.....

~:

____

'

r1

-::!:-

I

Connector

FG

Connect the shield wire to connector

~_..::c.

<-

.

rt---':~

,<-

.Jrt---':~,AL03

""--~...l..jI

,,'l-":')'~

~:'--'=::'f

It

....

~

i

"____

'r.-_-,2C(.7."

11-:';J:

,f~~i

"----!,i--~2~9."/BK-

:1~~·r.

!:--'£f/

~"!:-:.

_1,;'

__

:1-:~r.

~,--"-.L~ALM+

It-:~:

L_~_~'

__

shell

..

ALOI Alarm code output

37

38

39'

25

26

28

"-30".,,

31

,,"32".fALM-

}

AL02 voltage: 30 VDC

SG

ICOIN+

ICOIN- been completed)

IBK+

S-RDY

I5-RDY-

whcm

Maximum operating

Maximum operating

current: 20

Positioning

(ON when positioning has

Brake output

(ON when brake released)

Servo ready output

+

(ON when ready)

Servo alarm output

(OFF for an alarm)

PhotocQupler output

Maximum

voltage: 30 VDC

Maximum operating

current: 50 rnA DC

shell.

there is

no

Setti~gsfor

rnA

DC

completed

'3

operating

Figure

3.1

110

Signal Connections

3-6

for

CN1

Connectors

Page 35

3.3 1/0 Signals

2

4

6

8

10

12

14

16

18

20

22

24

3.3.2

SO

- -

SO

SO

- -

-

-

-

-

BATH

-

1/0

Signals Connector (CN1)

The following diagram shows the layout

•

CN1

Terminal Layout

I SO

aND

3

5

aND

7

aND

-

-

9

II

13

15

17

-

19

-

BAT (+)

21

Battery H 47 +24VIN

23

-

25

ICOIN+

aND

- -

- -

- -

- -

-

-

- -

Battery (+)

-

Positioning

complete

output

27

29 IS-RDY+

31

33

35

37 ALOI

-

39 AL03

41

-

43

45 ZERO

49

of

IBK+

(Note 3)

ALM+

- -

N-OT

-

eN I terminals.

Brake

inter-

lock

output

Servo

ready

output

Servo

alarm

output

Alarm code

output

(open-eollee-

tor output)

Reverse

prohibited

input

Home

tion

External

power supply

input

run

pasi-

signal

-

Positioning

26 leDlN- complete

output

IBK-

28

(Note 3)

IS-RDY-

30

32 ALM-

34

36

38 AL02

40

Brake

lock output

Servo

output

Servo

output

- -

Alann

output

inter-

ready

alann

code

Forward

P-OT

42

44

46

48

50

EMSTOP

prohibited

input

- -

Emergency

stop signal

- -

drive

Note

1.

Do

not use unused tenninals for relays.

2.

Connect

the

shield

of

the

110

signal

cable

to

the

3.

The

Make

shield

signal

is

connected

allocations

to

the

using

FG

(frame

parameters.

ground)

(Refer

connector

to

shell.

at

the

SERVOPACK-end

6.1.2 Standard Settings

connector.

for

CN1/IO

Signals.)

• CN1 Specifications

Specifications for Applicable

SERVOPACK

/

Connectors

1 0250·52A2J L 50·p

Right

Angle

Plug

Soldered

10

I 50-3000VE

3

-7

10350-52AO-OO8

Receptacles

Case

Manufacturer

Sumitomo 3M Ltd.

Page 36

Connectors

3.3.3 I/O Signal Names and Functions

3.3.3 1/0 Signal Names and Functions

The following section describes SERVOPACK 110 signal names and functions.

• Input Signals

Signal Name

Common

P·OT

N·OT

ZERO

EMSTOP

+24VIN

BAT (+)

BAT

Signal Name Pin

Common

ALM+

ALM-

IBK+

IBKIS·ROY+

IS·ROY-

AL01

AL02

AL03

FG

Position ICOIN+

ICOIN-

Note

1.

Pin numbers in parenthesis 0 indicate signal grounds.

2.

The functions allocated

signals can be changed to feLT.

Pin No.

42

Forward run prohibited I Overtravel prohibited; Stops servomotor

43

Reverse run prohibited beyond the allowable range of motion.

45

External latch signals for home position

46

External signal for emergency stop connected.

47

Control

Allowable voltage fluctuation range:

21

Connecting pin

(-)

22

Connect to either eN8

• Output Signals

No.

31

Servo

32

27

Brake interlock: Output that controls the brake.

28

29

Servo ready: Turns

30

37

Alarm code output: Outputs 3-bit alarm codes.

38

Open-collector:

39

(I)

Shell

to

Connected to frame ground

nector shell.

Positioning completed (output in Position Control Mode):

25

26

error pulses reaches the set value. The setting is

units (input pulse units defined by the electronic' gear).

IBK. IS-ROY. and ICOIN can

NLT,

ffGON,IWARN, or INEAR signals.

Func!ion

when

movable part travels

connect~d.

power

supply input for sequence signals: Users must provide the +24-V power sup-

ply.

11

to 25 V :

for

alarm:

the absolute encoder backup

or

eNI.

Turns OFF

ply

30

when

an

ON

if

there is no servo alarm when the controVrnain circuit

is

turned

ON.

V and

20

rnA rating maximum

if

the shield wire

be

changed via parameters.

error is detected.

battery.

Function

I

I

The

brake is released when this signal is ON.

of

the 110 signal

~he

number

The~K./S-ROY.

cable

1ums

of

error

and ICOIN output

-

is connected to the con-

ON

when

pulses set

the

power

number

in

reference

sup-

of

·8

3

Page 37

3.3.4 Interface Circuits

The

following diagram shows an example

signal

for

a SERVOPACK.

• Sequence Input Circuit Interface

3.3 1/0 Signals

of

connections between a host controller and the 110

The sequence

input

circuit

interface

connects

through a re1ay

Select a low-current relay, otherwise a faulty contact will result.

SERVOPACK SERVOPACK

24VDC 24VDC

50 rnA min.

+ 0

.24VI.

IDEC,

etc.

3.3

kG

i -

li

-~;fl

___

~.

• Output Circuit Interfaces

Any

of

the following three types

circuit at the host controller that matches one

• Connecting to an Open-collector Output Circuit

Alarm code signals are output from open-collector transistor output circuits.

Connect an open-collector output circuit through a photocoupler, relay, or line receiver cir-

cuit.

510

SERVOPACK

end

or----<~ri-_....J

r:I~

12VDC

Pholocoupler

of

SERVOPACK output circuits can be used. Form an input

of

these types .

SERVOPACK

end

so

mA

or

open-collector

min.

3.3kD:

51024

VDC

C~

transistor

Relay

circuit.

OV

5to12VOC

SERVOPACK

end

/

:

•....

3 -9

OV

Note

The

maximum

ties

for

·Voltage:

·Current:

allowable voltage

open-collector

30

VDC

max.

20

rnA

DC

output

max.

and

circuits

current

are

as

capaci-

follows:

Page 38

Connectors

3.3.4

Interface

Circuits

• Connecting to a Photocoupler Output Circuit

Photocoupler

output

circuits

are

used

for

servo

:alann,

servo

ready.

and

other

put signal circuits.

Connect a "hotocoupler output circuit through a relay or line receiver circuit.

5

to

24

voe

SERVOPACK

end

Relay

C-~

.SERVOPACK

end

,'

.....

51012VDC

ov

Note

The

maximum

circuits

.

Voltage:

-Current:

allowable voltage

are

as

follows:

30

VDC

50

rnA

DC

max.

max.

and

current

capacities

for

photocoupler

output

sequence

ov

out-

, .

3 -10

Page 39

3.4

Connections

for

DeviceNet

3.4 Connections for DeviceNet Communications

Communications

This section describes the connection and wiring

of

connectors for

DeviceNet

3.4.1 DeviceNet Communications Connection Example

The following diagram shows an example

NS3IO Unit (CN6) using DeviceNet communications cables.

T-Branch

(with

Adapter

terminator)

T

of

connections between a host controller

T

:

:

T : T·Branch Adapter

communications.

Terminator

Trunk

line

Drop

line

and

an

Figure

3.2

Network

Connections

• Configuration Elements

The network is configured from the following elements.

Nodes

A node is either a slave that connects

ages the

110

of

the slaves. There are no restrictions on the location

node in Figure 3.2 can be the Master or a slave.

to

an NS31 0 Unit or similar Unit, or the Master that man-

of

the Master or slaves.

Any

Trunk Line and Drop Lines

A cable with a terminator on each end is a trunk line. Any cable branching from the trunk line

is a drop line.

Connection Methods

A node is connected using the T-branch method

/

used to connect a node with the T-branch method. A node is directly connected to the trunk line

or

a drop line with the multi-drop method. Both T·branch and multi·drop methods

together in the same network, as shown in

or

multi-drop method. A T-Branch Adapter is

Figure 3.2.

can

be used

3

·11

Page 40

Connectors

3.4.1

DeviceNet

Communications

Terminator

Connection

Example

I

IMPORTANT

Both ends

and ensure stable network communications.

of

the trunk line must connect to terminating resistance to decrease signal reflection

Communications Power Supply

I

The communications connector

supply through the communications cable for DeviceNet communications.

1.

The

2.

3.

Both

Only

lightning

communications

ends

of

DeviceNet devices

arrester.

the

cable

trunk:

line

must

must

can

be a special

connect

be

connected

of

each node must

• Branching from the Trunk Line

There are three methods that can be used to branch from the trunk line.

Single Branching

Trunk

line

Trunk

line

DeviceNet

to a terminator.

to

the

network.

'be

provided with a communications power

cable.

Do

not

connect

any

other

devices,

such

as

a

T·Branch

Adapter

Branching to Three Drop Lines

Direct Node Connection

Trunk

line

-'-;1

Multi-drop

Trunk

line'

:;::~~~7~10~1

;;;.;;

methOd

• Branching from Drop Lines

There are three methods that can be used to branch

3

-12

~om

,

drop lines.

Page 41

Single Branching

Drop

line

Drop

T-Branch Adapter

3.4 Connections for DeviceNet Communications

line

Branching

to

Three Drop Lines

Direct Node Connection

Drop line

Drop

line

3.4.2 DeviceNet Communications Connectors (CN6)

The terminal layout and specifications

of

the CN6 connectors are shown below.

• Connector Specifications

The

following table

a flange attached.

Unit side DeviceNet-compatible

Cable side DeviceNet-compatible

/

shows

the

connector

Name

Micro-style Connector

(male)

Micro-style Connector

(female)

3

-13

specifications.

These

connectors

Model Manufacturer

CM02-8DR5P

Not specified. Not specified.

are metal plated

DDK

with

Page 42

Connectors

3.4.2

DeviceNet

Communications

• Connector Pin Arrangement

Connectors

The

connector

(eNS)

pin

arrangement

is

as

shown

below.;

Pin No.

and

Code

I SHIELD

2

3

4

5

SHIELD

Symbol

24

V 24 V

0(24

V)

CANH

CANL

CANH

,

Connect

o V

CAN bus line dominant H

CAN

to

external

extem~

bus

line

CANL

'the

wire

mesh

communications

communications

dominant

L

OV

Detail

around

power

the

power

cable.

supply

supply

3 ·14

Page 43

3.4

Connections

for

DeviceNet Communications

3.4.3 Precautions

Observe the following precautions when wiring DeviceNet cables.

• Maximum Network Length

The

maximum network length is either the line length between two nodes located farthest from

each other

longer.

IE

T·Branch Adapter

(with

terminator)

for

Wiring DeviceNet Cables

or

the line length between the terminators on the ends

~

The longer of the two distances is the maximum network length .

• 0

T

T

of

the trunk line, whichever is

~

Terminator

: Trunk line

: Drop

line

T :

T-Branch

Adapter

Special DeviceNet cables can be either thick cables or thin cables. The characteristics

of

each

type are given in the following table.

Item

Thick

Signal

decay

Communications

distance

Characteristics

The

maximum network length is determined by the type

Baud

rate

(Kbps)

Slight

Long

distance Short distance

Rigid (difficult

Maximum

Thick

500

250

125

/

100

250

500

Cable

to

cable

Cable

bend)

network

Type

Thin

Cable

Considerable

Pliable (bends easily)

of

cable, as shown in the following table.

length (m)

Thin

cable

100

100

100

3

-15

Page 44

Connectors

3.4.3

Precautions

(')INFO

for

Wiring

DeviceNet

The

I>

the

Baud Rate (Kbps) Maximum Network Length (m)

line

length

250

Note

Cables

connecting

of

each

500

125

LTHICK:

two

nodes

located

farthest

cable

satisfies

LTHICK + LTHIN

LTHICK

LTHICK + 5.0 X LTHIN S 500

Thick

the

conditions

+ 2.5 x

LTHIN

cable length

;;;

100

LTHIN:

• Drop Line Length

The

drop line length is the line lenglh between a branch point on the trunk line to iIle farthest node

Ihat is located on the drop line.

out

into

other

drop

lines.

The

maximum

from

each

othe~

in

the

following

;;;

250

Thin cable lenglh

drop

can

use

both

thick

table.

line lenglh is 6 m. A

and

drop

thin

cables

line

provided

can

be branched

that

• Total Drop Line Length

The

total drop line length is a total

of

all drop line lengths.

Length Limits

The total drop line length

be 6 m or less.

The

allowable range

table.

Baud Rate (Kbps) Total Drop Line Length (m)

500

250

125

39

78

156

oftolal

max.

max.

max.

must

be within the allowable range and even Ihen,

drop

line lenglh varies with Ihe baud rate as

each

shown

drop

line must

in

Ihe following

3 -16

Page 45

3.4

Connections

for

DeviceNet

Communications

TMBranch

(with

terminator)

The following example is for a baud rate

Adapter

T

T

of

500

Kbps.

~f

·1

g~

The above example must satisfy the following conditions .

•

b~6m

.c~6m

T

~h

T :

:

Trunk

Drop

T-Branch

Terminator

line

line

Adapter

·d~6m

•

d+f ~ 6m

• d+e+g ~ 6m

• d+e+h ~ 6m

The total drop line length must satisfy the following condition.

• Total drop line length = a+b+c+d+e+f+g+h ~ 39 m

• Basic Precautions

Basic precautions

o

The

• The communications power supply must have a sufficient margin

o Connect the communications power supply to the trunk line.

o

If

many nodes are provided with power from a single power supply, locate the

supply as close as possible to the middle

o

The

o

The

a drop line is, the

of

/

the allowable current consumption

following equation.

are

as follows:

communications power supply to the network must be

of

the trunk line.

ali ow able current flow in a thick cable is 8 A and that in a thin cable is 3 A.

power supply capacity for a drop line varies with the drop line length.

the thickness

lowerthe

of

the drop line. Obtain the aliowable current (I)

maximum current capacity

of

the drop line and devices connected to it) from the

24

VDC.

in

the capacity.

The

of

the drop line will be regardless

of

the

drop

power

longer

line (i.e.,

3

-17

Page 46

Connectors

3.4.3

Precautions

for

Wiring

DeviceNet

Cables

•

The

1=4.S7/L

•

If

only the communications

errors

. - ,

Location

following two types

6f

may

occur

Power Supply

I:

Allowable current (A)

L:

Drop line length

power

supply is turned

in

the

nodes

that

are

communicating

of

configuration are possible for the location

Nodes on-Both Sides of the Power Supply

Nodes

Power Supply

T-Branch

Communications

power

on

One Side of the Power Supply

Tap

Adapter

supply

or

,

(m)

OFF

while the network is operating,

at

that

time.

of

the

power

supply.

Note

Power

Supply

T·Branch

Communications

power

supply

The

"Nodes

on

er

supply

is

connected

Tap

Adapter

Both

Sides

or

to

of the

many

Power

nodes.

Supply"

method

is

recommended

if a

single

pow-

3 -18

Page 47

3.4.4 Grounding

3.4

Connections

for

DeviceNet

Communications

As shown below. connect the shield wire

of

the cable to the

power supply and ground the shield wire to a resistance

• Power Supply with Single-point Ground

T-Branch

Adapter

"\

-

'--

-=-

or

Power

Supply

Tap

CANH

v+

}

Shield

CANL

v-

FG

~ommunications

power

Ground

to a resistance

v+

supply

v

of

100 n

CommunicaUon

cable

or

less.

• Power Supply without Ground

Power Supply Tap

of

FG

terminal

100 n

or

of

the communications

less.

CANH . .

v+

}

Shield

Communications

CAN

L

cable

v-

n

FG

Communications

power

- -

-=-

Ground

to a resistance

If

more than one communications power supply is used, ground only the power supply that is

located closest to the middle

supply through the shield wire at any

is connected to the network, connect them using a

1.

Power

Ground

Do

not

Do

not

supplies

ground

I IMPORTANT I

2.

3.

/

4.

the

network

ground

are

the

the

network

network

v-

v+

supply

not

counted

to a resistance

together

through

of

100 n or

of

the network through the shield wire. Do not ground the

less.

otherpoint.lfmore

than one communications power supply

Power Supply Tap each.

as

nodes.

of

100.0:

or

less.

with

the

shield

servodrivers

wire

at

or

.more

inverters.

than

one

point;

ground

at

a single

point

power

only.

3 -19

Page 48

Page 49

Parameter Settings

This chapter explains the outline and details

4.1

Parameter

4.1.1

4.1.2

4.1.3 Editing

4.1.4 Effective TIming

4.2

Parameters

4.2.1

4.2.2 Homing

4.2.3 Machine System and

4.2.4 Speed, Acceleration, and Deceleration Parameters

4.2.5 Positioning Parameters

4.3

Parameter

4.3.1

4.32

4.3.3 Machine System and

4.3.4 Speed, Acceleration, and Deceleration Parameters 4 - 24

Outline

What Are Parameters?

Parameter Types

Parameters

Tables

Unit Parameters

Parameters

Peripheral Device Parameters

Details

Unit Parameters

Homing Parameters

Peripheral Device Parameters

....................

...........................

........................

............................

.....

...........................

........................

....................

........................

of

NS31 0 parameters.

......................

...............

.....................

:.

.

4-2

.

4-2

4-2

.

4-3

4-4

.

.

4-5

.

4-5

.

4-5

4-7

4-8

.

4 - 10

.

4 -

11

4 -11

.

4 -

14

4 - 18

4.3.5

Positioning Parameters

/

4 -I

......................

4 - 35