Page 1

Danger:

Improper

wiring can and will

cause

bodily harm

as well as damage

to the equipment

Please read this

sheet and the J1000

Quick Start Guide

(TOEPC71060626)

thoroughly before

attempting

any

installation.

OVERVIEW

YEA Document Number: TM.J1000.01 5/08/2013 ©2008 Yaskawa Electric America, Inc. - (800) YASKAWA (927-5292) Fax (847) 887-7310 DrivesHelpDesk@yaskawa.com www.yaskawa.com

J1000 AC Drive

Quick Start Procedure

Page 1 of 2

The following

procedure is a

supplement to other

documentation

supplied with this

equipment and will

guide the user in

properly wiring the

J1000 and motor. It

will also allow the

installer to check

motor direction and

correct if necessary.

When installing the

system be sure to

follow good wiring

practices and all

applicable codes.

Ensure that the

mounting of the

various components

are secure and that

the environment,

such as extreme

dampness, poor

ventilation etc. will

not cause system

degradation.

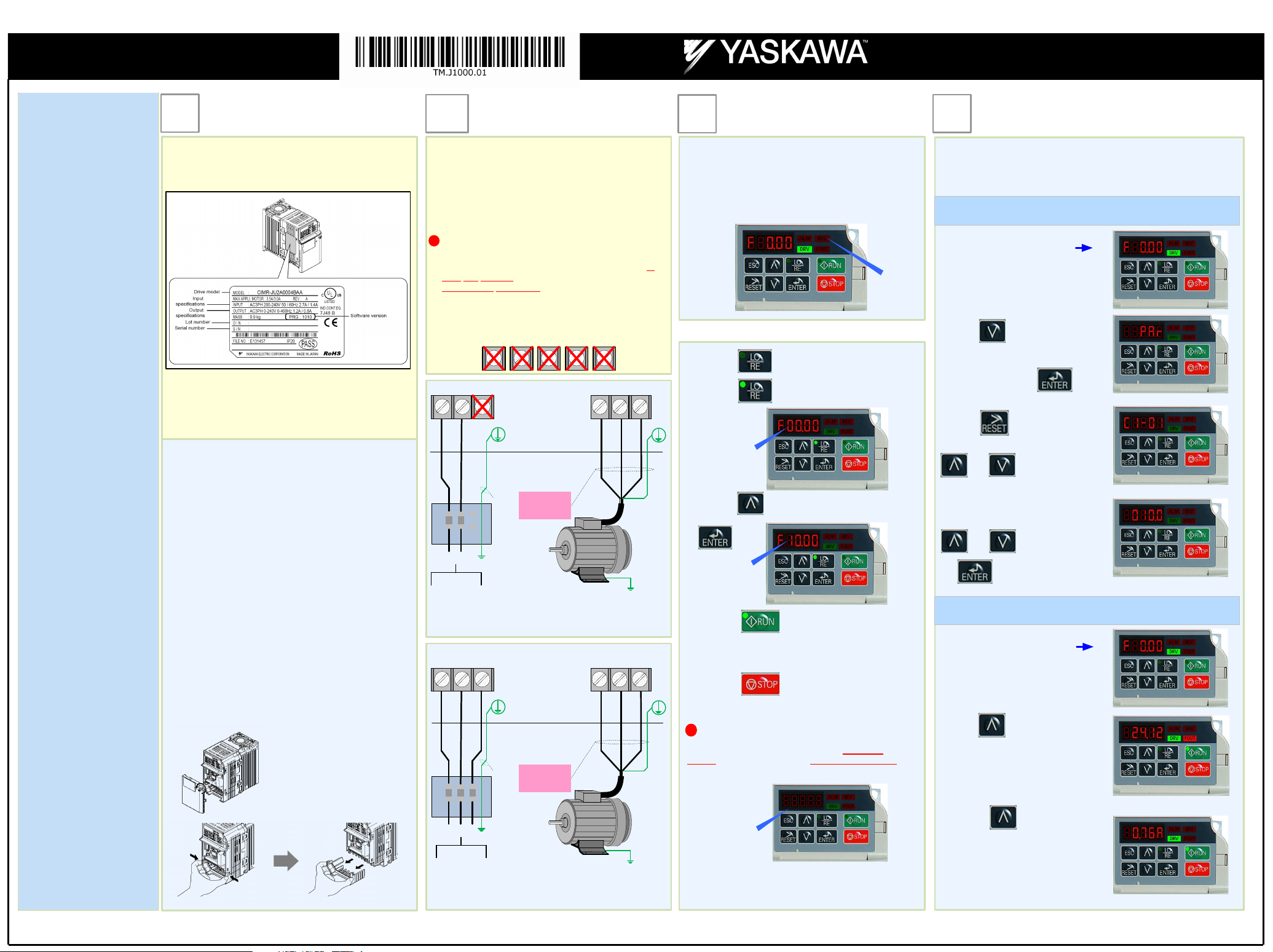

Step

To make sure you received the correct model it is essential

to verify the J1000 nameplate with your order; and make

sure that the drive has the correct rating so it can be used

with your motor. Please check the nameplate information

as shown in the example below.

Check that the available power meets the input power

Ensure that the output power from the VFD is

In the case of systems with multiple VFDs follow this

J1000 Model Identification and

1

requirements.

compatible with the motor requirements.

procedure for each VFD and motor connected.

Mounting

Mounting the J1000

The mounting of the J1000 is extremely important regarding

environment and accessibility. Depending on your system,

there are various models available and therefore the

mounting dimensions (footprint) may be different. Because

the mounting procedure is fairly extensive, it is beyond the

scope of this document, the user is referred to the J1000

Quick Start Guide (Manual No. TOEPC71060626) received

with the J1000, Section 2 Mechanical Installation. Match

up the model that you received and follow the procedure

described in the manual to ensure a safe and functional

installation. In the case where the system has more than one

J1000 refer to the proper clearances required for adequate

ventilation. Please pay particular attention to:

The clearances to be maintained around the enclosure

for adequate ventilation.

The environmental specifications such as avoiding

excessive dampness, extreme temperatures, chemical

exposure, corrosive areas etc. to avoid damage to the

equipment and to maintain safety.

Removing Protective Covers

Improper removal of the J1000 front cover and terminal

cover can cause extensive damage to the J1000. To avoid

damage to these items, please pay particular attention to the

J1000 Quick Start Guide, Section 3.5, Protective Covers.

IP20 / Open Chassis

Remove the Front Cover

Remove the Terminal Cover

Step

2

Fig.1 & 2 below show the electrical connections for the

input power and motor terminals for various J1000 Drive

Models. Select the proper diagram for the single or three

phase model you are installing (see Step 1) and WITH

POWER OFF make the appropriate connections.

Make sure to follow good wiring practices and all

applicable codes. Ensure that the equipment is

grounded properly as shown.

DANGER, LETHAL VOLTAGES ARE PRESENT- Before

!

applying power to the J1000, ensure that all protected

covers are fastened and all wiring connections are

secure. After the power has been turned OFF, wait at

least five minutes until the charge indicator

extinguishes

circuit boards or components.

WARNING DO NOT CONNECT ANY OF THE

FOLLOWING TERMINALS TO EARTH GROUND

R/L1 S/L2

Connect Motor and

Line Power

completely before touching any wiring,

B1 B2

-

+1 +2

U/T1 V/T2 W/T3

SINGLE PHASE

INPUT J1000

(R/L1) (S/L2)

To change direction of

Connect to

motor rotation swap any

chassis

two of the three motor

ground

leads (See Step 2)

Input

Protection

(Fuse or C.B.)

L1

L2

1Ø Input

Power

Fig. 1:

Input Power and Output Motor Electrical

Connections for Single Phase Input J1000

R/L1 S/L2

T/L3

(U/T1)

3Ø Induction

motor

U/T1 V/T2 W/T3

(V/T2)

THREE PHASE

INPUT J1000

(R/L1) (S/L2)

(T/L3)

To change direction of

Connect to

motor rotation swap any

chassis

two of the three motor

ground

leads (See Step 2)

Input

Protection

(Fuse or C.B.)

L1

L3

L2

3Ø Input

Power

Fig. 2:

Input Power and Output Motor Electrical

Connections for Three Phase Input J1000

(U/T1)

3Ø Induction

motor

(V/T2)

(W/T3)

Connect

frame to

ground

(W/T3)

Connect

frame to

ground

Step

Check Motor Direction

3

In this step the motor is checked for proper direction and

operation. This test is to be performed solely from the

digital operator. Apply power to the J1000 after all the

electrical connections have been made and protective

covers have been re-attached. At this point, DO NOT RUN

THE MOTOR, the Digital Operator should display as

shown below in Fig. 3.

REV LED

OFF

Fig. 3 Digital Operator

Next, press the

should turn on.

First Digit Flashing

Next, press the

button.the

First Digit Flashing

Next, press the

should now be operating at low speed running in the correct forward

(clockwise) direction.

Next, press the key on the Digital Operator.

If motor rotation is not correct, then power down the J1000 Drive.

DANGER

!

After the power has been turned OFF, wait at least five

minutes until the charge indicator extinguishes completely

before touching any wiring, circuit boards or components.

Digital Operator

turned off.

Using Safety precaution, and referring to Fig.1 or 2, swap any two

of the three output leads to the motor (U/T1, V/T2 and W/T3). After

the wiring change, repeat Step 3 and recheck motor direction.

Key on the Digital Operator; the green LED

key on the Digital Operator once, then press

key on the Digital Operator. The motor

Step

How to Change Parameters

4

This step shows how to access and modify a J1000 parameter as

well as how to monitor J1000 signals such as output frequency

and motor current. Make sure all protective covers have been reattached and power is turned on. DO NOT RUN THE MOTOR.

Access Parameter Menu and Change Parameter Value

J1000 Digital Operator power-up state

Press the

The digital operator shows the parameter

menu (PAr) then press the

Press the key to select the digit

you would like to change. Next use the

and keys to select the

parameter group, sub-group or number

Modify the parameter value using the

and key and press

the key to save the new value.

J1000 Digital Operator power-up state

Press the key until the FOUT

LED turns on. The display now shows

the actual drive output frequency in Hz.

Pressing the key again will

show the motor output current. The ‘A’

behind the value means ‘Amps’.

Please refer to the technical manual

on how to access other drive signals.

key once.

key.

Select Parameter Menu

Select Parameter

Change Parameter Value

Monitor Motor Frequency and Motor Current

Output Frequency

Motor Current

Page 2

This section may require you to change one or more J1000 parameters, please refer to Step 4 for a detailed explanation on how to

change parameters.

FREQUENTLY ASKED QUESTIONS

STANDARD APPLICATION PARAMETERS

Question:

Answer:

2220

3330

Question:

Answer:

Question:

OV

Answer:

Question:

OL1

Answer:

Question:

Answer:

Warning:

Yaskawa Electric America, Inc.

2121 Norman Drive South

Waukegan, IL 60085

(800) YASKAWA (927-5292)

Fax (847) 887-7310

DrivesHelpDesk@yaskawa.com www.yaskawa.com

YEA Document Number: TM.J1000.01 5/0

8/2013 ©2008 Yaskawa Electric America, Inc.

J1000 AC Drive

Quick Start Procedure

Page 2 of 2

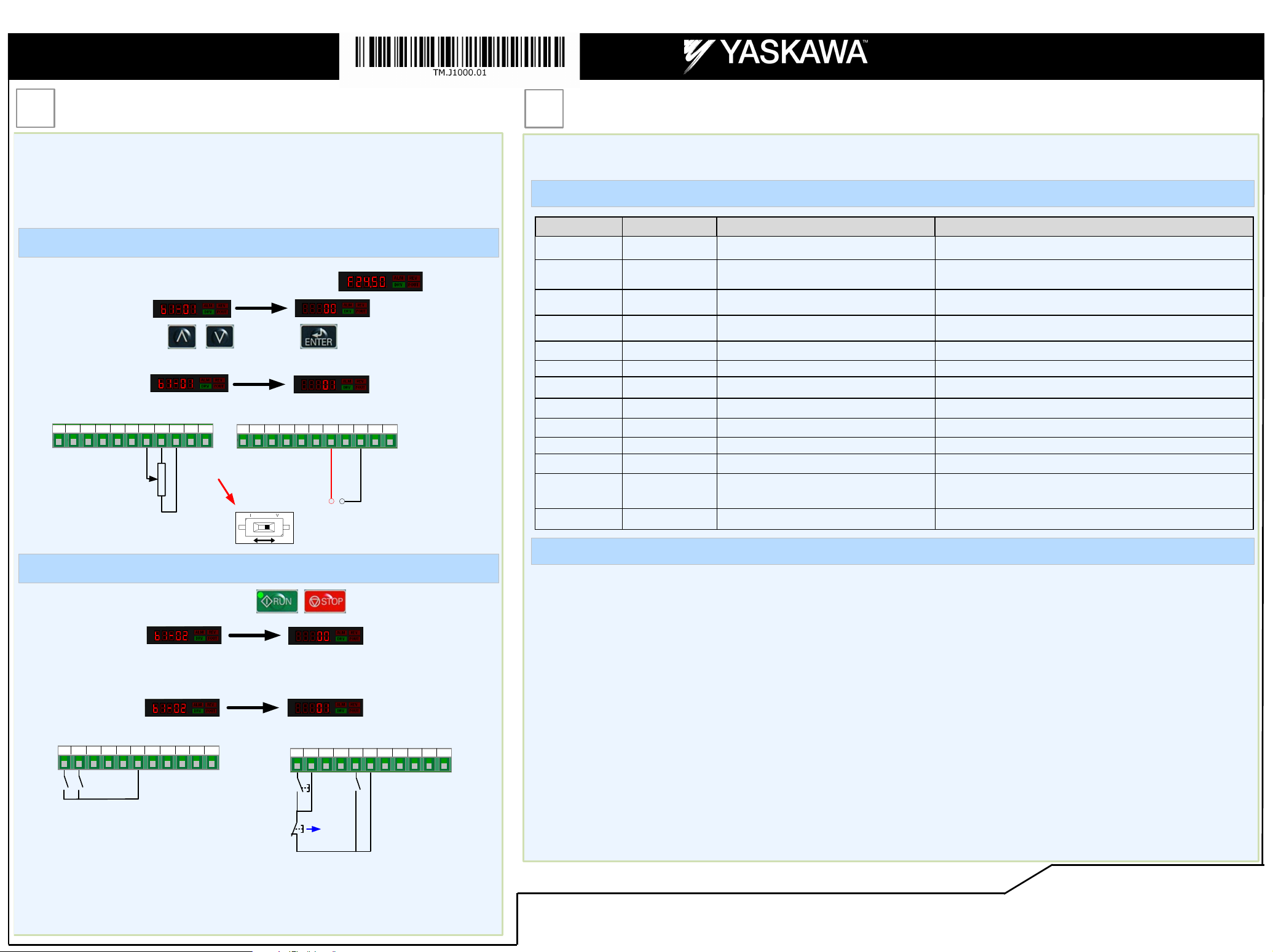

Step

5

Selecting Start/Stop and Speed Method

This step shows how to setup the sequence and reference method of the J1000. The sequence method

Step

6

The following table lists the general purpose application parameters as well as frequently asked questions.

determines how the J1000 drive receives its start and stop command and the reference method determines

how the speed of the motor is controlled. Make sure all protective covers have been re-attached and power

is turned on. DO NOT RUN THE MOTOR.

This section may require you to change one or more J1000 parameters, please refer to Step 4 for a

detailed explanation on how to change parameters.

SELECT SPEED METHOD

1.

Adjust motor speed / frequency from the Digital Operator

Go to parameter b1-01,

To adjust frequency use the / keys and press to save.

2.

Speed reference from external terminals (Potentiometer or Analog Signal)

Go to parameter b1-01,

User Terminals

S1 S2

S3S4S5 SC A1

AC

AC

AM

+V

Potentiometer

2K Ohm

Set Value to

(Factory Default)

Set Value to

User Terminals

S1 S2

S3S4S5 SC A1

Located inside the drive on

the control card

DIP switch S1

+

AC

+V

0 ~ 10Vdc

AC

AM

(Factory Default)

b1-01

PARAMETER DEFAULT VALUE DESCRIPTION COMMENTS

b1-01 1 Reference Source, Speed Control Method

b1-02 1 Run Source / Start/Stop Control Method

b1-03 1 Stop Method Selection

b1-04 0 Reverse Operation

C1-01 10.0 sec. Acceleration Time The time it takes to ramp up from 0 to maximum motor speed.

C1-02 10.0 sec. Deceleration Time The time it takes to ramp down from maximum motor speed to 0.

C6-01 1 Normal / Heavy Duty

d1-01 0.00 Hz Frequency Reference Frequency setting when speed is set from the keypad.

d2-01 100.0 % Frequency Upper Limit Maximum motor speed allowed (e.g. 100 % = Max rpm)

d2-02 0.0 % Frequency Lower Limit Minimum motor speed allowed (e.g. 100 % = Max rpm)

E2-01 * Motor Rated Current Motor nameplate current

L1-01 1 Motor Overload Selection

L1-02 1.0 min Motor Overload Time Sets the motor thermal overload protection time.

4 ~ 20mA

SELECT START / STOP CONTROL METHOD

1.

Start / Stop Control from Digital Operator

Go to parameter b1-02,

2.

Start / Stop Control from external terminals (switch or relay contact)

Go to parameter b1-02,

S1 S2

Forward

Wiring Diagram: 2-Wire Control

Use for maintained contacts

User Terminals

S3S4S5 SC A1

Reverse

AC

AM

+V

Set Value to

AC

Start

Switch

Stop

Switch

NOTE: It is beyond the scope of this document to program the J1000 drive for network communication control, please

refer to the technical manual (SIEPC71060631) for this selection. A communication adapter is required for network

communication.

Set Value to

Normally

Open

S1 S2

S3S4S5 SC A1

Normally

Reverse

Closed

( Factory Default)

User Terminals

Wiring Diagram: 3-Wire Control

Use for momentary contacts

(Set Parameter A1-03 to 3330)

b1-02

(Please refer to Step 5 for wiring diagram)

How do I reset the drive back to factory default settings?

Go to parameter A1-03 and set value 2

How do I adjust the time it takes the motor to speed up or slow down?

Adjust the acceleration time parameter C1-01 and deceleration time C1-02.

How do I prevent my drive from tripping on an

Increase deceleration time parameter C1-02.

AC

AC

AM

+V

How do I prevent my drive from tripping on an

Verify motor rated current parameter E2-01 and motor overload parameter settings

L1-01 Motor overload selection, L1-02 Motor overload protection time.

I want to run my motor above the nominal motor speed?

Increase the value of parameter E1-04 Maximum Frequency

Verify that the motor and system allow for this.

Quick Start Parameters

0 = Digital Operator (Adjust Motor Speed from keypad)

1 = Terminals (Speed Pot. / 0 – 10V / 4—20mA)

0 = Digital Operator (Start/Stop motor from keypad)

1 = Terminals (Start/Stop using external contact / switch)

0 = Ramp to stop (Motor ramps down at stop command)

1 = Coast to stop (Motor freewheels at stop command)

0 = Allow motor to run in reverse direction

1 = Reverse direction prohibited

0 = Normal Duty (Use for fan and pump applications)

1 = Heavy Duty (Use for conveyor, mixer, applications)

0 = Disabled

1 = Standard Fan Cooled Motor

2 = Standard Blower Cooled Motor

for 2 – wire control or 3

fault (overvoltage) while my motor is ramping down?

fault (overload) while my motor is ramping down?

for 3 – wire control

Loading...

Loading...