Page 1

iQpump Controller

Programming Manual

Document Number: TM.iQp.07 PRG: 0034 ~ 003X

Page 2

2 YASKAWA TM.iQp.06 iQpump Controller Programming Manual

Page 3

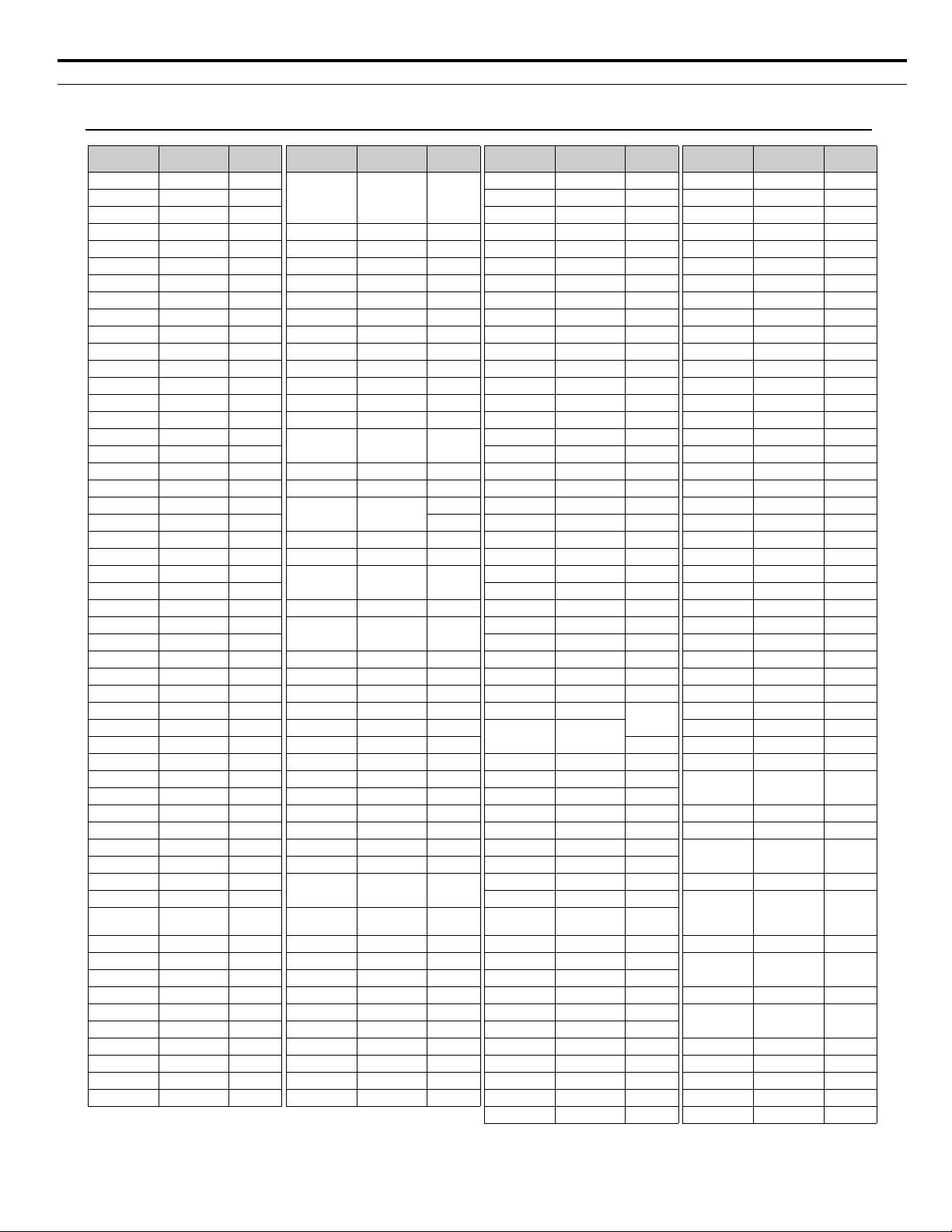

◆ Quick Reference for iQpump (P7U) <0034>

Parameter

Number

A1-00 0

A1-01 2

A1-03 0

A1-04 0 d1-01 0.00

A1-05 0 d1-02 0.00

b1-01 0 d1-03 0.00

b1-02 0 d1-04 0.00

b1-03 0 d1-17 0.00

b1-07 0 d2-01 100.0 %

b1-08 0 d2-02 0.0 %

b1-11 0 s d2-03 0.0 %

b2-01 0.5 Hz d3-01 0.0 Hz

b2-02 50 % d3-02 0.0 Hz

b2-03 0.00 s d3-03 0.0 Hz

b2-04 0.50 s d3-04 1.0 Hz

b2-09 0 %

b3-01 2

b3-02 120 % E1-03 F

b3-03 2.0 s E1-04 60.0 Hz

b3-05 0.2 s

b3-14 1

b4-01 0.0 s E1-06 60.0 Hz

b4-02 0.0 s E1-07 3.0 Hz

b5-01 1

b5-02 2.00

b5-03 3.0 s E1-09 1.5 Hz

b5-04 100.0 %

b5-06 100.00 %

b5-07 0.0 % E1-11 0.0 Hz

b5-08 0.00 s E1-12 0.0 Vac

b5-09 0 E1-13 0.0 Vac

b5-10 1.0 E2-01 kVA Dep

b5-12 2 E2-03 kVA Dep

b5-13 0 % E2-04 2

b5-14 2.0 s E2-05 kVA Dep

b5-17 0.0 s F6-01 1

b5-32 0.0 Hz F6-02 0 L3-04 1

Factory

Setting

User

Setting

Parameter

Number

Factory

Setting

C6-03 kVA Dep

E1-01

E1-05

E1-08

E1-10

240 V

480 V

230 V

460 V

17.2 Vac

34.5 Vac

10.3 Vac

20.7 Vac

User

Setting

Parameter

Number

Factory

Setting

User

Setting

Parameter

Number

H3-08 2 L8-09 1

H3-09 B** L8-10 0

H3-10 100.0 % L8-11 300 s

H3-11 0.0 % L8-12 45 ºC

H3-12 0.30 s L8-15 1

H3-13 0 L8-18 1

H4-01 2 L8-19 20.0 %

H4-02 100.0 % n1-01 1

H4-03 0.0 % n1-02 1.00

H4-04 8 n3-01 5 %

H4-05 50.0 % n3-02 150 %

H4-06 0.0 % n3-03 1.0 s

H4-07 0 n3-04 40 s

H4-08 0 o1-01 6

H5-01 1F o1-02 1

H5-02 3 o1-05 3

H5-03 0 o1-06 1**

H5-04 3 o1-07 2**

H5-05 1 o1-08 91**

H5-06 5 ms o2-01 1

H5-07 1 o2-02 1

H5-08 0 o2-03 0

H5-09 2.0 s o2-04 kVA Dep

L1-01 1 o2-05 0

L1-02 8.0 min o2-06 1

L1-03 3 o2-07 0 hr

L1-04 1 o2-08 1

L1-05 0.20 s o2-10 0 hr

L2-01 2 o2-12 0

L2-02 kVA Dep o2-14 0

L2-03 kVA Dep o3-01 0

L2-04 kVA Dep o3-02 0

L2-05

Voltage

Class Dep

P1-01 0

P1-02 1

L3-01 1 P1-03 00145

L3-02 120 %

P1-04

0.0

units P1-02)

b8-01 0 F6-03 1 L3-05 1 P1-05 1 s

b8-04 kVA Dep. F6-05 0

b8-05 20 ms H1-01 24

b8-06 0 % H1-02 14 L4-02 2.0 Hz

C1-01 20.0 s

C1-02 10.0 s

H1-03

3: 2-wire

0: 3-wire

C1-03 10.0 s H1-04 80 L5-01 5

L3-06 120 % P1-06 40.0 Hz

L4-01 0.0 Hz

P1-07

0.0

units P1-02)

L4-05 0 P1-08 5 s

L4-06 0

P1-09

units P1-02)

C1-04 10.0 s H1-05 84 L5-02 0 P1-10 2 s

C1-05 50.0 s H1-12 0.00 s

C1-06 50.0 s H1-13 0.00 s L6-01 0

L5-03 20.0 s

P1-11

0.0

units P1-02)

C1-09 10.0 s H1-14 0.00 s L6-02 15 % P1-12 60 s

C1-11 0.0 Hz H1-15 0.00 s

C2-01 0.20 s H1-16 0.00 s L8-01 0

L6-03 10.0 s

P1-13

0.0

units P1-02)

C2-02 0.20 s H2-01 40 L8-02 95 ºC P1-14 0.0 A

C4-01 1.00 H2-02 41

C4-02 200 ms H3-02 100.0 %

C6-02 kVA Dep H3-03 0.0 %

L8-03 4 P1-15 0

L8-05 1 P1-16 20 s

L8-06 kVA Dep P2-01 0

L8-07 1 P2-02 0.0

Factory

Setting

(system

(system

155.0

(system

(system

(system

User

Setting

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 3

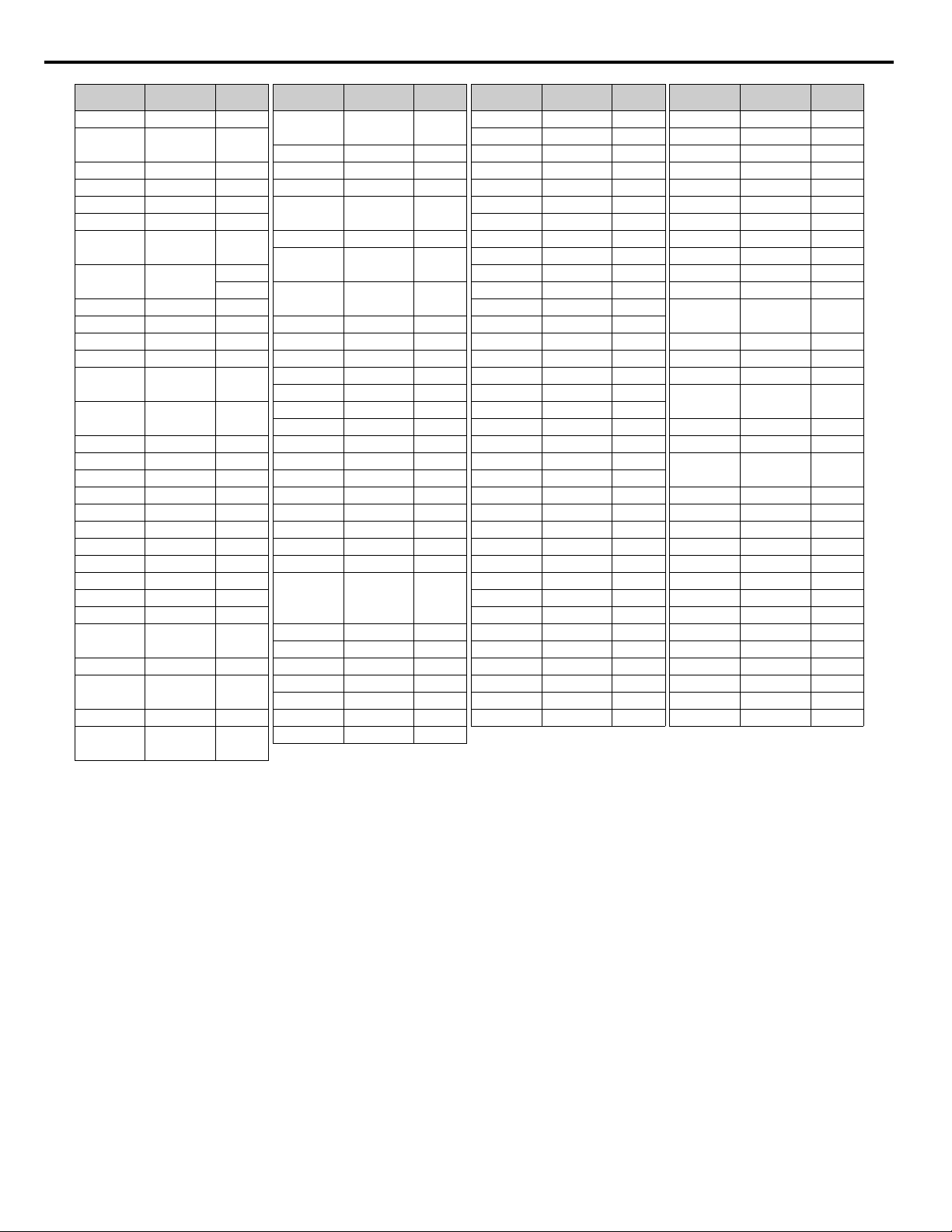

Page 4

Parameter

Number

P2-03 5 s

P2-04

P2-05 10 s P3-10 40.0 Hz

P2-06 0 P3-11 2 s

P2-07 300 s

P2-08 0

P2-09

P2-10

P2-11 0 rpm

P2-12 15 rpm P4-02 0.00 Hz P6-10 0 kgl

Factory

Setting

(system

0.0

units P1-02)

(system

0.0

units P1-02)

0.0

(system

units P1-02)

User

Setting

Parameter

Number

P3-08

P3-09 40.0 Hz

Factory

Setting

0.0

(system

units P1-02)

User

Setting

Parameter

Number

Factory

Setting

User

Setting

Parameter

Number

P5-02 40.00 Hz P8-09 1

P5-03 0 P8-10 2.00

P5-04 1 P8-11 5.0 s

Factory

P6-01 0.0 Gpm P9-02 0

P6-02 0 P9-03 24 hr

P3-12

(system

0.0

units P1-02)

P6-03 0 P9-04 0

P6-04 0.0 P9-05 0

P3-13 0.0 Hz P6-05 10 s P9-06 55.0 Hz

P3-14

P4-01

(system

0.0

units P1-02)

(system

0.0

units P1-02)

P6-06 0.0 min P9-07 5 s

P6-07 1 P9-08 0

P6-08 3.0 min P9-09 56.0 Hz

P6-09 0.0 gal

P9-10

0.0

units P1-02)

P2-13 5.0 s P4-03 0.0 min P6-11 1 P9-11 10 s

P2-14 5.0 s P4-04 1.0 s

P2-15

P2-16

1.0

(system

units P1-02)

(system

1.5

units P1-02)

P4-05 30.0 Hz P6-13 10 s P9-13 40.0 Hz

P4-06 1.0 s

P4-07 0 P7-01 0

P4-08 0 P7-02 1 P9-15 10 s

P2-17 2.0 s P4-09 0.2 min

P2-18 2.0 s P4-10 0

P2-19 0 P4-11 0.2 min P7-05 25.00 Hz

P6-12 0.0 P9-12 0

P6-14 1

P9-14

0.0

units P1-02)

P7-03 120 % P9-16 3 s

P7-04 0.3 s

P9-17

0.0

units P1-02)

P2-20 0.0 P4-12 0.00 Hz P7-06 10 s P9-18 90.0 %

P2-21 0.0 P4-13 0.0 min

P2-22 5.0 s P4-14 0

P2-23 0.40 % P4-15 0

P2-24 10.0 s P4-16 24.0 hr

P2-25 3.0 psi

P3-01 0

P3-02 59.0 Hz

0.0

P3-03

(system

units P1-02)

P4-17

P4-18 0.0 min P8-03 20.0 ft P9-26 4.0 s

P4-19 0.0 min

10.0

(system

units P1-02)

P3-04 2 s P4-20 0

P3-05

0.0

(system

units P1-02)

P4-21 1 P8-06 0.00 Hz P9-29 2.0 s

P4-22 10 s

P3-06 5 s P4-23 0.0 s

P3-07

0.0

(system

units P1-02)

P5-01 1

P7-07 10 s P9-19 0

P7-08 2.0 s P9-20 0

P7-09 2.0 s P9-21 8

P7-10 168.0 hr P9-22 5

P7-11 2.0 s P9-23 16

P8-01 0 P9-24 0 s

P8-02 100 psi P9-25 08 h

P8-04 10.0 ft P9-27 0

P8-05 30.0 ft P9-28 2.0 s

P8-07 0.0 ft T1-02 kVA Dep

P8-08 0.1 min T1-04 kVA Dep

Setting

(system

(system

(system

User

Setting

* Factory Setting changes to “B” when b5-01 = 1.

** Factory Setting changes to “B” when b5-01 = 1 as follows: o1-06 = 1, o1-07 = 38, o1-08 = 24.

4 YA SK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 5

Table of

Contents

TABLE OF CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

W

ARNINGS AND CAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

I

NTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

P

ROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

iQpump Drive Basic Programming Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

b1 Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

b2 DC Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

b3 Speed Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

b4 Delay Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

b5 PI Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

b8 Energy Savings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

C1 Accel / Decel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

C2 S-Curve Acc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

C4 Torque Comp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

C6 Carrier Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

d1 Setpoint and Jog References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

d2 Reference (Speed Command) Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

d3 Jump Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

E1 V/f Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

E2 Motor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

F6 Com OPT Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

H1 Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

H2 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

H3 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

H4 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

H5 Serial Communications Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

MEMOBUS / Modbus Function Code Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

MEMOBUS / Modbus Data Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

iQpump MEMOBUS / Modbus Status Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

L1 Motor Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

L2 Momentary Power Loss Ride-thru Function . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

L3 Stall Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

L4 Speed Command Loss Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

L5 Fault Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

L6 Torque Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

YAS K AW A TM.iQp.07 iQpump Controller Programming Manual 5

Page 6

L8 Hardware Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

n1 Hunting Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

n3 High-Slip Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

o1 Monitor Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

o2 Key Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

o3 Digital Operator Copy Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

P1 Pump Basic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

P2 Pump Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

P3 Pump Multiplex. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

P4 Pump Advanced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

P5 Hand Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

P6 Flow Meter Setup <0034> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

P7 Anti-Jam / De-Scale <0034> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

P8 Pressure and Level Control <0034> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

P9 Network Options <0034> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233

T1 Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .258

P

ARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Monitor List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Fault Trace List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .294

Fault History List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

F

ACTORY DEFAULT SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

6 YAS K AWA TM.iQp.07 iQpump Controller Programming Manual

Page 7

Warnings and Cautions

WARNING

This Section provides warnings and cautions pertinent to this product, that if not heeded, may

result in personal injury, fatality, or equipment damage. Yaskawa is not responsible for

consequences of ignoring these instructions.

YASKAWA manufactures component parts that can be used in a wide variety of industrial applications. The selection

and application of YASKAWA products remain the responsibility of the equipment designer or end user. YASKAWA

accepts no responsibility for the way its products are incorporated into the final system design. Under no circumstances

should any YASKAWA product be incorporated into any product or design as the exclusive or sole safety control.

Without exception, all controls should be designed to detect faults dynamically and fail safely under all circumstances.

All products designed to incorporate a component part manufactured by YASKAWA must be supplied to the end user

with appropriate warnings and instructions as to that part’s safe use and operation. Any warnings provided by

YASKAWA must be promptly provided to the end user. YASKAWA offers an express warranty only as to the quality of

its products in conforming to standards and specifications published in the YASKAWA manual. NO OTHER

WARRANTY, EXPRESS OR IMPLIED, IS OFFERED. YASKAWA assumes no liability for any personal injury,

property damage, losses, or claims arising from misapplication of its products.

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 7

Page 8

WARNING

• Read and understand this manual before installing, operating, or servicing this drive. All warnings, cautions, and

instructions must be followed. All activity must be performed by qualified personnel. The iQpump drive must be

installed according to this manual and local codes.

• Do not connect or disconnect wiring while the power is on. Do not remove covers or touch circuit boards while the

power is on. Do not remove or insert the digital operator while power is on.

• Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power

supply is turned off. Status indicator LEDs and Digital Operator display will be extinguished when the DC bus

voltage is below 50 Vdc. To prevent electric shock, wait at least five minutes after all indicators are OFF and

measure DC bus voltage level to confirm safe level.

• Do not perform a withstand voltage test on any part of the unit. This equipment uses sensitive devices and may be

damaged by high voltage.

• The iQpump drive is not suitable for circuits capable of delivering more than 100,000 RMS symmetrical amperes.

Install adequate branch short circuit protection per applicable codes. Refer to the specification. Failure to do so may

result in equipment damage and/or personal injury.

• Do not connect unapproved LC or RC interference suppression filters, capacitors, or overvoltage protection devices

to the output of the drive. These devices may generate peak currents that exceed iQpump drive specifications.

• To avoid unnecessary fault displays caused by contactors or output switches placed between iQpump drive and

motor, auxiliary contacts must be properly integrated into the control logic circuit.

• YASKAWA is not responsible for any modification of the product made by the user; doing so will void the warranty.

This product must not be modified.

• Verify that the rated voltage of the iQpump drive matches the voltage of the incoming power supply before applying

power.

• To meet CE directives, proper line filters and proper installation are required.

• Some drawings in this manual may be shown with protective covers or shields removed, to describe details. These

must be replaced before operation.

• Observe electrostatic discharge procedures when handling circuit cards to prevent ESD damage.

• The equipment may start unexpectedly upon application of power. Clear all personnel from the drive, motor, and

machine area before applying power. Secure covers, couplings, shaft keys, and machine loads before energizing the

drive.

• Please do not connect or operate any equipment with visible damage or missing parts. The operating company is

responsible for any injuries or equipment damage resulting from failure to heed the warnings in this manual.

◆ Intended Use

Drives are intended for installation in electrical systems or machinery.

For use in the European Union, the installation in machinery and systems must conform to the following product standards of

the Low Voltage Directive:

• EN 50178, 1997-10, Equipping of Power Systems with Electronic Devices

• EN 60201-1, 1997-12 Machine Safety and Equipping with Electrical Devices

• Part 1: General Requirements (IEC 60204-1:1997)

• EN 61010, 1997-11 Safety Requirements for Information Technology Equipment

• (IEC 950:1991 + A1:1992 + A2:1993 + A3:1995 + A4:1996, modified)

◆ Other

The iQpump (P7U) drive is suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical amperes,

240 Vac maximum (240 V Class) and 480 Vac maximum (480 V Class).

8 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 9

Introduction

This Section describes the applicability of this manual.

The iQpump (P7U) is a Pulse Width Modulated drive for 3-Phase AC induction motors. This type of drive is also known as an

Adjustable Frequency Drive, Variable Frequency Drive, AC Drive, AFD, ASD, VFD, and Inverter.

The iQpump (P7U) is a variable torque AC drive, designed specifically for Simplex and Multiplex pumping applications. The

pump applications include Booster Systems, Submersible Deep Well, Fluid Storage Tanks, Metering Pumps, Commercial and

Residential Irrigation Systems.

The iQpump (P7U) sets a new benchmark for size, cost, performance, ease-of-use benefits, comprehensive pump, motor

protection features, and quality. The iQpump includes numerous built-in features such as H/O/A Operation, Selectable Pump

Control Engineering Units, PI Control, Pump Basic Control, Pump Protection, Multi-Pump Control (Lead/Lag), and Pump

Messaging Terminology.

The LCD keypad/operator is equipped with Hand/Off/Auto functions, copy feature, and 5 lines of display with 16 characters

per line.

Built-in PI and pump-specific functions and parameters allow the operator to setup specific control values for a wide range of

applications. The iQpump (P7U) will optimize the pump performance by automatically adjusting the pump controller based on

operating conditions of the pump, such as process variable changes and pump protection requirements. The P Group

programming parameters are dedicated for pumping applications and help facilitate setup.

The iQpump (P7U) drive offers energy savings by controlling the flow rate and the number of operating pumps on the system.

The iQpump (P7U) can be configured using the most popular system control configurations including Simplex, Duplex, and

Triplex pumps systems. The iQpump is the master controller with the ability to add additional pumps on-line by controlling

the digital I/O to each individual motor starter.

The iQpump (P7U) has an optional feature to replace the motors starters with additional drives for a more precise pump

control system.

This manual is applicable to the iQpump (P7U) Drives defined by models CIMR-P7U - 107.

This manual is subject to change as product improvements occur. The latest version of the manual can be obtained from

Yaskawa. The date shown on the rear cover is changed when revisions are made.

This manual may describe trademarked equipment, which is the property of other companies. These trademarks are the

property of the registered owner companies and may include the following:

• Modbus

Other documents and manuals are available to support special use or installation of this product. These documents may be

provided with the product or upon request. Contact Yaskawa Electric America, Inc. as required. Documents may include the

following:

• TM.iQp.06 Users Manual

• TM.iQp.11 Modbus Manual

• PumpScada Software and Manual included on CD ROM with product

• Option Instructions included on CD ROM with product

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 9

®

, trademark of Schneider Automation, Inc.

Page 10

0.1 Conventions Used in this Manual

◆ Software Versions

Yaskawa recognizes the need to continuously improve product quality. This iQpump drive may receive feature enhancements in the form

of software or hardware changes in the future, and new functions may be added to the drive. When a new feature or function is added, the

software version <####> will be placed next to the feature or function.

EXAMPLE:

A1-00 Language Selection

Setting Description

0 English (factory default)

1 Japanese

2 Deutsche <0034>

3Francais <0034>

4 Italiano <0034>

5Espanol <0034>

6 Portugues <0034>

Figure 0.1

The example above shows that settings 2, 3, 4, 5, and 6 are added to parameter A1-00 for drive software version PRG: <0034>.

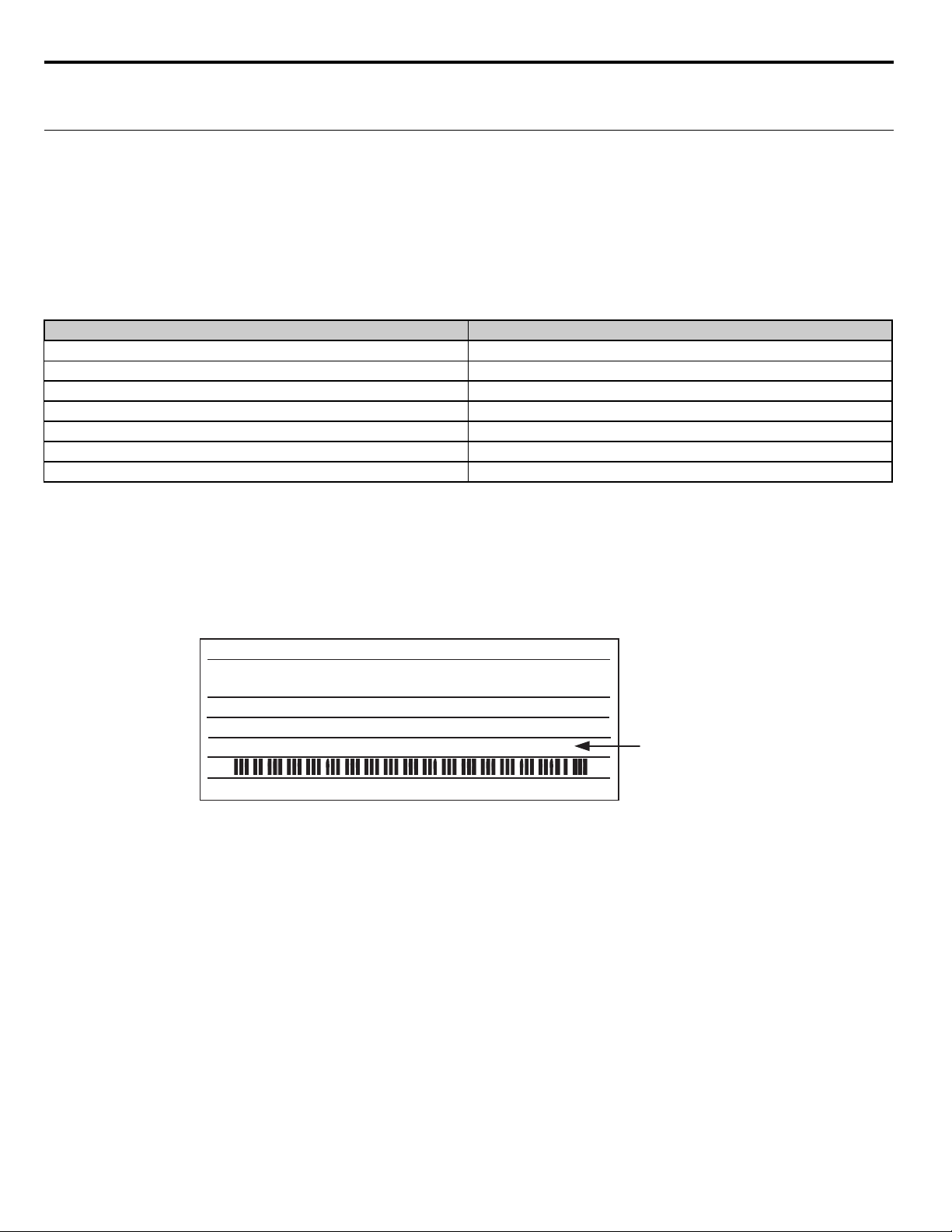

Figure 0.2

MODEL: CIMR-P7U2018 SPEC: 20181E

INPUT:

OUTPUT:

O/N:

S/N:

FILE NO: E131457 TYPE 1 ENCLOSURE

AC3PH 200-240V 50/60Hz HD:84A ND:89A

AC3PH 0-240V 0-400Hz HD:71A 27kVA ND:74.8A 29kVA

MASS: 11kg

1W9911234560123

PRG: 0034

IP20

DRIVE SOFTWARE

VERSION

Figure 1 Nameplate with PRG software number

The “PRG:” number on the drive nameplate reflects the software version. The software version normally increases to a higher number

with newer versions.

10 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 11

1

Programming

This chapter contains descriptions of all user accessible parameters contained in the drive.

Parameters are listed in alpha-numerical order. Parameter number and name, along with a detailed

description and its settings are described on the following pages.

iQpump BASIC PROGRAMMING PARAMETERS . . . . . . . . . . . . . . . . 12

MEMOBUS / MODBUS FUNCTION CODE DETAILS . . . . . . . . . . . . . 101

IQPUMP MEMOBUS / MODBUS STATUS REGISTERS . . . . . . . . . . . 111

PARAMETER LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

MONITOR LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

FACTORY DEFAULT SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 11

Page 12

iQpump Drive Basic Programming Parameters

The initialization group contains parameters associated with initial drive setup. Parameters involving the display language, access levels,

initialization, and password are located in this group.

◆ A1 Initialization

■ A1-00 Language Selection

Setting Description

0 English (factory default)

2Deutsch

3 Francais

4Italiano

5 Espanol

6 Portugues

*Not returned to factory setting by initialization

■ A1-01 Access Level Selection

Setting Description

0Operation Only

2 Advanced Level (factory default)

If the iQpump drive is programmed for Operation Only (A1-01 = “0: Operation Only”), then only the OPERATION and the

PROGRAMMING menus are accessible. Within the PROGRAMMING menu only parameters A1-01 and A1-04 are adjustable.

If A1-01 is configured for Advanced Access (A1-01 = “2: Advanced Level”), then all menus and all parameters are shown. If the Access

Level Selection is set to Advanced, all parameters should be adjustable unless:

The iQpump drive parameters are password protected (A1-04) which will prevent access to A1-00 through A1-03 and all A2 parameters.

A digital input has been configured as a Program Lockout (H1-0x = 1B) is active.

During serial communication writing, if a parameter change is also attempted via the digital operator, a “BUSY - WRITE PROTECTED”

message will display. Parameter change will not be possible from the digital operator until an Enter command is received via the serial

communication to finish the serial writing process.

■ A1-03 Initialize Parameters

Setting Description

0 No Initialize (factory default)

1110 User Initialize

2220 2-Wire Initialize

3330 3-Wire Initialize

The iQpump drive can be set back to one of three default states via the A1-03 parameter.

1. User Initialization – 1110: The modified iQpump drive parameters are returned to the values selected as user settings. User settings are

stored when parameter o2-03 = “1: Set Defaults”.

2. 2-Wire Initialization – 2220: The iQpump drive parameters are returned to factory default values with digital inputs S1and S2

configured as Forward Run.

3. 3-Wire Initialization – 3330: The iQpump drive parameters are returned to factory default values with digital inputs S1, S2, and S5

configured as Run, Stop, and Forward / Reverse respectively.

After an initialization is performed, parameter A1-03 will automatically be set back to 0.

12 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 13

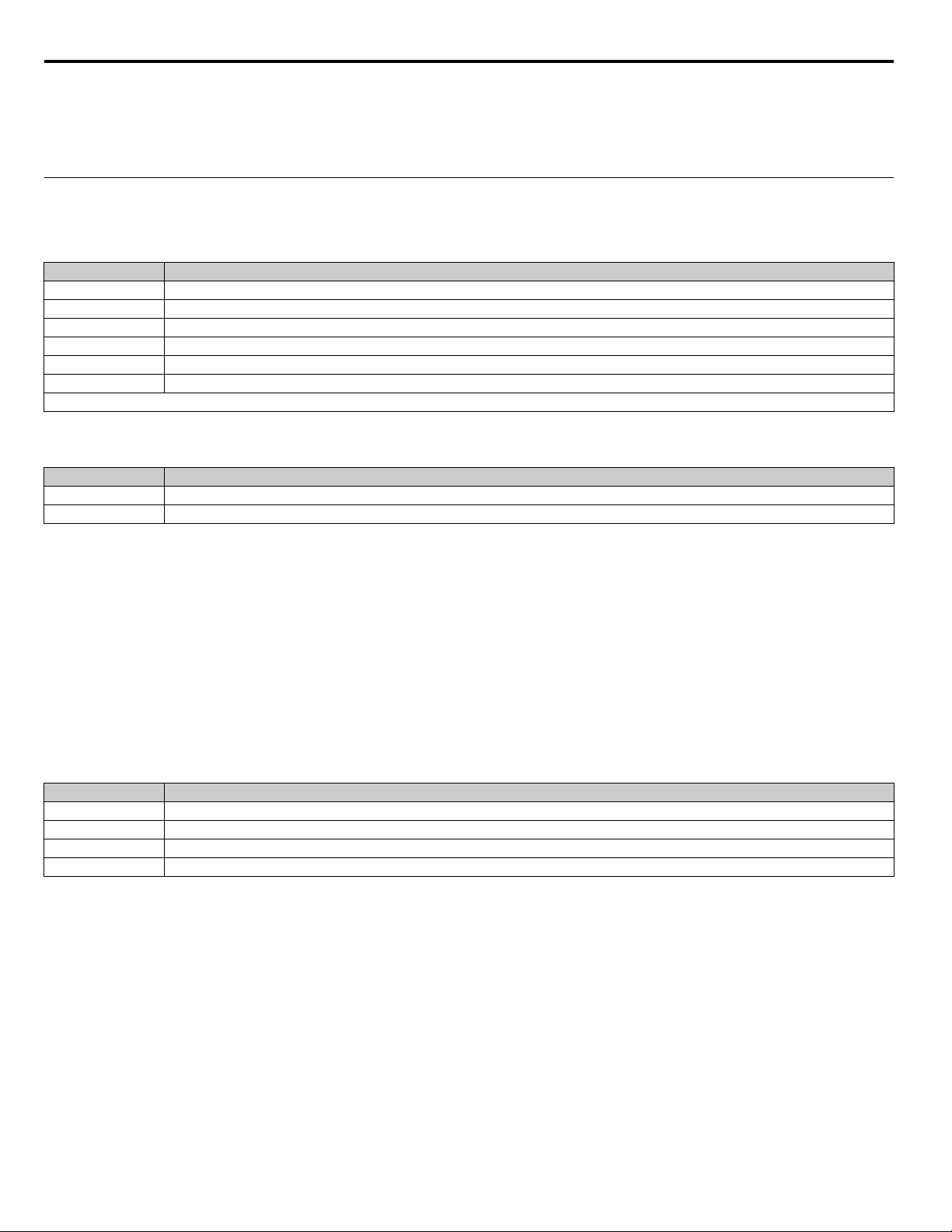

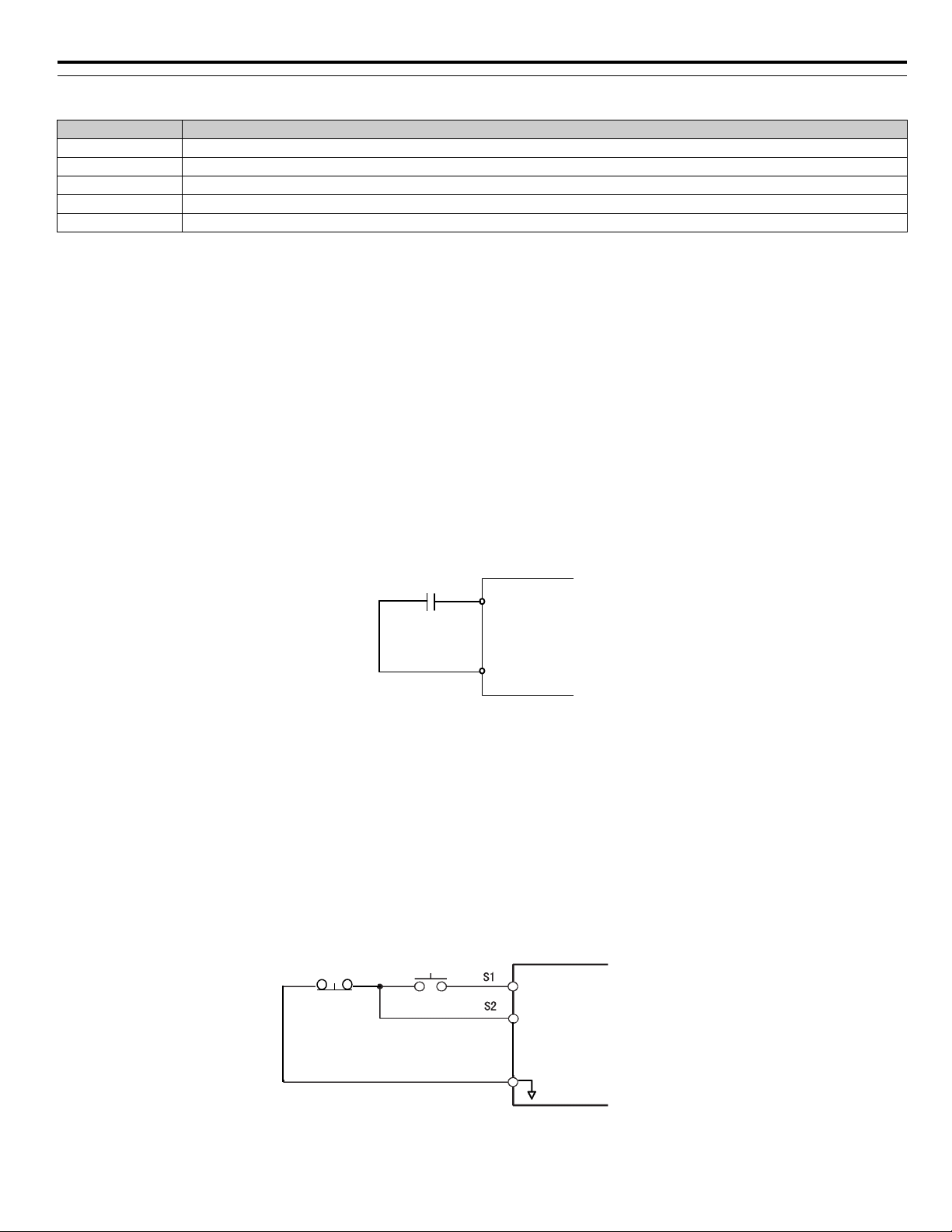

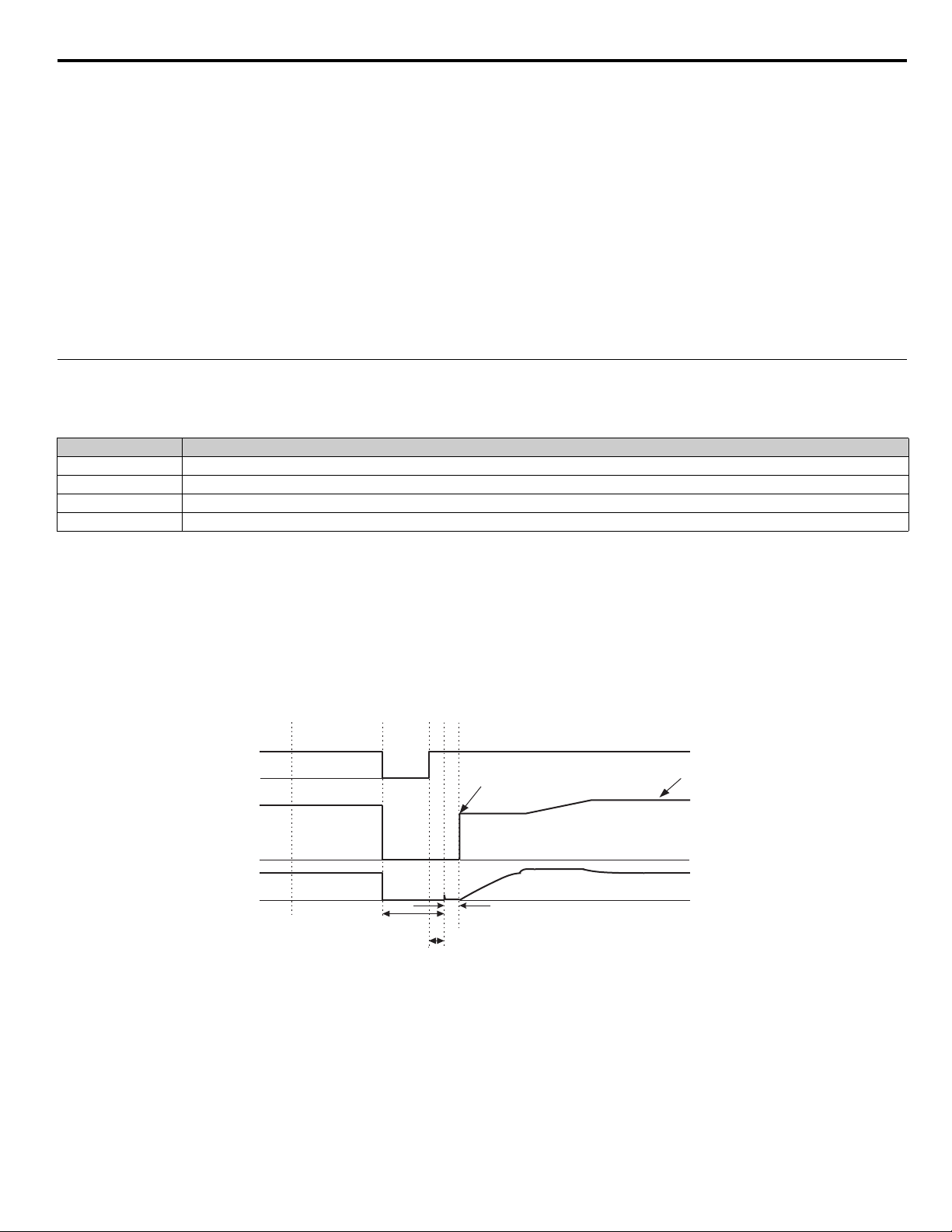

Figure 1.1

Note: 2-Wire Control is the most commonly used.

Stop switch

(NC contact)

Operation switch

(NO contact)

3-wire control

2-wire control

Run command

(run on momentary close)

Stop command

(stop on momentary close)

Sequence input common

S1

SN

S2

S1

SN

FWD Run/Stop

Figure 1. 2 and 3-Wire Control Wiring Examples

Important: Some parameters are unaffected by either the 2-Wire or 3-Wire initialization. The following parameters will not be reset

when parameter A1-03 = 2220 or 3330:

A1-00 Language Selection

E1-03 V/f Pattern Selection

o2-04 kVA Selection

■ A1-04 Password Entry

Setting Range: 0 ~ 9999

Factory Default: 0

If parameters A1-01 through A1-03 are locked (unchangeable), they can be unlocked by entering the correct password number into

A1-04.

Once the correct password number is entered and the specified parameters are unlocked, a 2-Wire or 3-Wire initialization will reset the

password to 0000.

Note: A1-04 will return to “0000” when the password has been entered.

■ A1-05 Select Password

Setting Range: 0 ~ 9999

Factory Default: 0

When the value set into A1-04 does NOT match the value set into A1-05, parameters A1-01 thru A1-03 cannot be changed. All other

parameters determined by A1-01 can be changed. Parameter A1-05 can be accessed by displaying parameter A1-04, then press and hold

the RESET key along with the MENU key simultaneously.

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 13

Page 14

b1 Sequence

The Sequence Group contains parameters associated with starting and stopping the drive. Parameters involving the Run Command, Speed

Reference location, Stopping Method and Hand / Auto changeover are located in this group.

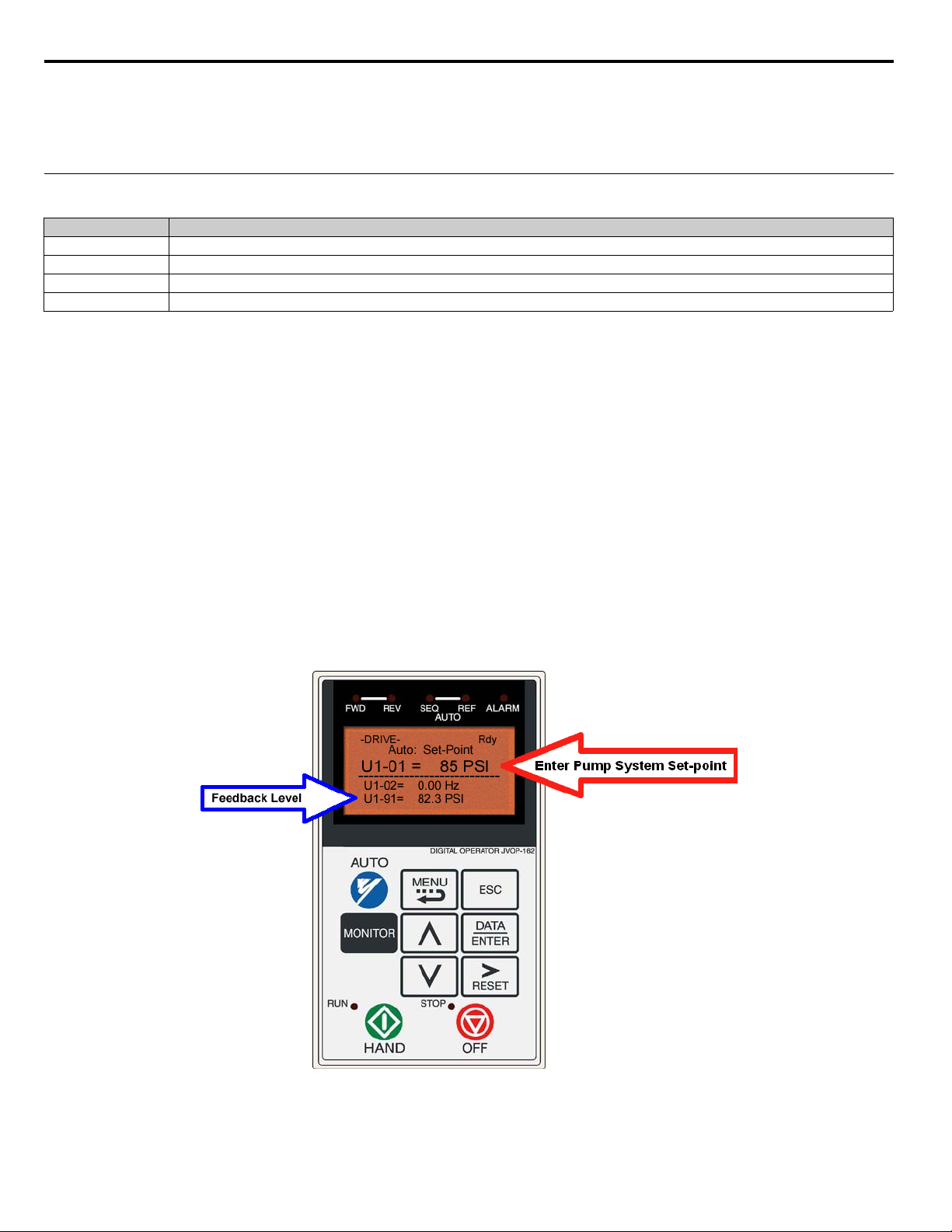

◆ b1-01 Reference (Auto Setpoint) Source Selection

Setting Description

0 Operator - Digital Preset Setpoint d1-01 (factory default)

1 Terminals - Analog Input Terminal A1 (or Terminal A2, see Parameter H3-13)

2 Serial Com - RS-485 Terminals R+, R-, S+ and S3 Option PCB - Option Board connected at 2CN

In order to run the iQpump drive and motor, the iQpump drive must receive a Run command and a Auto Setpoint command. Parameter

b1-01 specifies from where the Auto Setpoint is received when in the “Auto” mode. Switching into the “Auto” mode can be done by

pressing the AUTO button on the digital operator while the iQpump drive is stopped.

Important: If a Run command is input to the iQpump drive but no corresponding Auto Setpoint is input, the Run indicator on the digital

operator will turn on and the STOP indicator on the digital operator will blink.

To configure the iQpump drive to follow the “Hand Reference” set by the digital operator: Use the “Hand” mode by pressing the

hand key and set P5-01 = “1: Hand Reference (P5-02)”. The hand reference can then be entered into the P5-02 parameter.

The iQpump drive offers the ability to provide four types of “Auto Setpoint” reference sources. These Auto Setpoint reference sources are

determined by the setting of b1-01 and the drive set to “Auto” mode by pressing the Auto key on the digital operation.

Note: Prior to programming, it is recommended to first select the system units (P1-02) and the feedback device, Scaling

(P1-03). P1-03 will automatically scale the iQpump Setpoint.

Example:

P1-02 = 1: psi

P1-03 = 200, feedback range = 200 psi.

To configure the iQpump drive to follow an “Auto Setpoint” set by the digital operator: Set b1-01 = “0: Operator” (factory default),

The Auto Setpoint can then be entered into the U1-01 monitor parameter in the “-DRIVE-” menu.

Figure 1.2

Figure 2. Digital Operator Auto Setpoint

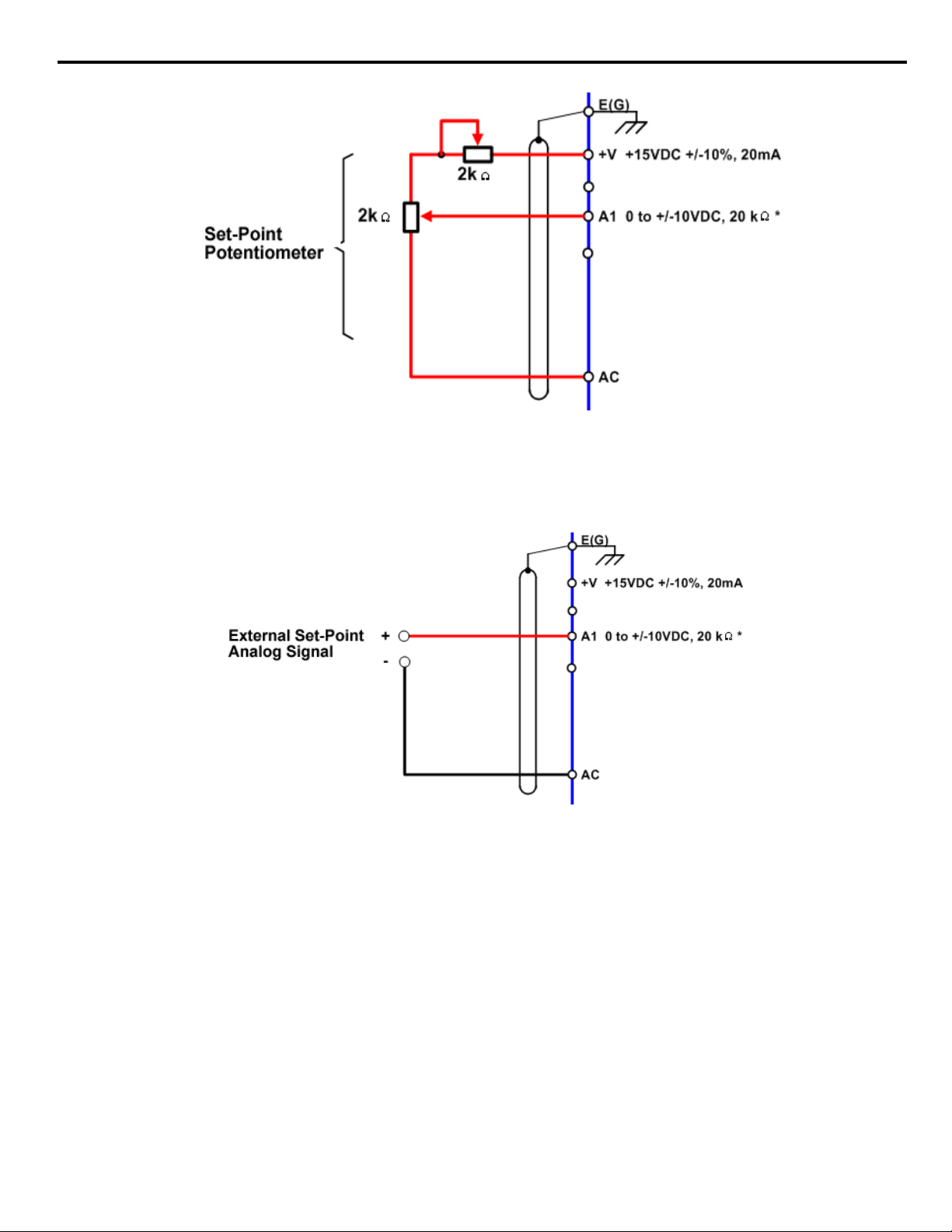

To configure the iQpump drive to follow an “Auto Setpoint” set by the analog input: Set b1-01 = “1: Terminals,” and connect a

potentiometer or external signal to the iQpump drive. Refer to Figu re 3. for connection diagram for the setpoint potentiometer.

14 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 15

Figure 1.3

Figure 3. Setpoint Potentiometer Connection Diagram

Refer to Figure 4. for the connection diagram for an external analog signal setpoint reference.

Note: When b1-01 = 1 (terminals) and P5-01 = 0 (hand mode reference source), the setpoint and the hand reference are

determined by the external analog signal.

Figure 1.4

Figure 4. External Analog Signal Setpoint Reference

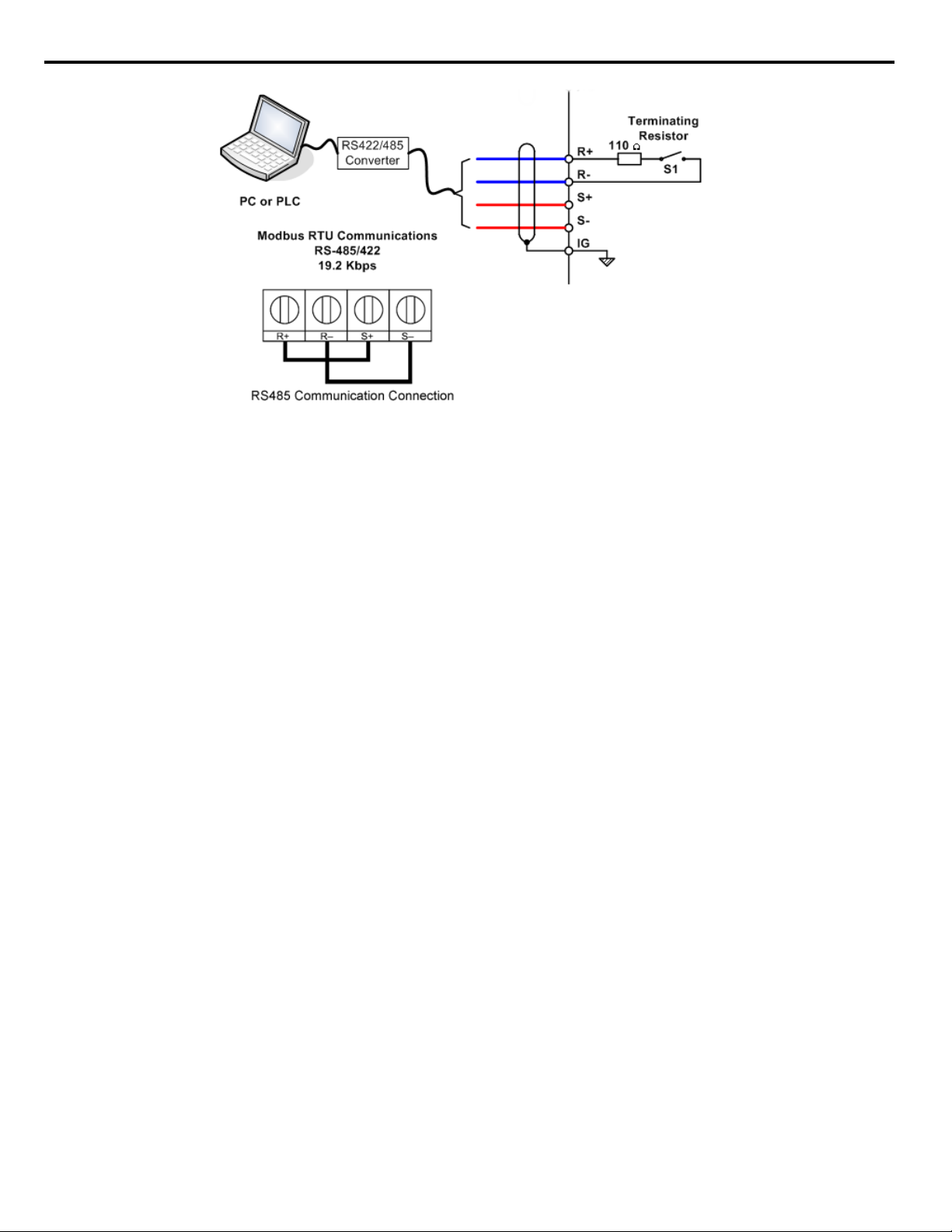

Setting the iQpump drive to receive the “Auto Setpoint” from serial communication: Set b1-01 = “2: Serial Com,” and connect the

RS-485 / 422 serial communications cable to terminals R+, R-, S+, and S- on the control I/O terminal block.

Refer to Figure 5. for the connection diagram using a PC to provide the auto setpoint reference to the iQpump drive. Further information

regarding communication protocols are referenced in Appendix A.

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 15

Page 16

Figure 1.5

Figure 5. Connection Diagram of PC or PLC

To configure the iQpump drive to receive the “Auto Setpoint” for a network communication option card: Set b1-01= “3: Option

PCB,” and plug a network option board (p/n SI-J) into the 2CN port on the iQpump drive Control PCB. Consult the manual supplied with

the option board for instructions on integrating the iQpump drive into the network system.

The iQpump drive can support the following network communication options. Refer to the appropriate Installation Guide (IG) and

Technical Manual (TM) for further details. These network communications documents can be located at http://iQpump.yaskawa.com.

Profibus DP Option Card CM061 Manual: IG.AFD.12

DeviceNet Option Card CM05X Manual: IG.AFD.14

Modbus Plus Option Card CM071 Manual: IG.AFD.17

Modbus TCP/IP Option Card CM090 Manual: IG.AFD.25

EtherNet/IP Option Card CM092 Manual: IG.AFD.26

Important: If b1-01 = “3: Option PCB” but a network card is not installed in 2CN, an OPE05 Operator Programming Error will be

displayed on the digital operator and the iQpump drive will not run.

■ Start / Stop from Comm. Option Card (Parameter b1-01 = 3):

The iQpump Controller allows for the setpoint reference to be set via any of the following communication option cards:

Profibus DP Option Card CM061 Manual: IG.AFD.12

DeviceNet Option Card CM05X Manual: IG.AFD.14

Modbus Plus Option Card CM071 Manual: IG.AFD.17

Modbus TCP / IP Option Card CM090 Manual: IG.AFD.25

EtherNet / IP Option Card CM092 Manual: IG.AFD.26

16 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 17

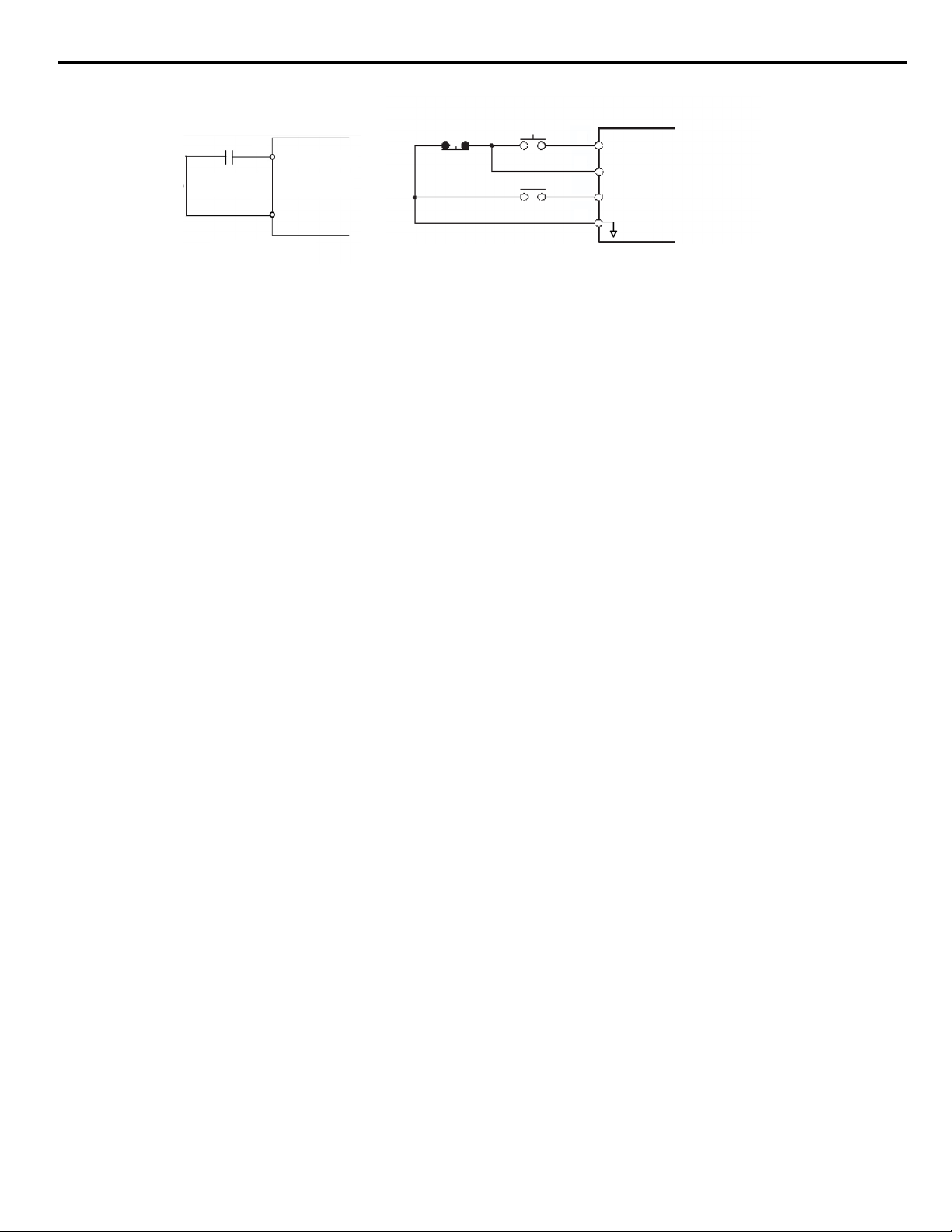

◆ b1-02 Run Command Selection

S1

S2

SN

FWD Run/Stop

REV Run/Stop

3-wire control

Stop switch

(NC contact)

Operation switch

(NO contact)

Run command

(run on momentary close)

Stop command

(stop on momentary open)

Sequence input common

SN

Setting Description

0 Operator (factory default)

1 Terminals

2Serial Com

3 Option PCB

5Timed Run

b1-02 = 0, Operator (factory default).

The iQpump drive comes factory programmed for Start and Stop from the Keypad.

The iQpump drive can be programmed to receiver a Run command from four different inputs: digital operator, terminals, serial

communications, or an option PCB.

If the Run command input is determined by the digital operator: Set b1-02 = “0: Operator,” and the HAND and OFF keys will be

used to provide the Run command to the iQpump drive.

b1-02 = 1, Terminals

If the Run command input is determined by the external terminals: Set b1-02 = “1: Terminals” and initiate an external Run

command by a contact closure between terminals S1 and SN. Refer to Figure 8. for the connection diagram of the external Run

command.

Note: To use the external terminals requires the iQpump drive to be set to “Auto” mode by pressing the Auto key.

Select between 2-wire and 3-wire control operation by doing the following:

2-Wire Control The factory default setting is for 2-wire operation. In the 2-wire configuration a closure between S1 and SN will be

interpreted as a Forward Run command by the drive.

Figure 1.6

Figure 6. 2-Wire Control

3-Wire Control When any of the multi-function digital input parameters, H1-01 through H1-05, is set to 0, terminals S1 and S2 become

Run and Stop, respectively. The multi-function digital input that was set to 0 will function as a Forward / Reverse input for the iQpump

drive. When the Forward / Reverse input is open the iQpump drive will run in the Forward direction and when the input is closed, the

iQpump drive will run in the Reverse direction.

In 3-wire operation a momentary closure (> 50mS) of S1 will cause the iQpump drive to run provided that S2 is held closed. The iQpump

drive will stop anytime the S2-SN connection is broken. If the 3-wire configuration is implemented via a 3-wire Initialization (A1-03 =

“3330: 3-Wire Initial”), then terminal S3 becomes the Forward / Reverse input.

Note: Reverse operation is disabled in the iQpump drive; however, in 3-wire control, one of the multi-function digital inputs

needs to be programmed to 0. Otherwise, the 3-wire control will not work.

Figure 1.7

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 17

Figure 7. 3-Wire Control

Page 18

Figure 1.8

b

b1-02 = 1

Auto Mode Start

External Switch or

Relay Contact

S1

S2

S3 (H1-01)

S4 (H1-02)

S5 (H1-03)

S6 (H1-04)

S7 (H1-05)

SN

SC

SP 24 VDC +/- 20%, 8 mA

E (G)

b1-02 = 2, Serial Com

Figure 8. Connection Diagram of External Start / Stop Switch

If the Run command is determined by Serial Communication:“b1-02 = 2: Serial Communications,” and initiate the Run command

through the serial communications. Refer to Figure 8. (in the previous b1 sequence section) for the connection diagram for serial

communications through the RS232 / 485 terminals to R+, R-, S+ and S-. The following is a simple setup procedure for programming the

iQpump drive and PC Serial communications to initiate Run and Stop commands through serial communications.

1. Program b1-02 = “2: Serial communications”.

2. Program the following H5 parameters:

H5-01 Serial Communication Address: 31

H5-02 Serial Baud Rate: 9600 Baud (setting 3).

H5-03: Serial Communication Parity Selection: None (setting 0)

3. Initiate a Start / Stop command

iQpump command register number: 0001

Stop Command: Transmit value of 0000 (16 bit) to iQpump command address.

Start Command: Transmit value of 0001 (16 bit) to iQpump command address.

Reset Command: Transmit value of 0008 (16 bit) to iQpump command address.

b1-02 = 3, Option PCB

If the Run command input is determined by a network communications option PCB: “b1-02 = 3: Option PCB,” and initiate the Run

command through the available network communications option PCB listed below. The Installation Guides (IG) and Technical Manuals

(TM) are available at http://iQpump.yaskawa.com.

The iQpump Controller allows for monitoring, diagnostics and control using any of the following communication option cards:

Profibus DP Option Card CM061 Manual: IG.AFD.12

DeviceNet Option Card CM05X Manual: IG.AFD.14

b1-02 = 5, Timed Run

If the Run command input is determined by a Timed Run: “b1-02 = 5: Timed Run,” when this feature is enabled, the drive will run at

the HAND frequency reference for the time specified in parameter P4-18. Timed Run cannot be enabled when in multiplex mode

(P1-01 > 0).

Modbus Plus Option Card CM071 Manual: IG.AFD.17

Modbus TCP / IP Option Card CM090 Manual: IG.AFD.25

EtherNet / IP Option Card CM092 Manual: IG.AFD.26

Note: Refer to the communication card instruction manual or consult factory for installation and operation instructions.

18 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 19

Run / Stop Control:

“Hand”

Key

“Off”

Key

P4-18

R-S Run Time

P4-19

R-S Stop Time

P4-18

R-S R un Time

P4-19

R-S Stop Time

P4-18

R-S Run Time

P4-19

R-S Stop Time

P4-18

R-S Run Time

P4-19

R-S Stop Time

P4-18

R-S Run T ime

Cycle

1

Cycle

2

Cycle

3

Cycle

4

Cycle

5

P4-18

R-S Run T ime

Cycle

1

(Cy cle 0)

Output

Frequency

P5-02

Sleep

Mess age

Run /Stop

Finished

Mess age

R-S Cycle Count

P4-20 = 5

• Only enabled when all three Run / Stop Control parameters are set to a value greater than zero (P4-18 > 0, P4-19 > 0, and P4-20 > 0).

• Available only when in HAND or LOCAL mode.

• PI control is disabled.

• Will always start off running when a run command is given.

• A stop command, power loss or fault will reset all timers and counters associated with the Run / Stop Control.

• A stop command will result in a stopping method set by parameter b1-03.

• When the “Run” portion of the timer expires, the drive stop using the stopping method set by parameter b1-03.

• When stopped due to the “Run” timer expired, the standard “sleep” message will be displayed on the operator.

• When stopped because the final cycle count has been exceeded, the digital operator will display “Run / Stop Finished”. The display

will be cleared when a stop command is given or power is lost.

• If a fault (not auto-restart) occurs during Run / Stop Control, all timers and counters are reset.

• If an auto-restart is in process, under most circumstances the Run / Stop Control will continue to operate. However, if the stop timer

expires prior to the auto-restart expiring, the drive will wait until the auto-restart time expires before resuming normal Run / Stop

Control.

When this feature is enabled and the drive is given a run command, the drive will run for the time specified in parameter P4-18, then stop

for the time specified in parameter P4-19. It will do this the number of times programmed in parameter P4-20. (Refer to parameters P418, P4-19 and P4-20.) The display will show one of two messages if the drive is stopped due to this feature. Run-Stop control cannot be

enabled when a multiplex mode (P1-01 > 0).

Timed Run:

If parameter b1-02 is set to 5 “Timed Run”, the timed run feature will be enabled. When “Timed Run” is enabled, Terminal S1 will be a

normally open “start” input and Terminal S2 will be a normally closed “stop” input. The drive can be started by either causing a rising

edge (open to close) on the S1 digital input when S2 is closed, or both S1 and S2 are closed when power is applied to the drive. The drive

will then start running at the HAND frequency reference P5-02 and run for the time specified in parameter P4-18. If the drive needs to be

stopped before the P4-18 timer expires, the circuit connected to Terminal S2 can be opened, or the Stop or Off keys on the digital operator

can stop the drive. The drive can be re-started by simply causing another rising edge on Terminal S1. There will be no modified display or

messages when the drive is stopped due to the Timed Run feature. If the drive is switched into HAND or LOCAL mode, the timed run

feature will be disabled.

1. Wire-Break detection for Terminal A2 will be completely disabled during Timed Run control.

2. The pre-charge feature is disabled during Timed Run control.

3. Uses the “Hand” reference as the frequency reference. If P5-01 is set to 1, parameter P5-02 will be used as the reference. If P5-02 is set

to 0, Terminal A1 will be used as the reference.

4. The “Not Maintaining Setpoint”, and “Low Feedback” faults are disabled during Timed Run control.

5. The “Loss of Prime” fault (if enabled) will become active when the output frequency comes to within 1 Hz of the frequency reference.

6. The Timed Run Control will take priority over the “Auto Mode Fixed Speed” mode (digital input).

When this feature is enabled, the drive will run at the “Hand” frequency reference for the time specified in parameter P4-18. Timed Run

cannot be enabled when in Multiplex Mode (P1-01 > 0). (Refer to parameter P4-18.)

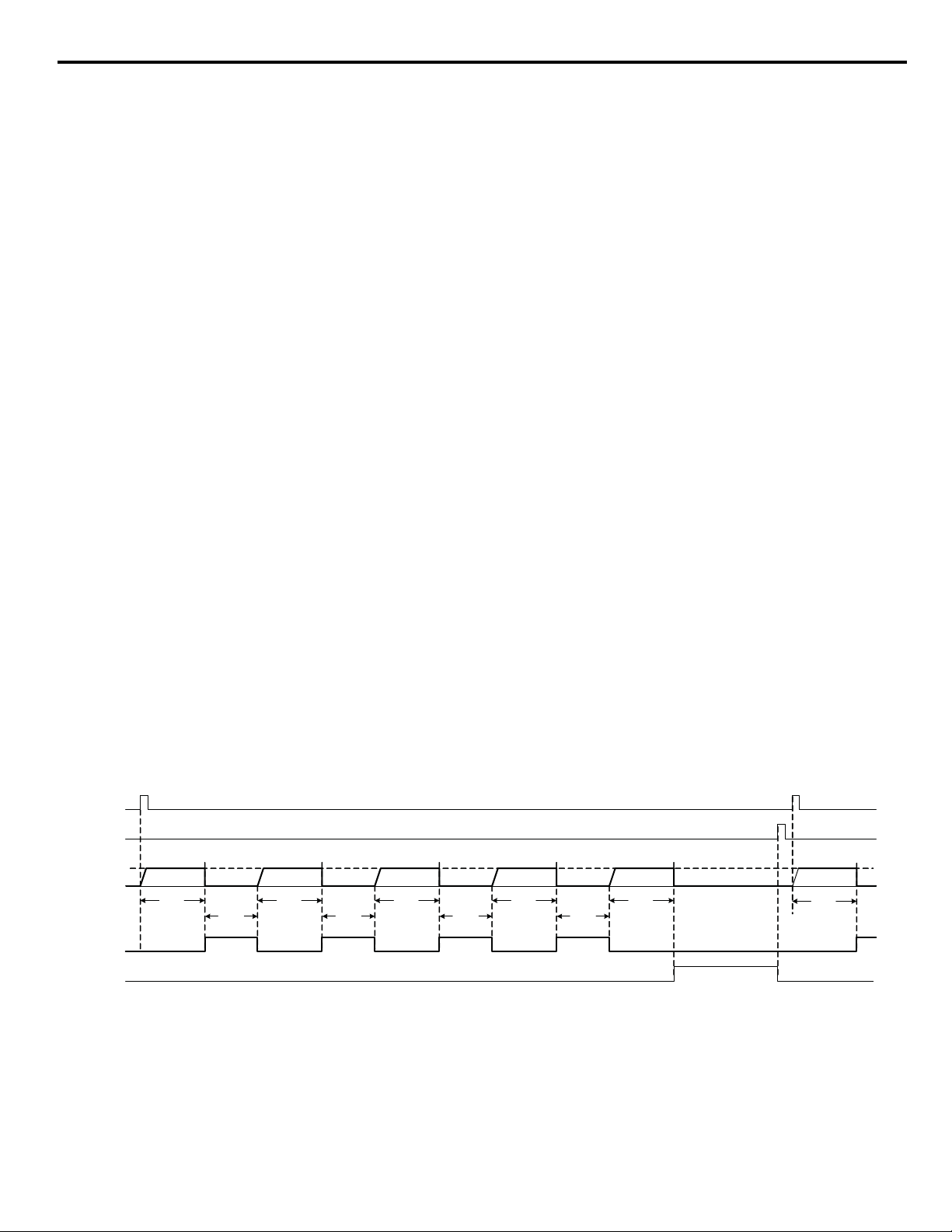

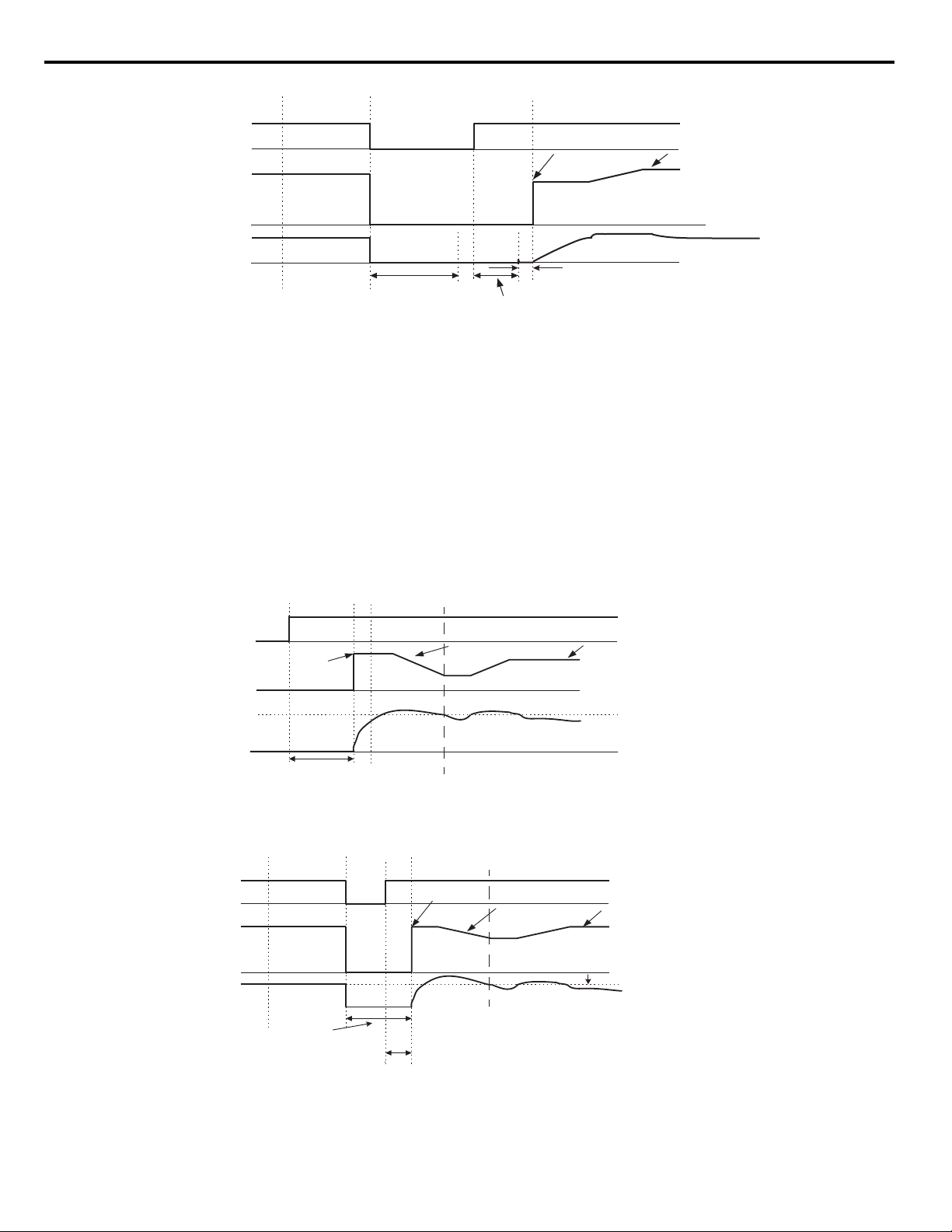

Figure 1.9

Figure 9. Run / Stop Control - HOA Operator JVOP162 - Coast to Stop

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 19

Page 20

Figure 1.10

Key

“Off”

Key

P4- 18

R-S R un Time

R-S Stop Time

P4-18

R-S Run Time

P4-19

R-S Stop Time

P4-18

R-S Run Time

P4-19

R-S Stop Time

P4-18

R-S Run Time

P4-19

R-S Stop Time

P4-18

R-S Run Time

Cycle

1

Cycle

2

Cycle

3

Cycle

4

Output

Frequency

P5-02

Sleep

Message

Run/Stop

Finished

Message

P4-19

Cycle

1

(Cy cle 0)

P4-19

R-S Stop Time

P4-18

R-S Run Time

R-S C yc le Count

P4- 20 = 5

“Hand”

“Run”

Key

“Stop”

Key

P4-1 8

R-S R un Time

R-S Stop Time

P4-18

R-S Run Time

P4-19

R-S Stop Time

P4-18

R-S R un Time

P4-19

R-S Stop Time

P4-18

R-S R un Time

P4-19

R-S Stop Time

P4-18

R-S Run Time

Cycle

1

Cycle

2

Cycle

3

Cycle

4

Output

Frequency

P5-02

Sleep

Message

Run/Stop

Finished

Message

P4-19

Cycle

1

(Cycle 0)

P4-19

R-S Stop Time

P4-18

R-S Run Time

R-S Cycle Count

P4-2 0 = 5

NOTE: I f the JVOP-160 is installed, t he drive must already be i n

“Local” mode for t he Run /Stop feature to operat e .

Figure 1.11

Figure 10. Run / Stop - HOA Operator JVOP162 - Ramp to Stop

Figure 1.12

Figure 1.13

“Hand” DI

(H1- 0x = 80)

Output

Frequency

Sleep

Mess age

Run /Stop

Finished

Mess age

P4-18

R-S Run Time

Terminal

S1

Terminal

S2

“Off ” or

“Stop”

Key

Output

Frequency

Cycle

1

R-S Stop Time

Figure 11. Run / Stop - HOA Operator JVOP160 - Ramp to Stop

P4-18

R-S R un Time

Cycle

P5- 02

P4- 19

(Cycle 0)

P4-18

R-S R un Time

Cycle

1

P4-19

R-S Stop Time

R-S C ycl e Count

P4-20 = 5

P4-18

R-S R un Time

Cycle

2

R-S S top Time

P4-19

Figure 12. Run / Stop - HOA Operator JVOP160 - Coast to Stop

P5-02

P4-18

R-S Run Time

P4-18

R-S Run Time

P4-18

R-S Run Time

Figure 13. Timed Run Operation (b1-02 = 5)

3

P4- 19

R-S S top Time

P4-18

R-S R un Time

P4-18

R-S Run Time

Cycle

4

R-S Stop Time

P4-19

P4-18

R-S R un Time

20 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 21

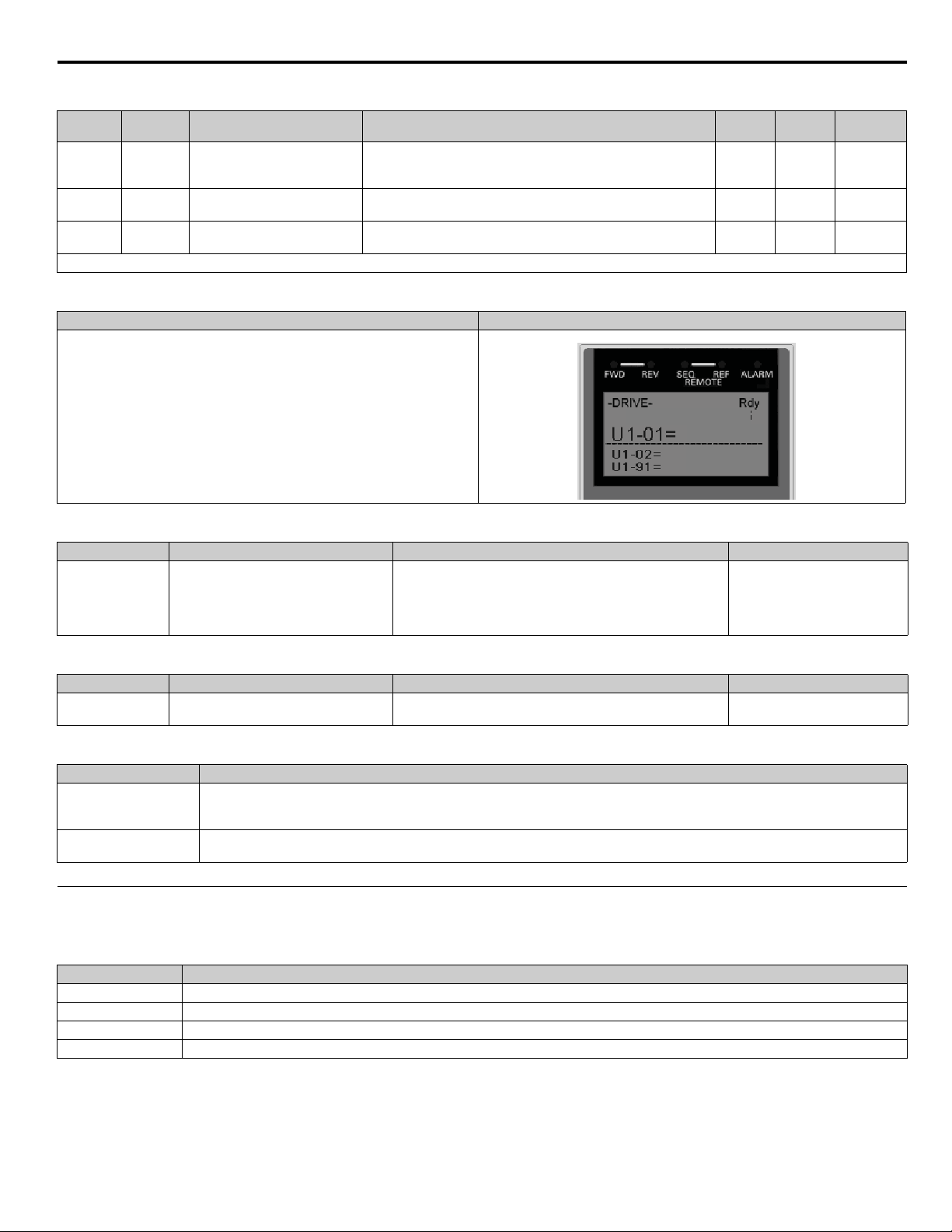

Table 1 Related Parameters <0034>

Run/Stop Control

40.00Hz

0.00 Hz

0.0 PSI

Parameter

No.

P4-18

P4-19

P4-20

Denotes that parameter can be changed when the drive is running.

Addr. Hex

831

832

833

Parameter Name

Digital Operator Display

Run / Stop Control Run Time

R-S Run Time

Run / Stop Control Stop Time

R-S Stop Time

Run / Stop Control Cycles

R-S Cycle Count

Description

This parameter sets the amount of time the drive will run for when

the Run / Stop Control is enabled. It will also set the “timed” run time

when enabled (b1-02 = 5).

This parameter sets the amount of time the drive will stop for when

the Run / Stop Control is enabled.

This parameter determines how many Run / Stop Cycles the drive

will execute before staying stopped.

Setting

Range

0.0 ~

6000.0 min

0.0 ~

6000.0 min

0 ~ 1000 0 Programming

Factory

Setting

0.0 min Programming

0.0 min Programming

Table 2 Digital Operator Display

Description Operator Display

When the Run / Stop function is enabled, the display will change as shown.

The Run / Stop function is enabled by setting parameters P4-18, P4-19 and P4-20

to values greater than zero.

Table 3 Fault <0034>

Fault Display Description Cause Countermeasures

Run / Stop Control has been enabled when in multiplex mode.

oPE15

Run / Stp-

Run / Stop or Timed Run enabled in

multiplex mode.

(P1-01 > 0, P4-18 > 0, P4-19 > 0 and P4-20 > 0).

OR

Timed Run Control has been enabled when in multiplex mode.

(P1-01 > 0 and b1-02 = 5).

Reprogram P1-01, P4-18 ~ P4-20,

or b1-02.

Menu

Location

Table 4 Message <0034>

Fault Display Description Cause Countermeasures

Run / Stop Finished Run / Stop Cycles have completed.

The number of Run / Stop Cycles since the last HAND command

has completed.

Press “Off” to clear the message.

Table 5 Multi-Function Output Setting <0034>

Setting Description

51

52

Run / Sto p - Stop

Closed: Drive is stopped due to the Run / Stop control (P4-18 and P4-19) OR

Closed: Drive is stopped because the Run / Stop cycles have completed (P4-20).

Run / Stop - Finish

Closed: Drive is stopped because the Run / Stop cycles have completed (P4-20).

◆ b1-03 Stopping Method

There are four methods of stopping the iQpump drive when the Run command is removed.

Setting Description

0 Ramp to Stop (factory default)

1Coast to Stop

2 DC Injection to Stop

3 Coast w / Timer

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 21

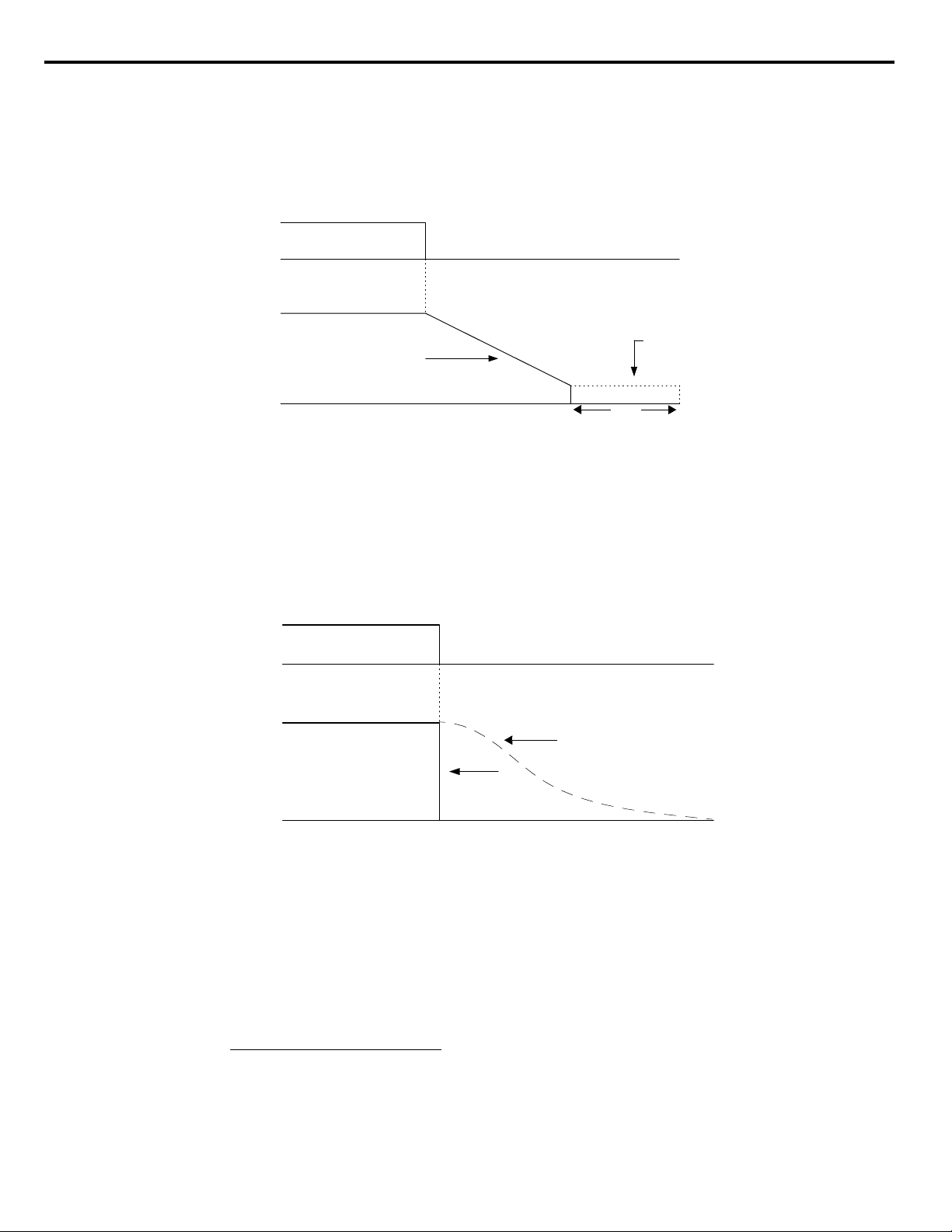

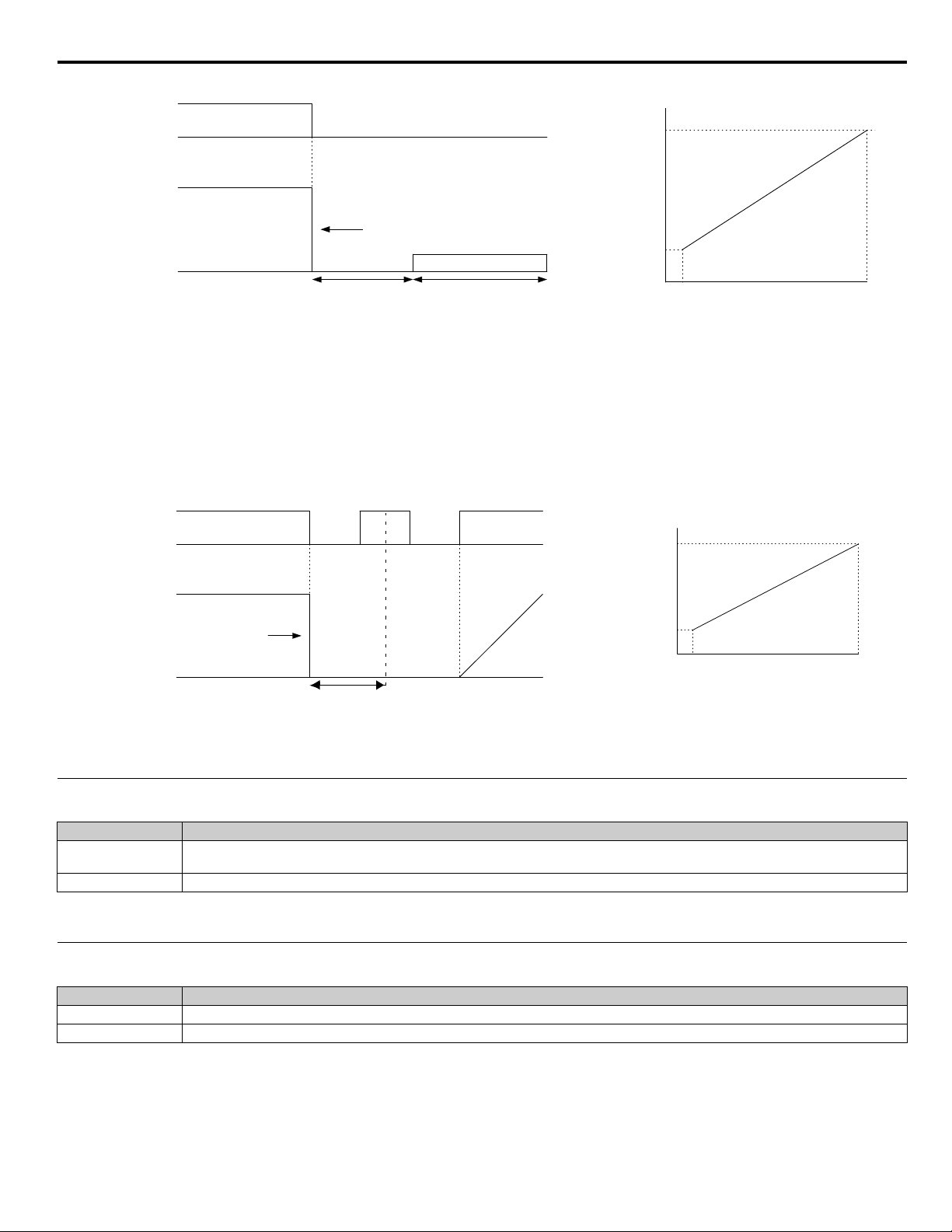

Page 22

0: Ramp to stop: When the Run command is removed, the iQpump drive will decelerate the motor to 0 rpm. The rate of deceleration is

ON

OFF

Run Command

Output Frequency

Deceleration Time (C1-02)

DC Injection Brake

100 %

0 %

TIME

| b2-04 |

b2-01

(CLOSED)

(OPEN)

Time to Stop

Output Freq. at time of stop command

Maximum Frequency (E1-04)

------------------------------------------------------------------------------------------- Se tt in g o f ac ti v e D e c el Ti m e ( C 1 -0 2 or C1-04)×=

ON

OFF

Run Command

Output Frequency

Drive Output Frequency Interrupted

100 %

0 %

TIME

Motor Speed

(CLOSED)

(OPEN)

04)-(E1Frequency Maximum

FrequencyOutput 1004)-(b2

Time BrakeInjection DC

××

=

determined by the active deceleration time. The factory default Decel Time is in parameter C1-02.

When the output frequency has dropped below the DC Injection Start Frequency in b2-01 (Default = 0.5 Hz) DC current will be injected

in the motor at a level determined by b2-02 (50% Default). The DC Injection condition will occur for the time specified by b2-04 (0.0

Default), to establish the end point of the ramp. DC injection can be used to insure the motor is at zero rpm prior to the iQpump drive

shutting off.

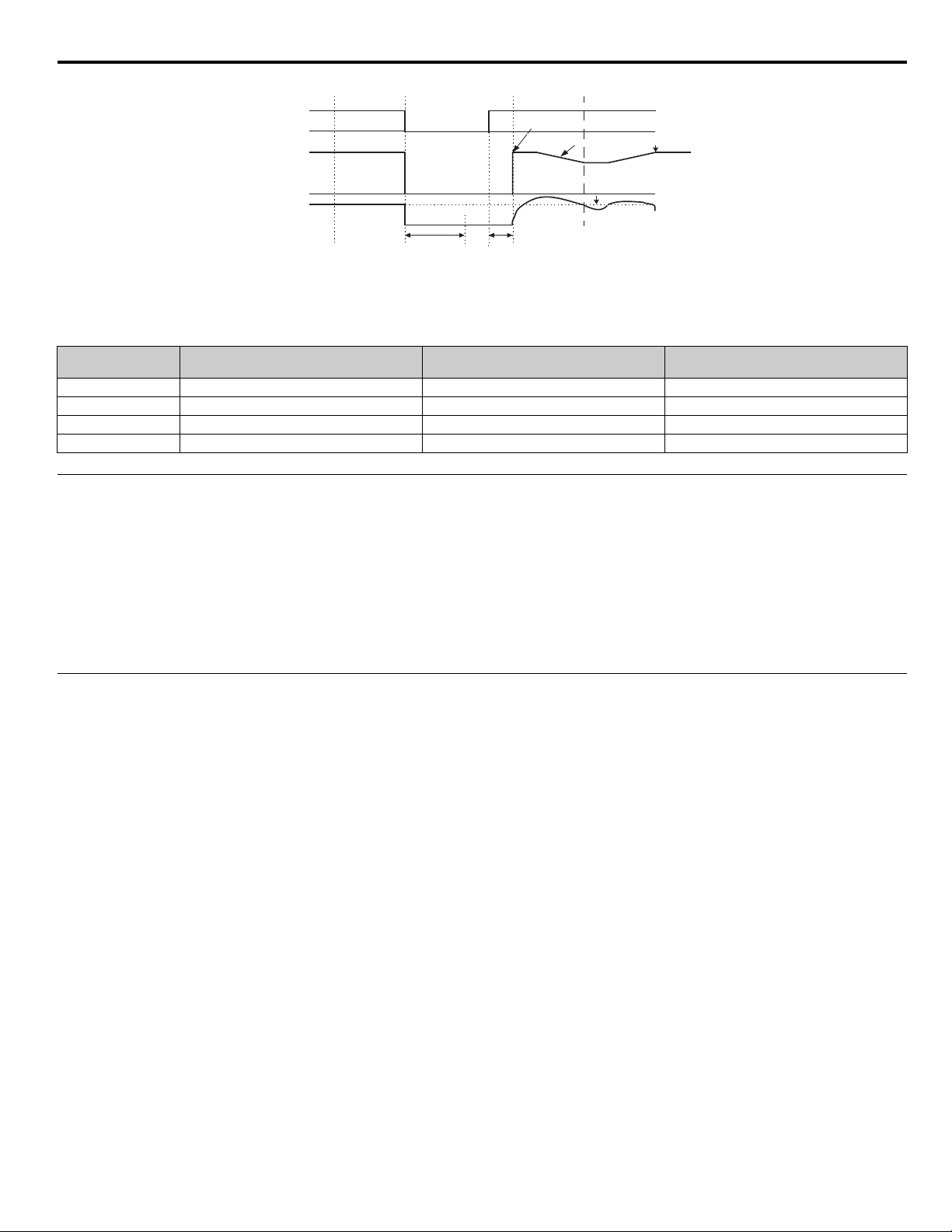

Figure 1.14

Figure 14. Deceleration to Stop

The actual deceleration time can be determined by the following formula.

If S-Curve characteristics are specified by the iQpump drive programming, they will add to the total time to stop.

1: Coast to stop: When the Run command is removed, the iQpump drive will turn off its output and the motor will coast (uncontrolled

deceleration). The friction of the driven equipment will eventually overcome any residual inertia of the system and the rotation will stop.

Figure 1.15

Figure 15. Coast to Stop

Important: After a stop is initiated, a subsequent Run commands input before the Minimum Baseblock Time (L2-03) has expired, will

be ignored.

2: DCInj to Stop: When the Run command is removed, the iQpump drive will Baseblock (turn off its output) for the Minimum

Baseblock Time (L2-03). Once the Minimum Baseblock Time has expired, the iQpump drive will inject DC current into the motor

windings to lock the motor shaft. The stopping time will be reduced as compared to Coast to Stop. The level of DC Injection current is set

by parameter b2-02 (50% Default). The DC Injection brake time is determined by the set value in b2-04 and the output frequency at the

time the Run command is removed.

22 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 23

Figure 1.16

ON

OFF

Run Command

Output Frequency

Drive Output Voltage Interrupted

DC Injection Brake

DC Injection Brake Time

Minimum Baseblock

Time (L2-03)

100 %

0 %

DC Injection Brake Time

b2-04 x 10

b2-04

10%

100% (Maxim um

Output Frequency)

b2-04

(CLOSED)

(OPEN)

Run Command

Output Frequency

Drive Output

Voltage

Interrupted

OFF

ON

Timer Value T

(C1-02)

100 %

0 %

Operat ion Wait Time ( T)

Deceleration

Time (C1-02 )

Minimu m

Baseblock

Time (L2-03)

Minimu m

Output

Frequency

100% (Maximum

Output

Frequency)

Output Fr equency at S top Command Input

Ignored

Run Command

Timer Value T

(OPEN)

(CLOSED)

Figure 16. DC Injection Braking to Stop

Important: If an overcurrent (OC) fault occurs during DCInj to Stop, lengthen the Minimum Baseblock Time (L2-03) until the fault no

longer occurs.

3: Coast w / Timer: When the Run command is removed, the iQpump drive will turn off its output and the motor will coast to a stop. If

a Run command is input before time T (operation wait time) expires, the iQpump drive will not run and the Run command will need to be

cycled before operation can occur. The time T (operation wait time) is determined by the output frequency when the Run command is

removed and the active deceleration time (C1-02).

Figure 1.17

◆ b1-07 Local / Remote Run Selection

◆ b1-08 Run Command Selection During Programming

As a safety precaution, the iQpump drive will not normally respond to a Run input when the digital operator is being used to adjust

parameters. If it is necessary that external Run commands be recognized even while the drive is being programmed, set b1-08 = “1:

Enabled.”

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 23

Figure 17. Coast to Stop with Timer

Setting Description

0

Cycle External Run - If the run command is closed when switching from Hand (local) mode to Auto (remote) mode, the drive will not run.

(factory default)

1 Accept External Run - If the run command is closed when switching from Hand (local) mode to Auto (remote) mode, the drive WILL run.

Note: Used with LCD Operator only.

Setting Description

0 Disabled (factory default)

1 Enabled

Page 24

◆ b1-11 Drive Delay Time Setting

DDLY

Waiting to RUN

Setting Range: 0 ~ 600 s

Factory Default: 0 s

If a time is set into parameter b1-11, the iQpump drive will delay executing any run command until the b1-11 time has expired. During

iQpump drive delay time execution, the digital operator will display:

Both the ALARM and Run indicators will blink while the iQpump drive waits to execute the Run command.

24 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 25

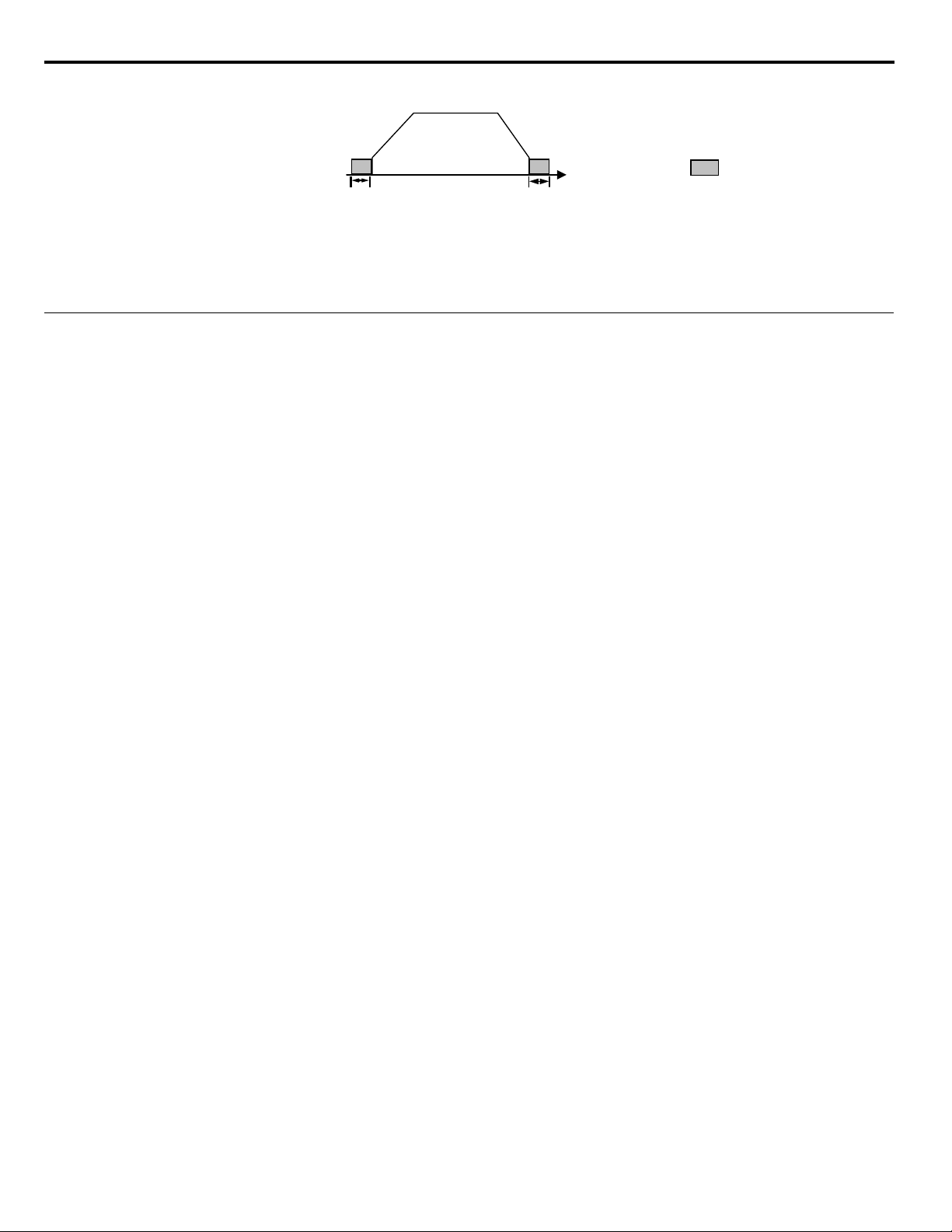

b2 DC Braking

Output Frequency

t

b2-01

||

b2-04

ime

The DC Braking Group contains parameters associated with the DC injection braking feature. Parameters involving the starting

frequency, current level, braking time, and motor pre heat current level are located here.

◆ b2-01 DC Injection Braking Start Frequency

Setting Range: 0.0 ~ 10.0 Hz

Factory Default: 0.5 Hz

Parameter b2-01 sets the output frequency where the iQpump drive begins DC Injection during Ramp to stop in order to lock the rotor

of the motor and established the end point of the ramp. If b2-01 < E1-09 (Minimum Frequency), then DC Injection begins at E1-09.

Parameter b2-01 also determines the output frequency that the iQpump drive must be at or below before a Zero Speed condition is

considered true. This affects any digital output configured as a Zero Speed signal (H2-0x = “1: Zero Speed”).

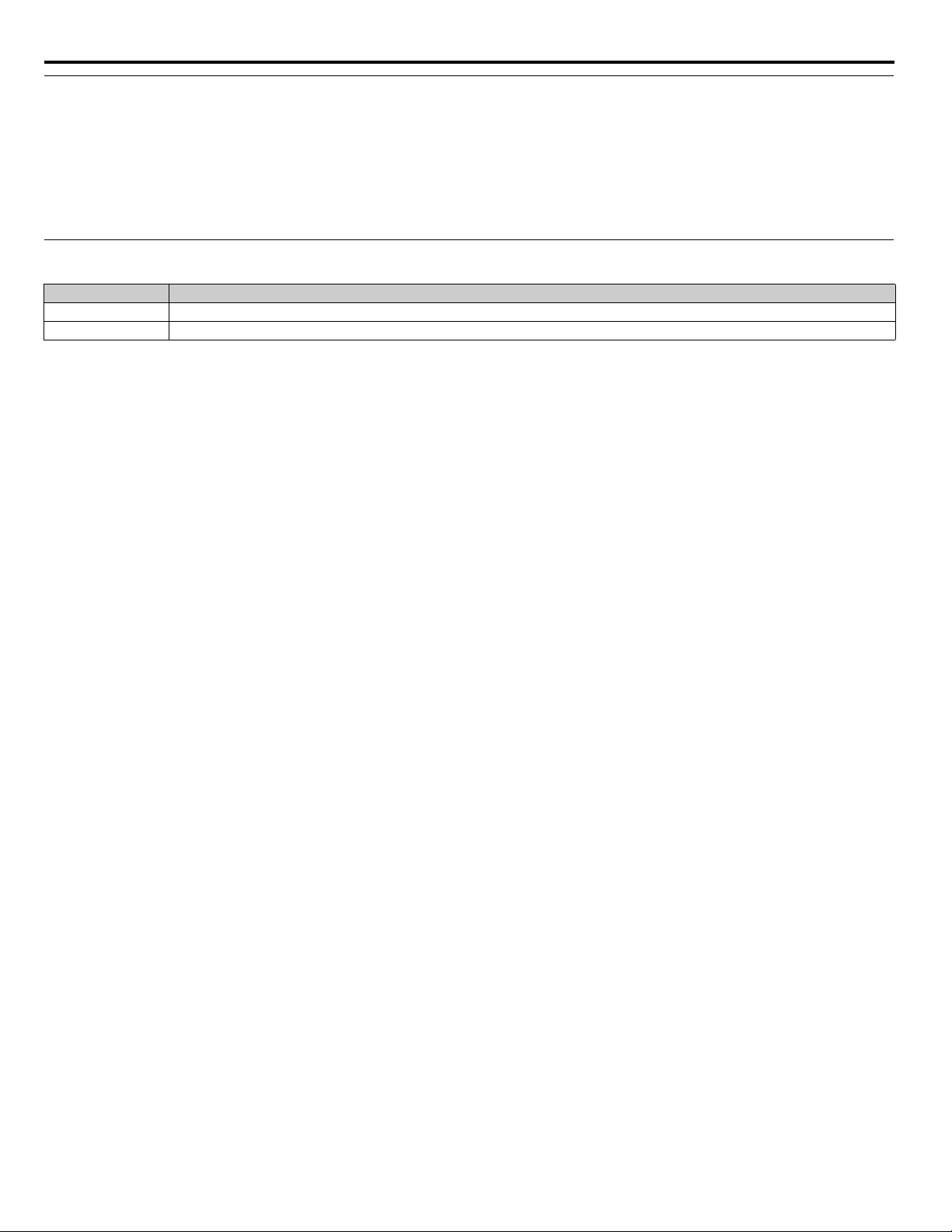

Figure 1.18

DC injection

Figure 18. DC Injection Braking During Stopping

◆ b2-02 DC Injection Braking Current

Setting Range: 0 ~ 100%

Factory Default: 50%

The level of DC Injection Braking Current affects the strength of the magnetic field attempting to lock the motor shaft. Increasing the

level of current will increase the amount of heat generated by the motor windings and should only be increased to the level necessary to

hold the motor shaft. DC Injection current is set in percentage of the iQpump drive rated output current. iQpump drive rated output

current is stated on the iQpump drive nameplate.

◆ b2-03 and b2-04 DC Injection Braking Time

Parameter No. Parameter Name

b2-03 DC Injection Braking Time at Start

b2-04 DC Injection Braking Time at Stop

Setting Range: 0.00 ~ 10.00 s

Factory Defaults: b2-03 = 0.00 s and b2-04 = 0.50 s

The iQpump drive can be programmed to automatically DC Inject for a predetermined amount of time prior to accelerating to speed (b2-

03) and / or at the end of a Ramp to stop (b2-04). Parameter b2-03 can be used to stop a rotating motor prior to attempting acceleration

(i.e. a wind milling fan). If DC Injection braking at start or Speed Search is not enabled, attempting to drive a spinning motor may cause

nuisance tripping.

Parameter b2-04 can be used to resist any residual motion of the load after the deceleration has finished.

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 25

Page 26

Figure 1.19

Output Frequency

DC injection

b2-03 b2-04

Figure 19. DC Injection Braking During Starting and Stopping

Parameter b2-04 also serves the function of affecting the length of time DC Injection to stop (b1-03 = “2: DC Injection to Stop”) will

occur.

◆ b2-09 Motor Pre-Heat Current

Setting Range: 0 ~ 100%

Factory Default: 0%

A DC current can be circulated within the motor windings while the motor is stopped. The current will produce heat within the motor and

prevent condensation. Parameter b2-09 determines the percentage of the iQpump drive rated output current that will be used for the motor

pre-heat function. This function can be useful in applications where the motor sits for extended periods of time in humid conditions.

Motor pre-heating can only be initiated by closing a digital input programmed as a Motor Pre-heat Input (H1-0x = 60). Check with the

motor manufacturer to determine the maximum acceptable current level the motor can withstand when stopped. Be sure not to exceed the

motor manufacturers recommended level.

26 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 27

b3 Speed Search

The Speed Search function allows the iQpump drive to determine the speed of a motor shaft that is being driven by rotational inertia.

Speed Search will allow the iQpump drive to determine the speed of the already rotating motor and begin to ramp the motor to a set speed

without first having to bring it to a complete stop. When a momentary loss of supply power is experienced, the iQpump drive output is

turned off. This results in a coasting motor. When power returns, the iQpump drive can determine the speed of the coasting motor and

start without requiring it to be brought to minimum speed. Speed Search can be programmed to always be active by setting b3-01 or it can

be commanded by remote contact closure by setting a digital input.

There are two forms of Speed Search in the drive, the speed estimation method and the current detection method.

Important: When setting the iQpump drive for remote Speed Search input, via a contact closure, the method of Speed Search is

determined by the setting of b3-01. If b3-01 = “0: SpdsrchF Disable” then the remote input will initiate speed estimation method, and if

b3-01 = “2: SpdsrchI Disable,” then the remote input will start the current detection method.

Parameters L2-03 and L2-04 also affect the current detection method of Speed Search operation.

◆ b3-01 Speed Search Selection

This parameter is effective only when the iQpump drive is given a new Run command.

Setting Description

0 SpdsrchF Disable

1SpdsrchF Enable

2 SpdsrchI Disable (factory default)

3SpdsrchI Enable

Speed Estimation: Method (b3-01 = 0 or 1) The speed estimation method will calculate the speed using measurements of residual

motor fields. The speed estimation version is bi-directional and will determine both the motor speed and direction. To enable speed

estimation Speed Search at start, set b3-01 = “1: SpdsrchF Enable”.

Important: If the speed estimation method of Speed Search is to be used, then Auto-tuning must be performed prior to using Speed

Search. If the length of cable between the iQpump drive and motor is ever changed after Auto-tuning then Auto-tuning should be

performed again

Important: The speed estimation mode cannot be used when there are multiple motors operated by one iQpump drive or the motor is two

or more frames smaller than the standard size motor per the iQpump drive capacity.

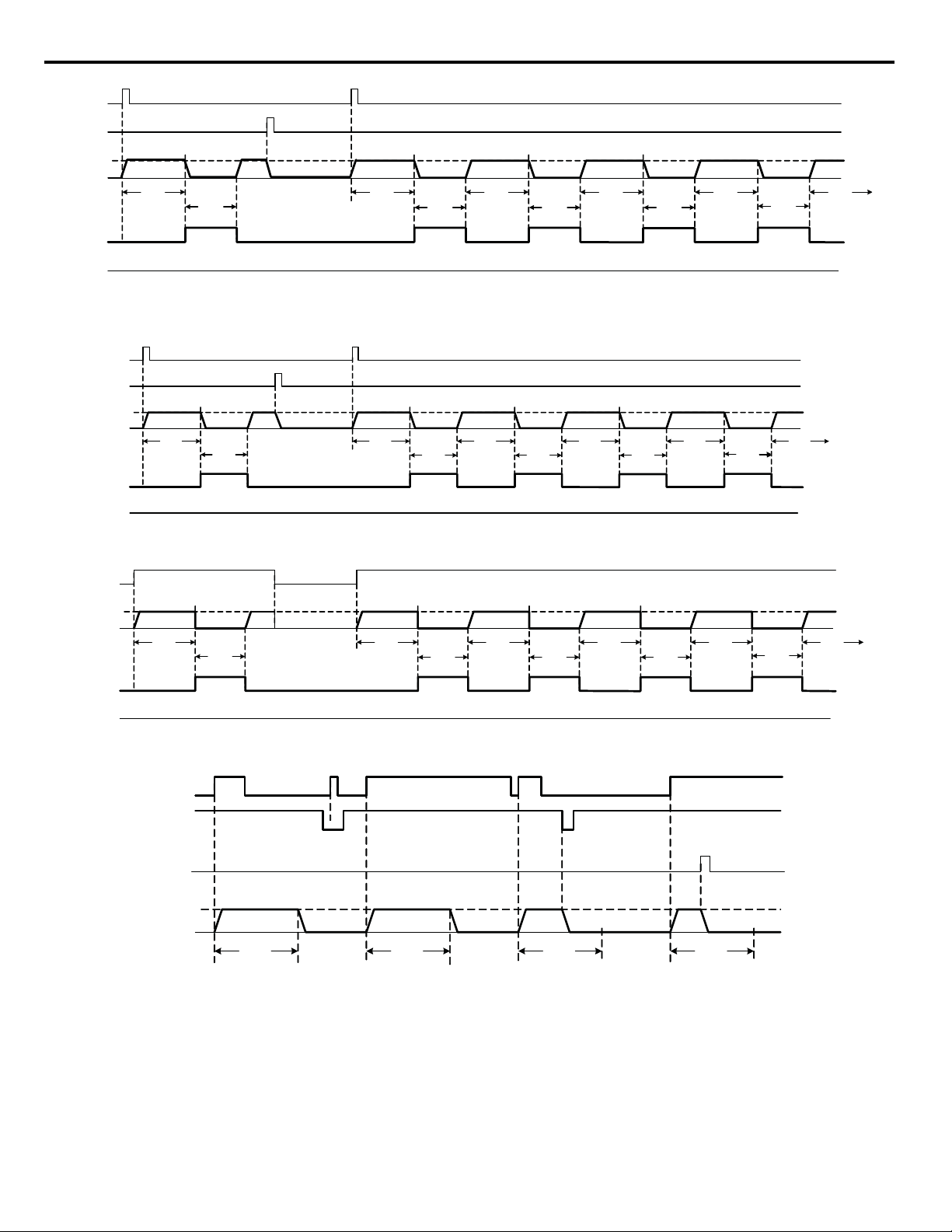

Figure 1.20

AC power supply

Output frequency

Output current

Minimum baseblock time (L2-03) x 0.75 *1

Minimum baseblock time (L2-03) x 0.75*1

OFFON

*2

Start using

speed detected

10 ms

*1 Baseblock time may be reduced by the output frequency

immediately before the baseblock.

*2

After AC power supply recovery, the drive waits for the

minimum Speed Search Wait Time (b3-05).

Set frequency

reference

Figure 20. Speed Search (Estimated Speed Method) after momentary power loss

where the power loss time is less than the minimum baseblock time

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 27

Page 28

Figure 1.21

AC power supply

Output frequency

Output current

OFFON

Start using speed detected

Set frequency

reference

Minimum baseblock time

(L2-03)

10 ms

Speed Search Wait Time

(b3-05)

Note: If the frequency immediately before the baseblock is low or the power supply break time is long,

operation may be the same as the search in case 1.

Note: If the frequency immediately before the baseblock is low or the power supply off time is long,

operation may be the same as the search in case 1.

Run command

Output frequency

Output current

OFF ON

b3-02

Deceleration time set in b3-03

Set frequency

reference

Minimum baseblock time

(L2-03)

Maximum output

frequency or

set frequency

* Lower limit is set using Speed Search Time (b3-05).

*

Search Delay Time (b3-05).

Speed search current level

AC power supply

Output frequency

Output current

OFFON

Output frequency before power loss

Set frequency

reference

Minimum baseblock time (L2-03)

*1 Baseblock time may be reduced by the output frequency

immediately before baseblock.

*2 After AC power supply recovery, drive waits for the minimum

Speed Search Wait Time (b2-03).

Deceleration

time set in b3-03

b3-02

speed search operating current

*2

*1

b3-05

Figure 21. Speed Search (Estimated Speed Method) after momentary power loss

where the power loss time exceeds the minimum baseblock time

Current Detection Method (b3-01 = 2 or 3): The current detection method starts searching from a predetermined frequency while

monitoring the iQpump drive output current to determine when the rotor speed and the iQpump drive output speed (frequency) match.

The current detection version is not bi-directional. To enable current detection Speed Search at start set b3-01 = “3: SpdscrhI enable” and

program any digital input equal to Speed Search 1 (H1-0x = 61) or Speed Search 2 (H1-0x = 62). Speed Search 1 will start searching from

the max. frequency (E1-04) and ramp down to meet the rotor speed. Speed Search 2 will start searching from the set frequency and ramp

down to meet the rotor speed.

Important: If a UV1 fault occurs when current detection Speed Search is attempted, increase the setting of L2-04.

Important: If an OC fault occurs when Speed Search is attempted after power loss recovery, increase the setting of L2-03.

Figure 1.22

Figure 22. Speed Search (Current Detection Method) at Startup

Figure 1.23

28 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Figure 23. Speed Search (Current Detection Method) after momentary power loss

where the power loss time is less than the minimum baseblock time

Page 29

Figure 1.24

AC power supply

Output frequency

Output current

OFFON

Output frequency before power loss

Set frequency

reference

Minimum baseblock time

(L2-03)

Deceleration speed set in b3-03

b3-02

Speed search operating time

Speed search wait time (b3-05)

Deceleration time set in b3-03

Figure 24. Speed Search (Current Detection Method) after momentary power loss

where the power loss time exceeds the minimum baseblock time

Setting of b3-01

0 No Yes - Speed Estimation Yes - Speed Estimation

1 Yes - Speed Estimation Yes - Speed Estimation Yes - Speed Estimation

2 No Yes - Current Detection Yes - Current Detection

3 Yes - Current Detection Yes - Current Detection Yes - Current Detection

Automatic Speed Search for all RUN

commands

Automatic Speed Search after

momentary power loss and baseblock

Speed Search Used for Run with

programmed multi-function input

◆ b3-02 Speed Search Deactivation Current

Setting Range: 0 ~ 200% of the iQpump drive rated output current

Factory Default: 120% of the iQpump drive rated output current

When using the current detection method of Speed Search, parameter b3-02 sets the current level that will determine when the search is

complete and the rotor and output speeds match. When the output frequency is higher than the actual rotor speed, the slip causes the

current to be high. As the output frequency is lowered, the closer it comes to the rotor speed, the lower the current draw will be. When the

output current drops below the level as set in b3-02 (100% = iQpump drive Rated Current) the output frequency stops decreasing and

normal operation resumes.

◆ b3-03 Speed Search Deceleration Time

Setting Range: 0.1 ~ 10.0 s

Factory Default: 2.0 s

Parameter b3-03 sets the deceleration ramp used by the current detection method of Speed Search when searching for the motor’s rotor

speed. Even if Speed Search 2 is selected, for Speed Search at start, the time entered into b3-03 will be the time to decelerate from

maximum frequency (E1-04) to minimum frequency (E1-09).

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 29

Page 30

◆ b3-05 Speed Search Delay Time

Setting Range: 0.0 ~ 20.0 s

Factory Default: 0.2 s

In cases where an output contactor is used between the iQpump drive and the motor, extra waiting time is provided after power returns

and before Speed Search is performed. This extra time allows for the contactor to operate. When Speed Search at start is used, b3-05 will

serve as the lower limit of the Minimum Baseblock Time (L2-03).

◆ b3-14 Bi-Directional Speed Search Selection

Setting Description

0Disabled

1 Enabled (factory default)

The b3-14 parameter can be used to turn off the bi-directional capabilities of the Speed Estimation form of Speed Search. By turning off

the bi-directional capability, the speed search will only try to match the speed in the last known direction.

30 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Page 31

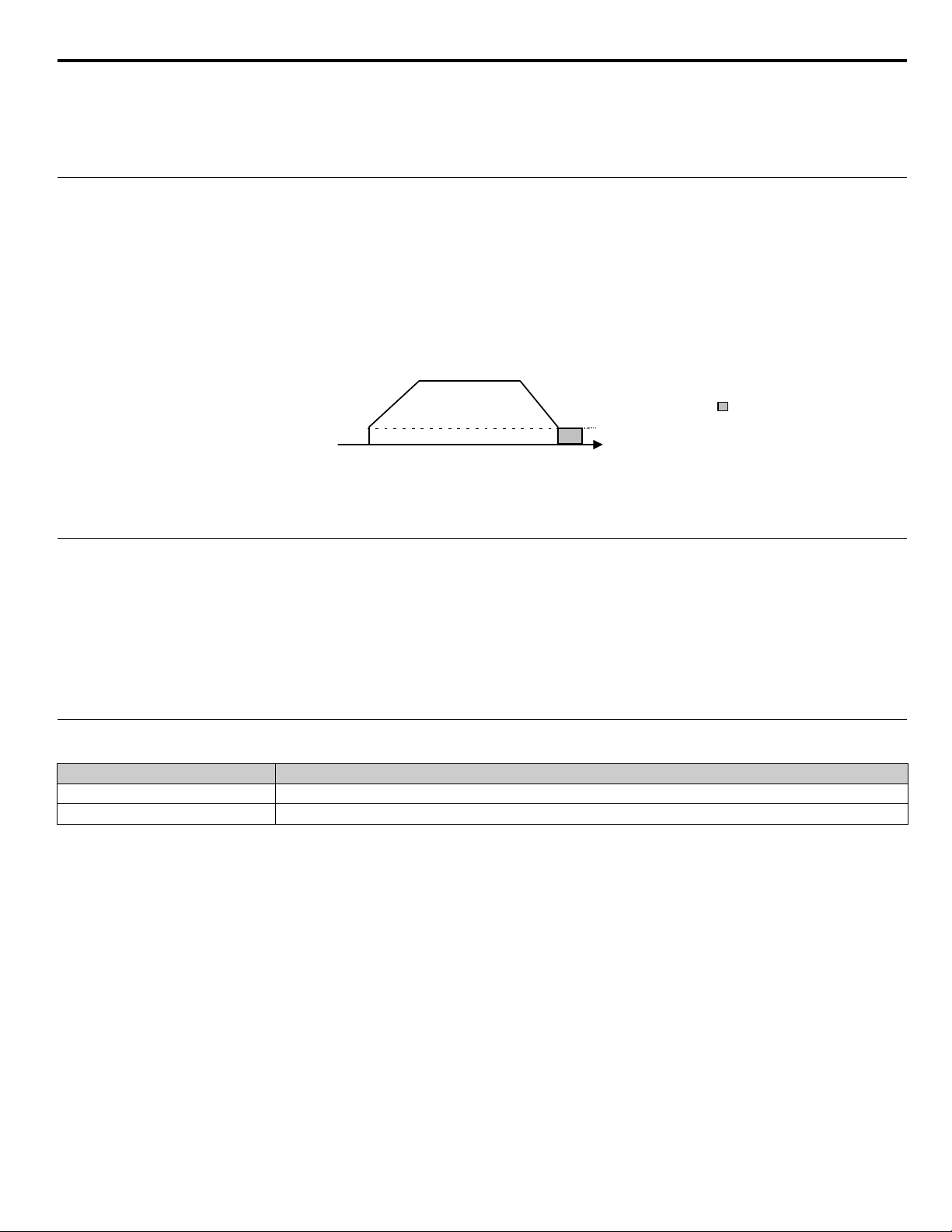

b4 Delay Timers

Multi-function Contact

Input: Timer Function

Multi-function Contact

Output: Timer Function

b4-01

b4-01

b4-02

ON (CLOSED)

OFF (OPEN)

ON (CLOSED

OFF (OPEN)

b4-02

The iQpump drive has an internal timer function that operates independently from the drive. A digital input must be programmed to be a

timer start input by setting H1-0x = 18. A digital output must be programmed as a timer output by setting H2-0x = 12. (Not to be

confused with the “Wait to Run Time” in b1-11.)

◆ b4-01 Timer Function ON-Delay Time

Setting Range: 0.0 ~ 3000.0 s

Factory Default: 0.0 s

The timer start input (H1-0x = 18) must be held on for at least the time specified in parameter b4-01 before the digital output programmed

as the timer output will close. See Figure 25. for timing details.

◆ b4-02 Timer Function OFF-Delay Time

Setting Range: 0.0 ~ 3000.0 s

Factory Default: 0.0 s

The timer start input (H1-0x = 18) must be held off for at least the time specified by b4-02 before the digital output programmed as the

timer output will open. See Figure 2 5. for timing details.

Figure 1.25

Figure 25. Timing Diagram of Timer Function

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 31

Page 32

b5 PI Function

Option Card

Serial Com

Terminal A1

D1-01

D1-04

D1-02

Output

frequency

P

1/t

1/t

Z

-1

b1-01

1

2

3

Frequency Reference

using multi-step

command

Frequency reference

(U1-01)

PI Set Point

(U1-38)

Proportional

gain

b5-02

I-time

b5-03

I - limit

b5-04

PI Limit

b5-06

PI delay time

b5-08

PI offse

t

(b5-07)

+

+

+

+

PI output monitor

(U1-37)

b5-01=0

ON

PI control is OFF under t he following

conditions:

- b5-01=0

- H3-xx=19 and the terminal status is

ON

Upper limit

Fmax x109%

+

+

b5-01=3

b5-01=1

Lower limit 0

4

Integral Hold

H1-xx=31

Integral Reset

H1-xx=30

PI Output

Characteristic

b5-09

1

0

PI SFS

b5-17

PI SFS cancel

H1-xx=34

0

1

P1-03

Scaling

Terminal A1

Terminal A2

PI Differential

Fdbk. H3-09=16

1

0

H3-09=B

1

0

1

0

PI Different ial

Fdbk. H3-09=16

PI Different ial

Fdbk. H3-09=16

Z

-1

1

0

1

0

PI Input

Caracteristic

H1-xx=35

1

0

Z

-1

PI SFS

b5-17

PI SFS cancel

H1-xx=34

0

1

Scaling

PI Input

(U1-36)

+

0

1

PI Different ial

Fdbk. H3-09=16

PI Feedback

(U1-24)

Scaling

10

10

b5-07

0

1

+

+

PI Different ial

Fdbk. H3-09=16

-

+

+

+

b5-10

PI Output

Gain

PI offset

H3-09=16

SFS

OFF

PI Different ial

Fdbk. H3-09=16

Characteristic

H1

P1-06

Minimum

Pump Speed

Speed Command / PI Setpoint

PI Setpoint

PI Feedback

The capability to accept an analog signal as feedback for a PI (Proportional + Integral) control function is built into the drive.

Figure 1.26

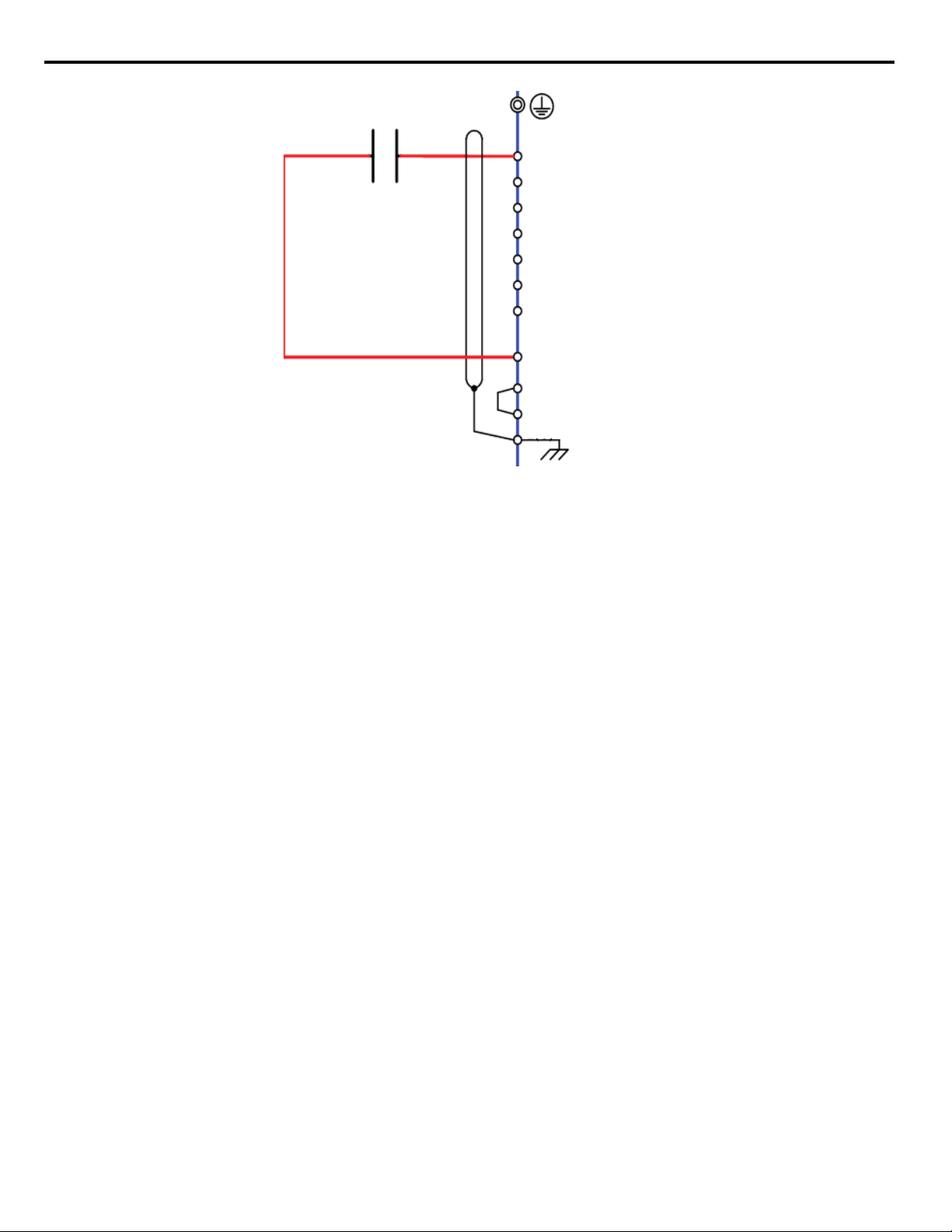

The analog feedback to the iQpump drive for the PI control is via the A2 terminal. The iQpump drive must be programmed (H3-09 = “B:

PI Feedback”) to use terminal A2 as feedback for the PI functionality of the drive.

The PI Setpoint can be configured to come from one of many different inputs or parameters. Table 6 on page 32 describes the options for

originating the PI Setpoint.

The PI Setpoint will be read from:

MEMOBUS/Modbus Register 06H 0 ON N/A

In some situations there are two feedback inputs. The drive can be programmed to maintain a set differential between two analog signals.

If input A2 is configured as a “PI Differential Mode” (H3-09 = “16: PI Differential”), then the iQpump drive will maintain a set

difference between the measurements read on inputs A1 and A2. This differential setpoint is programmed by parameter (b5-07).

32 YASK AWA TM.iQp.07 iQpump Controller Programming Manual

Figure 26. PI Block Diagram

Table 6 PI Setpoint Options

Status of b5-18 =

If these conditions are true

Status of MEMOBUS /

Modbus Register 0Fh bit 1

Status of b1-01 =

Parameter b5-19 1 N/A N/A

D1-01 0 OFF 0

Ter minal A 1 0 OFF 1

Serial Comm. 0 OFF 2

Option PCB 0 OFF 3

Page 33

◆ b5-01 PI Mode

Setting Description

0Disabled

1 Enabled (factory default)

2 Enabled - 2 Zone (dual zone PI enabled)

The iQpump drive can be used as a stand-alone PI controller. If PI functionality is selected by parameter b5-01, the iQpump drive will

adjust its output to cause the feedback from a transmitter to match the PI Setpoint (b5-19). The setting of b5-01 will determine whether PI

functionality is disabled (b5-01 = “0: Disabled”), enabled (b5-01 = “1: Enabled”), enabled - 2 zone (dual zone PI enabled) (b5-01 = 2).

b5-01 = 0, Disabled

PI functionality is disabled.

b5-01 = 1, Enabled (factory default)

PI functionality is enabled.

<0034>

b5-01 = 2, Enabled - 2 Zone (dual zone PI enabled)

<0034>

Enabled - 2 zone.

Provides automatic setpoint and feedback switching for dual zone pumping applications (geothermal).

• Terminal A1 is used as a feedback signal for “Zone 1”.

• Standard PI Feedback (H3-09 = B) as feedback for “Zone 2”.

• Based upon the two feedback levels, the drive determines which setpoint and feedback signal to use.

Figure 1.27

To:

Zone 1

Zone 1

Valve

Moto r

Pump

T1 T2 T3

Motor Leads

Zone 2

Valve

To:

Zone 2

A1

A2

Yaskawa

iQpump Drive

Figure 27. Dual Zone PI

Changes from standard product:

• When the Dual Zone PI is enabled (b5-01 = 2) Terminal A1 becomes the feedback signal for Zone 1.

• Multi-Step Frequency Reference Select digital inputs are ignored (H1-0x = 3 or 4) when the Dual Zone PI is enabled (b5-01 = 2).

• Transducer Loss Detection is enabled on Terminal A1 when b5-01 = 2.

YASK AWA TM.iQp.07 iQpump Controller Programming Manual 33

Page 34

Dual Zone PI Operation:

Set-Pt Zones 1&2

85 PSI

0.00 Hz

82.3 PSI

Set-Point Zone 1

85 PSI

0.00 Hz

82.3 PSI

Set-Point Zone 2

85 PSI

0.00 Hz

82.3 PSI

In order to enable the Dual Zone PI Operation:

b5-01 = 2 The PI Mode Setting Parameter must be set to “Enabled - 2 Zone”.

P1-01 = 0 Simplex mode only.

b5-09 = 0 Output Level Select set to “Normal Output” (Not Inverse PI Control).

When Dual Zone PI Operation is enabled:

• When the drive is in auto mode, the digital operator display will change as noted in Table 6 on page 32.

• Terminal A1 becomes a PI feedback, assigned to Zone 1.

• Standard PI feedback is assigned to Zone 2 (requires H3-09 = B).

• If feedback on Terminal A1 within the P4-17 value of the feedback on Terminal A2, the drive will use the d1-04 parameter as the

setpoint. It will use either Terminal A1 or Terminal A2 as feedback depending on which one is higher. The feedback signal(s) need to

be different for more than 5 seconds before any switching between the two will occur.

• If the feedback on Terminal A1 is more than the feedback on Terminal A2 plus the P4-17 value for more than 5 seconds, the drive will

then operate off of the Zone 1 setpoint (d1-02) and the Zone 1 feedback (Terminal A1).

• If the feedback on Terminal A2 is more than the feedback on Terminal A1 plus the P4-17 value for more than 5 seconds, the drive will

then operate off of the Zone 2 setpoint (d1-03) and the Zone 2 feedback (Terminal A2).

From the main “Auto Mode” display see Table 6 on page 32, if the <Data / Enter> key is pressed, the currently active setpoint will be

editable.

Note: To convert Terminal A1 to a 4 - 20 mA signal, connect a 250 Ohm precision resistor (1/4 Watt or greater) between A1

and AC. Then program H3-02 = 231.3% and H3-03 = 25.0%.

Table 7 Dual Zone PI