Page 1

YASKAWA iQpump

Intelligent Pump Controller

Manual Supplement

Software No.VSP130035 and VSP130036

Use this supplement with User Manual TM.iQp.06 and Programming

Manual TM.iQp.07. To properly use the product, read this manual

thoroughly and retain for easy reference, inspection, and maintenance.

Ensure the end user receives this manual.

MANUAL NO. TM.iQp.10

Page 2

2 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 3

Table of Contents

1 PREFACE AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 DRIVE CHANGE SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 FEATURE DETAILS - REMOTE DRIVE DISABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 FEATURE DETAILS - LOW CITY PRESSURE ALARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 SUCTION CONTROL VIA CONSTANT PRESSURE W/WELL DRAW DOWN. . . . . . . . . . . . . . . . . . . . . . . 14

8 GEOTHERMAL MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9 WATER LEVEL/SUCTION PRESSURE CONTROL IN MEMOBUS MULTIPLEX . . . . . . . . . . . . . . . . . . . . 26

10 IQPUMP MEMOBUS/NETWORK OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11 IMPROVED AND MISCELLANEOUS FUNCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

12 SPEED FOLLOWER DECELERATION TIME SWITCHOVER <0036>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13 TRANSDUCER WIRING USING AN EXTERNAL POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

PARAMETER LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Use this addendum with User Manual TM.iQp.06 and Programming TM.iQp.07.

To properly use the product, read this manual thoroughly and retain for easy reference, inspection, and

maintenance. Ensure the end user receives this manual.

.

YASK AWA TM.iQp.10 iQpump Technical Manual Supplement 3

Page 4

This Page Intentionally Blank

4 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 5

1 Preface and Safety

SUPPLEMENT

1 Preface and Safety

Yaskawa manufactures products used as components in a wide variety of industrial systems and equipment. The selection

and application of Yaskawa products remain the responsibility of the equipment manufacturer or end user. Yaskawa

accepts no responsibility for the way its products are incorporated into the final system design. Under no circumstances

should any Yaskawa product be incorporated into any product or design as the exclusive or sole safety control. Without

exception, all controls should be designed to detect faults dynamically and fail safely under all circumstances. All systems

or equipment designed to incorporate a product manufactured by Yaskawa must be supplied to the end user with

appropriate warnings and instructions as to the safe use and operation of that part. Any warnings provided by Yaskawa

must be promptly provided to the end user. Yaskawa offers an express warranty only as to the quality of its products in

conforming to standards and specifications published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESSED

OR IMPLIED, IS OFFERED. Yaskawa assumes no liability for any personal injury, property damage, losses, or claims

arising from misapplication of its products.

Applicable Documentation

The following manuals are available for the iQpump Controller:

Option Supplement

Yaskawa AC Drive - iQpump Controller Manual Supplement

Manual No: TM.iQp.10

Read this manual first.This document is a supplement to the iQpump Controller User Manual and

Technical Manual and Simplex Cheat Sheet. This supplement lists the effect of this custom software on

the parameters in the drive and function descriptions in the manual.

Access this web site to obtain a PDF or additional printed copies of this supplement.

U.S.: http://www.yaskawa.com

Yaskawa Drive

Yaskawa AC Drive-iQpump Controller

User Manual TM.iQp.06

Yaskawa AC Drive-iQpump Controller

Programming Manual TM.iQp.07

iQpump Controller Simplex Cheat Sheet

TM.iQp.04

To obtain instruction manuals for Yaskawa products access

these sites:

U.S.: http://www.yaskawa.com

Other areas: contact a Yaskawa representative.

For questions, contact the local Yaskawa sales office or the

nearest Yaskawa representative.

Terminology Used in this Manual

These terms are used in this manual.

iQpump Controller: The iQpump Controller may also be referred to as “drive” in this manual.

Obtaining Support

When seeking support for a drive with custom software, it is imperative to provide the unique part number shown on the

drive nameplate. The software is flashed to the control board memory and the operation of parameters, functions, and

monitors are different than the standard drive software, as described herein.

Refer to the Yaskawa office location listed on the back cover of this supplement for support inquiries.

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 5

Page 6

2 General Safety

NOTICE

2 General Safety

Abnormal Pump Operation Hazard

Important note when replacing an iQpump Controller.

Verify software ID drive monitor U1-14 when replacing an iQpump Controller in a multiplex network configuration.

Set parameter P9-99 to a value of 0 : "A-version 30034" if (ONE or MORE) iQpump Controllers on the network have

software version monitor U1-14=30034 and nameplate PRG: 0034. Otherwise do not change P9-99 setting from factory

default. Failure to comply will result abnormal drive operation.

Supplemental Safety Information

Read and understand this manual and the iQpump Controller User Manual before installing, operating, or servicing this

option unit. The drive must be installed according to the iQpump Controller User Manual and local codes. Observe all

cautions and warnings in this document and the standard drive manuals.

Refer to the iQpump Controller Simplex Cheat Sheet TM.iQp.04 and the iQpump Controller User Manual TM.iQp.06 for

safety information and installation and start-up instructions.

This document is a supplement to the standard iQpump Controller Manuals. It describes the enhanced functionality of

drive software version U1-14=30035 and nameplate PRG: 0035 or greater.

• Custom software is provided to add functionality to a standard AC drive to enhance or enable use in a specific

application.

6 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 7

3 Product Overview

3 Product Overview

About This Product

Yaskawa has simplified the application of variable frequency drives to pumping applications. Pumps are typically used

whenever water must be pumped from deep water wells or open bodies of water such as rivers, lakes, irrigation canals,

and water storage facilities. The integrated pump specific software and quick setup parameters, allow the operator easy

access to setup control values for a wide range of applications.

Feature Enhancement Summary

The following is a brief summary of features for drive software PRG:0035 that are added or enhanced over previous

iQpump Controllers:

Initialization Function: A special initialization function is created to quickly and conveniently configure the drive as a

generic speed controller. This initialization re-configures the Pump Quick Setup (Quick Start) menu to show parameters

likely to require adjustment in generic applications.

b1-04 (Reverse Operation Selection): Added new parameter B1-04 (Reverse Operation Selection) which allows the

motor phases to be exchanged.

FCarrier Frequency Selection (C6-02): Default has been changed to 1 (2.0 kHz).

Remote Drive Disable: This feature prohibits the drive from running when a new multifunction digital input is closed for

a set amount of time.

Low City Pressure Alarm Selection: Added a parameter that selects the Low City Pressure alarm text that will show

when in a Low City Pressure condition.

Suction Control Support via the Constant Pressure with Well Draw Down Control: Suction control option has been

integrated into the Water Level control.

Modified Terminal A1 Loss Detection: Different alarm/fault texts will occur when feedback loss is detected on

Terminal A1 to differentiate from PI feedback loss on Terminal A2.

iQpump Memobus Multiplex: Lag Drive Speed Follower: Lag drives follow the speed of the lead drive.

iQpump Memobus Multiplex: Lag Turn Off: Lag drives can run at a fixed speed for a set time before turning off.

iQpump Memobus Multiplex: Flow Meter: New option to stage or de-stage based on Flow Rate.

iQpump Memobus Multiplex: Stop History: A new lead drive selection (P1-01) option has been added.

Geothermal Mode: The speed of the drive is determined by an analog temperature input and a temperature-speed curve.

iQpump Multiplex: Water Level/Suction Pressure Control

• Ability to run the iQpump Controller Memobus network with just 1 drive connected to a Water Level or Suction

Pressure device

• Ability to automatically switch from the Analog Water Level/Suction Pressure Source to the Network Source in case of

transducer loss or wire breaks.

• Pump De-stage due to the Water Level being below the Minimum Water Level.

• Pump De-stage due to the Suction Pressure being below the Minimum Suction Pressure.

• Disallow Pump Staging when PI is being influenced by the Water Level/Suction Pressure control

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 7

Page 8

3 Product Overview

Applicable Models

The iQpump Controller is available in these models in Table 1.

Table 1 Applicable Models

Drive Software Version <1>

(All P7 drive models) CIMR-P7U-107

<1> See “PRG” on the drive nameplate or drive monitor U1-14 for the software version number.

Listed on the drive nameplate as PRG:0035 or PRG:0036

VSP1300035 or VSP1300036.

8 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 9

4 Drive Change Summary

4 Drive Change Summary

Overview

The following is an overview of changes made the drive with software PRG: 0035 and PRG: 0036.

Drive Software Changes

Table 2 Parameter Enhancements for PRG: 0035

Parameter Description Page

A1-01 Language Selection Selection 6:Portuguese is removed. 40

A1-03 Initialization Mode Added selection 7770:General Purpose. 38

b1-01 Frequency

Reference Selection

b1-03 Stop Method Default changed from: Ramp to Stop (0) to Coast to Stop (1). 41

C6-02 Carrier Frequency Default value changed to setting 1 (2.0 kHz) for all drive sizes. 41

P8-01 Water Lev./Suc.

Pres. Selection

P8-09 Low Level Behavior Added selection 3:Auto-Restart (time set by P8-12). 17

P9-01 Lead Drive

Selection

P9-05 Lag Drive Mode Added selection 3:Follow Lead Speed. 29

P9-08 Add Pump Mode Added selection 3:Flow Meter. 32

P9-12 Remove Pump

Mode

P9-23 Max Pumps

Running

P9-25 Highest Node

Address

Added selection 5:Geothermal Mode. 20

Selection 1: Changed from Enabled to Water Level Control.

Added selection 2:Suction Pressure Control.

Added selection 2:Stop History. 34

Added selection 3:Flow Meter. 33

Range changed from 1 - 16 to 1 - 8.

Default changed from 16 to 8.

Range changed from 2 – 16 to 2 - 8. 42

16

–

Table 3 Digital Input H1- Enhancements for PRG: 0035

Function Description Page

72 Remote Drive Disable

Function Description Page

4A Transducer Loss <1>

57 Low Water Level <1>

58 Low Suction Level

<1> Modified from previous version.

Function Description Page

20 Geothermal Mode Temperature input for geothermal mode operation. 21

Digital Input function (normally open or normally closed) that can be used to prevent the

drive from running with a programmable delay time.

Table 4 Digital Output H2- Enhancements for PRG: 0035

Closed: During a “Feedback Loss” alarm.

Closed: During a “FBL – Feedback Loss” fault”.

Closed: During an “A1-LOST Terminal A1 Lost” alarm. <1>New

Closed: During an “A1-LOST Terminal A1 Lost” fault. <1>New

This will energize if P8-01 = 1 and the level in the well drops below the Low Level

Detection Level (P8-07) for more than the Low Level Detection Delay Time

(P8-08), or if there is a LOWWL – Low Water Level Fault.

This will energize if P8-01 = 2 and the suction pressure drops below the Low Suction

Pressure Detection Level (P8-07) for more than the Low Suction Pressure Delay Time

(P8-08), or if there is a LOSUC – Low Suction Pressure Fault.

Table 5 Added H3-09 Analog Input Function for PRG: 0035

11

36

18

18

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 9

Page 10

4 Drive Change Summary

Table 6 Additional or Modified Fault Codes for PRG: 0035

Fault Code Description Page

OPE13

Terminal A1

OPE17

Run/Stp-CoastTmr

OPE18

Net Incompatible

OPE19

Geothermal Set

Tem p Lo st

Geothermal Input

LOSUC

Low Suction

Alarm Description Page

Net FlowMeter

Lost, Chk Source

LOSUC

Low Suction

Low Water

in Tank

Temp Lo st

Geothermal Input

R-DNE-S <1>

Remote Drv Dis

AnalogA1 Lost

Switched to Net

Net Wtr/Suctn

Lost, Chk Source

<1> The character is a place holder for the actual digital input designation, such as S1, S2, or S3.

Displayed when terminal A1 is assigned to more than one function. OPE13 is modified from

the previous software version PRG:0034.

Displayed when Run/Stop Control and Coast To Stop w/Timer are both enabled. 42

Displayed when using features specific to iQpump software version 30035+ and nameplate

PRG: 0035 or greater with parameter P9-99 set to (0: A:Version 30034).

Displayed when a parameter selection is not compatible with the Geothermal Mode

(b1-01 = 5) setting.

Displayed when geothermal input is not present. 23

Suction pressure is below programmed level. 18

Table 7 Additional Alarms or Messages for PRG:0035

Displayed when there is no drive on the Memobus Network with an analog Flow Meter. 28

Displayed when Low City Pressure is active and alarm selection P4-27 = 1. 13

Displayed when Low City Pressure is active and alarm selection P4-27 = 2. 13

Displayed when a geothermal input is not present. 23

Remote drive disable is active. 12

Displayed when there is a defective or broken analog input source. Analog Terminal A1 has

not been detected, and the Network Water Level or Suction Pressure signal is now used.

Displayed when a valid analog source for Water Level or Suction Control Pressure can not be

found on the network.

28

43

42

23

23

Table 8 Additional Alarms or Messages for PRG:0036

Alarm Description Page

OPE20

Net WL/SP Mode

Low WL/SP

Drive Disabled

10 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Incompatible Network Water Level / Suction Pressure Mode. -

Drive is unable to run because the Water Level or Suction Pressure is below the P8-05 setting. -

Page 11

5 Feature Details - Remote Drive Disable

iQpump Drive StoppingiQpump Drive Enabled

Time

Remote

Drive Disable

Active

P4-25 On-Delay Time

Inactive

5 Feature Details - Remote Drive Disable

Overview

This function allows users to prohibit the iQpump Controller from running by using a multi-function digital input set to

"Remote Drv Disbl" (72) in combination with a programmable on time (P4-25) and off time delay (P4-26).

The "Remote Drive Disable" input logic can be selected with parameter P4-24.

Function Operation

When the Remote Drive Disable (H1-0 = 72) input is active for the amount of time specified in P4-25 the drive will be

forced into a sleep-like state. Stopping method used is defined by b1-03 (Stopping Method Selection) setting.

If the iQpump Controller is running as part of a Memobus Network (multiplex system), it will be taken out and

considered unavailable to run.

Alarm "R-DNE-S" will be displayed, where S is the Terminal programmed for Remote Drive Disable (H1-0 = 72).

The iQpump Controller will restart and perform a pre-charge if needed when the Remote Drive Disable ( H1-0 = 72) is

inactive for the time specified in P4-26.

Note: When the drive run is disabled using this feature, the pre-charge function is reset and will run if necessary.

P4-24 Remote Drive Disable Selection

Selects the type of pressure switch connected to the “Remote Drv Disbl” digital input (H1-0 = 72).

Figure 1

Setting Description

0

1

Normally Open (factory default)

Closed indicates a "Remote Disable" condition - active

Normally Closed

Open indicates a "Remote Disable" condition - active

Figure 1 Remote Disable: Inactive to Active Operation

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 11

Page 12

5 Feature Details - Remote Drive Disable

iQpump Drive EnablediQpump Drive Stopped

Time

Remote

Drive Disable

Active

P4-26 Off-Delay Time

Inactive

Figure 2

Figure 2 Remote Disable: Active to Inactive Operation

P4-25 Remote Drive Disable On-Delay Time

Range Description Default

1 - 1000 sec

Sets the amount of time a “Remote Drive Disable” condition needs to be

present before the drive will stop.

0 sec

P4-26 Remote Drive Disable Off-Delay Time

Range Description Default

1 - 1000 sec

Multi-function Input Setting: Remote Drive Disable Function

Setting Description

72 Remote Drv Disbl

Alarm: Remote Drive Disable

Alarm Display Description

R-DNE-Sx

Remote Drv Dis

Note: S or Sx denotes the digital input terminal programmed for this function.

Sets the amount of time a "Remote Drive Disable" condition must be absent

before the drive will be allowed to run.

Remote Drive Disable: Prevents the iQpump Controller from running when active for the time set in

P4-25. Must be inactive for the time set in P4-26 to allow the drive to run again.

Note: Parameter P4-24 determines if this input is Normally Open or Normally Closed.

Multi-function Input Terminal S (H1-0 = 72) has been closed for the time set in P4-25 when P4-24 = 0.

or

Multi-function Input Terminal S (H1-0 = 72) has been open for the time set in P4-25 when P4-24 = 1.

0 sec

12 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 13

6 Feature Details - Low City Pressure Alarm

6 Feature Details - Low City Pressure Alarm

Overview

The alarm function is used for stopping the iQpump Controller or preventing the iQpump Controller from running based

on an external contact closure.

This function has been enhanced by parameter P4-27 which allows users to select the alarm message that will be

displayed when a Low City Pressure condition is detected.

Function Operation

P4-27 Low City Pressure Alarm Text

Selects the alarm message that will be displayed when a Low City Pressure condition is detected.

Setting Description

0 Low City Pressure (factory default)

1 Low Suction Pressure

2Low Water in Tank

Alarm: Low Pressure/Low Water in Tank

Alarm Display Description

Shown when P4-27 = 1 and when the digital input has been active (closed for P4-21 = 0, or open for

Low Suction Pressure

Low Water In Tank

P4-21 = 1) for the time set in P4-22. The drive, if running, coasts-to-stop and does not run until the digital

input has been inactive for the time set in P4-22.

Shown when P4-27 = 2 and when the digital input has been active

(closed for P4-21 = 0, or open for P4-21 = 1) for the time set in P4-22. The drive, if running, coasts-to-stop

and does not run until the digital input has been inactive for the time set in P4-22.

Related Parameters

P4-21 Low City Pressure Input Select

Setting Description

0 Normally Open (closed for the "Low City Pressure" condition)

1 Normally Closed (open for the "Low City Pressure" condition) (factory default)

P4-22 Low City Pressure Input Delay Time

Range Description Default

Sets the amount of time a "Low City Pressure" condition must be present before

1 - 1000 sec

Multi-function Input Setting H1-: Low City Pressure

Setting Description

73 Low City Pressure

the drives will stop. Also sets the amount of time that the pressure must be

adequate before the drive system will restart.

Indicates that sufficient/insufficient pressure is present on the inlet to the pump. This setting is used mainly

for pressure booster stations.

10 sec

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 13

Page 14

7 Suction Control via Constant Pressure w/Well Draw Down

7 Suction Control via Constant Pressure w/Well Draw Down

Overview

This function enables the iQpump Controller to monitor suction pressure at the inlet of the pumps.

Note: This function is active when parameter P8-01 is set to 2 for Suction Control.

Packaged Booster Systems have a desired discharge pressure and a given suction pressure from the city water system or

from a suction tank. Such systems are often designed to handle a specific pressure and flow rate.

The suction pressure may have a wide range between high and low pressures. The suction pressure typically decreases

with increased fluid flow rate. In some instances, pump cavitation may occur if suction pressure falls below a certain

pressure level.

In addition low or negative suction pressure can lead to damage such as pipe collapse due to external forces acting on the

pipe.

The iQpump Controller will accept an analog suction transducer (Terminal A1) and can be programmed to trigger an

alarm or shutdown the system when the suction pressure falls outside of a normal operating range.The iQpump Controller

will automatically restart and return to normal operation once the suction pressure returns to a normal level.

When operating in multiplex mode, additional control can be programmed to de-stage any active pumps as a method to

try and reduce pump loading to prevent suction pressure from continuing to drop below the shut down level.

Function Description

The iQpump Controller will regulate outlet pressure of the pump system using the standard iQpump Controller features

when there is adequate suction pressure available at the inlet of the pumps and offers two options to respond to a drop in

suction pressure.

1. Regulate Outlet Pressure and Suction Pressure: (P8-03 > or = P8-04)

To regulate suction pressure set the suction pressure setpoint (P8-03) to a value greater or equal than the minimum

suction pressure (P8-04). In this mode the iQpump Controller will try to regulate the suction pressure based on the

programmed suction pressure setpoint (P8-03) level.

As the suction pressure decreases and approaches the suction pressure setpoint level (P8-03), the iQpump Controller

will slow down causing the outlet pressure and flow to decrease. When the suction pressure rises above the P8-05 level

for more than the P1-05 time, normal operation (outlet pressure regulation) will resume.

When the suction pressure drops below Minimum Suction Pressure (P8-04), for more than the Sleep Delay Time

(P2-03), the iQpump Controller will go to sleep.

Note: The Suction Control Minimum Speed parameter (P8-06) should be set to a high enough value that will ensure flow.

2. Regulate Outlet Pressure Only: (P8-03 < P8-04)

Set the suction pressure setpoint (P8-03) to a value smaller than the minimum suction pressure (P8-04) to regulate

outlet pressure.

This mode allows the iQpump Controller to maintain the outlet pressure setpoint using the standard iQpump Controller

features and go to sleep immediately when the suction pressure drops below the Minimum Suction Pressure (P8-04),

for more than the Sleep Delay Time (P2-03).

Normal operation (outlet pressure regulation) will resume when the suction pressure returns above the P8-05 level for

more than the P1-05 time.

14 YAS KAWA TM.iQp.10 iQpump Technical Manual Supplement

Page 15

7 Suction Control via Constant Pressure w/Well Draw Down

Duplex System Example

A pump system consisting of a duplex domestic pressure booster system using a pressured city supply averaging 40

Example:

Pump System Settings

• All pumps have the same flow rate and will alternate

• Lag Pump will track speed of lead pump

• All drives have individual discharge transducers rated 150 psi. Upon failure, system will look to network for feedback

information.

• Suction Transducer is rated 75 psi

• Below 40 psi city pressure the pump system will start to reduce speed until reaching 30 psi

• System Auto setpoint 85 psi, with a 5 psi start level.

Duplex System Example (Related Parameters)

- 60 psi. If city pressure starts to fall below 40 psi the pump system will start to slow down to reduce the chances of

pump cavitation. When suction pressure (city pressure) drops to 30 psi, the pump system will shut down (sleep) and

wait until city pressure returns, after which the system will automatically start and operate under normal condition.

Parameter Description Booster Pump 1 Booster Pump 2

H3-02 Terminal A1 Gain 231.3% 231.3%

H3-03 Terminal A1 Bias -25.0% -25.0%

H3-08 Terminal A2 Signal 2 2

H5-01 Drive Node Network Address 1 2

P1-01 Pump Mode 3 3

P1-03 FD Device Scaling 150 psi 150 psi

P1-04 Start Level -5.0 psi -5.0 psi

P8-01 WtrLvl/SuctionPres Selection 2 2

P8-02 Suction Transducer Scaling 75 psi 75 psi

P8-03 Suction Pressure Setpoint 40.0 psi 40.0 psi

P8-04 Minimum Suction Pressure 30.0 psi 30.0 psi

P8-05 Wakeup Suction Pressure 40.0 psi 40.0 psi

P9-02 Feedback Source 2 2

P9-05 Lag Drive Mode 2 2

P9-25 Highest Node Address 3 3

P9-50 Suction Pressure Source 2 2

U1-01 Auto Setpoint 85 psi 85 psi

Note: In multiplex mode the network signal for suction pressure can be used. Refer to Transducer Wiring using an External Power

Supply on page 48.

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 15

Page 16

7 Suction Control via Constant Pressure w/Well Draw Down

Enabling Suction Pressure Control

The suction pressure control selection is added to parameter P8-01 Water Level/Suction Pressure Selection. Follow these

steps for basic suction pressure control setup:

1. Enable suction control by setting parameter P8-01 to 2 (Suction Control).

2. Set suction transducer scaling (P8-03) in psi, scaling for analog input A1 (20 mA scale).

3. Set suction pressure setpoint (P8-03) in psi.

4. Select iQpump operation when a drop in suction pressure occurs:

a. Regulate outlet pressure only and go to sleep immediately when suction pressure falls below minimum suction

pressure level (P8-04). Set suction pressure setpoint (P8-03) below minimum suction pressure level (P8-04).

b. Regulate suction pressure when pressure is below suction pressure setpoint (P8-03) but above the minimum

suction pressure level (P8-04). Set suction pressure setpoint (P8-03) to above the minimum suction pressure level

(P8-04).

5. Set minimum suction pressure (P8-04) – Sleep Level for Suction Control.

6. Set suction pressure wake-up level (P8-05) – Wake-up level.

7. Set suction control minimum speed (P8-06) – Minimum Flow Speed.

P8-01 Water Level/Suction Pressure Selection

Sets the mode of operation for the Water Level / Suction Control function.

Setting Description

0 Disabled (factory default)

1

2 Suction Pressure Control (New)

Note: The iQpump Controller will only perform the outlet pressure and suction pressure control when "normal" PI mode is enabled

(b5-01 > 0, not jogging, not disabled via MFDI, etc.).

P8-02 Suction Transducer Scaling

Water Level Control

(This function is defined as "Enabled" for iQpump software PRG: 0034)

Terminal A1 is used for the suction pressure analog input. The analog pressure sensor, mounted on the inlet side of the

pump(s) will provide the required signal. Set this parameter to the full-scale pressure of the transducer. The suction

pressure will then be displayed on the U1-98 monitor.

Range Description Default

5 - 500 psi

P8-03 Suction Pressure Setpoint

Range Description Default

0.0 - 1200.0 psi

P8-04 Minimum Suction Pressure

Sets the full scale (20 mA) output of the pressure transducer connected to

Terminal A1.

Sets the amount of suction pressure the iQpump Controller will attempt to

regulate.

100 psi

20.0 psi

Range Description Default

0.0 - 1200.0 psi

16 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

When the suction pressure drops to below this level for more than the P2-03

time, the drive will go to sleep and turn off all lag pumps.

10.0 psi

Page 17

7 Suction Control via Constant Pressure w/Well Draw Down

P8-05 Wake-Up Suction Pressure

Range Description Default

If the drive is forced to sleep based upon the minimum suction pressure

0.0 - 1200.0 psi

P8-06 Suction Control Minimum Speed

Range Description Default

0.00 - 120.00 Hz

P8-07 Low Suction Pressure Detection Level <1>

Range Description Default

0.0 - 1200.0 psi

(P8-04), the suction pressure must go above this level for more than the P8-13

time in order to wake up.

This parameter sets the minimum speed the drive will run when the drive is

controlling suction pressure. When the drive is controlling outlet pressure or

this parameter is set less than P1-06 and P4-05, P1-06 and P4-05 will be used as

the minimum speed.

When the amount of suction pressure drops below this level for more than the

P8-08 time, the drive will respond depending on the P8-09 setting. A setting of

0.0 disables this detection.

30.0 psi

0.00 Hz

0.0 psi

P8-08 Low Suction Pressure Detection Time

<1>

Range Description Default

0.0- 300.0 min

Sets the amount of time delay that the suction pressure must drop below the

P8-07 level before the drive will react. *Time units are defined by P8-14.

0.1 min

P8-09 Water Level/Suction Pressure Selection

Sets how the drive will respond when the water level in the well drops below the P8-07 level for more than the P8-08

time.

Setting Description

0 No Display (Digital Output Only)

1 Alarm Only (factory default)

2Fault

3 Auto-Restart (time set by P8-12) (New)

P8-10 Suction Control Proportional Gain

Range Description Default

0.00 - 25.00 Sets the proportional gain for the suction pressure control. 2.00

P8-11 Suction Control Integral Time

Range Description Default

0.0 - 360.0 sec

Sets the integral time for the suction pressure control. A setting of zero disables

the suction pressure control integrator.

5.0 min

P8-12 Suction Control Auto-Restart Time

Range Description Default

0.1 - 6000.0 min

<1>

Low Level/Low Suction Detection (P8-07/P8-08): This feature is disabled when the drive is in Run-Stop control

(b1-02 = 5, Timed Run).

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 17

Sets the amount of time the drive will wait before attempting an auto-restart of

the "Low Suction" fault. Effective only when P8-09 = 3 and L5-01 > 0.

5.0 min

Page 18

7 Suction Control via Constant Pressure w/Well Draw Down

P8-13 Suction Pressure Sleep Wake-Up Time

Range Description Default

If the iQpump Controller has been forced to sleep based upon the minimum

0 - 3600 sec

P8-14 Low Suction Pressure Detection Time Unit

suction pressure (P8-04), the pressure must go above the P8-05 level for more

than this time in order to wake up.

1 sec

Defines the time unit for P8-08.

Setting Description

0 Minutes (factory default)

1 Seconds

Suction Pressure Transducer Wire-break Detection

Wire-break detection is active on Terminal A1 when PI Feedback Loss Detection is enabled (b5-12 = 1 or 2) , Suction

control is enabled (P8-01 = 2) and PI control is NOT disabled via Multi-Function Digital Input.

The iQpump Controller detects a wire-break condition when the suction transducer signal on Terminal A1 falls below -

6.25 % or rises above 106.25 % for more than 1 second and will react according to parameter b5-12 (Feedback Loss

Detection).

Note: Wire-break detection on Terminal A1 detection is checked after the gain/bias parameters (H3-02 and H3-03) are applied.

Fault: Low Suction

Fault Display Description

LOSUC

Low Suction

Low Suction: Suction pressure is below the P8-07 level for more than the P8-08 time.

Parameters P8-12 to P8-14 are also available for Water Level control P8-01 set to 1. The parameter titles change

accordingly.

P8-12 Water Level Auto-Restart Time

Range Description Default

Sets the amount of time the iQpump Controller will wait before attempting an

0.1 - 6000.0 min

P8-13 Water Level Sleep Wake-Up Time

Range Description Default

0 - 3600 sec

P8-14 Low Water Detection Time Unit

auto-restart of the "Low Water" fault. Effective only when P8-09 = 3 and

L5-01 > 0.

If the iQpump Controller is forced to sleep based upon the minimum water

level (P8-04), the pressure must go above the P8-05 level for more than this

time in order to wake up.

5.0 min

1 sec

Setting Description

0 Minutes (factory default)

1 Seconds

Multi-function Output Setting H2-: Low Suction (Modified)

Setting Description

This output will energize if P8-01 = 1 and the level in the well drops below the Low Level Detection Level

57 Low Water

18 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

(P8-07) for more than the Low Level Detection Delay Time (P8-08), or if there is a LOWWL - Low Water

Level Fault.

Page 19

7 Suction Control via Constant Pressure w/Well Draw Down

Multi-function Output Setting H2-: Low Suction (New)

Setting Description

This output will energize if P8-01 = 2 and the suction pressure drops below the Low Suction Pressure

58 Low Suction

Detection Level (P8-07) for more than the Low Suction Pressure Delay Time (P8-08), or if there is a

LOSUC - Low Suction Pressure Fault.

Related Parameters

When P1-01 = 3 (Memobus Multiplex), the Water Level or Suction Pressure can be transmitted or read through the

network. Refer to Water Level/Suction Pressure Control in Memobus Multiplex on page 26.

P9-50 Water Level Source (P8-01 set to 0 or 1, Water Level Control)

Defines which signal to use for Water Level Control (P8-) when P1-01=3.

Setting has no effect when P1-01≠3.

Setting Description

0 Analog Only (factory default)

1 Analog -> Network, No Alarm

2 Analog -> Network, Alarm

3 Network Only

P9-50 Suction Pressure Level Source (P8-01 set to 2 Suction Control)

Defines which signal to use for Suction Pressure Control (P8-) when P1-01=3.

Setting has no effect when P1-01≠3.

Setting Description

0 Analog Only (factory default)

1 Analog -> Network, No Alarm

2 Analog -> Network, Alarm

3 Network Only

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 19

Page 20

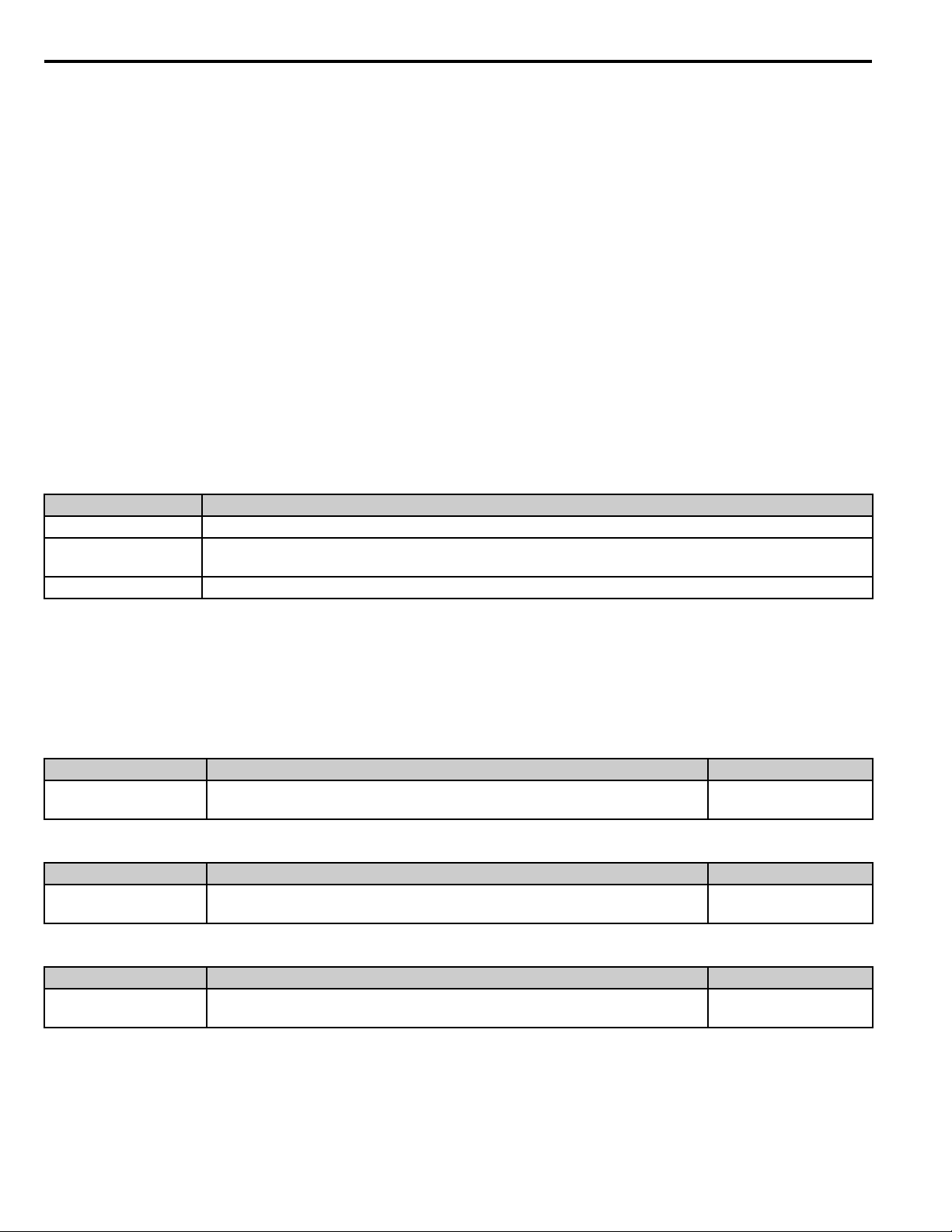

8 Geothermal Mode

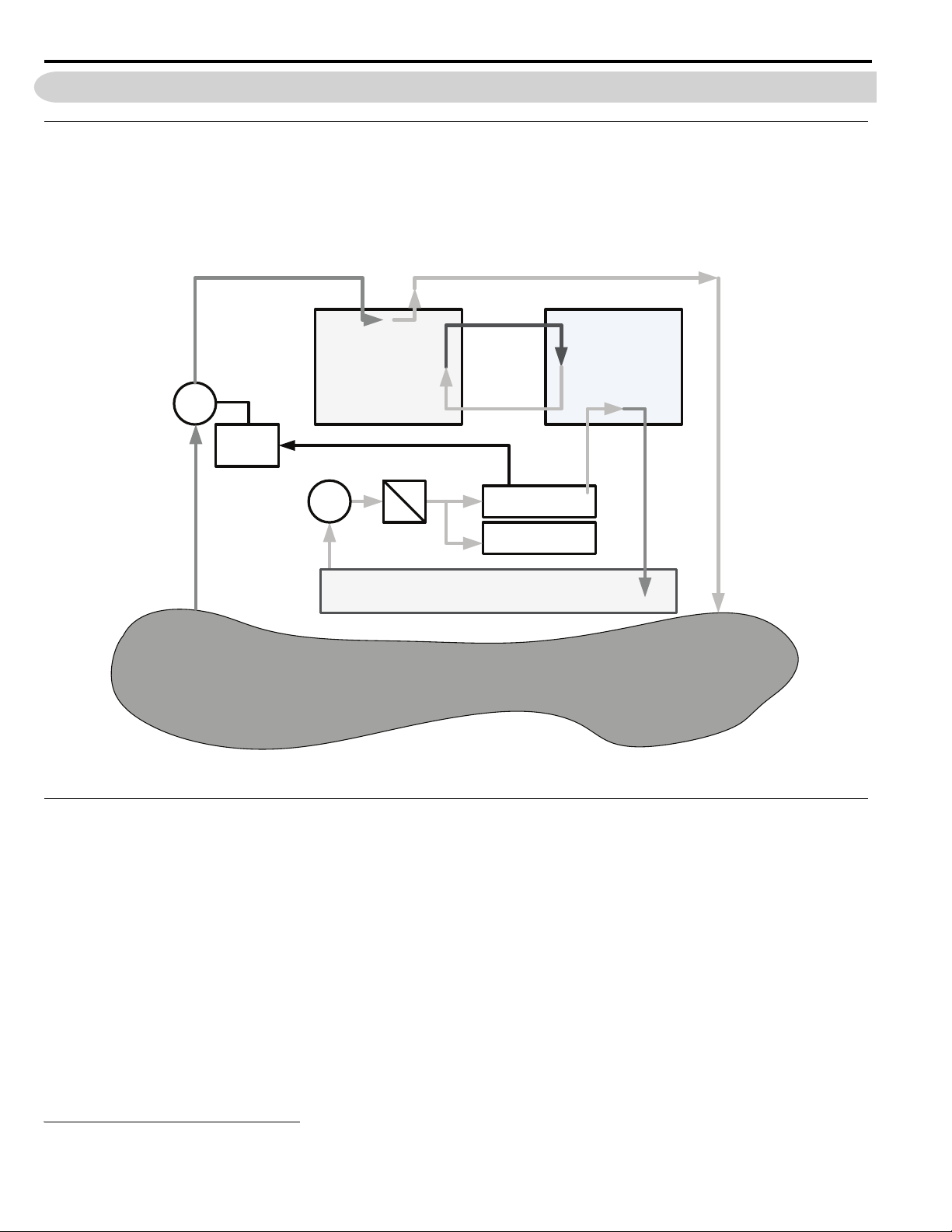

Aquifer

Heat

Exchanger

iQpump

Geothermal

Heater

Thermostat

Pool

M

Discharge Valve

Pool

Pump

Filter

M

Well

Pump

Discharge

Well

Warm Cold

Cold

Warm

Cold

Warm

Warm

Cold

Cold

8 Geothermal Mode

Overview

A geothermal well facilitates heat transfer between the earth and a known system, such as space heating, dehydration,

electric power generation and food processing.

The geothermal function has the ability to regulate the speed of the iQpump Controller based on an external temperature

signal following a preset temperature-speed curve.

Figure 3

Figure 3 Geothermal Pool Application

Geothermal Mode Setup Procedure

Follow these steps to setup the iQpump Controller in Geothermal Mode:

1. Set iQpump Controller parameters to factory default by setting parameter A1-03 to 2220 for "2 Wire" Initialization.

2. Disable PI Control by setting parameter b5-01 to 0 "Disabled"

3. Set multi-function analog input function H3-09 to 20 "Geothermal Temp"

4. Enable Geothermal Mode by setting parameter b1-01 to 5 "Geothermal Mode"

5. Set display monitor to selectable mode by setting o1-06 to 1 "3 Mon Selectable"

6. Select monitor display line #1 to display output frequency by setting o2-01 to 2 "Output Freq"

7. Select monitor display line #3 to display temperature by setting o1-08 to 80 "Geothermal Temp"

8. Set the temperature transducer range to properly scale the input. (P4-31 and P4-32)

9. Set the temperature-speed curve to the intended operation (P4-33 ~ P4-38)

<1>

"3330" for 3-Wire Initialization or "7770" for General Purpose Initialization can also be used.

20 YAS KAWA TM.iQp.10 iQpump Technical Manual Supplement

<1>

Page 21

Related Parameters

b1-01 Frequency Reference Source Selection

Set the frequency reference source (b1-01) to 5 for Geothermal mode operation.

Setting Description

0 Operator - Digital preset speed d1-01 (factory default)

1 Terminals - Analog input Terminal A1 (or Terminal A2, see parameter H3-13)

2 Serial Com - RS-485 terminals R+, R-, S+ and S-

3 Option PCB - Option board connected at 2CN

5

Geothermal Mode - Frequency reference is dependent on temperature input

(H3-09 = 20) <0035>

H3-09 Multi-function Analog Input Setting: Geothermal Temperature

Program H3-09 = 20 to use an external temperature sensor in Geothermal mode operation.

Setting Description

Geothermal Temperature

20

Analog input function for use with an external temperature sensor.

Range scaling: 0V (or 4 mA) = P4-31 ~ 10 V (or 20 mA) = P4-32

8 Geothermal Mode

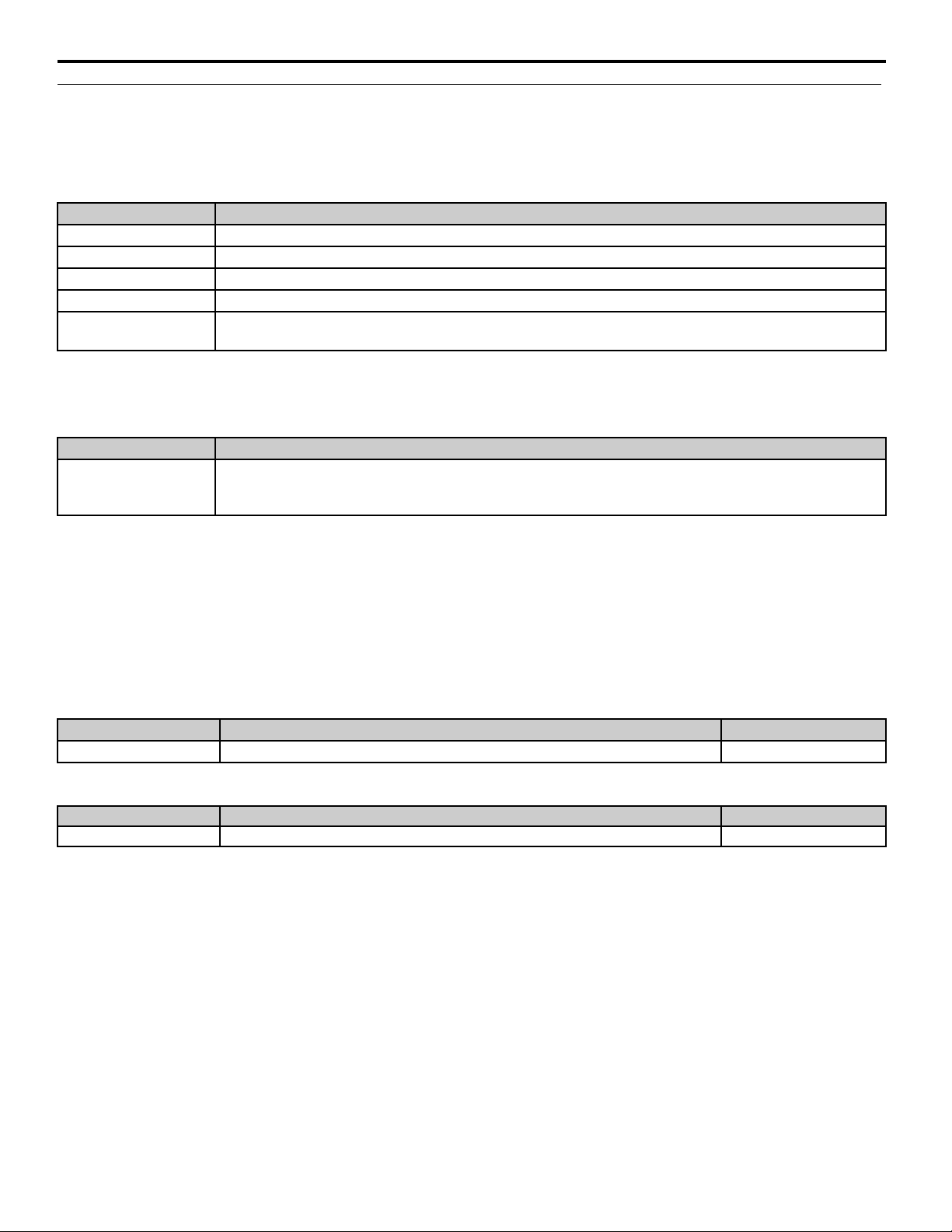

Geothermal Mode Frequency/Temperature Characteristic

When the iQpump Controller is set to operate in Geothermal Mode (b1-01 = 5), the drive's frequency reference is

determined by the analog input Geothermal Temperature (H3-09 = 20) and the setting of parameters P4-33 ~ P4-38. The

Geothermal characteristic can be programmed in normal or inverse operation.

Normal Operation: P4-33 < P4-34 and P4-35 < P4-36 < P4-37 < P4-38

Inverse Operation: P4-33 > P4-34 and P4-35 < P4-36 < P4-37 < P4-38

P4-31 Minimum Geothermal Temperature Input

Range Description Default

-110.0 ~ 440.0 °F Sets the temperature that corresponds to a 0V (or 4 mA) analog input. 0.0 °F

P4-32 Maximum Geothermal Temperature Input

Range Description Default

-110.0 ~ 450.0 °F Sets the temperature that corresponds to a 10V (or 20 mA) analog input. 150.0 °F

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 21

Page 22

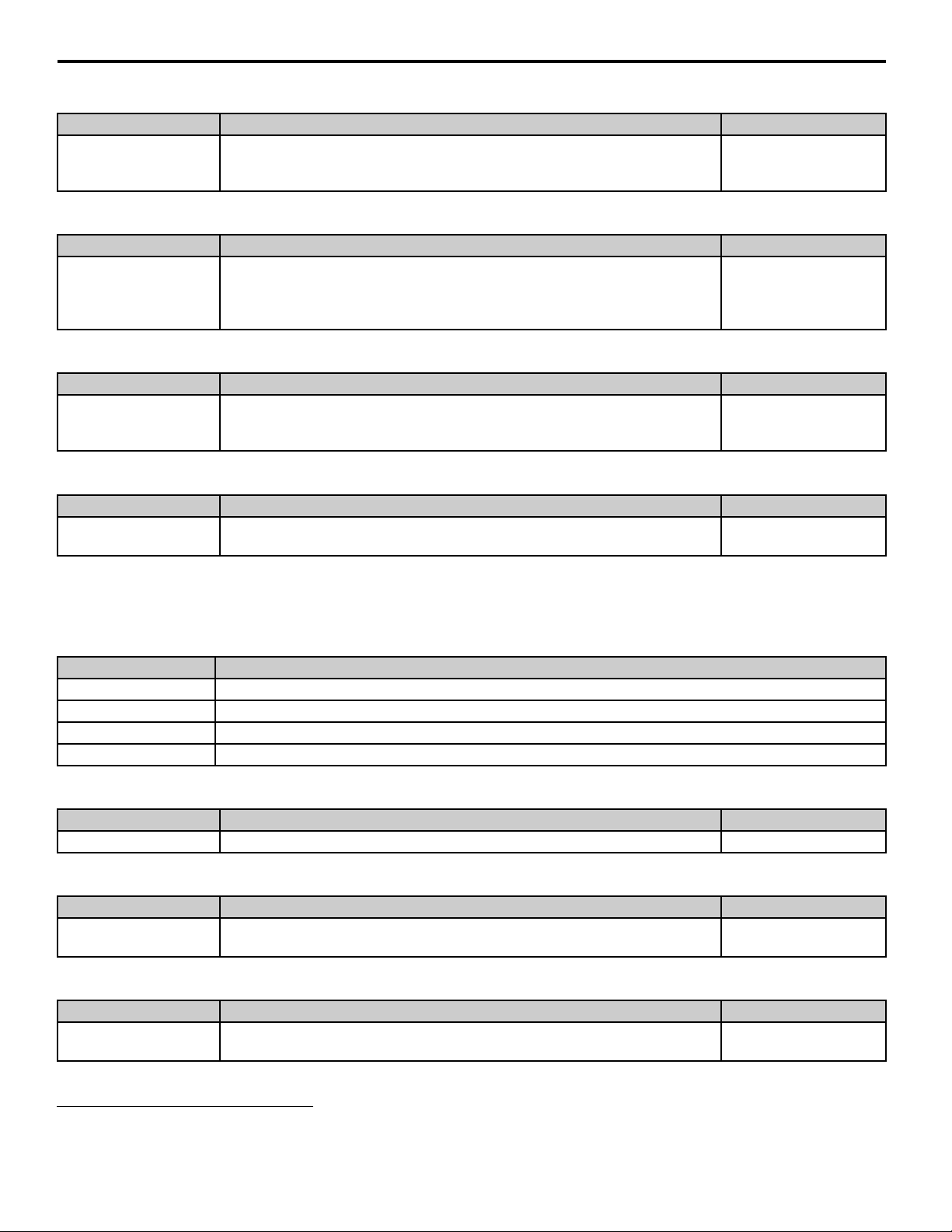

8 Geothermal Mode

Maximum

Geothermal Speed

㩿㪧㪋㪄㪊㪋㪀

Minimum

Geothermal Speed

㩿㪧㪋㪄㪊㪊㪀

Low Temp

@ Max

㩿㪧㪋㪄㪊㪌㪀

Low Temp

@ Min

㩿㪧㪋㪄㪊㪍㪀

Temperature (°F)

High Temp

@ Min

㩿㪧㪋㪄㪊㪎㪀

High Temp

@ Max

㩿㪧㪋㪄㪊㪏㪀

Maximum

Geothermal Speed

㩿㪧㪋㪄㪊㪋㪀

Minimum

Geothermal Speed

㩿㪧㪋㪄㪊㪊㪀

Low Temp

@ Max

㩿㪧㪋㪄㪊㪌㪀

Low Temp

@ Min

㩿㪧㪋㪄㪊㪍㪀

Temperature (°F)

High Temp

@ Min

㩿㪧㪋㪄㪊㪎㪀

High Temp

@ Max

㩿㪧㪋㪄㪊㪏㪀

Parameter No. Parameter Name Description Range Default

Sets the frequency reference characteristics based on the set

P4-33 Minimum Geothermal Speed

temperature points and the corresponding frequency.

For proper operation, P4-34 > P4-33 and P4-38 > P4-37 > P4-36 >

P4-35.

0.00 ~

120.00 Hz

40.00 Hz

P4-34 Maximum Geothermal Speed

P4-35

P4-36

P4-37

P4-38

Low Temperature to Run at

Maximum Geothermal Speed

Low Temperature to Run at

Minimum Geothermal Speed

High Temperature to Run at

Minimum Geothermal Speed

High Temperature to Run at

Maximum Geothermal Speed

Geothermal Mode Frequency/Temperature Characteristic|

(Normal Operation)

.

Geothermal Mode Frequency/Temperature Characteristic

(Inverse Operation)

0.00 ~

120.00 Hz

-110.0 ~

450.0 °F

-110.0 ~

450.0 °F

-110.0 ~

450.0 °F

-110.0 ~

450.0 °F

40.00 Hz

55.0 °F

65.0 °F

75.0 °F

85.0 °F

Figure 4

22 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Figure 4 Digital Operator Display Showing Geothermal Mode Operation

Page 23

8 Geothermal Mode

Geothermal Mode iQpump Controller Monitors

U1-80 Geothermal Temperature Input

Unit Description

0.1 °F

Note: Only shown when b1-05 = 5 (Geothermal Mode)

Displays Geothermal temperature input after gain and bias are applied. This is the temperature used by the

Geothermal Function to determine what frequency to run the iQpump Controller.

Geothermal Temperature Loss Detection

P4-39 Geothermal Temperature Loss Detection

Selects iQpump Controller action when the temperature sensor signal from Terminal A2 is below 3 mA or above 21 mA.

Setting Description

0Disabled

1 Alarm (factory default)

2Fault

Note: Only effective when H3-08 = 2 (4-20 mA) and H3-09 = 20 (Geothermal Temp).

Alarm: Temperature Sensor Lost (factory default)

Alarm Display Description

The geothermal temperature sensor is not present. Alarm occurs when:

1. b1-01 = 5, H3-09 = 20 (Geothermal Temp), H3-08 = 2 (4-20 mA), P4-39 = 1 (Alarm), and the input has

either dropped below 3 mA or went above 21 mA.

Check: Ensure the device connected to Terminal A2 is installed and working properly.

2. b1-01 = 5, and H3-09 ≠ 20 (Geothermal Temp), and P4-39 = 1 (Alarm).

Tem p Lo s t

Geothermal Input

Alarm: Geothermal Parameters Programming Error

Alarm Display Description

Geo Params

Check P4-35~P4-38

Fault: Temperature Sensor Lost

Fault Display Description

Tem p Lo s t

Geothermal Input

Check: Terminal A2 must be assigned to Geothermal Temp (H3-09 = 20).

3. b1-01 = 5, H3-09 = 20 (Geothermal Temp), H3-08 = 2 (4-20 mA), P4-39 = 2 (Fault), the drive is either

in HAND mode or has no run command, and the input is below 3 mA or above 21 mA.

Check: Ensure the device connected to Terminal A2 is installed and working properly.

4. b1-01 = 5, and H3-09 ≠ 20 (Geothermal Temp), P4-39 = 2 (Fault), and the drive is either in HAND mode

or has no run command.

Check: Terminal A2 needs to be assigned to Geothermal Temp (H3-09=20).

The drive is running at the P4-31 level because of an incorrect setting.

The temperature parameter values must be set in the following order:

P4-35 < P4-36 < P4-37 < P4-38

The geothermal temperature sensor is not present. Fault occurs when:

1.b1-01 = 5, and H3-09 ≠ 20 (Geothermal Temp), and P4-39 = 2 (Fault).

Check: Terminal A2 must be assigned to Geothermal Temp (H3-09 = 20).

2.b1-01 = 5, H3-09 = 20 (Geothermal Temp), H3-08 = 2 (4-20 mA), P4-39 = 2 (Fault), the drive is either in

HAND mode or has no run command, and the input is below 3 mA or above 21 mA.

Check: Ensure the device connected to Terminal A2 is installed and working properly.

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 23

Page 24

8 Geothermal Mode

60Hz

㩿㪧㪋㪄㪊㪋㪀

35Hz

㩿㪧㪋㪄㪊㪊㪀

55°F

㩿㪧㪋㪄㪊㪌㪀

65°F

㩿㪧㪋㪄㪊㪍㪀

Temperature (°F)

75°F

㩿㪧㪋㪄㪊㪎㪀

85°F

㪧㪋㪄㪊㪏㪀

Output

Temperature

Transducer

V+

A2

AC

+V

EG

iQpump

Output

V+

A2

AC

+V

EG

iQpump

Common

4-20mA

Temperature

Transducer

0-10V

Set S1-2 to OFF

O

F

F

1

2

Set S1-2 to ON

* Factory Default

O

F

F

1

2

Set parameter H3-08

Terminal A2 Signal to ‘0’

for 0 – 10V.

Fault: Geothermal Frequency Reference/Temperature Curve Error: OPE19

Fault Display Description

Parameter selection is not compatible with the Geothermal Mode (b1-01 = 5) setting. Fault occurs when

OPE19

Geothermal Set

b1-01 = 5 (Geothermal Mode), and one of the following is NOT set:

- b5-01 = 0 (PI Disabled)

- P1-01 = 0 (Simplex)

Check: Confirm parameter settings for b1-01, b5-01, and P1-01.

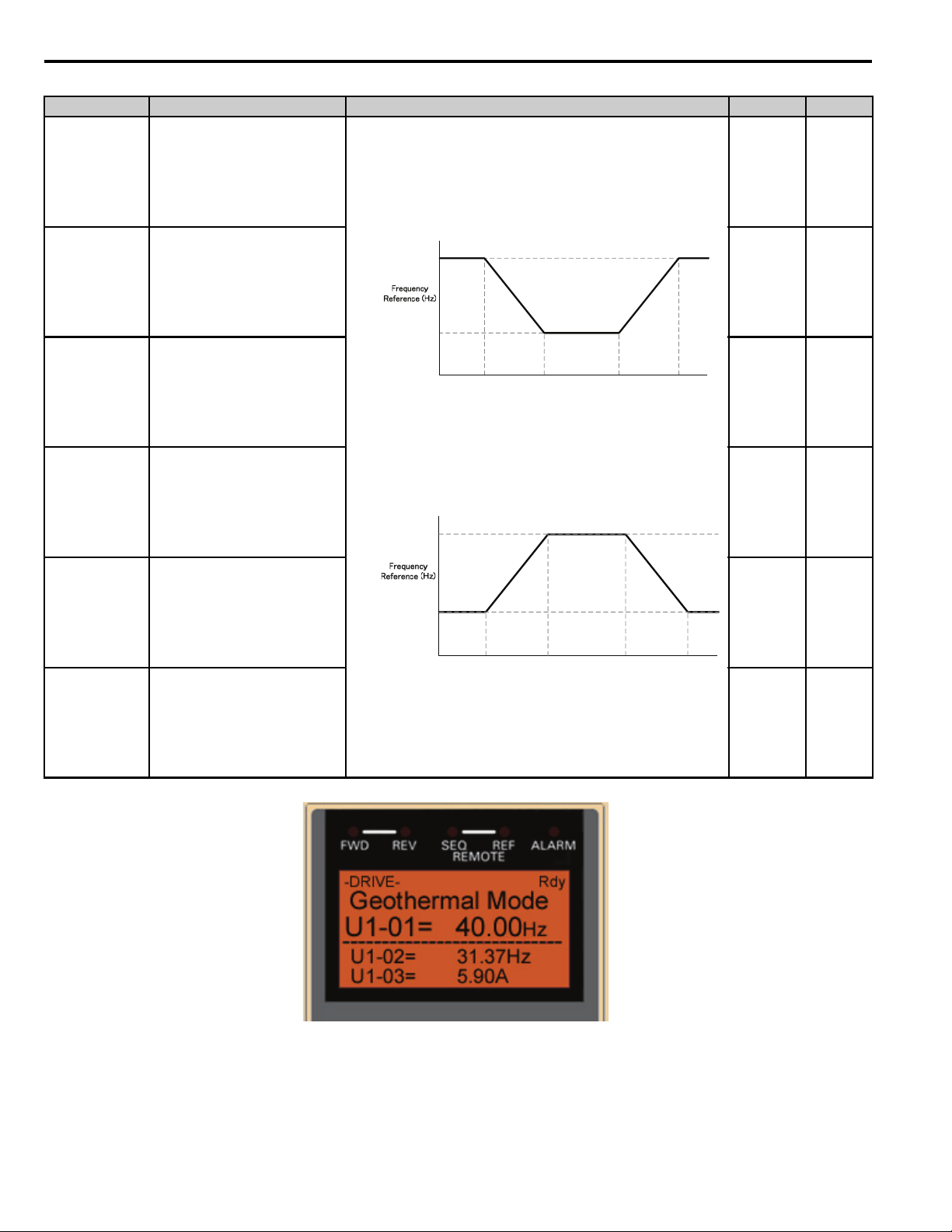

Example: Geothermal Pump System Transducer Setup

Geothermal Pump system using a temperature transducer 4 - 20 mA with a temperature range of 0 - 120 °F. The

Example:

system requires a minimum pump speed of 35 Hz. The system requires increased pump speed when the temperature

increases above 75 °F or when temperature falls below 65 °F.

Geothermal Mode Setup Procedure:

Refer to Geothermal Mode Setup Procedure on page 20 for steps to setup the iQpump Controller for Geothermal Mode.

24 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 25

8 Geothermal Mode

Related Parameters for Geothermal Mode Operation

Parameter Description iQpump Controller

b1-01 Frequency Reference Source 5

b5-01 PI Mode 0

H3-09 Terminal A2 Function Selection 20

o1-06 User Monitor Selection Mode 1

o1-02 <1>

o1-08 Third Line User Monitor Selection 80

P1-01 Pump Mode 0

P4-31 Minimum Geothermal Temperature Input 0.0 °F

P4-32 Maximum Geothermal Temperature Input 120.0 °F

P4-33 Minimum Geothermal Speed 35.00 Hz

P4-34 Maximum Geothermal Speed 60.00 Hz

P4-35 Low Temperature to Run at Max. Geothermal speed 55.0 °F

P4-36 Low Temperature to Run at Min. Geothermal speed 65.0 °F

P4-37 High Temperature to Run at Min. Geothermal speed 75.0 °F

P4-38 High Temperature to Run at Max. Geothermal speed 85.0 °F

P4-39 Geothermal Temperature Loss Detection 1

<1> After programming is completed, cycle power to the drive, as changes to the o1-02 monitor requires a drive power-up cycle to be effective.

User Monitor Selection After Power-Up 2

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 25

Page 26

9 Water Level/Suction Pressure Control in Memobus Multiplex

9 Water Level/Suction Pressure Control in Memobus Multiplex

Overview

When using Water Level or Suction Pressure Control in a Memobus Multiplex system, (see parameter P8-01). The

iQpump Controller can be programmed to receive the Water Level or Suction Pressure information from another drive on

the network with a Water Level or Suction Pressure input.

Parameters

Parameter representation for this function depends on the setting of parameter P8-01.

Parameter Settings

P8-01 Water Level/Suction Pressure Selection

Setting Description

0 Disabled (factory default)

1 Water Level Control (Previous version PRG: 0034 functionality for setting is "Enabled")

2 Suction Pressure Control

P9-50 Water Level Source (P8-01 set to 0 or 1, Water Level Control)

Setting Description

0 Analog Only (factory default)

1 Analog -> Network, No Alarm

2 Analog -> Network, Alarm

3Network Only

P9-50 Suction Pressure Level Source (P8-01 set to 2 Suction Pressure Control)

Setting Description

0 Analog Only (factory default)

1 Analog -> Network, No Alarm

2 Analog -> Network, Alarm

3Network Only

P9-50 = 0 (Analog Only)

This drive will transmit its Water Level/Suction Pressure signal to the network. If this signal is lost, the drive will not

switch to another signal on the network. The detection action in this mode is solely on parameter b5-12.

P9-50 = 1 (Ana->Net, No Alarm)

This drive will transmit its Water Level/Suction Pressure signal to the network when the analog input is healthy. If this

signal is lost, the drive will switch to another signal on the network if available. If there are no available network signals,

then this drive will act according to the setting of parameter b5-12 (when = 1 or 2).

Note: Setting parameter b5-12 to 0 will disable analog feedback detection and will prevent the iQpump Controller from switching to the

Network Water Level/Suction Pressure.

P9-50 = 2 (Ana->Net, Alarm)

This drive will transmit its Water Level / Suction Pressure signal to the network when the analog input is healthy. If this

signal is lost, the drive will switch to another signal on the network if available. An alarm will be displayed indicating that

the analog signal has been lost and that the signal is coming from the network. If there are no available network signals,

then this drive will act according to the setting of parameter b5-12 (when = 1 or 2).

Note: Setting parameter b5-12 to 0 will disable analog feedback detection and will prevent the iQpump Controller from switching to the

Network Water Level/Suction Pressure.

26 YAS KAWA TM.iQp.10 iQpump Technical Manual Supplement

Page 27

9 Water Level/Suction Pressure Control in Memobus Multiplex

P9-50 = 3 (Network Only)

The drive will always use a valid network Water Level / Suction Pressure signal. If there are no available network signals,

the drive will act according to the setting of b5-12 with the following differences:

Setting b5-12 to 1: Instead of an alarm, Network P8- Lost message is displayed.

Setting b5-12 to 2: Instead of a fault, Network P8- Lost message is displayed. In this condition the iQpump

Controller no longer accepts iQpump Controller Network run commands and the stopping method is fixed to coast-tostop.

b5-12 PI Feedback Reference Missing Detection Selection

Setting Description

0Disabled

1Alarm

2 Fault (factory default)

Any drive with b5-12 set to 0 (Disabled) and P9-50 ≠ 3 will effectively have no Terminal A1 signal loss detection and

will continuously send the Water Level/Suction Pressure to the iQpump Controller Network regardless of a faulty or an

invalid signal.

When b5-12 set to 2 (Fault) and P9-02 = 3, iQpump Controller will display a feedback loss alarm instead of a fault when

one of the following conditions active:

1. The iQpump Controller is in Hand Mode

2. There is no Lead iQpump Controller on the network

3. The iQpump Controller is not in Auto Mode

Minimum Water Level or Suction Pressure Detection Operation

In case of a minimum water level or suction pressure, the lead iQpump Controller will de-stage when one or more Lag

iQpump Controllers are present, otherwise the lead iQpump Controller will go to sleep.

Note: Setting parameter b5-12 to 0 will disable analog feedback detection and will prevent the iQpump Controller from switching to the

Network Water Level/Suction Pressure.

Related Parameters

b5-12 PI Feedback Reference Missing Detection Selection

Setting Description

0 Disabled (factory default)

1Alarm

2Fault

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 27

Page 28

9 Water Level/Suction Pressure Control in Memobus Multiplex

P2-03 Sleep Delay Time

Sets delay time when water level or suction pressure signal falls below the minimum level programmed (P8-04).

Range Description

Network Multiplex Mode: Water Level Control (P8-01 = 1): Parameter specifies the time delay before

the lead drive de-stages when the water level (U1-98) falls below the Minimum Water Level (P8-04).

Network Multiplex Mode: Suction Control (P8-01 = 2): Parameter specifies the time delay before the

0 - 3600 sec

Default: 5 sec

lead drive de-stages when the suction pressure (U1-98) falls below the Minimum Suction Pressure (P8-

04).

Contactor Multiplex Mode (P1-01 =1 or 2): There are two contactor multiplex modes, one for Water

Level and another for Suction. Contactors programmed for Multiplex (H2- = 40 and 41) will open

one by one when the Water Level (U1-98) is below the Minimum Water Level (P8-04) for the time set in

the Sleep Delay Time (P2-03).

IMPORTANT: Staging Restriction when in Water Level/Suction Pressure Control.

• When P1-01 = 3 (Memobus Network) and the iQpump Controller’s PI output is being influenced by the Water Level/

Suction Pressure Control, pump system staging is disabled.

• When P1-01 = 1 or 2 (Multiplex system) and the iQpump Controller’s PI output is being influenced by the Water Level/

Suction Pressure Control, Multi-function output contacts (H2- = 40 and 41) are prohibited from closing.

Alarm: Water Level/Suction Pressure Transducer Lost

Alarm Display Description

Analog Terminal A1 signal is lost and the Network Water Level or Suction Pressure signal is now used.

AnalogA1 Lost

Switched to Net

Alarm: Network Water or Suction Pressure Signal Lost

Alarm Display Description

Net Wtr/Suctn

Lost, Chk Source

Fault: Programming Error: OPE13 Terminal A1

Fault Display Description

OPE13

Terminal A1

Cause: Defective or broken analog input source.

Countermeasure: Check to ensure the Water Level or Suction Pressure source is installed and working

properly. If no signal is present, set P9-50 = 3 to have it always read from another drive's network Water

Level or Suction Pressure.

Network source for Water Level or Suction Control Pressure is lost.

Cause: Valid analog source for Water Level or Suction Control Pressure can not be found on the network.

Countermeasure: Check the source on drives configured as P9-50 ≠ 3.

Cause: Terminal A1 is assigned to more than one of the following functions.

• Frequency Reference (b1-01 = 1)

• Dual Zone PI is enabled (b5-01 = 2)

• Flow Meter Enabled (P6-01 > 0)*

• Water Level/Suction Pressure Control Enabled (P8-01>0)*

• Hand Mode Ref Term A1 (P5-01 = 0)

Note: An OPE13 error will not be generated if b1-01 = 1 and P5-01 = 0, and none of the other conditions

listed above apply.

*When P1-01 = 3 (Memobus), a setting of P6-01 > 0 and P8-01 > 0 is allowed only if P9-40 = 1 or

P9-50 = 3.

Countermeasure: Reprogram b1-01, b5-01, P6-01, or P8-01.

Note: The OPE13 fault is modified in drive software version PRG:0035. Previous software versions have

different functionality.

28 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 29

10 iQpump MEMOBUS/Network Operation

10 iQpump MEMOBUS/Network Operation

Lag Drive Speed Follower and Lag Turn Off

Certain multiplex pump systems require a common pump speed for all running pumps. To allow for this operation, a new

selection "Follow Lead Spd" is added to parameter P9-05.

Function Description

P9-05 Lag Drive Mode

Setting Description

0

1

2

3

Note: The rate at which the Lag drives follow the Lead drive's output speed is dependent on the communication speed of the iQpump

Controller network (H5-02), the maximum number of iQpump Controllers on the network (P9-25) and the current number of

iQpump Controllers online.

Fixed Speed (factory default)

Runs at the P9-06 setting after the P9-07 time expires.

PI Regulation.

Uses PI to determine speed.

Turn Off

The iQpump Controller stops running when it switches to a lag drive after P9-07 time expires.

Follow Lead Spd

The iQpump Controller follows the speed of the active Lead drive. Use P9-30 gain and P9-31 bias setting

to adjust reference signal.

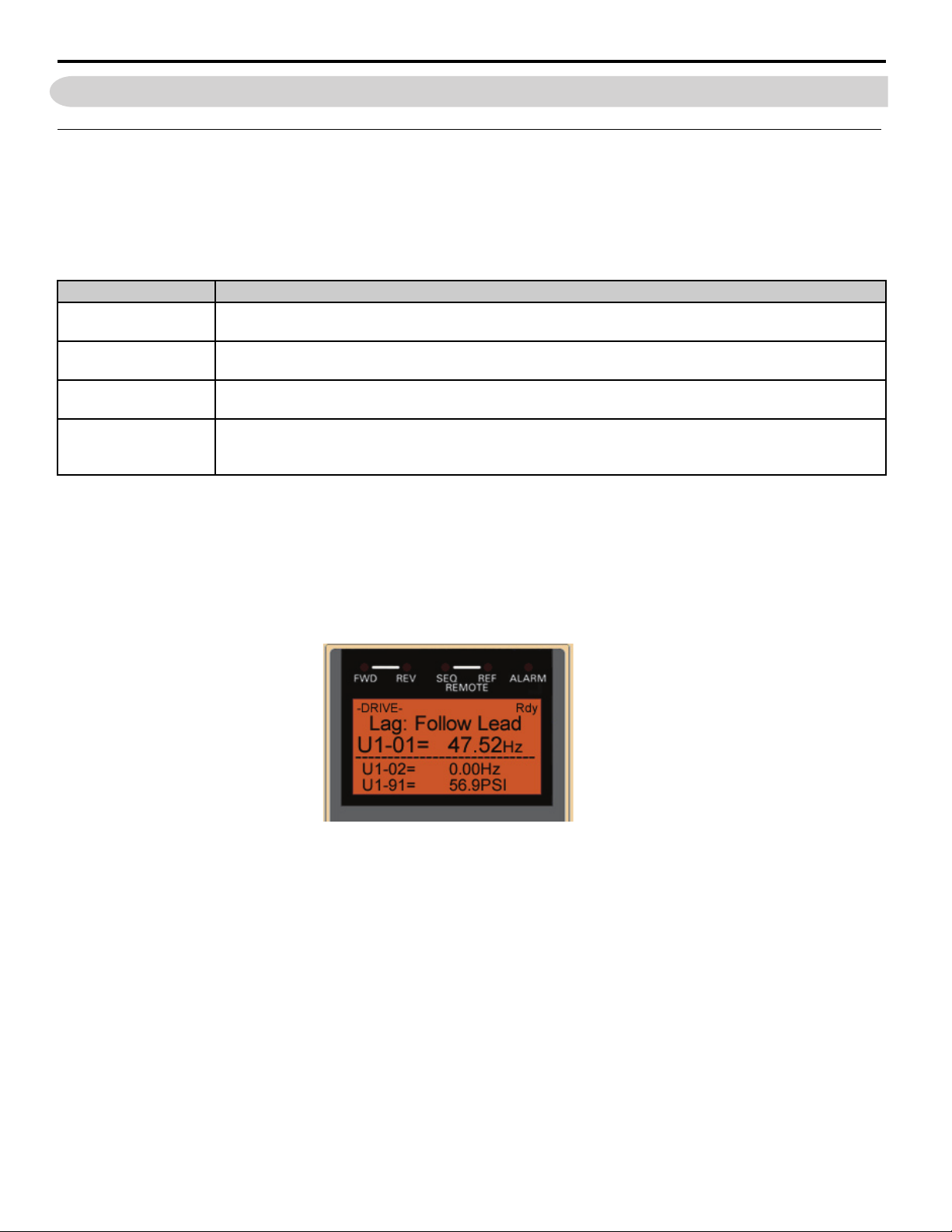

Display Message for Follow Lead Speed Operation:

When the iQpump Controller is operating in Auto Mode, Lag operation and the Follow Lead Speed function is active

(P9-05 = 3) then the display will show the actual frequency reference in Hz instead of the selected system units.

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 29

Page 30

10 iQpump MEMOBUS/Network Operation

Related Parameters

P9-06 Lag Fixed Speed

Range Description Default

0 - 120.0 Hz

P9-07 Lag Fixed Speed Delay

When the drive changes from a lead to a lag and P9-05 = 0, the drive will run at

this speed after P9-07 delay time expires.

Time delay before execution of P9-05 selection when the iQpump Controller changes from lead to lag.

Note: Only active when Lag Mode Selection (P9-05) is set to 0, 2 or 3.

Range Description Default

When the drive changes from a lead to a lag and P9-05 ≠ 1, this time specified

in parameter P9-07 determines how long the speed is latched before executing

0 - 1000 sec

one of the following operations:

1. P9-05 = 0: Run at P9-06

2. P9-05 = 2: Turn off

3. P9-05 = 3: Follow the Lead Drive's speed.

5 sec

New Parameters

P9-30 Lag Follower Gain

55.0 Hz

Range Description Default

0.0 -300.0%

P9-31 Lag Follower Bias

Range Description Default

-60.00 - 60.00 Hz

When P9-05 = 3, the drive will follow the speed of the active lead drive

applying this gain and P9-31 bias to the reference signal.

When P9-05 = 3, the drive will follow the speed of the active lead drive

applying this bias and P9-30 gain to the reference signal.

100.0 %

0.00 Hz

30 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 31

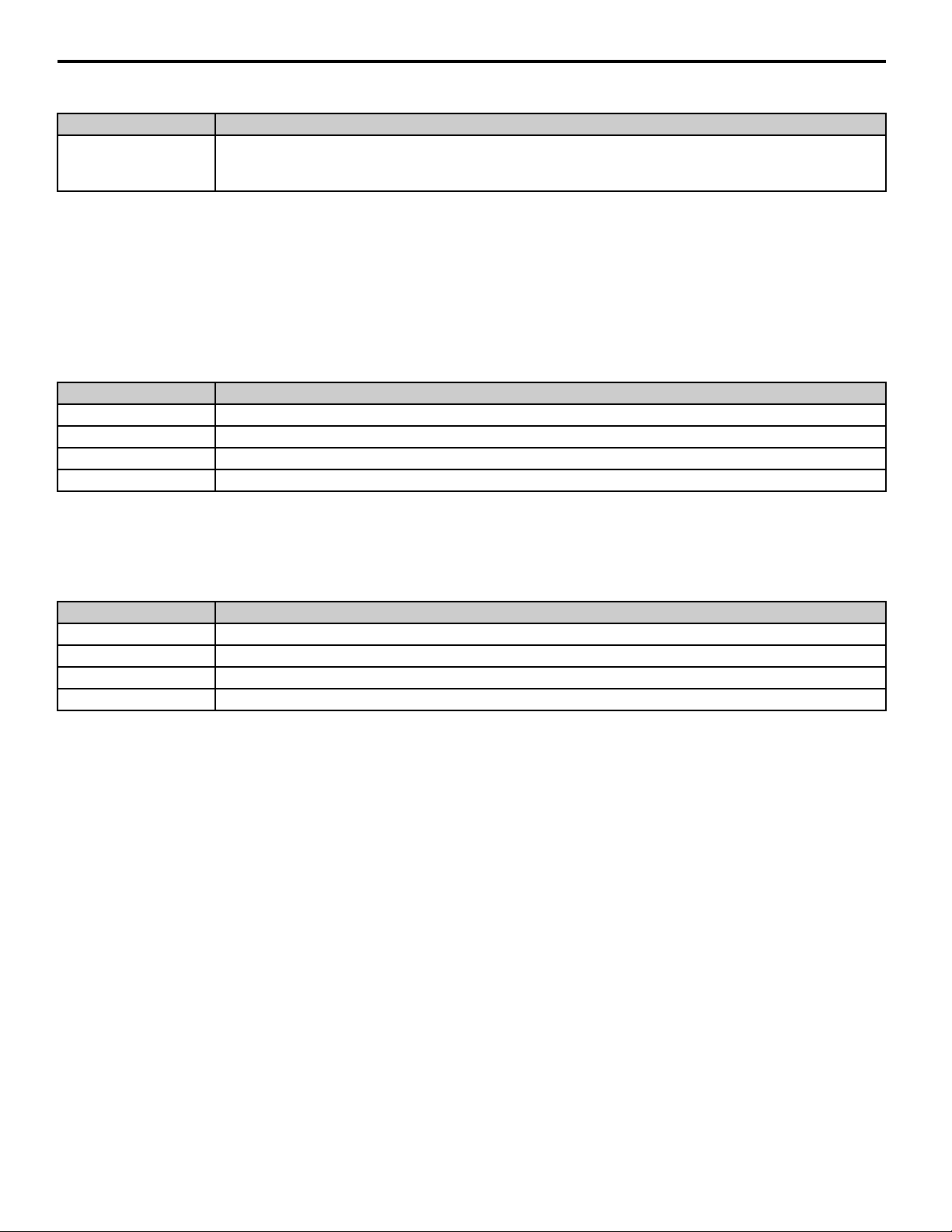

10 iQpump MEMOBUS/Network Operation

Flow Meter

Outlet

Pressure

Transducer

Inlet

Pump 2 Pump 3

Network

Pump 1

iQpump 2 iQpump 3iQpump 1

A1

A2

4-20mA

0-10V

Flow Pressure

Flow Meter

Certain multiplex pump systems require staging/de-staging based on the flow rate. The iQpump Controller offers a

dedicated set of parameters to operate multiplex pump systems based on flow control.

Multiplex Pump System Operation

Flow Rate Staging: Set P9-08 (Add Pump Mode) to 3: Flow Meter.

This mode monitors the Flow Rate to determine if staging is needed. If the Flow Rate of the lead iQpump Controller rises

above the Flow Staging level (no. of pumps running times P9-41) for the time set in P9-11, the drive will issue a network

stage request if an iQpump Controller is available to run.

If P9-41 Add Flow Rate Level set to 80.0 GPM, then the 2nd pump is called to run when the flow rate rises above

Example:

De-staging: Set P9-12 (Remove Pump Mode) to 3: Flow Meter.

This mode monitors the Flow Rate to determine if de-staging is needed. If the flow rate of the lead iQpump Controller

falls below the Flow De-Staging level ((no. of pumps running - 1) x P9-42) for the time set in P9-15, a de-stage request is

issued if two or more iQpump Controllers are running on the network.

Example:

NOTICE: Using Fixed Speed Lag Drive mode P9-05 = 0 in conjunction with Flow Meter Staging (P9-08 = 3) or Flow Meter De-staging

(P9-12 = 3) could result in an unstable system depending on the system and the parameter settings.

80.0 GPM. The 3rd pump is called to run the flow rate rises above 160.0 GPM and the 4th pump is called when the

flow rate rises above 240.0 GPM.

If P9-42 = 60.0 GPM, then the 4th pump is de-staged when flow rate falls below 180.0 GPM. The 3rd pump is destaged when the flow rate falls below 120.0 GPM (gallons per minute ) and the 2nd pump is de-staged when the

flow rate falls below

60.0 GPM.

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 31

Page 32

10 iQpump MEMOBUS/Network Operation

New Parameters

P9-40 Flow Rate Source

Defines the Flow Meter input source when P1-01=3 (Memobus Network).

Setting Description

0 Analog (factory default)

1

P9-41 Add Flow Rate Level

Range Description Default

0.0 ~ 6000.0 <1>

<1> Displayed units are determined by parameter P6-02.

P9-42 Remove Flow Rate Level

Range Description Default

0.0 ~ 6000.0 <1>

<1> Displayed units are determined by parameter P6-02.

Network

Uses PI to determine speed.

When P9-08=3 and the Flow Rate is above this level times (No. of pumps

running) for the time set in P9-11, the lead drive will request for a new lead

drive through the iQpump Controller Memobus network.

When P9-12=3 and the Flow Rate is below this level times (No. of pumps

running minus 1) for the time set in P9-15, the lead drive will request to be

removed from the system through the iQpump Controller Memobus network.

0.0

0.0

Related Parameters

P6-01 Flow Meter Scaling

Range Description Default

Sets the scaling for the flow meter connected to terminal A1. Enter the gal/min

0.0 ~ 6000.0 GPM

P6-02 Water Flow Units

Sets the units displayed for monitor U1-95. Also sets units for parameters P2-02, P6-04, P9-41 and P9-42.

Setting Description

0 U.S. Gallons/min (GPM) (factory default)

1 U.S. Gallons/Hr (GPH)

2 U.S. Barrels/min (BPM)

3 U.S. Barrels/hour (BPH)

4 U.S. Barrels/day (BPD)

P9-08 Add Pump Mode

Selects the detection method for staging a new pump.

Setting Description

0 Output Frequency (factory default)

1 Feedback

2 Feedback + Fout

3Flow Meter (New)

when the flow meter is at its rated output. A setting of 0.0 disables all flow

meter functions.

0.0 GPM

32 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 33

10 iQpump MEMOBUS/Network Operation

P9-11 Add Delay Time

Range Description Default

0 ~ 3600 sec Delay time before a new lead drive is added to the system. 10 sec

P9-12 Remove Pump Mode

Selects the detection method for de-staging to the previous lead pump.

Setting Description

0 Output Frequency (factory default)

1 Feedback

2 Feedback + Fout

3 Flow Meter

P9-15 Remove Delay Time

Range Description Default

0 ~ 3600 sec Delay time before the lead drive is removed from the system. 10 sec

Alarm: Network Water or Suction Pressure Signal Lost

Alarm Display Description

There is no drive on the Memobus Network with an analog Flow Meter.

Net FlowMeter

Lost, Chk Source

Cause: With P1-01 = 3, P6-01 > 0 and P9-40 = 1 (Network), the Flow Meter function needs a valid Flow

Rate from the network originating from another drive that is also running the Flow Meter function

(P6-01 > 0) with P9-40 = 0 (Analog).

Countermeasure: If the drive has an operational Flow Meter connected to Terminal A1, set P9-40 = 0. If

another drive on the Memobus Network has a Flow meter connected to Terminal A1, confirm that drive is

online, with P6-01 > 0 and P9-40 = 0.

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 33

Page 34

10 iQpump MEMOBUS/Network Operation

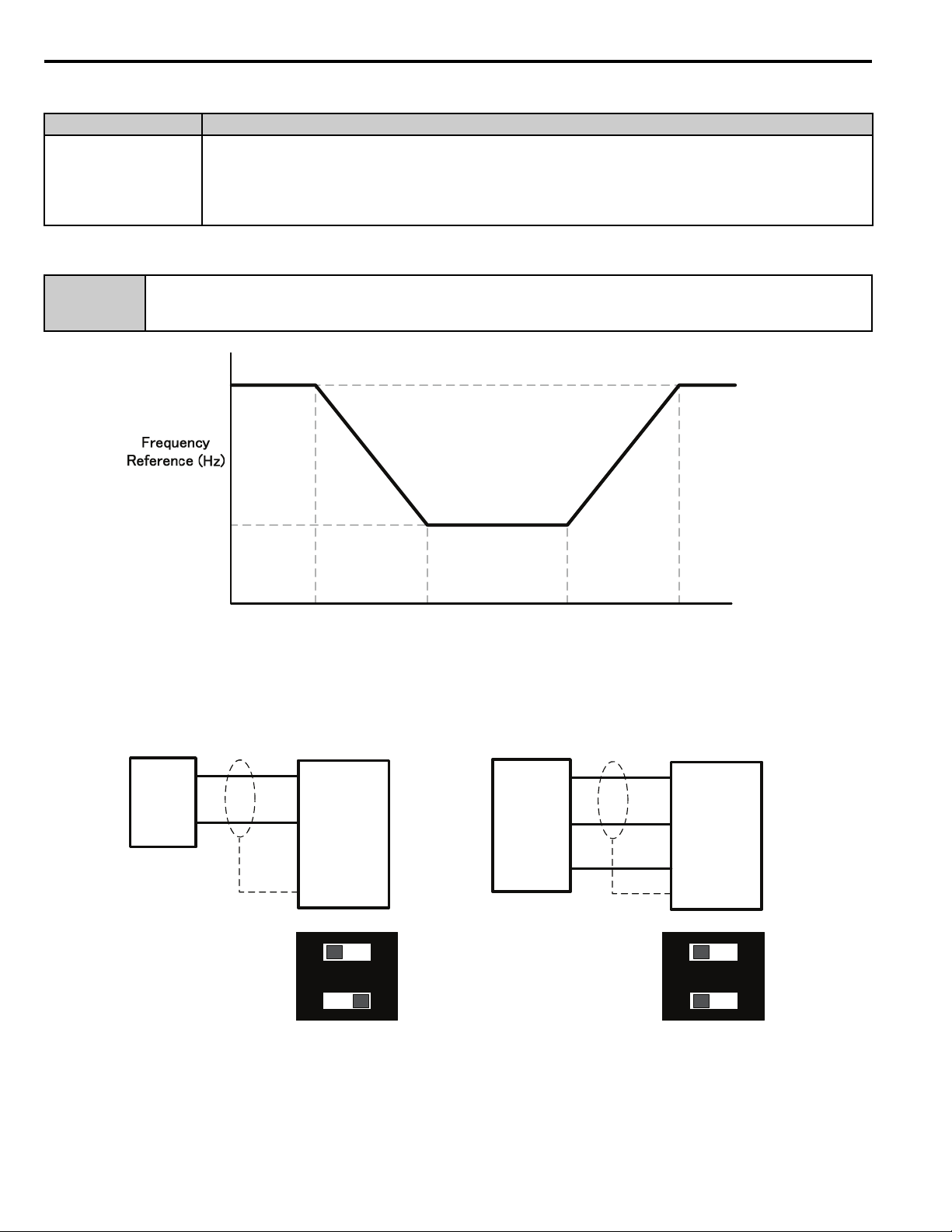

New Lead Drive Selection: Stop History

Overview

Many irrigation pumping skids consist of a PM pump (Pressure Maintenance) and typically two (2) larger booster pumps

to maintain high flow peak demands.

In many cases depending on the number of irrigation zones in combination with the type of sprinkler heads used, the flow

demand fluctuates and may not require the use of both larger booster pumps at the same time until higher flow rates are

required.

The iQpump Controller "Run Stop" history ensures that both booster pumps alternate each run cycle.

Parameters

P9-01 Lead Drive Selection

Selects the detection method for staging a new pump.

Setting Description

0

1

2

Next Available

Select next available drive on the network as the new lead drive.

Lowest Runtime (factory default)

Select the iQpump Controller with the lowest runtime as the new lead drive.

Stop History

Select the iQpump that had been stopped the longest time.

Note: This new lead drive selection also applies to Alternation (P9-03 > 0) and will use the Stop History list when finding the alternate

drive.

System Example: Triplex Irrigation Booster System-Using Stop History

Overview

A typical pump system operates as described below:

When pressure is dropping, the PM Pump (if installed) will attempt to return the system pressure to the desired setpoint

level. If the PM Pump is not able to return the system to the setpoint pressure, typically due to a greater flow demand, the

first booster pump (1) will be called to start.

The iQpump Controller will speed up or slow down the pump as needed to maintain the system pressure. When flow

decreases and the pump system is no longer required to run, the system will go to sleep waiting for the pressure to drop.

On the next run cycle the PM pump will start up again, and instead of running booster pump #1, booster pump #2 is

started, since booster #1 ran during the last cycle.

This method ensures that during normal operation both booster pumps will operate evenly as lead or lag pumps each run

cycle.

Detailed Description

Triplex irrigation booster system consisting of one PM Pump (pressure maintenance) and two larger booster pumps of the

same horsepower. The customer would like to ensure that the PM Pump is also the lead pump to recharge the system

during low flow usage, but during high demands the booster pumps alternate on each run cycle or if required will both run

to support very high flow demands.

• Jockey/PM Pump will also be lead to start.

• Jockey/PM Pump will stage booster pump 1 or 2 and stay running for 20 seconds and then shut off.

• Booster pump 1 will run system and if required, call for booster pump 2 or vice versa.

• On sleep mode, the lead drive for starting will swap back to Jockey/PM Pump.

• System setpoint 100 psi.

• Pressure drop of 10 psi will start the Jockey pump.

• All drives have individual transducers rated 200 psi maximum, but if there is a transducer failure, switch to network.

34 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 35

10 iQpump MEMOBUS/Network Operation

Related Parameters: Triplex Irrigation Booster System

Parameter Description PM Pump Booster Pump 1 Booster Pump 2

H5-01 Drive Node Network Address 1 2 3

P1-01 Pump Mode 3 3 3

P1-03 FD Device Scaling 200 psi 200 psi 200 psi

P1-04 Start Level -10.0 psi -10.0 psi -10.0 psi

P9-01 Lead Drive Select 2 2 2

P9-02 Feedback Source 2 2 2

P9-07

P9-20

P9-21 Run Priority 7 8 8

P9-24 Lead Swap @ Sleep 0 sec 1 sec 1 sec

P9-25 Highest Node Address 3 3 3

U1-01 Auto Setpoint 100 psi 100 psi 100 psi

Lag Fixed Spd Dly

(PM Pump will shut off after 20 sec)

Allow Net Run

(PM Pump will be lead Pump to start)

20 sec 5 sec 5 sec

200

Network

Transducer

System

Pressure

Feedback

PM

V+

A2

AC

PM

Pump

10 HP

Transducer

System

Pressure

Feedback

Pump 1

3 pmupQi2 pmupQiiQpump 1

V+

A2

AC

Transducer

V+

A2

AC

System

Pressure

Feedback

Booster

Pump 1

Pump 2

Booster

Pump 2

50 HP 50 HP

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 35

Page 36

11 Improved and Miscellaneous Functions

11 Improved and Miscellaneous Functions

Terminal A1 Loss Detection

Feedback loss detection alarm and fault messages are enhanced to differentiate between terminal A1 feedback loss and

Terminal A2 PI feedback loss.

Use parameter b5-12 is select feedback loss detection operation for terminal A1.

Parameters

b5-12 Feedback Loss Detection

Setting Description

0Disabled

1Alarm

2 Fault (factory default)

New Alarm Message: Feedback Loss Terminal A1 (Modified)

Fault Display Description

A1-LOST

Terminal A1 Lost

Shown when b5-12 = 1 and feedback signal on terminal A1 is lost. Check to ensure the device connected to

Terminal A1 is installed and working properly.

New Fault Message: Feedback Loss Terminal A1 (Modified)

Fault Display Description

A1-LOST

Terminal A1 Lost

Multi-function Output Setting: Transducer Loss (Modified)

Setting Description

4A

Shown when b5-12 = 2 and feedback signal on terminal A1 is lost. Check to ensure the device connected to

Terminal A1 is installed and working properly.

Transducer Loss

Closed: During a "Feedback Loss" alarm.

Closed: During a "FBL - Feedback Loss" fault".

Closed: During an "A1-LOST Terminal A1 Lost" alarm (New)

Closed: During an "A1-LOST Terminal A1 Lost" fault (New)

Function Description Feedback Loss Detection

Wire break (feedback loss detection) will be detected on Terminal A1 when all of the following conditions are satisfied:

• PI Feedback Loss Detection is enabled (b5-12 = 1 or 2).

• PI function is enabled (b5-01 > 0).

• Dual Zone PI or Water Level/Suction Pressure Control is enabled (b5-01 = 2 or P8-01 > 0, P1-01 = 0, b5-09 = 0, and

H3-09 = B).

• PI function is NOT disabled via Multi-Function Digital Input.

• Signal on Terminal A1 falls below -6.25 % or rises above 106.25 % for more than 1 second.

Note: Wire-break detection on Terminal A1 is checked after the gain/bias parameters (H3-02 and H3-03) are applied.

36 YAS KAWA TM.iQp.10 iQpump Technical Manual Supplement

Page 37

11 Improved and Miscellaneous Functions

Feedback Loss Detection Special Conditions:

Auto Mode Operation and b5-12 is set to 2 (Fault):

• Running: The iQpump Controller will fault on feedback loss detection.

• Stopped: The iQpump Controller will display feedback loss alarm.

Hand Mode Operation and b5-12 is set to 2 (Fault):

• Running: The iQpump Controller will display feedback loss alarm.

• Stopped: The iQpump Controller will display feedback loss alarm.

Both the alarm or fault message display in any of these scenarios is: "A1-LOST Terminal A1 Lost."

Note: To convert terminal A1 to a 4-20 mA signal, connect a 250 ohm precision resistor (1/4 Watt or greater) between iQpump

Controller terminals A1 and AC. Then program H3-02 = 231.3% and H3-03 = -25.0 %.

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 37

Page 38

11 Improved and Miscellaneous Functions

Initialization for Basic Applications (A1-03)

A new initialization mode setting 7770 is available under parameter A1-03 (Initialize Parameters). This setting allows

users to easily configure the iQpump Controller for use as a standard drive in simple applications. In this mode the

iQpump Controller defaults to start/stop operation from the terminals and speed control using a 0-10 Vdc signal to analog

input A1.

A1-03 Initialize Parameters

Setting Description

0 No Initialize (factory default)

User Initialize

1111

2220

3330

7770

The Table below shows the default parameters settings for the standard iQpump Controller 2-wire initialization (2220)

and the General Purpose Initialization (7770).

The modified iQpump Controller parameters are returned to the values selected as user settings. User

settings are stored when parameter o2-03 = 1: Set Defaults.

2-Wire Initialize

Initializes the iQpump Controller for 2 Wire Control Operation

3-Wire Initialize

Initializes the iQpump Controller for 3 Wire Control Operation

General Purpose

Configures the iQpump Controller for General Purpose Operation

Parameters Modified for General Purpose Initialization

Parameter No. Parameter Name Factory Default Setting

b1-01 Frequency Reference Selection 0 (Operator) 1 (Terminals)

b1-02 Run Command Selection 0 (Operator) 1 (Terminals)

b5-01 PID Mode Setting 1 (Enabled) 0 (Disabled)

C1-01 Acceleration Time 1 20.0 sec 25.0 sec

C1-02 Deceleration Time 1 10.0 sec 25.0 sec

C6-02 Carrier Frequency Selection 1 (2.0 kHz) kVA dependent

H1-04 Terminal S6 Selection 80 (Hand Mode) 4 (Multi-Step SP 2)

H1-05 Terminal S7 Selection 84 (Disable Pre-Charge) F (Term Not Used)

H2-01 Terminal M1-M2 Selection 40 (Pump 2 Control) 0 (During Run 1)

H2-02 Terminal M3-M4 Selection 41 (Pump 3 Control) A (Remote/Auto Oper)

H3-09* Terminal A2 Function Selection B (PID Feedback) 2 (Aux Reference)

L5-01 Number of Auto Restarts 5 0

L5-03 Maximum Restart Time 20.0 sec 180.0 sec

o1-06* User Monitor Selection Mode 1 (3 Mon Selectable) 0 (3 Mon Sequential)

P1-02 System Units 1 (psi:lb/SqrInch) 14 (Hz: Hertz)

P1-03 Feedback Scaling 145 26000

P1-05 Start Level Delay Time 1 sec 0 sec

P1-06 Minimum Pump Frequency 40.0 Hz 0.0 Hz

P4-05 Thrust Frequency 30.00 Hz 0.00 Hz

P4-11 Utility Delay Time 0.2 minutes 0.0 minutes

P5-02 Hand Reference 40.00 Hz 0.00 Hz

Setting After General

Purpose Initialize

(A1-03 = 7770)

Note: After performing a General Purpose initialization (7770), the parameters shown in this table will be visible in the Modified

Constants menu, with the exception of parameters marked by *.

38 YASK AWA TM.iQp.10 iQpump Technical Manual Supplement

Page 39

11 Improved and Miscellaneous Functions

Pump Quick Setup Menu

Initializing the iQpump Controller for General Purpose Operation also re-configures the Pump Quick Setup (Quick Start)

menu to show parameters for use in basic applications.

The table below shows the parameters that appear in the quick start menu for standard iQpump Controller 2-Wire

Initialization (2220) and the General Purpose Initialization (7770).

Quick Setup Overview

A1-03 = 2220, 3330

iQpump Quick Setup

E2-01 (Motor Rated FLA) b1-01 (Reference Source)

E2-04 (Number of Poles) b1-02 (Run Source)

P1-03 (FB Dev. Scaling) C1-01 (Accel Time 1)

D1-01 (Set-Point 1) C1-02 (Decel Time 1)

P1-04 (Start Level) E2-01 (Motor Rated FLA)

P1-06 (Min. Pump Freq.) E2-04 (Number of Poles)

P4-10 (AMO PwDn-Storage) L5-01 (Num of Restarts)

P5-04 (Oper HAND Key) L5-03 (Max Restart Time)

- P1-06 (Min. Pump Freq.)

General Purpose Quick Setup

A1-03 = 7770

YAS KA WA TM.iQp.10 iQpump Technical Manual Supplement 39

Page 40

11 Improved and Miscellaneous Functions

General Purpose Initialization: Carrier Frequency Adjustment

Initializing the iQpump Controller for General Purpose Operation adjust the carrier frequency setting as shown in table

below for each of the iQpump Controller models.

Carrier Frequency Setting for A1-03 = 7770 "General Purpose" Initialization

208-240 V Drives 480 V Drives

Model

CIMR-

P7

-107

20P41 3 8.0 kHz* 40P41 3 8.0 kHz*

20P71 3 8.0 kHz* 40P71 3 8.0 kHz*

21P51 3 8.0 kHz* 41P51 3 8.0 kHz*

22P21 3 8.0 kHz* 42P21 3 8.0 kHz*

23P71 3 8.0 kHz* 43P71 3 8.0 kHz*

25P51 3 8.0 kHz* 44P01 3 8.0 kHz*

27P51 3 8.0 kHz* 45P51 3 8.0 kHz*

20111 3 8.0 kHz* 47P51 3 8.0 kHz*

20151 3 8.0 kHz* 49P01 3 8.0 kHz*

20181 3 8.0 kHz* 40111 3 8.0 kHz*

20221 3 8.0 kHz* 40151 3 8.0 kHz*

20301 3 8.0 kHz* 40181 3 8.0 kHz*

20370 2 5.1 kHz 40221 3 8.0 kHz*

20450 2 5.1 kHz 40241 3 8.0 kHz*

20550 3 8.0 kHz* 40301 3 8.0 kHz*

20750 1 2.0 kHz 40371 3 8.0 kHz*