YASNAC i80M

CNC SYSTEM FOR MACHINING CENTERS

APPENDIX

Before initial operation read these instructions thoroughly, and retain for future reference

YASUAWA

This appendix is a supplement to the YASNAC i80M Instruction

Manual, Connection Manual and Service Manual.

Detailed data necessary for supplementary explanations

of the list of alarms, parameters and settings that appear in

these manuals are included in this supplement.

Use this manual as supplementary data for those who are

engaged in designing NC machine tools and in operation and

maintenance of machines.

— CONTENTS —

1. ADDRESS CHARACTER

2. FUNCTION CHARACTER

3. TAPE CODE

4. TAPE FORMAT

5. DATA SETTING RANGE

6. COMMAND VALUE RANGE

7. ALARM

7.1 NUMBERING OF THE ALARM NUMBERS

7.2 ALARM NUMBER TABLE

8. G CODE

9. PARAMETER

9.1 PARAMETER NUMBER LIST

9.2 PARAMETER NUMBER TABLE

10. STANDARD

10.1 STANDARD INPUT/OUTPUT DIAGNOSIS NUMBER LIST

10.2

10.3 OUTPUT SIGNAL

OO""""C"" ..".. C. 000"""0"""""0"" ".""" "". """"" """"" "".." oo"--"-o--<o----+ "---" "o-o--" "oo-" o"'--""" 119

INPLTT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C"""" "" OO"O. C"" O"""" "" C."." "--"" -o--" ""-----o ---"" """" ---oo-----o-""" ""o" -"-o" ""o-"-"-"

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

"." O"..

"".".. " . . ..

lNPUT/OUTPUT

SIGNAL

""""" """"..

""""" """.

PLC+NC

NC+PLC

"...

".""" .""" O.""o--oo-"---o ---oo-"-o"o"--" "-""" .-""" --oo- """

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

"...

O". OO"""""""O".". "" C"". "". "". """". """"" "". C. C"""" o-"" --oooo

." O"""" """"" -""". ""-" OO. "". """"" S"--4"--""oooooo

. . . . . . . . . . . . . . . .

."""" ."""" ."""" """"" "" OS..

OOO.COOO""""S""

"OO""O""".CCCCC

.

..o.. ooc..oocc

.o

. . . . . .

DIAGNOSIS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

-."...

O"""" """"" .OOI". "O" O"""" """o" o-o-o 12

."""" oo------"o ---------" ----- o---oo "-" 121

. .

...""""""""""""""""""""""""""""""""""""""""

..c

. .

..o

. . .

..-o" """"""""""""""""""""""""""""""

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

,.. .$,,,,,,,,.. ,, .,.,.,,..,,,,

..$

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

3

7

"----"-"--""-"-"-- 9

..O.

11

121

131

319

““””””.””.””

319

320

328

4

5

8

11

–2–

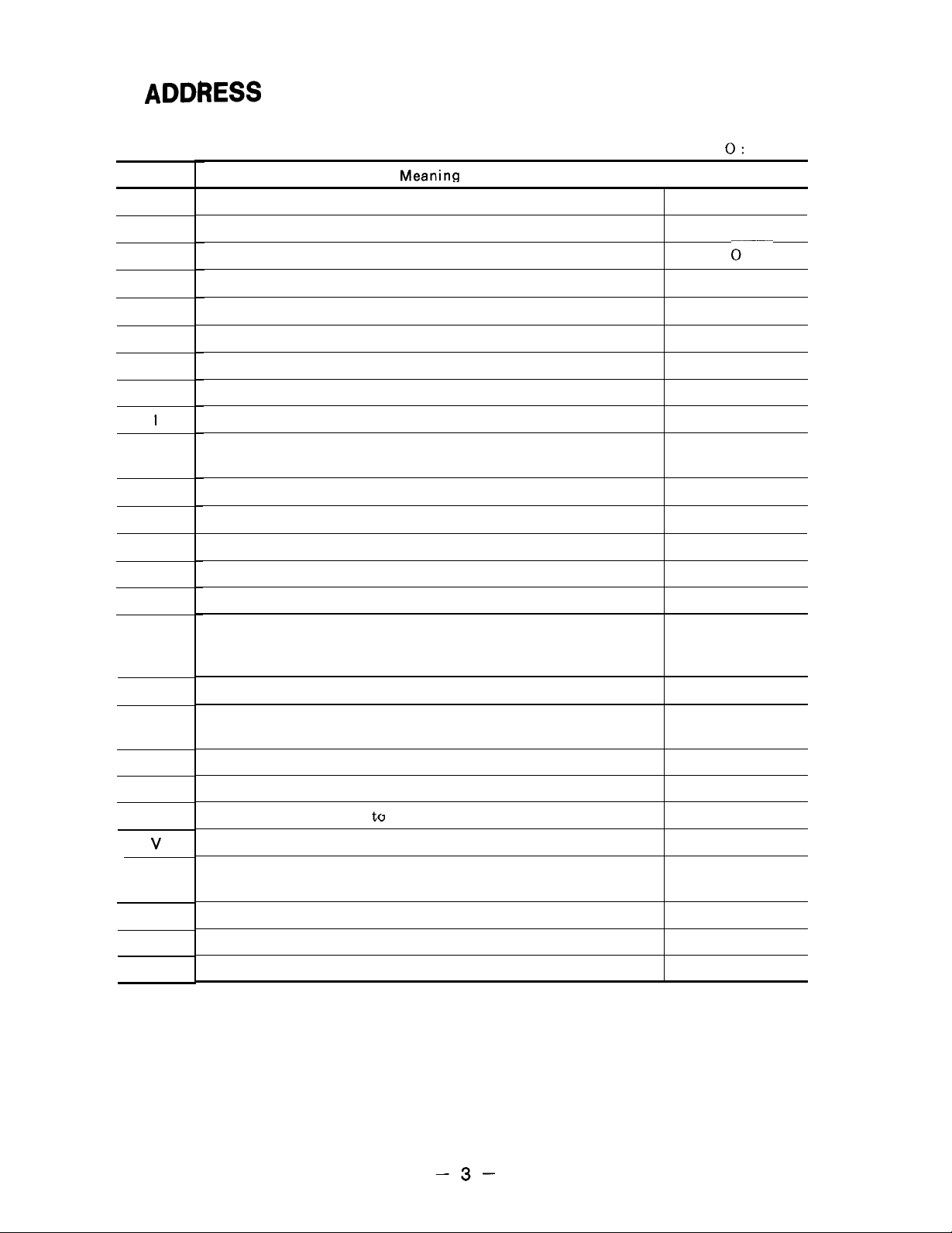

1.

ADDRESS

Address

A

B

c

D

CHARACTER

Meaning

Rotating axis around the axis parallel to the X–axis

Rotating axis around the axis parallel to the Y–axis

Rotating axis around the axis parallel to the Z–axis

Tool radius offset number

B: Basic

0:

Option

i Classification

o

o

o—

B, O

E

F

G

H

I

J

K

L

M

N

o

P

Q

R

s

T

u

v

—

w

x

Y

z

Microprogram characters and canned cycle feed

Cutting feedrate

Set–up function

Tool offset number

X coordinate of circular center, radius when cutting circle

Y coordinate of circular center, cutting allowance when cutting

circle

Z coordinate of circular center

Number of repetitions

Auxiliary function

Sequence number

Program number

Dwell time, specifications for G1O tool offset number

Specification of program number at a subprogram, and sequence

number

Depth of cut and amount of shift of canned cycle

Radius at point R of canned cycle

Specifications for G1O tool offset amount

Spindle function

Tool function

Additional axis parallel to the X– axis

Additional axis parallel to the Y–axis

Additional axis parallel to the Z–axis and new initial point of

canned cycle

X–axis coordinate value and dwell time

Y– axis coordinate value

Z–axis coordinate value

o

B

B, O

B

B, O

B, O

B

B, O

B

B

B

B

o

o

O, B

B

B

o

o

o

B

B

B

–3–

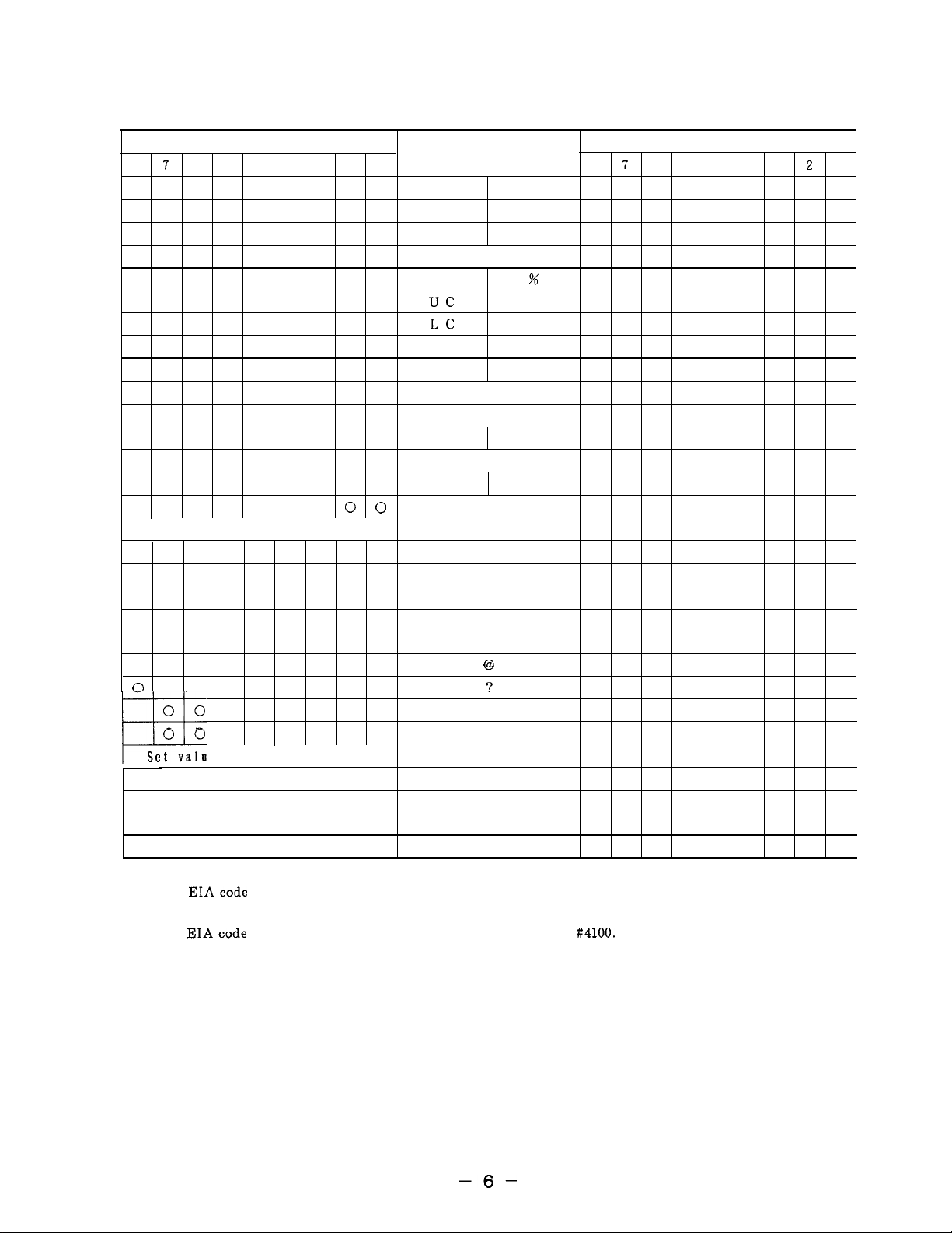

2. FUNCTION CHARACTER

E 1A Code

Blank

BS

Tab

CR

SP

ER

Uc

LC

2–4–5 Bit

2–4–7 Bit

+

oto9

atoz

I

ISO Code

Nul

BS

HT

LF/NL

CR

SP Space

%

(

)

+

—

oto9

Ato

Z

/

Meaning

Error in significant section of EIA and disregarded

in 1S0

Disregard

Disregard

End of block (EOB)

Disregard

Rewind stop

Up shift

Down shift

Control out (Comments start)

Control in (Comments end)

Disregard, microprogram operator

Minus sign, microprogram operator

Numbers

Address code

Optional block skip

Microprogram character

Remarks

EIA is a

special code

Del

.

Parameter

setting

*

=

[

1

0

$

@

?

Note:

1. All codes other than the above in the significant information section become errors.

2. Information sandwiched between the control out and control in codes become meaningless.

3. Tape code (EIA/ISO) can be specified with setting

DEL

.

#

*

—

—

(

1

$

@

?

Disregard (Including All Mark)

Decimal point

]

Sharp (Variable)

Asterisk (Multiplication operator)

I

Equal sign

Large left parenthesis

I

Large right

For microprogram comments

For microprogram comments

For microprogram comments

For microprogram comments

For microprogram comments

~arenthesis

#0004

DO.

I

I

I

EIA is a

special code

–4–

3. TAPE CODE

8

‘1

6

0 0

0

0 0 0

o

0 0

0

0 0 0 0

0

0

0

0 0

0,

0 0

0

0

0

0 0 0

0

0 0

0 0

10]

(-)

0

0 0

0 0

0

0 0

0

0 0 0 0

0

0 0

0

0

0 0

Iolololol

0

1

I

0

EIA Data

5

4

0

3

0 0

0 0

0 0 0

0

0

0 0

0 0

0

0 0

0 0

0 0

0

0

0 0

0

0

0

0 0

0

0 0

0

0 0

0 0

0

0

Iol Iol

o

0

0

0 0

0 0

010

0 0

0

0

0 0

0 0

0

0 0

0 0

0

0

0

0

0

0 0

0

0 0

o

2

0

lo\

010

0

0

0

0

0

0

0

0

0

0

0

0

0

101

1

Ctiaracter

8

7

0

1

2

0

0 0

3

4

0 0

5

6

7

8

0 0

0

9

a

b

c

d

e

f

g

h

i

j J

k

1

m

n

0

P

Q

r

s

t

u

v

w

x

Y

z

Blank

A

B

c

o

D

E

F

o

o

G

H

I

o

o

K

T.

(-lo

-

M

N

0

0

P

Q

R

o

o

s

T

o

u

v o 0

w

o

x o

Y

z

I

NUL

o

o

0

o

0

0

o

o

0

0

101

.

o

o

0

o 0

0

0

o 0

0

o

0

0

!

Iol

o

BS o

1S0 Data

6

5

4

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0 0

010

0

I

0

0

0

]Olol

101010

0

0

0

0

0 0 0

0

0 0 0

0

0 0

lo\olol

Io

lolo

0

0

3

2

0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0

0

0

0

0

0 0

0

0

0 0

0 0

0 0

0 0

0

0

0

0

0

0

10]0

0 0

0 0

0 0

0

0

0

0 0

0 0

0 0

0 0

0 0

0

0

0

101

o

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

o

–5–

3. TAPE CODE (Cent’d)

EIA Data

8

7 6

0 0

0 0 0

o 0 0

0 0

0 0 0 0

0 0

0

0 0 0

0 0 0 0

Note 2

0

0

0 0 0

0

0

0

0

00

00

t

value for parameter #4108

Se

w

Set value for parameter #4109

Set value for parameter #4144

Set value for parameter #4145

Set value for parameter #4146

Note :

1. The

used in this system as a temporary code.

2. The EIAcode of character “#” can be specified with parameter

5

4

0

3 2

0 0

0 0 0 0 /

0

EIAcode of character ‘#–?” is generally not defined. Theabove codeis

0 0 0 0

0

o

0

0 0 0

o

0

0

0 0

0 0 0

0 0

0

0 0 0

0 0 0 0

0 0 0

0 0

0 0 0

0

0 0

0 0 0

0 0 0

0 0

0 0 0

0 0

0

0

0

0

0

0

0

1

0

0

0

0

Tab

CR

—

ER

Uc

LC

—

.

0

Del

Character

HT o 0 0

LF/NL

CR o

SP o

+

—

DEL o 0

All Mark

#

*

—

.

[

1

$

@

?

.

.

<

>

)

%

—

—

(

1S0 Data

8 7

o

o 0

o 0 0 0

o 0

o 0

o 0

0 0 0 0 0

o 0

0 0

o 0

0 0

0 0 0

o 0 0 0 0

#4100.

6

5

4

o 0 0

0 0

0

0

o 0 0

0 0

o

o

0 0 0 0

0 0

0 0

0

o 0 0 0

0

o

0

0 0

0 0 0 0

0 0

0 0

0 0

0 0 0

0 0 0 0 0

0 0 0

0 0

0 0

0 0

0 0

0

3 2

0

0

0

0 0

0

0

0 0

0

0 0

0

0 0

0

0 0 0

0

0

0

0

0

0 0

0

0 0

0

0

0 0 0

0 0

0

0

0

0 0

1

0

0

0

0

0

–6–

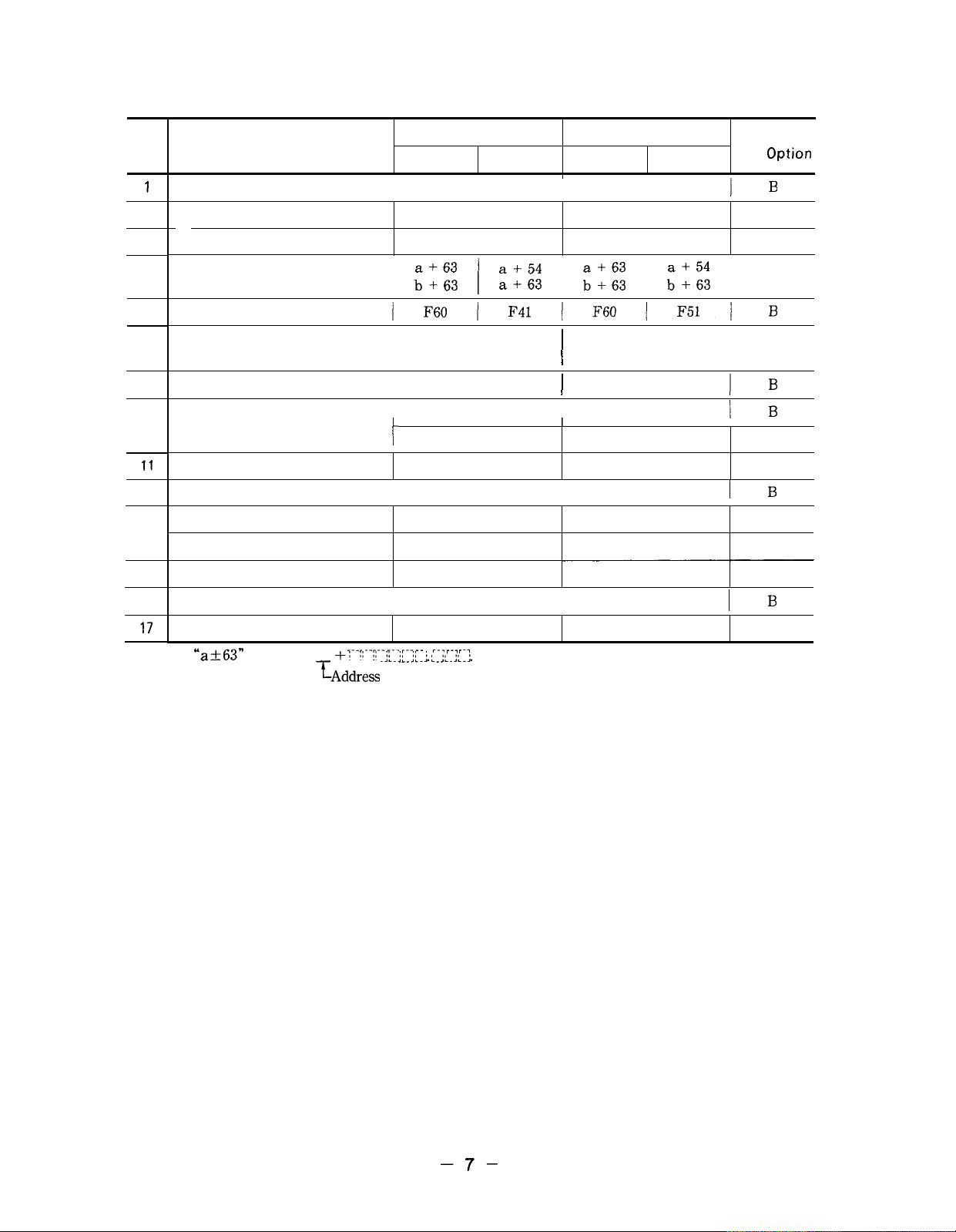

4. TAPE FORMAT

No.

1

2

—.

3

4

Coordinate word

5

Feed per minute multiplied by

6

1/10

9

10

11

12

13

14

15

Program number specification

Address

Program number

Sequence number

G Function

Linear axis

Rotating axis

Feed per minute

S Function

T Function

M Function

Tool offset number

B Function

Dwell

Output (mm)

Input (mm) Input (in. )

I

a+63

b+63

IF601F411F601F511B

F61

I

I

t

I

I

05

N5 N5

G3 G3

a+54

a+63

i

F42

I

S5

T2

T4 T4

M3

H4 or D4

B3

P63

P5 P5

Output (in. )

Input (mm) Input (in. )

I

a+63

b+63

i

F61

1

I

I

I

I

I

05

a+54

b+63

I

I

S5

T2

M3

H4 or D2

B3

P63

F52

B : Basic

0

:

‘Ption

,

IB

B

B

B

o

I

B

I

jB

IB

I

B

I

B

IB

o

B

B

16

Sequence number specification

17

Note :

Number of repetitions

“a~63”

indicates x

~Address

,-., -.r-. r-. r-. r-

~:.;:.;:.;:.;:.;:.;.

.

,-. r-.,-.

:.;:.;:.;.

representing coordinate

P5

L9

I

P5

L9

IB

B

–7–

5. DATA SETTING RANGE

Item

Minimum input unit

Max, stroke (distance from

reference point )

Amount of tool offset and tool

radius

Minimum amount of step/handle

feed

-

Rapid traverse rate

---- —

— ------ — ----- —----—---

Manual jog speed

-- —------ —----- —

Speed of F.

Upper limit of cutting feed

——----— —-----

Dry run speed

— ---- —----—

——---—

—--- ——

--

Output for screw (mm)

Input (mm)

0.001

or

0.01 mm

f

999999.999

o

to f 999.999

mm

0.001 mm

0.001 mm

0.001 mm

1 to 240000 mm/min

to

240000 mm/min

1

Input (in. )

to i 99.9999 0

0

Output for screw (in. )

I

Input (mm)

0.0001 or 0.001 or 0.0001 or

0.001 in.

mm.

0.01 mm

*

99999+9999 in.

Input (in. )

0.001 in.

I

to i 99.9999

0

0.0001 in.

0.0001 in.

0.0001 in

in.

0.0001 in.

0.0001 in.

to t 999.999

0.001 mm

0.001 mm

1

0.1 to

I

0.1 to

mm

24000.0 in. /rein

24000.0 in. /rein

I

in.

Stored pitch error compensation

and setting range of stored stroke

limit and No. 2–4 reference point

Amount of backlash compensation

-

Amount of work coordinate

system shift

Note :

1 pulse=

Minimum output unit.

to

99999.9999 in.

O

to i 999999.999 mm

(O : Reference point)

*32767

pulse

O

to f 127 pulse

I

1

0 to

L32767

o to * 9999.999 0 to t 999.9999 0 to *9999.999 o to * 999.9999

mm

pulse

in.

O

*32767

pulse

O

to *127 pulse

O to

*32767 pulse

mm

in.

–8–

6. COMMAND VALUE RANGE

—

No

—

1

Program number o

Address

Input (mm)

1

Output (mm)

to 99999

Input (in. )

1 to 99999

Output (in. )

Input (mm)

1

to 99999

Input (in. )

1

to 99999

2

Sequence number

3

G Function

coordinate

word

4

Max. accumulated command value

5

Feed per minute

Feed per minute

6

multiplied by 1/10

9

S Function

10

T Function

11

M Function

12

Tool offset number

13

B Function

14

Dwell

Program number

15

specification

Linear axis

Rotating axis

I

G \ Oto999

1

S5

I

T2 I Oto99

I

T4 I O to 9999

M

H

N

F

F

1 to 99999

\

o to 999

~

999999.999 mm

t

999999.999 degi 999999.999

t

999999.999 mm

1 to 240000

mm/min

1

0.1 to 240000.0

mm/min

o to 99999

0.01t09448.81

I oto99

I

o to 9999

t

o to 999

o

to

(1199) o

D

B

P

P 1 to 99999

o to (1199) o to (1199)

o

to

999

o to 999999.999$

‘ o

1

to 99999

+ 39370+.787”

t

999999.999 in.

0.1 to 9448.87

0

0 to 999 0 to 999

0 to 999

to

999999.999

1 to 99999

to

99999

to

(1199)

in,

in. /rein

in. /rein

1 to 99999 1 to 99999

I

o to 999

f

999999.999 mm

t

999999.999 deg

deg

i

999999.999 m m

1 to 609600 0.1 to 24000.0

0.1 to 609600.00

0 to 99999 0 to 99999

I

oto99 I oto99

I

o to 9999

1

o to(l199)

o to (1199)

0 to 999

o to 999999.999

s

1 to 99999

mm/min

mm/min

I

o to 999

t

999999.999 in.

k

999999.999 deg

t

999999.999 in.

in. /rein

0.01 to 24000.00

in. /rein

I

o to 9999

0

to

999

o to (1199)

o to (1199)

0

to 999

o to 999999.999

s

1 to 99999

s

Sequence number

16

specification

17

Number of repetitionsI L I lto999999999 I lto999999999 I

—

P

1 to 99999

1

to 99999

1 to 99999

lto999999999 I lto999999999

1 to 99999

–9–

( OUTLINE OF ALARM NO. )

X-A

DIR

Z-AXIS

k

t

DIR.

I

I

I

k

h

●

#ooo–-

#0499

Edit/operation-

related error

●

#looo–#lo99

Program error

“

#9000 –#9049

(Example)

#oo12

ILLEGAL

CTER

There are unusable

characters other than

ISO/EIA code with

PS-232C during tape

operation.

#lo90

MEMORY ERROR

(SET) :

Setting area total

check error

#9010

TH ERROR :

TH parity error during

tape 1/0 collation

CHARA-

:

●

#2000

–#2199

Machine-related

error

●

#5000– #5999

Sequence error

(Example)

#2061

ZR AREA ERROR

(x) :

Reference point

return area error

(x)

#2190

MACHINE

UNREADY :

Machine set-up not

ready

Ril

~

●

#3000 –#3299

Emergency stop

for servo and

spindle,

CPU monitor

(Example)

#3041

PULSE EXCEED (X) :

Error pulse exceed (X)

#3270

POWER OFF ERROR

(KEEP MEM) :

Data error when the

power is turned OFF

( mainly system error)

Memory check

error, watchdog

timer error, off

line error

. BAT display

(Example)

#8000

ROM ERROR :

ROM check error

#8001

RAM ERROR :

RAM check error

Note : When an alarm occurs, the alarm number and message will be displayed on the

lower left part of the CRT. Refer to the pertinent itern in the Service Manual to cope with

when

the situation

an alarm occurs.

–lo–

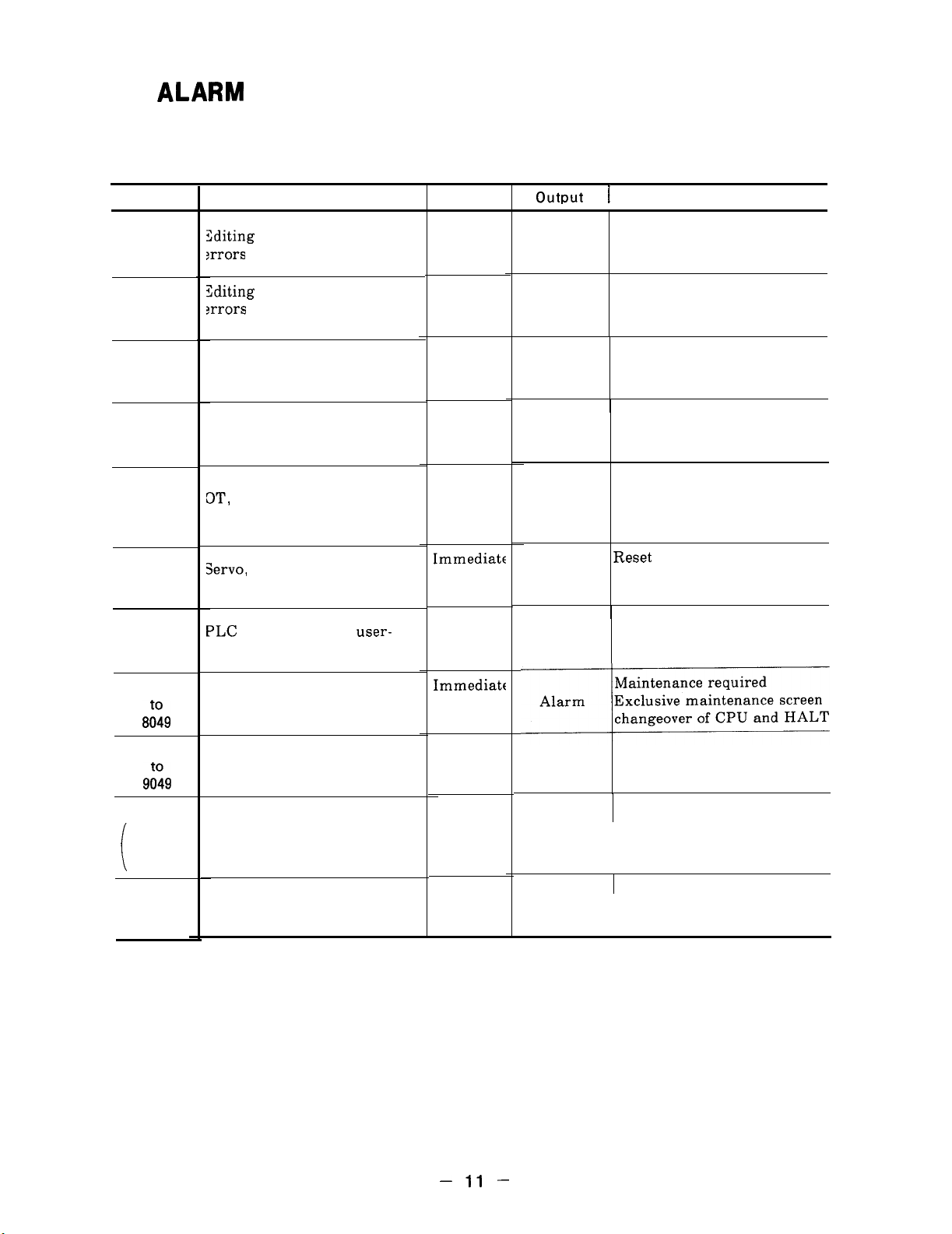

7.

ALARM

7.1 NUMBERING OF THE ALARM NUMBERS

Number

0000

to

0049

0050

to

0099

0100

to

0499

1000

to

1099

2000

to

2199

3000

to

3299

5000

to

5999

8000

8;9

9000

9:9

None

BAT

display

BAT. AXI!

[

None

Warning

message

(

Details

3diting

and operation–related

?rrors

that occur even in BG

3diting

?rrors

Program error

Program error

DNC, CMOS total etc.

Machine–related errors

DT,

machine preparation complete

in position, etc.

Servo,

ESP, CPU mutual monitoring

PLC

macro alarm message

Memory check error

Watchdog timer error

Offline error

Errors that occur with BG

operation (Basically same as

0000–0049)

Battery error

Encoder alarm

and operation–related

that do not occur even

n BG

reference point return,

spindle axis related

ladder message

When key operation error and

editing error are lit.

user-

stop

Block stop

Block stop

Block stop

Block stop

Coasting

stop or

immediate

stop

Immediat~

stop ,

Servo off

Block stop

Immediat[

stop ,

Servo off

Not stop

Not stop

Not stop

output

Input error

alarm

Input error

alarm

Input error

alarm

Input error

alarm

Alarm

Alarm

Alarm

=

BG error

output

None

\

Reset, method, remarks

Reset

Reset. However, power OFF

with 0050 and 0051

Reset

Reset

Reset after clearing cause.

However, MRDY is automatic

reset with first OFF– ON of

power supply.

Reeet

after clearing cause.

However, SV OFF automatically reset only with SV ON

Correct cause, then reset.

Otherwise, just reset.

Exclusive maintenance screen

Soft key

Reset or just reset.

I

Replace battery

I

Warning Next key operation

–11–

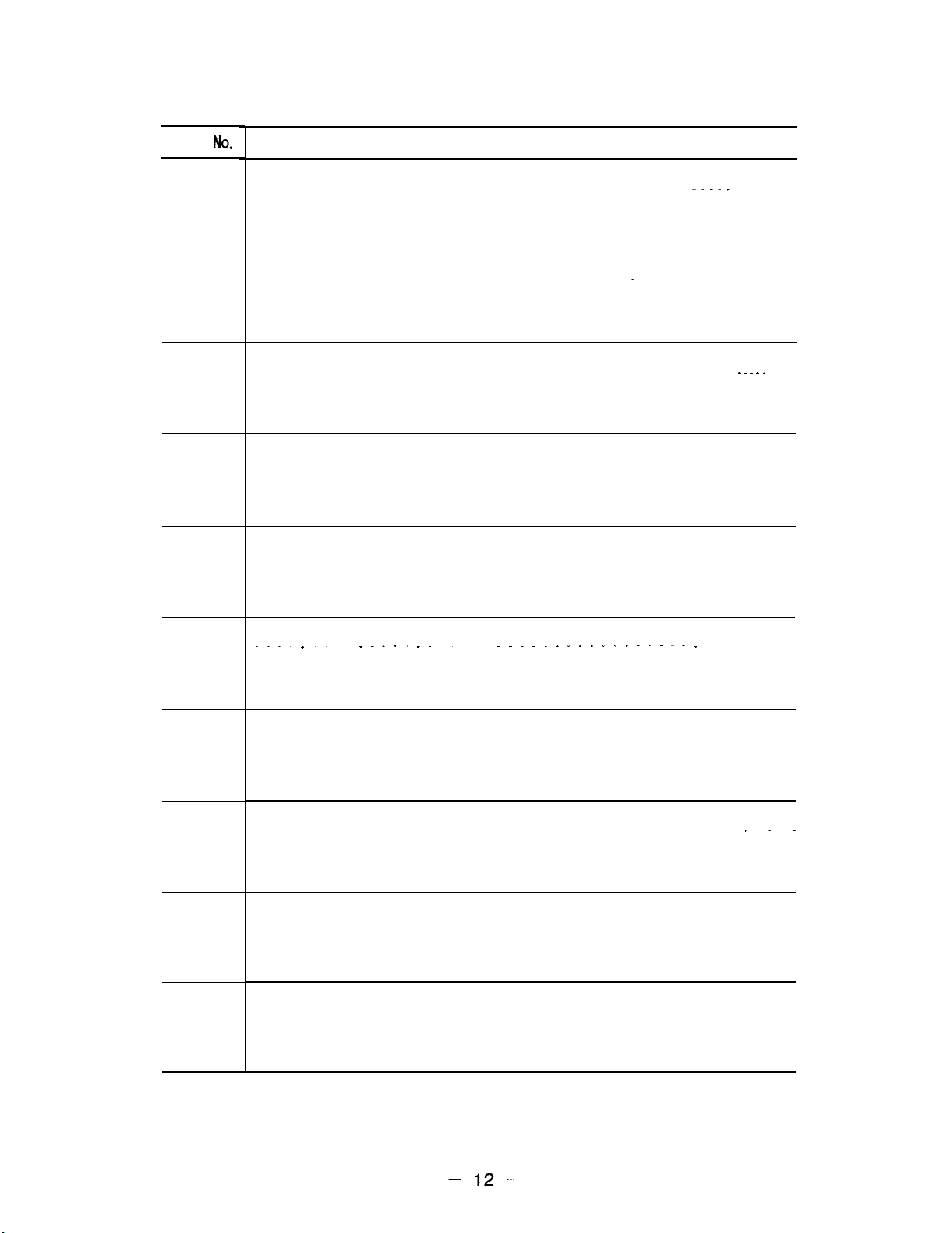

7.2 ALARM NUMBER TABLE

Alarm

No.

#oooo

#oool

#ooo2

#ooo3

Contents

. . . . .

.

. . . . .

#ooo4

#ooo5

#0006

#ooo7

#0008

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

#ooo9

–12–

Alarm No.

Contents

THERROR (TP)

#oolo

#ool 1

#oo12

#oo13

#oo14

TH parity error during tape operation.

I

TV ERROR

l------------------------------"`---""---""""--`"-"""`'"""""--"""-'"-""""-"-----'

TV parity error during tape operation.

ILLEGAL CHARACTER (TP)

There are unusable characters other than

during tape operation.

1 BLOCK LENGTH ERROR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

One block over capacity (128 characters) was detected during tape

operation 1.

DATA SET READY DOWN

Data set ready signal is not response in tape operation.

NUMERIC DATA OVERFLOW

(TP)

lSO/EIA

code with RS–232C

. .

#oo15

t-------------------------

#0016

#oo17

#0018

#oo19

Input data digits overflow in tape operation (Beyond 9 characters).

RS – 232C ERROR (CH SELECT)

RS–232C interface transmission abnormal.

Parity error occurs.

RS–232C ERROR (OVER RUN)

RS–232C interface overrun error.

(Improper protocol setting or transmission error).

RS – 232C ERROR (CH SELECT)

Error in selection of RS–232C interface circuit.

RS–232C ERROR (FRAMING)

RS–232C

(Improper stop-bit setting or transmission error).

. . . . . .

interface framing error.

–13–

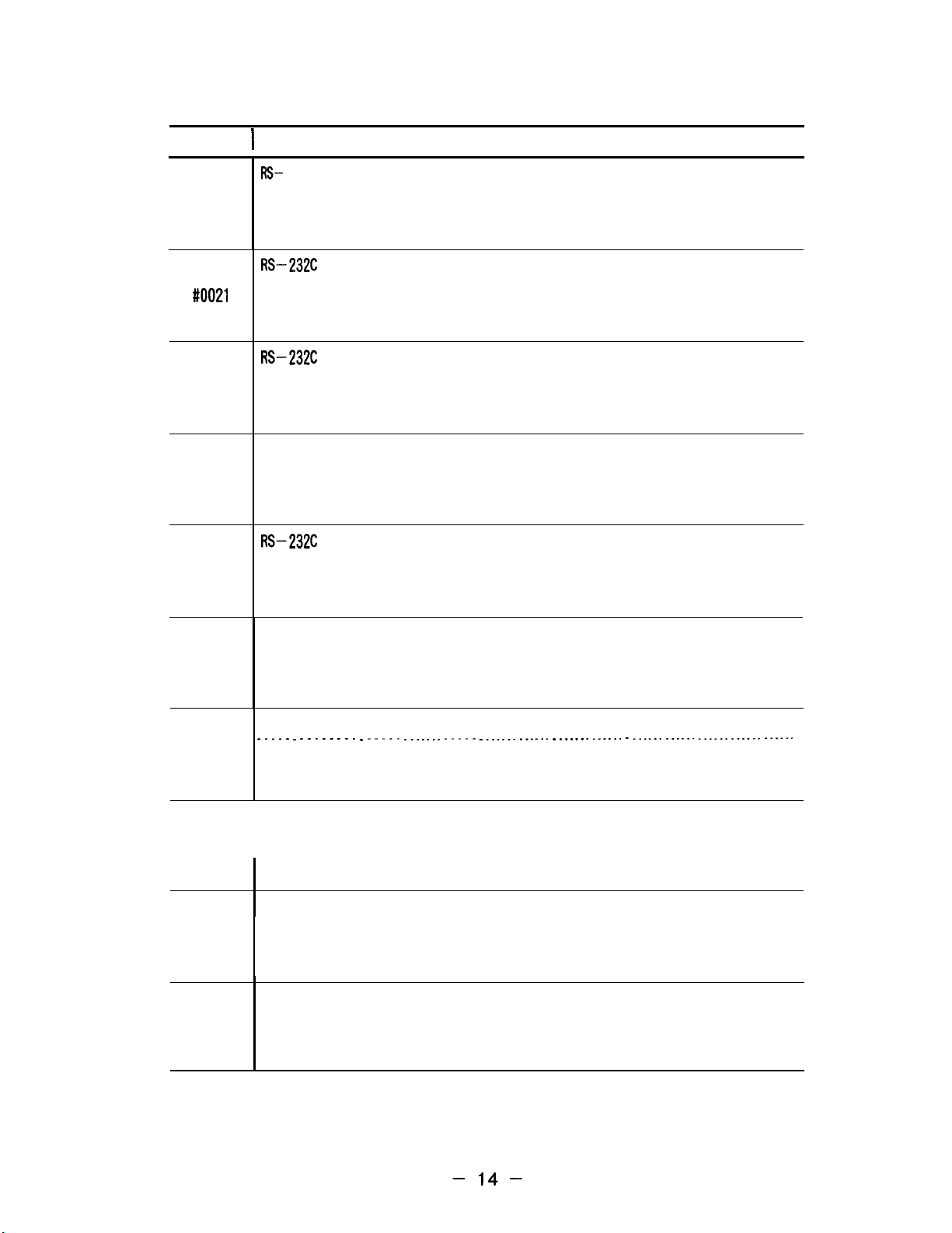

7.2 ALARM NUMBER TABLE (Cent’d)

Alarm No.

#oo20

#oo21

#oo22

#0023

#0024

I

RS–

232C ERROR (API– 1 )

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Line specified is already open.

RS–232C

ERROR (APL-2)

. . . . . . . .

Line specified is not open.

RS–232C

ERROR (APL-3)

Dual coil not being used in the correct combination.

RS–232C ERROR (APL-4)

Transmission was not conducted during the specified time.

RS–232C

ERROR (APL-5)

Transmission or receiving start processing not conducted.

#0025

#0026

#0027

#0028

#0029

RS–232C ERROR (APL--6)

. . . . . . . . . . . . . . . . . . . . . . . . . ------ ----

Error in specified parameter.

I

. . . . . . . . . . . . . . . . . . . . . ------ . . . . . . ------ ------ . ------ ------ . ------ ------ ------ ------ ------

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

–14–

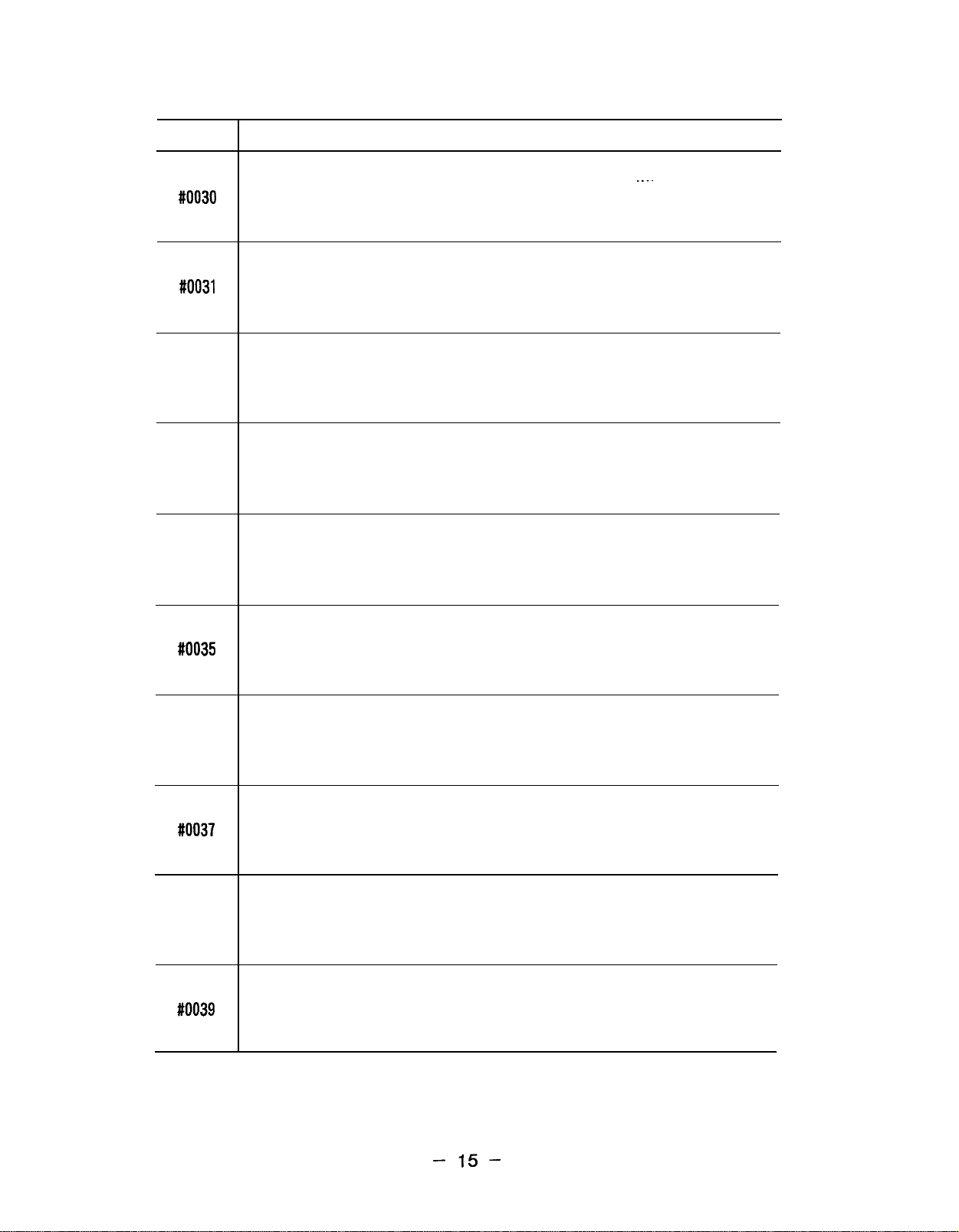

Alarm No.

Contents

#oo30

#oo31

#0032

#oo33

#oo34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ------ ------ ------ ------ .-

..-.

------ ------ ------ ------ ------

#oo35

#0036

#oo37

#0038

#oo39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–15–

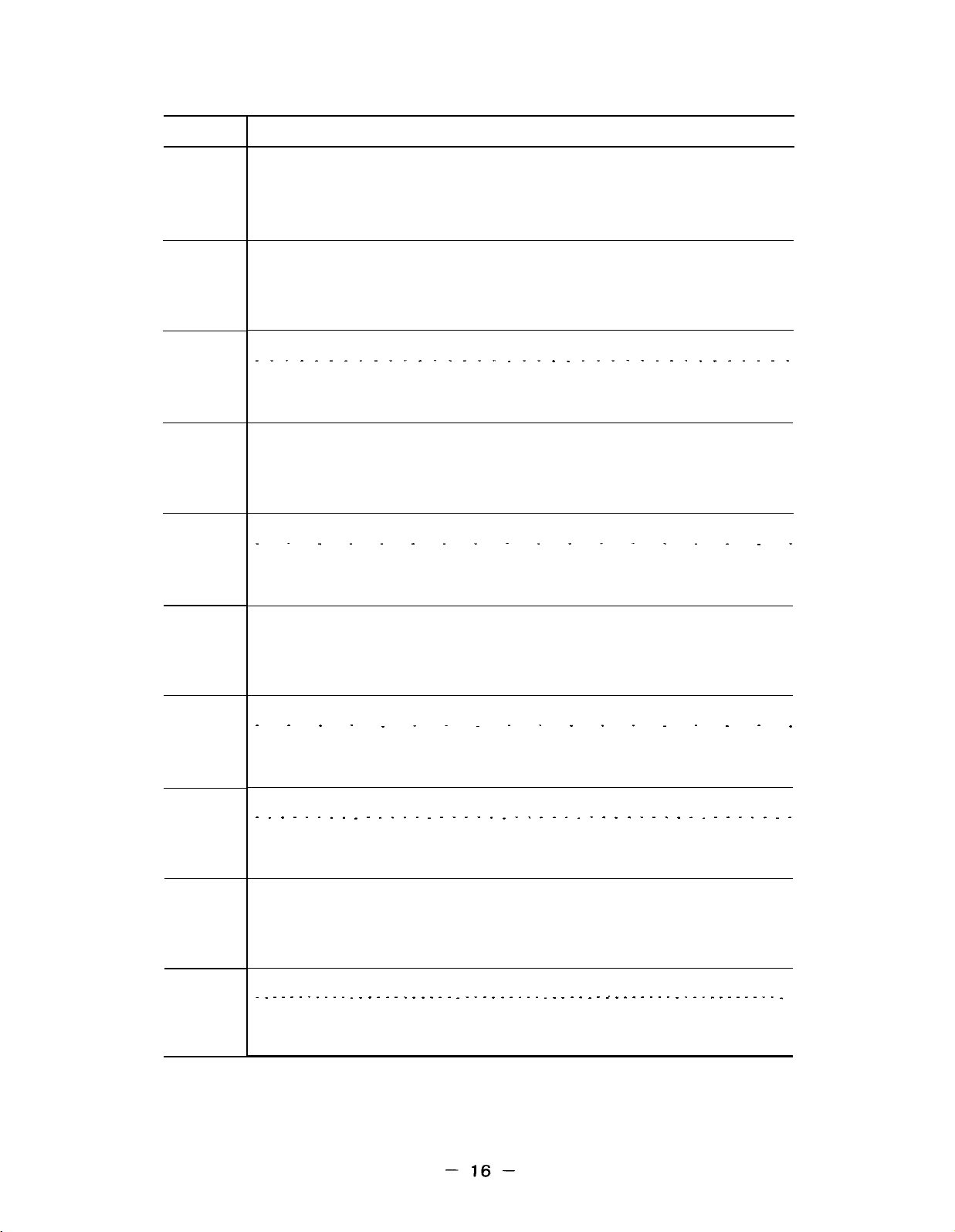

7.2 ALARM NUMBER TABLE (Cent’d)

Alarm No.

#oo40

#oo41

#0042

#oo43

#oo44

Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

#oo45

#0046

#oo47

#0048

#oo49

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–16–

Alarm No.

I

POWER OFF PM SET

Contents

#oo50

#oo51

#0052

#oo53

#oo54

A parameter was set that will not be effective unless power is turned

off,

Pm

PROG GEN

A parameter was set that will not be effective unless a program area

is generated.

SET

#oo55

#0056

#oo57

#0058

#oo59

l

--------------------------------------------------------------------------------

.

.

.

–17–

7.2 ALARM NUMBER TABLE (Cent’d)

Alarm No.

#0060

#0061

#0062

#0063

#0064

Contents

EXTERNAL (DATA)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rhere

is a data specification error with external data input.

EXTERNAL (NO

Program specified with external work number search cannot be found.

PROG)

#0065

#oo66

#0067

#oo68

#0069

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–18–

Alarm No.

#oo73

#oo74

Contents

. . . .

. . . . . . . . . . . .

l

------------------------------------------------------------

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . --------

#oo75

#0076

#oo77

#0078

l""'"

''""-"

"""-""

-"-"""

""""""

"""-"-""-""-"-"

. . . . . . . . . . . . . . . . . .

. . . . . . .

"""`-"

""""""-""""""-""-""-"""--""""-""-"-"""----"""""

.

–19–

7.2 ALARM NUMBER TABLE ( Cent’d)

Alarm No. Contents

l

---------------------------------------------------------------------------------------

#0081

#0084

#0085

#oo86

#0087

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l

---------------------------------------------------------------------------

. . . . . . . . . . .

. . . . . . . .

. . .

#oo88

#0089

l-------------------------------------------------------------------------------------

–20–

Alarm No.

#oo90

#oo91

#0092

#oo93

#oo94

Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

#oo95

#0096

#oo97

#0098

#oo99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–21–

7.2 ALARM NUMBER TABLE (Cent’d)

Alarm No.

#oloo

#ol

01

#ol 02

#olo3

#ol

04

I

1 BLOCK DATA OVERFLOW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Overflow of 1 block buffer capacity. (128 characters)

ADDRESS/DATA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

:~;:jre

““”

—

,.

Ml SUSE

no data after the address, or command was for data without

“

MISUSE

. . . . . . . . .

Address/data not being used correctly.

UNUSABLE CHARACTER

Command is for characters that cannot be used in the significant

information section.

NUMERIC DATA OVERFLOW

. . . . . . . . .

Numeric value input data overflow. (characters being exceeded)

#ol 05

#0106

#olo7

#0108

#olo9

I

UNUSABLE AXIS

1--.

-----. ------------------------------""--"""------"""""-'"""""""""-"-"-""""'"---""""""-""-"

Command is for an undefined axis.

DOUBLE ADDRESS

Command is over two times for the same address in one block.

“

lest

“ ) “ ERROR

(

“,

is “ ( “.

) “ is used without “ (

~.

There is no”)- for “( .

–22–

Alarm No.

!

Contents

—

#ollo

#oIll

#ol12

#ol13

#ol14

MULTI PLE M CODE

Command is for multiple Mcodes although there is no one block

multiple command option.

M

CODE DIGITS OVER

Number of M digit comands is excessive.

M91

FORMAT ERROR

P is not specified in the M91 block.

INTERNAL M

C~AND

ERROR

There is error in internal M code command.

M90/M91 CmAND

Comand

M90

ERROR

or M91 was used although it was unavailable.

. .

. . .

#ol 15

#0116

#ol17

#0118

#ol19

Ml

91 FORMAT ERROR

Input command

M191

contains an error.

M93 COMMAND ERROR

Command M93was used although itwas unavailable. (Option is

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ----------. . . . . . . . . . . . . . .

notset.)

--------------- ---------------

I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -------- ---------- ---------- ---------- . . -------- ----------

. . . . . . . . . . . . ..- --------------- --------------- --------------- --------------- --------------- ---------------

. .

““

–23–

7.2 ALARM NUMBER TABLE (Cent’d)

Alarm No.

#o120

#o121

#o122

#01

23

#01

24

Contents

#0125

#0126

#0127

#0128

#0129

M,

S, T CANNOT

~omand was for M, S, T in a block in which M, S, T cannot be

spec

i f i ed.

UOC~ETION CWND

There is no

MIRROR

IMAGE, ERROR

Command was for G in a mirror image

used, or a mirror image is ON in a mirror image prohibited mode.

K2/30

CHNR

completion comand in memory operation.

inwhich

a mirror image cannot be

.

–24–

Alarm No.

I

MULTI PLE S CODE

Contents

#o130

#o131

#0132

#o133

#o134

Command was for multiple S codes when there were no multiple S

control options.

S CODE DIGITS OVER

Command of the number of

Sdigits

was excessive.

#ol

35

#0136

#ol

37

#01 38

#ol

39

I

““””

. . . . . . . . . . . . . .

.

.

.

–25–

7.2 ALARM NUMBER TABLE (Cent’d )

Alarm No.

#o140

#o141

#0142

#o143

#0144

I

T CODE

DIGITS OVER

The T digit commands are excessive.

I

I

B CODE DIGITS OVER

l.-------------- . . ..----------- ..------- .---------

]More

digits than permitted were specified for Code B.

Contents

"-"""

"""-""""-"""""""""""""""""--"""--""--"--""""""-'

#o145

#0146

#o147

#0148

#o149

l--"" -"`"" """"" """"" """---

1

"""------

"""-----" """""-"""""""""-""-"""""-"""""""`----""""""""""""

–26–

Alarm No.

Contents

MAX OFFSET NO. OVER

#o150

#o151

#0152

#o153

#ol 54

#o155

Offset number is too large.

I

OFFSET NO. ERROR IN H/D

l

----------------------------------------------------------------------------------------------Off set number during H/D changeover is too I a rge,

WAND

NO. H

No command for offset number H.

.

. . . . .

.

#01 56

#ol 57

#0158

#ol

59

. . . .

–27–

7.2 ALARM NUMBER TABLE ( Cent’d)

Alarm No.

#0160

#0161

#0162

#01

63

#0164

Contents

INUSABLE G CODE

:mand is for an option

IWTCH

:ommand

~ne

.ACK

Iequi red address specification is lacking.

G CODE

is for a G code that cannot be used in combined form with

block.

OF ADDRESS

comanding

an unusable G code.

#0165

#o166

#01

67

#o168

#01 69

–28–

Alarm No.

#o170

Contents

UNUSABLE G CODE IN CYCLE

Comand

was for a G code unusable in a canned cycle.

G70–G72 USED IN NON CANNED CYCLE

#o171

#0172

#o173

#o174

#o175

#01

76

G70–G72 was used in other than a canned cycle.

I

I

R–POINT IN BACK BORING

1------------------”””

Returns to R–point in G77 (back boring

G73/G83

C~AND

There is no command for Qor I

G73/G83

in the

G70–G72 ADDRESS

""""" """"" """"" `"""" "`-'""-"-"""""""""""-"""-"""""""-""""""-"-""""`"

cycle).

ERROR

0=1=0

CMAND

(Q= I =

O)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ---------

inG73/G83,

or the command was for

state.

ERROR

. . . . . . . . . . . . . . . . -------------- --------------- --------------- -------

Specified address for command G70, G71, or G72 is invalid.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . --------- ---------- . . . . . . . . . . ---------- . . . . . . . . . . ---------- --------

#o177

#0178

#o179

.

. . . . . . . . . . . . ..- . . . . . . . . . . . . . . . --------------- ---------------

. . . . . . . . . . . . . . . --------------- ---------------

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–29–

7.2 ALARM NUMBER TABLE (Cent’d )

Alarm No.

#0180

#01

81

#0182

#0183

#01

84

Contents

?ADIUS C~START

Is in ARC mode with MOO, 01, 02, 30 and with no shift within3

]Iocks

during start up of tool radius compensation.

?ADIUS ~END ERROR

. . . . . . . . . . . . . . . . . . . . . .

1s

in ARC mode at end of tool radius compensation.

JNUSABLE

;ommand

NRFACE

;orrection

~ominand

RADIUS MCAL

Intersection cannot be obtained in tool radius compensation.

G

is for an unusable G code in tool radius compensation.

UNMATCH IN ~ MODE

was for an arc other than the correction plane.

UP ERROR

C~AND

plane was changed over during tool radius compensation or

ERROR

IN

CMP~DE

#0185

#ol

86

#01 87

#ol

88

#0189

REVERSE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comand is

approaching

ILL

Command was for a system variable that could not be read during tool

radius compensation.

CMP

INTERFERENCE CHECK ALARM

Interference check was started during tool radius compensation.

CMP

INTERFERENCE CHECK ERROR

Automatic interference correction is not being conducted dur

radius compensation.

W

ABNORMAL ERROR

=sation

* This” alarm normally does not occur.

CMAND

forretrogression

MACRO CWND

IN CMF’~DE

this.

IN

mode

abnormal or no output data during data output

of tool radius compensation or a shape

CMP=

ng

tool

. . . . .

(logic

–30–

Loading...

Loading...