Page 1

LT/‘W

T#‘W/‘

YASNAC

i80L

INSTRUCTIONS

TURNING

CNC

Before

SYSTEM

Til

HEiB

H;

>s

l

;

S

y.t

3

operation,

initial

FOR

FC241

these

read

FC300B

£

m

*

-

;;

*

instructions

APPLICATIONS

FC30C3

U

s

•

*

M

1

.?

!i

J:

''I

TA

.

thoroughly,

1

FC30C3

and

i<

«•

•.

::

retain

a:

a;

v?

si

FC310

for

future

FC310

reference.

&

V

r

N

•

:

m

z

o

POCEHC*

j,i,

50/#0**r-4?!

YASKAWA

TOE-C843-1

1

.20D

Page 2

PREFACE

This

manual

tions,

and

(basic)].

Easy-to-read

plied

with

This

each

with

This

1.

2

.

contains

operation

this

manual.

manual

other.

manual

NOTES

Optional

YASNAC

Unless

of

•

•

•

otherwise

programming

Dimensions:

Absolute

Reference

information

required

items

and

help

will

FOR

features

i80L,

refer

Zero

Zero

to

summarized

appendix

the

you

YASNAC

marked

are

to

specified,

examples

in

mm

Point:

Point:

such

as

YASNAC

use

in

(TOE-C-843-1

to

take

full

i80L

with

the

machine

following

the

shown

notes,

a

i80L

list

configuration,

basic

[NC-

format,

1.21)

advantage

OPERATOR’S

For

*.

tool

builder's

rules

in

this

manual.

operation

found

are

shouldberead

the

of

functions

MANUAL:

the

specifications

manuals.

apply

to

programming,

panel

in

the

with

appendix

the

in

conjunction

YASNAC

of

of

descriptions

9"

your

func¬

CRT

sup¬

i80L.

Operations

3

.

control.

4

The

.

bination

machine,

manual.

not

you

If

functions

of

the

described

have

and

a

machine

machine

in

this

questions,

any

performance

and

the

tool

builder's

manual

contact

as

an

NC

should

machine

NC

control.

manual

not

your

YASKAWA

For

shall

be

attempted

are

determined

operation

take

with

representative.

by

your

of

priority

over

a

the

com

NC

this

Page 3

i

CONTENTS

1

2

OVERVIEW

:

:

PROGRAMMING

-

DESCRIPTION

/

1

OF

5

/

OPERATION

r

E

347

3

E

:

Page 4

CONTENTS

Page

1

OVERVIEW

BASIC

1.1

.2

1

BASIC

MULTI-PROGRAM

1.3

PROGRAMMING

2

2.1

CONTROL

2.1.1

2.1.2

1.2.1

2.

2.

1.2.

2.1.3

PROGRAMMING

2.2

2.2.1

2.2.2

2.2.1

2.

2.2

2.2

2.2.2.3

2.

2.2.

2.

2.2.5

2.2.3

2.2.4

2.2.4.

2.2.4.

2.2.5

2.2.5.

5.2

2.

2.

2.2.S.3

5.

2.

2.

2.

5.5

2.

2.3

PREPARATORY

INTERPOLATION

2.4

2.4.1

2.4.1

2.4.

1.2

2.4.2

2.4.3

2.4:3.

4.3.

2.

2.4.4

2.4.5

2.4.6

2.4.7

CONFIGURATION

OPERATION

Increment

Least

Least

Axis

input

output

Control

Input

2

Maximum

Process

Programming

Label

Tape

Progarm

Progarm

4

Sheet

part

start/tape

Comment

Tape

EIA/ISO

Tape

NC

Paper

NC

NC

Splicing

Register

Code

codes

iape

tape

tape

Buffer

Tape

1

2

1

4

Keeping

Positioning

(modal

GOO

1

.

(non-modal

G06

Linear

Interpolation

Chamfering

Chamfering

1

Rounding

2

Circular

Polar

Interpolation

Coordinate

Cylindrical

Diameter

Tool

CONTROL

AXES

Number

and

and

increment

increment

Command

Move

Format

label

and

end

start/program

part

part

and

auto-select

punch

check

NC

tape

NC

tape

FUNCTION

G

code

G

Corner

command

designation

Interpolation

Interpolation

Compensation

NC

OF

of

Output

Increment

and

Values

skip

end

Multi-active

(G-FUNCTION)

r

group)

01

of

of

code

(G01)

(G11)

(G12)

(G02,

(G124,

Designation

G03,

Radius

MACHINE

when

(only

Simultaneously

least

Register

group)

input

The

increment

*

(G011,

G23)

G22,

(G126.

Functions

G127)*

G125)#

Available

Interpolation

TOOL

SYSTEM

multi-program

Controllable

x

10

G12)*

in

Polar

and

option

Axes

Coordinate

Cylindrical

provided)

is

Interpolation

1

2

3

4

5

7

7

8

8

8

9

10

10

10

12

12

13

14

22

24

25

25

25

27

27

27

27

28

28

29

33

33

33

34

35

39

39

40

42

46

51

54

—ii—

Page 5

Page

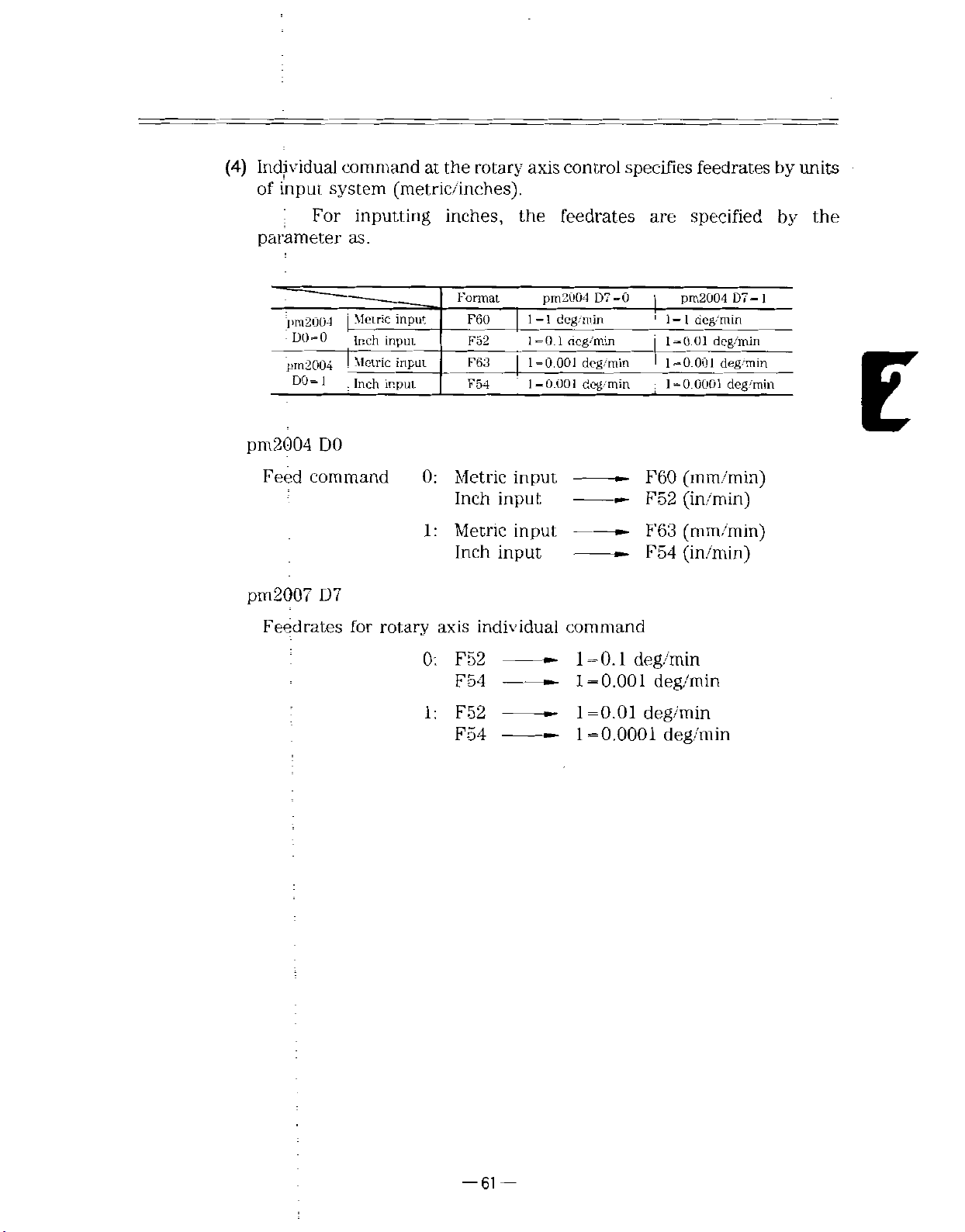

2.5

FEED

Rapid

2.5.1

Cutting

2.5.2

2.5.2.

1

Feed

2

2.5.2.

2.5.3

2.5.4

2.5.5

2.5.6

2.5.7

2.5.7.

2.5.7.

2.5.8

2.

2.5.

2.5.9

2.5.9.

2.5.10

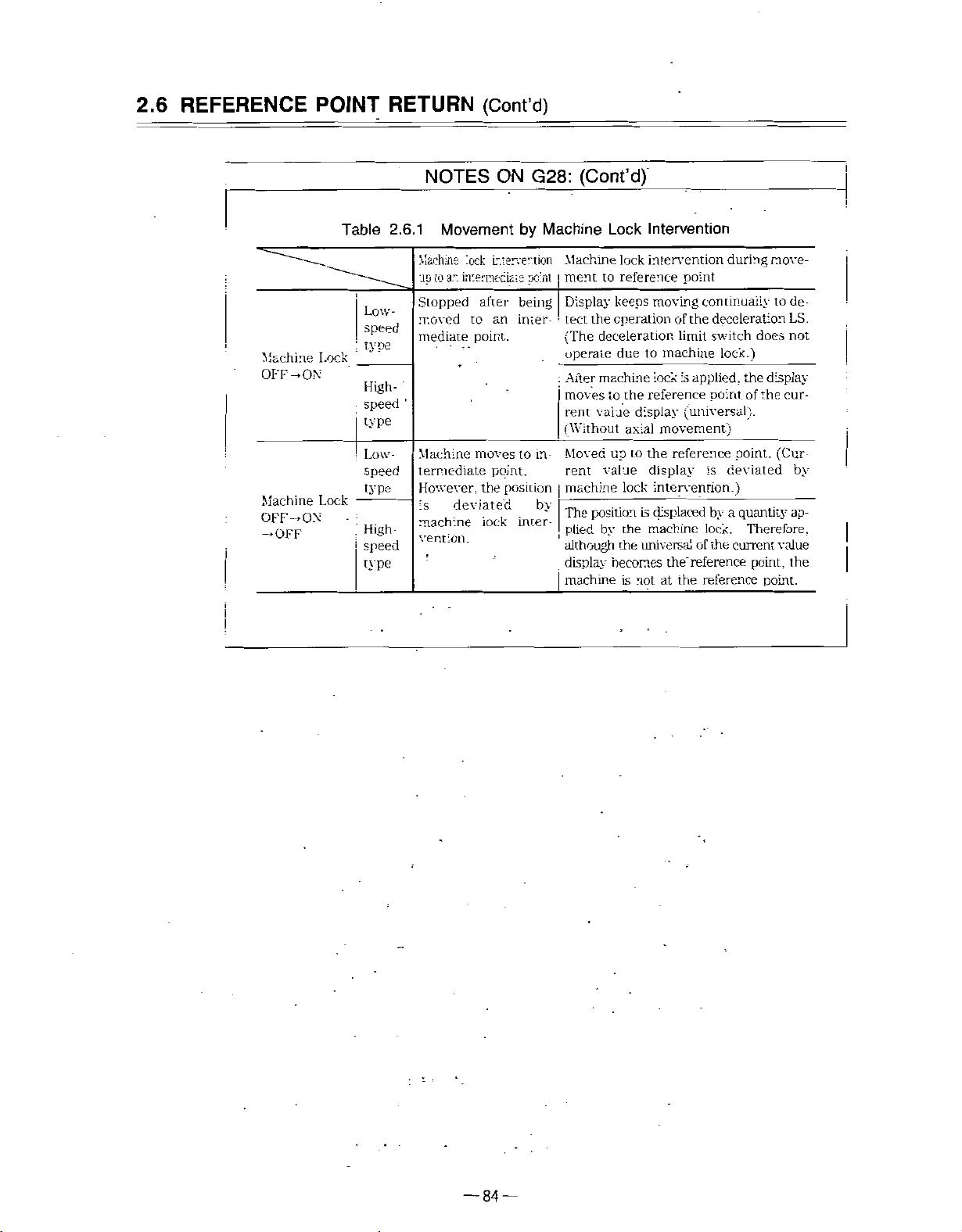

2.6

2.6.1

2.6.2

2.6.3

2.6.4

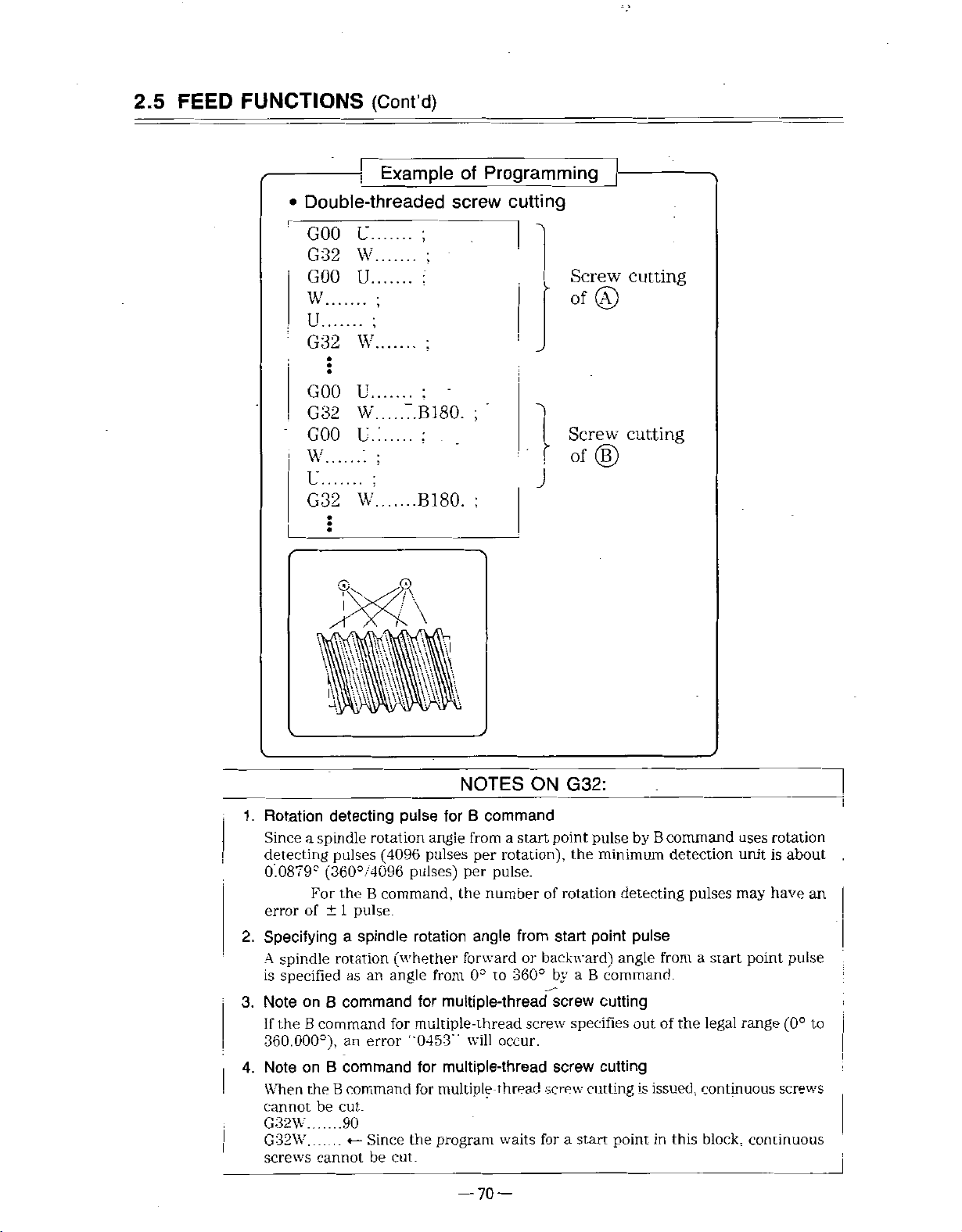

Feed

Switching

Screw

Multiple

Variable

Automatic

1

Accel/decel

2

Accel/decel

Override

5.8.1

Cutting

Rapid

2

8.

Dwell

Dwell

1

Speed

REFERENCE

Automatic

Reference

Return

Second

FUNCTIONS

Traverse

Feed

per

per

Cutting

Thread

Lead

Rate

.

rotation

minute

between

land

Screw

Screw

Acceleration

of

of

i

feed

override

traverse

(G04)

...:

per

minute

Control

Command

POINT

Reference

Point

Reference

from

Fourth

to

(G99

(G98

Feed

Continuous

Cutting

Cutting

and

rapid

traverse

cutting

override

feed

RETURN

Point

Return

Check

Point

Reference

mode)

Mode)

per

Minute

Screw

(G32)

(G34)*

Deceleration

and

Return

Return

Point

and

Cutting

*

manual

(G28)

(G29)

Return

Feed

(G32)

feed

(G30)*

per

Rotation

(G98/G99)

56

56

56

57

59

62

63

68

71

74

74

75

76

76

77

78

78

79

80

80

85

86

89

COORDINATE

2.7

Setting

2.7.1

2.7.2

Automatic

Shifting

2.7.3

Setting

2.7.4

2.8

ENTERING

Absolute

2.8.1

Selection

2.8.2

8;3

2

Inch/Metrjc

DecimaL-PoInnhput'

2.8.4

2;g

SPINDLE;

1

293

2.9.3

.2

Rotary

2.9.4

TOOL

2.10

2.10.1

Coordinate

Work

Work

COORDINATE

and

of

FUNCTION

Cancelling

Tool

FUNCTION

T

4-digit

Specification

SYSTEM

Setting

of

Coordinate

Coordinate

Incremental

Diameter.

Input

Specification

peripheral

Spindle

(T

System

Coordinate

System

VALUES’ÿ*:

Specification.

..ÿ.Z-T..'

:(SÿÿTÿP.FF;BATIQN)_'V;ÿ;

System

System

(G50T,

Qomijiandsÿ

a|id

(Gÿ

G51r)*5

.

Rayius

-

_

v*

of

-

.

SpecjfJpatloh

.

...ÿ

X-axis

r

;

.

iM*!-

speed

Selection

keeping

Function

control

(G97)*

*

FUNCTION)

v.v;:}

t"!

$<"«•

90

90

93

94

96

103.

105

106

108

i'r

109

109

111

112

112

113

116

117

117

Page 6

CONTENTS

(Cont’d)

Page

T

2.10.2

2.11

2.11.1

2.11.1.1

2.11.1.2

2.11.1.3

2.11.1.4

2.12

2.12.1

2.12.2

2.12.3

2.12.4

2.12.5

2.13

2.13.1

2.13.1.1

2.13.1.2

2.13.1.3

2.13.2

2.13.2.1

2.13.2.2

2.13.2.3

2.13.2.4

2.13.2.5

2.13.2.6

2.13.2.7

2.13.2.8

2.13.2.9

2.13.3

2.13.3.1

2.13.3.2

2.13.4

2.13.5

2.13.5.1

2.13.6

2.13.6.1

2.14

2.14.1

2,14.1.1

2.14.1.2

2.14.2

2.14.3

2.14.4

6-digit

MISCELLANEOUS

M

Function

M

codes

Internal

General

Move

TOOL

OFFSET

Offset

Position

Tool

Nose

Multi-active

Corner

PROGRAM

Canned

Cutting

Thread

Thread

Multiple

Overview

Outer

End

Closed

Finishing

End

Outer

Automatic

Remarks

Complex

Taper

Circular

Tool

Progarm

Subprogarm

Drilling

Drilling

MACRO

Macro

Macro

Argument

Variables

Spacifying

Quoting

Specification*

related

processing

other

one

than

Memory

Offset

Compensation

R

Register

Rounding

SUPPORT

(G90,

Cycle

cycle

cutting

cutting

Repetitive

diameter

rough

face

cutting

loop

cycle

cutting

face

diameter

thread

G70

on

Chamfering

complex

complex

Offset

Amount

Function

Call

Canned

canned

PROGRAM

Progarm

nesting

designation

Variables

Variables

FUNCTION

stopping

to

M

M

codes

command

M

(M92,

Judgement

FUNCTIONS

G92,

(G90)

A

cycle

cycle

Cycle

rough

cutting

cycle

(G70)

cycle

off

cutting

cutting

G78

to

(G

chamfering,

chamfering,

Setting

(M98,

M99)

Cycle

cycle*

(G65,

Call

call

FUNCTION)

(M

(MOO,

codes

in

G41/G42)*

(G40,

M93)*

Internal

G94)

(G92)

(G94)

(G70toG76)*

cycle

cycle

(G72)

cutting

(G73)

(G74)

(G75)

cycle

(G76)

cycle

,

1

G112)*

1

1

rounding

rounding

(G10)*

*

G66,

G67)*

a

block

M02,

M01,

*

Code

M

(G71)

command

command

M30)

(M96/M97)

(G111)*

(G112)*

117

118

118

118

119

120

120

121

121

123

128

172

173

174

174

175

178

185

188

188

190

200

205

209

212

215

218

224

227

..

227

240

248

250

250

252

252

267

269

274

276

280

297

298

-lv

—

Page 7

Page

**-,*=

-

2.14.5

2.14.6

2.14.7

2.14.8

2.14.9

2.14.10

2.14.11

2.15

2.15.1

2.16

2.16.1

2.16.2

2.17

2.17.1

2.17.2

2.17.3

2.17.4

2.17.5

2.17.6

2.17.7

3

3.1

3.2

3.3

3.3.1

3.3.

3.3.

3.3.

3.3.1

3.3.

'

3.31:/

3.3,1

3.3.1

3.3.1.10

3.3.1

,3

3.4.3

3.4.5

Undefined

Arithmetic

Control

Entering

RS-232C

Macro

Macro

AUTO

Skip

STORED

Stored

Stored

MULTI-SELECTION

Section

Password

Control

Local

Synchronous

Remote

Pulse

DESCRIPTION

OUTLINE

CONFIGURATION

NC

OPERATOR

Outline

Power

1.1

1.2

9-inch

Process

1.3

.4,

1.5

Address.

PaglkeysVÿÿÿ

'.s'

;.9

i4dionlÿ.:3

’Reset

•

.11

AUXvkeÿ|f|

4

dlSPLAY

3.4.1

;Constanfb[sjJaypÿÿÿg|

Pop-up

3.4.2

Key

3.4.4

Buzzer

PROG

|

|

Variables

Commands

Commands

Macro

Program

Program

MEASUREMENT

Function

STROKE

Stroke;

Stroke'

Synchronization

Axis

Section

Program

Copy

OF

of

Operator

on/off

graphic

keys

Programs

Output-2

Data

Examples

(G31)*

LIMIT

Limit

Limit

Command

Select

iSpindle

Feed

Function

OF

OPERATION

SCREENS

OF

FOR

buttons

display

keys

....

Alarm

SUPPORT

M,

PANEL

Panel

key’.:.

Menu

Editing

Buffer

Function

(Program

Function

:

i

Editing)

(BPRNT,

Numbers

FUNCTION

DPRNT)

CHECK

A

B

FUNCTION

Command

Command

Selection

Reference

T

Command

Function

Spindle

*

PROCESSES.

AND

Key

....

Process

JOBS.

DISPLAY

Functions

.....

..

.....

1

v:

-t,

*

*

Select

:*

-

(FOR

MULTI-SECTION

*

AND

FUNCTIONS

SCREEN

.......

.299

300

303

308

309

314

315

322

322

324

324

325

OPTION

’

>ÿ

ONLY)

332

332

337

340

341

343

344

345

347

350

351

354

354

354

355

356

...356

.358

:

359

359

360

361

362

.

.

362

363

363

368

369

370

371

—

—

V

Page 8

CONTENTS

(Cont’d)

Page

3.4.5.

3.4.5.2

5.3

3.

4.

3.4.6

3.4.6.

3.4.

6.

3.4.7

3.4.7.

7.

4.

3.

3.4.7.3

3.4.8

3.4.8.

3.

8.

4.

3.4.

8.3

program

Part

1

program

Part

program

Part

SET

Setup

|

|

1

2

Run

1

2

function

Offset

Work

coordinate

Process

Program

Command

Setting

job

Maintenance

1

Parameter

I/O

monitor

2

I/O

verification

editing

directory

I/O

Process

|RUN|

job

value

Process

job

job

job

job

verification

system

job

shift

COMMAND]

(I

|MAA~|

soft

(job

([IN/OUT]

function

[DIR])

key

job

VALUE

soft

job

key)

soft

key)

372

395

411

439

440

445

447

448

463

464

471

472

479

485

3.4.9

Common

3.4.9.

1

3.

9.

4.

2

3.4.

9.3

3.4.9.10

Absolute

Alarm

Time

job

job

Power-on

Process

position

(

ALARM

j

(

TIME

Initial

[COMN|

(

;

job

POS.

I

i

job

soft

job

I

Indication

soft

key)

job

key)

soft

key)

491

492

500

504

509

—

Vi

—

Page 9

INDEX

A

B

C

Subject

grapnic

9-inch

Absolute

Absolute

Accel/decel

Accei/decel

Action

Address

Alarm

Argument

Arithmetic

AUTO

Automatic

Automatic

Automatic

Automatic

AUX

BASIC

BASIC

Buffer

Buzzer

Cancelling

Canned

Chamfering

Chamfering

Circular

Circular

Closed

Command

Comment

and

position

keys

keys

(.1

job

designation

Commands

MEASUREMENT

Acceleration

Reference

Setting

thread

.

keys

CONFIGURATION

OPERATION

Register

Function

peripheral

Cycie

complex

Interpolation

loop

value

part

display

Incremental

job

rapid

of

of

ALARM

Command

corner

cutting

traverse

cutting

1

Coordinate

of

cutting

.

Multi-active

and

(G90,

Radius

chamfering,

cycle

job

U

Commands

(|POS.

I

and

feed

key)

soft

job

FUNCTION

Deceleration

and

Point

Return

cycle

NC

OF

speed

keeping

G94)

G92.

(G11)

Designation

rounding

G03,

(G02,

(G73)

COMMAND,

job

soft

manual

(G28)

System

(G76)

MACHINE

Register

G22,

key)

feed

-

.

....

control

(G011i

command

G23)

VALUE

.

.........

TOOL

SYSTEM

. .

(G97)*

GY2)*

(G112)*

job

soft

.

key)

Par.

3.3.1

8.1

2

3.4.9.

.2.5.7

7.

.2.

5.

.3.3.1.

.3.3.1.

.3.4

9.2

.2.14.1.2

2.14.6

.2.15

.2.5.7

.2.6.1

2.7.2

.2.13.2.8

.3.3.1.11

..

1.1

1.2

.2.2.3

.3.4.4

2

..........

..........

...........

......

..........

9.3.2

.2.13.1

2.4.3

.......

2.4.3

2.13.3

2.4.4

13.2.4

2

34.7.2

2

2.2.5

Page

.2

...

1

1

2

9

5

1

355

103

.493

74

75

361

358

500

....

.....

276

300

.322

74

80

93

218

362

2

3

24

.370

113

...

174

39

..

39

240

2

42

205

463

22

Common

Complex

CONFIGURATION

Constant

CONTROL

Control

Control

Control

COORDINATE

Corner

Cursor

Cutting

Cutting

Cutting

Cylindrical

D

Data

Decimal

DESCRIPTION

DISPLAY

Drilling

Axis

Axis

Commands

Rounding

keys

cycle

feed

Feed

keys

....

Canned

Process

Chamfering

Display

AXES

and

Number

Select

SYSTEM

...

(G90)

A

override

Interpolation

Input

Point

OF

WRITE

AND

Cycle

(

)

[COMN]

(G111,

OF

Command

Judgement

OPERATION

G112)*

PROCESSES,

.

Simultaneously

of

Interna!

.

(G124,

*

G125)*

....

JOBS,

M

Code

—

AND

FUNCTIONS

.

Controllable

.

(M96/M97)

—

vii

Axes

.

.3.4.9

.2.13.3

.3.2

.3.4.1

.2.1

.

.2.1.1

.2.17.3

.2.14.7

.2.7

5

.2.12

.3.3.1.

.2.13.1.1

.2.5.81

.2.5.2

.2.4.6

.3.3.1.

.2.8.4

.3

.3.4

2.13.6

.491

.227

.351

.363

7

7

.340

.303

90

173

.

.360

8

175

76

..

6

56

51

.359

108

.347

.363

.252

Page 10

INDEX

(Cont’d)

Subject

D

Drilling

(G04)

Dwell

per

Dwell

A/ISO

El

E

End

face

End

face

Entering

ENTERING

F

FEED

Feed

per

per

Feed

Finishing

G

I

K

L

M

(modal

GOO

(non-modai

G06

General

monitor

I/O

I/O

verification

Inch/Metric

Input

Increment

Internal

INTERPOLATION

Keeping

Key

Buffer

pad

Label

input

Least

output

Least

Linear

Section

Local

M

codes

M

Function

Macro

Macro

MACRO

Macro

Macro

canned

FUNCTIONS

processing

Interpolation

nesting

Progarm

Program

Program

cycle

minute

auto-seiec!

off

cutting

cutting

rough

Programs

Macro

COORDINATE

(G98

minute

rotation

cycle

other

NC

related

PROGRAM

(G99

(G70)

G

code

G

M

codes

job

job

Specification

Input

and

.....

tape

Editing

label

and

increment

increment

Spind'e

to

call

Call

Alarm

Examples

Function

.

*

cycle

cycle

Mode)

mode)

of

01

of

code

Output

M

codes

.

skip

and

(G01)

Selection

stopping

(G65.

Numbers

(G74)

(G72)

VALUES

group)

group)

.

(G20.

increment

input

least

.

Function

(M00;

G66

..

—

...

.

G21)

...

-

increment

..

*

M02,

M01

.

..

- - -

G67)*

1

2

1

...

1

Page

252

78

78

25

212

200

308

103

56

59

57

209

33

34

120

479

485

106

8

119

33

28

369

12

8

8

35

.341

118

118

274

269

267

314

315

Par.

.2.13.6.1

.2.5.9

-

.

-

:

10

*

M30)

.2.5.9.

.2.2.42

.2.13.2.6

.2.13.2.3

14.8

.2

.2.8

.2.5

2.5.2

.....

2.5.2.

.....

2.13.2.5

.....

.2.41.1

.2.4.

1.2

.2.11.1.3

3.4

......

.....

......

.......

.........

.........

.........

.......

.........

8.2

3.48.3

2.8.3

.

.....

2.1.2

2.11.1.2

2.4

.2.2.55

.3.4.3

.2.2.21

.2.1.2

,.2.1

.2.2

.2.4.2

.2.17.4

2.11.1.1

2.11.1

.....

2.14.1.1

2.14.1

2.14

2.14.10

2.14.11

Maintenance

Maximum

MISCELLANEOUS

than

Move

MULTI-PROGRAM

MULTi-SELECTiON

Multiple

Multiple

Multi-active

NC

N

NC

NC

NC

Nose

Repetitive

Thread

OPERATOR

tape

check

Tape

punch

tape

Compensation

R

Process

Move

M

one

Register

|MAN~]

Command

FUNCTION

command

CONTROL

SUPPORT

Cycle

Cutting

Screw

(M92,

PANEL

FOR

(G40,

Values

in

(only

FUNCTION

(G70

to

(G32)*

M93)H:

AND

G41/G42)*

FUNCTION)

(M

biock

a

when

G76)=H

DISPLAY

*

muiti-program

the

(FOR

MULTI-SECTION

SCREEN

—

viii

—

option

OPTION

provided)

is

ONLV)

.3.4.8

2.1.3

.

2.11

.2.11.1.4

1.3

2.17

.2.13.2

...2.12.4

,.3.3

5.

...2.

2.

...2.2.5

.2.2.52

..2.12.3

...

........

....2.5.5

.471

9

118

120

4

.332

188

68

172

.354

3

.

27

27

2

128

Page 11

Subject

Offset

O

Offset

Outer

Outer

Outline

OUTLINE

Override

OVERVIEW

Overview

function

Memory

diameter

diameter

Operator

or

OF

cutting

rough

SCREENS

cycle

cutting

Panel

.

(G75)

cycle

Key

(G71)

Functions

.

Par.

4.

.3.

6.1

.2.12.1

.2.13.2.7

2.13.2.2

1

.3.3

.3.1

.2.5.8

.1

.2.13.2.1

...

Page

440

,121

215

190

.354

.350

76

1

188

Page

P

Paper

Parameter

program

Part

program

Part

program

Part

Password

Peripheral

Peripheral

Polar

Positioning

Power-on

PREPARATORY

Process

Process

Progarm

Progarm

PROG

|

|

Progarm

PROGRAM

Program

PROGRAMMING

Programming

Pulse

Pop-up

keys

:

tape

............

..

job

..

directory

editing

I/O

Command

Speed

speed

Coordinate

.-

Initial

keys

Sheet

Function

Call

part

(Program

start/program

SUPPORT

job

Format

Copy

Function*

Menu

job

...

verification

Keeping

keeping

Interpolation

Indication

FUNCTION

..

Editing)

Process

end

FUNCTIONS

.

key

soft

(job

(.IN/OUT1

Control

control

(G93,

(G96)

G127)*

(G126,

(G-FUNCTION)

.

. .

!

DIR

job

G97)*

*

.

soft

)

key)

.

....

.3.3.17

.

........

........

________

........

...

5.1

2.2

3.4

8.1

3.4.5

3.4.5.

3.4.

5.

.....

..

.2.17.2

2.9.3

.....

...2.9.3.

.2.4.5

.2.4.1

.3.4.10

.2.3

.3.3.1.

.2.2.1

.2.13.5

.2.22.4

.3.4.5

.22.2.3

....

.2.13

.3.4.7.

.2

.2.2.2

.2.17.7

.3.4.2

.359

27

.472

2

.395

1

3

1

3

...

1

..

.372

.411

.

.337

112

112

46

33

.509

29

.356

10

.

.250

14

.371

13

174

.448

5

10

.345

.368

Q

Quoting

Rapid

R

Rapid

REFERENCE

Reference

Remarks

Remote

Reset

Return

Rotary

Rounding

RS-232C

Run

Variables

traverse

Traverse

Point

on

Program

key

from

Tool

designation

Data

Process

override

Rate

RETURN

POINT

Return

G78

to

G70

M,

T

Reference

Spindle

Selection

Output-2

I

JRUN|

Check

Command

Point

Return

Function

(G12)

(BPRNT,

*

(G29)

*

DPRNT)

—

ix-

.2.14.4

5.

8.

2

.2.

.2.5.1

.2.6

2.6.2

.2.13.2.9

.2.17.6

.3.3.1.10

.2.6.3

.2.9.4

.2.43.2

.2.14.9

.3.4.7

.298

77

56

80

85

224

.344

362

86

116

40

.

.310

.447

Page 12

INDEX

(Cont’d)

Subject

Screw

S

Second

Section

Selection

Setting

Setting

Setting

|

Shifting

Skip

Soft

Specifying

Speed

Spindle

SPINDLE

Spindle

Splicing

Stored

Stored

STORED

Subprogarm

Switching

Synchronous

T

T

T

Tape

Tape

Tape

Taper

Thread

Thread

Time

Tool

TOOL

Tool

TOOL

Tool

Undefined

U

Variable

V

Variables

W

Work

SET

4-digit

6-digit

|

keys

Cutting

Coordinate

Setup

Function

Control

Stroke

Stroke

Code

codes

start

complex

job

Diameter

FUNCTION

Offset

OFFSET

Position

coordinate

ana

Continuous

to

Synclro.nization

of

job

Work

Work

Command

FUNCTION

Maximum

NC

STROKE

between

Specification

Specification

Cape

cutting

cuttng

(

Leac

Reference

Fourth

Diameter

System

Coordinate

Process

Coordinate

(G31)*

Variables

Command

Rotat'on

tape

A

Limit

B

Limit

LIMIT

M99)

(M98.

Feed

Feed

Reference

end

chamfsnng«

cycle

cyc’e

job

TIME

I

Compensation

(T

Amount

Offset

Variables

Screw

system

(G92)

(G94)

Setting

Screw

Point

Command

Specification

.

System

(G50T.

System

...

(S

5-DIGiT

Speed

...

CHECK

per

Minute

Spmd'e

rounding

key)

soft

Functions

FUNCTION)*

(G10)*

ng

shift

(G34)*

function

Cutt

(G30)

Radius

G51)*

.

.

(G32)*

Specification

(G50S)

Cutting

Return

*

and

SPECIFICATION)

Command

..

Feed

per

and

Select

*

-

command

Available

Interpolation

{G

and

.

-

...

Rotation

111)*

in

Polar

Cylindrical

—

X-axis

of

-

(G98/G99)

Coordinate

Interpolation

Par.

.2.5.4

.2.6.4

.2.7.1

.....

2.8.2

.2.7.1

.34.7.3

2.7.4

.3.4.6

.2.7.3

.2.15.1

3.3.1.4

.2.14.3

.2.5.10

.2.9.1

.2.9

.2.9.2

.2.2.54

.2.16.1

.2.16.2

.2.16

.2.13.5.1

.

5.3

2

.

2.17

.2.10.1

.2.10.2

.2.2.4

.2.2.41

2.

.2.

2.

.2.13.3.1

.2.13.1.2

.2.13.1.3

.3.4

9.3

2.4.7

.2.10

.2.13.4

.2.12

.2.12.2

.2.14.5

.2.5.6

.2.14.2

.3.4.62

Page

..

..

...

...

.

.

.

...

.

....

5

.

.

...

2

...

63

89

332

105

90

.464

96

.439

94

.322

.356

.297

79

109

109

111

28

.324

.324

.325

250

62

.

343

117

117

25

25

12

227

178

.....

...

.185

.....

504

54

117

.248

121

123

299

71

280

.445

—X—

Page 13

SECTION

1

OVERVIEW

This

section

machine

SECTION

CONTENTS

1

OVERVIEW

1.1

BASIC

1

.2

BASIC

1.3

MULTI-PROGRAM

1

CONFIGURATION

OPERATION

describes

system.

tool

;

the

OF

CONTROL

basic

NC

MACHINE

(only

configuration

TOOL

when

the

and

SYSTEM

multi-program

operation

option

is

of

the

provided)

NC

r

Page

1

2

3

4

i

—

1

—

Page 14

BASIC

1.1

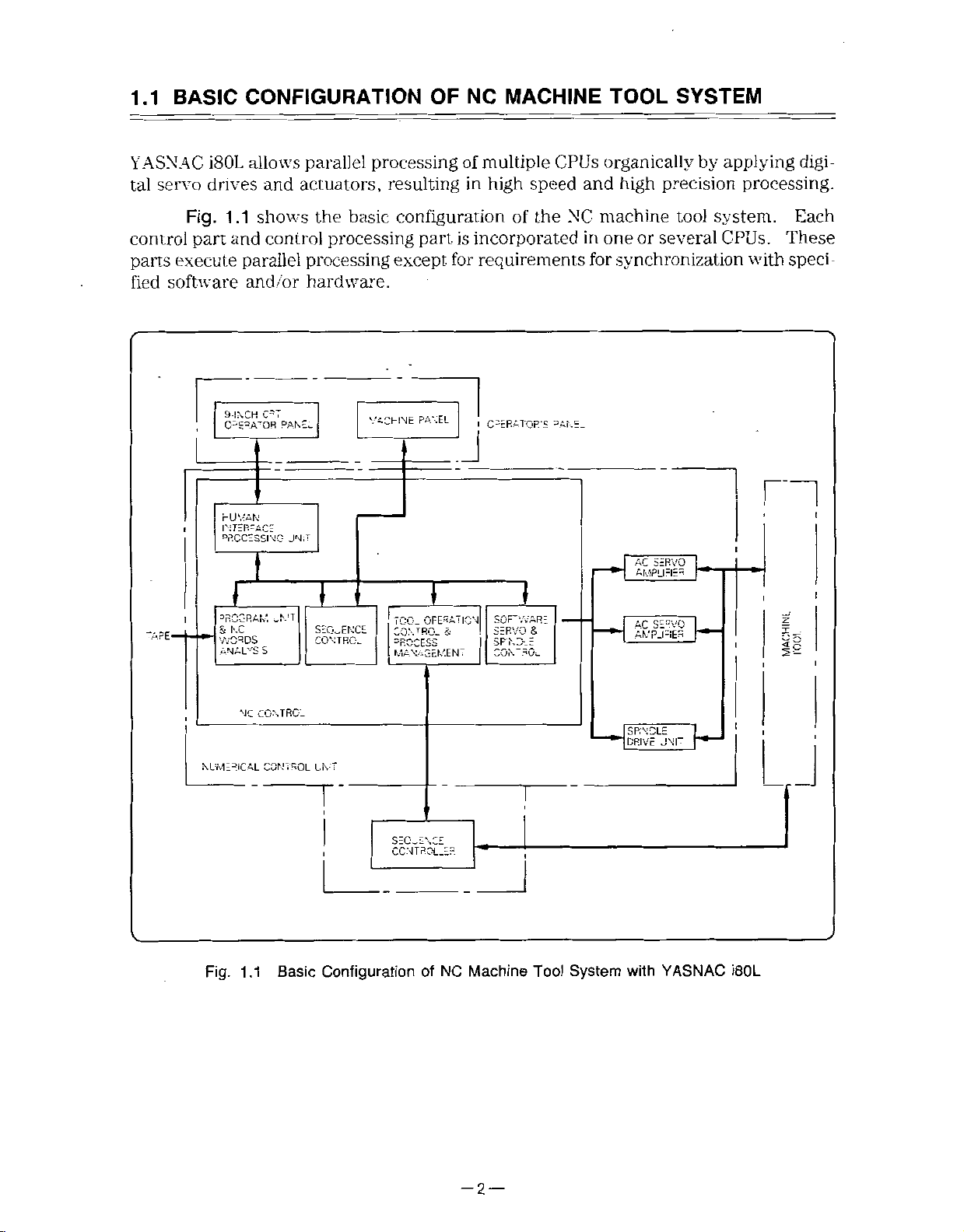

YASNAC

servo

tal

CONFIGURATION

and

parallel

actuators,

i80L

drives

allows

OF

processing

resulting

MACHINE

NC

multiple

of

high

in

CPUs

speed

TOOL

organically

high

and

SYSTEM

by

applying

precision

digi¬

processing.

control

parts

software

fied

-APE-

1.1

Fig.

part

execute

CÿSRAÿQR'

I

DRCCz

l

3RCG

S

SSSs

shows

and

parallel

and/or

T

RAM,

NC

control

processing

hardware.

PANEL

JN;T

\!G

I

oN'T

basic

the

processing

|

•!ONTRCC.E

configuration

part

except,

PANEL

CHINE

V-

SÿENT

is

for

the

of

incorporated

requirements

I

CURATOR'S

=AKE.

\

SSL

I

machine

NC

in

for

or

one

synchronization

r+rrnm

tool

several

system.

CPUs.

with

l

I

i

Each

These

sped

I

11

NC

NUMERICAL

Fig.

1.1

CONTRO-

CONTROL

Basic

L.NT

Configuration

of

NC

Machine

T

Tool

HISZH

System

with

YASNAC

J

I

i80L

-2

—

Page 15

1.2

BASIC

OPERATION

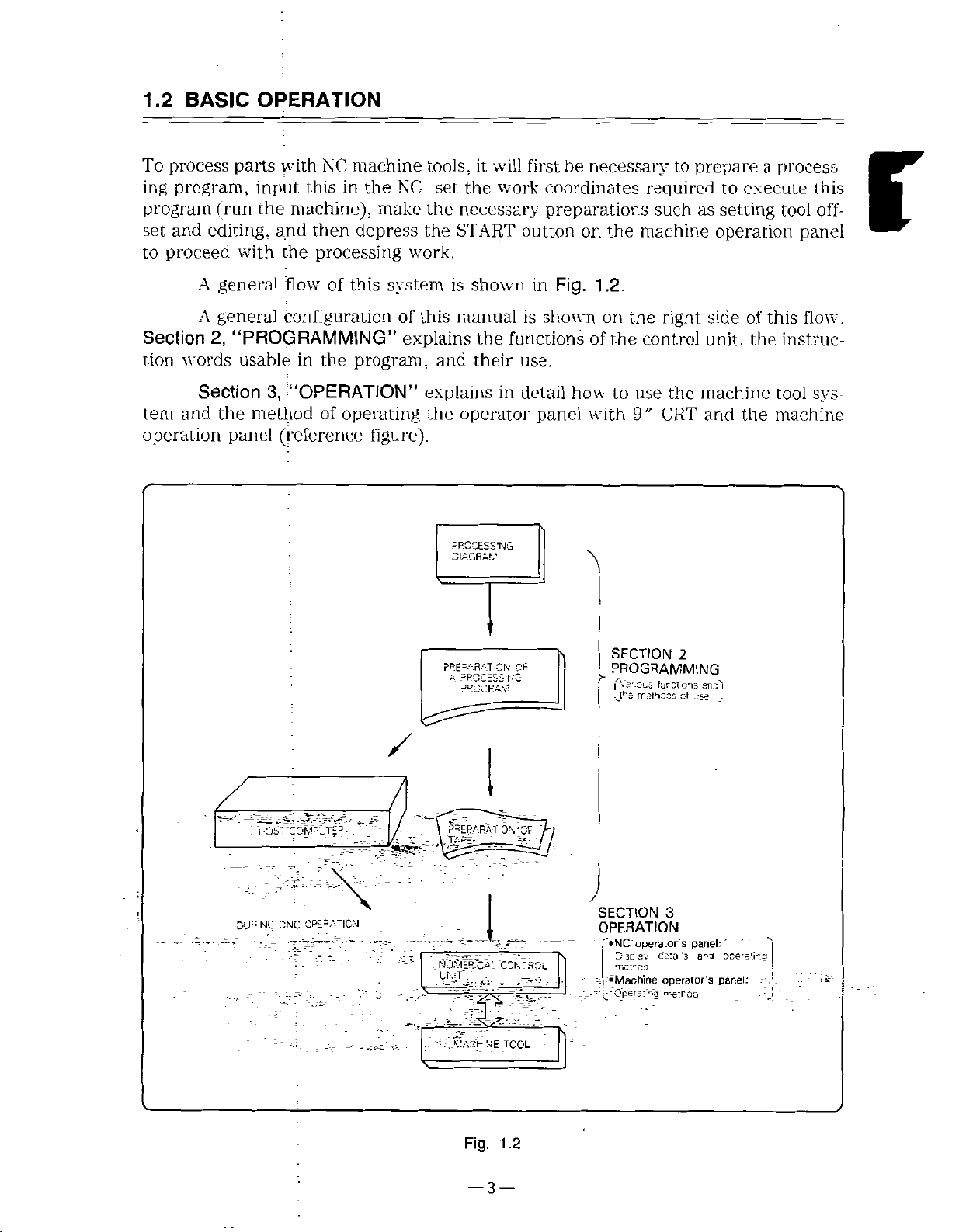

process

To

program,

ing

program

set

and

proceed

to

A

A

Section

tion

words

Section

and

tem

operation

parts

input

the

(run

editing,

with

general

general

2,

“PROGRAMMING”

usable

3,

the

method

panel

NC

with

thisinthe

machine),

and

then

processing

the

flow*

of

configuration

the

in

‘“OPERATION”

of

(reference

machine

NC,

make

depress

system

this

of

explains

program,

operating

Figure).

tools,

set

the

the

work.

this

and

explains

the

will

it

work

the

necessary

START

is

shown

manual

the

functions

their

in

operator

oS'NG

first

be

coordinates

preparations

button

in

is

use.

detail

on

Fig.

shown

how

panel

necessary

required

such

machine

the

1

.2.

on

the

the

of

with

to

control

use

9"

to

right

the

CRT

prepare

to

execute

setting

as

operation

sideofthis

unit,

the

machine

and

the

process¬

a

tool

panel

flow.

instruc¬

tool

machine

this

off¬

r

sys¬

DURING

-NC

CP-:-A-|CN

/

;._T5

t'ASHNE

TOOL

SECTION

I

PROGRAMMING

fVe*-Sks

I

mathoos

SECTION

OPERATION

operator's

T»NC

1

sp

D

sv

'.Machine

Oper=ij

....

2

furu

cis

Of

3

's

ds:a

operator's

,e,roo

ansi

_$=

panel:

a-o

_.

'

oce-=!i-.g

panel:

V

Fig.

1.2

—3—

Page 16

1

.3

MULTI-PROGRAM

The

environment

called

controlled

is

in

which

a

CONTROL

NC

program.

processing

when

(only

programs

the

multi-program

executed

are

option

and

servo

is

provided)

axes

are

YASNAC

compound

thereby

details,

For

manufacturer.

turning

Individual

program

The

enabling

number

The

Section

noted.

iSOL

programs

refer

2

assumes

Processing

!

Analysis,

allows

machines.

also

can

processing

the

available

of

command

to

single

a

program

execution!

I

up

to

can

execute

perform

that

programs

or

program

Expmple

!

three

programs

processing

one

processinginconjunction

could

reference

of

not

and

varied

manuals

explanation

for

Programming

Processing

Analysis,

program

execution'

operate

to

performed

be

operations

program

issued

purposes

same

the

at

independently.

other

with

single

in

a

depend

by

your

unless

Processing

|

i

Analysis,

time

programs,

program.

machines.

on

machine

otherwise

programÿ

execution

j

under

tool

Servo

NOTE

axis

The

multi-

l

1

X

program

d£J“

Z

1

control

1

function

Program

Program

as

an

—

(ft

option.

dSSr

2

X

provided

is

_4

<50r

3

X

Z

2

2

3

Program.

Z

-3

Page 17

SECTION

2

PROGRAMMING

section

This

tions

(*!)]

SECTION

CONTENTS

PROGRAMMING

2

CONTROL

2.1

Ccnt'ol

2.1.1

Controllable

Input

21.2

2.

1.2.1

2.

1.2.2

2.1.3

V.ax.mum

2.2

PROGRAMMING

Process

2.2.1

Programming

2.2.2

1

2.2.2.

2.2.

2.

2

2.2.3

2

2.2

2.4

5

2.

2.2.

3

Buffer

2.2

Tape

2.2.4

2.2.4.

1

2.2.4.2

2.2

NC

5

.2.5.1

2

2.2.5.2

2.

3

5.

2.

4

2.2.

5.

2.

2.

5

5.

2.3

PREPARATORY

2.4

INTERPOLATION

T

Position

2.4

2.4.11

2.4.1

2

2

2.4

Linear

Chamfering

2.4.3

Rad

2.4.3.''

4.3.2

2

2.4.4

Circular

{G02,

4.5

Polar

2

AXES

Axis

Increment

input

Least

east

input

output

Least

Sneet

Lace

part

start/tape

Tape

Progarm

P'ogarm

Comment

Register

Code

Tape

codes

El

A/ISO

Tape

Paper

taoe

NC

taoe

tape

NC

Spicing

Keeping

.....

(modal

GOO

(non-modai

G06

Interpolator!

Designaton

us

Charrrering

Rounai.ng

lnterpo.afon!

G03,

Coordinate

describes

of

2

Numbe'

and

Axes

...

and

nc'ement

increment

nc'ement

Move

Command

Format

and

label

enc

start/program

part

part

and

autc-se;eci

ounce

check

NC

tape

tape

..

NC

FUNCTION

G

code

G

‘(G01

Comer

command

designation

G23)

G22,

Interpolation

the

control

.

Simultaneously

of

Output

Increment

and

x

1C

Values

skip

end

Multi-active

(G-FUNCTION)

0;

of

graup)

cede

of

:

)

G‘2|*.

1

(G01

.

(G

11)

12)

(G

programming

axes.

.

Register

*

(G126,

gmup)

....

...

G127)*

and

Optional

1

functions

[(including

functions

are

marked

*

Page

2.4.6

5

7

7

8

8

8

9

10

1C

'0

12

12

13

14

22

.

24

25

25

25

27

27

27

27

28

28

29

33

33

,

33

34

•

•

l®ÿ-wr2ÿ'''Sffiÿ(jiÿaÿCporcinate

'v.

.;:..V.ÿ--39jÿl8y£NfERiNG

40

42

46

Cy

2.4.7

Too:

Available

and

2.5

FEED

t

Rapic

2.5.

2.5.2

Cutting

2.5.2

1

Feed

Feed

2

2.5

2

2.5.3

Switcning

Fees

Screw

2.5.4

Screw

Multipe

2

5

5

2.5

6

Variaoie

7

2.5

Automatic

'

2.5.7

Accel/dece:

2

Accel/decei

2.5.7

2.5.3

Ove'ride

1

Cutting

2.5.8.

2.5

8.2

Raod

2.5.9

Dvvel

1

Dwell

2.5.9.

Speed

2.5.10

2.6

REFERENCE

1

6

2

Automate

2

2.6

Reference

Return

2.6.3

Second

2.6.4

2.7

COORDINATE-SYSTEM

Setting

2>.1

AiitomaticiSetting

2.7.2

Setting

\

2.7.4

2.8.2

Select

Radius

2.8.3

Incn/Metnc

Decimal

2.8.4

Irterpoaton

indrica!

Diameter

in

Po:ar

Cylind'ica

FUNCTIONS

Traverse

=eec

per

rotation

per

minute

oerween

per

Rotation

ng

Cutt

Cutt

ng

Threac

Lead

Acceeration

feed

traverse

(G04)

oer

minute

Controi

POINT

Reference

Pont

Reference

Tom

ib-Fourth

Coordinate

Ccproinate

Wo'k

COORDINATE

andrincremental

of

on

D

Specification

Input

Pont

(G124.

Compensaton

Coordinate

Interpolat

Rate

(G99

(G98

Mode)

Feed

(G93/G99)

and

Continuous

(G32)

Cutting

Screw

Cutting

Screw

and

rapid

cutting

overrde

overrde

t'ave'se

feec

o'

ol

Commanc

RETURN

Point

Cneck

Return

PontReturn

Reference

System

‘or

Coordinate

Specificat

ameter

input

X-axis

of

Specification

or

mode)

oer

Return

:

System

System

VALUES

Commands

optional

with

Gi25>*

Functions

Interpo

at

M

and

nute

(G32)*

(G34)

Deceleration

ana

ma.nua!

(G28)

(G29)

3oint

Return

System

(G50T.

on

and

G21)

(G20.

func¬

...

on

....

.

(G30)*

G5D*

*

'eed

.

Page

...

..

106

]

51

E

54

56

56

56

57

59

62

63

68

71

74

74

75

76

76

77

78

78

79

80

80

85

86

69

90

90

93

94

96

103

103

105

108

—5—

Page 18

SECTION

2

PROGRAMMING

(Cont’d)

SECTION

CONTENTS

SPINDLE

2.9

1

2.9

2.9.2

2.9.3

2

9.3.1

9.3.

2.

2.9.4

2.10

2.10.'

2.10.2T6

2'1

2.11.1

2.11.1.1

.1.2

2.1'.

2.H.1

2.1

‘.14

2.12

2.12.1

2.12.2

3

2

12

2.12.4

5

2

12

2.13

13.'

2

1.1

2.-3

2.13.1.2

2.13.1.3

2.13.2

'3.2

2

2.13.2.2

2.13.2.3

2.13

2

2.13.2.5

2.13

2

2.13.2.7

2.13

2.8

FUNCTION

Sp.ncle

Command

Spinole

Maximum

Speed

Command

Peripheral

Peripheral

xeeping

centre’

Cancelling

2

Keeping

Rotary

TOOL

T

MISCELLANEOUS

M

3

TOOL

Ofset

Tool

Ncse

Multi-active

Corner

Interna

PROGRAM

Canned

Mult

1

4

6

control

Too

FUNCTION

Specfication

4-cigit

Spec

digit

Funct

on

M

codes

MO',

(MOO,

Infernal

General

Move

than

OFFSET

Memory

Position

R

Compensation

Rounding

M

Cyce

Cutting

Thread

Threac

Repetitive

pie

Overview

d;amete'

Outer

End

face

C'csed

Finshlng

End

face

Outer

diameter

Automatic

2

{Cont’d)

Rotation

(G50S)

Speec

Keecmg

speed

(G96)

peripneral

(G97)*

Spindle

(T

fication*

FUNCTION

related

M02,

processing

M

other

one

M

Offset

Register

Judgement

Code

(M96/M97)

SUPPORT

(G90.

A

(G90)

cycle

cyde

cuttng

cyde

cutt.ng

rough

rough

loop

cutting

(G70)

cyde

ng

cutt

cutting

thread

(S

5-DIGIT

Control

*

speed

Select.on

FUNCTION)

.

stopping

to

M30)

codes

M

coces

command

(G40,

(M92,

FUNCTIONS

G92.

(G92)

(G94)

Cycle

(G70

cutting

cutting

cycle

cycle

cycle

off

cycle

catling

SPECIFICATION)

(G93.

Function

*

FUNCTION)

(M

in

block

a

.

G41/G42)*

M93)*

...

G94)

to

G761*

(G7')

cycle

(G72)

...

(G73)

(G74)

(G75)

(G76)

cycle

G97)*

Page

109

..

..

.

.

...

109

11

112

112

'13

'16

'17

H7

117

1'8

r-8

18

1

119

120

120

121

121

123

128

'.72

173

174

174

175

178

185

188

188

i90

200

205

209

2'2

215

218

2.13.2.9

2

2.13.3.1

'

2.13.3.2

2.13.4

2.13.5

2.13.5.1

2.13.6

2.13.6.1

2.14

2.14.'

2.14'.1

2.141.2

2.14.2

2

2.

2.14.5

2.14.6

2.14.7

2.14.8

2.14.9

2.14.10

2.14.11

2

2.15.1

2.16

2.

2

2

2.17

2.17

2.17.3

2.17.4

2.17

2.17

2.'

Remarks

Complex

13.3

Taper

rounding

Circular

rounding

Toe:

Offset

Progarm

Subprogram

Dolling

Drilling

MACRO

Macro

Macro

Argument

Variables

Speo'ymg

3

“'4

'4.

4

Quoting

Undefined

Arithmetic

Control

Entering

RS-232C

Macro

Macro

MEASUREMENT

AUTO

15

Skip

Function

STORED

'6.1

Stored

16.2

Stored

17

MULTI-SELECTION

MULTI-SECTION

(FOR

1

Section

Passworc

2

Control

Loca.

Section

Synchronous

5

6

Remote

Pulse

7.7

Copy

G70toG78

on

Chamfering

complex

command

complex

command

Amount

Cali

Canned

canned

PROGRAM

Progarm

nesting

desgnaticn

......

...

Variables

Variables

Variables

Commands

Commands

Macro

Data

Program

Program

STROKE

Stroke

Stroke

(G111,

chamfering,

{G1

11)*

chamfering,

(G112)*

Setting

(G10)*

Function

M99)

(M98.

Cycle

*

cycle

*

G66,

(G65,

Call

cal:

.".

......

.....

....

......

.....

.

....

...

Programs

Output-2

(G31)*

Limit

Limit

Aia-m

Examples

FUNCTION

LIMIT

CHECK

A

.....

B

(BPRNT,

Numbers

.....

-

SUPPORT

OPTION

Select

Spindle

Feed

on

Command

Command

Selection

Reference

M,

T

Command

Synchronizat

Command

Axis

Program

Function*

G112)

*

G67)*

.

DPRNT)

:

FUNCTION

ONLY)

*

Function

Spindle

Select

*

Page

224

227

227

240

248

250

250

252

252

267

269

274

276

280

297

298

299

300

303

308

309

.

314

315

322

322

324

324

325

332

332

337

340

*

341

.

343

*

344

345

—

—

6

Page 19

2.1

CONTROL

AXES

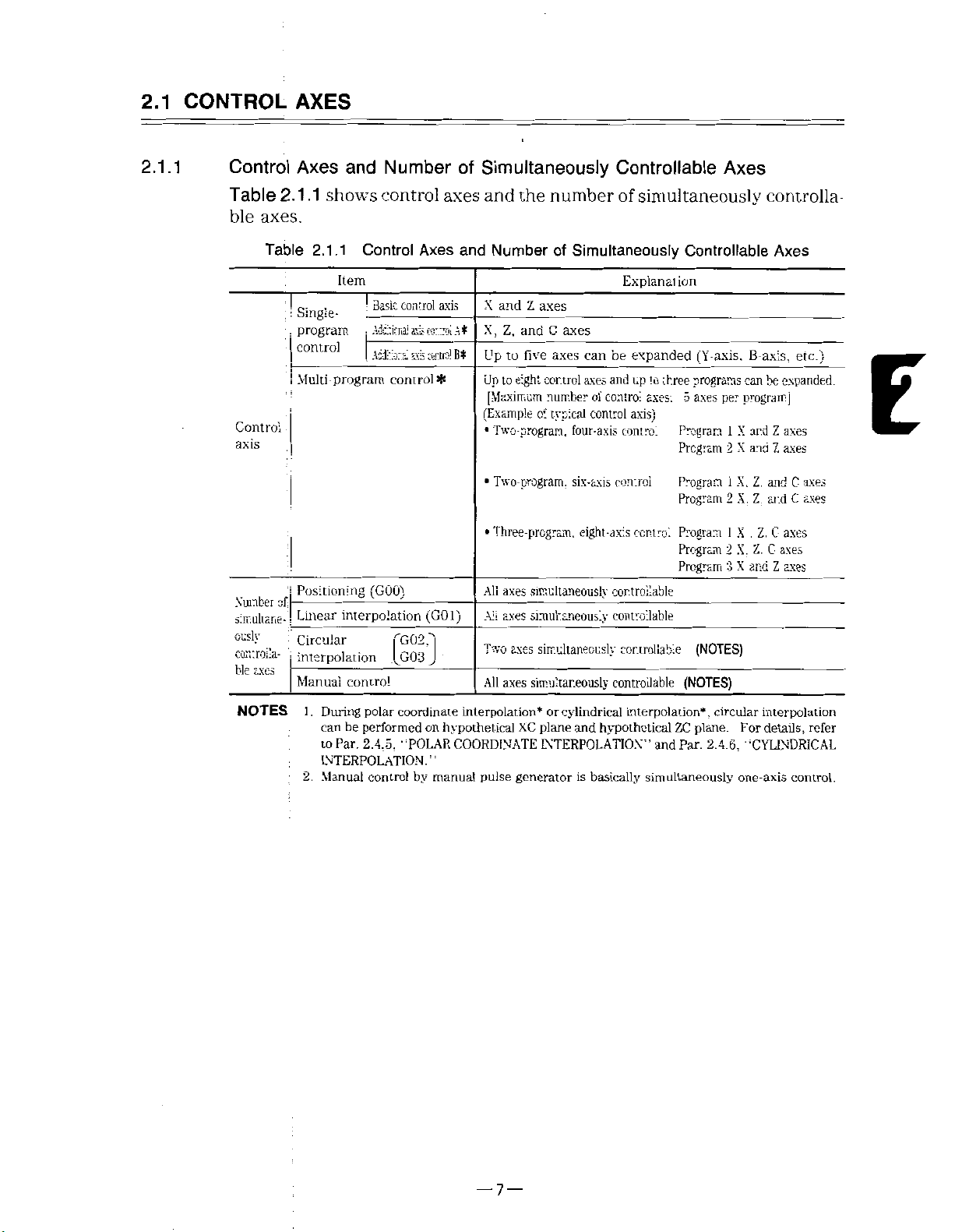

2.1.1

Control

Table

ble

Control

axis

Number

simultane-1

ously

controlla-

ble

2.1.1

axes.

Table

of;

axes

Axes

shows

2.1.1

:

Single-

;

program

.

control

Multi-program

Positioning

Linear

Circular

)

interpolation

Manual

and

Number

control

Control

Item

•

Basic

Adctienai

;

Actiora!

!

control*

(GOO)

interpolation

T

[C03

control

Axes

control

arts

cortroi

axis

ctcird

(G01)

G02T

of

Simultaneously

axes

and

and

Number

axis

At

Bt

X

X,

Up

Up

and

Z,

to

to

[Maximum

(Example

Two-program,

•

Two-program,

•

Three-program,

•

All

axes

AS

axes

axes

Two

All

axes

the

number

Simultaneously

of

Z

axes

C

and

axes

axes

five

eight

control

number

typical

o:

four-axis

six-axis

eight-axis

simultaneously

simultaneously

simultaneously

simultaneously

Controllable

simultaneously

of

Explanai

be

can

expanded

axes

up

and

of

control

control

axis)

control

control

controllable

controllable

controllable

controllable

control

to

three

axes:

ion

Program

Program

Program

Program

Program

Program

Program

Axes

Controllable

can

per

program]

1

X

X

2

1

X.

X.

2

1

X

2

X.

3

X

B-axis,

ar.d

ana

Z.

Z

.

Z.

and

(Y-axis.

programs

5

axes

(NOTES)

(NOTES)

controlla

Axes

etc.)

expanded.

be

Z

axes

axes

Z

and

C

C

ar.d

C-

axes

Z.

axes

C

Z

axes

E

axes

axes

NOTES

1

.

2.

.

polar

During

can

performed

be

to

Par.

2.4.5,

INTERPOLATION.”

Manual

coordinate

’TOLAR

controlbymanual

interpolation*

on

hypothetical

COORDINATE

pulse

cylindrical

or

plane

XC

generator

and

INTERPOLATION”

basically

is

interpolation*

hypothetical

simultaneously

and

ZC

Par.

,

circular

plane.

2.4.6.

interpolation

For

details,

refer

‘CYLINDRICAL

one-axis

control.

—

—

7

Page 20

2.1

CONTROL

AXES

(Cont'd)

2.1.2

2.

1.2.1

Input

Least

The

(1

)

are

Least

setting

(pm

(2)

Tool

or

(3)

In

in

(a)

(b)

(c)

Increment

input

increment

minimum

shown

input

parameter

Table

1000

Metric

Inch

Input

Input

DO-

2.1.3

'l

offset

0.001

mm

0.01

units

of

Write

Programming

Program

and

input

in

Table

increment,

Input

)

Lr.ear

Axis

:X.

ms:-.

0.0

1

0.001

value

deg*)

increment

0.01

operation

editing

Output

and

(prr.lOOG

-Vein;

lr.cn

pm

Increment

)

?t-:

V.

Z.

in

must

and

mm.

for

Increment

least

that

units

2.1.2.

2.1.2

Table

D0--O")

!r.pu:

Input

times

1000

C

Axis*

0.01

0.01

always

offset

is

system,

in

MDI

operation

operation

input

can

lira-

Ax'S

001

0

0.0001

ten

Do

at.

xK)

deg

deg

be

possible

mode

in

increment

instructed

be

Input

Least

V.

(X.

Z.

in

be

can

“1.”

NOTE

written

in

following

the

in

MEMORY

EDIT

Increment

C-

0.001

0.001

as

set

Metric

selected

G20/G21

in

0.001

these

mode

x

10

by

punched

Axis-

deg

deg

shown

input

by

command.

mm

units.

operation

mode

Table

in

and

setting

(or

tape

inch

pm0007

0.0001

must

2.1

input

be

or

MDI

.3

can

Ds

inch,

made

by

be

or

2.

1.2.2

1.

2.

3.

Least

Least

Metric

Out

Inch

NOTE

NC

If

mm

0.01

the

If

memory,

in

structed

When

punched

output

output

Table

X-Axis

Output

put

The

ieast

B-axis

manufacturer's

programs

increment,

increment

the

dimensions.

the

stored

out

increment

increment

2.1.4

value)

0.0005

mm

in

0.00005

output

depends

set

system

machine

program

stored”

“as

Least

increment

the

on

manual.

by

0.001

machine

the

is

is

the

Output

Z

0.001

0.0001

of

machine.

NOTES

mm

switched

move

will

punched

is

regardless

minimum

Increment

Axis

in

axes

extra

Refer

will

are

move

when

by

such

to

into

fed

ten

the

either

on

out

switching

of

unit

C

Axis*

deg

O.OOi

as

Y-axis

machine

the

the

of

tool

in

intended

of

NC

the

the

increment

motion.

stored

or

times

contents

timesorone-tenth

ten

the

tape,

of

and

equipment

dimensions.

are

tape

stored

figures

set

stored

of

the

system.

by

in¬

are

—

—

8

Page 21

2.1.3

Maximum

Move

Command

Values

Maximum

(1)

Table

W.

Metric

Output

Inch

Output

NOTE

The

cumulative

V,

and

,

;

the

If

In

1.

command

.

2

In

maximum

:

move

2.1.5

apply

H,

Table

Metric

|

Input.

Inch

j

Metric

|

Input.

Inch

i

maximum

incremental

absolute

value

Metric

input

Inch

command

only

not

alsotodistance

but.

2.1.5

Input

Input

value.

command

Maximum

Linear

values

are

programming,

programming,

value.

must

2.1.6

Table

Linear

input.

±

±39370.0787

±999999.999

±99999.9999

±999999.999

±99999.9999

values

move

to

Move

Axis

999999.999

exceeded,

move

not

Axis

Z,

(X.

correct

input

values

quantity

exceed

Maximum

Z.

:‘X.

are

shown

command

command

Command

V.

etc.)

mm

in

mm

in

operation

not

must

each,

axis

of

the

Cumulative

V,

etc.)

|

mm

in

below.

addresses

addresses

Values

C-Axis*

±999999.999

±999999.999

±999999.999

±999999.999

is

not

the

exceed

not

must

values

shown

Values

C-Axis*

±999999.999

±999999.999

I,

K.

deg

deg

deg

deg

guaranteed.

maximum

exceed

the

in

deg

deg

The

values

X.Z.Y.

R,

J,

A.

Table

C,

U.

and

B.

2.1.6.

in

E

NOTE

Listed

input

values

do

not

depend

bn

metric/inch

output

system.

—

9

—

Page 22

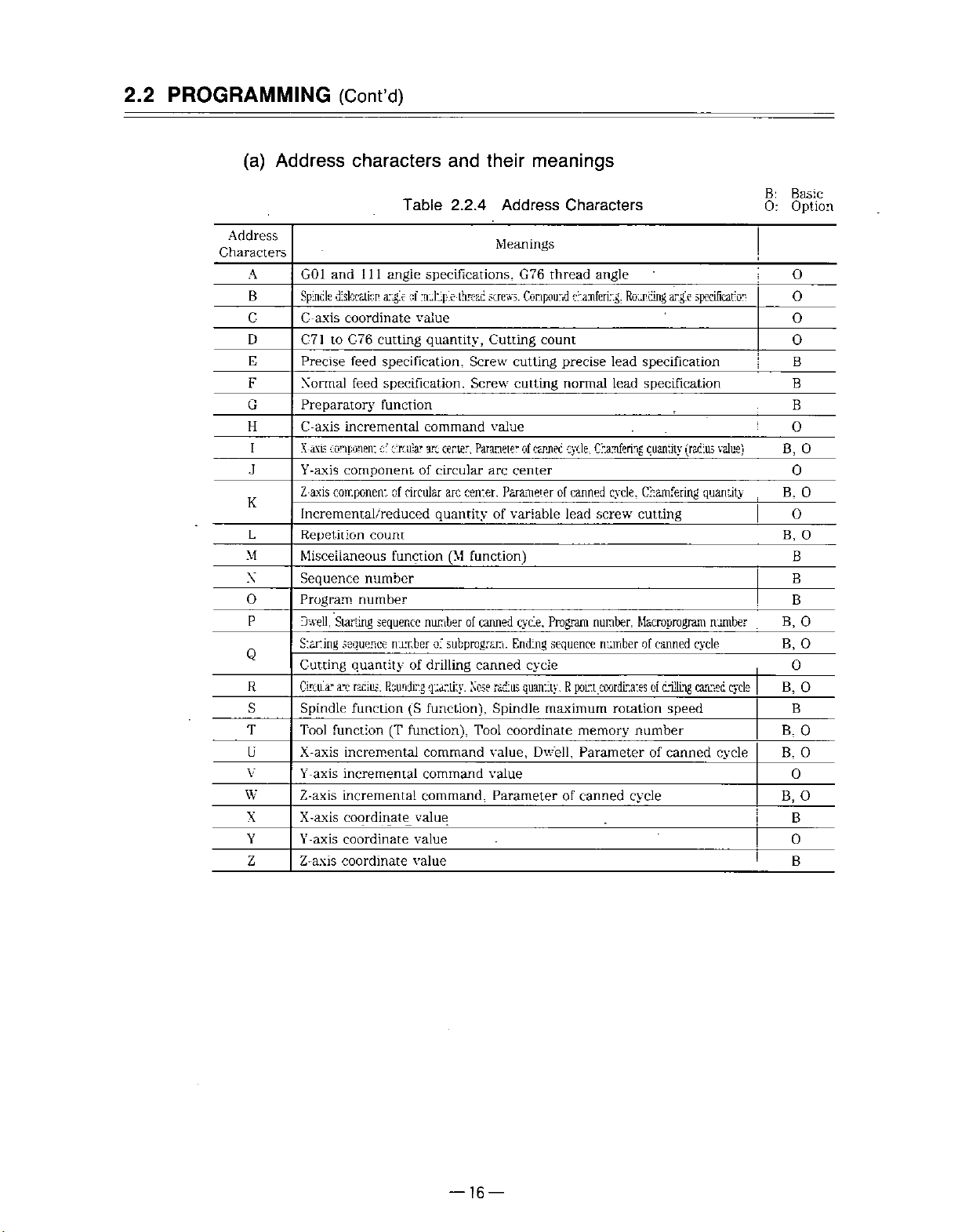

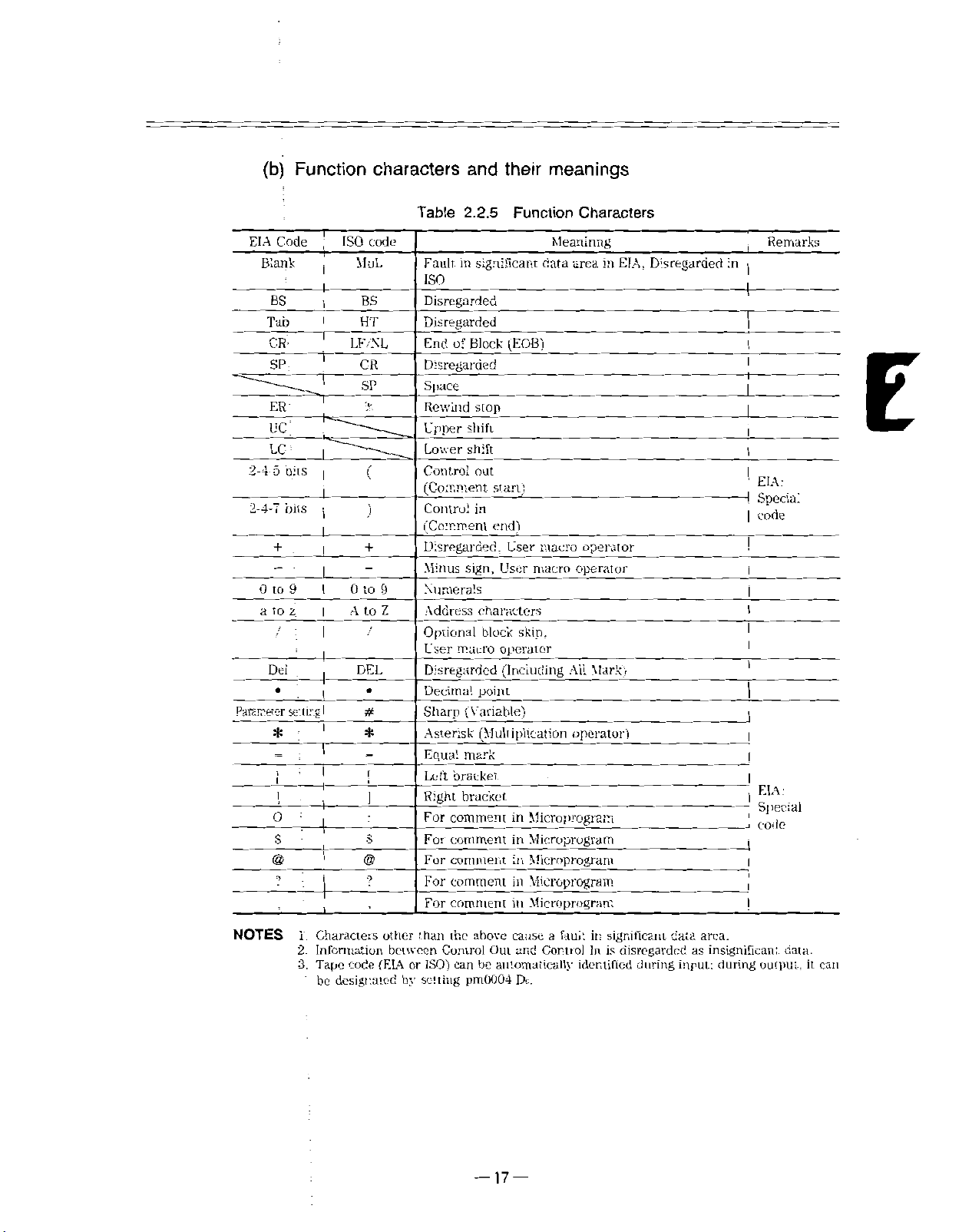

PROGRAMMING

2.2

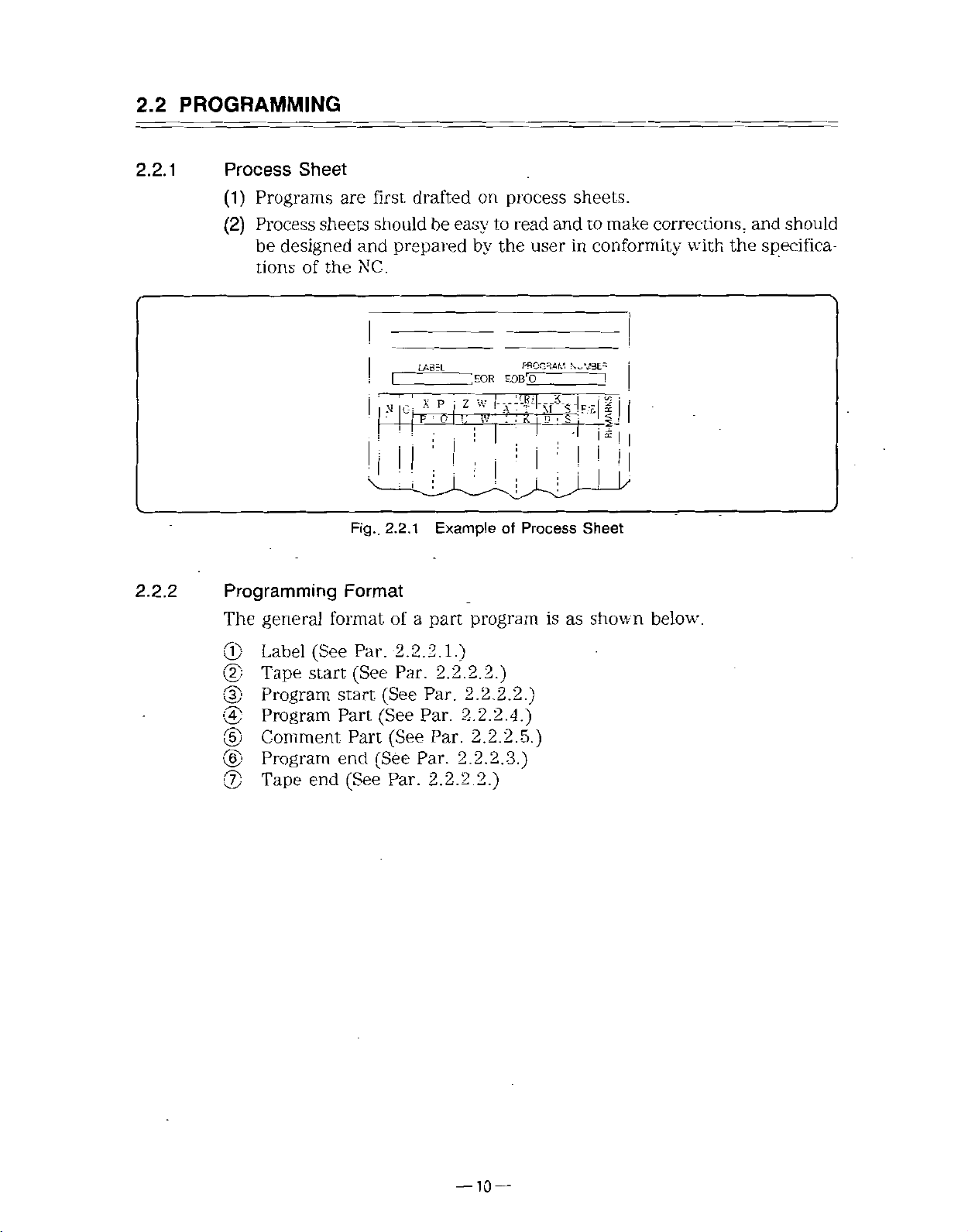

2.2.1

2.2.2

Process

(1)

(2)

Programming

The

Sheet

Programs

Process

be

tions

general

sheets

designed

of

are

and

NC.

the

Fig..

Format

format

first

should

prepared

i

N

i

!i

2.2.1

of

drafted

be

LA5=L

X

(C-j

;

i

a

part

on

easy

by

;EOR

w

P

z

±

i

'

Example

program

process

read

to

the

user

PPOGRAM

EOBÿCT

IKlD'3i

I

of

Process

is

sheets.

and

in

as

make

to

conformity

!

"ill

I

I

Sheet

shown

corrections,

with

below.

and

specifica¬

the

should

©

(2)

<D

0

(5)

(§)

>0

Label

Tape

Program

Program

Comment

Program

Tape

(See

start.

end

Par.

(See

start

Part

Part

end

(See

2.2.2.

Par.

(See

(See

(See

(See

Par.

2.

Par.

Par.

Par.

Par.

2.

1.)

2.

2.

2.

2.

2.

2.

2.

2.

2.

2.

2.)

2.)

2.

2.

2.

2.2.)

2.

4.)

2.

3.)

5.)

—

10

—

Page 23

:

o

NOTE

$

JStiS

Laoel

®

pan

(2;

As

Fig.

Taps

Tape

I

1

/

/

star

CT

the

2.2.2

E

P.

Start

E

R

/

(3)

i“Ffi"

ftog'*n

program

i

I

t

Program

cart,'

Tape

C

R

1

:

p-og!3TI

®

code

c

R

!

!

start

C-'

ends,

with

$

5‘D't

$

Icatec

“rew'nd

M02

P'ogtaT

Prcg'3'Ti

"ECB"

stop

and

Single

pan

cart

zoce

code

M

M99

'H4-

--ÿÿ'Cc'rrrsr:

1

i

'

end

Q:

")

I

3

0

erb

=-cg'3Ti

car.

Program

orrrrert

c--'

fc'ocsc

c

R

1

be

suosniuicd

(EIA

i

38rt-»»J

coos'

!

E

I

R

1

\'

\

(J

3D6

code)

l>

part

i

i

eno

for

E

M-30.

—

\

i

(J)

Program

Fig.

oar

Prog

(J)

2.2.3

'an

Tape

par

1

I

rj;

f

T

T

3

V.

1

'ogsrm,

with

Multi-Program

11

—

0

end

—

1

c

R

-

-,.Z

oar.

P'cgram

3>

'I

a

|jJ

(EIA

end

Code)

-;2D

j

R_

R

|

»ÿ

j««i

fc-j

i

,

\

‘

(D

305

nG

8

Page 24

2.2

PROGRAMMING

(Cont’d)

2.2.2.

2.

2.

2.2

1

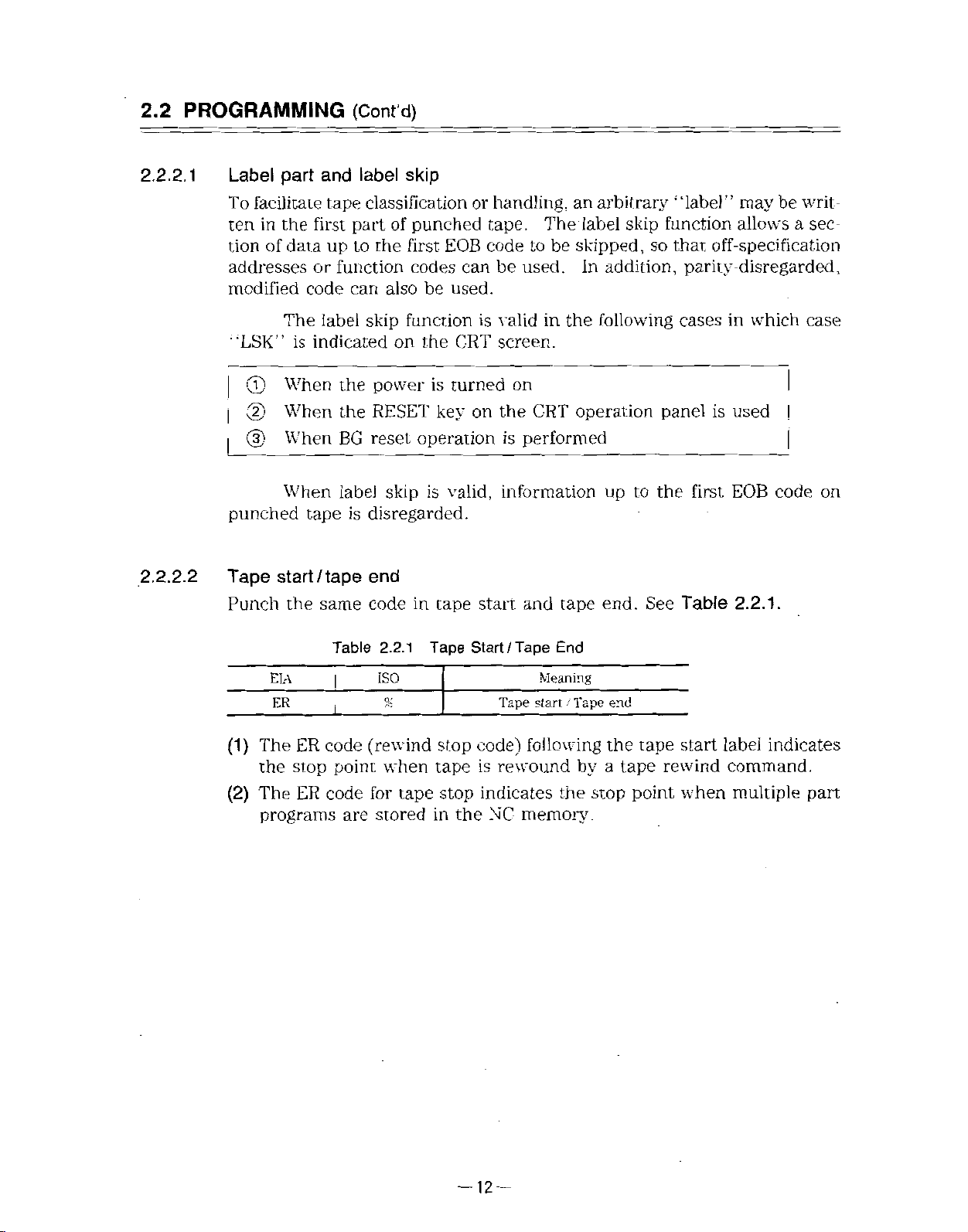

Label

To

ten

tion

part

facilitate

the

in

of

data

addresses

modified

The

;'LSK”

j

0

0

j

(3)

punched

Tape

Punch

is

When

When

When

When

start

the

label

and

tape

first

part

up

to

or

function

code

can

label

indicated

the

the

BG

label

is

tape

/tape

same

skip

classification

punched

of

the

first

EOB

codes

alsobeused.

skip

function

CRT

the

on

skip

is

turned

key

operation

valid,

is

power

RESET

reset

disregarded.

end

code

in

tape

handling,

or

tape.

code

be

can

is

valid

screen.

the

on

information

start

The

be

to

used.

in

on

CRT

performed

is

and

arbitrary

an

label

skipped,

addition,

In

following

the

operation

up

end.

tape

skip

to

‘‘label”

function

that

so

may

allows

off-specification

parity-disregarded,

is

first

Table

in

used

EOB

2.2.1.

cases

panel

the

See

be

which

|

code

a

I

writ¬

sec¬

case

on

(1)

The

the

(2)

The

programs

ElA

ER

ER

stop

ER

Table

i

code

point

code

are

2.2.1

ISO

%

(rewind

w’hen

for

tape

stored

Tape

stop

tape

stop

in

Start

code)

is

indicates

NC

the

/Tape

Tape

End

Meaning

start

following

rewound

memory.

/

the

Tape

by

stop

end

the

a

tape

tape

point

start

rewind

when

indicates

label

command.

multiple

part

—12—

Page 25

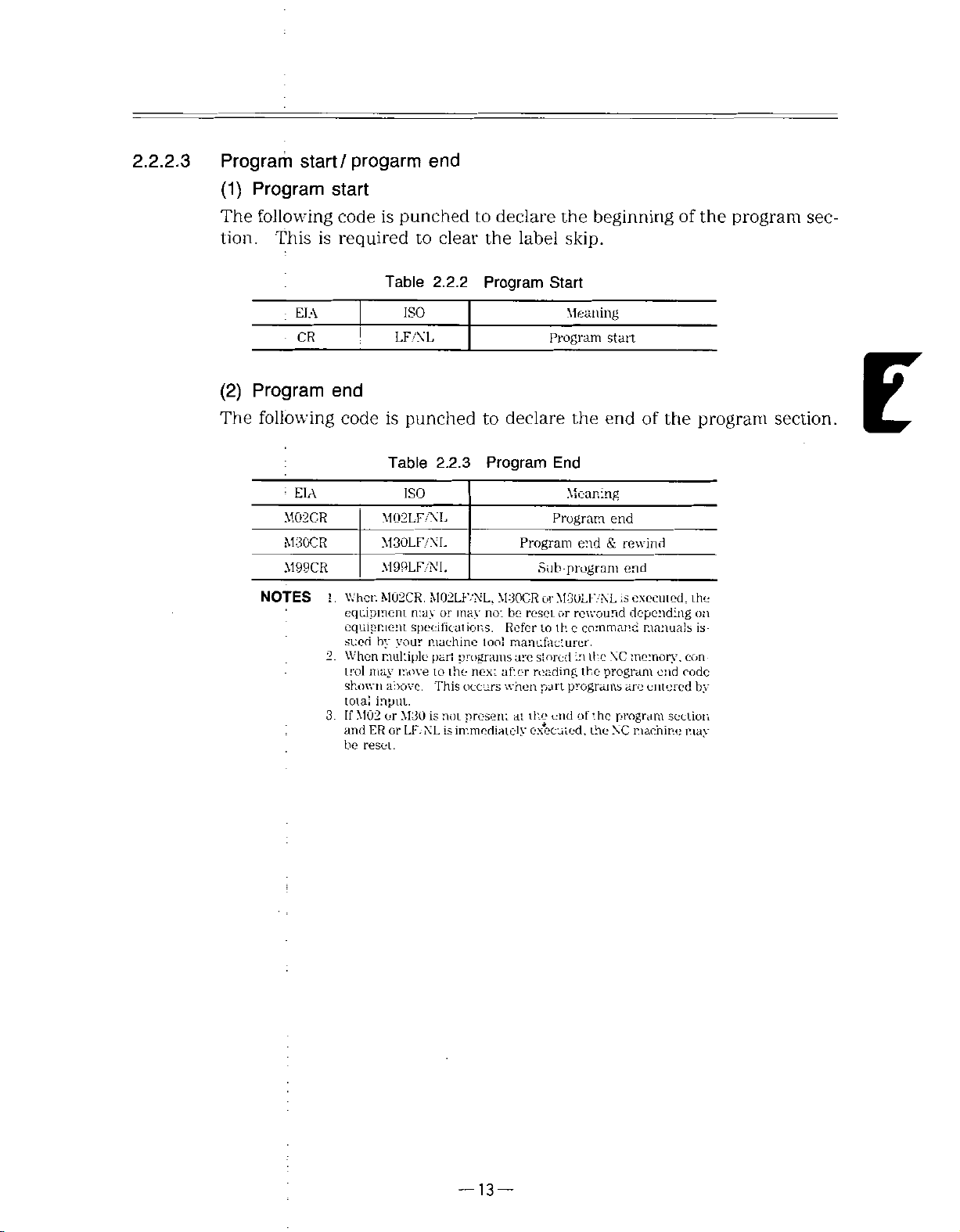

2.

2.2.3

Program

start/

progarm

end

(1)

The

tion.

(2)

The

Program

following

This

EIA

CR

Program

following

=

EIA

M02CR

M30CR

M99CR

NOTES

start

code

required

is

end

code

I

.

When

equipment

equipment

sued

2.

When

trol

shown

total

If

3

and

be

is

Table

is

Table

M02LF/NL

M30LF/NL

M99LFAM.

M02CR.

by

multiple

may

above.

input.

M02

or

ER

or

reset.

punched

clear

to

2.2.2

ISO

LF/N'L

punched

2.2.3

ISO

M02LK/NL,

may

or

specifications.

your

machine

part

to

move

This

is

M30

not

is

LF.-NL

to

declare

the

Program

to

Program

may

not

tool

programs

the

next

occurs

present

immediately

beginning

the

skip.

label

Start

Meaning

Program

declare

the

start

end

End

Meaning

Program

Program

M30C-RorM3ULF/NL

be

reset

Refer

manufacturer.

are

after

when

the

at

program

Sub

or

to

th

stored

reading

programs

part

end

executed,

end&rewind

rewound

command

c

in

the

program

the

of

the

the

of

end

end

executed,

is

depending

manuals

memory,

XC

are

program

machine

NC

of

the

end

entered

section

the

program

the

on

is¬

con

code

by

may

program

section.

sec¬

E

:

—13—

Page 26

2.2

PROGRAMMING

(Cont’d)

2.2.

2.

4

Program

A

punched

called

is

The

prised

of

Each

part

the

several

R

NOTE

section

program

program

words.

block

vvCFD

-m

-

EOB

(program

from

section.

section

separated

is

WORD

5_0C<

Fig.

the

consists

WOFC

-

start.;

2.2.3

program

of

by

the

BLOCK

-

is

represented

Block

Definition

start

several

EOB

PÿOGPAV

by

all

code

=>ART

‘V*

way

the

blocks,

(;).

in

this

and

manual.

to

the

each

program

block

is

end

com¬

(1)

Program

(a)

(b)

adding

Bv

is

it

A

program

lowing

equipment.

increased

be

number

a

possible

No.

address

program

discriminate

to

can

0.

However,

299

to

immediately

No.

specified

be

Up

to

the

999

or

your

by

program

99

maximum

by

adding

behind

program

to

five

up

Nos.

number

options.

the

from

digits

can

of

program

other

numbers

of

be

entered

program

start

code,

programs.

fol

the

for

Nos.

can

—

14

—

Page 27

(2)

Sequence

number

NOTE

(c)

1.

2.

3.

(a):

Integers

dress

:

Sequence

(b)

any

;

Therefore,

;

;

numbers.

Generally,

;

When

program

When

the

to

When

retrieved

Blocks

the

character

influence

sequential

searching

or

6

5th

two

and

without

address

consisting

numbers

on

they

numbers

numbers

digits

more

from

the

or

more

read,

sequence

data

contained

up

of

N

sequence

as

are

reference

the

meaning

may

be

are

sequence

for

beforehand.

are

written

trailing

blocks

and

end

have

no

more

numbers

in

5

digits

to

numbers.

numbers

or

sequential,

convenient

numbers,

NOTES

sequence

as

a

are

effective.

the

same

searching

can

also

blocks.

the

may

be

sequence

non

sequence

as

be

sequence

performed.

is

be

searched

written

blocks,

for

of

machining

-sequential,

numbers.

sure

number,

search

to

only

number,

for

with

following

and

do

processes.

duplicated

or

or

digits

the

only

one

respect

an

have

not

specify

up

is