YASNAC

v

CNC SYSTEM FOR MACHINE TOOLS

MAINTENANCE MANUAL

i80

. .

YASUAW14

This manual is primarily intended to give operators maintenance

instructions for YASNAC i80.

The information contained in manual does not provide all

details to be met concerning maintenance and troubleshooting. If

uncertainties be encountered for particular maintenance opera-

tion, refer to following YASNAC i80 documents for additional the

information:

● YASNAC i80 PLC SYSTEM (T OE-C843-11.1)

● YASNAC i80M SPECIFICATIONS (SIE-C843-11.30)

“

YASNAC i80L SPECIFICATIONS (S

“

YASNAC i80M INSTRUCTION MANUAL (T

● YASNAC i80M INSTRUCTION MANUAL APPENDIX

IE-C843-11.20)

OE-C843-11.30)

(TOE-C843-11.31)

“

YASNAC i80L INSTRUCTION MANUAL (T

● YASNAC i80L INSTRUCTION MANUAL APPENDIX

OE-C843-11.20)

(TOE-C843-11.21)

“

YASNAC i80 CONNECTING MANUAL (T

OE-C843-11.5)

I

ROUTINE INSPECTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

57

MAINTENANCE INSTRUMENTS . . . . ...67

TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

ADJUSTMENTS UPON

““””””””””””””””””””””””””””””

135

INSTALLATION

MODULE/UNIT REPLACEMENT

.0,43

PROCEDURE

SETTING AND ADJUSTMENT .00.00.197

OF EACH MODULE

OPERATIONS OF FIXED FILES . ..203

i

CONTENTS

Page

l. OUTLINE

l.l COMPONENTS AND INTERCONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 COMPONENTS

2. ROUTINE INSPECTIONSCH EDu LE . . . . . . . . . . . . . . . . . ...000. . . . . . . . . . . . . . . . . . . . . 57

2.1

ROuTINE

2.2 TAPE READER MAINTENANCE . . . .

2.3 CONTROL PANEL . . . . . .

2.4 AC SERVOMOTOR

2.5 BATTERY

MAl NT EN AN

3.

4. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.1’rRouBLE

4.1.1 RECOGNITION OF TROUBLE

4.1.2 RECOGNITION OF NC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...72

4.2 TROUBLESHOOTING BYALARM

4.2.1 DISPLAY METHOD....•

4.2.1 .1 ALARM INDICATION JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.2.2 ALARMS OOIOANDOO1l (PARITY

4.2.3 ALARMS 0016, 0017, 0018, 9016, 9017 AND 9018 (RS-232C ERROR) . “ . . . ...0... 83

4.2.4 ALARM 1099(TEMPERATURE ALARM INSIDE THE PANEL)

”C”””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

“.00 ”O””OO. .c. .oOOoo

CEl

NSTRUME

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...71

..C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...58

.. O

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

..o.

coo..o . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

NTS... C.........•

STATUS . . . .. O.

CODES S . . . . . . ..00 .0

. . . . . . . . . . . . . . . . .. C . . . . . . . ..

ERROR) . . . . . . . . . . . . . . . . . . . . .. O . . . . . ..O.

. . . . . . . . .. C . . . . . .. C . . . . . . . . . . . . . 67

.COOOO

. . .

..O

. . . . . . . . . . . . . . . . . . . 71

BOO

. . . . . . . . . . . . . . . . . . . . 77

C....•

. . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . .

1

11

60

-.82

88

4.2.5 ALARMS,2061 T02068 (ZERO POINT RETURN

4.2.6 ALARMS 2071 T02078,2081T0 2088

(REFERENCE POINT RETURN

4.2.7 ALARMS 2101 T02108(P-SET

4.2.8 ALARM 3000 (SERVO UNREADY) . . . . . . . . . . . . . .

4.2.9 ALARM 3001 (CONTROL NOT

4.2.1 0ALARM3002 (EMERGENCY STOP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.2.11 ALARMS 3041 T03048(EXCESSIVE POSITION LAG) . . . . . . . . . . . . . . . . . . . . . . 94

4.2.12 ALARMS 3051 T03054(EXCESSIVE POSITION LAG) . . . . . . . . . . . . . . . . . . . . . . 95

4.2.13 ALARMS 3061 T03068 (MOTOR

4.2.14 ALARMS 3081 T03088(PG DISCONNECTION ERROR) . . . . . . . . . . . . . . . . . . . . 96

4.2.15 ALARMS 3091 TO 3094 (SPINDLE PG DISCONNECTION ERROR)

4.2.16 ALARMS 3121 T03128 (EXCESSIVE

4.2.17,-ALARMS 3141 TO 3148 (PREVENTION OF UNCONTROLLED RUNNING)

4.2.18ALARMS 3161 T03168(ABSOLUTE

4.2.19 ALARMS 3181 T03188 (POSITION

AREA ERROR)......•

ERROR)• . . . ..

READY)

OVERLOAD) S . . . . . . . ..00 . . ..

. . . . .

SPEED) .. O . . . . .. O. C. C . . . . . . . . . . ..

ERRORS) . . . . . . . . . . . . . . . . . . . . .. C.

ERRORS) .. O . . . . . . . . . ..00 . . . . ..

AREA ERROR)

. . .. 00 . . . . . . . ..

O.. 000

. . . . . . . . . . .. O...

..s

. . . . . . . . . . . . . . . . . . . . . . . . . 92

..000 o.c.OOO. .o

. . . . . .

. . . . . ..coo

O.. O......

“.. ”””””89

OO... C

CO.......•

o...

. . . . 96

“ -.. “

. “ 0.. 97

O.....

OOO.

O.. OOO

.

90

91

. ...92

97

“

. 98

. . 98

...99

CONTENTS (Cent’d)

Page

4.2.20 ALARMS 3201 TO 3208 (SERVODRIVE UNIT COMMUNICATION

ERRORS) .. O

4.2.21 ALARMS 3301 T03305 (OVERCURRENT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...100

4.2.22 ALARMS 3311 T03315(MCCB TRIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.23 ALARMS 3321 TO 3325 (REGENERATIVE ERROR) . . . . . . . ..0 . . . . . . . . . . . . . .

4.2.24 ALARMS 3331 T03335 (OVERVOLTAGE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .. O . . . . . .. O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..99

100

100”

101

4.2.25 ALARMS 3341 T03345 (UNDERVOLTAGE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.26 ALARMS 3351 TO 3355 (HEAT SINK OVERHEAT) . . . . . . . . . . . ...-0.... . . . .

4.2.27 ALARMS 3361 TO 3365 (WIRE BREAK IN CURRENT INSTRUCTION

CABLE)"".".• "".

4.2.28 ALARMS 3371 T03375 (MISSING PHASE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

4.3 TROUBLESHOOTING WITHOUT ALARM

4.3.1

POWER CANNOT RESUPPLIED..

4.3.2 SOLUTION TO ERRORS DETECTED IN SELF-DIAGNOSIS . . ...0....

4.3.2

.lSELF-DIAGNOSIS

4.3.2 .2 DETAILS OF FUNCTION.•

4.3.3 CRT SCREEN DOES NOT DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 HANDLE MODE OPERATION

4.3.5 MANuALJOG M0DE0PERATIoN Faulty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.6 MANUAL RAPID MODE

4.3.7 MANUAL ZERO RETURN

4.3.8

CYCLE

START

4.3.9 OPERATION IS NOT AVAILABLE WITH GO1, G02, OR G03 .. 0.0...

4.3.1 OSPINDLE DOES NOT ROTATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.119’’ CRT SCREEN IS DARK . . . . . . . . . . . . . . .. O . . . . . ..

4.3.12 EDIT DOES NOT FUNCTION . . . . . . . . . . ..’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.13 FIN WAIT OCCURS BY SPINDLE RELATED INSTRUCTION . . . . . . . . . . “ . . . 125

C.".

O.. 00

. . . . .. C.

FUNCTIONS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .. 00 . . . . .

OPERATION

OPERATIoN

FAILURE

.00C ““. ”........

OOO.. 00

..s

FAULTY .. O

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

coDEs

. . . . . . . . . . . . . . . . . . . . . . . . ..$ . . . . . . . . . ...103

..

O

FAULTY......•

FAuLTy . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

. . . . .. O...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O.. .00

. .

..OO.

. . . . . . . . . .

. . ..

OO.. O.. C.....• O.. ll7

O..

O . . . . . . . . . . . . . . . . . . . . 123

“ 0... c o c 121

c

0.. c o

..I04

101

101

102

103

104

113

113

115

119

120

1,22

124

(G31)

4.3.14 SKIP FUNCTION

4.3.15 TAPE MODE DOES NOT FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4p0wER suppLyv0LTAGEcHEcK

4.4.1 CHECK AT POWER SUPPLY VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...128

4.4.2 INDICATION OF LAMP OF POWER SUPPLY UNIT . . . . . . . . . . . . . . . . . . . .

4.4.3 CHECK DC POWER SUPPLY VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 STATUS DISPLAY BY SELF-DIAGNOSIS FUNCTION (DGN) . . . . . . . . . . . . . . . .

4.5.1 OUTLINE OF DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 DISPLAYING INPUT/OUTPUT SIGNALS . . . . . . . . . . . . . . . . . . . . . . ..C. . . . . . . . .

4.

5.

ADJUST ME NTSUPON lNSTALLATl ON

OpERATIoN

Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

..c

. . . . . . . . . . . . . . . . . . . . . . . . . . .

126

127

128

.... 129

. . . . . . . ...129

130

130

131

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

. . .

111

CONTENTS (Cent’d)

Page

6. MOD ULE/UNIT REPLACEMENT PROCEDURE

6.1

NC RACK””””””””””””””””””””””””””

6.1.1

6.1.2 MODEL JANCD-FCIOOB ”.”.”. . ..”. o... o””” C. COB””””””””””””””””””

6.1.3

6.1.4

6.1.5

6.1.6 MODEL JANCD-FC222/FC224

6.1.7

6.1.8

6.1.9

POWER SUPPLY UNIT (MODEL

MODEL JANCD-FC190-1

MODEL JANCD-FC20000

MODEL JANCD-FC210-1

MODEL JANCD-FC230B .00”.”

MODEL JANCD-FC240 ””

MODEL JANCD-FC300B-3

6.1.10 MODEL

6.1.11 MODEL

6.1.12 MODEL JANCD-FC250-1, 2 (MOTION BOARD)

6.1.13

MODEL JANCD-FC310-1 ”” . . ..

6.1.14 MODEL JANCD-FC400

6.1.15 MODEL JANCD-FC41O

6.1.16 MODEL JANCD-FC420

6.1.17 MODEL JANCD-FC430

6.1.18 MODEL JANCD-FC440

JANCD-FC250

JANCD-FC251

”.””.” “0””

”O”” O0

O”””””

OO”””” “.-. ”.”” ””” O”””” O” C””” as””””-””””””””” “..”””..

CC... CO.

(INTEXB BOARD: STANDARD SPECIFICATIONS) “ “ . “ 162

(INTEXB BOARD: HIGH-SPEED SPECIFICATIONS) “ o 164

"""" """" """"

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O""" "O"" "" O""" 00"

""""""."""• OO"".

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

““””

”””””””””””””””””””””””””””””””””””” ““ 144

CPS-12N,

””””

00”” ”.OO””” ”O. ”.”- .””. ”.. ”OC” OC ..””””

““”” ”””” ”””” ””””

““”” ”””s

00”” ””..

C.OC CC OOCO””” OO”” OOO” O””” Q”” O”.

”””””””.”-.”.”..”””...””””””

s“””.. .””.O”” ”””””

o””s”””

.

...””””...”””””...”””””””””...”””””””

O""" .".. O."" OOOO""C

.“”o”.

”o”c”””

MODEL CPS-16F) “ “ o “ “ 00 “ “ “ “ . “ o 144

.””” 0””” 00..00 ..”o”” “... ””””.”

”””” 0” ”” ”””” ”””” .””” ””.....” 154

-”. ”””.

. . . .. O"

""" O"

o”c. o.co”

““””

””””.””””..””...””..””””

OO.

"""" o."o""e o-+--

O"" O"" O"" CC"" OO"""""O. O"" CO OOOO

”””” .c0.00”””cooc

””””” ““”””””””-

””.0000”0”””0 “s168

"""

C.o C-"" -"--

“...””””..

““””.”””””

.--oooo 170

.“....”””

oooo-ooo

““”.

143

146

148

150

152

156

158

160

166

172

-

174

176

178

6.1.19 BACK BOARD (MODELS

6.1.20 11-SLOT BACK BOARD (MODEL

6.2 MACHINE CONTROL STATION

6.2.1 9“ AMGC CONTROL PANEL (MODEL

6.2.1 .lMODEL

6.2.1.2MODEL

6.2.1.3MODEL

6.2.1.4 9“ MONOCHROME GRAPHIC CRT UNIT

6.2.1.5 KEYBOARD (MODEL DF8203788)

6.2.2 14” ACGC CONTROL PANEL (MODEL JZNC-IOP1l) ““ ““““ ““““““““ ““ .. ““ ““ ““ 191

6.2.2 .1 MODEL JANCD-FC950-100” O

6.2.2 .2

6.2.2.314” COLOR GRAPHIC CRT UNIT (MODEL

6.2.2.4 KEYBOARD (MODEL

MODEL JANCD-FC951”

JANCD-FC900B”

JANCD-FC901

JANCD-FC903-l

7. SETTING AN DADJUSTM EN TOF EACH MODULE

.-.

8. OPERATl ON SO

8.1

TYPES OF FIXED FILES “ “ o

8.2 DISPLAY

AND WRITING OF FIXED FILES

FFl XEDFl LES"""" OCOOOOO

JANCD-FCOO1, -FCO02, -FC050, -FC052) “ “ “ “ “ “ “ “

“00. ””O. o.coo”.

O”0

““”” ”O”””””

O""""• .""" ."..

.”. ”C”.

O”””. O“O””. o

DF8203921)

””””””0

“000

JANCD-FCO06) ““ .“ ““ .“ ““

”c”oo”o

JZNC-IOPO1) .COO”O”OOOOO”.”””CO”O”OO

””.O.OOOOo ooc”””””oo”” o”” “.””””.”””

""""""""CO""

00””

””””

(MDT948B-3B) c “ “ o “ “ “ “ “ “ “ . . “ “ “ “ “ 189

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

””””

”OOOOO” ””””” 00”” ”’”.

. . ..”oooo

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

o”””

TX1424AD) .0 “ “ “ “ “ o “ o “ s - “ “ ..0.. 194

”o”””.

“0”0””””0”0””0””.”oooooc”.

00”” ”.”OOO” ””””” ”O””. QO” OO””

”oo”. o.” . . .

“““O ““ “.

.””oo”oooo

”...0000O”

..oo” ““””.-”-o.

.“ ““ O. “O 182

““.”””””

““.

““””””””””””””””””””””””””

"O

O""""

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

"""" ".

“

".. "O" CC"" "C"" """o "". -""- o-oo

000""00 "Ooo". o-"oo-oo

. . 180

188

””” OO

-

-----

205

184

184

184

187

190

191

193

195

197

’203

204

iv

INDEX

Subject

A

AC SERVOMOTOR

ADJUSTMENTS UPON

Chapter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2 . . . . . ...2.4

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

. . . . . . . . . . . . . . . . . . . . ...135

Par

ALARM 1099 (TEMPERATURE ALARM INSIDE THE PANEL) . . . . . . . . 4 . . . . . . . 4.2.4

ALARM

ALARM 3002

ALARM INDICATION JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALARMS OOIOAND 0011

3001(CONTROL NOT

(EMERGENCY

(PARITY ERROR) . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . . . 4.2.2 . . . . . . . 82

READY ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOP)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . .

l........l.z.g

4

. . . . . . . .

..4.2.1o

4.2.1.1

. . . . . . . . 93

ALARMS 0016, 0017, 0018, 9016, 9017, AND 9018 (RS-232C ERROR) . . 4 . . . . . . . 4.2.3

“ ““ ~~ ““

ALARMS 2061 TO 2068 (ZERO POINT RETURN AREA ERROR) . . . . . . . . 4

4.2.5

ALARMS 2071 TO 2078, 2081 TO 2088

(REFERENCE POINT RETURN AREA ERROR) . . . . . . . 4 . . . . . 4.2.6 . . . . 90

4

ALARMS 2101 T02108(P-SET ERROR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . ...4.2.7

ALARMs3000 (sERVOUNREADY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4........4.2.8

ALARMS 3041 TO 3048 (EXCESSIVE POSITION LAG) . . . . . . . . . . . . . . . . 4 . . . . . 4.2.11

ALARMS 3051 TO 3054 (EXCESSIVE POSITION LAG) . . . . . . . . . . . . . . . . 4 . . . . . . . 4.2.12

ALARMS 3061

T03068

(MOTOR

OVERLOAD) . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . . . 4.2.13

ALARMS 3081 TO 3088 (PG DISCONNECTION ERROR) . . . . . . . . . . . . . . . . 4 . . . . . . . . 4.2.14

ALARMS 3091 TO 3094 (SPINDLE PG DISCONNECTION ERROR) . . ~ 4 . . . . . . . . 4.2.15

ALARMS 3121 T03128 (EXCESSIVE SPEED) . . . . . . . . . . . . . . . . . . . . .

ALARMS 3141 TO 3148 (PREVENTION OF UNCONTROLLED

RUNNING)

ALARMs3161 T03168(ABSOLUTE ERRORS)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

4........4.2.16

4

.“”””..

..4

. . . . . .

4.2.17

..4. 2.l8

ALARMS 3181 T03188 (POSITION ERRORS) . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . . . . 4.2.19

ALARMS 3201 TO 3208 (SERVODRIVE UNIT COMMUNICATION

ERRORS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . .

ALARMs3301

ALARMS 3311 TO 3315

ALARMS 3321

T03305(OVERCURRENT)

(MCCB

TRIP)

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..4

. . . .

4

T03325 (REGENERATIVE ERROR) . . . . . . . . . . . . . . . . . . 4 . . . . . . . . 4.2.23

..4.2.2l

““”.

””.. 4.2.22

..4.2.2o

Page

. . . . . . . . 62

. . . . . . . . 88

. . . . . . . 92

. . . . . . . . 79

.“”” ””””

83

““”’””

““”””””’

““””””””

““..

”...

89

91

92

94

. . . . . . . . 95

““”””.”.

96

. . . 96

““””””””

““”””””.

““”.””

97

97

98

. . . . . . . . 98

. . . . . . . . 99

““””””””

99

. . . . . . . . 100

““””””””loo

““”. ”...1OO

ALARMs3331 T03335(0VERV0LTAGE )

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . . . 4.2.24

ALARMs3341 T03345(UNDERV0LTAGE ) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . 4.2.25

ALARMS 3351

T03355(HEAT

SINK

OVERHEAT) . . . . . . . . . . . . . . . ...4 . . . . . . . . 4.2.26

ALARMS 3361 TO 3365 (WIRE BREAK IN CURRENT INSTRUCTION

CABLE )

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4......4.2.27

ALARMs3371 T03375(M1SSING PHASE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . . . . 4.2.28

B

BACK BOARD (MODELS JANCD-FCOO1,

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

c

CHECK AT POWER SUPPLY VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECK DC POWER SUPPLY VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . .

COMPONENTS

COMPONENTS AND

CONTROL

cRTscREEN

cycLE sTARTFAILURE

D

DETAILS OF FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIsPLAY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 . . . . . . . 1.2 . . . . . . . 11

INTERCONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 . . . 1.1

PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . . . . 2.3

DoEs

NoTDIsPLAY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4........4.3.3 . . . . . ...113

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4........4.3.8 . . . . . ...120

AND WRITING OF

FIXED FILES . . . . . . . . . . . . . . . . . . . . . ...8........8.2 . . . . . ...205

DISPLAY METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-FCO02, -FC050, -FC052)

. . . . 6 . . . . . . . . 6.1.19

2.......2.5

4

. . . . . ...4.4.1 . . . . ...128

4

. . . . . ...4.4.3 . . . . ...129

4

. . . . . .

4

..4.3 .2.2

. . . . . ...4.2.1 . . . . . .

. . . . .

DISPLAYING INPUT/OUTPUT SIGNALS . . . . . . . . . . . . . . . . . ...4.... . ...4.5.2 . . . . ...131

E

EDIT DOES NOT FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.......4.3.12

. . . . . ...124

ll-sLOT BACK BOARD(MODEL JANCD-FCO06) . . . . . . . . . . . . . . . . . . . . . . 6 . . . . . . . . 6.1.20 . . . . . . 182

F

FIN WAIT OCCURS

ACG~~ONTROL PANEL (MODEL JZNC-IOP1l) . . . . . . . . . . . . . . . . . . 6 . . . . . . . . 6.2.2

14”

14''COLOR GRAPHIC

H

HANDLE MoDEoPERATIoN

BY

SPINDLE RELATED INSTRUCTION ~~ . . . . . . . 4 . . 4.3.13 . . . . . . . . 125

CRT UNIT (MODE LTX1424AD)

. . . . . . . . . . . . . . . 6 . . . . . . . 6.2.2.3 . . . . ...194

FAuLTY . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4.......4.3.4 . . . . . ...113

. . . . . ...101

. . . . . ...101

. . . . . ...101

. . . . . ...102

. . . . . ...102

. . . . . ...180

. . . . . . . 63

. . . . . . . .

““”””

60

..lo5

. . . . . ...191

2

77

INDICATION OF LAMP OF POWER

I

K

KEYBOARD (MODEL DF8203788)

KEYBOARD (MODEL

DF8203921)

SUPPLY UNIT . . . . . . . . . . . . . . . . . . . 4 . . . . . 4.4.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6 . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 . . . . . . . .

. . . . ...129

6.2.1.5........190

6.2.2.4.......195

v

INDEX (Cent’d)

suDject

M

MACHINE CONTROL STATION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

MAINTENANCE INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

MANUAL JOG MODE

OPERATION FAULTY . . . . . . . . . . . . . . . . . . . . . . . . . . 4

MANUAL RAPID MODE OPERATION FAULTY . . . . . . . . . . . . . . . . . . . . . 4

MANuALzERo RETuRNoPERATIoN

MODEL JANCD.FCIOOC

MODEL

MODEL

MODEL

MODEL

MODEL

MODEL

MODEL

JANCD.FC190.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 . . . . . . . . . . . . .

JANCD.FC200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JANCD.FC210.1 . . . . . . . . . . . . . . .. O . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JANCD.FC222/FC224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

JANCD.FC230B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 . . . . . . . 6.1.7

JANCD.FC242 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JANCD-FC250

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 . . . . . ...6.1.2

(INTEXB BOARD : STANDARD

SPECIFICATIONS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6 . . . . ...6.1.10

MODEL

MODEL

JANCD-FC250-1,

JANCD-FC251

(INTEXB BOARD : HIGH SPEED

2 (MOTION BOARD)

FAuLTY . . . . . . . . . . .. - . . . . . . ...4 . . . . . . . . 4.3.7

. . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6

MODEL

MODEL

MODEL JANCD-FC400

MODEL

MODEL

MODEL

MODEL JANCD.FC440

MODEL

MODEL JANCD-FC901

MODEL JANCD-FC903-l

JANCD.FC300B.3 . . . . . . . . . . . . . . . . .. O . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

JANCD.FC310.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

.."......•

"".. " . .

..". """".

..

"""""6""""""""

JANCD.FC410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JANCD.FC420 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JANCD-FC430 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .."""

".""

.."" . .."

JANCD.FC900B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

...-"........"."""""""""""""."""

Chapter

6........6.2

. . . . . . . . . . . . . . . . . . . . . . . .

““.””

“...””.

6“”””’”””

..6

. . . . . .

6“””-.””

.”””.”

..6"" """. ""6.l.8

6

.“”””.

““”. ”6 .1.11 ““”””.164

.“o” ...1.9.9

6“””””.

...6"""""""

..< .6""""""

6“””””””” 6.1.17 ““.176

".6..""."".

6“””””

..6

. . . ..6.2

6“””””””

rar. rage

. . . . . ...184

4.3.5

4.3.6

““””””’”

““””””””117

““””””””119

. . . . ...146

6.1.3

..6.l.4

““””

..””

. . . . ...150

6.1.5 ““””””””152

6.1.6

““””””””

““. ””” 156

.“”” ””””

““”. .”.162

6.1.12 ‘.”. ”””166

. . . . . ...160

6.1.13

6.1.14

““168

““170

6.1.15

““””””172

6.1.16

““”””174

6.1.18 ““”178

6.2.1.1

““””184

.1.2” ”””” 187

6.2.1.3

““188

67

115

148

154

158

MODEL JANCD-FC950-l

MODEL JANCD-FC951

MODULE/UNIT REPLACEMENT PROCEDURE”” . . . . . . . . . . . . . . . . . . . . . 6

N

NC RACK

. . . . . . . . . . . . . . . . . . . . . . . .“

9“AMGCCONTROL PANEL

9"

CRT

SCREEN IS DARK

9“MONOCHROME GRAPHIC

o

OPERATION IS NOT AVAILABLE WITH GOI, G02, OR G03 . . . 4 .. ““ ““ “ 4.3.9

OPERATIONS OF

OUTLINE

OUTLINE OF

P

POWER CANNOT BE

. . . . . . . ...”.....”””.””””””

DISPLAY .".

POWER SUPPLY UNIT (MODEL

POWER

R

RECOGNITION OF NC SYSTEM."""."""""""""""""""""""""""""

SUPPLY

RECOGNITION OF TROUBLE STATUS””””””””””””””””””””

ROUTINE INSPECTION”.”.”””””””.”””””””””””””””””””

ROUTINE INSPECTION SCHEDULE..

s

SELF-DIAGNOSIS FUNCTIONS".""""""""""""""".""."""""""""-"

SETTING AND ADJUSTMENT OF EACH MODULE . . . . . . . . . . . . . . . . . . . .

SKIP FUNCTION (G31) OPERATION FAILURE""""""""""""""""""

. . . . . . . . . . . . . . . . . . . . ..

. . . . . . . . . . . . .

..". ".""" "". "". "."" """" """6 """" """6 .2.2. 2"". """""l93

"""""".""

.”””””..”””””””.”””.”””””””””

(MODEL JZNC-IOPO1) ””””””””””””

. . . . ..""

""".

"..

"". "."" """" ". """""""""""""4"".""""

CRT UNIT (MDT948-3B) ””””””

FIXED FILES

"""" """" """" """" """" """"

““”” ”””””””””””””””””””””””

"." "C"""""""""."".""""""""`"""""""""

SUPPLIED .. "" "" "" "" "" "" "" "" "" ""

CPS-12N,

MODEL

VOLTAGE CHECK”””””.”””””””””””””

......””””””.””””””””””””2

6

."8""".

""""" """" ""2o3

4“”.””””” 4.5.1

"""""".""

4“””””””. 4.3.1

CPS-16F) “.. ~~ .“ “

6

. . . . . . . . . . . . . . . . . . . ...143

6“”””””””

6

““””””

““””””

1

6 “ ““ ““ ““ 6.1.1

4

“””.”

4“”””””

4

2 ““””””” 2.1

4

7................197

4“”

SOLUTION TO ERRORS DETECTED IN SELF-DIAGNOSIS ““ “ ““ “ ““ “ 4 .. “. “ “ 4.3.2

SPINDLE DOES NOT ROTATE .

STATUS

T

TAPE MODE DOES NOT FUNCTION

TAPE READER

DISPLAY BY SELF-DIAGNOSIS FuNcTION

MAINTENANCE."".""""".""""""""."""'""."""

TROUBLE IDENTIFICATION.......”””””””””

TROUBLESHOOTING....””””

TROUBLESHOOTING BY

ALARM

TROUBLESHOOTING WITHOUT

TYPES OF FIXED

FILES..............””””””

..”””””””””””””””

(DGN)

.“””””””””””””””””””

““”””””””””””””””””””””

CODES ”””” ”””” ”.”” ”4. ””4.2

ALARM

CODES.”””””””””””””””

4“”’””’””

. . . . . . . . . . 4 . . . . . . . .

4“”.””

2“””””””

4

4:””””””””””””””””””””””””

4

““”””

8“

.“”6 .2.2.1

6.2.1

6.2.1.4

6.1

4.3.11

““””””191

. . . . . ...144

. . . .

..”. 184

..””

.””123

““”””” 189

.-

. . . ...121

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . 130

. . . . . ...103

. . . . . ...144

4.4

4.1.2

~~~~~~~~ 4.1.1

““”.”””””””””

““”4 .3.2.1

“... .””128

. . . . . . . . 72

.. ”...”” 71

. . . . . . . .

lo4

4.3.14 126

. . . . . . . .

58

57

104

4.3.1o ““””””’”122

4,5

4.3.15

2.2

““”””’”” 4.1

4.3

8.1

. . . . . . . 130

““””127

..”....

.

59

. . . . . . . . 71

69

““””””””

77

. . . . . ...103

. . . . ...204

1

vi

1. OUTLINE

The YASNAC i80 provides you with an internal self-diagnosis function. System maintenance can easily by accomplished with DGN

and other main functions as listed below;

(1)

Microprocessor

nally and can display the status with function keys.

If any failure occurs, NC immediately stops with the blinking

of alarm displays. Also the same precedure can be executed on

machine sequence for the application of built-in type programmable controller.

always monitors the machine operations inter-

ON/OF’F

(2)

displayed with DGN.

Setting value of various parameters such as

(3)

constant and rapid speed can be checked on the CRT,

1. OUTLINE

1.1 COMPONENTS AND INTERCONNECTIONS

1.2 COMPONENTS

SIGNAL of Input to

"..." C"

. . ..

C"""""• """"SO"""""""""""."• "" O". SO""" """." .". "". C.".".""""""• .""""""".".""""• ..". OOOC.. "... "...C.

-"..""• """ O""""• OO"OO."O"OO

NC/Output

CONTENTS

""""" "." C"""" """""""""""""""""C"• """"""""""• """"""""CC

""" O""" C." C"" S" BOO"""""" """""""""""""""• """""""""""O"""""""""""""""".

from NC can be

accel/decel

time

1

2

11

-.

1

1.1

3-PHASE

AC

POWER

SUPPLY

COMPONENTS AND INTERCONNECTIONS

(1) Component Arrangement

+

R—

s—

T—

/

POWER

INPUT

UNIT

ti

L,

?H

OH

&z

*

2*

.:

CONTROL UNIT

u-lb

ok

&a

ZIn

o

v

I

1

GENERAL

PURPOSE

1/0 MODULE

7

L

L

-

AC SERVO

DRIVE UNIT

F

*

AC SERVO

*

DRIVE UNIT

-

AC SERVO

~

DRIVE UNIT

DICITAL

DIGITAL

DIGITAL

lst-AXIS

MOTOR

2nd-AXIS

MOTOR

3~d-AXIS

MOTOR

-J

. . . .

SPINDLE

CONTROL

d

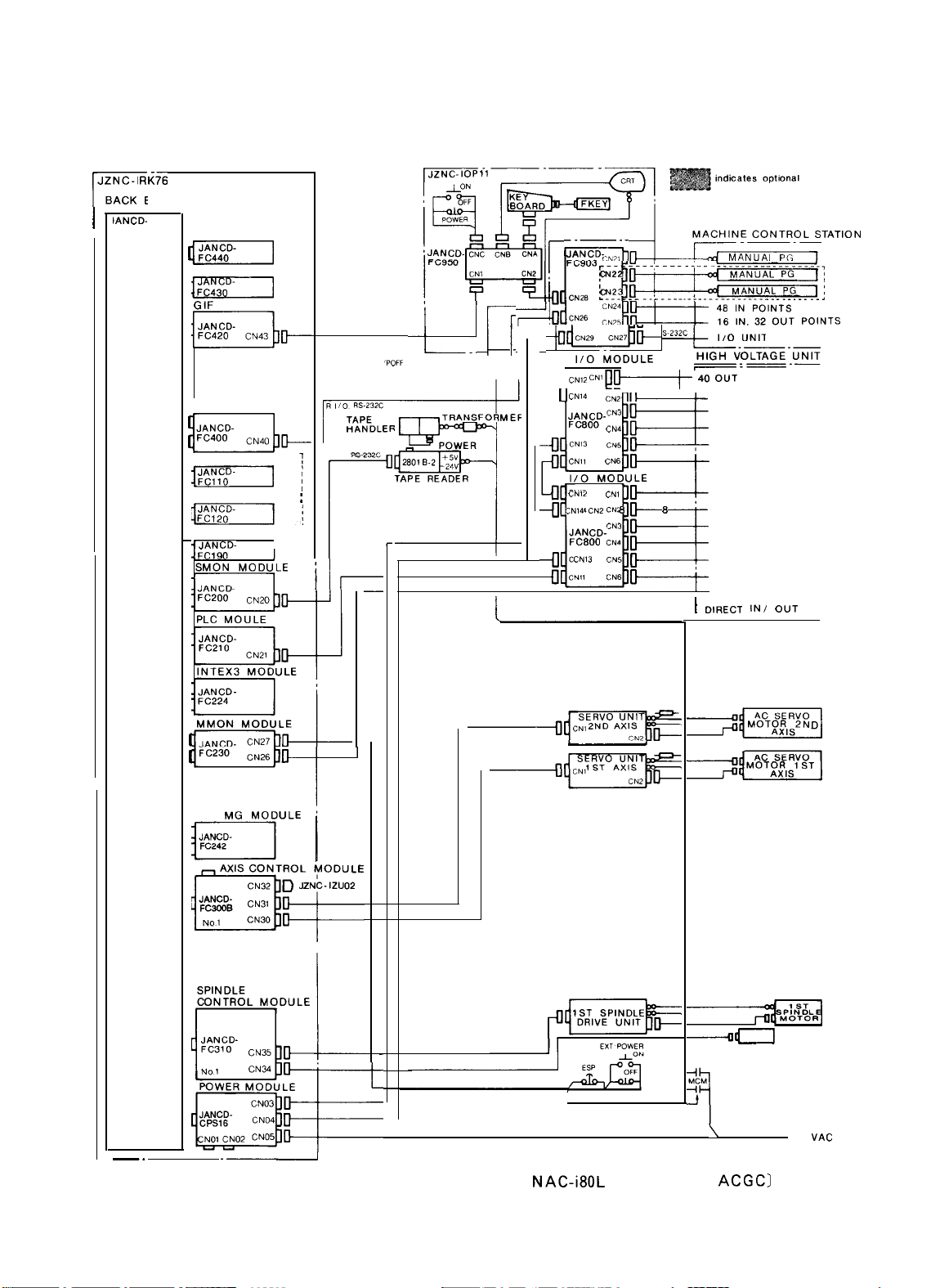

Fig. 1.1 Component Arrangement of YASNACi

CABINET

-

DRIVE

UNIT

SPINDLE

MOTOR

2

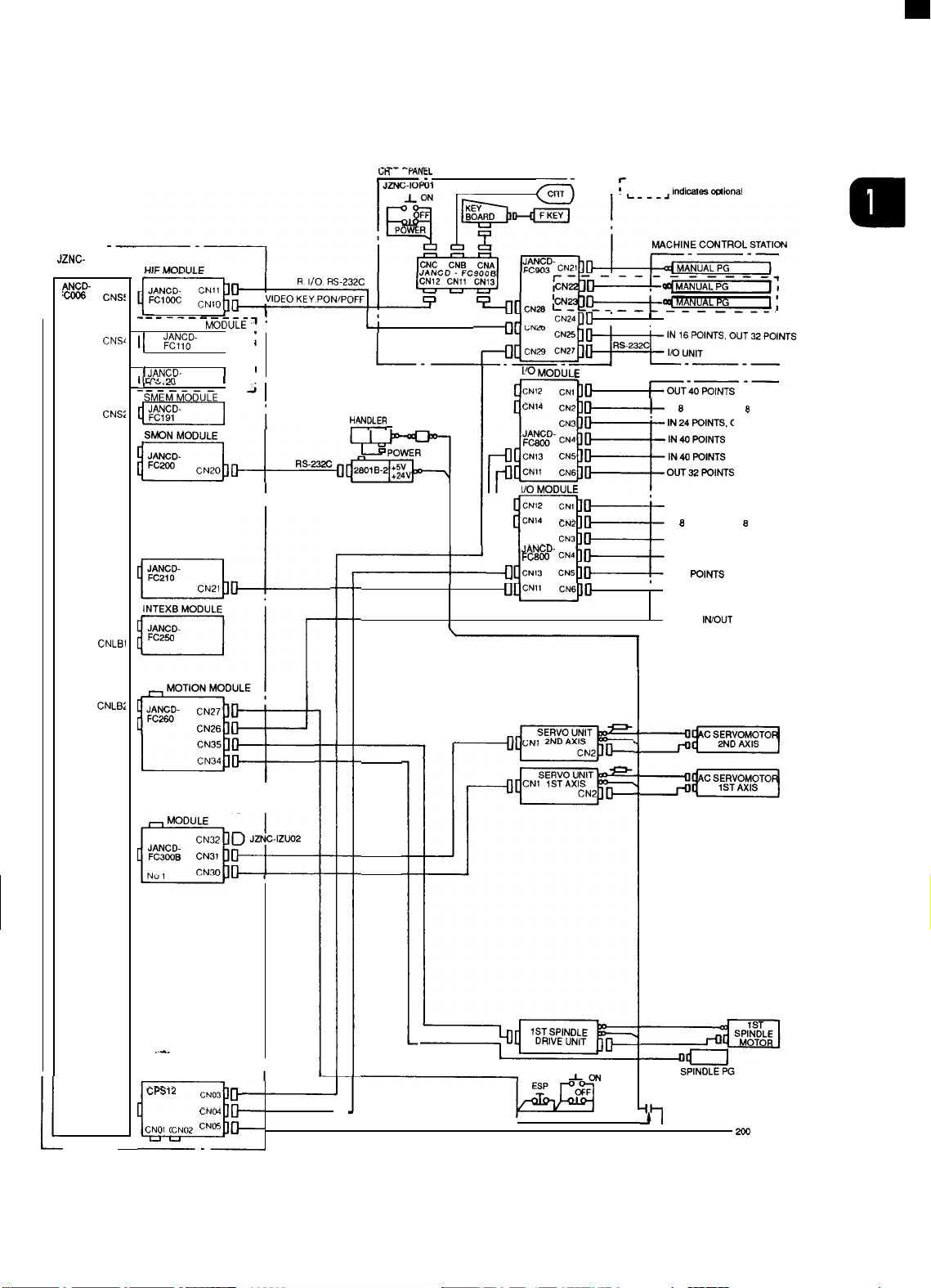

(2) Interconnection Diagram

U MODULE

zNc-l RK22-

ACK BOARD HIF MODULE

‘c””’

‘“s5

1

=~

; ‘co M-u-- M-o

c“” ~-,

‘“s3

i-...j

‘“s2

m

CNA3

CNBI

la

SMEM MODULE

INTEx

MODULE

JANCD-

FC224

b~-i~

CRT PANEL

.—

E“’e

MACHINE CONTROL STATION

—-—

. . . . .

. . . . . . . . . . . . . . . . . . . . . . .

-

?

~

TAPE HANDLER TRANSF~RME

~[

L____

,,,,,.’

POWER

:~

TAPE READER

T

I

+

48 IN POINTS

16 IN, 32 OUT POINTS

1.232C

T

1/0

UNIT

L

.—

HIGH VOLTAGE UNIT

—-

40 OUT POINTS

8 IN, 8 OUT POINTS

24 IN, 16 OUT POINTS

40 IN POINTS

40 IN POINTS

32 OUT POINTS

40 OUT POINTS

8 IN, 8 OUT POINTS

24 IN, 16 OUT POINTS

40 IN POINTS

40 IN POINTS

32 OUT POINTS

I

~

DIRECT

INOUT

-—

.—

SPINDLE

CND3

CONTROL MODULE

JANCD

CND4

FC31O

-’

ko

1

In

CN35 ~

CN34

~

Fig. 1.2

J

IODULE

:-

IZU02

~-

Interconnection Diagram

EXT POWER

L

ESP

[Y AS NAC-i80L

ON

for

SVM

-I(

Lathe]

SPINp\LE

200 vA’

3

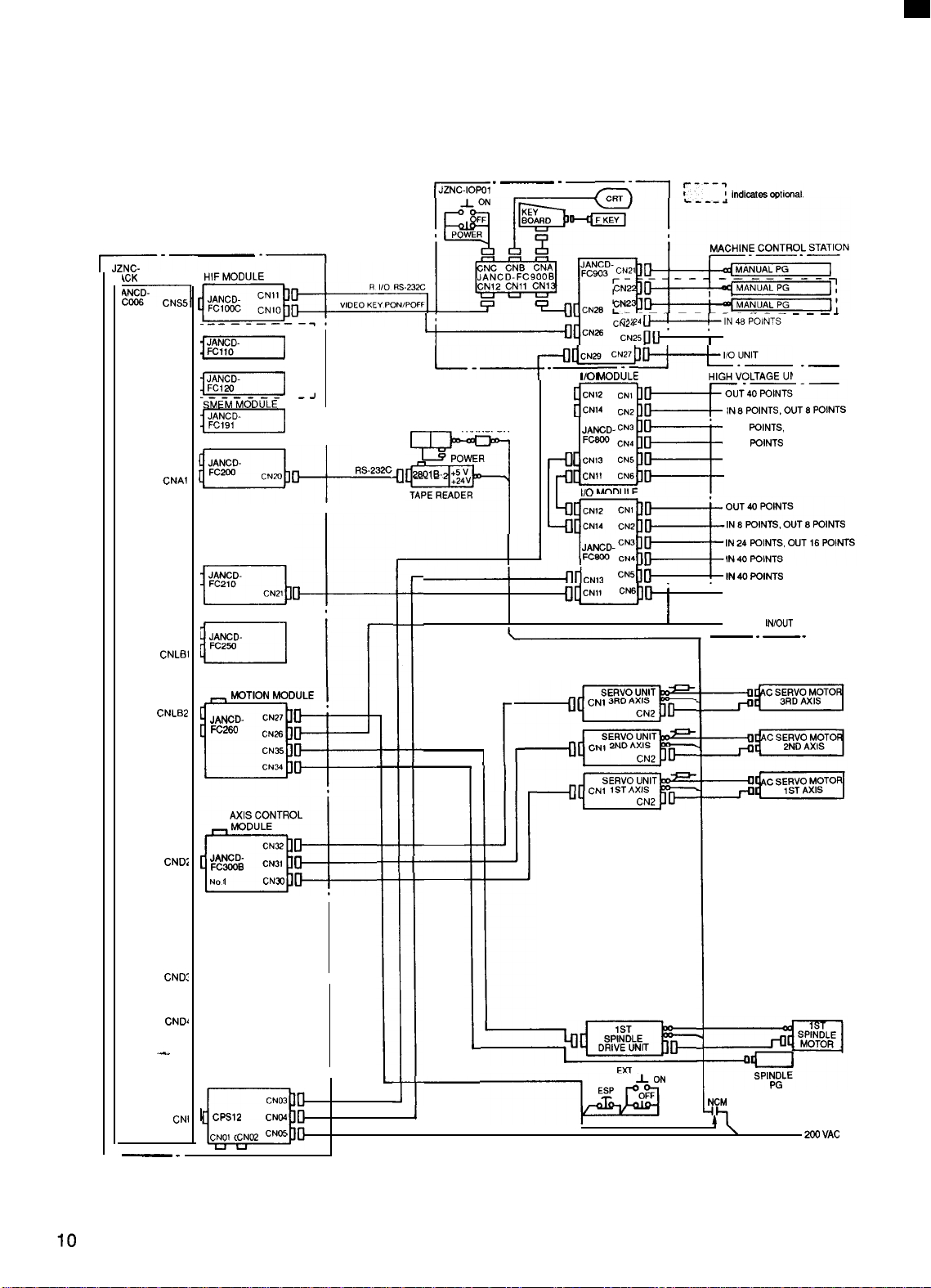

1.1 COMPONENTS AND INTERCONNECTIONS (Cent’d)

CPU MODULE

JZNC-l

Rk76

BACK BOARD

r

lANCD-

I

C050

CNG5

CNG4

CNG3

CNG2

CNG1

CNS5

CNS4

CNS3

CNS2

CNA1

APM2 MODULE

m

APM1 MODULE

=

GIF

MODULE

=.

ACP MODULE

m

NIF MODULE

n.

. . . . . . . . . .

COMU MODULE

-:

FILE MODULE

-:

----- . . . . . . . . . . . .

SMEM MODULE

4JANCD-

VIDEO KEY, PON

-F

;

;

r

RS-232C

CRT PANEL

E1@TC~:~;L:TATION

+1

‘POFF

POWER

28016.2

>~

TAPE READER

m

F1.

II

,

—.

ti

+=}LE –-–:

CN12 cN~~+

9

u CN14

‘“zcl~

JANcD-CN3

F c800

CN4

~H~

+ c.,,

+ CN13 CN5

,~~~

CN5

CN1l CN6

l/O

MODULE

CN12 CNI

CN2

‘ 6 IN, 8 OUT POINTS

JAN

CD-CN3

Fc600 CN4

CN6

CN11

MANUAI PG

HIGH VOLTAGE-UNIT

—-—

40

OUT

POINTS

8 IN, 8 OUT POINTS

24 IN, 16 OUT POINTS

40 IN POINTS

40 IN POINTS

32 OUT POINTS

40 OUT POINTS

24 IN, 16 OUT POINTS

40 IN POINTS

40 IN POINTS

32 OUT POINTS

I

OIRECT

IN,

OUT

—.

CNA2

CNA3

CNB1

CNA4

CNB2

CNB3

CND1

CND2

CND3

SPIN DLE

CONTROL MODULE

JANCD-

CND4

FC31O

r~l

a’~

CNP

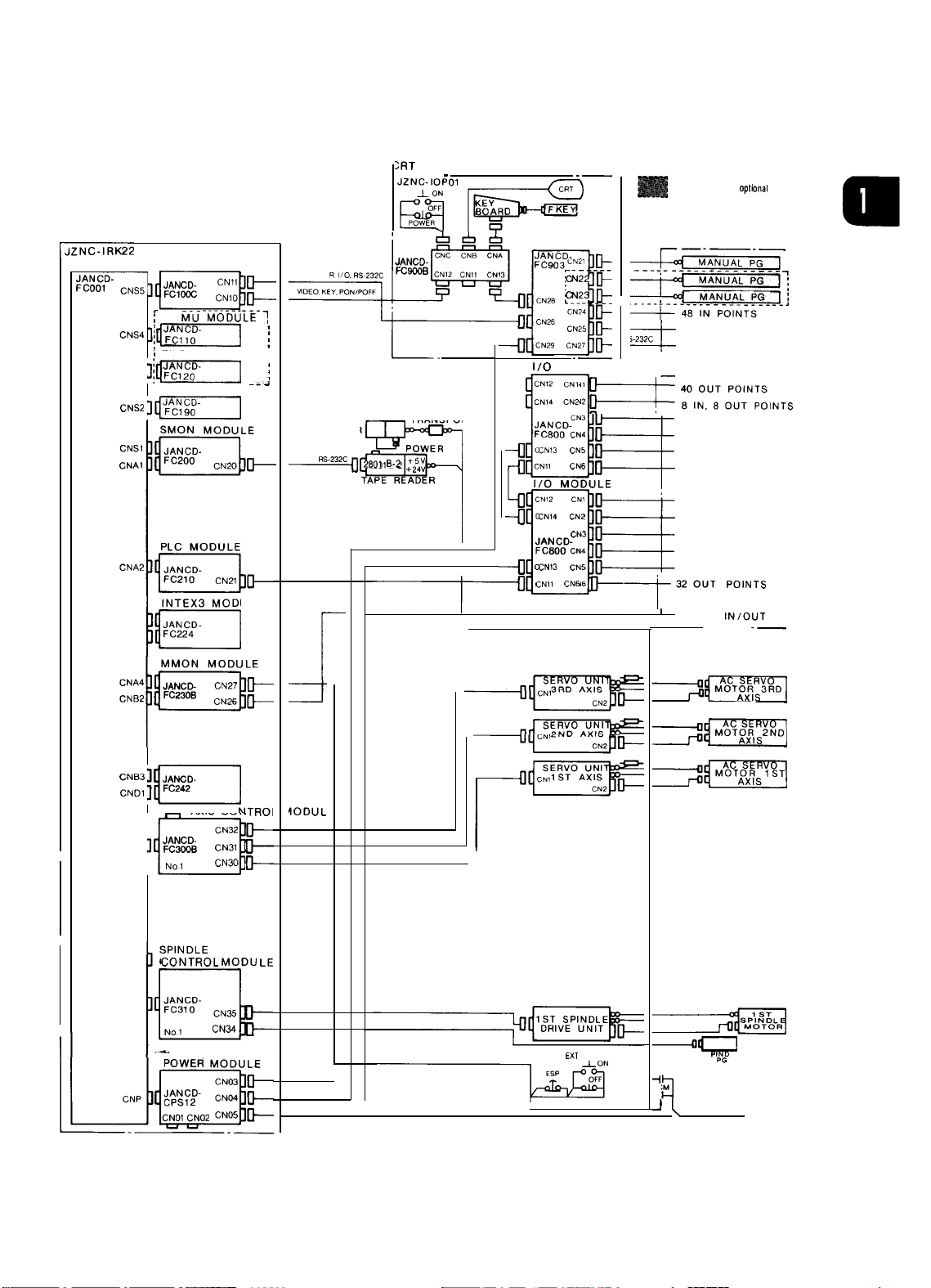

Fig. 1.3

.~

CN35

Interconnection Diagram [Y AS

I

NAC-i80L

I

~a

SVM

for Lathe with

\

ACGCI

SPINPLE

PG

200 VAC

4

2RT

PANEL

—

-

.—

m

indicates

optional

CPU MODULE

lJZNc-IRK22

BACK BOARD HIF MODULE

‘22:7-’”s;

-

‘m~

f

“co

ti-ti ‘ti-ob”uiE- ?

‘“s4

l~m

I

FILE MO OULE ;

CNS3

I-

. . . . . . . . . . . . . . .

SMEM MODULE

c“”

1-

INTEX3 MODULE

CNA3

JAN CD-

FC224

CNB1

~m

‘z”’

!

~

..J

TAPE

HANDLER

~

L.

POWER

2801

~.’

:2

TAPE READ R

T

~

P

TRANSFORMER

I

I

+0’”” ‘“”JE

+ c.,, CN5

c

+

+

.—

1/0 MODULE

‘: ‘: ~

CN3

JAN CD.

FC800

CN4

CN1l

CN6

Dl+

l/O MODULE

CN12 CN1

CN14 ..2

CN3

JANCD-

Fc600 CN4

c.,, ..5

~]B

c“”

‘“6 b-i-320uT

MACHINE CONTROL STATION

——-—

;-232C

*

16 IN, 32 OUT POINTS

l/O UNIT

L._._

HIGH VOLTAGE UNIT

—- —-—

~:”::::::NTs

24 IN, 16 OUT POINTS

40 IN POINTS

40 IN POINTS

32 OUT POINTS

40 OUT POINTS

8 IN, 8 OUT POINTS

24 IN, 16 OUT POINTS

40 IN POINTS

40 IN POINTS

I

DIRECT

I

‘O’NTs

lN/OUT

.—

.—

.—

MG MODULE

=

~m

AXIS CO

JANCD-

‘ND’

FC3WB

No 1

‘n

SPINDLE

C“D3 cONTROL MODu

JAN CD-

CND4

FC31 O

No 1

In

..-.

Fig. 1.4

NTROI

CN32

‘“31 ~

‘“30

CN35

CNW ~

Interconnection Diagram [Y AS NAC-i80M for Machining Center]

fiODUL

~

&

LE

~

J

~=

S

P

tpNGD

L

ExT

POWER

SVM

i

NCM

•1

J

2

(

E

200 VA’

5

1.1 COMPONENTS AND INTERCONNECTIONS (Cent’d)

CPU MODULE

JZNC-IRK76

BACK BOARD

r–

m

CNG5

CNG4

CNG3

CNG2

CNS5

CNS4

CNS3

CNS1

CNA1

CNA2

pg

m

QIF

MODULE

p,,

. . . . . . . . . . . . . . .

COMU MODULE :

-I

FILE MODULE

-

. . . . . . . . . .

SMEM MODULE

-

SMON MODULE

c.,o~~

-

VIDEO KEY

R 1’0 RS232C

.1

,,

J

‘

CRT PANEL

FC903FC.N::

+

I

I

,

I

?~~.

“

110

MODULE

CN12 CN1

CN14

CN2

JAN CD-

FCBOO

~’E-

~oM;{ti;:;;::;lNTS

JAN CD-

FCBOO

+

CN,, c.,

,~~~

CN1l CN6

CN3

CN4

CN3

c

:

,,

PON/POFF

TRANs Fnn MPn

“DLERm’’”’-’

TAPE READER

___ . -----

N4

m

inciic.tes option.1

MACHINE CONTROL STATION

—- —-—

+..!.?!!!.L-!!

,:,g;,;,,

HIGH V“OLTAGE UNIT

40 OUT POINTS

8 IN, 8 OUT POINTS

24 IN, 16 OUT POINTS

40 IN POINTS

24 IN, 16 OUT POINTS

40 IN POINTS

40 IN POINTS

‘

32 OUT POINTS

DIRECT

1

.—

--

.—

lN/OUT

.—

I

!:

I

CNA3

CNB1

CNA4

CNB2

CNB3

CND1

CND2

CND2

,QND4

CNP

Fig. 1.5

I

—

I

SPIN DLE

CONTROL MODULE

JANCDFC31O

{--1

POWER MODULE

ais

CN35

CN34

No 1

;;:::.

CN03

CN04

NO1 CN02 cNo5

Interconnection Diagram [Y AS NAC-i80M for Machining Center with

I

—

~m

SVM

+

ACM

2

4

SP;NGDLE

ACGC)

6

CRT PANEL

“P,f~

lndlcates

optional

CPU MODULE

‘“s4

CN’,

CNS2

CNB3

CND1

CN02

CND3

CND41SR=

-----

m

(1..!

SMEM MODULE

m

1

l—

mMG

<;;;;.

im

AXIS CONTROL MODULE

JANCD-

FC30f3B

No 1

‘n

AXIS CONTROL MODULE

JANCD-

FC3CQB

NO 2

‘n!

CN32

‘“31

‘NW

CN32

‘“31

CN30

MODULE

:

TAPE HANDLER

~o

~

-

K’p~

~uc””

L

“Y

TRANSFORMER

POWER

‘,,,,.’:;

TAPE READER

3

-

~1

I

0

~

F

““”

CNzsh=

-~+~

1/0

MODULE

::::

JAN

Fc800

+ CN13 CN5

~ CNI1 ..6

nl~

u~u

1/0

CN12

4

m

-n

‘“14

~N13RD

~N1

2ND AX,

a“

7*

CD-CN3

CN4

MOOUL

CN1 ~

‘N’ D

SERVO UN I

AX:,

SERVO UN I

ERVO UNIT

~N1 1S’

AXIS

SERVO UN I

~N1

6TH AXIS

SERVO uNIT

~N1

5TH AX I

SERVO UNIT

~N1

4TH AX I

2ND SPINDLE

DRIVE UNIT

q~-p~.

b

CN2

CN2

CN2

CN2

CN2

b

MACHINE CONTROL STATION

MANUAL PG ]

+

. . . . . ----- ------- ,

48 IN POINTS

16 IN. 32 OUT POINTS

‘N”

HIGH VOLTAGE UNIT

24 IN, 16 OUT POINTS

40 IN POINTS

40 IN POINTS

32 OUT POINTS

40 OUT POINTS

8 IN, 8 OUT POINTS

DIRECT lN /OUT

.— .—

=

MOTOR 2

m

m

=

m

*4

~

.—

ND

2ND

SMP&N7DOL;

SP;:DLE

POWER MODULE

JAN CD- ‘N04

CNP

CPS16

CNOI

Jill

—

Fig. 1.6

EXT POWER

_L

ESP

ON

,

CN03

‘“02 ‘“05

.—

Interconnection Diagram [Y AS NAC-i80L for Multi-Axis Lathe)

“

NCM

k;

SVM

200 VAC

7

1.1 COMPONENTS AND INTERCONNECTIONS (Cent’d)

.N

PU MODULE

— .

IZNC-IRK58

BACK BOARD

JAN CD-

FC052

c“”

c“” -

1

CNG3

c“’,bm

~~~ =~

CNS4

‘7

APM2 MODULE

m

APM1 MODULE

GIF MODULE

JAN CD.

F C420

/u

ACP MODULE

NIF

~-----

, COMU MODULE

1

CN43

MODULE

-- . . . . . . . . . . .,

-

I

1

~

&

VIDEO, KEY,

C

~g

~

1

CRT PANEL

En-=7

;

PDN/POFF

2,,,,.2 &v

APE READER

‘

T

y$S”*;N

.— .

FC903;!:’

l/O MODULE

-o

.F:::~~:*xT”Ts

c~~:ua::::::

+ c.,, CN2

JAN CD-

,

I

1

[

I

FC800

fl cN13 cN5

!IB

uu~

. . . . . ..__ ----

8 IN, 8 OUT POINTS

CN3

cN4

, 40 IN POINTS

‘i”d’ca’eso”’’”n’

.“!N_u.:L. -pa.....,

HIGH vOLTAGE UNIT

I

I

—

40 OUT POINTS

24 IN, 18 OUT POINTS

40 IN POINTS

32 OUT POINTS

DIRECT lN /OUT

.—

.—

MMON MODULE

CNA4

CN82

Im

Ifi

CNB3

CND1

lb

I I

CND4

~r

CN27

JANCD-

“*WB CN26

JAN CD-

$$;:;-

a~

AXIS CONTROL

N02

NDLE CONTROL MODULE

SPI

-+

~

&

MG MODULE

c“~o+

‘

,MODULE

—

—

----1’--”-

,

------u

—

r

.:1’ !7:

SERVO UNIT

~N1

4TH AXIS

%

-1,

~

.

I ,

!!1s

CN2

CN2

EXT POWER

.

I

m

m

I

-asp’BgLE

vAC

Fig. 1.7

8

Interconnection Diagram [Y AS NAC-i80L for Multi-Axis Lathe with

ACGC]

UK

—-

I

YANEL

fl-

1 ;

- -‘7

,.dicaIe30ui0nal,.”.

CPU MODULE

-—

JZNC-

BACK BOARD

ANCDm

CNS<

r

CNS~

CNS:

CNS

CNS1

CNA1

CNA2

CNA3

CNLBI

CNLB2

CND1

—-

-------

COMU ~DULE , ,

II

;:!::- ]

FILE MODULE

I

t JANCD-

II

Cf-,

., ,-

‘3MEKM-06U~E

m

——-.

1

!-.

I

1

- -

Hi

PLC MODULE

m.

L

1.

:

I

II

‘1

I

l!

TAPE

?AN?LE?

TRANSFORMER

TAPE READER

;2

----

CN’”UI.I

:==;~r:?

I/o

MODULE

-D

CN14

cN2

u

F!-:!+;;’F;;Ts

CN12

b

L

+

—

nmu

CN1

CN14

CN2

CN3

JANCD-

FC800

cN4

CN13 CN5 , IN 40 mlNTS

l-la

,

1

IN 48 POINTS

HIGH VOLTAGE UNIT

~

OUT 40 POINTS

r-—-—

IN 8 POINTS, OUT 8 POINTS

IN 24

WINTS,

OUT 16 POINTS

OUT 40 POINTS

IN 8 POINTS OUT 8 POINTS

IN 24 POINTS OUT 16 POINTS

IN 40 POINTS

OUT 32 POINTS

DIRECT

L. —._

IWOUT

1

—.

CND2

CND?

CND4

CNP

D:’

AXIS CONTROL

..-.

POWER MODULE

CPS12

CM,) CN02 CNK

a:,

CN03

CNM

Fig. 1.8 Interconnection Diagram [Y AS NAC-i80LB for Lathe]

i

EXT POWER

~

AON

NCM

37

\

~

VAC

9

1.1 COMPONENTS AND INTERCONNECTIONS (Cent’d)

CPU MODULE

~-—

\CK

BOARD

-

cNS4

CNS3

CNS2

CNS1

CNAi

CNA2

CNA3

CNLB1

COMU MODULE

n

FILE MODULE

‘sfiE-MfiO-D~L=

m

SMON MODULE

-

B,+

PLC MODULE

m

INTEXB MODULE

CRT PANEL

-

_J

I

I

1

I

I

I

I

=q

~“dcN=

l-_p-~:NL

TAPE

ANDLER

‘

TRANSFORMER

z~,~. ~;~

TAPE READER

%

~dcN13

L

POWER

.—

.

&l

CN24 ~~N48POl~T~

CN25BII

In

MOD~LE HIGH VOLTAGE UNIT

~A&D-

cN3

CN4

CN5

CN13

CN1l

CN6

u!~

1/0

MODULE

E

ms::::fl:uT,.NTs

cN56~IN4DPOINTS

UMD

~“”-~indicateswtio.al.

i

I

0uT32p0’NTs

I

I

~lNTS,

OUT 16 POINTS

~lNTS

lN/OUT

.—.

‘---

-—

—

IN 16 POINTS, OUT 32 POINTS

IN 24

IN 40

IN 40 POINTS

OUT 32 POINTS

DIRECT

—

CNLB2

CND1

CNM

CND:

CND~

.-.

CNI

-

=

MOTION MODULE

JANCD-

FC=

mug

JANCD-

FC-

No

I--*

I

POWER MODULE

I CPS12

CNOt CN02 CNW

a!

CN27

CN26

CN35

CN24

AXIS CONTROL

MODULE

CN32

CN31

CNm

1

CN03

CNW

‘r

I

I

EX7

POWER

NCM

3

L

~\

A9

~ VAC

Fig. 1.9 Interconnection Diagram [Y AS NAC-i80MB for Machining Center]

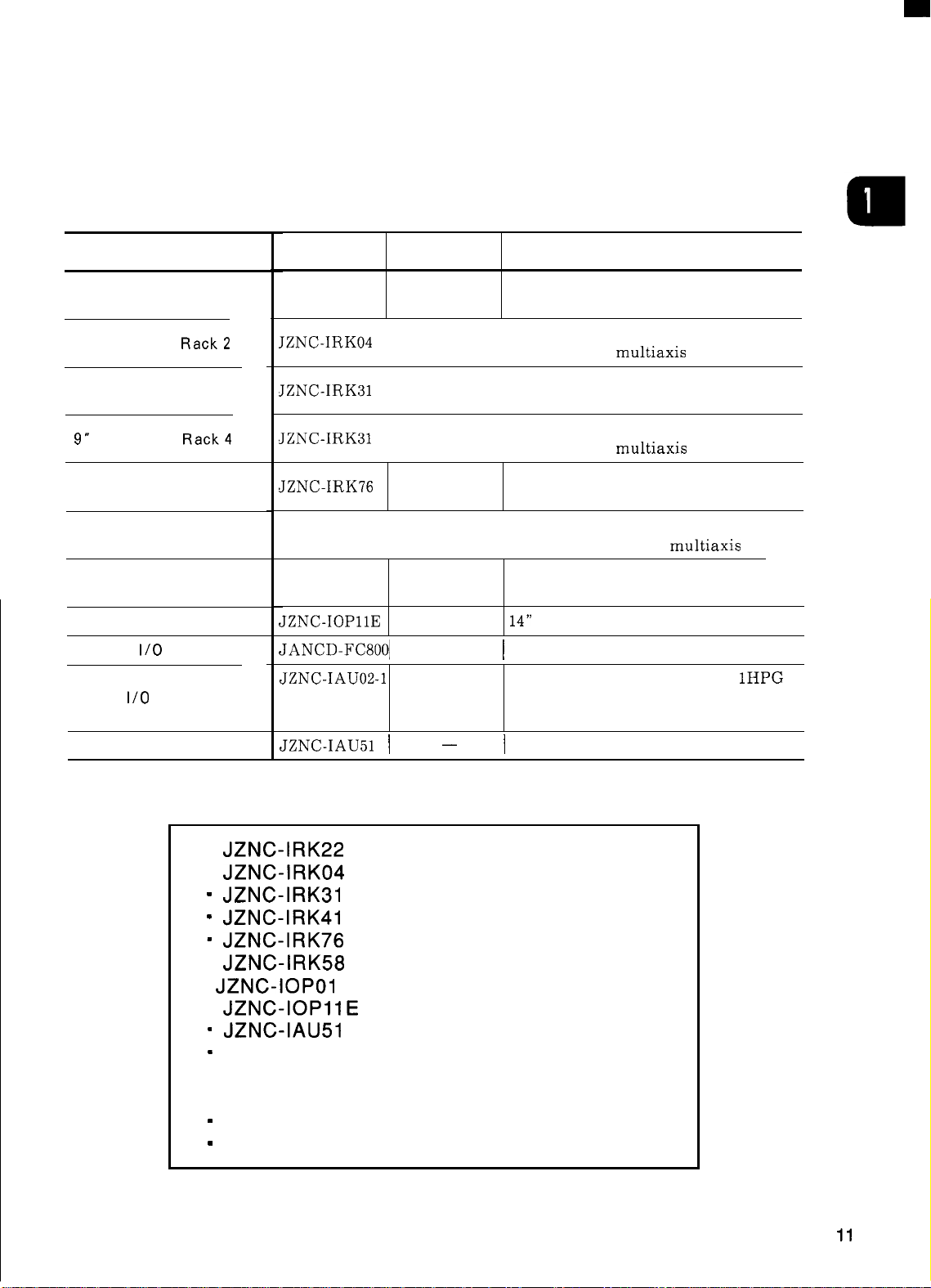

1.2 COMPONENTS

(1) NC Major Components

Component Name

9“ AMGC NC Rack 1

9“ AMGC NC

9“ AMGC NC Rack3

9“ AMGC NC

14” ACGC NC Rack 1

14” ACGC NC Rack 2

9“ AMGC Control Panel

14” ACGC Control Panel

Remote

Panel

Tape Reader Unit

1/0 Unit

Rack2

Rack4

1/0 Module

Table 1.1

Model Supply Code

JZNC-IRK22

JZNC-IRK04

JZNC-IRK31

JZNC-IRK31

JZNC-IRK76

JZNC-IRK58

JZNC-IOPOIE

JZNC-IOP1lE

JANCD-FC8001

JZNC-IAU02-1

JZNC-IAU02-2

JZNC-IAU02-3

JZNC-IAU51 I

NC Major Components

I

I

I

I

DUN20280

DUN2031O

DTN8150

DUN20820

DUN20830

DUN20840

—

—

—

Remarks

Feed control: 3 axes; spindle control: 1

axis; standard rack

Feed control: 6 axes; spindle control: 2

axes; rack for

Feed control: 3 axes; spindle control: 1

axis; standard rack

Feed control: 5 axes; spindle control: 2

axes; rack for

Feed control: 3 axes; spindle control: 1

axis; rack for ACGC

Feed control: 6 axes; spindle control: 2

axes; rack for ACGC

9“ black-and-white CRT. lHPG panel

with 1/0

14”

color CRT, without panel 1/0

I

112-point input, 96-point source output

Separated-type panel 1/0 unit,

Separated-type panel 1/0 unit, 2HPG

Separated-type panel 1/0 unit, 3HPG

I

200VAC input RS-232C tape reader unit

multiaxis

multiaxis

multiaxis

lHPG

■

JZNC-IRK22

■

JZNC-IRK04

“

JZNC-IRK31

“

JZNC-IRK41

= JZNC-IRK76

■

JZNC-IRK58

■ JZNC-IOPO1 E

■

JZNC-IOPIIE

“

JZNC-IAU51

=

Option Modules

● YASNAC i80 digital — Go to (12).

Module —

Module — Go to (3).

Module —

Module —

Module — Go to (6).

Module —

Module — Go to (8).

Module — Go to (9).

Module —

— Go to (11).

Go to (2).

Go to (4).

Go to (5).

Go to (7).

Go to (10).

AC servo drive unit

I

Spindle drive unit

“

Maintenance unit — Go to (14).

— Go to (13).

11

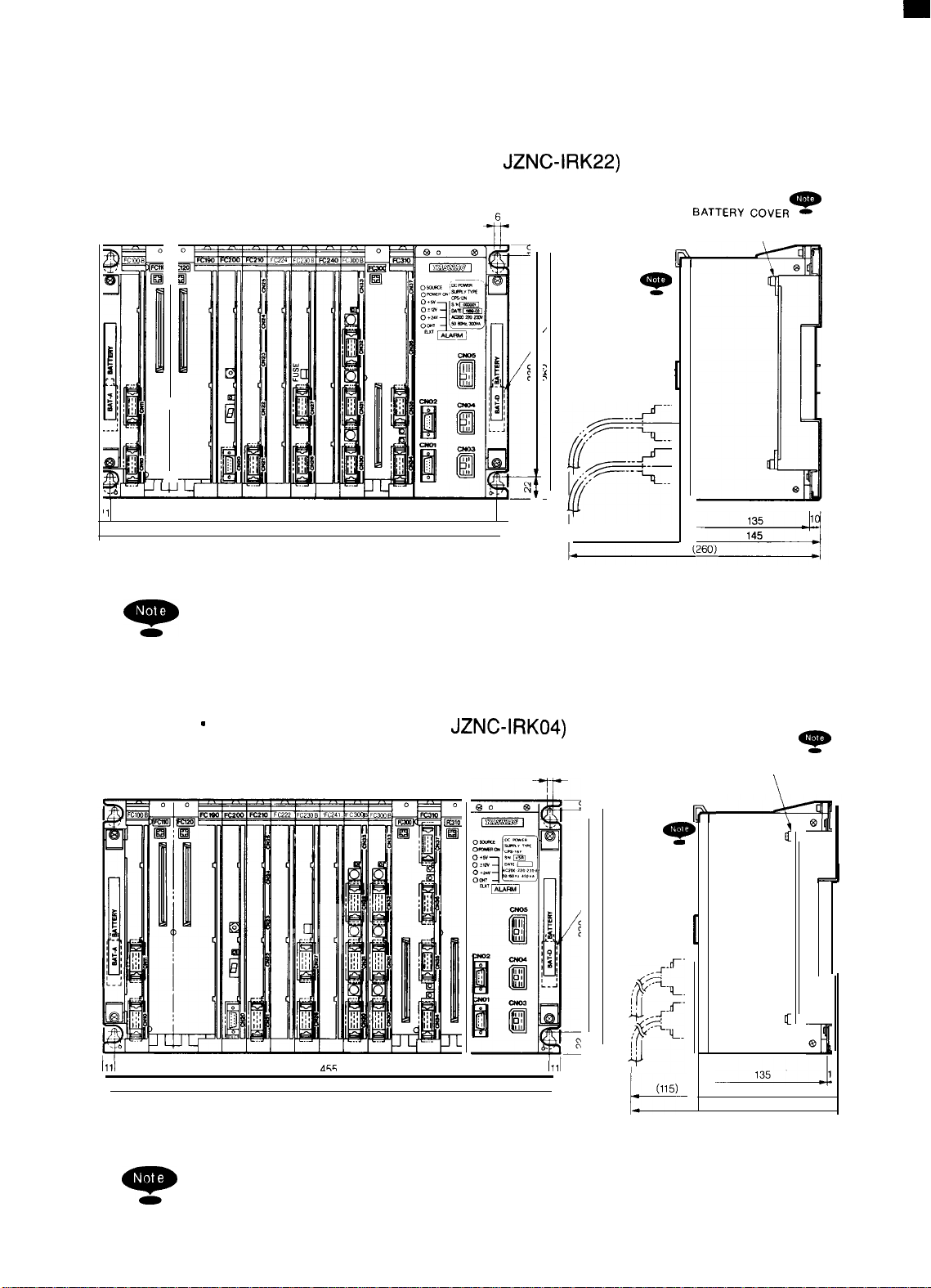

1.2 COMPONENTS (Cent’d)

‘1

● 9“ AMGC Standard Rack (Model

JZNC-IRK22)

~ATTERy

~ovER*

\

*

BATTERY FOR

BACKUP

404

426

9-

q

When replacing the battery for backup, remove the battery cover.

(one at each side)

11

(115)

L

Approx. mass :7.5 kg

II

1111

9

9“

AMGC Multiaxis (Model JZNC-IRK04)

6

q

BATTERY FO

BACKUP

A&c.

1111

(115)

k

a-

q

When replacing the battery for backup, remove the battery cover.

(one at each side)

BATTERY COVER

4

(260)

Approx. mass :8.0 kg

*

\

145

12

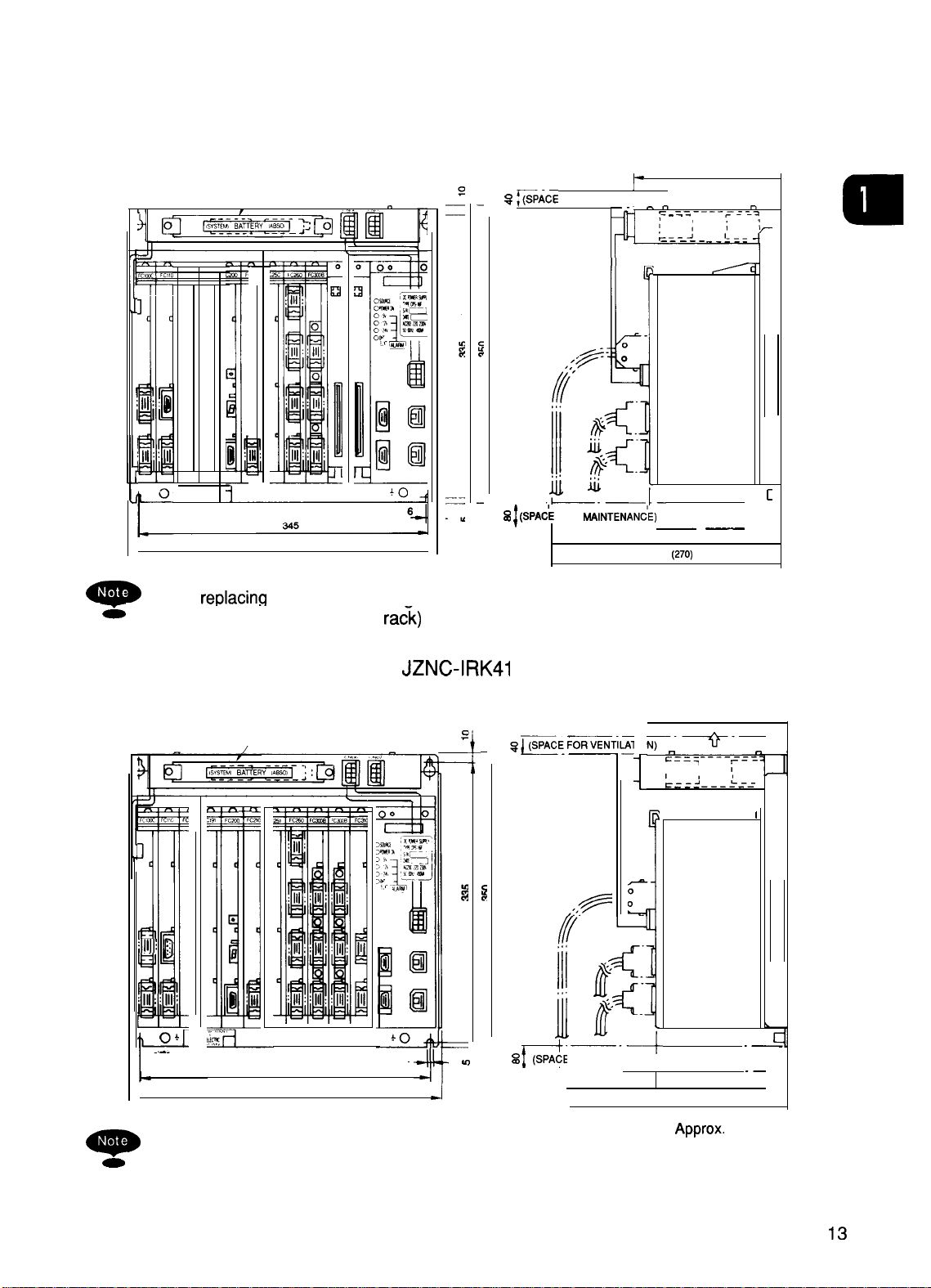

■ 9“ AMGC

BATTERY COVER

Standard

1111

370

When

-

-

(two on the ra&)

replacina

the battery for backup, remove the battery cover.

Rack (Model JZNC-IRK31 )

S SPACE FOR VENTILATION) “‘~”

% ~ (SPA~E

-

FOR WINTENAN;E)

—. — .—

(SPACE FOR CABLES)

(113)

174

P

~

. - = - — --_=_--_=

.-

—--—J-- ._!=.

—

—

“157.3

(270)

Approx. mass :12

_

[

—

,

,

kg

■

9“

AMGC Multiaxis (Model JZNC-IRK41 )

1

:111: j

;111::111’

i

—

0+

. . . .

r

,

_

When replacing the battery for backup, remove the battery cover.

=

(two on the rack)

BATTERY COVER

—

345

370

174

:

●

6

In

J

s

(SPACE FOR MAINTENANCE)

Y“

7-

—-+

.—

(113)

(SPACE FOR CABLES)

~.—~.._

~==i

1 ,

1,,

-----~ ----~--—-

r

(270)

‘Ppr”x”

_------c

:--

157.3

‘ass:’2 ‘g

.

I

o

c

.—

.—

1.2 COMPONENTS (Cent’d)

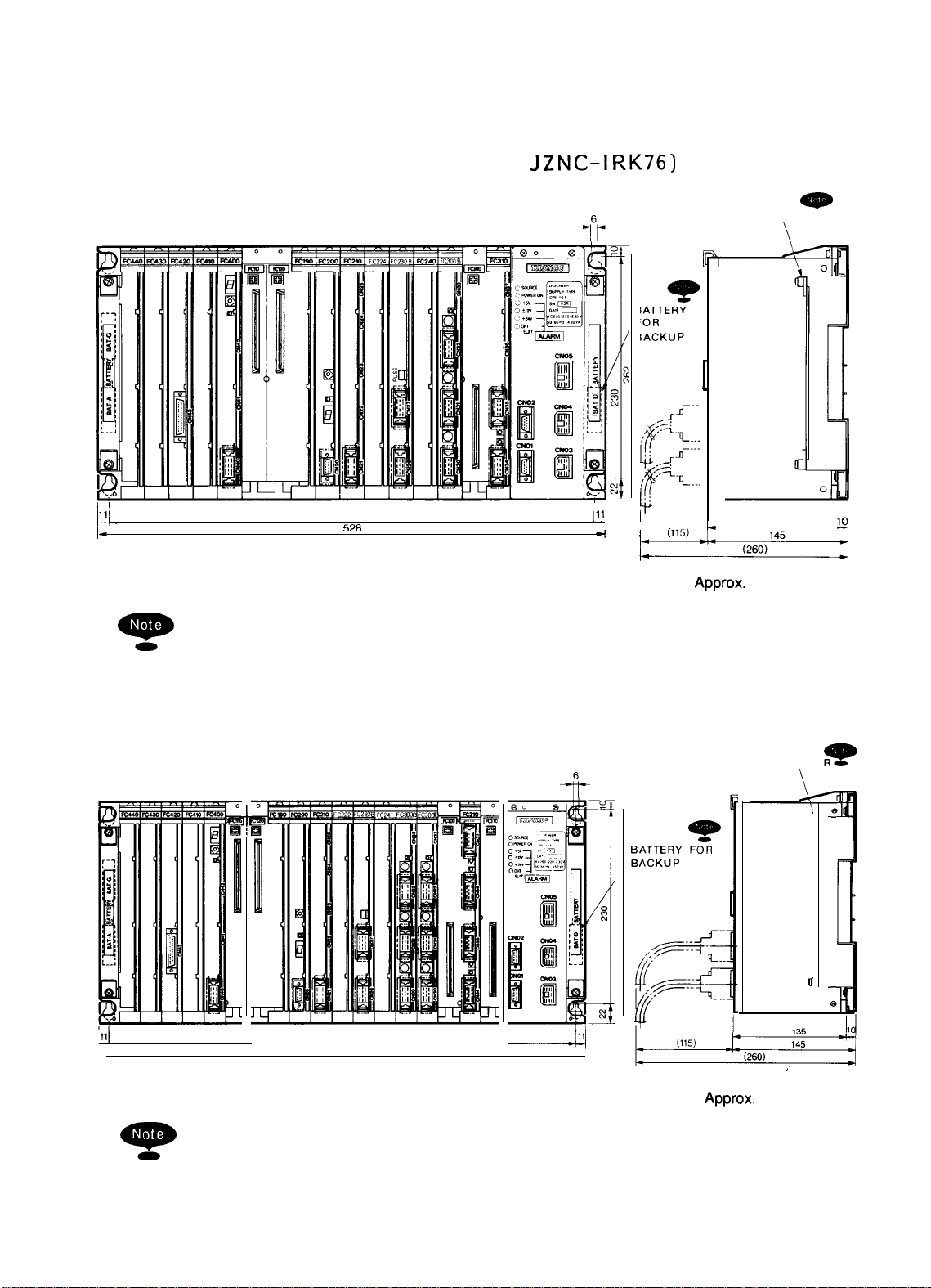

●

Rack for 14” ACGC (Model

JZNC-IRK76)

BATTERY COVER

-

\

-

Ill

1

,,-

1-

1’

506

69R

---

@-

q

When replacing the battery for backup, remove the battery cover.

(two at the left side and one at the right side)

● Rack for 14” ACGC (Model JZNC-IRK58)

Ill

‘1

I

4

~

k

,.

(115)

.-.

h

1=

Approx.

135

145

mass :9.0 kg

BATTERY COVER

II

1(

9

+

Q

14

u

Ill

Approx.

mass :10 kg

D.

~

When replacing the battery for backup, remove the battery cover.

(two at the left side and one at the right side)

●

_

>

z

w

CtJ

3

m

CN12

(FC9006

4

●

●

II

PA)KING

(ENTIRE CIRCUMFERENCE)

2470 R LESS

REAR VIEW

2

230 OR LESS

i

more.

equiva-

Approx. mass :5.5 kg

u

Japan Painting Institution Color number No. 1034

Japan Etching Co., Ltd. Satin finish No. 7

lent leather-tone painting

1. Panel surface finish:

~

Bot

Connector

material is 8 mm or more

Notch the slash portion with a depth of 8 mm or

2. When the thickness of the operation panel mounting

ml

—

c---

MR-20

CN12

CN21

Number

FC900B

Name

Boerd

JANCD

MR-20

MR-20

MR-50

CN23

CN24

CN22

MR-50

MR-

17SE

CN25

CN26

CN27

FC903

JANCD

PANEL

o

17

CN2817CN29

No cable connector is supplied. User must provide an

equivalent connector.

*

170

170

170

5

—

MOUNTING SIDE

I

—

FRONT VIEW 8-64’

--,

~-

,6

L...-..+d

‘B

n

170 170

170

!

OPERATi~N

TAP

;-M3

Operation Panel Mounting Hole Processing Diagram

1.2 COMPONENTS (Cent’d)

● 14” ACGC Operation Panel (Model

JZNC-IOP1l

E)

,

v

d

16

—

.

1-

2

0

a

L

—

—

u

CN1l

1/0

CN12

SHORT PLuG FOR

SW1,

SW2, AND SW3

IMSA-9202H–G

..i

. . . . . . . . . . .

.

..icih.ii:ti;--

. . .

. . .

. . ..

JAN

..j

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..e...

CD-FC800)

..i

. . . . . . . . . . .

. .

..i.4

a

IO-ADDRESS

i~~~”

. . .

5

..swp

y ::

u

SW)

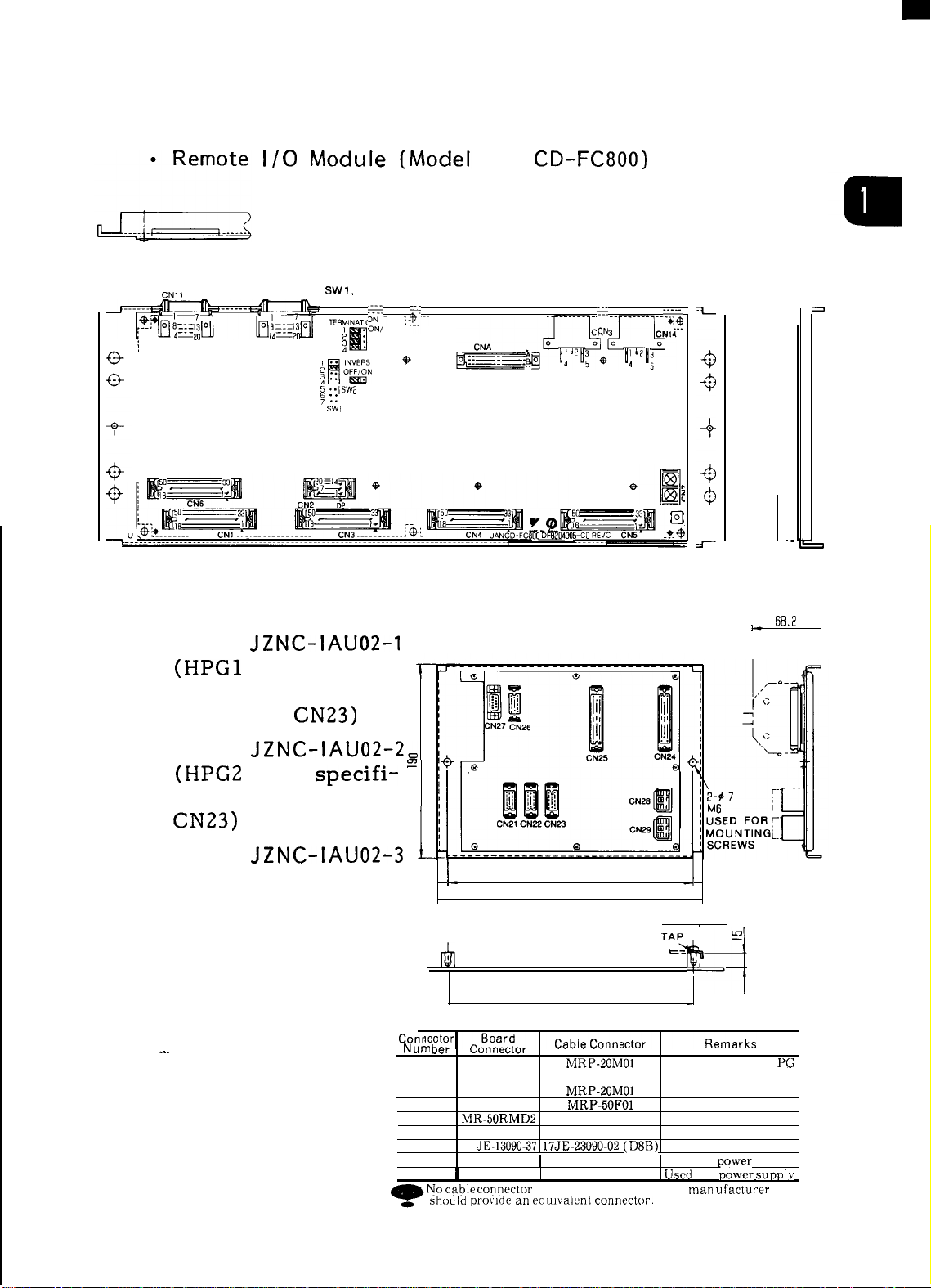

● Panel [/0 Unit

Model

(HPG1

JZNC-IAU02-1

axis specifi-

cations. Without

CN22 and

Model

(HPG2

axis

CN23)

JZNC-IAU02-2=

specifi- =

cations. Without

CN23)

?W

+

‘

*qG--G’

0 45

45

*

.

.

a

6Ei,2

1-

(Not include’

cable height)

I

Model

JZNC-IAU02-3

(HPG3 axis specifi-

cations)

-.

q.

1

L

Mounting Board

Processing Diagram ‘6 ‘AC

—

Conr

Nurr, vcr

CN21

CN22

CN23

CN24

CN25

CN26 M R-20RMD2

CN27

CN28

CN29

~utlile~lur

MR-20RFD2 MRP-20M01 Used for HANDLE

MR-20RFD2

MR-20RFD2

MR-50RMD2 MRP-50F01

MR-50RMD2 MRP-50F01

JE-13090-37

17

172037-1

172037-1

I

I No c~ble

connectnr is supplied, The machine man L] facturer

should

prov]de

240

260

240

MRP-20M01

MRP-20M01

MRP-20F01 Used for remote 1/0

17JE-23090-02 (D8B)

172026-1I Used for

I

172026-1

an cqulvalcnt connector.

-1

#12

t==.

Used for HANDLE PG

Used for HANDLE PG

Used for panel 1/0

Used for panel 1/0

Used for panel RS-232C

I Used

z

f

a+

po~ver

for po,,,cr

supply

suprIlv

PG

17

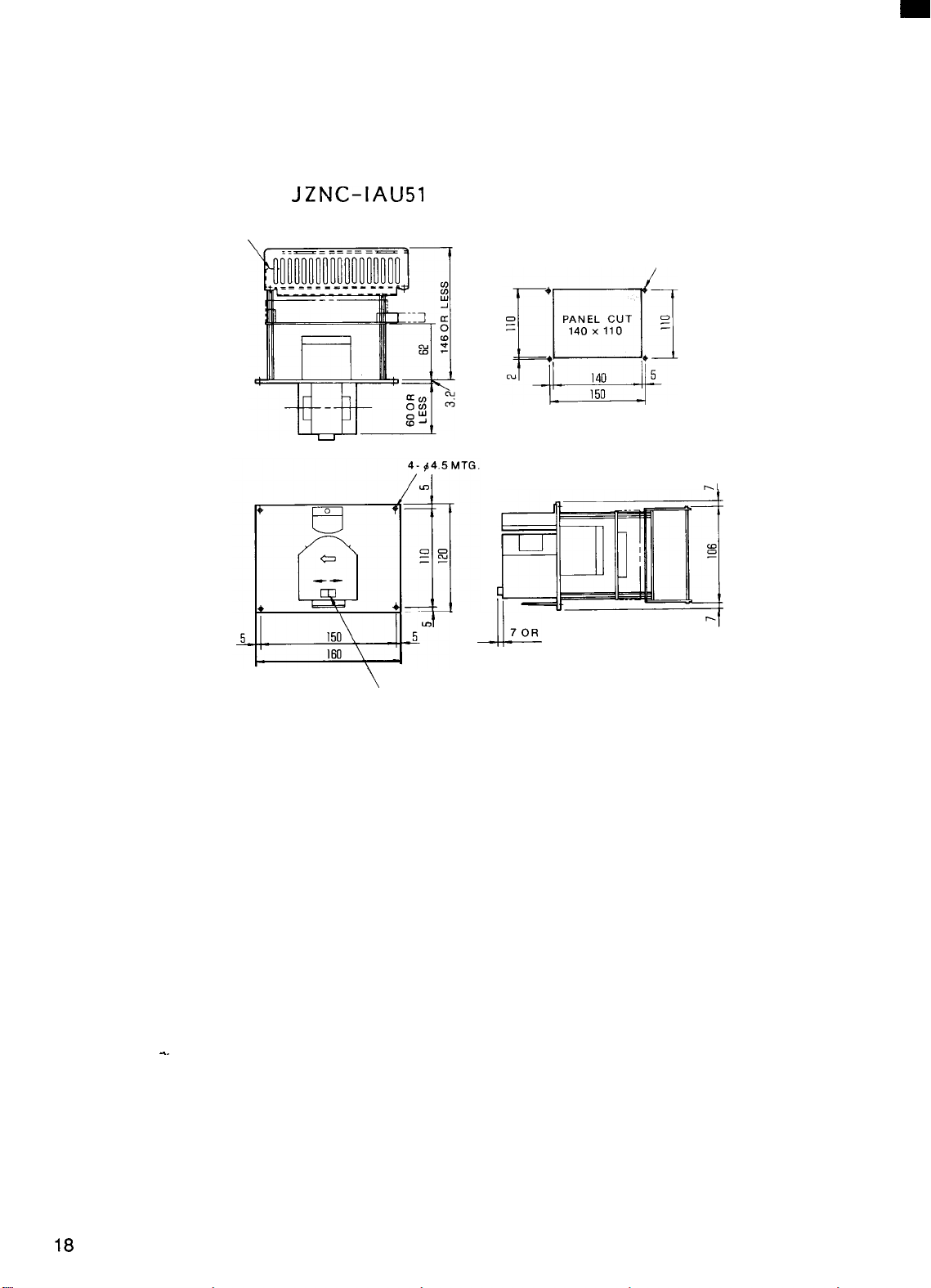

1.2 COMPONENTS (Cent’d)

● Tape Reader Unit (Power Built-in Type)

(Model

POWER TERMINAL

BLOCK

JZNC-IAU51

)

4- M4 TAP

Mounting Hole Processing Diagram

HOLE

r.

-..

\

/

MANUAL FEED

7 OR LESS

-.u--

SWITCH

‘--1

PAINT : SILVER METALLIC PAINT

DIMENSIONS IN

mm

(2) JZNC-IRK22

Module

Table 1.2

Model

CPS-12N

JAN

CD-FCOOI DTN701O

JAN CD-F C1OOC

JAN CD-

JAN CD- FC200 DTN6470

JAN CD-FC21O-1

JAN CD-FC224I DTN9450

JAN

JANCD-FC230B I DTN8490

JAN CD-FC242I DTN1026O I MG

JAN

JANCD-FC31O-1 I DTN6720 I AX2

FC190-1

CD-FC221

CD-

FC300B-31

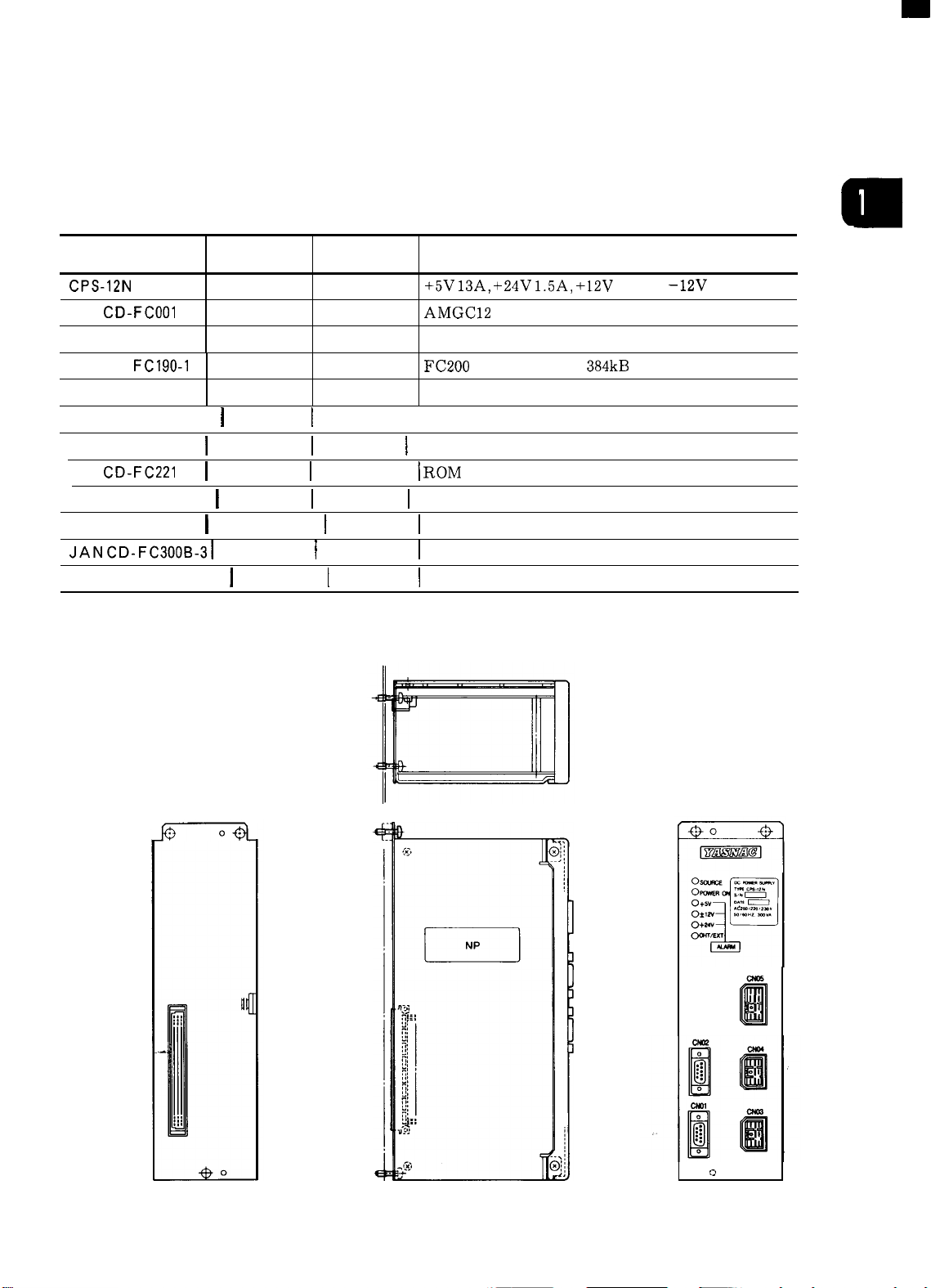

● Model CPS-12N

Supply Code Abbreviation Remarks

AVR0842

DTN9770

DTN7020

I

DTN6850

I

DTN801O

DTN8570

CPS

BB1

HIF

SMEM

SMON

I

PLC

I

INTEX3 \ NC program analysis

I

ROMS

I

MMON I Motion management

\

AX1

JZNC-IRK22 Module

+5V

13A, +24V

AMGC12 slot back board

9“ monochrome CRT/keyboard interface

FC200

memory RAM

System management

1.5A,

+12V

1.3A, –12V 0.3A

384kB

I Sequence controller, without RS-232C

I ROM

board (two boards for model FC224 are used)

I

Data distribution

I

Feed control: 3 axes

I

Spindle control: 1 axis

II

.

a

:>

.

I

Approx. mass :1.52

kg

19

.

I

--.---------.------ -------

~)----

)-

-----

WI

--_ fi___--n..___

om ~o+amvr

A

-__n__n.

c

___________ ~=.

● Model

JAN

CD-FC190-1

a

Approx. mass :0.32 kg

● Model

CD-FC200

JAN

Approx. mass :0.3 kg

be-----------_____

[_-------_ ---_ -__--.[

21

1.2 COMPONENTS (Cent’d)

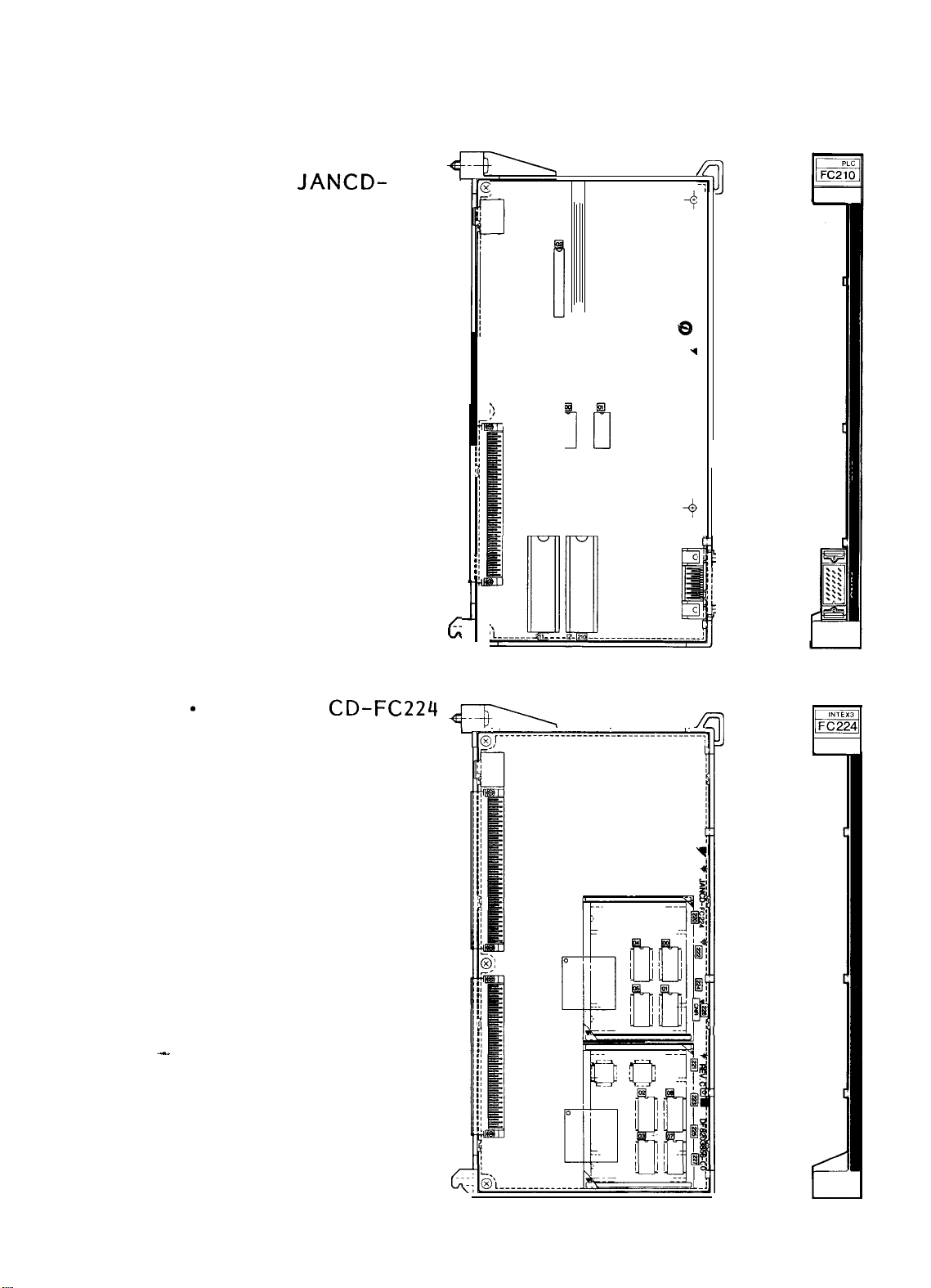

● Sequence Controller

(Model

FC21O-1)

JANCD-

),r-----------------------------------

]

4

.-.

Approx. mass :0.28 kg

Model JAN

(NC program

analysis)

CD-FC224

.

.

‘L

6

-— —...- 2,

----z

L

~@

JL..---.__--!-------_ -._----------! --;

-.--- ——— — — _________

1

m

22

Approx. mass : 0.42kg

● ROM Board (Model --

JANCD-FC221 )

5

(

,,

J

-FC221

● Model

FC230B

Approx.

mass :0.07

JANCD-

kg

+

01

,,

0,

@

Approx. mass :0.28 kg

G

23

1.2 COMPONENTS (Cent’d)

● Model JANCD-FC242

Approx. mass :0.26 kg

.- ———-—

—- —-

.

Y L------------------------------------

<

——.. ——. _—--— —----

/

● Model JANCD-FC300B-

3 (Feed control:

+

3 axes)

1

24

Approx. mass :0.34

@

kg -;

● Model JAN CD- FC31O-1 (Spindle control: 1 axis)

4

.___. .--. _.-_ - . . ..__ —---.

—~q

--. .. —.

-—- ,

FC31 O

R

,x,

a

Approx. mass :0.24 kg

L

25

1.2 COMPONENTS (Cent’d)

(3) JZNC-IRK04

Model

CPS-16F

JAN

CD-FCO02I

JAN CD-F C1OOC

JAN CD-F

JAN CD-FC200

JAN CD-F C21O-1

JAN

JAN

JAN CD-F C230B

JAN CD-FC241

JANCD-FC300B-31 I) TN8570

C190-1

CD-FC222

CD-FC221

JANCD-FC31O-2

Supply Code

AVR843 CPS

DTN8070 I

DTN9770

DTN7020

DTN6470

DTN6850

I

DTN8110 I

DTN801O

DTN8490

DTN8520 MG2

DTN6730

I

Module

Table 1.3

Abbreviation

BB2

HIF

SMEM

SMON

PLC

INTEX2 \ NC program analysis

ROMS

MMON Motion management

I

AX1

AX2

JZNC-IRK04 Module

+5V 21A, +24V 1.5A, +12V 1.3A, –12V 0.3A

I

AMGC,4

slot back

board

9” monochrome CRT/keyboard interface

FC200

memory RAM

System management

Sequence controller, without

ROM board (two boards for model FC222 are used)

Data distribution

I

Feed control: 3 axes

Spindle control: 2 axes

Remarks

384kB

RS-232C

“

Model CPS-16F

4

●

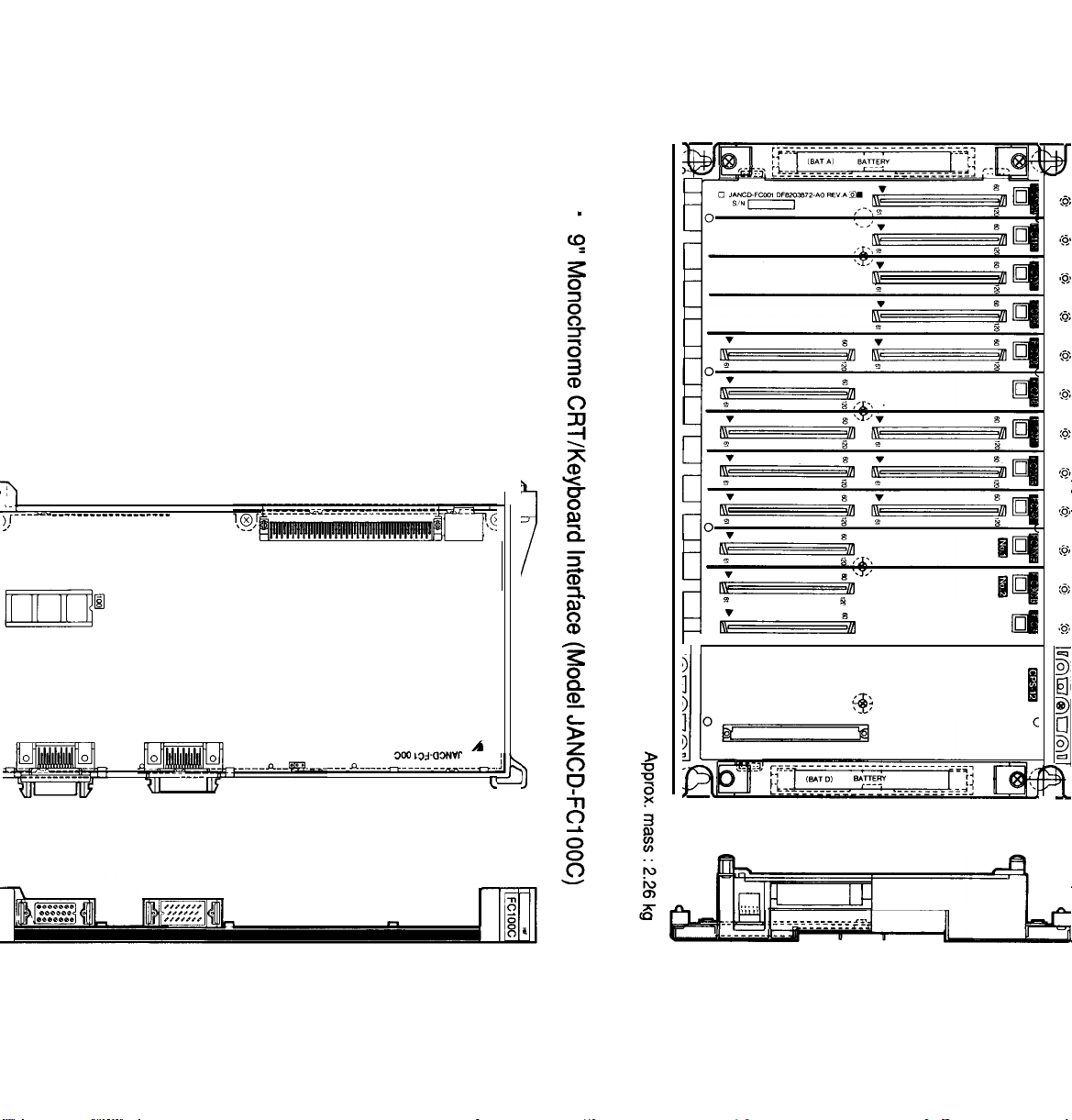

AMGC14

Slot Back Board (Model JAN

w

!9

I

1

CD-FCO02)

Approx. mass :2.26 kg

● JANCD-FC1OOC

●

JANCD-FC190-1

●

I

JANCD-FC200

● JANCD-FC21O-1

* JANCD-FC221

● JANCD-FC230B

●

JANCD-FC300B-3

I

For the models description shown above, see Table 1.2,

and for the model JANCD-FC222, see Table 1.11.

27

1.2

COMPONENTS (Cent’d)

c

Model JAN CD-FC31O-2 (Spindle control:

2 axes)

Approx.

mass :0.2 kg

● Model JAN

CD-FC241

I

FC241

n

2

28

Approx. mass: 0.28

kg

(4)

JZNC-IRK31 Module

Model

CPS-12N

JAN CD-

JAN CD-F C1OOC

JAN CD-

JAN CD-

JAN CD- FC21O-1

JAN CD- FC250

JAN CD-F

JAN CD-F

FCO06

FC191-1 I

FC200

C260-1

C300B-3

■ Model

Table 1.4

I

Supply Code lAbbt-eviation

AVR0842 CPS

DTN1023O

DTN9770

DTN1OO3O I SMEM2 ]

DTN6470

DTN6850

DTN1018O

DTN102OO

DTN8570

BB3 AMGC1l slot back board

HIF

SMON System management

PLC System controller, without RS-232C

INTEXB

MOTION

AX1 Feed control: 3 axes

JZNC-IRK31 Module

JANCD-FCO06

I

+5V 13A, +24V 1.5A, +12V 1.3A, –12V 0.3A

Remarks

9“ monochrome CRT/keyboard interface

FC200

memory RAM

NC program analysis

Motion management, data distribution, spindle

control: 1 axis

384kB

Approx.

mass :4.93 kg

. .

●

JANCD-FC1OOC

“

JANCD-FC300B-3

o

II

&

II

II

------ _________ ______________

@+ o

“

JANCD-FC200

0

II II

For the models description

0

II II II

II

“ JANCD-FC21O-1

shown above,

1

1]

rfiwfiu@

+0

see

Table 1.2.

0

+

1.2 COMPONENTS (Cent’d)

■ Model JANCD-FC191-I _

+-+>

@,r---––-–––––

———— —————— —————- .

1:

II

3

—-————

II

II

II

01

FC191

,E

Approx. mass :0.25 kg

.

Model JANCD-FC250

Onmaaaummm

On

I

H

I

FC250

Approx. mass :0.27 kg

I

“

Model JANCD-FC260-I

Ha

Approx.

mass :0.34 kg

1

1.2 COMPONENTS (Cent’d)

(5) JZNC-IRK41

Type

CPS-12N

JAN CDJAN CD- FC1OOC

JAN CD-F

JAN CD- FC200

JAN CD-F C21O-1

JAN CD- FC250

JAN CD-F

JAN CDJAN CD-F C31O-I

FCO06

C191-1

C260-1

FC300B-:

Supply

code

AVR0842

DTN1023O

DTN9770

DTN1OO3O

DTN6470

DTN6850

DTN1018O

DTN102OO

DTN8570

DTN6730

Module

Table 1.5

~bbreviation

CPS

BB3

HIF

SMEM2

SMON

PLC

INTEXB

MOTION

AX1 Feed control: 3 axes

AX2

JZNC-IRK41 Module

+5V 13A, +24V 1.5A, +12V 1.3A, –12V 0.3A

AMGC1l slot back board

9“ monochrome CRT/keyboard interface

FC200

memory RAM384kB

System management

Sequence controller, without RS-232C

NC program analysis

Motion management, data distribution, spindle

control: 1 axis

Spindle control: 3 axes

Remarks

●

JANCD-FC1OOC

“ JANCD-FC300B-3

“

JANCD-FC200

“ JANCD-FC31O-1

“ JANCD-FC21O-1

For the models description shown above, see Table 1.2.

“ JANCD-FCO06

● JANCD-FC260

“ JANCD-FC191-1

“ JANCD-FC250

For the models description shown above, see Table 1.4.

■ Model JANCD-FC251

Approx.

mass :0.27 kg

+

~,L -----------

~._————_

,1

,;

I

,1

,1

,1

,1

,[

II

II

II

,1

,1

,1

II

,1

,1

II

,1

,1

,1

,1

,1

I

;1

,1

II

II

II

I_\’ _____________

@L__________________-F

___

———-

__T

0

3

q

00 I

00 I

a

~

I

1/

I%t

:

l:’

I’?j

10,

I&l

II

\l

,1

II

,

1.

‘1

1,

,1

//

t;

an

lo!

10

3D:

3Q;

____. )

FC251

B

I

a

I

■ Model

JANCD-FC265

This figure shows

model JANCD-FC265

attached to model

JANCD-FC260.

_

—-— —---—- --- --— ---

.. —---— —- —----- ---

II

II

II

II

11

II II

I ill

FC265

D

!

8

I

I

Approx. mass :0.11

kg

(only JANCD-FC265 board)

33

1.2 COMPONENTS (Cent’d)

(6) JZNC-IRK76

Model

CPS-16F

JAN

CD-FC050

JAN CD-F

JAN CD-FC200

JAN CD- FC21O-1

JAN CD-FC224

JAN CD- FC221

JAN CD-F

JAN CD-FC240

JAN CD-F

JAN CD- FC31O-1

JANCD-FC400

JANCD-FC41O

C190-1

C230B

C300B-3

;upply

Code

AVR843

DTN8030

DTN7020

DTN6470

DTN6850

DTN9450

DTN801O

DTN8490

DTN6530

DTN8570

DTN6720

DTN7090

DTN7080

Module

Table 1.6

Abbreviation Remarks

CPS

ABB1

SMEM

SMON System management

PLC Sequence controller, without

INTEX3 NC program analysis

ROMS ROM board (two boards for model FC224 are used)

MMON Motion management

MG Data distribution

AX1 Feed control: 3 axes

AX2

NIF

ACP

JZNC-IRK76

+5V 21A, +24V 1.5A, +12V 1.3A, –12V 0.3A

ACGC16 slot back board

FC200

Spindle control: 1 axis

ACGC-NC interface module

I

ACGC main module

Module

memory RAM

384kB

RS-232C

JAN

CD-FC221

JANCD-FC420

JAN CD-FC430

JAN CD-FC440

DTN801O

DTN8040

DTN7060

DTN7070

ROMS ROM board (two pieces for FC41O are used)

GIF

APM1 ACGC application memory module

APM2 ACGC application memory module

ACGC graphic control module

:

. . .

rl

~=

2

11-

v

B’

-’;:.’

-“”

$

% r’-’>

JANCD Fc050

[

‘

•1

•1

!

q

1.2 COMPONENTS (Cent’d)

●

ACGC-NC

module (Model

CD-FC400)

JAN

Interface

Approx. mass :0.28 kg

9

ACGC Main

(Model JANCDFC41O)

Modul

e

36

Approx. mass :0.46 kg

● ROM Board (Model

JANCD-FC221 )

~

JANCD-FC22)

●

ACGC

(Model

FC420)

. .

Approx. mass :0.07 kg

Graphic Control Module

JANCD-

4

f

Approx. mass :0.28 kg “-

<

37

1.2 COMPONENTS (Cent’d)

● ACGC Application

Memory Module

(Model

JANCD-FC430)

Approx. mass :0.28 kg

+

~JL

-------------- -

. -----

-------------

ODOI

-; @’l------------------------------------

~

,

e.

● ACGC

Memor

(Model

Application

‘y

Module

JANCD-FC44

38

Approx. mass :0.28 kg

(7) JZNC-IRK58 Module

Table 1.7 JZNC-IRK58 Module

Model

CPS-16F

JANCD-FC052

JAN CDJAN

CD-FC200

JANCD-FC21O-1 I

JAN CD-FC222

JAN CD- FC221

JAN CD-

JAN

CD-FC241

JANCD-FC300B-31 I) TN8570 I AX1

JANCD-FC31O-2

FC230B I

JANCD-FC400

JAN CD-FC41O

JANCD-FC221

I Supply

j

AVR843 j CPS

I

FC190-1 I

I

DTN6470

Code

DTN8030

DTN7020

DTN6850 I

DTN8110

I

DTN801O

I

DTN8490 I MMON

I

DTN8520 I MG

DTN6730 AX2

I

DTN7090

I DTN7080 I

I DTN8010 I

lAbbreviation /

ABB2 ACGC18

I

SMEM]

I

SMON I

PLC

INTEX2

ROMS

NIF ACGC-NC interface module

ACP

ROMS

~OM

Remarks

I

+5V 21A,

FC200 memory

System management

I

Sequence controller, without RS-232C

+24V

1.5A,

slot back board

RAM

+12V

384kB

1.3A, -12V 0.3A

NC program analysis

ROM board (two boards for model FC222 are used)

I

Motion management

I

Data distribution

]

Feed control: 3 axes

Spindle control: 2 axes

I

ACGC main module

board (two pieces for

FC410

are used)

a

JANCD-FC420

JAN CD-FC430

JAN CD- FC440

I

I)TN8040 I GIF

DTN7060

I

DTN7070

I

APM1 ACGC application memory module

APM2 ACGC application memory module

I

ACGC graphic control module

1.2 COMPONENTS (Cent’d)

● Model JAN CD-FC052

ml

.

1

Juul

●

JANCD-FC190-1

●

JANCD-FC200

● JANCD-FC21O-1

●

●

L

JUUUI

JANCD-FC221

JANCD-FC230B

●

JANCD-FC300B-3

For the models description shown above, see Table 1.2.

For the models description shown above, see

●

JANCD-FC400

● JANCD-FC41O

●

JANCD-FC221

●

JANCD-FC420

●

JANCD-FC430

●

JANCD-FC440

Table

1.3.

For the models description shown above, see Table 1.6.

(8) JZNC-IOPOI E Module

Table 1.8 JZNC-IOPOIE Module

Model

JAN CD-

JAN

JAN CD-F

MD T948B-3B

D

E9400035

FC900B-1

CD-FC901

C903-1

● PaneI Interface

Supply Code

DTN8500

DTN6670

DTN8080

CRT16

,

SW825

(Model

Abbreviation Remarks

SP

FKEY

PI02

JANCD-FC900B)

4

Panel interface (for CRT)

Function keyboard

Panel 1/0 lHPG

9“ monochrome graphic CRT unit

Keyboard unit

● Panel

(Model

1/0

JANCD-FC903-1

)

Approx. mass :0.2 kg

,—.4

/—. ,

,— -—.

=4

CN,7

.<7,E !-37

+~

Approx.

“@e’

mass :0.3 kg

1.2 COMPONENTS (Cent’d)

(9)

JZNC-IOPI 1 E Module

Model

JAN CD-F

JAN

TX1424AD

DE8412739

C950-1

CD-FC951 DTN8050

I

SW826

● Panel Interface

(Model

Table 1.9

Supply Code Abbreviation

DTN8190

CRT13

ASP

FKEY Function keyboard

]

JZNC-IOP1l

JANCD-FC950-1

E Module

Remarks

Panel interface

14” monochrome graphic CRT unit

I

Keyboard unit

)

r

42

(1 O)

Model

MO DE L2801 B-2

EYG300/55GTL

MOD

EL1500

MOD

EL1402-1

JZNC-IAU51

Table 1.10

Supply Code

RED18

AVR904

RED14

RED13

Approx. mass :0.18 kg

Module

JZNC-IAU51

Abbreviation

RS-232C

I

I

I

I

Composite power for 5/24V tape reader

I

Option

I

Option

Module

Remarks

tape reader

(11

) Option Modules

Table 1.11 Option Modules

Model

JAN

CD-FCIIO

JAN CD-F

JAN CDJAN CDJAN CD-F

JAN CD-F

JAN CD-F

JAN CD-

JAN CDJAN CD-

JAN CD- FC21O-2

JAN

JAN CD-F

JAN CD-F

C120-I

FC120-2

FC120-3

C120-4

C120-5

C190-2

FC191-2

FC191-3

FC191-4

CD-FC222

C245-1

C245-2

JANCD-FC251

JANCD-FC260-2

JANCD-FC265

upply Code Abbreviation

DTN6450

DTN6370

DTN6760

DTN6770

DTN6980

DTN6990

DTN7030

DTN1OO4O

DTN1OO5O

DTN1OO6O

DTN6500

DTN811O

DTN6820

DTN6590

DTN1018O

DTN1024O

DTN1021O

COM

FILE

FILE Expanded RAM

FILE Expanded RAM

FILE Expanded RAM

FILE

SMEM

SMEM2

SMEM2

SMEM2

PLC

INTEX2 NC program analysis (With extended CPU)

FG

FG

INTEXB2

I

MOTION

I

FG2

Remarks

Communication module

Expanded RAM

Expanded RAM

FC200

memory RAM

FC200

memory RAM

FC200 memory RAM 384kB, with printer I/F

FC200 memory RAM 640kB, with printer I/F

Sequence controller 2 CH RS-232C

Interpolation computing element x

Interpolation computing element x 2

NC program analysis (with high-performance

CPU)

Motion management, data distribution, without

spindle control

Interpolation calculator (for FC 260)

64kB

192kB

448kB

960kB

1984kB

(320 m)

(640 m)

(1280 m)

(2560 m)

(5120 m)

512kB

640kB

I

JANCD-FC301-3

JANCD-FC401

JANCD-FC470

JANCD-FC801

JANCD-FC802

JAN CD-

FC803-3

JANCD-FC900B-:

JAN CD-

FC903-2

JANCD-FC903-3

JAN CDJAN CD-

FC950-2

FC950-3

JAN CD- FC950-4

DTN6660

DTN7050

DTN7040

DTN8160

I)

TN8170

DTN8140

DTN8530

DTN8090 PIo2

DTN81OO

DTN8200

DTN821O

DTN8220

LIF

FDC

I

ARM

I

ADM

DAM Remote 1/0 A/D module

DLB

SP

PI02

ASP

ASP Panel interface, JIS keyboard

ASP Panel interface, video printer, JIS keyboard

Linear scale interface: 3 axes

Floppy disk control

I ACGC debug memory module

] Remote~O

Branch board : 3 axes

Panel interface (for EL)

Panel 1/0 2HPG

Panel 1/0 3HPG

Panel interface, video printer

A/D module

43

1.2 COMPONENTS (Cent’d)

.

Communication Module

(Model

JANCD-FC1l O)

11q-.——— —————— —.-—-——

w

t,

I

,! ,

Ill

1,[

111

1

1

1

1,1

1

1

1

111

111

1

1

1

111

1,1

1,1

Q

I_

I

.

Approx. mass :0.31 kg

.

Expanded RAM

(Model

JANCD-FCI

20)

FC 120

B

u

44

Approx. mass :0.27 kg

.

Sequence Controller

(Model

JANCD-

FC21 O-2)

4

Approx. mass :0.32 kg

.

NC Program Analysis

(Model JANCD-FC222)

~r-----

. . . . . . . . . . . . . . -----------------

~

1!

Approx. mass :0.42 kg

I

1

45

1.2 COMPONENTS (Cent’d)

● Floppy Disk Control

(Model

FC401 )

-

This figure shows

model

attached to model

JANCD-FC400.

JANCD-

JANCD-FC401

Approx.

mass :0.22 kg

+

c

~L___-____________--____

<

,,::=

,,, -.:

(,.+:

-_-__-_---_-@.!

9

ACGC Debug Memory

Module (Model

JAN CD-FC470)

-

-

-

L

L

------------

L

L

.

]0

]

.

D

46

Approx.

mass : 0.35kg

I

● Panel 1/0 (Models JAN

/—. +

/—. ,

/

—-—.

CD-FC903-2

and -3)

..2! w