Page 1

For GPD 515/G5

j

ustable Frequency Drives

Ad

Spindle Orientation Software

FLASH Memory Software Option (114740)

Part Number: GPD515C-ZZZZ-CS104

Software Revised: 07/21/00

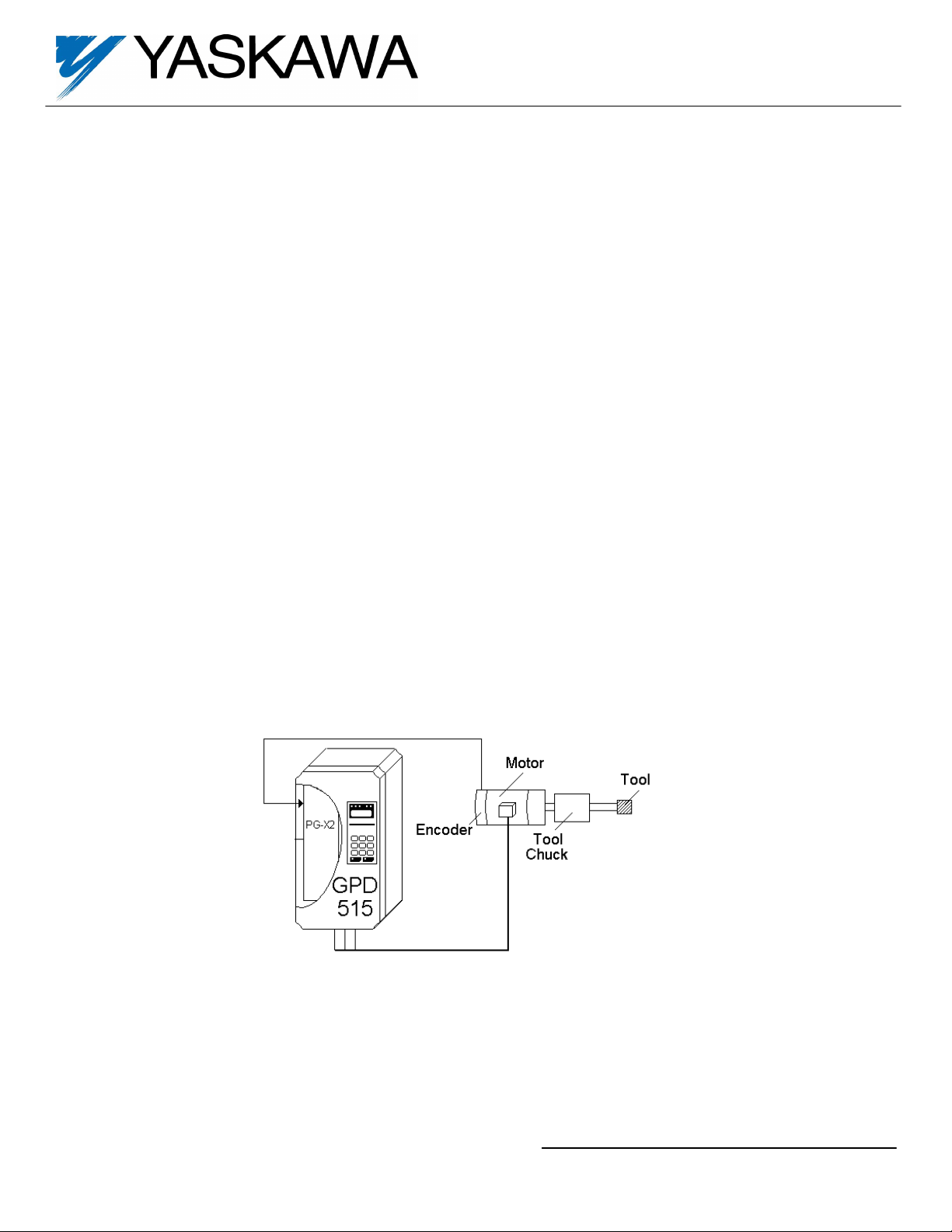

This software enhances a GPD515 AC drive with the ability to control the stopped position of the motor’s shaft; the

targeted application is for spindle equipment with automatic tool changers. Orientation is achieved by processing feedback

from a quadrature encoder connected to the spindle shaft. The positioning is based on a defined zero point which may be

the marker pulse from the encoder or a switch.

The enhancements provided include:

Open Loop Vector Operation

The drive may be used without an encoder attached to the motor, the feedback encoder can be used on the spindle.

Closed Loop Vector Operation

The drive may be used with an encoder attached for better low speed control and positioning characteristics. This provides

for better control when using the gearing option. If the motor is not directly coupled to the spindle shaft or gearing is used a

feedback encoder on the spindle is required.

Gearing Ratio

The spindle to motor ratio may be adjusted between 1:10 to 10:1. This option may be used with open loop control,

although closed loop control provides better performance.

Orient Command Input

This input initiates the orientation process and will stop the shaft in the desired position.

Marker Pulse Input

This input is provided through the PG option card. The marker or Z pulse from the encoder may be used to identify actual

position. An external switch may also use this input.

Marker Offset Parameter

This parameter contains the actual stopping position and is measured in the number of counts since the marker pulse.

Oriented Output

This output indicates that the spindle shaft is oriented.

(1)

Two monitors are provided to indicate relative position to the marker and the angle relative to the orient position.

(1) ZZZZ refers to the base Model Number of the drive in which the software is installed.

This document is an addendum to the Technical Manual TM4515, listing the effect of this software on the parameters

in the drive and the function descriptions in the manual.

Yaskawa Electric America Inc-www.drives.com

02Y00025-0526 Sheet 1 of 9

Date: 09/19/00

Page 2

j

Example Applications

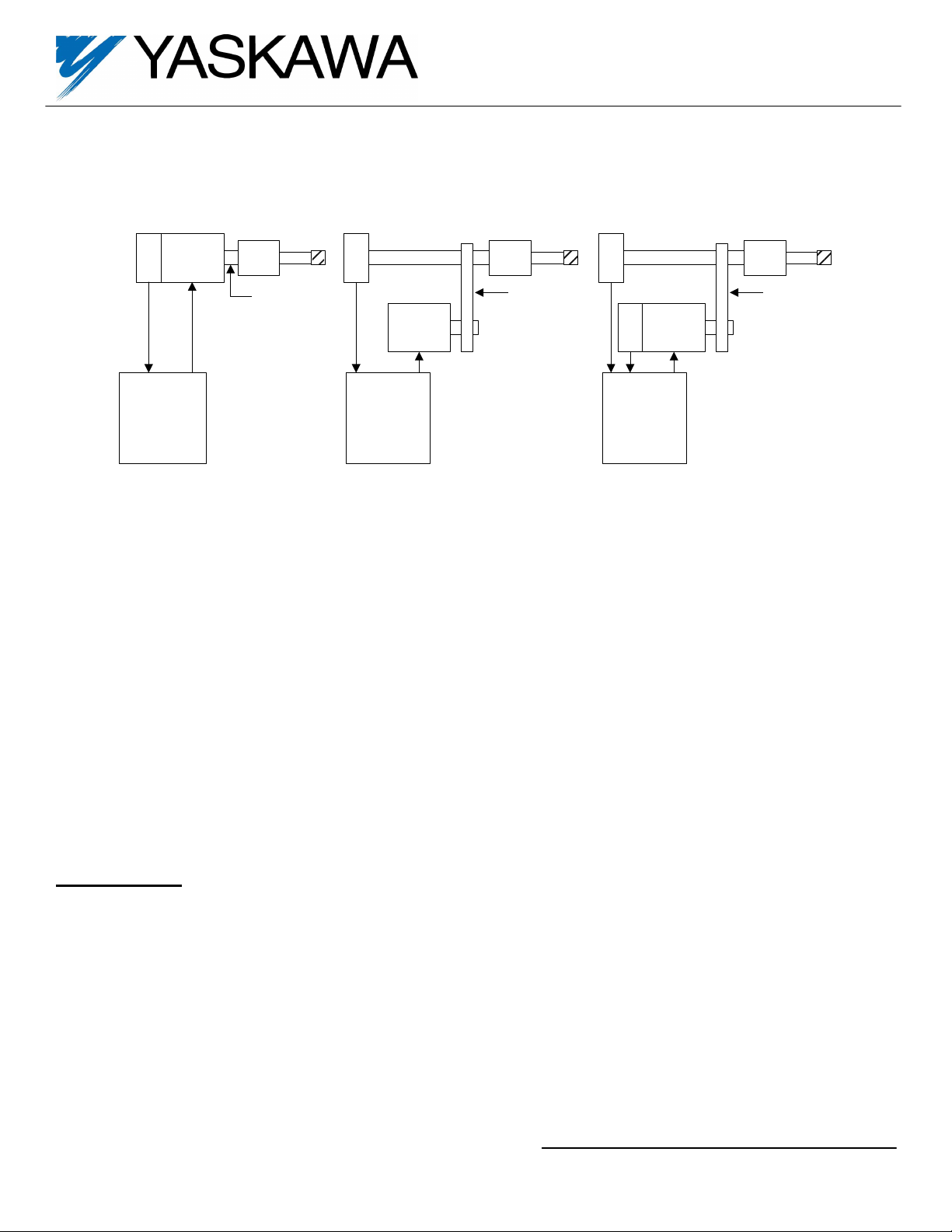

Example 1 Example 2 Example 3

For GPD 515/G5

ustable Frequency Drives

Ad

Encoder

GPD515

Controller

with

PG-X2

Option Card

Motor

Tool

Chuck

Spindle Shaft

Tool

Spindle Shaft

Encoder

GPD515

Controller

with

PG-X2

Option Card

Motor

Tool

Chuck

Belt or Gear

(Gear Ratio)

Tool

Spindle Shaft

Encoder

Encoder

GPD515

Controller

with

PG-W2

Option Card

Motor

Tool

Chuck

Belt or Gear

(Gear Ratio)

Tool

These examples show typical applications. In these examples the encoder Z or Marker pulse is used to indicate the zero

position. An external switch may be used as the Marker pulse to indicate the zero position.

Example 1

This is a direct drive system where the encoder, motor and spindle shafts are directly coupled. This system can use the

encoder for positioning and closed loop vector operation to provide the best performance.

Example 2

This is an indirect drive system where the motor to spindle shaft connection may change. This method also provides for

gearing. The encoder is coupled to the spindle shaft to eliminate possible positioning errors. This method must use open

loop vector speed control and will not provide the performance of a closed loop system.

Example 3

This is an indirect drive system where the motor to spindle shaft connection may change. This method also provides for

gearing. The encoder is coupled to the spindle shaft to eliminate possible positioning errors. The encoder on the motor

allows for closed loop vector speed control. This method will provide the best indirect positioning performance.

NOTE: This software requires a PG-X2 – Speed Control Card (MagneTek part # DS003) be installed on the drive for

examples 1 and 2. For example 3 a PG-W2 – Dual Encoder Feedback Option Board (MagneTek part # DS014) is

required.

1.0 Wiring

Wire the incoming power, motor, accessories and control wiring as specified in the GPD515 Technical Manual TM4515.

Wire the encoder(s) to the PG-X2 or the PG-W 2 according to the instruction sheets 02Y00025-0398 or 02Y00025-0397

respectively.

NOTE: The +12V supply on the PG-W2 card is capable of only 200mA, be sure not to overload it.

Yaskawa Electric America Inc-www.drives.com

02Y00025-0526 Sheet 2 of 9

Date: 09/19/00

Page 3

j

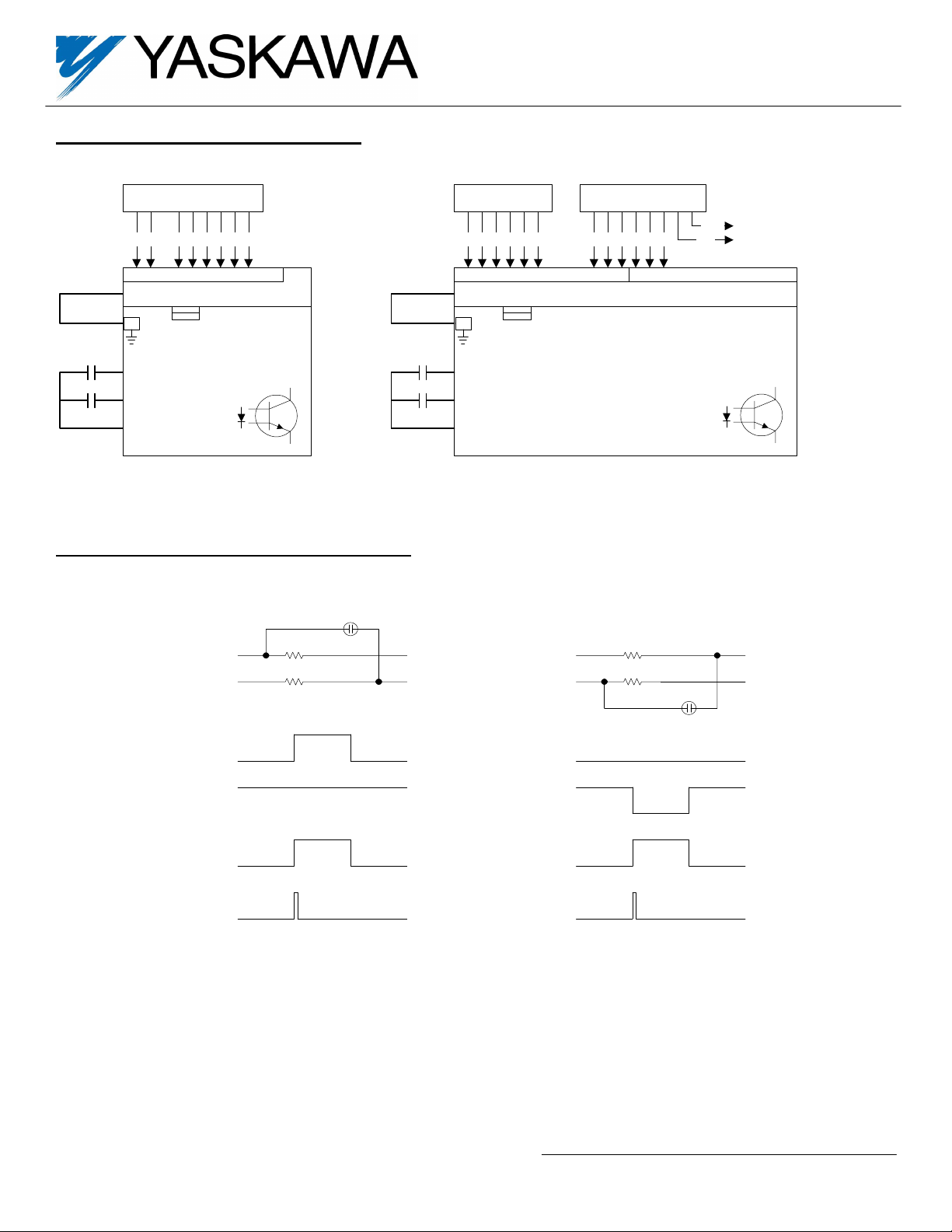

1.1 Encoder Wiring Examples

For GPD 515/G5

ustable Frequency Drives

Channel 1 Channel 2Channel 1

Ad

Run

Orient

Spindle Encoder

+12Com A+ A- B+ B-1Z+ Z-

2453 678910

E

PG-X2

12

4CN

1

7

11 Common

(48v 50ma Max.) (48v 50ma Max.)

TA1

25

26

Run

Orient

Oriented

Motor Encoder

+12 C A+ A- B+ B-

1

2453 678910

TP1

12

1

7

11 Common

J1

4CN

Spindle Encoder

Com

External

+12A+ A- B+ B- Z+ Z-

11 12 13 14 15 16 17 18 21 22 23 24

PG-W2

Power

2019

J2

GPD515GPD515

25

Oriented

26

The diagrams shown indicate the default setup that will result from an initialize. The multifunction inputs and outputs may

be redefined within the limits of the GPD515 to accommodate the application.

1.2 Marker Pulse Wiring Examples

If a proximity switch is going to be used as the marker pulse this is the recommended wiring.

Sinking Proximity SwitchSourcing Proximity Switch

Switch

+Z Input

-Z Input +12 vdc

1K 1/8 W

1K 1/8 W

- Com

+Z Input

-Z Input

1K 1/8 W

1K 1/8 W

- Com

+12 vdc

Switch

+Z Input

-Z Input -Z Input

Switch

Marker

Pulse

+Z Input

Switch

Marker

Pulse

The diagrams show how either a sourcing or sinking proximity switch may be used to trigger the marker pulse. It is

recommended that an external power supply be used to power the switching device.

Yaskawa Electric America Inc-www.drives.com

02Y00025-0526 Sheet 3 of 9

Date: 09/19/00

Page 4

For GPD 515/G5

j

ustable Frequency Drives

Ad

2.0 I/O Definitions

2.1 New Multi-Function Digital Input Settings

For constants H1-01 through H1-06.

Setting Display Description

80 Orient Cmd Command the drive to orient the spindle shaft

2.2 New Multi-Function Digital Output Settings

For constants F5-01 and F5-02, and H2-01 through H2-03.

Setting Display Description

40 Orient Complete Turns on when the orientation command is complete.

2.3 New Multi-Function Analog Input Settings

For constants H3-05 through H3-09.

None

2.4 New Multi-Function Analog Output Settings

For constants F4-01, F4-03, H4-01, and H4-04.

None

3.0 Startup Procedure

The following startup guide is for example one, in which the drive is to be in closed loop vector and the motor and the

spindle are directly coupled.

1. Perform the flux vector start-up procedure in Section 2.2b of the GPD515 Technical manual.

2. Select the encoder channel for spindle only (P1-01 = 1).

3. Set the spindle encoder’s Pulses Per Revolution (PPR) into parameter P1-02.

4. Set the Position Speed (P1-04). When an orient is commanded, the drive will decelerate down to the value set into

parameter P1-04. A low value in parameter P1-04 will increase orient time, a higher value will be more likely to

overshoot.

5. Verify that one of the function terminals (H1-01 through H1-06) is set to Orient Cmd (80) (Typically H1-05,

Terminal 7).

Yaskawa Electric America Inc-www.drives.com

02Y00025-0526 Sheet 4 of 9

Date: 09/19/00

Page 5

For GPD 515/G5

j

ustable Frequency Drives

6. Set the Orient Offset (P1-03), which is the distance after the marker at which the motor will stop. The desired

value may be found by running the drive and initiating the Orient command. When the drive stops remove the run

input. Determine how far the spindle is from it’s desired position. Change the value in P1-03. (A value equal to

the pulses per revolution of the spindle encoder will result in ¼ revolution of the spindle). Repeat step 6 until

desired stopping position is found.

7. To control the stop response use parameters P1-06 and P1-07.

8. Done.

NOTE: the following factory default parameters/terminal assignments have changed:

C2-01 = 0.00 S curve set to zero (formerly 0.2).

C2-02 = 0.00 S curve set to zero (formerly 0.2).

C2-03 = 0.00 S curve set to zero (formerly 0.2).

H1-05 = 80 Terminal 7 is set to be the orientation command (formerly “Jog”).

H2-02 = 40 Terminal 25 Orientation complete (formerly “Zero Speed”).

Ad

4.0 Custom Software Parameters

4.1 New Program Group

Group P

Spindle Orient

4.2 New Program Function

Function P1

Orient Settings

Yaskawa Electric America Inc-www.drives.com

02Y00025-0526 Sheet 5 of 9

Date: 09/19/00

Page 6

j

4.3 New Program Parameters

PG Channel

For GPD 515/G5

ustable Frequency Drives

Ad

P1-01= 1

P2-01 PG Channel

Setting Range 1 or 2

Factory Default: 1

Either channel 1 or 2 may be used for positioning. Set this for the channel that is connected to the positioning encoder.

When a PG-X2 option card is used this setting must be 1. Channel 2 is only available with a PG-W2 option card.

Q Q Q Q

Spindle PPR

P1-02= 1024 PPR

P1-02 Spindle Encoder PPR

Setting Range: 1 to 32767 Pulses per revolution

Factory Default: 1024 Pulses per revolution

Enter the pulses per revolution rating of the positioning encoder here.

Q Q Q Q

Orient Offset

P1-03= 0

P1-03 Orient offset distance

Setting Range: 0 to 32767

Factory Default: 0

This parameter contains the number of quadrature counts offset past the marker that the shaft will travel before stopping.

This is the Orient position. When this value is 0 the shaft will stop at the marker. The desired value may be found by

running the drive and initiating the Orient command. When the drive stops remove the run input. The shaft should turn

freely. Rotate the shaft to the desired position. Read the value of U1-50 (Marker Offset) and enter it here.

The value of U1-50 is a rolling counter ranging from 0 to the number of quadrature counts per revolution. The direction of

rotation is irrelevant. The value indicates a relative position to the marker and is the same in either direction.

This value may also be used to add counts to the positioning algorithm. Adding the number of positioning encoder

quadrature counts per revolution increases the stopping distance by one revolution.

Q Q Q Q

Yaskawa Electric America Inc-www.drives.com

02Y00025-0526 Sheet 6 of 9

Date: 09/19/00

Page 7

For GPD 515/G5

j

ustable Frequency Drives

Ad

Position Speed

P1-04= 0.10 HZ

P1-04 Position Speed

Setting Range: 0.00 to 10.00 Hertz

Factory Default: 0.10

This parameter sets the minimum speed that may be used during positioning. This speed is also used when the shaft is

within the number of quadrature counts set in P1-05 (Position Count). If this speed is set to high the drive will oscillate

when trying to hold the orient position. The positioning algorithm will decrease the speed until zero speed is reached at the

orient position or this speed is reached and maintained until the orient position.

Q Q Q Q

Position Count

P1-05= 0

P1-05 Position Count

Setting Range: 0 to 4096

Factory Default: 0

This parameter sets the number of quadrature counts before the orient position that the drive will hold the speed set in P1-

04 (Position Speed). This may be used to prevent overshooting the orient position. If this count is set to high the drive will

slow down to soon and cause extended positioning times.

Q Q Q Q

Stop Count

P1-06= 0

P1-06 Stop Count

Setting Range: 0 to 100

Factory Default: 0

This parameter sets the number of quadrature counts before and after the actual orient position that will not result in a

correction. This creates a stop range that prevents oscillation while the drive is in zero servo. The effect of this is

dependent on the encoder resolution.

Q Q Q Q

Yaskawa Electric America Inc-www.drives.com

02Y00025-0526 Sheet 7 of 9

Date: 09/19/00

Page 8

For GPD 515/G5

j

ustable Frequency Drives

Ad

Stop Spd Gain

P1-07= 0

P1-07 Stop Speed Gain

Setting Range: 0 to 10

Factory Default: 0

This parameter sets the frequency threshold where the positioning algorithm takes control of stopping the drive. It is

based on a minimum threshold of 4.096 Hz with a 1 setting. The minimum threshold is multiplied by this value to achieve

a maximum threshold of 40.96 Hz. This value also controls the rate of deceleration. The positioning algorithm will bring

the drive to a stop in the orient position within 2 revolutions after initiated.

Q Q Q Q

Spindle Ratio Num

P1-08= 1

P1-08 Spindle Ratio Numerator

Setting Range: 1 to 10

Factory Default: 1

This parameter and P1-09 (Spindle Ratio Div) must be set to the proper spindle to motor ratio. This ratio is required for

the positioning to function properly.

Q Q Q Q

Spindle Ratio Div

P1-09= 1

P1-09 Spindle Ratio Divisor

Setting Range: 1 to 10

Factory Default: 1

This parameter and P1-08 (Spindle Ratio Num) must be set to the proper spindle to motor ratio. This ratio is required for

the positioning to function properly.

Q Q Q Q

Yaskawa Electric America Inc-www.drives.com

02Y00025-0526 Sheet 8 of 9

Date: 09/19/00

Page 9

j

5.0 New Monitors

Shaft Angle

For GPD 515/G5

ustable Frequency Drives

Ad

U1-36 103.4°

U1-36 Shaft Angle

Displays the angle between the shaft position and the orient position. The display will indicate +/- 180 degrees.

Marker Offset

U1-50 2303 cts

U1-50 Marker Offset

Displays the number of quadrature encoder counts the shaft is past the marker pulse. This is a rolling count and always

indicates the relative position with respect to the marker. The counter values are controlled by the quadrature counts of

the encoder used. A 1024 PPR encoder has a quadrature count of 1024 X 4 or 4096. Using this encoder this value will

increment from 0 to 4095 in the forward direction. It will decrement from 4095 to 0 in the reverse direction. The 0 position

indicated the marker.

6.0 New Alarm and Fault Codes

None

Yaskawa Electric America Inc-www.drives.com

02Y00025-0526 Sheet 9 of 9

Date: 09/19/00

Loading...

Loading...