Page 1

DWG. NO. 02Y00025-0351

SHEET NO. 1 OF 7

EFF. 12/7/93 (m-df)

For GPD 333 230V 1/4-5HP,

460V 1/2-5HP

Adjustable Frequency Drives

CHANGE RECORD

1

STD-5980 2-16-95

DYNAMIC BRAKING (DB) OPTION

(BRAKING RESISTOR (3%) OR

BRAKING RESISTOR UNIT(10%))

(PART NUMBERS DETERMINED BY DRIVE RATING)

Before installing this option, a TECHNICALLY

QUALIFIED INDIVIDUAL who is familiar with this

type of equipment and the hazards involved, should

READ this ENTIRE INSTRUCTION SHEET.

IMPORTANT

This option may have been installed by the

factory. However, certain steps can only be

completed at the installation site. Therefore,

review and perform those steps which

complete the installation process.

DESCRIPTION

Installation of this option enables the motor to be

brought to a smooth and rapid stop. This is achieved

by dissipating the regenerative energy of the AC

motor across the resistive components of the

Dynamic Braking option.

Dynamic Braking Operation

Whenever an excited motor is operated in the

negative slip region (or is subjected to an overhauling

load), the motor will behave as an induction

generator. In this mode, energy will actually flow from

the motor back into the drive, as shown in illustrations

(A) and (B).

This energy will cause the DC Bus voltage to rise.

Another condition that will cause the DC Bus voltage

to rise is when the input voltage to the drive is high.

When the DC Bus voltage reaches a certain level, the

Dynamic Braking option will activate. The option will

actually “shunt” the regenerative energy away from

the Bus capacitors, as shown in illustration (C), and

will dissipate it as heat in the DB resistors. Since the

regenerative energy is dissipated in the DC resistors,

the Overvoltage (OV) trip is prevented; thus the motor

remains excited and continues to produce braking

torque. However, for the high input voltage condition,

an input contactor (1M) should be used (see Figure 4

or Figure 5) to disconnect the drive when the high

input voltage exists for a long period of time.

BUS

CAPS

MOTOR

(A) "MOTORING" POWER FLOW

BUS

CAPS

MOTOR

(C) POWER SHUNTED FROM BUS CAPS

DB OPTION

BUS

CAPS

MOTOR

(B) "GENERATING" POWER FLOW

Page 2

DWG. NO. 02Y00025-0351

SHEET NO. 2 OF 7

EFF. 12/7/93 (m-df)

Refer to Sheet 1 for latest change.

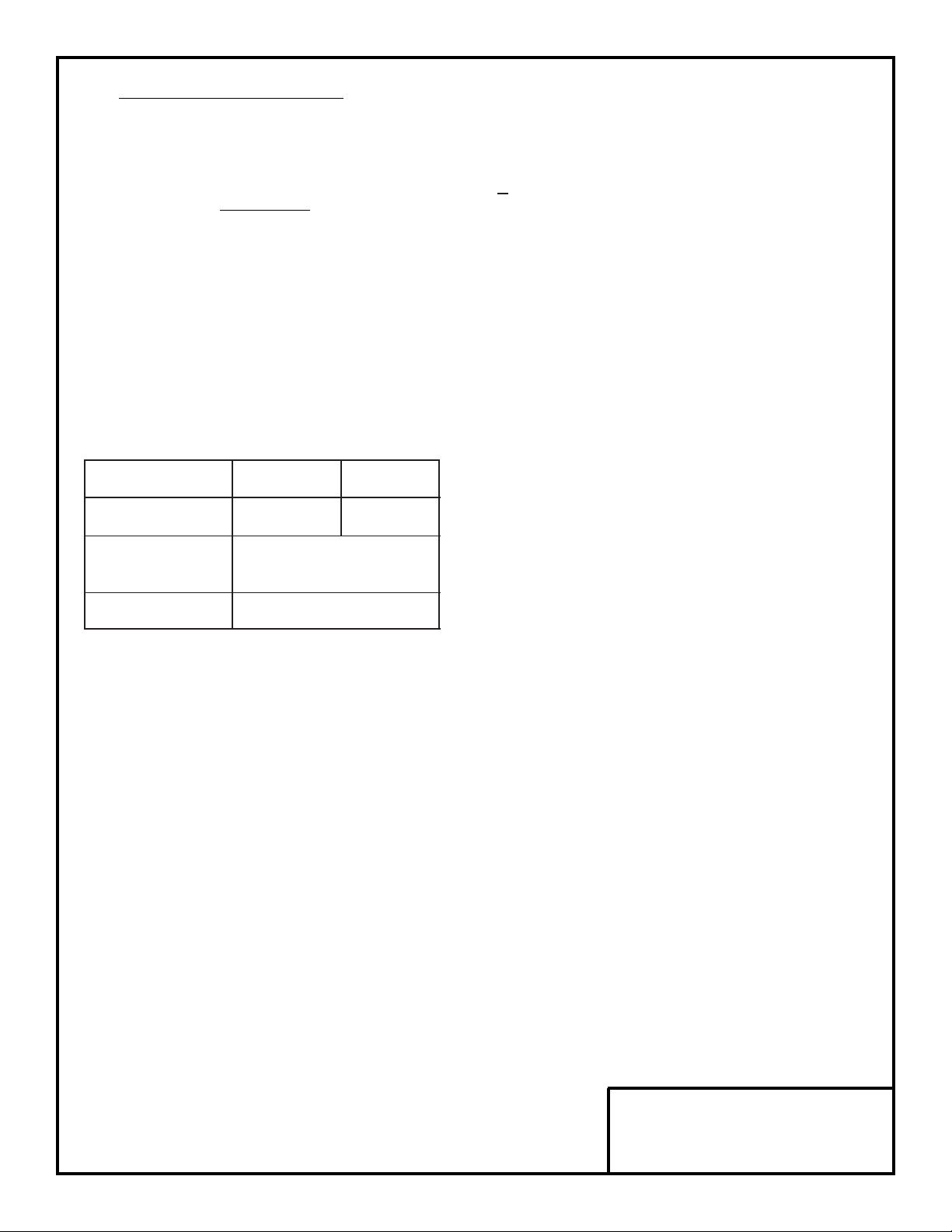

Table 1

Drive Braking Resistor Unit

Voltage HP(CT) Part Number H W D H1 W1 Mtg Screws

1/4 —— — — — — — ——

2 3/4 5P41-0742 13.00 12.00 5.00 9.00 11.00 3/4 (4)

3

1 5P41-0742 13.00 12.00 5.00 9.00 11.00 3/4 (4)

1.5 5P41-0743 13.00 12.00 5.00 9.00 11.00 3/4 (4)

0 3 5P41-0744 13.00 12.00 5.00 9.00 11.00 3/4 (4)

5 5P41-0745 13.00 12.00 5.00 9.00 11.00 3/4 (4)

1/2 —— — — — — — ——

4 3/4 5P41-0752 13.00 12.00 5.00 9.00 11.00 3/4 (4)

6

1.5 5P41-0752 13.00 12.00 5.00 9.00 11.00 3/4 (4)

2 5P41-0753 13.00 12.00 5.00 9.00 11.00 3/4 (4)

0 3 5P41-0754 13.00 12.00 5.00 9.00 11.00 3/4 (4)

5 5P41-0755 13.00 12.00 5.00 9.00 11.00 3/4 (4)

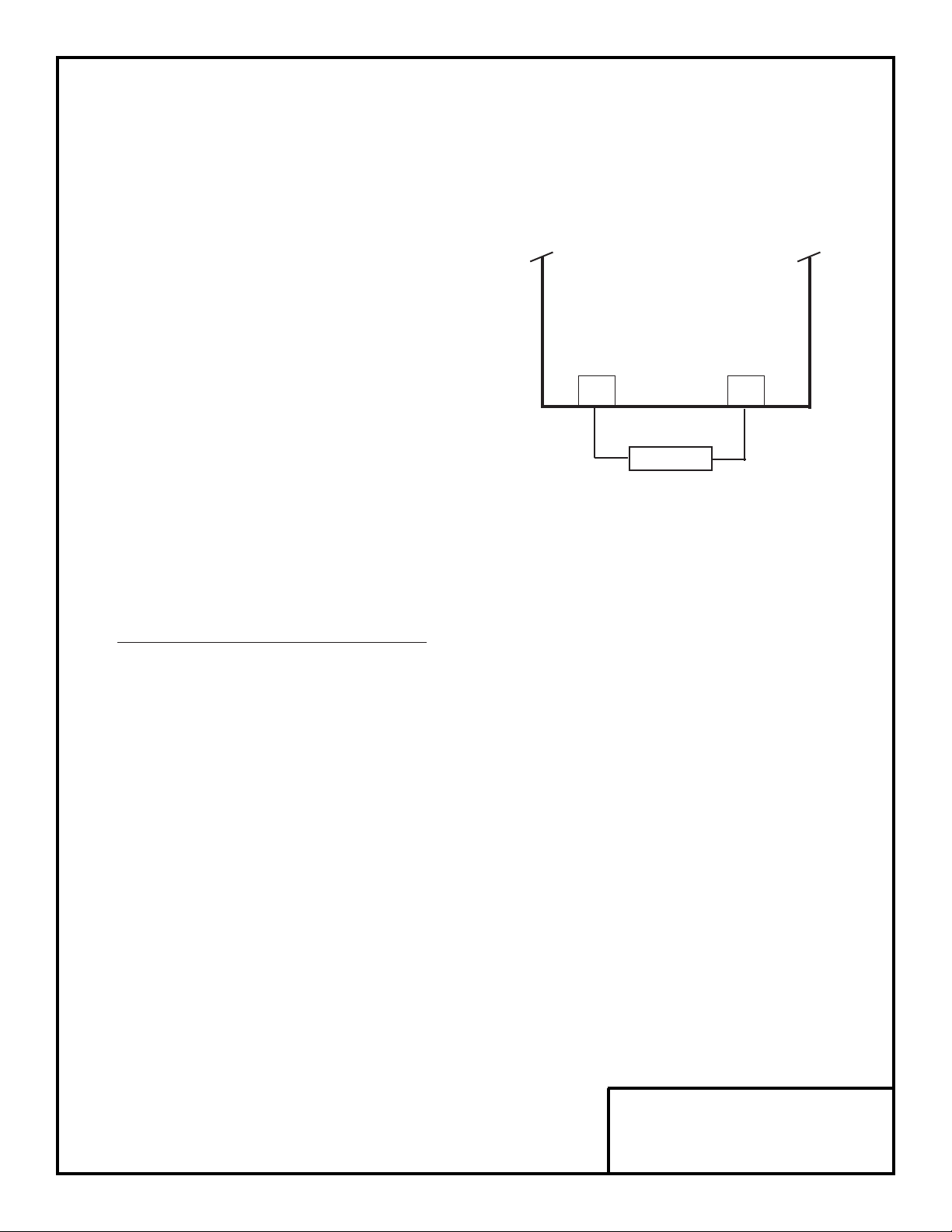

Figure 1. Braking Resistor

(3% Duty Cycle)

RECEIVING

All equipment is tested against defect at the factory.

Report any damages or shortages evident when

equipment is received immediately to the commercial

carrier who transported the equipment. Assistance, if

required, is available from your MagneTek sales

representative.

STORAGE

If the option is not to be installed immediately, it must

be stored under the following conditions:

– Ambient temperature: -10 to +40° C.

– Protected from rain and moisture.

– Free from corrosive gases or liquids.

– Free from dust or metal particles.

– Clean and dry.

– Free from excessive vibration.

Page 3

DWG. NO. 02Y00025-0351

SHEET NO. 3 OF 7

EFF. 12/7/93 (m-df)

Refer to Sheet 1 for latest change.

Figure 2. Braking Resistor Unit

(10% Duty Cycle)

Page 4

DWG. NO. 02Y00025-0351

SHEET NO. 4 OF 7

EFF. 12/7/93 (m-df)

Refer to Sheet 1 for latest change.

INSTALLATION

Preliminary Procedure

WARNING

HAZARDOUS VOLTAGE CAN CAUSE

SEVERE INJURY OR DEATH.

LOCK ALL POWER SOURCES

FEEDING DRIVE IN “OFF” POSITION.

1. Disconnect all electrical power to drive.

2. Remove drive front cover.

3. Verify that voltage has been disconnected by

using a voltmeter to check for voltage at the incoming

power terminals.

NOTE

Since the drive has integral braking transistors, the Dynamic Braking option only requires

addition of the braking resistor (3% duty cycle)

OR the remote-mounting braking resistor unit

(10% duty cycle).

A. Braking Resistor (3% Duty Cycle) Installation

4. The 3% duty cycle braking resistor is

supplied with 6 inch leads, as shown in Figure 1.

5. The braking resistor requires vertical

installation with ample space to achieve high efficiency

cooling.

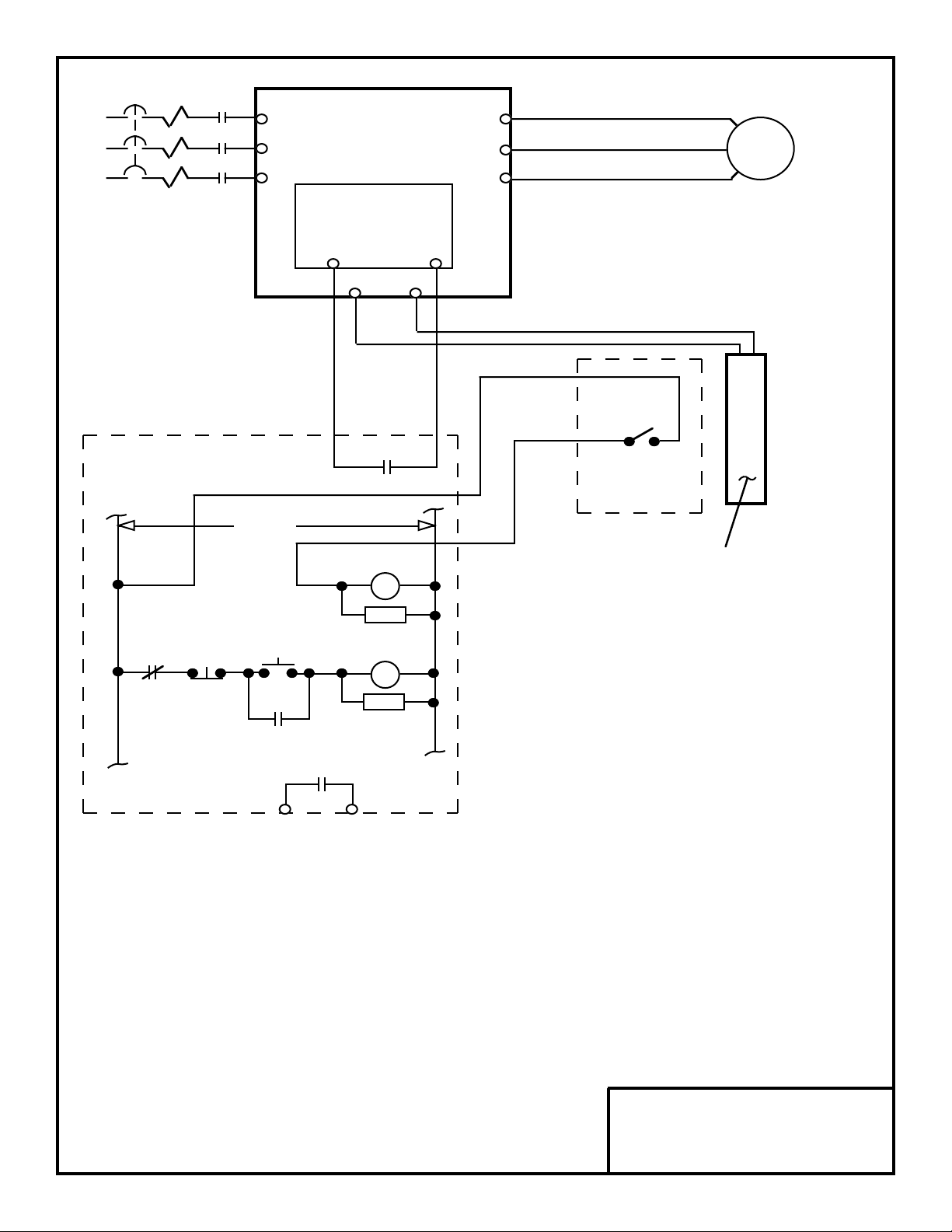

6. Connect leads from the braking resistor to

drive terminals according to Figure 3 and Figure 4.

NOTE

External control components shown in Figure

5 are not supplied with the option. These

components are necessary for safe operation

of the Dynamic Braking option.

Figure 3. Lead Connections For Braking

Resistor (3% Duty Cycle)

B1/+ B2

BRAKING

RESISTOR

P

B

GPD 333

Page 5

DWG. NO. 02Y00025-0351

SHEET NO. 5 OF 7

EFF. 12/7/93 (m-df)

Refer to Sheet 1 for latest change.

B. Braking Resistor Unit Installation

7. The braking resistor unit requires vertical

installation with ample clearance space (see Figure 2)

to achieve high cooling efficiency.

IMPORTANT

Since the braking resistor unit generates heat

during dynamic braking operation, install it in

a location away from other equipment which

emits heat.

8. Open the braking resistor terminal box for

access to terminals. Connect the braking resistor unit

to the drive according to Table 2 and Figure 5.

ADJUSTMENTS

9. The braking resistor (3% duty cycle) and the

braking resistor unit (10% duty cycle) require drive

re-programming. Program constant

no-20

to

1 X X X

, which disables stall prevention during decel.

10. Reinstall and secure front cover on the drive

and close and secure the terminal box on the the

remote-mount braking resistor unit.

11. Place this instruction sheet with the GPD 333

Technical Manual.

This completes the installation of this option.

Table 2

Terminals B, P 1, 2

✱

Lead Size (AWG) 12-10 18-14

✱

Lead Type 600V ethylene propylene

rubber insulated or equiv.

Terminal Screw M4

✱

Power leads are for the braking resistor unit

generate high levels of electrical noise; these

signal leads must be grouped separately.

NOTE

External control components shown in Figure

5 are not supplied with the option. These

components are necessary for safe operation

of the Dynamic Braking option.

Page 6

DWG. NO. 02Y00025-0351

SHEET NO. 6 OF 7

EFF. 12/7/93 (m-df)

Refer to Sheet 1 for latest change.

T1T2T3RSTUVW

GPD 333

CONTROL

PCB

46B1/+

B2

PART OF

EXTERNAL

CIRCUIT

BRAKING

RESISTOR

(3% DUTY

CYCLE)

THERMOSTAT

OR OVERLOAD

THRX

1M1M1MCBL1L2L3

120VAC

THRX

FAULT

CONTACT

THRX

RC1MRC1MTHRX

POWER

ON

POWER

OFF

***

CUSTOMER SUPPLIED COMPONENTS

Figure 4. Wiring Braking Resistor (3% Duty Cycle) to Drive

Page 7

DWG. NO. 02Y00025-0351

SHEET NO. 7 OF 7

EFF. 12/7/93 (m-df)

Refer to Sheet 1 for latest change.

T1T2T3RSTUVW

GPD 333

CONTROL

PCB

46B1

B2

PART OF

EXTERNAL

CIRCUIT

BRAKING

RESISTOR

UNIT

(10% DUTY

CYCLE)

BP21THG

THRX

1M1M1MCBL1L2L3

120VAC

THRX

FAULT

CONTACT

THRX

RC1MRC1MTHRX

POWER

ON

POWER

OFF

*

*

CUSTOMER SUPPLIED COMPONENTS

Figure 5. Wiring Braking Resistor Unit (10% Duty Cycle) to Drive

Loading...

Loading...