Page 1

CopyCentre C118,

WorkCentre M118,

Service Documentation

701P23530

December 2004

CAUTION

Certain components in the CopyCentre C118,

WorkCentre M118, are susceptible to damage from

electrostatic discharge. Observe all ESD

procedures to avoid component damage.

Page 2

©

NOTICE

While Xerox has tried to make the documentation accurate, Xerox will have

no liability arising out of any inaccuracies or omissions.

NOTICE

All service docu mentation i s suppli ed to Xer ox exter nal cus tomer s for i nformational purposes only. Xerox service documentation is intended for use by

certified, product -trained s ervice pe rsonnel only. Xerox does not wa rrant or

represent that it will notify or provide to such customer any future change to

this documentation. Customer performed service of equipment, or modules,

components, or parts of such equipment may affect whether Xerox is

responsible to fix machine defects under the warranty offered by Xerox with

respect to such equipment . You shoul d consult the applicabl e warranty for

its terms regarding customer or third-party provided service.

WARNING

This equipment generates, uses and can radiate radio frequency

energy, and if not installed and used in accorda nce with the instructions documentation, may cause interference to radio communications. It has been tested and found to comply with the limits for a

Class A computing device pursuant to subpart J of part 15 of FCC

rules, which are designed to provide reasonable protection against

such interference w hen operat ed in a c ommercial envir onment. O peration of this equipment in a residen tial area is lik ely to cau se interference in which case the user, at his own expense, will be required to

correct the interference.

Published by The Document Company Xerox GKLS European Operations Bessemer Road

Welwyn Garden City Hertfordshire AL7 1HE ENGLAND

2004 by Fuji Xerox Co.,Ltd. All rights reserved.

The Document Company® and Xerox® are trade marks of the Xerox Corporation.

Xerox and all identifying numbers used in connection with the Xerox products mentioned in this

publication are trademarks of the Xerox Corporation.

Page 3

About this Manual .......................................................................................... .... .... .... ..... iii

Organization . ...................................................................................................................iii

How to Use this Document ation...................................................................................... iv

Symbology and Nomenclature........................................................................................ v

Translated Warnings..................................................................... .................................. viii

Introduction

Initial Issue

CCC118, WCM118

12/2004

i

Introduction

Page 4

About this Manual

This Service Manual is part of the multinational documentation system for

Copy Centre C118,Wor k Centre M118 copier/printers. The Service Documentation is used in

order to diagnose machine malfunctions, adjust components and has information which is

used to maintain the product in superior operating condition. It is the controlling publication for

a service call. Information on its use is found in the Introduction of the Serv ice Documentation.

This manual contains information that applies to NASG (XC) and ESG (XE) copiers.

Service Manual Revision

The Service Manual will be updated as the machine changes or as problem ar eas are identified.

Organization

This Service Manual is divided into eight sections. The t itles of the sections and a desc ription

of the information contained in each section are contained in the following paragraphs:

Section 1: Service Call Procedures

This section contains procedures that determine what actions are to be taken during a service

call on the machine and in what sequence they are to be completed. This is the entry level for

all service calls.

Section 2: Status Indicator RAPs

This section contains the diagnostic aids for troubleshooting the Fault Code and non-Fault

Code related faults (with the exception of image quality problems).

Section 3: Image Quality

This section contains the diagnostic aids for troubleshooting any image quality problems, as

well as image quality specifications and image defect samples.

Section 4: Repairs/Adjustments

This section contains all the Adjustments and Repair procedures.

Repairs

Repairs include procedures for removal and replacement of parts which have the following

special conditions:

When there is a personnel or machine safety issue.

When removal or replacement cannot be determined from the exploded view of the

Parts List.

When there is a cleaning or a lubricating activity associated with the procedure.

When the part requires an adjustment after replacement.

When a special tool is required for removal or replacement.

Use the repair procedures for the correct order of removal and replacement, for warnings, cautions, and notes.

Initial Issue

CCC118, WCM118

Adjustments

Adjustments include procedures for adjusting the parts that must be within specification for the

correct operation of the system.

Use the adjustment procedures for the correc t sequence of operation for s pecifications, wa rnings, cautions and notes.

Section 5: Parts Lists

This section contains the Copier/Printer Parts List.

Section 6: General Procedures Information

This section contains General Procedures, Diagnostic Programs, and Copier/Printer Information.

12/2004

iii

Introduction

Page 5

Section 7: Wiring Data

This section contains drawings, lists of plug/jack locations, and diagrams of the power distribution wire networks in the machine. This section also contains the Block Schematic Diagrams.

How to Use this Documentation

The Service Call Procedures in Section 1 describe the sequence of activities used during the

service call. The call must be entered using these procedures.

Section 8: Accessories

This section contains installation information for option and accessory.

Use of the Circuit Diagrams

All wirenets are shown on the Circuit Diagrams (CDs). Power distribution wirenets are shown

in Section 7 (Wiring Data) of the Service Ma nual. The power distribution wirenets on the C Ds

will end at the terminal board for the power being distributed. Find the wirenet for that power

and locate the terminal board on the wirenet. Use the wirenet to troubleshoot any power distribution wiring not shown on the CD.

Use of the Block Schematic Diagrams

Block Schematic Diagrams (BSDs) are included in Section 7 (Wiring Data) of the Service Manual. The BSDs show the functional relationship of the electrical circuitry to any mechanical, or

non-mechanical, inputs or outputs throughout the machine. Inputs and outputs such as motor

drive, mechanical linkages, operator actions, and air flow are shown. The BSDs will provide an

overall view of how the entire subsystem works.

It should be noted that the BSDs no longer contain an Input Power Block referring to Chain 1. It

will be necessary to refer to the Wirenets in order to trace a wire back to its source.

Introduction

12/2004

iv

Initial Issue

CCC118, WCM1 18

Page 6

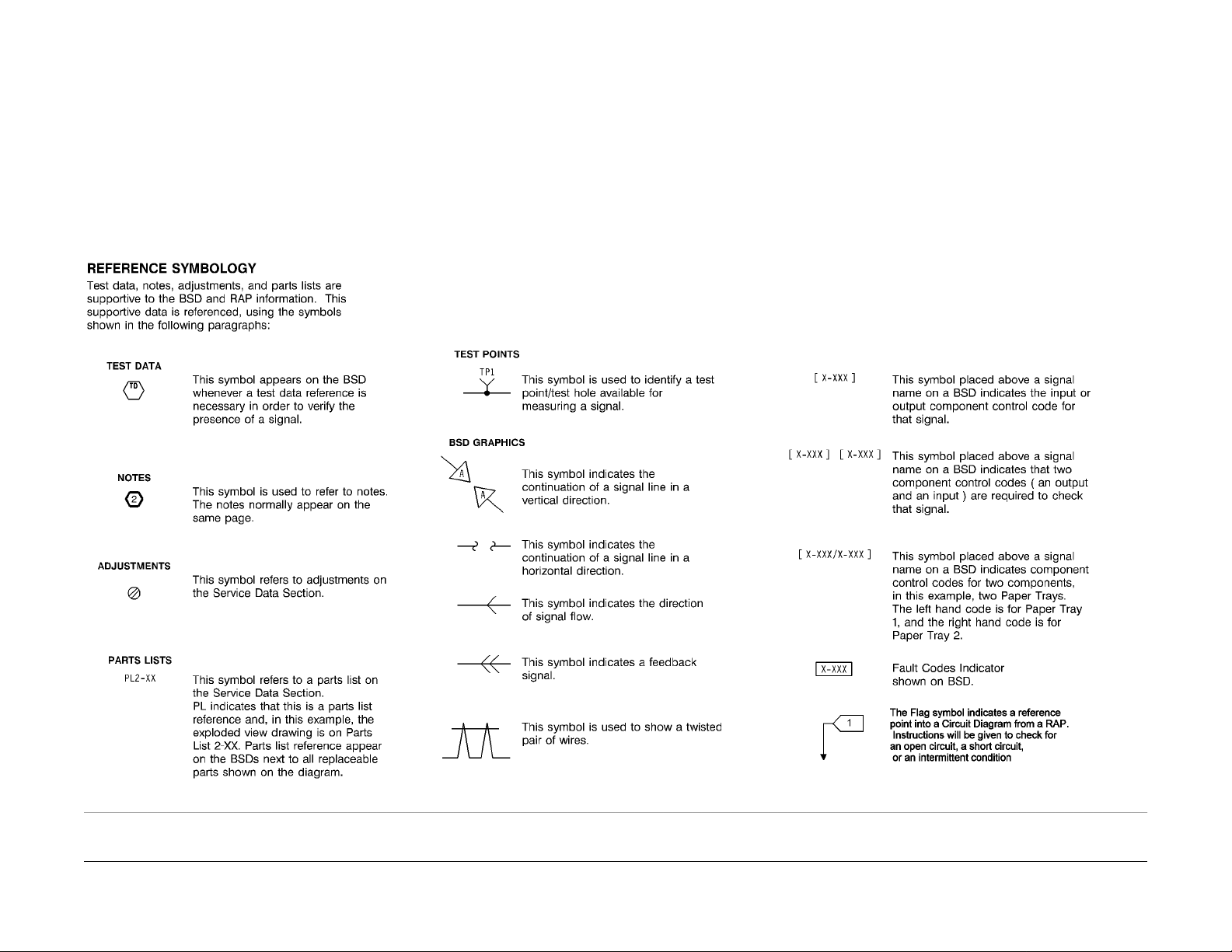

Symbology and Nomenclature

The following reference symbols are used throughout the documentation.

Warnings, Cautions, and Notes

Warnings, Cautions, and Notes will be found throughout the Service Documentation. The

words WARNING or CAUTION may be listed on an illustration when the specific component

associated with the potential hazard is pointed out; however, the message of the WARNING or

CAUTION is always located in the text. Their definitions are as follows:

WARNING

A Warning is used whenever an operating or maintenance proce dure, a p ractice, co ndition, or statement, if not strictly observed, could result in personal in j ury.

CAUTION

A Caution is used whenever an operating or maintenance procedure, a practic e, condition, or

statement, if not strictly observed, could result in damage to the equipment.

NOTE: A Note is used whenever it is necessary to highlight an operating or maintenance procedure, practice, condition, or statement.

Machine Safety Icons

The following safety icons are displayed on the machine:

WARNING

This machine contains an invisible laser. There is no visual indication that the laser

beam is present. During servicing, the machine is a Class 3B product because of the

invisible laser. the laser beam could cause eye damage if lo oked at directly. Service procedures must be followed exactly as written without change. The service representative

must observe the established local laser safety precautions when servicing the

machine. Do not place tools with a reflective surface in the area of the ROS opening. Do

not look in the area of the ROS window if the power is On and the laser is energized.

The following symbol and statement appear on a label in the machine. The symbol by

itself, or the symbol and the statement may also appear in the service documentation

and in the training program. When this symbol appears, the service representative is

warned that conditions exist that could result in exposure to the laser beam.

WARNING

Do not try to bypass any laser interlocks for any reason. Permanent eye damage could

result if the laser is accidentally directed into your eye.

CAUTION

The use of controls or adjustments other than those specified in the Laser Safety Training Program may result in an exposure to dangerous laser radiation.

For additional information, review the Laser Safety Training program.

An arrow points to the location to install, to gain access to, or to release an object.

Figure 2 Customer Access Label

This symbol indicates that a surface can be hot. Use caution when reaching in the machine to

avoid touching the hot surfaces.

Figure 3 Heated Surface Label

Danger label indicates where electrical currents exist when the machine is closed and operating. Use caution when reaching in the machine.

Figure 4 Shock Hazard Label

These symbols indicate components that may be damaged by Electrostatic Discharge (ESD).

Figure 1 Laser Hazard Symbol

Laser Hazard Statement

DANGER INVISIBLE LASER RADIATION WHEN OPEN. AVOID DIRECT EXPOSURE TO

BEAM.

Initial Issue

CCC118, WCM118

12/2004

v

Figure 5 ESD warning Label

Introduction

Page 7

Electrostatic Discharge (ESD) Field Service Kit

The purpose of the ESD Protection Program is to preserve the inherent reliability and quality of

electronic components that are handled by the Field Service Personnel. Th is prog ram is being

implemented now as a direct result of advances in microcircuit ry technology, as well as a new

acknowledgment of the magnitude of the ESD problem in the electronics industry today.

This program will reduce Field Service costs that are charged to PWB failures. Ninety percent

of all PWB failures that are ESD related do not occur immediately. Using the ESD Field Service

Kit will eliminate these delayed failures and intermittent problems caused by ESD. This w ill

improve product reliability and reduce callbacks.

The ESD Field Service Kit should be used whenever Printed Wiring Boards or ES D sensitive

components are being handled. This includes activities like replacing or reseating of circ uit

boards or connectors. The kit should also be used in order to prevent additional damage when

circuit boards are returned for repair.

The instructions for using the ESD Field Service Kit can be found in ESD Field Service Kit

Usage in the General Procedures section of the Service Documentation.

Illustration Symbols

Figure 6 shows symbols and conventions that are commonly used in illustrations.

Introduction

Figure 6 Illustration Symbols

12/2004

vi

Initial Issue

CCC118, WCM1 18

Page 8

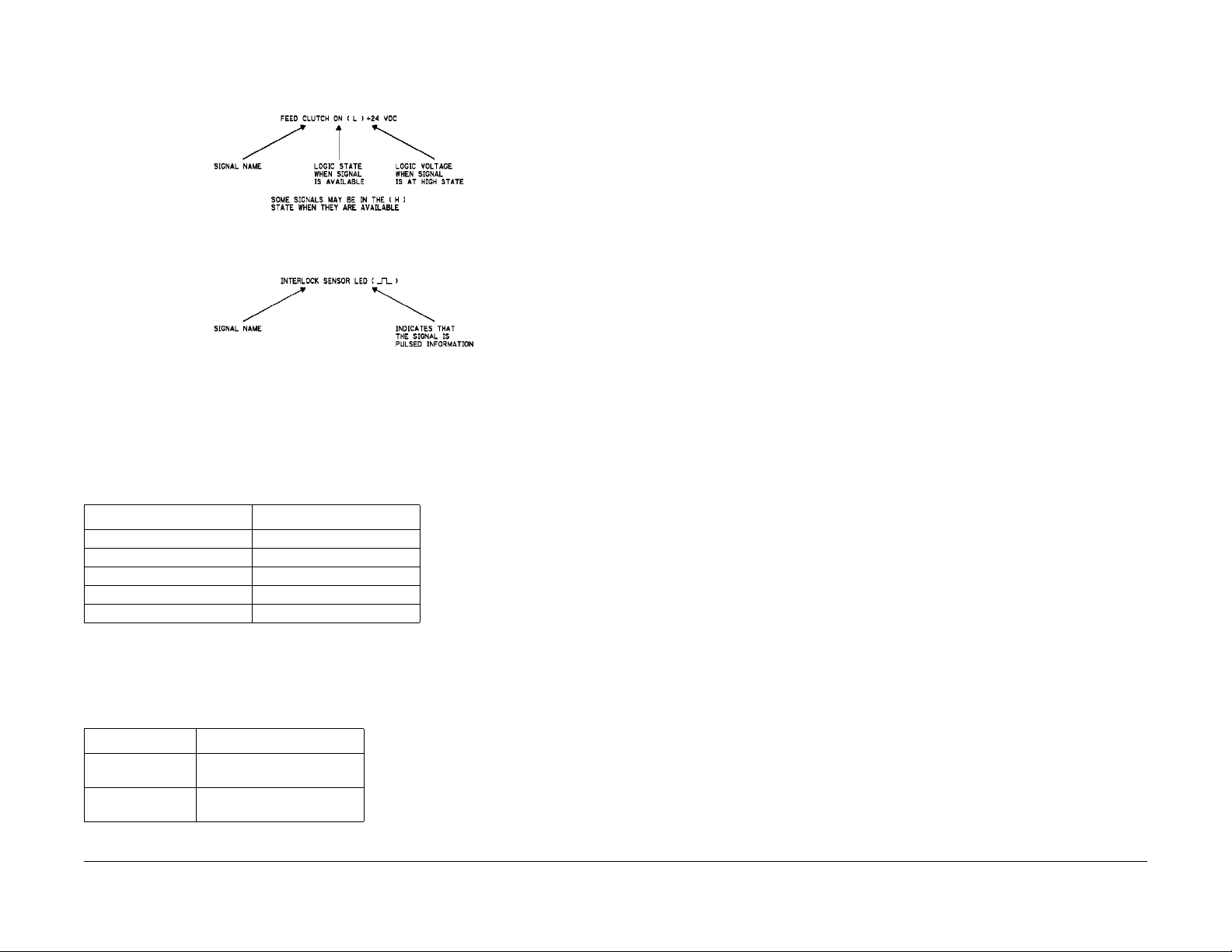

Signal Nomenclature

Refer to Figure 7 for an example of Signal Nomenclature used in Circuit Diagrams and BSDs.

Figure 7 Signal Nomenclature

Voltage Measurement and Specifications

Measurements of DC voltage must be made with reference to the specified DC Common,

unless some other point is referenced in a diagnostic procedure. All measurements of AC voltage should be made with respect to the adjacent return or ACN wire.

Table 1 Voltage Measurement and Specifications

VOLTAGE SPECIFICATION

INPUT POWER 220 V 198 VAC TO 242 VAC

INPUT POWER 100 V 90 VAC TO 135 VAC

INPUT POWER 120 V 90 VAC TO 135 VAC

+5 VDC +4.75 VDC TO +5.25 VDC

+24 VDC +23.37 VDC TO +27.06 VDC

DC Voltage Measurements in RAPs

The RAPs have been designed so that when it is required to use the DMM to measure a DC

voltage, the first test point listed is the location for the red (+) meter lead and the second test

point is the location for the black meter lead. For example, the following statement may be

found in a RAP:

There is +5 VDC from TP7 to TP68.

In this example, the red meter lead would be placed on TP7 and the black meter lead on TP68.

Another example of a statement found in a RAP might be:

There is -15 VDC from TP21 to TP33.

In this example, the red meter lead would be placed on TP21 and the black meter lead would

be placed on TP33.

If a second test point is not given, it is assumed that the black meter lead may be attached to

the copier frame.

Logic Voltage Levels

Measurements of logic levels must be made with reference to the specified DC Common,

unless some other point is referenced in a diagnostic procedure.

Table 2 Logic Levels

VOLTAGE H/L SPECIFICATIONS

+5 VDC H= +3.00 TO +5.25 VDC

L= 0.0 TO 0.8 VDC

+24 VDC H= +23.37 TO +27.06 VDC

L= 0.0 TO 0.8 VDC

Initial Issue

CCC118, WCM118

12/2004

vii

Introduction

Page 9

T rans lat ed Warnings

Introduction

12/2004

viii

Initial Issue

CCC118, WCM1 18

Page 10

Introduction

Symbology and Nomenclatur e

WARNING

A Warning is used whenever an operating or maintenance proce dure, a p ractice, co ndition, or statement, if not strictly observed, could result in personal in j ury.

DANGER: Une note DANGER est utilisée à chaque fois qu'une procédure de maintenance ou qu'une manipulation présente un risque de blessure si elle n'a pas été strictement observée.

WARNING

This machine contains an invisible laser. There is no visual indication that the laser

beam is present. During servicing, the machine is a Class 3B product because of the

invisible laser. the laser beam could cause eye damage if lo oked at directly. Service procedures must be followed exactly as written without change. The service representative

must observe the established local laser safety precautions when servicing the

machine. Do not place tools with a reflective surface in the area of the ROS opening. Do

not look in the area of the ROS window if the power is On and the laser is energized.

DANGER: L'équipement contient un faisceau laser invisible et aucune indication visible

signale la présence du faisceau laser. De ce fait le produit est classé 3B pour tout ce qui

concerne la maintenance. L'exposition directe des yeux au faisceau laser peut entraîner

des lésions visuelles. Les procédures de maintenance doivent être réalisées sans

aucun changement comme indiqué dans la documentation. Le représentant Xerox lors

d'interventions sur l'équipement doit respecter les consignes de sécurité locales concernant les faisceaux laser. Ne pas placer d'objet réfléchissant dans la zone du ROS

quand il est ouvert. Ne pas regarder dans la zone du ROS lorsque la machine est sous

tension et que le laser est en fonctionnement.

The following symbol and statement appear on a label in the machine. The symbol by

itself, or the symbol and the statement may also appear in the service documentation

and in the training program. When this symbol appears, the service representative is

warned that conditions exist that could result in exposure to the laser beam.

DANGER: Les symboles et instructions suivants sont indiqués sur des étiquettes dans

la machine et sont identifiés dans la documentation technique et dans le manuel de formation. Quand ces symboles s'affichent le représentant Xerox est prévenu d es risques

encourus concernant une exposition au rayon laser.

WARNING

Do not try to bypass any laser interlocks for any reason. Permanent eye damage could

result if the laser is accidentally directed into your eye.

DANGER: Ne pas essayer de shunter les contacts laser pour quelques raisons que ce

soit. Si le faisceau laser est dirigé accidentellement vers les yeux il peut en résulter des

lésions oculaires permanentes.

4 Repairs and Adjustments

Drives

REP 1.1.1 Main Drive Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

Paper Transportation

REP 2.2.1 Retard Pad

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 2.4.1 Registration Unit

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 2.5.1 Left Chute Unit

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 2.5.2 BTR

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

ROS

REP 3.1.1 ROS Unit

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

Xerographics/Development

REP 4.1.1 XERO/Developer Cartridge

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

Initial Issue

CCC118, WCM118

12/2004

ix

Introduction

Page 11

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer mainte-

nance ou reglage avec le cordon d'alimentation branche.

REP 4.1.2 Toner Cartridge

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 4.2.1 Dispense Motor

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

Fuser

REP 5.1.1 Fuser Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

Exit

REP 6.1.1 Exit + OCT Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

MPT

REP 7.1.1 MPT Unit

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 7.2.1 MPT Retard Pad

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

Electrical Components

REP 9.1.1 MCU PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 9.2.1 ESS PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

Covers

REP 10.1.1 Top Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 10.2.1 Rear Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

IIT

REP 11.1.1 Control Panel

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 11.2.1 IIT Carriage Assembly

Introduction

12/2004

x

Initial Issue

CCC118, WCM1 18

Page 12

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 11.2.2 NBCR-Host/NBCR-Power Cable

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 11.4.1 Exposure Lamp

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 11.5.1 Front/Rear Carriage Cable

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 11.5.2 NSC/NBCR PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 11.5.3 Image Inverter PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 11.6.1 MFC and EXT PWB Box

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer mainte-

nance ou reglage avec le cordon d'alimentation branche.

REP 1 1.6.2 EXT PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

Tray Module -2T

REP 12.1.1 Tray 3 Feeder

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 12.1.2 Tray 4 Feeder

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 12.3.1 Feed/Retard/Nudger Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 12.6.1 2TM PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 12.7.1 Left Lower Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

Tray Module -ST

Initial Issue

CCC118, WCM118

12/2004

xi

Introduction

Page 13

REP 13.1.1 Tray 2 Feeder

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 13.3.1 Feed/Retard/Nudger Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

DADF/ADF

REP 15.1.1 DADF/ADF

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.1.2 DADF/ADF Platen Cushion

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.2.1 Document Tray Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.2.2 DADF/ADF Feeder Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.2.3 Front Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.2.4 Rear Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.3.1 DADF/ADF Control PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.3.2 Left Counter Balance

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.3.3 Right Counter Balance

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.4.1 Top Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

REP 15.8.1 Retard Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

Introduction

12/2004

xii

Initial Issue

CCC118, WCM1 18

Page 14

REP 15.9.1 Pickup Roll, Feed Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

IIT

ADJ 11.1.1 Carriage Assembly Position Adjustment

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical

power applied to the machine.

DANGER: Afin d'eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d'alimentation branche.

8 Accessories

8.1 FAX KIT

WARNING

Switch off the machine and disconnect the power cord.

DANGER: Mettre la machine sur ARRET et debrancher le cordon dalimentation.

8.2 Foreign Interface

WARNING

Switch off the machine and disconnect the power cord.

DANGER: Mettre la machine sur ARRET et debrancher le cordon dalimentation.

Initial Issue

CCC118, WCM118

12/2004

xiii

Introduction

Page 15

Service Call Procedures.................................................................................................. 1-3

Initial Actions................................................................................................................... 1-3

Call Flow .................................................................... ................................................ .. ... 1-4

Detailed Maintenance Activities (HFSI)........................................................................... 1-5

Cleaning Procedures.................................................................................... .... .. .. .... .. ..... 1-5

Final Actions.................................................................................................................... 1-6

1 Service Call Proced ur es

Initial Issue

CCC118, WCM118

12/2004

1-1

Service Call Procedures

Page 16

Service Call Procedures

Service Strategy

The service strategy for the Copy Centre C118,Work Centre M118 Copier/Printers are to

perform any High Frequency Service Item (HFSI) actions before attempting to repair any

problems. Some problems will be corrected by this strategy without the need to diagnose them.

The Repair Analysis Procedures (RAPs) will be used for any remaining problems.

Problems that occur in the Basic Printer mode will be repaired before problems that occur when

using the accessories.

Image Quality problems should be repaired after all other problems are repaired.

Service Call Procedures

The Service Call Procedures are a guide for performing any service on this machine. The

procedures are designed to be used with the Service Manual. Perform each step in order.

Initial Actions

The Initial Actions gather information about the condition of the machine and the problem that

caused the service call.

Call Flow

Call Flow summarizes the sequence of the Service Call Procedures.

Detailed Maintenance Activities

This section provide s the informa tion needed to perform the H igh Frequen cy Service It em

(HFSI) actions.

Cleaning Procedures

The cleaning procedures list what needs to be cleaned at each service call.

Final Actions

The Final Actions will test the copier/printer and return it to the customer. Administrative

activities are also performed in the Final Actions.

Initial Actions

Purpose

The purpose of the Initial Action section of the Service Call Procedures is to determine the

reason for the service call and to identify and organize the actions which must be performed.

Procedure

1. Gather the information about the service call and the condition of the copier/printer.

a. Question the operator(s). Ask about the location of most recent paper jams. Ask

about the image quality and the copier/printer performance in gene ral, including any

unusual sounds or other indications.

b. After informing the customer, disconnect the machine from the customer’s network.

c. Check that the pow er cords are in good condition, correctly plugged in the power

source, and free from any defects that would be a safety hazard. Repair or replace

the power cords as required. Check that the circuit breakers are not tripped.

d. Inspect any rejected co pies. In quire as t o, or oth erwise det ermine, the pap er qualit y and

weight. Look for any damag e to the c opies, oi l marks , image q uality de fects, o r other

indications of a problem.

e. Record the billing meter readings.

f. Enter the Diagnostics Mode.

NOTE: If a fault code is displayed while performing a diagnostics procedure, go to

that fault code RAP and repair the fault. Return to Diagnostics and continue with the

dC procedure that you were performing.

g. Determine what HFSI action is required based on the customer output volume. Refer

to the Detailed Maintenance Activities section for the detailed HFSI information.

Record any items th at require action.

h. Print the CE Report and record the information in the Jam History (IIT), Jam History

(IOT), Fatal Error History and Fax Error History. Classify this information into

categories:

Information that is related to the problem that caused the service call.

Information that is related to secondary problems.

Information that does not require action, such as a single occurrence of a

problem.

i. Check the Service Log f or any recent activities that are related to the problem that

caused the service call or any secondary problem.

2. Perform any required HFSI activities identified above . Refer to t he Detailed Maintenance

Activities section.

3. Exit diagnostics. Try to duplicate the problem by running the same jobs that the customer

was running.

4. Go to Call Flow.

Initial Issue

CCC118, WCM118

12/2004

1-3

Service Call Procedures

Service Call Procedures, Initial Actions

Page 17

Call Flow

This procedure should be performed at every service call.

Initial Actions

Ask the operator about the problem. If the problem appears to be related to operat or error, or

an attempt to perform a job outside of the machine specifications, assist the customer in learning

the correct procedure.

Procedure

Ask the operator about the problem.

• If the problem is identified by a fault code (including Paper/Document Jams), refer to

Chapter 2 for the procedure and then proceed with servicing.

• If the problem is noise or smell, select a mode (1 Sided/2 Sided etc.), find the cause of the

problem and then proceed with servicing.

The operator operated the machine correctly.

YN

Explain to the operator how to operate the machine correctly.

The UI displa y is normal.

YN

Refer to BSD (CH2.X) and repair the failure in the UI display.

The problem occurs only in Print mode.

YN

The problem occurs only in Copy mode.

YN

The problem occurs only in Fax mode.

YN

If the cause of the problem is an accessory or the Foreign Interface, check that

the machine settings are correct, refer to the appropriate service manual for the

procedure and then proceed with servicing.

E

There is a problem with R eceive transmission test. Perform Rece ive

transmission tests with other stations within the company. Check that

there is no problem with the machine and then ask the customer to

check the status of the rem ote mach ine.

Analyze the protocol trace, refer to Chapter 2 and then proceed with servicing.

Check the machine settings and if necessary, ask the customer for permission to

test the machine in the mode in which the problem occurs.

Analyze the protocol trace when the problem reoccurs, refer to Chapter 2 and then

proceed with servicing.

There is an image quality problem.

YN

If there is an alignment problem, obtain separate Platen/DADF output samples, refer

to Chapter 4 Adjustments and then proceed with servicing.

Refer to Chapter 3 IQ1 IOT Image Quality Entry RAP and then proceed with servicing.

There is a problem with the network.

YN

There is a problem with network connection.

YN

There is an image quality problem.

YN

The problem lies in a certain Client PC.

YN

There is a problem with a certain application or programming language A.

Obtain the latest information on restrictions and technical information.

Proceed accordingly.

Check the settings of that particular Client PC and if necessary ask the user to

reinstall the printer driver.

The problem occurs only in certain modes such as Broadcast transmission.

YN

Perform a transmission test with the call center or stat ion. Th e pr ob l em r eo ccu rs .

YN

Ask the customer for permission to establish communications

with the remote machine that is causing the problem. Perform a

Send transmission test with the remote machine. Transmission

was normal.

YN

AABBCCDDE

Service Call Procedures

Call Flow

Enter [Trace Dump] in [CE Setting], print the protocol trace to

identify whether it i s the remote machine or the m achine that is

causing the problem .

• If the problem lies in the machine:

Analyze the protocol trace, refer to Chapter 2 and then proc eed

with servicing.

• If the problem appears to lie in the remote machine:

Ask the customer to check the status of the remote machine.

Refer to Chapter 3 IQ1 IOT Image Quality Entry RAP and then proceed with

servicing.

If the problem persists, ask the user to reinstall the printer driver.

Check the machine settings and if necessary ask the user to reinstall the printer driver.

If the problem persists, replace the network cable. Check the machine settings and discuss the

problem with the customer's network administrator.

12/2004

1-4

CCC118, WCM1 18

Initial Issue

Page 18

Detailed Maintenance Activities (HFSI)

Procedure

1. Enter Diagnostics and select CE Setting.

2. Perform the Service Actions in Table 1 for any High Frequency Service Item (HFSI)

counters that are over threshold or approaching the threshold. Using the customer's

output volume numbers (high, medium, or low volume), evaluate which HFSI actions

should be accomplished now to avoid an additional service call in the near future.

3. Refer to Cleaning Procedures for detailed cleaning instructions.

Cleaning Procedures

Purpose

To provide cleaning procedures to be performed at every call.

Procedure

CAUTION

Do not use any solvents unless directed to do so by the Service Manual.

General Cleaning

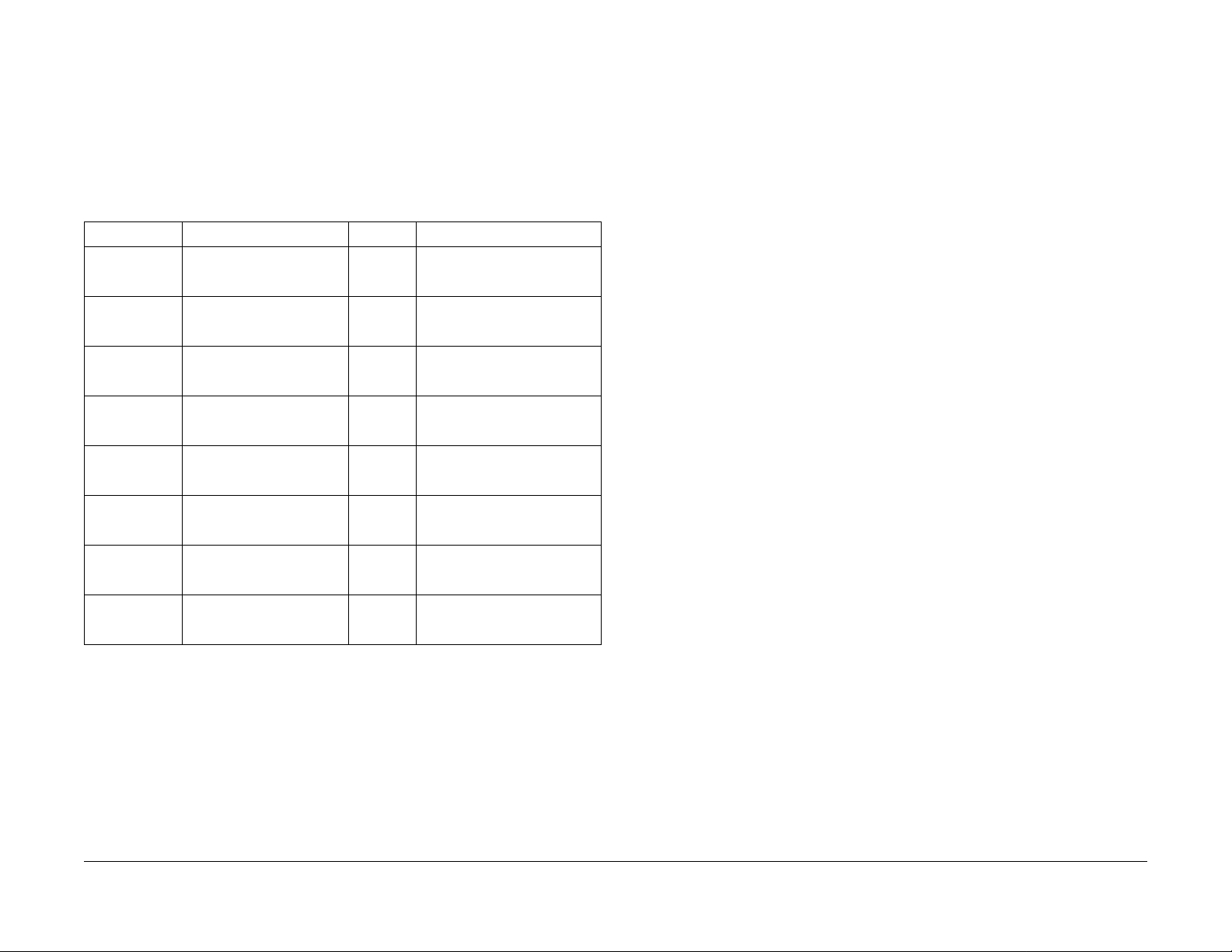

T able 1 High Frequency Service Items

Counter Name Threshold Service Action

Chain-Func Tray 1 Feed counter

[NVRAM R/W]

[29/34][29/24][29/14][29/4]

Chain-Func Tray 2 Feed counter

[NVRAM R/W]

[29/35][29/25][29/15][29/5]

Chain-Func Tray 3 Feed counter

[NVRAM R/W]

[29/36][29/26][29/16][29/6]

Chain-Func Tray 4 Feed counter

[NVRAM R/W]

[29/37][29/27][29/17][29/7]

Chain-Func MPT Feed counter

[NVRAM R/W]

[29/39][29/29][29/19][29/9]

Chain-Func Bias Transfer Roll

[NVRAM R/W]

[30/44][30/43][30/42][30/41]

Chain-Func Fuser Assembly

[NVRAM R/W]

[21/39][21/29][21/19][21/9]

Counter IIT Counter

[IIT]

[Feed]

50K Replace the Feed Roll,

Retard Pad.

Reset the cou nter.

300K Replace the Feed Roll,

Retard Roll, Nudger Roll.

Reset the cou nter.

300K Replace the Feed Roll,

Retard Roll, Nudger Roll.

Reset the cou nter.

300K Replace the Feed Roll,

Retard Roll, Nudger Roll.

Reset the cou nter.

50K Replace the Feed Roll,

Retard Pad.

Reset the cou nter.

300K Replace the Bias Transfer Roll.

Reset the cou nter.

175K Replace the Fuser Assembly.

Reset the cou nter.

100K Replace the Pick up Roll,

Feed Roll, Retard Roll.

Use a dry lint free cloth or a lint free cloth moistened with water for all cleaning unless directed

otherwise by the Service Manual. Wipe with a dry lint free cloth if a moistened cloth is used.

1. IOT Feed Com ponents (Rolls an d Pads)

Follow the General Cleaning procedure above.

2. Toner Disp ense Units

Vacuum the Toner at the Toner Housing.

3. Jam Sensors

Clean the sensors with a dry cotton swab.

4. Scanner

a. Switch off the power and allow the Exposure Lamp to cool off.

b. Using the optical Cleaning Cloth, clean the front and rear of the Document Glass,

Document Cover, White Reference Strip, Reflector, and Mirror.

c. Clean the Exposure Lamp with a clean cloth and Film Remover.

d. Clean the Lens with Lens and Mirror Cleaner and lint free cloth.

5. DADF/ADF

Check the paper path for debris or damage. Clean the rolls with a clean cloth and Film

Remover as required.

6. Sheet Platen Glass and DADF Platen Glass.

Follow the General Cleaning procedure above.

Initial Issue

CCC118, WCM118

12/2004

1-5

Service Call Procedures

Detailed Maintenance Activities, Cleani n g Proce-

Page 19

Final Actions

Purpose

To provide a guide for procedures to be performed at the end of every service call.

Procedure

1. Ensure that the exterior of the copier/printer and the adjacent area are clean. Use a dry

cloth or a cloth moistened with water to clean the copier/printer. Do not use solvents.

2. Check the supply of consumable. Ensure that an adequate supply of consumable is available according to local operating procedures.

3. Complete the Service Log.

4. Perform the following steps to make a copy of the Demonstration Original for the

customer:

a. Load Tray 1 with 8.5 x 11 inch (A4) or 11 x 17 inch paper.

b. Place the Tes t Pattern on t he glass with the short edge of the test pattern registered

to the left edge of the glass. Select Tray 1 and make a single copy.

c. Print out the CE Report. Store this report with the service log in the Inner Cover.

d. Ask the customer to verify the Print and Scan functions.

e. Present the copies to the customer.

5. Reconnect the machine to the customer network. Verify the function.

6. Issue copy credits as needed.

7. Discuss the service call with the customer to ensure that the customer understands

what has been done and is satisf ied with the results of the service call.

Service Call Procedures

Final Actions

12/2004

1-6

Initial Issue

CCC118, WCM1 18

Page 20

2 Status Indicator RAPs

C-Status Code

C1-3000 Registration Sensor On JAM RAP (Tray 1 Feed)............................................ 2-3

C2-2000 Tray 2 Feed Out Sensor On JAM RAP (Tray 2 Feed)..................................... 2-4

C2-3000 Registration Sensor On JAM RAP (Tray 2 Feed)............................................ 2-5

C3-1000 Tray 3 Feed Out Sensor On JAM RAP (Tray 3 Feed)..................................... 2-6

C3-2000 Tray 2 Feed Out Sensor On JAM RAP (Tray 3 Feed)..................................... 2-7

C3-3000 Registration Sensor On JAM RAP (Tray 3 Feed)............................................ 2-8

C4-0000 Tray 4 Feed Out Sensor On JAM RAP (Tray 4 Feed)..................................... 2-9

C4-1000 Tray 3 Feed Out Sensor On JAM RAP (Tray 4 Feed)..................................... 2-10

C4-2000 Tray 2 Feed Out Sensor On JAM RAP (Tray 4 Feed)..................................... 2-11

C4-3000 Registration Sensor On JAM RAP (Tray 4 Feed)............................................ 2-12

C6-1000 Registration Sensor On JAM RAP (DUP Feed/Stop Case) ............................ 2-13

C6-2000 Registration Sensor On JAM RAP (DUP Feed/Nonstop Case) ...................... 2-14

C8-2000 Tray 2 Feed Out Sensor Static JAM RAP ....................................................... 2-15

C8-3000 Tray 3 Feed Out Sensor Static JAM RAP ....................................................... 2-15

C8-4000 Tray 4 Feed Out Sensor Static JAM RAP ....................................................... 2-16

C8-6000 Duplex Sensor Static JAM RAP ...................................................................... 2-16

C9-3000 Registration Sensor On JAM RAP (MPT Feed) .............................................. 2-17

E-Status Code

E1-1000 Registration Sensor Off JAM RAP................................................................... 2-19

E1-2000 Fuser Exit Sensor On JAM RAP...................................................................... 2-20

E1-6000 Registration Sen sor Static JAM RAP ............... ............................................... 2-21

E3-1000 Fuser Exit Sensor Off JAM RAP...................................................................... 2-21

E3-2000 Fuser Exit Sensor Off JAM RAP (Too Short) .................................................. 2-22

E3-6000 Fuser Exit Sensor Static JAM RAP ................................................................. 2-23

E8-2000 Duplex Sensor On JAM RAP........................................................................... 2-23

H-Status Code

H1-2000 Tray 2 Lift Up / No Tray Failure RAP................................................................ 2-25

H1-3000 Tray 3 Lift Up / No Tray Failure RAP................................................................ 2-26

H1-4000 Tray 4 Lift Up / No Tray Failure RAP................................................................ 2-27

H2-7000 DUP Module Communication Failure RAP...................................................... 2-28

H3-1000 OCT1 Failure RAP .......................................................................................... 2-28

H4-1000 Tray 1 Cassette Size Failure RAP................................................................... 2-29

H4-2000 Tray 2 Cassette Size Failure RAP................................................................... 2-30

H4-3000 Tray 3 Cassette Size Failure RAP................................................................... 2-30

H4-4000 Tray 4 Cassette Size Failure RAP................................................................... 2-31

H7-3000 2TM NVM Out-Of-Order RAP.......................................................................... 2-31

H7-4000 2TM NVM R/W Error RAP............................................................................... 2-32

H7-7000 2TM Communication Failure RAP.................................................. .... .. .... .. ..... 2-32

H7-8000 TM Type Error RAP......................................................................................... 2-33

H8-1000 Tray 1 Paper Size Switch Broken RAP........................................................... 2-33

H8-2000 Tray 2 Paper Size Switch Broken RAP........................................................... 2-34

H8-3000 Tray 3 Paper Size Switch Broken RAP........................................................... 2-34

H8-4000 Tray 4 Paper Size Switch Broken RAP........................................................... 2-35

H9-3000 STM NVM Out-Of-Order RAP ......................................................................... 2-35

H9-4000 STM NVM R/W Error RAP .............................................................................. 2-36

H9-7000 STM Communication Failure RAP................................................................... 2-36

J-Status Code

J1-2000 Toner Cartridge Empty Failure RAP................................................................. 2-37

J3-1000 XERO/Developer Cartridge Set Failure RAP................................................... 2-37

J4-1000 ATC Sensor Failure RAP...................................................................... ........... 2-38

J6-1000 XERO/Developer Cartridge Life Over RAP...................................................... 2-39

J7-1000 XERO/Developer Cartridge CRUM Communication Failure RAP.................... 2-40

J7-2000 XERO/Developer Cartridge CRUM Data Write Failure RAP........................... . 2-40

J7-3000 XERO/Developer Cartridge CRUM ID Failure RAP ......................................... 2-41

J8-1000 Toner Cartridge CRUM Communication Failure RAP...................................... 2-41

J8-2000 MCU Toner Cartridge CRUM Data Write Failure RAP..................................... 2-42

J8-3000 Toner Cartridge CRUM ID Failure RAP ........................................................... 2-42

S-Status Code

S1-0000 Carriage Error RAP.......................................................................................... 2-43

S1-0001 DADF/ADF Top Cover Open During Platen Scan RAP................................... 2-44

S1-0010 Jam During Feed RAP.................................................................................... . 2-44

S1-0011 Jam During Scan RAP..................................................................................... 2-45

S1-0012 Long Document JAM RAP. .............................................................................. 2-46

S1-0013 Short Document JAM RAP.............................................................................. 2-47

S1-0014 ADF Static JAM RAP....................................................................................... 2-48

S1-0015 Platen Cover Open During ADF Scan RAP..................................................... 2-49

S1-0016 ADF Top Cover Open During ADF Scan RAP................................................. 2-49

S1-0020 Jam During Feed RAP.................................................................................... . 2-50

S1-0021 Jam During Scan RAP..................................................................................... 2-51

S1-0022 Long Document JAM RAP. .............................................................................. 2-52

S1-0023 Short Document JAM RAP.............................................................................. 2-53

S1-0024 Jam During Invert Transport RAP................................................................... 2-53

S1-0025 DADF Static JAM RAP ....... ............................................................................. 2-54

S1-0026 Platen Cover Open During DADF Scan RAP.................................................. 2-55

S1-0027 ADF Top Cover Open During DADF Scan RAP.............................................. 2-56

U-Status Code

U0-1000 Main Motor Stop Error RAP............................................................................. 2-57

U0-2000 Image Ready Error RAP.................................................................................. 2-57

U1-1000 Main Motor Failure RAP .................................................................................. 2-58

U3-5000 ROS Motor Failure RAP .................................................................................. 2-59

U4-1000 Fuser On Time Failure RAP............................................................................ 2-59

U4-2000 Over Heat Temp Failure RAP.......................................................................... 2-60

U4-3000 Control Thermistor Failure RAP ...................................................................... 2-61

U4-9000 Fuser Fan Failure RAP.................................................................................... 2-61

U5-1000 Dispense Motor Failure RAP........................................................................... 2-62

U6-2000 RAM Read/Write Check Failure RAP.............................................................. 2-62

U6-3000 NVM Data Defect RAP .................................................................................... 2-63

U6-4000 NVM Read/Write Cannot Be Executed RAP................................................... 2-63

U6-5000 CPU Power To Access NVM Is Not Enough RAP........................................... 2-64

U6-6000 CRUM ASIC Failure RAP................................................................................ 2-64

Initial Issue

CCC118, WCM118

12/2004

2-1

Status Indicator RAPs

Page 21

Z-Status Code

Z1-0000 Billing Counter Failure RAP............................................................................. 2-65

Fax Error Code

00xxxx Polling Operation Error RAP.............................................................................. 2-67

01xxxx Document Feed Failure RAP............................................................................. 2-67

02xxxx Dial Setting Failure RAP............................................ ........................................ 2-68

03xxxx Password Mismatch During Send RAP ............................................................. 2-68

04xxxx Password Mismatch During Receive RAP......................................................... 2-69

05xxxx Password Mismatch During Polling RAP........................................................... 2-69

06xxxx Relay Broadcast Not Allowed RAP. . .................................................................. 2-70

07xxxx Mailbox Receive Not Allowed RAP............. ....................................................... 2-70

09xxxx Transmission Type Mismatch RAP.................................................................... 2-71

10xxxx F Code Send Error RAP .................................................................................... 2-71

11xxxx F Code Receive Error RAP................................................................................ 2-72

33xxxx V.34 Protocol Error RAP.................................................................................... 2-72

45xxxx Memory Overflow RAP.............. ........................................................................ 2-73

46xxxx Document JAM RAP............................................................ .............................. 2-73

47xxxx Error During Receive RAP ................................................................................. 2-74

70xxxx Busy Tone RAP ................................................................................................. 2-74

71xxxx No Response RAP . ............................................................................................ 2-75

72xxxx Remote Machine Error RAP .............................................................................. 2-75

74xxxx Transmission Error RAP .................................................................................... 2-76

76xxxx Polarity Reversal Detected Other Than While Waiting To Receive Initial Identification

Signal RAP....................................................................... ....... .. .... .. .... .. ......... .. .... .. .... .....2-76

77xxxx No Response To Post Message RAP................................................................ 2-77

78xxxx DCN Received While Waiting For Response To Post Message RAP ............... 2-77

79xxxx PIP Received In Response To Post Message RAP........................................... 2-78

7Axxxx RTN Received In Response To Post Message RAP......................................... 2-78

7Cxxxx CRP Received RAP .................. ................................................. ....................... 2-79

7Dxxxx Command Error For Receive RAP............................................... ..................... 2-79

7Fxxxx No Response From Remote Machine After Mode Change (T1 Time out) RAP 2-80

8Fxxxx PIN Received In Response To Post Message RAP .......................................... 2-80

91xxxx No Response RAP . ............................................................................................ 2-81

92xxxx DCN Received While Waiting For Command Other Than DCN In PHASE-B RAP 2-81

95xxxx Time out 10 sec. After Detecting Low Speed Flag While Waiting For Image Signal Car-

rier (HMCD ON) Detection RAP...................................................................................... 2-82

96xxxx Carrier Was Broken Within 15 sec. When Receiving G3 Image Signal RAP .... 2-82

97xxxx T2 Time out RAP............................................................................................... 2-83

98xxxx DCN Received While Waiting For Command Other Than DCN In PHASE-D RAP 2-83

99xxxx PRI-Q Received RAP ......................................................................................... 2-84

9Axxxx Decoding Error RAP.......................................................................................... 2-84

9Cxxxx CRP Was Received Three Times While Waiting For Response To Initial Identification

Signal RAP....................................................................... ....... .. .... .. .... ....... .... .. .... .... .. .....2-85

9Dxxxx Command Error For Receive (Carrier Was Not Broken) RAP .......................... 2-85

9Fxxxx EOR-Q RAP................ .......... ........... .................... ..... ................. .............. ....... ... 2-86

B0xxxx Power Supp ly Was Cut Off RAP ....................................................................... 2-86

B2xxxx System Error RAP.......................................... ................................................... 2-87

B4xxxx Modem Error RAP ............................................................................................. 2-87

B5xxxx Modem Error During Send RAP ........................................................................ 2-88

B6xxxx Modem Error During Receive RAP.. .................................................................. 2-88

B7xxxx Image Data Conversion System Error RAP ...................................................... 2-89

E1xxxx Scan to E-mail Transmission Error RAP......... ................................................ ... 2-89

E2xxxx Direct Fax Transmissio n Error RAP.................... ............................................... 2-90

EPxxxx EP Related RAP................................................................................................ 2-90

ESS Failure List

PRINTER ESS Failure List.............................................................................................. 2-91

Other Faults

OF1 Warning Toner Cartridge Was PRENEAR Empty RAP........................................... 2-109

OF2 Warning Drum Life Was Near To End RAP ............................................................ 2-110

OF3 Warning No Paper In The Select Paper Tray RAP ................................................. 2-110

OF4 Warning Paper Size Mismatch In Length RAP........................................................ 2-111

OF5 Warning Paper Size Mismatch In Width RAP . ........................................................ 2-112

OF6 Cover Left Cover Assembly Open RAP .................................................................. 2-113

OF7 Cover IOT Front Cover Open RAP.......................................................................... 2-114

OF8 Cover STM Left Cover Open RAP .......................................................................... 2-114

OF9 Cover 2TM Left Cover Open RAP........................................................................... 2-115

OF10 Cover Duplex Cover Open RAP............................................................................ 2-115

OF11 Size Switch Assy RAP......................................................................... .................. 2-116

OF12 Receive Fax No t Output RAP............................................................................... 2-117

OF13 Abort Code RAP.............................................................. ..................................... 2-118

Status Indicator RAPs

12/2004

2-2

Initial Issue

CCC118, WCM118

Page 22

C1-3000 Registration Se nsor On JAM RAP (Tray 1 Feed)

After the Tray 1 Feed Clutch turned On, the Registration Sensor did not turn On within the

specified time.

Initial Actions

Refer to BSD 8.1/8.6.

A

YN

Connect P/J217 and P/J415.

Measure the resistance of the Tray 1 Feed Clut ch (PL 2.3) (BSD 8.1 Flag 2). (Between

P217-1 and P217-4). The resistance is approx. 186Ohm.

YN

Replace the Tray 1 Feed Clutch (PL 2.3).

Power OFF/ON

Procedure

Check the Transport Roll for wear and paper powder. The Transport Roll is ok.

YN

Replace the Transport Roll.

Check for foreign substances, distortion and paper powder in the paper transport path. No

foreign substances, distortion or paper powder are found in the paper transport pa th.

YN

Clear away the foreign substances and paper powder. Correct the distortion.

Execute Input/Output Check[8-5 Registration Sensor]. Manually act ivate the actuator of the

Registration Sensor (PL 2.4). The display changes.

YN

Check the connection of P/J104. P/J104 is connected correctly.

YN

Connect P/J104.

Check the wire between J104 and J403 for an open circuit or a short circuit (BSD 8.6 Flag

1/Flag 2). The wire between J104 and J403 is conducting without an open circuit or

a short circuit.

YN

Repair the open circuit or short circuit.

Measure the voltage between the MCU PWB P403-B15 (+) and the GND (-) (BSD 8.6

Flag 2). The voltage is approx. +5VDC.

YN

Replace the MCU PWB (PL 9.1).

Check the wire between J217 and J415 for an open circuit or a short circuit (BSD 8.1 Flag

2). The wire between J217 and J415 is conducting witho ut an op en circuit or a short

circuit.

YN

Repair the open circuit or short circuit.

Replace the MCU PWB (PL 9.1).

Replace the MCU PWB (PL 9.1).

Measure the voltage between the MCU PWB P403-B14 (+) and the GND (-) (BSD 8.6

Flag 1). Place paper in front of the Registration Sensor. The voltage changes.

YN

Replace the Registration Sensor (PL 2.4).

Replace the MCU PWB (PL 9.1).

Execute Input/Output Check[8-12 Tray 1 Feed Clutch ON]. The Tray 1 Feed Clutch (PL 2.3)

can be heard.

YN

Check the connections of P/J217 and P/J415. P/J217 and P/J415 are connected

correctly.

A

Initial Issue

CCC118, WCM118

12/2004

2-3

Status Indic a tor RAPs

C1-3000

Page 23

C2-2000 Tray 2 Feed Out Sensor On JAM RAP (Tray 2

Feed)

After the Tray 2 Feed/Lift Up Motor turned On, the Tra y 2 Feed Out Sensor did not turn On

within the specified time.

YN

Check the connections of P/J281 and P/J661C. P/J281 and P/J661C are connected

correctly.

YN

Connect P/J281 and P/J661C.

Initial Actions

Refer to BSD 7.6/8.2.

Power OFF/ON

Procedure

Check the Transport Roll for wear and paper powder. The Transport Roll is ok.

YN

Replace the Transport Roll.

Check for foreign substances, distortion and paper powder in the paper transport path. No

foreign substances, distortion or paper powder are found in the paper transport pa th.

YN

Clear away the foreign substances and paper powder. Correct the distortion.

Execute Input/Output Check[8-6 Tray 2 Feed Out Sensor]. Place paper in front of the Tray 2

Feed Out Sensor (PL 13.5). The display changes.

YN

Check the connections of P/J182 and P/J548C. P/J182 and P/J548C are connected

correctly.

YN

Connect P/J182 and P/J548C.

Check the wire between J182 and J548C f or an open circuit or a s hort circuit (BSD 8.2

Flag 1/Flag 2). The wire between J182 and J548C is conducting without an open

circuit or a short circuit.

YN

Repair the open circuit or short circuit.

Check the wire between J281 and J661C for an open circuit or a short circuit (BSD 7.6

Flag 1). The wire between J281 and J661C is conducting without an open circuit or

a short circuit.

YN

Repair the open circuit or short circuit.

Replace the Tray 2 Feed/Lift Up M oto r (PL 13 .3) followed by the MCU PWB (PL 9.1).

Replace the MCU PWB (PL 9.1).

Measure the voltage between the STM PWB P548C-3 (+) and the GND (-) (BSD 8.2 Flag

2). The voltage is approx. +5VDC.

YN

Replace the STM PWB (PL 13.6).

Measure the voltage between the STM PWB P548C-5 (+) and the GND (-) (BSD 8.2 Flag

1). Place paper in front of the Tray 2 Feed Out Sensor (PL 13.5). The voltage changes.

YN

Replace the Tray 2 Feed Out Sensor (PL 13.5).

Replace the STM PWB (PL 13.6).

Execute Input/Output Check[8-13 Tray 2 Feed/Lift Up Motor ON]. The Tray 2 Feed/Lift Up

Motor (PL 13.3) can be heard.

Status Indicator RAPs

C2-2000

12/2004

2-4

Initial Issue

CCC118, WCM1 18

Page 24

C2-3000 Registration Se nsor On JAM RAP (Tray 2 Feed)

After the Tray 2 Feed Out Sensor turned On, the Registration Sensor did not turn On within the

specified time.

Initial Actions

Refer to BSD 8.2/8.6.

A

YN

Connect P/J280 and P/J552C.

Measure the resistance of the STM Takeaway Roll Clutch (PL 13.6) (BSD 8.2 Flag 2).

(Between P280-1 and P280-2) There is no open circuit.

YN

Replace the STM Takeaway Roll Clutch (PL 13.6).

Power OFF/ON

Procedure

Check the Transport Roll for wear and paper powder. The Transport Roll is ok.

YN

Replace the Transport Roll.

Check for foreign substances, distortion and paper powder in the paper transport path. No

foreign substances, distortion or paper powder are found in the paper transport pa th.

YN

Clear away the foreign substances and paper powder. Correct the distortion.

Execute Input/Output Check[8-5 Registration Sensor]. Manually act ivate the actuator of the

Registration Sensor (PL 2.4). The display changes.

YN

Check the connection of P/J104. P/J104 is connected correctly.

YN

Connect P/J104.

Check the wire between J104 and J403 for an open circuit or a short circuit (BSD 8.6 Flag

1/Flag 2). The wire between J104 and J403 is conducting without an open circuit or

a short circuit.

YN

Repair the open circuit or short circuit.

Measure the voltage between the MCU PWB P403-B15 (+) and the GND (-) (BSD 8.6

Flag 2). The voltage is approx. +5VDC.

YN

Replace the MCU PWB (PL 9.1).

Check the wire between J280 and J552C for an open circuit or a short circuit (BSD 8.2

Flag 2). The wire between J280 and J552C is conducting without an open circuit or

a short circuit.

YN

Repair the open circuit or short circuit.

Replace the STM PWB (PL 13.6) followed by the MCU PWB (PL 9.1).

Replace the MCU PWB (PL 9.1).

Measure the voltage between the MCU PWB P403-B14 (+) and the GND (-) (BSD 8.6

Flag 1). Place paper in front of the Registration Sensor. The voltage changes.

YN

Replace the Registration Sensor (PL 2.4).

Replace the MCU PWB (PL 9.1).

Execute Input/Output Check[8-24 STM Takeaway Roll Clutch ON]. The STM Takeaway Roll

Clutch (PL 13.6) can be heard.

YN

Check the connections of P/J280 and P/J552C. P/J280 and P/J552C are connected

correctly.

A

Initial Issue

CCC118, WCM118

12/2004

2-5

Status Indic a tor RAPs

C2-3000

Page 25

C3-1000 Tray 3 Feed Out Sensor On JAM RAP (Tray 3

Feed)

After the Tray 3 Feed/Lift Up Motor turned On, the Tra y 3 Feed Out Sensor did not turn On

within the specified time.

YN

Check the connections of P/J220B, P/J661B and P549. P/J220B, P/J661B and P549

are connected correctly.

YN

Connect P/J220B, P/J661B and P549.

Initial Actions

Refer to BSD 7.7/8.3.

Power OFF/ON

Procedure

Check the Transport Roll for wear and paper powder. The Transport Roll is ok.

YN

Replace the Transport Roll.

Check for foreign substances, distortion and paper powder in the paper transport path. No

foreign substances, distortion or paper powder are found in the paper transport pa th.

YN

Clear away the foreign substances and paper powder. Correct the distortion.

Execute Input/Output Check[8-8 Tray 3 Feed Out Sensor]. Place paper in front of the Tray 3

Feed Out Sensor (PL 12.5). The display changes.

YN

Check the connections of P/J821, P/J841 and P/J548. P/J821, P/J841 and P/J548

are connected correctly.

YN

Connect P/J821, P/J841 and P/J548.

Check the wire between J821 and J548 for an open circuit or a short circuit (BSD 8.3 Flag

1/Flag 2). The wire between J821 and J548 is conducting without an open circuit or

a short circuit.

YN

Repair the open circuit or short circuit.

Remove the Tray 3 Feed/Lift Up Motor (PL 12.3) and the Tray 4 Feed/Lift Up Motor (PL

12.3). Replace the Tray 3 Feed/Lift Up Motor with the Tray 4 Feed/Lift Up Motor. Execute

Input/Output Check[8-14 Tray 3 Feed/Lift Up Motor ON]. The Tray 4 Feed/Lift Up Motor

(PL 12.3) can be heard.

YN

Return the Tray 4 Feed/Lift Up Motor to its original position. Check the wire between

J220B and J549 for an open circuit or a short circuit (BSD 7.7 Flag 1). The wire

between J220B and J549 is conducting without an open circuit or a short

circuit.

YN

Repair the open circuit or short circuit.

Replace the 2TM PWB (PL 12.6).

Return the Tray 4 Feed/Lift Up Motor to its original position.

Replace the Tray 3 Feed/Lift Up M oto r (PL 12.3).

Replace the 2TM PWB (PL 12.6).

Measure the voltage between the 2TM PWB P548-8 (+) and the GND (-) (BSD 8.3 Flag

2). The voltage is approx. +5VDC.

YN

Replace the 2TM PWB (PL 12.6).

Measure the voltage between the 2TM PWB P548-10 (+) and the GND (-) (BSD 8.3 Flag

1). Place paper in front of the Tray 3 Feed Out Sensor (PL 12.5). The voltage changes.

YN

Replace the Tray 3 Feed Out Sensor (PL 12.5).

Replace the 2TM PWB (PL 12.6).

Execute Input/Output Check[8-14 Tray 3 Feed/Lift Up Motor ON]. The Tray 3 Feed/Lift Up

Motor (PL 12.3) can be heard.

Status Indicator RAPs

C3-1000

12/2004

2-6

Initial Issue

CCC118, WCM1 18

Page 26

C3-2000 Tray 2 Feed Out Sensor On JAM RAP (Tray 3

Feed)

After the Tray 3 Feed Out Sensor turned On, the Tray 2 Feed Out Sensor did not turn On within

the specified time.

YN

Check the connections of P/J220B, P/J661B and P549. P/J220B, P/J661B and P549

are connected correctly.

YN

Connect P/J220B, P/J661B and P549.

Initial Actions

Refer to BSD 7.7/8.2.

Power OFF/ON

Procedure

Check the Transport Roll for wear and paper powder. The Transport Roll is ok.

YN

Replace the Transport Roll.

Check for foreign substances, distortion and paper powder in the paper transport path. No

foreign substances, distortion or paper powder are found in the paper transport pa th.

YN

Clear away the foreign substances and paper powder. Correct the distortion.

Execute Input/Output Check[8-6 Tray 2 Feed Out Sensor]. Place paper in front of the Tray 2

Feed Out Sensor (PL 13.5). The display changes.

YN

Check the connections of P/J182 and P/J548C. P/J182 and P/J548C are connected

correctly.

YN

Connect P/J182 and P/J548C.

Check the wire between J182 and J548C f or an open circuit or a s hort circuit (BSD 8.2

Flag 1/Flag 2). The wire between J182 and J548C is conducting without an open

circuit or a short circuit.

YN

Repair the open circuit or short circuit.

Remove the Tray 3 Feed/Lift Up Motor (PL 12.3) and the Tray 4 Feed/Lift Up Motor (PL

12.3). Replace the Tray 3 Feed/Lift Up Motor with the Tray 4 Feed/Lift Up Motor. Execute

Input/Output Check[8-14 Tray 3 Feed/Lift Up Motor ON]. The Tray 4 Feed/Lift Up Motor

(PL 12.3) can be heard.

YN

Return the Tray 4 Feed/Lift Up Motor to its original position. Check the wire between

J220B and J549 for an open circuit or a short circuit (BSD 7.7 Flag 1). The wire

between J220B and J549 is conducting without an open circuit or a short

circuit.

YN

Repair the open circuit or short circuit.

Replace the 2TM PWB (PL 12.6).

Return the Tray 4 Feed/Lift Up Motor to its original position.

Replace the Tray 3 Feed/Lift Up M oto r (PL 12.3).

Replace the 2TM PWB (PL 12.6).

Measure the voltage between the STM PWB P548C-3 (+) and the GND (-) (BSD 8.2 Flag

2). The voltage is approx. +5VDC.

YN

Replace the STM PWB (PL 13.6).

Measure the voltage between the STM PWB P548C-5 (+) and the GND (-) (BSD 8.2 Flag

1). Place paper in front of the Tray 2 Feed Out Sensor (PL 13.5). The voltage changes.

YN

Replace the Tray 2 Feed Out Sensor (PL 13.5).