Page 1

damage from electrostatic discharge. Observe all

DocuPrint C55/C55mp/[NC60]

Color Laser Printer

(50/60 Hz)

Service Manual

701P14760

February, 1999

CAUTION

Certain components in the DocuPrint C55/C55mp/

[NC60] Color Laser Printers are susceptible to

ESD procedures to avoid component damage.

Page 2

NOTICE

CLASS 1 LASER PRODUCTS

“All Service documentation is supplied to Xerox

external customers for informational purposes

only. Xerox Service Documentation is intended

for use by certified, product trained personnel

only. Xerox does not warrant or represent that

such documentation is complete, nor does Xerox

represent or warrant that it will notify or provide

to such customer any future changes to this

documentation. Customer performed service of

equipment, or modules, may affect the warranty

offered by Xerox with respect to such equipment.

You should consult the applicable warranty for its

terms regarding customer or third party provided

service. If the customer services such

equipment, modules, components or parts

thereof, the customer releases Xerox from any

and all liability for the customer actions, and the

customer agrees to indemnify, defend and hold

Xerox harmless from any third party claims

which arise directly or indirectly from such

service.”

This product is certified as a Class 1 Laser

product and complies with DHHS LaserRadiation Standards, 21 CFR Chapter 1 Subchapter J.

WARNING

Use of controls, adjustments, or performances of procedures other than those

specified in this manual may result in

hazardous radiation exposures.

The C55/C55mp/[NC60] each contain an

invisible laser. There is no visual indication that

the laser beam is present. During servicing, the

C55/C55mp/[NC60] remain a Class 1 product

because of the interlock system. Do not attempt

to cheat the interlock switches on this printer.

Prepared by:

Xerox Corporation

Multinational Customer and Service Education

780 Salt Road

Webster, New York 14580

©1999 by Xerox Corporation. All rights reserved.

Xerox and all Xerox products mentioned in this publication

are registered trademarks of the Xerox Corporation

Page 3

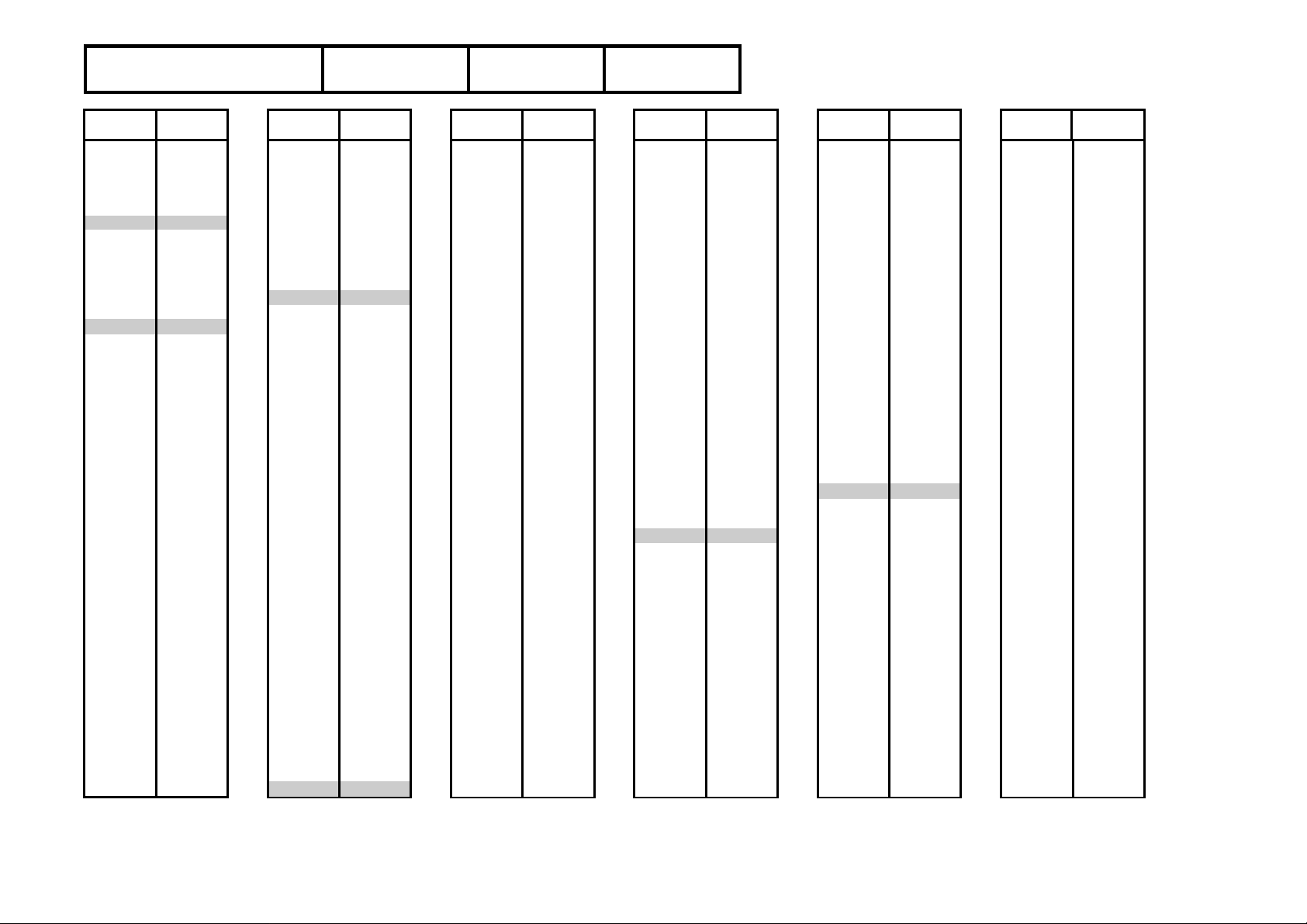

Product

DocuPrint C55/C55mp/[NC60]

Title

Service Manual

Part Number

701P14760

Date

February 1999

Page Rev.

Title 2/99

i 2/99

ii 2/99

iii 2/99

iv 2/99

1-1 2/99

1-2 2/99

1-3 2/99

1-4 2/99

1-5 2/99

1-6 2/99

2-1 2/99

2-2 2/99

2-3 2/99

2-4 2/99

2-5 2/99

2-6 2/99

2-7 2/99

2-8 2/99

2-9 2/99

2-10 2/99

2-11 2/99

2-12 2/99

2-13 2/99

2-14 2/99

2-15 2/99

2-16 2/99

2-17 2/99

2-18 2/99

2-19 2/99

2-20 2/99

2-21 2/99

2-22 2/99

2-23 2/99

2-24 2/99

2-25 2/99

2-26 2/99

2-27 2/99

2-28 2/99

2-30 2/99

2-31 2/99

2-32 2/99

Page Rev.

2-33 2/99

2-34 2/99

2-35 2/99

2-36 2/99

2-37 2/99

2-38 2/99

2-39 2/99

2-40 2/99

2-41 2/99

2-42 2/99

3-1 2/99

3-2 2/99

3-3 2/99

3-4 2/99

3-5 2/99

3-6 2/99

3-7 2/99

3-8 2/99

3-9 2/99

3-10 2/99

3-11 2/99

3-12 2/99

3-13 2/99

3-14 2/99

3-15 2/99

3-16 2/99

3-17 2/99

3-18 2/99

3-19 2/99

3-20 2/99

3-21 2/99

3-22 2/99

3-23 2/99

3-24 2/99

3-25 2/99

3-26 2/99

3-27 2/99

3-28 2/99

3-29 2/99

3-30 2/99

3-21 2/99

3-32 2/99

Page Rev.

4-1 2/99

4-2 2/99

4-3 2/99

4-4 2/99

4-5 2/99

4-6 2/99

4-7 2/99

4-8 2/99

4-9 2/99

4-10 2/99

4-11 2/99

4-12 2/99

4-13 2/99

4-14 2/99

4-15 2/99

4-16 2/99

4-17 2/99

4-18 2/99

4-19 2/99

4-20 2/99

4-21 2/99

4-22 2/99

4-23 2/99

4-24 2/99

4-25 2/99

4-26 2/99

4-27 2/99

4-28 2/99

4-29 2/99

4-30 2/99

4-31 2/99

4-32 2/99

4-33 2/99

4-34 2/99

4-35 2/99

4-36 2/99

4-37 2/99

4-38 2/99

4-39 2/99

4-40 2/99

4-41 2/99

4-42 2/99

4-43 2/99

4-44 2/99

Page Rev.

4-45 2/99

4-46 2/99

4-47 2/99

4-48 2/99

4-49 2/99

4-50 2/99

4-51 2/99

4-52 2/99

4-53 2/99

4-54 2/99

4-55 2/99

4-56 2/99

4-57 2/99

4-58 2/99

4-59 2/99

4-60 2/99

4-61 2/99

4-62 2/99

4-63 2/99

4-64 2/99

4-65 2/99

4-66 2/99

4-67 2/99

4-68 2/99

4-69 2/99

4-70 2/99

5-1 2/99

5-2 2/99

5-3 2/99

5-4 2/99

5-5 2/99

5-6 2/99

5-7 2/99

5-8 2/99

5-9 2/99

5-10 2/99

5-11 2/99

5-12 2/99

5-13 2/99

5-14 2/99

5-15 2/99

5-16 2/99

5-17 2/99

Page Rev.

5-18 2/99

5-19 2/99

5-20 2/99

5-21 2/99

5-22 2/99

5-23 2/99

5-24 2/99

5-25 2/99

5-26 2/99

5-27 2/99

5-28 2/99

5-29 2/99

5-30 2/99

5-31 2/99

5-32 2/99

5-33 2/99

5-34 2/99

5-35 2/99

5-36 2/99

5-37 2/99

5-38 2/99

5-39 2/99

5-40 2/99

6-1 2/99

6-2 2/99

6-3 2/99

6-4 2/99

6-5 2/99

6-6 2/99

6-7 2/99

6-8 2/99

6-9 2/99

6-10 2/99

6-11 2/99

6-12 2/99

6-13 2/99

6-14 2/99

6-15 2/99

6-16 2/99

6-17 2/99

6-18 2/99

6-19 2/99

6-20 2/99

Page Rev.

6-21 2/99

6-22 2/99

6-23 2/99

6-24 2/99

6-25 2/99

6-26 2/99

6-27 2/99

6-28 2/99

6-29 2/99

6-30 2/99

6-31 2/99

6-32 2/99

6-33 2/99

6-34 2/99

6-35 2/99

6-36 2/99

6-37 2/99

6-38 2/99

6-39 2/99

6-40 2/99

6-41 2/99

6-42 2/99

6-43 2/99

6-44 2/99

6-45 2/99

6-46 2/99

6-47 2/99

6-48 2/99

6-49 2/99

6-50 2/99

6-51 2/99

6-52 2/99

6-53 2/99

6-54 2/99

6-55 2/99

6-56 2/99

6-57 2/99

6-58 2/99

6-59 2/99

6-60 2/99

6-61 2/99

6-62 2/99

6-63 2/99

6-64 2/99

Page 4

Page Rev.

6-65 2/99

6-66 2/99

6-67 2/99

6-68 2/99

6-69 2/99

6-70 2/99

6-71 2/99

6-72 2/99

6-73 2/99

6-74 2/99

6-75 2/99

6-76 2/99

7-1 2/99

7-2 2/99

7-3 2/99

7-4 2/99

7-5 2/99

7-6 2/99

7-7 2/99

7-8 2/99

7-9 2/99

7-10 2/99

7-11 2/99

7-12 2/99

7-13 2/99

7-14 2/99

7-15 2/99

7-16 2/99

7-17 2/99

7-18 2/99

7-19 2/99

7-20 2/99

7-21 2/99

7-22 2/99

7-23 2/99

7-24 2/99

7-25 2/99

7-23 2/99

7-24 2/99

7-25 2/99

7-26 2/99

7-27 2/99

7-28 2/99

Page 5

TABLE OF CONTENTS

TITLE PAGE

INTRODUCTION

About This Manual --------------------------------- ii

Organization -----------------------------------------ii

How to use This Manual--------------------------iii

Reference Symbology-----------------------------iii

SERVICE CALL PROCEDURES

Contents------------------------------------------- 1-1

STATUS INDICATOR RAPS

Contents------------------------------------------- 2-1

IMAGE QUALITY RAPS

Contents------------------------------------------- 3-1

REPAIR/ADJUSTMENT PROCEDURES

Contents------------------------------------------- 4-1

TABLE OF CONTENTS

PARTS LIST SECTION

Contents------------------------------------------- 5-1

GENERAL PROCEDURES/INFORMATION

Contents------------------------------------------- 6-1

WIRING DATA

Contents------------------------------------------- 7-1

DocuPrint C55/C55mp/[NC60] i

2/99

Page 6

INTRODUCTION

INTRODUCTION

ABOUT THIS MANUAL

This manual is part of a multinational

documentation system which includes

Training.

This manual contains information that applies

to:

• USCO

• XE

• XCL

• ACO

This service manual covers both the C55 and

NC60 product families.

Unique NC60 directions will be given in [ ]s.

For example:

Press the On Line [0] key.

The On Line key is unique to the C55 family

and the [0] key is unique to the NC60.

If the entire procedure is unique to a product

family, it will be noted at the top of the page

and in the footer at the bottom of the page.

“USCO” references apply to 115 Volt printers.

“XE” references apply to 220/240 Volt printers.

“Dry Ink” means the same as “Toner” and

“Tag” means the same as “Mod”.

ORGANIZATION

This manual is divided into seven sections

organized as follows:

A Publications comment sheet is provided at

the end of this manual.

Section 1 - SERVICE CALL PROCEDURES

This section contains the following:

• Call Flow Instructions

• Initial Actions

• System Checks

• Every Call Activities

• Scheduled Maintenance

• Final Action

Call Flow

The call flow chart shows you how to conduct

the service call.

Initial Actions

The initial actions suggests how to collect data

necessary to proceed with the service call.

System Checks

The System Checks procedures details the

steps for effective repair and verification of

repair of problems found in Initial Action.

Every Call Activities

These are cleaning and maintenance activities

which are performed on every call.

Scheduled Maintenance

Scheduled Maintenance consists of checking

the life remaining on the CRUs.

Final Action

Final Action ensures that image quality is

acceptable, and that printer performance and

appearance is satisfactory. Details are

included for completing administrative tasks

and closing out the service call.

Section 2 - STATUS INDICATOR REPAIR

ANALYSIS PROCEDURES (RAPs)

This section contains the Repair Analysis

Procedures (RAPs) necessary to repair faults

other than image quality faults.

Section 3 - IMAGE QUALITY REPAIR

ANALYSIS PROCEDURES (RAPs)

This section contains the Repair Analysis

Procedures (RAPs) necessary to repair image

quality faults.

Section 4 - REPAIR/ADJUSTMENT

PROCEDURES

This section contains the Repair and

Adjustment procedures for the printer. All

unique procedures will be identified as follows:

• USCO

• XE

Section 5 - PARTS LIST

This section contains exploded view drawings

and referenced replaceable parts lists for the

Printer.

Section 6 - GENERAL PROCEDURES

This section contains Diagnostic procedures,

Menus, Product Specifications, ESS/IOT test

patterns, and other General Procedures.

Section 7 - WIRING DATA

This section contains Block Schematic

Diagrams (BSDs), Plug/Jack/PWB Location

Diagrams and wiring diagrams.

2/99

ii DocuPrint C55/C55mp/[NC60]

Page 7

INTRODUCTION

HOW TO USE THIS MANUAL

GND

A/D

Section 1, Service Call Procedures will direct

you to each section of the manual necessary

to perform a service call.

You will begin with Initial Actions which

suggest how to collect problem symptoms and

evidence to be used in the next section, the

System Checks Section.

Details in the System Checks are designed to

assist you in classifying, repairing and verifying

the repair of the problem. From here, you may

be directed to any of the other six sections of

the service manual depending on the

symptoms observed and the results of

suggested tests. After a repair has been

verified (or during a repair activity) instructions

are included to direct you into Every Call

Activities.

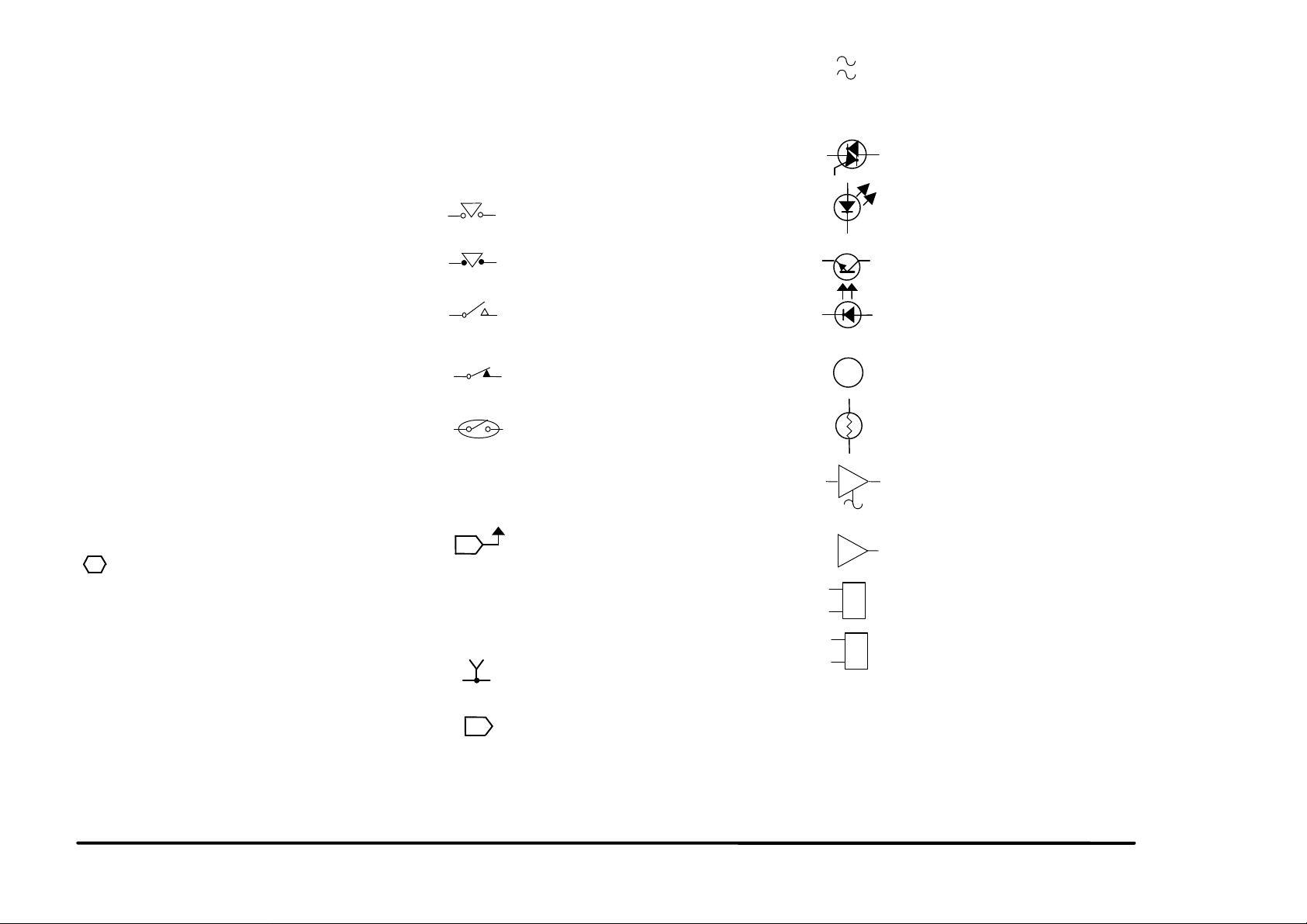

Descriptions of commonly used graphic

symbols are included in order to aid

troubleshooting when using the circuit

diagrams.

Switches/Relays

Safety interlock switch, circuit open.

Safety interlock switch, circuit closed.

Switch/relay with momentary contacts

shown normally open.

Switch/relay with momentary contacts

shown normally closed.

MOT

This symbol, used with a number,

indicates that the actual number may

be equal to or very near the value of

the designated number.

Triac, used to switch AC power.

Light Emitting Diode (LED).

Led/Phototransistor Sensor.

Motor.

REFERENCE SYMBOLOGY

Reference Symbology provides supportive

data for Repairs, Adjustments, and the RAPs.

The symbols that refer to this supportive data

are shown in the paragraphs that follow.

Note:

1

Parts Lists

PL 2.4 (example)

In the example above, the parts list reference

and the exploded view drawing would be found

in Section 5 on sub-section 2.4.

This symbol is used to refer to notes,

usually found on the same page.

Magnetically actuated Switch.

Miscellaneous Symbols

2

A flag that identifies a wire that has

been referred to in the text.

[ 8-2 ] Indicates a Diagnostic Code used to

check a particular component.

Identifies a test point, test hole or test

stake on a PWB.

A

Auditron/Key Counter connection.

2/99

Thermistor Bead, used to sense

temperature.

A Driver which is used to switch on

DC Components.

Analog to Digital Converter.

RL

Relay

Solenoid

DocuPrint C55/C55mp/[NC60] iii

Page 8

INTRODUCTION

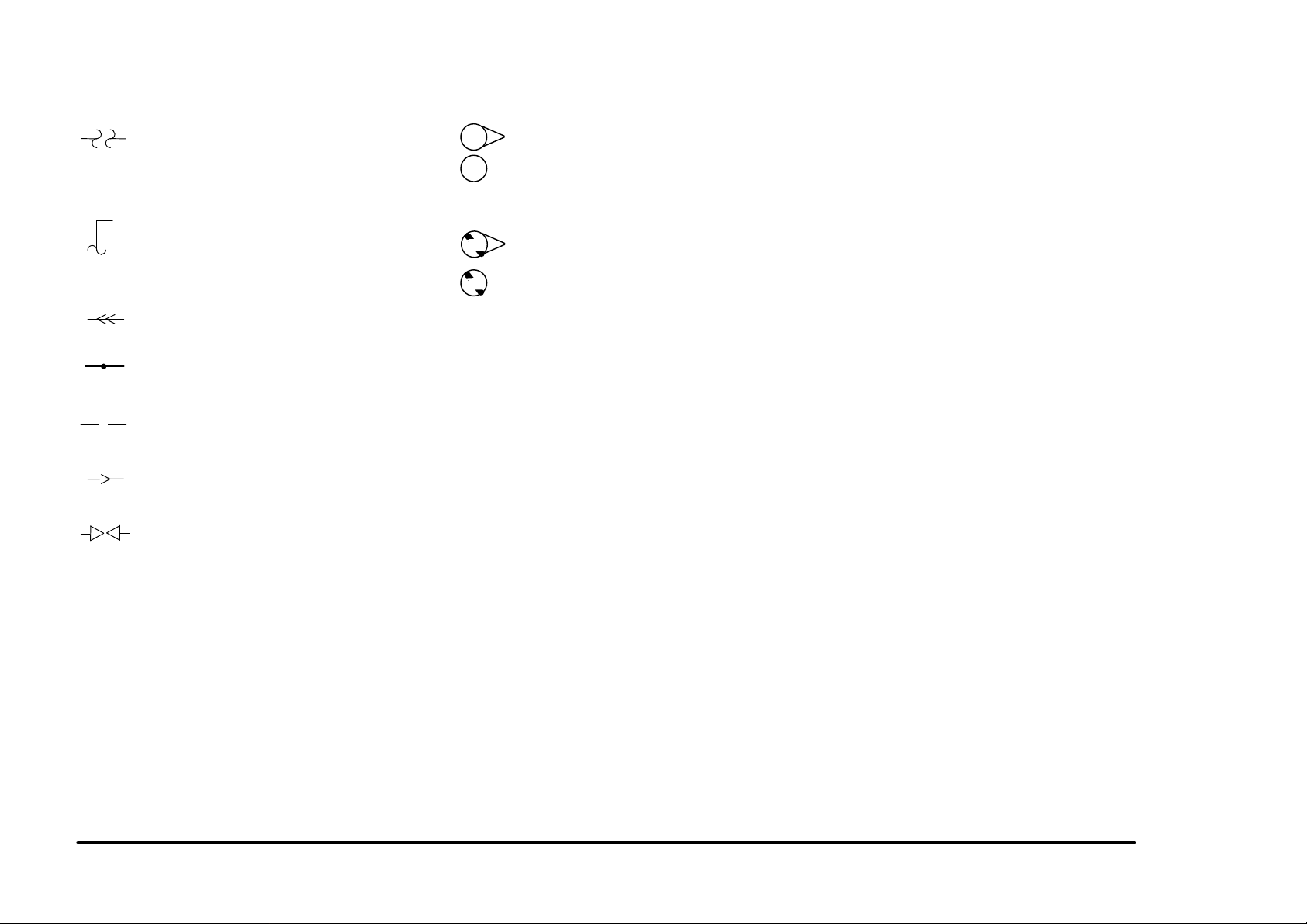

Signal Continuation/Flow

47

47

Tag Identification

Indicates the continuation of a signal

line interrupted in a horizontal

direction.

Represents the continuation of a

standby power line interrupted in the

vertical direction. In all cases, the

supply is from Standby Power

Indicates a feedback signal.

Indicates a common splice of wires.

Indicates a common splice of wires at

a pin.

Indicates the direction of signal flow.

Indicates that the wire continues to

the adjacent page.

47

This WITH TAG Symbol is used to

identify the components or configura-

47

tion that are part of a printer change

covered by the Tag number.

This WITHOUT TAG Symbol is used

to identify the components or

configuration that are not part of a

printer change covered by the Tag

number

2/99

iv DocuPrint C55/C55mp/[NC60]

Page 9

TITLE PAGE

CALL FLOW---------------------------------------1-2

INITIAL ACTION ---------------------------------1-3

SYSTEM CHECKS ------------------------------1-3

EVERY CALL ACTIVITIES --------------------1-4

SCHEDULED MAINTENANCE---------------1-4

FINAL ACTION-----------------------------------1-5

1. SERVICE CALL PROCEDURES

2/99 SERVICE CALL PROCEDURES

DocuPrint C55/C55mp/[NC60] 1-1 SECTION CONTENTS

Page 10

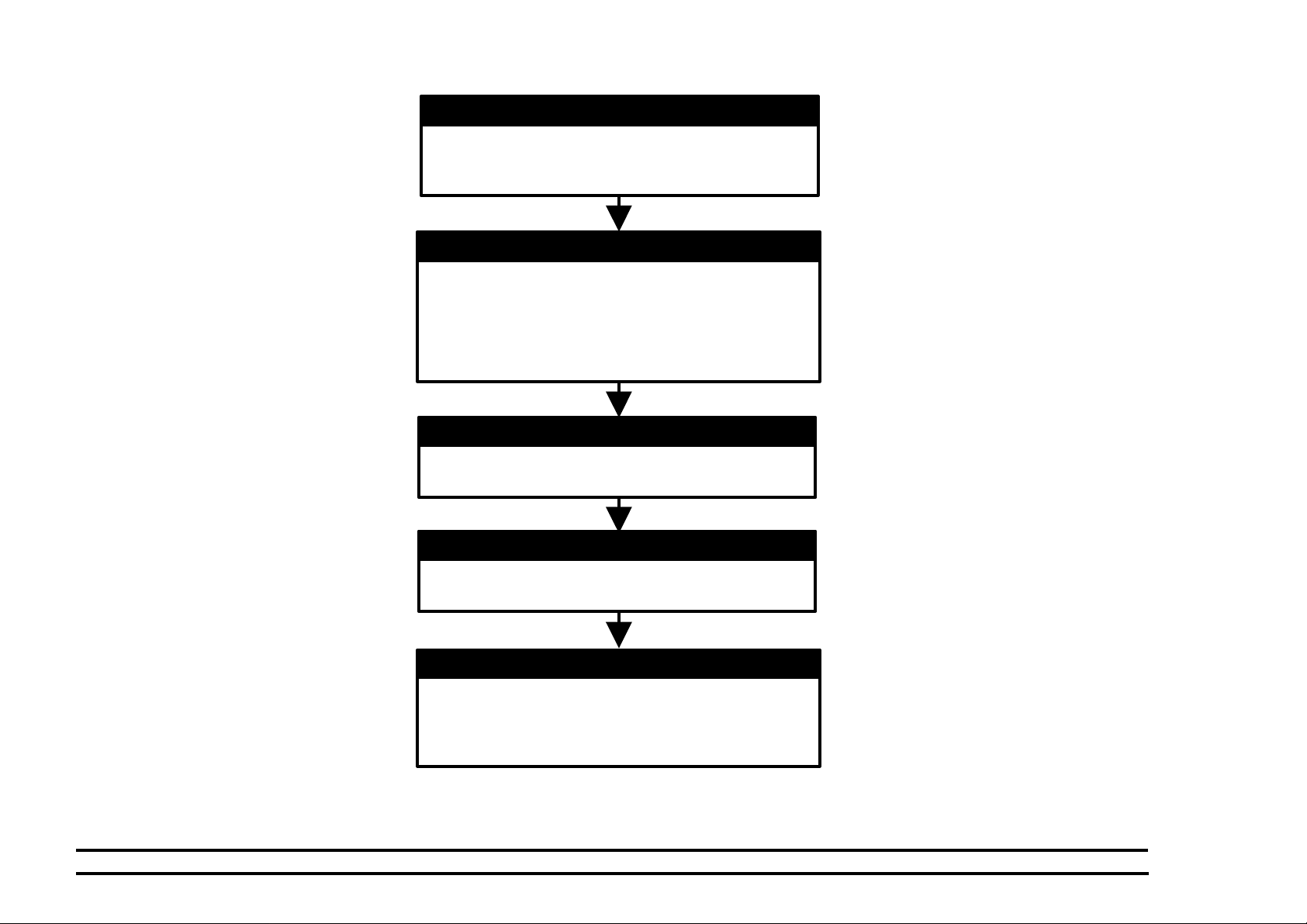

CALL FLOW

INITIAL ACTION

This step is used to gather information about the

reason for the call, to determine the machine

condition, and to run print samples.

SYSTEM CHECKS

This step is used to suggest a direction for using the

information, obtained during Initial Action. You can

then repair and verify the repair of the problem. This

step may also provide information to assist in the

identification of new problems and suggest actions to

take to repair/resolve them.

EVERY CALL ACTIVITIES

This step consists of every call cleaning and

maintenance activities.

SCHEDULED MAINTENANCE

This step is used to check the life remaining on the

CRU’s.

FINAL ACTIONS

This step is used to ensure that the print quality, the

printer performance, and the printer appearance is

satisfactory. It will also provide direction to help

complete administrative tasks.

SERVICE CALL PROCEDURES 2/99

CALL FLOW 1-2 DocuPrint C55/C55mp/[NC60]

Page 11

INITIAL ACTION

Purpose

To suggest how to gather information about

the service call, the machine condition, and to

direct the user through the call.

PROCEDURE

1. Ask the customer to describe the problem

that causes the service call and the job

being run when the problem occurred.

2. Inspect any rejected prints for evidence of

defects.

3. Switch the printer power Off/On and check

for and note/record any fault codes in the

Control Panel Display.

4. Examine the Machine Service Log (under

the Left Side Cover) for previous problems

or activities that may be related to this

service call.

5. Go to (SYSTEM CHECKS).

SYSTEM CHECKS

Purpose

To suggest a direction for effective repair and

verification of repair of problems found in Initial

Action.

PROCEDURE

1. Select the appropriate situation from a-g

below, then diagnose and repair the

problem.

a. Replace any obviously broken parts.

b. If this is an Image Quality problem, go

to IQ1 Image Quality Entry RAP in

Section 3.

c. If there is a Fault Code, go to Section

2 Table of Contents. Locate and

perform the RAP associated with the

Fault Code.

d. If there is NO fault code associated

with the problem, go to Section 2

Table of Contents. Locate and

perform the RAP which most closely

matches the problem described by the

customer.

e. If the problem is not repeatable,

operate the printer in the same job

conditions the customer used and

recheck for a problem in the

categories listed here.

f. If the problem still is not reproduced,

check the printer Fault History.

(C55/C55mp)

Off Line, Menu, then scroll to

<SERVICE>, <ERROR LOGS>,

<FAULT HISTORY>. Scroll through

the Fault History and note any

repeating faults. Refer to the RAP for

these fault codes in Section 2 and

read the fault code description to see

if the code relates to the customer

problem. If so, perform the RAP

[NC60]

Menu Up until Print Menu. Item Up

until Fault History then press Enter.

Look through the Fault History and

note any repeating faults. Refer to the

RAP for these fault codes in Section 2

and read the fault code description to

see if the code relates to the customer

problem. If so, perform the RAP.

g. If none of the above situations applies

go to EVERY CALL ACTIVITIES.

2. Verify that the problem is corrected and go

to EVERY CALL ACTIVITIES.

2/99 SERVICE CALL PROCEDURES

DocuPrint C55/C55mp/[NC60] 1-3 INITIAL ACTION/SYSTEM CHECKS

Page 12

EVERY CALL ACTIVITIES

Purpose

To list service activities required for specific

subsystems.

PROCEDURE

1. Open the printer and Clean the Charge

Scorotron using the Scorotron cleaner.

2. Clean the toner loading area.

3. Remove the Following:

a. Print Drum Module. (GP I)

b. Color Developer Module. (GP 2)

c. Black Developer Module (GP 3)

d. Toner Collector. (GP 4)

4. Vacuum the Drum, Developer, and Toner

Collector areas.

5. Replace the Toner Collector if required.

6. Reinstall the following:

a. Black Developer Module (GP 3)

b. Color Developer Module. (GP 2)

SCHEDULED MAINTENANCE

Purpose

To check the life remaining on the CRUs.

PROCEDURE

1. Check the life of the Customer Replaceable Units (CRUs).

a. (C55/C55mp)

Enter the Off Line mode, press Menu

and scroll to <MAINTENANCE>.

[NC60]

Menu Up until Service Menu, Item Up

until CRU Usage, Value Up to see %

remaining on the CRUs.

b. Check the life remaining on the

following:

• Black Developer Cartridge.

• Color Developer Cartridge.

• Print Drum.

• Fuser Module.

2. If any of the CRUs are near end of life,

notify the customer.

c. Print Drum Module. (GP I)

d. Toner Collector. (GP 4)

7. Use Film Remover to clean the Feed

Rollers. Do not rotate the Feed Rollers

more than 270° while cleaning. Apply

Rubber restore if available.

8. Check the Transfer Drum Nip Adjustment

(ADJ 11.1)

9. Wipe the outside of the printer.

SERVICE CALL PROCEDURES

EVERY CALL ACTIVITIES/ 2/99

SCHEDULED MAINTENANCE 1-4 DocuPrint C55/C55mp/[NC60]

Page 13

FINAL ACTION

Purpose

To ensure the image quality is acceptable,

printer performance and appearance is

satisfactory and to complete administrative

tasks.

PROCEDURE

1. Install/close all covers and doors.

2. Run the Print Quality sample set.

a. (C55/C55mp)

Enter the Off Line mode, press Menu

and scroll to <SERVICE>. Select

<TEST PATTERNS>, and print the

PQ set.

[NC60]

Menu Up until Service Menu, Item

Down until Print PQ Set and press

Enter.

3. If possible, ask the customer to print one

of their representative prints to examine

and comment on.

Wrap-Up Procedure

1. Record your service activities in the

service log.

2. Record the Total meter reading (from the

Diagnostic Test Pattern) in the service log.

3. Record the ESS software level (from the

Diagnostic Test Pattern) in the service log.

4. (C55/C55mp)

(Off Line, Print, Settings). Record the NIC

software level (from the Settings page) in

the service log.

5. Put the Printer PQ set and service log into

the service log folder.

NOTE: It is very important to save the PQ

set. There is information on the Diagnostic

sheet (Toner Concentration setpoints) which

will be needed if the NVM is reset or the PCU

PWB is replaced.

2/99 SERVICE CALL PROCEDURES

DocuPrint C55/C55mp/[NC60] 1-5 FINAL ACTION

Page 14

Notes:

SERVICE CALL PROCEDURES 2/99

NOTES 1-6 DocuPrint C55/C55mp/[NC60]

Page 15

2. STATUS INDICATOR RAPs

TITLE PAGE

TROUBLESHOOTING TIPS ------------------2-2

C1-CHECK TRAY 1 -----------------------------2-3

C2-CHECK TRAY 2 -----------------------------2-3

E1-TRAY 1 JAM----------------------------------2-4

E2-TRAY 2 JAM ---------------------------------2-5

E3-BYPASS JAM --------------------------------2-5

E4-INPUT JAM -----------------------------------2-6

E5 FUSER JAM ----------------------------------2-7

E6-DRUM JAM -----------------------------------2-8

E7-PRINT DRUM JAM------------------------2-10

E8-OUTPUT JAM------------------------------2-10

E9-CLOSE PRINTER-------------------------2-10

EA-COLOR DEV. MISINSTALLED--------2-11

EB-BLACK DEV. MISINSTALLED---------2-11

EC-PRINT DRUM MISINSTALLED--------2-11

F1-DISK ERROR (FLOPPY) ----------------2-12

F2-DISK I/O ERROR (FLOPPY) -----------2-12

F3-ACTION FAILED (FLOPPY) ------------2-12

H1-HARD DISK ERROR---------------------2-13

H2-HARD DISK CONTROLLER

ERROR -------------------------------------2-13

H3-HARD DISK FULL-------------------------2-14

H4-FORMAT HARD DRIVE-----------------2-14

TITLE PAGE

J1-ADD YELLOW TONER-------------------2-15

J2-ADD MAGENTA TONER ----------------2-16

J3-ADD CYAN TONER-----------------------2-17

J4-ADD BLACK TONER ---------------------2-18

J5-REPLACE COLOR DEVELOPER

CARTRIDGE--------------------------------2-19

J6-REPLACE BLACK DEVELOPER

CARTRIDGE--------------------------------2-19

J7-TONER COLLECTOR FULL------------2-20

J8-REPLACE PRINT DRUM----------------2-20

J9-REPLACE FUSER MODULE -----------2-20

JA-REPLACE OIL/PAD-----------------------2-21

T0-FUSER THERMISTOR ERROR-------2-21

T1- UNDER TEMPERATURE --------------2-22

T2- OVER TEMPERATURE ----------------2-23

U0-IOT ROM ERROR ------------------------2-23

U1-IOT RAM ERROR-------------------------2-24

U2-IOT NVM RAM ERROR -----------------2-24

U3-IOT/ESS COMMUNICATION

ERROR -------------------------------------2-24

U4-OPTICS FAULT ---------------------------2-25

U5-POLYGON MOTOR FAULT------------2-25

U6-MOTOR FAULT (DEVELOPER) ------2-26

U7- MOTOR FAULT (MAIN) ----------------2-27

TITLE PAGE

W1-COLOR DEVELOPER MODULE

(NEAR END OF USE)-------------------2-28

W2-BLACK DEVELOPER MODULE

(NEAR END OF USE)-------------------2-28

W3-PRINT DRUM (NEAR

END OF USE)-----------------------------2-28

W4-FUSER MODULE

(NEAR END OF USE)-------------------2-29

W5-FUSER OIL BOTTLE/PAD

(NEAR END OF USE)-------------------2-29

OF1 DEAD PRINTER RAP ---------------- 2-30

OF2 CONTROL PANEL RAP ------------- 2-32

OF3 TRAY 1 PAPER SIZE

SENSING RAP-------------------------2-35

OF4 TRAY 2 PAPER SIZE

SENSING RAP-------------------------2-36

OF5 LOAD PAPER RAP--------------------2-37

OF6AESS RAP (C55/C55mp)--------------2-38

OF6BESS RAP [NC60]-----------------------2-39

OF7 ESS BOOT FAILURE

ERROR CODES [NC60] -------------2-40

OF8 ARCING RAP---------------------------2-41

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-1 SECTION CONTENTS

Page 16

TROUBLESHOOTING TIPS

The following are some general troubleshooting tips and hints which will help you

locate components and test points.

1. The procedures for entering, exiting and

using the C55/C55mp/[NC60] diagnostic

programs can be found in Section 6,

General Procedures. Refer to the Table of

Contents found on page 6-1 for the

specific program.

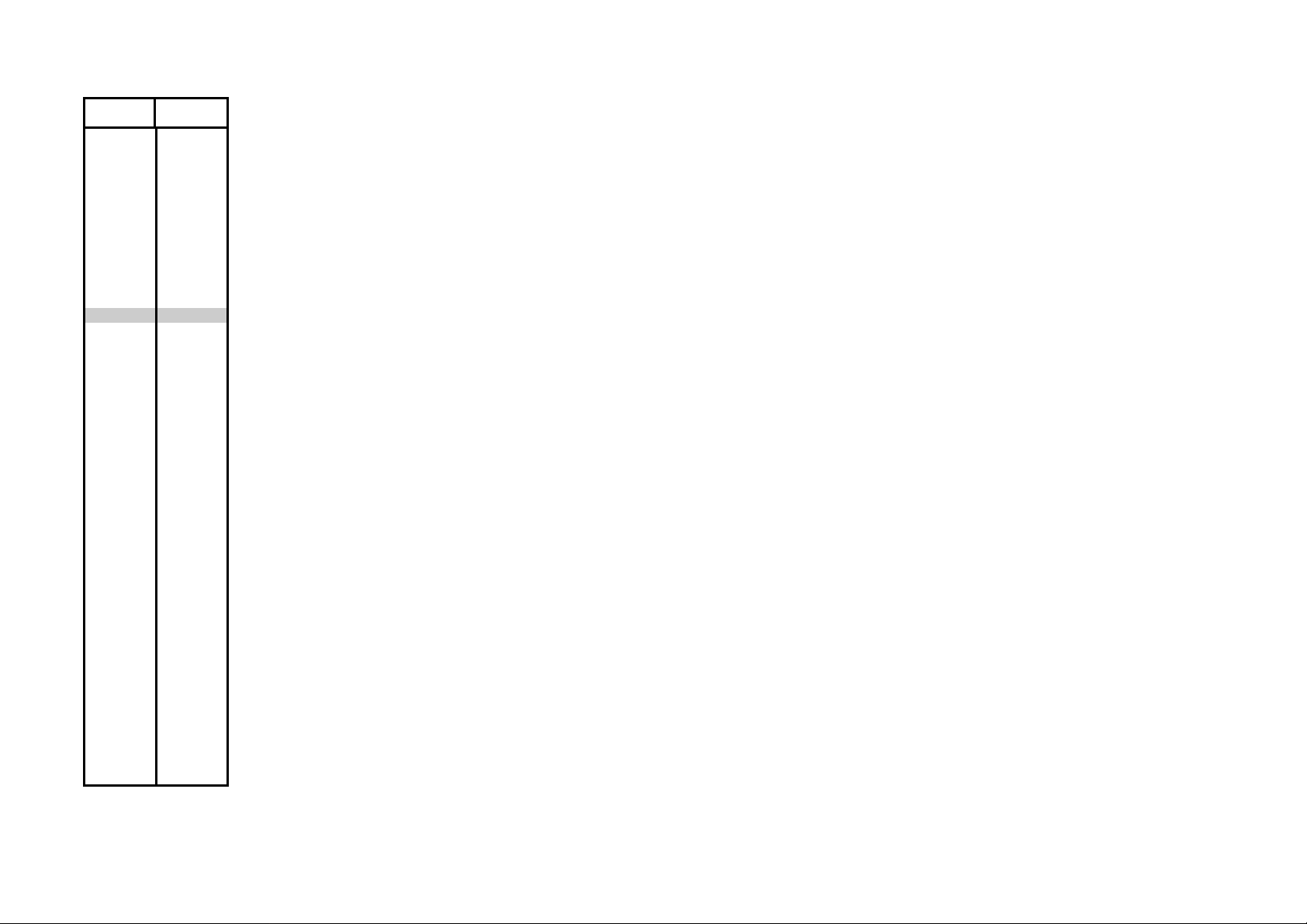

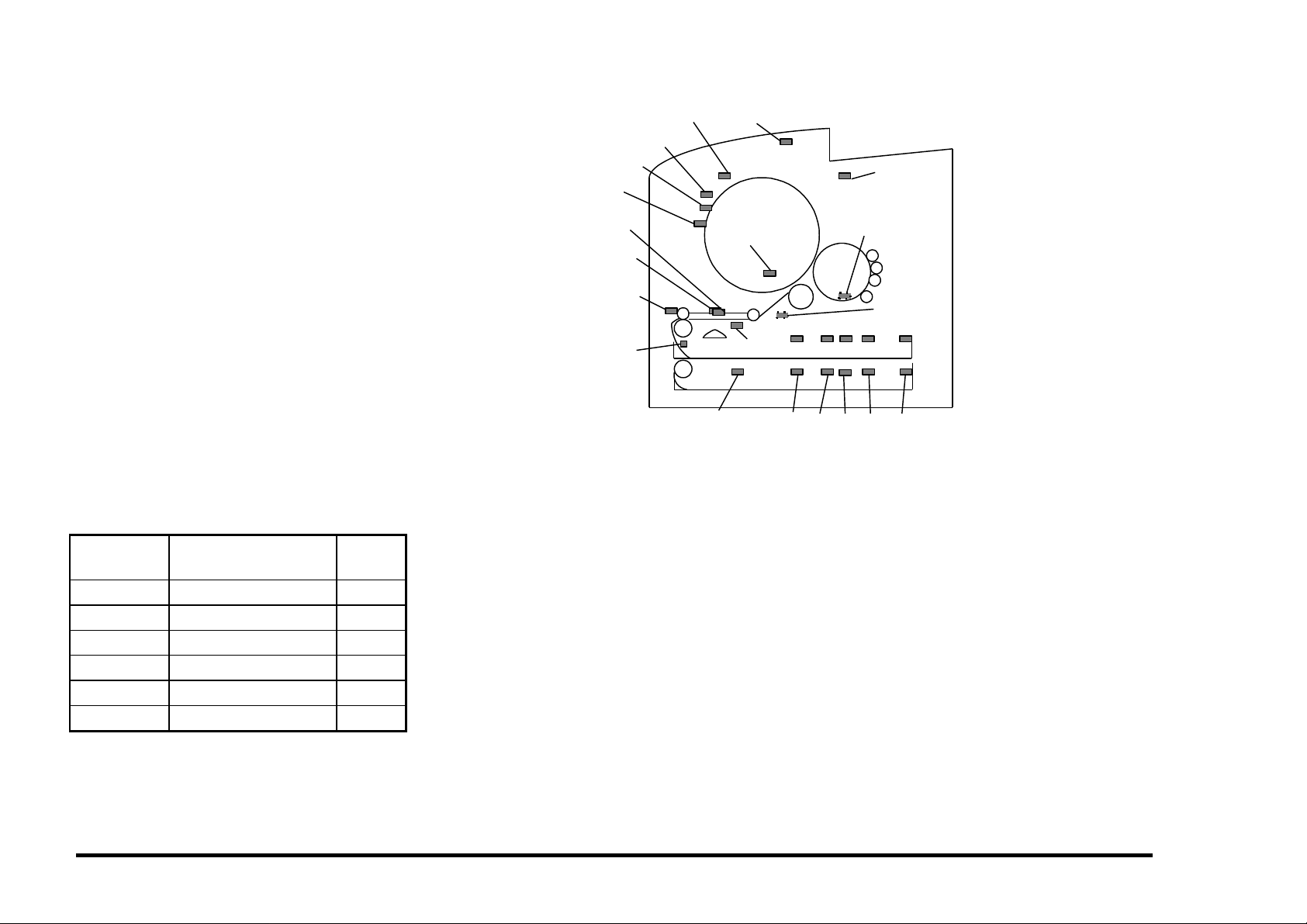

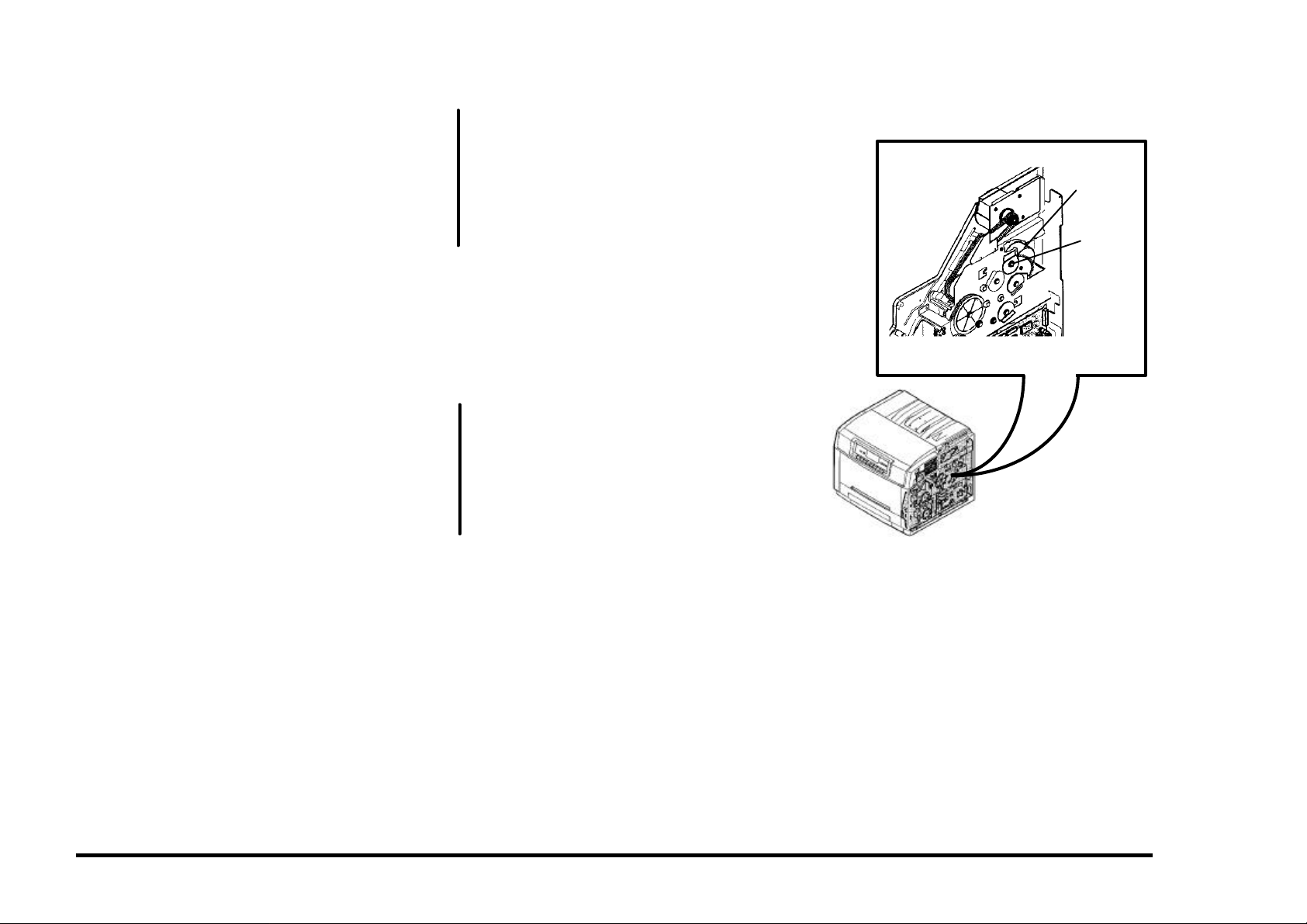

2. Figure 2-1 on the right is also located in

Section 6 and shows the location of the

input electrical components in the printer.

It is especially helpful when using the

Switch Scan program. Refer to this figure

if you are unsure of input component

location. The BSDs in Section 7 may also

prove helpful when locating the various

electrical components.

3. The Connectors can be located in

Section 7. Refer to Section 7 Table of

contents on page 7-1. The table below

shows the location of the most common

connectors:

TRANSPARENCY

JAM SENSOR

CLEANER JAM

SWITCH

TRANSPARENCY

SENSOR

REGISTRATION

SENSOR

BYPASS SWITCH

TEMPERATURE/

HUMIDITY SENSOR

OIL

GAMMA

SENSOR

SENSOR

EXIT SENSOR

TRANSFER DRUM

HOME SENSOR

TRAY EMPTY

SENSOR

T2 TRAY EMPTY

SENSOR

PS0

T2

S0

PS1 PS2 PS3

T2

T2

S1

S2

+24 V

INTERLOCK

SWITCH

PHOTORECEPTOR

DETECT

WASTE TONER

BOTTLE SENSOR

PS4

T2

T2

S4

S3

Figure 2-1. Input Component Location

Connector

Numbers

Location Figure

CN100’s PCU PWB/ESS PWB 7-1

CN200’s Cassette PWB 7-4

CN300’s Connector PWB 7-2

CN400’s Control Panel PWB 7-2

CN700’s LVPS PWB 7-2

CN800’s HVPS PWB 7-3

STATUS INDICATOR RAPs 2/99

TROUBLESHOOTING TIPS 2-2 DocuPrint C55/C55mp/[NC60]

Page 17

C1 CHECK TRAY 1 RAP

Cassette 1 is not in the printer.

INITIAL ACTION

Load paper and insert Cassette 1 into the

printer.

Switch the power off wait 10 seconds and

switch the power on. Recheck for the fault.

PROCEDURE

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

01, Press Form Feed [1].

Remove Cassette 1. Manually make and

break Paper Size Sensor 0 while observing the

Cyan LED. (Sensor 0 is the first one on the

left when viewed from the front of the printer.)

The Cyan LED switches on and off.

Y N

Go to BSD 7.2 in Section 7 and troubleshoot the Paper Size 0 Sensor signal

(CN107-8) for a short to ground.

If no short is found, replace the PCU

PWB. If the problem still exists, replace

the Cassette PWB.

Check for a broken Sensor Flag on the Tray 1

Cassette.

If the problem still exists, replace the PCU

PWB. If the problem still exists, replace the

Cassette PWB.

C2 CHECK TRAY 2 RAP

Cassette 2 is not in the printer.

INITIAL ACTION

Move the length stop to the 11 inch position

(Figure 2-2), load paper, and insert Cassette 2

into the printer.

Switch the power off wait 10 seconds and

switch the power on. Recheck for the fault.

PROCEDURE

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

03. Press Form Feed [1].

Remove Cassette 2. Manually make and

break T2 Paper Size Sensor 0 while observing

the Cyan LED.

The Cyan LED switches on and off.

Y N

Refer to BSD T2, 7.2 in Section 7 and

check the following:

• T2 Paper Size 0 Sensor signal CN109-

1 for an open.

• +5 VDC CN109-5

If no problem is found, replace the PCU

PWB. If the problem still exists, replace

the T2 Cassette PWB.

Check for a broken Sensor Flag on the Tray 2

Cassette.

If the problem still exists, replace the PCU

PWB. If the problem still exists, replace the

Cassette PWB.

14"10.5" 11", A4

Figure 2-2. Length Stop Location

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-3 C1, C2

Page 18

E1 TRAY 1 JAM RAP

Paper fed from Tray 1 did not reach the

Registration Sensor.

INITIAL ACTION

Remove the cassette and check that the paper

is loaded correctly and is in good condition.

Switch the power off wait 10 seconds and

switch the power on. Recheck for the fault.

PROCEDURE

Check the following:

• Obstructions in the paper path.

• Dirty Feed Rolls.

• Dirty Drive Rollers.

• Mechanical drive problem.

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

00. Press Form Feed [1].

Open the Printer. Actuate and deactuate the

Registration Sensor while observing the

Magenta LED.

The Magenta LED switches on and off.

Y N

Go to BSD 8.1 in Section 7 and troubleshoot the Registration Sensor signal, +5

VDC and GND (CN102-9, 7, 8) for an

open.

If no open exists, replace the PCU PWB.

If the problem still exists, replace the

Registration Sensor.

Press Media Server [2]. Select Scan Row 01.

Press Form Feed [1].

Remove the cassette and actuate and

deactuate the Tray Empty Sensor while

observing the Black LED.

A

A

The Black LED switches on and off.

Y N

Go to BSD 7.1 in Section 7 and troubleshoot the Tray Empty Sensor signal

(CN102-6) for a short to ground.

If no short exists, replace the PCU PWB. If

the problem still exists, replace the Tray

Empty Sensor.

Exit from the SWITCH SCAN program.

Close the Printer.

Remove the paper cassette. Scroll to the

MOTOR TEST program. Press Form Feed

[1] to switch on the motors while observing the

Paper Feed Motor.

The Paper Feed Motor is rotating normally.

Y N

Go to BSD 7.3 in Section 7 and trouble-

shoot the +24 VDC Interlocked (CN111-5)

and Paper Feed Motor for an open. If the

motor was noisy, check the clock lines.

If the lines are OK, replace the PCU PWB.

If the problem still exists, replace the

Paper Feed Motor.

Exit from diagnostics.

Set up the meter to read +24 VDC. Measure

between CN101-5 (+) and ground (−).

Make one print while monitoring the meter.

The meter swings from +24 VDC to 0.

Y N

Go to BSD 7.4 in Section 7 and trouble-

shoot the Feed Solenoid signal, and +24

VDC Interlocked (CN101-5, 3) for an

open.

B C

B C

If no open exists, replace the PCU PWB. If

the problem still exists, replace the Paper

Feed Solenoid.

Check for a mechanical problem with the feed

clutch.

STATUS INDICATOR RAPs 2/99

E1 2-4 DocuPrint C55/C55mp/[NC60]

Page 19

E2 TRAY 2 JAM RAP

Paper fed from Tray 2 did not reach the

Registration Sensor.

INITIAL ACTION

Remove the cassette and check that the paper

is loaded correctly and is in good condition.

Check the position of the rear stop.

Make sure that Tray 1 is pushed all the way in.

Switch the power off wait 10 seconds and

switch the power on. Recheck for the fault.

PROCEDURE

Try to run a print from Tray 1.

The print feeds OK from Tray 1.

Y N

Go to E1 TRAY 1 JAM RAP.

Check the following:

• Obstructions in the paper path.

• Dirty Feed Rolls.

• Dirty Drive Rollers.

• Mechanical drive problem.

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

03. Press Form Feed [1].

Remove cassette 2. Actuate and deactuate

the Tray 2 Empty Sensor while observing the

Black LED.

The Black LED switches on and off.

Y N

Go to BSD T2 7.1 in Section 7 and

troubleshoot the T2 Tray Empty Sensor

signal (CN109-4) for a short to ground.

If no short exists, replace the PCU PWB.

If the problem still exists, replace the Tray

2 Empty Sensor.

A

A

Exit from diagnostics.

Set up the meter to read +24 VDC. Measure

between CN109-8 (+) and ground (−).

Make one print while monitoring the meter.

The meter swings from +24 VDC to 0 and

back to +24.

Y N

Go to BSD T2 7.3 in Section 7 and

troubleshoot the T2 Feed Solenoid signal,

and +24 VDC Interlocked (CN109-8, 7) for

an open.

If no open exists, replace the PCU PWB. If

the problem still exists, replace the T2

Feed Solenoid.

Measure between CN109-9 (+) and ground

(−).

Make one print while monitoring the meter.

The meter swings from +24 VDC to 0 and

back to +24.

Y N

Go to BSD T2 7.4 in Section 7 and

troubleshoot the T2 Drive Clutch signal

(CN109-9) for an open.

If no open exists, replace the PCU PWB.

If the problem still exists, replace the T2

Drive Clutch.

Check for a mechanical problem with the Feed

Clutch and Drive Clutch

E3 BYPASS JAM RAP

Paper fed from the Bypass Tray did not reach

the Registration Sensor.

INITIAL ACTION

Carefully inspect the bypass opening for

paper.

Switch the power off wait 10 seconds and

switch the power on. Run another print and

recheck for the fault.

PROCEDURE

If paper does not feed from the Bypass but

does feed from Tray 1, check for an

obstruction in the bypass slot.

Check to ensure that the switch is installed

correctly and has not fallen out.

If no paper is loaded in the Bypass when the

E3 occurs, refer to BSD 7.5 in Section 7 and

check the Bypass Switch signal (CN312-2) for

a short to ground.

If no short exists, replace the PCU PWB. If

the problem still exists, replace the Bypass

Switch.

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-5 E2, E3

Page 20

E4 INPUT JAM RAP

Paper was on the Registration Sensor too

long.

INITIAL ACTION

Open the printer and check for any obstruction

in the register roller area.

Switch the power off wait 10 seconds and

switch the power on. Run another print to

recheck for the fault.

Make sure the Grounding Roller is rotating

freely.

Perform the Transfer Drum Nip Adjustment

(ADJ 11.1)

PROCEDURE

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

00. Press Form Feed [1].

Open the Printer. Actuate and deactuate the

Registration Sensor while observing the

Magenta LED.

The Magenta LED switches on and off.

Y N

Go to BSD 8.1 in Section 7 and troubleshoot the Registration Sensor signal

(CN102-9) for a short to ground.

If no short exists, replace the PCU PWB.

If the problem still exists, replace the

Registration Sensor.

Press Media Server [2]. Select Scan Row 04.

Press Form Feed [1].

Actuate and deactuate the Transparency

Sensor while observing the Cyan LED.

A

A

The Cyan LED switches on and off.

Y N

Go to BSD 8.4 in Section 7 and trouble-

shoot the Transparency Sensor signal

(CN311-1) for a short to ground.

If no short exists, replace the PCU PWB.

If the problem still exists, replace the

Transparency Sensor.

Exit from the SWITCH SCAN program.

Close the Printer.

Remove the paper cassette. Scroll to the

MOTOR TEST program and press Form Feed

[1] to switch on the motors while observing the

Paper Feed Motor.

The Paper Feed Motor is rotating normally.

Y N

Go to BSD 7.3 in Section 7 and trouble-

shoot the Paper Feed Motor clock lines.

If the lines are OK, replace the PCU PWB.

If the problem still exists, replace the

Paper Feed Motor.

Exit from diagnostics.

Set up the meter to read +24 VDC. Measure

between CN103-4 (+) and ground (−).

Make one print while monitoring the meter.

The meter swings from +24 VDC to 0 and

back to +24.

Y N

Go to BSD 9.16 in Section 7 and trouble-

shoot the Stripper Solenoid signal and +24

VDC Interlocked (CN103-4, CN303-2,1) for

an open.

If no open exists, replace the PCU PWB. If

the problem still exists, replace the

Stripper Solenoid.

B

B

Set up the meter to read +24 VDC. Measure

between CN101-5 (+) and ground (−).

Make one print while monitoring the meter.

The meter swings from +24 VDC to 0 and

back to +24.

Y N

Go to BSD 7.4 in Section 7 and troubleshoot the Feed Solenoid signal (CN101-5)

for a short to ground.

If no short exists, replace the PCU PWB.

If the problem still exists, replace the Feed

Solenoid.

Set up the meter to read +24 VDC. Measure

between CN101-4 (+) and ground (−).

Make one print while monitoring the meter.

The meter swings from +24 VDC to 0 and

back to +24.

Y N

Go to BSD 8.2 in Section 7 and troubleshoot the Registration Clutch signal and

+24 VDC Interlocked (CN101-4, 1) for an

open.

If no open exists, replace the PCU PWB. If

the problem still exists, replace the

Registration Clutch.

Check the following:

• Obstructions torn paper etc. in the paper

path.

• Mechanical drive problem.

STATUS INDICATOR RAPs 2/99

E4 2-6 DocuPrint C55/C55mp/[NC60]

Page 21

E5 FUSER JAM RAP

Paper did not reach the Exit Sensor.

INITIAL ACTION

Open the Printer and remove the Fuser

Assembly. Check for any obstructions in the

fuser paper path.

Switch the power off wait 10 seconds and

switch the power on. Run another print to

recheck for the fault.

PROCEDURE

Check the following:

• Obstructions in the paper path.

• Defective stripper fingers.

• Mechanical drive problem.

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

00. Press Form Feed [1].

Open the Printer, then open the Fuser cover.

Actuate and deactuate the Exit Sensor while

observing the Yellow LED.

The Yellow LED switches on and off.

Y N

With SCAN ROW 00 still selected, actuate

and deactuate the Bypass Switch while

observing the Cyan LED.

The Cyan LED switches on and off.

Y N

Go to BSD 10.2 and troubleshoot the

Strobe 2 signal CN103-18 for an open.

If no open exists replace the PCU

PWB.

A B

A B

Go to BSD 10.2 in Section 7 and troubleshoot the Exit Sensor signal, +5 VDC and

GND (CN308-1, 3, 2) for an open.

If no open exists, replace the PCU PWB.

If the problem still exists, replace the Exit

Sensor.

Exit from the SWITCH SCAN program.

Remove the Front Cover and then close the

Printer.

Scroll to the MOTOR TEST program and

press Form Feed [1] to switch on the motors

while observing the Fuser Drive Motor.

The Fuser Drive Motor is rotating normally.

Y N

Go to BSD 10.1 in Section 7 and trouble-

shoot the Fuser Drive Motor clock lines.

If the lines are OK, replace the PCU PWB.

If the problem still exists, replace the

Fuser Drive Motor.

• Make sure the Fuser Cover fits correctly.

• Check for a Mechanical problem.

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-7 E5

Page 22

E6 DRUM JAM RAP

Paper is jammed on the Transfer Drum and

could be caused by one of the following:

• Transfer Drum Cleaner not cleaning the

Transfer Drum or resting on the Transfer

Drum during the Print cycle.

• Paper did not reach the Gamma Sensor.

• Paper did not tack to the Transfer Drum and

actuated the Transparency Jam Sensor.

• Paper did not tack to the Transfer Drum

and actuated the Cleaner Jam Switch.

• Arcing between the Charge Scorotron

connectors and the Print Drum.

INITIAL ACTION

Open the Printer and check for torn paper or

an obstruction in the paper path. Check for a

sheet of paper or a transparency actuating the

Transparency Jam Sensor or the Cleaner Jam

Switch.

Check the Toner Collector for “layered” toner

(sand-art effect). If layered toner is present,

refer to OF8 Arcing RAP.

If the problem only occurs when running color

prints, check the Stripper Fingers for binding

or interference.

Open the Printer and position the Transfer

Drum Home Position Sensor flag at the

3 o’clock position. The Lead edge of the white

patch should be at the tips of the stripper

fingers. If not, replace the Transfer Drum.

PROCEDURE

Switch the Printer off. Remove the front cover

and tape the Control Panel up so that you can

view the operation of the Transfer Drum

Cleaning Solenoid.

Switch the Printer on. Observe the Transfer

Drum Cleaning Solenoid and the Cleaner

Assembly.

If you see solid development during the copy

quality setup, go the OF8 Arcing RAP.

The Transfer Drum Cleaning Solenoid should

energize and move the Cleaner Assembly

against the Transfer Drum while the patches

are generated during the Copy Quality Setup.

When the Copy Quality Setup is complete the

Transfer Drum Cleaning Solenoid should

deenergize and move the Cleaner Assembly

away from the Transfer Drum.

If the E6 jam occurs before paper is fed and

the patches are not being cleaned the Transfer

Drum Cleaner assembly is not camming into

the cleaning position.

If the machine prints OK when printing black

only but jams (E6) when printing color, it is an

indication that the Transfer Drum Cleaner

assembly is staying cammed against the

Transfer Drum.

The Transfer Drum Cleaning Solenoid and

Transfer Drum Cleaner Assembly are

operating correctly.

Y N

Check that when the solenoid energizes

the camshaft turns 180 degrees and is

stopped by the outer tab on the cleaner

clutch sleeve. Ensure that the solenoid is

tight and the actuator catches the inner tab

when de-energized, and stops the outer

tab when energized. Check for flashing on

the plastic assembly, a bent solenoid

actuator or other things that could interfere

with proper operation. Clean the cams

and the cam followers with film remover to

minimize friction. Do not attempt to

lubricate these cams. Observe the operation several times and look for smooth,

consistent operation. Do not attempt to

disassemble and adjust the clutch. If the

clutch is defective order the new Cleaner

Clutch Shaft Assembly.

A B

A B

Set up the meter to read +24 VDC. Measure

between CN103-3 (+) and ground (−).

Switch the power off wait 10 seconds and

switch the power on while monitoring the

meter.

The meter swings from +24 VDC to 0

and back to +24.

Y N

Go to BSD 9.14 in Section 7 and

troubleshoot the Transfer Drum

Cleaning Solenoid signal and

+24 VDC Interlocked (CN103-3,

CN316-2, 1) for an open or a short.

If 24 VDC is not available at 316-1 on

the Connector PWB, go to BSD 1 and

troubleshoot the 24 VDC Interlocked

(CN114-1, CN103-1).

Check the Transfer Drum Cleaning

Solenoid and the cleaner assembly for

binding.

If the sheet appears to be stopping at the

Transfer Drum to Print Drum Nip, check the

Transfer Drum Nip Adjustment (ADJ 11.1).

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

05. Press Form Feed [1].

Open the Printer. Actuate and deactuate the

Transparency Jam Sensor while observing the

Black LED.

The Black LED switches on and off.

Y N

Check for an obstruction that is keeping the

Transparency Jam Sensor actuator raised.

C D

STATUS INDICATOR RAPs 2/99

E6 2-8 DocuPrint C55/C55mp/[NC60]

Page 23

C D

If OK, refer to BSD 9.17 and check the

Transparency Jam Sensor signal CN314-2

for a short to ground.

If no short exists, replace the PCU PWB.

If the problem still exists, replace the

Transparency Jam Sensor.

Open the printer and remove the Transfer

Discharge Corotron from the left side of the

printer. You will need to squeeze the corotron

handle to release the corotron.

With Scan Row 05 still selected, actuate and

deactuate the Cleaner Jam Switch while

observing the Magenta LED.

The Magenta LED switches on and off.

Y N

Check for an obstruction that is keeping

the Cleaner Jam Switch actuated.

If OK, refer to BSD 9.18 and check the

Cleaner Jam Switch signal CN318-2 for a

short to ground.

If no short exists, replace the PCU PWB.

If the problem still exists, replace the

Cleaner Jam Switch.

Exit from the Switch Scan Program.

Scroll to the MOTOR TEST program and

switch on the motors while observing the

Fuser Drive Motor

The Fuser Drive Motor is rotating normally.

Y N

Go to BSD 10.1 in Section 7 and troubleshoot the Fuser Drive Motor for an open.

If the motor was noisy, check the clock

lines for an open or short

If the lines are OK, replace the PCU PWB.

If the problem still exists, replace the

Fuser Drive Motor.

E

E

Set up the meter to read +24 VDC. Measure

between CN103-4 (+) and ground (−).

Make one print while monitoring the meter.

The meter swings from +24 VDC to 0 and

back to +24.

Y N

Go to BSD 9.16 in Section 7 and troubleshoot the Stripper Solenoid signal and +24

VDC Interlocked (CN103-4, CN303-2, 1)

for an open or a short.

If no short or open can be found, replace

the PCU PWB. If the problem still exists,

replace the Stripper Solenoid.

Set up the meter to read +5 VDC. Measure

between CN103-11 (+) and ground (−).

Switch the power off wait 10 seconds and

switch the power on.

The meter swings from 3.8 VDC to .5 when

the white patch passes in front of the

Gamma Sensor.

Y N

Go to BSD 8.5 in Section 7 and troubleshoot

the Gamma Sensor, all lines, for an open.

If the lines are OK, replace the PCU PWB.

If the problem still exists, replace the

Gamma Sensor.

Refer to Section 6, GP 9.3 and perform the

Transfer Voltage Check.

The Transfer voltage is within specification.

F

F

Y N

Go to BSD 9.1 in Section 7 and troubleshoot the following for an open or short.

• Black Transfer Lead from the Power

Supply.

• Transfer On Signal (CN106-3).

• Transfer Control Signal (CN106-5).

• Bias Control Signal (CN106-6).

• +24 VDC to Power Supply (CN106-1).

If no wiring problem can be found, replace

the PCU PWB. If the problem still exists,

replace the High voltage Power Supply.

Refer to BSD 9.1 in Section 7 and check the

Charge On Signal (CN106-2) for an open.

Check the following:

• Obstructions in the paper path.

• Dirty Feed Rolls.

• Mechanical drive problem.

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-9 E6

Page 24

E7 PRINT DRUM JAM RAP

INITIAL ACTION

Open the Printer and clear the jam.

If problem reoccurs refer to E4 RAP.

E8 OUTPUT JAM RAP

Paper was on the Exit Sensor too long.

INITIAL ACTION

We have seen some machines where the

actuator for the Exit Sensor has become stuck

during shipping. When this happens, the

sensor does not change state, and the E8 jam

occurs. If you remove the sensor cover

(PL 2.1) by removing the two screws that

secure it, you can ensure that the actuator is

free and that the sensor is secured in the

proper position in the sensor cover.

Open the Printer and remove the Fuser

Assembly. Check for any obstructions in the

fuser paper path.

Switch the power off wait 10 seconds and

switch the power on. Run another print to

recheck for the fault.

PROCEDURE

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

00. Press Form Feed [1].

Open the Printer, then open the Fuser Cover.

Actuate and deactuate the Exit Sensor while

observing the Yellow LED.

The Yellow LED switches on and off.

Y N

Go to BSD 10.2 in Section 7 and troubleshoot the Exit Sensor signal (CN308-1) for

a short to ground.

If no short exists, replace the PCU PWB.

If the problem still exists, replace the Exit

Sensor.

Check the following:

• Obstructions in the paper path.

• Mechanical drive problem in the feedout

area.

E9 CLOSE PRINTER RAP

The Printer is open.

INITIAL ACTION

Open and reclose the printer.

PROCEDURE

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

00. Press Form Feed [1].

Open and close the Printer while observing the

Black LED.

The Black LED switches on and off.

Y N

Go to BSD 1 (G1) in Section 7 and

troubleshoot the 24 VDC Interlock Switch.

If no open exists, replace the PCU PWB.

If the problem still exists, replace the

24 VDC Interlock Switch.

Replace the PCU PWB.

STATUS INDICATOR RAPs 2/99

E7, E8, E9 2-10 DocuPrint C55/C55mp/[NC60]

Page 25

EA COLOR DEV. MISINSTALLED

RAP

The Color Developer Module was installed

incorrectly or overtoning has occurred.

INITIAL ACTION

Enter IOT normal diagnostics. Scroll to the

TEST PRINT program and press Form Feed

[1] to run a test print. While the print is

running, observe the KT=__, CT=__, MT=__,

YT=__ values.

If any of the three color (C, M, Y) toner

concentration values are below 10, that color

is overtoned. Refer to ADJ 9.1 EA “Tone

Down” Procedure in Section 4.

If the values are NOT too low, continue with

this RAP.

Remove the Color Developer Module.

Check the Developer Module connector to be

sure it is clean.

Reinstall the Color Developer Module.

If the problem persists, check connector

CN118 for a good connection or any loose

wiring before replacing the Color Developer

Module.

If the problem still exists, replace the PCU

PWB.

EB BLACK DEV. MISINSTALLED

RAP

The Black Developer Module was installed

incorrectly or the contacts are dirty.

INITIAL ACTION

Remove the Black Developer Module.

Check for binding in the housing.

Check to be sure that the seal has been

removed.

Check the Developer Module connector to be

sure it is clean.

Reinstall the Black Developer Module.

If the problem persists, check connector

CN107 for a good connection or any loose

wiring before replacing the Black Developer

Module.

If the problem still exists, replace the PCU

PWB.

EC PRINT DRUM MISINSTALLED

RAP

The Print Drum Module was installed

incorrectly or is not making a good connection.

INITIAL ACTION

Remove then reinstall the Print Drum Module.

This problem is usually caused by a poor

connection on the left side of the Print Drum

Module. Three contacts are cammed out

when the Print Drum Module is installed.

These contacts make a connection with the

Drum Link PWB located on the left side of the

Print Drum Module. Check to make sure there

is a good connection and the contacts cam

out.

Refer to BSD 9.2 in Section 7 and check the

Drum Detect (H) signal.

If the problem persists, replace the Print Drum

Module.

If the problem still exists, replace the PCU

PWB.

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-11 EA, EB, EC

Page 26

F1 DISK ERROR (FLOPPY) RAP

The Floppy Disk cannot be read.

INITIAL ACTION

Note: The Floppy Disk must be a DOS format.

Load a different floppy and try to read it.

If the floppy still cannot be read, check the

following for a good connection:

• CN102 between the Floppy drive and the

ESS. (BSD 13 in Section 7).

• CN103 the flat cable between the Floppy

drive and the ESS. (BSD 13 in Section 7).

If the problem still exists, replace the Floppy

Drive before replacing the ESS PWB.

F2 DISK I/O ERROR (FLOPPY) RAP

The Floppy Disk cannot be read.

INITIAL ACTION

Note: The Floppy Disk must be a DOS format.

Load a different floppy and try to read it.

If the floppy still cannot be read, check the

following for a good connection:

• CN102 between the Floppy drive and the

ESS. (BSD 13 in Section 7).

• CN103 the flat cable between the Floppy

drive and the ESS. (BSD 13 in Section 7).

If the problem still exists, replace the Floppy

Drive before replacing the ESS PWB.

F3 ACTION FAILED (FLOPPY) RAP

The Floppy Disk cannot be accessed.

INITIAL ACTION

Note: The Floppy Disk must be a DOS format.

Load a different floppy and try to read it.

If the floppy still cannot be read, check the

following for a good connection:

• CN102 between the Floppy drive and the

ESS. (BSD 13 in Section 7).

• CN103 the flat cable between the Floppy

drive and the ESS. (BSD 13 in Section 7).

If the problem still exists, replace the Floppy

Drive before replacing the ESS PWB.

STATUS INDICATOR RAPs 2/99

F1, F2, F3 2-12 DocuPrint C55/C55mp/[NC60]

Page 27

H1 HARD DISK ERROR RAP

The Hard Disk cannot be read.

C55/C55mp

NOTE: If no hard disk is installed on this

printer, print a Settings page (Off Line, Print,

Settings) to record the customer network

settings. Tell the customer that you are going

to do a factory reset and they will need to

reinstall the printer on their network. Perform

a Factory Reset (Off Line, Setup, Factory

Reset).

[NC60]

NOTE: If no hard disk is installed on this

printer, print a Config. sheet (Menu Up to

Service Menu, Item Up to Config Sheet,

Enter) to record the customer network

settings. Tell the customer that you are going

to do a factory reset and they will need to

reinstall the printer on their network. Perform

a Factory Reset. Power Off. Press and hold

On Line and Enter. Switch the power on.

Continue holding the On Line and Enter keys

until the display indicates Power On Version

X.XX, then release the keys. This will enable

the Reset Menu. Menu Up until Reset Menu,

Item Up until Factor Defaults, Value Up until

Yes, then press Enter.

INITIAL ACTION

Switch the power off wait 10 seconds and

switch the power on. This will force the ESS to

retry reading the Hard Disk.

If the Hard Disk still cannot be read, check the

following:

• (C55/C55mp)

Check the Hard Disk to ensure that the

new Relay Interface PWB is installed.

Look for a small PWB mounted to the left

of the hard drive.

• All Printers, check for a good connection

between the Hard Disk and the ESS

(CN101). (BSD 13 in Section 7).

If the problem still exists, replace the Hard

Disk before replacing the ESS PWB.

H2 HARD DISK CONTROLLER

ERROR RAP

The Hard Disk Controller has failed.

INITIAL ACTION

Switch the power off wait 10 seconds and

switch the power on. Retry reading the Hard

Disk.

If the Hard Disk still cannot be read, check the

following for a good connection :

• Between the Hard Disk and the ESS

(CN101). (BSD 13 in Section 7).

If the problem still exists, replace the ESS

PWB.

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-13 H1, H2

Page 28

H3 HARD DISK FULL RAP

The Hard Disk is full.

INITIAL ACTION

Switch the power off wait 10 seconds and

switch the power on. This will force the ESS to

retry reading the Hard Disk.

If the Hard Disk still does not write, have the

customer remove some of the files from the

Hard Disk.

H4 REFORMAT HARD DISK RAP

The Hard Disk needs to be formatted.

INITIAL ACTION

Switch the power off wait 10 seconds and

switch the power on to retry reading the Hard

Disk.

If the H4 occurs again, reformat the hard disk:

STATUS INDICATOR RAPs 2/99

H3, H4 2-14 DocuPrint C55/C55mp/[NC60]

Page 29

J1 ADD YELLOW TONER RAP

The yellow toner concentration sensor has

detected low yellow toner in the yellow

developer assembly. When this occurs, the

Printer will display “Adjusting Print Quality” and

attempt to tone up.

NOTE: If a new color developer housing has

been installed, make sure the 3 seals have

been removed from the left side of the

housing.

INITIAL ACTION

Check with the customer to see if they have

already added Yellow Dry Ink. Add Yellow Dry

Ink, if required.

Adding too much toner can cause the toner to

“cake” and not be dispensed.

(C55/C55mp)

Put the printer in the Off Line mode.

Select the SERVICE Menu and print a

Diagnostic Test Sheet.

Determine the Engine Software version from

the Diagnostic Test Sheet. If the Software

level is Version 66, replace the PCU PWB.

All Printers, switch the power off wait 10

seconds and switch the power on. Allow the

Printer to try to tone up to recheck for the fault.

PROCEDURE

Enter IOT normal diagnostics. Scroll to the

MOTOR TEST program and Press Form

Feed [1] to switch on the motors while

observing the Color Toner Motor.

The Color Toner Motor is rotating normally.

A

A

Y N

Refer to BSD 9.11 in Section 7 and

troubleshoot the Color Toner Motor lines

(CN116-1, 2) for an open or a short to

ground.

If no wiring problem exists, replace the

PCU PWB. If the problem still exists,

replace the Color Toner Motor.

Exit from diagnostics .

Set up the meter to read +24 VDC. Measure

between CN115-16 (+) and ground (−).

Switch the power off wait 10 seconds and

switch the power on while monitoring the meter.

The meter swings from +24 VDC to 0.

Y N

Go to BSD 9.10 in Section 7 and trouble-

shoot the Yellow Toner Solenoid signal

and +24 VDC Interlocked (CN115-16, 15)

for an open.

If no open exists, replace the PCU PWB.

If the problem still exists, replace the

Yellow Toner Solenoid.

Check the Yellow Dispense Shaft to see if it

rotates when the Solenoid energizes. If not,

look for a mechanical problem (gears etc.).

Check the ground to the Yellow Toner

Concentration Sensor (CN118-4 to CN1009-7)

BSD 9.10.

If the ground is OK, replace the PCU PWB.

Color

Toner

Motor

Y Disp.

Shaft

01/02

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-15 J1

Page 30

J2 ADD MAGENTA TONER RAP

The magenta toner concentration sensor has

detected low magenta toner in the magenta

developer assembly. When this occurs, the

Printer will display “Adjusting Print Quality” and

attempt to tone up.

NOTE: If a new color developer housing has

been installed, make sure the 3 seals have

been removed from the left side of the

housing.

INITIAL ACTION

Check with the customer to see if they have

already added Magenta Dry Ink. Add Magenta

Dry Ink, if required.

Adding too much toner can cause the toner to

“cake” and not be dispensed.

(C55/C55mp)

Put the printer in the Off Line mode.

Select the SERVICE Menu and print a

Diagnostic Test Sheet.

Determine the Engine Software version from

the Diagnostic Test Sheet. If the Software

level is Version 66, replace the PCU PWB.

All Printers, switch the power off wait 10

seconds and switch the power on. Allow the

Printer to try to tone up to recheck for the fault.

PROCEDURE

Enter IOT normal diagnostics. Scroll to the

MOTOR TEST program and Press Form

Feed [1] to switch on the motors while

observing the Color Toner Motor.

The Color Toner Motor is rotating normally.

A

A

Y N

Refer to BSD 9.11 in Section 7 and

troubleshoot the Color Toner Motor lines

(CN116-1, 2) for an open or a short to

ground.

If no wiring problem exists, replace the

PCU PWB. If the problem still exists,

replace the Color Toner Motor.

Exit from diagnostics.

Set up the meter to read +24 VDC. Measure

between CN115-14 (+) and ground (−).

Switch the power off wait 10 seconds and

switch the power on while monitoring the meter.

The meter swings from +24 VDC to 0.

Y N

Go to BSD 9.10 in Section 7 and trouble-

shoot the Magenta Toner Solenoid signal

and +24 VDC Interlocked (CN115-14, 13)

for an open.

If no open exists, replace the PCU PWB.

If the problem still exists, replace the

Magenta Toner Solenoid.

Check the Magenta Dispense Shaft to see if it

rotates when the Solenoid energizes. If not,

look for a mechanical problem (gears etc.).

Check the ground to the Magenta Toner

Concentration Sensor (CN118-5 to CN1009-

21) BSD 9.10.

If the ground is OK, replace the PCU PWB.

Color

Toner

Motor

M Disp.

Shaft

01/02

STATUS INDICATOR RAPs 2/99

J2 2-16 DocuPrint C55/C55mp/[NC60]

Page 31

J3 ADD CYAN TONER RAP

The cyan toner concentration sensor has

detected low cyan toner in the cyan developer

assembly. When this occurs, the Printer will

display “Adjusting Print Quality” and attempt to

tone up.

NOTE: If a new color developer housing has

been installed, make sure the 3 seals have

been removed from the left side of the

housing.

INITIAL ACTION

Check with the customer to see if they have

already added Cyan Dry Ink. Add Cyan Dry

Ink, if required.

Adding too much toner can cause the toner to

“cake” and not be dispensed.

(C55/C55mp)

Put the printer in the Off Line mode.

Select the SERVICE Menu and print a

Diagnostic Test Sheet.

Determine the Engine Software version from

the Diagnostic Test Sheet. If the Software

level is Version 66, replace the PCU PWB.

All Printers, switch the power off wait 10

seconds and switch the power on. Allow the

Printer to try to tone up to recheck for the fault.

PROCEDURE

Enter IOT normal diagnostics. Scroll to the

MOTOR TEST program and Press Form

Feed [1] to switch on the motors while

observing the Color Toner Motor.

The Color Toner Motor is rotating normally.

A

A

Y N

Refer to BSD 9.11 in Section 7 and

troubleshoot the Color Toner Motor lines

(CN116-1, 2) for an open or a short to

ground.

If no wiring problem exists, replace the

PCU PWB. If the problem still exists,

replace the Color Toner Motor.

Exit from diagnostics.

Set up the meter to read +24 VDC. Measure

between CN115-12 (+) and ground (−).

Switch the power off wait 10 seconds and

switch the power on while monitoring the meter.

The meter swings from +24 VDC to 0.

Y N

Go to BSD 9.10 in Section 7 and trouble-

shoot the Cyan Toner Solenoid signal and

+24 VDC Interlocked (CN115-12, 11) for

an open.

If no open exists, replace the PCU PWB.

If the problem still exists, replace the Cyan

Toner Solenoid.

Check the Cyan Dispense Shaft to see if it

rotates when the Solenoid energizes. If not,

look for a mechanical problem (gears etc.).

Check the ground to the Cyan Toner

Concentration Sensor (CN118-6 to CN1009-

17) BSD 9.10.

If the ground is OK, replace the PCU PWB.

Color

Toner

Motor

C Disp.

Shaft

01/02

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-17 J3

Page 32

J4 ADD BLACK TONER RAP

The black toner concentration sensor has

detected low black toner in the black developer

assembly. When this occurs, the Printer will

dead cycle and attempt to tone up.

NOTE: If a new black developer housing has

been installed, make sure the packing material

has been removed.

INITIAL ACTION

Check with the customer to see if they have

already added Black Dry Ink. Add Black Dry

Ink, if required.

Adding too much toner can cause the toner to

“cake” and not be dispensed.

Check the Black toner hopper to ensure that it

is latched closed and is opening the shutter to

the developer housing.

(C55/C55mp)

Put the printer in the Off Line mode.

Select the SERVICE Menu and print a

Diagnostic Test Sheet.

Determine the Engine Software version from

the Diagnostic Test Sheet. If the Software

level is Version 66, replace the PCU PWB.

All Printers, switch the power off wait 10

seconds and switch the power on. Recheck

for the fault.

PROCEDURE

Remove the Printer Rear Cover. There is a

hole located at the left rear of the printer. This

hole is used to view the gears for the Toner

motor.

NOTE: In the following steps, we will be

operating the Black Toner Motor. Do not allow

the motor to run for over 2 seconds or

overtoning can result.

A

A

Enter IOT normal diagnostics. Scroll to the

MOTOR TEST program and press Form Feed

[1] to switch on the motors. Look through the

hole and switch on the Black Toner Motor by

pressing On Line [0]. Release On Line [0] to

stop the motor. Press Media Server [2] to

stop the test.

The Motor Runs.

Y N

Set up the meter to read +24 VDC.

Measure between CN107-13 (+) and

ground (−). Press Form Feed [1] to

switch on the motors. Press On Line [0]

to switch on the Black Toner Motor.

Release On Line [0] to stop the motor.

Press Media Server [2] to stop the test.

The meter reads approximately 12 VDC

when On Line [0] was pressed.

Y N

Go to BSD 9.8 in Section 7 and

troubleshoot the Black Toner Motor

lines (CN107-13, 14) for an open.

If the lines are OK, replace the Black

Toner Motor

Check the Black toner box for auger

binding.

Check the ground to the Black Toner

Concentration Sensor (CN107-2 to

CN1001-4) BSD 9.7.

If the ground is OK, replace the PCU

PWB.

Toner should be dispensed, check the Black

toner box for auger binding.

Check the ground to the Black Toner

Concentration Sensor (CN107-2 to CN1001-4)

BSD 9.7.

If the ground is OK, replace the PCU PWB.

STATUS INDICATOR RAPs 2/99

J4 2-18 DocuPrint C55/C55mp/[NC60]

Page 33

J5 REPLACE COLOR DEVELOPER

CARTRIDGE RAP

NOTE: This code is normally preceded by a

W1 code.

The Color Developer Cartridge is at end of life.

INITIAL ACTION

Check the Color Developer Cartridge life.

(C55/C55mp)

Press On Line, then press Menu, use Next to

scroll to the MAINTENANCE menu, press

Enter. Use Next to scroll to COLOR DEV

CART, press Enter.

[NC60]

Press Menu Up until Service, Item Down until

CRU Usage. Press Value Up to scroll to the

Color Dev. Cart.

Check the % remaining on the Color

Developer Cartridge. If the cartridge is at end

of life, notify the customer and have them

install a new Color Developer Cartridge.

PROCEDURE

Check the developer drive motor, belts and

gears to ensure that they are rotating.

If the J5 code does not clear when a new Color

Developer Cartridge is install, go to BSD 9.10

and check the New Developer Sense signal

(CN118-7) for an open or short to ground.

If the J5 code exists even though the Color

Cartridge has not reached end of life refer to

BSD 9.10 and check the following:

• Cyan Toner Sense signal for an open or a

short to ground (CN118-10).

• Cyan Toner +5 VDC for an open (CN118-3).

• Magenta Toner Sense signal for an open or

a short to ground (CN118-9).

• Magenta Toner +5 VDC for an open

(CN118-2).

A

A

• Yellow Toner Sense signal for an open or a

short to ground (CN118-8).

• Yellow Toner +5 VDC for an open

(CN118-1).

If all of the above check OK, replace the Color

Developer Cartridge. If the problem still exists,

replace the PCU PWB.

J6 REPLACE BLACK DEVELOPER

CARTRIDGE RAP

NOTE: This code is normally preceded by a

W2 code.

The Black Developer Cartridge is at end of life.

INITIAL ACTION

Check the Black Developer Cartridge life.

(C55/C55mp)

Press On Line, then press Menu, use Next to

scroll to the MAINTENANCE menu, press

Enter. Use Next to scroll to BLACK DEV

CART, press Enter.

[NC60]

Press Menu Up until Service, Item Down until

CRU Usage. Press Value Up to scroll to the

Black Dev. Cart.

Check the % remaining on the Black

Developer Cartridge. If the cartridge is at end

of life, notify the customer and have them

install a new Black Developer Cartridge.

PROCEDURE

If the J6 code does not clear when a new

Black Developer Cartridge is install, go to BSD

9.7 and check the New Developer Sense

signal (CN107-3) for an open or short.

If the J6 code exists even though the Black

Cartridge has not reached end of life refer to

BSD 9.7 and check the following:

• Black Toner Sense signal for an open or a

short to ground (CN107-4).

• Black Toner +5 VDC for an open

(CN107-1).

If all of the above check OK, replace the Black

Developer Cartridge. If the problem still exists,

replace the PCU PWB.

2/99 STATUS INDICATOR RAPs

DocuPrint C55/C55mp/[NC60] 2-19 J5, J6

Page 34

J7 TONER COLLECTOR FULL RAP

The Toner Collector is full or not installed

correctly.

INITIAL ACTION

Remove the Toner Collector and ensure that it

is not full.

Check to ensure that the channel that the

sensor “looks” through is not blocked with

toner.

Reinstall the Toner Collector.

PROCEDURE

Enter IOT normal diagnostics. Scroll to the

SWITCH SCAN program and select Scan Row

02. Press Form Feed [1].

Open the Printer. Remove and reinstall the

Toner Collector while observing the Yellow

LED.

The Yellow LED switches on and off

Y N

Go to BSD 9.21 in Section 7 and troubleshoot the Waste Toner Sensor signal,

+5 VDC, and GND (CN102-3, 1, 2) for an

open.

If no open exists, replace the PCU PWB.

If the problem still, exists replace the

Waste Toner Sensor.

Install a new Toner Collector.

J8 REPLACE PRINT DRUM RAP

The Print Drum is at end of life, is not in place,

or is not installed correctly.

NOTE: This code is normally preceded by a

W3 code.

INITIAL ACTION

Check the Print Drum Cartridge life.

(C55/C55mp)

Press On Line, then press Menu, use Next to

scroll to the MAINTENANCE menu, press

Enter. Use Next to scroll to PRINT DRUM,

press Enter.

[NC60]

Press Menu Up until Service, Item Down until

CRU Usage. Press Value Up to scroll to the

Print Drum.

Check the % remaining on the Print Drum

Cartridge. If the cartridge is at end of life,

notify the customer and have them install a

new Print Drum Cartridge.

PROCEDURE

If the J8 code does not clear when a new Print

Drum Cartridge is installed, go to BSD 9.2 and

check the New Drum Detect signal

(CN107-15) for an open or short to ground.

Also check +5 VDC (CN107-17) for an open.

If the J8 code exists even though the Print

Drum Cartridge has not reached end of life,

refer to BSD 9.2 and check the Drum Detect

signal (CN107-19).

If all of the above check OK, replace the Print

Drum Cartridge. If the problem still exists,

replace the PCU PWB.

J9 REPLACE FUSER MODULE RAP

The Fuser is at end of life.

NOTE: This code is normally preceded by a

W4 code.

INITIAL ACTION

Check the Fuser Cartridge life.

(C55/C55mp)

Press On Line, then press Menu, use Next to

scroll to the MAINTENANCE menu, press

Enter. Use Next to scroll to FUSER

MODULE, press Enter.

[NC60]

Press Menu Up until Service, Item Down until

CRU Usage. Press Value Up to scroll to the

Fuser Module.

Check the % remaining on the Fuser Module.

If the module is at end of life, notify the

customer and install a new Fuser Module.

PROCEDURE

If the J9 code does not clear when a new

Fuser Module is install, go to BSD 10.5 and

check the New Fuser Detect signal (CN103-8,

CN306-4) for an open or short to ground. Also

check +5 VDC (CN306-1) for an open.

If all of the above check OK, replace the Fuser

Module. If the problem still exists, replace the

PCU PWB.

STATUS INDICATOR RAPs 2/99

J7, J8, J9 2-20 DocuPrint C55/C55mp/[NC60]

Page 35

JA REPLACE OIL/PAD RAP

The Oil/Pad needs to be replaced.

INITIAL ACTION

Check the Oil Bottle and sump. If required,

replace the Wiper Roll and Oil Bottle. If this

code persists after a new Oil Bottle is installed

or the Oil is OK, continue with this RAP.

Paper dust and other contaminants can cause

the fuser oil to get cloudy and solidify causing

the ball that triggers the Low Oil Sensor to

stick. When low oil is detected, the printer will

stop and the fuser will be powered off after 50

prints to prevent Fuser damage. If the fuser

has the contamination described above, the

ball could be stuck in a position that will

prevent the fuser from warming up.