Xerox DocuPrint

96/4635/180/2000

NPS/IPS

Troubleshooting Guide

721P90211

Version 8.0

October 2002

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

©2002 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable

material and information now allowed by statutory or judicial law or hereinafter

granted, including without limitation, material generated from the software

programs which are displayed on the screen, such as icons, screen displays,

looks, etc.

Printed in the United States of America.

Publication number: 721P90210

Xerox® and all Xerox products mentioned in this publication are trademarks of

Xerox Corporation. Products and trademarks of other companies are also

acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent editions.

Table of contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Ozone information: U. S. only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Operation safety: U. S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Operation safety: Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Warning markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Operator accessible areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Before cleaning your product . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

CE mark: Europe only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Radio and telecommunications equipment directive (Europe only) . . . . . x

For further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1. Calling for service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Information to have on hand when calling for service . . . . . . . . . . . . . . 1-1

Enabling and disabling the modem for remote service . . . . . . . . . . . . . 1-2

2. Fault masking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

3. Troubleshooting Xerox Client Software installation. . . . . . . . . . .3-1

4. Troubleshooting a Novell implementation . . . . . . . . . . . . . . . . . .4-1

5. Clearing paper misfeeds and jams. . . . . . . . . . . . . . . . . . . . . . . . .5-1

Clearing a feeder tray fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Frequent misfeeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Clearing paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Checking job integrity following a paper jam . . . . . . . . . . . . . . . 5-7

Printer areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Clearing bypass transport paper jams . . . . . . . . . . . . . . . . . . . 5-22

Troubleshooting Guide iii

Table of contents

Paper curl and paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Measuring the paper curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Adjusting the decurler lever . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

6. Optimizing print quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Installing the custom transfer assist blade . . . . . . . . . . . . . . . . . . . . . . 6-1

Correcting skewed printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Product features that affect PostScript print quality . . . . . . . . . . . . . . . 6-4

Proprietary PostScript extensions . . . . . . . . . . . . . . . . . . . . . . . 6-4

Device-dependent operators . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Gray shading—setscreen and setcolorscreen . . . . . . . . . 6-4

Gray shading—settransfer and transfer function . . . . . . . 6-5

Smooth curves—setflat . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Invisible strokes—0 setlinewidth . . . . . . . . . . . . . . . . . . . 6-6

Scan conversion—fill, eofill, and stroke . . . . . . . . . . . . . . 6-6

7. Resolving printer problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

8. Resolving system problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

iv Troubleshooting Guide

Laser safety

Safety

WARNING

Adjustments, use of controls, or performance of procedures

other than those specified herein may result in hazardous

light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance stan dards of the U.S. Department of Health,

Education, and Welfare for Class 1 laser products. Class 1 laser

products do not emit hazardous radiation. The DocuPrint printers

do not emit hazardous radiation because the laser beam is

completely enclosed during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must

be removed with a tool.

DO NOT REMOVE LABELED PANELS OR PANELS NEAR

LABELS. ONLY XEROX SERVICE REPRESENTATIVES HAVE

ACCESS TO THESE PANELS.

Troubleshooting Guide v

Safety

Ozone information: U. S. only

This product produces ozone during normal operation. The

amount of ozone produced depends on copy volume. Ozone is

heavier than air. The environmental parameters specified in the

Xerox installation instructions ensure that concentration levels

are within safe limits. If you need additional informat ion

concerning ozone, call 1-800-828-6571 to request the Xerox

publicat ion 600P83222, OZONE.

Operation safety: U. S.

Your Xerox equipment and supplies have been designed and

tested to meet strict safety requirements. They have been

approved by safety agencies, and they comply with

environmental standards. Please observe the following

precautions to ensure your continued safety.

WARNING

Improper connection of the equipment grounding conductor

may result in risk of electrical shock.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

• Never use a ground adapter pl ug t o connect equipment to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed fo r

your Xerox equipment. Use of unsuitable materials may result

in poor performance and may create a hazardous situation.

• Never move either the printer or the printer controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. Th ere are no oper ator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

vi Troubleshooting Guide

• Never use supplies or cleaning materials for other than the ir

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet

and call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety

at the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States, contact your loc al

Xerox representative or operating company.

Operation safety: Eur o pe

Safety

This Xerox product and supplies are manufactured, test ed and

certified to strict safety regulations, electromagnetic regulations

and established environmental standards.

Any unauthorised al teration, which may include the addition of

new functions or conn ection of external devices, may impact the

product certification.

Please contact your Xerox representative for more information.

Warning markings

All warning ins tructions ma rked on or supplied with the product

should be followed.

This WARNING alerts users to areas of the product where there

is the possibility of personal damage.

This WARNING alerts users to areas of the product where there

are heated surf ace s, which should not be touched.

Troubleshooting Guide vii

Safety

Electrical supply

This product shall be operated from the type of electrical supply

indicated on the product’s data plate label. If you are not sure

that your electrical supply meet s the requirem ents, please

consult your local power co mpany for advice.

WARNING

This product must b e connected t o a protectiv e earth circuit. This

product is supplied with a plug that has a protective earth pin.

This plug will fit only into an earthed electrical outlet. This is a

safety f eature . Always co nnect equipment to a properly gr ounded

electrical outlet. If in doubt, ha ve the ou tlet check ed b y a qualified

electrician.

To disconnect all electrical power to the product, the disconnect

device is the power cord. Remove the plug from the electrical

outlet.

Ventilation

Slots and ope ning in the enclosure of the product are provid ed

for ventilation. Do not block or cover the ventilation vents, as this

could result in the product overheating.

This product should not be placed in a built-in installation unless

proper ventilation is provided, please contact your Xerox

representative for advice.

Never push objects of any kind into the ventilation vents of the

product.

Operator accessible areas

This product has been designed to restrict operator access to

safe areas only. Operator access to hazardo us areas is restricted

with covers or guards, which would require a tool to remove.

Never remove these covers or guards.

viii Troubleshooting Guide

Maintenance

Any operator product maintenance procedures will be described

in the user docume ntation supplied with the product. Do not

carry out any maintenance on the product, which is not

described in the customer documentation.

Before cleaning your product

Before cleaning this product, unplug the product from the

electrical outlet. Always use materials specifically designated for

this product, the use of other materials may result in poor

performance and may create a hazardous situation. Do not use

aerosol cleaners , they may be flammable under certain

circumstances.

Safety

CE mark: Europe only

January 1, 1995: Council Directive 73/23/EEC, amended by

Council Directive 93/68/EEC, approximation of the laws of the

member states related to low voltage equipment.

January 1, 1996: Council Directive 89/336 /EEC, approximation

of the laws of the member states related to electr omagnetic

compatibility.

March 9, 1999: Council Directive 99/5/EC, on radio equipment

and telecommunications terminal equipment and the mutual

recognition of their conformity.

A full declaration of conformity, defining the relevant directives

and referenced standards, can be obtained from your Xerox

representative.

In order to allow this equipment to operate in proximity to

Industrial, Scientific and Medical (ISM) equipment, the external

radiation for the ISM equipment may have to be limited or special

mitigation measures taken.

This is a Class A product. In a domestic environment this product

may cause radio frequency interference, in which case the user

may be required to take adequate measures.

Shielded interface cables must be used with this product to

maintain compliance with Council Directive 89/36/EEC.

Troubleshooting Guide ix

Safety

Radio and telecommunications equipment directive (Europe only)

Certification to 1999/5/EC Radio Equipment and

Telecommunications Terminal Equipment Directive:

This Xerox product has been self-certified by Xerox for panEuropean single terminal connection to the analog public

switched telephone network (PSTN) in accordance with Directive

1999/5/EC.

The product has been design ed to w ork with the nation al PSTNs

and compatible PBXs of th e following countries:

Austria Germany Luxembourg Sweden

Belgium Greece Netherlands Switzerland

Denmark Iceland Norway United Kingdom

Finland Ireland Portugal

France Italy Spain

In the event of problems, contact y our local Xe ro x r epres entative

in the first instance.

This product has bee n tested to, and is compliant with, TBR2 1, a

specification for terminal equipment for use on analog switched

telephone networks in the European Economic area.

The product may be configured to be compatible with other

country networks. Please contact your Xerox representative if

your product needs to be reconnected to a network in another

country. This product has no us er-adjustable settings.

NOTE: Although this product can use either loop disconnect

(pulse) or DTMF (tone) signaling, it should be set to use DTMF

signaling. DTMF signaling provides reliable and faster call setup.

Modification or connection to external control software, or to

external control apparatus not authorized by Xerox, invalidates

its certification.

x Troubleshooting Guide

For further information

For more information on Enviro nment, Health and Safety in

relation to this Xerox product and supplies, please contact the

following customer help lines:

Europe:+44 1707 353434

USA:1 800 8286571

Canada:1 800 8286571

Safety

Troubleshooting Guide xi

Safety

xii Troubleshooting Guide

About this guide

Introduction

This guide describes how to solve some specific problems that

may occur when you are using the Xerox DocuPrint 96/4635/

180/2000 Series NPS/IPS.

NOTE: You may be using the DocuPrint NPS/IPS software

extension on a DocuPrint 2000 EPS system. The 2000 Series

printer models are the 100, 135, 155, and 180. These printers

are comparable in capabilities to the DocuPrint NPS/IPS models

96, 4635, an d 180.

Contents

This guide is designed for Xerox DocuPrint 96/4635/180/2000

Series NPS/IPS operator s whose job consists of the routine

operation of one of these systems .

Users should have an understanding of printer controller

operations.

Before using this guide, become familiar with its contents and

conventions.

This section lists the contents of this guide:

• Chapter 1, “Calling for service,” describes the information to

have on hand when calling for support service, and provides

information on using the Sixth Sense Technology.

• Chapter 2, “Fault masking,” describes how the Model 96/

4635/180 NPS/IPS masks a problem so that the job will

continue to print.

• Chapter 3, “Troubleshooting Xerox Client Software

installation,” provides solutions to common problems with

software installation.

Troubleshooting Guide xiii

Introduction

Conventions

• Chapter 4, “Troubleshooting a Novell implementation,”

describes some ways to troubleshoot a Nove ll

implementation by viewing log messages.

• Chapter 5, “Clearing paper misfeeds and jams,” illustrates

how to clear paper misfeeds and jams from various parts of

the paper path.

• Chapter 6, “Optimizing print quality,” discusses methods of

checking and improving print quality.

• Chapter 7, “Resolving printer problems,” describes printerrelated problems other than paper jams, and suggests

corrective acti o ns.

• Chapter 8, “Resolving system problems,” describes various

system problems and suggests corrective actions.

An index is provided at the back of the guide.

This guide uses the following conventions:

• All caps and angle brackets: Withi n procedures , the names

of keys are shown in all caps within angle brackets (for

example, press <ENTER>).

• Angle brackets: Variable information, or the positi on of a

specified argument in the command syntax, appears in angle

brackets (for example, List Fonts <Pattern>).

• Bold: Within procedures , te xt and number s that you e nter are

shown in bold (for example, enter privilege operator).

• The word “enter” within pr ocedures: The two-step process

of keying in data and p ressing <ENT ER> (for example,

enter y).

• Italics: Document and library names are shown in italics (for

example, the Xerox DocuPrint NPS/IPS Guide to Managing

Print Jobs).

• Quotation marks: Keywords you can enter as arguments

appear in quotes (for example, “USLetter”).

• Vertical bars: Alternatives to specifie d ar guments are

separated by vertical bars (for example, Set Time <Time |

Remote Host Name | IP Address>).

xiv Troubleshooting Guide

NOTE: Notes are hints that help you perform a task or

understand the text.

Cautions alert you to an action that could damage hardware or

software.

Warnings alert you to conditions that may affect the safety

of people.

Related publications

The Xerox DocuPrint NPS/IPS documentation set includes the

documents listed below.

Introduction

CAUTION

WARNING

NOTE: For a list of IBM reference manuals for IPDS printing,

refer to the Solutions Guide for IPDS Printing.

• Guide to Configuring and Managing the System

• Guide to Managing Print Jobs

• Guide to Performing Routine Maintenance

• Guide to Submitting Jobs from the Client

• Guide to Using Page Description Languages

• Installation Planning Guid e

• System Overview Guide

• Troubleshooting G uide

• Solutions Guide for IPDS Printing

• Decomposition Service and Tools Guide

• Glossary

• Master Index

• Generic MICR Fundamentals Guide

• Customer Information Quick Reference Card

• Printer Contr o ller Comman d s Qu ick Reference Ca r d

• Operator Quick Reference Card

• Submitting your Jobs from Macintosh Quick Reference Card

Troubleshooting Guide xv

Introduction

• Submitting your Jobs from UNIX & DOS Quick

Reference Card

• Submitting your Jobs from Windows NT 4.0

(QuickPrint) Quick Reference Card

• Submitting your Jobs Using Windows NT 4.0 Drivers

Quick Reference Card

The documentation set also includes an electronic

version, the DocuPrint NPS/IPS Interactive Customer

Documentation CD.

xvi Troubleshooting Guide

1. Calling for service

Before calling your customer service support center, make sure

you have read this chapter and have tried the corrective actions

described here. If the problem persists, gather the necessary

information and call the customer support center.

Information to have on hand when calling for service

To report hardware or software problems in the United States,

call the following number:

1-800-822-2979

For customers outside the United States, call your local service

representative.

Before calling, make note of the following:

• Status code numbers and messages that appear on the

controller screen and the printer console

• Indicator lights that are lit

• Name of your printer: DocuPrint 96 or 4635 or 180 or 2000

Series NPS/IPS

• Serial number for your printing system (located on the frame

behind the narrow door to the far left, at the front of the

printer)

• Problems you are having with the system.

Additional information you may wish to note prior to calling

includes:

• An expl an atio n of how outpu t d iffers from what was expected.

• An assessment of whether the symptoms fo llow a pattern or

occur randomly.

• A list of special conditions that may be related to the

problems:

– New applications

– Changes made to the software

Troubleshooting Guide 1-1

Calling for service

– Recent service performed

– Previous conditions under which the application has

printed pr operly.

Give this information to a customer service representative, who

will discuss the information and give you an estimated time of

arrival or assist you over the phone to resolve the problem.

Enabling and disabling the modem for remote service

Your system may be set up to use Sixth Sense Technology—a

remote communication capability. Sixth Sense Technology is a

suite of tools that allow service personnel to connect with a

system and ev aluate its perf ormance. The service representative

can troubleshoot problems remotely, transfer, apply, and remove

patches remotely, and, if an on-site call is required, arrive with

the solution to fix the problem.

An external modem allows your system to be accessed by

remote service technicians.

You may be instructed to enable the modem so that the

technician can dial into your system. Follow this procedure:

1. Stop all printing and queueing during the remote service

session.

2. Follow the instructions of your ser vice representative to

enable the modem.

3. When the remote service session is complete, disable the

modem.

4. Resume pr inting and queueing.

Refer to the Guide to Configuring and Managing the System,

“Using utility commands” chapter, for more information on the

commands used for remote service.

If security is a concern, you can turn off the modem, or you can

physically disconnect the cable from the system when it is not

being used.

CAUTION

Depending on the com mand s u sed by the technician, the printer

may start up during the remote service session. You should not

attempt to operate the system or perform any tasks at the printer

while remote service is in process.

1-2 Troubleshooting Guide

2. Fault masking

This chapter describes the behavior of the 96/4635/180 NPS/IPS

while printing with fault conditions.

The DocuPrint 96, 4635, and 180 NPS/IPS enable you to

continue printing while certain faults or conditions exist in parts

of the printer that are not currently in use. Such faults or

conditions are said to be masked. An example of a masked fault

condition is when feeder tray 1 is in use and feeder tray 2 is

jammed, or stacker bin B is full.

When there is a masked fault or condition, the Hint icon (a light

yellow circle with an asterisk inside) appears on the printer

console and the goes on. A message, preceded by an asterisk,

also appears in line 3 of the message area of the p rinter console .

To display the area containing the masked fault, touch the Fault

List Icon (shown below) on the printer console. The Fault List

Icon appear s.

Figure 2-1. Fault List icon

Troubleshooting Guide 2-1

Fault masking

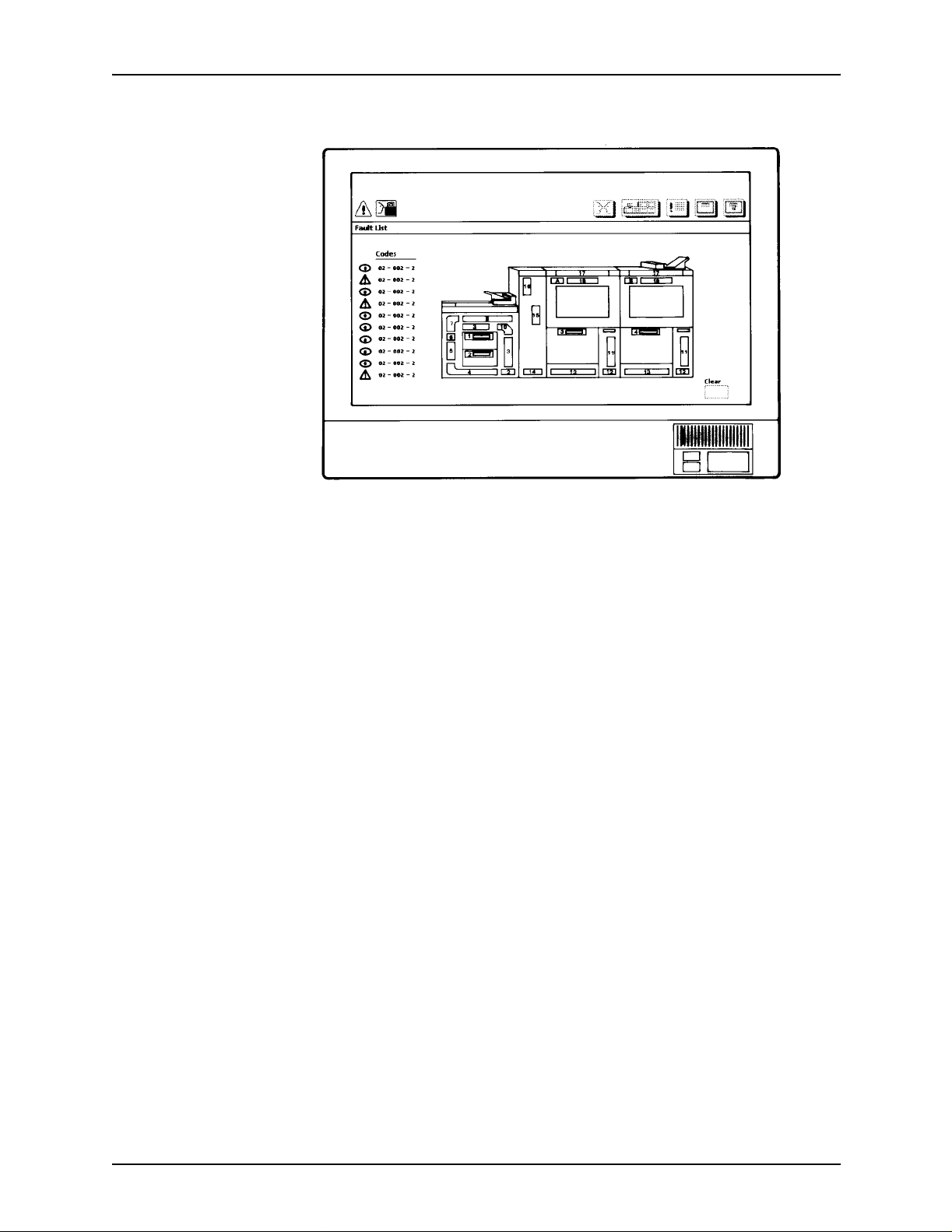

Figure 2-2. Fault List screen

The Fault List screen displays any outstanding fault codes and

shows a mimic of the printer; the area containing the masked

fault is highlight ed in light y ello w . F or greate st printer product ivity,

clear any masked faults at your earliest opportunity.

When the printer stops because of a fault, display the Fault List

screen after clearing the fault to see if there are any masked

faults. Clear these masked faults before continuing with the print

job.

When there is a fault that cannot be masked and therefore

causes the printer to stop, the Fault icon (a dark yellow triangle

with an exclamation point inside) appears on the printer console

and the Attention light flashes. The Fault screen appears on the

printer console, highlighting (in dark yellow) the area(s) o f t he

printer containing the fault and giving instructions for clearing the

fault.

If a fault exists in the system at the time that a masked fault

occurs, the printer console displays only the Fault icon. The

remaining masked fault condition messages still display in the

message area of the printer console.

2-2 Troubleshooting Guide

3. Troubleshooting Xerox Client Software installation

Xerox Client Software is downloaded from the printer controller

to a netwo rk client w orkstation to enab le a print command. Ref er

to the Guide to Submitting Jobs from the Client for more

information.

If you are unable to install the Xerox Client Software, or if you

install it and all requests submitted fail, try the following:

• Make sure the Xerox Client print command does not conflict

with the local print command on the client system. To verify

this, at the prompt (or on a new shell window prompt, for Sun

clients), enter print. You should see the usage message for

the Xerox Client print command.

If not, make sure that the environment variable path includes

the subdirectory /usr/xerox/nps/client/bin and /usr/bin before

the subdirectory containing the local print command. Also,

resolve any print command aliases that might be set in

the.cshrc file.

If you see the message “Server or Directory Unreachable”

after executing a print command, perform the following steps:

1. If the printer controller software is newly installed, verify

that queuing has started at the printer controller.

2. At the client, verify the host file exists and contains the

printer controller name and TCP/IP address.

3. Verify the network connections between the printer

controller and the client. Enter ping <Printer Controller

name>; if that fails, enter ping <Printer Controller TCP/

IP address>. V erify th at the TCP /IP addr ess of the printer

controller is the same as the one in the host file on the

client.

4. Check for hardware problems.

Troubleshooting Guide 3-1

Troubleshooting Xerox Client Software insta llation

• Verify that the cconf file (/usr/xerox/nps/client/cconf) contains

the default printer controller name that most recently

performed the client installation. Try submitting requests to

another printer controller by using the server override switch

in the print command.

• If you are unable to install the software, make sure the client

hard disk meets the minimum requirements. Otherwise, you

may run out of disk space during the installation, and you

may get misleading error messages.

The following table provides a reference to error messages that

may display during installation of Xerox Client Software.

Table 3-1. Xerox Client Software installation error messages

Error message Description

Installation not complete. Problems may have

occurred during the transfer of files. Please verify

that all files have been transferred and contact your

system administrator for assistance.

Usage: <Printer__Controller__Name> or

Usage: instsun4 <Printer__Controller__Name> or

Usage: instsun3 <Printer__Controller__Name> or

Usage: instult <Printer__Controller__Name>

The attempt to communicate to the

<Print__Controller__Name> has failed. Make sure

the name <Print__Controller__Name> is correct.

Make sure your /etc/hosts file contains correct

information. Make sure the machine is operational

and is in the network mode.

Problems may have occurred in ftp to the Print

Server. Verify disk space. If the problem still exists,

contact your system administrator for assistance.

Problems may have occurred in setting permissions

for the executables . You have to be at the super user

level to install. Please contact your system

administrator for assistance.

Appears if any of the client files are missing at

the end of installation.

Appears when the Printer Controller Name is

not used as the argument to the installation

commands. The <Printer__Controller__Name>

is the name of the Printer Controller that the

installation commands use to install the Client

Software.

UNIX clients only. Indicates that the installation

script’s attempt to communicate with the Printer

Controller has failed.

UNIX clients only. Indicates problems occurred

while using ftp to the Printer Controller to

retrieve client files.

UNIX clients only. Indicates that the installation

script’s attempt to set permissions for the

executables in

/usr/xerox/client/nps/bin has failed.

Problems may have occurred in making the

commands available. Please contact your system

administrator.

Unable to set permission for dir <path>. You have to

be at the super user level to install. Contact your

system administrator for assistance.

UNIX clients only. Indicates that the attempt to

copy the executables in /usr/xerox/client/nps/bin

to

/usr/bin has failed.

UNIX clients only. Indicates that the attempt to

set permission for the client directory structure

has failed. Make sure that you are executing the

installation script at the super user level.

3-2 Troubleshooting Guide

4. Troubleshooting a Novell

implementation

The tables in this chapter describe some ways to troubleshoot a

Nove ll impleme ntation fr om the log m essages that appear in t he

var/log/DocuPrint.

The following table describes how to troubleshoot PSERVER

problems.

Table 4-1. PSERVER problems

Problem Probable Cause Resolution

Log message says there

is a problem locating a

NetWare server.

Log message says there

is an error in connecting to

the file server.

NPS/IPS is not getting SAP packets for

the server.

• There is a basic connectivity or

routing problem.

• The framing type has been set

incorrectly during installation.

• The file server name has been set

incorrectly during installation.

NPS/IPS is getting SAP packets with

information about the server, but

cannot communicate with it.

• There is a basic connectivity or

routing problem.

• NPS/IPS has an incorrect network

number.

If there is an external connectivity

problem:

• Check Novell file server

console screen for messages.

• Check that the server is

running and connected to the

network.

If it is an incorrect framing type or

server name, your Xerox service

representative must change the

configuration on the printer

controller.

If there is an external connectivity

problem:

• Check Novell file server

console screen for messages.

• Check that the server is

running and connected to the

network.

If it is an incorrect network number,

your Xerox service representative

must change the configuration on

the printer controller.

Troubleshooting Guide 4-1

Troubleshooting a Novell implementation

Table 4-1. PSERVER problems (Continued)

Problem Probable Cause Resolution

Log message says there

is a failure to log in.

Log message indicates

failure to login and

password settings are

correct.

Log message says "Error

finding queue."

Password problem.

• Server does not accept

unencrypted logins

• NPS/IPS does not have the correct

password.

A PSERVER with the printer's

PSERVER name is running on the file

server or on another machine (this

could even be another NPS/IPS

configured to use the same PSERVER

name). The file server should only

have a PSERVER defined with the

same name as the printer’s

PSERVER, th ere should not be an

instance of PSERVER running under

that PSERVER definitio n.

Queue not created. At the file server, create the queue,

If the server is not properly

configured, enter SET ALLOW

UNENCRYPTED

PASSWORDS=ON at the server

console.

If NPS/IPS has the wrong

password, your Xerox service

representative must change the

password.

Stop the PSERVER instance.

set up the printer for the

PSERVER and be sure it will

service the appropriate queue.

Log message says

"Netware PServer

<name> not found.”

Log message says that

there was an error

attaching to the queue.

The PSERVER has not been defined

on the file server.

NPS/IPS does not have access to the

queue.

Define a PSERVER with the

correct n ame on the fi le server and

restart t he system.

Ensure that there is a printer

defined for the PSERVER on the

file server and that the printer is

defined to service the desired

queue.

4-2 Troubleshooting Guide

Troubleshooting a Novell implementation

The follo w ing table describes troubleshooting RPRINTER

problems.

Table 4-2. RPRINTER problems

Problem Probable Cause Resolution

Log message says:

• "Cannot locate any

Netware print server

from the net."

• "Requested server

<name> not

responding.”

NPS/IPS is not getting SAP packets

advertising the print server.

• There is a basic connectivity or

routing problem.

• The incorrect framing type has

been set.

• The print server is not running. For

RPRINTER, there must be a

PSERVER runnin g on the file

server with the name specified to

NPS/IPS at installation time.

If there is an external connectivity

problem: PSERVER should work

when it is repaired.

If it is an incorrect framing type,

your Xerox serv ice re pr es en t at ive

must change the configuration on

the printer controller.

If print server is not running, start

one.

Troubleshooting Guide 4-3

Troubleshooting a Novell implementation

4-4 Troubleshooting Guide

5. Clearing paper misfeeds and jams

This chapter shows the steps for clearing paper misfeeds and

jams from various areas of the printer.

Clearing a feeder tray fault

When paper is misfed from the paper trays, complete the

following steps:

1. Go to the paper tray indicated by the message and graphic

displays of the printer console.

2. Press the Tray Unlock button o n the front left of the paper tr a y.

Troubleshooting Guide 5-1

Clearing paper misfeeds and jams

3. When the Ready To Open indicator is lit, pull the bar up and

out to open the tray. Pull the tray all the way out for best

results.

4. Press the green lever to unlatch the paper feeder assembly.

5. Remove and discard any partially fed paper. Make sure that

the paper supply is neatly stacked and that the stack is not

higher than the MAX line on the length guide. Make sure

that the length guide is firmly touching the back edge of the

stack.

5-2 Troubleshooting Guide

Clearing paper misfee ds and jams

6. Latch the paper feeder assembly by pressin g the green dot

until the assembly clicks into place.

Frequent misfeeds

7. Slide the tray back into the printer until the tray latches and

press the Continue button to resume printing.

8. Discard any pages sent to the sample tray or unused stacker

tray when the paper jam was detected.

NOTE: If the 96/4635/180 NPS/IPS does not continue printing

after a paper tray fault or after paper is loaded, open and close

the tray. The system should resume printing.

Frequent misfeeds may be caused by a glazed feed belt. A

glazed belt is the most common cause of one tray misfeeding

more than another tray when the same kind of paper is used.

(Glazing is caused by a buildup of the chemicals found on most

papers.)

If you suspect that the belt is glazed, try cleaning it with film

remover that is obtained from your servi ce representative.

Troubleshooting Guide 5-3

Clearing paper misfeeds and jams

Clean the feed belt only to correct misfeeds, not as routin e

maintenance. Because the belt is rubber, frequent cleaning dries

it out and makes it fail prematurely.

1. Clear any misfeeds that have occurred, but do not latch the

paper feeder assembly. If necessary, unlatch it by pressing

down on the brig ht green lever on the right side of the paper

tray.

CAUTION

2. Lightly moisten a lint-free towel with film remover and

thoroughly wipe the outside surface of the feed belt in the

same direction as the ribs on the belt. (Wiping from side to

side might pull the belt off its track.) Allow a few seconds for

the film remover to evaporate.

5-4 Troubleshooting Guide

Clearing paper misfee ds and jams

3. Latch the paper feeder assembly by pressing down on the

bright green dot . Slide the paper tr a y completely back into the

printer

Clearing paper jams

Operate the system as usual. If y ou still e xperience misf eeds,

place a service call.

Detailed message labels i nside of the printer tell y ou how to clea r

the jam.

Each handle, lever, or knob that must be moved to clear a jam is

bright green and marked with an arrow indicating the direction it

moves.

Troubleshooting Guide 5-5

Clearing paper misfeeds and jams

Follow these steps to clear a paper jam:

1. Go to the area of the prin ter that is i ndicated b y the displ ay o n

the printer console.

NOT READY

Fault Instructions

Clear any paper in areas 8, 15, 16, 17, and 18

Follow the instructions on the labels 8,15,16,17,and 18 to clear paper from theses areas.

Clear any paper in areas 8, 15, 16, 17, and 18

Clear

2. Open any printer doors necessary to access the area.

3. To clear the jammed paper from the area, follow the

instructions on the message labels inside of the printer and

on the printer console. Refer to the section “Printer areas” for

more information.

NOTE: You may find that the printer has already cleared the

jam and sent the paper to the sample or purge tray.

4. Close any printer doors that were opened.

5. Press the Continue button to resume printing.

6. Discard any damaged sheets sent to the sample tray or purge

tray.

NOTE : You may find that the printer ha s already cl eared the j am

and sent the pa per to the sample or purge tray.

5-6 Troubleshooting Guide

Clearing paper misfee ds and jams

Checking job integrity following a paper jam

There is a sligh t possibility of dupli cate or missing pages when a

paper jam occurs while a job prints. For that reason, you should

check for job integrity once the job has been pr inted.

Follow this procedure:

1. The printer offsets the rest of the job following a paper jam.

Locate that section.

2. Check this section an d the sheets immediatel y before the first

offset sheet to see if there are any missing or duplicate

sheets in the job.

3. Check the output for data missing from the pages.

Printer areas

This section provides illustrations of the various areas of the

printer where jams may occur .

The following illustration shows all the jam clearance areas for

the 96/4635/180 printer.

Areas 17, 18

Area 8

Areas

19, 20

Area6Areas 2,

3,4,5,7,

9,10

Areas

14,15,

16

Area13Areas

11,12

Area13Areas

11,12

The following illustrations show the individual jam clearance

areas of the 96/4635/180 printer.

Troubleshooting Guide 5-7

Clearing paper misfeeds and jams

Area 2

Area 2

Area 3

5-8 Troubleshooting Guide

Area 4

Clearing paper misfee ds and jams

Area 5

Troubleshooting Guide 5-9

Clearing paper misfeeds and jams

Area 6

5-10 Troubleshootin g Guide

Area 7

Clearing paper misfee ds and jams

Troubleshooting Guide 5-11

Clearing paper misfeeds and jams

Area 8

NOTE : If jammed paper rips as y ou a re r emo ving it f rom a rea 8,

you may need to use the pinch lever in area 9 to remove the

paper. Ref er to the “Notes” section following the figure illustrating

area 9.

5-12 Troubleshootin g Guide

Area 9

Clearing paper misfee ds and jams

NOTE: Pull the area 9 green lever toward you to unlatch it. Make

sure you relatch the lever once you have cleared any paper in

this area. You may also want to pull out tray 1 and hold the green

lever down in order to remove paper wedged in this area m ore

easily.

Area 9 also has a green knob (located to the right of the leve r),

which can be turned to help you clear paper.

Using the pinch lever to access area 9: If you have difficulty

removing paper from this area, you can use the pinch lever

located further inside area 9. Follow this procedure:

1. Locate the green pinch lever directly behind area 9.

2. Carefully reaching your hand into the area, press the edges

of the pinch lever and lift it up.

3. Remove any paper caught in this area.

Troubleshooting Guide 5-13

Clearing paper misfeeds and jams

4. Replace the green pinch lever to its original position.

5. Discard any paper you removed.

Area 10

5-14 Troubleshootin g Guide

Area 11

Clearing paper misfee ds and jams

Troubleshooting Guide 5-15

Clearing paper misfeeds and jams

Area 12

NOTE: For 180 printers, when clearing area 12, you are

required to clear areas 12 and 13.

5-16 Troubleshootin g Guide

Area 13

Clearing paper misfee ds and jams

Area 14

NOTE: You may sometimes find paper lying on top of area 14,

even though there is no message that indicates a jam in this

area. Discard the paper.

Troubleshooting Guide 5-17

Clearing paper misfeeds and jams

Area 15

5-18 Troubleshootin g Guide

Area 16

Clearing paper misfee ds and jams

NOTE: For 180 printers, when clearing area 16, you are

required to clear areas 16 and 17.

Troubleshooting Guide 5-19

Clearing paper misfeeds and jams

Area 17

5-20 Troubleshootin g Guide

Area 18

Clearing paper misfee ds and jams

NOTE: Sometimes the messages at the printer console direct

you to discard the last sheet from the stack following a jam in

area 18. Check for this message when clearing a paper jam in

area 18 .

If your printer has frequent jams in this area, you may need to

clean the Q1107A sensor. Refer to the “Cleaning the sensors

and the reflecting surfaces” section of the Guide to Performing

Routine Maintenance.

Troubleshooting Guide 5-21

Clearing paper misfeeds and jams

Clearing bypass transport paper jams

If your printer is configured with a bypass transpor t module, you

should check for paper jams in areas 19 and 20 after clearing a

paper jam in area 18.

To clear bypass transport jams:

1. Open the bypass transport module door.

2. Locate area 19 and press the green lever in the direction of

the arrow that is printed on the lever.

Area 19

3. Remove any paper in the exposed area.

4. Press the green lever to the left until the latch catches.

5. Locate area 20 and press the green lever in the direction of

the arrow that is printed on the lever.

5-22 Troubleshootin g Guide

Area 20

Clearing paper misfee ds and jams

6. Remove any paper in the exposed area.

7. Press the green lever down and to the left until the latch

catches.

8. Close the bypass transport

Paper curl and paper jams

Too much curl in the pap er sto c k can ca use pa per jam s. You can

adjust the decurler lever to eliminate most of these problems.

Refer to the paper curl chart at the end of this chapter to

determine the amount of curl in the paper stock.

Troubleshooting Guide 5-23

Clearing paper misfeeds and jams

Measuring the paper curl

To measure the paper curl:

1. Print five one-sided (simplex) 8.5 by 11 inch or A4 sheets.

2. Measure the amount of curl in the prints by holding the five

prints in the top center of the short edge.

Keep the image toward you.

Figure 5-1. Measuring the paper curl

3. Place the bottom edge of the prints over the paper curl

measurement chart located at the end of this chapter.

• If the print curl on the printed paper stock measures

between +2 and -2, do not change the decurler setting.

• If the curl is between +2 and +3, or -3 and -4, use the

following procedure to adju st the decurler lever.

5-24 Troubleshootin g Guide

Adjusting the decurler lever

To adjust the decurler lever:

1. Open the right door of the printer and locate the decurler

lever.

Clearing paper misfee ds and jams

Figure 5-2. Decurler lever

2. If the print curl i s +2 or more, mov e t he gre en decurler l e ver to

the right.

3. If the print is -3 or more, move the green decurler lev er to th e

left.

4. If the decurler adjustment does not eliminate the paper curl

problem, turn the paper stack over in the feeder tray.

5. If there is still a paper curl problem, perform steps 1 to 4

again.

6. If all else fails, insert paper from a new ream.

Troubleshooting Guide 5-25

Clearing paper misfeeds and jams

Figure 5-3. Paper curl chart

5-26 Troubleshootin g Guide

6. Optimizing print quality

This chapter discusses metho ds of checking and improving print

quality.

NOTE: One way to test print quality is to print a sample

document. For information on printing sample documents, refer

to the Guide to Configuring and Managing the System.

Installing the custom transfer assist blade

If you use nonstandard paper sizes, you should install the

custom transfer assist blade to ensure good print quality.

CAUTION

The custom transfer assist blade comes as a kit with detailed

instructions. Be sure to follow the instructions carefully.

To prevent damage to the printer, have your service

representative show you how to customize and install a custom

transfer assist blade for the first time.

You must use the standard transfer assist blade with standard

paper of the following sizes:

• In U.S. markets

– 11.1—11.4 inches (282—290 mm)

– 11.8—12.1 inches (300—307 mm)

– 13—13.5 inches (330—343 mm)

• In non-U.S. markets

– 11.1—11.4 inches (282—290 mm)

– 11.8—12.1 inches (300—307 mm)

NOTE: With these paper sizes, transfer efficiency may be

reduced.

Troubleshooting Guide 6-1

Optimizing print quality

Correcting skewed printing

If the printed output is repea tedly delivered with the image

skew e d ( cr oo ked on the page), or the pages are d amag ed w he n

delivered to the output bin, you may need to adjust the

registration transport roll (heavy paper) levers. This may occur

with heavy weight papers. Follow this procedure to correct this

situation:

1. Open the right and left doors of the printer and locate the

heavy paper levers, behind areas 2 and 4.

2. Pull the levers forward (toward you) on the silver latch

release.

3. Turn both of the levers to the left (counter-clockwise), as

illustrated in the following figure.

Figure 6-1. Adjusting the registration transport roll levers

NOTE: If your system is equipped with the optional 7 by 10inch paper enab lement kit, it has thr ee le vers , as shown in th e

next illustration. (This kit is not available for the Model 96

NPS/IPS.)

Turn the left-most le v er to th e left (co unter-c loc kwise) an d the

other two levers to the right (clockwise).

6-2 Troubleshooting Guide

Optimizing print quality

Figure 6-2. Three registration transport roll levers on

system with 7 by 10-inch enablement kit

a. Lever 1: Left - Maximum Pressure setting

b. Leve r 2: Right - Maximum Pressure setting

c. Lever 3: Right - Maximum Pressure setting

4. When the print job is complete, return the levers to their

norma l position.

5. Close the doors.

NOTE: Here are a few things for adjusting the registration

transport roll lever:

• Position all lev ers f or the same (either minimum or maximum)

pressure setting. Do not intermix the positions of the levers.

• Paper greater than 14 inches / 352 mm in any dimension is

considered oversized.

• Paper heaver than 24 pounds / 90 gsm is considered heavy

weight.

• The following factors may affect the positioning of the paper

levers:

– Machine tolera nce

– Paper supplier

– Job type (e.g., duplex).(clockwise).

Troubleshooting Guide 6-3

Optimizing print quality

Product features that affect PostScript print quality

You can improve the appearance of your documents by being

aware of potential problems created through the use of

proprietary PostScript extensions and device-dependent

operators.

Proprietary PostScript extensions

PostScript masters that use proprietary printer features may

cause appearance inconsistencies between different Po stScr ipt

printers. Some PostScript printers contain proprietary P ostS cript

extensions. For example, some versions of the Apple Macintosh

PostScript driver download encrypted proprietary image

“smoothing” operators to Apple LaserWriters. The downloaded

PostScript code uses the product operator to determine if it is

being used on a LaserWriter. If not, the proprietary c ode is

bypassed by doing a flushfile. This allows the PostScript master

to print on non–LaserWriter products. As a result, PostScript

masters generated on a Macintosh with Apple proprietary

features may produce output that varies between LaserWriter

and non–LaserWriter PostScript printers.

Device-dependent operators

Some P ostScript operators result in de vice-dependen t PostScript

files. “Device dependence” means that devices having different

output characteristics may produce different-looking o utp ut even

though they use the same software. This section documents the

most serious examples of device dependence. The PostScript

Language Reference Manual, second edition, lists all of the

graphics state operators that are considered device-dependent.

Gray shading—setscreen and setcol or s cre en

The PostScript operators setscreen and setcolorscreen control

the PostScript halftone software that simulates various intensity

levels of gra y an d color inks. Since each PostScript product ma y

have a different default halftone definition, the halftone patterns

and gray scale range may differ also. Because setscreen is

inherently device dependent (especially when used for pattern

fills), PostScript masters look different on almost every different

model of PostScript printer.

6-4 Troubleshooting Guide

Optimizing print quality

The operators are also used to pe rform pattern fills, since

PostScript Level 1 does not have a pattern fill operator.

(PostScript Level 2 has pattern fill operators.) As stated in the

PostScript Language Re ference Manual, first edition,

“Remember that everything pertaining to halftones is, by

definition, device-dependent. In general, when an application

provides its own halftone specifications, it sacrifices portability.

Associated with every device is a default halftone definition that

is appropr i ate for most applications.”

In addition to the device-dependent nature of halftoning, a spot

function is used by setscreen and setcolorscreen to determine

the order of pixel darkening in the halftone cell. When two pixels

have the same spot function value, their ordering values are

determined arbitrarily. Duplicate spot function values are very

common. In fact, almost all the various default spot functions

generate duplicate values. Therefore, different PostScript

implementations yield different halftone patterns, resulting in

visual differences in the output.

Gray shading—settransfer and transfer function

The PostScript operators settransfer and setcolortransfer are

used to change the procedure for mapping perceived color

values in th e out put of the print device into specified color values

in the PostScript master. PostScript devices use an internal

transfer array or procedure that takes into account the printing

characteristics of their marking engines in order to produce

levels of color.

Transfer functions are called by the setcmykcolor, setbsbcolor,

setrgbcolor, and setgray operator before processing of the

desired color level that is specified in the master. The transfer

function takes a value from the stack and leaves another value

on the stack for each color component (red, green, blue, and

gray).

The PostScript language provides a scheme for overwriting the

internal transfer function of a printing device by providing the

settransfer and setcolortransfer operators. However, some

Xerox PostScript devices do not allow you to overwrite their

internal transfer function.

Typically, a master tries to replace the internal transfer function

with a null transfer function such as:

{} settransfer, or

{} {} {} {} setcolortransfer

Troubleshooting Guide 6-5

Optimizing print quality

If either of the above procedures is successful, the transfer

functions return the same color levels that are passed to them

without modifying or map pi ng th e l evel. On printers wh i ch do not

allow the overwriting of the transfer function, the settransfer

operator does not affect the mapping of gray values between th e

output of the print device and specified levels of color.

NOTE: Settransfer actually sets the transfer functions for all

four color components ( r ed, green, blue, and gray) to the same

value. The setcolortransfer operator sets the transfer functions

individually.

Smooth curves—setflat

PostScript masters that use the PostScript operator setflat

produce inconsistent output across different PostScript printers.

setflat controls curve rendering smoothness. PostScript curve

operators use cubic Bezier control points to define the curve

shape. These curves can be rendered from straight line

segments. Normally the line segments are so short that the

curve appears smooth. The setflat operator indirectly controls

the length of the straight line segments. As stated in the

PostScript Language Re ference Manual, second edition, “If the

flatness parameter is large enough to cause visible straight line

segments to appear, the result is unpredictable. Setflat sets a

graphics state parameter whose effect is device-dependent. It

should not be used in a page description that is intended to be

device-independent.”

Invisible strokes—0 setlinewidth

P ostScript masters that use the P ostScript ope rator setlinewidth

are not consistent across different PostScript printers.

setlinewidth controls the width of a stroked line. When

setlinewidth is ex ecuted with an input of zero, it produces a line

that is one pix el wide . On d e vices whose dot size is small, singlepixel-width lines may be invisible.

Scan conversion—fill, eofill, and stroke

Scan conversion algorithms are implementation-dependent, so

different PostScript printers paint (“turn on”) different dots,

resulting in output differences. For filled circles, PostScript

printers differ in the dots the y paint at the edge of the circle; thus,

some printers produce slightly larger circles than others. For

large circles this is not noticeable, but for small circles, it is.

6-6 Troubleshooting Guide

Optimizing print quality

Sections 2.2 and 6.5 of the PostScript Language Reference

Manual, second edition, discuss scan conversion. Section 6.5

states that scan conversion details are not part of the PostScript

standard.

Troubleshooting Guide 6-7

Optimizing print quality

6-8 Troubleshooting Guide

7. Resolving printer problems

This chapter describes various system problems and suggests

corrective actions.

Symptom Probable cause Action

Papers are thrown around

the stacker.

Paper stack falls over or

slides around the bin

Printing stops and the

printer console displays a

message indicating that an

incorrect paper size is

loaded in a feeder tray.

Someone unloaded paper

by opening the top cover of

the stacker bin.

Excessive paper curl Try adjusting for paper curl (See “Paper curl

Incorrect paper size, a

misfeed in feeder trays 3 or

4, or a damaged sheet.

Unload the bin following the normal

procedure. See “Unloading Stacker bin” in

Guide to P er form ing Ro uti ne M ain tena nce ).

and paper jams” in Guide to Performing

Routine Maintenance

1. Check the paper in the indicated tray.

2. Check trays 3 and 4, and remove any

miisfed sheets.

3. If the paper is not the correct size, load

the correct size paper.

If the paper size is correct, press the

Continue button to resume printing.

Troubleshooting Guide 7-1

Resolving prin te r pr ob lems

7-2 Troubleshooting Guide

8. Resolving system problems

This chapter describes various system problems and suggests

corrective actions.

NOTE: The syntax for the actions listed is f or CLI use rs. If using

the GUI, refer to the online help for equivalent procedures.

Symptom Probable cause Action

Blank display: pressing a

key fails to restore image.

NOTE: If you have a

SunBlade 1000, the

monitor takes one minute

to display following restart.

Do not restart the system

while waiting for the

monitor to display.

The first job to print after a

reboot or a diagnostics

session takes 30 to 60

seconds longer than usual.

User says a job is not

printing.

Monitor is powered off;

brightness and contrast

controls are misadjusted;

or there’s a more serious

problem.

This is normal operation. No action is needed. Subsequent jobs should

The jobs is ineligible due to

unavailable resource.

Queueing is stopped. • Enter Show Status.

The virtual printer is

stopped.

1. Make sure that the monitor is powered

on.

2. Make sure that the brightness and

contrast controls (if available) are turned

far enough to the left to brighten the

screen.

3. If the monitor is powered on and controls

are turned to the left, call the service

representative.

print without a delay.

• Enter List Documents Ineligible.

• Load the appropriate resource.

• Enter the Start Queueing command.

• Enter List Virtual Printers.

• Enter Start Virtual Print er

<printer_name>.

The jobs are held. • Enter List Documents Held.

• Release the job if appropriate.

The job never arrived. • Enter List Documents All.

• Ask the user to resend. If the job still does

not arrive, consult with the network or

workstation administrator.

Troubleshooting Guide 8-1

Resolving system problems

Symptom Probable cause Action

No jobs appear to be

printing.

Queueing or printing may

be stopped.

Scheduling policy may be

First Come First Served

(FCFS) and the next job

may be ineligible.

Possible system problem • Enter Print Sample Document to see if

Printer controller is not

communicating with the

network. (Does not apply

to channel-attached host.)

Printer controller is off or

needs to be restarted.

• Enter Show Status.

• Enter Start Queueing or Printing.

• Enter Show Scheduling Policy to

determine current se tting.

• If scheduling policy is FCFS and the next

job is ineligible, no jobs will print. Either

load the media the job is waiting for, or

Set Scheduling Policy to

ResourceMatch so the next eligible job

prints.

jobs can print from the controller to the

printer.

• If the sample document does not print,

there may be a system problem.

• Ping the printer controller; check the

cabling/connections.

• Reconnect the network cable. Use the

network di agnostics to ch eck the networ k

devices.

• Check the printer controller operation.

• Restart the printer controller.

User cannot send a job

from a workstation.

The workstation is not

communicating with the

network.

For TCP/IP: Printer

controller host name and

address are not in the

workstation hosts file.

• Ping the printer controller or another

workstation. Look at the workstation

network cable.

• Reconnect the network cable.

• View the workstation hosts file.

• Add the printer controller name and

address to the hosts file.

8-2 Troubleshooting Guide

Symptom Probable cause Action

Resolving system problems

Job prints on the wrong

paper, or is otherwise not

as expected.

Job prints correctly on the

right media, but an error

message on the trailer

page indicates a media

error.

Paper in the tray and tray

settings do not match.

Job has a job ticket and

specified virtual printer has

SkipJTPreScan set to

True. (Does not apply to

IPDS.)

Job has attributes from

some other source (DSC,

embedded from job ticket,

etc.)

User error in entering print

options from the client

workstation.

There are PostScript

setpagedevice operators in

the job that specify the

media to use, and the job

submission method or

virtual printer specified

other media.

• Check the trays and Enter Show Status.

• Change paper in the tray or set the

correct paper type using Set Tray.

• Enter List Virtual Printers.

• Send to another virtual printer with

SkipJTPreScan se t to Fals e.

• Enter Show Document Attributes.

• Resend if necessary. Enter Change

Document Attributes to specify desired

attributes.

• Ensure that “Fit to Paper” or an

equivalent selection is not selected in

user print driver.

• Enter Show Document Attributes.

• Resend if necessary using correct

options, or enter Change Document

Attributes to specify the desired

attributes.

• Enter Show Document Attributes to

view the requested media and compare

with output. Then check the PostScript

code of the file. You can enter Examine

Document, but it may be easier to do this

from a user workstation.

• If the job has printed as desired, do

nothing. If you want the job to print using

the media set by the setpagedevice

operators, do not use a job submission

method that creates a job ticket, or use a

virtual printer with SkipJTPreScan set to

True, and no media attributes.

Troubleshooting Guide 8-3

Resolving system problems

Symptom Probable cause Action

The IPDS host receives a

Not Ready message from

the DocuPrint NPS/IPS.

If a virtual printer is

specified for a job, and the

virtual printer properties

are changed, then the

virtual printer stops and

sends a not ready

message to the host.

Queueing has stopped.

The job pool manager

cannot accept any jobs

when queuing has

stopped.

The IPDS job is not

selected for printing

because printing has

stopped.

Out of paper condition 1. Enter Show Status.

1. Enter Show Status to ensure there is no

other problem. If you have a stoppage

due to the status shown, correct the

problem status.

2. Enter List Virtual Printer or Show IPDS

Virtual Printer to see if the virtual printer

is stopped.

3. Enter Star t Vir tua l Prin t er <v pn a m e> .

1. Enter Show Status to determine if

printing is stopped.

2. Enter Star t Queu eing .

1. Enter Show Status to determine if

printing is stopped.

2. Enter Show IPDS Status to determine if

IPDS printing is stopped.

3. Enter Star t Pr in ti ng or Start IPDS

Printing.

2. Reload the paper tray.

Restarting the

system

after an error

condition when

printing an IPDS

job

To restart the system after you have cleared an error condition:

1. Drain the printer at th e host. ( Follow procedures for your host

system.)

2. In an MVS environment, cancel the FSS (Functional

Subsystem), which automatically drains the printer.

3. Restart the Printer Controller.

4. Restart the printer at the host.

8-4 Troubleshooting Guide

Index

A

Attention light2-1

C

CE mark ix

clearing

feeder trays 5-1–5-5

conventions xiv

curl, paper 5-23

custom transfer assist blade, installing 6-1

D

decurler lever, adjusting 5-25

device-dependent operators 6-4

documentation xv

E

eofill 6-6

error condition, restarting printer 8-4

error messages, Client Software installation

3-2

I

installing, custom transfer assist blade 6-1

invisible strokes, setlinewidth 6-6

J

job integrity, checking after paper jam5-7

L

laser safety v

M

masking faults 2-1–2-2

measuring, paper curl 5-23

messages

Client Software installation 3-2

modem

enable 1-2

N

Novell implementation, troubleshooting 4-1–

4-3

F

Fault List

screen 2-1

faults, masking2-1–2-2

feeder trays, clearing faults 5-1–5-5

fill 6-6

flushfile 6-4

G

glazing 5-3

gray shading

setcolorscreen 6-4–6-5

setscreen 6-4–6-5

settransfer function 6-5

transfer function 6-5

H

hard disk, Xerox Client Software

requirements3-2

Hint icon 2-1

O

operation safety, Europevii–ix

operation safety, U. S. vi–vii

ozone production inform ation vi

P

paper

curl

adjusting 5-25

measuring 5-24

jams, checking job integrity 5-7

misfeeds, frequent5-3

paper curl, measuring 5-23

PostScript, proprietary extensions6-4

print quality 6-1

printer problems 7-1

printers

paper jam areas 5-7–5-21

restarting 8-4

Troubleshooting Guide INDEX-1

INDEX

printing

correcting skewed 6-2

quality, features affecting 6-4

problems

printer 7-1

stacker 7-1

system 8-1

procedures6-2

see also paper, clearing jam s

feed belt, cleaning 5-4–5-5

paper trays, clearing misfeeds 5-1–5-3

printers, restarting 8-4

product ope rator 6-4

PServer problems4-1

publications xv

Q

Q1107A sensor5-21

R

Ready To Open indicator5-2

remote service 1-2

requirements, hard disk 3-2

RPrinter problems 4-3

system problems 8-1

System unresponsive8-1

T

transfer 6-5

transfer functions 6-5

Tray Unlock button 5-1

troubleshooting

Novell implementation 4-1–4-3

Xerox Client Software installation 3-1–

3-2

X

Xerox Client print command 3-1

Xerox Client Software, troubleshooting

installation 3-1–3-2

S

safety

hotline numbersvii

laser v

operation vi–ix

SAP packets 4-1

scanconversion 6-6

server override switch, Xerox Client print

command 3-2

service call, required information 1-1

setbscolor 6-5

setcmykcolor 6-5

setcolorscreen 6-4–6-5

setflat 6-6

setgray 6-5

setlinewidth 6-6

setrgbcolor 6-5

setscreen 6-4–6-5

settransfer 6-5

skewed printing, correcti ng6-2

smooth curves 6-6

stacker

problems 7-1

stroke 6-6

INDEX-2 Troubleshooting Guide

Loading...

Loading...