Page 1

Xerox DocuPrint 96/DocuPrint 96MX

Laser Printing System

Operations Reference

April 1998

721P85610

Page 2

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

©1998 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are displayed

on the screen, such as icons, screen displays, looks, etc.

Printed in the United States of America.

Publication number: 721P85610

Xerox® and all Xerox products mentioned in this publication are

trademarks of Xerox Corporation. Products and trademarks of other

companies are also acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent

editions.

This document was created on a PC using Frame software. The

typeface used is Helvetica.

Page 3

Relate d pu blicatio ns

The

Xerox DocuPrint 96/DocuPrint 96MX Laser Printing System

Operations Reference

your laser printing system. The entire reference set is listed in the

table below. Several other related documents are also listed for your

convenience. For a complete list and description of available Xerox

documentation, refer to the Xerox Documentation Catalog

(Publication number 610P17417) or call the Xerox Documentation

and Software Services (XDSS) at 1-800-327-9753.

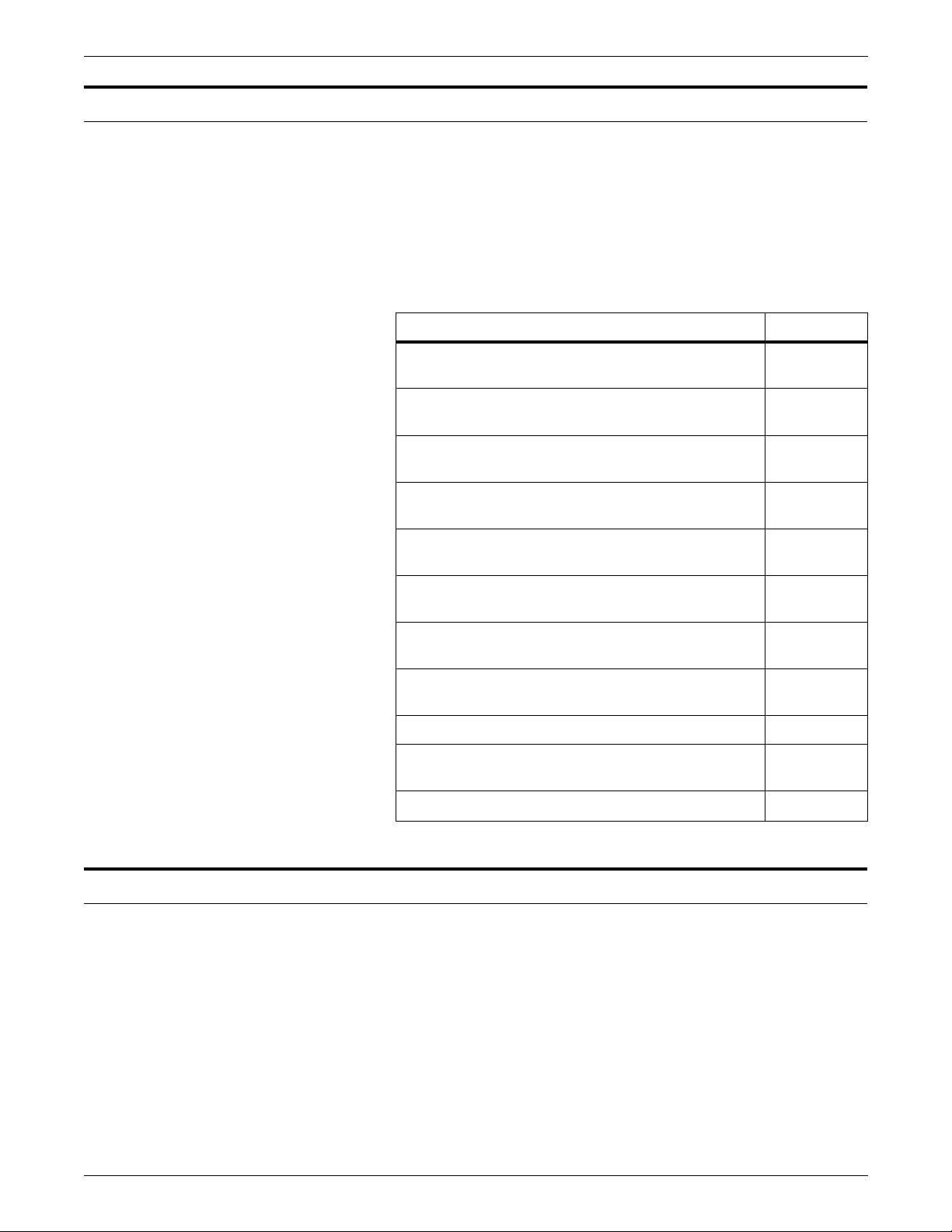

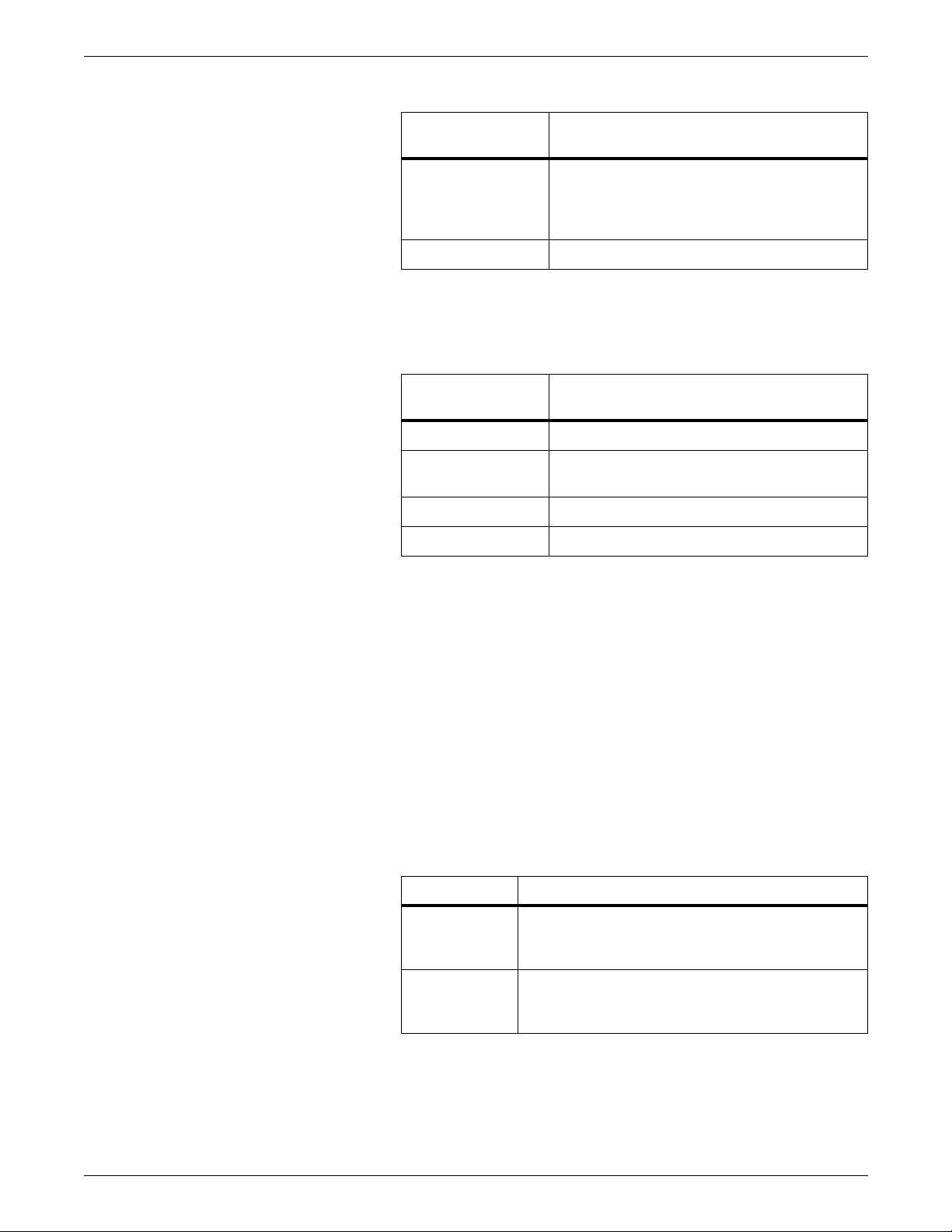

Table 1. Related P ubl i ca tio ns

Publicat io n Number

is part of the eight manual reference set for

Xerox DocuPrint 96/DocuPrint 96MX Laser Printing

System Operator Guide

Xerox DocuPrint 96/DocuPrint 96MX Laser Printing

System Operations Reference

Xerox DocuPrint 96/DocuPrint 96MX Laser Printing

System Message Guide

Xerox DocuPrint 96/DocuPrint 96MX Laser Printing

System PDL Reference

Xerox DocuPrint 96/DocuPrint 96MX Laser Printing

System Forms Creation Guide

Xerox DocuPrint 96/DocuPrint 96MX Laser Printing

System System Generation Guide

Xerox DocuPrint 96/DocuPrint 96MX Laser Printing

System Installation Planning Guide

Xerox DocuPrint 96/DocuPrint 96MX Laser Printing

Operator Command Summary Card

Xerox Laser Printing Systems Tape Formats Manual

X

erox Laser Printing Systems Standard Font Library

Font User Guide

Helpful Facts About Paper

721P85590

721P85610

721P85650

721P85640

721P85630

721P85620

721P85600

721P85660

600P86175

600P86174

721P82492

Notice

This publication may contain descriptions of concepts and features

not currently available for your Xerox Laser Printing System. Consult

your Xerox sales represent ative or your operating system software

program description for additional information.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE iii

Page 4

iv XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 5

Table of Contents

Related publications iii

Notice iii

Introduction xxiii

About the reference set xxiii

DocuPrint 96/DocuPrint 96MX Laser Printing System document set xxiii

Who should use this manual xxv

LPS system administrators, programmers, operators xxv

How to use this manual xxvi

If the LPS is new to you xxvi

Know the key terms and conventions xxvi

Use the table of contents, index, and glossary xxvi

Refer to the related publications list xxvi

Key terms and conventions xxvii

Key terms xxvii

Syntax conventions xxvii

Masking conventions xxvii

Contents of this manual xxviii

Statement command summaries and appendices xxix

About the DocuPrint 96/DocuPrint 96MX LPS xxx

DocuPrint 96/DocuPrint 96MX system controller components xxxi

DocuPrint 96/DocuPrint 96MX tape and cartridge devices xxxii

DocuPrint 96/DocuPrint 96MX printer components xxxiii

1. Setting LPS parameters 1-1

Communicating with the LPS 1-1

Installation and system generation 1-3

User interface keyboard display 1-3

Powering on and booting the LPS 1-4

Power loss 1-5

System verification messages 1-6

Printer communication link 1-8

PSC (printer subsystem controller) 1-10

Configure a finishing or feeding device 1-11

Create the FCG.LIB file 1-11

FCG (display the profile labels) 1-15

FCG (configure a finishing or feeding device) 1-16

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE v

Page 6

TABLE OF CONTENTS

FCG SHOW (check finishing or feeding device settings) 1-16

FCG procedures 1-17

Verifying LPS status 1-18

Verifying system version and time 1-18

OCS (system version display) 1-18

Time and date displays 1-18

Verifying syst em status 1-20

PROBLEM 1-20

Setting LPS parameters 1-22

Setting system parameters 1-22

SETTIME (set time or date) 1-22

ALIGN (set page print alignment) 1-23

DISPLAY (set display format for messages) 1-24

ENERGY 1-25

MICR (set MICR mode) 1-26

Setting parameters for print jobs 1-27

Reallocating space to the print file 1-27

REA (reallocate print fil e) 1-27

REA and disk management 1-30

REA and online report spooling 1-30

Setting job parameters 1-31

FONTS 1-31

FORMS 1-32

GRAPHIC 1-32

Adjusting print image darkness 1-33

DARKNESS 1-33

Lightening high-density images 1-34

EDGE 1-34

Finishing Exercise r Ut ilit y 1-34

FEX 1 -3 4

Setting file access and task execution privileges 1-36

Protecting access to files 1-36

LOGON (restrict file access) 1-36

SECURE (restrict file access) 1-37

Secured files, access, and manipulation 1-38

Security breach 1-38

Limiting task execution privileges 1-39

RCU (restrict command usage) 1-39

Tracking console activity with Data Capture Utility (DCU) 1-42

DCU CAPTURE 1-42

vi XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 7

TABLE OF CONTENTS

DCU DELETE 1-43

DCU EXIT 1-43

DCU FORMAT DISPLAY 1-44

DCU FORMAT PRINT 1-45

DCU HELP 1-46

DCU REMINDER 1-46

DCU RESET 1-46

DCU SHOW 1-47

Limitation during SYSGEN 1-47

Comment capability 1-47

2. Managing LPS resources 2-1

Maintaining optimal disk usage 2-1

Files on system disks 2-1

Operating on system files 2-1

Necessary free space on system disks 2-3

File biasing by disk configuration 2-4

Checking usage of disk space 2-6

FCHECK (file check) 2-6

Reorganizing usage of disk space 2-9

COMPRESS 2-9

PURGE 2-11

Backing up and copying system files 2-12

Setting default tape device 2-12

Identif y c ur r e nt TAPE & CARTRIDGE device (SUB DEV) 2-12

SUBSTITUTE DEVICE (general information) 2-12

Assign a controller device to TAPE or CARTRIDGE (SUB

DEV) 2-14

Know the Xerox tape and cartridge format 2-15

Prepare the tape or cartridge 2-16

TAPE [CARTRIDG E | TDn] VOLINIT 2-16

Copying files 2-17

COPY (disk to disk) 2-17

COPY (disk to labeled tape or cartridge) 2-18

COPY (disk to unlabeled tape) 2-19

COPY (labeled tape or cartridge to disk) 2-20

COPY (unlabeled tape to disk) 2-22

Manipulating files 2-23

DELETE 2-23

FID (build fi le lis t) 2- 2 4

FILE (display file list) 2-24

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE vii

Page 8

TABLE OF CONTENTS

FIX (modify font or logo file) 2-28

REVIEW (review files) 2-29

RNAME (rename a file or directory) 2-29

TYPE 2-29

List tape or cartridge files 2-31

TAPE [CARTRIDG E | TDn] LIST 2-31

Locate tape or cartridge files 2-33

TAPE [CARTRIDG E | TDn] FIND (find file) 2-33

TAPE [CARTRIDG E | TDn] N E X T (move to ne xt file) 2-3 3

TAPE [CARTRIDG E | TDn] SKIP (move to 1st or 2nd... file)

2-34

TAPE [CARTRIDG E | TDn] EOF or NOEOF or ENDFILE 2-35

Backing up system files to tape or cart ri dge 2-37

DSR (disk save and restore) 2-37

Starting DSR 2-37

File protection 2-39

Disk space for restore 2-39

Multivolume files 2-40

Device error handling 2-40

Aborting the save process 2-40

Incomplete resto ration 2-40

Aborting the restore process 2-41

Special file handling 2-41

Copying a DSR file to the LPS 2-42

SFT (single file transfer ut ilit y ) 2-42

Managing files on floppy disks 2-45

FLOPPY FORMAT 2-45

FLOPPY SAVE 2-46

FLOPPY DELETE 2-47

FLOPPY C LE AR 2-48

FLOPPY FILE 2-48

FLOPPY FCHECK 2-50

FLOP PY REST O R E 2-51

FLOPPY LIST 2-52

Copying the system software tape 2-53

SST (system software tape or cartridge) 2-53

3. Tracking system activity 3-1

Accounting data in the status file 3-1

How the system adds data to the status file 3-1

Status file creation during sysgen 3-2

viii XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 9

TABLE OF CONTENTS

Backing up status file information 3-2

Status file data in the online accounting page 3-4

Status file data 3-5

DATE entry 3-5

DEPARTMENT entry 3-5

JOB ID entry 3-5

REPORT NO. entry 3-5

FILE ID entry 3-5

INPUT PROCESSING TIME entry 3-5

OUTPUT PROCESSING TIME entry 3-5

Report completion codes 3-6

PAGES TO BIN entry 3-7

PAGES TO TRAY entry 3-7

PAPER PATH HOLES entry 3-7

GRAPHIC PAGES PRINTED entry 3-7

LINES PRINTED entry 3-8

GRAPHIC EXCEPTION CODE entry 3-8

ONLINE IDLE (SEC) entry 3-8

TAPE MOUNTS entr y 3-8

BLOCKS READ entry 3 -8

BLOCKS SKIPPED entry 3-8

RECORDS READ entry 3-8

DJDE RECORDS READ entry 3-8

MAXIMUM COPY COUNT entry 3-8

OVERPRINTS entry 3-8

COLLATE entry 3-9

SF/MF entry 3-9

SIMPLEX/DUPLEX entry 3-9

JDE , JDL USE D entry 3-9

ACCTINFO entry 3-9

INITIAL FONT LIST entry 3-9

INITIAL FORM LIST entry 3-9

INITIAL CME LIST entry 3-10

Using accounting and system activity commands 3-11

Generating system activity reports 3-11

REPORT 3-11

Establishing accounts and copying account data to tape 3-16

ACCOUNT 3-16

Tape format of data written by ACCOUNT 3-18

Modifying the status file 3-21

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE ix

Page 10

TABLE OF CONTENTS

SFS (status file services) 3-21

SFS CLEAR 3-22

SFS CREATE 3-23

SFS DISPLAY 3-24

SFS file- name 3-26

SFS HARDCOPY 3-27

SFS HOST 3-29

SFS TAPE 3-30

SFS TDn 3-31

SFS ? 3-31

SFS ! 3-31

Creating the SFS user form file 3-32

Tape format of data written by SFS 3-34

Structure of an SFS report entry 3-36

Forward and backward pointers 3-38

Dumping the status file to tape 3-38

XPS 3-39

4. Editing source files 4-1

What the editor is 4-1

How the editor works 4 -1

Source files 4-1

Viewing source files 4-1

Storing source files 4-2

Files you can edit 4-2

Edi tor comman ds 4-4

Three types of editor commands 4-4

Composite editor commands 4-4

Editor syntax conventions 4-5

Using the <TAB> key 4-6

Sta ck pri nting 4-6

Running an editing session 4-6

EDIT 4-6

CONVERT 4-7

NOCONVERT 4-7

GET 4-8

KEYS 4-8

MERGE 4-9

SAVE 4-9

CLEAR 4-10

x XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 11

TABLE OF CONTENTS

END 4-10

Modifying records 4-11

DISPLAY (display lines) 4-11

DUPLICATE (copy lines) 4-12

FIND (find lines with match) 4-12

INSERT (insert lines) 4-13

MODIFY (modify lines) 4-14

MOVE (move lines) 4-14

PRINT (print lines) 4-15

REMOVE (delete lines) 4-16

RENUMBER (renumber lines) 4-16

REPLACE (substitute lines) 4-17

SORT (sort lines) 4-17

STEP (display next line) 4-18

Modifying parts of records 4-19

C (change string) 4-19

D (delete string) 4-20

P (insert prior) 4-21

F (insert following) 4-21

O (overlay string) 4-22

S (substitute string) 4-23

Examples of editor sessions 4-24

Create and save a .JSL file 4-24

Modify and resave the.JSL file 4-25

List other .JSL files and insert one into the .JSL file 4-26

5. Using command files 5-1

Command files 5-1

System, editor, and font editor command files 5-1

Using system command files 5-2

Operator entries during execution 5-2

Error processing 5-2

.PAUSE processing 5-2

.WAIT processing 5-3

Using editor command files 5-4

Points to note 5-4

Using font editor command files 5-4

Verifying command file type 5-5

.BCP 5-5

Commands in command files 5-6

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xi

Page 12

TABLE OF CONTENTS

Displaying messages 5-6

Documenting the command file 5-6

Summary table of command file commands 5-7

Using the basic command file commands 5-8

.CHAIN 5-8

.DELAY 5-8

.EXIT 5-8

.HOME 5-9

.PAUSE 5-9

.WAIT 5-9

Using the logical processing command file commands 5-10

Using symbol setting commands 5-10

Using string substitution commands 5-11

Using sequence control commands 5-12

Using debugging commands 5-12

Sample command files 5-13

Editor command file to delete files 5-13

Sample verification of command file type 5-14

6. Editing font files 6-1

About the font editor 6-1

Reference documentation for fonts 6-1

Font editor 6-1

How to use the font editor 6-2

Summary table of font editor commands 6-3

Running a font editing session 6-4

Messages during the session 6-4

Starting a font editor session 6-4

Reordering a font file 6-5

REORDER and FEDIT 6-5

Specifying the primary source font file 6-5

FEDIT 6-5

INPUT 6-6

Selecting characters using the correct mode 6-7

Specifying new font file characters 6-8

INCLUDE 6-8

SUBSTITUTE 6-9

RECODE 6-9

Using a secondary source font file 6-10

OPEN 6-10

CLOSE 6-11

xii XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 13

TABLE OF CONTENTS

Closing font file without using CLOSE 6-12

Saving font files you create 6-12

OUTPUT 6-12

Ending the font editing session 6-13

END 6-13

7. LPS print processing 7-1

Overview 7-1

Laser printing systems (LPS) 7-2

LPS component types 7-2

LPS hardware components 7-2

CRIB 7-2

Advanced imaging subsystem (AIS) 7-2

LPS software components 7-3

Thr ee LPS user roles 7-6

System administrator role 7-6

Programmer role 7-6

Operator role 7-7

Key terms in job processing 7-7

Job flow overview 7-8

Inpu t s o u r ces 7-8

Job flow 7-8

Preparing for a print job 7-8

Job flow steps 7-10

Input processing 7-13

Output processing 7-15

Operator interaction with input and output processing 7-16

LPS processing status 7-18

Types of LPS processing 7-21

Utility, command, compiler, and editor processing 7-21

Running utilities 7-21

Executing command files 7-22

Running compilers 7-22

Running editors 7-23

Online printing systems 7-24

Channel-attached LPS 7-24

System generation 7-24

Online 3211/4245 mode 7-24

Print description language (PDL) statements 7-25

Copy-sensitive copy modification entries (CMEs) 7-26

Report separation 7-27

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xiii

Page 14

TABLE OF CONTENTS

Universal character set buffers (UCSBs) 7-27

Forms control buffer (FCB) 7-28

Online record length 7-29

Points to note 7-29

Operating the system 7-31

Placing the system online or off li n e 7-31

Starting an online job 7-31

Monitoring online operations 7-31

Printing all completed pages 7-32

Ending an online job 7-32

Multicopy disk saturation 7-32

Handling MOUNT FORM message 7-33

Host-induced idle time 7-34

Online recovery 7-35

Online dump 7-36

Starting and ending dump sessions 7-36

Dump format 7-36

Points to note 7-37

Downloading files from the host to the LPS 7-38

Valid download file types 7-38

HOSTCOPY 7-38

Card-image format files 7-39

Font and logo tape file format 7-39

File transmission 7-40

DJDE FILE 7-42

Card-image file processing 7-42

LPS-labeled file processing 7-43

Delimited records for LPS-labeled files 7-44

Small print files and online report control 7-44

LEASH 7-44

8. HIP processing on the LPS 8-1

HIP-accessed communication modes 8-1

Initiating communications 8-1

Operator commands 8-2

HIP 8-2

HIP ABORT 8-3

HIP CONCATENATE 8-4

HIP CHANGE 8-4

HIP DRAIN 8-5

xiv XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 15

TABLE OF CONTENTS

HIP END 8 -5

HIP EXIT 8-5

HIP HOST 8-6

HIP JOBS 8-6

HIP LOG 8-7

HIP OFFLINE 8-8

HIP OFFLINE and END processing with XNS host 8-8

HIP ONLINE 8-9

HIP RESET 8-9

HIP SHOW BUFFER 8-10

HIP SHOW HOSTS 8-10

HIP SHOW JOBS 8-10

HIP SHOW LOG 8-15

HIP SHOW VERSION 8-16

HIP SJC 8-16

HIP SLC 8-16

HIP START 8-17

HIP STOP 8-18

HIP library commands 8-19

ACCEPT 8-20

ACFILES 8-20

ACTREPORTS 8-21

BLOCKSIZE 8-21

BUFFERS IZE 8-22

CONCATENATE 8-22

DRAINTIMER 8-23

ENETMAXCONS 8-23

HOST 8-24

LOGENTRIES 8-24

MAXXNSPKTSIZE 8-25

NAME 8-25

QUEUESIZE 8-26

STARTCOMMANDS 8-26

XNSJOB 8-28

XPFJOB 8-28

XPSJOB 8-28

XOPERATIONS 8-28

Nonprint transfer file control 8-29

File recovery 8-29

Ethernet 8-30

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xv

Page 16

TABLE OF CONTENTS

Software 8-30

XNS internet transport protocols 8-31

Level 0 8-31

Level 1 8-31

Level 2 8-31

Higher-level communication protocols 8-32

Level 3 8-32

Level 4 8-32

Limited clearinghouse service 8-33

Time service 8-33

Ethernet network number 8-33

Hardware 8-34

Workstations 8-34

Graphic stations 8-34

XNS spool file saturation 8-35

HIP job queue saturation 8-36

Interpress 8-37

Levels of support 8-37

Interpress sources 8-37

Paper size support 8-38

Interpress image scaling 8-39

Integral scaling 8-39

Character not in font file 8-39

Error summary sheet and break page 8-40

Interpress printing instructions 8-40

Content instructions 8-40

IDENTIFIER and STRING arguments 8-40

Printing instruction override 8-40

Media instruction 8-40

Interpress font utility (IFU) 8-42

Floatin g acc ents 8-43

Rendered and composite characters 8-43

Interpress fonts 8-44

Font file management 8-44

Font header extensions 8-44

IFU commands 8-45

IFU command syntax 8-45

IFU COMPRESS 8-45

IFU COPY 8-46

IFU DEFAULT 8-47

xvi XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 17

TABLE OF CONTENTS

IFU DELETE 8-47

IFU FDR (recreate the font directory file) 8-47

IFU FILE 8-47

IFU IPFNTS 8-48

IFU LIST 8-48

IFU MOVE 8-48

IFU PRINTER 8-49

IFU REWIND 8-49

IFU SAMPLE 8-49

IFU SUBSTITU TION 8-49

IFU UNLOAD 8-49

IFU VOLINIT 8-50

Font substitution 8-50

Character code identifier 8-50

Environment font name 8-51

Orientation and point size 8-51

IPFNTS 8-52

IPFNTS terminology 8-52

Font sets 8-52

Split fonts 8-53

Character code mapping 8-53

Interpress fonts .JSL 8-54

Basic structure of IPFNTS.JSL 8-58

Interpress font mapping 8-60

Interpress mappings limitation 8-61

Mapping in generic IPFNTS.JSL files 8-61

Generic IPFNTS.JSL file compilation 8-61

Critical fil e s 8-61

9. Graphics on the LPS 9-1

Input for graphics 9-1

Processing modes 9-1

Random mode 9-2

Move mode 9-2

Block mode 9-2

Batch mode 9-2

Tape formats 9-3

Noninterleaved 9-3

Document interleaved 9-3

Page interleaved 9-4

Batch mode 9-4

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xvii

Page 18

TABLE OF CONTENTS

Online formats 9-4

Noninterleaved 9 -4

Document and page interleaved 9-4

Batch mode 9-5

Document interleaved graphic file transfers 9-5

Management of image files 9 -5

Scaling 9-6

PDL graphics options 9-7

FDL GRAPHIC statement 9-8

Operational considerations 9-8

Recovery 9-8

Accounting 9-9

Graphic messages 9-10

Disk saturation 9-11

Imaging dump utility 9-11

Image Dump or Print 9-11

Image Fix 9-16

Performance 9-18

Random mode 9-18

Online 9-18

Document interleaved file creation 9-18

Restrictions 9-19

Graphic feature restrictions 9-19

10. Setting up prin t jobs 10-1

Compare V3B with other Xerox software versions 10-1

Compare job processing 10-1

Identify how print jobs run on V3B 10-1

Compare file compilation 10-2

Comp are OS S comm and ex ecution 10-3

Identify how V3B handles other OSS commands 10-3

Converting DocuPrint 96/DocuPrint 96MX files to print on the 4650

LPS 10-4

SCALE 10-4

Controlling stock input to print jobs 10-5

High-capacity feeder (HCF) 10-5

What clusters are 10-5

Cluster features 10-5

Cluster processing overview 10-6

Cluster classifi ca tion 10-7

xviii XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 19

TABLE OF CONTENTS

What clusters do for the programmer and operator 10-8

Where clusters are stored 10-8

How applications use clusters 10-9

Simple and OTEXT applications 10-9

Stockset applications 10-9

Mixing applications 10-10

Defining clusters and stocksets with PDL and DJDE 10-11

Basic considerations 10-11

Steps for creating clusters 10-12

RFEED (record feed) 10-14

Keeping stockset changes to a minimum 10-15

Using clusters with ordered or tab stocks 10-15

Cluster commands 10-16

Using cluster commands 10-18

Cluster command examples 10-19

Keeping clusters in the database 10-19

Operator tasks using clusters 10-19

Irregular screen displays 10-20

Changing stock in trays 10-20

Sample operator procedure 10-21

A current tray in two clusters 10-22

Assigning the input trays with FEED 10-23

FEED (select input tray) 10-23

The FEED override sequence 10-25

Assigning an input tray for purge sheets 10-26

PFEED (purge feed) 10-26

Using stocks of varying sizes 10-27

Printing system pages 10-27

Supported paper sizes 10-27

SET CONTAINER 10-28

SET TRAY 10-28

Feeding paper from the short edge 10-31

Feeding sequenced stocks 10-32

OSTK (ordered stock) 10-32

Setting up output from print jobs 10-33

Stock size and stacker bins 10-33

Assigning the stacker bins 10-33

SELECT 10-33

BLIMIT (b in limit) 10-35

SEPARATE (non- U.S. only) 10-35

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xix

Page 20

TABLE OF CONTENTS

UNLOAD (lowering trays and bins) 10-36

BINFULL (setting maximum output to bin) 10-37

TRANS (running transparency jobs) 10-37

Backward compatibility 10-38

11. Running print jobs 11-1

Printing samples o f system files 11-1

SAMPLE (during a print job) 11-2

SAMPLE (form, font, or logo) 11-2

SAMPLE (multiple copies of a form) 11-3

SAMPLE (extended .IMG options) 11-4

HARDCOPY 11-8

Controlling offline input for print job s 11 -1 3

SPACE (position tape or cartridge by report) 11-13

SPACE (position report printing by page) 11-14

MOVE (position tape or cartridge by block or file) 11-16

Rewind a tape or cartridge 11-17

Unload a tape or cartridge 11-17

Controlling online input for print job s 11- 1 8

ONLINE 11-18

DRAIN (print completed pages) 11-18

ENDJOB (end online job) 11-18

OFFLINE 11-18

Controlling remote input for print jobs 11-19

Using the host interface processor (HIP) 11-19

HIP (host interface processor) 11-19

Printing user files 11-20

Controlling print processing 11-20

START (start a print job) 11-20

START (print a tape or cartridge dump) 11-24

STOP (stop processing) 11-24

CONTINUE (resume printing) 11-25

ABORT (abort job) 11-26

LOCKOUT 11-28

RESET (stop all system processing) 11-29

CLEAR 11-29

FHI (fault, hint, information) 11-29

Checking print job status 11-30

Using the JOBS command 11-30

JOBS (job queue/report status) 11-30

JOBS ALL options 11-34

xx XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 21

TABLE OF CONTENTS

NULL (X) 11-34

Using the PSTATUS command 11-35

PSTATUS 11-35

Responding to the Attention light or alarm 11-38

ATTENTION 11-38

A. System command summary A-1

B. Editor command summary B-1

C. Font editor command summary C-1

D. Command file command summary D-1

E. Character code assignment tables E-1

IBM BCD table (6-bit representation) E-1

Honeywell 200/2000 BCD table (6-bit representation) E-2

Honeywell 6000 BCD table (6-bit representation) E-3

Fieldata translation table E-4

UNIVAC ASCII character set E-5

Standard ASCII character set E-6

Standard EBCDIC character set E-7

F. Page formatting F-1

Page orientations F-1

Landscape orientation F-2

Portrait orientation F-3

G. Cras h recovery and dump G-1

H. Offline notes H-1

Input unpacking examples H-1

Valid host computer/label specification table H-2

Host system JDLs on the system software tape H-3

I. Online notes I-1

Processing 3211/4245 commands I-1

Universal Character Set Buffer (UCSB) I-3

Forms Control Buffer (FCB) I-4

Character correspondence in UCSB associative field I-5

Emulated command codes I-6

Online dump example I-7

Glossary GLOSSARY-1

Index INDEX-1

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xxi

Page 22

TABLE OF CONTENTS

xxii XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 23

About the reference set

Introduction

The

DocuPrint 96/DocuPrint 96MX LPS Operations Reference

discusses the functional characteristics of the DocuPrint 96/

DocuPrint 96MX Laser Printing System (LPS) and operating

software in order to support the LPS operator, the application

programmer, and the host or Ethernet user. Its purpose is to:

• Provide an overview of laser printing system operations

• Describe individual commands for system operation,

management, and job control

• Describe editor and operator command files

• Explain the special considerations applicable to user interface,

communication, and graphics features

This document is part of a reference set designed to help you receive

maximum benefit from your DocuPrint 96/DocuPrint 96MX laser

printing system.

To help you select the appropriate document for your needs, the

following section identifies the documents in the set and describes

the information contained in each.

DocuPrint 96/Docu Print 96MX Laser Printing System document set

The DocuPrint 96/DocuPrint 96MX LPS document set includes the

following:

Xerox DocuPrint 96/DocuPrint 96MX

LPS Operat or Gui de

This reference contains the following information:

• System overview

• Paper facts and procedures

• Operating procedures

• Maintenance

• Problem solving

• Supplies

• Meter reading and reporting

Xerox DocuPrint 96/DocuPrint 96MX

LPS PDL Reference

This reference contains the following information:

• Print Description Language components and processes

• Input processing functions

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xxiii

Page 24

INTRODUCTION

• Output processing functions

• PDL command summa ry

• Page formatting guidelines

• Character code assignment tables

• PDL programming information with step-by-step instructions

Xerox DocuPrint 96/DocuPrint 96MX

LPS System Generation Guide

Xerox DocuPrint 96/DocuPrint 96MX

LPS Operations Referenc e

Xerox DocuPrint 96/DocuPrint 96MX

LPS Forms C reation Guide

This reference contains the following information:

• Configuration options

• Commands

• OSS software installation, upgrade, and modification

This reference contains the following information:

• Command syntax for operator and system administrator

procedures

• LPS de faults

• LPS resources

• Command summaries

• Communication and graphics on the LPS

• Command files

This reference contains the following information:

• Basic concepts for creating forms

• Coding and compiling for LPS Forms Description Language

• Sample form setup command sets

Xerox DocuPrint 96/DocuPrint 96MX

LPS Operator Command Summary

Card

Xerox DocuPrint 96/DocuPrint 96MX

LPS Message Guide

Xerox DocuPrint 96/DocuPrint 96MX

LPS Installation Planning Guide

• Tips for successful forms creation

This reference provides a quick reference of commonly-used

commands.

This reference contains the following information:

• OSS and other messages

• Meaning and recovery procedures

This reference contains the following information:

• LPS basic components and options

• Tasks that must be accomplished before installation

• Preinstallation requirements

• Installation process

• Postinstallation activities

xxiv XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 25

Xerox LPS Tape Formats Manual This reference contains the following information:

• Characteristics of different formats

• File organization

• Data formats

• Carriage control conventions

INTRODUCTION

Xerox LPS S ta nd ard Font Library Fon t

User Guide

Helpful Facts About Pa per This reference contains the following information:

Who should use this manual

This reference contains the following information:

• Font naming conventions

• Listing of standard fonts

• Data Sheets

• Glossary to typography terminology

• Selection and guidelines

• Storage

• Specifications for different printers

This manual serves the information needs of three types of readers

who use the DocuPrint 96/DocuPrint 96MX LPS. The two sections

below describe the three reader groups and the DocuPrint 96/

DocuPrint 9 6 MX LPS.

LPS system administrators, programmers, operators

This manual is written to help you use your laser printing system

(LPS) effectively. You can find helpful information in this manual if

you are:

• A system administrator managing a DocuPrint 96/

DocuPrint 96MX LPS

• A programmer writing print applications for a DocuPrint 96/

DocuPrint 96MX LPS

• An operator running print jobs on a DocuPrint 96/

DocuPrint 96MX LPS.

The reader who must use the information in any section is always the

most important reader of that section. Therefore, the manual

addresses “you” directly, regardless of whether the material is

pertinent for the system administrator, the programmer, or the

operator.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xxv

Page 26

INTRODUCTION

How to use this manual

The following section describes how to use this manual most

effectively.

If the LPS is new to you

If your experience with the LPS is limited, read all the information in

this introduction and the overview of LPS processing presented in the

“LPS print processing” chapter.

Know the key terms and conventions

Become familiar with the key terms, command syntax conventions,

and masking conventions presented in the “Key terms and

conventions” section of this introduction. Refer to this section

whenever necessary.

The first time this manual uses a term, the term appears in italics and

is followed by a definition.

Use the “Contents of this manual” later in this section to pinpoint

quickly the chapter that provides the information you seek.

Use the table of contents, index, and glossary

Use either the table of contents or the index to identify which pages

or sections of this manual provide the information you seek. Note

that each chapter also begins with its own table of contents.

Use the glossary to look up the acronyms or terms that are unfamiliar

to you.

Refer to the related publications list

Identify sources of additional information on your LPS system and

related material by referring to the “Related publications” listing that

precedes the table of contents in this manual. The listed publications

address topics such as:

• Interpress

• Print Description Language

• Forms Description Language

• LPS network and host options

• Fonts

• Training

• System generation

• Tape formats.

xxvi XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 27

Key terms and conventions

Key terms

Syntax conventions

KEYWORD variable Command keywords are shown in uppercase letters; variable

INTRODUCTION

Terms and conventions used in this manual are described below.

The following LPS terms are considered equivalent in this manual:

• Enter key (<ENTER>)

• Print tray (output tray, stacker tray, bin).

Note: Print tray refers to a stacker tray; sample tray refers to the

tray used only for sampled output.

The following are some syntax conventions used in this manual.

information that you determine is shown in lowercase italics.

Only the characters “A” to “Z” and “0” to “9” are valid characters for

use in file names. You can use the period (“.”) only as a delimiter

between the file name and the file type. If you work on an Ethernet

workstation, ensure that your document file names follow these rules.

Otherwise print errors occur when you send files to the LPS.

Avoid using any PDL, FDL, DJDE reserved word or file name, or any

other utility keyword as a file, form, font, or logo name. Doing so

causes unpredictable results.

COMMAND or COM Enter command keywords in full or abbreviate them to the first three

letters.

Choices are listed horizontally with vertical bars separating the

choices. The default value is underlined.

| c

a | b

Required choices are enclosed in braces.

| c}

{a | b

Optional choices are enclosed in brackets.

| c]

[a | b

x, [x, ...] or x1, x2, x3, ... xn An ellipsis ( ... ) indicates repetition of a previous element or

continuation of a series of elements.

Masking conventions

A mask is a generic file name used to specify a multiple number of

files. Within the mask, you can substitute one or more question

marks (?) or asteri sks (* ) for vali d alphanumeric characters. Existing

file names are compared to the mask. An asterisk or question mark

equals all characters. If the last character of the mask is an asterisk,

any subsequent positions equal the asterisk. If the last character of

the mask is a question mark, subsequent positions must be blank (for

example, files with names longer than the mask are not equal).

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xxvii

Page 28

INTRODUCTION

Contents of this manual

? example. File mask AB??.FNT represents all .FNT files with

names:

• AB.FNT

• AB(3rd character).FNT

• AB(3rd&4th characters).FNT

* example. Where x represents any letter or any digit between 0 and

9, file mask AB*.FNT represents all .FNT files with names:

• AB.FNT

• ABx.FNT

• ABxx.FNT

• ABxxx.FNT

• ABxxxx.FNT

The

DocuPrint 96/DocuPrint 96MX LPS Operations Reference

divided into the following tabbed sections and chapters.

is

Relat ed publi c ations Lists associated Xerox publications.

Table of contents Lists the contents of this manual by chapter headings and section

and subsection headings. Ends with separate lists of the tables and

figures in this manual.

Introduction This introduction identifies the readers of this manual and the LPS

systems they use. It describes the contents of this manual, and

explains how to use it.

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Setting LPS parameters

presents the commands that establish LPS operating parameters.

Managing LPS resources

usage, back up system files, and modify font and logo files.

Tracking system activity

activity data and how you can access, modify, print, and back up this

data.

Editing source files

console for creating and modifying files.

. Explains procedures for LPS booting, and

. Explains how to maintain optimal disk

. Explains how the LPS records system

. Describes the file editor available on the operator

Chapter 5

Chapter 6

xxviii XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Editing command files

files, and special command file commands.

Editi n g fo nt fil e s

users to create font files by using specified font files which exist at an

installation as source files.

. Describes command files, editor command

. Explains the utility used by font knowledgeable

Page 29

INTRODUCTION

Chapter 7

Laser printing system (LPS) print processing

printing systems. It identifies their components, explains the

processing flow of a print job, defines key job processing terms and

describes the programmer and operator roles.

Chapter 8

HIP processing on the LPS

Processor (HIP) communication modes (Xerox Network Services

(XNS) and the DocuPrintServer (formerly XPSM) interface) and

provides an overview of Ethernet and Interpress.

Chapter 9

Graphics on the LPS

modes, and the various media formats supported for graphics.

Chapter 10

Setting up print jobs

and how to set up the output options for print jobs. Explains the

programmer and operator roles involved.

Chapter 11

Running print jobs

tape input, host online input, Ethernet online input, how to run a print

job and how to check print job status.

Statement command summaries and appendices

. Briefly introduces laser

. Provides an overview of Host Interface

. Describes the system featu r e s, pr oc es si ng

. Explains how to control paper stock to print jobs,

. Explains how to print samples, how to control

The following are the appendices contained at the end of this

manual:

Appendix A System command summary

Appendix B Editor command summary

Appendix C Font editor command summary

Appendix D Command file command summary

Appendix E Character code assignment tables

Appendix F Page formatting

Appendix G Crash recovery and dump

Appendix H Offline notes

Appendix I Online notes.

A glossary and an index are provided at the back of the manual.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xxix

Page 30

INTRODUCTION

About the DocuPrint 96/DocuPrint 96MX LPS

The DocuPrint 96/DocuPrint 96MX laser printing system is a highspeed, high-performance printing system. It processes and prints

data from a variety of sources. It enables host mainframe computers

and network-connected devices (such as workstations and graphic

scanners) to produce publications that incorporate text in a variety of

fonts with accompanying graphics, logos, forms, and signatures.

Management information systems (MIS) and data processing (DP)

environments use the DocuPrint 96/DocuPrint 96MX LPS as a highperformance printer that also provides built-in storage and

management of forms, fonts, and other document resources.

In general, the DocuPrint 96/DocuPrint 96MX LPS operating system

software is compatible with 4850/4890 LPS V4.0, 9790/8790 LPS

V3.9, 4050 LPS V3.8, 4135 LPS V1.5, and 4635 LPS V3A software.

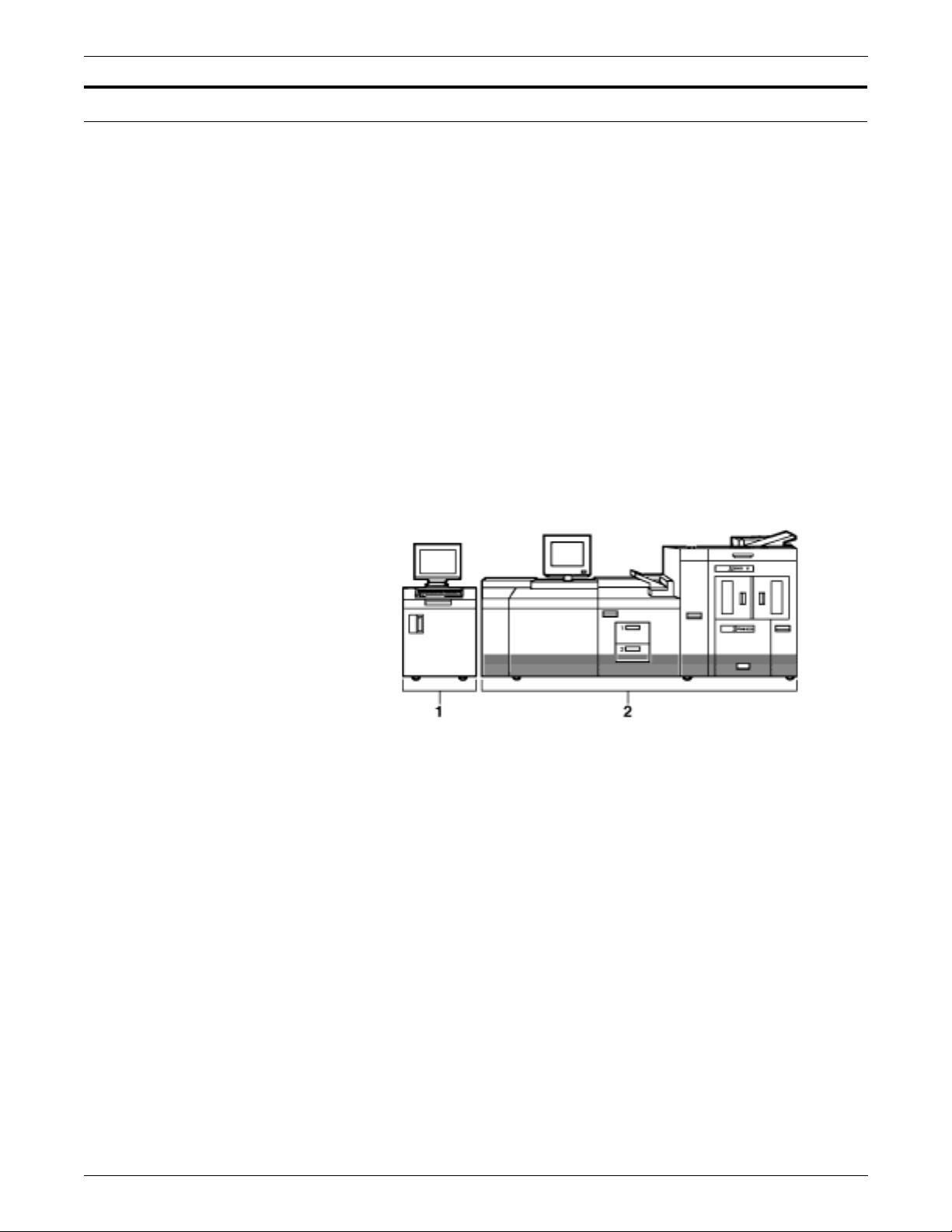

The DocuPrint 96/DocuPrint 96MX LPS consists of two separate

units illustrated in figure 1.

• System controller

• Printer.

Figure 1. DocuPrint 96/DocuPrint 96MX LPS

1 System controller

2 Printer

xxx XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 31

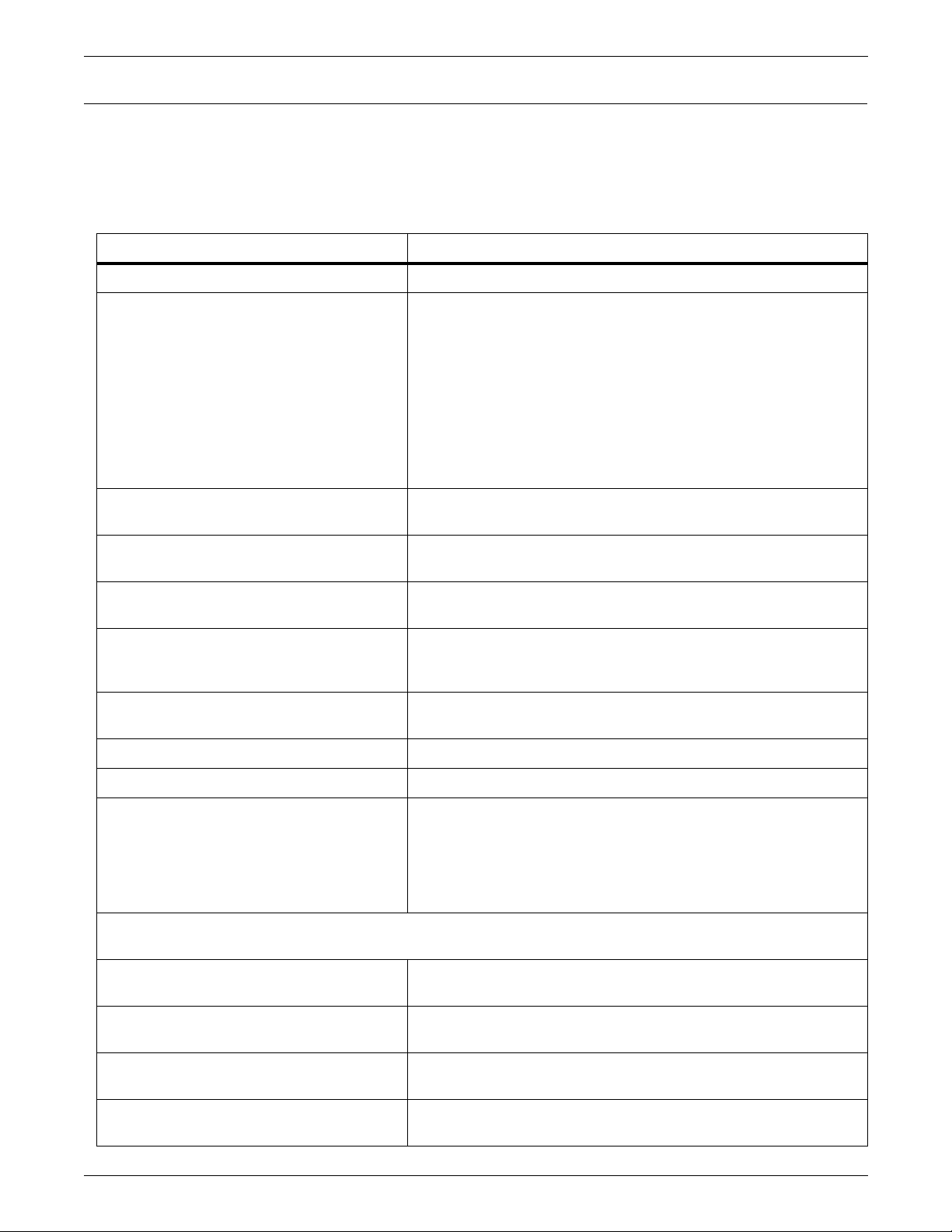

DocuPrint 96/DocuPrint 96MX system controller components

The system controller is the LPS subsystem that allows you to

interact with the printer. Use the keyboard display to enter

commands and select options that control the operation of the

printer.

Figure 2 shows the components of the system controller.

Figure 2. System controller components

INTRODUCTION

1 Keyboard display

2 Operator control panel

3 .25-inch cartridge tape drive

Keyboard display The keyboard display consists of a keyboard and display. Figure 3

shows the keyboard display.

Figure 3. Keyboard display

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xxxi

Page 32

INTRODUCTION

Operator control panel The operator control panel allows you to power the printer on and off,

boot the operating system software, and switch the LPS between

remote and local operation.

Figure 4 depicts the operator control panel

Figure 4. Operator control panel

1 Power On switch

2 Power Off switch

3 Power On indicator

4 Boot switch

5 Remote switch and indicator

6 Local switch and indicator.

DocuPrint 96/DocuPrint 96MX tape and cartridge devices

The DocuPrint 96/DocuPrint 96MX system uses three types of

devices. These devices are referenced by the labels TD0, TD1, and

TD2 since the physical device names are assigned with the

appropriate TDn at sysgen or at mini-sysgen.

For systems with an open-reel tape:

• TD0 is the default for the open-reel tape drive

• TD1 is the default for the 1/4 inch cartridge tape drive

• TD2 is the default for the 18/36 track cartridge tape drive

For systems without an open-reel tape:

• TD0 is the default for the 1/4 inch cartridge tape drive

• TD1 is the default for the 18/36 track cartridge tape drive

Refer to the

Guide

DocuPrint 96/DocuPrint 96MX LPS System Generation

for more information.

xxxii XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 33

DocuPrint 96/DocuPrint 96MX printer components

The printer is the LPS subsystem that processes the electronic

images and produces the printed report. Figure 5 depicts the

components of the DocuPrint 96/DocuPrint 96MX printer.

Figure 5. DocuPrint 96/DocuPrint 96MX printer

1 Processor feeder trays

2 Inverter feeder/stacker module (containing inverter, high-

capacity feeder, and high-capacity stacker bin)

3 Purge tray

4 Attention lig ht

5 Sample tray

6 Printer control console

INTRODUCTION

For more detailed information refer to the

DocuPrint 96MX LPS Operator Guide

.

DocuPrint 96/

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE xxxiii

Page 34

INTRODUCTION

xxxiv XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 35

Communicating with the LPS

1. 1Setting LPS parameters

This chapter describes the parameters that may be set for the LPS.

The commands you enter control functions such as:

• Loading the operating syste m

• Switching between online and offline processing modes

• Setting the system to MICR mode

• Initiating printing

• Building and modifying source files

• Requesting sample prints of data, forms, fonts, and logos

• Obtaining accounting summaries

While print jobs are running, messages are displayed concerning the

status of the jobs and, if necessary, the unexpected occurrences that

require operator intervention.

The DocuPrint 96/DocuPrint 96MX LPS user interface:

• System keyboard display. Use the system keyboard display

to handle:

— Job programming and control features

— S ys te m utilit ies and diagnostics

— Paper management and feeder/stacker control

— Da ta Capture Utility

—Editor

The operator commands you can enter at the system controller

keyboard display are documented by this manual.

• Printer control console. Use the printer control console to

handle:

— Paper management and feeder/stacker control

— Jam clearanc e

— Printer diagn ostic functions

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-1

Page 36

SETTING LPS PARAMETERS

When you communicate with the printing system:

• Abbreviate all commands to the first three characters or spell

them out fully.

• Do not use a command entered in one language (for example,

English) interchangeably with the equivalent command in

another language (for example, French).

• Pressing a function key invokes the specified action. Do not

also press the <ENTER> key.

• Keyed-in commands are executed when you press the

<ENTER> key.

• Command delimiters are blank (space), end of line, comma,

and slash.

• Use only uppercase letters A to Z, and digits 0 to 9 in source file

names.

• System error and information messages are preceded by OS

and a four-digit code. The complete set of system messages is

documented in the

Message Guide

Xerox DocuPrint 96/DocuPrint 96MX LPS

.

• Messages without the OS four-digit code prefix are also

documented in the

Message Guide

Xerox DocuPrint 96/DocuPrint 96MX LPS

.

• A message acknowledging your request is displayed to provide

you with positive feedback. In system and operator dialog

examples, these messages are underlined to differentiate them

from system messages.

• The error message OS2710 Invalid command re-enter

displays when you enter an erroneous command or keyword

within a command.

1-2 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 37

Installa tio n an d sys te m ge ne ra tio n

The initial considerations and procedures for installing a Xerox laser

printing syst em (LPS) and the operati ng system soft ware (OSS), th at

can be tailored to a site-specific configuration, are documented in the

Xerox DocuPrint 96/DocuPrint 96MX LPS Installation Planning

Guide

Generation Guid

preceding the table of contents in this manual.)

Your LPS service representative oversees the installation of the

DocuPrint 96/DocuPrint 96MX LPS.

User interface keyboard display

The DocuP rint 96/D ocuPrint 96MX LPS keyb oard d i splay major

steps are:

• Back up customer files.

• Install DocuPrint 96/DocuPrint 96MX multinational keyboard.

• Install DocuPrint 96/DocuPrint 96MX printer software.

SETTING LPS PARAMETERS

and

Xerox DocuPrint 96/DocuPrint 96MX LPS System

e. (Refer to the “Related publications” section

Detailed instructions are provided by the “Steps to perform a full

sysgen in character emulation mode” section in the

DocuPrint 96/DocuPrint 96MX LPS System Generation Guide

Xerox

.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-3

Page 38

SETTING LPS PARAMETERS

Powering on and booting the LPS

This section discusses the power-on and boot process you use after

the first sysgen has been run.

If the LPS is online to a host computer and it has an emergency

power off cable, use the Remote button instead of the Local button.

The Remote button means that the host system controls powering

the LPS on or off. If you turn the power off by pushing the Off button

on the control panel, however, you can restart it by holding down the

On button until the Power indicator comes on.

If Autoboot was selected in the sysgen, the DocuPrint 96/

DocuPrint 96MX LPS system controller boots the operating system

automatically.

If not, follow this procedure:

Step 1. Press <B> on the keyboard to load the operating system software

(OSS).

Note: The operating system software must be loaded before

the system can finish the warm-up cycle.

Step 2. When loading is complete, the following messages appear on the

system controll er display:

LOADING PROGRAM.....

XEROX DP 96

LASER PRINTING SYSTEM

VERSION X REVISION Y

Copyright . . .

DISK ID: [ThirtycharacterIDrecord]

Step 3. Allow four to seven minutes for the printer to complete its warm-up.

Note: Before the LPS starts printin g , the syste m che cks print

quality and controls. Any adjustments, if necessary, are made by

the system to give you the best quality prints. The system also

checks print quality on an ongoing basis and may stop printing,

correct a quality problem, and resume where it left off.

Important If you enter a boot command for a device contained within the

peripheral cabinet, but the LPS is not configured with the specified

device, the system displays SCSI error messages and then displays

the boot menu.

Remedy this by pressing the Boot button again. When the LPS

displays the $ prompt, check the hardware configuration if the

peripheral cabinet is installed. If it is not installed, enter the BOOT

command for the configured device.

1-4 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 39

Power loss

SETTING LPS PARAMETERS

If the DocuPrint 96/DocuPrint 96MX LPS loses power or the

communications link during online job processing, enter C or press

the Power Off button. The LPS responds by running its job recovery

procedures and displaying the job queue information it displayed

prior to the power loss. If the LPS does not respond this way, call your

LPS service representative for assistance.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-5

Page 40

SETTING LPS PARAMETERS

System verification messages

If problems occur while OSS is performin g its syste m verif ication

tests, the DocuPrint 96/DocuPrint 96MX LPS displ a ys syste m

verification messages.

Table 1-1 shows system verification messages.

Table 1-1. System verification messages

Message Explanation

Operating in degraded mode Problem detected. Other messages will follow.

Devices not accessible

name,name,--

A configured syste m device is not in the system configur ation. The

missing devices are indicated by the following names:

DISK (disk)

FLOPPY (floppy)

TAPE (tape)

CARTP (quarter-inch tape)

HOST (online channel interface)

ENET (Ethernet)

RIP (raster image processor)

3480TP (1/2 inch tape)

Main memory missing: BankS) xx,

xy, xz,...

Hardware version mismatch -update configuration

Memory specified during the system configuration phase is

missing. The banks are displayed in 16K word sections.

The configured Advanced Imaging Subsystem (AIS )version and

the hardware AIS version number do not match.

AIP Firmware error A firmware error was detected. There is a fault in some part of the

AIP firmware.

AIP Download error There is a missing firmware file, a firmware file cannot be read, a

problem with the contents of the firmware file, or a download error

occurred causing the checksum to be incorrect.

Problem with AIPOS.sys --

Problems with accessing or reading the AIS firmware file.

file missing or invalid

Missing text and metric memory Problem accessing text and metric memory.

Missing bitmap memory Bad bank, cannot access bitmap memory.

Missing Ink-1 memory,

Missing Ink-2 memory,

Indicate that there is a bad bank, cannot access memory, or

memory is not available (not sysgened).

Missing PB-A-1 memory,

Missing PB-A-2 memory,

Missing PB-B-1 memory, or

Missing PB-B-2 memory

If any of the next four messages is displayed, re-sysgen the system and update the configuration. If this should

fail, contact your systems specialist or Xerox Customer Service for resolution.

Graphics memory not available-Update configuration

Ink memory not available-Update configuration

PB-B memory not available-fatal error

n

-2 memory not available--

PBfatal error

1-6 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Graphics memory is not present according to the hardware, but is

sysgened in.

Ink memory is not present according to the hardware registers, but

is configured into the system.

Page buffer B memory is not present according to the hardware

registers, but is configured into the system.

Highlight page buffers memory is not present according to the

hardware registers, but is configured into the system.

Page 41

SETTING LPS PARAMETERS

Table 1-1. System verification messages (continued)

Message Explanation

SYSTEM NOT OPERATIONAL Devices were missing, or main memory i s below 128K words. The

system probably is unable to function even in a degraded mode if

this message is displayed. If this message is not displayed, the

system may be able to print, but its operation is degraded.

You can invoke any system function, although some functions may

not execute or may cause a system crash. For example, the lack

of AIS memory does not impact a file editing session, but that lack

of AIS memory would abort printing.

The above messages indicate that the system is not fully

functional. Use of the system at such a point is questionable.

Contact the LPS service representative for assistance in making

your LPS operational.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-7

Page 42

SETTING LPS PARAMETERS

Printer communication link

The system stops all processing and restarts if a system controller

problem occurs.

The DocuPrint 96/DocuPrint 96MX LPS has an interface between the

system controller and the printer, part of which is called the client

layer. The system initializes the client layer to establish

communication between the system controller and the printer after

system initialization, after communication is lost, or at the request of

technical personnel (see the section “PSC (printer subsystem

controller)“ later in this chapter).

The system's ancillary Printer message (AIM) processor task

establishes communication with the printer, executes client layer

initialization, and displays status messages. If a problem initializing

the client layer occurs, AIM attempts to establish communication two

more times and to initialize the client layer. An attempt lasts between

20 seconds and two minutes. If these attempts fail, AIM prompts you

with Retry ClientLayer initialization? (Y/N).

If you enter N, AIM displays Enter PSC when you wish to

attempt connection to Printer.

Thus you choose between using the system controller for nonprint

tasks and loading the communication software again with the PSC

command.

Note: If the PSC command fails two times, reinitialize the printer by

turning the power off, then on again.

1-8 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 43

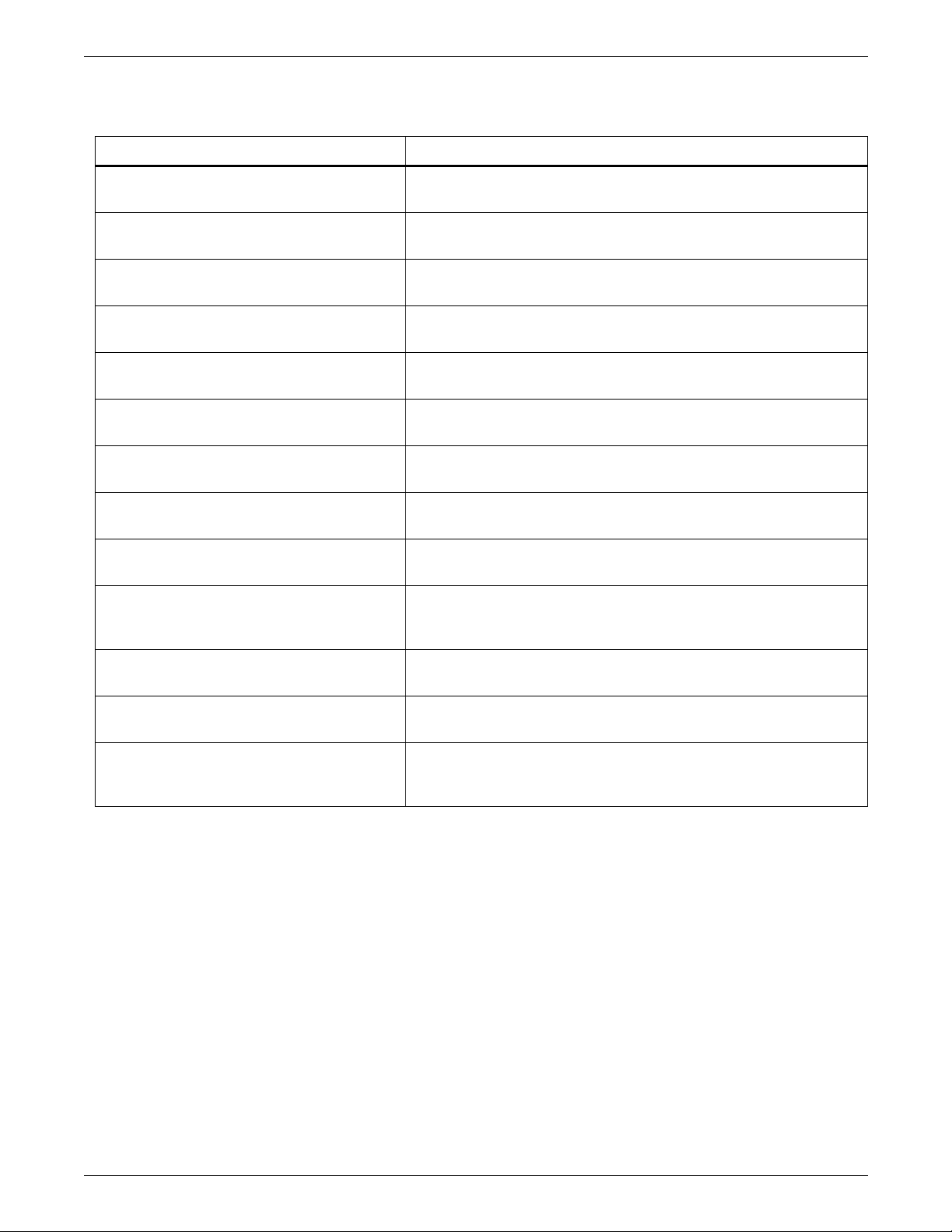

Table 1-2 lists sample messages.

Table 1-2. Sample messages

Message Explanation

SETTING LPS PARAMETERS

Attempting to establish

The system controller is connecting with the printer.

communication with the printer...

Communication with the printer is

System and printer communication is successfully established.

established

Initializing Client-Layer

Client laye r in it ialization is beginning .

protocol

Client-Layer is established The client layer has been initialized without errors. The system is

functional.

Printer Client-Layer is not

The printer does not answer client-layer requests.

responding

Printer failed to send

configuration

Failed to establish communication

The printer does not send all the printer configuration messages

during client layer initia l iz a ti on .

Three attempts to bring up the link layer have failed.

with the printer

!Link to printer is down Communication with the printer was lost during execution of a

nonprint task. Displays when the nonprint task completes.

!Loss of communication with the

The system controller is not receiving messages from the printer.

printer

Retry Client-Layer

Initialization? Y/N

Several attempts to initialize the client-layer have failed. You can

request initialization again or terminate the process to run nonprint

tasks on your DocuPrint 96/DocuPrint 96MX LPS.

!Sequence error-ESS is attempting

reconnection to printer.

!Link down-ESS is attempting

reconnection to printer.

!Device not ready-ESS is

attempting reconnection to

printer.

The system controller has attempted to send a message when the

line has failed. AIM is attempting to reestablish communication.

The link has dropped. AIM is attempting to establish

communication.

The printer is not acknowledging a message, the CSI controller is

not responding, or the printer is aborting its own messages. AIM is

attempting to establish communication.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-9

Page 44

SETTING LPS PARAMETERS

PSC (printer subsystem controller)

Syntax PSC [AIP[,CSI][,CRIB][ [:0][:1][:2][:3]][,SCSI][,CLI]]

Parameters Table 1-3 describes the tasks initialized by utilization of the PSC

Use this command to download firmware to the specified printed wire

board assemblies (PWBAs) in the system controller.

command.

Table 1-3. Parameters of the PSC command

Parameter Description

AIP Downloads the AIPO S.SYS firmware and

performs diagnostics to check and initialize the

various types of memory used by AIS. The

messages Initializing AIP and

Downloading firmware (version ###)

display, followed by memory test messages.

CSI Sends the software for printer and controller

communication and reinitializes the client-layer.

The PS1061 Initializing CSI message

displays.

CRIB Downloads the CRIB firmware. If the CRIB

download was invoked by the operator or from a

hard boot, the firmware is downloaded

unconditionally. However, after a system crash,

the checksum of the firmware on the CRIB PWBA

is checked first. If the checksum is correct, the

download is not executed. The message

Downloading CRIB firmware (version)

displays.

SCSI Displays the current SCSI firmware version.

CLI Reinitializes the client-layer.

The SCSI firmware is downloaded to the SCSI printed wire board

(PWB) automatically.

If the download succeeds, no more messages display. If an error

occurs, refer to the

Message Guide

Xerox DocuPrint 96/DocuPrint 96MX LPS

.

Examples The CSI firmware can be downloaded at any time by entering:

PSC CSI

On the DocuPrint 96/DocuPrint 96MX LPS the printer must be idle to

run the PSC task. If the HIP task is in process when you request

PSC, the system prompts you to confirm the PSC request. If HIP is

running when you confirm the PSC request, then the HIP

communication line is disconnected. In addition, printer messages

sent but not yet processed may be lost.

Restriction You can restrict access to PSC with RCU.

1-10 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 45

Configure a finishing or feeding device

The following describes how to configure a finishing or feeding

device.

Create the FCG.LIB file

Before you can configure a finishing or feeding device, you must

modify a text file called FCG.LIB containing the array of bytes (timing

values, constants, flags, and so on) that are loaded into the LPS nonvolatile memory (NVM) by the configuration process. The array is

known as the “personality profile” of the finishing device because it

indicates to the LPS how to communicate with the finishing or feeding

device.

The FCG.LIB file must have one entry for each finishing or feeding

device. Each entry consists of a label, an equal sign (=), and a set of

values. You create the label, which should help you identify the

device and indicate its configuration if possible. For example, a

saddle-stitch profile might be given the label SADLSTCH.

• Entries must begin with an alphanumeric character (0-9, A-Z).

• Each entry provides the NVM values for one finishing or feeding

SETTING LPS PARAMETERS

device.

Finishing device entry syntax

• Each entry must have a label that begins the record.

• Although the label may consist of more than eight characters,

the LPS processes only the first eight characters.

• The equal sign separates the label from the array values.

• Commas separate each array value from preceding and

following values.

• Only whole numbers can be entered for parameter values (no

decimals).

• There are no defaults for any parameter. All values must be

specific for the entry to be accepted.

• Each entry is terminated by a semicolon (;).

The FCG.LIB file can also include comment lines. Comment lines

must begin with a non-alphanumeric character.

label=OUT135, p1, p2, p3, p4, p5, p6, p7, p8, p9, p10, p11;

name attached to the profile entry.

label

OUT135

DocuPrint 96MX output device profile.

distinguishes the entry as a 4635 or DocuPrint 96/

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-11

Page 46

SETTING LPS PARAMETERS

Parameters Table 1-4 shows the parameters of the Finishing device entry.

Table 1-4. Parameters of the Finishing device entry

Parameter Description

p1= Time between Sheets

p2= Sheet Jam Time

p3= Time between Sets

p4= Set Ja m Time

p5= Time to Cycle Up

p6= Attributes

Specifies the minimum time the device

requires between the trail edge of one

sheet to the lead edge of the next sheet.

Range is 0-32767 ms.

Specifies the maximum time the LPS

waits for a sheet delivery signal after a

sheet exits before declaring a jam. Range

is 0-13000 ms.

Specifies the minimum time between the

trail edge of the last sheet of one set to the

lead edge of the first sheet of the next set.

Range is 0-32767 ms.

Specifies the maximum time the LPS

waits for a set delivery signal after a set

exits before declaring a jam. Range is 013000 ms.

Specifies the amount of time the LPS

should wait after the cycle up signal is

sent before the bulk input feeder is

capable of sending a sheet. Range is 032767 ms.

Allows additional control of the SF1 and

SF2 function signals. Valid values are 0:

ESS control, 4: Always on, and 8: Always

off.

p7= Statuses Supported

p8= Delivery Signal Type

p9= Delivery Start Adjust

Expects a status from the finishing device

as listed below:

S0: Offline or Not Ready, value is 1.

S1: Faulted, value is 2.

S2: Full, value is 4.

S3: Sheet delivered, value is 8.

S4: Set delivered, value is 16.

Range is 0-31. If all statuses are

supported, the value is 31. If no statuses

are supported, the value is 0.

Identifies the required delivery signal as

triggered by the lead edge or the trail

edge. Range is 0-1:

Lead Edge triggered = 0

Trail Edge triggered=1.

Adjusts the timing of the start of the

delivery signal. Range is -100 to +300 ms

for the lead edge, -100 to +75 ms for the

trail edge.

1-12 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 47

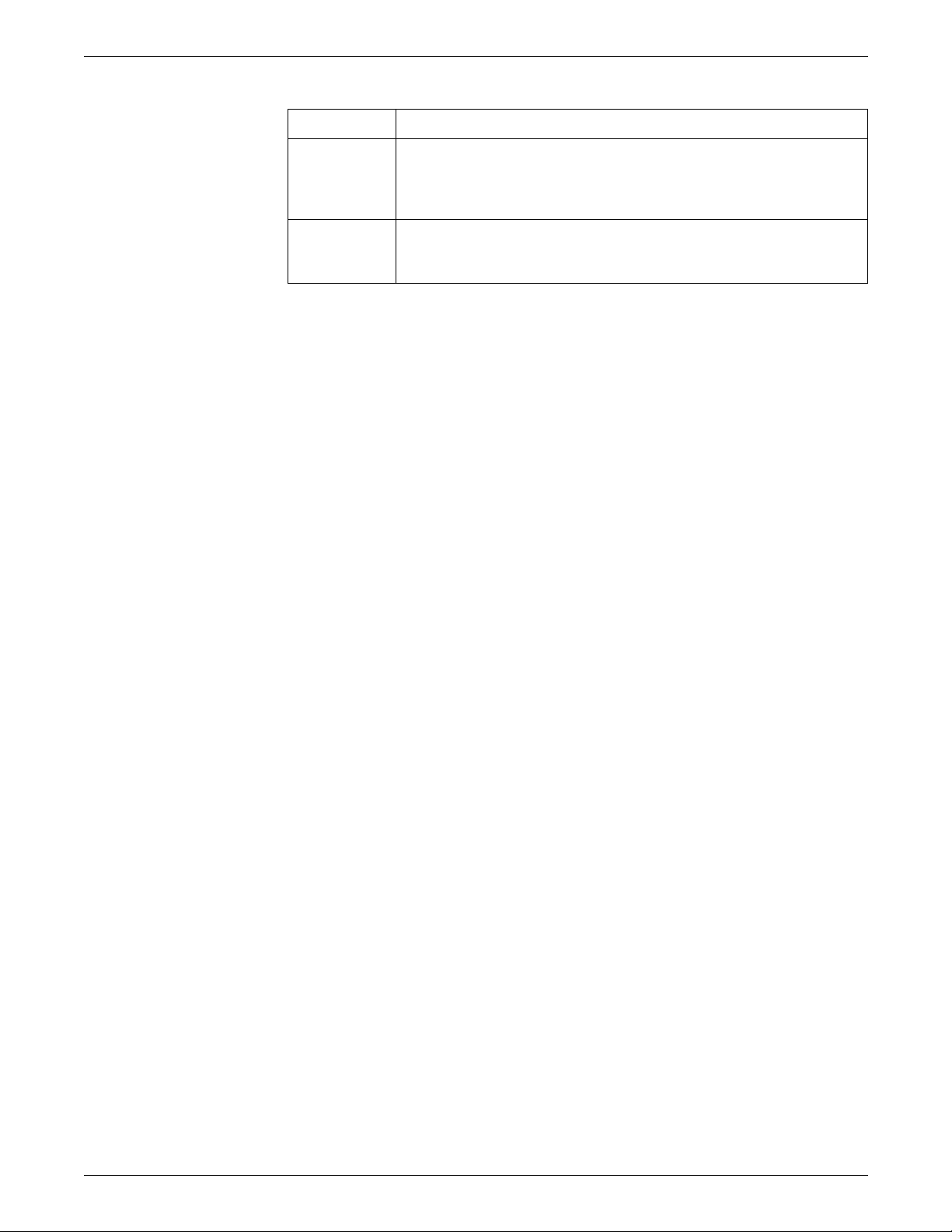

Table 1-4. Parameters of the Finishing device entry

Parameter Description

SETTING LPS PARAMETERS

p10= Delivery Pulse Width

p11= End of Set Offset

Example GNTST = OUT13 5, 1000 , 1500, 2000, 3500, 0, 2, 31, 0, 0, 0, 0;

Feeding device entry syntax

Adjusts the timing of the termination of the

delivery signal. Only applies to the trail

edge of the sheet; not applicable to the

lead edge. Range is 30—110 ms.

Informs the LPS of the amount of time

required between the sheet delivery and

set delivery signals. Range is 0-255.

label=IN135, p1, p2, p3, p4, p5;

name attached to the profile entry.

label

IN135 distinguishes the entry as DocuPrint 96/DocuPrint 96MX input

device profile.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-13

Page 48

SETTING LPS PARAMETERS

Parameters Table 1-5 shows the parameters of the Feeding device entry

command.

Table 1-5. Parameters of the Feeding device entry command

Parameter Description

p1= Time to Feed sheet

p2= Time to Cycle Up

p3= Attributes

p4= Statuses Supported

Specifies the time required by the bulk

feeder between the feed sheet command

being received and the required sheet’s

arrival at the first LPS sensor. Range is 0500 ms.

Specifies the amount of time the printer

should wait after the cycle up signal is

sent before the feeder is capable of

delivering the first sheet of paper. Range

is 0-32767 ms.

Specifies which speci fi c sto cks ar e

supported by the bulk feeder, as listed

below:

D1: Drilled pap e r

D2: Ordered stock

Range is 0-7.

Receives a status from the feeding

device, as listed below:

S5: Bulk Input Medium Low

S6: Not Ready

S7: Sheet fed

Range is 0-7.

p5= Feed Signal Adjust

Specifies the duration of the feed sheet

command the LPS gives to the bulk

feeder. Range is 10-100 ms.

Example GENFD =IN1 35, 200, 800, 7, 3, 45;

Procedure The procedure follows:

Step 1. Open this file within the text editor by entering: EDIT FCG.LIB.

Step 2. Key in the entry record for the finishing device to be configured or

modify the array values if necessary.

Step 3. Save the file.

Step 4. Exit the Editor.

1-14 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 49

SETTING LPS PARAMETERS

Step 5. Submit the values for the printer specified by the entry by entering

profile-label

FCG

.

System response:

1. The LPS verifies that no print job is being processed. If the LPS

is processing a print job, the LPS displays the message

OS1970 FCG exiting: Unable to run during a

print job.

2. If no print job is being processed, the LPS accesses the

FCG.LIB file. If this file does not exist, the LPS displays the

message OS1971 FCG exiting: FCG.LIB not present

on system.

3. If FCG.LIB is found, the LPS checks for the specified entry label

in the file. If the entry label is not in the file, the LPS displays

the message OS1972 FCG exiting: Unable to locate

entry label. If the specified entry label appears in the file

more than once, the LPS displays the message OS1973 FCG

exiting: Duplicate profile entries.

4. If the specified entry label is found, the array values for the

entries are checked to verify that they are integers within range.

If they are not, the LPS displays the message:

OS1978 FCG exiting: Data value is out of range.

5. Finally, the number of values in the entry is checked to verify

that no more than 11 values are specified. If an incorrect

number of parameters are specified, the LPS displays the

message OS1976 FCG exiting: Invalid profile

encountered.

6. If an error occurs during step 4 or 5, the LPS displays the

message Profile not loaded.

7. If no error occurs during step 4 or 5, the LPS copies the array

values to the printer’s, and the LPS displays the message

OS1974 FCG exiting: Profile for

successfully loaded.

FCG (disp lay the prof i le l abe l s)

Use this command to display the profile labels in the FCG.LIB file.

Logon Level Levels 2 through 5.

Syntax FCG

<profile-name>

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-15

Page 50

SETTING LPS PARAMETERS

FCG (c onfigure a fin i shing or feedi ng devi ce)

Use this command to load into printer memory the personality profile

the LPS must use to communicate with the finishing device or bulk

feeder. The personality profile is an entry in a text file called

“FCG.LIB.” On ce this f ile i s cr eated, i t is preser ved across sy sgens.

Logon Level Levels 2 through 5.

Syntax FCG {

profile-label

}

Parameters Table 1-6 shows the parameters used in FCG to configure a finishing

or feeding device.

Table 1-6. Parameters of the FCG (configure a finishin g or

feeding device) command

Parameter Description

profile-label

Specifies the entry in the FCG.LIB file to be sent to

the printer.

Reference For more detailed procedural information, refer to the

DocuPrint 96MX LPS Operator Guide

.

DocuPrint 96/

FCG SHOW (check finishing or feeding device settings)

Use this command to check the settings for the finishing or feeding

devices configured for the LPS.

Logon level Levels 2 through 5.

Syntax FCG SHOW

Restrictions SHOW cannot be abbreviated to SHO.

Reference For procedural information, refer to the

DocuPrint 96MX LPS Operator Guide

1-16 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

DocuPrint 96/

.

Page 51

SETTING LPS PARAMETERS

FCG procedures

Use this task to:

• Send the configuration values for a feeding or finishing device

to the printer

• Display the current device configuration values.

Configure task Table 1-7 shows the command to send feeding or finishing device

configurations to the printer.

Table 1-7. Parameters of the FCG SHOW (check finishing or

feeding device settings) command

Parameter Description

FCG

profile-label

profile-label

To display all profile labels for the feeding or finishing device, enter

the following command:

FCG

To display the current device configuration values, enter the following

command:

FCG SHOW

Note: SHOW cannot be abbrev iated to SHO.

The name assigned to the feeding or finishing

device configuration.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-17

Page 52

SETTING LPS PARAMETERS

Verifying LPS status

Verifying system version and time

OCS (system version display)

Syntax OCS

Status lines Figure 1-1 is an example of the OCS status display.

The system automatically displays messages describing paper tray

status, output bin status, and required operator actions in the system

message area. These messages are OSXXXX messages such as

OS2080 Paper tray x is empty and OS2210 Bin x full.

The following describes how to verify system version and time.

Use this command to verify OSS version information.

OCS

System version xx; IOT Software version xx;

OCS version xxx; Command table version xxxx;

System class x; Disk ID: xxxx

OS1000 Ready For Commands

Time and date displays

The following describes how to verify time, date and status.

Keyboard display The date and time display (figure 1-2) appears on the keyboard

display in the upper right corner of the screen. The input device,

output device, and host device have status lines that are always

displayed under the time entry. These lines are described in the

“Status lines” section (table 1-8).

Status lines Figure 1-2 shows the various lines of the time, date and processing

status display.

HH:MM:SS

uuuuvvvv

wwww

yyyzzzz

1-18 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 53

SETTING LPS PARAMETERS

Table 1-8 shows the status display entries for time and date displays.

Table 1-8. S tatus display entri es

Status Explanation

uuuu Input status. May be all blanks, Wait , Actv, Sat., or

Stop.

vvvv Input source. May be all blanks, Tape, Disk, Host, or

Enet.

wwww Output status. May be all blanks, Wait, Actv, Stop, C-

up, or Jam.

yyyy Current host. May be all blanks, XNS, or Host.

zzzz Host stat us. May be Offl, Nrdy , Wait, Recv, Send, Spnd,

OnLP, ATTN, or Sesn.

XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE 1-19

Page 54

SETTING LPS PARAMETERS

Verifyi ng syst em stat us

PROBLEM

You can increase the efficiency of service calls by providing the

representative with the 6-digit dispatch code generated by the OSS

problem utility. Run this utility:

• Before placing a service call

• When the system directs you to key in the PROBLEM

command (since it detects a problem it cannot correct).

Use this command to access the dispatch code.

Syntax PROBLEM

Procedure The display shown in figure 1-3 appears.

Figure 1 -3. Initia l P ROBL E M displa y .

PROBLEM C00 PROBLEM ANALYSIS RUNNING

PROBLEM ANALYSIS RESULTS-- DISPATCH CODES

1. TO REPORT ADDITIONAL PROBLEMS

2. NO MORE PROBLEMS TO REPORT.

INDICATE SELECTION BY ENTERING NUMBER.

##.##.##

(message)

A sample dispatch code is 10.00.18 SYSTEM REPORTED

PRINTER PROBLEM.

If you want to report additional problems, enter the number 1. Then

the system prompts you to identify the type of problem (figure 1-4).

Figure 1 -4. Prompt for PROBLEM type.

WHICH OF THE FOLLOWING TYPES OF PROBLEMS DO YOU WISH

TO REPORT?

1. COPY QUALITY PROBLEMS

2. FREQUENT JAMS

3. OUTPUT TRAY PROBLEMS

4. PAPER TRAY PROBLEMS

5. TAPE PROBLEMS

6. OTHER SYSTEM PROBLEMS

7. NO OTHER SYSTEM PROBLEMS

INDICATE SELECTION BY ENTERING NUMBER.

1-20 XEROX DOCUPRINT 96/DOCUPRINT 96MX LPS OPERATIONS REFERENCE

Page 55

SETTING LPS PARAMETERS

When you enter 7, the system provides a code that you should record

and report to your LPS service technician (figure 1-5).

Figure 1 -5. Field Service code display.

CALL THE FIELD SERVICE DISPATCHER AND REPORT THESE

NUMBERS

##.##.##

OPERATOR---INDICATE THE ACTION YOU HAVE TAKEN.

1. SERVICE CALL HAS BEEN PLACED.

WAITING FOR SERVICE

2. SERVICE CALL HAS BEEN PLACED.

RETURN TO THE OPERATING SYSTEM

3. SERVICE CALL HAS BEEN COPIED FOR LATER CALL.

RETURN TO THE OPERATING SYSTEM

4. NONE OF THE ABOVE.

RETURN TO THE OPERATING SYSTEM

INDICATE SELECTION BY ENTERING NUMBER

Before entering 1, 2, 3, or 4, ensure that you record the 6-digit

dispatch code to report to your service representative.