Page 1

Sheetfed Scanner

Service Manual

Version 1.0

Page 2

Sheetfed Scanner

Contents

1. INTRODUCTION...........................................................................................................................1-1

1.1 GENERAL NOTES FOR SERVICING..............................................................................................1-1

1.2 GENERAL DESCRIPTION ...........................................................................................................1-2

1.3 BASIC SPECIFICATIONS ...........................................................................................................1-2

2. UNPACKING, INSTALLATION, AND TRANSPORTATION..............................................2-1

2.1 PRECAUTIONS OF INSTALLATION..............................................................................................2-1

2.2 UNPACKING PROCEDURE..........................................................................................................2-1

2.3 INSTALLATION .........................................................................................................................2-3

2.3.1 Installing the ADF Paper Tray............................................................................2-3

2.3.2 Installing the ADF Output Paper Tray ..............................................................2-4

2.3.3 Connecting the Cables.........................................................................................2-5

2.3.4 Turning on the Power ..........................................................................................2-5

2.4 PLACING THE ORIGINAL ...........................................................................................................2-6

3. THEORY OF OPERATION..........................................................................................................3-1

3.1 INTRODUCTION........................................................................................................................3-1

3.2 MAIN CONTROL UNIT................................................................................................................3-2

3.2.1 System diagram....................................................................................................3-2

3.2.2 Main control circuit...............................................................................................3-3

3.2.3 Video circuit: .........................................................................................................3-4

3.2.4 LED and Push Button Module Circuit................................................................3-6

3.2.5 Sensor input ..........................................................................................................3-7

3.2.6 Sub power supply circuit.....................................................................................3-8

3.2.7 Power supply .........................................................................................................3-9

4. PROBLEM SOLVING....................................................................................................................4-1

4.1 DIAGNOSTICS..........................................................................................................................4-1

4.1.1 Online diagnostics ................................................................................................4-1

4.1.2 Offline diagnostics ................................................................................................4-2

4.1.3 Diagnostic flowcharts...........................................................................................4-3

4.2 TROUBLESHOOTING .................................................................................................................4-6

4.2.1 Flowcharts..............................................................................................................4-6

4.2.2 Tables......................................................................................................................4-9

5. DISASSEMBLY.............................................................................................................................. 5-1

5.1 SERVICE TOOL.........................................................................................................................5-1

5.2 CLEANING THE ADF ................................................................................................................5-2

5.3 CLEANING THE CALIBRATION AREA..........................................................................................5-3

5.4 PROCEDURE FOR DISASSEMBLY AND REASSEMBLY ....................................................................5-4

5.4.1 Notes on disassembly..........................................................................................5-4

5.4.2 Removing the Upper Housing ............................................................................5-5

5.4.3 Removing the Upper Optical Assembly............................................................5-7

5.4.4 Removing the Upper Optical Chassis ...............................................................5-9

5.4.5 Removing the Lamp in Upper Optical Assembly..........................................5-10

ii

Page 3

Service Manual

Removing the ADF Pad......................................................................................5-11

5.4.6

5.4.7 Removing the Main Control Board..................................................................5-12

5.4.8 Removing the Motor in Lower Optical Assembly .........................................5-14

5.4.9 Removing the Inverter in the Lower Optical Assembly..............................5-15

5.4.10 Removing the Lower Optical Chassis..........................................................5-16

6. PARTS..............................................................................................................................................6-1

6.1 SPARE PART DIAGRAM..............................................................................................................6-1

iii

Page 4

Service Manual

1. INTRODUCTION

1.1 General Notes for Servicing

1.2 General Description

This manual is intended to be used by the maintenance engineers. It describes areas to be

maintained, the detailed installation, the disassembly of optional ADF, and the component

replacement procedures as well as the main trouble shooting guides.

Please take your time to read this manual thoroughly to obtain comprehensive knowledge

about the scanner before serving the unit.

1.1 General notes for servicing

(1) Before trying to disassemble the scanner, make sure the power supply cord of

theAV220 is disconnected from the power outlet. Under any circumstance, do not

remove or install the connectors on the scanner with the power supply turned ON.

(2) Use caution not to drop small parts or screws inside the unit when disassembling and

reassembling. If left inside, they might cause the malfunction of the unit.

(3) Do not pull the connector cable when disconnecting it. Hold the connector.

(4) When carrying the scanning head unit, put it in an anti-static bag.

(5) Keep the document table glass surface always clean. If contaminated, use a dry

clean cloth for cleaning.

(6) Use caution not to injure your fingers or hands when disassembling or reassembling

the unit.

1-1

Page 5

Sheetfed Scanner

1.2 General Description

The scanner which features small footprint and fast scan rate is the perfect companion at

your desktop. The build-in automatic document feeder allows 50 sheets of documents to be

scanned continuously at one time and achieves fast scan rate of 25 pages per minute in

simplex mode and 50 images per minute in duplex mode.

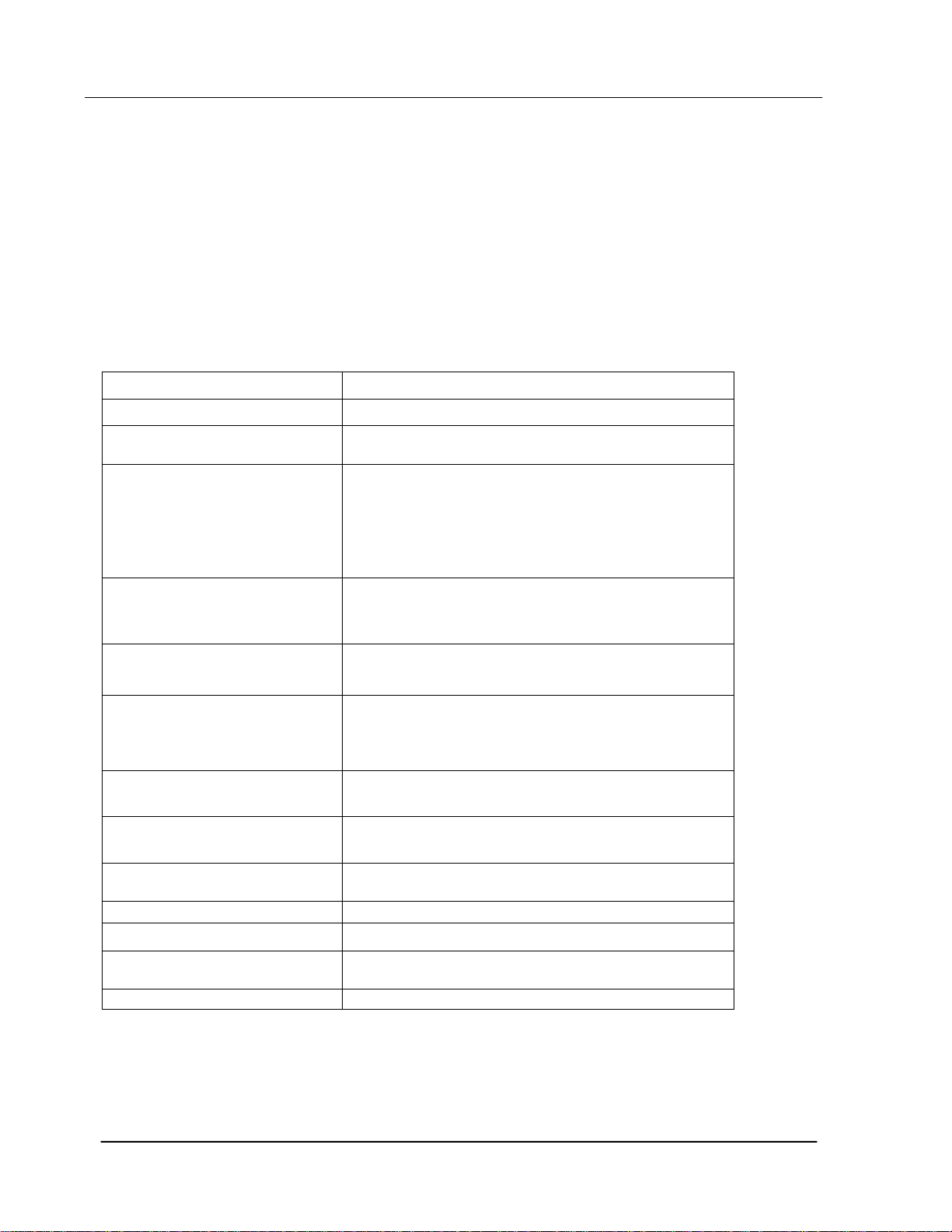

1.3 Basic Specifications

Type: Sheetfed scanner, duplex

Optical Resolution: 600 dpi

Color Depth: 48-bit Color (input)

24-bit Color (output) single pass color (R, G, B)

Image Type:

ADF Scan Speed:

(NONE Channel at 200dpi

B&W A4 size)

256 shades of gray scale

64 shades of gray for halftones

Line art (binary)

Error diffusion

8-bit Color

24-bit Color

25 pages per minute (simplex mode)

50 images per minute (duplex mode)

Scan Area:

Paper Size:

Paper Thickness: 16 – 28 lbs/0.002” ~ 0.006”

Paper Input (ADF): up to 50 sheets

Physical Dimension:

HxWxD

Weight: 4.3 kg

Interface: USB 2.0

Power Source: Input: 100~240V, AC, 50/60 Hz

Power Consumption: ≤ 30 Watts

ADF: minimum: 3.5” x 2” (88 x 50 mm)

ADF: maximum: 8.5”x 14” (215 x 355 mm)

ADF Max.: 8.5” x 14” (Legal)

ADF single page min.: 3.5” x 2”

ADF duplex multipage min.: 3.5” x 3.0”

6.37 x 13,2 x 6.5 inches (without tray)

(162.3 x 337.2 x 167.8 mm)

Output: 24V, DC, 2.0A

1-2

Page 6

Service Manual

2. UNPACKING, INSTALLATION, AND TRANSPORTATION

2.1 Precautions of Installation

2.2 Unpacking Procedure

2.3 Installation

2.4 Placing the Original

2.5 Transportation

2.1 Precautions of Installation

Pay attention to the following matters before unpacking and installation.

• Do not install in a place where vibration may occur.

• Keep the scanner out of direct sunlight. Do not install near a heat source.

• Do not place the scanner around materials which shut off the circulation of air.

• Do not install in a humid or dusty place.

• Use care not to scratch the glass surface of the scanner or the document holding

pad with a clip or staple.

• Do not use the wall socket with connecting devices which may generate noise, for

example, air-conditioner, etc.

• Use a suitable AC power source.

• Place the scanner on a level surface.

2.2 Unpacking Procedure

Unpack the scanner according to the following procedure.

• Remove the packing material.

• Remove the scanner from the shipping container.

• Remove the scanner from the PVC bag.

• Check the items by referring to Figure 2.1.

• For any missing items, please contact your nearest dealer or distributor.

Note: Keep all the packing material in case you may need to return the scanner.

2-1

Page 7

2

1

4 5

1. Main Unit

2. Input Paper Tray

3. Output Paper Tray

4. USB Cable

5. Power Adapter

6. Power Cord

Figure 2.1 Package Contents

3

6

2-2

Page 8

Service Manual

2.3 Installation

2.3.1 Installing the ADF Paper Tray

1. Attach the ADF Paper Tray to the clip joint of the scanner as indicated below. When

properly insert, you will hear a snap-in sound.

ADF Input

Paper Tray

Scanner

Clip Joint

Figure 2.2 Installing the ADF Paper Tray

2-3

Page 9

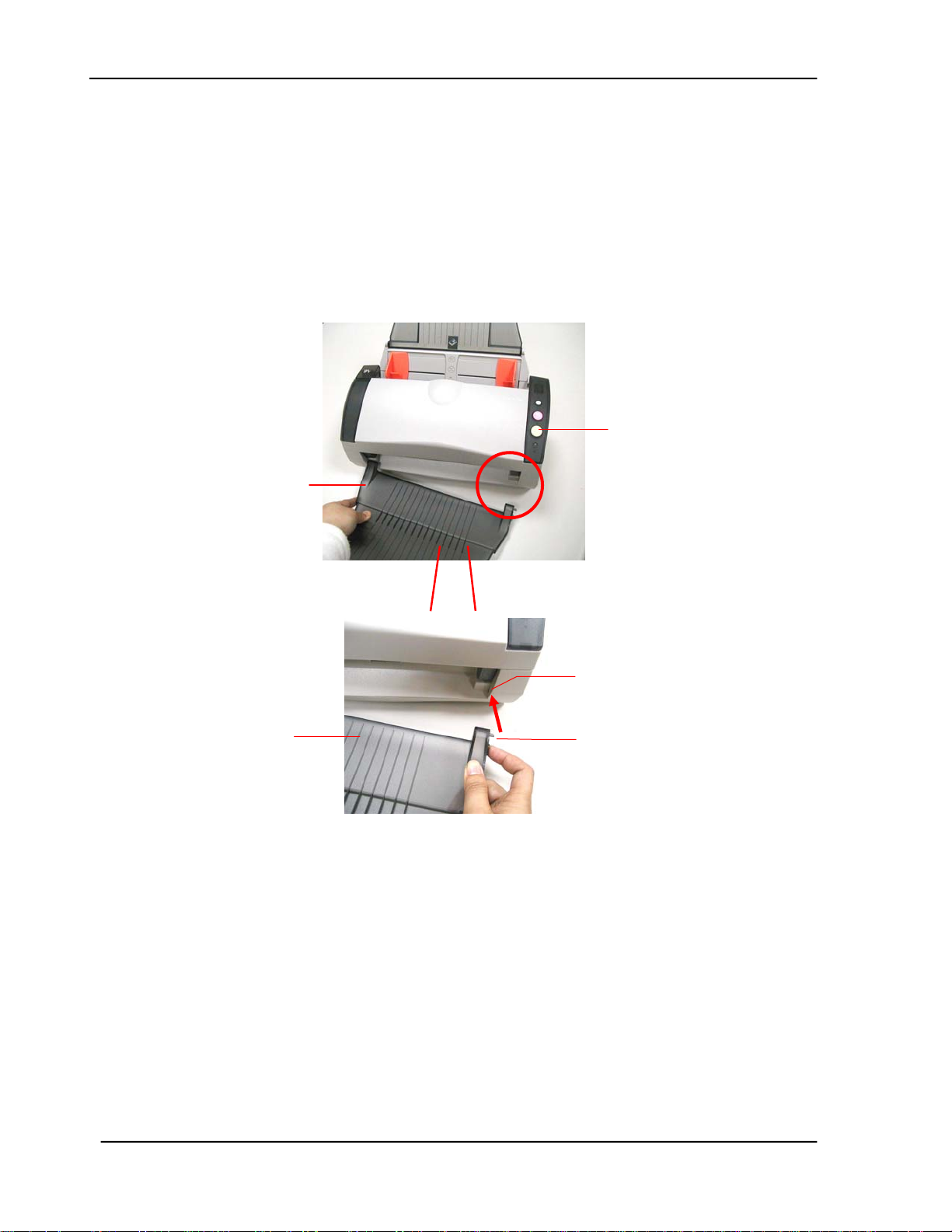

2.3.2 Installing the ADF Output Paper Tray

1. Hold the Output paper tray some 30 degrees as shown in below.

2. Insert the right protrusion of the Output Paper Tray into the hole on the front of the

scanner.

3. Insert the left protrusion of the Output Paper Tray slightly into the hole on the front of

the scanner.

Scanner

Output

Paper Tray

Output

Paper Tray

Hole

Protrusion

Figure 2.3 Installing the Output Paper Tray

2-4

Page 10

Service Manual

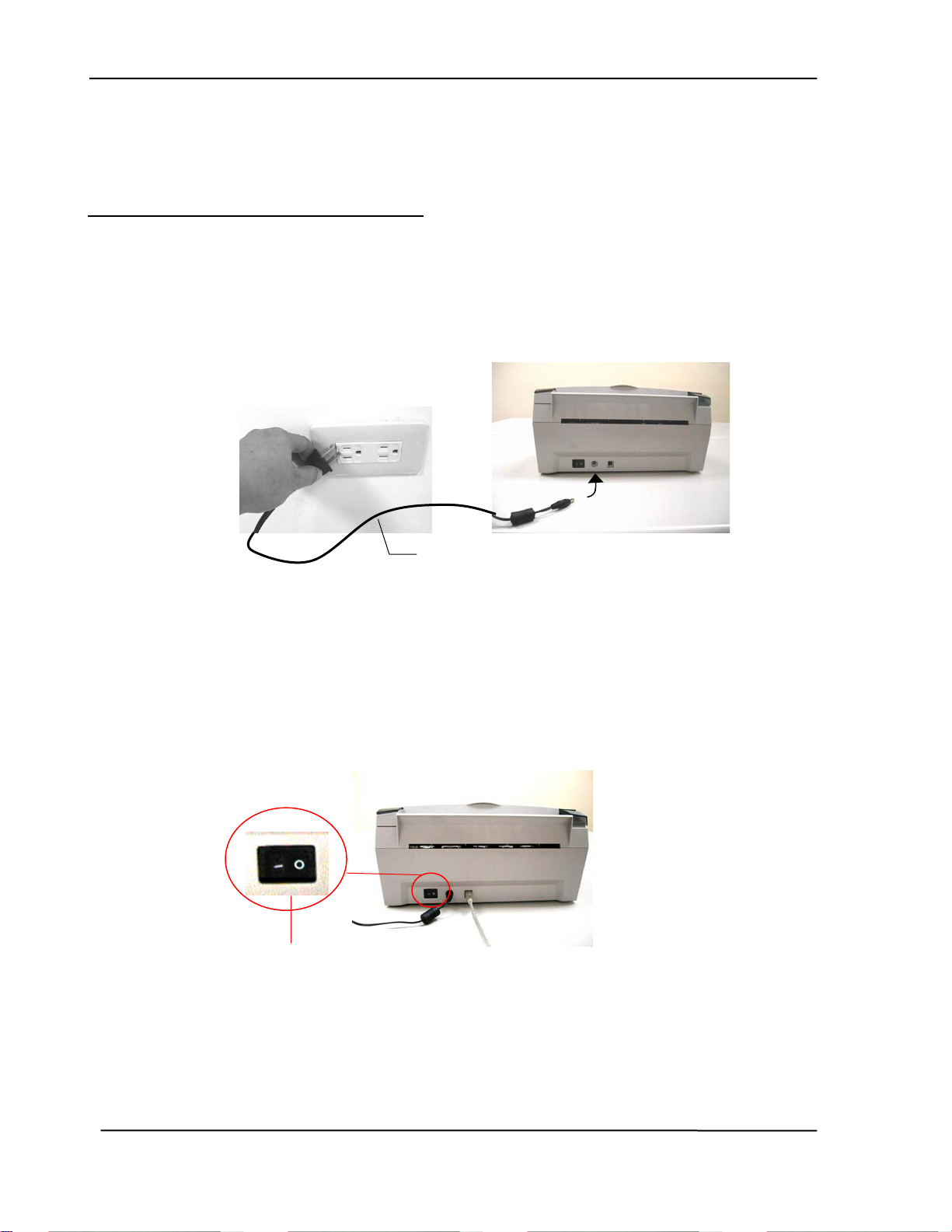

2.3.3 Connecting the Cables

Make sure the power of scanner is off.

2.3.3.1 Connecting to Power

Plug the small end of the power adaptor into the power jack of your scanner. Insert the

other end to an appropriate power outlet.

Power Cable

Figure 2.4 Installing the Power Cable

2.3.4 Turning on the Power

After the power cable and the USB cable have all connected, press the power switch to

the “I” position to turn on the scanner. To turn off the scanner, please press the power

switch to the “O” position.

Power Switch

Figure 2.5 Turn on the scanner

2-5

Page 11

2.4 Placing the original

Document feeding

Place your document with the text face down on the ADF Input Paper Tray. Align the

two sides of the document with the slide guides. Please note that the ADF Input Paper

Tray can hold up to 50-page document at a time.

Your

Document

(Face

Paper Slider

Figure 2.6 Place the document

2-6

Page 12

Service Manual

A

r

3. THEORY OF OPERATION

3.1 Introduction

3.2 Main Control Unit

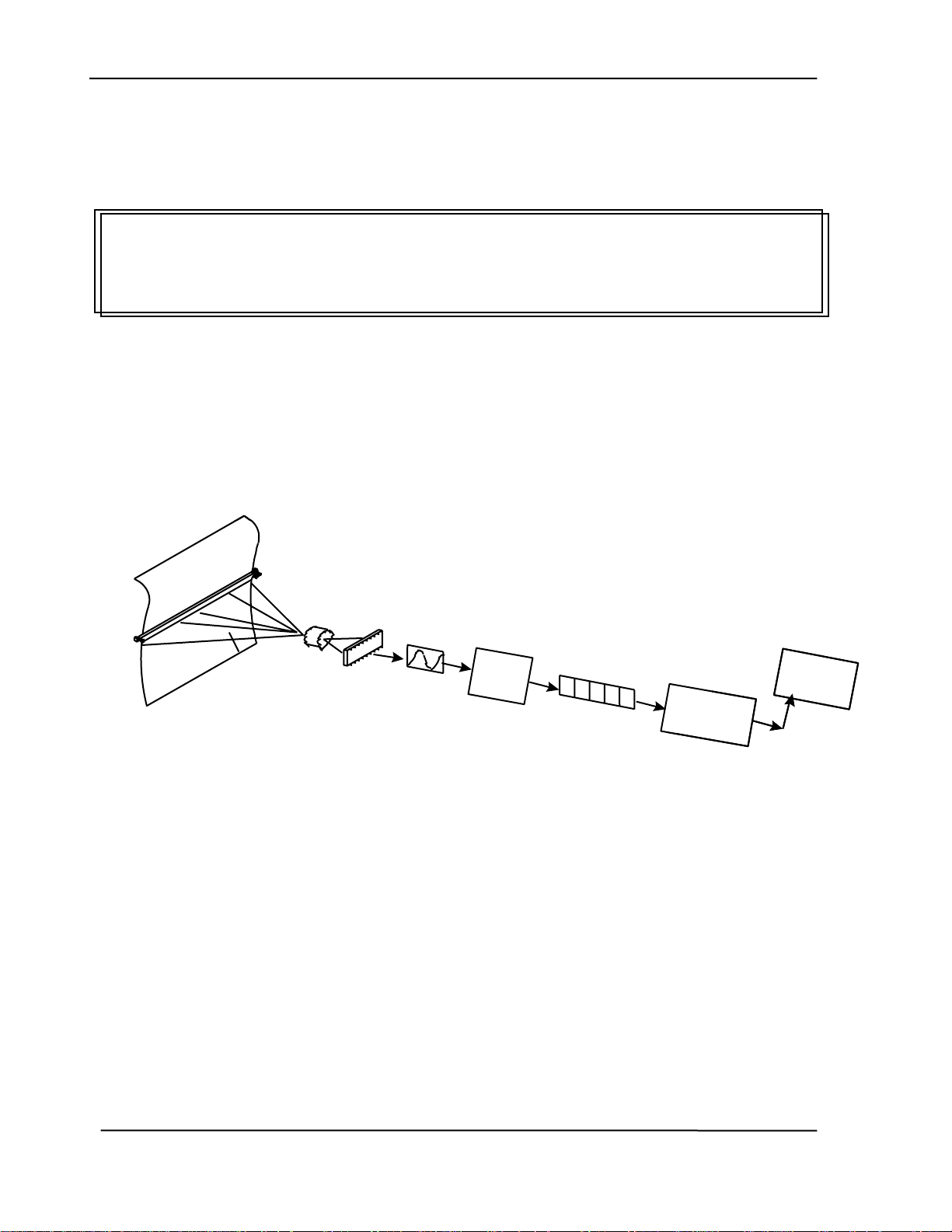

3.1 Introduction

Cold

The reflected rays of your original as shown in the above Figure 3.1 pass through the lens

and create an image on the CCD (Charged Coupled Device). Then, according to the

different light intensity perceived by the CCD, the CCD will transfer these data into a series

of analog signals to the main board, where the signals are turned into digital signals.

These digital signals flow to the USB 2.0 Controller to transfer to a host computer.

Reflecte

Reflected

Ray

Ray

Cold

Fluorescent

Fluorescent Lamp

Len

Len

CCD

CCD

Figure 3.1 Theory of Operation

Analogu

nalogue

Signa

Signal

Mai

Main

Boar

Board

Digital

Digital

Signa

Signal

1

1

0

0

0

0

Hos

1

1

0

0

USB 2.0

Controlle

Host

3-1

Page 13

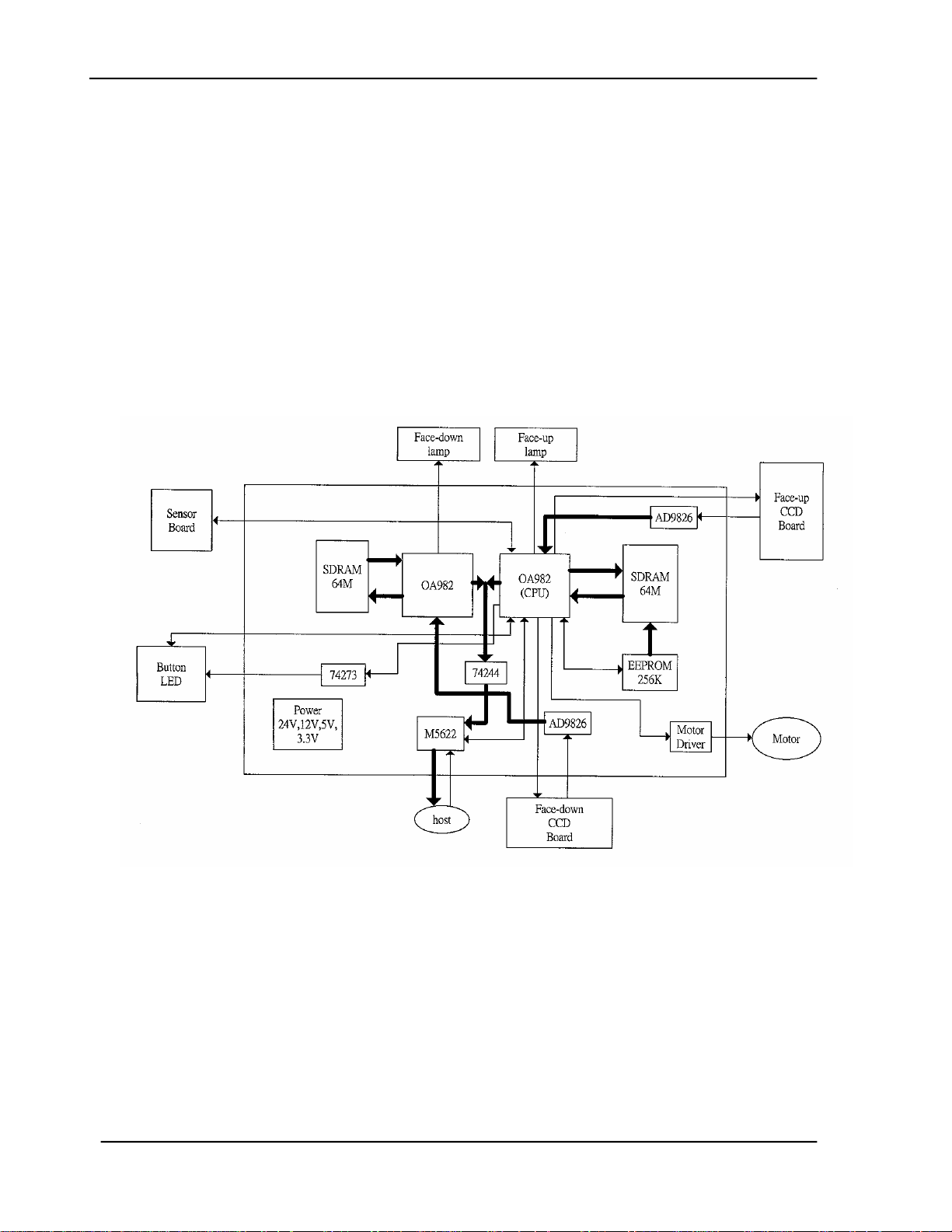

3.2 Main control unit

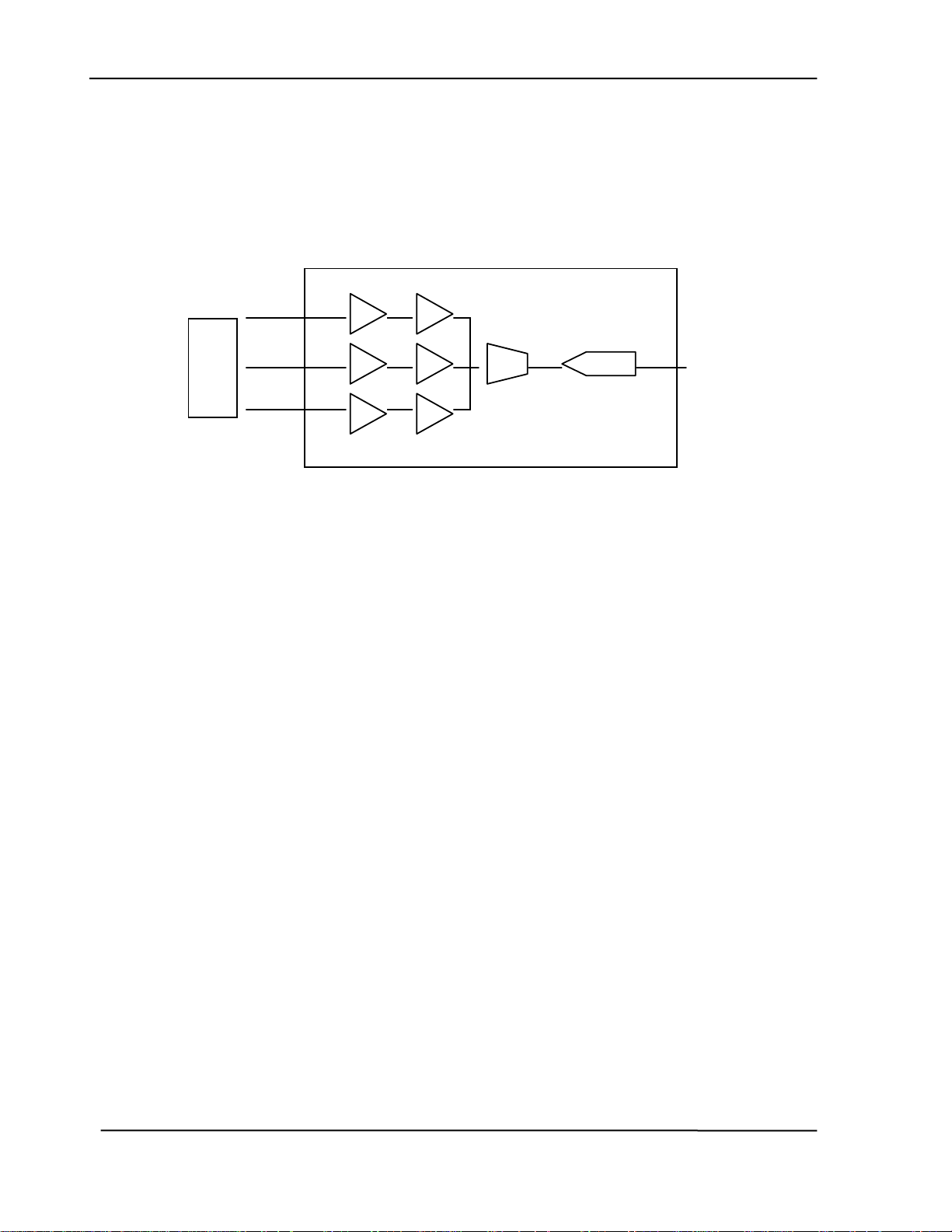

3.2.1 System diagram

Figure 3.2 System block diagram

3-2

Page 14

3.2.2 Main control circuit

This scanner is controlled by the 80C32. The 80C32 is configured with a 64-KB

external ROM program area, a 256-BYTE internal RAM work area, a 64-KB external

RAM work area, 2 timer / counters, 4 I/O ports, 2 external interrupts, and 2 internal

interrupts for 2 internal timer / counters.

Address Maps:

• ROM program area:

0000

FFFF

• Internal RAM working area:

00

FF

y External SRAM working area:

0000

FFFF

64KB Program

256-byte

Internal Registers

64 KB

External Program

Service Manual

3-3

Page 15

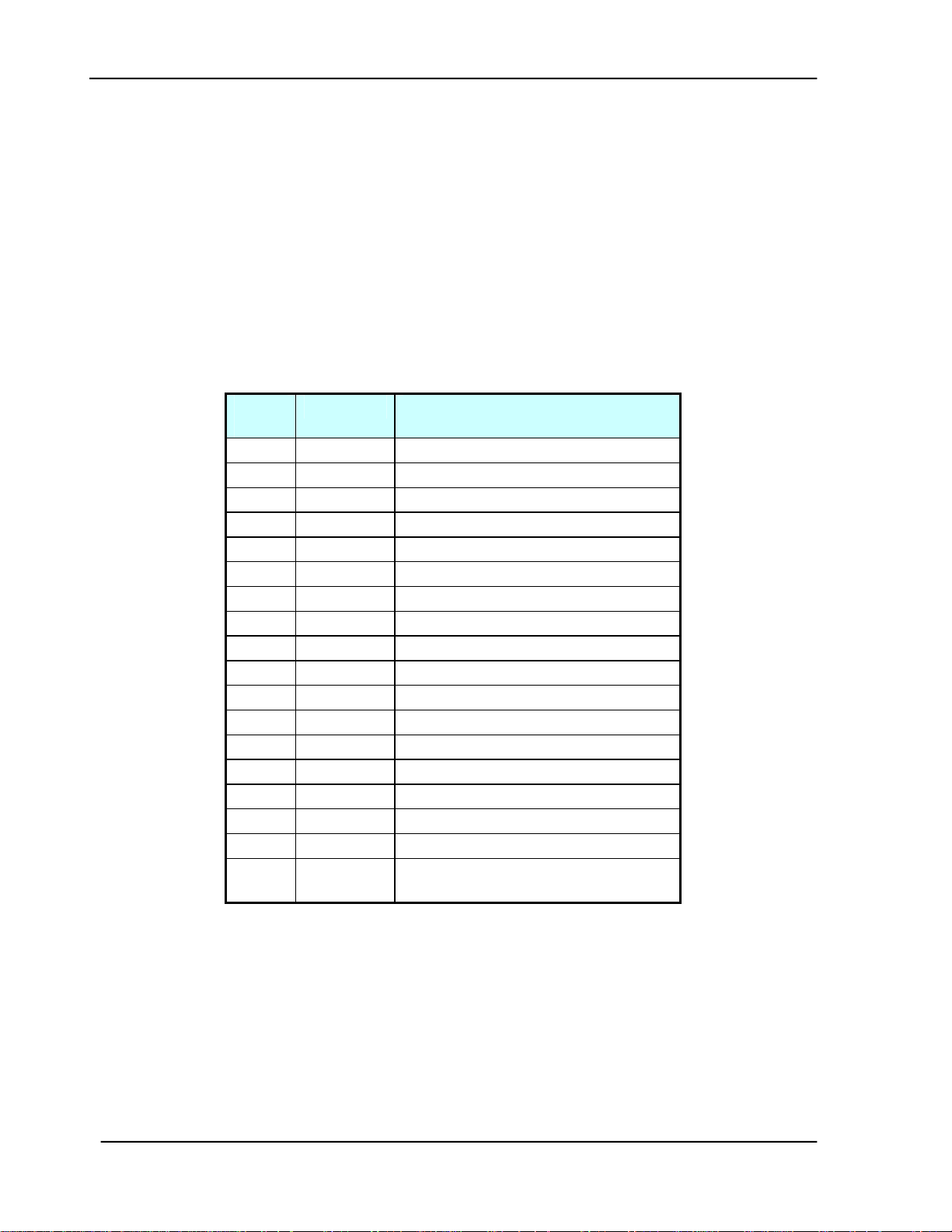

3.2.3 Video circuit:

The video circuit of the scanner includes: 1. CCD driving circuit, 2. CCD signal

processing circuit.

1. CCD Driving Circuit

The CCD driving circuit is used to generate correct signals to the CCD, so that the

CCD may generate the correct image data.

Signals for CCD:

Pin Assignment for CCD cable

Pin

No.

1 AG Analog Ground

2 VOR CCD Red Channel Output Signal

3 AG Analog Ground

4 VOG CCD Green Channel Output Signal

5 AG Analog Ground

6 VOB CCD Blue Channel Output Signal

7 AG Analog Ground

8 12VDC CCD Power Supply

9 SH CCD RGB Channel Shift Gate

10 PHI1 CCD Clock Phase

11 DG Digital Ground

12 PHI2 CCD Clock Phase

13 DG Digital Ground

14 RS CCD Reset Gate

15 DG Digital Ground

16 CP Clamp Gate

17 VCC Digital 5V Power Supply

18 SW Changeover Switch (color and

Name Function

B/W)

3-4

Page 16

Service Manual

2. CCD signal processing circuit

CCD

R

G

CDS

CDS

PGA

PGA

MUX ADC

Dout

B

CDS

PGA

CCD Signal Processor

The CCD signal processor includes all the necessary circuitry to perform threechannel conditioning and sampling. The signal chain consists of three-channel

correlated double sampling (CDS) and programmable gain adjustment of the CCD

output (PGA) is a 16 bit analog to digital connector (ADC) quantizes the analog

signal.

3-5

Page 17

3.2.4 LED and Push Button Module Circuit

The circuit for the LED and Push Button modules showes the function of the entire

scanner including the Error LED (Red), the Ready LED (Green) and the Push Button.

.

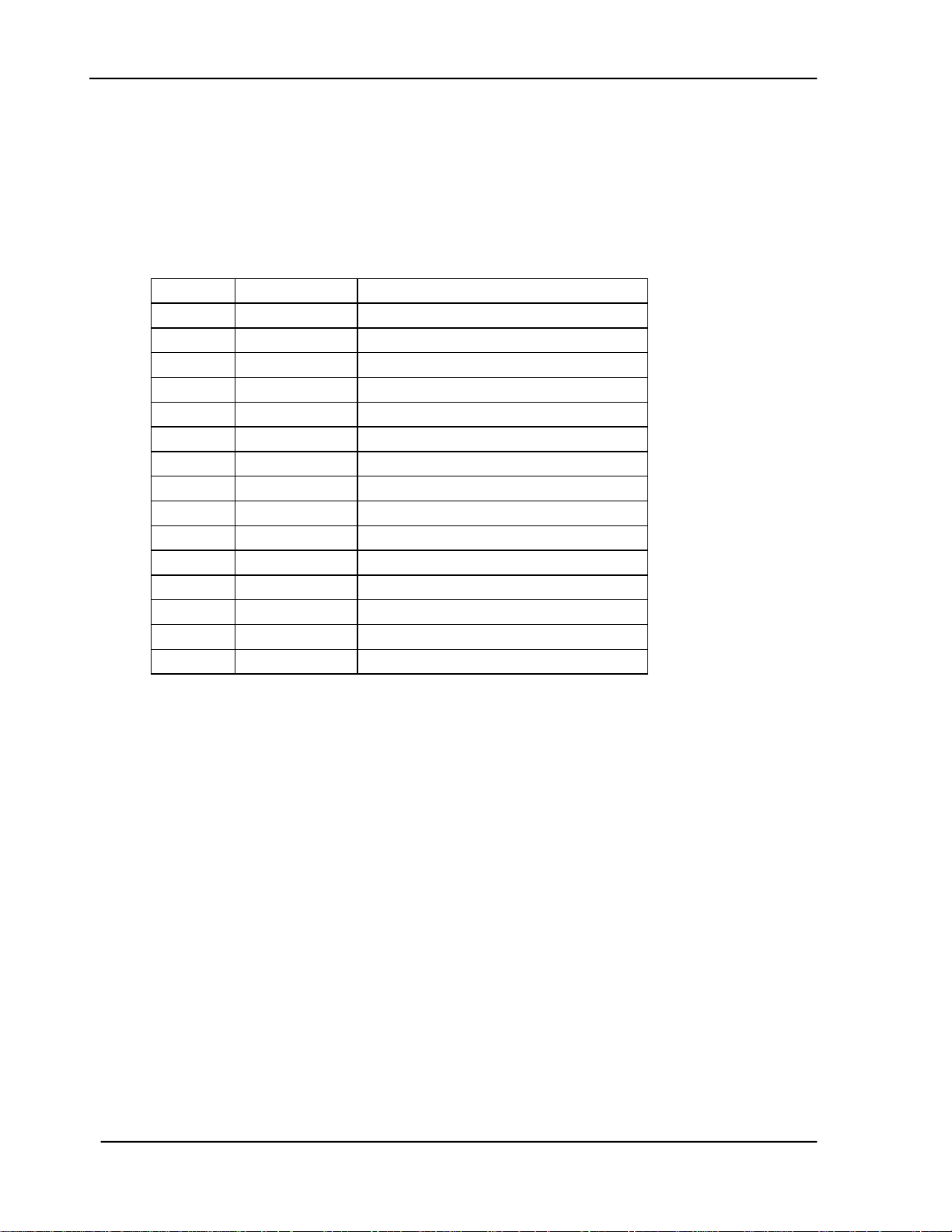

Pin assignment of LED module

Pin No. Name Function

1 Ground Ground

2 Ground Ground

3 Button Scan

4 Button Cancel

5 Button Function select

6 LED G Ready status indicator

7 LED R

8 Seven 1

9

10

11

12

13

14

15

Seven 2 Seven segment display

Seven 3 Seven segment display

Seven 4 Seven segment display

Seven 5

Seven 6 Seven segment display

Seven 7 Seven segment display

Seven 8 Seven segment display

Seven segment display

Seven segment display

Seven segment display

3-6

Page 18

V

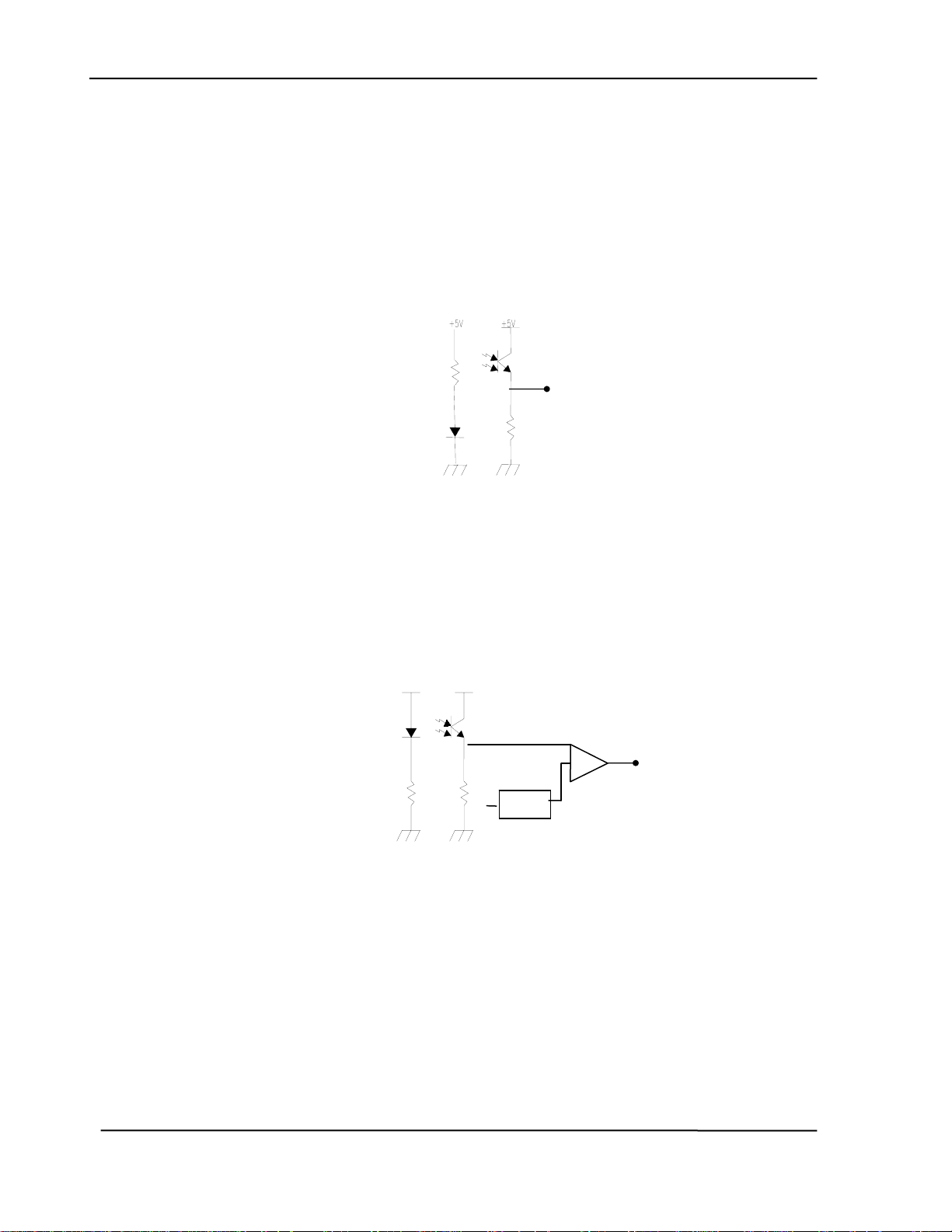

3.2.5 Sensor input

A. Photo_Sensor

The sensor input includes paper in/out sensor.

Paper In/Out sensor

The paper position is detected by photo sensor. The photo transistor transmission

to the photo sensor receiver circuit is shown below.

The paper in/out sensor is detected when the paper passes between the LED and the

photo transistor.

B. IR-Sensor

Service Manual

Out

Figure 3.3 Paper in/out sensor

+5V +5

Out

DAC

+

_

-

(OP)

Figure 3.4 IR_Sensor

3-7

Page 19

g

r

g

r

g

r

r

g

3.2.6 Sub power supply circuit

The sub power supply circuit is provided for the internal analog circuit. Input is

24V and output is Vcc and +5Va. The circuit configuration is shown below:

+24Vdc Vcc

+12V +5Va

+24Vdc +12V

Vcc +3.3V

The sub power supply is used for: A/D, and logic circuits.

Switching

ulato

Re

Linear

ulato

Re

Linear

ulato

Re

Linear

ulato

Re

3-8

Page 20

3.2.7 Power supply

In this system, there is only one type of power supply. Please see Table 3.1 for

details.

Characteristic

Input voltage range 100-240V

Input current (at the

rated input/output)

Input frequency 50-60Hz

Max. in-rush

current(@full load,

cold start)

Output voltage +24Vdc

Min. load current 0.0A

Max. load current 2A

Total power (at full

load)

Table 3.1 The Power Adapter

Type

Wall-mount

2A type or less

45A

30W

Service Manual

3-9

Page 21

4. PROBLEM SOLVING

4.1 Diagnostics

4.2 Troubleshooting

This chapter supplies two paths for dealing with operational problems. The first relies

on the scanner’s internal diagnostics. The second uses troubleshooting flowcharts and

tables to isolate the problem. In many cases, the internal diagnostics will help you to

locate the source of the problem quickly. Use these diagnostics first. If the

diagnostics do not locate the source of the problem, refer to Section 4.2

Troubleshooting.

4.1 Diagnostics

Service Manual

The scanner has internal diagnostics to help you determine the cause of operational

problems. Some of the diagnostics function with the scanner online, while others are

part of a separate offline diagnostics feature.

4.1.1 Online diagnostics

Determine operational problems by observing the display panel Error, Ready, and

Check LEDs. With the scanner online and operating normally, the Ready LED is on

and the Error LED is off. Any other Error LED indicates a problem, as shown in the

following table.

Ready LED Green LED On

Check LED Green LED Blinking

Error LED

Indication

Table 4.1 Online diagnostics

RED LED Blinking

(Group Error)

If the ADF cover is open, close it. For the group errors, see the flowcharts later in this

section.

4-1

Page 22

4.1.2 Offline diagnostics

To run the offline diagnostics, and turn the power back on. When you first turn the

scanner back on, the READY light will blink, indicating that the diagnostics are in

progress. Observe the front panel Error LED closely. In a short time, the Error LED

indicates the results of the offline diagnostics as explained in the table below.

Ready LED

(Green)

ON (No blinking) OFF OK (Ready)

OFF 1 Face down SDRAM failure

OFF 2 Face up DRAM failure

OFF 3 CPU DRAM failure

OFF 4 Face down DC offset adjust

OFF 5 Face up DC offset adjust failure

OFF 6 Cover open error

OFF 7 Face down light check failure

OFF 8 Face up light check failure

OFF 9 Paper jam

OFF 0 USB disconnect

Error LED (RED) Error Indication

failure

Table 4.2 Offline diagnostics results

For SRAM & DRAM error, refer to Main Control PCBA Replacement in Chapter 5. For the

Group 2 error, see the flowchart in the following section.

To return the scanner to online operation, turn off the scanner, turn the scanner back on.

4-2

Page 23

r

N

r

4.1.3 Diagnostic flowcharts

Use the flowcharts that follow to determine the exact problem when either the online

or offline diagnostics indicate a group error. Refer to Chapter 4 for parts replacement.

4.1.3.1 Group 1 error flowchart (CCFL assembly)

This flowchart applies when the Error LED shows number 7 and 8.

Group 1 Erro

Yes No

CCD error

Replace optical

assembly

CCFL is on?

Inverter erro

Replace lamp

inverter circuit

End of test

Yes

CCFL is on?

Replace the CCFL

o

Service Manual

4-3

Page 24

r

4.1.3.2 Group 2 error flowchart (paper in ADF paper tray)

This flowchart applies when the Ready LED is off and Error LED shows number 9

with the scanner online, and there is paper in the ADF paper tray.

Group 2 erro

Open cover and then

remove the papers from

ADF’s input paper tray,

and wait for 3 seconds

than close the cover.

Yes

ADF

motor

No

ADF paper-in sensor error Place paper in the ADF

Replace ADF paper-in

sensor or SB12 PCBA

paper tray and wait for 3

seconds

IR-sensor

error

Replace IR

sensor or

SB12

PCBA

Yes

Try again,

ADF motor

moves?

No

OK

OK

Yes

ADF m

moves

otor

?

No

IR-sensor error or

scanner inside

contains paper

4-4

Page 25

r

4.1.3.3 Group 3 error flowchart (no paper in ADF paper tray)

This flowchart applies when the Ready LED is off and Error LED shows number 6

with the scanner online, and there is no paper in the ADF paper tray.

Group 3 Error

Open cover, then close the

cove

No

Check Ready LED on?

Refer to the

Result in Table

3.2

Yes

OK

Place a piece of paper

into ADF Input Paper

Tray and waits for 3 secs.

Service Manual

4-5

Page 26

4.2 Troubleshooting

Refer first to the applicable troubleshooting flowchart in the following three sections.

The flowcharts refer you to the appropriate table for detailed troubleshooting.

4.2.1 Flowcharts

This section provides the following troubleshooting flowcharts:

• Troubleshooting from power on to scanner ready

• Online troubleshooting (ADF operation)

4-6

Page 27

Service Manual

N

N

4.2.1.1 Troubleshooting flowchart: power on to scanner ready.

Troubleshooting From Power on

Power

LED on

o

See Table 4.3

Cover open test

Yes

IR sensor test

DRAM Test

Face down SDRAM test

Face up SDRAM test

Face down light check

Face up light check

Warming-up Check

(Green LED Blinking)

Warming-

up Finish?

o

Wait for command

(Green LED on)

Yes

from host

4-7

Page 28

N

N

N

N

N

N

N

g

4.2.1.2 Troubleshooting flowchart: online ADF operation

Online Troubleshooting

(ADF mode)

Frequent

Paper Jam?

Yes

See Table 4.9

o

Frequent

double feed

Yes

See Table 4.10

o

Large skew

volume?

Yes

See Table 4.10

o

Large jitter

Yes

See Table 4.6

o

Reading

position

deviation?

Yes

See Table 4.7

Image

unclear

o

Yes

See Table 4.8

o

Strange

sound

enerated?

o

End

Yes

See Table 4.11

4-8

Page 29

4.2.2 Tables

The tables in this section provide detailed troubleshooting information.

4.2.2.1 The Power LED does not go on

Cause Relevant Unit Check Method

Unplugged from

outlet

AC power

unplugged at

unit

Power switch is

OFF

AC voltage

failure

Power unit AC

input connector

disconnected

Power switch

connector

disconnected

Power unit-main

PCBA connection

failure

Power unit

output voltage

failure

PCBA Failure Main control

LED board-main

PCBA connection

failure

None Visual check Insert the AC

None Visual check Insert the AC

None Visual check Turn the power

None AC outlet voltage

check

None Visual check Connect the

None Visual check Connect the

None Visual check Connect the

Power unit Output voltage

(+24V) check

Tester check

PCBA

LED board

None Visual check Connect the

(+24V, GND)

Maintenance

Method

plug into the

outlet.

cable into unit.

switch on.

None

connector.

connector.

connector.

Replace the

power unit

Remove the

cause or replace

the PCBA.

connector

Table 4.3

Service Manual

4-9

Page 30

4.2.2.2 Reading is not performed

Cause Relevant

Unit

ADF cover open ADF cover Visual check Close the ADF

4.2.2.3 Image does not appear

Cause Relevant

Unit

ADF cover

open

Power supplymain control

board

connection

failure

Power supply

fails.

Lamp failure Lamp Visual check Replace the

Inverter failure Inverter Visual check Replace the

CCD boardmain control

board

connection

failure

CCD board

fails.

ADF cover Visual check Close the ADF

None Visual check Connect the

Power supply Tester check

None Visual check Connect the

CCD Board Visual check Replace the

Check

Method

Table 4.4

Check

Method

(+24V, GND)

Table 4.5

Maintenance

Method

cover.

Maintenance

Method

cover

connector.

Replace the

power supply.

lamp.

inverter.

connector.

optical unit.

4-10

Page 31

4.2.2.4 Large jitter

Cause Relevant

Power supplymain control

board connection

failure

Power supply fails Power

Motor-main

control PCBA

connection failure

Motor failure Motor Visual check Replace the

Service Manual

Check Method Maintenance

Unit

None Visual check Connect the

Tester check

supply

None Visual check Connect the

(+24V, GND)

Table 4.6

Method

connector.

Replace the power

supply.

connector.

motor.

4-11

Page 32

4.2.2.5 Reading position deviation

Cause Relevant Unit Check Method Maintenance

Power supplymain control

board

connection

failure

Power supply

fails

Motor- main

control PCBA

connection

failure

Motor failure Motor Visual check Replace the

IR sensor

board- main

control PCBA

cable failure

IR sensor

board- main

control PCBA

cable failure

IR sensor

board (SB21)

failure

None Visual check Connect the

Power supply Tester check

None Visual check Connect the

None Visual check Connect the

Sensor boardmain control

PCBA cable

Sensor board Tester check Replace the

(+24V, GND)

Tester or visual

check

Method

connector.

Replace the

power supply.

connector.

motor

connector

Replace the IR

sensor cable

PCBA.

Table 4.7

4-12

Page 33

4.2.2.6 Image unclear

Cause Relevant Unit Check Method Maintenance

Method

Lamp too dark Lamp Visual check Replace with a

new lamp.

Dirt on calibration

reference plate

Dirt on calibration

reference plate

Dirt on the mirrors Mirrors Visual check Clean the

Dirt on the lens Lens Visual check Clean the lens

Calibration

reference plate

Calibration

reference plate

Visual check Clean the glass

with isopropyl

alcohol.

Visual check Clean the

calibration

reference plate

with isopropyl

alcohol.

mirrors with

isopropyl

alcohol.

with isopropyl

alcohol.

Table 4.8

4.2.2.7 Frequent paper jam

Cause Relevant

Unit

Paper setting

failure

Paper failure operation

Pad assembly

failure

Operation

error

error

Pad assembly Check the pad

Check

Method

Is the paper

correctly set in

the paper

chute?

Is the

specified

paper used?

assembly for

wear and tear

Maintenance

Method

Educate users

to properly

position the

paper.

None None

Replace the

pad assembly/

touch spring

unit.

Table 4.9

Service Manual

Remar

k

None

None

None

None

None

Remark

None

None

4-13

Page 34

4.2.2.8 Frequent double feed and skew

Cause Relevant

Unit

Paper setting

failure

Operation

error

Paper failure Operation

error

Pad assembly

Pad assembly Check the pad

failure

Check

Method

Is the paper

correctly set in

the paper

chute?

Is the

specified

paper used

assembly for

wear and tear.

Table 4.10

4.2.2.9 Strange sound generated (ADF)

Cause Relevant

Check Method Maintenance

Unit

Paper setting

failure

Operation

error

Is the paper

correctly set in

the paper chute?

paper failure Operation

error

Is the specified

paper used?

Table 4.11

Maintenance

Method

Teach users to

properly position the

paper

None

Replace the pad

assembly/ touch

spring unit.

Method

Teach users to

properly position

the paper

None

4-14

Page 35

5. DISASSEMBLY

5.1 Service Tools

5.2 Lubricants

5.3 Procedure for Disassembly and Reassembly

5.1 Service Tool

Service Manual

Table 5.1 describes the maintenance tools necessary for the maintenance of this

equipment.

No

Name Description

.

1 Minus screwdriver Idler pulley module screw

2 Philips screwdriver

(magnetic)

3 Oil Shell “Terrace Oil 46”

4 Grease Shell “Alvania Grease No.2”

5 Alcohol (Isopropyl 91% >) Cleaning

6 Digital voltmeter With 0.01 V range

7 Oscilloscope 100 MHz or more with

Nominal No.2 M3, M4

external sweep

Table 5.1 Maintenance tools

5-1

Page 36

5.2 Cleaning the ADF

From time to time the pad assembly and feeding rollers may become

contaminated with ink, toner particles or paper dust. In this case the scanner

may not feed documents smoothly. If this occurs please follow the cleaning

procedures to return your machine to its original state.

The Cleaning Procedures

1) Soak a cotton swab with some isopropyl alcohol. (95%).

2) Press the ADF Release button on the upper-left. Open the front door slightly to

the left. Wipe the upper feeding roller by moving the swab from side to side.

Rotate the roller forward with your finger and repeat the cleaning steps above

until the entire roller is cleaned.

3) Wipe the ADF pad in one direction from top to bottom or the other way around.

Be careful not to damage the pick springs.

4) Close the scanner front door. Your scanner is now ready for use.

ADF Release

button

ADF Pad

Feeding Roller

5-2

Page 37

Service Manual

5.3 Cleaning the Calibration Area

1. Press the Paper Jam Clearing button. Open the front door to the left.

2. Wet a cotton swab with some isopropyl alcohol. (95%)

3. Wipe the glass and the white area as illustrated in below by moving the swab from side

to side to rid the dust or dirt.

Calibration

Area

Glass

ADF Front Door

5-3

Page 38

5.4 Procedure for disassembly and reassembly

5.4.1 Notes on disassembly

(1) Clean the disassembly and assembly location.

(2) Disconnect the power cable and remove the AC plug from the outlet before

disassembly and assembly.

(3) Follow the disassembly and assembly procedures. Never loosen the screws of

parts that must not be disassembled.

(4) Store the disassembled parts in a clean place to avoid loss.

(5) After replacement, check the contacts and spare part mounting.

(6) Assemble the parts in reverse order of disassembly procedure.

5-4

Page 39

Service Manual

5.4.2 Removing the Upper Housing

1. Hold the Output Paper Tray and push your finger inwardly to remove the Output Paper

Tray.

2. Hold the Input Paper Tray and lift the Tray to remove it.

3. Press the ADF release button to open the cover.

4. Remove 2 fixing screws.

5. Unscrew the 4 fixing screws on the upper housing.

6. Remove the Upper Housing.

Press inwardly to remove Remove Input Paper Tray

the Output Paper Tray

Press the ADF release button Remove 2 fixing screws

5-5

Page 40

Remove 4 fixing screws Remove the upper housing

5-6

Page 41

5.4.3 Removing the Upper Optical Assembly

1. Press the Paper Jam Release Button to open the cover.

2. Loosen 2 fixing screws on the upper case.

3. Remove the fixing sponge.

4. Loosen 2 fixing screws on the left side.

5. Loosen 1 fixing screw on the right side.

Service Manual

Paper Jam

Released Button

Sponge

Fixing Screw x 2

Fixing screws x 2

5-7

Page 42

6. Disconnect the inverter cable with red and black colors.

7. Disconnect the lamp inverter cable (in white color) to remove the inverter.

Fixing Screw x 1

Inverter Cable

Power cable

Inverter

5-8

Page 43

Service Manual

5.4.4 Removing the Upper Optical Chassis

1. Remove the inverter in the upper optical assembly. (See preceding section 5.3.3)

2. Disconnect two cables on the optical chassis.

Cables

Optical Chassis

CCD Board

Note:

During assembling or disassembling procedure, please pay special attention not to touch the

CCD board on the optical chassis. Otherwise, the scanning quality may be affected.

5-9

Page 44

5.4.5 Removing the Lamp in Upper Optical Assembly

1. Remove the upper optical chassis. (See preceding section 5.3.4)

2. Loosen two fixing screws on the lamp cover.

3. Use a flat screwdriver to loosen the lamp assembly.

4. Gently remove the lamp assembly.

Fixing Screw x 2

Lamp assembly

Flat screwdriver

5-10

Page 45

Service Manual

5.4.6 Removing the ADF Pad

Use your fingers to press two sides of the ADF pad and lift the pad on the upper optical

assembly to remove it.

ADF Pad

5-11

Page 46

5.4.7 Removing the Main Control Board

1. Unscrew 1 fixing screw on the right side.

2. Unscrew 2 fixing screws on the left side and close the cover.

3. Raise the main unit and disconnect the motor cable and flat cable.

4. Unscrew all fixing screw.

5. Disconnect all cables.

6. Remove 4 fixing screws on the main board.

Remove one fixing screw on the right

side

Raise the main unit a bit

Remove two fixing screws on the left side

Disconnect flat cable

Disconnect cables

Disconnect motor cable

5-12

Page 47

Service Manual

Power cable

2 Fixing

screw

2 fixing

screw

Remove 4 fixing screw and disconnect the power cable

The main board

5-13

Page 48

5.4.8 Removing the Motor in Lower Optical Assembly

1. Turn the scanner over.

2. Remove 2 fixing screws on the external side of the metal plate.

3. Remove the motor.

Remove 2 fixing screws

The motor

5-14

Page 49

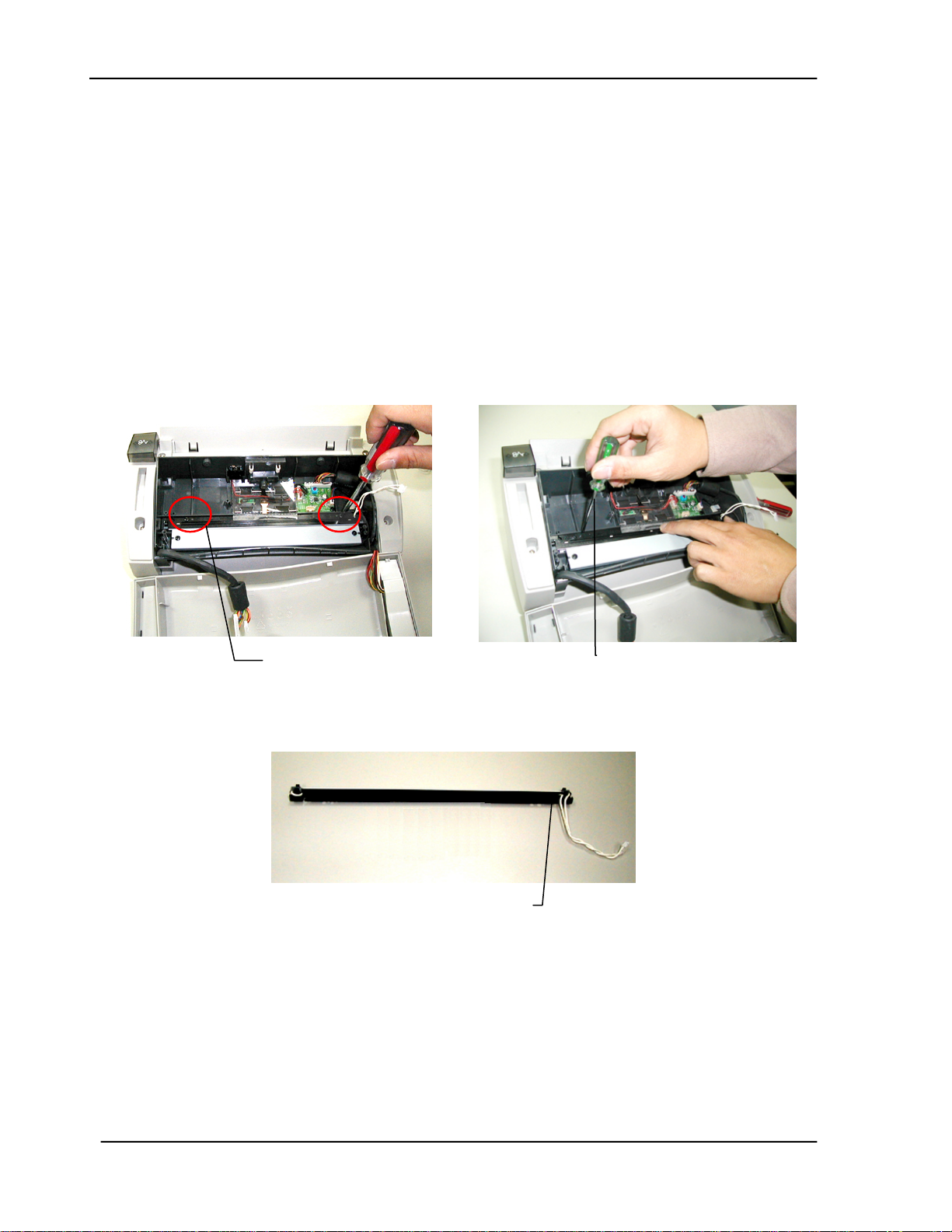

5.4.9 Removing the Inverter in the Lower Optical Assembly

1. Cut the cable bondage.

2. Remove the inverter from the plastic fixing plate.

3. Disconnect the inverter cable.

Service Manual

Inverter

The inverter

cable

Release the inverter from the plastic plate and disconnect the inverter cable

The inverter

5-15

Page 50

5.4.10 Removing the Lower Optical Chassis

1. Remove 2 fixing screws on the left and external side of the metal plate.

2. Remove 2 fixing screws on the right and internal side of the metal plate.

3. Remove the Optical Chassis.

Remove 2 fixing screws on the left external side Remove 2 fixing screws on the right internal side

Optical Chassis

5-16

Page 51

5.4.11 Removing the Lamp in the Lower Optical Assembly

1. Remove 2 fixing screws on the lamp assembly.

Service Manual

2. Remove the lamp.

Remove 2 fixing screws on the lamp assembly

The lamp assembly

5-17

Page 52

6. PARTS

6.1 Spare Part Diagram/Table

6.1 Spare part diagram

Service Manual

6-1

Page 53

6-2

Page 54

Service Manual

6-3

Page 55

Xerox DocuMate 252 Spare Parts List:

XEROX DocuMate 252

SERVICE PARTS TABLE

VISIONEER P/N

DESCRIPTION

65-0247-000

OPTICAL, LOWER, W/LAMP

65-0295-000

ASS'Y, LOWER OPTICAL: FOR FACE-DOWN

65-0296-000

ASS'Y, LAMP MOUNT, FACE DOWN

65-0248-000

INVERTER

65-0249-000

ROLLER, FEED, PAPER IN

65-0250-000

ASS'Y, MOTOR

65-0251-000

ASS'Y, PAPER PATH LOWER

65-0242-000

OPTICAL, FACE DOWN, W/LAMP, GREEN CCD

65-0297-000

ASS'Y, OPTICAL, FACE DOWN, TRANSTION

65-0298-000

ASS'Y, LAMP, FACE DOWN

65-0248-000

INVERTER, 24VDC

65-0252-000

ASS'Y, PAPER GUIDE, UPPER, W/O LAMP

65-0253-000

PCBA, LB47

65-0299-000

CABLE: 2/2 HOUSING,

65-0300-000

CABLE: 12P

65-0254-000

ROLLER, FEED, PAPER OUT

65-0255-000

BEARING COVER HINGE

65-0256-000

HOUSING, BOTTOM

65-0302-000

PCBA

65-0303-000

POWER S/W 5 pin

65-0304-000

ASS'Y, COVER UNIT

65-0305-000

ASS'Y, UPPER HOUSING

57-0104-000

ASS'Y, ADF INPUT TRAY / DM252

57-0105-000

ASS'Y, PAPER OUTPUT TRAY / DM252

65-0306-000

OPTICAL, UPPER, W/LAMP

65-0307-000

ASS'Y, OPTICAL, UPPER

65-0308-000

ASS'Y, LAMP MOUNT, FACE UP

65-0258-000

INVERTER (CCFL-T)

65-0310-000

OPTICAL, FACE UP, W/LAMP, GREEN CCD

65-0311-000

ASS'Y, OPTICAL, FACE UP, TRANSITION

65-0312-000

ASS'Y, LAMP

ACCESSORIES

65-0313-000

EPS FOAM, L: 310x278x160

65-0314-000

EPS FOAM, R: 310x278x160

65-0259-000

ADAPTOR, WITH EMI CORE

35-0071-000

AC POWER CORD, UL/CSA, PLUG

65-0497-000

AC POWER CORD: EUR

65-0498-000

AC POWER CORD: UK

65-0499-000

USB 2.0 CABLE

65-0500-000

S/W PACKAGE

65-0501-000

S/W PACKAGE: EUR/UK (EFIGS)

65-0502-000

CARTON: 470x290x340, A/F

Page 56

Xerox DocuMate 262 Spare Parts List:

XEROX DocuMate 262 GREEN

SERVICE PARTS TABLE

VISIONEER P/N

DESCRIPTION

65-0372-000

S-PARTS: ASS'Y, PAPER GUIDE, UPPER W/O LAMP, RoHS

65-0322-000

S-PARTS: PCBA: LBA69, RoHS

65-0299-000

S-PARTS: CABLE: 2/2 HOUSING, 14P+6P, P=2.0mm, L=420mm,

28AWG,聯 穎, W/TUBE, W/CORE, RoHS

65-0324-000

S-PARTS: CABLE: 2 HOUSING, 12P/12P, P=2.0mm, L=420mm, 28AWG,

1500.002147.00, 聯穎, W/TUBE, RoHS

65-0377-000

S-PARTS: PCBA: SBA45, IR Sensor Board, RoHS

65-0326-000

S-PARTS: PCBA: SBA51, RoHS

65-0328-000

S-PARTS: ASS'Y,SENSOR:SG-413JAV01,3P,P=2.0mm,L=120mm,RoHS

65-0380-000

S-PARTS:SHEET,CALIBRATION,UPPER,230X6.5X0.3T,MELINEX

329,210,(5PCS),RoHS

65-0255-000

S-PARTS: BEARING COVER HINGE, OD=13, ID=10, POM, WHITE, RoHS

65-0331-000

S-PARTS: Screw & Damper, For Optical module, (1SET=10PCS), RoHS

65-0332-000

S-PARTS: ASS'Y, OPTICAL, FACE UP, W/LAMP(002-3087-0),

W/INVERTER(005-0021-09), RoHS

65-0384-000

S-PARTS: ASS'Y, OPTICAL, FACE UP, RoHS

65-0312-000

S-PARTS: ASS'Y, LAMP, FACE UP, RoHS

65-0335-000

S-PARTS: INVERTER: 24V, 6mA, 35KHz, XAD355SR-1, TDK, RoHS

65-0336-000

S-PARTS: ASS'Y, OPTICAL, FACE DOWN, W/LAMP( 002-3343-0),

W/INVERTER (005-0022-09), RoHS

65-0337-000

S-PARTS: ASS'Y, OPTICAL, FACE DOWN, RoHS

65-0398-000

S-PARTS: ASS'Y, LAMP, FACE DOWN, RoHS

65-0339-000

S-PARTS: INVERTER:24V,6mA,35KHz,XAD3552,TDK,WIRE:200mm,RoHS

65-0340-000

S-PARTS: ASS'Y, PAPER GUIDE, LOWER,W/O LAMP(002-3343-0),RoHS

65-0341-000

S-PARTS: BELT, 58T, MXL, W=4.8, (10PCS), RoHS

65-0250-000

S-PARTS: ASS'Y, MOTOR, RoHS

65-0343-000

S-PARTS: ASS'Y, RELEASE HOOK, RoHS

65-0395-000

S-PARTS: ASS'Y, ADF ROLLER, RoHS

65-0254-000

S-PARTS: ROLLER, FEED, PAPER OUT, φ14.5, EPDM, 298.5, RoHS

65-0347-000

S-PARTS: BELT, 65T, MXL, W=4.8, (10PCS), RoHS

65-0249-000

S-PARTS: ROLLER, FEED, PAPER IN, φ14.5, EPDM, 316.25, RoHS

65-0349-000

S-PARTS: IDLE ROLLER, φ10.4x16, (8 PCS), RoHS

65-0350-000

S-PARTS: BELT, 68T, MXL, W=4.8, (10PCS), RoHS

65-0351-000

S-PARTS: IDLE PULLEY, 11x25, POM+鐵氟龍, (1SET=10PCS), RoHS

65-0352-000

S-PARTS: MOUNT, IDLE SECC, (1SET=10PCS), RoHS

65-0404-000

S-PARTS: ASS'Y, COVER TOP UNIT, RoHS

65-0258-000

S-PARTS: ASS'Y, ADF INPUT TRAY

65-0305-000

S-PARTS: ASS'Y, UPPER HOUSING, RoHS

65-0356-000

S-PARTS: FFC CABLE:18P, P=1.0mm, L=160mm, FF-18-1.0-C-160D(4/4/8/8)AA,今皓, 兩端導體不同面, RoHS, (5 PCS)

65-0408-000

S-PARTS: PCBA, MB325 WITH FW (259-0147-1), RoHS

Page 57

65-0256-000

S-PARTS: HOUSING, BOTTOM, ABS, 2.5t,337x168x100, SILVER, RoHS

65-0359-000

S-PARTS: ASS'Y, POWER S/W: GF037RA-090,驊 陞, 5P, P=2.5mm,

L=50mm, W/TUBE, RoHS

57-0105-000

S-PARTS: ASS'Y, PAPER OUTPUT TRAY

ACCESSORIES

65-0094-000

S-PARTS: ADAPTER:DESK-TOP,IEC 320-C6,3P,100~240Vac,4Vdc,

2A,48W,HEG42-240200-7L(A)LF, HITRON(海昌),CLASS I, ENER, RoHS

65-0413-000

S/W PACKAGE,RoHS

65-0365-000

S-PARTS: USB CABLE: USB A(M)/B(M), 4P, L=1850mm, UL2725

28AWG, SV-0411016, 昇文, COLOR:透明, W/CORE, RoHS

65-0182-000

S-PARTS: AC POWER CORD, EUR.(CEE), 2P+G. BASE, 16A/250V,

L=1800mm, 3C*0.75mm2, BLACK,良維, PG8B9CIJG0A-05B, RoHS

65-0097-000

S-PARTS: AC POWER CORD: US, 3P, 10A/125V, L=1800mm,

3C*18AWG, BLACK,良 維, PH8B2EDJF0A-05B, RoHS

65-0183-000

S-PARTS: AC POWER CORD, UK (BS/PSB),3 P, 3A/250V, L=1800mm,

3C*0.75mm2, BLACK,良 維, PG8B9X3JG0A-05B, RoHS

65-0369-000

FOAM, EPS, L:310x278x160,發泡倍率:62.5,白色, RoHS

65-0370-000

FOAM, EPS, R:310x278x160,發泡倍率: 62.5,白色, RoHS

65-0420-000

CARTON: 470x290x340, A/F, RoHS

Page 58

Xerox DocuMate 272 Spare Parts List:

XEROX DocuMate 272 GREEN

SERVICE PARTS TABLE

VISIONEER

P/N

DESCRIPTION

65-0320-000

S-PARTS: ASS'Y, PAPER GUIDE, UPPER, W/O LAMP (002-3087-0), RoHS

65-0322-000

S-PARTS: PCBA: LBA69, RoHS

65-0299-000

S-PARTS: CABLE: 2/2 HOUSING, 14P+6P, P=2.0mm, L=420mm, 28AWG,聯

65-0324-000

S-PARTS: CABLE:2 HOUSING, 12P/12P

65-0325-000

S-PARTS: PCBA:SBA45, IR Sensor Board,RoHS

65-0326-000

S-PARTS: PCBA: SBA51, RoHS

65-0327-000

PARTS: CABLE: 3P/4P, P=2.0mm, L=730mm, 28AWG, T105005020503, TC&C,

W/TUBE

65-0328-000

S-PARTS: ASS'Y,SENSOR:SG-413JAV01,勁昇,3P,P=2.0mm,L=120mm,RoHS

65-0380-000

S-PARTS: SHEET,CALIBRATION,UPPER,230X6.5X0.3T,MELINEX 329,210

65-0255-000

S-PARTS: BEARING COVER HINGE, OD=13, ID=10, POM, WHITE, RoHS

65-0331-000

S-PARTS: Screw & Damper, For Optical module, (1SET=10PCS), RoHS

65-0332-000

S-PARTS: ASS'Y, OPTICAL, FACE UP,W/LAMP (002-3087-0),W/INVERTER

65-0333-000

S-PARTS: ASS'Y, OPTICAL, FACE UP, RoHS

65-0312-000

S-PARTS: ASS'Y, LAMP, FACE UP, RoHS

65-0335-000

S-PARTS: INVERTER: 24V, 6mA, 35KHz, XAD355SR-1, TDK, RoHS

65-0336-000

S-PARTS: ASS'Y,OPTICAL,FACE DOWN,W/LAMP(002-3343-0)w/INVERTER

65-0337-000

S-PARTS: ASS'Y, OPTICAL, FACE DOWN, RoHS

65-0298-000

S-PARTS: ASS'Y, LAMP, FACE DOWN, RoHS

68-0339-000

S-PARTS: INVERTER: 24V,6mA,35KHz,XAD355-2,TDK,WIRE:200mm,RoHS

65-340-000

S-PARTS: ASS'Y, PAPER GUIDE, LOWER, W/O LAMP (002-3343-0), RoHS

65-0341-000

S-PARTS: BELT, 58T, MXL, W=4.8, (10PCS), RoHS

65-0250-000

S-PARTS: ASS'Y, MOTOR, RoHS

65-0343-000

S-PARTS: ASS'Y, RELEASE HOOK, RoHS

65-0395-000

S-PARTS: ASS'Y, ADF ROLLER, RoHS

65-0254-000

S-PARTS: ROLLER, FEED, PAPER OUT, φ14.5, EPDM, 298.5, RoHS

65-0347-000

S-PARTS: BELT, 65T, MXL, W=4.8, (10PCS), RoHS

65-0249-000

S-PARTS: ROLLER, FEED, PAPER IN, φ14.5, EPDM, 316.25, RoHS

65-0349-000

S-PARTS: IDLE ROLLER, φ10.4x16, (8 PCS), RoHS

65-0350-000

S-PARTS: BELT, 68T, MXL, W=4.8, (10PCS), RoHS

65-0351-000

S-PARTS: IDLE PULLEY, 11x25, POM+鐵氟龍, (1SET=10PCS), RoHS

65-0352-000

S-PARTS: MOUNT, IDLE SECC, (1SET=10PCS), RoHS

65-0353-000

S-PARTS: ASS'Y, TOP COVER

57-0104-000

S-PARTS: ASS'Y, ADF INPUT TRAY

65-0305-000

S-PARTS: ASS'Y, UPPER HOUSING, RoHS

65-0356-000

S-PARTS: FFC CABLE: 18P, P=1.0mm, L=160mm, FF-18-1.0-C-160-D

(4/4/8/8)AA

65-0357-000

S-PARTS: PCBA, MB325 WITH FW (259-0148-1), RoHS

65-0358-000

S-PARTS: HOUSING, BOTTOM, ABS, 2.5T, 337x168x100, SILVER

65-0359-000

S-PARTS: ASS'Y, POWER S/W: GF037RA-090

57-0105-000

S-PARTS: ASS'Y, PAPER OUTPUT TRAY

65-0361-000

S-PARTS: ASS'Y, INPUT TRAY, REAR, RoHS

Page 59

65-0362-000

S-PARTS: PCBA, SBA53, BACK-SENSOR, RoHS

ACCESSORIES

65-0094-000

S-PARTS: ADAPTER: DESK-TOP, IEC 320-C6, 3P 100-240VAC, HITRON

65-0364-000

S/W PACKAGE, RoHS

65-0365-000

S-PARTS: USB CABLE:USB A(M)/B(M),4P,L=1850mm,UL2725 28AWG,SV-

65-0182-000

S-PARTS: AC POWER CORD, EUR.(CEE), 2P+G.

65-0097-000

S-PARTS: AC POWER CORD:US,3P,10A/125V,L=1800mm,3C*18AWG,BLK

65-0183-000

S-PARTS: AC POWER CORD UK

65-0369-000

FOAM, EPS, L:310x278x160,發泡倍率:62.5,白色, RoHS

65-0370-000

FOAM, EPS, R:310x278x160,發泡倍率: 62.5,白色, RoHS

65-0371-000

CARTON: 470x290x340, A/F, RoHS

Loading...

Loading...