Page 1

Version 1.0

August 2009

DocuColor® 7002/8002

System Administration Guide

Page 2

©

2009 Xerox Corporation. All rights reserved. Xerox, Xerox Canada Ltd, Xerox Limited, and the

sphere of connectivity design are trademarks of Xerox Corporation in the United States and/or

other countries.

Changes are periodically made to this document. Changes, technical inaccuracies, and

typographic errors will be corrected in subsequent editions.

Page 3

Table of contents

1. Tools Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Entering and exiting Tools Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Navigating in Tools Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Machine Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Machine Defaults 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Initial Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

NVM Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Special Media Setting for Drilled Papers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Special Media Setting for LEF Tab Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Carbonless Media Enablement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Tray Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

System Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Power Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Screen Saver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Job Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Tools Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Auto Resume Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Auto Resume Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Auto Resume Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Audio Tones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Productivity Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Single Paper Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Mixed Paper Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

All Weights Rated Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Productivity charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Single Paper Weight 19

Mixed Paper Weight 20

All Weights Rated Speed 21

Productivity Setting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Auto Tray Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Oversize Paper Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Set Date & Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Setting the Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Setting the Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Dual Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Non-Standard Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Machine Defaults 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

Decurler Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Custom Paper procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Access the Custom Paper Profile feature . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Select the specific Paper Tray and Paper Type Switch options. . . . . . 1-30

Select Custom Paper Adjustment option . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Select a Custom Paper Profile option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

System Administration Guide i

Page 4

Table of contents DocuColor 7002/8002

Base Range of Paper Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

2nd BTB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Decurler Penetration Amount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Aligner NIP Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Air Assist Operation Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Select an Alignment Adjustment Profile (if necessary). . . . . . . . . . . . . . 1-39

Load paper tray and run a Test Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

Alignment Adjustment Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

Access the Alignment Adjustment feature . . . . . . . . . . . . . . . . . . . . . . . . . 1-42

Select a paper tray and a profile number . . . . . . . . . . . . . . . . . . . . . . . . . . 1-43

Select an Alignment Profile button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

Run a Test Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

Select an Alignment Adjustment feature . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

Lead Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

Side Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

Perpendicularity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

Side Skew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

FS Direction Image Magnification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-48

SS Direction Image Magnification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

Run more Test Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-50

Deactivating an Alignment Adjustment Profile . . . . . . . . . . . . . . . . . . . . . 1-51

Finishing System Module Profile (DFA device) . . . . . . . . . . . . . . . . . . . . . . . . . 1-52

2. Auditron. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Create/Modify User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Creating a User Account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Modifying a User Account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Changing the Tools Mode Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Creating a Password for the Auditron Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Review Printer Job Account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3. Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

E Table Settings Chart: Type E1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

E Table Settings Chart: Type E2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

E Table Settings Chart: Type E3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

E Table Settings Chart: Type E4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

E Table Settings Chart: Type E5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

E Table Settings Chart: Type E6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Custom Paper Setup Chart 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Custom Paper Setup Chart 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Custom Paper Setup Chart 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Custom Paper Setup Chart 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Alginment Adjustment Profile Chart 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Alginment Adjustment Profile Chart 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Alginment Adjustment Profile Chart 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Alginment Adjustment Profile Chart 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

ii System Administration Guide

Page 5

Tools Mode

1

Overview

The Tools Mode enables you to establish the default settings for your digital press to fit your

individual requirements. You can change the settings for a variety of features, such as the initial

screen to display when the press is powered on, the language to display on the Touch Screen,

special paper sizes that can be used in the Paper Trays, timers, audio tone controls, default

settings for scanner features, image quality settings, and more.

Entering and exiting Tools Mode

Tip

Keep the following in mind as you learn about the Tools Mode:

• If you attempt to access the Tools Mode while a job is printing, access to the Tools screens

is delayed until the job completes the printing process.

• Jobs will queue, but will not print while the Tools Mode is active.

• You cannot access the Tools Mode if the digital press is in a Fault condition.

• You cannot access the Tools Mode if the Pause key on the Control Panel was pressed to halt

a job. When the halted job completes the printing process, the Tools Mode may be

accessed.

Use the following procedure to enter and exit the Tools Mode:

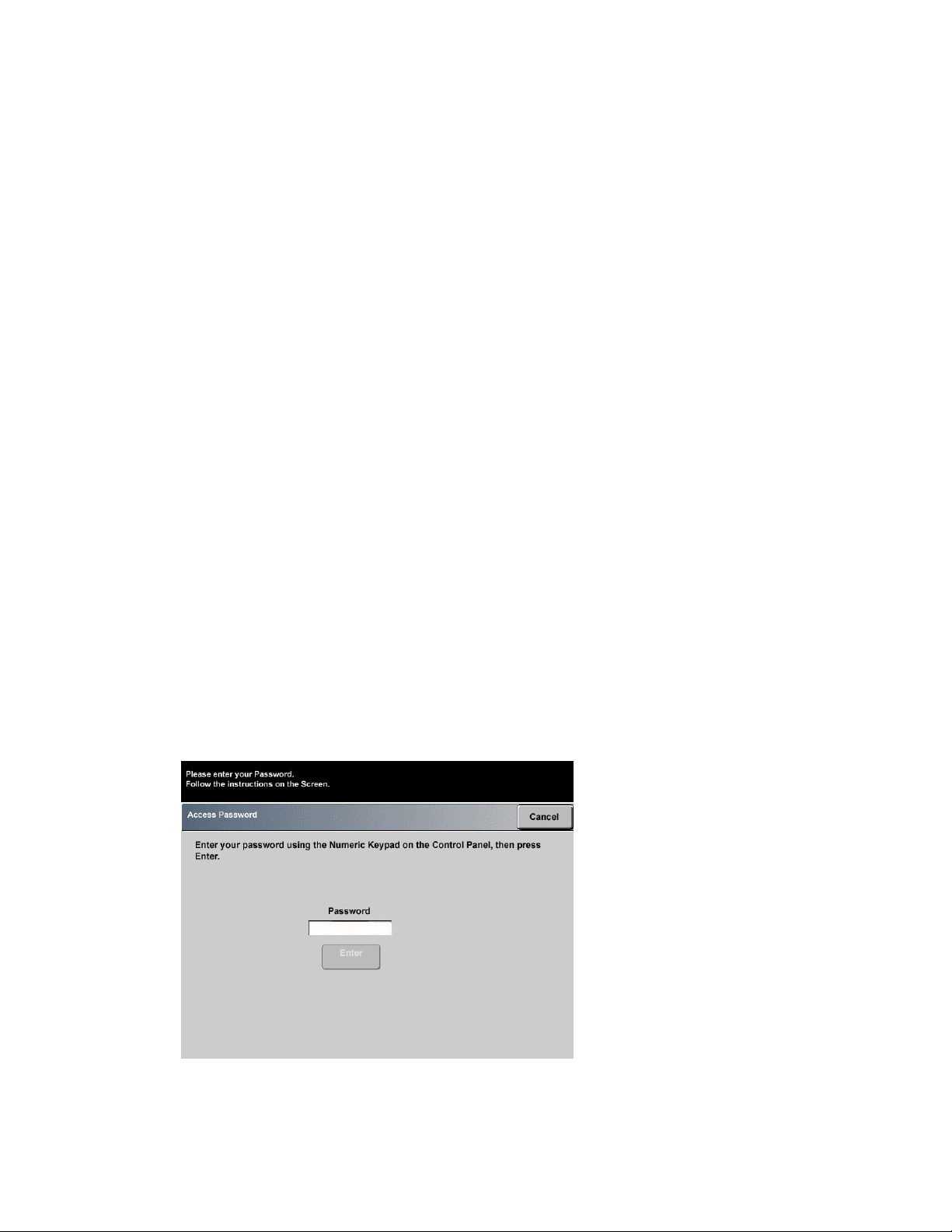

1. Press the Access button on the Control Panel. The Access Password Screen appears.

2. Use the keypad to enter the Tools Mode password.

The default password is five ones (11111).

System Administration Guide 1-1

Page 6

Tools Mode DocuColor 7002/8002

For security reasons, only asterisks are displayed on the screen.

3. Touch the Enter button.

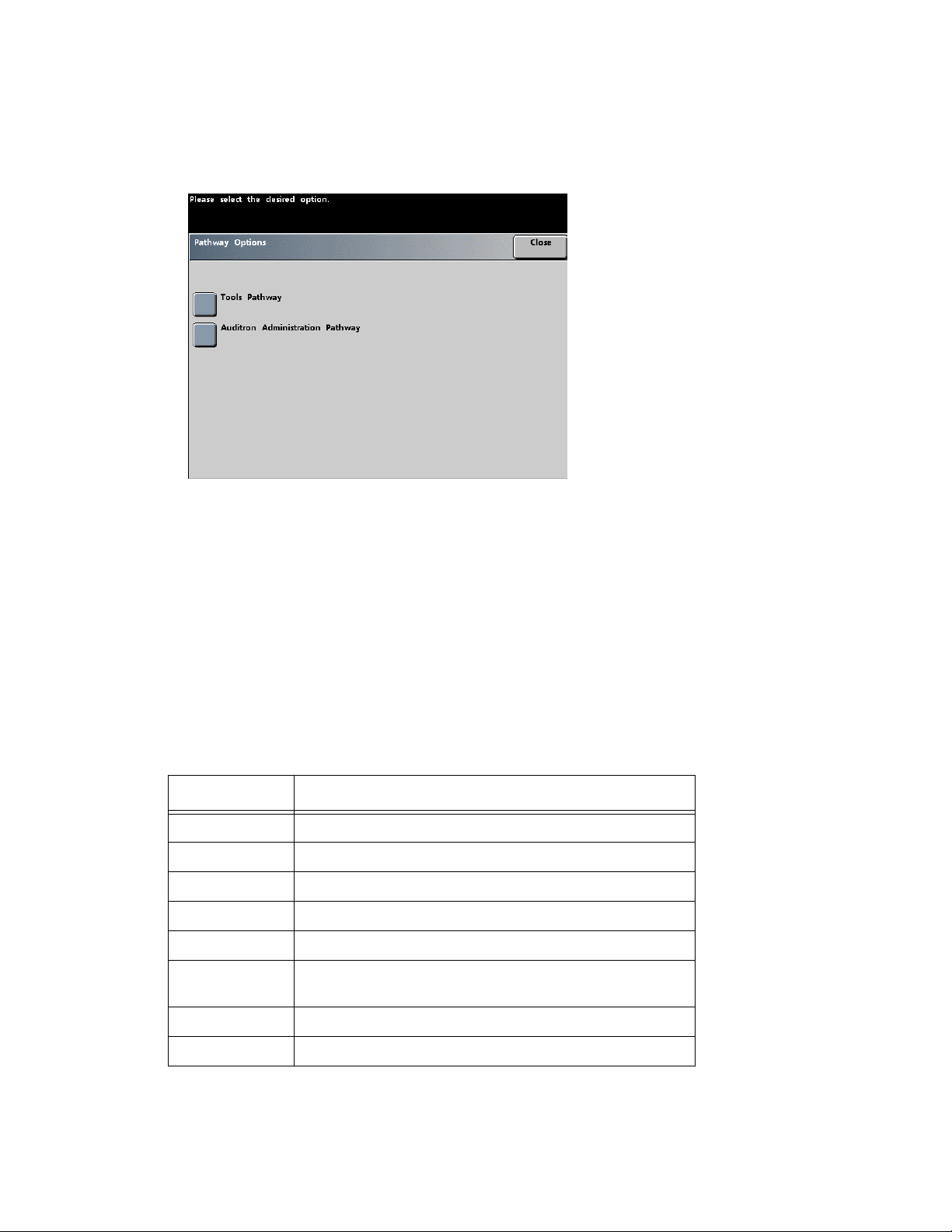

The Pathway Options screen appears.

Note

It is recommended that you change the Tools password as soon as possible after installing

the digital press in order to prevent unauthorized access to the Tools Mode. The procedure

for changing the password is in Chapter 2 of this manual.

4. Touch the Tools Pathway button on the screen; you are now in the Tools Mode.

5. To exit the Tools Mode, touch the Exit Tools button.

Navigating in Tools Mode

The following table tells you how to navigate in Tools Mode by touching buttons.

Button Result

Tabs Allows you to view the options available on that screen.

Enter Saves any changes you made on the screen.

System Default Returns the settings on the screen to the factory default settings.

Close Closes the screen and returns the system to the previous screen.

Off Deactivates the feature.

Reset Returns the settings on the screen to the settings that were in

effect when the screen opened.

Cancel Cancels the changes made on the screen.

Exit Tools Exits the Tools Mode.

Note

Changes made to default settings in the Tools Mode take effect when you exit Tools Mode.

1-2 System Administration Guide

Page 7

DocuColor 7002/8002 Tools Mode

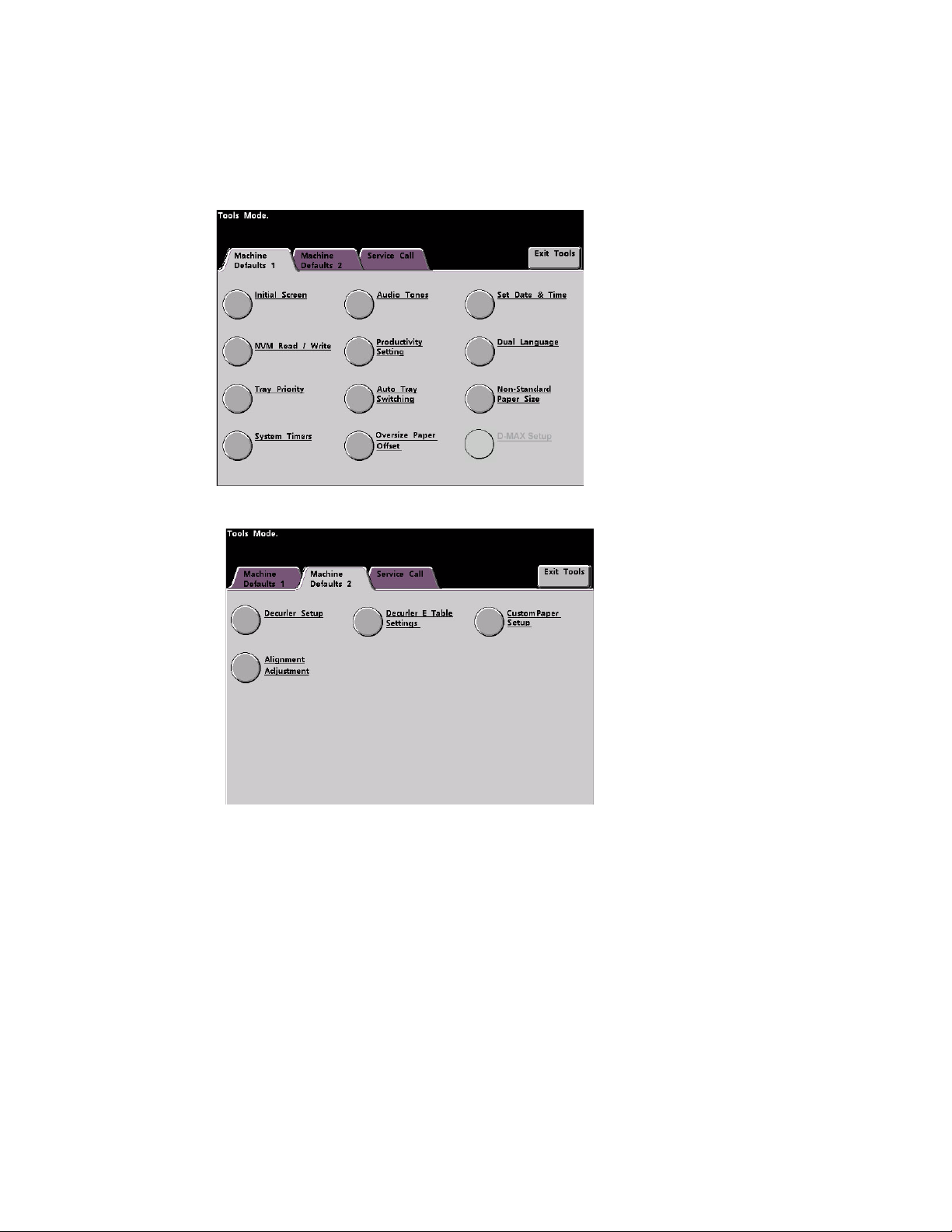

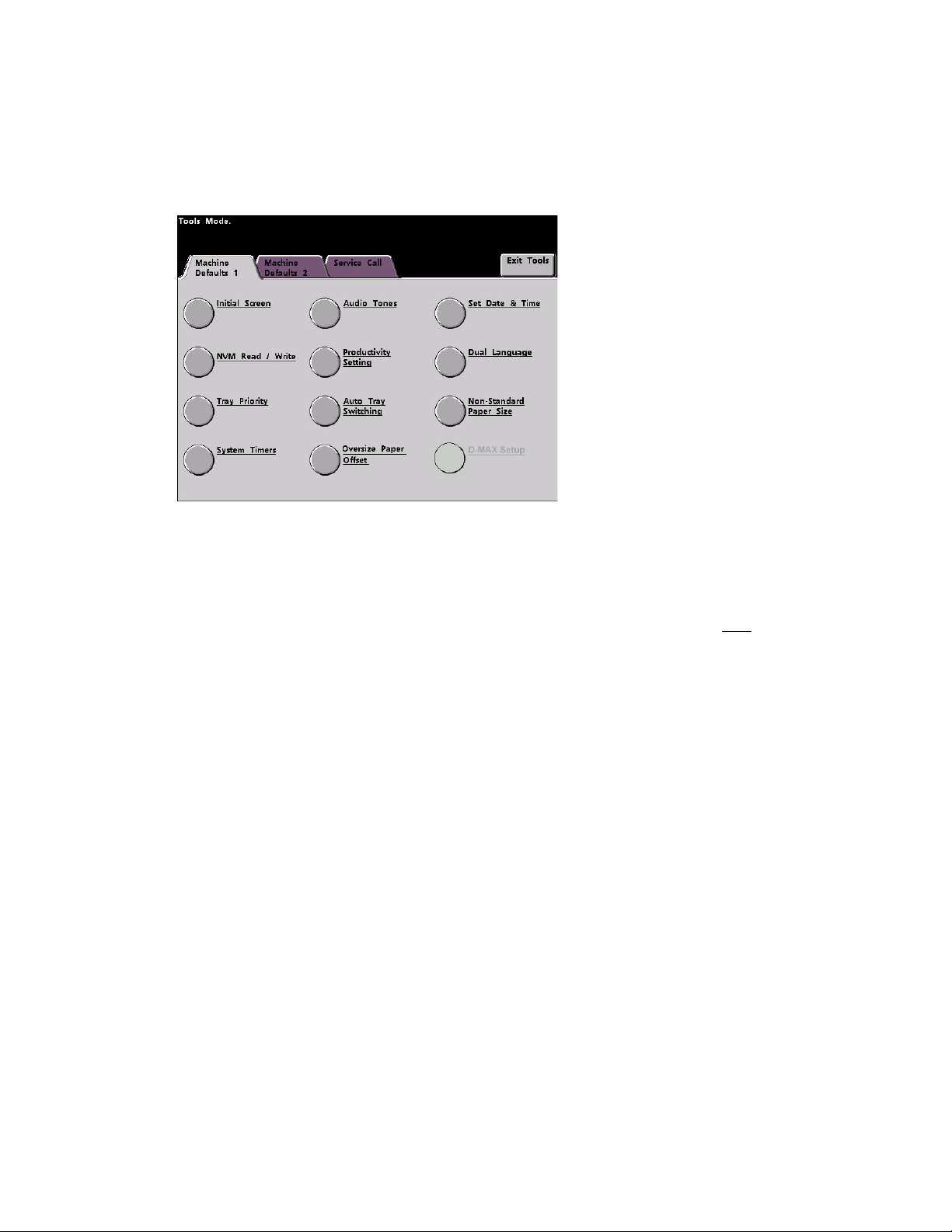

Machine Defaults

Two Machine Defaults screens are available for changing default settings. Each of the features

shown on the below screen is described throughout the remainder of this chapter.

Note

The Service Call feature is not available.

System Administration Guide 1-3

Page 8

Tools Mode DocuColor 7002/8002

Machine Defaults 1

This section describes the default settings available to you on the Machine Defaults 1 screen

and include the following (as shown in the illustration):

The default settings procedures on the following pages are accessed from The Machine

Defaults 1 screen.

Note

The D-MAX Setup feature may or may not be selectable with your DocuColor 7002/8002 Digital

Press configuration. In either case, this feature is for the Xerox Service Representative only

is not for customer use.

and

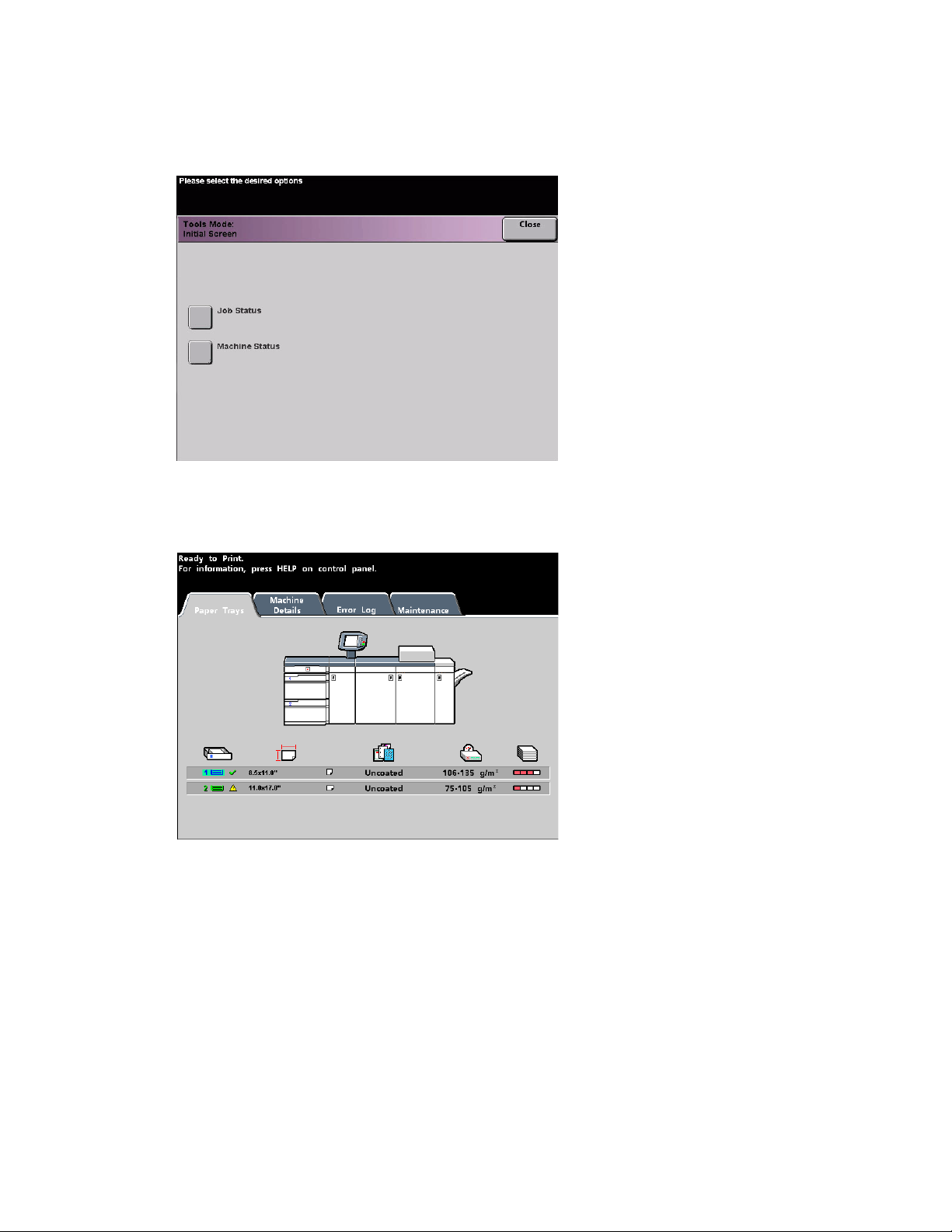

Initial Screen

Use the Initial Screen to select the screen that displays when the digital press is powered on.

You can choose from two screens:

•Job Status

• Machine Status

Note

The Machine Status screen is the factory default setting.

1-4 System Administration Guide

Page 9

DocuColor 7002/8002 Tools Mode

Use the following procedure to change the default initial screen.

1. Touch the Initial Screen button on the Machine Defaults 1 screen. The Initial Screen screen

appears.

2. Touch the Machine Status or Job Status button.

If you select the Machine Defaults screen, the screen below appears when the machine is

powered on.

System Administration Guide 1-5

Page 10

Tools Mode DocuColor 7002/8002

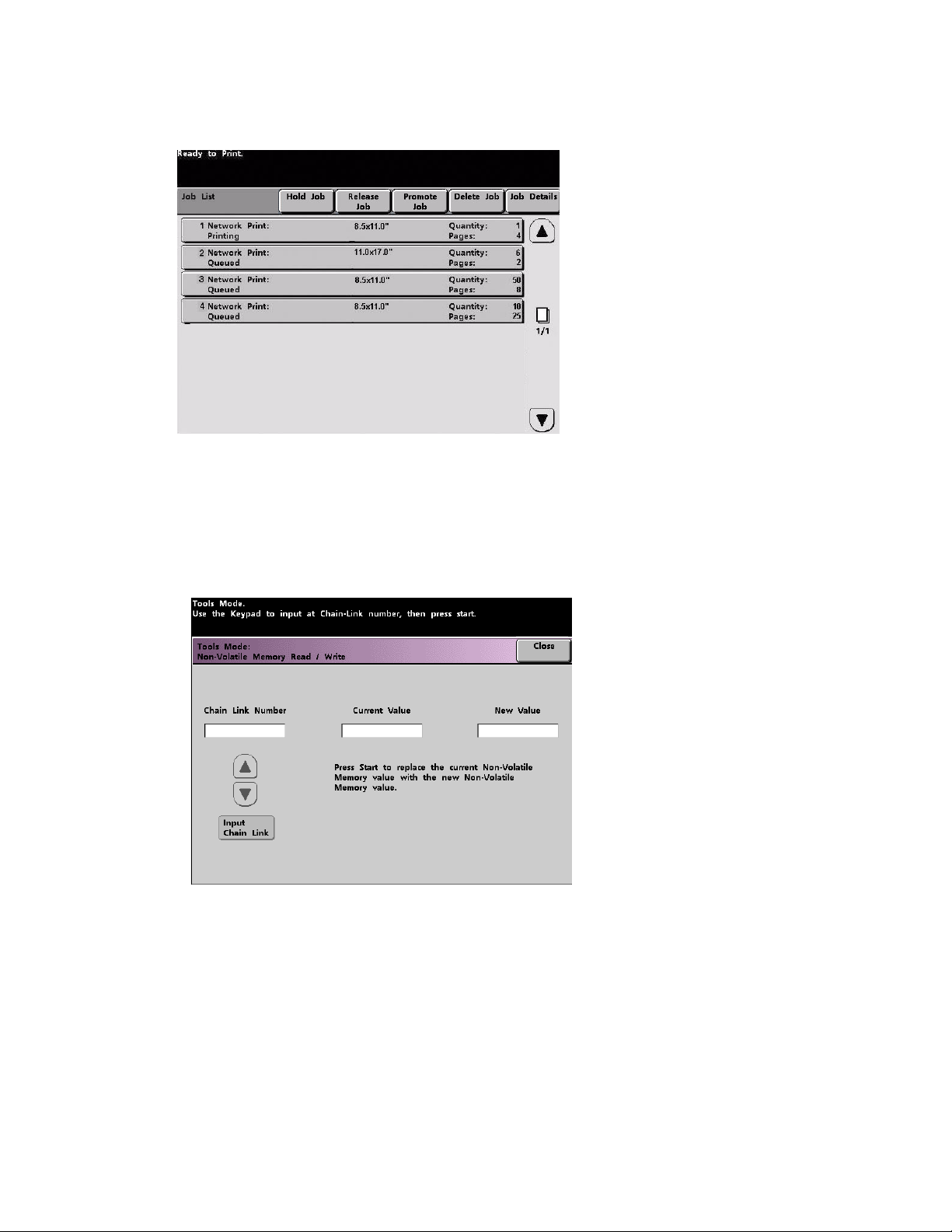

If you change the default setting to the Job Status screen, the screen below appears when

the machine is powered on. This screen displays all the jobs currently queued for printing.

Note

Refer to the User Guide for more information about the Machine Status and Job Status screens.

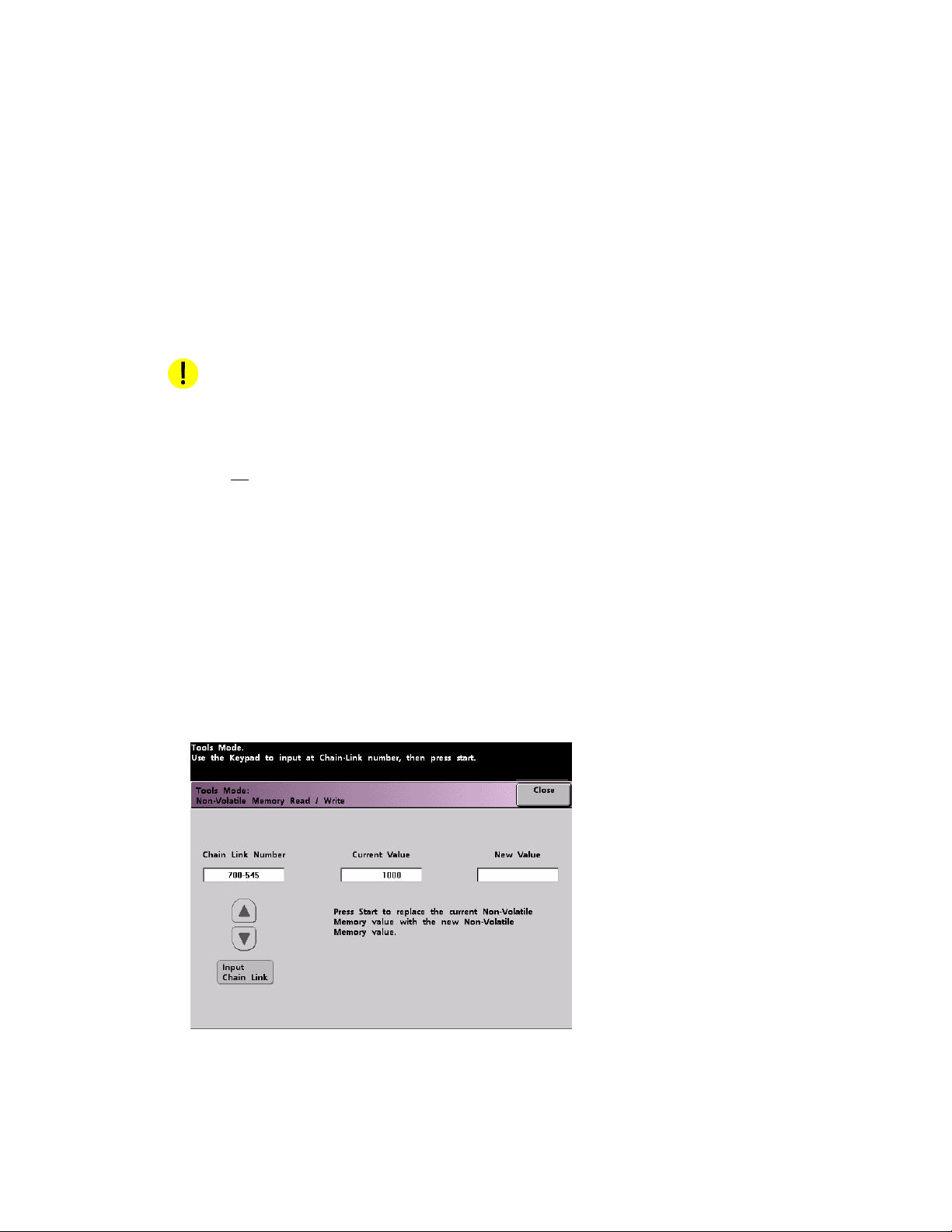

NVM Read/Write

Your Xerox service representative uses this feature to change certain system settings. It also

may occasionally be used by system administrators.

Under most conditions, this feature is not used by system administrators; however, there are

limited circumstances under which this feature is used. These circumstances include:

Special Media Setting for Drilled Papers

If you use 3-hole, predrilled paper on a regular basis and continually encounter an inordinate

amount of paper jams, and/or

Special Media Setting for LEF Tab Stock

If you regularly run tab stock and continually encounter paper jams.

1-6 System Administration Guide

Page 11

DocuColor 7002/8002 Tools Mode

Carbonless Media Enablement

• Carbonless papers are coated with several functional coatings which promote the image

transfer through the form set and enable the form sets to separate appropriately after

padding with a special adhesive. Each supplier of xerographic carbonless paper has

developed their own unique chemistry, which is why the following procedure enabling this

application, works best with Xerox Premium Digital Carbonless Paper.

• In order to avoid problems when running carbonless media, you may use the NVM Read/

Write feature to switch on the carbonless media feature.

If any of the above conditions exist in your environment, you may use the NVM Read/Write

feature to swi ch on a feature.

CAUTION

Do not enter any numbers on this screen other than the ones described in this procedure.

Entering and saving numbers, other than the ones described, changes the system settings which

may result in a service call to restore the system to the correct settings.

To switc h on

1. From the NVM Read/Write screen, use the keypad on the Control Panel and enter the Chain

Link Number:

• The Chain Link Number for Special Media Setting for Drilled Papers is 700 545.

• The Chain Link Number for Special Media Setting for LEF Tab Stock is 700 546.

• The Chain Link Number for Carbonless Media Enablement is 700-920.

Note

For the purpose of this procedure, the following screens show the Chain Link Number,

Current Value, and New Value for Special Media Setting for Drilled Papers. The Current

Value and New Value numbers will vary depending on the Chain Link Number entered.

2. After entering the desired Chain Link Number, press the Start button on the Control

Panel. The UI displays this screen:

a feature, perform the following:

System Administration Guide 1-7

Page 12

Tools Mode DocuColor 7002/8002

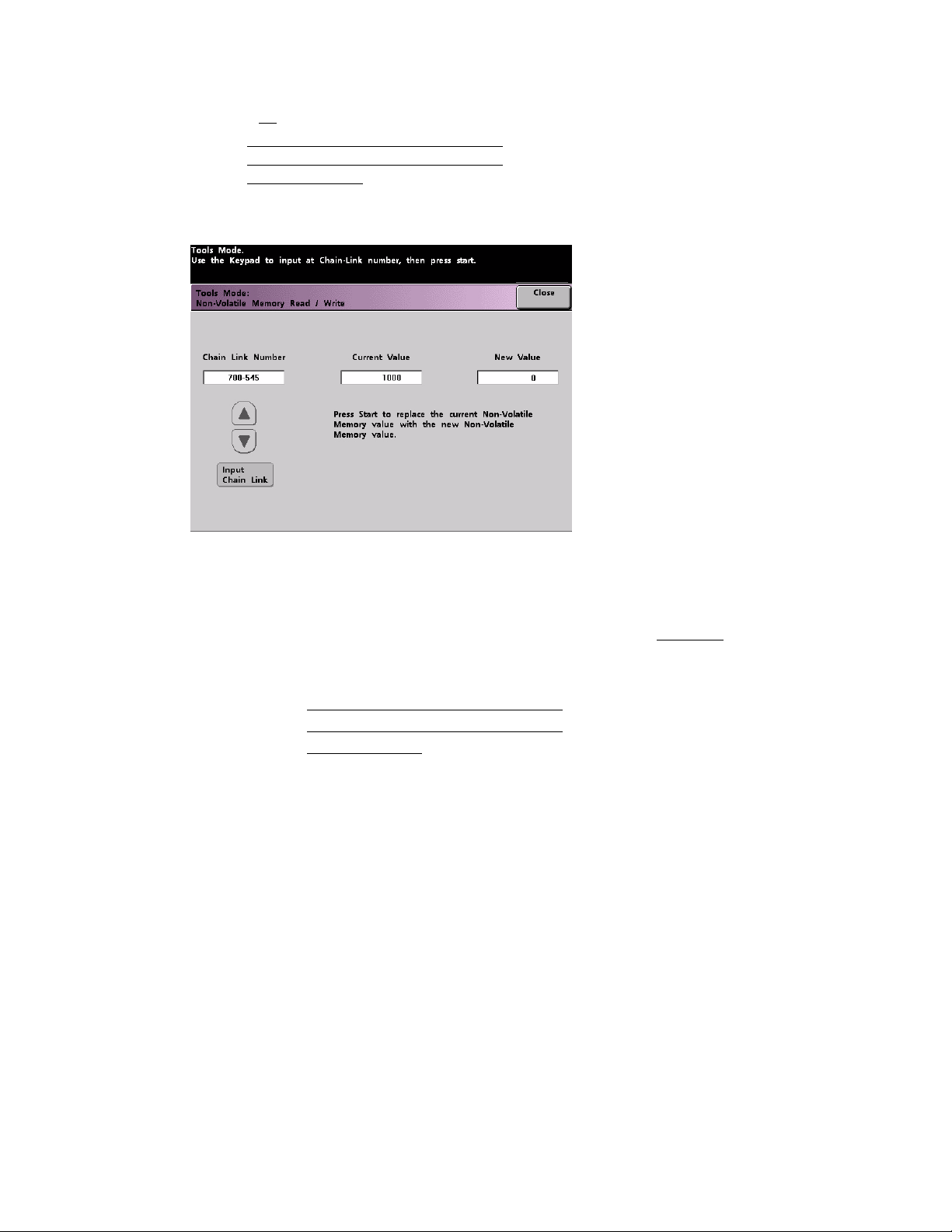

3. To switch on a feature, press the appropriate button on the Control Panel keypad:

• For Special Media Setting for Drilled Papers

• For Special Media Setting for LEF Tab Stock

• For Carbonless Media

, press 1.

, press 0.

, press 1.

4. After entering the New Value number, press the Start button. The UI displays the

following screen:

5. Touch the Close button to save and close your new setting.

6. Exit Tools Mode and run your print job.

Tip

After running your print job, reenter Tools Mode, NVM Read/Write, and switch off

the

feature that is currently on. Follow the steps outlined in this procedure and use these

settings for the New Value number:

• To switch off the Special Media Setting for Drilled Papers

• To switch off the Special Media Setting for LEF Tab Stock

• To switch off the Carbonless Media

, enter 0.

, enter 1000.

, enter 0.

Tip

To prevent paper jams from occurring with stock types other than the ones mentioned in this

procedure, you must switch off the NVM Read/Write feature before running other print jobs.

1-8 System Administration Guide

Page 13

DocuColor 7002/8002 Tools Mode

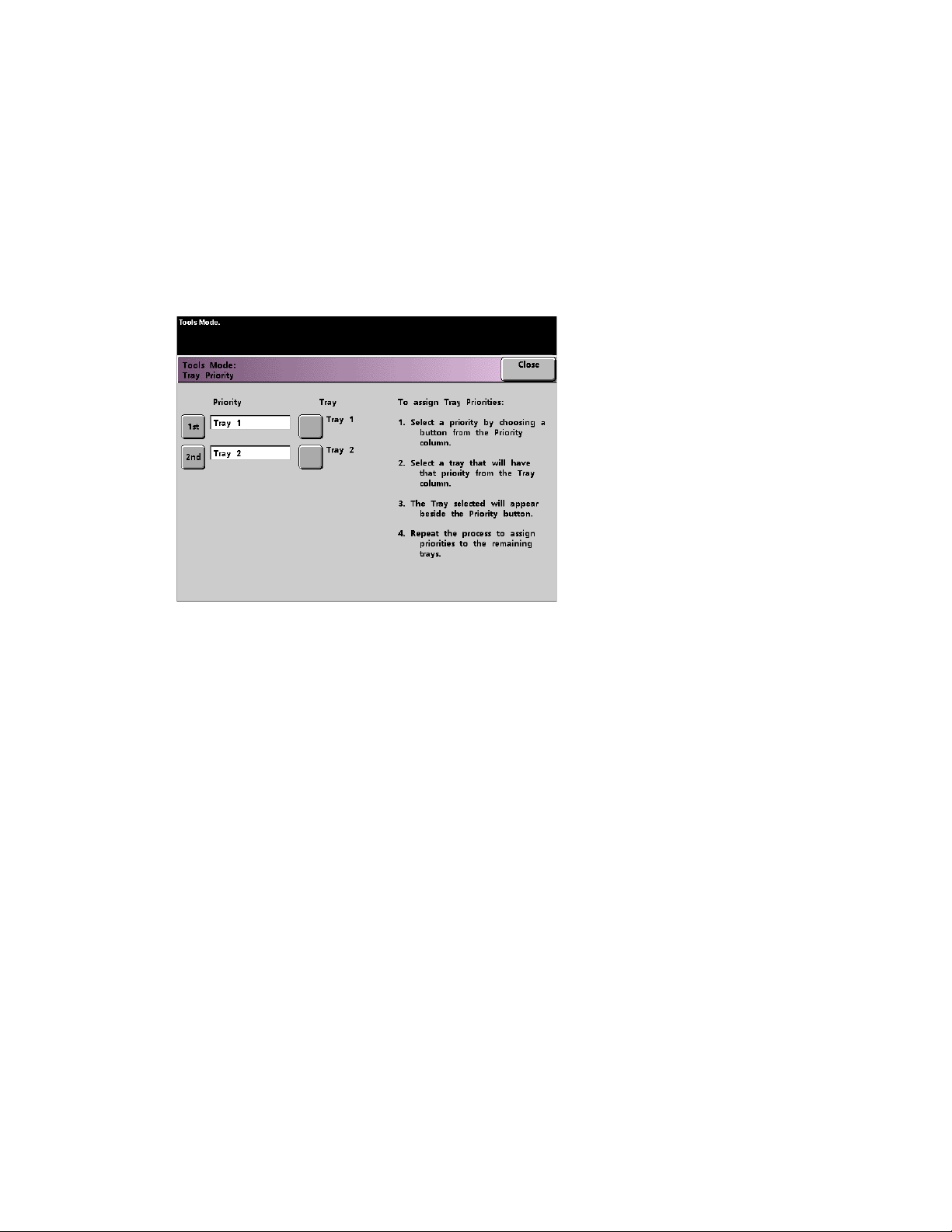

Tray Priority

Select the priority order for each paper tray. If the Auto Tray Switching feature is enabled and

each paper tray contains the same paper size and weight, the digital press feeds paper from the

tray set at Priority 1. If there is no paper in the Priority 1 tray, the Priority 2 tray is automatically

selected and so on.

Use the following procedure to set the priority for each paper tray.

1. Touch the Tray Priority button on the Machine Defaults 1 screen. The Tray Priority screen

appears.

2. Touch the desired Priority button in the Priority column.

3. Touch the button for the Paper Tray that will have that priority. The number of the selected

Paper Tray appears next to that Priority button.

4. Repeat this procedure for each Priority. You cannot set the same paper tray for more than

one Priority at a time.

5. Touch the Close button to return to the Machine Defaults 1 screen. You cannot touch the

Close button until you set paper trays for each Priority.

System Administration Guide 1-9

Page 14

Tools Mode DocuColor 7002/8002

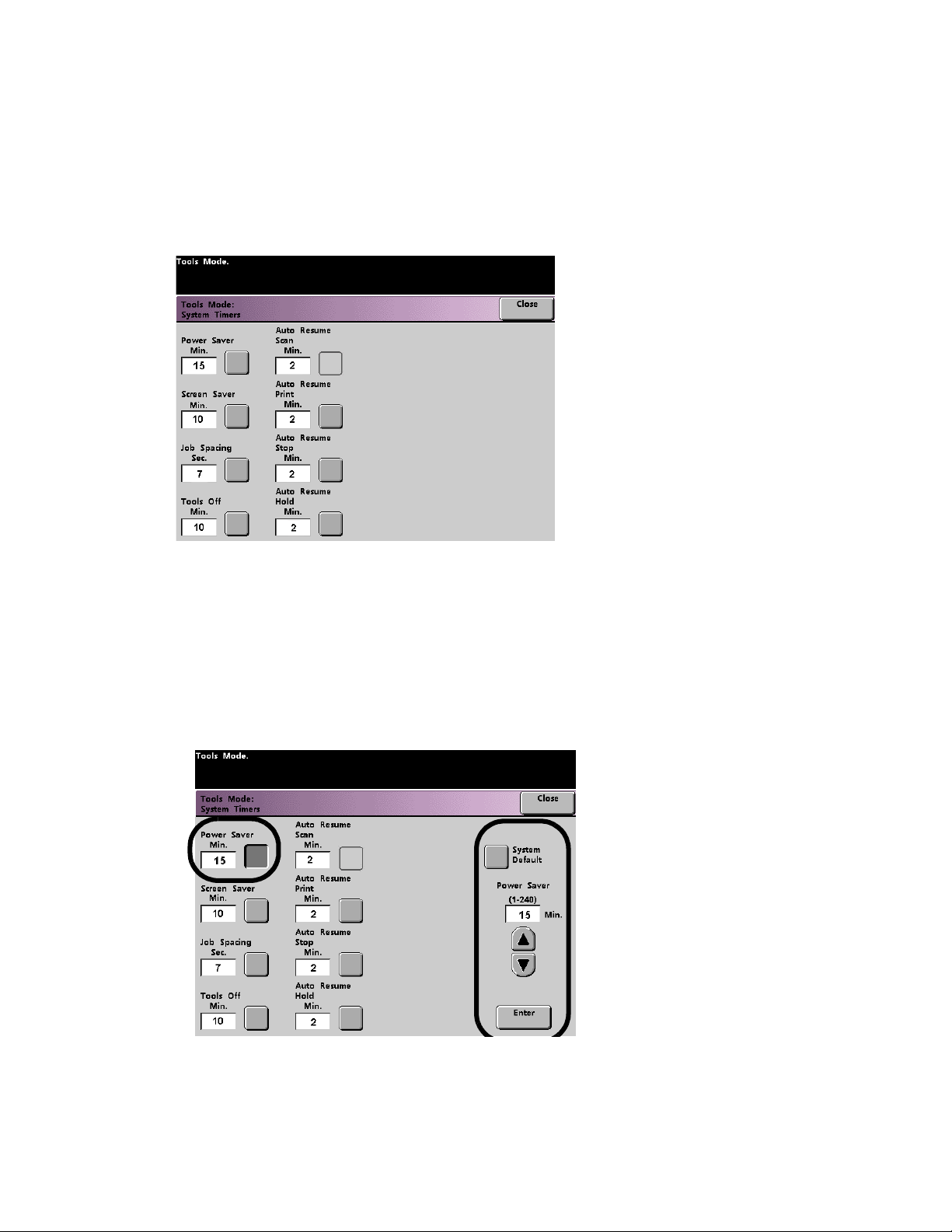

System Timers

Use this feature to change the factory default settings for the timers in the digital press. To

access the various timers, touch the System Timers button on the Machine Defaults 1 screen.

The System Timers screen appears. From this screen you can view the time currently set for each

of the timers, and select the one you want to change.

Power Saver

Use this feature to set the time that elapses until the digital press enters a reduced power

consumption mode. This timer is activated when all print jobs have been completed and there

are no jobs in the job queue.

The digital press exits the Power Saver mode when a job is sent to be printed or the Touch

Screen is activated

1. Touch the Power Saver button on the System Timers screen.

2. Use the up or down arrow buttons to change the time. The range available is one to 240

minutes.

1-10 System Administration Guide

Page 15

DocuColor 7002/8002 Tools Mode

To use the system default time of fifteen minutes, touch the System Default button.

3. Touch the Enter button on the screen to enter the new time into the system.

4. Touch the Close button to return to the Machine Defaults 1 screen or to select another

timer to change.

Screen Saver

The Screen Saver feature allows you to protect the screen from being damaged with permanent

marks if the digital press is idle for a period of time.

1. Touch the Screen Saver button on the System Timers screen.

2. Use the up or down arrow buttons to change the time. The range available is ten to sixty

minutes.

To use the system default time of ten minutes, touch the System Default button.

3. Touch the Enter button on the screen to enter the new time into the system.

4. Touch the Close button to return to the Machine Defaults 1 screen or select another timer

to change.

System Administration Guide 1-11

Page 16

Tools Mode DocuColor 7002/8002

Job Spacing

Use the Job Spacing feature when there are multiple jobs queued and you would like to allow

seven seconds to unload prints from a finishing device before the next job starts printing.

1. Touch the Job Spacing button on the System Timers screen.

2. Touch the 7 Seconds button to enable the feature or touch the Off button to disable the

feature.

3. Touch the Close button to return to the Machine Defaults 1 screen or select another timer

to change.

1-12 System Administration Guide

Page 17

DocuColor 7002/8002 Tools Mode

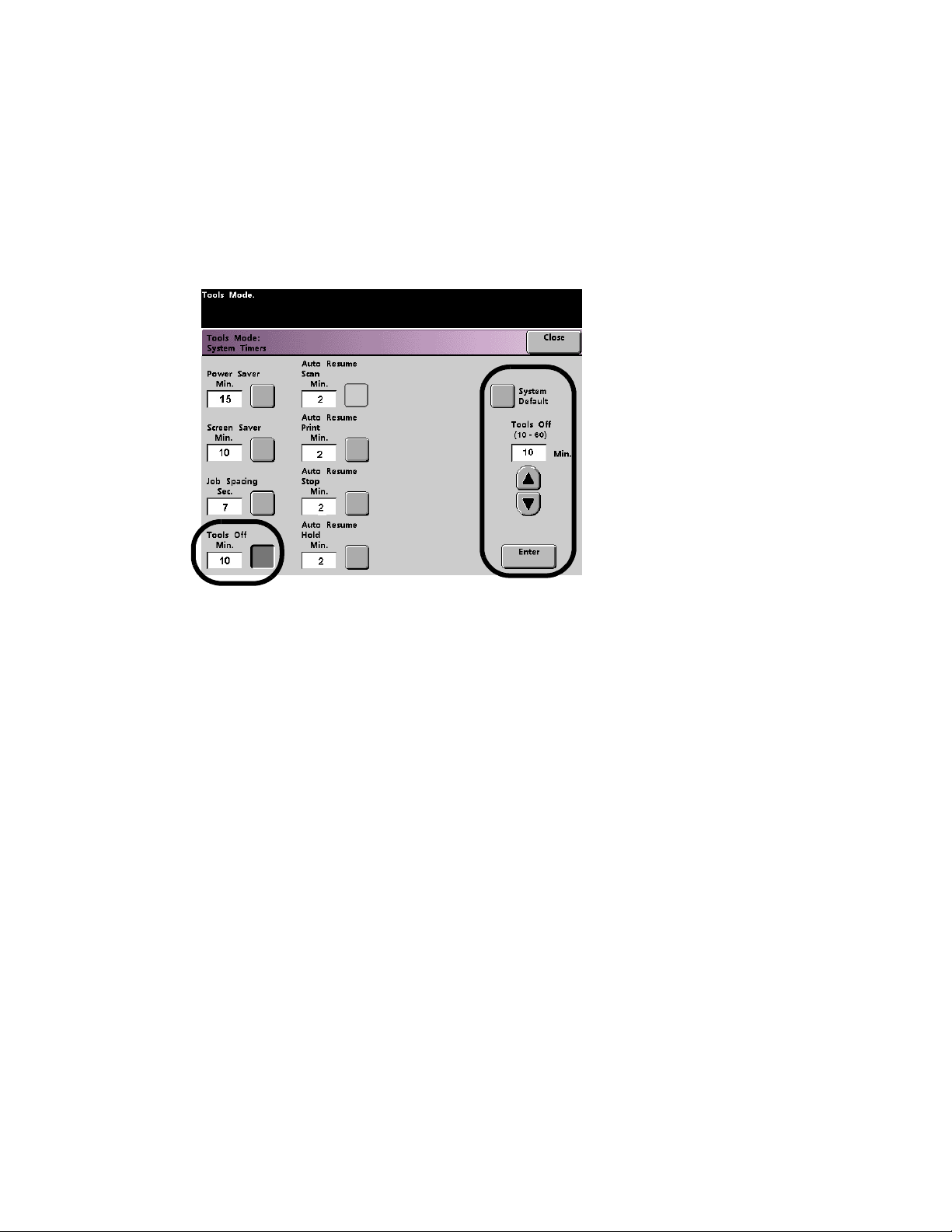

Tools Off

Use the Tools Off feature to have the digital press automatically return to the printing mode

when no action is taken on the Tools Mode screens after the set amount of time.

Tip

Jobs sent over the network will queue but will not print while the Tools Mode is active.

1. Touch the Tools Off button on the System Timers screen.

2. Use the up or down arrow buttons to change the time. The range available is ten to sixty

minutes.

To use the system default time of ten minutes, touch the System Default button.

3. Touch the Enter button on the screen to enter the new time into the system.

4. Touch the Close button to return to the Machine Defaults 1 screen or select another timer

to change.

System Administration Guide 1-13

Page 18

Tools Mode DocuColor 7002/8002

Auto Resume Print

Use the Auto Resume Print feature to restart a job automatically after a fault is cleared and a

job received over the network is waiting for user instruction.

1. Touch the Auto Resume Print button on the System Timers screen.

2. Use the up or down arrow buttons to change the time. The range available is one to ten

minutes.

To use the system default time of two minutes, touch the System Default button.

3. Touch the Enter button on the screen to enter the new time into the system.

4. Touch the Close button to return to the Machine Defaults 1 screen or select another timer

to change.

1-14 System Administration Guide

Page 19

DocuColor 7002/8002 Tools Mode

Auto Resume Stop

Use the Auto Resume Stop feature to restart a job automatically after the Pause button on the

Control Panel is pressed and the job is waiting for user instruction.

1. Touch the Auto Resume Stop button on the System Timers screen.

2. Use the up or down arrow buttons to change the time. The range available is one to ten

minutes.

To use the system default time of two minutes, touch the System Default button.

3. Touch the Enter button on the screen to enter the new time into the system.

4. Touch the Close button to return to the Machine Defaults 1 screen or select another timer

to change.

System Administration Guide 1-15

Page 20

Tools Mode DocuColor 7002/8002

Auto Resume Hold

Use the Auto Resume Hold feature to automatically print the next job in the queue if the

current job is waiting for user instruction to clear a certain type of fault.

1. Touch the Auto Resume Hold button on the System Timers screen.

2. Use the up or down arrow buttons to change the time. The range available is one to ten

minutes.

To use the system default time of two minutes, touch the System Default button.

3. Touch the Enter button on the screen to enter the new time into the system.

4. Touch the Close button to return to the Machine Defaults 1 screen or select another timer

to change.

1-16 System Administration Guide

Page 21

DocuColor 7002/8002 Tools Mode

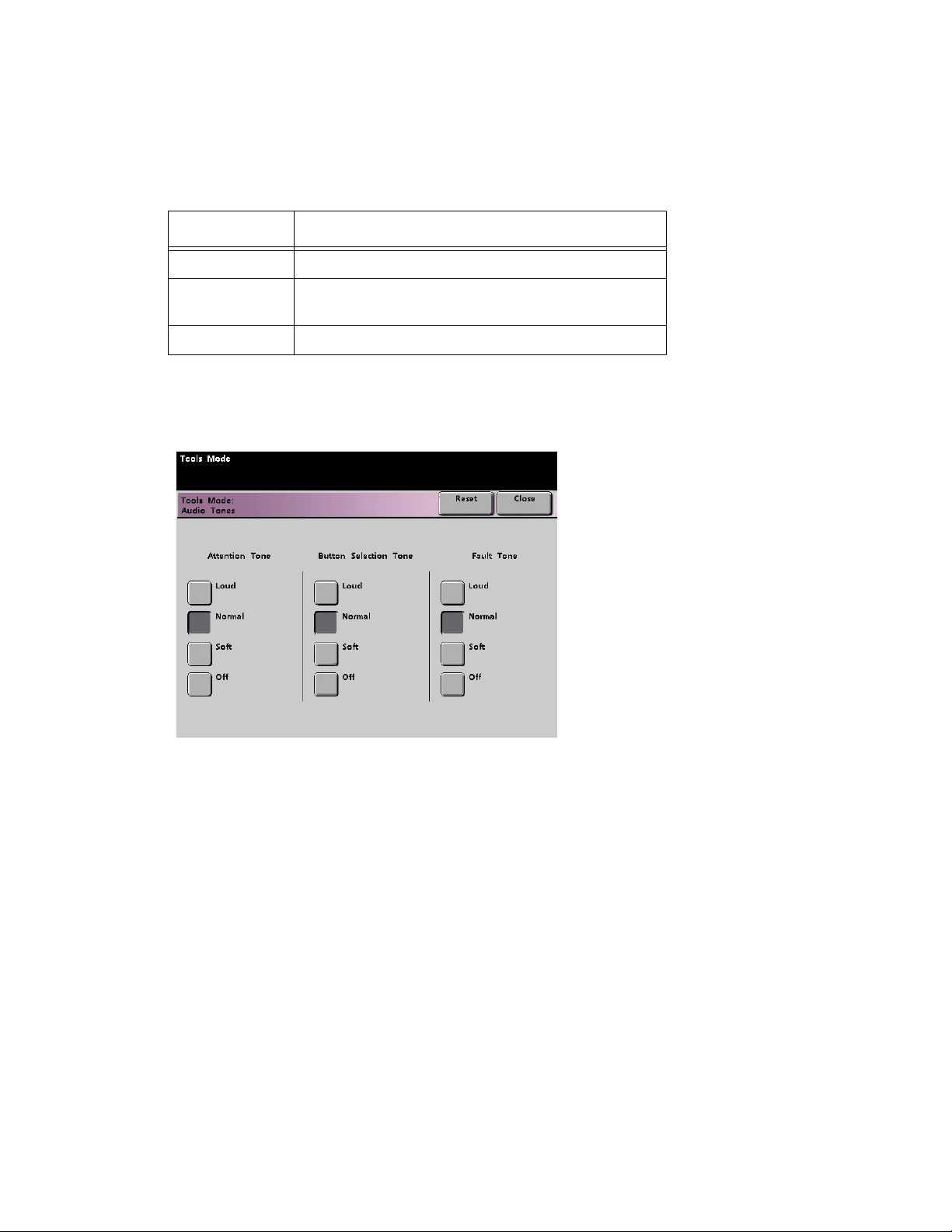

Audio Tones

There are three types of audio tones that can be activated on the digital press, as shown in the

following table.

Tone What the Tone Indicates

Attention Tone An unselectable button has been touched.

Button Selection

To n e

Fault Tone The press is in a fault condition and cannot continue printing.

A selectable button has been touched.

Each of these tones can be deactivated or set to Soft, Normal, or Loud. The factory default

setting is Normal.

1. Touch the Audio Tones button on the Machine Defaults 1 screen.

2. Touch the button for the desired volume setting for each tone. To deactivate a tone, touch

the Off button for that tone.

3. Touch the Reset button to restore the factory default setting for the three tones.

4. Touch the Close button to return to the Machine Defaults 1 screen.

System Administration Guide 1-17

Page 22

Tools Mode DocuColor 7002/8002

Productivity Setting

The productivity of the digital press relates to the continuous speed of the media output as

measured in prints per minute (ppm). The continuous speed is dependent on paper size, paper

weight, and fuser temperature.

Use this setting to optimize the throughput speed for the type of paper you run most

frequently. Productivity Setting options are shown and explained in the following illustration:

Single Paper Weight

This setting optimizes the throughput speed for light weight or heavy weight papers, according

to the weight range that is set in the paper tray.

Mixed Paper Weight

This setting optimizes the throughput speed of print jobs that contain mixed media weights

from different paper trays.

All Weights Rated Speed

This setting allows all print jobs to run at the same, or rated, throughput speed, regardless of

weight. The digital press produces/prints images with a reduced level of gloss on the output.

Productivity charts

The following productivity charts lists the various paper weights and sizes and their related print

speeds for 1 Sided and 2 Sided output. Each chart outlines the print speed parameters for both

productivity settings.

1-18 System Administration Guide

Page 23

DocuColor 7002/8002 Tools Mode

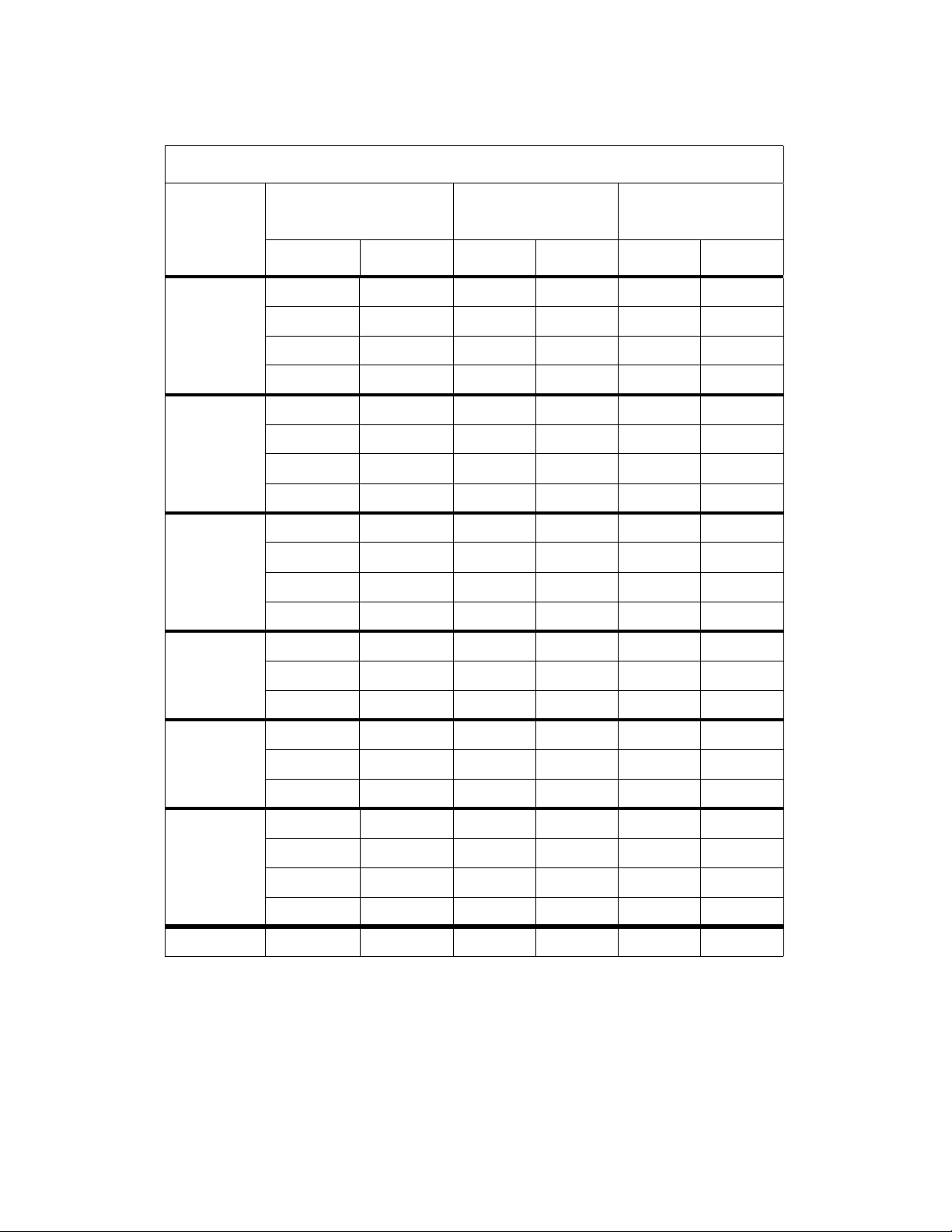

Single Paper Weight

Single Paper Weight Mode

Paper

Weight

60 - 80

g/m

81 - 105

g/m

106 - 135

g/m

136 - 186

g/m

Paper Size(Feed

direction length)[mm]

Print Speed for

DocuColor 8002

Print Speed for

DocuColor 7002

Min. Max 1 Sided 2 Sided 1 Sided 2 Sided

2

2

2

2

182.0 216.0 80 40 70 35

216.1 297.0 60 30 60 30

297.1 458.0 40 20 35 17.5

458.1 488.0 30 15 30 15

182.0 216.0 80 40 70 35

216.1 297.0 60 30 60 30

297.1 458.0 40 20 35 17.5

458.1 488.0 30 15 30 15

182.0 216.0 80 40 70 35

216.1 297.0 60 30 60 30

297.1 458.0 40 20 35 17.5

458.1 488.0 30 15 30 15

182.0 216.0 60 30 50 25

216.1 450.0 30 15 25 12.5

450.1 488.0 20 10 15 7.5

187 - 220

2

g/m

221 - 300

2

g/m

Transparency 210.0 216.0 30 - 30 -

182.0 216.0 60 30 50 25

216.1 450.0 30 15 25 12.5

450.1 488.0 20 10 15 7.5

182.0 216.0 40 20 35 17.5

216.1 280.0 30 15 30 15

280.1 458.0 20 10 15 7.5

458.1 488.0 10 5 10 5

Notes

2

• 2-Sided printing is not available for transparency and paper that is 221 g/m

or greater.

• There is no decrease in productivity (ppm) from the second feeder module to the first

feeder module.

• Transparency is only available for 1 Sided, A4 or 8.5 in. x 11 in.LEF.

System Administration Guide 1-19

Page 24

Tools Mode DocuColor 7002/8002

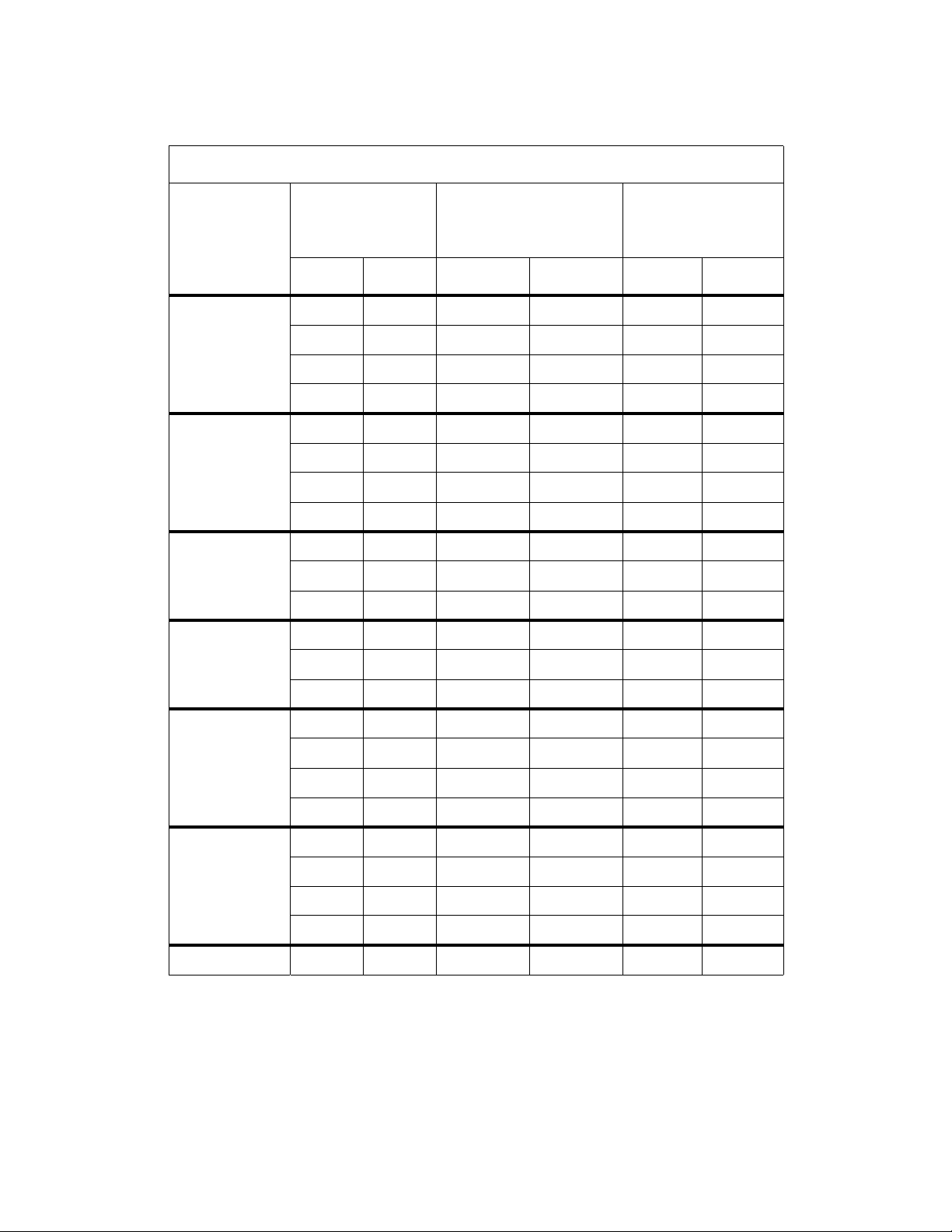

Mixed Paper Weight

Mixed Paper Weight Mode

Paper Weight

60 - 80

2

g/m

81 - 105

2

g/m

106 - 135

2

g/m

136 - 186

2

g/m

Paper Size(Feed

direction

length)[mm]

Print Speed for

DocuColor 8002

Print Speed for

DocuColor 7002

Min. Max Simplex Duplex Simplex Duplex

182.0 216.0 80 40 70 35

216.1 297.0 60 30 60 30

297.1 458.0 40 20 35 17.5

458.1 488.0 30 15 30 15

182.0 216.0 80 40 70 35

216.1 297.0 60 30 60 30

297.1 458.0 40 20 35 17.5

458.1 488.0 30 15 30 15

182.0 216.0 60 30 60 30

216.1 450.0 30 15 30 15

450.1 488.0 20 10 20 10

182.0 216.0 60 30 50 25

216.1 450.0 30 15 25 12.5

450.1 488.0 20 10 15 7.5

187 - 220

2

g/m

221 - 300

2

g/m

Transparency 210.0 216.0 30 -- 30 --

182.0 216.0 40 20 40 20

216.1 280.0 30 15 30 15

280.1 458.0 20 10 20 10

458.1 488.0 10 5 10 5

182.0 216.0 40 20 35 17.5

216.1 280.0 30 15 30 15

280.1 458.0 20 10 15 10

458.1 488.0 10 5 10 5

Notes

2

• 2-Sided printing is not available for transparency and paper that is 221 g/m

or greater.

• There is no decrease in productivity (ppm) from the second feeder module to the first

feeder module.

• Transparency is only available for 1 Sided, A4 or 8.5 in. x 11 in.LEF.

1-20 System Administration Guide

Page 25

DocuColor 7002/8002 Tools Mode

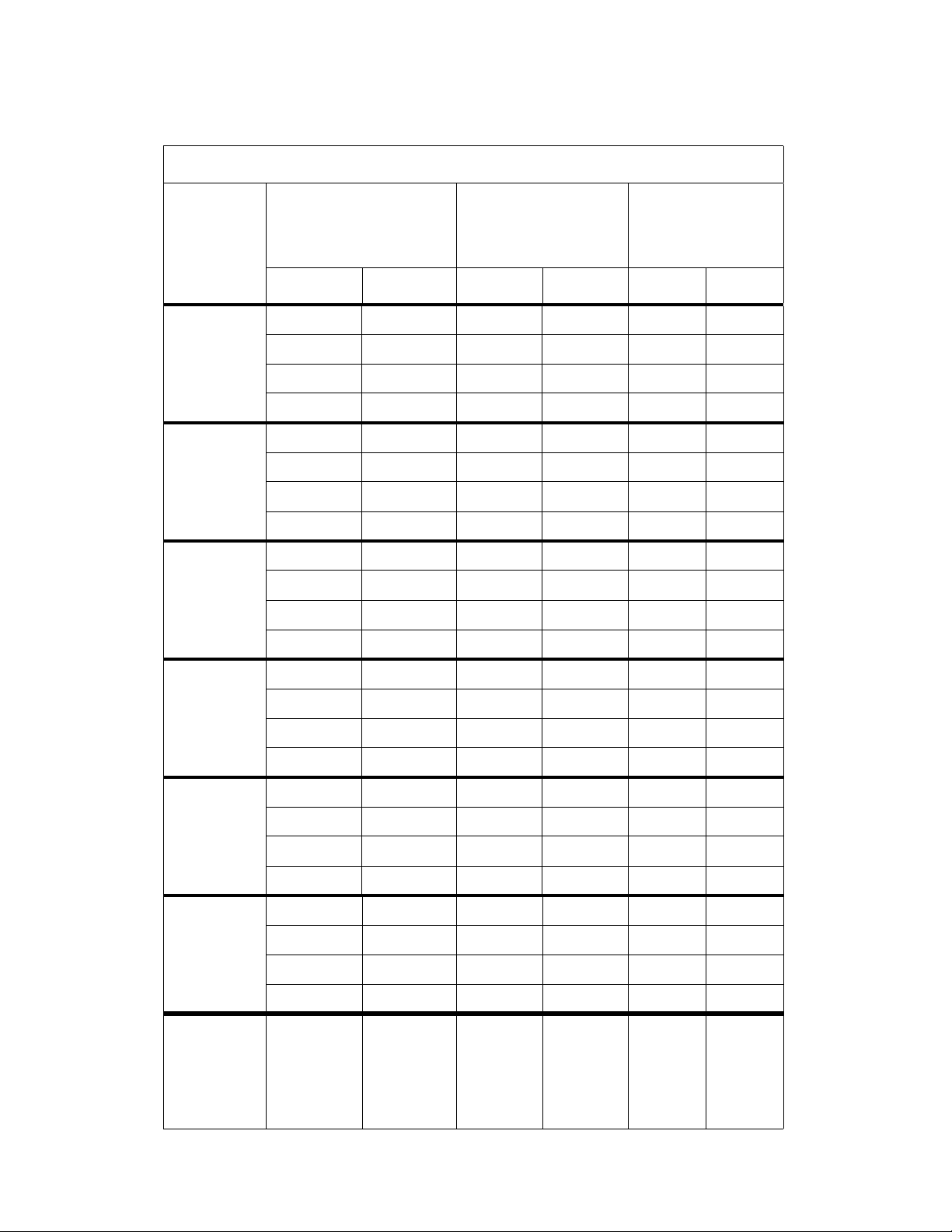

All Weights Rated Speed

All Weights Rated Speed Mode

Paper

Weight

60 - 80

2

g/m

81 - 105

2

g/m

106 - 135

2

g/m

Paper Size (Feed

Print Speed for

DocuColor 8002

Print Speed for

DocuColor 7002

direction length) [mm]

(prints per minute)

(prints per minute)

Min. Max 1 Sided 2 Sided 1 Sided 2 Sided

182.0 mm 216.0 mm 80 40 70 35

216.1 mm 297.0 mm 60 30 60 30

297.1 mm 458.0 mm 40 20 35 17.5

458.1 mm 488.0 mm 30 15 30 15

182.0 mm 216.0 mm 80 40 70 35

216.1 mm 297.0 mm 60 30 60 30

297.1 mm 458.0 mm 40 20 35 17.5

458.1 mm 488.0 mm 30 15 30 15

182.0 mm 216.0 mm 80 40 70 35

216.1 mm 297.0 mm 60 30 60 30

297.1 mm 458.0 mm 40 20 35 17.5

458.1 mm 488.0 mm 30 15 30 15

136 - 186

2

g/m

187 - 220

2

g/m

221 - 300

2

g/m

Transp are ncy

(Only

available for

1-Sided, 8.5 x

11 inch/A4

LEF)

182.0 mm 216.0 mm 80 40 70 35

216.1 mm 297.0 mm 60 30 60 30

297.1 mm 458.0 mm 40 20 35 17.5

458.1 mm 488.0 mm 30 15 30 15

182.0 mm 216.0 mm 80 40 70 35

216.1 mm 297.0 mm 60 30 60 30

297.1 mm 458.0 mm 40 20 35 17.5

458.1 mm 488.0 mm 30 15 30 15

182.0 mm 216.0 mm 80 40 70 35

216.1 mm 297.0 mm 60 30 60 30

297.1 mm 458.0 mm 40 20 35 17.5

458.1 mm 488.0 mm 30 15 30 15

210.0 mm 216.0 mm 30 - 30 -

System Administration Guide 1-21

Page 26

Tools Mode DocuColor 7002/8002

Notes

2

• 2-Sided printing is not available for transparency and paper that is 221 g/m

or greater.

• There is no decrease in productivity (ppm) from the second feeder module to the first

feeder module.

• Transparency is only available for 1 Sided, A4 or 8.5 in. x 11 in.LEF.

Productivity Setting procedure

Use the following procedure for choosing the setting which is best for your environment.

1. Touch the Productivity Setting button on the Machine Defaults 1 screen.

2. Select the button for the type of paper you use most frequently in the digital press, either

Single Paper Weight, Mixed Paper Weight, or All Weights Rated Speed.

3. Touch Close to return to the Machine Defaults 1 screen.

1-22 System Administration Guide

Page 27

DocuColor 7002/8002 Tools Mode

Auto Tray Switching

This feature allows you to set the default settings for the following options:

Default Setting What the Default Does

Auto Tray Switching (ATS) Allows the digital press to automatically select another paper tray,

containing the appropriate paper, if the selected paper tray becomes

unusable

Auto Paper Selection (APS) Allows the digital press to automatically select the appropriate paper

size for the job being processed, without a specific paper tray being

selected

Inhibited Tray Allows you to select a specific paper tray, or trays, that you want the

digital press to bypass, regardless of the Tray Priority settings

1. Touch the Auto Tray Switching button on the Machine Defaults 1 screen.

2. Touch the Enable or Disable button for the Auto Tray Switching option.

3. Touch the Enable or Disable button for the Auto Paper Selection option.

4. To instruct the digital press to bypass one or more of the paper trays, touch the desired

Paper Tray button in the Inhibited Tray column.

• To deselect a paper tray, touch that Paper Tray button again.

• To return the settings to the last saved values, touch the Reset button.

5. Touch the Close button to return to the Machine Defaults 1 screen.

System Administration Guide 1-23

Page 28

Tools Mode DocuColor 7002/8002

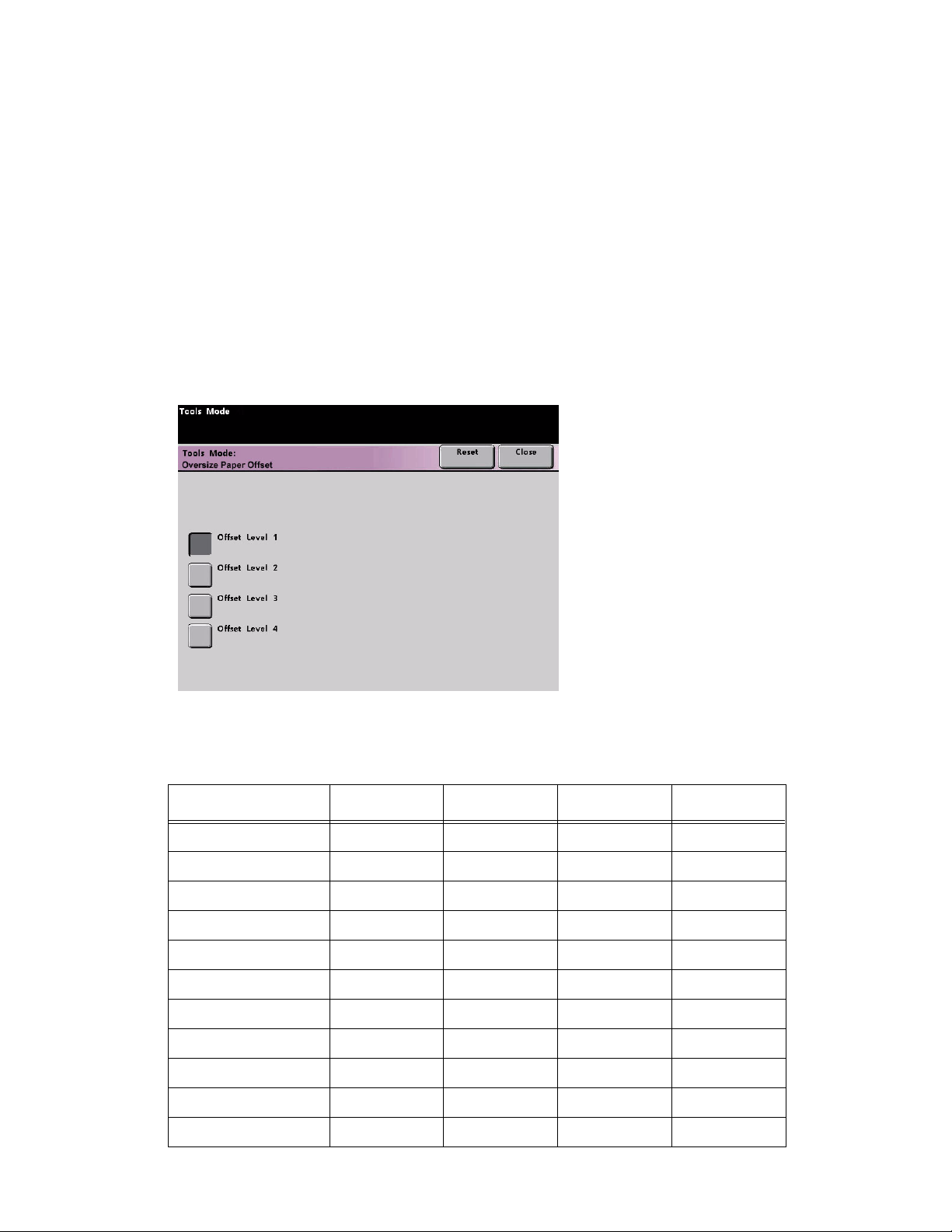

Oversize Paper Offset

Use this feature for media that is larger than long edge feed, 8.5x11 inch/A4 paper, such as 12

x 18 in. (304.8 x 457.2 mm).

Note

Some color server manufacturers have an oversize paper offset feature that you can also use to

adjust the position of the image on the paper. Refer to the documentation that came with your

color server.

Use the following procedure to adjust the registration on paper that is larger than 8.5 x 11 in./

A4.

1. Select the Oversize Paper Offset feature.

2. From the Oversize Paper Offset screen, select the desired Oversize Paper Offset button to

adjust the registration on paper larger than 8.5x11 inch or A4 LEF.

The table on the following page defines each offset level.

3. Touch the Offset Level 1, 2, 3, or 4 button to adjust the position of the paper as it feeds.

Refer to the following table for the adjustments made for each Offset Level.

Paper Size Level 1 Level 2 Level 3 Level 4

310mm 10.0mm 10.0mm 10.0mm 10.0mm

311mm 9.5mm 9.5mm 9.5mm 9.5mm

312mm 9.0mm 9.0mm 9.0mm 9.0mm

313mm 8.5mm 8.5mm 8.5mm 8.5mm

314mm 8.0mm 8.0mm 8.0mm 8.0mm

315mm 7.5mm 7.5mm 7.5mm 8.0mm

316mm 7.0mm 7.0mm 7.0mm 8.0mm

317mm 6.5mm 6.5mm 7.0mm 8.0mm

318mm 6.0mm 6.0mm 7.0mm 8.0mm

319mm 5.5mm 6.0mm 7.0mm 8.0mm

320mm 5.0mm 6.0mm 7.0mm 8.0mm

1-24 System Administration Guide

Page 29

DocuColor 7002/8002 Tools Mode

The following illustration demonstrates how the image is shifted on the paper after

selecting an Oversize Paper Offset level.

Image is

shifted away

from the edge

of the paper.

This dimension

increases

with higher

offset values.

Image

Paper

Lead edge

of paper

Set Date & Time

Use this feature to set the date and time for the system. The date and time is displayed on the

Error Log screen and on the Date and Time screens.

Setting the Date

1. Touch the Set Date & Time button on the Machine Defaults 1 screen. The Set Date and

Time screen appears with the Set Date button selected and options for setting the date

displayed on the right.

2. Select the date format you wish to use.

3. Use the up or down arrow buttons to enter the correct year, month, and day.

4. Touch the Enter button on the screen to save your selections.

The next time you enter the Tools Mode, the date that you set is displayed.

System Administration Guide 1-25

Page 30

Tools Mode DocuColor 7002/8002

Setting the Time

1. Touch the Set Date & Time button on the Machine Defaults 1 screen. The Set Date and

Time screen appears with the Set Date button selected and options for setting the date

displayed on the right.

2. Touch the Set Time button. Options for setting the time appear in the Set Time screen.

3. Touch the 12 Hour Clock or the 24 Hour Clock button.

4. Use the up or down arrow buttons to set the correct hour and minutes.

If you selected the 12 Hour Clock, touch the AM or PM button.

5. Touch the Enter button on the screen to save your selections.

The next time you enter the Tools Mode, the time that you set will be displayed.

6. Touch the Close button to return to the Machine Defaults 1 screen.

Dual Language

This feature enables you to set one of two available languages as the default for the Touch

Screen. When your digital press was installed, your Xerox service representative loaded onto

your system your choice of two languages that you can choose from to be displayed on the

Touch Scre en .

1. Touch the Dual Language button on the Machine Defaults 1 screen.

2. Touch the button for the default language you want to appear on the Touch Screen.

After exiting the Tools Mode, you can switch the Touch Screen to the other language by

pressing the Dual Language button on the Control Panel.

1-26 System Administration Guide

Page 31

DocuColor 7002/8002 Tools Mode

3. Touch the Close button to return to the Machine Defaults 1 screen.

Non-Standard Paper Size

You can run non-standard sized paper from any paper tray by entering the paper size on the

Non-Standard Paper Size screen for the tray being used.

Tip

Be sure to select Non-Standard Size on the top front of the tray, and use the Paper Weight

Indicator at the right side of the tray to select the paper weight being used.

1. Touch the Non-Standard Size Paper button on the Machine Defaults 1 screen.

2. Touch the desired Paper Tray button on the Non-Standard Paper Size screen.

3. Use the up or down arrow buttons on the screen to enter the X and Y dimensions of the

paper being used in the tray. The dimensions shown on the screen above the X and Y boxes

indicate the minimum and maximum sizes you can enter.

4. Touch the Close button to return to the Machine Defaults 1 screen.

5. To use these settings, exit the Tools Mode and ensure that Non-Standard Size has been

selected on the top/front of the tray.

System Administration Guide 1-27

Page 32

Tools Mode DocuColor 7002/8002

Machine Defaults 2

This section describes the features available to you through the Machine Defaults 2 screen.

Select the Machine Defaults 2 tab, and one of the following screens appears.

If your system has an optional finishing device attached, this screen may reflect a finishing

device option as shown below:

Use the procedures on the following pages to make default settings for the available features.

Decurler Adjustment

For information on the Decurler and the step-by-step instructions on using it, refer to the

document entitled DocuColor 8002/7002 Decurler Adjustment

.

1-28 System Administration Guide

Page 33

DocuColor 7002/8002 Tools Mode

Custom Paper procedure

Use the following procedure for creating/modifying a Custom Paper Profile.

Tip

Before creating or modifying Custom Paper Profiles, copy and use the chart at the back of this

book to record your Custom Paper Profile settings. This will ensure that you select the correct

profile for a custom job.

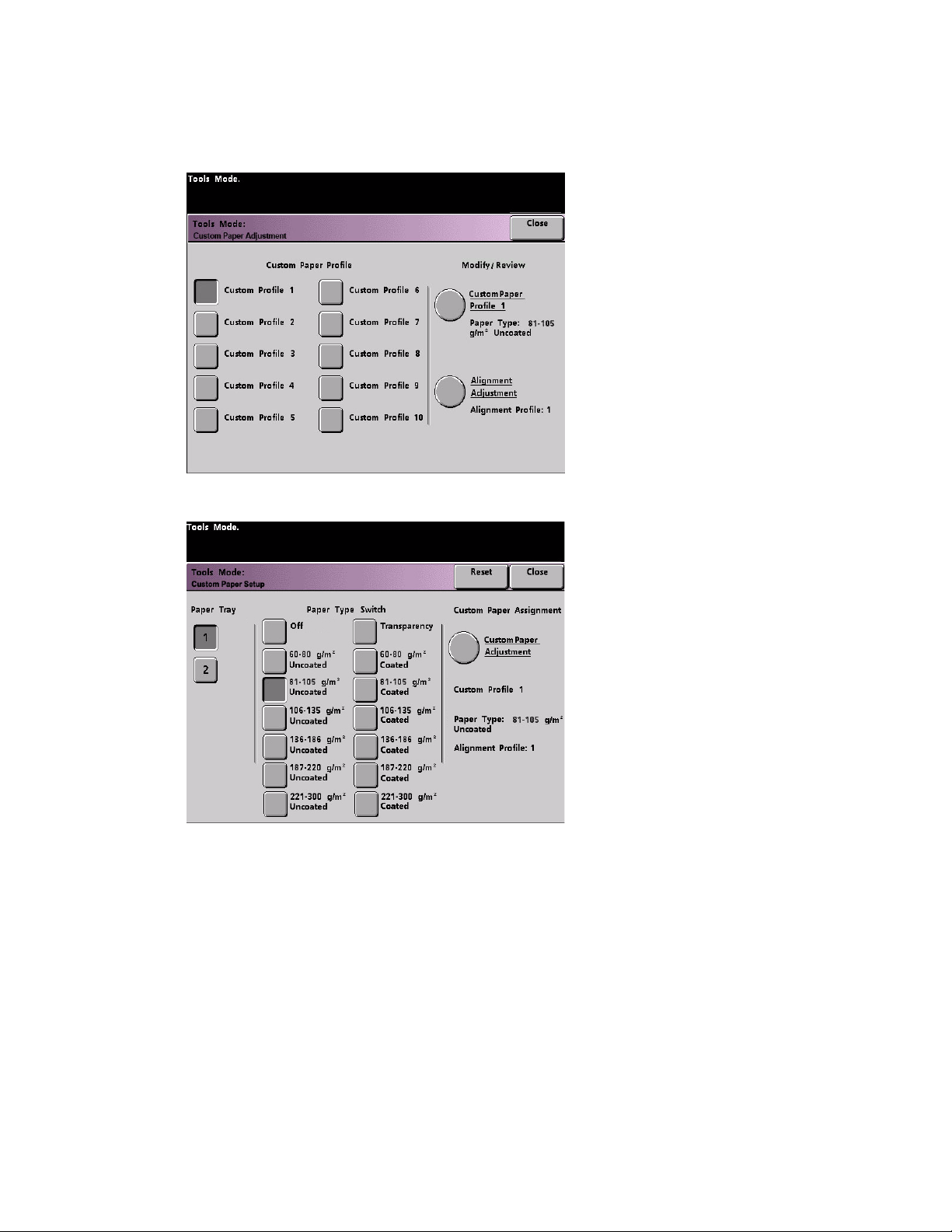

Access the Custom Paper Profile feature

1. Select the Custom Paper Profile feature from Machine Defaults 2.

2. The Custom Paper Setup window opens.

System Administration Guide 1-29

Page 34

Tools Mode DocuColor 7002/8002

Select the specific Paper Tray and Paper Type Switch options

3. Select the specific Paper Tray for which the Custom Paper Profile will be created. If you

have a SFM attached, this screen reflects the additional Paper Trays 3 and 4.

4. Select the Paper Type Switch.

Note

The default setting is Off.

• The Paper Type Switches correspond with the media buttons/switches on the paper

trays:

• Selecting a Paper Type Switch informs the digital press that custom paper is loaded in

the tray and to use the corresponding Custom Paper Profile when those buttons/

switches are selected on the specified paper tray.

1-30 System Administration Guide

Page 35

DocuColor 7002/8002 Tools Mode

Refer to the following example:

Tip

This is an example only. Do not

perform these steps at this time.

1. The Paper Type Switch

corresponds with the selections

on the paper tray.

2. Select a Custom

Paper Profile.

3. Select the

corresponding buttons

on the specified

paper tray.

4. The digital press will use the assigned Custom Paper Profile

when running the print job.

Tip

The Paper Type Switch does not

have to match the actual type of paper you are

loading in the tray. When creating a Custom Paper Profile, select a Paper Type that is

rarely or never

used as your Paper Type Switch. This ensures that when running commonly

used paper types, the digital press does not load a Custom Paper Profile for those types.

System Administration Guide 1-31

Page 36

Tools Mode DocuColor 7002/8002

Select Custom Paper Adjustment option

5. Select Custom Paper Adjustment.

The Custom Paper Adjustment window opens.

Select a Custom Paper Profile option

6. Select a Custom Paper Profile button.

• After selecting a Custom Paper Profile button, the Custom Paper Profile and Alignment

Adjustment buttons on the right are selectable.

Tip

Important information about this feature includes the following:

• You can create and store up to ten different Custom Paper Profiles.

• Only one custom profile is enabled for each tray.

• If you create and store multiple profiles for a specific tray, ensure that you select the

desired profile (1-10) you want to use for that tray before exiting Tools. That Custom

Paper Profile is reflected on the Machine Status screen.

1-32 System Administration Guide

Page 37

DocuColor 7002/8002 Tools Mode

7. From the Modify/Review area, select the Custom Paper Profile button.

The Custom Paper Profile window opens.

These options allow you to further “fine-tune” your custom paper profile and are explained

in more detail on the following pages.

System Administration Guide 1-33

Page 38

Tools Mode DocuColor 7002/8002

These options include:

Base Range of Paper Type

•This is the actual

type of paper you are loading in the paper tray.

2nd BTB

• The Second Bias Transfer Belt is a feature that is normally used with heavier weight

2

paper (220 g/m

and greater, 10 pt, 12 pt).

• The default settings for 2nd BTB Side 1 and Side 2 are both 100%.

• Adjust Side 1 for all simplex jobs. If defects remain in a printed job, perform the

following steps to determine if Side 1 or Side 2 adjustments are appropriate.

• If the job is face down or 1-N, use Side 1 for defects on the topside of the

stacked sheets, and use Side 2 for the downside.

• If the job is face up or N-1, use Side 2 for defects on the topside of the stacked

sheets, and use Side 1 for the downside.

1-34 System Administration Guide

Page 39

DocuColor 7002/8002 Tools Mode

Use This feature when your:

a. Prints may have mottle, which is uneven spotty toner coverage that occurs when

printing large, solid areas of flat color (refer to the below illustration)

No Mottle

Mottle

If mottle exists and it is heavy weight

paper, increase one or both of the

2nd BTB values.

If mottle exists and it is light weight

paper, increase one or both of the

2nd BTB values. Evaluate the image

quality. If the image quality is equal

to or worse than the 100% default

setting, decrease one or both of

the 2nd BTB values until a satisfactory

image quality is obtained.

System Administration Guide 1-35

Page 40

Tools Mode DocuColor 7002/8002

b. Prints have a color shift where the colors are much different than what you desire (refer

to the below illustration).

This test pattern represents an

output with the desired colors.

If mottle color shift exits, increase

one or both of the 2nd BTB values.

This test pattern represents

an output with a shift in colors,

and thereby an undesired output.

1-36 System Administration Guide

Page 41

DocuColor 7002/8002 Tools Mode

Decurler Penetration Amount

• Use this feature to compensate for paper curl in your output prints. This is the same as

the Decurler Setup feature.

For specific Decurler information, refer to the Decurler Setup and Decurler E Table Settings

section earlier in this chapter.

Aligner NIP Pressure

• Use this feature with paper types that slip and skew or have damaged edges.

Examples:

• Some coated paper types slip and skew, thereby having the image misregistered on the

output prints. In this case, you may want to increase

the NIP pressure in order to

compensate for the slippage and skewing.

• Some light-weight papers may have too much NIP pressure applied to them, thereby

causing edge damage to the output prints. In this case, you may to decrease

the NIP

pressure.

• If you are experiencing numerous 8-154 faults, increase the NIP pressure and continue

to run the digital press.

System Administration Guide 1-37

Page 42

Tools Mode DocuColor 7002/8002

Tip

Increasing the NIP pressure for numerous 8-154 faults, allows you to postpone a service

call. However, call your service representative as soon as possible in order to restore the

digital press to its full feeding capabilities.

Air Assist Operation Selection

• Use this feature to switch on or switch off the fans in a paper tray in order to eliminate

misfeeds, paper jams, or other possible tray feeding problems. You can also select Auto

if you want the digital press to decide whether or not to switch on or off the fans for a

paper tray.

Note

The default setting is Auto.

Examples:

• If the digital press is producing multifeeds, try setting this option to Operate (On)

instead of Auto.

• If your output contains two sheets that are stuck together, try setting this option

to Operate (On).

• If misfeeds are occurring (the paper is not leaving the tray) and the environment is

too dry, try setting this option to Do Not Operate (Off) instead of Auto.

8. Make the desired selections from the Custom Paper Profile selections. Select Close to save

the changes and close the window.

1-38 System Administration Guide

Page 43

DocuColor 7002/8002 Tools Mode

Select an Alignment Adjustment Profile (if necessary)

9. If necessary, you can select or create an Alignment Adjustment Profile for this Custom

Paper Profile.

Note

For information on the Alignment Adjustment feature refer to the section later in this

chapter entitled Alignment Adjustment.

Load paper tray and run a Test Print

10. Load your custom paper in the same paper tray as the one you selected for this Custom

Paper Profile. Ensure that you set the tray buttons to reflect the same information as

your Paper Type Switch settings.

11. After you select all the desired settings for this Custom Paper Profile, run a Te st Pr i nt to

ensure that the output is satisfactory.

12. If the output is not satisfactory, perform Steps 1-10 again to readjust the parameters for

this Custom Paper Profile.

• Run another Test Print to ensure that your output is satisfactory.

• Continue to perform these steps until your output is satisfactory.

System Administration Guide 1-39

Page 44

Tools Mode DocuColor 7002/8002

13. Once your output is satisfactory, select the Close button.

This returns you to the Custom Paper Adjustment screen:

14. Select the Close button to return to the Custom Paper Setup screen:

15. Select the Close button to save and close these settings for this Custom Paper Profile.

If you do not want to save this profile, select the Reset button to discard all the selections

for this profile and reset them to the machine defaults.

1-40 System Administration Guide

Page 45

DocuColor 7002/8002 Tools Mode

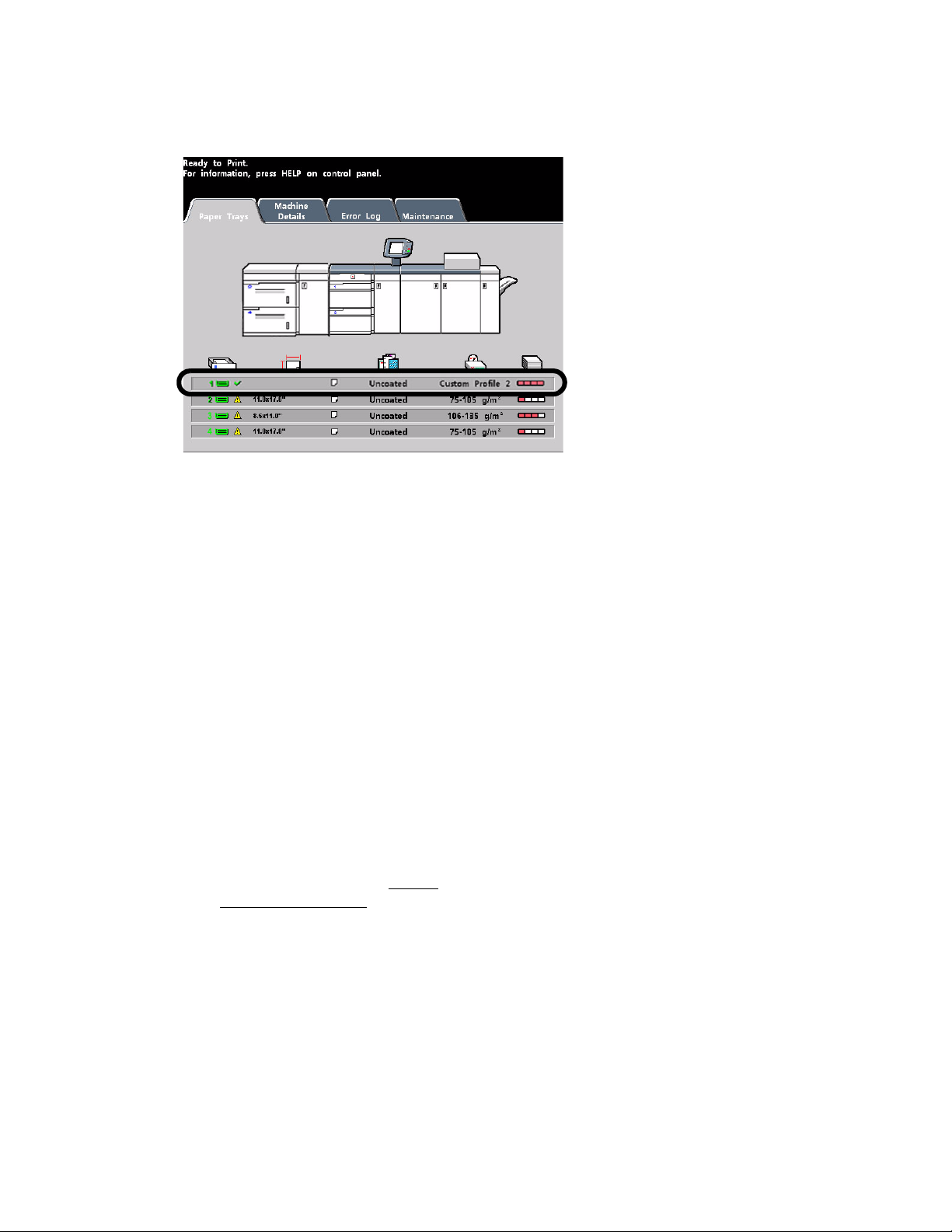

16. Close out of Tools Mode and return to the Machine Status screen. The Machine Status

screen now displays your new Custom Paper Profile:

17. To switch off the Custom Paper Profile without going into or deleting it in Tools Mode,

simply open the paper tray and select different paper type information (weight, coating,

etc.) by changing the tray buttons/switches.

You can return to this saved Custom Paper Profile any time by changing the tray buttons/

switches to reflect the desired profile.

Alignment Adjustment Profile

When printing duplex jobs and using different media types (including paper type, weight, and

coating/uncoating), the output may require specific handling by the digital press as it is moving

through the paper path. With certain media types and duplex jobs, the images on Side 1 and/

or Side 2 may be misregistered, skewed, perpendicularly misaligned, or stretched.

As with the Custom Paper Setup feature, Alignment Adjustment feature allows you to create

and store a maximum of twenty different Alignment Adjustment Profiles. These profiles allow

you to accommodate different media types and how the image is registered, aligned, or

magnified for Side 1 and Side 2 output. These profiles may be used at point of need in order to

ensure optimum output quality of your print.

Note

You can create Alignment Profiles without

Profile. The reverse is also true

specific Custom Paper Profile. For example, Custom Paper Profile 2 may be affiliated with

Alignment Profile 2, so that when Custom Paper Profile 2 is in use, so is Alignment Profile 2.

: You can create an Alignment Profile and associate it to a

associating them to a specific Custom Paper

System Administration Guide 1-41

Page 46

Tools Mode DocuColor 7002/8002

When creating Alignment Profiles for Side 1 and/or Side 2 prints, be aware of the following:

• Side 1/Side 2 images may be misregistered because the paper is not the exact same size. It

may vary slightly, with differences of plus or minus 1mm, causing the image to be

misregistered. To reduce the possibility of size differences, it is recommended that you use

paper from the same lot when running duplex jobs.

• During the fusing process, the heat and pressure applied to the paper causes the paper to

stretch. If the images on Sides 1 and 2 are the same size, the stretching of the paper may

cause the image on Side 1 to be slightly larger than the image on Side 2.

• Creating an Alignment Profile for these types of jobs allows you to reduce or eliminate the

images being larger on Side1 than on Side 2 prints.

Notes

• Remember: Your Alignment Profile may or may not

Profile.

• Once an Alignment Profile is set and in use, your color server will not reflect that profile in

the print options for print jobs.

• After an Alignment Profile is set, it remains active until you reenter Tools Mode and switch it

off. If an active Alignment Profile is not associated with a Custom Paper Profile, it is used

for each paper tray to which it is assigned.

be affiliated with a Custom Paper

Access the Alignment Adjustment feature

Use the following procedure to create/modify an Alignment Profile for adjusting Side 1/Side 2

image output.

Tip

Before creating or modifying Alignment Profiles, copy and use the chart at the back of this book

to record your Alignment Profile settings. This will ensure that you select the correct profile for

a custom job.

Note

If you require a Custom Paper Profile associated with this Alignment Profile, you can set the

Custom Paper Profile information either now or after you create the Alignment Profile.

1. Access Tools Mode and touch the Alignment Adjustment button on the Machine Defaults

2 screen; the following window opens.

1-42 System Administration Guide

Page 47

DocuColor 7002/8002 Tools Mode

Select a paper tray and a profile number

2. Select a Paper Tray.

Tip

If you are creating an Alignment Profile in affiliation with a Custom Paper Profile and have

arrived here from the Custom Paper Setup procedure, then this screen will not reflect any

Paper Tray information. The Paper Tray information was selected earlier in your associated

Custom Paper Profile.

Note

If you have an optional SFM attached to your digital press, this screen will reflect the

additional Paper Trays 3 and 4.

3. Select a Profile number from 1-20 by touching the desired button.

The Modify/Review button is now selectable, as shown above.

System Administration Guide 1-43

Page 48

Tools Mode DocuColor 7002/8002

Select an Alignment Profile button

4. Touch one of the Alignment Profile buttons; the Alignment Profile window opens.

Run a Test Print

5. Touch the Tes t Prin t button; a new window opens.

a. Touch the 2 Sided button.

Note

If you want to check the registration for 1 Sided prints only, touch the 1 Sided button.

b. Select 10 test prints by touching the Up arrow button to change the number of test

prints generated.

c. Touch the Pattern Generator button.

d. Retrieve your output test prints from the digital press.

e. Discard the first few prints, as inconsistency tends to be greater with these images.

1-44 System Administration Guide

Page 49

DocuColor 7002/8002 Tools Mode

6. Evaluate the test prints by holding your 2 Sided output at eye level near a light source. This

will allow you to see the registration marks for both Side 1 and Side 2 of the output.

a. If you determine that the registration between Side 1 and Side 2 is significant and

needs adjusting, proceed to the Step 7.

b. If the registration between Side 1 and Side 2 is okay, stop now:

• Touch the Close button to return to the Alignment Profile window.

• Ensure that the Default button is selected and touch the Close button.

•Exit Tools Mode.

Select an Alignment Adjustment feature

7. Select the desired Alignment feature that you want to adjust.

Each of the above Alignment features is discussed on the following pages.

Lead Registration

• Use this feature to adjust the lead edge of the image for Side 1 and/or Side 2

registration.

System Administration Guide 1-45

Page 50

Tools Mode DocuColor 7002/8002

• The factory default setting is zero (0).

• The arrows on the right side of the illustration show the paper feed direction.

•The + sign, the left-pointing arrow, and the red lines shows the direction the image

will move on the paper when the value is increased.

• If you select a negative value (for example, -1.0 mm), the image on the paper

moves toward the right.

Side Registration

• Use this feature to adjust the side edge of the image for Side 1 and/or Side 2

registration.

• The factory default setting is zero (0).

•The + sign, the up arrow, and the red lines shows the direction the image will move

on the paper when the value is increased.

• If you select a negative value (for example, -1.0 mm), the image on the paper

moves downward.

Perpendicularity

• Use this feature to adjust the image digitally on the drum so that it will align with the

paper for both Side 1 and Side 2.

1-46 System Administration Guide

Page 51

DocuColor 7002/8002 Tools Mode

• The factory default setting is zero (0).

• The arrows on the right side of the illustration show the paper feed direction.

•The + sign, the left-pointing arrow, and the red lines shows the direction the image

will move on the paper when the value is increased.

• If you select a negative value (for example, -1.0 mm), the image on the paper

moves toward the right.

Side Skew

• Use this feature to adjust the paper so that the image for Side 1 and/or Side 2 are not

skewed but aligned with each other.

• The factory default setting is zero (0).

• The arrows on the right side of the illustration show the paper feed direction.

•The + sign, the right-curved arrow, and the red lines shows the direction the image

will move on the paper when the value is increased.

• If you select a negative value (for example, -1.0 mm), the image on the paper

moves toward the left.

System Administration Guide 1-47

Page 52

Tools Mode DocuColor 7002/8002

FS Direction Image Magnification

• Use this feature to correct for image stretch from Side 1 to Side 2. The image may be

enlarged or reduced as necessary.

• FS stands for Fast Scan and it enlarges or reduces the image in the direction shown

in the illustration above.

• The factory default setting is zero (0).

• The arrows on the right side of the illustration show the paper feed direction.

•The + sign, the up arrow, and the red line shows the direction the image will move

on the paper when the value is increased.

• If you select a negative value (for example, -1.0 mm), the image on the paper

moves down.

1-48 System Administration Guide

Page 53

DocuColor 7002/8002 Tools Mode

SS Direction Image Magnification

• Use this feature to correct for image stretch from Side 1 to Side 2. The image may be

enlarged or reduced as necessary.

• SS stands for Slow Scan and it enlarges or reduces the image in the direction

shown in the illustration above.

• The factory default setting is zero (0).

• The arrows on the right side of the illustration show the paper feed direction.

•The + sign, the left-pointing arrow, and the single, black line shows the direction

the image will move on the paper when the value is increased.

• If you select a negative value (for example, -1.0 mm), the image on the paper

moves toward the right.

8. Make the desired adjustments for one the Alignment Profile features (Lead Registration,

Side Registration, etc.).

Note

It is recommended that you choose only one Alignment Profile feature until you run

another set of Test Prints and evaluate the registration on that output. If you want

multiple Alignment Profile features selected, individually select each feature, run Test Prints

for that feature, and evaluate the output. After you determine that the output for the

selected feature is acceptable, then you can select another Alignment Profile feature to

adjust.

System Administration Guide 1-49

Page 54

Tools Mode DocuColor 7002/8002

Touch the Close button on the appropriate screen to save the settings and return to the

Alignment Profile window.

Run more Test Prints

9. Select Test Print to ensure that the output is satisfactory.

a. Touch the 2 Sided button.

Note

If you want to check the registration for 1 Sided prints only, touch the 1 Sided button.

b. Select 10 test prints by touching the Up arrow button to change the number of test

prints generated.

c. Touch the Pattern Generator button.

d. Retrieve your output test prints from the digital press.

e. Discard the first few prints, as inconsistency tends to be greater with these images.

10. Evaluate the test prints by holding your 2 Sided output at eye level near a light source. This

will allow you to see the registration marks for both Side 1 and Side 2 of the output.

a. If you determine that the registration between Side 1 and Side 2 is significant and

needs adjusting, repeat Steps 7-9 until you achieve satisfactory output. Proceed to the

Step 11.

b. If the registration between Side 1 and Side 2 is okay, stop now and proceed to the next

step.

1-50 System Administration Guide

Page 55

DocuColor 7002/8002 Tools Mode

11. Once your output is satisfactory, select Close to save these settings and return to the

Alignment Adjustment window.

12. Select Close to save all the settings for this Alignment Profile and return to the Machine

Defaults 2 screen.

13. Close out of Tools Mode.

Tip

The Alignment Profile you just created/modified is now in affect for the specific Paper Tray that

you selected in the procedure. This Alignment Profile remains in affect until you reenter Tools

Mode and deactivate it. To deactivate an Alignment Profile, continue to the next page.

Deactivating an Alignment Adjustment Profile

To switch off or deactivate an Alignment Profile, perform the following steps:

1. Reenter Tools Mode.

2. Select Alignment Adjustment from the Machine Default 2 screen.

3. Refer to your Alignment Adjustment Profile Chart where you recorded the selections made

for the profile you want to switch off/deactivate.

System Administration Guide 1-51

Page 56

Tools Mode DocuColor 7002/8002

4. Select the Paper Tray for the profile you want to switch off/deactivate.

The Profile number button selected for this Alignment Profile will be selected. For example,

the above illustration shows that Tray 1 is assigned Alignment Profile 1.

5. Touch the Default button. This switches off the Alignment Adjustment Profile.

• Select Close to return to the Machine Defaults 2 screen.

6. Exit the Tools Mode by touching the Close button.

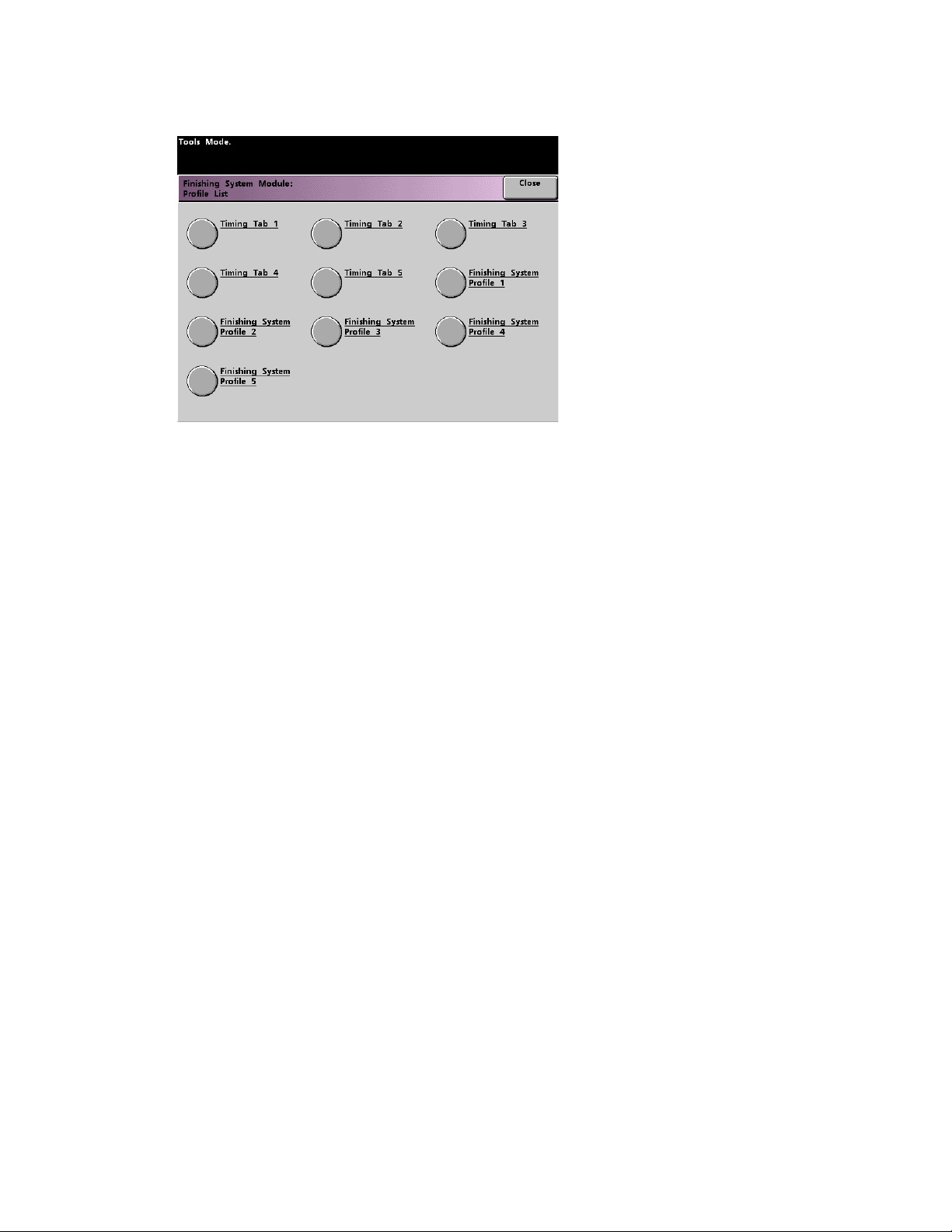

Finishing System Module Profile (DFA device)

If your digital press has a third-party, Digital Finishing Architecture (DFA) device, connected,

enabled, and powered on, the option entitled “Finishing System Module Profile” is displayed

on the Machine Defaults 2 tab.

1-52 System Administration Guide

Page 57

DocuColor 7002/8002 Tools Mode

Touch the Finishing System Module Profile button to display the Profile List.

To view the settings for a Timing Tab or a Finishing System Profile, touch that button. The

settings for a DFA device can only be viewed on the digital press Touch Screen. The settings are

enabled on the color server connected to your digital press.

System Administration Guide 1-53

Page 58

Tools Mode DocuColor 7002/8002

1-54 System Administration Guide

Page 59

Auditron

2

Tip

Some features or options described in this chapter may not display or be selectable depending

on the configuration of your machine.

Overview

The Auditron Mode enables you to:

• Change the Tools Mode password

• Establish a separate password for access to the Auditron Mode

• View the number of prints sent through the color server.

Use the following procedure to access the Auditron Administration screens.

1. Press the Access button on the Control Panel.

2. Use the Control Panel keypad to enter the Tools Mode five-digit password, and then touch

the Enter button on the Touch Screen.

3. Touch the Auditron Administration Pathway button on the screen. The Auditron

Administration screen appears.

System Administration Guide 2-1

Page 60

Auditron DocuColor 7002/8002

Initialization

User Accounts are individual accounts that can be set up with print limits, color limits, a

password, and copy volume limits. The Initialization screen allows you to reset information in

User Accounts.

The Initialization screen allows you to:

• Select a total number of User Accounts; the maximum is 300,

• Change the number of User Accounts, or

• Reset all the User Account information and passwords.

Whenever you perform one of the above options, a confirmation screen asks if you are sure you

want to initialize the Auditron:

Responding with a “Yes” deletes all the established accounts, and returns the Tools Mode

password to the factory default of five ones (11111).

2-2 System Administration Guide

Page 61

DocuColor 7002/8002 Auditron

Whether you initially setting up the Auditron, changing the total number of user accounts, or

resetting the Auditron, a message appears at the top of the screen when you touch the Close

button. This message informs you that you must Initialize the Auditron after performing one of

the aforementioned functions. Touch the Initialize Auditron button and select “Yes” to

complete the task.

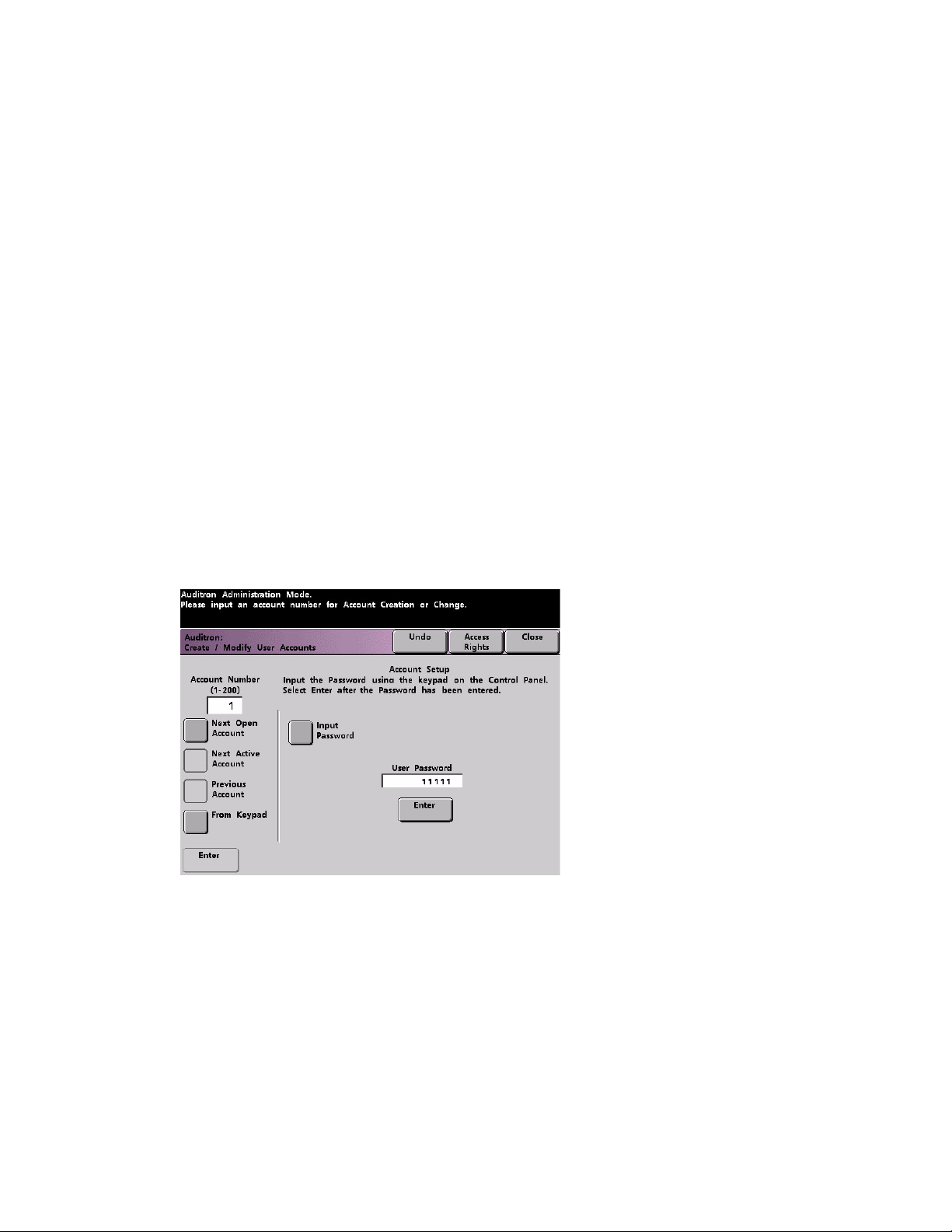

Create/Modify User Accounts

The Create/Modify User Accounts screen enables you to create user accounts, passwords, or

review existing account privileges. You are also able to change the default password for entering

the Tools Pathway and to create a new password for the Auditron Mode, if so desired.

Account 1 is reserved for the System Administrator by factory default. This account is set up

with access to both Tools and Auditron. The default password is set to 11111 and can be

changed by the System Administrator.

Creating a User Account

Use the following procedure to create a User Account.

Note

To undo the last change that you made, touch the Undo button at the top of the screen. The

last setting that you changed is returned to its previous value.

1. Touch the Create/Modify User Accounts button on the Auditron Administration screen. The

Create/Modify User Accounts screen appears.

2. Select the next open account by doing one of the following:

a. Touch the From Keypad button.

• Use the Control Panel keypad to enter the account number for this User Account.

• Touch the Enter button on the bottom left side of the screen to save your entry; or

System Administration Guide 2-3

Page 62

Auditron DocuColor 7002/8002

b. Simply touch the Next Open Account button.

3. Set the level of access for the individual using the account by touching the Access Rights

button.

4. Touch one of the following buttons:

• Key Operator Access

• Auditron Administrator

• Technical Key Operator Access

Note

The optional Technical Key Operator feature may or may not be activated with your

configuration.

5. Touch the Close button to return to the Create/Modify User Accounts screen.

6. Touch the Input Password button.

a. Use the Control Panel keypad to enter the unique five-digit password for this account.

b. Touch the Enter button in the center of the screen. The password you enter is displayed

in the User Password field.

7. Touch the Enter button in the center of the screen to enter your settings into the system.

8. Touch the Close button to return to the Auditron Administration screen.

9. Exit the Auditron Mode to activate the new settings for this User Account.

2-4 System Administration Guide

Page 63

DocuColor 7002/8002 Auditron

Modifying a User Account

Use the following procedure to modify a User Account.

Note

To undo the last change that you made, touch the Undo button at the top of the screen. The

last setting that you changed will be returned to its previous value.

1. Touch the Create/Modify User Accounts button on the Auditron Administration screen. The

Create/Modify User Accounts screen appears.

2. Review Steps 2-9 in Creating a User Account on for information on how to change specific

settings on this screen.

3. Touch the Next Open Account or Previous Account button to modify the settings for

additional User Accounts. Touch the Next Active Account button to modify the settings for

the next active User Account.

4. Touch the Close button to return to the Auditron Administration screen.

5. Exit the Auditron Mode to activate the new settings for this User Account.

Changing the Tools Mode Password

Use the following procedure to change the Access password for the Tools Mode.

1. Touch the Create/Modify User Accounts button on the Auditron Administration screen. The

Create/Modify User Accounts screen appears.

Account 1 is displayed on the next screen with the default password of five 1s (11111).

2. Touch the Input Password button. Use the Control Panel keypad to enter a new password.

The new password is displayed in the User Password field.

3. Touch Enter on the Touch Screen. The new password takes effect the next time you access

the Tools Mode.

System Administration Guide 2-5

Page 64

Auditron DocuColor 7002/8002

Creating a Password for the Auditron Mode

Use the following procedure to create a unique password for accessing the Auditron Mode.

1. Touch the Create/Modify User Accounts button on the Auditron Administration screen. The

Create/Modify User Accounts screen appears.

2. Touch the Next Open Account button. The number 2 is displayed in the Account Number

field.

You can use any open account number for the Auditron Pathway password by touching the

Next Active Account button.

3. Touch the Input Password button. Use the Control Panel keypad to enter the unique fivedigit password for this account. The password you enter is displayed in the User Password

field.

4. Touch the Enter button to save your entry.

5. Touch the Access Rights button at the top of the screen. The Access Rights screen appears.

6. Touch the Auditron Administrator Access button.

7. Touch the Close button.

8. Touch the Enter button on the Create/Modify User Accounts screen.

9. Touch the Close button on the Create/Modify User Accounts screen.

10. Exit the Auditron Mode to activate the new password.

2-6 System Administration Guide

Page 65

DocuColor 7002/8002 Auditron

Review Printer Job Account

Use the Review Printer Job Account screen to determine the number of print jobs sent from the

color server connected to your digital press.

The meters show volumes for the following copy types:

Depending on your digital press configuration, you may or may not have an additional printing

volume meter on this screen.

To reset these meters to zero, touch the Reset button. A confirmation screen asks if you are sure

you want to reset the meters.

Note

Resetting these meters does not reset the meters shown on the Meters screen that is accessed

through the Machine Details screen on the Touch Screen.

System Administration Guide 2-7

Page 66

Auditron DocuColor 7002/8002

2-8 System Administration Guide

Page 67

DocuColor 7002/8002 Charts

Charts

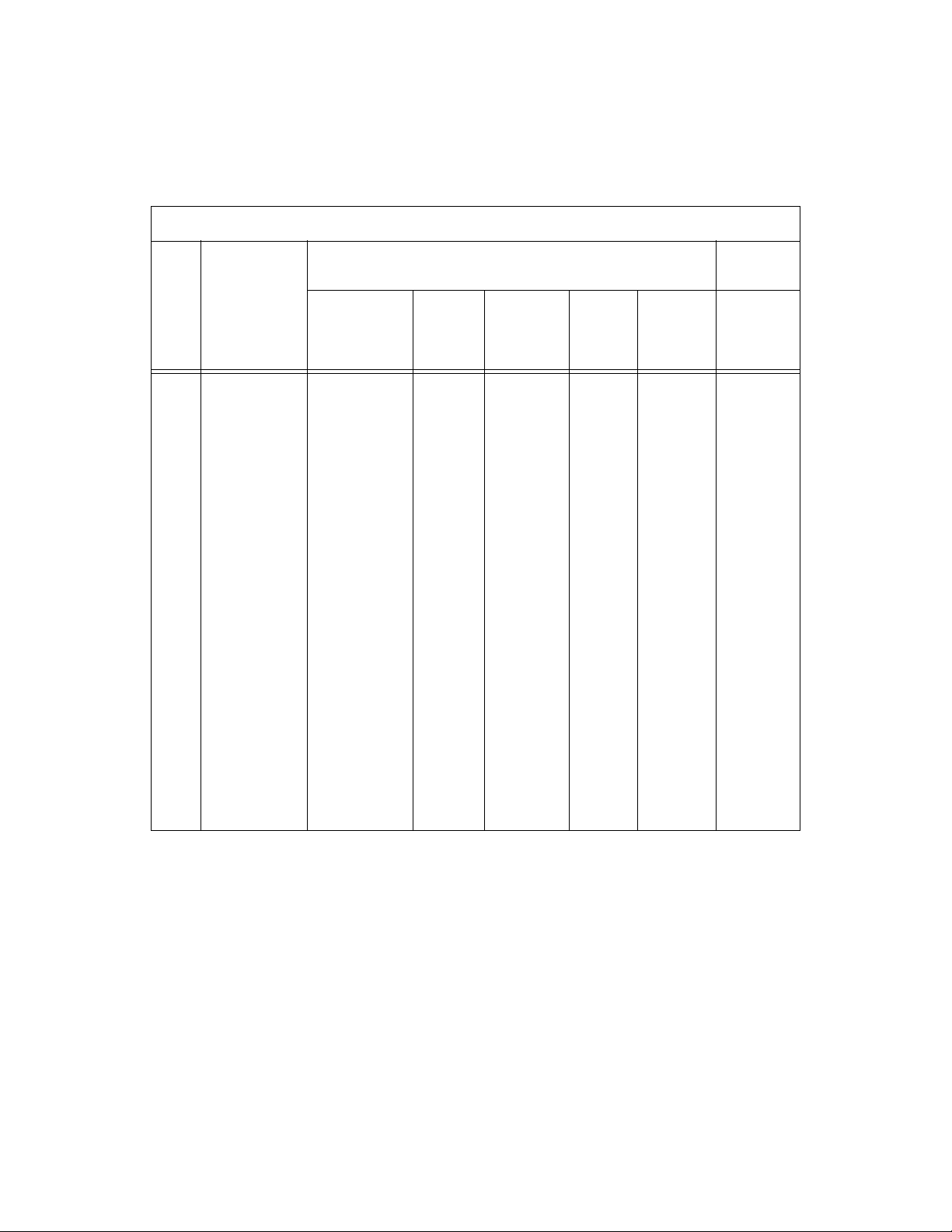

E Table Settings Chart: Type E1

E Table Settings

Paper

Type

Single

Paper

Wei ght

Mixed

Paper

Wei ght

E Table

Ty pe

E1

Ty pe

E2

Ty pe

E3

Ty pe

E4

Ty pe

E5

Ty pe

E6

Decurler

Type

Simplex:

Straight

Simplex: In

Reverse

Duplex:

Side 1 to

Side 2

Duplex:

Side 2 to

Side 1

Duplex

Decurler

Lower

(10

mm)

_______

mm

Lower

(6 mm)

_______

mm

Lower

(2 mm)

________

mm

Upper

(10

mm)

_______

mm

Upper

(6 mm)

______

mm

Upper

(2 mm)

______

mm

1. Record the original, manufacturer default settings by placing a check mark in the

appropriate boxes that apply for the original E Type settings, including Paper Type, E Table,

and Decurler Type.

2. Touch the E Table Settings button (from the Decurler E Table Settings window) and then

enter the number for each E Type Table Setting in the E Table Settings columns above.

System Administration Guide 3-1

Page 68

Charts DocuColor 7002/8002

E Table Settings Chart: Type E2

E Table Settings

Paper

Type

Single

Paper

Wei ght

Mixed

Paper

Wei ght

E Table

Ty pe

E1

Ty pe

E2

Ty pe

E3

Ty pe

E4

Ty pe

E5

Ty pe

E6

Decurler

Type

Simplex:

Straight

Simplex: In

Reverse

Duplex:

Side 1 to

Side 2

Duplex:

Side 2 to

Side 1

Duplex

Decurler

Lower

(10

mm)

_______

mm

Lower

(6 mm)

_______

mm

Lower

(2 mm)

________

mm

Upper

(10

mm)

_______

mm

Upper

(6 mm)

______

mm

Upper

(2 mm)

______

mm

1. Record the original, manufacturer default settings by placing a check mark in the

appropriate boxes that apply for the original E Type settings, including Paper Type, E Table,

and Decurler Type.

2. Touch the E Table Settings button (from the Decurler E Table Settings window) and then

enter the number for each E Type Table Setting in the E Table Settings columns above.

3-2 System Administration Guide

Page 69

DocuColor 7002/8002 Charts

E Table Settings Chart: Type E3

E Table Settings

Paper

Type

Single

Paper

Wei ght

Mixed

Paper

Wei ght

E Table

Ty pe

E1

Ty pe

E2

Ty pe

E3

Ty pe

E4

Ty pe

E5

Ty pe

E6

Decurler

Type

Simplex:

Straight

Simplex: In

Reverse

Duplex:

Side 1 to

Side 2

Duplex:

Side 2 to

Side 1

Duplex

Decurler

Lower

(10

mm)

_______

mm

Lower

(6 mm)

_______

mm

Lower

(2 mm)

________

mm

Upper

(10

mm)

_______

mm

Upper

(6 mm)

______

mm

Upper

(2 mm)

______

mm

1. Record the original, manufacturer default settings by placing a check mark in the

appropriate boxes that apply for the original E Type settings, including Paper Type, E Table,

and Decurler Type.