2. Fault Code Procedures

Section Contents Page

Introduction . . . . . . . . . . . . . . . . . . . . . . .2-3

Section 2 Entry Flow Chart . . . . . . . . . . .2-4

Paper Jam Entry Flow Chart . . . . . . . . . .2-5

Status Fault Codes

Table 1. Status Code Entry Table 1 . . . .2-6

02-282, 283, 330 . . . . . . . . . . . . . . . . . . .2-7

02-340, 350 . . . . . . . . . . . . . . . . . . . . . . .2-6

03-315, 317, 330, 336, 338 . . . . . . . . . . .2-7

03-352, 357, 370 . . . . . . . . . . . . . . . . . . .2-7

03-371 . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

03-600 . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

04-200 . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

05-110 . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

05-111 . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

05-115, 116 . . . . . . . . . . . . . . . . . . . . . .2-11

05-195 . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

05-273 . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

05-280 . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

05-340 . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

ADF Interlock Fault . . . . . . . . . . . . . . . .2-14

ADF “Other” Faults. . . . . . . . . . . . . . . . .2-15

06-310, 311 . . . . . . . . . . . . . . . . . . . . . .2-15

06-340, 359 . . . . . . . . . . . . . . . . . . . . . .2-16

06-361 . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

06-364 . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

06-370 . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

06-371 . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

06-372 . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

06-380, 384 . . . . . . . . . . . . . . . . . . . . . 2-18

06-389 . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

06-390 . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

06-391 . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

06-398 . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

07-281, 282, 283, 284 . . . . . . . . . . . . . 2-20

Tray Load Paper for Tray 1, Tray 2, Tray 3,

Tray 4, or the Bypass Tray . . . . . . . . . . 2-20

Tray Paper Size Sensing for Tray 1, Tray 2,

Tray 3, Tray 4, or the Bypass Tray. . . . . 2-21

08-105, 110, 115, 120 . . . . . . . . . . . . . 2-21

08-138 . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

08-161 . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

08-165 . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

08-167 . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

08-168 . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

08-169 . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

08-170 . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

08-171, 172, 173, 174 . . . . . . . . . . . . . 2-25

08-175, 176, 177, 178, 179 . . . . . . . . . 2-26

08-198 . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

08-380 . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

08-385. . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

08-900. . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

09-363. . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

09-365, 366, 367, 368. . . . . . . . . . . . . . 2-28

09-376. . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

09-620. . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

10-105, 106. . . . . . . . . . . . . . . . . . . . . . 2-29

10-358. . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

10-359. . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

10-360. . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

10-361. . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

10-362. . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

10-363. . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

10-364. . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

10-365. . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

10-366, 367. . . . . . . . . . . . . . . . . . . . . . 2-32

10-368. . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

10-369. . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

10-370. . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

10-371. . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

10-372. . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

10-373. . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

10-374. . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

10-375, 376. . . . . . . . . . . . . . . . . . . . . . 2-34

11-100, 101. . . . . . . . . . . . . . . . . . . . . . 2-35

11-340. . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

5/98

5750 DocuCare Service Manual 2-1

Fault Code Procedures

11-380. . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

11-381. . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Sorter Interlock RAP. . . . . . . . . . . . . . . 2-36

15-280. . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

15-281, 282, 283. . . . . . . . . . . . . . . . . . 2-37

15-340. . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

15-360, 361, 362. . . . . . . . . . . . . . . . . . 2-38

15-380, 381, 382, 383, 384, 385. . . . . . 2-39

15-386, 387, 388, 389, 390, 391. . . . . . 2-39

18-340. . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Fault Code Procedures

5/98

2-2 5750 DocuCare Service Manual

Introduction

This section contains status code procedures. Each procedure represents a status

code, or group of status codes that may be

displayed, indicating a problem.

The status codes are numerical (e.g. 5-901),

with the number to the left of the hyphen indicating the area of the machine and the

remaining digit(s) indicating a particular fault

to that area. Using the example of status

code 5-901, the first number (5) indicates

that the fault has occurred in the ADF (Automatic Document Feeder). A “10-106” code

would indicate a duplex jam.

To access the correct procedure, use the

section content page to locate the indicated

status code and the appropriate page number. The Status Code Entry Table is composed of two columns. The left column

contains the status code fault indicator. The

right column includes a description of the

fault and the actions to take in resolving the

problem. The actions are the “most likely”

suspects. In each case, if you try to resolve

the fault and all attempts fail, y ou are directed

to call for service.

Always Heed The Following Warning....

.

WARNING

Switch off the Main Power Switch, and

disconnect the Power Cord. Install Lockout tag. Failure to do so could result in

severe electrical shock.

Table 1. Fault Code Subsystems

Area Description

02

03 IOT

04 Machine Clock

05 ADF Failures

06 Scanning/ROS/Communica-

07 Paper Tra ys

08 Paper Tra y/Registration Jams

09 Developer/Toner/ADC

10 Fuser

11 Sorter

15 PWB Failure

18 PWB Read/Write Error

User Interface

tions failure

Anytime the fault code is not listed, or if you

are unable to clear the problem within reasonable time you should call for assistance.

Always follow the Repair procedures carefully. Whenever directed, be sure to Switch

off the Main Power Switch and disconnect

the Power Cord.

5/98

5750 DocuCare Service Manual 2-3

Fault Code Procedures

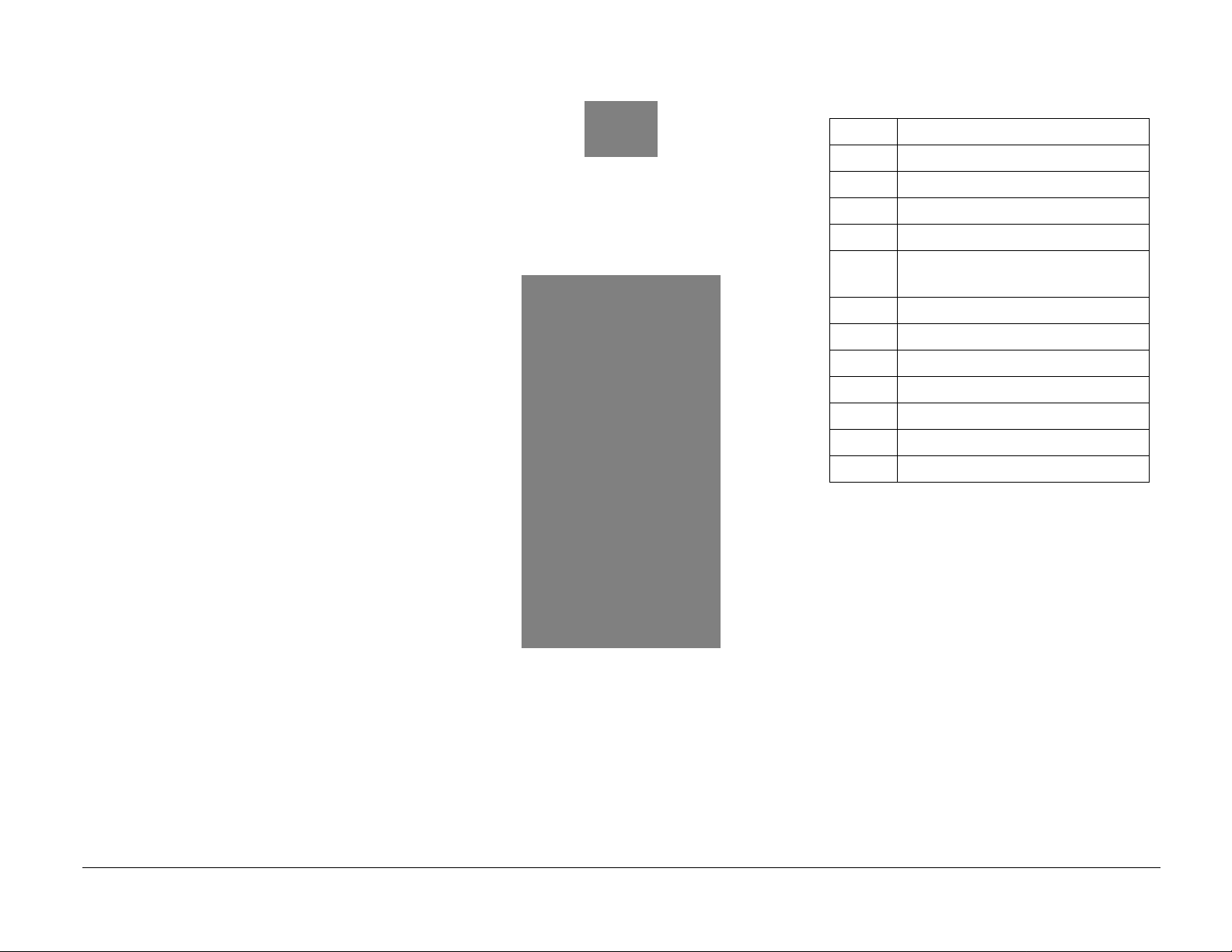

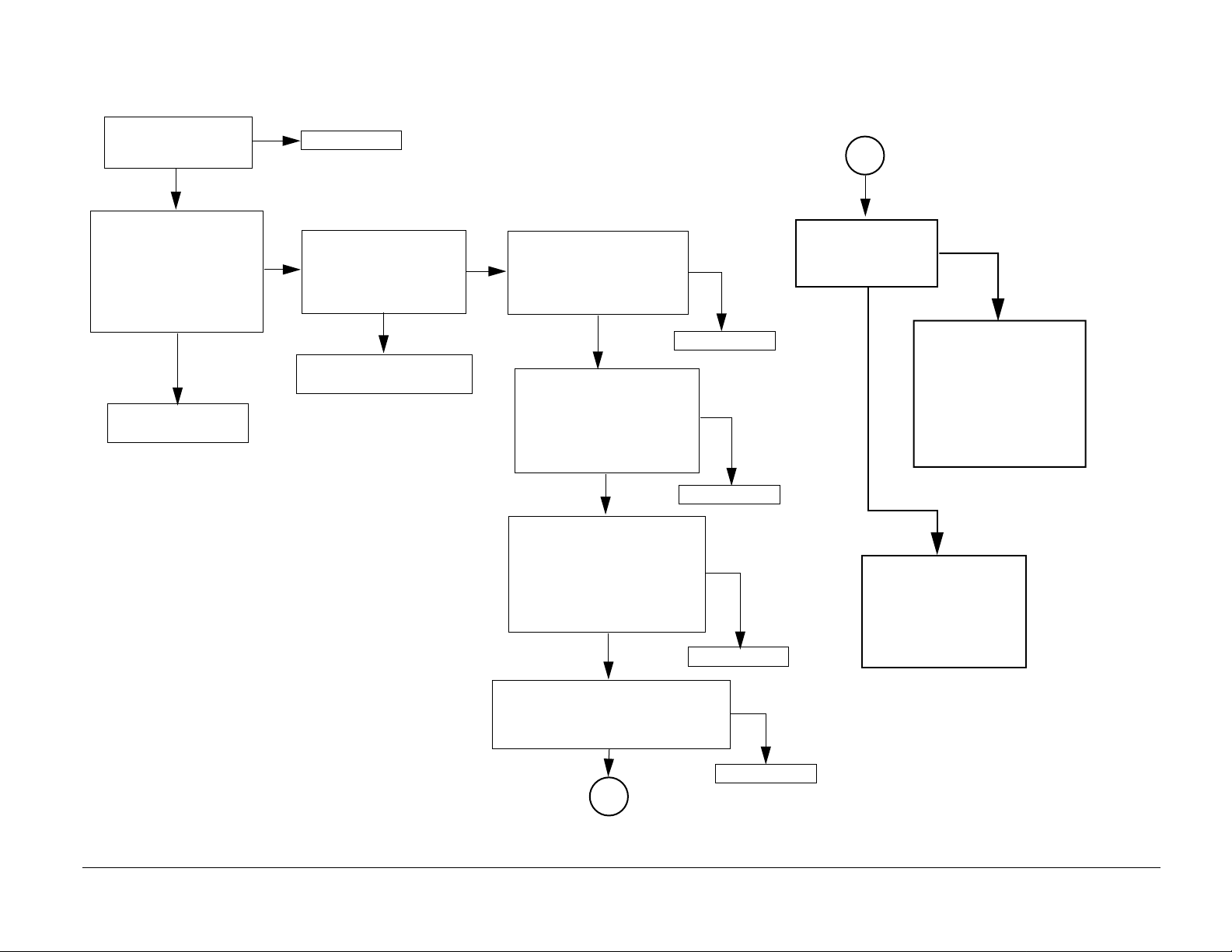

Section 2 Entry Flow Chart

Start Here

The display screen

appears to be functioning properly

YES

NO

Call for service

Press the Stop button

on the Control Panel. A

status code is shown on

the Display Screen.

YES

The Status Code is accompanied by a Jam Message

YES

A Status Code 5-xxx

is displayed

YES

Go to the Status

Code Entry Table 1

in this section.

NO

NO

The following components

are functioning properly:

-Control Panel Push buttons

-Control Panel LEDs

-LCD Touch Screen

-Edit Pad

YES

NO

Go to the Status

Code Entry Table 1

in this section.

Go to the Paper

Jam Entry Flow

Chart. Next page.

NO

Call for service

One of the following paper

tray related problems is

occurring:

-Incorrect Paper Size sensing

-Paper not sensed in trays

-Paper tray binding

-Tray fault message

-Incorrect Paper/image orientation

YES

Go to the Paper

Jam Entry Flow

Chart. Next page.

The machine is operating

NO

but an operator message

is displayed.

YES

Switch the power off,

wait 5 seconds, switch

the power on. The

message clears.

YES

Go to Final Actions

Section 1

NO

Call for service

Fault Code Procedures

5/98

2-4 5750 DocuCare Service Manual

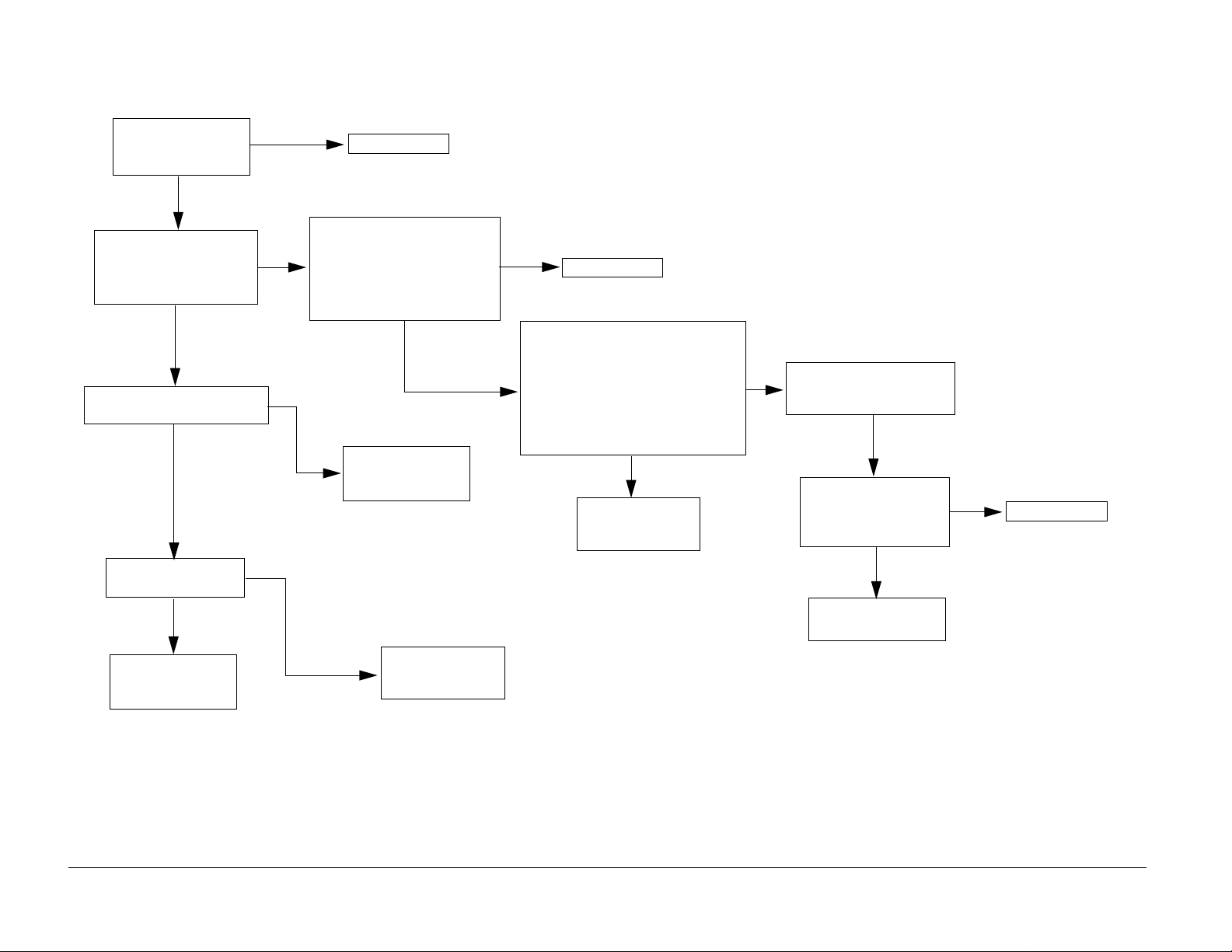

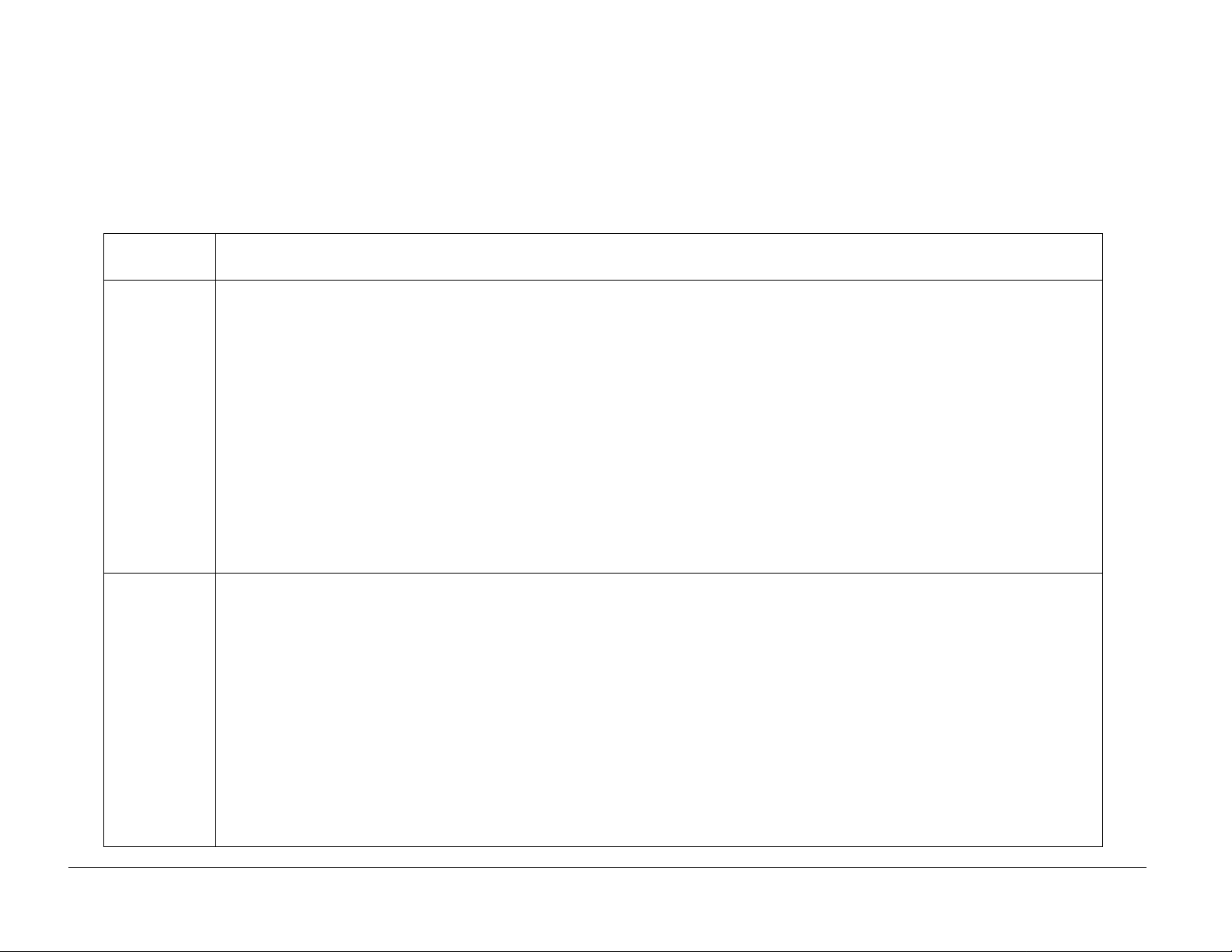

Paper Jam Entry Flow Chart

Start Here

The paper trays and

assemblies slide out

and in without binding

YES

NO

Call for service

A

Open the front doors and

pull out the Transfer Belt

Module. Clear the paper

path of any jams and inspect the Transfer Belt.

The Transfer Belt is out of

alignment.

YES

Perform the Transfer

Belt Walk Adj.

Close all of the doors.

NO

Switch on the power.

The paper jam message

is displayed immediately

at power on.

YES

Go to the Status Code

Entry Table/ (08-900 code)

Select Trays 1, 2, and 3

while observing the display

NO

screen. All three trays can

be selected without a tray

fault being indicated.

YES

Verify that paper is loaded

into all of the paper trays.

Select Trays 1, 2, and 3

while observing the screen.

The presence of paper in

each tray is being detected.

YES

While observing the Touch

Screen, select each of the

paper trays and individually

open and close each paper

tray. The position of the paper

trays, open or closed, is being

detected correctly.

YES

NO

Call for service

NO

Call for service

NO

Call for service

Make several copies

to try to duplicate the

paper jam. A paper

jam occurs.

YES

Enter diagnostics. Select

History Files and Jam

counter. Scroll through the

counter and determine

which jams have occurred

most frequently. Refer to

the appropriate jam code

in the Status Code Entry

Table.

Press and hold the Stop

button on the Control

Panel. Record the jam

code. Refer to the appropriate paper jam code in

the Status Code Entry

Table.

NO

Check the size of the paper loaded

into the trays and compare it to the

size indicated on the Touch Screen.

The paper size is correctly detected.

YES

A

5/98

5750 DocuCare Service Manual 2-5

NO

Call for service

Fault Code Procedures

Status Code Entry Table 1

Procedure

Go to the Status Code Entry Table, below

Status Code Entry Table

Status

Code

02-282,

283, 330

02-340, 350 The control logic sensed an error in the self test routines of the Ram test (02-340), or the EEP ROM test (02-350).

The control logic sensed a communications failure between the UI (User Interface) PWB and the LED Switch Panel

PWB (282), the Edit Pad PWB (02-283) or the AIFU PWB (02-331).

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed Section 5-Repairs.

Power the machine on.

If the problem still exists:

Place a service call.

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Description/Direction

If the problem still exists:

Fault Code Procedures

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed Section 5-Repairs.

Power the machine on.

Place a service call.

5/98

2-6 5750 DocuCare Service Manual

Status

Code

03-315,

317, 330,

336, 338

03-352,

357, 370

Description/Direction

The control logic sensed a communications failure between the IOT PWB and the IISS PWB (03-315), the UI PWB

and the AIFU PWB (03-317 or 330), or the IOT PWB and the Foreign Interface PWB (03-336 or 338).

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed Section 5-Repairs.

Power the machine on.

If the problem still exists:

Place a service call.

The control logic sensed errors in the self test routines of the RAM test (03-352), the IOT PWB NVM test (03-357),

or the IOT PWB ASIC test (03-370).

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed Section 5-Repairs.

Power the machine on.

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-7

Fault Code Procedures

Status

Code

03-371

03-600 The control logic sensed a Billing Data Recovery Failure.

The control logic sensed that the IOT PWB detected a data mismatch

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Clean and inspect all corotrons for defects and ensure they are properly installed.

Power the machine on.

If the problem still exists:

Place a service call.

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Description/Direction

If the problem still exists:

Fault Code Procedures

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed Section 5-Repairs.

Power the machine on.

Place a service call.

5/98

2-8 5750 DocuCare Service Manual

Status

Code

04-200

Description/Direction

The control logic sensed that the IOT PWB detected a Machine Clock Failure.

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed Section 5-Repairs.

Power the machine on.

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-9

Fault Code Procedures

Status

Code

05-110

Description/Direction

The control logic sensed a timing problem with the ADF Registration On Jam Check.

Initial action:

Check the paper path for pieces of ripped paper or other foreign objects.

Check the following for contamination, excessive wear or damage:

· Nudger Roll (REP 5.22)

· Feed Roll (REP 5.22)

· Mylar guards on the underside of the ADF Feed Cover

· Retard Rolls (REP 5.24)

· Nudger Chute

Open and close the ADF left cover. Check for binding or other mechanical problems with the left cover.

Observe the UI and make sure the customer message to close the left cover appears in a timely fashion.

Verify that the jams are not being caused by operator error. Possible operator errors include:

· Using originals of the wrong type. Recommended originals are described in the User Guide.

· Document Guide adjusted incorrectly.

· Trying to copy more than 30 originals at a time.

If the problem still exists:

Fault Code Procedures

Place a service call.

5/98

2-10 5750 DocuCare Service Manual

Status

Code

05-111

05-115, 116 The control logic sensed a timing problem with the ADF Exit Sensor On Jam Check (05-115) or the ADF Exit Sensor

The control logic sensed a timing problem with the ADF Registration Off Jam Check.

Initial action:

Check the paper path for pieces of ripped paper or other foreign objects.

Inspect the Platen Belt for contamination, excessive wear or damage.

Check the Platen Glass for contamination (REP 5.2).

Open and close the ADF left cover. Check for binding or other mechanical problems with the left cover.

Observe the UI and make sure the customer message to close the left cover appears in a timely fashion.

If the problem still exists:

Place a service call.

Off Jam Check (05-116).

Initial action:

Check the exit paper path for pieces of ripped paper or other foreign objects.

Inspect the Platen Belt for contamination, excessive wear or damage.

Description/Direction

Check the Platen Glass for contamination (REP 5.2).

Verify that the Exit Chute Cover is installed correctly.

Check the Static Eliminator for damage and correct installation.

NOTE : Certain types of coated originals may leave a residue on the platen glass when heated by the expo-

sure lamp. This residue may cause the original to stick to the platen glass and not feed out of the ADF To

avoid this prob lem make only a few copies of coated originals at a time or do not use the ADF when copying

coated originals

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-11

Fault Code Procedures

Status

Code

05-195

Description/Direction

The control logic sensed that a document fed through the ADF was a different size than the previous document.

NOTE : Document size is determined based on original length in the feed direction.

Initial action:

Verify that NVM location 4439 is set to the correct market value.

Clean the ADF Registration Sensor and check for paper or other foreign objects in the sensor path.

Check the Platen Glass for contamination.

Check the following for contamination, excessive wear or damage:

· Nudger Roll (REP 5.22)

· Feed Roll (REP 5.22)

· Mylar guards on the underside of the ADF Feed Cover

· Retard Rolls (REP 5.24)

· Nudger Chute

If the problem still exists:

Place a service call.

Fault Code Procedures

5/98

2-12 5750 DocuCare Service Manual

Status

Code

05-273

05-280 The control logic sensed a timing problem with the ADF Nudger Roll Home Sensor.

The control logic sensed that the ADF Drive Motor failed to operate.

Initial action:

Check the following for contamination, excessive wear, damage or binding:

· ADF Registration Roll bearings

· ADF Registration Pinch Roll oil-less bearings

· Platen Belt Drive Roll bearings

· Nudger Roll bearings

· Feed Roll bearings

If the problem still exists:

Place a service call.

Initial action:

Inspect the Nudger Home Sensor actuator for damage and proper installation.

Clean the ADF Nudger Home Sensor and check for foreign objects in the sensor path.

Description/Direction

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-13

Fault Code Procedures

Status

Code

05-340

ADF

Interlock

Fault

Description/Direction

The control logic sensed an error in the self test routine of the Ram test.

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed Section 5-Repairs.

Power the machine on.

If the problem still exists:

Place a service call.

The control logic has sensed a problem with the ADF interlocks.

Initial action:

Inspect the feeder cover for any foreign material that would prevent the cover from closing correctly.

Inspect the feeder cover for damage or warping.

If the problem still exists:

Fault Code Procedures

Place a service call.

5/98

2-14 5750 DocuCare Service Manual

Status

Code

ADF

“Other”

Faults

06-310, 311 The control logic sensed a communications failure between the IISS PWB and the IPS PWB (06-310), or the ADF

Use this RAP to troubleshoot ADF problems not covered by other RAPs.

Initial action:

Inspect the Document Set Sensor for contamination, foreign material or damage.

Make sure the Document Set Sensor is installed correctly and that the actuator can move freely.

Inspect the document tray f or contamination or damage that would pre v ent the document from actuating the

Document Set Sensor.

If the problem still exists:

Place a service call.

PWB (06-311).

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Description/Direction

Clean and inspect all corotrons for defects and ensure they are properly installed Section 5-Repairs.

Power the machine on.

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-15

Fault Code Procedures

Status

Code

06-340, 359

06-361 The control logic sensed a fault with the Scan Carraige Registration Sensor.

The control logic sensed an error in the self test routines of the IISS PWB Ram test (06-340), or the IISS PWB ROM

test (06-359).

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed Section 5-Repairs.

Power the machine on.

If the problem still exists:

Place a service call.

Initial action:

Switch off the machine power.

Description/Direction

If the problem still exists:

Fault Code Procedures

Verify that the IIT (Image Input Terminal) Registration Sensor is correctly aligned and free from contamination.

Power the machine on.

Place a service call.

5/98

2-16 5750 DocuCare Service Manual

Status

Code

06-364

06-370 The control logic sensed a timing problem with the exposure lamp.

The control logic sensed a fault with the IIT Limit Sensor

Initial action:

Switch off the machine power.

Power the machine on.

If the problem still exists:

Place a service call.

Initial action:

Switch off the machine power.

Wait ten seconds

Power the machine on.

If the problem still exists:

Place a service call.

Description/Direction

06-371 The control logic sensed a problem with the Exposure Lamp.

Initial action:

Switch off the machine power.

Wait ten seconds

Power the machine on.

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-17

Fault Code Procedures

Status

Code

06-372

06-380, 384 The control logic sensed a timing problem with the ROS (Raster Output Scanner).

The control logic sensed that the Polygon Motor failed to operate.

Initial action:

Switch off the machine power

Verify that the Drum Unit is firmly seated and that the screws that hold the unit in place are installed (REP

5.4).

Power the machine on.

If the problem still exists:

Place a service call.

Initial action:

Switch off the machine power.

Wait ten seconds

Power the machine on.

If the problem still exists:

Description/Direction

06-389 The control logic sensed a timing problem with the Scan Carraige at End of Scan (EOS).

Initial action:

If the problem still exists:

Fault Code Procedures

Place a service call.

Switch off the machine power.

Wait ten seconds.

Power the machine on.

Place a service call.

5/98

2-18 5750 DocuCare Service Manual

Status

Code

06-390

06-391 The control logic sensed that the Scan Carraige did not initialize properly.

The control logic sensed that the Scan Carraige did not stop in the home position.

Initial action:

Switch off the machine power.

Power the machine on.

If the problem still exists:

Place a service call.

Initial action:

Switch off the machine power.

Wait ten seconds.

Power the machine on.

If the problem still exists:

Place a service call.

Description/Direction

06-398 The control logic sensed a timing problem with the Scan Carraige at Start of Scan (SOS).

Initial action:

Switch off the machine power.

Wait ten seconds.

Power the machine on.

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-19

Fault Code Procedures

Status

Code

07-281,

282, 283,

284

Tray Load

Paper for

Tray 1, Tray

2, Tray 3,

Tray 4, or

the Bypass

Tray

Description/Direction

The control logic sensed a timing error for the Lift Up Time of T r a y 1(07-281), T r a y 2 (07-282), T ray 3 (07-283) or Tray

4 (07-284).

Initial action:

Switch off the machine power.

Power the machine on.

If the problem still exists:

Place a service call.

The control logic has sensed that no paper is being detected in one of the paper trays.

Initial action:

Go to the Paper T r ay which was selected on the Control Panel and verify that the Paper Size Indicator is set

to the correct paper size that is loaded in the Paper Tray.

Go to the Paper Tray which was selected on the Control Panel and verify that the paper is loaded correctly.

For the appropriate tray, clean the Tray Feed, Retard, Nudger, Preregistration and Registration Rolls with a

damp cloth (water). (REP 5.22) (REP 5.24)

NOTE : Check for obvious damage, missing or broken Drive Motor gear assemblies and drive belts. These

items may cause a sensor failure to be displayed as an operator error message.

If the problem still exists:

Fault Code Procedures

Place a service call.

5/98

2-20 5750 DocuCare Service Manual

Status

Code

Tray Paper

Size

Sensing for

Tray 1, Tray

2, Tray 3,

Tray 4, or

the Bypass

Tray

08-105,

110, 115,

120

Description/Direction

The control logic has sensed that the the paper size is not being detected correctly.

Initial action:

Go to the Paper T r ay which was selected on the Control Panel and verify that the Paper Size Indicator is set

to the correct paper size that is loaded in the Paper Tray.

Go to the Paper Tray which was selected on the Control Panel and verify that the paper is loaded correctly.

NOTE : Check for obvious damage, missing or broken Drive Motor gear assemblies and drive belts. These

items may cause a sensor failure to be displayed as an operator error message.

If the problem still exists:

Place a service call.

The control logic sensed a timing problem from the Feed Out sensor for Tray 1 (08-105), Tray 2 (08-110), Tra y 3 (08-

115) or Tray 4 (08-120).

Initial action:

For the appropriate tray, check the Tray Feed Out Sensor actuator for freedom of movement and proper

installation.

Check for proper installation of the appropriate Paper Guide.

For the appropriate tray, check the Feed Sensor, Nudger, Retard and Feed Rolls shaft, for cleanliness,

damage and excessive wear.

Clean the Feed, Retard and Nudger Rolls with a damp cloth (water) (REP 5.22) (REP 5.24).

Fan the paper or replace the paper with a new ream of paper.

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-21

Fault Code Procedures

Status

Code

08-138 The control logic sensed a timing problem from the Bypass Tray Registration Sensor.

Initial action:

Clean the Bypass Tray Feed, Retard, Nudger, Preregistration and Registration Rolls with a damp cloth

(water) (REP 5.27).

Fan the paper or replace the paper with a new ream of paper.

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

Check for paper path obstructions.

If the problem still exists:

Place a service call.

08-161 The control logic sensed a timing problem from the Stripper Jam Sensor.

Initial action:

Ensure that there is no paper jammed at the CTR (Charged Transfer Roll) Cleaner.

Clean Tray 1, 2, 3 or 4 Feed, Retard, Nudger, Preregistration and Registration Rolls with a damp cloth

(water) (REP 5.22) (REP 5.24).

Description/Direction

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures 2-22 5750 DocuCare Service Manual

Status

Code

08-165 The control logic sensed a timing problem from the TC (Transfer Corotron) Jam Sensor.

Initial action:

Ensure that there is no paper jammed at the CTR (Charged Transfer Roll) Cleaner.

Clean the TC (Transfer Corotron) Jam Sensor.

Clean Tray 1, 2, 3 or 4 Feed, Retard, Nudger, Preregistration and Registration Rolls with a damp cloth

(water) (REP 5.22) (REP 5.24).

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

Check that there is no paper tacked to the Drum.

If the problem still exists:

Place a service call.

08-167 The control logic sensed a timing problem from the Misstrip Sensor On Check.

Initial action:

Ensure that there is no paper jammed at the CTR (Charged Transfer Roll) Cleaner.

Clean the TC (Transfer Corotron) Jam Sensor.

Description/Direction

Clean Tray 1, 2, 3 or 4 Feed, Retard, Nudger, Preregistration and Registration Rolls with a damp cloth

(water) (REP 5.22) (REP 5.24).

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

Check for excessive wear, damage or proper installation of the Stripper Finger.

Check for a broken or arcing Transfer Corotron (TC) wire (REP 5.17).

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-23

Fault Code Procedures

Status

Code

08-168 The control logic sensed a timing problem from the Misstrip Jam Sensor.

Initial action:

Ensure that there is no paper jammed at the CTR (Charged Transfer Roll) Cleaner.

Clean Tray 1, 2, 3 or 4 Feed, Retard, Nudger, Preregistration and Registration Rolls with a damp cloth

(water) (REP 5.22) (REP 5.24).

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

Check for excessive wear, damage or proper installation of the Stripper Finger.

Check for a broken or arcing Transfer Corotron (TC) wire (REP 5.17).

If the problem still exists:

Place a service call.

08-169 The control logic sensed a timing problem from the Stripper Jam Sensor.

Initial action:

Ensure that there is no paper jammed at the CTR (Charged Transfer Roll) Cleaner.

Clean Tray 1, 2, 3 or 4 Feed, Retard, Nudger, Preregistration and Registration Rolls with a damp cloth

(water).

Description/Direction

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

Check for excessive wear, damage or proper installation of the Stripper Finger.

Check for a broken or arcing Transfer Corotron (TC) wire (REP 5.17).

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures 2-24 5750 DocuCare Service Manual

Status

Code

08-170 The control logic sensed a timing error from the preregistration sensor while feeding from the bypass tray.

Initial action:

Check for proper installation of the Bypass Tray Paper Guide.

Check the Preregistration, Nudger and Feed Roll for binding or excessive wear (REP 5.27).

Clean the Bypass Tray Feed, Retard, Nudger, Preregistration and Registration Rolls with a damp cloth

(water) (REP 5.27).

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

Check the Retard Pad for wear (REP 5.27)

If the problem still exists:

Place a service call.

Description/Direction

08-171,

172, 173,

174

5750 DocuCare Service Manual 2-25

The control logic sensed a timing error from the preregistration sensor while feeding from tray 1(08-171), tray 2 (08-

172), tray 3 (08-173), or tray 4 (08-174).

Initial action:

Clean the Feed, Retard, Nudger, Preregistration and Registration Rolls with a damp cloth (water), for the

appropriate tray (REP 5.22) (REP 5.24).

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

Check for paper path obstructions.

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures

Status

Code

08-175,

176, 177,

178, 179

08-198 The control logic sensed a timing error from the registration sensor off signal while feeding from the bypass tray.

The control logic sensed a timing error from the registration sensor on signal while feeding from the bypass tray (08-

175), tray 1(08-176), tray 2 (08-177), tray 3 (08-178), or tray 4 (08-179).

Initial action:

Check the Registration Chute for paper path obstructions and damage.

Clean the Registration Sensor (REP 5.28).

Clean the Feed, Retard, Nudger, Preregistration and Registration Rolls for the appropriate tray with a damp

cloth (water) (REP 5.22) (REP 5.24).

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

If the problem still exists:

Place a service call.

Initial action:

Check for multiple feed of transparencies, if applicable.

Clean the Bypass Tray Feed, Retard, Nudger, Preregistration and Registration Rolls with a damp cloth

(water) (REP 5.27).

Description/Direction

Check the Bypass Tray Retard Pad for damage.

If the problem still exists:

Place a service call.

08-380 The control logic sensed a failure of the position of the Curler Cam through the Curler Cam sensors 1 & 2.

Initial action:

Check the Curler Cam for damage and obstructions.

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures 2-26 5750 DocuCare Service Manual

Status

Code

08-385 The control logic sensed a timing error between the TR0 (Transfer Roll Zero) sensor and the IOT PWB.

Initial action:

Check the TR0 (Transfer Roll Zero) Sensor Actuator for damage (located inside and at the front of the CTR

(Charged Transfer Roll) Assembly).

If the problem still exists:

Place a service call.

08-900 The control logic sensed a paper static jam.

Initial action:

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Check Tray 1, 2, 3 or 4 for a cracked or broken tray stop.

Clean the CTR (Charged Transfer Roll) Film with a dry cloth (REP 5.10).

Verify Heavy Weight Paper and Transparencies Control Panel settings are correct, if applicable.

If the problem still exists:

Place a service call.

Description/Direction

09-363 The control logic sensed a failure of the Developer Rotary Home Sensor to detect the position of the Developer

Rotary.

Initial action:

Verify that the Drum unit is firmly seated and secured (REP 5.4).

Inspect the installation of the Developer Units (REP 5.7). Make sure all screws are secure and that the

clamps are in place

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-27

Fault Code Procedures

Status

Code

09-365,

366, 367,

368

09-376 The control logic sensed that the Waste Toner Sump is full.

The control logic sensed a failure of one of the toner dispensing systems. Yellow (09-365), Magenta (09-366), Cyan

(09-367), or Black (09-368).

Initial action:

Remove the corresponding toner cartridge and check for caking of the toner or blockage of the opening.

Verify that there is adequate toner in the cartridge.

If the problem still exists:

Place a service call.

Initial action:

Refer to proceedure (REP 5.5) to clean the waste toner sump.

Reset NVM6060 to 0.

If the problem still exists:

Place a service call.

Description/Direction

09-620 The control logic sensed a failure of the ADC sensor setup.

Initial action:

Check the drum surface for damage or deformities (REP 5.4).

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures 2-28 5750 DocuCare Service Manual

Status

Code

10-105, 106 The control logic sensed a timing error from the Fuser Exit Sensor.

Initial action:

Check for deformation of the Exit Chute (Lower/Upper).

Check for paper path obstructions.

Check for contamination, damage or wear on the Heat Roll (REP 5.31) and Pressure Roll (REP 5.35) sur-

face.

Check the Stripper Finger for defects and obvious damage (REP 5.38).

If the problem still exists:

Place a service call.

10-358 The control logic sensed an error from the Thermistor failure detection circuit.

Initial action:

Check the Heat Roll Control and Overheat Thermistors for cleanliness, damage and excessive wear at the

point where the Thermistor contacts the Heat Roll (REP 5.37).

Check the Pressure Roll Control and Overheat Thermistors for cleanliness, damage and excessive wear at

the point where the Thermistor contacts the Pressure Roll (REP 5.37).

Description/Direction

If the problem still exists:

Place a service call.

10-359 The control logic sensed an open circuit from the Heat Roll Control Thermistor.

Initial action:

Check the Heat Roll Control Thermistor for cleanliness, damage and excessive wear at the point where the

Thermistor contacts the Heat Roll (REP 5.37).

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-29

Fault Code Procedures

Status

Code

10-360 The control logic sensed an open circuit from the Heat Roll Overheat Thermistor.

Initial action:

Check the Heat Roll Overheat Thermistor for cleanliness, damage and excessive wear at the point where

the Thermistor contacts the Heat Roll (REP 5.37).

If the problem still exists:

Place a service call.

10-361 The control logic sensed that the Heat Roll did not reach operating temperature.

Initial action:

Ensure that the Heat Roll surface is clean and not damaged (REP 5.31).

Check the Heat Roll Control Thermistor for cleanliness, damage and excessive wear at the point where the

Thermistor contacts the Heat Roll (REP 5.37).

If the problem still exists:

Place a service call.

Description/Direction

10-362 The control logic sensed that the Heat Rod did not turn off after the Heat Roll reached operating temperature.

Initial action:

Ensure that the Heat Roll surface is clean (no debris, paper, etc.) (REP 5.31)

Check the Heat Roll Control Thermistor for cleanliness, damage and excessive wear at the point where the

Thermistor contacts the Heat Roll (REP 5.37).

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures 2-30 5750 DocuCare Service Manual

Status

Code

10-363 The control logic sensed that the Heat Roll did not return to operating temperature after a job run.

Initial action:

Ensure that the Heat Roll surface is clean (no debris, paper, etc.) (REP 5.31)

Check the Heat Roll Control Thermistor for cleanliness, damage and excessive wear at the point where the

Thermistor contacts the Heat Roll (REP 5.37).

If the problem still exists:

Place a service call.

10-364 The control logic sensed that the Heat Roll could not maintain temperature during a copy run.

Initial action:

Ensure that the Heat Roll surface is clean (no debris, paper, etc.) (REP 5.31)

Check the Heat Roll Control Thermistor for cleanliness, damage and excessive wear at the point where the

Thermistor contacts the Heat Roll (REP 5.37).

If the problem still exists:

Place a service call.

Description/Direction

10-365 The control logic sensed that the Heat Roll did not reach operating temperature within 150 seconds after Power

Saver mode was exited.

Initial action:

Ensure that the Heat Roll surface is clean (no debris, paper, etc.) (REP 5.31)

Check the Heat Roll Control Thermistor for cleanliness, damage and excessive wear at the point where the

Thermistor contacts the Heat Roll (REP 5.37).

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-31

Fault Code Procedures

Status

Code

10-366, 367 The control logic sensed that the Heat Roll temperature exceeded 180˚.

Initial action:

Check the Heat Roll Control Thermistor for cleanliness, damage and excessive wear at the point where the

Thermistor contacts the Heat Roll (REP 5.37).

If the problem still exists:

Place a service call.

10-368 The control logic sensed an open circuit from the Pressure Roll control thermistor.

Initial action:

Check the Pressure Roll Control Thermistor for cleanliness , damage and excessive wear at the point where

the Thermistor contacts the Pressure Roll (REP 5.37).

If the problem still exists:

Place a service call.

10-369 The control logic sensed an open circuit from the Pressure Roll overheat thermistor.

Description/Direction

Initial action:

Check the Pressure Roll Control Thermistor for cleanliness , damage and excessive wear at the point where

the Thermistor contacts the Pressure Roll (REP 5.37).

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures 2-32 5750 DocuCare Service Manual

Status

Code

10-370 The control logic sensed that the Pressure Roll did not reach operating temperature.

Initial action:

Ensure that the Pressure Roll surface is clean (no debris, paper, etc.) (REP 5.35)

Check the Pressure Roll Control Thermistor for cleanliness , damage and excessive wear at the point where

the Thermistor contacts the Pressure Roll (REP 5.37).

If the problem still exists:

Place a service call.

10-371 The control logic sensed that the Pressure Roll Heat Rod did not turn off after the Pressure Roll reached operating

temperature.

Initial action:

Ensure that the Pressure Roll surface is clean (no debris, paper, etc.) (REP 5.35)

Check the Pressure Roll Control Thermistor for cleanliness , damage and excessive wear at the point where

the Thermistor contacts the Pressure Roll (REP 5.37).

If the problem still exists:

Place a service call.

Description/Direction

10-372 The control logic sensed that the Pressure Roll did not return to operating temperature after a job run.

Initial action:

Ensure that the Pressure Roll surface is clean (no debris, paper, etc.) (REP 5.35)

Check the Pressure Roll Control Thermistor for cleanliness , damage and excessive wear at the point where

the Thermistor contacts the Pressure Roll (REP 5.37).

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-33

Fault Code Procedures

Status

Code

10-373 The control logic sensed that the Pressure Roll could not maintain temperature during a copy run.

Initial action:

Ensure that the Pressure Roll surface is clean (no debris, paper, etc.) (REP 5.35)

Check the Pressure Roll Control Thermistor for cleanliness , damage and excessive wear at the point where

the Thermistor contacts the Pressure Roll (REP 5.37).

If the problem still exists:

Place a service call.

10-374 The control logic sensed that the Pressure Roll did not reach operating temperature within 150 seconds after P o wer

Saver mode was exited.

Initial action:

Ensure that the Pressure Roll surface is clean (no debris, paper, etc.) (REP 5.35)

Check the Pressure Roll Control Thermistor for cleanliness , damage and excessive wear at the point where

the Thermistor contacts the Pressure Roll (REP 5.37).

If the problem still exists:

Place a service call.

Description/Direction

10-375, 376 The control logic sensed that the Pressure Roll temperature exceeded 180˚.

Initial action:

Check the Pressure Roll Control Thermistor for cleanliness , damage and excessive wear at the point where

the Thermistor contacts the Pressure Roll (REP 5.37).

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures 2-34 5750 DocuCare Service Manual

Status

Code

11-100, 101 The control logic sensed that the Sorter Feed Sensor did not energize within the specified time.

Place a service call.

11-340 The control logic sensed a failure of the Sorter Control PWB.

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed.

Power the machine on.

If the problem still exists:

Place a service call.

Description/Direction

11-380 The control logic sensed a failure of the Sorter Bin Home Switch.

Initial action:

Check for obstructions in the sorter bins.

Check the Sorter Drive Motor Belt for damage and proper tension.

If the problem still exists:

Place a service call.

5/98

5750 DocuCare Service Manual 2-35

Fault Code Procedures

Status

Code

11-381 The control logic sensed a failure of the Sorter Bin drive motor.

Initial action:

Check for obstructions in the sorter bins.

Check the Sorter Drive Motor Belt for damage and proper tension.

If the problem still exists:

Place a service call.

Description/Direction

Sorter

Interlock

RAP

Use this RAP to troubleshoot when there is a customer message instructing the operator to close the sorter top

cover or to push the sorter into place.

Initial action:

Ensure that the sorter is properly mated with the machine.

Ensure that the top cover is closed and the interlock is being actuated.

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures 2-36 5750 DocuCare Service Manual

Status

Code

15-280 The control logic sensed a communications failure between the IPS PWB and the BR PWB.

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed.

Power the machine on.

If the problem still exists:

Place a service call.

Description/Direction

15-281,

282, 283

5750 DocuCare Service Manual 2-37

The control logic sensed that paper money has been placed on the document glass to be copied. This is a prohibited from copy item.

Initial action:

Verify that the original is not paper money.

If the problem still exists:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed.

Power the machine on.

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures

Status

Code

15-340 The control logic sensed a failure of the IPS PWB RAM.

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed.

Power the machine on.

If the problem still exists:

Place a service call.

Description/Direction

15-360,

361, 362

The control logic sensed a failure of the IPS PWB Self Test.

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed.

Power the machine on.

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures 2-38 5750 DocuCare Service Manual

Status

Code

15-380,

381, 382,

383, 384,

385

Description/Direction

The control logic sensed a failure of the AGC (Automatic Gain Control).

Initial action:

Verify that the platen glass has not been damaged and/or has been properly installed.

If the problem still exists:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed.

Power the machine on.

If the problem still exists:

Place a service call.

15-386,

387, 388,

389, 390,

391

5750 DocuCare Service Manual 2-39

The control logic sensed a failure of the AOC (Automatic Offset Control).

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed.

Power the machine on.

If the problem still exists:

Place a service call.

5/98

Fault Code Procedures

Status

Code

18-340 The control logic sensed a failure of the AIFU PWB RAM Test.

Initial action:

Switch off the machine power.

If there is other equipment close by that may be generating electrical noise or radio frequency interference,

power it off also.

Contact Building Maintenance and have them verify the proper voltage at the machine plug.

Clean and inspect all corotrons for defects and ensure they are properly installed.

Power the machine on.

If the problem still exists:

Place a service call.

Description/Direction

5/98

Fault Code Procedures 2-40 5750 DocuCare Service Manual

Loading...

Loading...