Page 1

Introduction

DocuColor 40 Pro/ CP

Special Materials Information

Revision 2

In response to customer requests to use special materi als in the

DocuColor 40 Pro/ CP, Xerox has done extensive testi ng on a variety

of materials. This guide contains descripti ons of and details about the

special materials that have been approv ed by Xerox for use in the

DocuColor 40 Pro/ CP. As the Xerox on-going materials testi ng

program discovers new infor m at ion, materials, or dev elops

recommendations, revisions will be made to this guide.

Each section of this gui de descr i bes a single material. Descriptions

include:

• General information about t he unique and approved material.

• Expectations of the feeding reliability and performance of the

DocuColor 40 Pro/ CP when using the material.

• Usage techniques and applications to obtain opt imum performance

of the material when used with the DocuColor 40 Pro/ CP.

Each material described in thi s gui de has specific conditi ons and

requirements to produce accept able perfor m ance. To achieve this

performance and to meet t he st ated expectations, these condi t ions and

requirements should be monitored car ef ully.

WARRANTY DISCLAIMER

Xerox makes no guarantees or warranties, either express or implied,

concerning the performance, use or r eplacement of non- Xer ox br anded

media or throughput product s . Custom er s should inquir e directly of

their paper distr i but or or m anufacturer for any guarantees they may

offer. When purchasing a particular media product for the f i r s t t ime,

customers are advised t o pur chase sm all quantities to i nsure t hat their

expectations are met.

The materials with Xerox part number s listed i n t his guide, can be

purchased by calling the Xerox Supply Net at 1-800-822-2200 from t he

United States and Canada.

DocuColor 40 Pro/ CP Special Materials Information September 1998 1

Page 2

Table of Contents

Special Materials

Tabs _____3

LaserCard _____5

Teslin® _____6

DocuCard 7

Color Xpressions Gloss and Matte Labels 8

Neato® CD Labels and Jewel Cases 9

DocuColor 40 Pro/ CP Special Materials Information September 1998 2

Page 3

Tabs______________________________________________________________________

Material Description and Expectat i on:

Tabs are made of Xerox 90lb. Index or glossy coated cover, which has been convert ed into full one-half

inch tabs and divider s that offer durability and sti f f ness. Tabs can be used to protect, or ganize, highlight,

and divide impor t ant documents such as manuals, reports, cat alogs, and pric e lists.

When 90lb Index tabs are run as descri bed below, feeding will be optimized. However, performance will

not equal the performance of Xerox 24lb Color Xpressions or other sim i lar laser papers. Feeding

performance will be good, but increased jamming may occur. Image m ot tle (light cloudy patches) may

occur when printing on the larger portion of t he t abs. Image m ottle is more likely to occur when printing

uniform halftone areas.

When Color Xpressions T abs ar e r un as det ailed below, feeding will be optimized. However,

performance will not equal the performance of Xerox 24lb Color Xpressions or other similar laser papers.

Feeding performance will be good, but increased jamming m ay occur. Because coat ed paper s ar e very

susceptible to humidity, the mat er ial should be stored in moisture proof packaging when not in use t o

enable best feeding performance and image quality.

The recommended tabs are conf i gur ed as f ive position t abs. The dimensions of each sheet is 9 x 11”.

Tabs are packaged in two different m et hods: straight and reverse precollated. Customers preferring a

portrait style report with the fi r s t t ab beginning at the upper ri ght cor ner of t he docum ent and with the

tabs running from top to bottom would choose straight collation (i.e. 1, 2, 3, 4, 5) . Customers preferri ng

landscape documents where the first tab would be at the lower left corner and proceed right would

choose reverse collated (i.e. 5, 4, 3, 2, 1) .

Recommended Materials:

Xerox White Straight Collated Tabs 3R4417

Xerox White Straight Collated Tabs (3HD) 3R4418

Color Xpressions Glossy Coated Tabs Straight Collated 3R6254

Color Xpressions Glossy Coated Tabs Straight Collated (3HD) 3R6255

Xerox White Reverse Collated Tabs 3R4415

Xerox White Reverse Collated Tabs (3HD) 3R4416

Xerox Plastic Reverse Collated Tabs 3R5520

Xerox Plastic Reverse Collated Tabs (3HD) 3R5521

Steps for Success:

For printing tabs f r om a di gital front end:

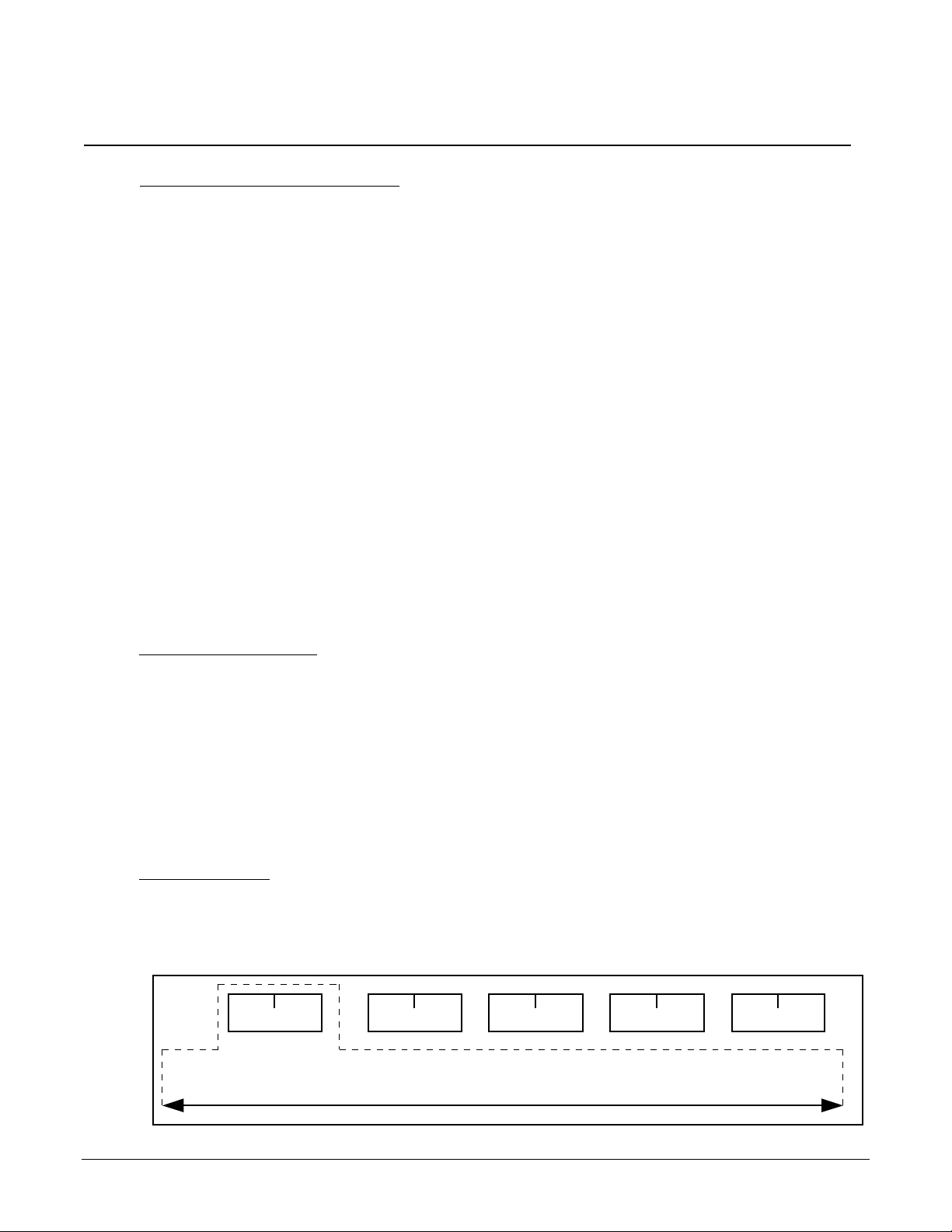

1) Design a tab template to match t he f ollowing diagram. The di m ensi ons of the paper should be 9 x

11”. The center of t he f ive tabs should be 1.5”, 3.5”, 5. 5” , 7.5” and 9.5”. T he t abs ar e 1. 5” wide. The

configuration would be similar to the following diagram which is not drawn to scale:

1.5” 3.5” 5.5” 7.5” 9.5”

11”

DocuColor 40 Pro/ CP Special Materials Information September 1998 3

Page 4

2) Place tabs in the Paper Tray Bypass . The 9” side should be loaded as the lead edge (short edge

feed) and the tab positi ons should be toward the rear of t he DocuColor 40 Pro/ CP.

Back of DocuColor 40

Paper T ray Bypass

3) Select Paper Tray Bypass and 9 x 11” for the size input.

4) Select Heavy Weight Paper M ode.

For copying from the platen glass:

1) Design a template on an 8.5 x 11” paper with the spacing descr ibed for printi ng. The template should

be placed on the glass with the tab information toward the rear of t he m achine.

2) Place tabs in the Paper Tray Bypass. The 9” side should be loaded as the lead edge (short edge

feed) and the tab positi ons should be toward the front of the machine.

3) Select Paper Tray Bypass.

4) Select Heavy Weight Paper M ode.

5) Select Input Size; enter the following values: X = 279mm (11”), Y = 229m m ( 9” )

6) Place the original .5” from the top of the platen glass (toward the operator). Cover t he t op . 5” of the

exposed platen glass with white paper.

Hints, Tips, and T est Results

Xerox tests have shown the following:

Skew may cause the printing to be uneven or of f cent er on t he tabs.

Load tabs carefully, do not bend the corners of the tabs. Tabs with bent cor ner s m ay cause feedi ng

related jams or degraded image quality. Remove bent tabs from the set and r eplace with a non

damaged tab of the same posit i on bef or e loading in the Paper Tray Bypass.

Tabs should be loaded in groups of 5. Do not load materials above the fill line, located on the edge guide

of the Paper Tray Bypass.

The DocuColor 40 Pro/ CP HCF 2500 is not currently enabled to feed tabs.

Toner saturation on electroni c or i ginals should be limited to a total of 220% (55% for each color). Higher

toner saturation can result in poor ly fused prints and dam age to the heat roll.

DocuColor 40 Pro/ CP Special Materials Information September 1998 4

Page 5

LaserCard__________________________________________________________________

Material Description and Expectat i on:

LaserCard is a unique self-sealing laminated card designed for a variety of end-use applications:

membership cards, student and library cards, health histor y cards, em ployee cards, and warranty cards.

Features of LaserCard include: durability, ease of use, m ylar overlaminate f or pr ot ection, waterproof,

and tear resistant.

When LaserCar ds ar e r un as det ai led below, feeding will be optimized. However, performance will not

equal the performance of Xerox 24lb Color Xpressions or other simi lar laser papers. Feeding

performance will be good, but increased jamming may occur. Image m ot tle (light cloudy patches) may

occur when printing on the parent sheet. Image m ottle is more likely to occur when printing uniform

halftone areas.

Recommended Materials:

Xerox LaserCard Must be ordered as Xerox custom pr oduct ; call your

Document Supply Account Manager, 1-800-822-2200

Steps for Success:

1) Design a template similar to the following schematic (not drawn to scale). The card dimensions are 2

x 3.5”. The actual placement of the card on the par ent sheet m ay v ar y according to the application.

Your template should match the media if t he m edi a has been custom made for your application.

2”

3.5”

2) Load LaserCard in the Paper Tr ay Bypass or HCF 2500.

3) Select Heavy Weight Paper M ode

Hints, Tips, and T est Results

Xerox tests have shown the following:

Printing within .25” of t he edge of the card should be avoided or deletions are likely to occur.

To avoid jam s and poor i m age quality, t he m at er i al should be stored in the sealed package or placed in a

resealable container.

To improve f eeding reliability, fan sheets vigor ously before loading.

Toner saturation on electroni c or i ginals should be limited to a total of 220% (55% for each color). Higher

toner saturation can result in poor ly fused prints and dam age to the heat roll.

DocuColor 40 Pro/ CP Special Materials Information September 1998 5

Page 6

Teslin®_________________________________________________________________

Material Description and Expectat i on:

Teslin® is a synthetic materi al composed of a si ngle layer, highly filled microporous, polyolefin

plastic film. Teslin® is water, chemical, and abrasion r esistant. The mat er ial is tear resistant i n t he

cross direction. T eslin® can be used for t elecards, ident i f ications documents or badges, electronic

gift certif icates, signage, and short r un m enus. Teslin® has a matte finish and pr ovides excellent

image quality under optimum condit i ons.

When T eslin® is r un as det ai led below, feeding performance will not equal the performance of Xerox

24lb Color Xpressions or other similar laser papers. Feeding performance will be good, but

increased jamming m ay occur. Feedi ng r eliability and im age quality degrade with humi di t y levels

greater than 50%. As medi a quality may vary, Xer ox guar ant ees t he quality and consist ency of

Xerox branded products only.

Recommended Materials:

Teslin 1000 spid 10mil 8.5 x 11” and 11 x 17”

Teslin 1400 spid 14mi l 8.5 x 11” and 11 x 17”

Custom sheet sizes are available on request. For more information or or der ing call PPG Industries,

1-800-437-8318.

Teslin® is a registered trademark of PPG Industries Inc.

Steps For Success:

1) Load Teslin® in the Paper Tray Bypass or HCF 2500. Use the Paper T r ay Bypass for simplex

only.

2) Select Heavy Weight Paper m ode.

Hints, Tips, and T est Results

Xerox tests have shown the following:

Manual duplex applications should be run from the HCF 2500 only.

To avoid jam s and poor i m age quality, t he m at er i al should be stored in the sealed package or

placed in a resealable container.

Improperly clearing paper jams can cause machine damage. Pull the transfer drawer out carefully to

clear any jams.

Toner saturation on electroni c or i ginals should be limited to a total of 220% (55% for each color).

Higher toner saturati on can r esult in poor ly fused prints and dam age t o the heat roll.

To improve f eeding reliability, fan sheets before loading.

DocuColor 40 Pro/ CP Special Materials Information September 1998 6

Page 7

DocuCard

Material Description and Expectat i on:

The DocuCard is a printable membershi p i dent ification card m ade f r om Xer ox 90lb Index paper and a

7mil material that has been specially coated to accept toner. DocuCards have a v ar iety of end use

applications: membership cards, st udent and library cards, health histor y cards, em ployee cards, and

warranty cards. DocuCards are heat, tear, and water resistant. The only compatible DocuCard

configuration is the 1up (non W indoW ell) card.

When DocuCards are r un as det ailed below, feeding will be optimized. However, performance will not

equal the performance of Xerox 24lb Color Xpressions or other simi lar laser papers. Feeding

performance will be good, but increased jamming may occur. Image m ot tle (light cloudy patches) may

occur when printing on the parent sheet. Image m ottle is more likely to occur when printing uniform

halftone areas. DocuCards should only be used with machines equipped with catch t r ays. DocuCards

are not compatible with the DocuColor 40 Pro/ CP Stacker/Stapler or Sorter due t o poor st acking.

Recommended Materials:

Xerox 1up DocuCards Must be ordered as Xerox custom pr oduct ; call your

Document Supply Account Manager, 1-800-822-2200

Steps for Success:

1) Design a template with the following dimensions: Card size: 2.75” x 3.5”; placement on t he page:

9.125” from top, . 75” from bottom, and 2. 56” f r om sides

2) Place DocuCards in the Paper Tray Bypass . The 8.5” side should be loaded as the lead edge (short

edge feed) and the card should be loaded face up and toward the rear of the DocuColor 40 Pro/ CP.

A maximum of 20 cards may be placed in the tray.

Back of DocuColor

Paper Tray

3) Select Heavy Weight Paper M ode

4) The catch tray must be unloaded every 40-60 sheets.

Hints, Tips, and T est Results

Xerox tests have shown the following:

To avoid jam s and poor i m age quality, t he m at er i al should be stored in the sealed package or placed in a

resealable container.

Printing within .25” of t he edge of the card should be avoided or deletions are likely to occur.

Over loading DocuCards in the Paper T r ay Bypass may cause jams (a maxi m um of 20 sheet s can be

placed in the tray).

DocuCards should be unloaded from the output catch tray frequently (40-60 sheets) to av oi d jamming.

DocuColor 40 Pro/ CP Special Materials Information September 1998 7

Page 8

Color Xpressions Gloss and M atte Label s

Material Description and Expectat i on:

Color Xpressions Gloss and Matte labels are coated paper labels with glossy and matte finishes that

offer photographic like image quality. Color Xpressions labels offer a variety of end use applications:

wine bottle labels, commemorative items, r eal-estate labels, and many types of promotional materi als.

There are two configurati ons f or bot h the gloss and matte finishes: 1up and 4up.

When Color Xpressions Labels are run as detai led below, feeding will be optimized. However,

performance will not equal the performance of Xerox 24lb Color Xpressions or other similar laser

papers. Feeding performance will be good, but increased jamm ing may occur. Because coated papers

are very susceptible to humidit y, the m aterial should be stored in moisture proof packagi ng when not in

use to enable best feeding performance and im age quality.

Recommended Materials:

Color Xpressions Gloss Label 1up 3R5770

4up 3R5771

Color Xpressions Matte Label 1up 3R5772

4up 3R5773

Steps for Success:

1) Load labels in Paper Tray Bypass or HCF 2500.

2) Select Heavy Weight M ode.

3) Remove sheets from exi t t r ay fr equent ly (40-60 sheets) and fan them to avoid sheet s st i cking

together.

Hints, Tips, and T est Results

Xerox tests have shown the following:

To avoid jam s and poor i m age quality, t he m at er i al should be stored in the sealed package or placed in a

resealable container.

Improperly clearing paper jams can cause machine damage. Pull the transfer drawer out carefully to

clear any jams.

Toner saturation on electroni c or i ginals should be limited to a total of 220% (55% for each color). Higher

toner saturation can result in poor ly fused prints and dam age to the heat roll.

To improve f eeding reliability, fan sheets before loading.

Coated labels exit the machine extremely hot and will stick together if not removed f r om t he exit tray

frequently.

Avoid loading labels above the fill line in the Paper Tray Bypass. Jams or misfeeds may result if too

many labels are loaded into the tray.

DocuColor 40 Pro/ CP Special Materials Information September 1998 8

Page 9

Neato® CD Labels and Jewel Cases

Material Description and Expectat ion:

Neato® CD labels and jewel cases are used to create and personalize CD’s and their cases. T he CD

labels are plain paper labels designed two per sheet and the jewel cases are an index stock designed

two per sheet. Software with templates of the labels and jewel cases are provided by Neato®.

When Neato® CD labels and jewel cases are run as detailed below, feeding will be optimized. However,

performance will not equal the performance of Xerox 24lb Color Xpressions or other similar laser papers.

Feeding performance will be good, but increased jamming may occur. Image mottle (light cloudy

patches) may occur when printing on the labels or cases. Image mottle is more likely to occur when

printing unifor m halftone ar eas.

Recommended Materials:

Neato® CD Labels

Jewel Case Inserts

For more informat ion or ordering call Neato Inc., 1-800-984-9800.

Steps for Success:

1) Select applicable template for labels or jewel cases.

2) Load labels or jewel cases in Paper Tray Bypass or HCF 2500.

3) Select Heavy Weight M ode.

Hints, Tips, and T est Results:

Xerox tests have shown the following:

To improve f eeding reliability, fan sheets before loading.

For full bleed labels or jewel cases, design document so the print extends across the dye cut edge of the

label or jewel case.

Avoid loading labels and jewel cases above the fill line in the Paper Tray Bypass. Jams or mi sf eeds m ay

result if too many labels are loaded into the tray.

DocuColor 40 Pro/ CP Special Materials Information September 1998 9

Loading...

Loading...