Page 1

DocuColor

2045/2060

System

Administration

Guide

Page 2

©1999, 2000, 2001 Xerox Corporation. All rightsreserved.

Copyright protection claimed includes all forms and matters of copyrightable material and informationnowallowedbystatutoryorjudiciallawor hereinaftergranted,includingwithoutlimitation,

material generated from the software programs that are displayed on the screen suchas styles,

templates, icons, screen displays,l ooks, etc.

Xerox®, The Document Company®, the digital X®, and all Xerox product names and product

numbers mentioned in this publication are registered trademarks of Xerox Corporation.

Xerox Canada is a licensee of all the trademarks.Other company brands and product names

may be trademarks or registered trademarks of their respective companies and are also

acknowledged.

Changes are periodicallymade to this document. Technical updates will be included in

subsequent editions.

Printed in the United States of America.

Page 3

TABLE OF C ONTENTS

Table of Contents

Safety Notes

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Disconnect Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Maintenance Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Operational Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Ozone Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Notices

TABLE OF CONTENTS

Radio Frequency Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

FCC in the USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

In Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Safety Extra Low Voltage Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Certifications in Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

It’s Illegal in the USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

It’s Illegal in Canada. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Environmental Notices for the USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Environmental Notices for Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Conventions

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Writing Style Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Tools Mode

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Entering and Exiting Tools Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

i

Page 4

TABLE OF C ONTENTS

Navigating in Tools Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Machine Defaults and Feature Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Machine Defaults 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Initial Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

Auto Color Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–11

Run Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–15

Check Gradation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–17

Manual Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–19

Tray Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–21

System Timers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–23

Power Saver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–23

Screen Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–25

Job Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–26

Tools Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–27

Auto Resume Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–28

Auto Resume Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–29

Auto Resume Stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–30

Auto Resume Hold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–31

Auditron Mode Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–32

Job Complete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–33

Job Program Incomplete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–34

Audio Tones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–35

Productivity Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–37

Auto Tray Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–39

Transparency Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–41

Set Date & Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–42

Setting the Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–42

Setting the Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–43

Dual Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–44

Non-Standard Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–46

Oversize Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–47

Machine Defaults 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–48

Paper Registration Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–49

100% Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–54

Special Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–55

Additional Originals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–56

Stored Program Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–57

Auto Recognition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–58

Reduce/Enlarge Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–61

Photo Reproduction Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–63

ii

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 5

TABLE OF C ONTENTS

Color Adjust & Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–64

Auto Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–66

Maximum Scan to Print Quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–69

Decurler Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–70

Decurler Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–70

Feature Defaults 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–74

Color Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–75

Paper Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–76

Edge/Center Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–77

Turning Edge Erase Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–77

Border Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–78

Edge Center Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–79

Color Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–80

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–81

Without a Finishing Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–81

Using a High Capacity Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–82

Using a High Capacity Stacker Stapler . . . . . . . . . . . . . . . . . . . . . .1–84

2 Sided Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–86

Original Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–89

Chroma . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–92

Reduce/Enlarge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–93

100% or Auto. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–93

Preset/Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–94

Image Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–95

Color Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–99

Lighten/Darken . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–100

Feature Defaults 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–102

Sharpness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–102

TABLE OF CONTENTS

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

iii

Page 6

TABLE OF C ONTENTS

Auditron

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Authentication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Create/Modify User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Creating a User Account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Modifying a User Account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

Changing the Tools Mode Password . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

Creating a Password for the Auditron Mode . . . . . . . . . . . . . . . . . . . . 2–11

Review User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–13

Review General Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–15

Review Printer Job Account. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–17

Review Service Prints Account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–18

iv

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 7

Electrical Safety

Safety Notes

This Xerox digital press and the recommended supplies have been designed and

tested to meet strict safety requirements. Attention to the following notes will

ensure the continued safe operation of your digital press.

SAFETY NOTES

• Use only the power cord supplied with this equipment.

• Plug the power cord directly into a correctly grounded electrical outlet. Do

not use an extension cord. If you do not know whether or not an outlet is

grounded, consult a qualified electrician.

• Do not use a ground adapter plug to connect this equipment to an electrical

outlet that lacks a ground connection terminal.

SAFETY NOTESSAFETY NOTESSAFETY NOTES

WARNING: You may get a severe electrical shock if the outlet is not correctly

grounded.

• Do not place the press where people may step on or trip on the power cord.

Do not place objects on the power cord.

• Do not override or disable electrical or mechanical interlocks.

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE v

v

Page 8

SAFETY N OTES

• Do not obstruct the ventilation openings. These openings are provided to

prevent overheating of the machine.

WARNING: Never push objects of any kind into slots or openings on this

equipment. Making a contact with a voltage point or shorting out a part could

result in fire or electrical shock.

• If any of the following conditions occur, immediately switch off the power to

the machine and disconnect the power cord from the electrical outlet. Call

an authorized Xerox service representative to correct the problem.

– The machine emits unusual noises or odors.

– The power cord is damaged or frayed.

– A wall panel circuit breaker, fuse, or other safety device has been

tripped.

– Liquid is spilled into the press.

– The machine is exposed to water.

– Any part of the machine is damaged.

Disconnect Device

The power cable is the disconnect device for this equipment. It is attached to the

back of the machine as a plug-in device. To remove all electrical power from the

machine, disconnect the power cable from the electrical outlet.

vi

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

Page 9

Laser Safety

SAFETY N OTES

Use of controls, adjustments, or procedures other than those specified in this

documentation may result in a hazardous exposure to laser radiation.

This equipment complies with international safety standards.

With specific regard to laser safety, the equipment complies with performance

standards for laser products set by government, national, and international

agencies as a Class 1 laser product. It does not emit hazardous light, as the beam

is totally enclosed during all phases of customer operation and maintenance.

SAFETY NOTES

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

vii

Page 10

SAFETY N OTES

Maintenance Safety

• Do not attempt any maintenance procedure that is not specifically described

in the documentation that is supplied with your press.

• Do not use aerosol cleaners. The use of supplies that are not approved may

cause poor performance of the press, and could create a dangerous

condition.

• Use the supplies and cleaning materials only as directed in this manual.

Keep all of these materials out of the reach of children.

• Do not remove the covers or guards that are fastened with screws. There are

no parts behind these covers that you can maintain or service.

Do not perform any maintenance procedures unless you have been trained to do

them by a Xerox representative, or unless a procedure is specifically described in

one of the manuals included with your press.

viii

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

Page 11

Operational Safety

SAFETY N OTES

Your Xerox equipment and supplies were designed and tested to meet strict

safety requirements. These include safety agency examination, approval, and

compliance with established environmental standards.

Your attention to the following safety guidelines will help ensure the continued

safe operation of your digital press:

• Use the materials and supplies specifically designed for your digital press.

The use of unsuitable materials may result in poor performance of the

machine and possibly a hazardous situation.

• Follow all warnings and instructions that are marked on or supplied with the

machine.

• Place the machine in a room that provides adequate space for ventilation

and servicing.

• Place the machine on a level, solid surface (not on a thick pile carpet) that

has adequate strength to support the weight of the machine.

• Do not attempt to move the machine. A leveling device that was lowered

when your machine was installed may damage the carpet or floor.

SAFETY NOTES

• Do not install the machine near a heat source.

• Do not install the machine in direct sunlight.

• Do not install the machine in line with the cold air flow from an air

conditioning system.

• Do not place containers of coffee or other liquid on the machine.

• Do not block or cover the slots and openings on the machine. Without

adequate ventilation, the machine may overheat.

• Do not attempt to override any electrical or mechanical interlock devices.

WARNING: Be careful when working in areas identified with this warning

symbol. These areas may be very hot and could cause personal injury.

If you need any additional safety information concerning the machine or

materials, contact your Xerox representative.

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

ix

Page 12

SAFETY N OTES

Ozone Safety

This product produces ozone during normal operation. The ozone is heavier than

air, and the quantity is dependent on print volume. Providing the correct

environmental parameters, as specified in the Xerox installation procedures,

ensures that concentration levels meet safe limits.

If you need additional information about ozone, request the Xerox publication,

OZONE, 600P83222, by calling 1-800-828-6571 in the USA. For a French language

version, call 1-800-828-6571 in the USA, then press 2.

x

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

Page 13

Notices

Radio Frequency Emissions

FCC in the USA

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the Federal Communications Commission

Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his/her own expense.

NOTICES

NOTICES

In Canada

Changes or modifications to this equipment not specifically approved by the

Xerox Corporation may void the user’s authority to operate this equipment.

Shielded cables must be used with this equipment to maintain compliance with

FCC regulations.

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus as defined in the Radio interference regulations

of Industry Canada.

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

xi

Page 14

N OTICES

Safety Extra Low Voltage Approval

This Xerox digital press is in compliance with various governmental agencies and

national safety regulations. All system ports meet the Safety Extra Low Voltage

(SELV) circuits for connection to customer-owned devices and networks.

Additions of customer-owned or third-party accessories that are attached to the

press must meet or exceed the requirements previously listed. All modules that

require external connection must be installed per the installation procedure.

xii

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

Page 15

Certifications in Europe

NOTICES

The CE marking that is applied to this product symbolizes Xerox Europe’s

Declaration of Conformity with the following applicable Directives of the

European Union as of the dates indicated:

January 1, 1995: - Council Directive 73/23/EEC amended by Council Directive 93/

68/EEC, approximation of the laws of the member states related to low voltage

equipment.

January 1, 1996: - Council Directive 89/336/EEC, approximation of the laws of

the member states related to electromagnetic compatibility.

Changes or modifications to this equipment not specifically approved by Xerox

Europe may void the user’s authority to operate the equipment.

Shielded cables must be used with this equipment to maintain compliance with

the EMC Directive 89/336/EEC.

This equipment is not primarily intended for use in a domestic environment.

A full declaration defining the relevant Directives and referenced standards can

be obtained from your Xerox Europe representative.

WARNING: In order to allow this equipment to operate in proximity to

Industrial, Scientific and Medical (ISM) equipment, the external radiation from

ISM equipment may have to be limited or special mitigation measures taken.

WARNING: This is a Class A product. In a domestic environment, this product

may cause radio interference, in which case the user may be required to take

adequate measures.

NOTICES

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

xiii

Page 16

N OTICES

It’s Illegal in the USA

Congress, by statute, has forbidden the reproduction of the following subjects

under certain circumstances. Penalties of fine or imprisonment may be imposed

on those guilty of making such reproductions.

1. Obligations or Securities of the United States Government, such as:

Certificates of Indebtedness National Bank Currency

Coupons from Bonds Federal Reserve Bank Notes

Silver Certificates Gold Certificates

United States Bonds Treasury Notes

Federal Reserve Notes Fractional Notes

Certificates of Deposit Paper Money

Bonds and Obligations of certain agencies of the government, such as

FHA, etc.

Bonds. (U.S. Savings Bonds may be photographed only for publicity purposes

in connection with the campaign for the sale of such bonds.)

Internal Revenue Stamps. (If it is necessary to reproduce a legal document

on which there is a canceled revenue stamp, this may be done provided the

reproduction of the document is performed for lawful purposes.)

Postage Stamps, canceled or uncanceled. (For philatelic purposes, Postage

Stamps may be photographed, provided the reproduction is in black and

white and is less than 75% or more than 150% of the linear dimensions of

the original.)

xiv

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

Page 17

NOTICES

Postal Money Orders.

Bills, Checks, or Drafts of money drawn by or upon authorized officers of the

United States.

Stamps and other representatives of value, of whatever denomination,

which have been or may be issued under any Act of Congress.

2. Adjusted Compensation Certificates for Veterans of the World Wars.

3. Obligations or Securities of any Foreign Government, Bank, or Corporation.

4. Copyrighted material, unless permission of the copyright owner has been

obtained or the reproduction falls within the “fair use” or library

reproduction rights provisions of the copyright law. Further information of

these provisions may be obtained from the Copyright Office, Library of

Congress, Washington, D.C. 20559. Ask for Circular R21.

5. Certificates of Citizenship or Naturalization. (Foreign Naturalization

Certificates may be photographed.)

6. Passports. (Foreign Passports may be photographed.)

7. Immigration Papers.

8. Draft Registration Cards.

NOTICES

9. Selective Service Induction Papers that bear any of the following

Registrant’s information:

Earnings or Income Dependency Status

Court Record Previous military service

Physical or mental condition

Exception: United States military discharge certificates may be

photographed.

10. Badges, Identification Cards, Passes, or Insignia carried by military

personnel, or by members of the various Federal Departments, such as FBI,

Treasury, etc. (unless photograph is ordered by the head of such department

or bureau.)

Reproducing the following is also prohibited in certain states:

Automobile Licenses - Drivers’ Licenses - Automobile Certificates of Title.

The above list is not all inclusive, and no liability is assumed for its completeness

or accuracy. In case of doubt, consult your attorney.

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

xv

Page 18

N OTICES

It’s Illegal in Canada

Parliament, by statute, has forbidden the reproduction of the following subjects

under certain circumstances. Penalties of fines or imprisonment may be imposed

on those guilty of making such copies.

1. Current bank notes or current paper money.

2. Obligations or securities of a government or bank.

3. Exchequer bill paper or revenue paper.

4. The public seal of Canada or of a province, or the seal of a public body or

authority in Canada, or of a court of law.

5. Proclamations, orders, regulations or appointments, or notices thereof (with

intent to falsely cause same to purport to have been printed by the Queen’s

Printer for Canada, or the equivalent printer for a province).

6. Marks, brands, seals, wrappers or designs used by or on behalf of the

Government of Canada or of a province, the government of a state other

than Canada or a department, board, Commission or agency established by

the Government of Canada or of a province or of a government of a state

other than Canada.

7. Impressed or adhesive stamps used for the purpose of revenue by the

Government of Canada or of a province or by the government of a state other

than Canada.

8. Documents, registers or records kept by public officials charged with the

duty of making or issuing certified copies thereof, where the reproduction

falsely purports to be a certified copy thereof.

9. Copyrighted material or trademarks of any manner or kind without the

consent of the copyright or trademark owner.

The above list is provided for your convenience and assistance, but it is not all

inclusive, and no liability is assumed for its completeness or accuracy. In case of

doubt, consult your solicitor.

xvi

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

Page 19

Environmental Notices for the USA

As an ENERGY STAR® partner, Xerox Corporation has determined that this digital

press model meets the ENERGY STAR

®

ENERGY STAR

The ENERGY STAR program is a team effort between the Environmental

Protection Agency and the office equipment industry to promote energy-efficient

personal computers, monitors, printers, digital presses, fax machines and

copiers. Reducing the energy consumption of this equipment will help combat

smog, acid rain and long-term changes to the climate by decreasing the

emissions that result from generating electricity.

is a US registered trademark.

®

guidelines for energy efficiency.

NOTICES

NOTICES

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

xvii

Page 20

N OTICES

Environmental Notices for Canada

As a participant in the Environmental Choice program, Xerox Corporation has

determined that this digital press model meets the Environmental Choice

guidelines for energy efficiency.

Environment Canada established the Environmental Choice program in 1988 to

help consumers identify environmentally responsible products and services.

Copier, printer, digital press, and fax products must meet energy efficiency and

emissions criteria, and exhibit compatibility with recycled supplies. Currently,

Environmental Choice has more than 1600 approved products and 140 licensees.

Xerox has been a leader in offering EcoLogo approved products. In 1996, Xerox

became the first company licensed to use the Environmental Choice EcoLogo for

its copiers, printers, and fax machines.

xviii

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

Page 21

Symbols

C ONVENTIONS

Conventions

Standardized conventions have been used in this manual to assist you in visually

locating and identifying information quickly.

CONVENTIONS

CAUTION: This symbol alerts you to an action that may cause damage to

hardware or software, or result in the loss of data.

WARNING: Warnings alert you to an action that may cause bodily injury.

WARNING: This symbol identifies an area on the machine that is HOT and

may cause burn injuries.

WARNING: This symbol indicates a laser is being used in the machine and

alerts you to refer to the appropriate safety information.

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

xix

Page 22

C ONVENTIONS

KEY POINT: This symbol identifies information that is being emphasized and

is important for you to remember.

1 The 1 2 3... symbol indicates the beginning of a task or work process you should

use to complete a procedure and is followed by the first step of a numbered

procedure, task, or work process.

2

3

NOTE: This symbol calls your attention to information that is helpful, but not

essential to complete a procedure or task.

Writing Style Conventions

• Bold type indicates the name of a button to press or touch.

• Underlining

• Italic type is used for the text associated with symbols such as Cautions,

• Italic type is also used to indicate names, such as the name of a chapter, or

• Procedures direct you to press

• Text referring to illustrations or screen samples precedes

is used to emphasize a word or term.

Notes, Key Points, etc. to visually bring the information to your attention.

the name of a screen.

buttons located on the Control Panel, and

buttons located on the Touch Screen.

touch

the image.

xx

DOCUCOLOR 2060/2045 SYSTEM ADMINISTRATION GUIDE

Page 23

Overview

1. Tools Mode

KEY POINT: Some features or options described in this chapter may not

display or be selectable depending on the configuration of your machine.

The Tools Mode enables you to establish the default settings for your DocuColor

2060/2045 digital press with scanner to fit your individual requirements. You can

change the settings for a variety of features, such as the initial screen to display

when the press is powered on, the language to display on the Touch Screen,

special paper sizes that can be used in certain Paper Trays, timers, audio tone

controls, default settings for scanner features, image quality settings, and more.

Entering and Exiting Tools Mode

KEY POINT:

• If you attempt to access the Tools Mode while a job is printing, access to the

screens will be delayed until the job completes printing.

• Jobs will queue, but will not print while the Tools Mode is active.

• You cannot access the Tools Mode if the 2060/2045 is in a Fault condition.

• You cannot access the Tools Mode if the Pause key on the Control Panel has

been pressed to halt a job. When the job that was stopped has been

completed, Tools Mode may be accessed.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–1

Page 24

TOOLS M ODE

Entering Tools Mode

Use the following method to enter the Tools Mode:

1 Press the Access button on the Control Panel. The Access Password Screen

appears.

2 Use the keypad to enter the Tools Mode password. The default password is five

1s (1 1 1 1 1). For security reasons, only asterisks are displayed on the screen.

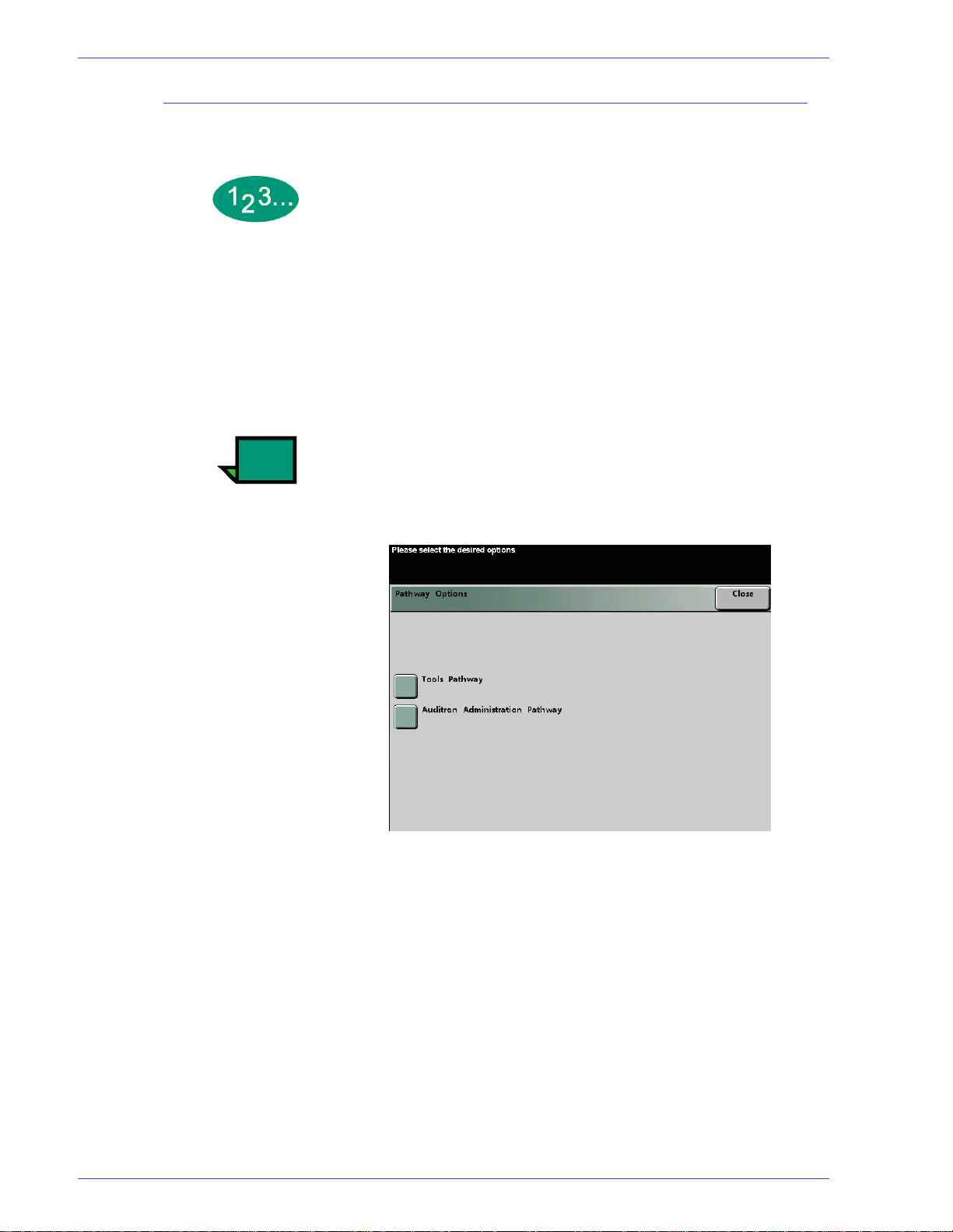

3 Touch the Enter button on the screen. The Pathway Options screen appears, as

shown in Figure 1.

NOTE:It is recommended that you change the Tools password as soon as

possible after installing the DocuColor 2060/2045 to prevent unauthorized

access to the Tools Mode. The procedure for changing the password is in Chapter

4 of this manual.

1–2

Figure 1. Pathway Options screen

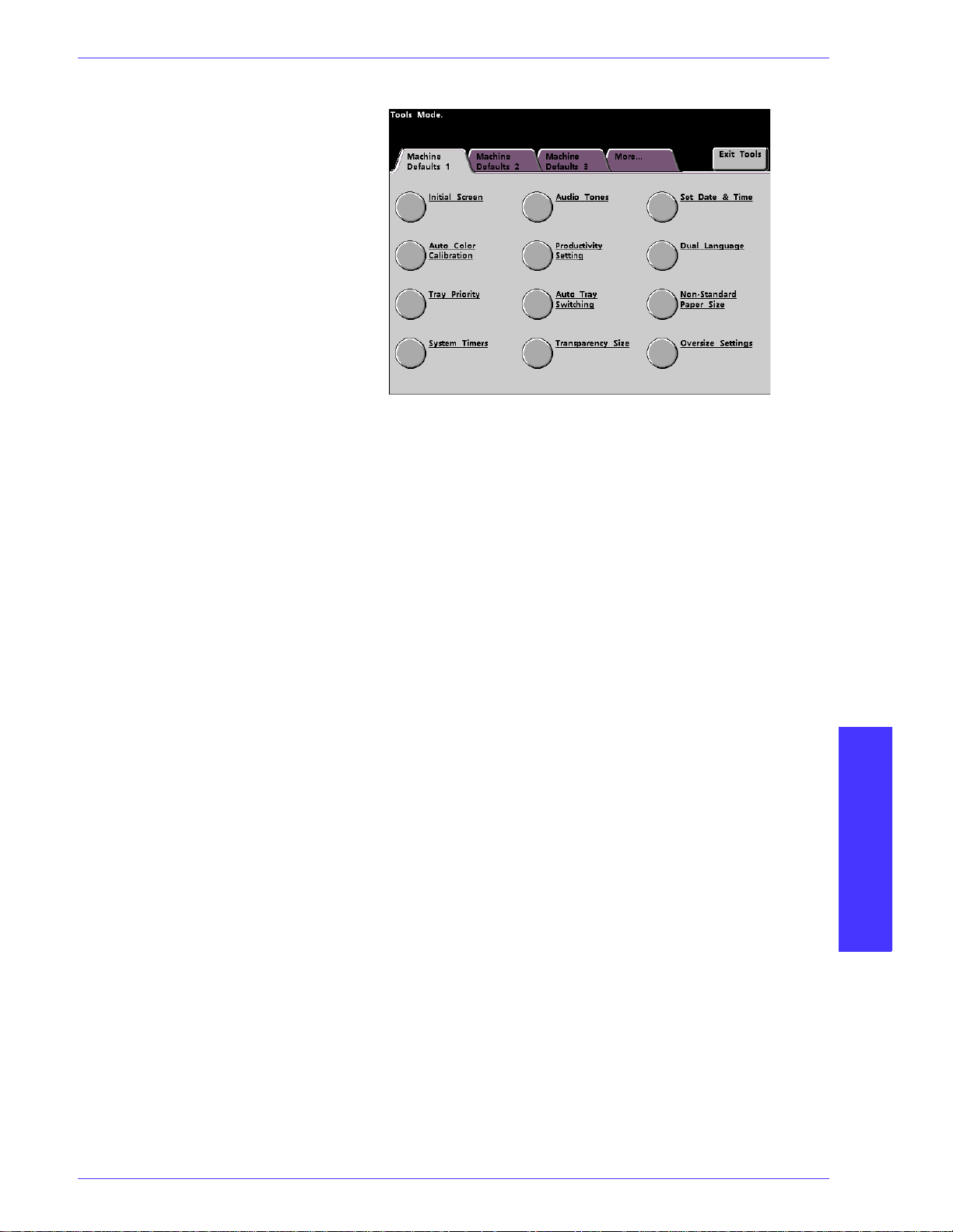

4 Touch the Tools Pathway button on the screen. The Machine Defaults 1 screen

appears.

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 25

TOOLS M ODE

Figure 2. Machine Defaults 1 screen

NOTE:The Machine Defaults 3 tab will be used for AssetManager updates.

5 Touch the Exit Tools button to exit the Tools Mode.

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–3

Page 26

TOOLS M ODE

Navigating in Tools Mode

The following table provides tells you how to navigate in Tools Mode by pressing

or touching keys or buttons.

Key or Button Result

Tabs Allows you to view the options available on that screen.

Enter Saves any changes you made on the screen.

System Default Returns the settings on the screen to the factory default

Close Closes the screen and returns the system to the previous

Off Deactivates the feature.

Reset Returns the settings on the screen to the settings that

settings.

screen.

were in effect when the screen opened.

Cancel Cancels the changes made on the screen.

Exit Tools Exits the Tools Mode.

NOTE: Changes made to features in the Tools Mode take effect when you exit

Tools Mode.

Machine Defaults and Feature Defaults

The Machine Defaults 1 screen appears when you first enter the Tools Mode.

You can change the default settings for the options shown on the Machine

Defaults 1, Machine Defaults 2, Feature Defaults 1, and Feature Defaults 2

screens. The Feature Defaults 2 screen is accessed by touching the More... tab.

The procedures used to change settings for the options shown on the screens are

described in detail after the figures below.

1–4

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 27

TOOLS M ODE

Figure 3. Machine Defaults 1 screen

NOTE:The Machine Defaults 3 tab will be used for AssetManager updates.

The Machine Defaults 2 screen is illustrated in the following figure.

Figure 4. Machine Defaults 2 screen

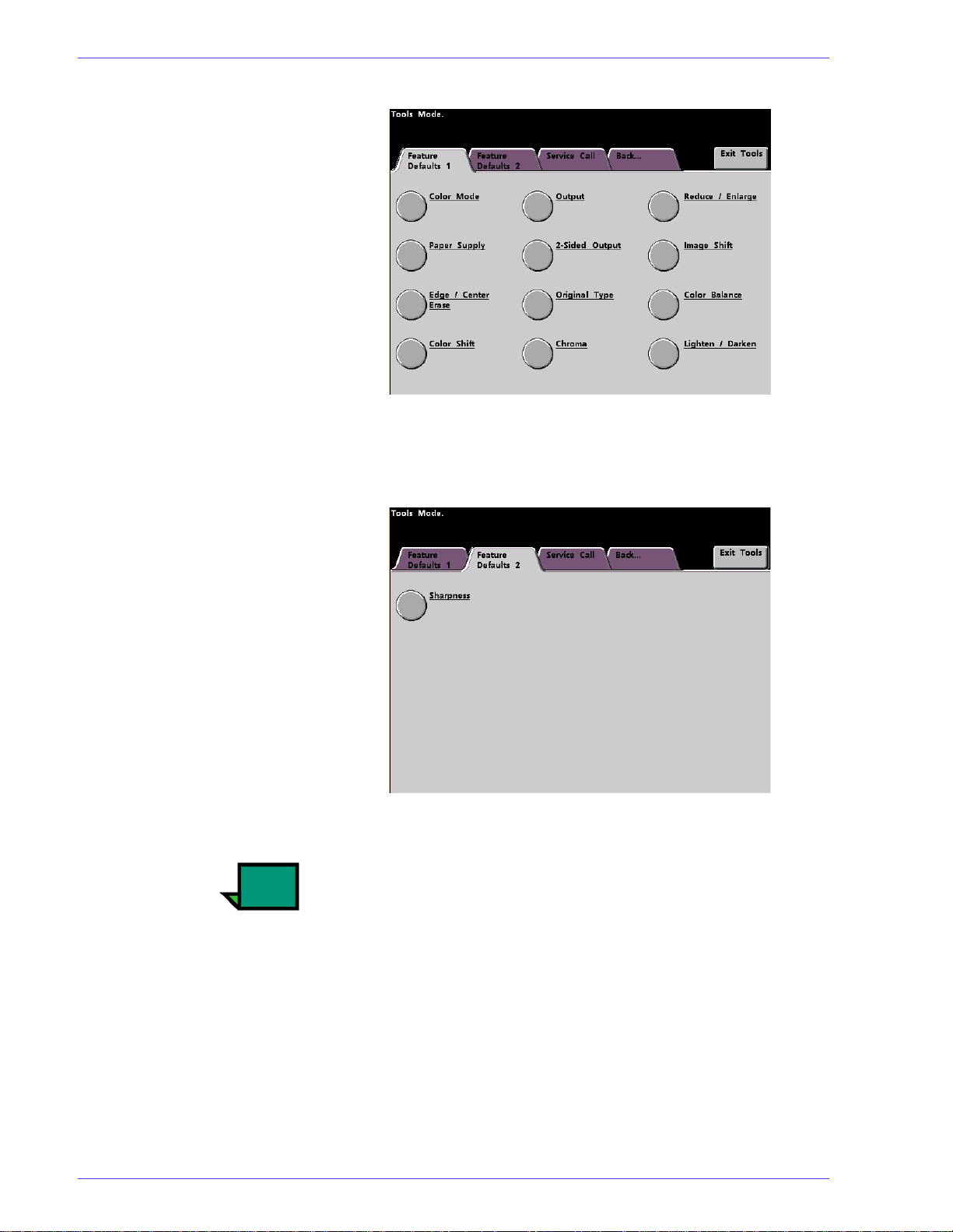

The Feature Defaults 1 screen is illustrated in the following figure.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–5

Page 28

TOOLS M ODE

Figure 5. Feature Defaults 1 screen

The Feature Defaults 2 screen is illustrated in the following figure.

1–6

Figure 6. Feature Defaults 2 screen

NOTE:The Service Call feature is not yet available.

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 29

TOOLS M ODE

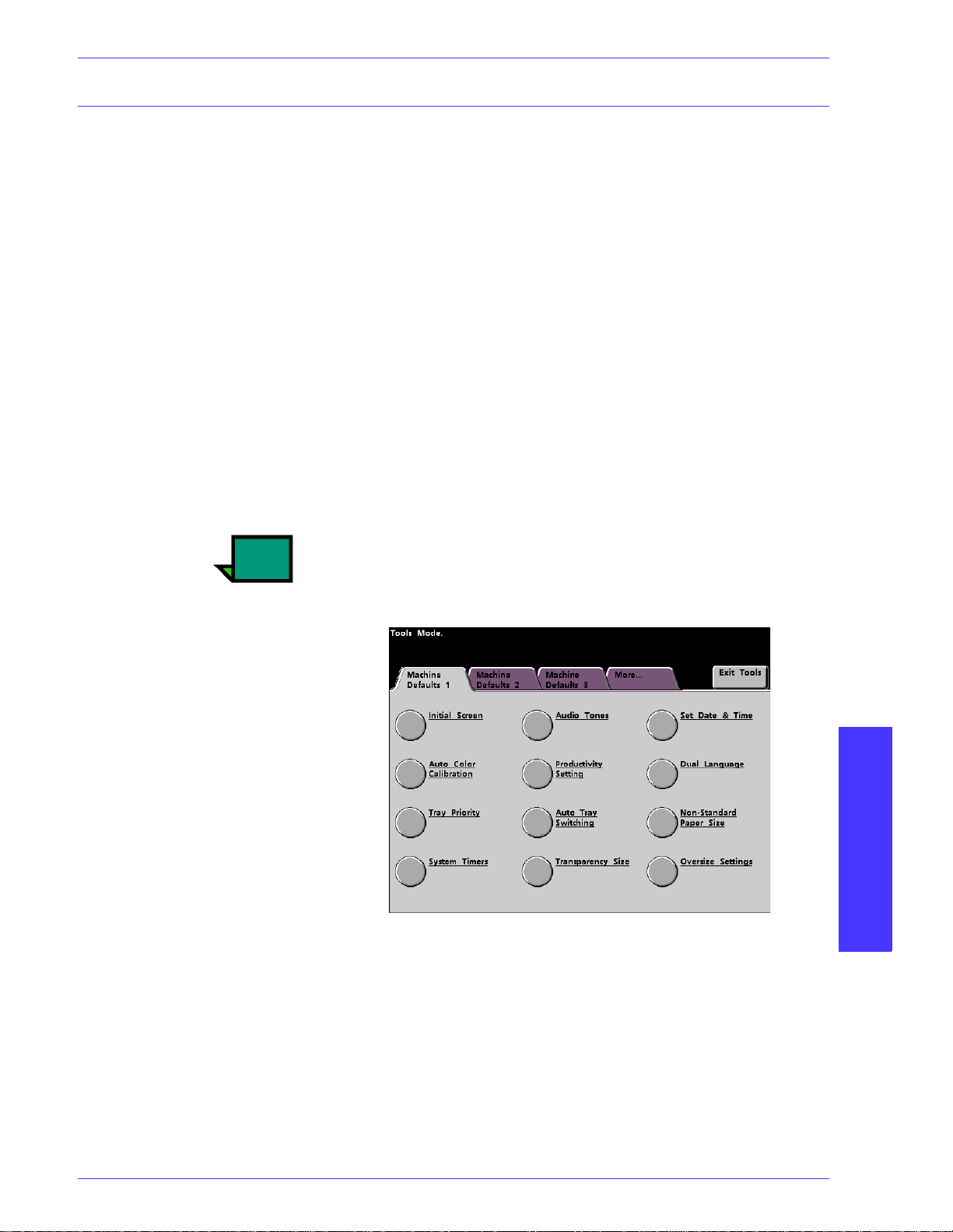

Machine Defaults 1

This section describes the features available to you through the Machine

Defaults 1 screen. You can access the following DocuColor features through the

Machine Defaults 1 screen:

• Initial Screen

• Auto Color Calibration

• Tray Priority

• System Timers

• Audio Tones

• Productivity Setting

• Auto Tray Switching

• Set Date & Time

• Dual Language

• Non-Standard Paper Size

• Oversize Settings

NOTE:The Tray Priority and Auto Tray Switching features may not be available,

depending on your DocuColor software version.

Touch the Machine Defaults 1 tab. The Machine Defaults 1 screen appears.

Figure 7. Machine Defaults 1 screen

NOTE:The Machine Defaults 3 tab will be used for AssetManager updates.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–7

Page 30

TOOLS M ODE

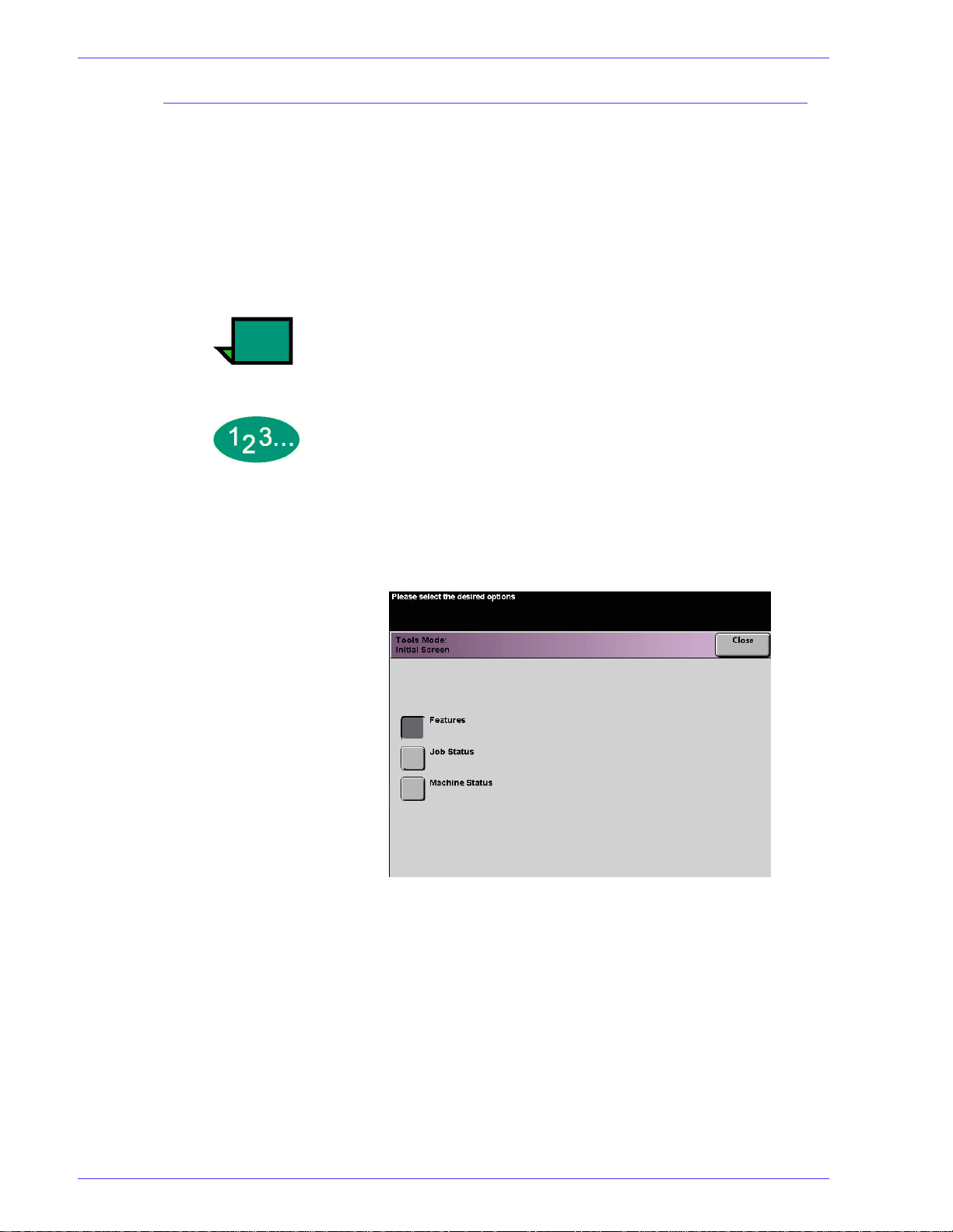

Initial Screen

Use the Initial Screen to select the default screen when the DocuColor is

powered on. You can choose from three screens:

• Features

• Job Status

• Machine Status

NOTE:The Basic Features screen is the factory default setting.

1 Touch the Initial Screen button on the Machine Defaults 1 screen. The Initial

Screen screen appears.

Figure 8. Initial Screen screen

1–8

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 31

TOOLS M ODE

2 Touch the Features, Job Status or Machine Status button.

NOTE:Refer to the DocuColor 2060/2045 Operator Manual for information

regarding the features on this screen and regarding the Added Features, Image

Quality, and More... screens.

If you leave the setting at the Features screen, the screen shown below appears

when the machine is powered on. This screen displays the Basic Features tab for

scan to print jobs.

Figure 9. Basic Features screen

If you change the default setting to the Job Status screen, the screen below

appears when the machine is powered on. This screen displays all the jobs

currently queued for printing.

Figure 10. Job List screen

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–9

Page 32

TOOLS M ODE

If you change the default setting to the Machine Status screen, the

following screen appears when the machine is powered on. The appearance

of your Machine Status screen depends on the accessories you have

connected.

Figure 11. Machine Status screen

NOTE:Refer to the DocuColor 2060/2045 Operator Manual for more

information about the Machine Status screen.

1–10

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 33

TOOLS M ODE

Auto Color Calibration

KEY POINT: The DocuColor 2060/2045 Color Calibration procedure does not

affect the quality of print jobs sent through your Raster Image Processor. It is for

scan to print jobs only.

The DocuColor 2060/2045 has a number of monitoring sensors, as well as

feedback and control mechanisms, that are designed to enhance overall

calibration stability. Image quality is also automatically adjusted periodically

during operation to keep the calibration as close as possible to the initial setup

conditions.

The Raster Image Processor (RIP) connected to your digital press with scanner

also has calibration procedures that you can use for network jobs.

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–11

Page 34

TOOLS M ODE

KEY POINT: Calibration targets can be printed only on A4 or letter sized

paper. Ensure that your IOT has A4 or Letter paper loaded in one of the paper

trays.

KEY POINT: You should be skilled in color science and calibration procedures

before attempting to use the options available on these screens.

What to know about screening

The digital press with scanner uses an advanced proprietary screening

technology to produce the colors, pictures, tints, and shades required to produce

high-quality prints.

PG is an abbreviation for Pattern Generator. The R in 200R refers to Rotated Line

screen, and the C in 200C and 15C refers to Cluster Dot screen.

1–12

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 35

TOOLS M ODE

The five screening methods and what you should remember about each are

described in the following table.

Screening

Method

150C (LPI Cluster

Dot)

200C (LPI Cluster

Dot)

200R (LPI

Rotated Line

screen)

What to Remember

Provides better coverage on rough paper

Larger dot provides better color stability

Reduces black and other solid color mottle

Provides better black coverage due to black toner

granularity

Dot size is better for impressions containing tints,

highlights, and pastels

Most suitable for pages requirement careful control of

highlights

Poorest performance on text

Produces fine rosettes that can better emulate offset

lithography.

May leave jaggies on text (fonts)

Better for creating smooth gradients with minimum

contouring

Best for graphics and images

Switch to the 200R screen if banding occurs

The angle is fixed and cannot be adjusted

Has vertical screening for black, which is better for text

and line art.

Switch to the 200C screen if banding occurs.

Best all-purpose screen.

300 LPI Line

screen

Generally considered a special use screen.

Better edges on colored text with fewer jaggies.

Poor color stability due to small size of dot.

The entire color gamut must be reproduced in two-micron

area.

600 LPI Line

screen

Least color stability due to small size of dot.

Not recommended for most workflows.

Used primarily for testing.

The Raster Image Processor uses information from the PostScript job and the

software print driver to determine which screen is used for a particular job.

To access the calibration procedures:

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–13

Page 36

TOOLS M ODE

1 Touch the Auto Color Calibration button on the Machine Defaults 1 screen.

The Auto Color Calibration screen appears.

Figure 12. Auto Color Calibration screen

From this screen, you can perform the following tasks:

• Run Calibration

• Check Gradation

• Manual Adjust

KEY POINT: Touch the Reset button on the Auto Color Calibration screen to

return any settings you changed to their last saved values. Once you exit Tools

Mode, any changes you have made are set.

Refer to the following procedures for detailed information regarding each option

displayed on this screen.

1–14

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 37

TOOLS M ODE

Run Calibration

Use the Run Calibration feature if it is visually obvious that the gray balance on

your scan to print jobs is not correct. During the Run Calibration procedure, the

digital press creates a Look Up Table by reading the 12 Toner Density Patches

that print out. The digital press then compares those readings to the factory-set

target values and makes the necessary adjustments to bring the values within

the target range.

NOTE:PG is an abbreviation for Pattern Generator. The R in 200R indicates

Rotated Line screen, and the C in 200C and 150C indicates Cluster Dot screen.

1 Touch the Run Calibration button on the Auto Color Calibration screen to begin

the calibration process. The Run Calibration screen appears.

Figure 13. Run Calibration screen

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–15

Page 38

TOOLS M ODE

2 Do one of the following:

• Touch the 300 PG button to calibrate the 300 Line screens (200R, 200C, and

150C screens). Use this option only if you have noticed a problem with

halftone screening.

• Touch the 600 PG button to calibrate the 600 Line screen. Use this option

only if you have noticed a problem with the gray scale on text.

• Touch the 300 PG & 600 PG button to calibrate all the screens.

3 Press the Start button on the Control Panel. The calibration process starts and

color patch prints are printed.

1–16

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 39

TOOLS M ODE

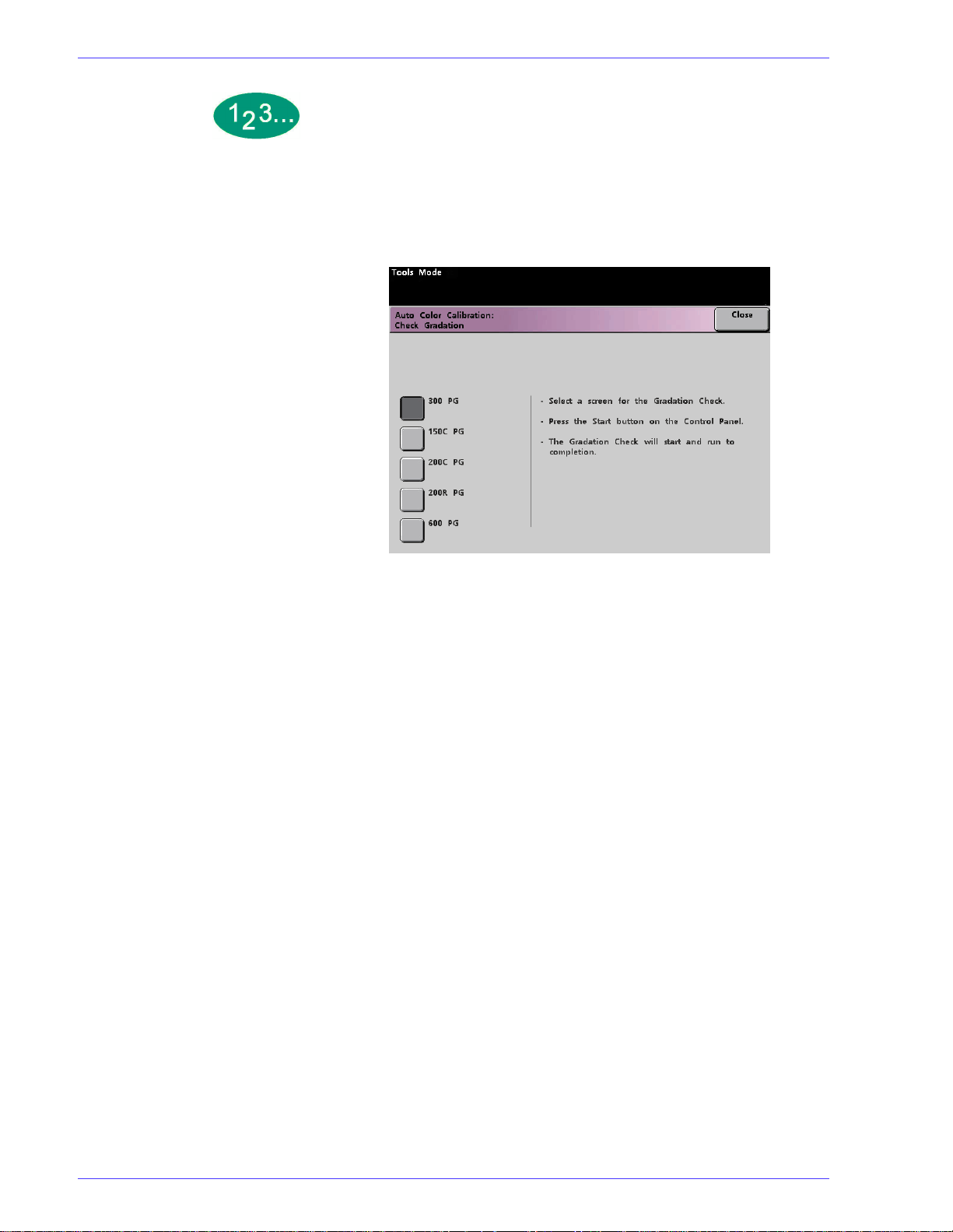

Check Gradation

The Check Gradation feature allows you to print gradated color patch prints for

each line screen on the digital press. These gradated color patch prints are used

to verify that the dry ink/toner densities for CMYK and Grey balance are correct.

If you are dissatisfied with the appearance of any color on the print, you can

manually adjust the dry ink/toner densities for Cyan, Magenta, Yellow, and Black

using the Manual Adjust feature. It is recommended that you begin your

calibration by calibrating the 300 PG screen first. This is the basic line screen

that is used, and all other line screens are calibrated against the 300 PG screen.

Use this feature daily and compare the output of gradated color patches to the

color patch prints from the previous day. Under normal operating conditions,

there should be no difference between them. Automatic sensors and control

mechanisms in the digital press with scanner should maintain consistent

calibration.

If there is an obvious visual difference between two days’ color patches, run the

calibration process on the Raster Image Processor, then run this gradation

process again.

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–17

Page 40

TOOLS M ODE

1 Touch the Check Gradation button on the Auto Color Calibration screen to

begin the process. The Check Gradation screen appears.

Figure 14. Check Gradation screen

2 Touch the button for the screen for which you want to check the gradation.

3 Press the Start button on the Control Panel. The gradation check process starts

and gradated color patch prints are printed.

4 Repeat the process for each screen for which you want to check the gradation.

1–18

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 41

TOOLS M ODE

Manual Adjust

The Manual Adjust feature enables you to modify each color (CMYK) for Low,

Mid, and High densities. You can also modify the same settings for the highlight

values of each screen.

KEY POINT: Manual Adjust should be used only by an expert in color science.

Any changes made on this screen remain in effect for all future scanned jobs,

until it is changed again.

1 Touch the Manual Adjust button on the Auto Color Calibration screen. The

Manual Adjust screen appears.

Figure 15. Manual Adjust screen

The value displayed for each setting, 128, is the mid point between 0 and 255.

Entering a lower number produces a lighter color. Entering a higher number

produces a darker color. If you make any changes, run test prints to evaluate the

output prints.

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–19

Page 42

TOOLS M ODE

2 Follow the directions on the screen and touch the button for the value you wish

to adjust.

3 Touch the up or down arrow buttons until the value you want is displayed in the

field above the arrow buttons.

KEY POINT: You should not adjust the value more than 5 counts at a time.

4 Touch the Enter button on the screen.

5 Repeat steps 2, 3, and 4 to enter other new values.

6 Press the Start button on the Control Panel to enter the new values into the

system.

KEY POINT: It is recommended that you run the Check Gradation procedure

for the screening type that you are adjusting. Do a before and after comparison

to verify your changes.

1–20

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 43

TOOLS M ODE

Tray Priority

The Tray Priority feature allows you to select priorities for each paper tray. If the

Auto Tray Switching feature is enabled, and each paper tray contains the same

size and weight paper, the digital press feeds paper from the paper tray set at

Priority 1. If there is no paper in the Priority 1 paper tray, the Priority 2 paper tray

is automatically selected, and so on.

KEY POINT: Depending on your software version, the Tray Priority feature

may not be available. This feature must be enabled by a Xerox Service

Representative using the correct version of software.

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–21

Page 44

TOOLS M ODE

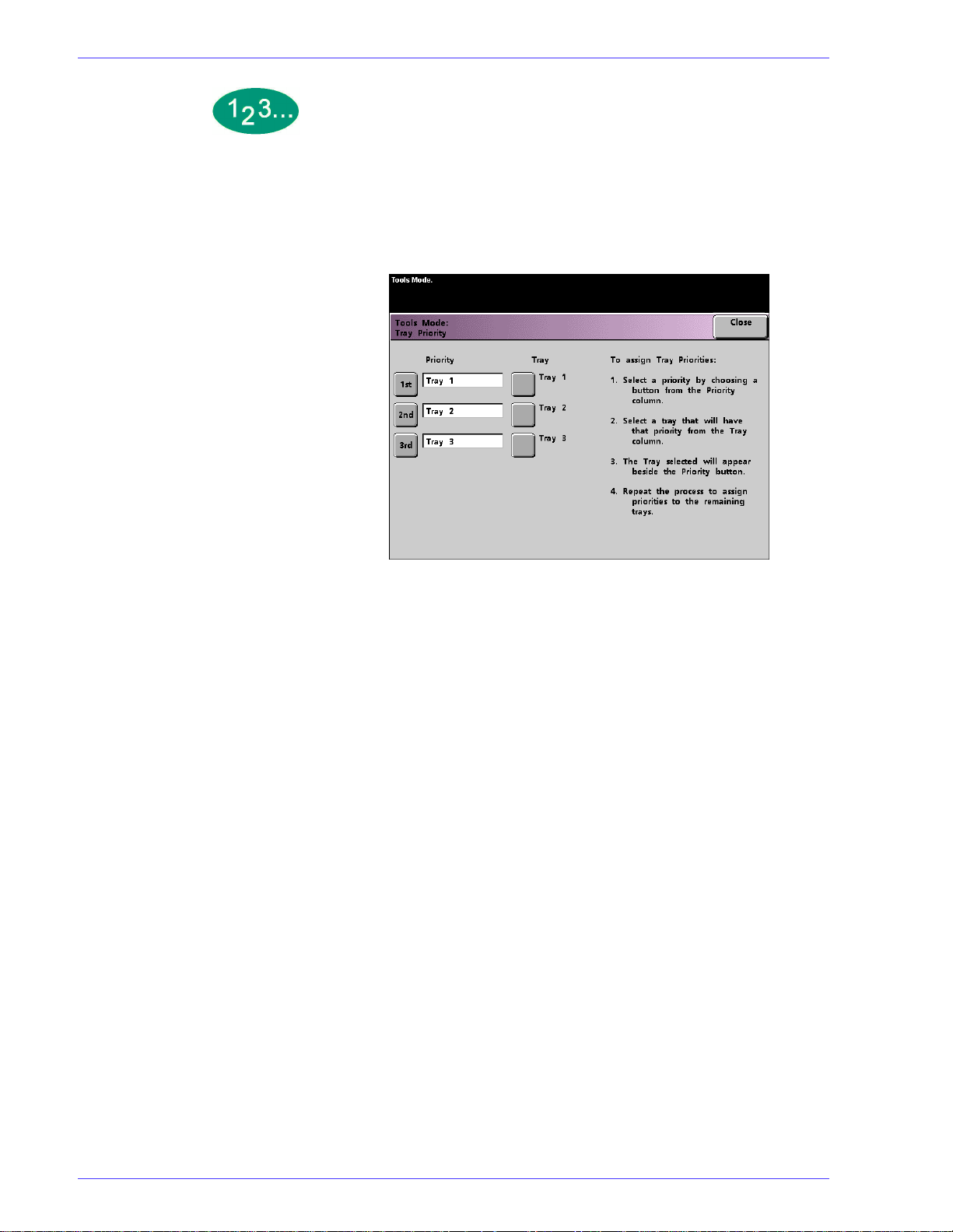

1 Touch the Tray Priority button on the Machine Defaults 1 screen. T he Tray

Priority screen appears.

Figure 16. Tray Priority screen

2 Touch the desired Priority button in the Priority column.

3 Touch the button for the Paper Tray that will have that priority. The number of the

selected Paper Tray appears next to that Priority button.

4 Repeat this procedure for each Priority. You will not be able to set the same

Paper Tray at more than one Priority at a time.

5 Touch the Close button to return to the Machine Defaults 1 screen. You will not

be able to touch the Close button until you have set Paper Trays for each Priority.

1–22

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 45

TOOLS M ODE

System Timers

The System Timers feature allows you to change the factory default settings for

the timers in the digital press with scanner.

To access the various timers, touch the System Timers button on the Machine

Defaults 1 screen.

The System Timers screen appears. From this screen you can view the time

currently set for each of the timers, and select the one you want to change.

Power Saver

Use this feature to set the time that elapses until the digital press with scanner

enters a reduced power consumption mode. This timer is activated when all print

jobs have been completed and there are no jobs in the job queue.

The digital press with scanner exits the Power Saver mode when a job is sent to

be printed.

Figure 17. System Timers screen

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–23

Page 46

TOOLS M ODE

1 Touch the Power Saver button on the System Timers screen. The Power Saver

screen appears.

Figure 18. Power Saver screen

2 Use the up or down arrow buttons to change the time. The range available is 1 to

240 minutes.

To use the system default time of 60 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

1–24

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 47

TOOLS M ODE

Screen Saver

The Screen Saver feature allows you to protect the screen from being damaged

with permanent marks if the digital press with scanner is idle for a period of

time.

1 Touch the Screen Saver button on the System Timers screen. The Screen Saver

screen appears.

Figure 19. Screen Saver screen

2 Use the up or down arrow buttons to change the time. The range available is 10

to 60 minutes.

To use the system default time of 10 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–25

Page 48

TOOLS M ODE

Job Spacing

Use the Job Spacing feature when there are multiple jobs queued and you would

like to allow 7 seconds to unload prints from a finishing device before the next

job starts printing.

1 Touch the Job Spacing button on the System Timers screen. The Job Spacing

screen appears.

Figure 20. Job Spacing screen

2 Touch the 7 Seconds button to enable the feature or touch the Off button to

disable the feature.

3 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

1–26

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 49

TOOLS M ODE

To o l s O f f

Use the Tools Off feature to have the digital press with scanner automatically

return to the printing or scanning mode when no action has been taken on the

Tools Mode screens after the set amount of time.

KEY POINT: Jobs sent over a network will queue but will not print while the

Tools Mode is active.

1 Touch the Tools Of f button on the System Timers screen. The Tools Off screen

appears.

Figure 21. Tools Off screen

2 Use the up or down arrow buttons to change the time. The range available is 10

to 60 minutes.

To use the system default time of 10 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–27

Page 50

TOOLS M ODE

Auto Resume Scan

Use the Auto Resume feature to restart a copy job automatically after a fault is

cleared and a scanned job is waiting for user instruction, or to restart a copy job

waiting for user instruction after the Job Interrupt button on the Control Panel

has been pressed.

1 Touch the Auto Resume Scan button on the System Timers screen. The Auto

Resume Scan screen appears.

Figure 22. Auto Resume Scan screen

2 Use the up or down arrow buttons to change the time. The range available is 1 to

10 minutes.

To use the system default time of 2 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

1–28

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 51

TOOLS M ODE

Auto Resume Print

Use the Auto Resume Print feature to restart a job automatically after a fault is

cleared and a job received over the network is waiting for user instruction, or to

restart a job waiting for user instruction after the Interrupt button on the Control

Panel has been pressed.

1 Touch the Auto Resume Print button on the System Timers screen. The Auto

Resume Print screen appears.

Figure 23. Auto Resume Print screen

2 Use the up or down arrow buttons to change the time. The range available is 1 to

10 minutes.

To use the system default time of 2 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–29

Page 52

TOOLS M ODE

Auto Resume Stop

Use the Auto Resume Stop feature to restart a job automatically after the Pause

button on the Control Panel is pressed and the job is waiting for user instruction.

1 Touch the Auto Resume Stop button on the System Timers screen. The Auto

Resume Stop screen appears.

Figure 24. Auto Resume Stop screen

2 Use the up or down arrow buttons to change the time. The range available is 1 to

10 minutes.

To use the system default time of 2 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

1–30

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 53

TOOLS M ODE

Auto Resume Hold

Use the Auto Resume Hold feature to automatically proceed to print the next job

in the queue if the job currently printing is waiting for user instruction to clear a

certain type of fault.

1 Touch the Auto Resume Hold button on the System Timers screen. The Auto

Resume Hold screen appears.

Figure 25. Auto Resume Hold screen

2 Use the up or down arrow buttons to change the time. The range available is 1 to

10 minutes.

To use the system default time of 2 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–31

Page 54

TOOLS M ODE

Auditron Mode Off

Use the Auditron Mode Off feature to set the time that it takes the digital press

to return to the initial Password screen after the cessation of user activity while

in Auditron Mode.

1 Touch the Auditron Mode Off button on the System Timers screen. The Auditron

Mode Off screen appears.

Figure 26. Auditron Mode Off screen

2 Use the up or down arrow buttons to change the time. The range available is 1 to

10 minutes.

To use the system default time of 2 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

1–32

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 55

TOOLS M ODE

Job Complete

The Job Complete feature determines when the digital press returns to the

system default settings after a scanned job with programmed settings is

complete. If a user has completed a job and failed to return the system settings

to their default values by pressing the Clear All button on the Control Panel, the

machine automatically restore thes default settings after the amount of time set

in the Job Complete screen.

1 Touch the Job Complete button on the System Timers screen. The Job Complete

screen appears.

Figure 27. Job Complete screen

2 Use the up or down arrow buttons to change the time. The range available is 1 to

10 minutes.

To use the system default time of 2 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen, or select

another timer to change.

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–33

Page 56

TOOLS M ODE

Job Program Incomplete

The Job Program Incomplete feature allows users to set the time that it takes the

digital press to return to the default feature settings after features buttons have

been selected to program a job, but the job has not been started and no user

activity has occurred for the amount of time selected.

1 Touch the Job Program Incomplete button on the System Timers screen. The

Job Program Incomplete screen appears.

Figure 28. Job Program Incomplete screen

2 Use the up or down arrow buttons to change the time. The range available is 1 to

10 minutes.

To use the system default time of 2 minutes, touch the System Default button.

3 Touch the Enter button on the screen to enter the new time into the system.

4 Touch the Close button to return to the Machine Defaults 1 screen.

1–34

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 57

TOOLS M ODE

Audio Tones

There are three types of audio tones that can be activated on the digital press

with scanner, as shown in the following table.

To ne What the Tone Indicates

Attention Tone An unselectable button has been touched.

Button Selection

Tone

Fault Tone The press is in a fault condition and cannot continue

Each of these tones can be deactivated or set to Soft, Normal, or Loud. The

factory default setting is Normal.

A selectable button has been touched.

printing.

1 Touch the Audio Tones button on the Machine Defaults 1 screen. The Audio

Tones screen appears.

Figure 29. Audio Tones screen

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–35

Page 58

TOOLS M ODE

2 Touch the button for the desired volume setting for each tone. To deactivate a

tone, touch the Off button for that tone.

3 Touch the Reset button to restore the factory default setting for the three tones.

4 Touch the Close button to return to the Machine Defaults 1 screen.

1–36

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 59

TOOLS M ODE

Productivity Setting

KEY POINT: If you have a DocuColor 2045, this feature is not available.

Use this setting to optimize the throughput speed for the type of paper you run

most frequently. Productivity Setting Feature options are provided in the

following table.

Selection What this Selection Does

Auto Selects a Fuser temperature based on the paper weight

selected in the paper tray, improving average power

consumption, but slower operation while waiting for the

Fuser to either heat up or cool down

Light Weight

Heavy Weight

Sets the Fuser temperature to 160oC, which optimizes the

throughput speed for light weight papers, and uses lower

power consumption

Sets the Fuser temperature to 175oC, which optimizes the

throughput speed for heavier papers, and results in higher

power consumption

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–37

Page 60

TOOLS M ODE

1 Touch the Productivity Setting button on the Machine Defaults 1 screen. The

Productivity Setting screen appears.

Figure 30. Productivity Setting screen

2 Select the button for the type of paper you use most frequently in the digital

press with scanner, or select Auto to use the throughput speed for the paper

weight selected on the Paper Tray Weight Indicator.

3 Touch Close to return to the Machine Defaults 1 screen.

1–38

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 61

TOOLS M ODE

Auto Tray Switching

This feature allows you to set the default settings for the Auto Tray Switching,

Auto Paper Selection, and the Inhibited Tray options.

Default Setting What the Default Does

Auto Tray

Switching

Allows the digital press to automatically select another

paper tray, containing the appropriate paper, if the

selected paper tray becomes unusable

Auto Paper

Selection

Allows the digital press to automatically select the

appropriate paper size for the job being processed,

without a specific paper tray being selected

Inhibited Tray Allows you to select a specific paper tray, or trays, that

you want the digital press to bypass, regardless of the

Tray Priority settings

KEY POINT: Depending on which version of software you have installed, the

Auto Tray Switching feature may not be available. This feature must be enabled

by a Xerox Service Representative using the correct version of software.

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

TOOLS MODE

1–39

Page 62

TOOLS M ODE

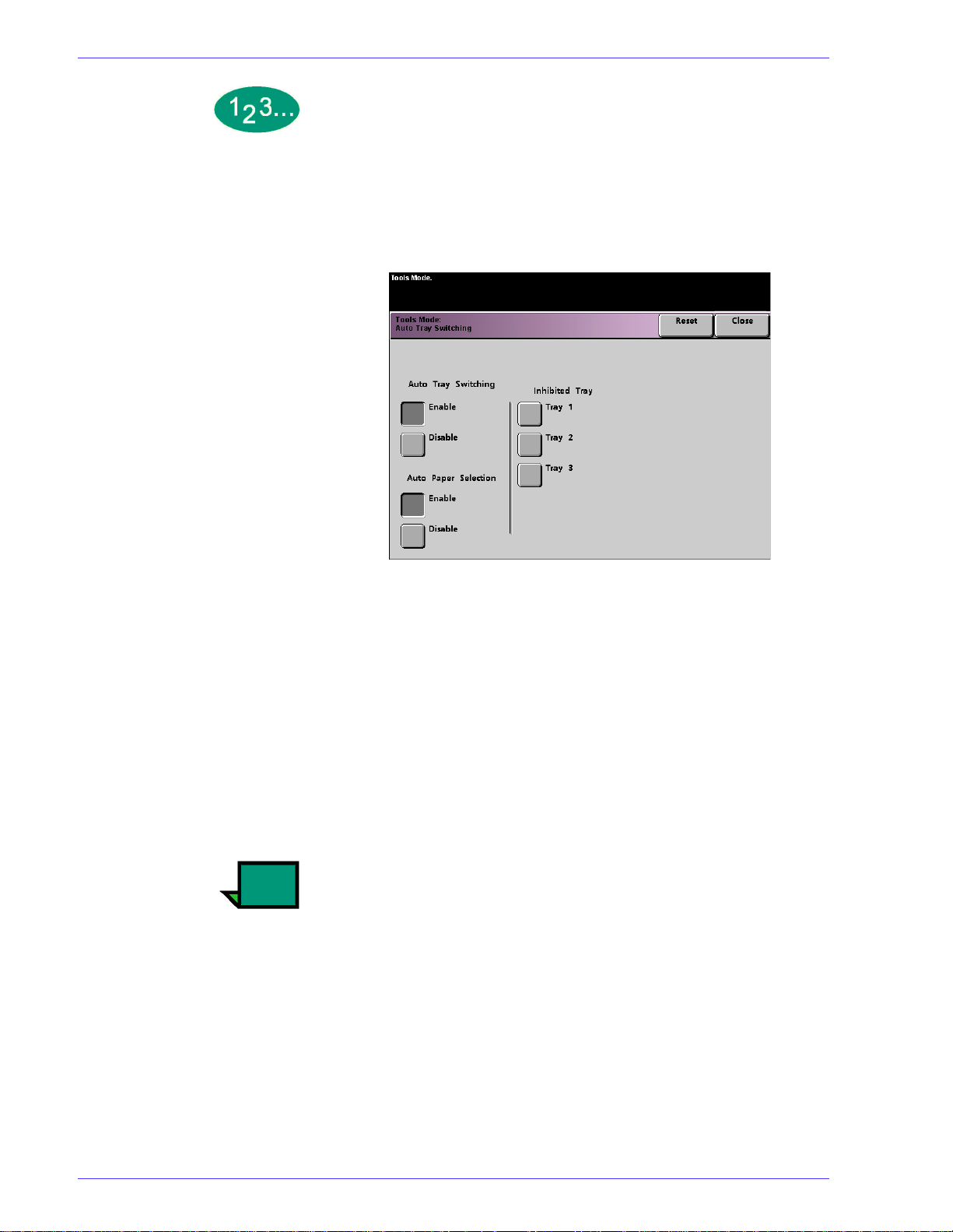

1 Touch the Auto Tray Switching button on the Machine Defaults 1 screen. The

Auto Tray Switching screen appears.

Figure 31. Auto Tray Switching

2 Touch the Enable or Disable button for the Auto Tray Switching option.

3 Touch the Enable or Disable button for the Auto Paper Selection option.

4 To instruct the digital press to bypass one or more of the paper trays, touch the

desired Paper Tray button in the Inhibited Tray column.

To deselect a paper tray, touch that Paper Tray button again.

To return the settings to the last saved values, touch the Reset button.

5 Touch the Close button to return to the Machine Defaults 1 screen.

NOTE:A button for Tray 4 appears only if you have this optional accessory

connected to your digital press.

1–40

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 63

TOOLS M ODE

Transparency Size

Use the Transparency Size button to change the default size for printing on

transparencies. Your options are 8.5x11.0” and 8.3x11.7” (or A4).

1 Touch the Transparency Size button on the Machine Defaults 1 screen. The

Transparency Size screen appears.

Figure 32. Transparency Size screen

2 Select one of the sizes displayed for the default transparency size.

3 Touch the Close button to return to the Machine Defaults 1 screen.

NOTE:You can also set the transparency size by adjusting paper guides in the

paper trays. The machine uses the size defined by the paper tray guides only if

the Transparency Options feature is not selected.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–41

Page 64

TOOLS M ODE

Set Date & Time

Use the Set Date & Time feature to set the date and time for the system. The

date and time is displayed on the Error Log screen and on the Date and Time

screens.

Setting the Date

1 Touch the Set Date & Time button on the Machine Defaults 1 screen. The Set

Date and Time screen appears with the Set Date button selected and options for

setting the date displayed on the right.

1–42

Figure 33. Set Date screen

2 Select the date format you wish to use.

3 Use the up or down arrow buttons to enter the correct year, month, and day.

4 Touch the Enter button on the screen to save your selections.

The next time you enter the Tools Mode, the date that you set is displayed.

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 65

TOOLS M ODE

Setting the Time

1 Touch the Set Date & Time button on the Machine Defaults 1 screen. The Set

Date and Time screen appears with the Set Date button selected and options for

setting the date displayed on the right.

2 Touch the Set Time button. Options for setting the time appear in the Set Time

screen.

Figure 34. Set Date & Time screen with Set Time button selected

3 Touch the 12 Hour Clock or the 24 Hour Clock button.

4 Use the up or down arrow buttons to set the correct hour and minutes.

If you selected the 12 Hour Clock, touch the AM or PM button.

5 Touch the Enter button on the screen to save your selections.

The next time you enter the Tools Mode, the time that you set will be displayed.

6 Touch the Close button to return to the Machine Defaults 1 screen.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–43

Page 66

TOOLS M ODE

Dual Language

This feature enables you to set one of two available languages as the default for

the Touch Screen. When your DocuColor 2060/2045 was installed, your Xerox

service representative loaded onto your system your choice of two languages

that you can choose from to be displayed on the Touch Screen.

1 Touch the Dual Language button on the Machine Defaults 1 screen.

2 Touch the button for the default language you want to appear on the Touch

Screen.

1–44

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 67

TOOLS M ODE

After exiting the Tools Mode, you can switch the Touch Screen to the other

language by pressing the Dual Language button on the Control Panel.

3 Touch the Close button to return to the Machine Defaults 1 screen.

Figure 35. Dual Language screen

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–45

Page 68

TOOLS M ODE

Non-Standard Paper Size

You can run non-standard sized paper from Trays 3 and 4 by entering the paper

size on the Non-Standard Paper Size screen for the tray being used. Tray 4 is

optional equipment; therefore the Tray 4 button appears on the screen only if Tray

4 is connected to the DocuColor 2060/2045.

KEY POINT: Be sure to select Non-Standard Size on the top front of the tray,

and use the Paper Weight Indicator at the right side of the tray to select the

paper weight being used.

1 Touch the Non-Standard Size Paper button on the Machine Defaults 1 screen.

The Non-Standard Paper Size screen appears.

1–46

Figure 36. Non-Standard Paper Size screen

2 Touch the desired Paper Tray button on the Non-Standard Paper Size screen.

3 Use the up or down arrow buttons on the screen to enter the X and Y dimensions

of the paper being used in the tray. The dimensions shown on the screen above

the X and Y boxes indicate the minimum and maximum sizes you can enter.

4 Touch the Close button to return to the Machine Defaults 1 screen.

5 To use these settings, exit the Tools Mode and ensure that Non-Standard Size

has been selected on the top/front of the tray.

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 69

TOOLS M ODE

Oversize Settings

You can use Trays 1 and 2 to run 12 x 18 inch or SRA3 (12.6 x 17.7 inch, 320 x 450

mm) paper by having your Xerox representative remove the side paper guide on

the paper tray, then selecting the tray and the paper size on this screen.

1 Touch the Oversize Settings button on the Machine Defaults 1 screen. The

Oversize Settings screen appears.

Figure 37. Oversize Settings screen

2 Touch the Tray 1 or Tray 2 button on the Oversize Settings screen.

3 Touch the button for the oversize paper you want to run in the tray.

4 Touch the Close button to return to the Machine Defaults 1 screen.

5 To use these settings, exit the Tools Mode and run the job from the tray

programmed.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–47

Page 70

TOOLS M ODE

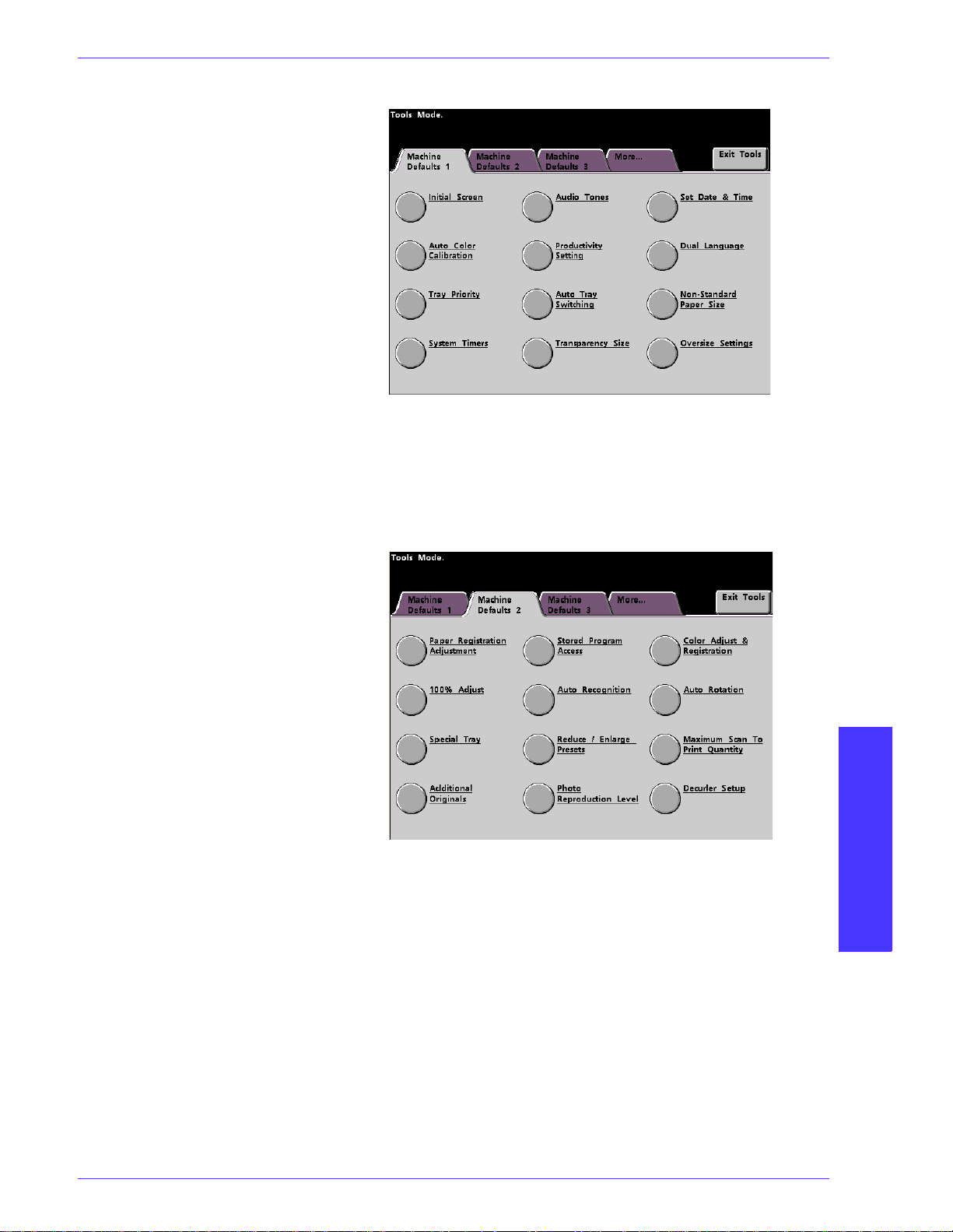

Machine Defaults 2

This section describes the features available to you through the Machine

Defaults 2 screen. You can access the following DocuColor features through the

Machine Defaults 2 screen:

• Paper Registration Adjustment

• 100% Adjust

• Special Tray

• Additional Originals

• Stored Program Access

• Auto Recognition

• Reduce/Enlarge Presets

• Photo Reproduction Level

• Color Adjust & Registration

• Auto Rotation

• Maximum Scan To Print Quantity

• Decurler Setup

Select the Machine Defaults 2 tab, and the Machine Defaults 2 screen

appears.

Figure 38. Machine Defaults 2 screen

1–48

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 71

TOOLS M ODE

Paper Registration Adjustment

Use the Paper Registration Adjustment feature when running duplex jobs to

adjust the image position if the registration is not correct.

Image adjustment may be necessary for a couple of reasons:

• Paper is not always the exact same size. It may vary slightly, with

differences of plus or minus 1mm, causing the image to be misregistered. To

reduce the possibility of size differences, it is recommend that you use paper

from the same lot when running duplex jobs.

• During the fusing process, the heat and pressure applied to the paper causes

the paper to stretch. If the images on sides one and two are the same size,

the stretching of the paper will cause the image on side one to be slightly

larger than the image on side two.

Some RIP manufacturers have a paper registration feature that you can also use

to adjust the position of the image on the paper. Refer to the documentation that

came with your RIP.

Use the following procedure to adjust for side one/side two registration

problems:

1 Prepare the image, or images, by noting a reference point on side one, or by

placing registration marks at the image border. You can use a reference point

within the image or at the corner of the image.

KEY POINT: Remember that the digital press does not print bleed edge

images.

2 Output 10 duplex prints and compare the registration mark or reference point on

side one to side two. Discard the first few prints, as inconsistency tends to be

greater with these images. If there is misregistration, continue with this

procedure.

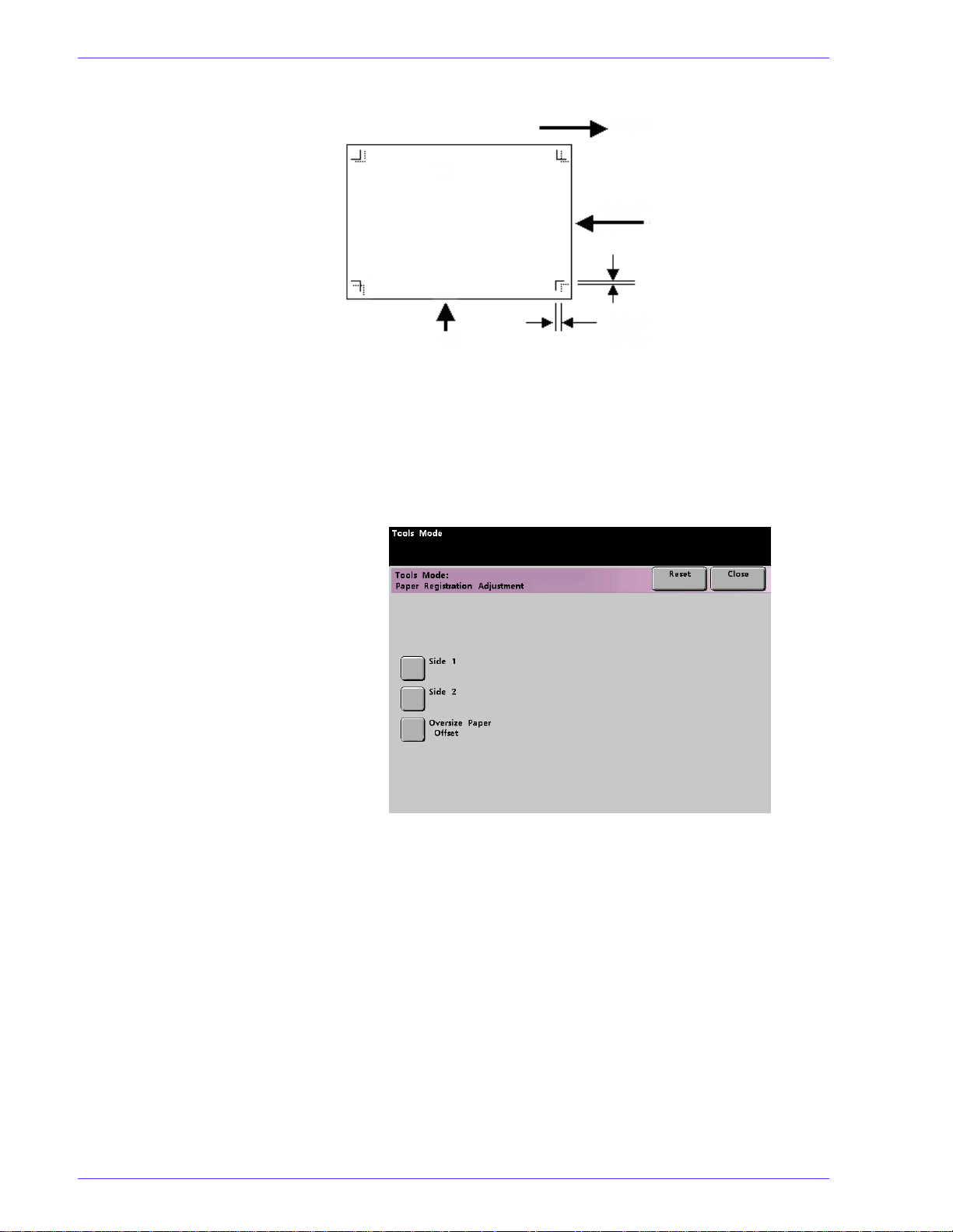

3 Measure the distance between the registration point and the edge of the paper

on both the lead edge (Y) of the paper and the side edge (X).

Refer to the Measuring Misregistration figure below. The solid line registration

marks indicate the reference point on side one. The dotted lines indicate the

reference point on side two.

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–49

Page 72

TOOLS M ODE

Paper Feeding Direction

in the Tray

Lead Edge of

paper

Misalignment of

reference point on side 1

to side 2 (X)

Side Edge

of paper

Misalignment of reference

point on side one to side 2 (Y)

Figure 39. Measuring Misregistration

4 Access Tools Mode and touch the Paper Registration Adjustment button on

the Machine Defaults 2 screen. The Paper Registration Adjustment screen

appears.

1–50

Figure 40. Paper Registration Adjustment screen

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 73

TOOLS M ODE

5 Select either the Side 1 or Side 2 button to adjust the registration.

KEY POINT: Use the Oversize Paper Offset button only for papers larger than

long edge feed, 8.5x11 inch or A4 paper. Refer to Step 8 if using this option.

6 On the next screen, select the tray from which the paper is feeding.

Figure 41. Paper Registration Adjustment screen

TOOLS MODE

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–51

Page 74

TOOLS M ODE

NOTE:The button for Tray 4 does not appear unless you have this optional

accessory connected to your DocuColor 2060/2045.

7 Use the up or down arrow buttons to enter the amount of adjustment for either

edge or both edges.

KEY POINT: Remember that the Lead Edge Registration adjustment is the

feeding edge, or Y direction. The Side Edge Registration adjustment is the front

to back, or X, direction.

KEY POINT: If the reference point on side two is closer to the edge of the

paper compared to the reference point on side one, enter a plus figure. If the

reference point on side two is further from the edge of the paper compared to

side one, enter a minus figure.

KEY POINT: EXAMPLE: If the measurement is 1.2mm closer to the edge of

the paper, enter +1.2mm.

1–52

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 75

TOOLS M ODE

8 If you selected the Oversize Paper Offset button to adjust the registration on

paper larger than 8.5x11 inch or A4 LEF, the following screen appears.

Figure 42. Paper Registration Adjustment screen

9 Touch the OffsetLevel1,2,3,or 4 button to adjust the position of the paper as

it feeds. Refer to the following table for the adjustments made for each Offset

Level.

Paper

Size

310mm 10.0mm 10.0mm 10.0mm 10.0mm

311mm 9.5mm 9.5mm 9.5mm 9.5mm

312mm 9.0mm 9.0mm 9.0mm 9.0mm

313mm 8.5mm 8.5mm 8.5mm 8.5mm

314mm 8.0mm 8.0mm 8.0mm 8.0mm

315mm 7.5mm 7.5mm 7.5mm 8.0mm

316mm 7.0mm 7.0mm 7.0mm 8.0mm

317mm 6.5mm 6.5mm 7.0mm 8.0mm

318mm 6.0mm 6.0mm 7.0mm 8.0mm

319mm 5.5mm 6.0mm 7.0mm 8.0mm

Level 1 Level 2 Level 3 Level 4

TOOLS MODE

320mm 5.0mm 6.0mm 7.0mm 8.0mm

D OCUCOLOR 2060/2045 SYSTEM A DMINISTRATION G UIDE

1–53

Page 76

TOOLS M ODE

100% Adjust

Use the 100% Adjust feature to fine tune the 100% magnification value on your

digital press with scanner. The available adjustment range is from 98.0% to

102.0%.

1 Touch the 100% Adjust button on the Machine Defaults 2 screen. The 100%

Adjust screen appears.

Figure 43. 100% Adjust screen

2 Use the up or down arrow buttons to set the desired percentage for the x value.

The available range is 98.0% to 102.0%.

3 Use the up or down arrow buttons to set the desired percentage for the y value.

The available range is 98.0% to 102.0%.

4 Touch the Close button to return to the Machine Defaults 2 screen.

1–54

D OCUC OLOR 2060/2045 SYSTEM A DMINISTRATION GUIDE

Page 77

TOOLS M ODE

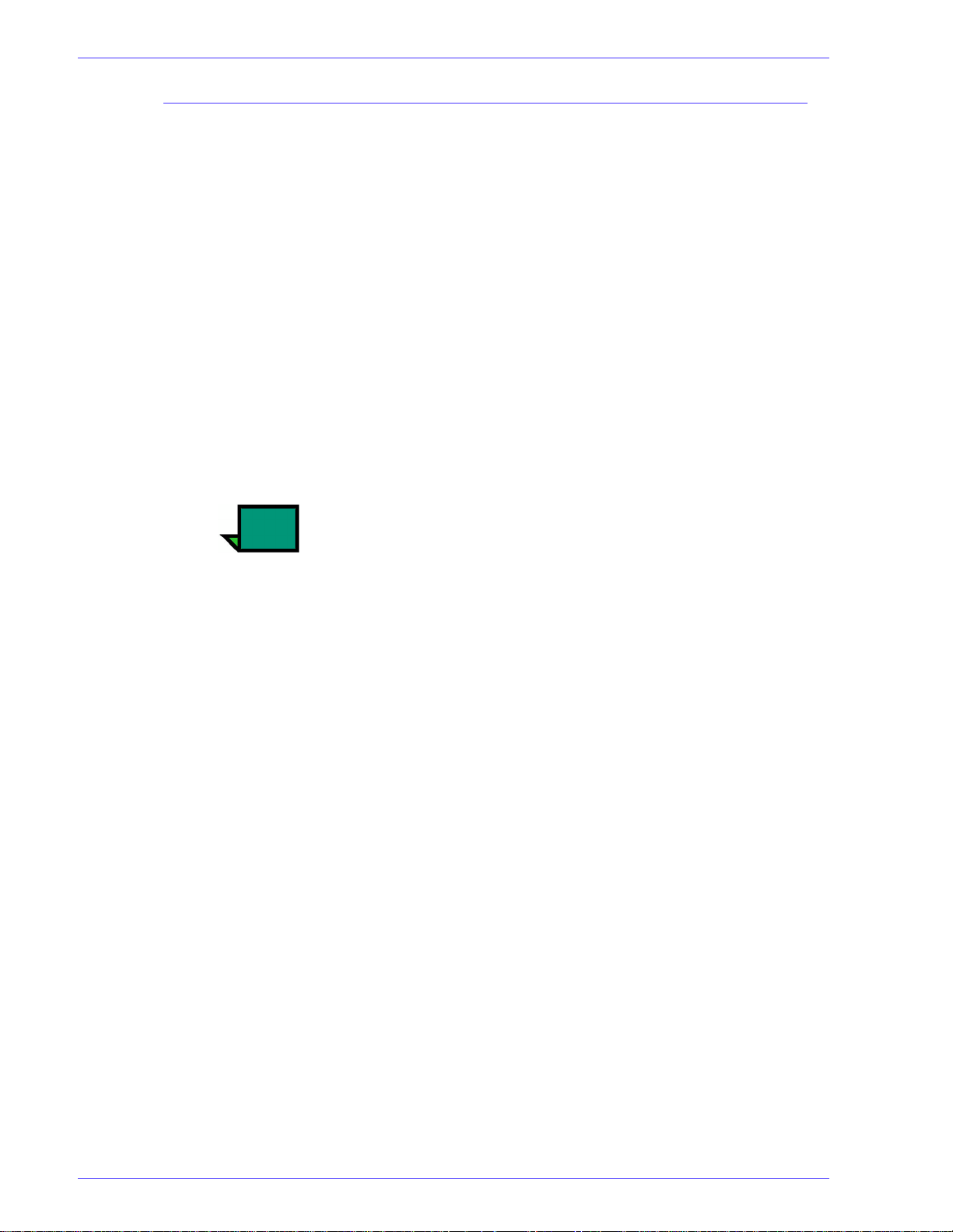

Special Tray

Use the Special Tray feature to select a default tray that holds special materials

for each of the following features:

• Covers

• Inserts

• Transparency Dividers

• Booklet Creation