Page 1

THE DOCUMENT COMPANY

XEROX

Phaser 790/DocuColor 2006

Service Manual

March 2001

701P35949

CAUTION

Certain components in the Phaser 790/DocuColor

2006 are susceptible to damage from electrostatic

discharge. Observe all ESD procedures to avoid

component damage.

Page 2

Prepared by:

Xerox Corporation

Global Knowledge & Language Services

800 Phillips Road Bldg. 845-17S

Webster, New York 14580-9791

USA

© 2000 by Xerox Corporation. All rights reserved. Copyright protection

claimed includes all forms and matters of copyrightable material and information now allowed by statutory or judicial law or hereinafter granted,

including without limitation, material generated from the software programs

that are displayed on the screen such as styles, templates, icons, screen

displays, looks, etc.

***XEROX DocuLock Pr otect Until Forever ***

XEROX®, The Document Company®, the stylized X and the identifying

product names and numbers herein are trademarks of XEROX CORPORATION. Other company trademarks are also acknowledged.

NOTICE

While every care has been taken in the preparation of this manual, no liability will be accepted by Xerox Corporation arising out of any inaccuracies or

omissions.

NOTICE

All service documentation is s upplied t o X erox external customers for informational purposes only. Xerox service documentation is intended for use by

certified product trained service personal only. Xerox does no t warrant or

represent that such documentation i s complete, nor does Xerox represent

or warrant that it will notify or provide to such customer any future changes

to this documentation. Custo mer performed service of equipment, or modules, components or parts of such equipment may affect the warranty

offered by Xerox with respect to such equipment. You should consult the

applicable warranty for its terms regarding customer or third party provided

service. If the customer services such equipment, modules, components or

parts thereof, the customer releases Xerox from any and all liability for the

customer actions, and the customer agree s to indemnify, defend and hold

Xerox harmless from any third party claims which arise directly or indirectly

from such se r vice.

WARNING

This equipment generates, uses an d can radia te radio frequ ency

energy, and if not installed and used in accordance with the instructions documentation, may cau se interferen ce to radio commu ni cations. It has been tested and found to comply with the limits for a

Class A computing device pursuant to subpart J of part 15 of FCC

rules, which are designed to provide reas onabl e prote ction agains t

such interference when operated in a comme rci al environm en t. Operation of this equipment in a residential area is likely to cause interference in which case the user, at his own expense, will be required to

correct the interference.

WARNING

This machine contains an invisible laser. There is no visual indication

that the laser beam is present. During servicing, the machine is a

Class 3B product because of the invisible laser. the laser beam could

cause eye damage if looked at directly. Service procedures must be

followed exactly as written without change. The service representative

must observe the established local laser safety precaution s when servicing the machine. Do not place tools with a reflective surface into

the ROS opening. Do not look in the area of the ROS window if the

power is On and the laser is energized.

Page 3

About this Manual ........................................................................................................... iii

Organization....................................................................................................................iii

How to Use this Docum en ta tio n. ............... .... .... ............... .... .... ............... .... .... ............... . iii

Symbology ...................................................................................................................... iii

Introduction

Initial Issue

Phaser 790/DocuColor 2006

10/00

i

Introduction

Page 4

Introduction

10/00

ii

Initial Issue

Phaser 790/DocuColor 2006

Page 5

About this Manual

This Service Manual is part of the multinational documentation system for the Phaser 790

Printe r and D C 20 06 Copie r./Prin ter The Se rv ice Do cum ent atio n is u sed in or der t o d iagn ose

machine malfunctions, adjust components and has information which is used to maintain the

product in superior operating condition. It is the controlling publication for a service call. Information on its use is found in the Introduction of the Service Documentation.

Adjustments

Adjustments include procedures for adjusting the parts that must be within specification for the

correct operation of the system.

Use the adjustment procedures for the correct sequence of operation for specifications, warnings, ca utions and notes.

This ma nual contains information that applies to NASG and ESG copiers.

Service Manual Revision

The Service Manual will be updated as the machine changes or as problem areas are identified.

Organization

This Service Manual is divided i nto nine sections. The titles of t he sections a nd a description of

the information contained in each section are contained in the following paragraphs:

Section 1 Service Call Procedures

This se ct ion contai ns pr o c ed ur e s t ha t de te r mi ne w ha t ac ti on s are to be t ak e n d ur i ng a service

call on the machine and in what sequence they are to be completed. This is the entry level for

all service calls.

Section 2 Status Indicator RAPs

This s ection co ntains the diagnostic aids for troublesho oting th e Fault Co de and no n-Fault

Code rel ate d faults (with the exceptio n of co py qua lity problem s ) .

Section 3 Image Quality

This sect io n con tai ns t he diagno st i c aid s for trou bl es ho otin g an y cop y qu alit y pr obl ems , as well

as copy quality specifications and copy defect samples.

Section 4 Repairs/Adjustments

This section contains all the Adjustments and Repair procedures.

Repairs

Repair s include p rocedures f or remov al and replac ement of pa rts which have the fol lowing

special co nditions :

When removal or repla c ement cann ot be determined from the expl oded view of the

Parts List.

When there is a cleaning or a lubricating activity associated with the procedure.

When the part requires an adjustment after replacement.

When a special tool is required for removal or replacement.

Use the repair proc edures for the correct order of r emoval and replacement, fo r warnings, cautions, an d no tes .

Section 5: Parts Lists

This section con tains the Prin ter/Copier Parts List.

Section 6: General Procedures/Inform ation

This section contains General Procedures, Diagnostic Programs, and Copier Information.

Section 7: Wiring Data

This sec tion contains drawings, lists of plug/jack locations, and diagrams of the power distribution w i re networ ks i n the mac hi ne . I nd ividual w i re networks a r e s h ow n in the Circ ui t D i ag r am s

contained in Section 2. This section also contains the Block Schematic Diagrams.

How to Use this Documentation

The Service Call Procedures in Section 1 describe the sequence of activities used during the

service call. The call must be entered using these procedures.

Use of the Circuit Diagrams

Circuit Diagrams (CDs) are included in Sections 2 (Status Indicator RAPs) and 3 (Image Quality RAPs) of the Service Manual. All wirenets, with the exception of power distribution wirenets,

are shown on the CDs. Po wer distribution wirenets are show n in Section 7 (W iring D ata) of the

Service Manual. The power distribution wirenets on the CDs will end at the terminal board for

the power being distributed. Find the wirenet for that power and locate the terminal board on

the wirenet. Use the wirenet to troubleshoot any power distribution wiring not shown on the

CD.

Use of the Block Schematic Diagrams

Block Schematic Diagrams (BSDs) are included in Section 7 (Wiring Data) of the Service Manual. The BSDs show the functional relationship of the electrical circuitry to any mechanical, or

non-m echa nic al, input s or outpu ts t hroug hout the mach ine. Inpu ts an d out puts suc h as mo to r

drive, mechanical li nkages, operator actions, a nd air flow are shown. The BSDs will provide an

overa ll view of how the entire sub s ys te m, such as ADF, works.

It should be not ed th at the BS Ds no lon ger co nt ain an Inp ut Power Bloc k re f err ing to Chai n 1. It

will be necessary to refer to the Wirenets in order to trace a wire back to its source.

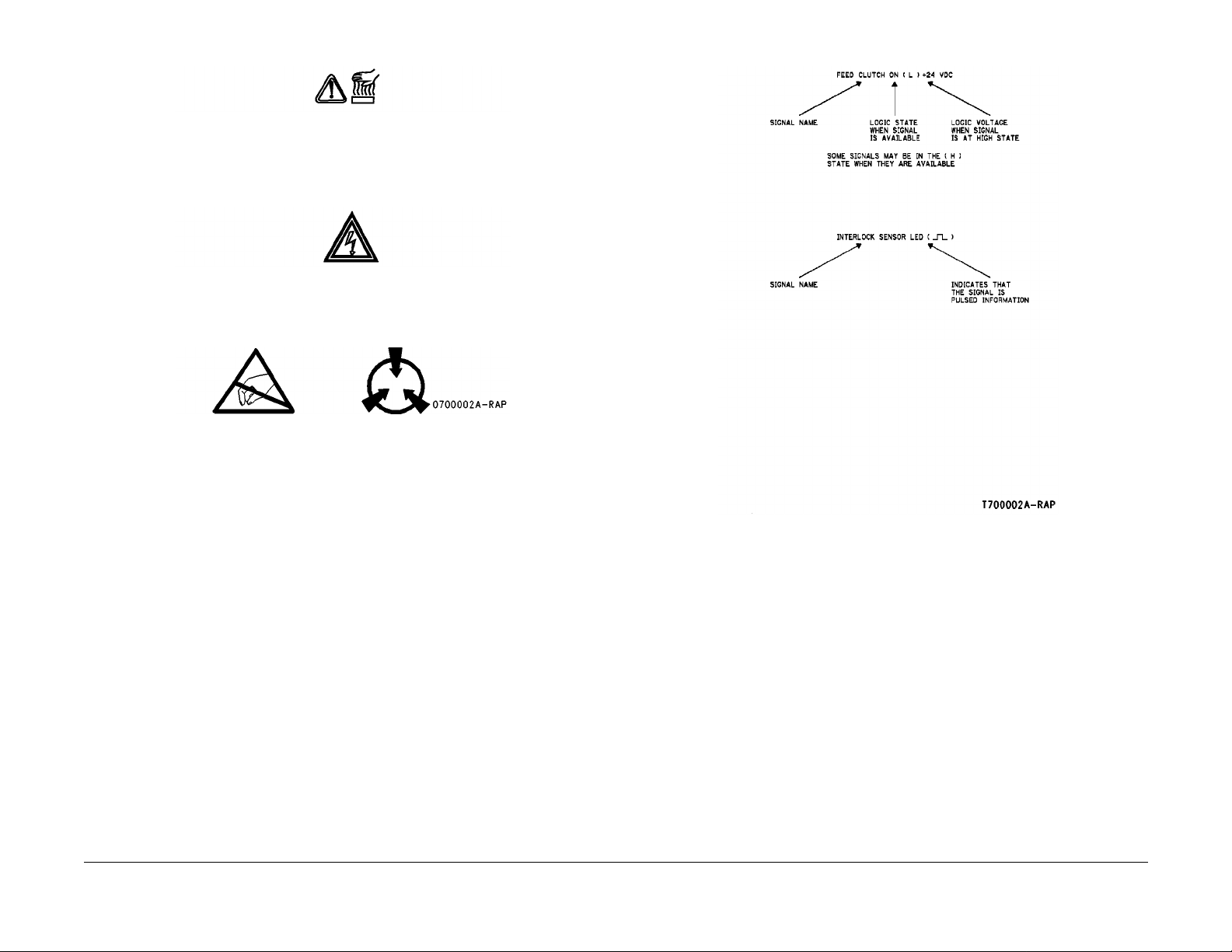

Symbology

The following reference symbols are used throughout the documentation.

Initial Issue

Phaser 790/DocuColor 2006

10/00

iii

Introduction

Page 6

Warnin gs, Ca utions, and Notes

Warnings, Cautions, and Notes will be found throughout the Service Documentation. The

words WARNING or CAUTION may be liste d on an illustra tion when the specif ic comp onent

associated with the potential hazard is pointed out; however, the message of the WARNING or

CAUTION is always located in the text. Their definitions are as follows:

WARNING

A Warning is us ed whenev er an op e rat ing or main t en an ce procedu r e, a p rac t ic e, condition, or statement, if not strictly observed, could result in personal injury.

CAUTION

A Cautio n is us ed whe ne ver an o perat ing or main te nanc e proc edur e, a p ractic e , cond ition , or

statement, if not strictly observed, could result in damage to the equipment.

NOTE: A Note i s us ed when ev er i t i s n ec e ss ary to hig h l igh t a n op erating or mainten an ce procedure, practice, condition, or statement.

Flags

The Flag symbol indicates a reference point into a Circuit Diagram from a RAP. Instructions will

be given to check for an open circuit, a short circuit, or an intermittent condition.

Note

This sy mbol refers to notes which are found on the same page as the Circuit Diagram.

Parts List

In this symbol, exampl e (PL2.1), refers to the Parts List on which the part can be found.

Machine Safety Icons

The following sa fety icons are displayed on the machine:

WARNING

The Phaser 790/Dc 2006 contains an invisible laser. There is no visual indication that the

laser b eam is pr esent . Du rin g ser vicin g, the mach ine is a Class 3 B pr odu ct bec au se of

the in vi sible laser. th e l as er be am could ca us e ey e d am ag e i f lo ok ed at d i rec t ly. Serv ice

proced ure s must be fol low ed ex ac tly as w ri tte n wi tho ut cha nge. The se r vic e r epr es ent ative m ust observe the establis hed local laser safety precaution s when serv icing the

machi ne. Do not pl ac e t oo ls with a reflective surface in th e ar e a of the Char ge Co r otr o n

or the RO S op eni ng. Do not lo ok in the a rea o f the RO S wind ow if the powe r is O n and

the las er i s en er gized.

The following symbol and statement appear on a label in the machine. The symbol by

itself , or the sym bol and the st atemen t may also appear in the servi ce docu menta tion

and in the training program. When this symbol appears, the service representative is

warned that conditions exist that could result in exposure to the laser beam.

WARNING

Do not t ry to byp ass an y la ser interl ocks for an y rea son. P erma ne nt eye d ama ge coul d

result if the laser is accidentally directed into your eye.

Figure 1 Laser Hazard Symbol

Adjustments

The adjustment symbol refers to an procedure in the Adjust ment section of t his Manu al.

Test Points, Test Stakes, Test Holes

This symbol is used to indicate that a test point, test stake, or test hole is available for accessing a sign al line . The pref ix befo re th e iden tific at ion num ber in di cate s whe ther the acc ess is a

test point (TP), a test stake (TS), or a test hole (TH).

Bracket

The bracket symbol indicates a C omponent Control Code se lection in a Diagnostic Program.

Introduction

Laser Hazard Statement

DANGER INVISIBLE LASER RADIATION WHEN OPEN. AVOID DIRECT EXPOSURE TO

BEAM.

CAUTION

The use of controls or adjustments other than those specified in the Laser Safety Training Program may result in an exposure to da ngerous laser radiation.

For additional information, review the Laser Safety Training pr ogram.

An arrow points to the location to install, to gain access to, or to release an object.

This symbol indicates that a surface can be hot. Use caution when reaching in the machine to

avoid t ouching the hot surfaces.

10/00

iv

Phaser 790/DocuColor 2006

Initial Issue

Page 7

Danger l ab e l in di cates wh er e electrical curr e nt s exist when the m a chine is cl os ed and op er a ting. Use caution when reaching in the machine.

These symbols indicate components that may be damaged by Electrostatic Discharge (ESD).

Electrostatic Discharge (ESD) Field Service Kit

The purpose of the ESD Protection Program is to preserve the inherent r eliability and qu ality of

electro ni c c om po nents that ar e ha nd le d by the Field S erv ic e Pe rs on ne l. Th is pr o gra m is be ing

implem e nte d now as a di r ec t r e su lt of adva nc e s i n m ic ro ci r c uit r y tec h nology, as well as a new

acknowledgment of the magnitude of the ESD problem in the electronics industry today.

This program will reduce Field Service costs that are charged to PWB failures. Ninety percent

of all PWB fa il u res th at are E SD rel at e d do no t occu r immedi at el y. Using th e ESD Fi el d Ser vi ce

Kit will eliminate these delayed failures and intermittent problems caused by ESD. This will

improv e product rel ia bi lity and red uc e ca ll ba cks.

The ESD Field Service Kit should be used whenever Printed Wiring Boards or ESD sensitive

components are being handled. This includes activities like replacing or reseating of circuit

boards or connectors. The kit s hould also be used in order to prevent additional damage when

circuit boards are returned for repair.

The instr uctions for us ing the ESD Fi eld Service Ki t can be found in ES D Field Service Kit

Usage in the Gen eral Pr ocedures secti on of the Service Documentati on.

Signal Nomenclature

Refer to Figure 2 for an example of Signal Nomenclature.

Initial Issue

Phaser 790/DocuColor 2006

10/00

v

Figure 2 Signal Nomenclature

Introduction

Page 8

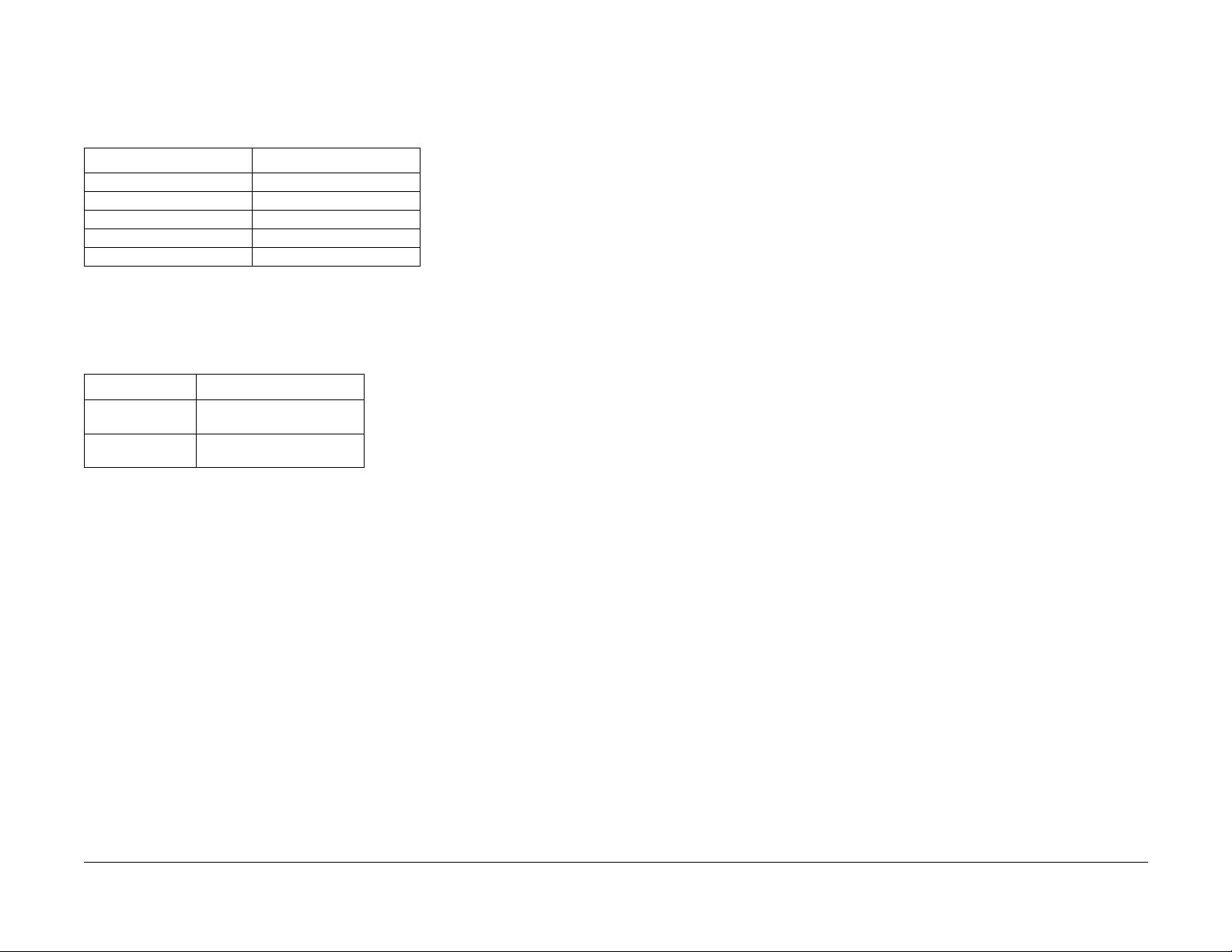

Voltage Measurement and Specification s

Measurements of DC voltage must be made with reference to the specified DC Common,

unless some other poin t is refer enced i n a diagnostic procedure. All me asurements of AC volt-

age should be made with respect to the adjacent return or ACN wire.

T able 1 Vol tage Measurement and Specifications

VOLTAGE SPECIFICATION

INPUT POWER 220 V 198 VAC T O 242 VAC

INPUT POWER 100 V 90 VAC T O 135 VAC

INPUT POWER 120 V 90 VAC TO 135 VAC

+5 VDC +4.75 VDC TO +5.25 VD C

+24 VDC +23.3 7 VDC TO +27.06 VD C

Logic Voltage Levels

Measurements of logic levels must be made with reference to the specified DC Common,

unless some other point is referenced in a diagnostic procedure.

Table 2 Logic Levels

VOLTAGE H/L SPECIFICATIONS

+5 VDC H= +3.00 TO +5.25 VD C

L= 0.0 TO 0.8 VDC

+24 VDC H= +23.37 TO +27.06 VDC

L= 0.0 TO 0.8 VDC

DC Voltage Measurements in RAPs

The RAPs have been designed so that when it is required to use the DMM to measure a DC

voltage, the first test point listed is the location for the red (+) meter lead and the second test

point is the location for the black meter lead. For example, the following statement may be

found i n a RAP:

There is +5 VDC from TP7 to TP68.

In this example, the red meter lead would be placed on TP7 and the black meter lead on TP68.

Another example of a statement found in a R AP might b e:

There is -15 VDC from TP21 to TP33.

In thi s ex am p l e , t he red me ter lead w o ul d be place d on T P 21 a nd the bl ac k m eter lead w ou ld

be placed on TP33.

If a seco nd tes t poi nt is no t given , it is ass ume d th at the bl ack m ete r lead m ay be at tac hed to

the copier frame.

Introduction

10/00

vi

Initial Issue

Phaser 790/DocuColor 2006

Page 9

Service Call Procedures.................................................................................................. 1-3

Initial Actions Procedure ................................................................................................. 1-3

Call Flow Procedure........................................................................................................ 1-4

Cleaning Procedures....................................................................................................... 1-5

Final Actions.................................................................................................................... 1-5

1 Service Call Procedures

Initial Issue

Phaser 790/DocuColor 2006

10/00

1-1

Service Call Proce dure s

Page 10

Service Call Proce dure s

10/00

1-2

Initial Issue

Phaser 790/DocuColor 2006

Page 11

Service Call Procedur es

Service Strategy

The service strategy for the Phaser 790 Printer and the DC 2006 Copier/Printer is to run to failure. The Repair Analysis Procedures (RAPs) will be used to diagnose and repair any problems.

Problem s that oc cur in the B asic Print er mode wi ll be repa ired befo re problem s that occ ur

when using the accessories.

Image quality problems should be repaired after all other problems are repaired.

Service Call Procedures

The Service Call Procedures are a guide for performing any service on the Phaser 790

Printer and the DC 2006 Copier/Printer. The procedures are designed to be used with the

Phaser 79 0 Printer and th e DC 2006 Copier/ Printer Service Manual. Perform each step in

order.

Initial Actions

The Ini tial Actions gath er informa t io n ab ou t th e condition o f th e ma c hine and the problem t h at

caused the service call.

Call Flow

Call Flow summarizes the sequence of the Service Call Procedures .

Cleaning Proc ed ures

The clea nin g pr o c ed ur e s lis t w ha t nee ds t o be cl ea ne d at ea ch serv ic e call.

Final Actions

The Final Action s will test the copier /printer and return it to th e customer. Ad ministrative activities are also perform ed in the Final Actions.

Initial Actions Procedure

Purpose

The p urpose of the Initia l Acti ons se ction of the Servic e Cal l Proc edures is to d eterm ine the

reason for the se rvice call and to identif y and organize the actions which m ust be performed.

Procedure

1. Gather the information about the service call and the condition of the copie r/prin ter.

a. Question the operator(s). Ask about the location of the most recent paper jams. Ask

about th e image qu al ity and the ge neral performanc e of the c op ie r /p r in te r, inc lu di ng

any unusual sounds or other indications (if applicable).

b. Check that the power cords are in good condition, correctly plugged into the power

source, and free from any defects that would be a safety hazard. Repair or replace

the power cords as required. Check that the circu it breakers are not tripped.

c. Ensure that all paper trays are loaded with paper.

d. Inspect an y rejected c op ie s. I n qu ire as to, o r ot he r wis e determi ne, the pap er quality

and weight. The specified paper for optimum image quality for the Phaser 790

Printer is Hammermill Laser Print 24. The specified paper for optimum image quality

for t he DC 20 06 Co pier/P rinter is 24# X erox COLOR Xpre ssions o r Col otech + 90

gms. Look for any damage to the copies, oil marks, image quality defects, or other

indica tions of a problem.

e. Record the billing meter r eadings .

f. Check the Service Log for any recent activities that are related to the problem that

caused the service call or any secondary problem.

2. Check the Image Quality by performing the V isual Calibration (GP 16 ).

a. Run four copies of the 82E13030 Test Pattern.

b. Check the image quality. If the customer has identified any Image Quality Defects or

problem s, go to the IQ1 Imag e Q uality Entry RAP.

3. If there is a problem in the Basic Printer Mode, go to the Call Flow Procedure.

4. If there are no problems in the Basic Printer Mode, go to the Final Actions.

Initial Issue

Phaser 790/DocuColor 2006

10/00

1-3

Service Call Proce dure s

Service Call Procedures, Initial Actions Procedure

Page 12

Call Flow Procedure

This procedure should be performed at every serv ice cal l.

Procedure

The copier/printer is capable of making a copy/print to the Output Tray.

YN

The copier/printer is capable of making a copy/print to the Top Tray.

YN

The problem is in the paper path.

YN

A Fault Code or a message is constantly displayed.

YN

The Display is blank or garbled.

YN

If one or mo re of the butto ns or LEDs doe s not functi on, go to the

002-702 IOT Control Panel Button/LED RAP.

Go to the 002-701 Blank/Gar bled IO T Display RAP.

F

Go to the area w here the no ise is bein g gene rat ed and troubl esh oo t

that area.

If a sorter fault code is present, go to the RAP associated with that fault

code.

If a sorter message is present, go to the Section 2, Fault Message/RAP

Cross-Reference Table.

Check for mechanical binding.

Check the AD F Documen t Sensor s for debris or damage.

Check that the document mechanical drives and feed rolls are free from wear, damage, con tamination, and binding.

Check the pape r path se nsors for debri s or dama ge. Chec k that pa per is l oaded in all

trays correctly.

Check the paper path mechanical drives and rolls for contamination, glazing, wear, damage, or binding.

Go to the IQ1 Image Quality Entry RAP.

If a fault code is dis p laye d, g o to the Fault C o de RAP for th e Fa ul t Cod e th at is

displayed.

If a message is displayed, go to the Fault Message/RAP Cross-Reference in

Section 2.

Check t he pape r pat h s enso rs fo r de br is or dama ge. Chec k th at pape r is l oa ded i n

all trays correctly.

Check t h e pa pe r p ath m ec hanical dri ves and rol ls f o r contamin a tion, glaz in g, wear, damage, or binding.

The copier is capable of making a copy/print to the Top Tray.

YN

Check t h e pa pe r p ath m ec hanical dri ves and rol ls f o r contamin a tion, glaz in g, wear, damage, or binding.

A Fault Code or message is constantly d isplayed.

YN

The problem is Image Quality.

YN

The problem is in the ADF.

YN

The problem is in the Scanner.

YN

The problem is in the Sorter.

YN

The problem is noise.

YN

The problem is inte r m itt ent. Go to th e BS D an d perform a resistance c he c k o f t h e wires in qu es t io n . G en t ly pu ll on t he wir e s to

ensure that they are properly connected.

If a fault code is displayed, go to the Fault Code RAP for the Fault Code that is displayed.

If a message is displayed, go to the F ault Message/RAP Cross-Reference in Section 2.

AABBCCDDEEF

Service Call Proce dure s

Call Flow Procedure

10/00

1-4

Initial Issue

Phaser 790/DocuColor 2006

Page 13

Cleaning Procedures

Purpose

The purpose is to provide cleaning procedures to be per formed at every call.

Final Actions

Purpose

The intent of this procedure is to be used as a guide to follow at the end of every service call.

Procedure

CAUTION

Do not use any solvents unless directed to do so by the Service Manual.

Gene ral Cleaning

Use a dry lint free cloth or a lint free cloth moistened with water for all cleaning unless directed

otherwise by the Service Manual. Wipe with a dry lint free cloth if a moistened cloth is used.

1. Feed Components (Rolls and Pads)

Follow the General Cl eaning procedure above.

2. Dry Ink Dispense Uni ts

Vacuum the Dry Ink Dispense units.

3. Jam Sensors

Clean the sensor s with a dry cotton swab.

4. IBT Cle ani ng

Check the IBT Belt surface and wipe with a dry lint free clot h. If the surface is exce ssively

dirty, replace the IBT Belt (PL 7.2).

5. Fus e r Compon en t s (best cleaned w hen hot).

Wipe with a lint free c loth.

6. Scanner

a. Switc h off the power and allow the Exposure Lamp to cool off.

b. Using the optical Cleaning Cloth, clean the front and rear of the Document Glass,

Document Cover, White Reference Strip, Reflector, and Mirror.

c. Clean the Exposure Lamp with a clean cloth and Film Remover.

7. ADF

Check the paper path for debris or damage. Clean the rolls with a clean cloth and Film

Remover as required.

8. Sorter

Check the paper path for debris or damage. Clean the Sorter with a dry lint free cloth.

Procedure

1. Ensure that the exterior of the copier/printer and the adjacent area are clean. Use a dry

cloth or a cloth moistened with water to clean the copier/printer. Do not use solvents.

2. Check the supply of consumables. Ensure that an adequate supply of consumables is

avail ab le acc ording to loca l op er a tin g pr o c ed ur e s.

3. Conduct any operator training that is needed. Ensure that the operator understands that

the Visu alCal proced ure in the Ope rator Manual should be used to adju st the colors .

Ensure that the operator can perform the VisualCal procedure (reference the GP 16

Visual Calibration procedure).

4. Complete the Se rvice Log.

5. Perform the following steps to make a copy of the Demonstration Original for the Customer:

a. Load Paper in Tray 1 with 8-1/2 x 11 inch (A4) or 11 x 17 inch, 24# Xerox COLOR

Xpressions or Colotech + 90 gms for the DC 2006 Copier/Printer, or Hammermill

Laser Print 24 for the Phaser 790

b. Place Test Pattern 82E13030 on the glass with the short edge of the test pattern reg-

istered to the left edg e of the glass. Sel ect Tray 1 and make a single copy.

c. Print a Configuration Page (GP 14).

d. Print a test page (for the printer only).

e. Present the copies to the customer.

6. Issue copy credits as neede d.

7. Discuss the service call with the customer to ensure that the customer understands what

has been done and is satisfied with t he results of the service call.

Initial Issue

Phaser 790/DocuColor 2006

10/00

1-5

Service Call Proce dure s

Cleaning Procedures, Final Actions

Page 14

Service Call Proce dure s

Cleaning Procedures, Final Actions

10/00

1-6

Initial Issue

Phaser 790/DocuColor 2006

Page 15

2 Status Indicator RAPs

Fault Message Cross-ref erence

Fault Message/RAP Cross-Reference............................................................................ 2-3

Standby Power

001-701 AC Power RAP ................................................................................................. 2-5

001-702 +5 VDC Power RAP.......................................................................................... 2-7

001-703 +24 VDC Interlocked Power RAP..................................................................... 2-9

001-704 Front Cover Open RAP..................................................................................... 2-11

001-705 ROS +5 VDC Switched Voltage RAP ............................................................... 2-13

001-706 Area 1 Open RAP ............................................................................................. 2-15

001-707 Area 2 Open RAP ............................................................................................. 2-17

001-708 Area 3 Open RAP ............................................................................................. 2-19

001-709 Area 4 Open RAP ............................................................................................. 2-21

001-710 Area 5 Open RAP ............................................................................................. 2-23

001-711 Area 6 Open RAP ............................................................................................. 2-25

001-712 IIT DC Power RAP............................................................................................ 2-27

User Interface

002-310, 906, 907, 908 IIT Control Panel Failure RAP.................................................. 2-29

002-701 Blank/Garbled IOT Display RAP ....................................................................... 2-29

002-702 IOT Control Panel Button/LED RAP ................................................................. 2-31

Machine Run Control

003-310 Feeder Communications Failure RAP .............................................................. 2-33

003-311 Duplex Communications Failure RAP............................................................... 2-35

003-312 Sorter Communications Failure RAP................................................................ 2-37

003-333 Foreign Interface RAP ...................................................................................... 2-39

003-334 Foreign Interface Compatibility RAP................................................................. 2-41

003-356 IOT NVM RAM Error RAP................................................................................. 2-43

003-400 IOT Firmware Error RAP................................................................................... 2-45

003-701 Copy/Print Cartridge Error RAP........................................................................ 2-45

Start Print Power

004-320 Paper Handling Motor RAP............................................................................... 2-47

004-322 Fuser Motor RAP.............................................................................................. 2-49

Document Transportat ion

005-210 Nudger Home RAP ........................................................................................... 2-51

005-211 ADF Power RAP ............................................................................................... 2-53

005-220/221 ADF Communications RAP........................................................................ 2-55

005-700 ADF Fault Entry RAP........................................................................................ 2-57

005-701 ADF Entrance Jam RAP ................................................................................... 2-58

005-702 ADF Exit Jam RAP............................................................................................ 2-60

005-703 ADF No Feed RAP............................................................................................ 2-62

005-704 Unfinished Copy Job RAP ................................................................................ 2-64

Imaging

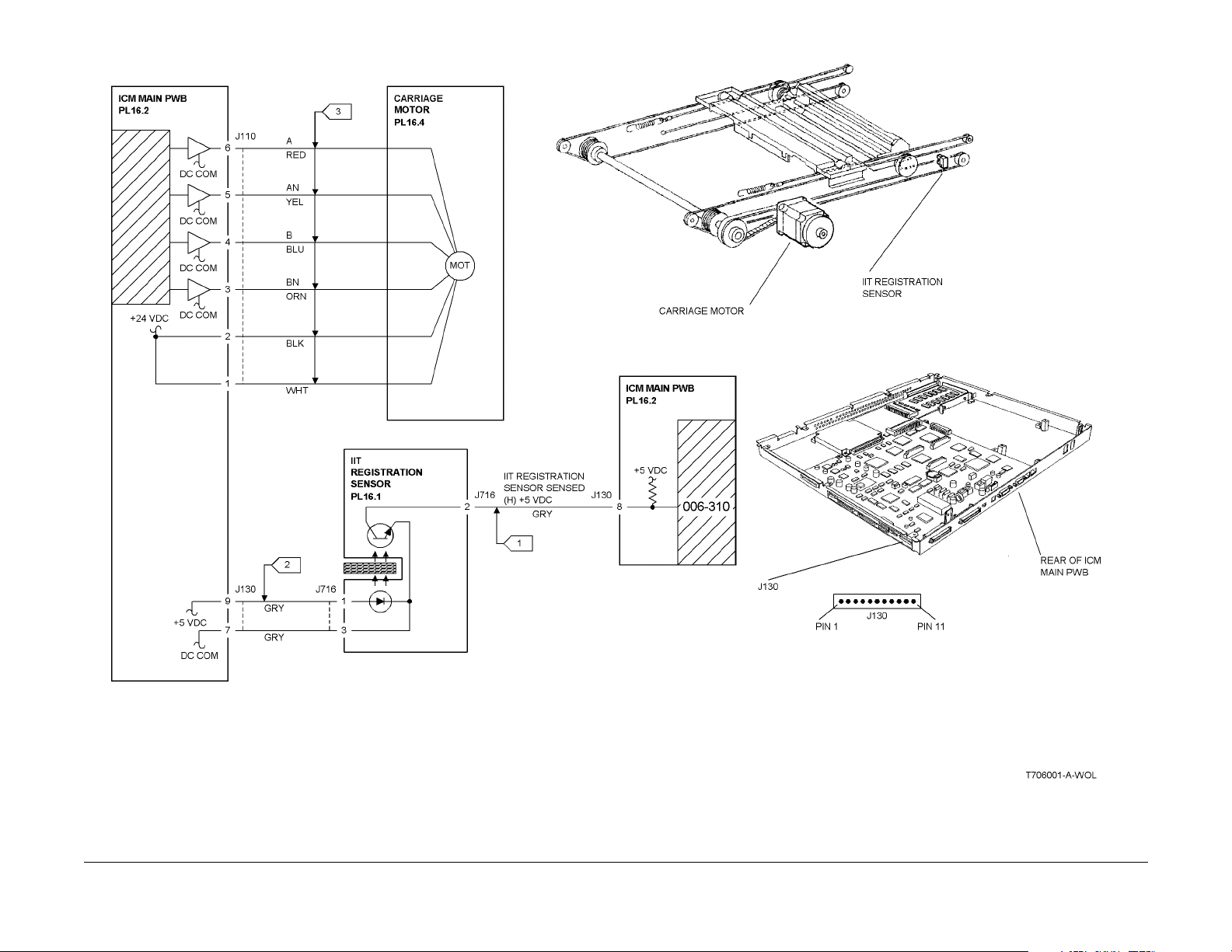

006-310 IIT Registration RAP ......................................................................................... 2-67

006-311 Exposure Lamp RAP ........................................................................................ 2-69

006-312 FPC CCD RAP.................................................................................................. 2-70

006-313 IIT Cooling Fans RAP ....................................................................................... 2-71

006-372 Start of Scan Error RAP.................................................................................... 2-73

006-701 Angle Sensor RAP............................................................................................ 2-75

006-702 Platen Switch RAP............................................................................................ 2-77

006-703 Scanner Error RAP ........................................................................................... 2-79

006-704 System Error (093-XXX) RAP........................................................................... 2-79

006-906/907/908/909 RAP.............................................................................................. 2-80

Paper Supply

007-324 Environment Sensor RAP ................................................................................. 2-81

007-340 Feeder Motor Fail RAP ..................................................................................... 2-83

007-341 Inverter Motor Fail RAP..................................................................................... 2-85

007-700 Tray 1 Open RAP.............................................................................................. 2-87

007-701 Tray 2 Open RAP.............................................................................................. 2-89

007-702 Tray 3 Open RAP.............................................................................................. 2-91

007-703 Tray 1 Empty RAP ............................................................................................ 2-93

007-704 Tray 2 Empty RAP ............................................................................................ 2-95

007-705 Tray 3 Empty RAP ............................................................................................ 2-97

007-706 Bypass Tray Empty RAP................................................................................... 2-99

007-707 Paper Length Mismatch RAP............................................................................ 2-101

007-708 Bypass Tray Lift RAP........................................................................................ 2-102

007-709 Tray 2 Lift Up RAP ............................................................................................ 2-104

007-710 Tray 3 Lift Up RAP ............................................................................................ 2-107

007-711 Tray 1 Paper Size Not Detected RAP............................................................... 2-110

007-712 Tray 2 Paper Size Not Detected RAP............................................................... 2-112

007-713 Tray 3 Paper Size Not Detected RAP............................................................... 2-114

Paper Transportation

008-700 Area 1 Jam RAP ............................................................................................... 2-117

008-701 Area 2 Jam RAP ............................................................................................... 2-120

008-702 Area 3 Jam RAP ............................................................................................... 2-123

008-703 Area 4 Jam RAP ............................................................................................... 2-125

008-704 Area 6 Jam RAP ............................................................................................... 2-127

008-705 Top Tray Full RAP............................................................................................. 2-130

008-706 OHP Sensor RAP.............................................................................................. 2-132

008-707 Duple x Tra y Open RA P.. .... .... ............... .... .... ............... .... .... ............... .... .... ... ... 2-1 34

Xerographics

009-321 TR0 Sensor RAP............................................................................................... 2-137

009-323 Process Motor RAP........................................................................................... 2-139

009-326 Rotary Motor RAP............................................................................................. 2-141

009-340 ADC Cleaning Failure RAP............................................................................... 2-143

009-341 ADC Sensor Background RAP.......................................................................... 2-145

009-342 Patch Error RAP................................................................................................ 2-147

009-343 PCDC Error RAP............................................................................................... 2-149

009-344 Image Density Error RAP.................................................................................. 2-149

009-358 BTR 2 Home Position RAP............................................................................... 2-150

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-1

Status Indicator RAPs

Page 16

009-359 BTR 2 Bias RAP ............................................................................................... 2-152

033- 320/321 Scanner ErrorCheck RAP............................................................................ 2- 214

033-910 Scanner Memory Overflow RAP......................................................................... 2- 216

033-942 SCSI Bus Reset RAP.......................................................................................... 2- 217

021-210/211 Accessories Error RAP................................................................................. 2- 212

XX82 Fault Code RAP.........................................................................................................2- 211

009-360 Developer Fan RAP.......................................................................................... 2-154

009-700 Toner Cartridge Detached RAP........................................................................ 2-156

009-701 Toner Cartridge Empty RAP............................................................................. 2-158

009-702 Waste Container Full RAP................................................................................ 2-160

009-703 Waste Container Detached RAP ...................................................................... 2-162

009-704 Belt Cleaner RAP.............................................................................................. 2-164

Fusing and Copy Transportation

010-317 Temperature Sensor Circuit Error RAP ............................................................ 2-167

010-353/3 56 /3 57 Fuse r Low/ U nd er Te mpera tu re C ondi tio n R AP .. ................ ... .... ......... 2-168

010-354 Fuser Te mp era tu re Not D et ecte d RA P.................. .... .... ... ................ ... .... ......... 2-170

010-355 Fuser Overheat Error RAP................................................................................ 2-172

010-358 Fuser Fan Error RAP ........................................................................................ 2-174

010-359 Exit Chute Fan Failure RAP.............................................................................. 2-176

010-700 Area 5 Jam RAP............................................................................................... 2-178

010-701 Faulty Temperature Sensor RAP...................................................................... 2-180

010-702 Faulty Entrance Sensor RAP............................................................................ 2-182

010-703 Faulty Fuser Exit Sensor RAP .......................................................................... 2-184

010-704 Faulty Fuser Chute Fan RAP............................................................................ 2-186

010-705 Faulty Exchange Solenoid RAP........................................................................ 2-188

Sorter

011-700 Sorter Not In Correct Position RAP................................................................... 2-191

011-701 Sorter Bin Jam RAP.......................................................................................... 2-193

011-702 Sorter Cover Open RAP ................................................................................... 2-196

011-703 Sorter Transport Jam RAP................................................................................ 2-198

011-704 Sorter Noise RAP.............................................................................................. 2-200

011-705 Full Sensor RAP ............................................................................................... 2-202

011-706 Cannot Select Sorter RAP ................................................................................ 2-204

Imaging Control

016-310 Font ROM Checksum Error RAP...................................................................... 2-207

016-312 ESS Hard Drive Error RAP ............................................................................... 2-207

016-313 ASIC Access Error RAP.................................................................................... 2-208

016-315 ESS RAM (Bank 1) RAP................................................................................... 2-208

016-316 ESS RAM (Bank 2) RAP................................................................................... 2-209

016-317 ESS ROM RAP ................................................................................................. 2-209

016-323/324/325 ESS NVM RAM Failure RAP .............................................................. 2-210

016-330/331/332/333/334/335/336 Interface Error RAP................................................. 2-210

016-370 IOT to ESS Communication Failure RAP ......................................................... 2-211

IIT Communications

033-210 Print er Dete c tio n RAP.. .... ............... .... .... ............... .... .... ............... .... ... ............. 2-21 3

033-211/212 IOT/IIT Disconnection RAP........................................................................ 2-213

033-221/222/223/224/225/226/226/227/228 IOT/IIT Communication RAP .................... 2-214

033-330/331/332 Software Error RAP ............................................................................ 2-214

033-340/341/342/343/344/345/350 ASIC Error RAP ...................................................... 2-215

033-360/3 61 /3 70/37 1 M emory Er ror RAP..... .... ............... .... .... .... ............... .... ... ............. 2-215

033-380/390 1394 Failure RAP....................................................................................... 2-216

033-921/922/930/934/935/936/937 IOT/IIT Communication RAP .................................. 2-216

033-940/9 41/9 43 /94 4/ 94 5 SCSI Erro r RAP .. .... ............... .... .... ............... .... .... ... ............. 2-21 7

Status Indicator RAPs

10/00

2-2

Initial Issue

Phaser 790/DocuColor 2006

Page 17

Fault Message/RAP Cross-Reference

For all "??82 Faults" displayed on Prnter Display, go to XX82 Fault Code RAP

NOTE:

NOTE: For all ADF Jam messages displayed on the Scanne r Display, go to the 005-700 RAP.

For all Scanner Error messages displayed on the Scanner Display, which do not have an

associ ated Fault Code RAP, go to the 006-7 03 RAP.

For all Sy st em Er ror (093-XXX) messages displayed on the Scanner Display, go to the 006-

704 RAP.

If the message on the IOT display contains a numeric fault code, go to the RAP for that code.

To find the appropriate RAP for an unclearable message that does not contain a fault code, go

to Table 1. Locate the message in column one, and go to the RAP listed in column two.

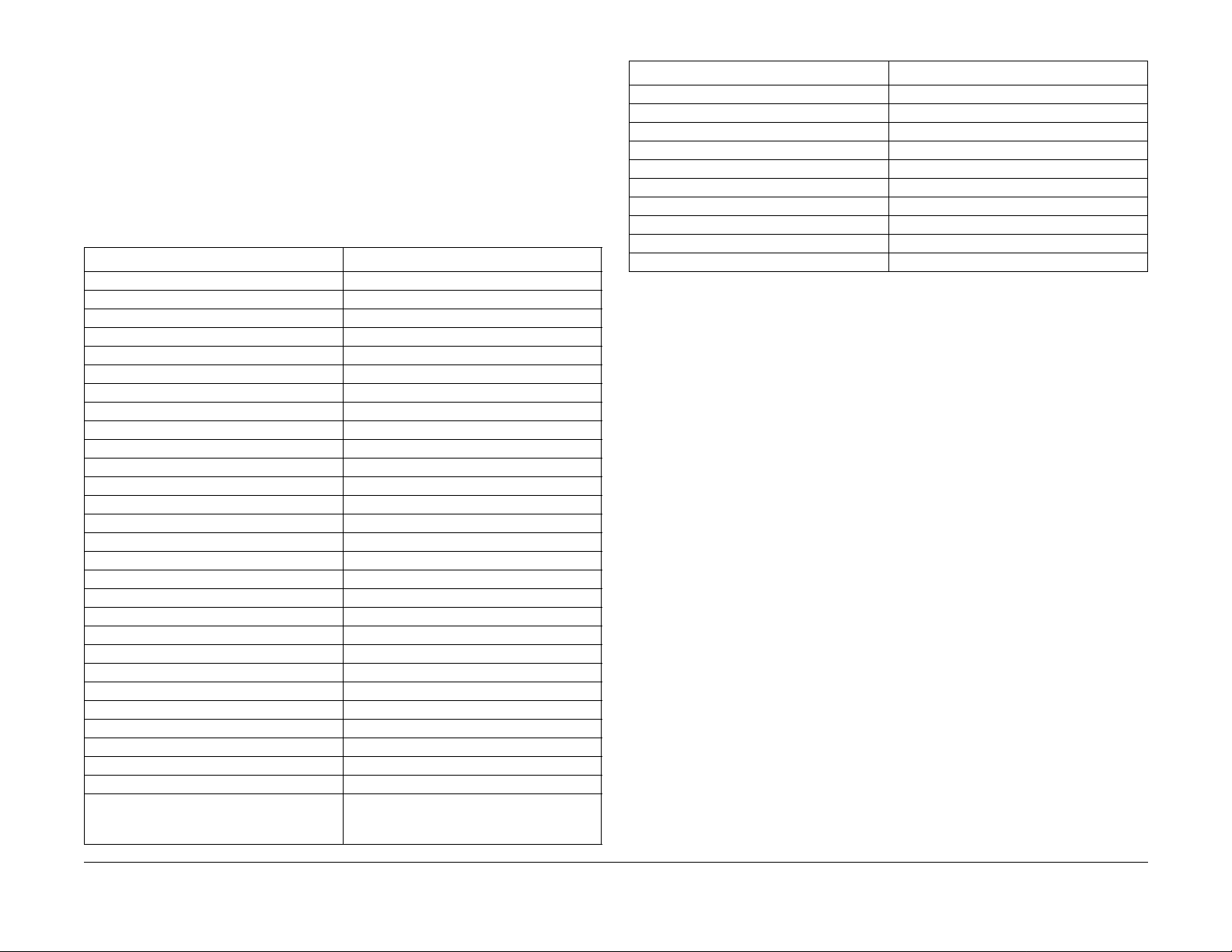

T able 1

If this message is displayed Go to this RAP

Check Loading of <tray> In Use 007-707 Paper Length Mismatch RAP

Check Sorter Position 011-700 Sorter Not In Correct Position RAP

Clear Jam In Area 1 008-700 Area 1 Jam RAP

Clear Jam In Area 2 008-701 Area 2 Jam RAP

Clear Jam In Area 3 008-702 Area 3 Jam RAP

Clear Jam In Area 4 008-703 Area 4 Jam RAP

Clear Jam In Area 5 010-700 Area 5 Jam RAP

Clear Jam In Area 6 008-704 Area 6 Jam RAP

Clear Jam In Duplex Tray 008-707 Duplex Tray Jam RAP

Close Area 1 001-706 Area 1 Open RAP

Close Area 2 001-707 Area 2 Open RAP

Close Area 3 001-708 Area 3 Open RAP

Close Area 4 001-709 Area 4 Open RAP

Close Area 5 001-710 Area 5 Open RAP

Close Area 6 001-711 Area 6 Open RAP

Close Duplex Tray 008-707 Duplex Tray Open RAP

Close Fr on t C ov er 00 1- 704 Front Cov er Op en RA P

Close Paper T ray 1 007-700 Tray 1 Open RAP

Close Paper T ray 2 007-701 Tray 2 Open RAP

Close Paper T ray 3 007-702 Tray 3 Open RAP

Close Sorter Cover 011-702 Sorter Top Cover Open RAP

Empty Sorter Bins 011-701 S orter Bin Jam RAP

Empty Stacker Tray 011-705 Full Sensor RAP

Empty Top Tray 008-705 Top Tray Full RAP

Install <col or> Ink Ca rtrid ge 009-700 Toner Cartridge Detache d RAP

Install Copy/Print Cartridge 003-701 Copy/Print Cartridge Error RAP

Install Waste Container 009-703 Waste Container Detached R AP

Jam in Sorter 011-701 Sorter B in Jam RAP

Load <s iz e> 007-711 Tray 1 Paper Siz e N ot D et ec t ed RA P

007-712 Tray 2 Paper Size Not Detected RAP

007-713 Tray 3 Paper Size Not Detected RAP

Table 1

If this message is displayed Go to this RAP

Load <s ize> In Bypass Tray 007-706 Bypass Tray Empty RAP

Load <size> In Tray 1 007-703 Tray 1 Empty RAP

Load <size> In Tray 2 007-704 Tray 2 Empty RAP

Load <size> In Tray 3 007-705 Tray 3 Empty RAP

Order Copy/Print Cartridge 003-701 Copy/Print Cartridge Error RAP

Reload <size> in Bypass Tray 007-708 Bypass Tray Lift RAP

Reload <size > in Tray 2 007-709 Tray 2 Lift Up RAP

Reload <size > In Tray 3 007-710 Tray 3 Lift Up RAP

Replace Copy/Print Cartridge 003-701 Copy/Print Cartridge Error RAP

Waste Container Full 009-702 Waste Container Full RAP

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-3

Status Indicator RAPs

Fault Message/RAP Cross-Reference

Page 18

Status Indicator RAPs

Fault Message/RAP Cross-Reference

10/00

2-4

Initial Issue

Phaser 790/DocuColor 2006

Page 19

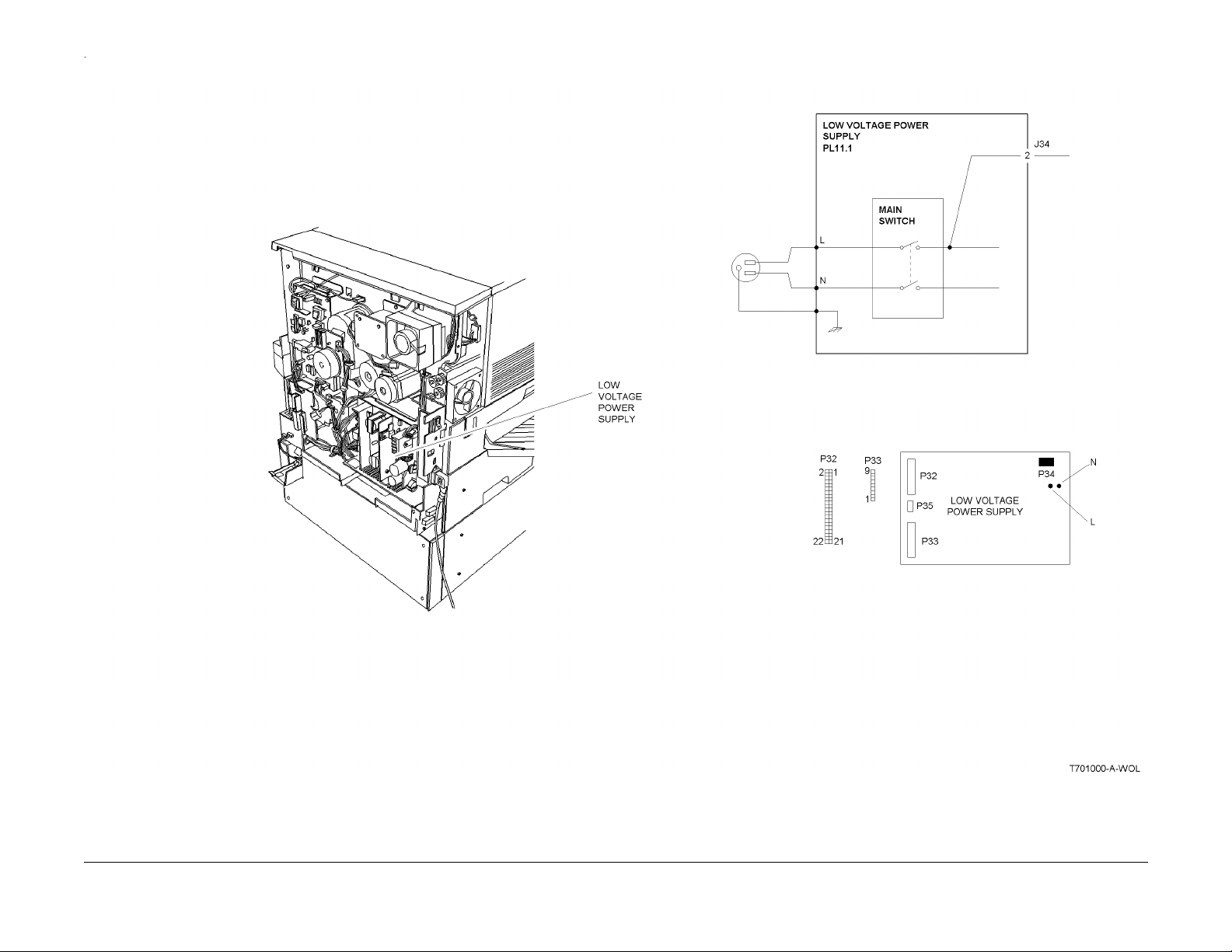

001-701 AC Power RAP

Initial Actions

• Ensure AC Power is available at the wall receptacle.

• Ensure the Power Cord is good. Replace the Power Cord if it is defective (PL 11.1).

Procedure

Switch off the power. Remove the Rear Cover. Switch on the power. If AC Power is not measured at J34 -2 to terminal N on the Low Voltage Power Supply, replace the Low Voltage Power

Supply (PL 11.1).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-5

Status Indicator RAPs

001-701

Page 20

Figure 1 001-701 Circuit Diagram

Status Indicator RAPs

001-701

10/00

2-6

Initial Issue

Phaser 790/DocuColor 2006

Page 21

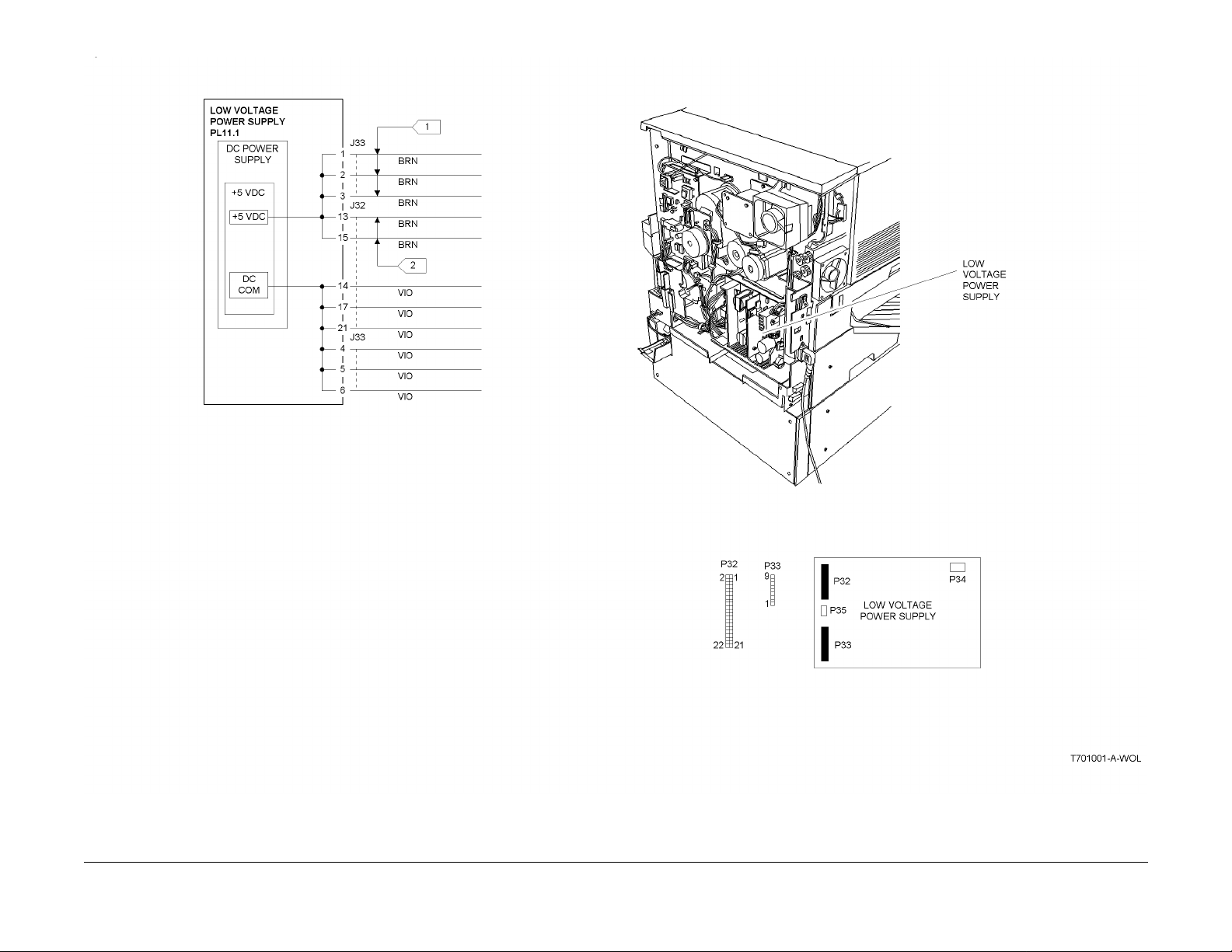

001-702 +5 VDC Power RAP

Initial Actions

• Ensure AC Power is available at t he wall receptacle.

• Ensure the Power Cord is good. Replace the Power Cord if it is defective (PL 11.1).

Procedure

Switch off the power. Remove the Rear Cover. Switch on the power. +5 VDC is measured

betwe en J33-1 and J33-4.

YN

Switc h off th e pow er. Di sconn ec t J3 2 an d J33 from the Low V o lt ag e Pow er Suppl y. Switch

on the power. +5 VDC is measured between P33-1 and P33-4 on the Low Voltage

Power Supply.

YN

Replace the Low Voltage Power Supply (PL 11.1).

Switch off the power. Reconnect J32 to the Low Voltage Power Supply. Switch on the

power. +5 VD C is measure d between P 33-1 and P3 3-4 on the Lo w Voltage P ower

Supply.

YN

Go to Flag 2. Refer to the +5 VDC Wirenet to troubleshoot a short circuit in the wires

from P32.

Go to Flag 1. Refer to the +5 VDC Wirenet to troubleshoot a short circuit in the wires from

P33.

The Low Voltage Power Supply appears to be operating correctly .

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-7

Status Indicator RAPs

001-702

Page 22

Figure 1 001-702 Circuit Diagram

Status Indicator RAPs

001-702

10/00

2-8

Initial Issue

Phaser 790/DocuColor 2006

Page 23

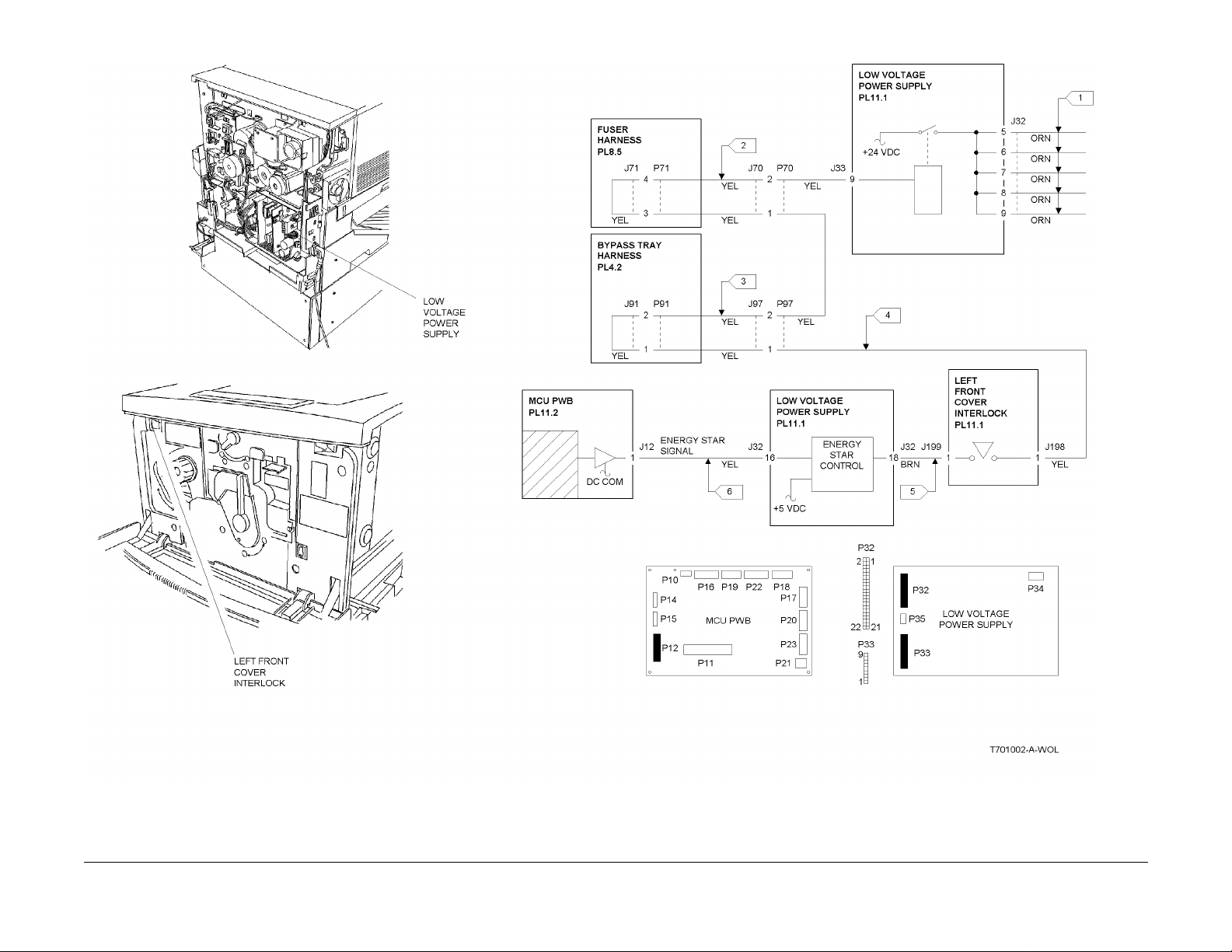

001-703 +24 VDC Interlocked Power RAP

Initial Actions

Ensure the Left Front Cover, the Registration/Bypass Tray Drawer, and the Main Fuser Assembly are closed and in the correct position.

Ensure that the actuator for the Left Front Cover Interlock is not broken.

Procedure

Switch off the power. Remove the Rear Cover. Switch on the power. +24 VDC is measured

betwe en J32-5 on the Low Voltage Power Supply and mach ine frame.

YN

+5.0 VDC is measured between J32-18 and machine frame.

YN

Approximately +4.4 VDC is measured between J32-16 and machine frame.

YN

Go to Fla g 6. Check th e wire for an open circuit. If the wire is good, replace the

MCU PWB (PL 11.2).

Replace the Low Voltage Power Supply (PL 11.1).

+5.0 VDC is measured between J33-9 on the Low Voltage Power Supply and

machine frame.

YN

+5.0 VDC is measured be tween J199-1 (brown wire) on the Left Front Cover

Interlock and machine frame.

YN

Go to Flag 5. Check the wir e for an open circuit.

+5.0 VDC is measured between J198-1 (yellow wire) on the Left Fron t Cover

Interlock and machine frame.

YN

Replace the Left Front Cover Int erlock ( PL 11.1).

Check the following:

• Go to Flag 2, Flag 3, and Flag 4. Check the wires for an open circuit.

• If the w ires are go od, chec k the conn ectors between th e Low Voltage Po wer

Supply and the Left Front Cover Interl ock for bent or bro ken pin s or for damaged connectors (P/J70, P/J71, P/J97, and P/J91).

Replace the Low Voltage Power Supply (PL 11.1).

The Low Voltage Power Supply appears to be operating correctly .

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-9

Status Indicator RAPs

001-703

Page 24

Figure 1 001-703 Circuit Diagram

Status Indicator RAPs

001-703

10/00

2-10

Initial Issue

Phaser 790/DocuColor 2006

Page 25

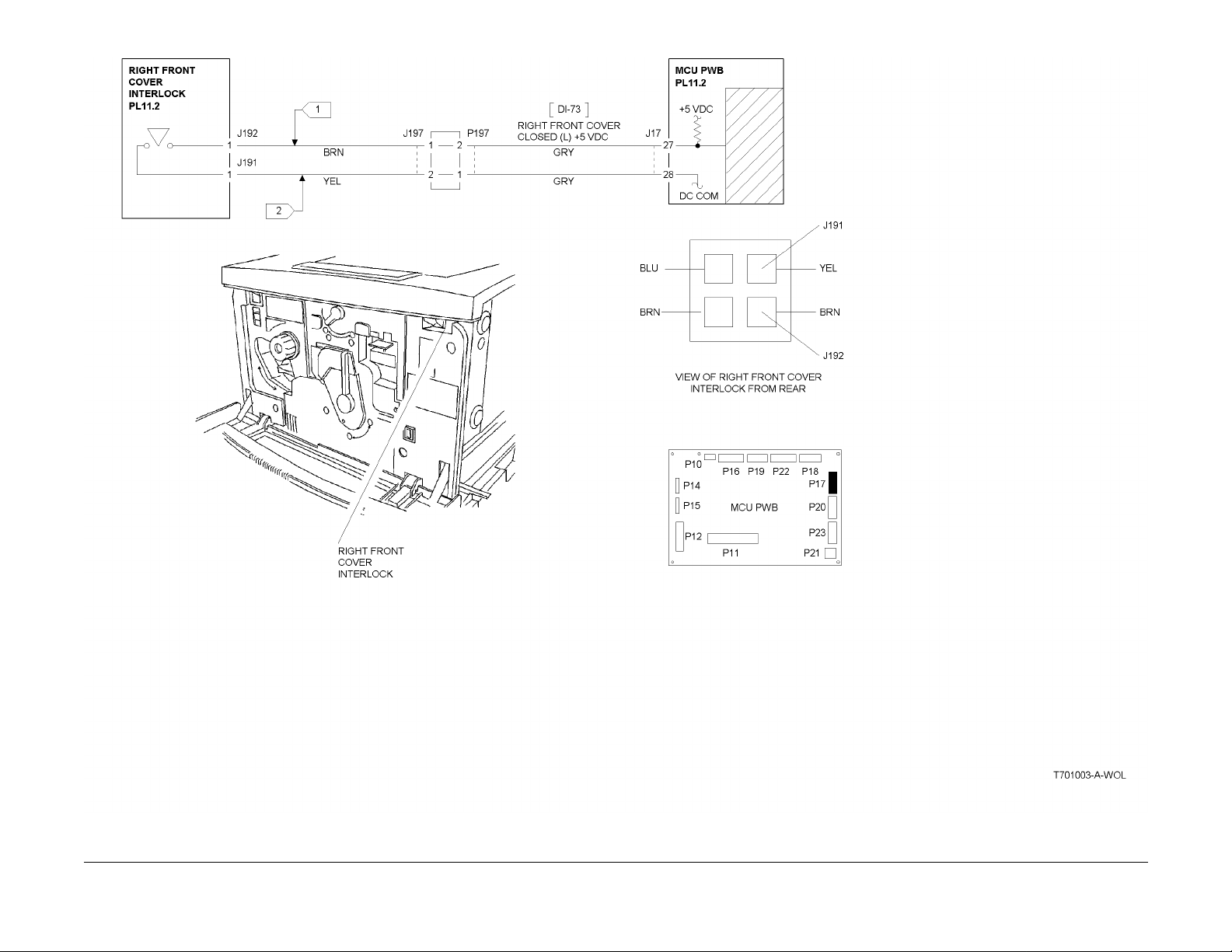

001-704 Front Cover Open RAP

Initial Actions

Ensure the Right Front Cover is closed and that the actuator for the interlock is not damaged.

Procedure

Access the Digital Input (DI) test from the Control Panel. Enter code [73]. Press the Item/Enter

button. The display indicates 0.

YN

Go to Flag 1 and Flag 2 and check the wires for an open circuit. If the wires are good,

replace the Right Front Cover Interlock (PL 11.2). If the problem continues, replace the

MCU PWB (PL 11.2).

The problem may be intermittent. Go to Flag 1 and Flag 2 and check for loose or damaged

connections or damag ed wires. If the proble m persists, replace the Right Fr ont Cover Interlock

(PL 11.2). If the problem continues, replace the MCU PWB (PL 11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-11

Status Indicator RAPs

001-704

Page 26

Figure 1 001-704 Circuit Diagram

Status Indicator RAPs

001-704

10/00

2-12

Initial Issue

Phaser 790/DocuColor 2006

Page 27

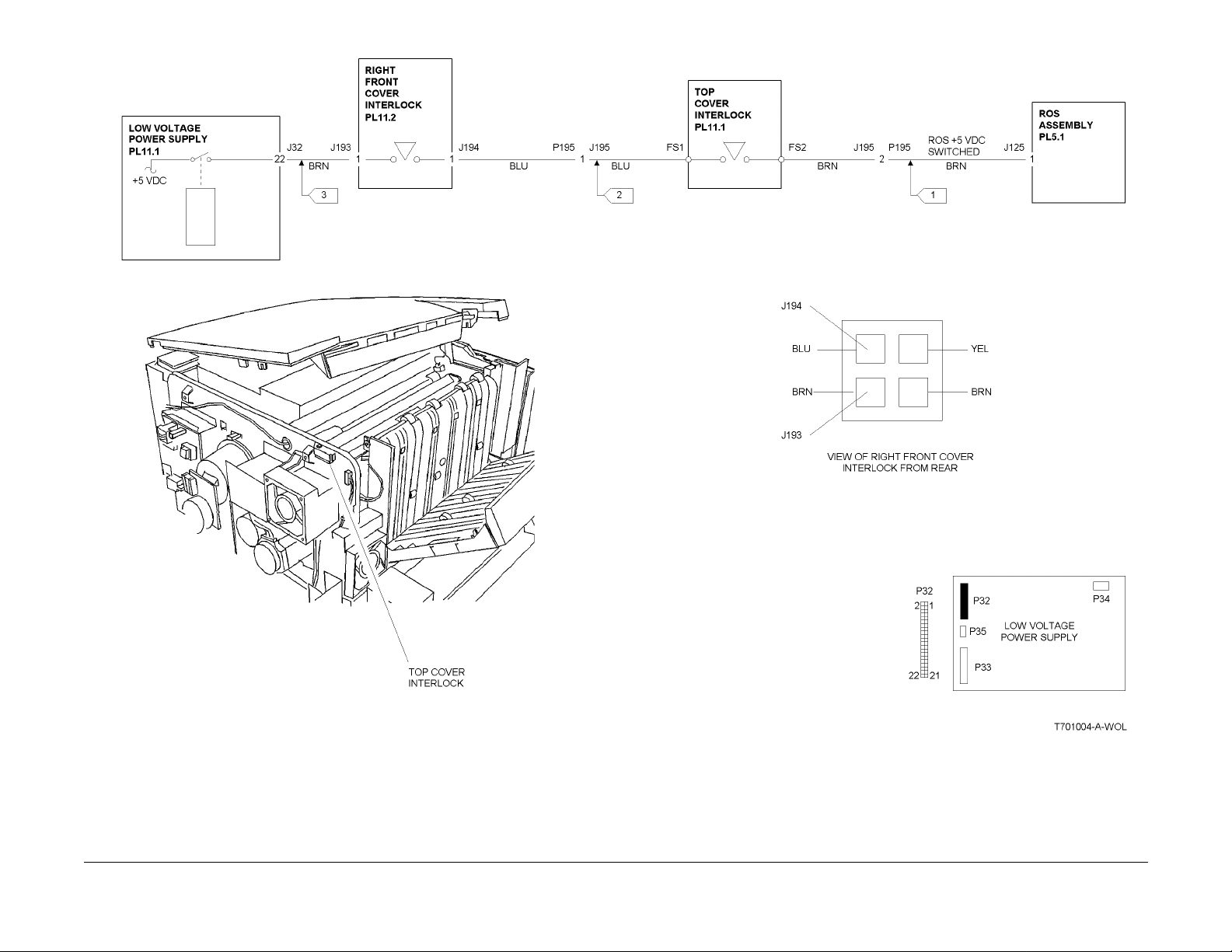

001-705 ROS +5 VDC Switched Voltage RAP

Initial Actions

Check the following:

• Ensure the Right Front Cover is closed.

• Ensure the Top Cover is correctly pos itioned and is ac tuating the Top Cover Inter lock.

Procedure

Switch off the power. Remove the Rear Cover. Switch on the power. +5 VDC is measured

betwe en J32-22 on the Low Volta ge Power Supply an d machine frame.

YN

Replace the Low Voltage Power Supply (PL 11.1).

Remove the Top Cover. Actuate the T o p Cover Interlock. +5 VDC is measured between

J125-1 on the ROS Assemb ly and machine frame.

YN

With the Top Cover Interl o ck st il l actuated , +5 V DC is measured be t ween FS2 (blue

wire) on the Top Cover Interlock and machine frame.

YN

+5 VDC is measured between FS1 (blue wire) on the Top Cover Interlock and

machine frame.

YN

+5 VDC is measured between J194-1 (bl ue wire) o n the Right Fron t Cover

Interlock and machine frame.

YN

+5 VDC is measured between J193-1 (brown wire) on the Right Front

Cover Interlock and machine frame.

YN

Go to Flag 3. Check the wir e for an open circuit.

Replace the Ri ght Front Cover Interlock (PL 11.2).

Go to Flag 2. Check the wir e for an open circuit.

Replace the Top Cover Interlock (PL 11.1).

Go to Flag 1. Check the wir e for an open circuit.

The ROS +5 VDC Switched circuit appears t o be functioning correctly.

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-13

Status Indicator RAPs

001-705

Page 28

Figure 1 001-705 Circuit Diagram

Status Indicator RAPs

001-705

10/00

2-14

Initial Issue

Phaser 790/DocuColor 2006

Page 29

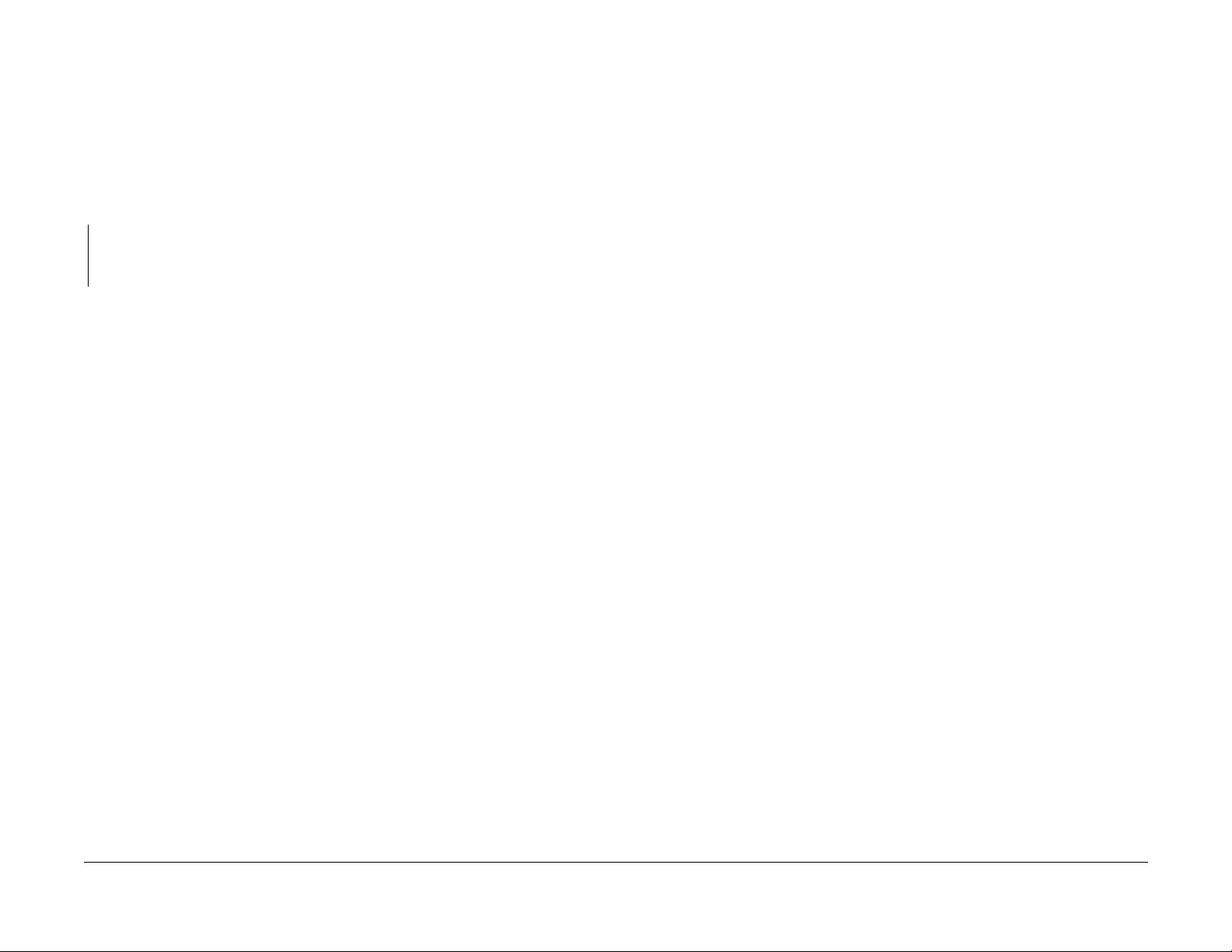

001-706 Area 1 Open RAP

Initial Actions

Perform the following:

• Check the actuator for the Bypass Tray Interlock. Ensure it is not broken or damaged.

• Ensure the Bypass Tray is clos ed and is in the operating position.

Procedure

Access the Digital Input (DI) test from the Control Panel. Enter code [77]. Press the Item/Enter

button. The display indicates 0.

YN

Go to Flag 1 an d Fl a g 2. Ch ec k the w ire s fo r an op en ci rcu it . If th e wir es are go od , rep la ce

the Bypa ss Tra y Inte rlo ck (PL 4.1 ). If th e pr oble m co ntinu es, r epl ace th e MC U PWB (PL

11.2).

The problem may be intermittent. Go to Flag 1 and Flag 2 and check for loose or damaged

connections or damaged wires. If the problem persists, replace the Bypass Tray Interlock (PL

4.1). If the problem c ontinues, replace the MCU PWB (PL 11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-15

Status Indicator RAPs

001-706

Page 30

Figure 1 001-706 Circuit Diagram

Status Indicator RAPs

001-706

10/00

2-16

Initial Issue

Phaser 790/DocuColor 2006

Page 31

001-707 Area 2 Open RAP

Initial Actions

Perform the following:

• Check the actuator for the Turn Chute Interl ock. Ensure it is not broken or damaged.

• Ensure the Turn Chute is closed.

Procedure

Access the Digital Input (DI) test from the Control Panel. Enter code [84]. Press the Item/Enter

button. The display indicates 0.

YN

Go to Flag 1 an d Fl a g 2. Ch ec k the w ire s fo r an op en ci rcu it . If th e wir es are go od , rep la ce

the Turn Chute Interl ock (PL 3.3). I f the p roble m cont inues, repla ce th e MCU P WB ( PL

11.2).

The problem may be intermittent. Go to Flag 1 and Flag 2 and check for loose or damaged

connections or damaged wires. If the problem persists, replace the Turn Chute Interlock (PL

3.3). If the problem c ontinues, replace the MCU PWB (PL 11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-17

Status Indicator RAPs

001-707

Page 32

Figure 1 001-707 Circuit Diagram

Status Indicator RAPs

001-707

10/00

2-18

Initial Issue

Phaser 790/DocuColor 2006

Page 33

001-708 Area 3 Open RAP

Initial Actions

Perform the following:

• Ensure the Right Cover is fully closed.

• Check the actuators for both Feeder Right Cover Switches. Ensure they are not broken or

damaged.

Procedure

Access the Digital Input (DI) test from the Control Panel. Enter code [C0]. Press the Item/Enter

button. The display indicates 0.

YN

Remove the Feeder Rear Cover (PL 13.2). Less than +1.0 VDC is measured between

J217-8 on the Feeder PWB and machine frame.

YN

Go to Flag 1. Check the wires for an open circuit. If the wires are good, replace the

Feeder R ig ht C ov er I nt erlock 1 (PL 13.2).

Replace the Feeder PWB (PL 13.4).

Enter code [C1]. Press the Item/Enter button. The dis pla y in d ica t e s 0.

YN

Remove the Feeder Rear Cover. Less than +1.0 VDC is measured between J217-10

on the F eeder PWB and mach ine frame.

YN

Go to Flag 2. Check the wires for an open circuit. If the wires are good, replace the

Feeder R ig ht C ov er I nt erlock 2 (PL 13.2).

Replace the Feeder PWB (PL 13.4).

The problem may be in ter m i tt e nt. Go t o Fig ur e 1 an d ch ec k f or lo os e or damaged connecti on s

or damag ed wire s. If th e prob lem pers ists, r eplac e the Feed er Ri ght Cove r Inter lock 1 and 2

(PL 13.2). If t he problem continues, r eplace t he Feeder PWB (PL 13.4).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-19

Status Indicator RAPs

001-708

Page 34

Figure 1 001-708 Circuit Diagram

Status Indicator RAPs

001-708

10/00

2-20

Initial Issue

Phaser 790/DocuColor 2006

Page 35

001-709 Area 4 Open RAP

Initial Actions

Perform the following:

• Check the actuator for the Exit Chute Interlock. Ensure it is not broken or damaged.

• Ensure the Exit Chute is closed.

Procedure

Access the Digital Input (DI) test from the Control Panel. Enter code [74]. Press the Item/Enter

button. The display indicates 0.

YN

Go to Flag 1 an d Fl a g 2. Ch ec k the w ire s fo r an op en ci rcu it . If th e wir es are go od , rep la ce

the Exit Chute Interlock (PL 9.2). If the problem continues, replace the MCU PWB (PL

11.2).

The problem may be intermittent. Go to Flag 1 and Flag 2 and check for loose or damaged

conne ctions or da maged wires. If the proble m persi sts, repl ace the E xit Chute Interloc k (PL

9.2). If the problem c ontinues, replace the MCU PWB (PL 11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-21

Status Indicator RAPs

001-709

Page 36

Figure 1 001-709 Circuit Diagram

Status Indicator RAPs

001-709

10/00

2-22

Initial Issue

Phaser 790/DocuColor 2006

Page 37

001-710 Area 5 Open RAP

The Control Logic detected that the Fuser Drawer in not fully closed.

Initial Actions

Perform the following:

• Ensure th at the Fuse r Assembl y is fully closed.

• Ensu re tha t the Fu ser As sembl y is mo unted corre ctly an d secur ely. Repai r any ob viou s

defects.

Procedure

Access the Digital Input (DI) test from the Control Panel. Enter code [62]. Press the Item/Enter

button. The display indicates 0.

YN

Go to Flag 1 an d ch eck the wir e for a open circ uit . If t he wir e is good , re plac e th e MC U

PWB (PL 11.2).

The problem may be intermitt ent. Go to Flag 1 and check for loose o r damaged connections or

damage d wires. If the problem persists, replace the MCU PWB (PL 11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-23

Status Indicator RAPs

001-710

Page 38

Figure 1 001-710 Circuit Diagram

Status Indicator RAPs

001-710

10/00

2-24

Initial Issue

Phaser 790/DocuColor 2006

Page 39

001-711 Area 6 Open RAP

The Control Logic has detected that area 6 is open.

Initial Actions

Perform the following:

• Ensure that the I nverter Chute (PL 15.5) is fully closed.

• Ensure that the actuator for the CAB Interlock is not broken. Repair any obvious defects.

Procedure

Access the Digital Input (DI) test from the Control Panel. Enter code [93]. Press the Item/Enter

button. The display indicates 0.

YN

Go to Flag 1 and Flag 2. Check the wires for a open circuit. If the wires are good, replace

the Duplex Controller PWB (PL 15.6).

The problem may be intermittent. Go to Flag 1 and Flag 2 and check for loose or damaged

connections or da maged wires. If the problem pers ists, replace the replace the Duplex Controller PWB (PL 15.6).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-25

Status Indicator RAPs

001-711

Page 40

Figure 1 001-711 Circuit Diagram

Status Indicator RAPs

001-711

10/00

2-26

Initial Issue

Phaser 790/DocuColor 2006

Page 41

001-712 IIT DC Power RAP

Initial Actions

Ensure AC power is avail able at the wall outlet.

Ensure that the AC Power Cor d is securely connected to the system.

Procedure

Remove the Rear Cover (REP 6.4) from the IIT. Check the following voltages at P91 (Figure 1)

on the IIT LVPS:

• P91-1 (Orange Wire) for +24 VDC

• P91-2 (Orange Wire) for +24 VDC

• P91-3 (Gray Wire) for +5 VDC

• P91-4 (Gray Wire) for +3.5 VDC

All of the vol t ag e ar e av ai lable.

YN

All of the voltages are missing.

YN

Check th e pi ns on conn ect o r P/ J91. Loo k f or lo ose or da mag ed pins. If the co nn ec tor

is OK, replace the IIT LVPS (PL 16.1).

Check the Fuse (Figure 1) on the IIT LVPS. The Fuse is defective.

YN

AC line voltage is available between JN1-1 an d JN1-2 (Figure 1).

YN

Replace the AC Switch/Harness (PL 16.6).

Replace the IIT LVPS (P L 16.1).

Replace the Fuse. If the Fuse blows again, replace the IIT LVPS (PL 16.1).

Go to the wirenets to check for any wires that may be open.

Check the IIT LVPS connectors for any loose or da maged pi ns.

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-27

Status Indicator RAPs

001-712

Page 42

Figure 1 001-712 Circuit Diagram

Status Indicator RAPs

001-712

10/00

2-28

Initial Issue

Phaser 790/DocuColor 2006

Page 43

002-310 IIT Control Panel Failure RAP

The IIT Con tr o l Pa ne l ha s failed.

Procedure

Check th e cabl e betwee n the ICM M ain PWB and the C ontrol Pa nel for an y pinche d wires.

Check the connectors fo r any loose or damaged pins. If the harness and connectors are good,

replace the Control Panel Assembly (PL 16.6).

002-701 Blank/Garbled IOT Display RAP

Initial Actions

Remove the Right Cover (REP 14.9) in order to check the LEDs on the ESS PWB (Figure 1).

LED D5 (r ed LED) should not be lit and LED D4 (green LED ) should be lit. If LED D5 is l it, or is

flashing, replace the ESS PWB (PL 12.1).

Procedure

The Control Panel is blank.

YN

Reseat the Panel Harness between the ESS PWB and the Control Panel. If the problem

continues, replace the following components in the order listed until the problem is

resolved:

• Panel Harne ss (PL 12.1)

• Control Panel (PL 1.2)

• ESS PWB (PL 12.1)

NOTE: The following voltage measurement is made at the solder points for J11 on the ESS

PWB. Refer to the Cir cuit Diagram for the correct location to make the measurements.

+5 VDC is measured between J11 pins A1, A2, B1, and B2 on the ESS PWB to machine

frame.

YN

Go to the 001-702 +5 VDC Power RAP.

Reseat the Panel Harness between the ESS PWB and the Control Panel. If the problem continues , replace the followi ng compon ents in the order listed until the problem is resolved:

• Panel Har ness (PL 12.1)

• Control Panel (PL 1.2)

• ESS PWB (PL 12.1)

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-29

Status Indicator RAPs

002-310, 002-701

Page 44

Figure 1 002-701 Circuit Diagram

Status Indicator RAPs

002-701

10/00

2-30

Initial Issue

Phaser 790/DocuColor 2006

Page 45

002-702 IOT Control Panel Button/LED RAP

Initial Actions

Reseat the connectors on the cable between the ESS PWB and the Control Panel (P/J34 and

P/J 317. Check for any loose or damaged pins in the harness connectors.

Procedure

Ensure that the Initial Actions has been performed. If the problem continues, replace the Control Panel (PL 1.2). If the problem continues, replace the ESS PWB (PL 12.1).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-31

Status Indicator RAPs

002-702

Page 46

Status Indicator RAPs

002-702

10/00

2-32

Initial Issue

Phaser 790/DocuColor 2006

Page 47

003-310 Feeder Communications Failure RAP

The Control Logic detected a communication failure with the Feeder PWB.

Initial Actions

• Ensure that connector P/J 212 is properly seated on the Fe eder PWB.

• Remove the ESS PW B (R EP 1.9 ) and ch eck the P/J 22 on t he MCU PW B. En su re tha t it

is properly seated on the PWB.

Procedure

Perform the following:

• Go to Flag 1. Check the wires between the Feeder PWB and the MCU PWB for an open

circuit.

• If the prev ious check is OK, rep lace the Feed er PWB (P L 13 .4 ) .

• If the problem continues, replace the MCU PWB (PL 11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-33

Status Indicator RAPs

003-310

Page 48

Figure 1 003-310 RAP Cir c uit Diagram

Status Indicator RAPs

003-310

10/00

2-34

Initial Issue

Phaser 790/DocuColor 2006

Page 49

003-311 Duplex Communications Failure RAP

The Control Logic detected a communication failure with the Duplex Controller PWB.

Initial Actions

• Ensure that connector P/J 142 is properly seated on the Duplex Controller PWB.

• Remove the ESS PW B (R EP 1.9 ) and ch eck the P/J 22 on t he MCU PW B. En su re tha t it

is properly seated on the PWB.

Procedure

Perform the following:

• Go to Flag 1. Check the wires between the Duplex Controller PWB and the MCU PWB for

an open circuit.

• If the previous check is OK, replace the Duplex Co ntroller PWB (PL 15.6).

• If the problem continues, replace the MCU PWB (PL 11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-35

Status Indicator RAPs

003-311

Page 50

Figure 1 003-311 RAP Circuit Diagram

Status Indicator RAPs

003-311

10/00

2-36

Initial Issue

Phaser 790/DocuColor 2006

Page 51

003-312 Sorter Communications Failure RAP

The Sorter Control Logic did not successfully receive the Start signal from the MCU PWB.

Procedure

Go to Flag 1 and check the wires for an open or short circ uit. The wires are good.

YN

Repair the wires.

Replace the Sorter Control PWB (PL 19.1). If the problem continues, replace the MCU PWB

(PL 11.2)

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-37

Status Indicator RAPs

003-312

Page 52

Figure 1 003-311 RAP Circuit Diagram

Status Indicator RAPs

003-312

10/00

2-38

Initial Issue

Phaser 790/DocuColor 2006

Page 53

003-333 Foreign Interface RAP

This Fault C o de in di cate s tha t a c om m unic at ions fa ilure w as d ete cted b etwe en th e ESS P WB

and the Foreign Interface.

Procedure

Switch the IOT power off, then on. Fault Code 003- 333 is still present.

YN

If interm it te nt pe rf o rmance is susp ected, per for m t he foll ow i ng:

• Check the connections between the ESS PWB and the Foreign Interface and the

interconnecting harness.

• Reseat the P/J 17 connector on the ESS PWB and P/J 905 on the Foreign Interface.

Go to Flag 1 and check the wires for an open or short circ uit. The wires are good.

YN

Repair the wires.

There is +5 VDC between J905-8 and machine fram e.

YN

There is +5 VDC between J 17-7 and machine frame.

YN

Replace the ESS PWB (PL 12.1).

Go to Flag 2 and check the wire for an open circuit.

Go to Flag 3 and check the wires for an open or short circ uit. The wires are good.

YN

Repair the wires.

Replace the ES S PWB (PL 12 .1). If the problem continues, replace the Fo reign Interfac e.

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-39

Status Indicator RAPs

003-333

Page 54

Figure 1 003-333 RAP Cir c uit Diagram

Status Indicator RAPs

003-333

10/00

2-40

Initial Issue

Phaser 790/DocuColor 2006

Page 55

003-334 Foreign Interface Compatibility RAP

This Fa ult Co de ind icates that a com patibil ity p roblem was detecte d bet ween t he ESS PWB

and the Foreign Interface (an incorrect Foreign Interface device may be installed).

Procedure

Switch the IOT power off, then on. Fault Code 003- 334 is still present.

YN

If interm it te nt pe rf o rmance is susp ected, per for m t he foll ow i ng:

• Check the connections between the ESS PWB and the Foreign Interface and the

interconnecting harness.

• Reseat the P/J 17 connector on the ESS PWB and P/J 905 on the Foreign Interface.

The Foreign Interface device is the correct device for the P790/DC2006.

YN

Install the corre ct Fo rei gn Inter face .

Go to Flag 1 and check the wires for an open or short circ uit. The wires are good.

YN

Repair the wires.

Replace the Foreign Interface.

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-41

Status Indicator RAPs

003-334

Page 56

Figure 1 003-334 RAP Cir c uit Diagram

Status Indicator RAPs

003-334

10/00

2-42

Initial Issue

Phaser 790/DocuColor 2006

Page 57

003-356 IOT NVM RAM Error RAP

The system detected an IOT NV RAM error at power on.

Procedure

Switch the power off then switch the power on. The fault code occurs.

YN

If the proble m seems to be in termittent , reseat all con nectors on th e MCU PWB. If the

problem occurs again, replace the MCU P WB (PL 11.2).

Go to Flag 1. Check the wires for an open or short circuit. If the wires are good, replace the

Communication PWB. If the probl em continues, rep lace the MC U PWB (PL 11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-43

Status Indicator RAPs

003-356

Page 58

Figure 1 003-356 RAP Cir c uit Diagram

Status Indicator RAPs

003-356

10/00

2-44

Initial Issue

Phaser 790/DocuColor 2006

Page 59

003-400 IOT Firmware Error RAP

The system detected a n IOT firmware error.

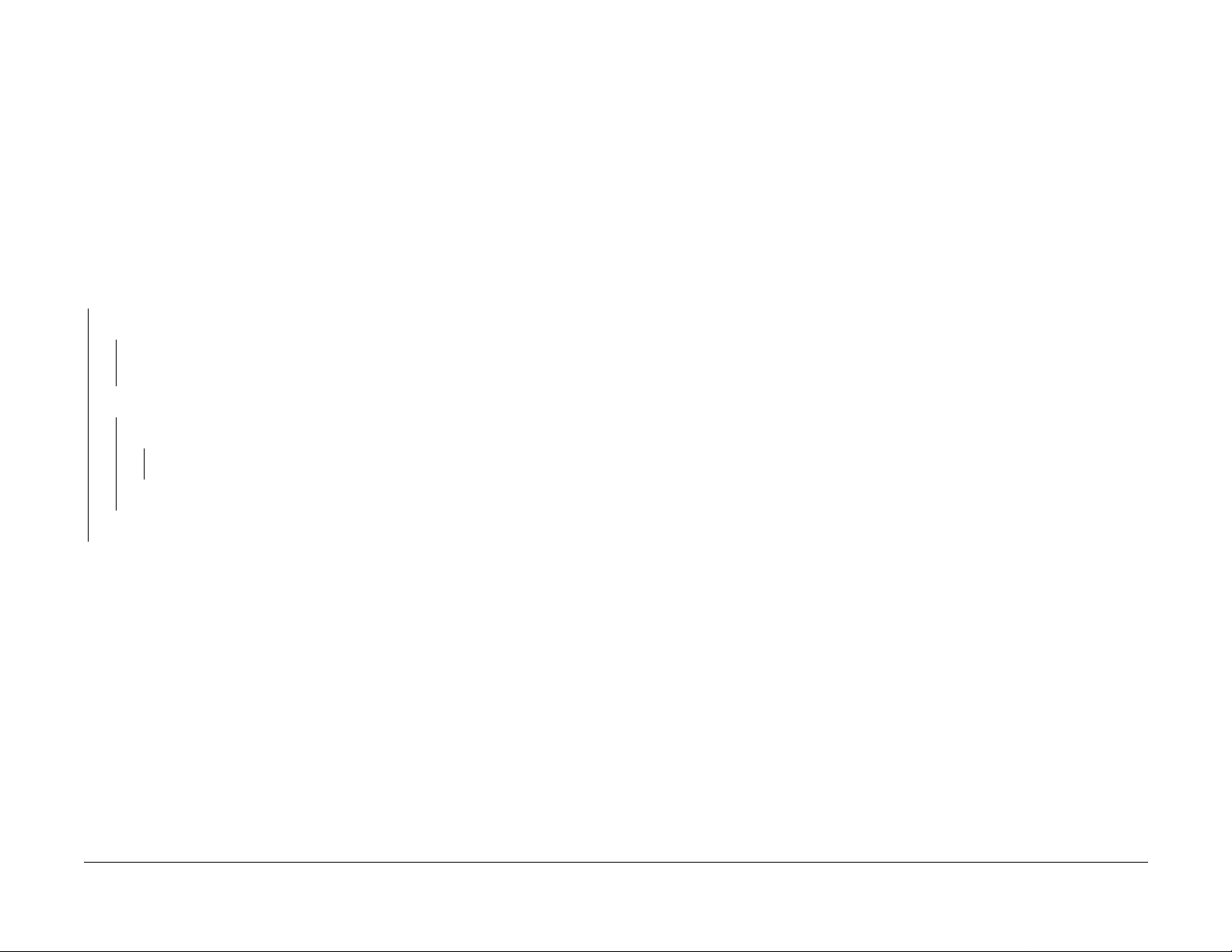

003-701 Copy/Print Cartridge Error RAP

The Control Logic detected an error with the Copy/Print Cartridge CRUM.

Procedure

Switch the power off then switch the power on. The Fault Co de occurs.

YN

If the proble m seems to be in termittent , reseat all con nectors on th e MCU PWB. If the

problem occurs again, Perform GP 8, IOT Software Installation. If the problem is still not

resolved, replace the MCU PWB (PL 11.2).

Perform GP 8, IOT Software Installation. If the problem continues, replace the MCU PWB (PL

11.2).

Initial Actions

• If the Copy/Print Cartridge is due to be replaced, refer to REP 9.1 and replace the cartridge.

• Check the CRUM connector on the Copy/Print Ca rtridge. Ensure that the contacts are

clean an d not dam aged. Replace the Copy/ Print Cartridge if required (PL 5.1) .

Procedure

Perform the following:

• Go to Flag 1 and che ck the co nn ect or s on th e MCU PWB, P/J 84, an d on t he CRU M Connector.

• If the previous check is OK, replace the MCU PWB (PL 11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-45

Status Indicator RAPs

003-400, 003-701

Page 60

Figure 1 003-701 RAP Cir c uit Diagram

Status Indicator RAPs

003-701

10/00

2-46

Initial Issue

Phaser 790/DocuColor 2006

Page 61

004-320 Paper Handling Motor RAP

The Control Lo gic detected that the Paper Handling Motor is not functionin g.

Initial Actions

Check the connectors on the Drive Motor PW B. Ensure that th ey are cor rectly seated.

Procedure

Switc h off the power then switch on the power. The 04-32 0 fa u l t co d e is declar ed at th e end

of self-test.

YN

Go to Fl ag 2 a nd ch eck the h arn ess betw een t he D rive M ot or PW B and th e Pap er Ha ndling M otor f or da mag ed w ires o r co nnec tor pins . If th e wir es ar e OK, repl ace t he Paper

Handling Motor (PL 10.1). If the problem continues, replace the Drive Motor PWB (PL

10.1).

Access the Dig ital Outpu t (DO) test from th e Control Pane l. Enter co de [53]. Press the Item/

Enter button. The Paper Handling Motor e nergizes.

YN

Access the DO Stop Test from the Control Panel. Enter code [53]. Press the Item/Enter

button. +5 VDC is me asured be tween J5 0-2 on the Driv e Motor PW B and machin e

frame.

YN

Go to Fl ag 3 a nd ch ec k the wire s for an o pen c irc uit. I f th e wi res ar e go od, r epl ace

the MCU PWB (PL 11.2).

Access the Dig ital Output (DO) test from the Cont rol Panel. Enter code [53]. Press the

Item/Enter button. The voltage at J50-2 goes to less than +1.0 VDC

YN

Replace the MCU PWB (PL 11.2).

+24 VDC is measur ed between J49-2 on the Drive Motor PWB and machine frame.

YN

Go to Flag 4 and check the wires for an open circuit (refer to the +24 VDC Interlocked Wirenet).

Go to Fl ag 2 a nd ch eck the h arn ess betw een t he D rive M ot or PW B and th e Pap er Ha ndling M otor f or da mag ed w ires o r co nnec tor pins . If th e wir es ar e OK, repl ace t he Paper

Handling Motor (PL 10.1). If the problem continues, replace the Drive Motor PWB (PL

10.1). If the problem can not be resolved, replace the MCU PWB (PL 11.1)

Check the following:

• Go to Flag 1 and check the wire for an open circuit.

• Go to Fl ag 2 and chec k th e har nes s be twee n the Driv e Mo tor PWB a nd th e Pa per H an-

dling Motor for damaged w ires or co nnector pins.

• The proble m may be in te rmi tt e nt. Go to Fi gu re 1 an d ch eck for lo os e or da mag ed conn ec tions or damaged wires. If the problem persists, replace the replace the MCU PWB (PL

11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-47

Status Indicator RAPs

004-320

Page 62

Figure 1 004-320 RAP Cir c uit Diagram

Status Indicator RAPs

004-320

10/00

2-48

Initial Issue

Phaser 790/DocuColor 2006

Page 63

004-322 Fuser Motor RAP

The Control Logic detected that the Fuser Motor is not functioning.

Initial Actions

Check the conn ecto r s on the Driv e Moto r PWB an d the Fu se r Moto r. Ensure that th ey are c orrectly se ated.

Procedure

Switc h off the power then switch on the power. The 04-32 2 fa u l t co d e is declar ed at th e end

of self-test.

YN

Go to Flag 2 and check the harness between the Drive Motor PWB and the Fuser Motor

for dama ged, or l oose, wi res or co nnector pin s. If the wires a re OK, rep lace the F user

Motor ( PL 10.1) . If the problem continues, replace the Drive Motor PWB (PL 10.1).

Access the Dig ital Outpu t (DO) test from th e Control Pane l. Enter co de [53]. Press the Item/

Enter button. The Fuser Motor energizes.

YN

Go to Flag 2 and check the harness between the Drive Motor PWB and the Fuser Motor

for damaged wires or connector pins. If the wires are OK, replace the Fuser Motor (PL

10.1). If the prob lem co ntin ues, re plac e the D rive Motor PWB ( PL 10 .1). I f the proble m

can not be resolved, replace the MCU PWB (PL 11.1)

Check the following:

• Go to Flag 1 and check the wire for an open circuit.

• Go to Flag 2 and check the harness between the Drive Motor PWB and the Fuser Motor

for damaged wires or conn ector pins.

• The proble m may be in te rmi tt e nt. Go to Fi gu re 1 an d ch eck for lo os e or da mag ed conn ec tions or damaged wires. If the problem persists, replace the replace the MCU PWB (PL

11.2).

Initial Issue

Phaser 790/DocuColor 2006

10/00

2-49

Status Indicator RAPs

004-322

Page 64

Figure 1 004-322 RAP Cir c uit Diagram