Page 1

Xerox 4635 Laser Printing System

Product Reference

XEROX

January 1996

721P83071

Page 2

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

© 1991, 1992, 1993, 1994, 1995, 1996 by Xerox Corporation. All

rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory

or judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are

displayed on the screen, such as icons, screen displays, looks,

etc.

Printed in the United States of America

Publication number: 721P83071

Xerox®, 4635, and all Xerox products mentioned in this

publication are trademarks of Xerox Corporation. Products and

trademarks of other companies are also acknowledged.

DEC and VAX are trademarks of Digital Equipment Corporation.

IBM and all IBM products mentioned in this publication are

trademarks of International Business Machines, Inc.

WARNING: This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Changes are periodically made to this document. Changes,

technical inaccuracies, and typographic errors will be corrected in

subsequent editions.

This document was created on the Xerox 6085 Professional

Computer System using VP software. The typeface is Optima.

Page 3

Related publications

The Xerox 4635 Laser Printing System Product Reference is part

of the ten-manual reference set for your laser printing system.

The entire reference set is listed in the table below. Several

other related documents are also listed for your convenience.

For a complete list and description of available Xerox

documentation, refer to the Xerox Documentation Catalog

(Publication number 610P17417) or call the Xerox

Documentation and Software Services (XDSS) at 1-800-445-5554.

Publication Number

Xerox Dynamic Document Interface

Operator Guide

Xerox Dynamic Document Interface

Command Summary

Xerox 4635 Laser Printing System

Operator Guide

Xerox 4635 Laser Printing System

Operations Reference

Xerox 4635 Laser Printing System

Sysgen Guide

Xerox 4635 Laser Printing System

Message Guide

Xerox 4635 Laser Printing System

PDL/DJDE Reference

Xerox 4635 Laser Printing System

Forms Creation Guide

Xerox 4635 Laser Printing System

Product Reference

Xerox 4635 Laser Printing System

Installation Planning Guide

720P13670

720P13680

721P83011

721P83021

721P83030

721P83040

721P83050

721P83060

721P83071

721P83081

Xerox 4635 Laser Printing System

Operator Command Summary Card

Xerox 4635 Laser Printing System

PC UI Reference

Xerox Laser Printing Systems

Tape Formats Manual

Xerox Laser Printing Systems

Standard Font Library Font User Guide

Helpful Facts About Paper 721P82490

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE iii

721P83090

721P83101

600P86175

600P86174

Page 4

Notice

This publication may contain descriptions of concepts and

features not currently available for your Xerox Laser Printing

System. Consult your Xerox sales representative or your

operating system software program description for additional

information.

iv XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 5

Table of contents

Related publications iii

Notice iv

Introduction viii

4635 LPS Product Reference viii

About the reference set ix

4635 Laser Printing System document set ix

Document conventions xii

1. 4635 LPS overview 1-1

4635 LPS 1-2

Software 1-2

Options 1-3

9-track magnetic tape drive 1-3

18-track cartridge tape drive 1-3

Bypass transport 1-3

Input enablement device 1-3

5.25-inch floppy disk drive 1-4

Expanded disk memory 1-4

Expanded bitmap memory 1-4

Bar code reader 1-4

Raster image processor 1-4

LPS connection 1-4

4635 LPS specifications 1-6

Equipment dimensions 1-6

Clearance requirements 1-6

Environmental requirements 1-6

Electrical requirements 1-7

4635 LPS features 1-8

2. Basic concepts 2-1

LPS overview 2-1

System controller 2-2

LPS interfaces 2-2

LPS system disk storage and memory 2-2

Printer 2-3

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE v

Page 6

TABLE OF CONTENTS

Imaging subsystem 2-3

Xerographic subsystem 2-3

Output subsystem 2-4

LPS production process overview 2-4

Input 2-4

Sources of input for the LPS 2-4

Types of data 2-6

Special processing 2-6

Output 2-7

Job source library (JSL) files 2-7

Fonts 2-8

3. 4635 LPS hardware components 3-1

Major components 3-1

System controller hardware components 3-1

Printer hardware components 3-5

Attention light 3-8

Attention alarm 3-8

4. 4635 LPS software components 4-1

LPS operating system 4-1

Operating system software functional description 4-2

Printer software 4-4

User interface software and user dialog software 4-4

Software 4-4

Optional host-resident software packages 4-5

5. Product differences/user considerations 5-1

LPS compatibility and comparison 5-1

Using your 4635 LPS as a backup LPS 5-2

Checking paper sizes and special stocks 5-8

Comparing LPS print job resolution 5-10

Checking JDL compatibility 5-10

Checking PDL compatibility 5-11

LPS comparison 5-13

4635 LPS user considerations 5-17

4635 LPS edgemarking 5-17

Registration shift and skew 5-19

Paper size 5-20

System page size 5-20

Virtual page size 5-21

Error messages 5-21

vi XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 7

TABLE OF CONTENTS

Deletions 5-21

Print Darkness 5-22

Interpolation and scanned images 5-23

Switching paper size and feed modes 5-23

Cleaning time between pitch mode changes 5-24

6. Xerox customer resources 6-1

Xerox support services 6-1

Xerox Customer Support Center 6-1

Customer Service Support Center 6-2

Xerox Connection 6-2

Xerox Font Center 6-3

Xerox Customer Documentation Catalog 6-3

Xerox Documentation and Software Services 6-3

Xerox Supplies Order Service 6-4

Appendices

A. Audit log record A-1

Master audit directory A-1

Audit log data A-3

Log header record A-3

Page detail record A-5

Waste management detail record A-6

Operations log data record A-7

Notes A-8

Strings A-8

Dates A-8

Record type codes A-8

Error flags A-8

Log flags A-8

Audit flags A-9

Completion status codes A-9

Key audit report calculations A-10

Glossary GLOSSARY-1

Index INDEX-1

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE vii

Page 8

Page 9

4635 LPS Product Reference

Introduction

The purpose of the 4635 LPS Product Reference is to:

• Introduce the Xerox 4635 Laser Printing System (LPS)

hardware and software

• Introduce basic concepts associated with LPS printing

• Compare the 4635 LPS to other LPS products

• Describe some of the user considerations associated with

4635 LPS performance.

Since the 4635 LPS Product Reference is a composite of

information aimed at satisfying a variety of reader requirements,

certain chapters or chapter sections may be skipped by the

experienced LPS user. For example, the basic concepts in

chapter 2 would be desirable reading for someone with little or

no LPS experience, while an experienced LPS user need not read

it. The contents of each chapter are described below.

Chapter 1: Overview. Presents 4635 LPS features, options, and

specifications.

Chapter 2: Basic concepts. Introduces basic concepts

associated with LPS printing, as well as an overview of the LPS

production process.

Chapter 3: Hardware. Introduces major standard and optional

hardware components.

Chapter 4: Software. Introduces LPS software, describes the

functional operation of the software, and provides an overview of

software features.

Chapter 5: Product differences. Provides a comparison of LPS

products, addresses compatibility issues, and explains inherent

user considerations.

Chapter 6: Xerox customer resources. Provides descriptions

and telephone numbers for service, customer support, upgrades,

and supplies for Xerox customers in the United States.

A glossary and an index are provided at the back of this guide.

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE viii

Page 10

INTRODUCTION

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

About the reference set

This document is part of a reference set designed to help you

receive maximum benefit from your 4635 laser printing system.

To help you select the appropriate document for your needs, the

following section identifies the documents in the set and

describes the information contained in each.

4635 Laser Printing System document set

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

4635 LPS

Product

Reference

• Product overview

• Hardware and software

• LPS connections

• User considerations

• LPS comparisons

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

4635 LPS

Operator

Guide

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

4635 LPS

PDL/DJDE

Reference

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

4635 LPS

System

Generation

Guide

• System overview

• PC UI procedures

• Paper facts and procedures

• Operating procedures

• Maintenance

• Problem solving

• Supplies

• Meter reading and reporting

• Print Description Language components and processes

• Input processing functions

• Output processing functions

• PDL/DJDE command summary

• Page formatting guidelines

• Character code assignment tables

• PDL/DJDE programming information with step-by-step

instructions

• Configuration options

• Commands

• OSS software installation, upgrade, and modification

procedures

ix XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 11

INTRODUCTION

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

4635 LPS

Operations

Reference

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

4635 LPS

Forms

Creation

Guide

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

4635 LPS

PC UI

Reference

• Command syntax for operator and system administrator

procedures

• LPS defaults

• LPS resources

• Command summaries

• Communication and graphics on the LPS

• Command files

• Basic concepts for creating forms

• Coding and compiling for LPS Forms Description Language

• Sample form setup command sets

• Tips for successful forms creation

• PC UI procedures

• Hierarchy of PC UI windows

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

4635 LPS

Operator

Command

Summary

Card

aaaaaaaaaaaaaaa

4635 LPS

Message

Guide

• Provides a quick reference of commonly-used operator

commands.

• OSS and other messages

• Meaning and recovery procedures

XEROX 4635 LASER PRINTING SYSTEM LPS PRODUCT REFERENCE x

Page 12

INTRODUCTION

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

4635 LPS

Installation

Planning

Guide

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

Tape Formats

Manual

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

LPS Standard

Font Library

Font User

Guide

• LPS basic components and options

• Tasks that must be accomplished before installation

• Preinstallation requirements

• Installation process

• Postinstallation activities

• Characteristics of different formats

• File organization

• Data formats

• Carriage control conventions

• Font naming conventions

• Listing of standard fonts

• Data sheets

• Glossary of typography terminology

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

Helpful Facts

About Paper

• Selection and guidelines

• Storage and handling

• Specifications for different printers

xi XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 13

Document conventions

INTRODUCTION

This guide uses the following conventions:

< > Angle brackets are used for keys on the system controller

keyboard.

{ } Curly brackets are used for required characters.

... Ellipses indicate that you can repeat a parameter or list a series of

parameters.

[ ] Square brackets are used for optional command characters.

| Vertical bars are used to separate parameters in a series. The

vertical bar stands for “or.”

bold Bold is used for characters you enter at the command line.

italics Italics is used for variable information.

terminal font Terminal or monospace font is used to display system responses.

underline

System default parameters are underlined.

UPPERCASE Uppercase letters are used for command names.

Note: You may key in entire words for each command, or the

first three characters of each word. In this manual the entire

word of each command is spelled out.

CAUTION: Cautions alert you to an action that could damage

hardware or software.

WARNING: Warnings alert you to conditions that may affect

the safety of people.

XEROX 4635 LASER PRINTING SYSTEM LPS PRODUCT REFERENCE xii

Page 14

1. 4635 LPS overview

The Xerox 4635 Laser Printing System (LPS) is a versatile, highperformance printing system that processes and prints data from

a variety of sources. It enables host mainframe computers and

network-connected devices (such as workstations and graphic

scanners) to produce publications and other documents,

incorporating graphics, forms, logos, signatures, and a variety of

fonts.

With the 4635 LPS, management information systems (MIS) and

data processing (DP) environments have a high-performance

printer in which built-in intelligence eliminates the need for the

host computer to store and manage forms, fonts, and other

document resources.

Data is printed at a rate of up to 135 pages per minute (154 with

the optional Paper Feeding Enhancement Kit installed). A variety

of fonts ranging in size from 3 points to 36 points, in all four

orientations (portrait, inverse portrait, landscape, inverse

landscape), and many publishing typefaces are available to meet

your printing requirements. In addition to the standard set of

fonts that is delivered with the LPS, special or customized fonts

can be developed by the Xerox Font Center. Your sales

representative will provide you with further information.

The Xerox 4635MX Laser Printing System (LPS) is the same system

as the 4635 LPS with the addition of Magnetic Ink Character

Recognition (MICR) functionality. Except where explicitly stated,

all references in this document to the 4635 LPS apply to both the

4635 LPS and the 4635MX LPS.

The following material is presented in this chapter:

• Hardware and software components

• Options

• Specifications

• Features list

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 1-1

Page 15

4635 LPS OVERVIEW

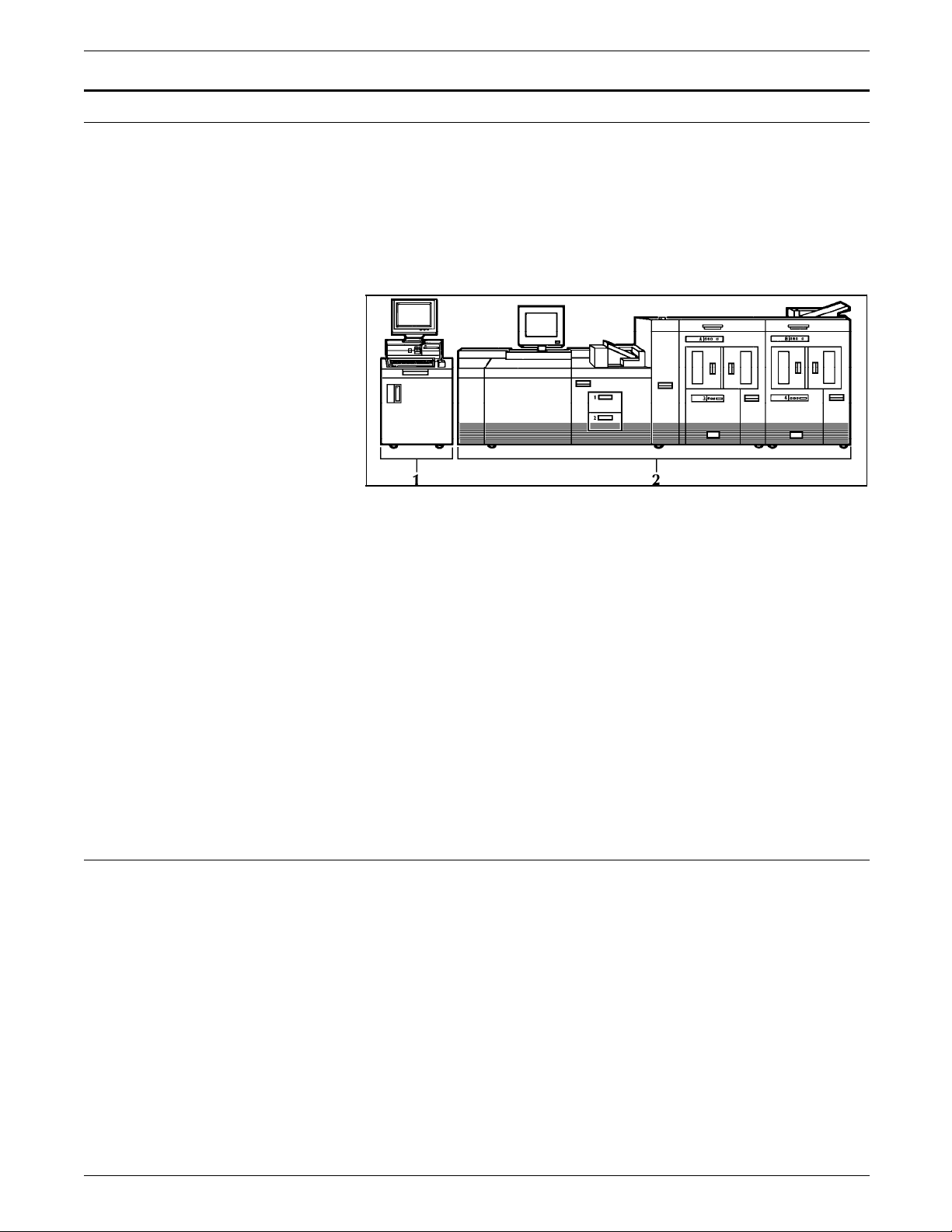

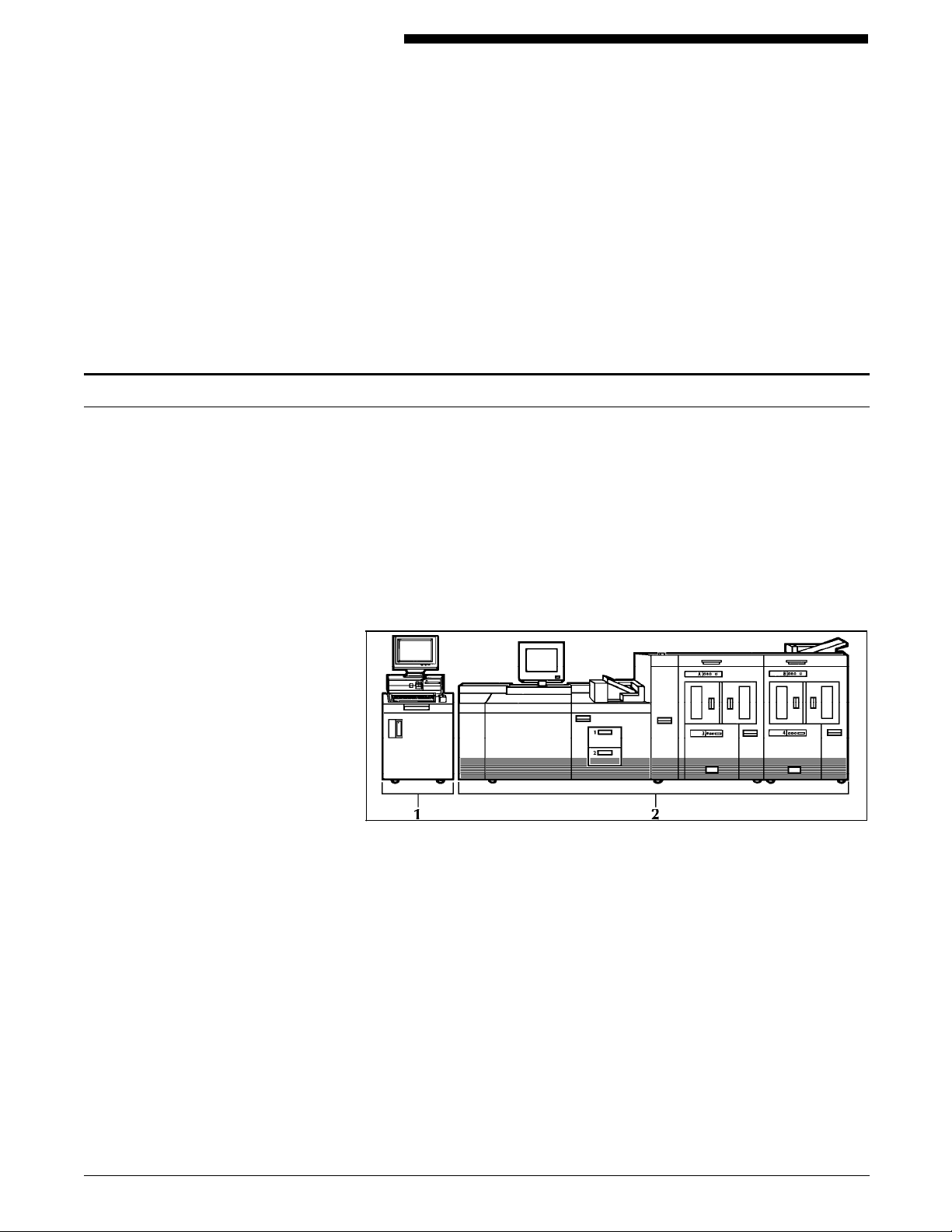

4635 LPS

The standard 4635 LPS consists of two main components:

1. System controller

2. Printer.

Figure 1-1 shows the 4635 LPS with the optional bar code

device.

Figure 1-1. 4635 Laser Printing System

Software

The system controller is a minicomputer which manages the

processing of input data; processes operator commands;

provides for the entry and compiling of form, print, and job

description files; executes job processing commands; and

manages low-level control of the printer.

Your 4635 LPS has a PC user interface (PC UI) that enables you

to start and monitor print jobs. In figure 1-1, the PC UI is shown

on top of the system controller.

The printer contains the mechanics and electronics involved in

the imaging and paper handling processes. Touch screen control

on the printer control console allows you to easily monitor and

control printer functions. Jam clearance areas and instructions

are clearly displayed with color graphics.

For more detailed descriptions of the 4635 LPS hardware

components, refer to the “4635 LPS hardware components”

chapter.

LPS software functionally consists of several components to

manage printing system resources. Refer to the “System

software functional description” section of the “4635 LPS

software components” chapter for additional information.

Among these components are two LPS-resident languages: FDL

and PDL.

1-2 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 16

Forms description language (FDL)

Print description language (PDL)

Options

4635 LPS OVERVIEW

(standard) FDL is a laser printing system resident language for designing

electronic forms which can include logos, signatures, and

shading. Form libraries (source and object) are stored on the

system disks. Refer to the Xerox 4635 LPS Forms Creation Guide

for more information.

(standard) PDL is a laser printing system resident language used to describe

the input, logical processing, and output requirements of a print

job. Refer to the Xerox 4635 LPS PDL/DJDE Reference for more

information.

The following options are available to further enhance the

capabilities of your 4635 LPS.

Note: For detailed information regarding these options, please

contact your sales representative.

9-track magnetic tape drive

18-track cartridge tape drive

Bypass transport

The 9-track (1600/6250) magnetic tape drive is an alternative or

additional offline capability to the 18-track cartridge tape drive for

inputting print and nonprint data to the 4635 LPS. (Refer to

figure 3-5.)

Refer to the Xerox 4635 LPS Operator Guide and to the LPS

Tape Formats Manual for additional information.

The 18-track cartridge tape drive is an alternative or additional

offline capability to the 9-track magnetic tape drive for inputting

print and nonprint data to the 4635 LPS. It reads and writes IBMand ANSI-compatible half-inch tape in the 18-track IBM 3480 data

format. There is also an option available which allows it to read

and print from the IBM 3490 format.

Refer to the Xerox 4635 LPS Operator Guide and to the LPS

Tape Formats Manual for additional information.

The bypass transport increases your production capabilities by

providing you with a means of using finishing devices with your

4635 LPS. Conforming to Xerox Document Feeding and

Finishing Architecture (DFA) Level 1 specifications, it allows you

to choose from a variety of finishers.

Input enablement device

The input enablement device provides the means to directly

connect bulk feeders to your 4635 LPS.

XEROX 4635 LASER PRINTING SYSTEM LPS PRODUCT REFERENCE 1-3

Page 17

4635 LPS OVERVIEW

5.25-inch floppy disk drive

Expanded disk memory

Expanded bitmap memory

Bar code reader

The 5.25-inch floppy disk drive is another means of downloading

or backing up files, such as fonts, to the 4635 system disk.

The 4635 has as a standard feature one 651 MB unformatted

system disk, and can support up to three additional 651 MB

unformatted system disks.

The 4635 has as a standard feature 32 Mbits of bitmap memory

that supports font and graphics. The bitmap memory can be

expanded to 256 Mbits.

The bar code reader adds a set of features that allow processing

of bar code data streams. A cross-checking mechanism allows

the 4635 to ensure that any bar code sheets printed have been

accounted for by each component of the software.

Raster image processor

LPS connection

Online interface The online channel interface receives input directly from the host

Offline interface The offline interface is an excellent alternative or addition to an

Raster image processor (RIP) performs vector to raster conversion

in support of the Interpress 3.0 Publication Set. It provides

multiple forms capability for any given page and permits printing

of text and image files which would otherwise be unprintable or

incomplete because of complexity. RIP allows you to use two

forms per page and more than 16 graphics on a page for

Interpress applications.

The 4635 may be ordered with the following optional

connections:

system. All IBM systems which support the channel-attached

3811/3211 or 4245 interface are supported. Non-IBM systems

are supported through a variety of connections such as DDI.

(Refer to the DDI description below.)

online operation. It supports 9-track (1600/6250 bpi) and 18track (3480 format) tapes conforming to one of the following

formats:

— American National Standards Institute (ANSI)

— IBM (OS/VS/370, OS/360, DOS/VS/370. DOS/360/370)

— Burroughs (MCP 2500-4700, 6700)

— Honeywell (OS 200/2000, OS 200/6000 series)

— Sperry/Univac Series 70 (1100-OS standard files

— DEC (RSX-11)

1-4 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 18

4635 LPS OVERVIEW

— CDC (external format)

— NCR (Century-B1)

— Tape input codes: EBCDIC, ASCII, BCD

— Interpress on tape

— Univac (SDF-formatted tapes)

— ICL (2900 VME/B)

Refer to the Xerox 4635 LPS Operator Guide and to the LPS

Tape Formats Manual for additional information.

DDI interface The Dynamic Document Interface (DDI) enables communication

between a 4635 LPS and other products via a shared disk

mechanism. The interface allows the other products (such as

DEC, PC, MAC, and UNIX local area network (LAN) workstations)

to save print files to an external hard disk. The 4635 LPS then

directly accesses the external hard disk to retrieve files for

printing. The DDI passes data over a high performance SCSI bus.

Ethernet interface Ethernet is the Xerox local area network (LAN) that allows data to

be transmitted by cable from one device to another. As an

Ethernet member, your LPS can receive and print from other

network “citizens” such as Ethernet workstations and graphic

scanners.

Ethernet workstations

With the Ethernet option, an LPS can receive and print input data

from workstations, such as the Xerox 8010, 6085, and the XPS

700 series. Workstations can transfer Interpress files using

Ethernet to the LPS and invoke LPS-stored forms and graphics for

printing.

Interpress is a page description language capable of describing

any two-dimensional image intended for a raster device, such as

a Xerox LPS. Its function is to describe previously created data

on a page; it is not a page composition language. This

functionality includes vector graphics (sometimes referred to as

line art), contour fonts, and pixel arrays. Interpress also includes

job management features such as paper tray selection, output

offsetting, stock selection, copy count, and page selection on a

copy basis.

An Interpress master can be created at a host or at a workstation

for transporting (offline or Ethernet modes) to the LPS.

Refer to the Xerox 4635 LPS Operations Reference and to the

workstation's documentation for more information.

Ethernet graphic scanners

With the Ethernet option, an LPS can receive and print scanned

graphic data (both line art and continuous tone images) from the

7650 Pro Imager (using the Xerox Publishing Illustrator's

Workstation).

Refer to the Xerox 4635 LPS Operations Reference and the Xerox

7650 Pro Imager Reference Manual for more information.

XEROX 4635 LASER PRINTING SYSTEM LPS PRODUCT REFERENCE 1-5

Page 19

4635 LPS OVERVIEW

4635 LPS specifications

Listed below are specifications for the 4635. For more

information on 4635 installation planning and specifications, refer

to the Xerox 4635 LPS Installation Planning Guide.

Equipment dimensions

Hardware Width Depth Height Weight

System controller

—with optional

peripheral

cabinet (fully loaded)

Printer

—with monitor and two

feeder/stacker

modules

—with monitor, two

feeder/stacker

modules, and

optional bypass

transport

—with monitor and

three feeder/

stacker modules

(one optional)

—with monitor and

four feeder/ stacker

modules (two

optional)

24 in./610 mm

48 in./1219 mm

151.2 in./3842 mm

170.2 in./4324 mm

183.5 in./4661 mm

215.8 in./5480 mm

28 in./712 mm

28 in./712 mm

35.9 in./711 mm

35.9 in./711 mm

35.9 in./711 mm

35.9 in./711 mm

38.2 in./970 mm

38.2 in./970 mm

59.6 in./1513 mm

59.75 in./1518 mm

59.6 in./1513 mm

59.6 in./1513 mm

300 lbs./136 kg

616 lbs./280 kg

2588 lbs./1174.9 kg

2768 lbs./1255.6 kg

3109 lbs./1411.9 kg

3630 lbs./1648.9 kg

Clearance requirements

System controller Requires 36 inch/914 mm clearance on each side.

Finishers and bulk feeders Finishers and bulk feeders attached to your bypass transport

Environmental requirements

Operating temperature 74° F ± 4° F/24° C ± 4° C (recommended)

Printer Requires 36 inch/914 mm clearance on each side. 50 inches/1270

mm required at front of printer.

require 36 inch/914 mm clearance on each side.

54° - 85° F/14° - 29° C (min-max)

Humidity 45% ± 10% (recommended)

15-85% (min-max)

1-6 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 20

Heat dissipation, printer Operating: 28,140 Btu per hour

Standby: 4,454 Btu per hour

Heat dissipation, system controller 3,754 Btu per hour

Heat dissipation, optional peripheral

cabinet (fully configured) 3,195 Btu per hour

Electrical requirements

For more information on 4635 LPS electrical requirements,

including power cord and outlet specifications, refer to the Xerox

4635 LPS Installation Planning Guide.

System controller U.S./Canada, 60 Hz: 208/240 (1 phase) or 208/220 VAC

4635 LPS OVERVIEW

(line 1 to line 2)

15 amp service

NEMA 6-15R or ANSI C73, 20R

KVA 1.1 (operating)

International, 50 Hz: 200/230 VAC (1 phase)

15 amp service

Power connector per local codes

Printer U.S./Canada, 60 Hz: 120/240 VAC or 120/208 VAC

50 amp service

NEMA 14-50R

KVA 7.3 (operating)

International, 50 Hz: 380, 400, 415 VAC (3 phase, 5 wire)

(WYE): 20 amp service (WYE)

International, 50 Hz: 220, 230, 240 VAC (3 phase, 4 wire)

(DELTA): 30 amp service (DELTA)

Optional bypass transport The bypass transport uses the Printer module as its power

source, therefore all power requirements for the bypass transport

are satisfied by the 4635 LPS.

Optional peripheral cabinet U.S./Canada, 60 Hz: 208/240 VAC (1 phase) or 208/220

(line 1 to line 2)

15 amp service

NEMA 6 to 15R or ANSI C73, 20R

KVA .9 in both standby and operating

International, 50 Hz: 200/230 VAC (1 phase)

15 amp service

Power connector per local codes

Agency certification UL, CSA, IEC, VDE

XEROX 4635 LASER PRINTING SYSTEM LPS PRODUCT REFERENCE 1-7

Page 21

4635 LPS OVERVIEW

4635 LPS features

Listed below are features of the 4635 LPS.

LPS connection • Online interface for all IBM systems which support the

channel-attached 3811/3211 or 4245 interface

• Offline interface for any 9-track (1600/6250 bpi) or 18-track

cartridge tape conforming to one of the following formats:

— American National Standards Institute (ANSI)

— IBM (OS/VS/370, OS/360, DOS/VS/370. DOS/360/370)

— Burroughs (MCP 2500-4700, 6700)

— Honeywell (OS 200/2000, OS 200/6000 series)

— Sperry/Univac Series 70 (1100-OS standard files

— DEC (RSX-11)

— CDC (external format)

— NCR (Century-B1)

— Tape input codes: EBCDIC, ASCII, BCD

— Interpress on tape

— Univac (SDF-formatted tapes)

— ICL (2900 VME/B)

• Dynamic Document Interface (DDI) for network connected

devices sending Page Description Language (PDL), LCDS

print data, or Interpress data to the shared disk subsystem.

• Ethernet interface for network-connected devices sending

the XNS protocol.

Refer to the “Options” section of this chapter for more

information.

System controller • PC UI (refer below) or multinational terminal (non-U.S.

market option)

• One 651 MB unformatted system disk standard; up to three

additional optional disks (651 MB unformatted) available

• 1024K words of control memory

• 32 Mbits of font memory; expandable to 128 Mbits

• 5.25-inch floppy disk drive (optional Media Conversion Kit)

• Quarter-inch cartridge tape drive (QIC); up to 320 MB

capacity in streaming mode; quarter-inch ANSI (standard)

• Front loading 9-track (1600/6250 bpi) magnetic tape drive

(requires optional peripheral cabinet)

• Xerox 18-track cartridge tape drive; read/write capability for

IBM- and ANSI-compatible half-inch tapes in the 18-track IBM

3480 data format (requires optional peripheral cabinet).

PC UI • IBM-compatible 486 PC hardware; includes mouse pointing

device, 4 MB memory, 80-MB hard disk, 3.5-inch floppy disk

drive, 14-inch color monitor, multinational keyboard

• Color graphic windows and icons

• Full text editor allows you to perform complete textual

editing tasks (such as moving, searching and replacing,

1-8 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 22

adding and deleting text, and so on) on the entire file, within

a window environment

• File transfer provides a two-way file transfer between the PC

UI floppy or hard disk drive and the system controller hard

disk

• Start command library stores often-used start commands for

easy selection with mouse; no need to key in start

commands repeatedly

• Command line mode accessible from PC UI windows

• Console logging allows you to print, display, or save LPS

activity record for tracking or service purposes

• Multinational language and feature support.

Printer • Xerographic engine

• Laser raster scanning

• Optional bar code reader

• Rated speed of up to 135 pages per minute (up to 13,800

lines per minute) simplex; up to 68 pages per minute duplex

(with the optional Paper Feeding Enhancement Kit installed,

the rated speed for simplex is 154 pages per minute)

4635 LPS OVERVIEW

• Multiple-pitch feature allows the printer to change between

five pitch modes (from 3 pitch to 8 pitch), depending on the

paper size

• 300 spi input data interpolated to produce 600 spi output

print resolution

• Prints on front and back side (duplex) of paper under

software control

• Page inversion printing that allows the system to invert the

image on a physical page by 180 degrees

• Printer control console with color touch screen graphically

displays printer jam clearance information and allows control

of paper loading/unloading

• Stop, continue, and print sample buttons on printer control

console

• 100-sheet sample print tray using 20-pound/75-gsm bond

• Feeder trays:

Main tray 1 (Main) = 1100-sheet, 20-pound/75-gsm

paper

Auxiliary tray (tray 2) = 600-sheet, 20-pound/75-gsm

paper

• Feeder/stacker modules:

Each high-capacity = 2600 sheets of 20-pound/75feeder (HCF) tray gsm paper

(two standard and

two optional)

Each high-capacity = 2500 sheets of 20-pound/75stacker (HCS) bin gsm paper

(two standard and

two optional)

XEROX 4635 LASER PRINTING SYSTEM LPS PRODUCT REFERENCE 1-9

Page 23

4635 LPS OVERVIEW

• Attention light, located on top of the inverter-feeder/stacker

module, alerts operator when printer needs attention

• Attention alarm, located within the printer, alerts the operator

when the printer needs attention

• Screen saver on the printer monitor

Paper handling • 16-pound bond to 110-pound index/60-gsm to 200-gsm, cut-

sheet paper, colored, preprinted, predrilled, or preperforated

paper

• Variable paper sizes such as A3 (11.69 by 16.54 inches/297 by

420 mm, 11 by 17 inches/297 by 432 mm), B4 (10.12 by 14.3

inches/257 by 363 mm), and B5 (7.17 by 10.12 inches/182 by

257 mm)

• Transparencies, high-speed label stock, oversized covers, tab

stock, and other specialized application materials

• Software-controlled paper stock management with four

feeder trays

• Waste management and audit logging that allow more

control of sensitive paper stocks by increasing the amount of

information available with regard to how many sheets were

fed from which tray as well as the final destination of the

sheets.

Forms • Electronically created and stored at LPS or host

• Changeable on a page-to-page basis

• Functionally compatible with Xerox 9790/8790/4090/4050 LPS

forms, logos, and signatures

• Electronic form and variable data printed at the same time for

accurate registration

• Multiple forms per page with Interpress and RIP options

• Preprinted forms.

Fonts • Proportional or fixed character spacing

• Variable character size of 3 to 36 points

• Spacing of 4 to 30 characters per inch (cpi)

• Up to 128 fonts per page from extensive library of standard

and optional fonts

• 300 dots per inch (dpi) font data interpolated to produce 600

spi print resolution

• Logo and signature fonts

• Multinational character set

• Loadable from host, magnetic tape, or cartridge tape

• 32 Mbits font memory; expandable to 128 Mbits

• Selectable on a character-to-character basis.

Printed format • Variable spacing of 3 to 18 lines per inch (lpi)

• Spacing of 4 to 30 characters per inch (cpi)

1-10 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 24

• Landscape or portrait orientation

• Up to 38K alphanumeric characters per 8.5 by 14-inch/216 by

356 mm page total variable density

• 252 maximum lines per 8.5 by 14 inch/216 by 356 mm

portrait page; 198 (5 points, 18 lpi) maximum lines per 8.5 by

11-inch/216 by 279 mm landscape page

• Up to 150 lines with 132 characters per line on 8.5 by 11inch/216 by 279 mm landscape page

• Up to 16 images per page; over 16 images per page and

vector graphics capability with Interpress and RIP

• Multiple logical pages on a physical page

• Simplex or duplex printing.

Types of output • Interspersed reports

• Stacked reports

• Multiple sets

• Offsetting

4635 LPS OVERVIEW

• Report and job accounting

• Collated or uncollated.

XEROX 4635 LASER PRINTING SYSTEM LPS PRODUCT REFERENCE 1-11

Page 25

Page 26

LPS overview

2. Basic concepts

This chapter introduces basic concepts associated with a Xerox

Laser Printing System (LPS). Major sections in this chapter cover

the following topics:

• LPS overview

• LPS production process overview

• Fonts.

The 4635 LPS provides innovative solutions for a variety of

business requirements. It consists of two separate units:

• System controller

• Printer.

Figure 2-1 shows the 4635 LPS with the optional bar code

device. Refer to the “4635 LPS hardware components” chapter

for further information on available options.

Figure 2-1. 4635 Laser Printing System

1. System controller

2. Printer

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 2-1

Page 27

BASIC CONCEPTS

System controller

The system controller contains the input subsystem and the

control subsystem electronics.

The input subsystem provides interfacing capability (online,

offline, Ethernet, and Dynamic Document Interface (for DEC, PC,

MAC, and UNIX LAN connectivity) for a variety of input sources

(host, magnetic tape, workstations, and graphic scanners).

Note: Your quarter-inch cartridge tape and floppy disk drives are

not input sources for print jobs (refer to the “4635 LPS hardware

components” chapter).

The control subsystem performs all data handling, formatting,

buffering, and operational control of the system. It also provides

operator control through the LPS terminal or PC User Interface

(UI). Refer to the “4635 LPS hardware components” chapter for

more information on system controller components and these

subsystems.

LPS interfaces

The following LPS interfaces are available to connect a variety of

input sources to the LPS:

Offline interface The offline interface permits input from a computer-prepared

magnetic tape which is loaded onto the magnetic tape drive.

The 9-track and 18-track magnetic tape drives are the optional

offline interfaces available for the 4635 LPS. Refer to the “4635

LPS hardware components” chapter for more information.

Online interface The online interface permits input from a channel-attached host

computer.

Ethernet interface The Ethernet interface, using the host interface processor (HIP)

task, permits input from workstations or graphic scanners on a

shared or an unshared, but accessible, network.

DDI interface The Dynamic Document Interface (DDI) enables communication

between a 4635 LPS and network via a shared disk mechanism

over a SCSI bus. Refer to the Xerox Dynamic Document

Interface Operator Guide for information regarding the DDI.

LPS system disk storage and memory

The system disks store the operating system software (OSS) as

well as the system resources (fonts, forms, and graphics) that are

to be loaded into memory for use during input processing. Refer

to the “LPS software components” chapter for more information

on OSS.

2-2 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 28

Printer

BASIC CONCEPTS

The printer contains the imaging, xerographic, and output

subsystems.

Imaging subsystem

The imaging subsystem accepts a formatted page of data from

the system controller (forms and graphics have already been

merged) for the xerographic process:

Xerographic subsystem

One of the important keys to LPS print quality lies in the

xerographic process itself. The print image produced by the dry

ink is very dark to create more contrast between the printing and

the page, making images easier to read.

The following steps describe the xerographic process:

1. A band full of video data (1s and 0s) is transferred from the

band buffer to the laser scanner.

2. The laser beam moves across the surface of the

photoreceptor belt based on the value of the incoming bit (1

or 0), producing a latent image.

In this step, a charge is applied to the surface of the

photoreceptor belt. The surface is discharged when it is

exposed to the laser beam, thus creating a pattern of dots

corresponding to the page that is to be printed.

3. The photoreceptor belt is then exposed to dry ink. The dry

ink clings to the pattern of dots corresponding to the page

that is to be printed.

4. A sheet of paper traveling along the paper path is brought

into contact with the surface of the photoreceptor belt. The

dry ink is then transferred from the photoreceptor belt onto

the paper.

5. The paper carrying the pattern of dots passes through a

fusing mechanism that permanently affixes the dry ink to the

paper.

6. The finished page is deposited in the output tray or bin. The

data from that page is erased from memory. The

photoreceptor belt is then cleaned and prepared for the next

page.

Resolution An LPS imaging system converts a character from digitized form

into a printed image composed of tiny dots. These dots are so

small and close together that they appear to form solid black

areas. Image clarity is determined largely by the resolution or the

number of dots per inch printed. Within the 4635 LPS Reference

Set, the terms spots, dots, and pixels are used interchangeably.

The 4635 accepts 300 dots per inch (dpi) print data and images

and electronically modifies them to produce 600 dpi print

resolution. 600 dpi input print data is not accepted by the 4635

for printing. References to 300 dpi or 600 dpi apply to both

coordinate axes (300 by 300 dpi or 600 by 600 dpi).

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 2-3

Page 29

BASIC CONCEPTS

LPS production process overview

Output subsystem

The output subsystem provides paper stacking, report collating,

and sample print capabilities.

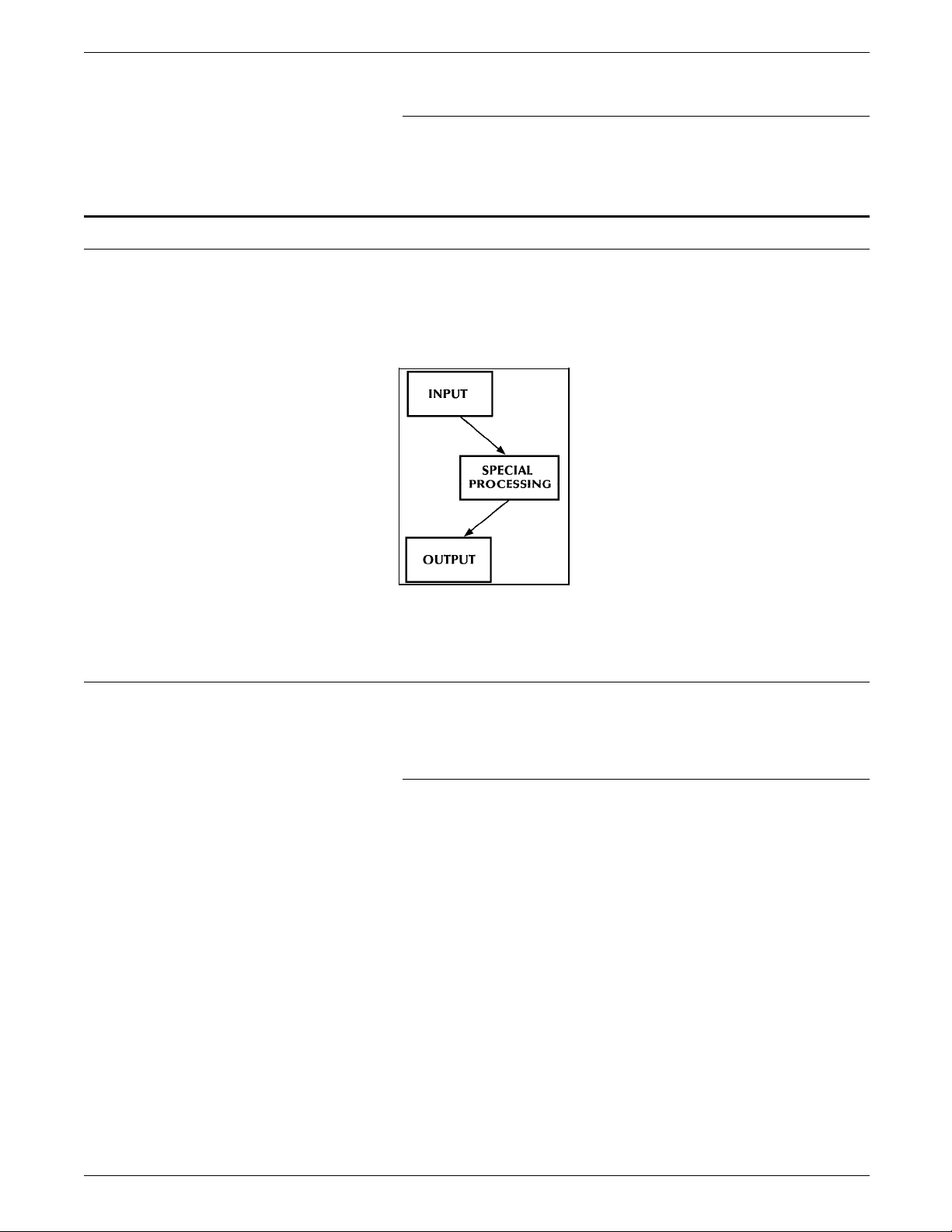

As illustrated in figure 2-2 below, the process of producing a job

on an LPS can be broken down into three distinct phases: input,

special processing, and output.

Figure 2-2. Basic processing flow

Input

Each phase is described in the text that follows.

The input phase of job production begins with the collecting and

inputting of data using one of the following sources.

Sources of input for the LPS

Several data input methods are available, as shown in figure 2-3.

2-4 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 30

Figure 2-3. 4635 input options

BASIC CONCEPTS

Online The channel-attached host computer input is received by the LPS

online interface. In an online environment, the system controller

is physically wired to the host computer. The host computer

“thinks” it is communicating with an IBM 3211 line printer and an

IBM 3811 printing system controller, or an IBM 4245 line printer.

DDI interface The Dynamic Document Interface (DDI) enables communication

between a 4635 LPS and network via a shared disk mechanism

over a SCSI bus. Refer to the Xerox Dynamic Document

Interface Operator Guide for information regarding the DDI.

Offline Magnetic tape input (9- or 18-track) is received by the offline

interface. The LPS Tape Formats Manual describes the tape

format and encryption schemes which a Xerox LPS recognizes.

Ethernet Input from workstations, such as the Xerox 6085, and graphic

scanners, such as the 7650 Pro Imager (using XPIW), is received

by the Ethernet interface using the HIP task.

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 2-5

Page 31

BASIC CONCEPTS

Ethernet is the Xerox local area network (LAN) which allows data

to be transmitted by cable from one device to another on a

shared or an unshared, but accessible, network.

Types of data

Data is created at one of the above sources and transmitted to

the LPS. As mentioned previously (refer to the “LPS overview”

section in this chapter), the system controller receives the

incoming data using one of the interfaces for processing. If the

input is print data, a stream of data is sent to the printer for

imaging. If the input is nonprint data, it is stored on the system

disks.

The following types of data can be printed by an LPS:

• Variable data

• Fixed (forms) data

• Graphic data (usually merged with variable data or form data).

Variable data Variable data changes from page to page; for example, the text

in this document or the numbers in a financial report.

Fixed data Fixed (forms) data (FRM file) remains constant from page to page

(for example, letterheads and column headings). Forms data

usually refers to information found on preprinted forms or

overlays.

Note: A host-resident forms design software package, such as

HFDL, is required for form generation at a host.

Any form suitable for computer printout can be described and

entered into system storage. Once stored on the system, a form

can be activated by referencing the form's name in the job

source library (JSL) file or job descriptor entry (JDE).

All Xerox laser printing systems have as a standard feature a line

editor utility for the creation and modification of program source

files (FSL and JSL extension files). Refer to the Xerox 4635 LPS

Operations Reference for more information on the LPS Editor.

Forms are entered into the system as data using the LPS Editor.

They are described using forms description language (FDL)

commands to design the form for variable data. These

commands create what is referred to as a forms source library

(FSL) file which, when compiled, becomes an FRM file. Refer to

the Xerox LPS Forms Creation Guide for more information on

creating electronic forms.

Graphic data Graphic data (IMG file) refers to digitized images (both line art

and continuous tone images) that are to be merged with variable

or forms data. Sources of graphic data include (but are not

limited to): (1) graphic data generated by XPPI/XDGI host-resident

software, and (2) scanned images from the Xerox 7650 Pro

Imager (using XPIW).

Special processing

Special processing features distinguish the Xerox LPS from an

impact printer. By using commands such as RFEED, ROFFSET,

and RPAGE you can specify that certain logical functions

2-6 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 32

Output

BASIC CONCEPTS

including: switching paper trays, offsetting certain pages or

logically repositioning a page, be performed during the printing

process. Refer to the Xerox 4635 LPS PDL/DJDE Reference for

more information on these command functions.

DJDE A Dynamic Job Descriptor Entry (DJDE) command enables you to

modify the printing environment dynamically. These commands

are inserted into the input data stream to modify command

characteristics of the existing JDE. DJDEs can take effect on a

report-to-report, page-to-page, and record-to-record basis. Refer

to the Xerox 4635 LPS PDL/DJDE Reference for more

information.

CME A Copy Modification Entry (CME) command enables you to

replace certain parts of a report with predefined static data on

selected copies or to specify font changes within the variable

data. Refer to the Xerox 4635 LPS PDL/DJDE Reference for more

information.

The final production phase is output. The Xerox LPS provides

powerful finishing and disbursement features. You can have a

true cover-to-cover printing process on any job. This means that

an inventory stock report job could have:

• Blue card stock front cover, with the title in a 24-point bold

font

• Forty-nine pages of equipment inventory, with the last page

designed to summarize totals

• Thirty-seven pages of equipment description, with pricing

information removed and a shaded grid filling all page

columns

• A matching blue card stock back cover printed on the

reverse side with “END OF REPORT” in a 14-point bold font.

Each copy of the inventory report can be offset in a stacker bin

(no offsetting in the sample tray) for easy identification, with a

routing sheet on top of each offset stack which contains such

information as “Jones and Smith Supplies, Inc.” This particular

feature is useful when individual copies must be separated for

binding or distribution to different groups. By adding the

optional bypass transport and a third-party finisher to your 4635

LPS, you expand your finishing choices for your report to include

options such as making it into a booklet and shrink wrapping it.

Job source library (JSL) files

Print description language (PDL) commands are used to describe

the data layout and provide instructions for data placement on a

page with or without an FDL-created form. The JSL file contains

PDL statements defining the format of the input, processing

requirements, and the format of printed output. When the JSL

file is compiled, it is referred to as a job descriptor library (JDL)

file and is referenced for printing a job.

Within a JDL file, there may be one or more unique definitions

for different processing features, output formats, and tape

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 2-7

Page 33

BASIC CONCEPTS

Fonts

formats. Each set of unique definitions represents a job and is

called a JDE or a job.

A JDL (compiled JSL) file containing printing instructions for the

LPS is required to print any job on any configuration. Many

specialized functions can be accomplished with PDL statement

commands. Refer to the Xerox 4635 LPS PDL/DJDE Reference

for specifics.

Several basic JSL files are provided with the OSS; for example,

ENET.JSL is provided for printing Ethernet jobs, ONLINE.JSL is

provided for printing online jobs, a XEROX.JSL is provided for

printing magnetic tape jobs, and so on. To meet specific

application needs, any OSS-supplied JSL can be copied and

modified. All Xerox LPSs have as a standard feature the LPS

Editor utility for the creation and modification of program source

files (FSL and JSL extension files).

A font is a character set which has a unique typestyle, type size,

and orientation. Both fixed and proportionally spaced fonts are

available for use on an LPS. Each font character occupies an area

called a character cell. All character cells in a fixed font are the

same width, while character cells in a proportional font vary in

width, as shown in figure 2-4.

Figure 2-4. Character spacing

Because the length of a line printed with a proportional font is

relatively unpredictable, fixed fonts are used for variable data on

a report to avoid overprinting of forms by variable data.

Proportional fonts are normally used for forms data, such as,

titles, headings, and so on. A business letter is an example of

the use of proportional fonts for variable data. The difference in

line length is illustrated in figure 2-5.

Figure 2-5. Character spacing examples

2-8 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 34

BASIC CONCEPTS

Fonts are available in various typefaces (such as, OCR and Titan),

sizes, styles (such as, serif and sans serif), and weights (such as,

medium and bold). The LPS Standard Font Library Font User

Guide lists the standard fixed and proportional fonts.

In addition to typeface, style, and size, a font can be defined by

its orientation:

• Landscape

• Portrait

• Inverse landscape

• Inverse portrait.

Refer to the Xerox 4850 HighLight Color and 4135 Laser Printing

Systems Font User Guide for specific font information, the Xerox

LPS Forms Creation Guide for using fonts in a form, and the

Xerox 4635 LPS Operations Reference for information on Font

Editor keyword commands (used to create source font files from

existing licensed and non-licensed font files).

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 2-9

Page 35

Page 36

Major components

3. 4635 LPS hardware

components

The 4635 Laser Printing System (LPS) consists of two separate

units:

• System controller

• Printer.

Figure 3-1 shows the 4635 LPS with the optional bar code

device.

Figure 3-1. 4635 Laser Printing System

1. System controller

2. Printer

System controller hardware components

The system controller components are the system disks, the

system controller panel, the PC user interface (PC UI), the

quarter-inch cartridge (QIC) tape drive and optional floppy disk

drive. A 9-track magnetic tape drive and an 18-track cartridge

tape drive are available as options and are housed in the

peripheral cabinet.

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 3-1

Page 37

4635 LPS HARDWARE COMPONENTS

Figure 3-2 shows the 4635 LPS system controller with the

cartridge tape drive.

Figure 3-2. 4635 system controller

1. System user interface (PC UI)

2. Operator control panel

. QIC tape drive

3

Quarter-inch cartridge tape drive The standard QIC tape drive (up to 320 MB in streaming mode;

quarter-inch ANSI) provides an alternative source for the loading

and backing up of user files (extension files such as .FRM) and

fonts to and from the system disk. Disk save and restore (DSR)

and system generation (sysgen) functions can be performed from

the quarter-inch tape drive. It is not an input source for print

jobs.

Floppy disk drive The optional floppy disk drive is located in the front panel of the

system controller. It provides an alternative way of backing up

and restoring system controller rigid disk files.

System disks One 651 MB (unformatted) fixed system disk is provided as a

standard feature. It resides inside the system controller and

stores the operating system, fonts, forms, and general user files

for the 4635. Optionally, up to three additional system disks

(each 651 MB unformatted) can be installed, depending on

storage needs.

3-2 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 38

4635 LPS HARDWARE COMPONENTS

System controller panel As shown in figure 3-3, the system controller is powered on or

off, booted, and switched between local and remote using the

buttons on this panel.

Figure 3-3. System controller panel

1. Power On switch

2. Power Off switch

3. Power On indicator

4. Boot switch

5. Remote switch and indicator

6. Local switch and indicator

PC UI Your 4635 LPS has a PC UI connected to the system controller.

The PC UI is an IBM-compatible Pentinum-based personal

computer (PC) with a 100 MB or larger hard disk, 3.5-inch floppy

disk drive, keyboard, color monitor, mouse, and a mouse pad.

The PC UI allows you to communicate with the 4635 LPS, to start

and monitor print jobs. Tasks are performed through a dynamic

set of windows and graphic objects displayed on the PC UI

screen. Windows and options are selected with the mouse

pointing device or by pressing certain keys on the keyboard.

You can also key in commands through a command line window

on the PC UI display screen.

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 3-3

Page 39

4635 LPS HARDWARE COMPONENTS

Figure 3-4 shows the 4635 LPS PC UI.

Figure 3-4. PC UI

As shown in figure 3-5, the optional peripheral cabinet houses

the 9-track magnetic tape drive and 18-track cartridge tape drive.

Figure 3-5. Optional peripheral cabinet with 9-track and 18-

track tape drives

1. 9-track magnetic tape drive

2. 18-track cartridge tape drive

9-track magnetic tape drive The 9-track magnetic tape drive is optional. It provides an offline

capability for inputting data to the 4635. The 9-track can also be

used for DSR or sysgen. Refer to the Xerox 4635 LPS Operator

Guide for more information. The “Options” section of the “4635

LPS overview” chapter describes supported tape formats.

3-4 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 40

18-track cartridge tape drive The 18-track cartridge tape drive is an alternative to the 9-track

Printer hardware components

4635 LPS HARDWARE COMPONENTS

magnetic tape drive or an additional offline capability for the

system. It reads and writes IBM- and ANSI-compatible half-inch

tape in the 18-track IBM 3480 data format, and has an option

allowing it to read and print from the IBM 3490 format. Like the

9-track magnetic tape drive, the 18-track can be used as a source

for the loading and backing up of user files (extension files such

as .FRM) and fonts to and from the system disks as well as

providing an input source for print jobs. The 18-track tape drive

can also be used for DSR or sysgen. The “Options” section of

the “4635 LPS overview” chapter describes supported tape

formats.

Figure 3-6 shows the components of the 4635 printer module.

Figure 3-6. 4635 printer

Note: Configuration shown in Figure 3-6 does not depict the

optional Bypass Transport, Input Enablement feature or Bar

Code Reader devices.

1. Processor feeder trays

2. Inverter-feeder/stacker module (containing inverter, highcapacity feeder, and high-capacity stacker)

3. Feeder/stacker module (containing high-capacity feeder and

high-capacity stacker)

4. Purge tray

5. Attention light

6. Sample tray

7. Printer control console

Processor feeder tray 1 Located in the main part of the printer, the capacity of feeder

tray 1 is 1,100 sheets of 20-pound/75-gsm paper.

Processor feeder tray 2 The capacity of feeder tray 2 is 600 sheets of 20-pound/75-gsm

paper.

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 3-5

Page 41

4635 LPS HARDWARE COMPONENTS

High-capacity feeders (HCF)—

trays 3, 4, 5, and 6 Each HCF can hold up to 2,600 sheets of 20-pound/75-gsm

(5 and 6 optional) paper as small as 7 by 10 inches and including large paper sizes

High-capacity stackers (HCS)—

bins A, B, C, and D Each HCS can hold up to 2,500 sheets of 20-pound/75-gsm

(C and D optional) paper, if a stacking container is not used. Printed sets can be

Trays 1 and 2 can handle paper sized from 8 by 10 inches to 9 by

14 inches/203 by 254 mm to 229 by 356 mm.

such as 11.69 by 16.54 inches (A3), 11 by 17 inches (297 by 432

mm), and 10.12 by 14.33 inches (B4).

offset in the HCS for easier separation of reports.

Sample tray The capacity of the sample tray is 100 sheets of 20-pound/75-gsm

paper.

Purge tray The purge tray located at the top of the last feeder/stacker

module is where waste sheets are sent when cleared from the

printer. The purge tray can hold 100 sheets of paper.

Printer control console The printer control console located on top of the printer

contains the continue, stop, and sample buttons. The console

has a color monitor with a touch-sensitive screen which displays

detailed graphics showing jam clearance instructions and

feeder/stacker status. Printer tasks, such as lowering feeder trays

and stacker bins, can be performed by touching areas of the

console screen.

Optional bypass transport The ability to increase your production capability by adding

finishing devices to your 4635 is made possible by the Bypass

Transport option. Finishers give you the ability to choose a wide

range of finishing options, such as shrink wrapping and stitching.

The bypass transport processes simplex and duplex jobs and

accepts any type of paper that your 4635 LPS is capable of

handling (refer to the “4635 LPS overview” chapter).

Connected to the feeder/stacker, the bypass transport allows

finishing devices to interface directly with your 4635 LPS. It is

fully integrated into your 4635 LPS hardware and software

utilities, allowing you to select it at the UI or within your job

setup. The bypass transport meets the Xerox Document Feeding

and Finishing Architecture (DFA) Level 1 specifications.

Optional input enablement device The input enablement device is connected to the right side of

the feeder/stacker module and provides the means to add bulk

feeders to your 4635 LPS. Fully integrated into your 4635 LPS

hardware and software utilities, your input enablement device is

selectable at the UI or within your job setup.

Figure 3-7 shows the 4635 LPS with the optional bypass

transport.

3-6 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 42

4635 LPS HARDWARE COMPONENTS

Figure 3-7. 4635 LPS with optional bypass transport

As shown in figure 3-8, the printer control console is where you

perform many printer adjustments and select printer functions.

Figure 3-8. Printer control console

1. Brightness control thumbwheel. Use this thumbwheel to

adjust the brightness of the printer control console display.

2. Sample button. Press this button to cause a sample sheet of

the current print job to be sent to the sample tray.

3. Stop button. Press this button to stop printing.

4. Continue button. Press this button to resume printing.

5. Clear button. Select this button to clear fault messages.

6. Guarded Tools icon. This icon is reserved for the Xerox

service representative and operators who have completed

Advanced Customer Training (ACT).

7. Tools icon. Select this icon to display call for service

information and to adjust display features of the printer

control console (for example, alarm loudness).

8. Fault icon. Select this icon to display the Fault List screen.

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 3-7

Page 43

4635 LPS HARDWARE COMPONENTS

9. Printer icon. Select this icon to display the printer mimic.

(This is the default display on the printer control console.)

10. Language icon. Select this icon to choose the language for

the printer control console messages.

11. Message area, used as follows:

• Lines 1 and 2. These lines display the current status of

the printer, for example, READY.

• Line 3. This line displays messages concerning masked

conditions, such as low dry ink. These messages are

preceded by an asterisk.

• Line 4. This line displays messages that originate at the

system controller.

12. Area where the following icons appear:

Hint icon. This icon appears when a masked fault or

condition exists in the printer. (Refer to the Xerox 4635 LPS

Operator Guide, “Fault masking and the printer control

console” section.) The icon also appears on the PC UI.

Fault icon. This icon appears only when a fault exists in the

system that stops the printer or prevents it from printing.

The icon also appears on the PC UI.

ACT icon. This icon appears when a maintenance task

requiring an ACT trained operator must be performed. If you

have successfully completed ACT, either check the PC UI for

messages concerning the maintenance task or touch the

Guarded Tools icon to display the Guarded Tools screen. If

you are not an ACT trained operator, notify your lead

operator or an ACT trained operator at your site.

Note: The bypass transport is optional and appears on the

printer control console of those systems that are configured as

such.

Attention light

An attention light is mounted on top of the inverter module.

(Refer to figure 3-6.) The attention light can be enabled or

disabled. (Refer to the Xerox 4635 LPS Operator Guide for

instructions.) When enabled, the light has three states:

• Off. No printer problems exist that require your attention.

• Steady light. A situation exists that needs your attention

(such as a low dry ink condition).

• Flashing. The printer has stopped and your attention is

required immediately.

Attention alarm

An attention alarm is located within the printer. Like the

attention light, the attention alarm is enabled and disabled by the

operator (refer to the Xerox 4635 LPS Operator Guide). When

enabled, the alarm has two states:

• Off. No printer problems exist that require your attention.

• Beeping. The printer has stopped and your attention is

required immediately.

3-8 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 44

LPS operating system

4. 4635 LPS software

components

This chapter describes the software components associated with

the 4635 Laser Printing System (LPS). The major topics are as

follows:

• LPS operating system

• Operating System Software (OSS) functional description

• Optional host-resident software packages.

The 4635 System Software consists of the Xerox OSS, System

User Interface (UI) Software, User Interface Dialog, and the

Printer Software. The OSS is the primary software; however,

each software type working in conjunction controls and monitors

the operation of your 4635 LPS.

The LPS OSS, like any other operating system, is a set of

programs which allow the printing system to manage its own

resources. Xerox distributes new versions of the 4635 OSS on 9track, 18-track cartridge, or quarter-inch cartridge tape. The OSS

tape contains:

• New system files

• A system generation processor program that is used to load

the new system files onto the system disks and configure

them for a particular system

• A concatenated version of the system files and system

generation processor which is used for performing an online

system generation (wherein the processor and files are

downloaded to the printing system from a host computer)

• Patch files which are used to modify the new system files for

optimal performance.

Refer to the “System software functional description” section of

this chapter for more details on OSS contents.

The process by which the OSS is installed, upgraded, or modified

is called system generation or sysgen. There are three types of

sysgens that can be performed: mini, update, or full.

• In a mini sysgen, an existing operating system is modified in

a way that does not require new system file input or

patching. For example, an existing feature is deactivated or

reactivated, or a specification is changed that is independent

of the operating system files.

• In an update sysgen, an existing operating system is

upgraded to include new features or is replaced with a new

version of the system.

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 4-1

Page 45

4635 LPS SOFTWARE COMPONENTS

During this process, some or all of the existing system files

on the system disks are replaced with new files; user files are

not affected.

• In a full sysgen, a new operating system is built on empty

system disks; that is, new or used disks that have been

cleared and formatted prior to sysgen.

Complete instructions for each of these sysgens are contained in

the Xerox 4635 LPS System Generation Guide.

The UI Software consists of two 3.5-inch floppy diskettes (one

supports the system UI Software, and one supports the UI

Dialog). The Printer Software also consists of several 3.5-inch

floppy diskettes. Refer to the “System software functional

description” section for further information on the System UI

Software, UI Dialog, and Printer Software.

Operating System Software functional description

The LPS OSS, or system controller, runs both background and

foreground processing. All Xerox LPS systems are run by

basically the same software. The OSS is delivered for installation

and sysgen on 9-track magnetic tapes, and 18-track or quarterinch cartridge tapes. The major utilities or “tasks” run by the

system controller are shown in their hierarchical relationships in

the chart below.

Figure 4-1 illustrates the hierarchy of the major LPS processing

tasks. Following the figure is an overview of each task.

Figure 4-1. Major LPS processing tasks

Operating System Executive (OSEXEC)

File Control Program (FCP)

Operator Communication Subsystem (OCS)

Utilities Editor FDL Processor

Diagnostics Font Editor PDL Processor Output

Input

DJD IPD RPT

Host Interface Processor (HIP)

4-2 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 46

4635 LPS SOFTWARE COMPONENTS

Operating system executive task The OSEXEC task is always running. It interfaces with the LPS

hardware and logs hardware errors. In addition, it queues

devices, manages resources, establishes priority for software

tasks, and schedules processing.

File control program The FCP or FMS task manages disk resources. It manages and

allocates all disk space, creates all disk files, and accesses disk

files.

Operator communication

subsystem The OCS task acts as an interface between the operator and

software tasks by receiving input from and displaying messages

to the operator. OCS also interfaces between system tasks.

Diagnostic tasks The OSDS runs either under the OSEXEC task or from offline

sources. It controls the processing for the PROBLEM command.

Diagnostic support is also provided to your service technician by

the stand-alone field engineering software (SAFES) task.

System utilities The LPS has many utility programs which run under the OSEXEC

task that provide maintenance services such as: backing up the

system (DSR); tracking the unusable sectors on disks (FCHECK);

assigning a maximum size to the working print file

(REALLOCATE); eliminating wasted space on the disks

(COMPRESS); and making used space available again (PURGE).

Editor task The Editor task creates and modifies disk files. When you save a

work file, it stores the contents permanently on the disk. It

sends files to print; sends FSL and JSL files to be compiled;

directs CMD files to execute; and manipulates temporary (TMP),

miscellaneous (MSC), patch (PCH), and data (DAT) files.

Font Editor task The Font Editor task creates and modifies font files. The font

files are stored permanently on the disk when you save them.

Input task The input task reads in print job data, creates a job control block

file, and delivers job messages to the operator. Then the input

task unpacks and converts the data; selects and deletes blocks or

records; records any special processing instructions (for page

offsets, DJDE records, CMEs); and records the disk addresses of

the font, form, and image files used for the job. The result is a

page buffer, consisting of the variable data and print instructions

for the page, and the page log, consisting of tracking information

used to process the page.

Dynamic job descriptor task The DJD task compiles the Dynamic Job Descriptor Entries

(DJDEs) in the job stream. (The DJDEs give the printer

instructions for printing based on the result of true/false tests of

the data in the job stream.

Interpress decomposer task The IPD task translates input data sent in Interpress format into

ASCII raster format.

XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE 4-3

Page 47

4635 LPS SOFTWARE COMPONENTS

Output task The output task uses the page logs written by the input task to

load fonts in the font memory and variable data in the CD. It

causes paper to feed from the indicated tray and manages report

integrity with multiple checks. It sends the page buffer

information to the CD and coordinates the activity of the CD/IG

and RIP with the printer. In addition, Output manages delivery of

the printed pages to the correct bins and performs page recovery

if necessary.

Print description language compiler The PDL task loads the PDL compiler and looks in the JSL library

for the file to be compiled. Then it analyzes the JSL statements

and creates the object module (the JDL file).

Forms description language compiler The FDL task loads the FDL compiler and looks in the FSL library

for the file to be compiled. Then it analyzes the FSL statements

and creates the object module (the FRM file).

Host interface processor task The HIP task controls LPS communications with an online host.

It transfers SNA/SDLC or BSC files from the host to the LPS,

storing or printing them as directed. HIP also transfers files from

the host for storage and transfers Interpress files from a Xerox

Ethernet to the LPS for printing.

Report (RPT) task Works in connection with the Input task.

Printer Software

The Printer Software works in conjunction with the OSS (system

controller) to print your job. The system controller interprets the

user instructions contained in JDLs, DJDEs, and operator input, as

well as the data being printed on each page. The system

controller, driven by the OSS, sends this information to the

printer. Once the information reaches the printer, it is the Printer

Software that identifies the best way to carry out the task.

User Interface Software and User Dialog Software

As with the OSS and Printer Software, the System UI Software

and the User Interface Dialog interact together to control your

PC UI. Along with establishing and managing the

communication between the PC UI and the printer, the User

Interface Software displays the objects on the UI screen and

performs the actions input by the operator, as specified within

the UI Dialog.

Software

4635 LPS software features include:

• Interpress 3.0 Publication Set. Refer to the Xerox 4635 LPS

Operations Reference for additional information.

• Xerox Network Services (XNS) printing, filing subset for

printing, and clearinghouse services. Refer to the Xerox 4635

LPS Operations Reference for additional information.

4-4 XEROX 4635 LASER PRINTING SYSTEM PRODUCT REFERENCE

Page 48

4635 LPS SOFTWARE COMPONENTS

• Continuous printing even when excessive character and IG

local density stress conditions occur (Interpress only). Refer

to the Xerox 4635 LPS Operations Reference for additional

information.

• Cluster printing (user-defined logical grouping of trays).

Refer to the Xerox 4635 LPS Operations Reference and to

the Xerox 4635 LPS Operator Guide for additional

information.

• Printing of over 16 images on a page with Interpress and

raster image processor (RIP). Refer to the Xerox 4635 LPS

Operations Reference for additional information.

• Variable paper sizes up to the physical capacity of the feeder

trays: 7 by 10 inches to 14.33 by 17 inches (178 by 254 mm

to 279 by 432 mm, including A3, A4, B4, and B5). 7 by 10

inch thruput is enabled when the optional Paper Feeding

Enhancement Kit is installed. Refer to the “4635 LPS

edgemarking” section of this chapter for additional

information.