Xantrex Technology XDC 20-600, XDC 150-80, XDC 40-300, XDC 100-120, XDC 10-600 User Manual

...Page 1

XDC 6000 Watt and

12000 Watt Series

XDC 10-600

XDC 20-300

XDC 30-200

XDC 40-150

XDC 60-100

XDC 80-75

XDC 100-60

XDC 150-40

XDC 300-20

XDC 600-10

XDC 10-1200

XDC 20-600

XDC 30-400

XDC 40-300

XDC 60-200

XDC 80-150

XDC 100-120

XDC 150-80

XDC 300-40

XDC 600-20

Operating Manual

Digital Programmable

DC Power Supply

Page 2

Page 3

XDC 6000 Watt and 12000

Watt Series Digital

Programmable Power

Supply

Operating Manual

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products

from 50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells, microturbines,

and backup power applications in both grid-connected and stand-alone systems. Xantrex products include

inverters, battery chargers, programmable power supplies, and variable speed drives that convert, supply, control,

clean, and distribute electrical power.

Trademarks

XDC 6000 Watt and 12000 Watt Series Digital Programmable Power Supply is a trademark of Xantrex

International. Xantrex is a registered trademark of Xantrex In ternational.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are

used herein for identification purposes only.

Notice of Copyright

XDC 6kW and 12kW Series Digital Programmable Power Supply Operating Manual © July 2006 Xantrex

International. All rights reserved.

Exclusion for Documentation

U

NLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(

A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL

OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES,

WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF

THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE

USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH

STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY

CANNOT BE GUARANTEED. APPROVED XANTREX CONTENT IS CONTAINED WITH THE ENGLISH

LANGUAGE VERSION WHICH IS POSTED AT WWW.XANTREX.COM.

Date and Revision

July 2006 Revision A

Part Number

TM-XDOP-01XN

Contact Information

Telephone: 1 800 670 0707 (toll free in North America)

1 360 925 5097 (direct)

Fax: 1 800 994 7828 (toll free in North America)

1 360 925 5134 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

Page 5

About This Manual

Purpose

The purpose of this Operating Manual is to provide explanations and procedures

for installing, operating, maintaining, and troubleshooting the XDC 6000 Watt

and 12000 Watt Series Digital Programmable Power Supply.

Scope

The Manual provides safety guidelines, detailed planning and setup information,

procedures for installing the unit, as well as information about operating and

troubleshooting the unit.

Audience

This manual is designed for users who understand basic electrical theory,

especially as applied to the operation of power supplies. This implies a

recognition of constant voltage and constant current operating modes and the

control of input and output power, as well as the observance of safe techniques

while making connections to the supply and any changes in settings.

iii

Page 6

Organization

This Manual is organized into five chapters and 5 appendixes:

Chapter 1, “About The XDC Power Supply”, Chapter 1 lists the features of

the XDC and shows diagrams of the front and rear panel.

Chapter 2, “Installation” Chapter 2 explains how to mount and wire the XDC

and also how to perform basic functional tests.

Chapter 3, “Operation” Chapter 3 explains how to power on and power off the

power supply. It provides information about configuring the power supply, and

also gives procedures for operating the supply via the front panel controls and

menu functions.

Chapter 4, “Remote Operation” Chapter 4 provides an overview of how to

use remote analog control, gives information on the setup and use of Multichannel

functionality and explains how to send commands to the power supply using the

SCPI programming language

Chapter 5, “Current Sharing” Chapter 5 explains what current sharing is, and

shows how to configure and operate units in current sharing mode.

Appendix A, “Specifications and Characteristics” Appendix A lists all of the

electrical, environmental and mechanical specifications of the XDC.

Appendix B, “Calibration (6000 Watt only)” Appendix B lists the calibration

procedures for the 6000 W unit. If you purchased a 12000 Watt unit, please

contact your supplier or Xantrex directly (see “Warranty” for contact

information).

Appendix C, “SCPI Command Reference” Appendix C provides a summary

of the Standard Commands for Programmable Instruments (SCPI) that are

supported by the this Programmable Power Supply.

Appendix D, “Error Messages” Appendix D lists all the error codes and their

meanings.

Appendix E, “GPIB” Appendix E describes the General Purpose Interface Bus

(GPIB) commands and lines supported by this model.

“Warranty and Product Information” This section explains the warranty and

provides information on returning your unit for service.

iv TM-XDOP-01XN

Page 7

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions that cou ld resul t in perso nal injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to the unit or

other equipment.

Important:

but not as serious as a caution or warning.

Related Information

You can find more information about Xantrex Technology Inc. as well as its

products and services at www.xantrex.com

These notes describe things which are important for you to know,

TM-XDOP-01XN v

Page 8

vi

Page 9

Important Safety Instructions

WARNING: High energy and high voltage

Exercise caution when using and calibrating a power supply. High energy levels can be

stored at the output voltage terminals on a power supply in normal operation. In addition,

potentially lethal voltages exist in the power circuit and on the output and sense

connectors of a power supply with a rated output greater than 40 V. Filter capacitors store

potentially dangerous energy for some time after power is removed.

WARNING: Limitations on use

The XDC is not intended for use in connection with life support systems or other medical

equipment or devices.

CAUTION

Operate the power supply in an environment free of flammable gases or fumes. To ensure

that the power supply’s safety features are not compromised, use the power supply as

specified in this manual and do not substitute parts or make any unauthorized

modifications. Contact the service technician for service and repair help. Repairs must be

made by experienced service technicians only.

CAUTION: For use as a battery charger

When you are using any of these power supplies for battery charging applications, it is

essential to provide an appropriately sized fuse or circuit breaker in series between the

power supply output and the battery.

Installation of a protector (fuse or DC circuit breaker) rated for about 115% of the

maximum current rating of the power su pply and designed specifically to interrupt the DC

voltage of the battery, will provide adequate reverse polarity current protection. Where

several power supplies are in parallel, it is best to fuse each one, rather than one large fuse

for all.

vii

Page 10

Approvals

Units bearing the c(CSA)us mark are certified by CSA to the following:

CAN/CSA C22.2 No. 1010.1-92 and CAN/CSA C22.2 No. 1010.1B-97 and to

ANSI/UL 61010B-1

Units bearing the CE mark meet the requirements of:

EMC Directive (standards EN50081-2 and EN50082-1) and Low Voltage

Directive (safety standard IEC 61010:1990 +A.1:1992 +A.2:1995).

FCC part 15 Class A limits for radio frequency emissions.

Canadian EMC standard ICES-001, Class A limits.

viii TM-XDOP-01XN

Page 11

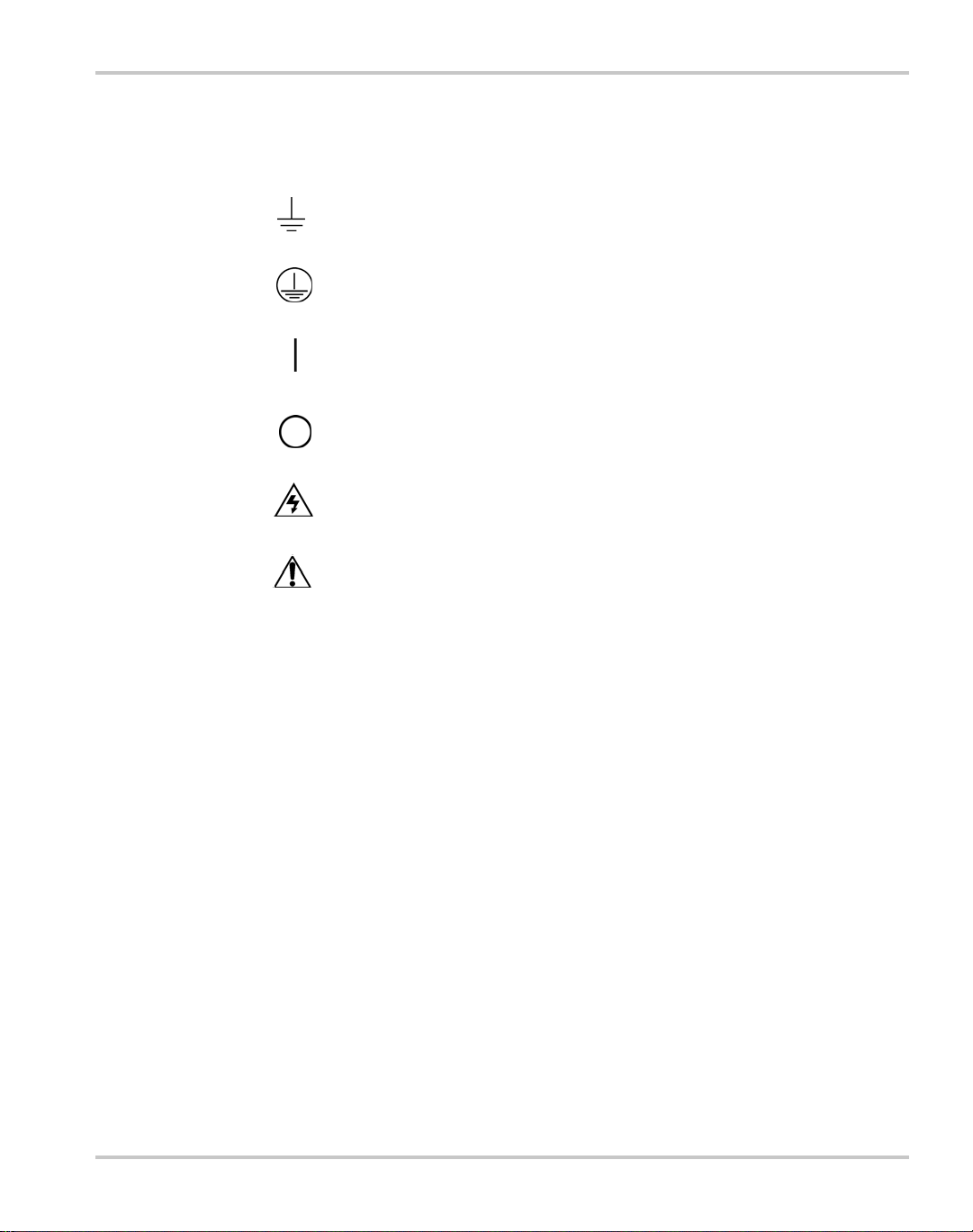

IEC Symbols Used in This Manual

Earth (Ground) Terminal

Protective Conductor Terminal

On (Supply)

Off (Supply)

Warning (Shock Hazard)

Caution (Check manual for specific information.)

TM-XDOP-01XN ix

Page 12

x

Page 13

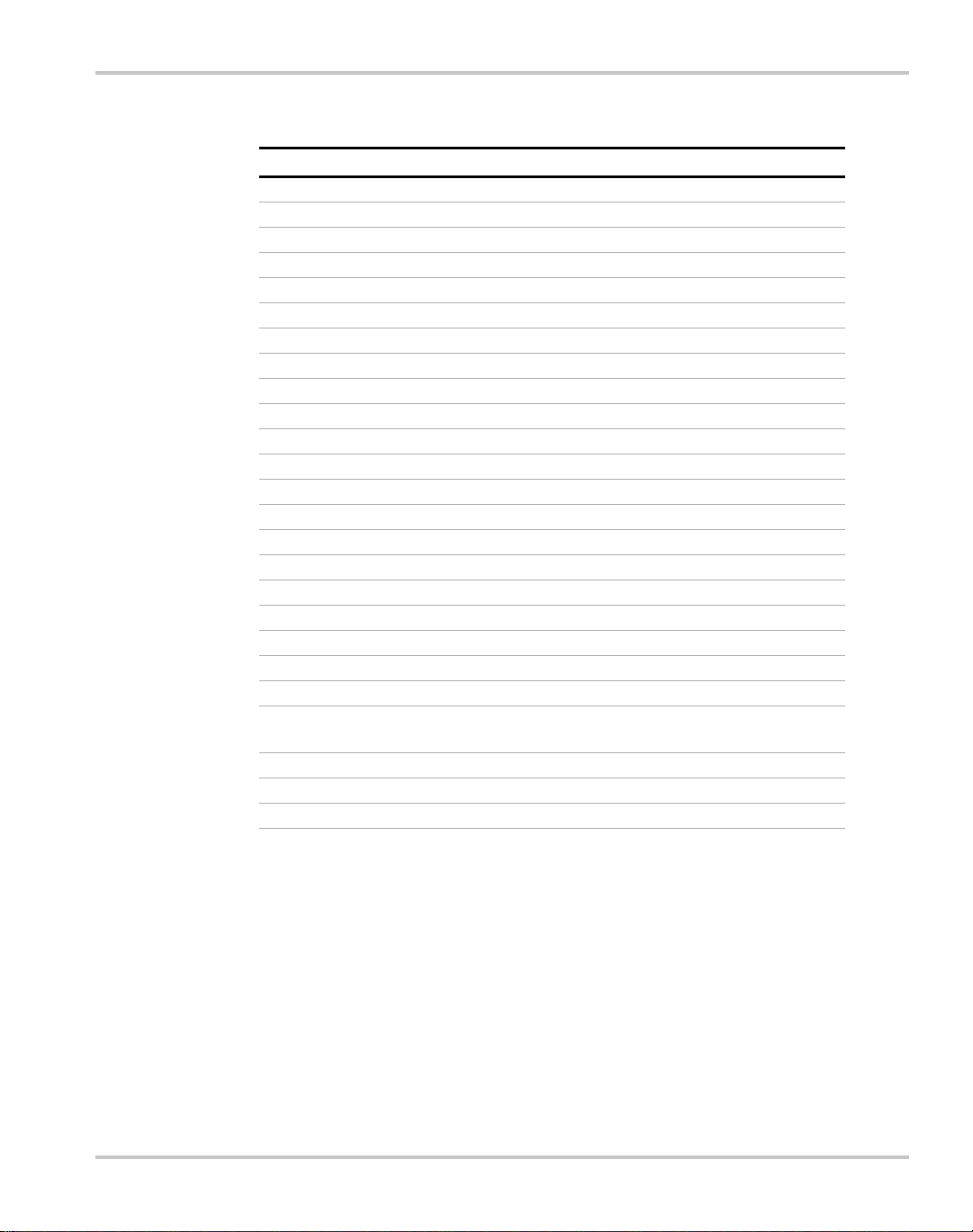

Contents

Important Safety Instructions

Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -viii

IEC Symbols Used in This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -ix

1

About The XDC Power Supply

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Front Panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Status Annunciators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–11

Overview of Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–12

Power ON - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–12

Control Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–12

2

Installation

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Basic Setup Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Inspection, Cleaning, and Packaging- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Initial Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Packaging for Shipping or Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Location, Mounting, and Ventilation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Rack Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Ventilation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

AC Input Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

AC Input Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

AC Input Wire - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

AC Wire Input Connection for 6000 W - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

AC Wire Input Connection for 12000 W - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Basic Checks or Self-Tests - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–13

Equipment Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–13

Display Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–13

Power ON Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–13

Voltage Mode Operation Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–14

TM-XDOP-01XN xi

Page 14

Current Mode Operation Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15

Load Wiring- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–16

Current Carrying Capacity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–16

Load Wiring Length for Operation with Sense Lines - - - - - - - - - - - - - - - - - - - - - - - - 2–16

Noise and Impedance Effects - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–17

Load Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Wire Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Isolation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Single Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

Multiple Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–19

Output Strain Relief/Cover - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–20

Remote Sensing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

3

Operation

Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–2

Powering ON the Power Supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–2

Powering OFF the Power Supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–2

Power Supply Operating States - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–3

Power Supply Regulation Modes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–4

Remote Control Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

Front Panel Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

Function Keys - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

Menu Navigation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–6

Top Level Menu Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–6

Control Knobs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Power Supply Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–8

Set Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–8

Set Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–8

Set Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–9

Turn Output On or Off - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–9

Set Output Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–10

Set Shutdown Recovery for AC Off and OTP - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–15

Respond to Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–16

Shutdown vs Protection Alarm - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–17

Set Up Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–18

Toggle Local/Remote - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–18

Select Remote Control Source - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–19

Configure Remote Control Source - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–20

Store User Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–21

Change Stored Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–22

xii TM-XDOP-01XN

Page 15

Recall Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–23

Read Error Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–26

Configure User Lines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–27

Configure Power ON Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–29

Factory Preset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–30

User Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–31

Last Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–32

Auto-Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–32

Program Auto Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–33

Programming a Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–33

Deleting a Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–36

Editing a Sequence Step - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–37

Inserting a Sequence Step - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–38

Deleting a Sequence Step - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–39

Editing Repeat Times of a Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–40

Editing Trigger Source of a Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–41

Using Auto Sequencing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–42

Configure Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–43

Lock Out Control Knobs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–44

Set V, I, and P Limits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–45

Slew Rate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–49

View Model Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–50

Default Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–51

View Power Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–51

Monitor Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–51

4

Remote Operation

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Making Connections for Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Remote Analog Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Analog Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Pin Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–6

Remote Interlock Using a Contact Closure - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–7

Configure Analog Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–8

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–8

SCPI - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–9

Using Remote Analog Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–10

Multichannel Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–11

Multichannel Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–11

CANbus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–11

TM-XDOP-01XN xiii

Page 16

Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–12

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–12

SCPI - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–12

Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–13

Using Multichannel Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–14

Multichannel Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–15

Multichannel Broadcast Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–15

Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–15

RS-232 Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–16

RS-232 Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–16

Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–17

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–17

SCPI - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–18

Using RS-232 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–18

GPIB Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–19

GPIB Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–19

Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–20

Front panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–20

SCPI - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–21

Using GPIB - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–21

SCPI Commands for Digital Interfaces - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–22

Set Up Power ON Defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–22

Factory Preset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–22

Last Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–23

User Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–23

Auto Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–23

Power On Output State - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–24

Reset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–24

Store User Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–25

Change Remote/Local Control of Power Supply - - - - - - - - - - - - - - - - - - - - - - - - - - -4–26

Enable Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–26

Program V,I,P - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–27

SCPI - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–27

Configure V, I, P Protection Limits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–29

Over-Voltage Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–29

Under-Voltage Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–29

Over-Current Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–30

Under-Current Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–30

Over-Power Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–31

Under-Power Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–31

Configure Other Protection Mechanisms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–32

xiv TM-XDOP-01XN

Page 17

Fold Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–32

Over Temperature Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–32

AC Off Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–33

Clear Protection Event - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–33

View Power Supply Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–33

Configure Auxiliary Status Lines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–34

Read Error Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–35

Triggering Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–36

Auto Sequencing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–37

Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–37

Editing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–37

Programming Sequences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–38

Select Sequence to Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–38

Editing the Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–38

Setting Sequence Repetitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–38

Selecting a Trigger Source - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–39

Editing Step Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–39

Deleting Sequences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–39

Auto Sequence Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–40

Select Sequence to Run - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–40

Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–40

Slew Rate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–41

Identification Query - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–42

Option Identification Query - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–42

SCPI Version Query - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–42

Status Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–43

OPERation Status Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–44

REGulating Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–47

SHUTdown Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–47

Protection SHUTdown Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–48

Remote CONtrol Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–49

Current SHare Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–50

QUEStionable Status Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–50

VOLTage Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–53

CURRent Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–53

POWer Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–53

TEMPerature Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–54

Standard Event Status Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–54

Status Byte - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–55

Error/Event Queue (ERR) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–56

Questionable Status Register Summary (QSR) - - - - - - - - - - - - - - - - - - - - - - - - -4–56

TM-XDOP-01XN xv

Page 18

Message Available (MAV) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–56

Standard Event Status Summary (ESB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–56

Master Summary Status (MSS) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–56

Request Service (RQS) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–57

Operation Status Register Summary (OSR) - - - - - - - - - - - - - - - - - - - - - - - - - - -4–57

Status Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–58

SCPI Status Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–58

IEEE 488.2 Status and Event Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–59

Operation Status Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–62

Regulating Sub-Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–63

Shutdown Sub-Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–64

Protection Shutdown Sub-Register Commands - - - - - - - - - - - - - - - - - - - - - - - - -4–65

Remote Control Sub-Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–65

Current Share Sub-Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–67

Questionable Status Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–68

Voltage Sub-Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–69

Current Sub-Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–70

Power Sub-Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–71

Temperature Sub-Register Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–72

5

Current Sharing

Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–2

Setting up Current Sharing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–3

Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–5

Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–6

CANbus Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–6

A

Specifications and Characteristics

Electrical Specifications—Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

AC Line Input Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

AC Line Input Voltage Operating Ranges - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

Output Performance Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–7

Environmental Specification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–12

Thermal Specification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–12

Humidity Specification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–12

International Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–13

Mechanical Specification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–14

Weight - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–14

Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–14

xvi TM-XDOP-01XN

Page 19

B

Calibration (6000 Watt only)

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Entering Calibration Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–3

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–3

SCPI - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–4

Security code - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Setup and Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–6

Front Panel Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–7

Output Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–7

Output Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–7

Analog Programming Interface 0-5V Range - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–8

Analog Programming Interface Voltage Programming Calibration - - - - - - - - - - - - B–8

Analog Programming Interface Voltage Readback Calibration - - - - - - - - - - - - - - - B–9

Analog Programming Interface Current Programming Calibration - - - - - - - - - - - - B–9

Analog Programming Interface Current Readback Calibration - - - - - - - - - - - - - - B–10

Analog Programming Interface 0-10V Range - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–10

Remote Interface Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–11

Output Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–11

Output Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–11

Analog Programming Interface 0-5V Range - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–12

Analog Programming Interface Voltage Programming Calibration - - - - - - - - - - - B–12

Analog Programming Interface Voltage Readback Calibration - - - - - - - - - - - - - - B–13

Analog Programming Interface Current Programming Calibration - - - - - - - - - - - B–13

Analog Programming Interface Current Readback Calibration - - - - - - - - - - - - - - B–14

Analog Programming Interface 0-10V Range - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–14

Exit calibration mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–15

Restore Factory Calibration- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–15

C

SCPI Command Reference

Codes and Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

IEEE 488.2 Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

SCPI Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

IEEE-488.2/SCPI Syntax and Style - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–3

Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–3

Units of Measure and Multipliers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–3

SCPI Command Hierarchy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–4

Using SCPI Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–5

Using Minimum and Maximum - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–6

Using Queries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–6

TM-XDOP-01XN xvii

Page 20

Terminating Characters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–7

Common Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–7

Parameter Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–8

SCPI Command Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–9

Notations Used in the Tables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–9

Expressions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–33

D

Error Messages

Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

Command Error List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

Execution Error List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–3

Device-Specific Error List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–5

Query Error List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–6

User Request Event - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–6

Operation Complete Event - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–6

Front Panel Error Codes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–7

CPU Error Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–7

Analog Programming Interface Error codes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–7

Auto Sequencing Error Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–7

CANbus Error Codes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–8

Multichannel Error Codes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–8

Current Share Error Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–9

E

GPIB

Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–2

Codes and Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–2

Message Terminators- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–2

Address Range - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–2

Primary Address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–2

Secondary Address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–2

Service Request and Polling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–2

Protocol Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–3

Multiline Control Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–3

Interface Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–3

Electrical Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–4

Driver Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–4

xviii TM-XDOP-01XN

Page 21

Mechanical Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–4

Performance Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–4

Warranty and Product Information

Index

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -IX–1

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - WA–1

TM-XDOP-01XN xix

Page 22

xx

Page 23

Figures

Figure 1-1 Front Panel (6000 Watt) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-2 Front Panel (12000 Watt) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Figure 1-3 Keypad - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Figure 1-4 Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Figure 1-5 Front Panel Display, Status Annunciators - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Figure 1-6 Rear Panel (6000 Watt) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

Figure 2-1 Typical Box Label for Storage- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Figure 2-2 Unpacking the Power Supply- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Figure 2-3 Mounting the Power Supply in the Rack With Support Rails - - - - - - - - - - - - 2–6

Figure 2-4 AC Input Connector for 6000 Watt units - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Figure 2-5 Attaching the AC Input Wires for 6000 Watt units - - - - - - - - - - - - - - - - - - 2–10

Figure 2-6 Attaching the AC Input Wires for 12000 Watt units - - - - - - - - - - - - - - - - - 2–12

Figure 2-7 Fastening the Output Wires (6000 Watt) - - - - - - - - - - - - - - - - - - - - - - - - - 2–19

Figure 2-8 Output Bus Bar Cover for 6000 Watt units - - - - - - - - - - - - - - - - - - - - - - - 2–20

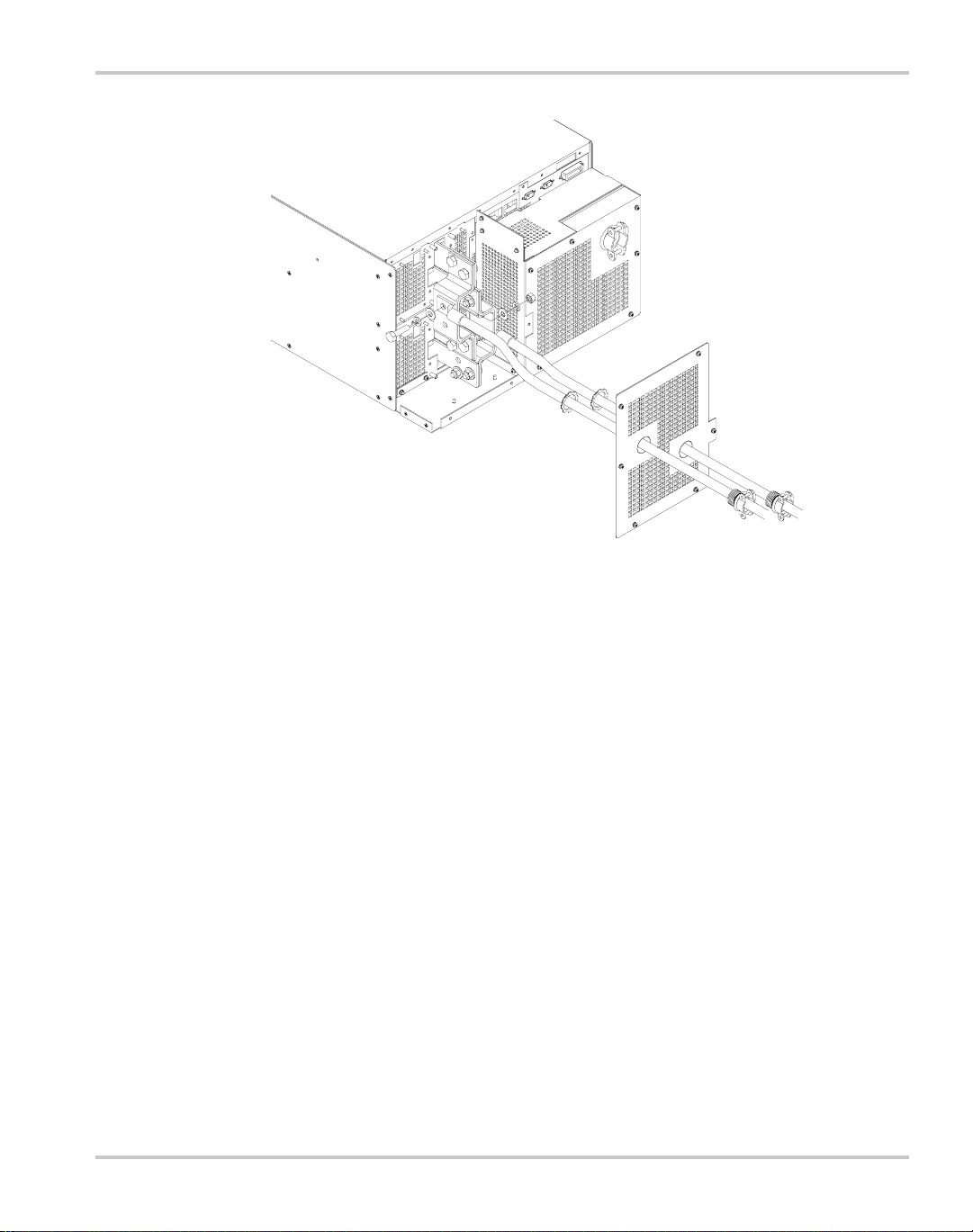

Figure 2-9 Output for 12000 Watt units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–21

Figure 2-10 Output Cover with Strain Relief for 6000 Watt units - - - - - - - - - - - - - - - - - 2–22

Figure 2-11 Output for 12000 Watt units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Figure 4-1 View of Remote Interface Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Figure 4-2 Schematic For User Line Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–6

Figure 4-3 Connections for Multichannel Operation - - - - - - - - - - - - - - - - - - - - - - - - - 4–13

Figure 4-4 Operation Status Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–45

Figure 4-5 Questionable Status Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–51

Figure 4-6 IEEE 488.2 Status Register and Status Byte- - - - - - - - - - - - - - - - - - - - - - - 4–54

Figure 5-1 Connections for Current Share Operation - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Figure A-1 Power Supply Dimensions (6000 Watt unit)- - - - - - - - - - - - - - - - - - - - - - - A–14

Figure A-2 Power Supply Dimensions (12000 Watt unit)- - - - - - - - - - - - - - - - - - - - - - A–15

TM-XDOP-01XN xxi

Page 24

xxii

Page 25

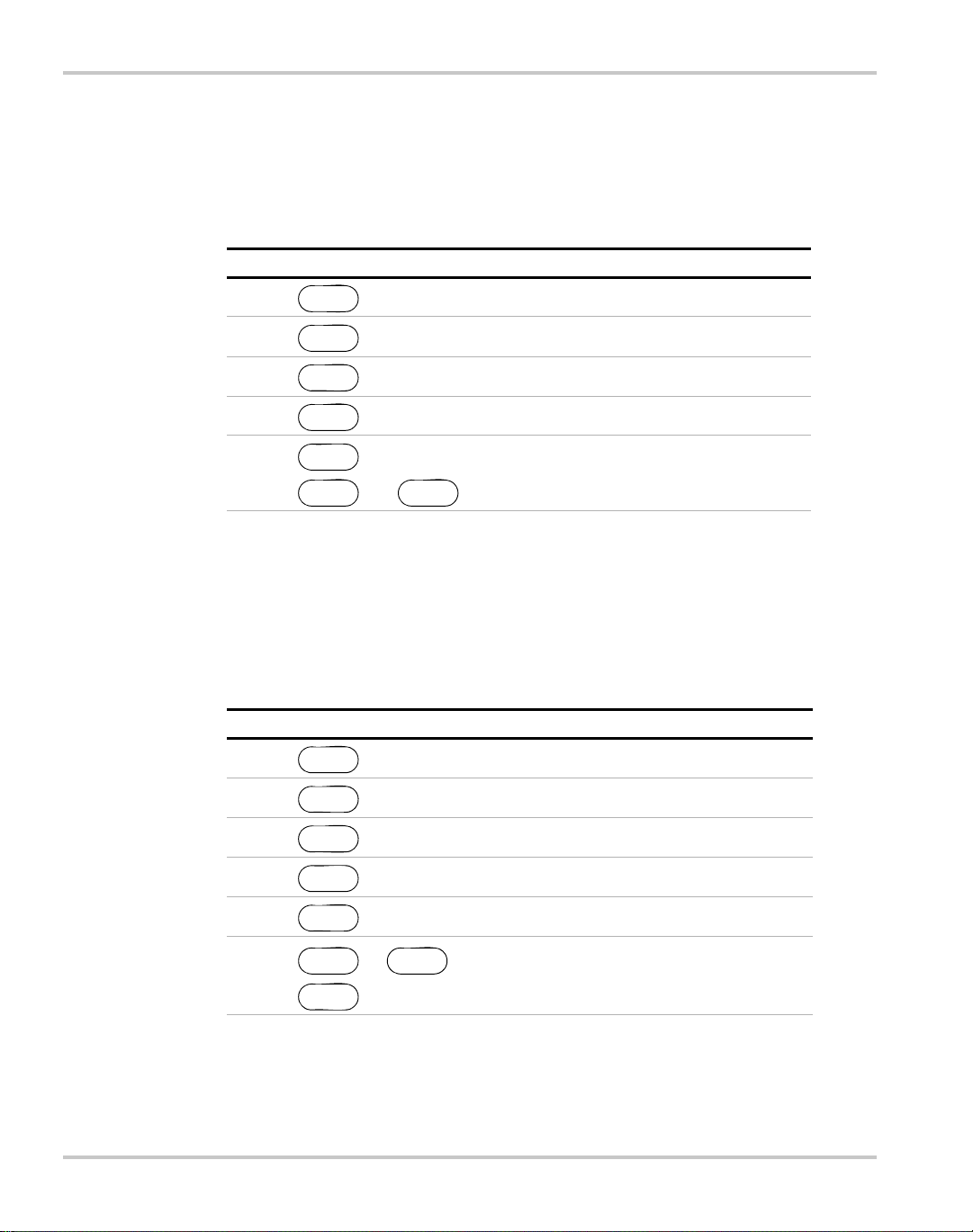

Tables

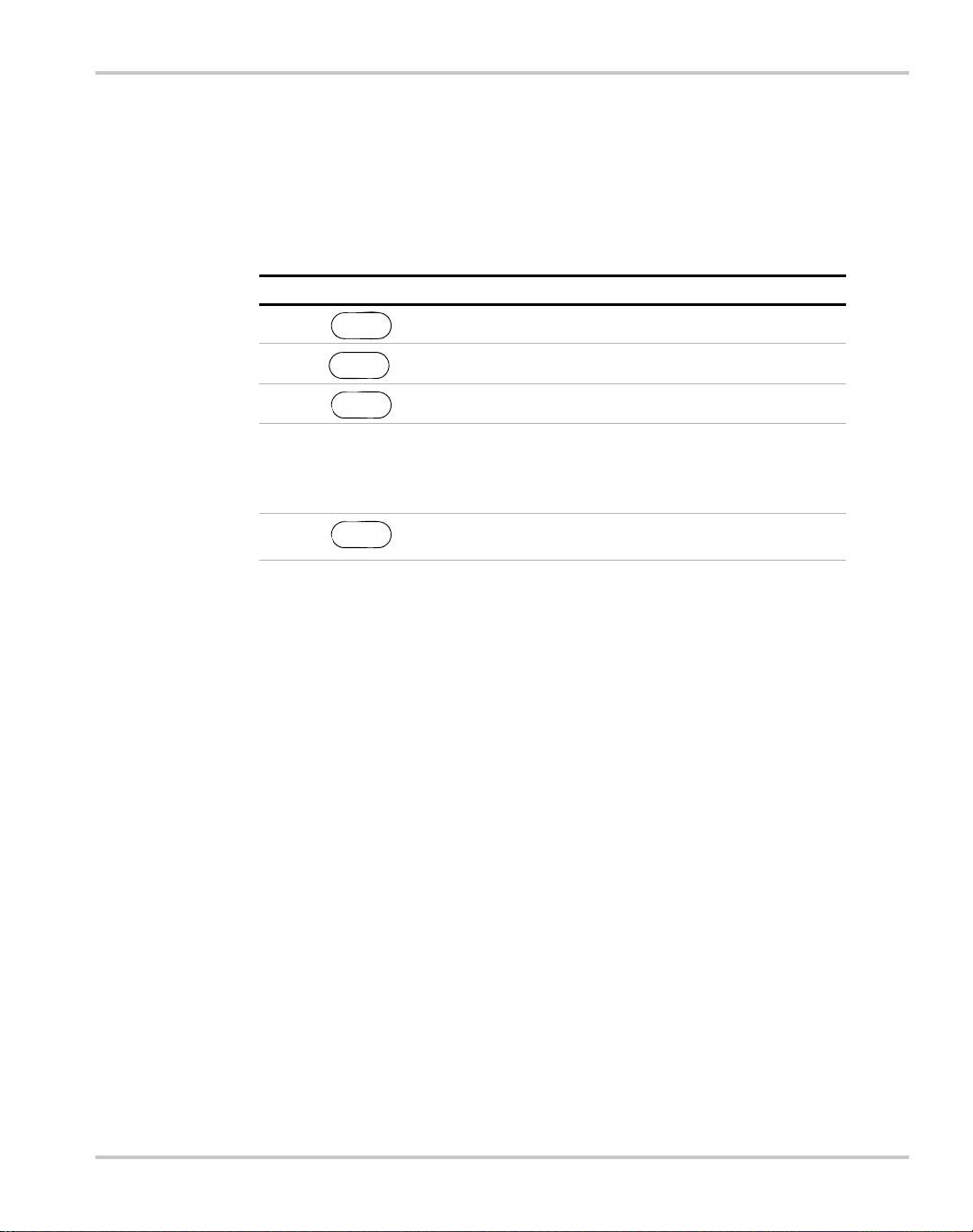

Table 1-1 Item Descriptions for Figure 1-1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Table 1-2 Item Descriptions for Figure 1-2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Table 1-3 Item Descriptions for Figure 1-3 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Table 1-4 Front Panel Functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Table 1-5 Item Descriptions for Figure 1-4 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Table 1-6 Item Descriptions for Figure 1-5 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Table 1-7 Item Descriptions for Figure 1-6 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

Table 2-1 Basic Setup Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Table 2-2 AC Wire Specification for 6000 Watt Units- - - - - - - - - - - - - - - - - - - - - - - - 2–8

Table 2-3 AC Wire Specification for 12000 Watt Units - - - - - - - - - - - - - - - - - - - - - - - 2–8

Table 2-4 Current Carrying Capacity for Load Wiring- - - - - - - - - - - - - - - - - - - - - - - 2–16

Table 3-1 Settings Affected by Recall- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–25

Table 3-2 To Program a Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–33

Table 4-1 User Line Pins- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–6

Table 4-2 Analog Programming Pins - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–7

Table 4-3 Analog Pin Connections for Power Loop Back- - - - - - - - - - - - - - - - - - - - - - 4–7

Table 4-4 Analog Pin Connections with a Contact Closure- - - - - - - - - - - - - - - - - - - - - 4–7

Table 4-5 CANbus Pins - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–11

Table 4-6 RS-232 Pins - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–16

Table 4-7 GPIB Pins - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–19

Table 4-8 Features Affected by Reset (*RST) Command - - - - - - - - - - - - - - - - - - - - - 4–24

Table 4-9 OPERation Status Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–46

Table 4-10 REGulating Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–47

Table 4-11 SHUTdown Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–47

Table 4-12 Protection SHUTdown Sub-Register- - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–48

Table 4-13 Remote CONtrol Sub-Register- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–49

Table 4-14 Current SHare Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–50

Table 4-15 QUEStionable Status Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–52

Table 4-16 VOLTage Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–53

Table 4-17 CURRent Sub-Register- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–53

Table 4-18 POWer Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–53

Table 4-19 TEMPerature Sub-Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–54

Table 4-20 Standard Event Status Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–55

Table 4-21 Status Byte Summary Register- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–56

Table 4-22 Preset Values of User Configurable Registers- - - - - - - - - - - - - - - - - - - - - - 4–58

TM-XDOP-01XN xxiii

Page 26

Table A-1 Specifications for 6000 Watt units (10V to 60V Models)- - - - - - - - - - - - - - - A–2

Table A-2 Specifications for 6000 Watt units (80V to 600V Models) - - - - - - - - - - - - - - A–3

Table A-3 Specifications for 12000 Watt units (10V to 60V Models) - - - - - - - - - - - - - - A–4

Table A-4 Specifications for 12000 Watt units (80V to 600V Models) - - - - - - - - - - - - - A–5

Table C-1 IEEE 488.2 Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–10

Table C-2 Readback Commands- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–12

Table C-3 Commands for Output Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–13

Table C-4 Commands for Current Share - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–15

Table C-5 Commands for Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–16

Table C-6 Command to Clear all Protection Mechanisms- - - - - - - - - - - - - - - - - - - - - C–17

Table C-7 Commands for Fold Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–18

Table C-8 Commands for Triggering- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–18

Table C-9 S ystem Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–19

Table C-10 Status Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–20

Table C-11 Protection Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–27

Table C-12 User Lines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–27

Table C-13 Output State - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–28

Table C-14 Auto Sequence Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–29

Table C-15 Legacy Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–32

Table C-16 Expressions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–33

Table D-1 Command Error List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

Table D-2 Execution Error List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–3

Table D-3 Device-Specific Error List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–5

Table D-4 Query Error List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–6

Table D-5 User Request Event - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–6

Table D-6 Operation Complete Event - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–6

Table D-7 Front Panel Error Codes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–7

Table D-8 CPU Error Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–7

Table D-9 Analog Programming Interface Error code - - - - - - - - - - - - - - - - - - - - - - - - D–7

Table D-10 Auto Sequencing Error Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–7

Table D-11 CANbus Error Codes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–8

Table D-12 Multichannel Error Codes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–8

Table D-13 Current Share Error Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–9

Table E-1 Multiline Control Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–3

Table E-2 Interface Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–3

Table E-3 Driver Types for Interface Lines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–4

xxiv TM-XDOP-01XN

Page 27

About The XDC P ower

1

Supply

Chapter 1 lists the features of the XDC and shows diagrams of

the front and rear panel.

Page 28

About The XDC Power Supply

Overview

The XDC Series of digital, programmable DC power supplies is designed for use in

OEM, ATE, burn-in, magnet charging, and other high power systems for a broad

range of applications. The XDC uses our newly developed digital technology which,

combined with “Soft Switching,” provides superior performance and a high level of

user control through both front panel and remote interfaces.

Features

• Digital processing for highly accurate control

• Ten, 99-step auto sequences for easy bench-top programming of complex test

routines

• Ten stored settings

• Zero voltage (soft) switching for low noise output, improved efficiency and

higher reliability

• Active Power Factor Correction (PFC) for lower input current draw and lower

current harmonic generation

• Remote voltage sense with 5V line drop compensation

• Automatic Voltage/Current mode crossover

• Constant power mode

• Seven load protection mechanisms

• Alarms and messages for over- and under-programmed trip points

• Auxiliary status lines for monitoring power supply conditions

• Remote interlock and trigger ports

• Selectable standby, last setting, programmed sequence and other power-on

defaults

• Active current sharing with parallel connected units for higher power

requirements. (These features are available when the power supply is equipped

with the optional GPIB/CANbus interface card.)

• Standard RS-232 remote control interface and optional GPIB (IEEE 488.2) port

• CANbus communications link for multichannel addressing, and master/slave

current sharing*

• Extensive SCPI command set

• Keypad, knobs, and arrow keys for fast and tactile front panel operation

• Bright vacuum fluorescent display with annunciators to indicate complete

supply status at a glance

• Front panel, software-based calibration

• Fully isolated analog programming and readback capabilities

• CE Mark, CSA Certified, FCC Compliance

1–2 TM-XDOP-01XN

Page 29

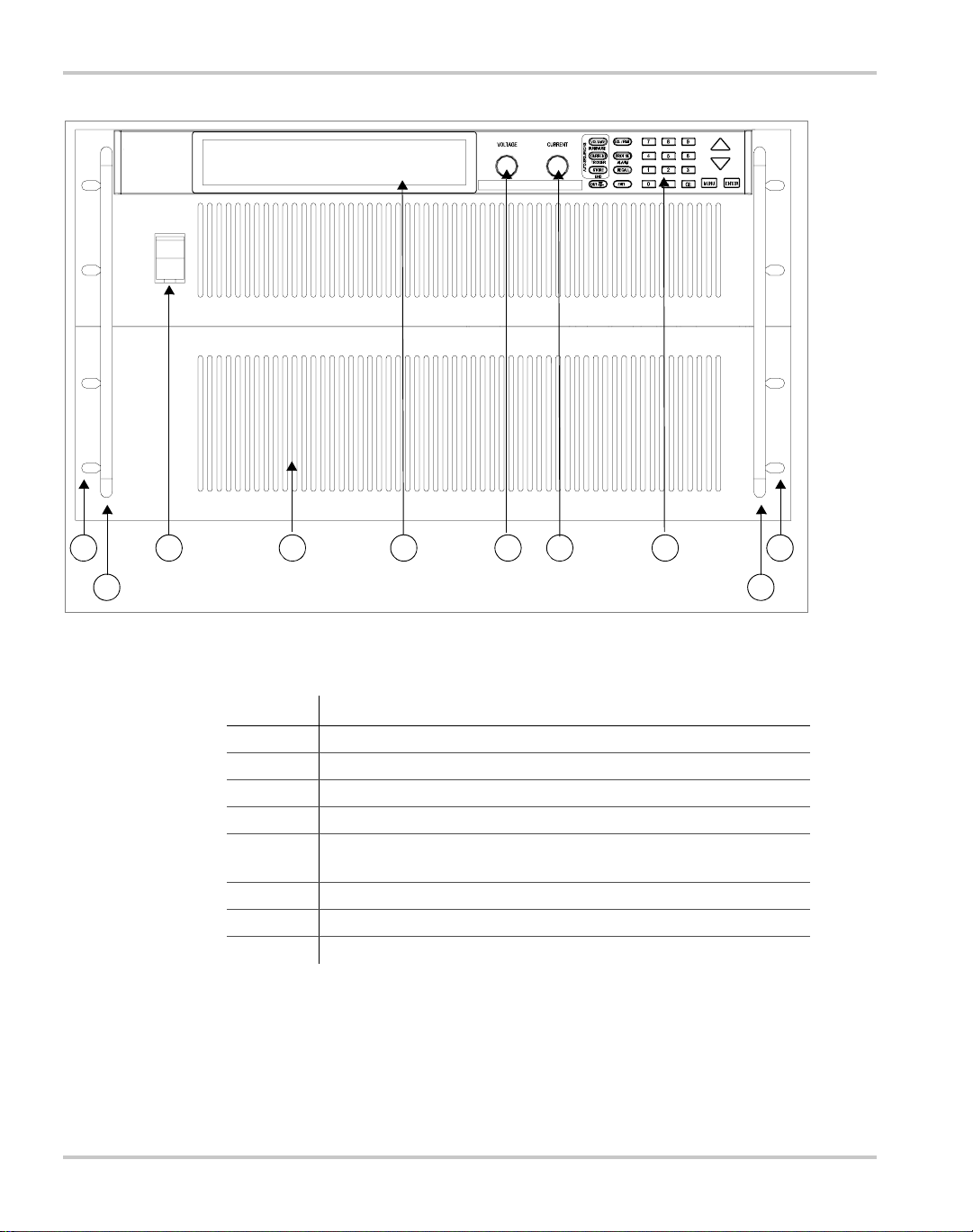

Front Panel

Front Panel

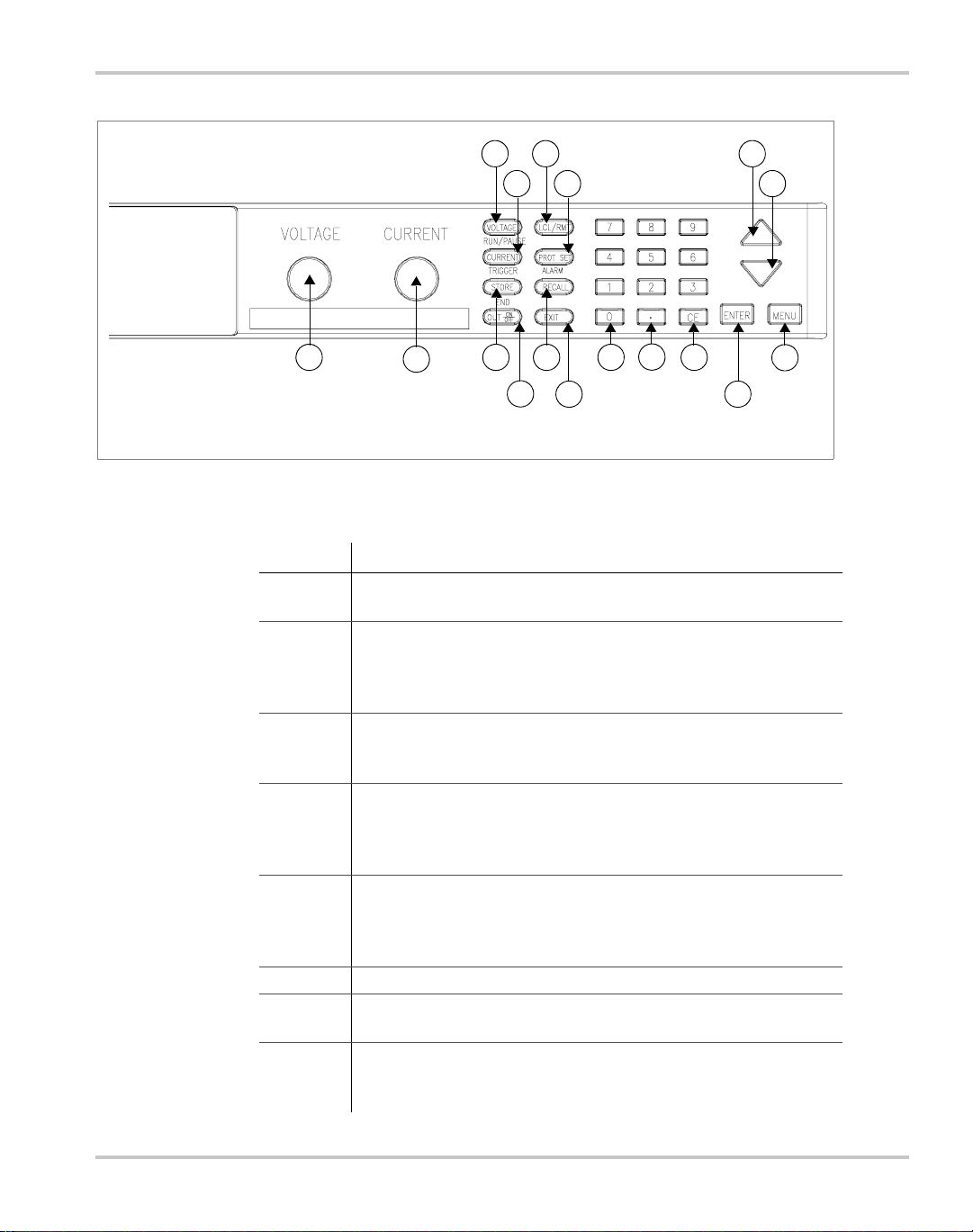

1

2

Figure 1-1

3 4

Front Panel (6000 Watt)

Table 1-1

Item Description

1 Rack mount brackets

2 Handles

3On/Off Switch

4 Air intake vents

5 Front panel display (vacuum fluorescent display). See Figure 1-4

6 Voltage knob

7 Current knob

8 Keypad. (See Figure 1-3 for details.)

Item Descriptions for Figure 1-1

for details.

5

6 7 8 1

2

TM-XDOP-01XN 1–3

Page 30

About The XDC Power Supply

1

2

Figure 1-2

3 4 5 6 7 8 1

2

Front Panel (12000 Watt)

Table 1-2

Item Description

1 Rack mount brackets

2 Handles

3On/Off Switch

4 Air intake vents

5 Front panel display (vacuum fluorescent display). See Figure 1-4

6 Voltage knob

7 Current knob

8 Keypad. (See Figure 1-3 for details.)

Item Descriptions for Figure 1-2

for details.

1–4 TM-XDOP-01XN

Page 31

Front Panel

3

7

4

8

5

1

2

9

6

10

11

12

13

14

15

17

16

Figure 1-3

Keypad

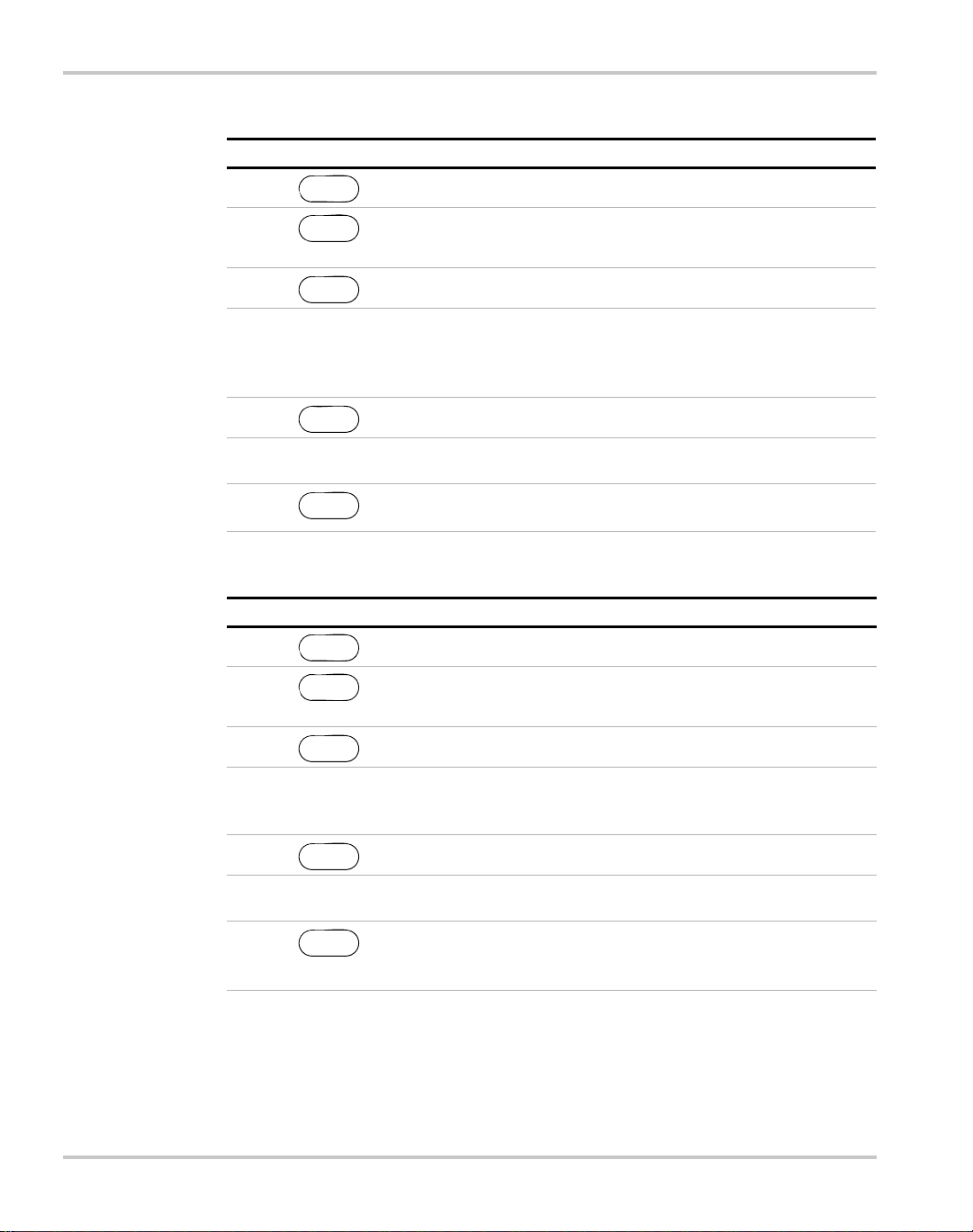

Table 1-3

Item Description

1 Voltage knob: Turn knob to increase or decrease output voltage.

2 Current knob: Turn knob to increase or decrease output current

3 VOLTAGE set key: View and set voltage output setpoint.

4 CURRENT set key: View and set current output setpoint.

5 STORE settings key: Save power supply output settings to one of

6 OUT ON/OFF key: Toggle between Output ON and Output OFF .

7 LCL/RMT key: Toggle between local mode and remote mode (or

8 PROTECTION SET key: View and set protection setpoints.

Item Descriptions for Figure 1-3

(This is a velocity- sensitive rotary encoder.)

limit. (This is a velocity-sensitive rotary encoder.) The secondary

functions for keys 3-5 listed below operate when the power supply

is in Auto Sequence.

RUN/P AUSE Auto Sequence Program: Start a selected program

or pause the program.

TRIGGER for Auto Sequence Program: Apply a trigger when

requested. This key may also be used to advance to the next step

in the program by pressing and holding.

ten locations.

END Auto Sequence Programming: Stop the program. The

program will start from the beginning when RUN is pressed.

Go to Local for GPIB operation) except during calibration.

ALARM response: Read and clear alarm messages. ALARM

annunciator indicates if there are any alarm messages.

TM-XDOP-01XN 1–5

Page 32

About The XDC Power Supply

Table 1-3

Item Description

9 RECALL settings key: Apply stored power supply settings.

10 EXIT key: Cancel operation, exit menu or get out of Calibration

11 Numeric keypad: Numbers 0 to 9, used for data entry.

12 Decimal key: Enter a decimal. Used for data entry.

13 CE key: Clear the entire data field. Used for data entry. In Store

14 Up arrow key: Scroll through menus and lists, or, in data entry

15 Down arrow key : Scroll through menus and lists, or, in data entry

16 ENTER key: Select a menu item or accept data.

17 MENU key: Access all menu functions.

Item Descriptions for Figure 1-3

mode or Auto Sequence mode. Automatic timeout will also cancel

operation except calibration and auto sequence operation.

User Setting mode, used to delete selected setting or program.

mode, increase the displayed value. In default operating mode, use

this key to view the output power. In Auto Sequence Operating

mode, use this key to view present sequence number, step

numbers, and sequence loop count.

mode, decrease the displayed value.

1–6 TM-XDOP-01XN

Page 33

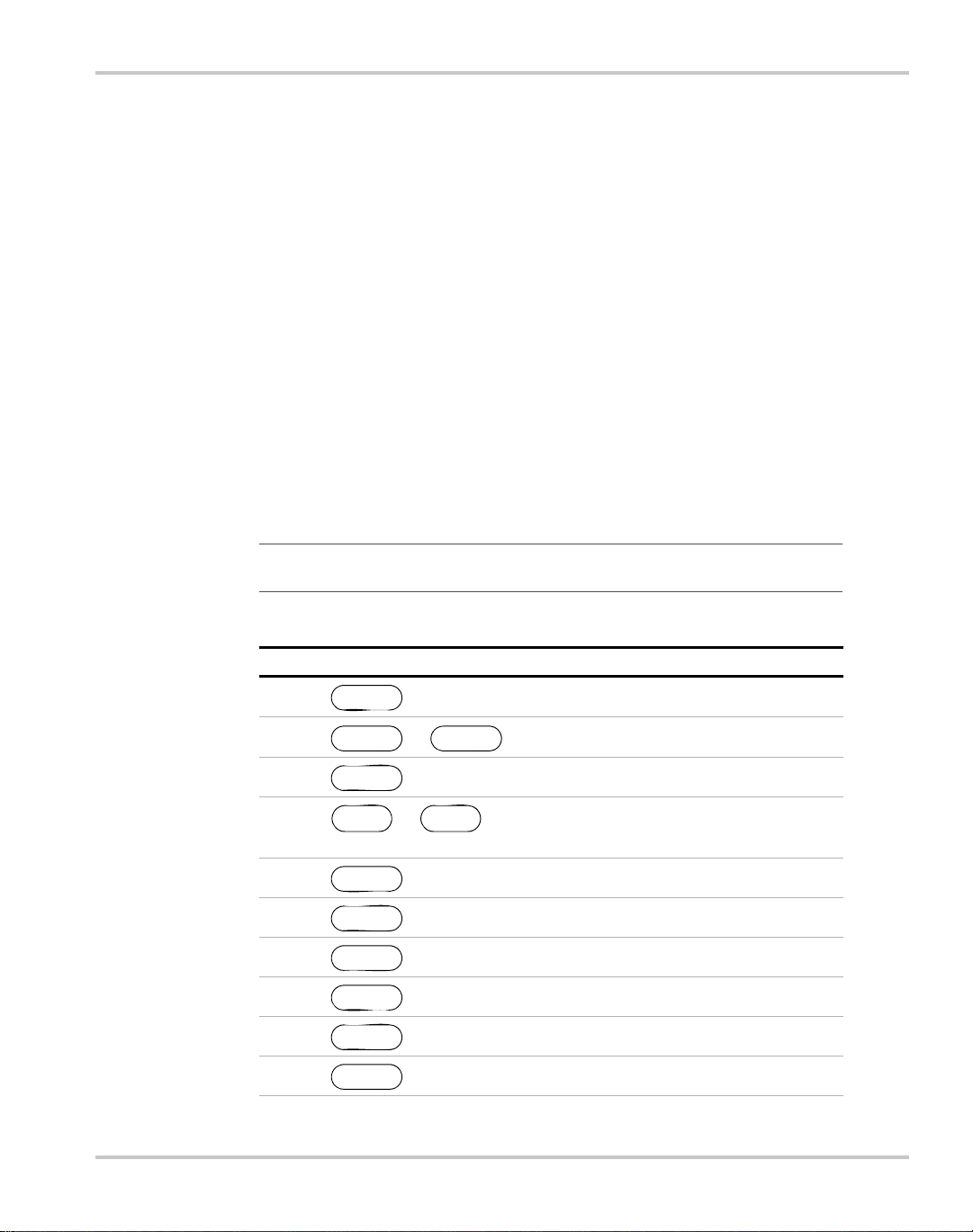

Front Panel

Table 1-4

Key Functions

Voltage Setpoint Enter voltage

Current Setpoint Enter current

Output ON/OFF Toggle

Local/Remote Mode Toggle

Protection Set OVP level

Read Alarms Read alarm msgs

Store User Setting Select 1 to 10

Recall Factory default

Auto Sequence Operation (Run/Pause, Trigger, Stop)

MENU Access menu functions

ENTER Make a selection

UP/DOWN Scroll to view selections, increment numerical entries

CE Clear entry

Numeric keypad Enter data

EXIT Cancel operation

Special Key Functions

UP View power readback (from default win dow)

CE Deletes a selected user setting from memory (Hold for 2 seconds)

EXIT Exit auto sequence

Front Panel Functions

UVP level

OCP level

UCP level

OPP level

UPP level

Fold Mode

Last setting

User setting

Auto sequence

Enter OV level

Enter UV level

Enter OC level

Enter UC level

Enter OP level

Enter UP level

Select fold mode

Select 1 to 10

Select 1 to 10

S/D if tripped?

S/D if tripped?

S/D if tripped?

S/D if tripped?

S/D if tripped?

Select fold delay

Select Y or N

Select Y or N

Select Y or N

Select Y or N

Select Y or N

Menu Function

ERROR MSGS Read error msgs

USER LINES Aux line A

Aux line B

PON CONFIG Factory default

Last setting

User setting

Auto sequence

S/D RECOVERY Select OTP

recovery

REMOTE

SELECT

TM-XDOP-01XN 1–7

Select remote interface

Configure aux line A

Configure aux line A

Set output on/off

Set output on/off

Select 1 to 10

Select 1 to 10

Select AC Off recovery

Set aux line A polarity

Set aux line B polarity

Set output on/off

Set output on/off

Page 34

About The XDC Power Supply

Table 1-4

REMOTE

CONFIG

AUTO SEQ PGM Select Sequence Edit Sequence Select Step Edit Step Enter Value/Duration

CURRENT

SHARE

POWER

SETPOINT

DISPLAY

CONFIG

KNOB LOCKOUT Lock voltage knob? Lock current knob?

SETPOINT LIMIT Voltage limit

SLEW RATE Voltage slew Enter voltage step

CALIBRATION Calibrate voltage

MODEL INFO View info

Front Panel Functions

RS-232

GPIB

Analog

Multichannel

No sharing

Master

Slave

Set power

Set display config

Current limit

Power limit

Voltage slew default

Calibrate current

Calibrate analog 5V voltage programming

Calibrate analog 5V voltage readback

Calibrate analog 5V current programming

Calibrate analog 5V current readback

Calibrate analog 10V voltage programming

Calibrate analog 10V voltage readback

Calibrate analog 10V current programming

Calibrate analog 10V current readback

Restore factory calibration

Change calibration security code

Select baud rate

Select address

Select input voltage

range

Select address

Set Repeat #Select repetitions for sequence

Trig Source Select trigger source

Delete SequenceConfirm delete

Display summed

current?

Enter max limit

Enter max limit

Enter max limit

Select flow

control

Select PON SRQ

To Next Step

or EXIT to finish

Insert Step

Delete Step

Select Y or N

Enter min limit

Enter min limit

Enter min limit

Enter time

interval

1–8 TM-XDOP-01XN

Page 35

Display

Display

Figure 1-4

Front Panel Display

Table 1-5

Item Description

1 Main Display: Shows setpoints, readback, and menus. There are

2 Status Annunciators: See “Status Annunciators” on page 1–9

3 Voltage, Current, and Power Bar Graphs: Show present

Item Descriptions for Figure 1-4

Status Annunciators

1

14 characters. Each character is 5 pixels wide by 7 pixels high.

and Figure 1-5 for detailed information.

voltage, current limit, and power output in graphical format. Also

indicates regulation mode.

2

3

1

Figure 1-5

TM-XDOP-01XN 1–9

3 5 7 11 13 15 17

2 4 6 8

9

10 12 14 16 18

Front Panel Display, Status Annunciators

19

20

21

22

Page 36

About The XDC Power Supply

Table 1-6

Item Description

1 AUX A: Condition selected for auxiliary line A is TRUE.

2 Master: Power supply is selected to be the master in current share

3 Master: Power supply is selected to be the master in current share

4 Slave: Power supply is selected to act as a slave in current share

5 AUTO: Power supply is in auto sequence operation.

6 Pause: Auto sequence program is paused. (Output is still on.)

7 SEQ: Power supply is in auto sequence setup mode (if Set is also

8 Trigger?: Auto sequence program is waiting for a trigger signal to

9 ERR: An error has occurred.

10 Set: Setting or setpoint is to be entered.

11 ADR: Power supply is being addressed (receiving data). (All

12 LCL: Power supply is under local (front panel) control.

13 SRQ: Service request. GPIB only.

14 RMT: Power supply is under remote control.

15 ALARM: Power supply is operating outside the parameters the

16 OUT OFF: Power supply output is disabled; all other circuits are

17 OVP: Power supply has exceeded an over-voltage trip point.

18 Interlock: Signals that the external shutdown line (the safety

19 OTP: Power supply has exceeded an over-temperature trip point,

20 OUT ON: Output is on.

21 Bar graphs: Graphical representation of output voltage, current,

22 CV, CC, CP: Power supply is in constant voltage mode, constant

Item Descriptions for Figure 1-5

configurations.

configurations.

configurations.

Press RUN/PAUSE key to continue.

turned on) or in auto sequence operation.

continue execution.

remote digital interfaces.)

user set by using PROT SET, or the power supply’s internal

temperature has exceeded an internally set trip point (OTP).

active; unit is in standby mode.

interlock line) has been activated, disabling the supply output.

disabling the supply output.

and power.

current mode, or constant power mode.

1–10 TM-XDOP-01XN

Page 37

Rear Panel

Rear Panel

Figure 1-6

2

1 3

Rear Panel (6000Watt)

(low and medium output shown)

Table 1-7

Item Description

1 Fan Exhaust Vents: Do not obstruct.

2 Remote Sensing Ports: From the rear point of view, left is

3 DC Output: Bus bars are shown. Terminal blocks are used for

4 Auxiliary Status Lines, External Interlock, and Trigger Input

5 Analog Program and Readback

6 CANbus Port: For current sharing or multichannel operation

7 RS-232 Connector

8 GPIB (optional)

9 Protective Conductor Ground Screw

10 AC Input

11 Chassis ground stud

Item Descriptions for Figure 1-6

4 5 6 7

1 1

negative; right is positive.

higher voltages (300 and 600 Vdc only).

(optional)

86

9

1

1

10

TM-XDOP-01XN 1–11

Page 38

About The XDC Power Supply

Overview of Operation

Power ON

Power ON describes the period between the time the AC power is turned ON and

the time the power supply is ready for normal operation. Each supply comes with

a series of factory default settings that may be in effect at the conclusion of the

Power ON period. These include:

• Output OFF: No current is sent to the DC output connections. You must

press Out ON/OFF to activate the supply output.

• Voltage 0V: The Voltage setpoint is zero.

• Current 0A: The Current setpoint is zero.

• Local mode operation

The output state depends on the Power ON output setting. You can customize the

Power ON settings to suit your needs. See “Configure Power ON Settings” on

page 3–29 for more information.

Control Modes

One local method and 4 remote methods are available for controlling the power

supply:

• Local Mode: Where the user operates the menu keypad and knobs

• RS-232: Where the user operates the supply remotely through a serial port

connection (standard feature).

• GPIB: Where the user operates the supply remotely through the faster

General Purpose Interface Bus. The GPIB bus follows the IEEE 488.2

standard and is an optional feature of this power supply.

• Multichannel: Where the user operates the supply remotely through the

optional multichannel link between 2 or more (up to 50) power supplies

(optional feature).

• Analog: Where the user operates the supply remotely through the isolated

analog programming and readback port (standard feature). Three options are

available:

• Analog V and I

• Analog V

• Analog I

Each of these methods is referred to as a control mode.

1–12 TM-XDOP-01XN

Page 39

2

Installation

Chapter 2 explains how to mount and wire the XDC and also

how to perform basic functional tests.

Page 40

Installation

Overview

Chapter 2, “Installation” provides recommendations and procedures for

inspecting, installing, and testing the power supply. For more information about

controls and connectors, refer to the front panel diagrams (Figure 1-1 to Figure 1-

5) as well as the rear panel diagram (Figure 1-6) in Chapter 1.

Basic Setup Procedure

Table 2-1 provides a summary of the setup procedure and an overview of the

subsections in this chapter. Use this table as a quick reference if you are familiar

with the installation requirements for the power supply. If you require more

information, each step in the table refers to a subsequent section which contains

more details. Complete each step in the sequence given.

Table 2-1

Step # Description Action Reference

1 Inspection Visually inspect the power supply. “Inspection, Cleaning, and

2 Installation Install the power supply, ensuring adequate

3 Input Power Connect AC input power. “AC Input Power” on page 2–7

4 Test Perform functional tests for volt a ge mo de

5 Select Wires Select wires that can tolerate the DC current

6 Connect Load Connect the load wires to the DC output. “Load Connections” on page 2–18

7 Connect Remote

Basic Setup Procedure

ventilation.

operation, current mode operation, and front

panel controls.

output.

Connect remote sensing connectors on power

Sensing

(if required)

supply to load.

Packaging” on page 2–2

“Location, Mounting, and

Ventilation” on page 2–4

“Basic Checks or Self-Tests” on

page 2–13

“Load Wiring” on page 2–16

“Remote Sensing” on page 2–24

Inspection, Cleaning, and Packaging

Initial Inspection

When you receive your power supply, do a quick visual check.

1. Ensure that the box contains the power supply, the operating manual, the AC

input cover and strain relief, and the output cover.

2. Inspect the unit for scratches and cracks as well as broken switches,

connectors, or displays.

2–2 TM-XDOP-01XN

Page 41

If the unit is damaged, save all packaging materials and notify the carrier

immediately. Follow the instructions in “Warranty and Product Information” and

the instructions on page 2–3 to return the unit.

Maintenance

Routine servicing of the power supply is not required except for periodic cleaning.

Whenever a unit is removed from operation, clean the metal surfaces with naphtha

or an equivalent mild solvent, and clean the front panel with a damp cloth using a

weak solution of soap and water. Use low-pressure compressed air to blow dust

from in and around vent openings and components on the printed circuit boards.

Packaging for Shipping or Storage

Follow these instructions to prepare the power supply for shipping or storage.

1. When returning the unit or sending it to the service center, attach a tag to the

unit stating its model number (located on the front panel label) and serial

number (located on the rear panel label). Give the date of purchase and an

invoice number, if you have it, as well as a brief description of the problem.

2. For storage and shipping, repack the power supply in its original container. If

the original container is not available, seal the unit in a plastic bag and then

pack it into a wooden or sturdy cardboard box large enough to allow 2 in.

(5cm) of cushioning material to surround the unit. For cushioning, use

material such as foam slabs that are capable of supporting the unit.

3. Label the box as shown below in Figure 2-1.

4. If shipping, mark the service center address and your return address on the

carton.

5. If storing, stack no more than 5 boxes high. Check the storage tempe rature

range specification in Appendix A.

Inspection, Cleaning, and Packaging

POWER SUPPLY

Model Number:

Serial Number:

___________________________

___________________________

FRAGILE – ELECTRONIC EQUIPMENT

Figure 2-1

TM-XDOP-01XN 2–3

Typical Box Label for Storage

Page 42

Installation

Location, Mounting, and Ventilation

Use the power supply in rack-mounted applications only. The power supply is

designed to fit in a standard 19 in. (483mm) equipment rack.

Rack Mounting

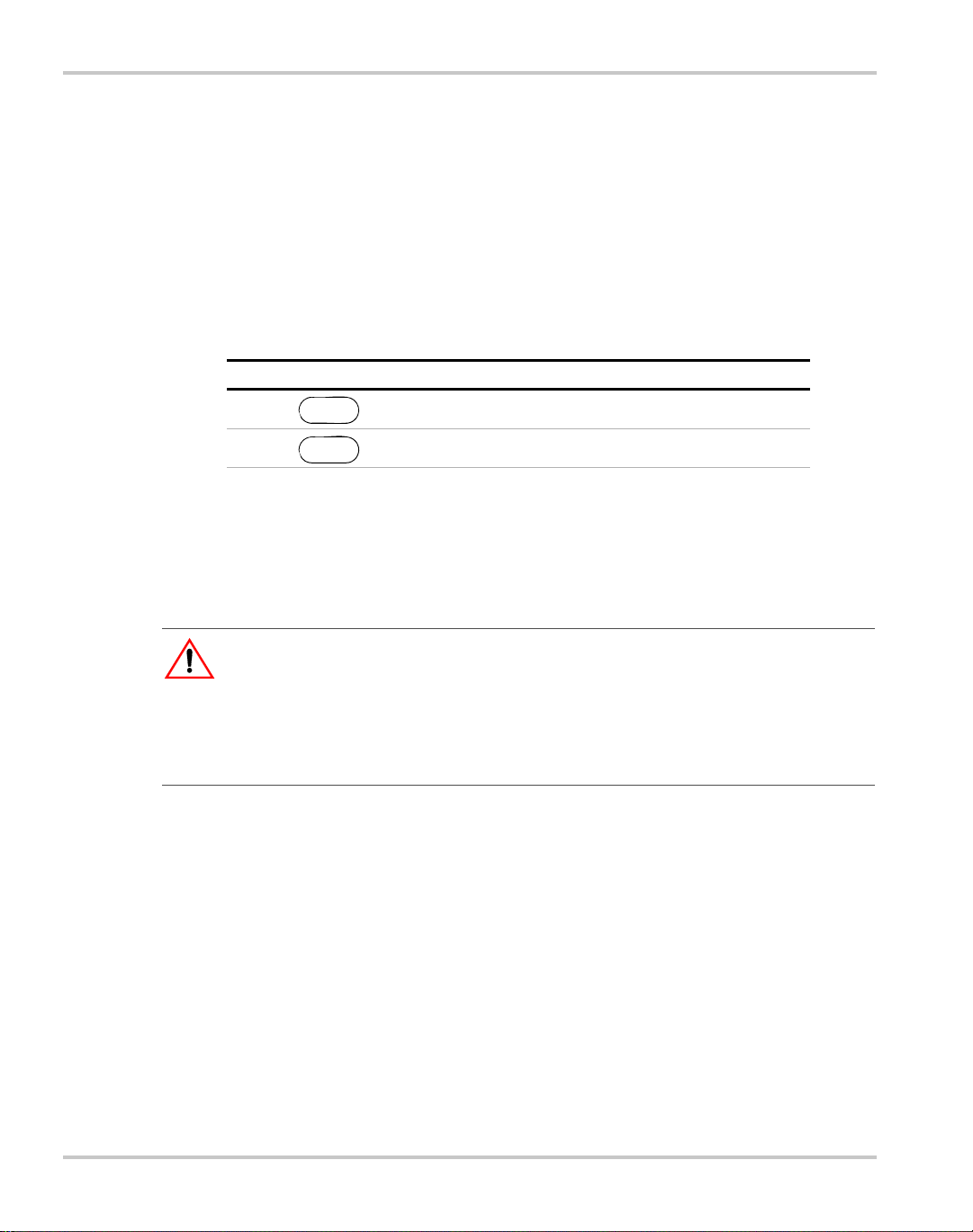

WARNING: High energy and high voltage

Ensure that the 8-32 rack mounting screws do not extend more than 1/8 in.

(3.0mm) into the sides of the power supply.

To install the power supply in an equipment rack:

1. Open the box containing the unit. See Figure 2-2.

2. With the help of at least one other person, lift the unit out of its package and

slide it into an empty space in a mounting rack equipped with rails that are

rated to support the unit’s weight. See Figure 2-3.

On 12000 Watt units, remove the temporary lifting handles before installing

the unit in a rack.

CAUTION

The power supply is too heavy for one person to safely lift and mount. To avoid

injury, ask a co-worker for assistance.

3. While your assistant(s) holds the unit steady, fasten it to the rack by inserting

bolts through the mounting brackets on either side of the front pan el and

securing them with a washer and nut.

4. The front panel mounting brackets are designed to prevent the unit from

sliding out of the rack, not to support its full weight. Provide adequate support

for the rear of the unit without obstructing the ventilation inlets. Use slide rails

as illustrated in Figure 2-3 or slide brackets attached to the 8-32 mounting

holes on each side of the unit. Follow the manufacturer’s instructions to install

rails or slides.

2–4 TM-XDOP-01XN

Page 43

Location, Mounting, and Ventilation

Figure 2-2

TM-XDOP-01XN 2–5

Unpacking the Power Supply

(6000 Watt shown)

Page 44

Installation

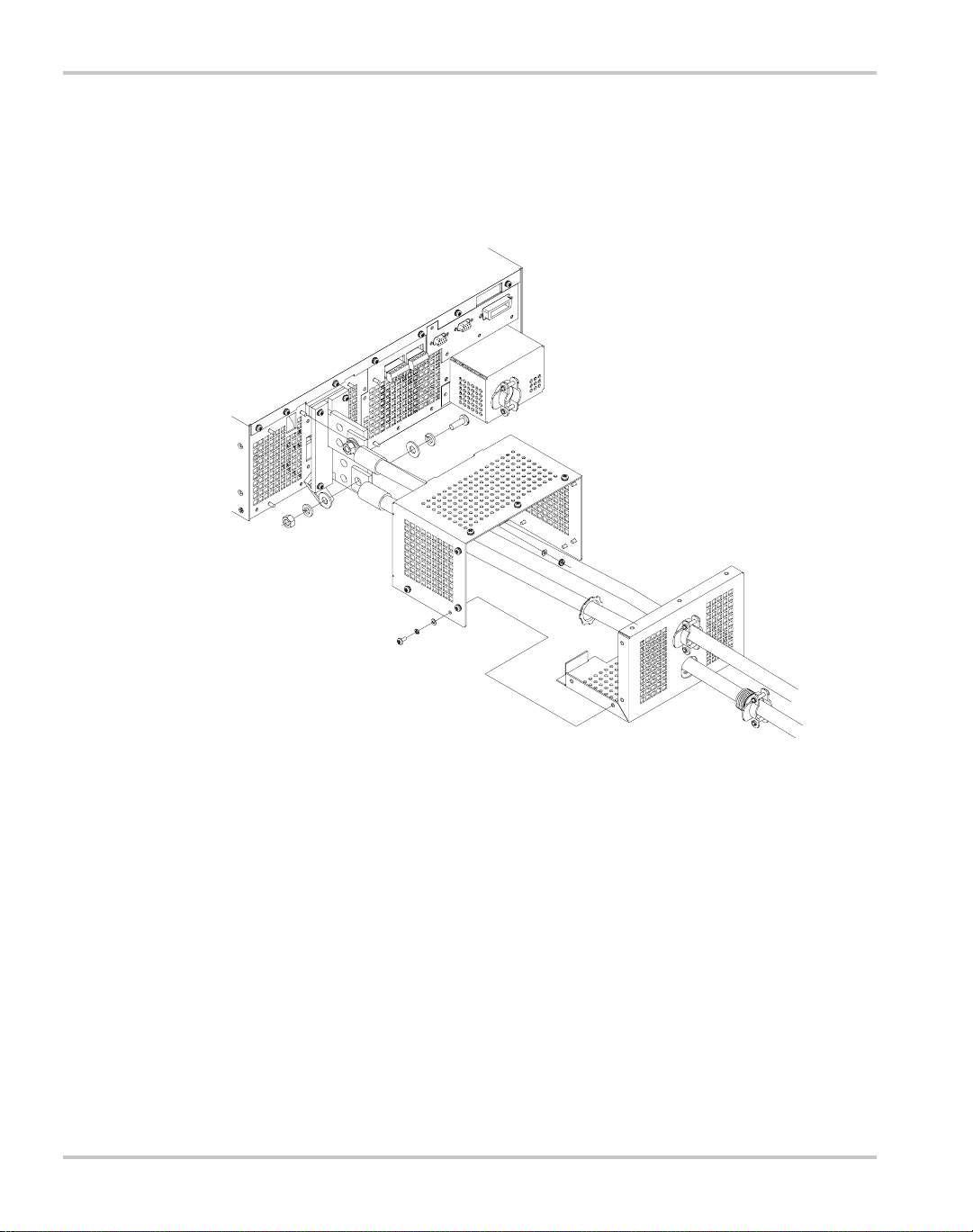

Figure 2-3

a. Available from rack or cabinet vendors (e.g. Schroff, part number 30150-094).

Mounting the Power Supply in the Rack With Support Railsa

(6000 W shown)

Ventilation

Allow cooling air to reach the ventilation inlets on the front of the unit and allow

4 in. (10 cm) of unrestricted air space at the rear of the unit for the fan exhaust.

Ventilation inlets are located on the top and sides; they are not required, however,

and may be blocked, if required.

See “Specifications and Characteristics” on page A–1 for the operating ambient

temperature range.

2–6 TM-XDOP-01XN

Page 45

AC Input Power

WARNING

Disconnect AC power from the unit before removing the connector cover. Live

line voltages may be exposed when the cover is removed.

WARNING

A safety ground wire must be connected to the unit as shown in Figure 2-4 and

Figure 2-6 to ensure operator safety

CAUTION

When the power switch is turned on, output voltage or current previously set may