Page 1

Xantrex

XC3012, XC5012,

XC1524 and XC2524

Owner’s Guide

12 V / 30 A

12 V / 50 A

Battery Charger

24 V / 15 A

24 V / 25 A

Page 2

Page 3

Xantrex XC3012, XC5012,

XC1524 and XC2524

Battery Charger

Owner’s Guide

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with

products from 50 watt mobile units to one MW util ity-s cale system s for wind, sol ar , ba tteri es, fuel cel ls,

microturbin es, and backup powe r appl icat ions in bot h grid- connec ted and sta nd-alone systems . Xantrex

products inc lude inverters, battery charge rs, programmable power supplies, and variable speed drives

that convert, su pply, control, clea n, and distribute el ectrical power.

T rademarks

Xantrex XC3012, XC5012, XC1524 and XC2524 Battery Charger is a trademark of Xantrex

Intern ational. Xantrex is a registered trademark of Xantrex International.

Other trademar ks, registered trademarks, and product names are the property of their respective owners

and are us ed herein for identification purposes only.

Notice of Copyright

Xantrex XC3012, XC5012, XC1524 and XC2524 Battery Charger Owner’s Guide© August 2005

Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC.

(“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENT AL, WHICH MIGHT ARISE OUT OF

THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE

ENTIRELY AT THE USER’S RISK.

Date and Revision

August 2005 Revision B

Part Number

975-0187-01-01

Contact Inform a tion

Phone: 1 800 670 0707 (toll free North America)

+34 93 470 5330 (Europe)

1 360 925 5097 (direct and rest of world)

Fax: 1-800 994 7828 (toll free North America)

Email: customerservice@xantre x.com (North America)

Web: www.xantrex.com

+34 93 473 6093 (Europe)

1 360 925 5143 (direct and rest of world)

support.euro pe@xantrex.com (Europe)

customerservice@xantrex.com (rest of world)

Page 5

About This Guide

Purpose

The purpose of this Owner’s Guide is to provide explanations and procedures for

installing, operating, maintaining, and troubleshooting the Xantrex XC3012,

XC5012, XC1524 and XC2524 Battery Charger.

Scope

The Guide provide s safety guidelines, detailed planning and setup information,

procedures for insta lling the charger, as well as information about operating and

troubleshooti ng the unit. It does not provide details about particular brands of

batteries. Consult individual battery m anufacturers for this information.

Audience

The Guide is intended for anyone who ne eds to install and operate the Xantrex

XC3012, XC5012, XC1524 and XC2524 Battery Charger . Installers should be

certified tech ni ci ans or electri ci a ns.

Organization

This Guide is organized into 4 chapters and 1 appendix:

Chapter 1, “Introduction”: Chapter 1 describes the XC Se ries standard features. It

also provides information to prepare for instal lation of the XC Series.

Chapter 2, “Installation”: Chapter 2 pr ovides procedures for installing, testing and

configuring the XC Series.

Chapter 3, “Operation”: Chapter 3 describes the operating states and provides

procedures for char ging a battery and performing an equalization.

Chapter 4, “Troubleshooting”: Chapter 4 contains information on error codes and

procedures for troubl eshooting your XC Series char ger.

Appendix A, “Spe cifications”: Appendix A details the specifications for the

XC Series.

iii

Page 6

About This Guide

Conv en t io n s Used

The following conventions are used in this guide.

WARNING

Warnings identify conditi ons or practices that could result in personal inj ury or loss of life

CAUTION

Cautions ide ntify conditions or practices that could result in dama ge to the unit or other

equipment.

Important:

serious as a caution or warning.

This Guide contains information for fou r versions of the XC Series.

The Xantrex XC3012 Battery Charger (12 V, 30 A) will be referred to as the

XC3012 when it is being referenced individually.

The Xantrex XC5012 Battery Charger (12 V, 50 A) will be referred to as the

XC5012 when it is being referenced individually.

The Xantrex XC1524 Battery Charger (24 V, 15 A) will be referred to as the

XC1524 when it is being referenced individually.

The Xantrex XC2524 Battery Charger (24 V, 25 A) will be referred to as the

XC2524 when it is being referenced individually.

When the Xantrex XC3012, XC5012, XC1524 and XC2524 Battery Chargers are

being refere nced tog eth er, they will be refer red to as the X C Series.

These notes describe things which are important for you to know, but not as

Relat ed Inf o rmation

You can find more information about Xantrex Technology Inc. as well as its

products and services at www.xantrex.com

iv 975-0187-01-01

Page 7

Important Safety Instructions

WARNING

This chapte r contains important safety and operating instructions as prescribed by safety

standards for chargers used in RV and marine application s. Read and keep this Owner’s

Guide for future reference.

1. Before installi ng or using the Xantrex XC3012, XC5012, XC1524 or XC2524

Battery Charge r (XC Series ), read all instructions and cautionary markings on

the XC Series, the batteries , and all appropriate sections of this guide.

2. Do not expose t he XC Series to rain , snow, spray, or bilge water. T o reduce risk

of fire hazard, do not cover or obstruct the ventilation openings. Do not install

the XC Seri es in a zero -c le ara n ce co mpartment. Over he at ing may result.

3. Use only attachments recommend ed or sold by Xantre x. Doing otherwise may

result in a risk of fire, elect ric shock, or injury to persons.

4. The XC Series is designe d to be permanently connected to the AC and DC

electrical sys tems. Xantrex recommends that all wiring be done by a certif ied

technician or electrician to ensure compliance with the local and national

electrical codes relevant to your installation. It is the responsibility of the

installer to ensure that the installation of the XC Series complie s with all

relevant elect rical codes.

5. T o avoid a risk of fire and electric shock, make sure that existing wiring is in

good condition and that wire is not undersized. Do not operate the XC Series

with damaged or substandard wiring.

6. Do not disassemble the XC Series. It contains no user-servi ceable parts.

Attempti ng to serv i ce th e XC Series your se lf may resu lt in a risk of elec t rical

shock or fire.

NOTE: Disassembling the XC Series will void your warrant y.

7. T o reduce the risk of electrical shock, disconnect both AC and DC power from

the XC Series before attempting any maintenance or cleaning or before

working on any circuits connected to the XC Series. Turning the XC Series off

using the remote display will not reduce this risk.

v

Page 8

Safety

8. The XC Series is provide d with an AC ground conductor that must be

connected to the AC input ground and a DC ground stud which must be

connected to the DC system ground.

9. For marine applications in the United States, external connections to the

charger shall comply with the United States Coast Guard Electrical Regulations

(33CFR183, Sub pa rt 1).

Explo sive Gas and Battery Precauti on s

WARNING: Explosion or fire hazard

1. Read this guide and follow the instructions exactly before installing or using

your XC Series.

2. Follow all instructi ons published by the battery manufacturer and the

manufacturer of the equipment in which the battery is installed.

3. Working in the vicinity of lead-acid batteries is dang erous. Batteries generate

explosive gases during nor mal operation.

4. The XC Series has been approved as Ignition Protected. It may be installed in

areas containing gasoline tanks and fittings which require Ignition Protected

equipment. Xantrex recommends, nevertheless, that it is safest not to install

electrical equip me n t in thes e area s.

5. Make sure the area around the battery is well ventilated.

6. Never smoke or allow a spark or flame near the engine or batteries.

7. Use caution to reduce the risk of dropping a metal tool on the battery. It could

spark or short circuit the battery or other electrica l parts a nd could cause an

explosion.

8. Remove all metal items, like rings, bracelets, and watches when working with

lead-acid batteries. Lead-acid batteries produce a short circuit current high

enough to weld metal, causing a severe skin burn.

9. Have someone within range of your voice or clos e enough to come to your aid

when you work near a lead-acid battery.

vi 975-0187-01-01

Page 9

10. Have plenty of fresh water and soap nearby in case bat tery acid contacts skin,

clothing, or eyes.

11. Wear complete eye protection and clothing protection. Avoid touching your

eyes while wo rki ng near batteries.

12. If battery acid conta cts sk in or cl othin g, wash immediate ly wit h soap and wat er.

If acid enters your eye, immed iately fl ood it with running cold water for at least

twenty minutes a nd get medical attention immediately.

13. If you need to remove a battery, always remove the ground terminal from the

battery first. Make sure al l accessories are off to reduce the possibility of

causing a spark.

FCC Information

This equipment has been tested and found to comply with the limits for a C lass B

digital device, pursuant to part 15 of the FCC Rules. These lim its are designed to

provide reasonabl e protection against harmful interference in a residential

installati on. This eq uipment gener ates , uses, and can radiat e radio fr equency e nergy

and, if not installed and used in accordance with the instructions, may ca use

harmful interfere nce to radio communications.

However, there is no guarantee that inter ference will not occur in a particula r

installati on. I f this equipment does cause harmful interference to radio or television

reception, which can be determine d by turning the equipment of f and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

Safety

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit differ ent from that to which

the receiver is connect ed.

• Consult the dealer or an experienced radio/TV technici an for help.

975-0187-01-01 vii

Page 10

viii

Page 11

Contents

Important Safety In str uctions

Explosive Gas and Battery Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

FCC Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vii

1

Introduction

Xantrex XC3012, XC5012, XC1524 and XC2524 Battery Charger Features - - - - - - 1–2

XC Series Appearance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Information Centers of the XC Series- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Remote Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Onboard Status Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Rear Panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Preparing for Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Tools and Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Wiring Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

Battery Bank Size Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–14

2

Installation

Installing the XC Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Installation Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Pre-Installing DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Pre-Installing AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Mounting the Remote Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Final Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Final DC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Final AC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Powering Up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

975-0187-01-01 ix

Page 12

Contents

Installing Optio nal Accessories- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Battery Temperature Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Drip Protection Rubber Boots - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Configuring the XC Series- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

3

Operation

About Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Multiplex 3-Stage Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Sequential 2-Stage Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Charging Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Charging Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Equalizing Flooded Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Transitioning the XC Series to On, Disabled or Off - - - - - - - - - - - - - - - - - - - - - - 3–10

Accessing Charger Inform ation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

Reading Remote Display and Onboard Status Indicator Lights - - - - - - - - - - - 3–11

Reporting While Charging or Equaliz ing - - - - - - - - - - - - - - - - - - - - - - - - - - 3–13

Reporting While Battery Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Reporting While Disable d - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Using A Generator As Source Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

4

Troubleshooting

Care and Maintenance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

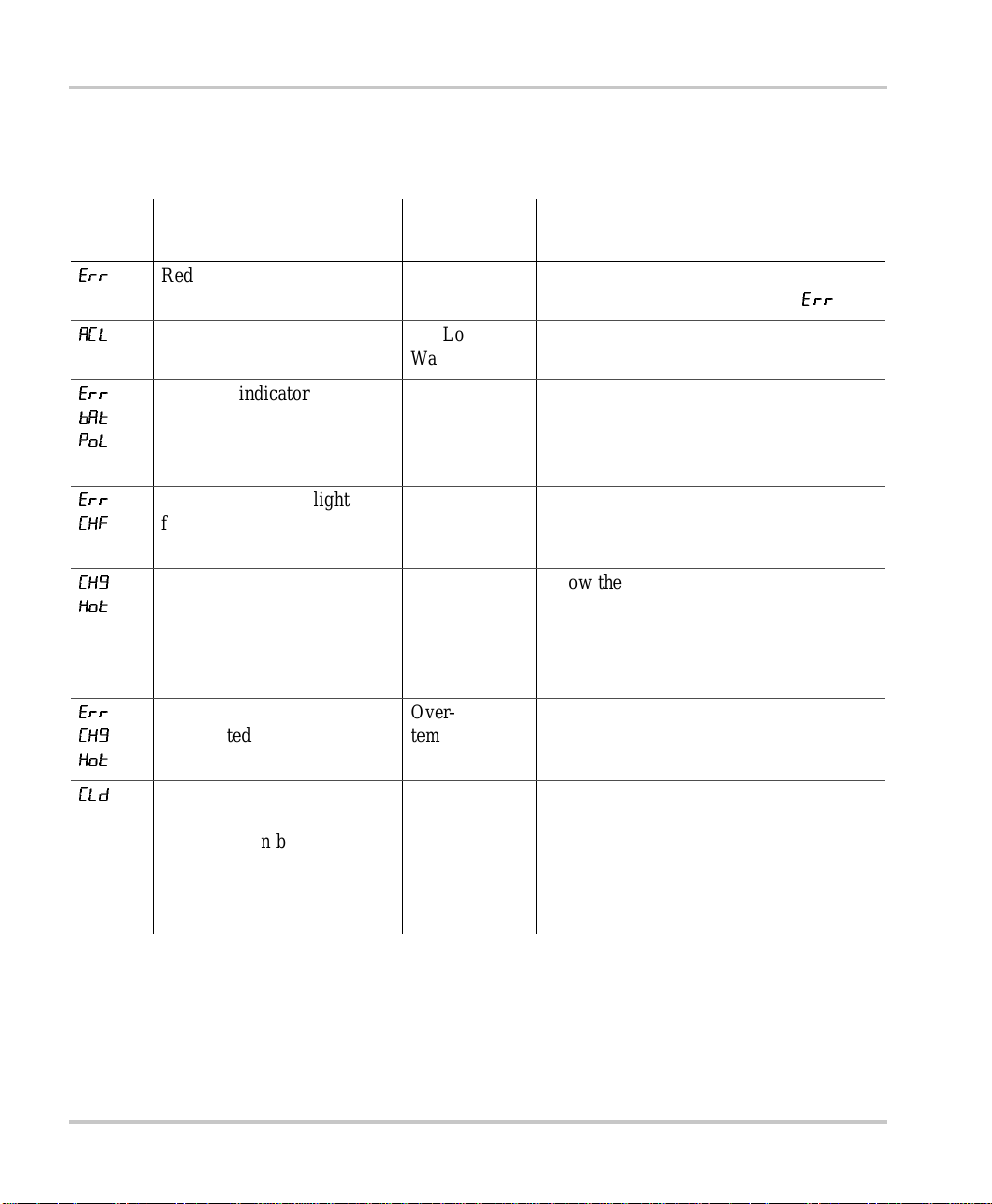

Indicator Light Flashing Sequences- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Error Messages on Remote Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Problem Solving - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–7

A

Specifications

Physical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

AC Input Specification s - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

Temperature Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–4

Protection Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–4

Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–5

Warranty and Product Information

x 975-0187-01-01

- - - - - - - - - - - - - - - - - - - - - - - - - - WA–1

Page 13

1

Introduction

Chapter 1 describes the XC Series standard features. It

also provides information to prepare for installation of

the XC S er ies.

Page 14

Introduction

Xantrex XC3012, XC5012, XC1524 and XC2524 Battery

Charger Feat u res

The XC Series provides the following standard features:

• three full current rated, independently controlled outputs which enable it to

charge thre e diff erent batte rie s or battery banks . Each bank can be of a dif ferent

battery type, stage of charging, and temperature compensation

• one battery tempera ture sensor (BTS) is included. Optional BTSs may be

purchased for the other two outputs, to provide complete optimal battery

charging to each battery or bank

• battery monitor ing functions while in float mode or rest mode

• correct char ging voltage for your batterie s when connecte d to almost any sing le

phase AC power outlet in the world

• invertable rem ote display panel which can also be removed from the charger

and mounted up to 20 m (65 ft) away for remote control and monitoring

The XC Series provides the following protection features:

• true “fuseless” reve rse polarity protection to guard against continuous r everse

battery polarity without charger damage

• AC over voltage protection shutdown

• over temperature protection shutdown

• electronic current limiting for protec tion against short circuit on the unit’s

output

• built-in prote ction against accidental connection to a higher battery voltage , up

to 24 VDC

• battery temper ature compensation to 0 °C (32 °F) (with BTS installed)

• ignition prot ected rating, enabling installation in engine spaces

• isolated design to reduce shock hazard

• automatic char ge resumption after AC power interr uption

1–2 975-0187-01-01

Page 15

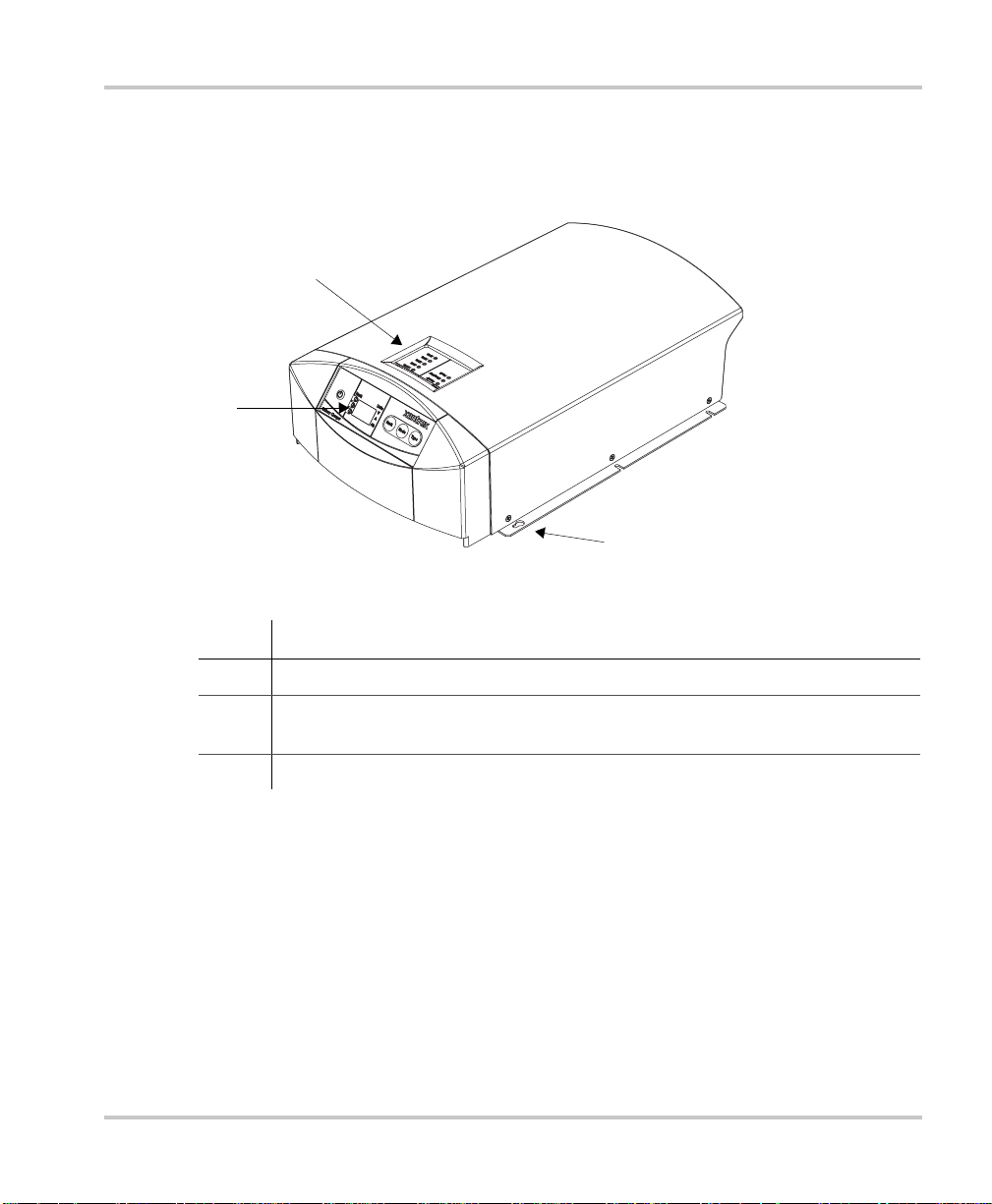

XC Series Appearance

This section describes the parts of the XC S eries. Figure 1-2 shows the XC Series.

2

1

XC Series Appearance

3

Figure 1-1

Item Description

1 Remote display for all programming functions and monitoring of the XC Series.

2 Onboard status panel for monitoring charger status and charging current a t the

3 Mounting flanges

975-0187-01-01 1–3

XC Series

XC Series when the remote display is mounted remotely from the charger.

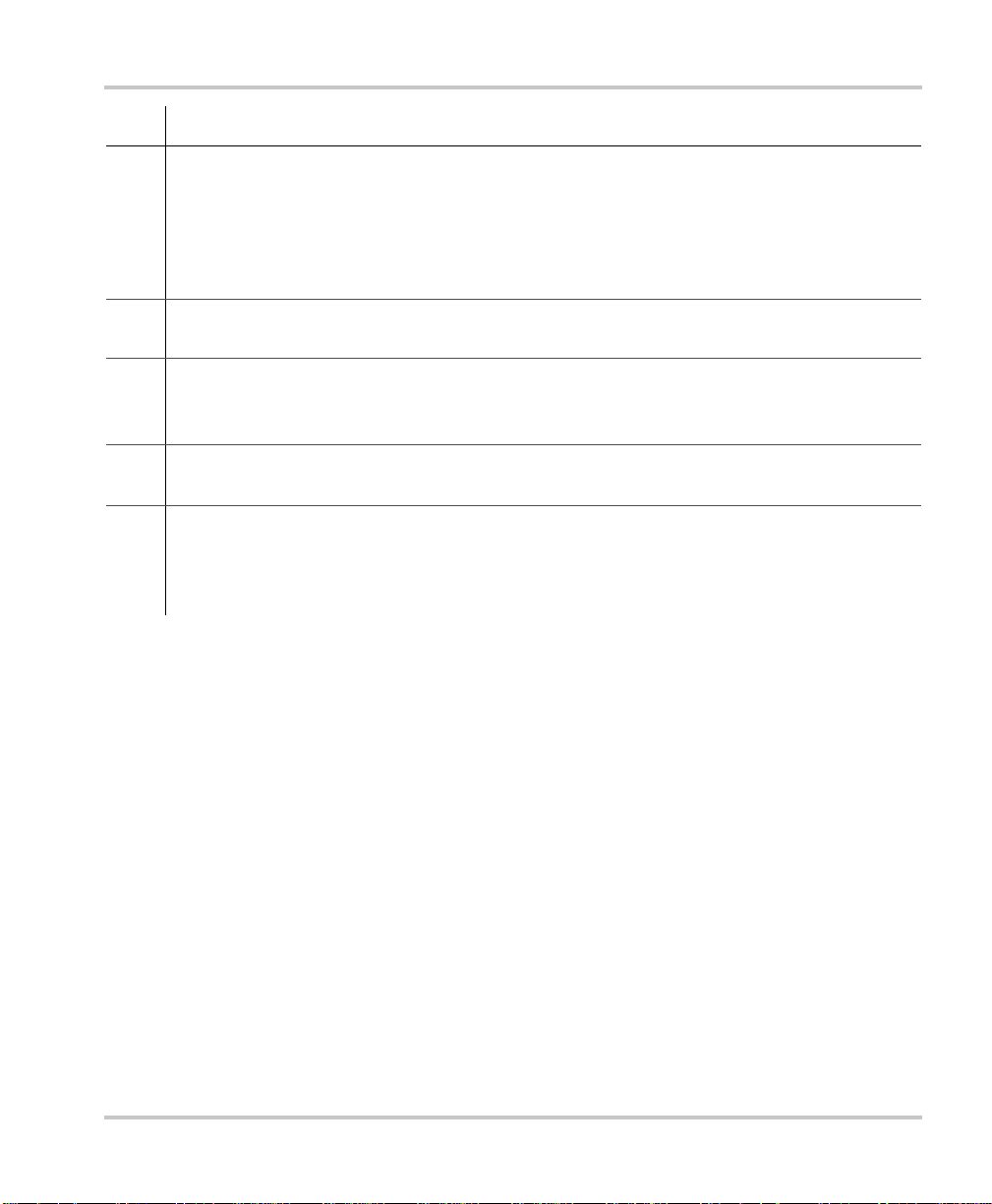

Page 16

Introduction

Inform ation Centers of the XC Series

Remote Display

This section describe s the parts of the remote display of the XC Series. The remote

display can be rotated 180°, or it can be r emoved and remotely mounted up to 20 m

(65 ft) from the XC Series for convenience. Figure 1-2 shows the remote display.

A “press and h old” action on the remote display means that the button must be held

down for more than 2 seconds in order to send the instruction. A “press” action on

the remote display means that the button must be pressed and re leased before 2

seconds have elapsed.

2 3 4 5

1

7

Figure 1-2

Item Description

1

ON/STANDBY push button

• Press to turn on or disabl e the charger while AC powe r is conne cted

• Press and hold to apply selection when in setup or equalization mod e

• Press to show battery bank voltages when AC is disconnected

2 Battery bank indicator lights

• Illuminate to sh ow which bank has been selected for setup or status dis play

• Illuminate during a fault or warning to show which bank ha s the fault or warning, or

illuminate all three if the charger itself has the f ault or warning

XC Series Remote Display

6

1–4 975-0187-01-01

Page 17

Information Centers of the XC S eries

Item Description

3 Alpha-numeric dis play shows

• Configuration

• Fault or warning message s (see T able 4-2 on page 4–4)

• Battery bank voltage and c urrent

• Type of charging (2 stage or 3 stage)

• State of charge

4 Units indica tor lights

• Illuminate to sh ow unit of m easure for the numeric read-out on the alpha-numeric display

5

BANK selection pus h button

• Press to select a bank during setup

• Press at the same time as

6

TYPE selection push button

MODE to enter o r ex it equalizatio n mode.

• Press to select flooded (lead acid), gel, AGM, or lead calcium batteries.

7

MODE selection push button

• Pres s to select chargi n g st at e du r i ng s et u p : 2 st ag e o r 3 stag e.

• Press at the same time as

BANK to enter or exit equalization mode.

• Press and hold to enter setup.

The indicator li ghts and dis play are also used to indi cate err or co des. See Chapter 4,

“Troubleshooting” for a list of faults and how to clear them.

975-0187-01-01 1–5

Page 18

Introduction

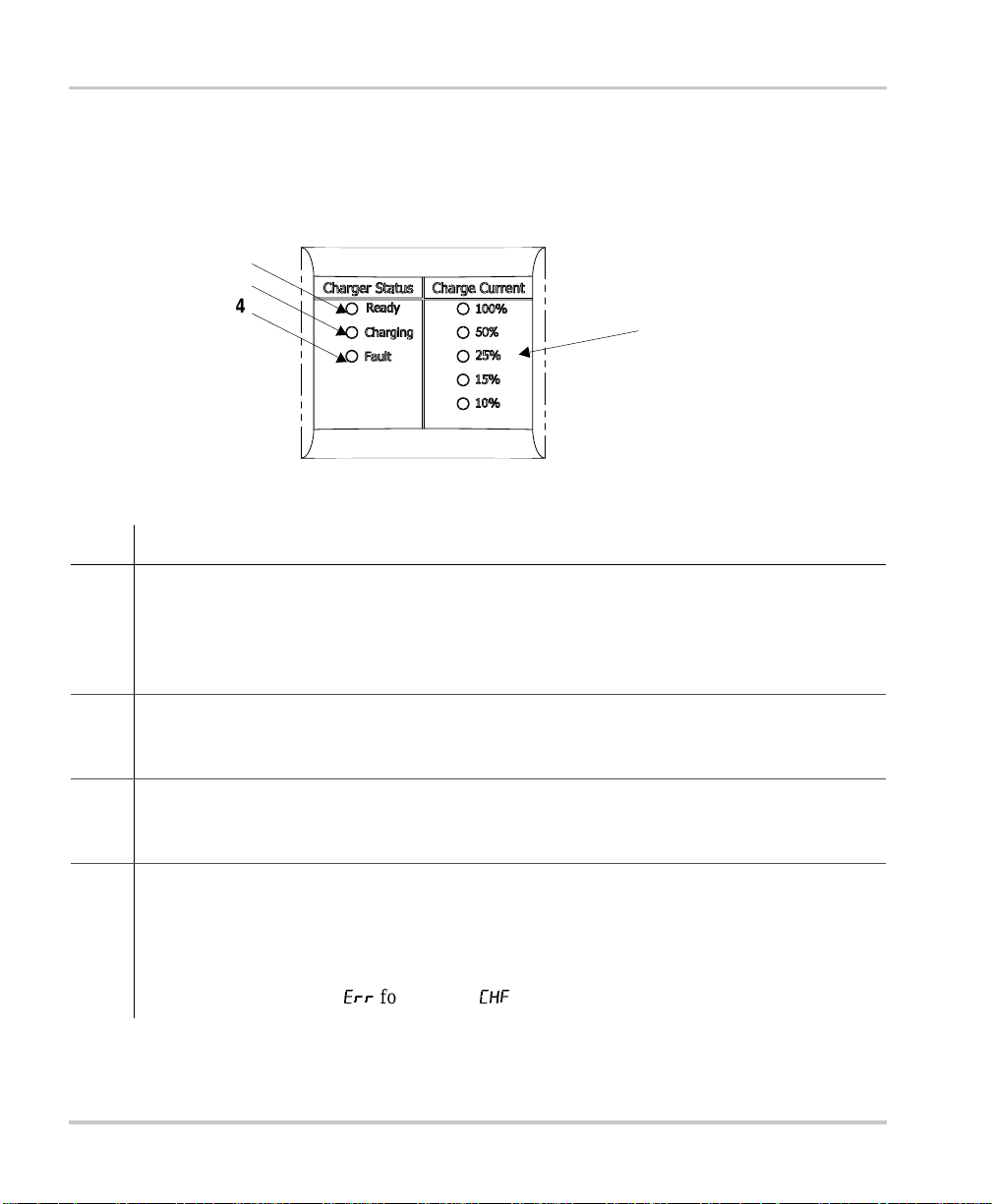

Onboard Status Panel

This section describes the parts of the onboard status panel of the XC Series.

Figure 1-3 shows the panel.

2

3

4

1

Figure 1-3

Item Description

1 Charg e Cu rrent

• Displays the output charge current in % of charger maximum for the bank being charged

• 100% indicator ligh t flashes to indicate battery temperature too high (> 50 °C, 122 °F)

• 10% indicator light flashes to indicate battery temperature too low (< 0 °C, 32 °F)

• 25% indicator light flashes to indica te that a battery has been disqualified (see page 3–4)

2

3

4

Charger Status -

• Ready indicator light illuminated indicates all batteries are fully charged, and are now in

float or rest

Charger Status -

• Charging indicator light illuminated indicates unit is performing a normal charge cy cle

• Charging indica tor lig ht flashing indi ca tes that the unit is performing an equa liza tion cycl e

Charger Status -

• Fault indicator light continuously illuminated indicates any fault condition that prevents

the XC Series from charging one or more batteries, but is not a charge r failure - remote

display shows details of fault

• Fault indicator light flashing indicates the XC Series has experienced a charger failure remote display shows

XC Series Onboard Status Panel

READY

CHARGING

FAULT

err

followed by

CHf

1–6 975-0187-01-01

Page 19

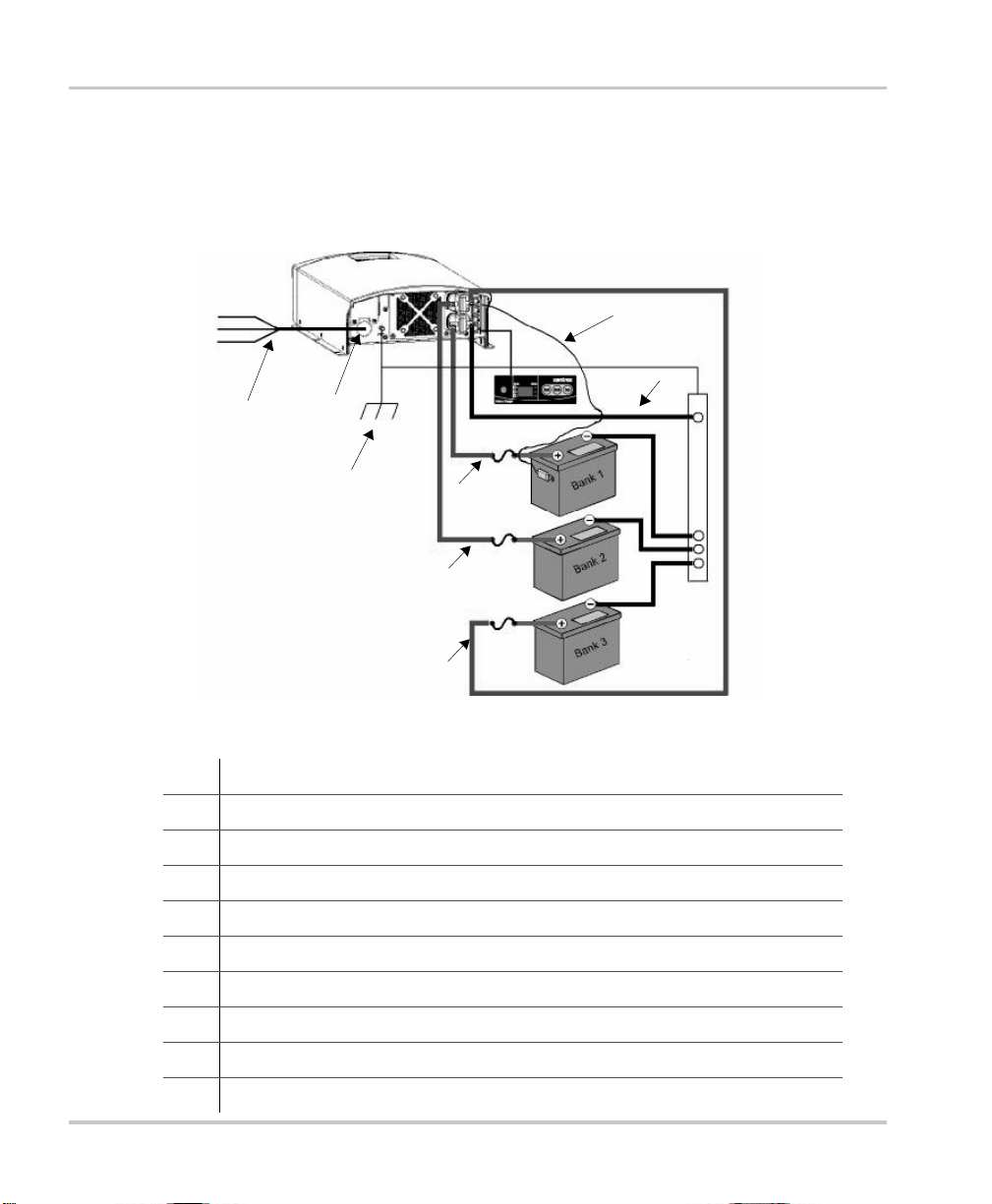

Rear Panel

This section desc ribes the part s of the rea r panel of the XC Series. Figure 1-4 shows

the rear panel.

Rear Panel

9

7

11

++

2

Bank3Bank

Figure 1-4

10

XC Series Rear Panel

6

Item Description

1 Remote displa y com munication connector

2 BTS1 (battery temper ature sensor for bank 1) connector

3 BTS2 (battery temper ature sensor for bank 2) connector

4 BTS3 (battery temper ature sensor for bank 3) connector

5 Battery negative, common for all 3 banks (6 mm stud)

8

2

3

4

1

5

6 Battery positive for bank 1 (6 mm stud)

7 Battery positive for bank 2 (6 mm stud)

8 Battery positive for bank 3 (6 mm stud)

9 Fan asse m b l y

10 Chassis ground (earth) for DC wiring

11 AC wiring access panel

975-0187-01-01 1–7

Page 20

Introduction

Preparing for Installation

The XC Series is designe d to be permanently mounted. Figure 1-1 shows a typical

installati on with three batteries, a BTS and a remote display. It also shows the AC

and DC wiring and protection device s requir ed for a successful installa tion.

L

N

G

1

Figure 1-5

2

10

XC Series System

8

5

4

5

4

5

4

9

3

7

6

6

6

1 AC mains source with correct s ize and type of circuit breaker

2 AC input wiring compartment

3 DC negative c able

4 DC positive cables

5 DC circuit breaker or DC fuse and disconnect

6 Battery or battery bank

7 Engine ground bus or DC negative bus

8 Remote display panel

9 Battery temper ature sensor (#1 is standard equipment. #2 a nd #3 are optional)

10 DC chassis ground (earth)

1–8 975-0187-01-01

Page 21

Tools and Materials

To mount and connect the XC Series you need the following tools:

• 10 mm wrench or socket for the DC terminals and ground stud

• Phillips screwdriver for securing the AC wiring compartment cover

• power drill

• drill bit for pil ot holes for mounting screws

• wire stripper

• manufacturer's recommended crimp tool for any crimp terminals that are being

used

You need the following mate ri als:

• 3 conductor AC input wiring

Use the inf ormation in “AC Wiring” on page 1–13 and your local electrical

codes to determine the corre ct wire and breaker or fuse.

• AC cable str ain relief (if the one included is not sufficient for your local

electrical code requirements)

• appropriat ely sized D C ca bles fo r each b at tery, with suitable c onnectors at the

battery end

• appropriate ly sized DC chassis ground (earth) with suita ble connectors

• ring terminals to fit 6 mm (1/4 in.) studs at the charger end

• DC fuse and disconnect or circuit breaker for each battery bank

• mounting hardware, 3 m m (#6) corrosion resistant 6 piec es.

• other means to route and secure AC and DC wiring

Preparing for Installation

975-0187-01-01 1–9

Page 22

Introduction

Location

Install the XC Series in a location that meet s the following requirements :

Condition Requirement

Dry The XC Series must be installed in a dry location not subj ec t to rain, spray or splashing

bilge water.

Clean The XC Series should not be exposed to metal filings or any other form of conductive

contamination.

Cool The ambient air temperat ure should be between 0 °C - 50 °C (32 °F - 122 °F) for best

performance.

Ven t il at ed There must be at least 76 mm (3 in.) of clearanc e on each end of the XC Ser i es f or ai r

flow. Ventilation openings on the unit must not be obstructed. If mounting in a tight

fitti ng co m p a r tment, th e co mp artmen t m u st be v e n t il at ed w it h cut - o ut s to pr e vent

overheating.

Safe This battery charger is ignition protected, so it can be installed in areas containing

gasoline tanks or fittings which usually require ignition protected equipment. Xantrex

recommends, however, that it is safest not to install el ectrical equipment in these areas.

Close to

batteries

The XC Series should be installed as close as possible to the batteries, but not in the

same compartment to prev ent excess corrosion. Avoid excessive ca ble lengths and use

the recommended wire sizes. Xantrex recommends <3% wire voltage drop (r ound

circuit) on battery cables under full load.

When planning where and how to mount the XC Series, be sure the installa tion

allows the charge r to be mounted in one of the permitted vertical or horizonta l

orientations.

For marine installat ions, only the mounting configura tions with a check mark in

Figure 1-6 meet the North American and Europea n marine requirements. Marine

products are required to meet drip tests, to ensure safety in the presenc e of

condensation. If you are cert ain your installation is not subject to moisture,

configuration d) in Figure 1- 6 may be used.

1–10 975-0187-01-01

Page 23

a) b)

Preparing for Installation

Vertical

c) d)

Horizontal

Figure 1-6

XC Series Mounting Orientations

Vertical - this c onf igurat ion i s unsaf e and

should not be used

Vertical - thi s configuration may be used

in an environ ment wh ich is dr y and clean

only (non-mari ne)

975-0187-01-01 1–11

Page 24

Introduction

Wiring Requirements

WARNING

Wire and fuse sizes ar e dict ated by electrical standards. D ifferent standards apply in

differe nt countries and different types of installations, for example, boat, home or RV. It is

the resp onsibility of the install er to ensure that the installation comp lies with all applicable

standards.

CAUTION

Ensure that both wires and fuse s are corr ectly sized .

Maximum conti nuous c urrent a vaila bl e from t he cha rger may be an add iti onal 6 –10% abov e

the nominal current rating of the charger. Out put current may also vary depending on

ambient tempe rature conditions.

DC Wiring

The following two tables show some typica l wire sizes, based on 3% voltage drop

(round circuit) , 75 °C (167 °F) rated wire and wiring being inside the engine

compartment – assumed ambient of 50 °C (122 °F).

Table 1-1

DC Wiring Requirements

Wire Length

(

maximum length one way) Wire Size (AWG and mm

2

)

feet meters XC3012 XC5012 XC2524 XC1524

51.5No. 10

2

5mm

7.5 2.25 No. 8

2

8mm

20 6 No. 6

13 mm

No. 6

13 mm

No. 6

13 mm

No. 4

2

19 mm

2

2

2

No. 10

5mm

No. 10

5mm

No. 10

5mm

2

3mm

2

No. 12

No. 12

2

3mm

2

No. 12

2

3mm

2

1–12 975-0187-01-01

Page 25

AC Wiring

Preparing for Installation

Over-current protect ion disco n nect

The DC circuit from the battery to the char ge r must be equipped with a disconnect

and over-cur rent protection device. The device usually consists of a DC-rated

circuit breaker, a “fused disconnect”, or a separate fuse and disconnect. These

devices must be rated for DC voltage and current. Do not substitute devices rate d

only for AC voltage; they may not operate prope rly.

The current rating of the DC fuses must be matched to the size of the DC wiring

used, in accord an ce wi th the appl icab l e cod es.

The DC chassis ground (earth) shoul d not be more than one siz e smaller than the

DC wiring size selected (see Table 1-1). Refer to your local electrical codes for

verification.

The AC wiring must meet the following requir ements before you install the

XC Series:

The AC input wiring for the XC Series should be three-conductor cable, providing a

line, neutral, and ground conductor (or L1, N,

GND) in an outer jacket.

For example, in North America for 120 VAC use a 14 AWG wire with a 15 A

breaker; or typical ly in Europe for 230 VAC use either a 2.5mm

2

wire with a 16 A,

double pole breake r or fu se or u se 1.5 mm2 wire with a 10 A, double pole breaker or

fuse. Note that every jurisdiction will have different requirements, so see the

regulations for your local jurisdiction to determine which wire size and type is

correct. A seco nd ex am p le:

• for marine applica tions the United States ABYC requires stranded wire, which

is more robust than solid wire when exposed to vibr ation

• for RV applications, the United States NEC allows solid wire in multi-

conductor cable, but stranded wire will withstand vibration better.

The circuit supplying the XC Series must be protected by the cor rect size and type

of breaker to meet the code for your local jurisdiction and application. If a fuse is

used, a disconn ect swi t ch is ne ed ed ah ead o f the fu se.

975-0187-01-01 1–13

Page 26

Introduction

Battery Bank Size Requirements

The XC Series is designe d to work with a minimum battery bank size. Each bank

should meet the minimum Ah rating shown in Table 1-2.

Table 1-2

Models XC 1524 XC 2524 XC 3012 XC 5012

Minimum Battery

Bank Size (Ah)

Minimum Battery Bank Size

30 50 60 100

1–14 975-0187-01-01

Page 27

2

Installation

Chapter 2 provides procedures for installing, testing

and configuring the XC Series.

The unit is packed with the following materials:

• Owner’s Guide

• AC cable strain relief

• Two DC cable boots

• Blank plate for remote display cavity

• One battery temperature sensor (BTS)

• Five #6 lockwash ers

• Five #6 flatwashers

• Five #6 nuts

After unpacking the unit, record the serial number and

other purchase information on page WA–4 of this

guide.

Page 28

Installation

Instal ling the XC Series

WARNING: Shock and Energy Hazards

Be sure to read the safe ty guidelines and pay attention to all cautions and warnings

throughout th e installation procedure. The installer is responsibl e for en suring compliance

with the installation codes for your particular application.

Disconnect all sources of AC and DC power before proceeding.

Installation S equence

T o make charger installation quick and easy, Xantrex recommends that the

installation tasks be pe rformed in the following sequence:

1. Select charger mounting position and plan AC and DC cable routing (page 1–8)

2. Install DC cable runs and fuses or breakers (page 2–3)

3. Make the AC connections at the charger (page 2–4)

4. Mount the remote display and charger in position (page 2–7)

5. Make the final DC and then AC cable connections (including earth grounds)

(page 2–10)

2–2 975-0187-01-01

Page 29

Pre-Installing DC Wiring

The procedure for installing the DC wiring applies to a single battery or multiple

batteries or batter y banks.

WARNING: Shock or arc burn hazard

To help prevent accidental short s or sparks, leave the DC disconnects or breakers in the Off

position or fuses removed from their fuse holders until installation is complete.

Installing the XC Series

Important:

terminals to prov ide drip protection and increased protection from short circuits. You nee d

to install the boot s before doing any other DC wiring. See “To install rubber boots:” on

page 2–14.

Xantrex recommends th at you inst all t he rubbe r boot s over the XC Series DC

To install DC wiring:

1. Identify the battery or bank that most frequently becomes deeply discha rged.

This bank will often be a deep cy cle battery referred to as the House Bank on a

boat, as opposed to an engine Start Battery. This high priority bank should be

connected to bank 1 on the XC Series, which is the default ban k.

2. Plan the route that the DC wires will follow, keeping it as short as possible.

Measure and cut the required wire length. Allow some extra length for

connections and to provide slack in the wires.

Note: The connection to the battery negative cir cuit may not be at a battery, but

may be at an engine negative bus or a DC negative bus. If in doubt, consult the

boat schematics.

3. Identify the positi ve wires, by using color- coded wire or by marking both ends

of the wire with colo red tape or simi lar kind of marking. Repeat with a dif fere nt

color for the negative . Most install ation cod es recommend color ing the positi ve

red and the negative black.

Important:

bank it is connected to. For example, bank 1 (–), bank 1 (+), bank 2 (–).

Yo u m ay fi n d it helpfu l to la bel each cable, as so ciatin g it wi th the bat t er y

4. Install a DC circuit breaker or fuse/disconnect in each positive cable close to

each battery. For your appli cations a nd juri sdiction , consu lt you r loc al electr ical

codes regarding th e distance between the battery and the disconnect device . B e

sure the breaker is open or fuse is not inserted at this time.

975-0187-01-01 2–3

Page 30

Installation

5. Route the wiring to the batteries and to the XC Series, but don’t connect it yet.

A void routing wiring thr ough an electrical dist ribution panel, battery isolator , or

other device that will add volta ge drops.

6. Install crimp lugs on ea ch end of the battery cables using the crimp

manufacturer’s instructions and tool.

7. Install rubber boots ove r the charger end of the DC cables.

Xantrex recommends that you inst all rubber boots over the XC Series DC

terminals to provide drip protection. Follow the procedure on page 2–14 to

install rubber boot s.

8. Route the battery temperature sensor from each batte ry to the charger location.

9. Proceed to “Pre-Installing AC Wiring”.

Pre-Installing AC Wiring

Before connecting AC wiring, make sure the AC source circuit is protected by a

breaker switch of the correct size and type, to comply with the electrical code for

your location and applic ation.

To install AC wiring:

1. Disconnect the AC source by turning off the breaker feeding the circuit,

unplugging from shorepowe r and disconnecting any other power sources (such

as a generator).

2. Plan the route that the AC wiring will foll ow from the source (usually an AC

distribution pan el) to the XC Series. Measure and cut the required length of

three-conduct or cable.

For example, in North America for 120 VAC use a 14 AWG wire with a 15 A

2

breaker; or typical ly in Europe for 230 VAC use either a 2.5mm

16 A, double pole breaker or fuse or use 1.5 mm

2

wire with a 10 A, double pole

wire with a

breaker or fuse . Note tha t eve ry jurisdi ct ion will ha ve dif fer ent re quiremen ts, so

see the regulations for your local jurisdiction to determine which wire size and

type is correct.

Allow some extra length for connections and to provide slack.

3. Make the AC connections to the back of the charger when it is sitting on a table

or other convenient work surfa ce.

Route the AC ca bles to the source after the charger is mounted in position.

4. Unscrew the wiring compartment co ver from the left rear of the XC Series to

expose the AC wiring access hole.

2–4 975-0187-01-01

Page 31

Installing the XC Series

5. Install the cab le strain relie f on the X C Series end of the s our ce A C cabl e.

6. Carefully remove 50 – 75 mm (2 – 3 in.) of the outer jacket, being c areful not to

cut or nick the insulation on the indi vidual conductors.

7. Pull the XC Series pigtail wires out through the access hole.

8. Thread the source AC cable through the knockout beneath the wiring

compartment cover and then pull it out through the access hole.

9. Connect the AC wiring to the XC Series pigtail wire s, being sure to connect the

line conductor to the line, the neutral to the neutral, and the ground to the

ground. The pigtail wires are color coded as follows:

Conductor Color code

Line Black or brown

Neutral White or blue

Ground Green with yellow stripe

10. Make the connections with twist-on or crimp-on connectors or with other

approved connectors suitable for your install ation. For example, the ABYC

Standards and Recommended Practices for Small Craft prohib it twist-on

connectors for AC connecti ons on a boat. For non-marine installations in

locations not subject to vibration, either type of connector may be used.

For marine installations, follow the procedure for installing butt splice

connectors.

975-0187-01-01 2–5

Page 32

Installation

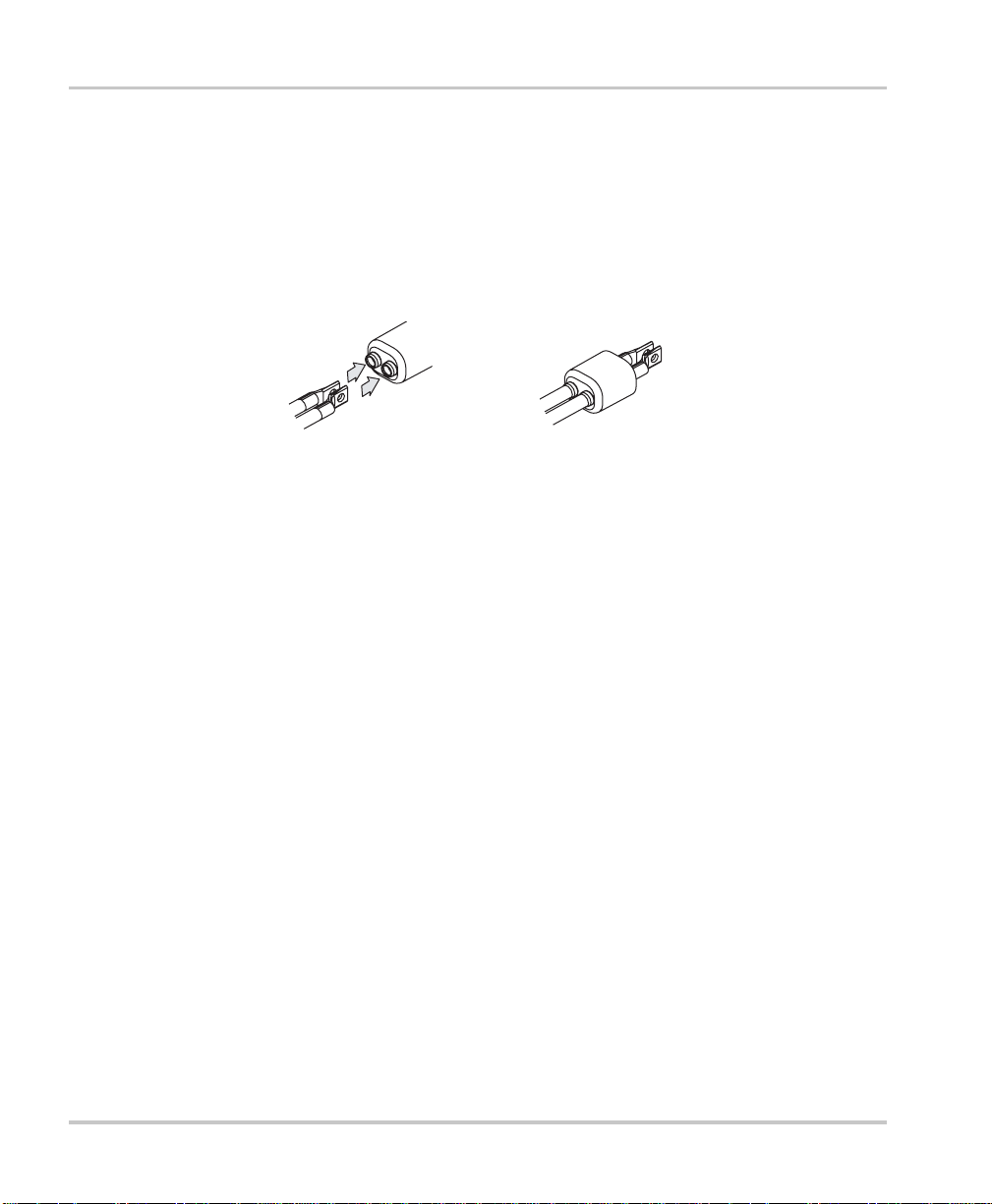

To connect AC wires with the crimp-on butt-splice connector:

Important:

You must exercise care when crimping butt -splice connectors. Use the

crimp tool recommended by the manufac turer for the connec tor used.

a) Using a wire stripper, carefully strip 8 mm (5/16 in.) from the ends of the

two wires be ing connected.

b) Insert one wire into one end of the butt-splice, until the insulation hits the

internal metal crimp section, insert the butt-splice into the crimping tool,

and crimp firmly. The proper location f or the crimp is approximately

1.6 mm (1/16 in.) past where the butt-splice insulation tapers down as

shown.

1/16 “

STRIP 5/16”

CRIMP TOOL

c) Repeat Step b for the othe r en d of the bu tt-sp l ice.

11. Push the AC cable str ain r elief into the electr ical jun cti on box hole unti l it sna ps

into place.

12. When all connections are completed, push the wiring and connectors inside the

wiring compartment. Install the wir ing compartment cover an d fasten with the

supplied blunt-tip screws and lockwashers.

2

1

13. Proceed to “Mounting the Remote Display”.

2–6 975-0187-01-01

Page 33

Mounting the R emote Display

WARNING: Shock hazard

Even if you intend to leave the remote dis play in the shipped orientation in the XC Series,

you must remove the remote dis play and secure it in place by removing the non-stick

backing on the rear and pre ssing the remote display flanges in place. If you do not use the

non-stick backing, the XC Series will not be drip protected.

To accommodate the charger mounting orientation, the remote display can be

removed and turned 180 ° for readability. If you intend to mount the display

remotely, up to 20 m (65 ft), remove the display before mounting the charger and

secure the blank plate to cover the display socket on the unit.

CAUTION

Ensure you are placing the display in the correct orientation before remo ving the adhesive

backing. T he adhesive tape for attaching the remote is extremely strong and you may be

unable to remove it without damaging the dis play or other equipment.

To remove the display:

Installing the XC Series

1. Unplug the display cable from the tel ephone-type connector on the back of the

unit.

2. Release the display cable from the retaining clips on the underside of the unit.

3. Remove the remote display f rom the charger and read and then remove the

warning label that is attached to it.

To secure the display or blank plate on the unit:

1. Choose the display orientation that is appropriate for the charger orientation.

2. Remove the adhesive backing on the back of the display or blank plate .

3. Line up the display or blank plate with the display socket, making sure it is in

the chosen orientati on.

4. Firmly press the flanges in pla ce. Do not press in the middle of the display.

5. Route the display’s North American style telephone-type cable under the unit

and plug the cable into the bottom connector on the rear panel of the unit.

975-0187-01-01 2–7

Page 34

Installation

To remot el y mount the display :

1. Remove the display as described on page 2–7.

2. Secure the blank plate in the display socket as described.

3. Ensure that the extension cable used for the remote display is long enough to

suit the installation. A standard North American style, 4 conductor (RJ-11)

telephone cable exten der is ad equate.

4. Use the enclosed mounting template to cut a hole for the display in the c hosen

mounting surface.

T ake care that there is nothing behind the surface for you to damage.

5. Feed the remote display extension cable through the hole and route it to the

charger. Be careful not to damage the telephone connector locking tab when

routing the cable. You can use some tape to protect the locking tab from

catching on something and breaking off when routing the cable.

6. Remove the adhesive backing on the back of the display.

7. Line up the display with the mounting hole .

8. Firmly press the flanges in pla ce. Do not press in the middle of the display.

9. Once the XC Series is mounte d, plug the cable i nto th e bottom connec tor on th e

rear panel of the XC Series.

10. Proceed to “Mounting”.

Mounting

Mount the XC Series using the mounting slots pro vided.

For marine installat ions, only the mounting configura tions with a check mark in

Figure 1-6 on page 1–1 1 meet the North American and European requirement s.

This is to ensure that any mois ture that may be present will not ent er the XC Series.

Important:

before drilling the pilot holes for mounting the XC Series.

To mount the XC Series:

1. Keep the carton and packing material in case you need to return the XC Series

for servicin g.

2. Ensure that you have selected a mounting surface that is clear, flat and allows

for a minimum of 76 mm (3 in.) of clearance on each end for fan circulation.

2–8 975-0187-01-01

Be sure to measure you r AC and DC cables and pl an th e routing of the cabl es

Page 35

3. Secure the enclosed mounting template to the mounting surface with tape.

4. Drill the six pilot holes for the mounting screws, taking ca re that there is

5. Mount the XC Series using corrosion res istant, #6 (3 mm) round, pan head (or

Grounding

WARN ING: Electric shock hazard

Do not make an ungrounded installation. Have an electrician install a properly grounded

circuit if one is not available. Improper connection ca n res ult in risk of an electri c shock.

The XC Series Battery Charger must be grounded to reduce the risk of electrical

shock. The AC input ground wire of the charger must be properly connected to

ground in accordance with the applicable electrical codes, this is usually a ground

terminal in the AC distribution panel where the branch circuit originates.

Xantrex recommends that you inst all a DC chassis ground (earth) from the ground

stud on the XC Series to the engine negative bus or DC ground bus . The DC chas sis

ground (earth) should not be more than one size smaller than the power conductors,

and must be rated for the battery fuses that are used to protect the DC wiring. Refer

to your local electrica l codes to verify if this is required in your jurisdiction or in

your application.

Installing the XC Series

nothing behind the surfac e that can be damaged by the drill.

similar) screw s.

The top two keyhol e-style mounting holes can be used to hold the XC Series in

place while fa stening the bottom four screws. For se cure, permanent mounting,

use all six mounting slots.

Proceed to “F inal Co n nect io n s”.

975-0187-01-01 2–9

Page 36

Installation

Final Connections

Once the DC cab les , AC cab l es an d XC Series are all in pl ace the fina l con n ecti o n

may be made.

Figure 2-1 shows the connectio n order.

15

4

263

1

14

8

5

10

9

11

13

12

7

Figure 2-1

2–10 975-0187-01-01

DC Wiring Connection Order

Page 37

Final DC Connections

WARNING: Shock hazard

Make sure that the DC fuse or circu it breaker is still open.

To make the last DC connections:

1. Connect the negative cable from the negative ter minal on the battery (if you are

using only one battery or bank), or the negative ground bar or bus (if you are

using more than one battery or bank), to the negative DC terminal on the

XC Series (Figure 2-1). Use a flatwasher, a lockwasher and a nut (5 included in

the installation kit) to secure the connection.

Tight en the nuts to 3 N-m (30 lb-in.) torque and test that the wire is secure.

2. Connect each positive cable to the cor rect positive DC terminal on the

XC Series (Figure 2-1). Use a flatwasher, a lockwasher and a nut (5 included in

the installation kit) to secure the connection.

Tight en the nuts to 3 N-m (30 lb-in.) torque and test that the wire is secure.

3. Connect the free end of ea ch positive cable to the correct positive terminal of

the battery, using sufficient torque as recommended by your battery

manufacturer.

Installing the XC Series

4. Connect the free end of the negative cable to the negative terminal on the

battery, using sufficient torque as recom mended by your battery manufacturer.

Note: If you are using more than one battery, you will need to connect the

negative cable from each of the batteries to the negative ground bar or bus. The

negative ground bar or bus will then have a single negative cable connecting to

the negative charger terminal.

5. Before proceeding, carefully check the wiring polarity – make sure the positive

terminals of the XC Series are connected to the correct terminals of the battery

(fuses or bre akers) and from there to the positive terminals of the battery . Make

sure the negative terminal of the XC Series is c onnected to the battery negative

terminal (or engine negative bus/DC negative bus). Do not reverse the

connections.

6. Install the DC chassis ground (ea rth) from the ground stud on the XC Series to

the engine negative bus or DC ground bus.

7. Connect the BTS cable and the remote display cable to the rear of the charger.

975-0187-01-01 2–11

Page 38

Installation

8. Secure cables in place using tie-wraps, P-clamps or cable straps according to

electrical codes. Coil and tie any extra BTS or remote display extension cable.

9. The DC breakers may be closed or fuses inserted at this time.

Final AC Connections

To make the last AC connections:

1. Complete the installation by routing the AC cable to the AC source.

2. Connect the AC cable to the AC disconnect breaker and ground in accordance

with the color codes on page 2–5.

3. Secure cables in place using tie-wraps, P-clamps or cable straps according to

electrical codes.

Powering Up

Make one last check that all connections and connectors are secure.

The XC Series charger may now be powered up. Switch the AC powe r on at the

source breaker. It is normal to see a 7-10 second delay while the unit powers up.

During this time, the indicator lights on the onboard status panel and the remote

display will not displa y any information.

At very low AC source voltage s (for example, less than 105 VAC) the start up time

will increase proportionally up to as much as 40 seconds.

2–12 975-0187-01-01

Page 39

Instal ling Optional Acce ssories

The XC Series ships with a battery temperature sensor (BTS) and drip protection

rubber boots f or the DC cables.

Battery Temperature Sensor

Xantrex strongly re commends that you install a Battery Te mper ature Sensor (BTS)

to protect your battery and improve charging accuracy. It is best to use a separate

BTS with each individual batte ry bank, to provide optimal charging and protection

of each bank. If no BTS is connected, the charger defaults to the charging

conditions fo r 40 °C (104 °F). At this temper ature the charging voltage is lower to

keep batteries from overcharging; charging will be slower and the batteries will be

slightly unde rcharged.

One BTS is provided with with your XC Series and additiona l battery temperature

sensors may be purchased separately.

To install a BTS:

1. Switch off all devi ces operating from the battery.

2. Connect the ring te rminal on the sensor directly on to the negative battery stud,

or affix the double -sided adhesive backing (included) to the sensor back and

attach the sensor to the side of the battery to be monitored.

Installing Optional Accessories

3. Route the senso r cable to the char ger an d plug it into t he bank 1 (de fault if usi ng

only one BTS), bank 2 or bank 3 connector on the rear panel.

975-0187-01-01 2–13

Page 40

Installation

Drip Protection Rubber Boots

Xantrex recommends that you inst all the supplied rubber boots over the XC Series

DC terminals to provide drip protection.

To install rubber boots:

1. Before making the DC connectio ns to the charge r, feed the rubber boot over the

charger end of the DC cables.

2. Perform all other DC connections a s described in “To install DC wiring:” on

page 2–3.

3. After the DC cables are connected to the charger, slide the boot up the cables

and over the DC terminals. If you are only using one batte ry, slide the spare

boots over the unused DC terminals.

2–14 975-0187-01-01

Page 41

Configuring the XC Series

Once the charger is conne cted to a battery on bank 1 or to AC, it is live and it may

be configured. There will be a short delay of about 15 seconds before the remote

display begins re porting. The remote display will use this time to query the charger

for the current operating conditions.

Configuring the XC Series

If AC was already applied, ens ure that the char ger is in on by pressing

ON/STANDBY

if necessary.

To configure the battery bank type:

1. Press and hold

2. Press

TYPE to select the battery type configuration programm ing mode.

MODE until

set

(setup) is displ ayed.

The XC Series will default to Bank 1 and will show the present battery type

setting.

3. Press

BANK repeatedly to select which bank you are setting up. The bank

indicator light will illuminate to show which bank has been selected.

4. Press

TYPE repeatedly to select the battery type for each bank. When you have

selected a batter y type that is different from the present con figuration, the bank

indicator light fl ashes.

Set th e

TYPE accor ding to the table below:

If your ba ttery is then s elect

Flooded Lead Acid (has removable caps intended for refilling)

GEL (any sealed type except AGM)

Absorbed Glass Mat (AGM)

Lead Calcium

FLa

GEL

AGM

LdC

Custom (if pre-configured at facto r y)

5. Press and hold

ON/STANDBY until

yes

is displayed to store the selec te d battery

CUS

type. If no is displayed, verify that you are setting the correct battery type and

try again.

6. Repeat steps 1 throu gh 4 for all banks a ttached to the XC Series. Each time

yes

is displayed for a newly programmed battery type, the charg er exi ts the

programming mode.

7. At any time during setup, you can press

ON/STANDBY once to cancel the current

change and return to char ging or battery monitoring.

975-0187-01-01 2–15

Page 42

Installation

To configure the charging type:

1. Press and hold

MODE until

set

(setup) is displ ayed.

2. Press

MODE to select 2-stage (

2st

) or 3-stage (

3st

) charging. When you have

selected a c harging type that is different from the present configuration, the

bank indicator light flashes.

See “About Charging” on page 3–2.

3. Press and hold ON/STANDBY until

4. At any time during setup, you can press

yes

is displayed to store the selec ted mode.

ON/STANDBY once to cancel the current

change and return to char ging or battery monitoring.

2–16 975-0187-01-01

Page 43

3

Operation

Chapter 3 describes the operating states and provides

procedures for charging a battery and performing an

equalization.

Page 44

Operation

About Charging

The XC Series has three full current rated, independently controlled outputs which

enable it to charge three different batteries or ba ttery banks. Each output can

accommodate any one of the four allowable battery types, regardl ess of what

battery types are connected to the other outputs. Each output can be in a differe nt

stage of charge, rala tive to the other banks; for exampe, Bank 1 in float, Bank 2 in

absorption and Bank 3 in bulk. Each bank can accommodate a separate battery

temperature sensor. The XC Series can also perform either multiplex (3 stage)

charging, or sequential (2 stage) charging.

Important:

common negative.

The battery banks are not galvanic ally isolated from each other. They sha re a

Multiplex 3-Stage Charging

In multiplex c harging mode the charger will check all qualified battery banks every

15 seconds to determine which bank is most in need of charging. That bank will

then be charge d for the next 15 se conds. Eve ry 15 min utes the c har ger will que ry a ll

outputs and detect which batt ery banks are present and healthy.

The multiplex char ging mode employs the 3-stage charging algorithm: Bulk,

Absorption, and Float. During the Bulk stage the battery is accepting high current.

In the Absorption sta ge the batter y volt age is held consta nt and the curr ent decl ines.

A battery will also "gas" (produce hydrogen and oxygen) during this stage. Finally,

in the Float stage, the charger continues to provide voltage at a lower level to

maintain the battery in a fully charged state. If the re is no load on the battery, it will

typically dra w very littl e cur rent. The c har ger , howeve r , is a ble to provi de cur rent to

its full rating to power DC loads on the batt ery. In float, if bat teries are very new or

a battery is on the low end of the size range and if it is fully char ged to the point

where it will not acc ep t any mo re curr en t, then t he charger wil l enter an adap tiv e

float/no float beha viour where it will alternate between float chargi ng (

resting the battery (

The charger will restart the charging cycl e in the Bulk stage if the battery voltage

drops below 12.5 V (12 V units) or 25 V (24 V units) for 15 minutes. Afte r 21 days,

the charger will automatically restart charging in order to refresh the batte ries.

rdy

).

flo

) and

3–2 975-0187-01-01

Page 45

Sequential 2-Stage Charging

In sequential charging mode the charger will check all battery banks every 15

minutes to determine which banks are prese nt, healthy, and in most in need of

charge. The bank most in need of charge will then be charge d for the next 15

minutes.

The sequential charging mode employs the 2-stage charging algorithm. It is the

same as the 3-stage algorithm except that there is no float stage; after the absorption

stage the charger stops providing voltage and current to the battery and enters a

"rest stage". Like the 3-stage algorithm, the charger will restart the charging cycle in

the Bulk stage if the battery voltage drops below 12.5V (12 V units) or 25 V (24 V

units) for 15 minutes. After 21 days, the charger will automatically restart charging

in order to refresh the batteries.

Charging Overview

The XC Series will perform a battery detection sequence every 15 minutes, or on

reapplication of AC, to determ ine which battery banks are present and health y.

If you connect a batter y when AC is disconnecte d, the remote will not recognize it

until the unit has performe d a battery de tection with AC applied.

To force a battery detection sequence,

About Charging

1. Turn off AC.

2. Wait approximately 20 seconds or until a ll lights on the charger or remote have

gone out .

3. Turn on AC.

The charger will then perform a battery detection when AC is reappli ed

The charger does not charge the banks in a pre-determined sequence. The bank

most in need of charging is the one that receives the charge. For example, if Bank 1

and Bank 2 are both charged, but Bank 1 has a load and Bank 2 does not, then the

charger may rarel y cha rge Ba nk 2.

975-0187-01-01 3–3

Page 46

Operation

Disqualified Batt eries

The XC S eri es can identify when a batt ery will not accep t a charge (bat tery is

damaged) or when it is fully charged (healthy) and does not require further charge.

Batteries that will not accept a charge will be removed (disqua lified) from the

charging se quence un til all banks a re check ed again ( every 15 minute s). A dam aged

battery will contin ue to be disqualified each cycle and the charger will not waste

energy trying to charge it. Under some conditions it is also possible that a healthy

battery that is fully charged but unable to accept current (for example, at the

moment it transit ions from Absor ption to Fl oat or Rest ) will be deemed unabl e to be

charged and temprar ily removed from the charging sequen ce. The charger will enter

an adaptive float/ no flo at beha vio ur w here it will alternate bet w een fl oa t chargi ng

flo

) and resting the battery (

(

rdy

) and the 25% Charge Current indicator light on

the onboard status panel will flash. The battery will be evaluat ed every 15 minutes

and added back to the charging sequence when it is later able to accept char ge.

If disqualification occur s during Bulk or Absorption, the battery is damaged or

there is another charging source present other than the charger itself. The remote

display will show

dis

and the 25% Charge Current indicator light on the onboard

status panel will flash.

Measuring Battery Voltage

Use a voltmeter that has a stated accuracy of 0.5% or better on DC voltage. Place

the probes of the meter directly on the studs or plates of the charger terminals. Do

not probe on the wire lugs or other places in the battery wiring system as this will

introduce error into the measure ment: the charger monitors battery voltage as

measured at the charge r ter min als .

Tem per a ture C ons id er at ion s

Xantrex strongly re commends that you install a Battery Te mper ature Sensor (BTS)

to protect your battery and improve charging accuracy. It is best to use a separate

BTS with each individual batte ry bank, to provide optimal charging and protection

of each bank. If no BTS is connected, the charger defaults to the charging

conditions fo r 40 °C (104 °F). At this temperature the charging voltage is lower to

keep batteries from overcharging; charging will be slower and the batteries will be

slightly unde rcharged.

3–4 975-0187-01-01

Page 47

About Charging

Things to be aware of

When the XC Series is operating, fans and lights (DC loads) may vary in speed or

intensity. This is norm al. The XC Series will not harm any load connected to it as

long as there is a battery present on that bank.

When you initially turn the XC Series on and configure it, it is possible that some

banks may be disqu alified. Because the charger is a ble to detect unhealthy batteries

and disqualify them, batteries that may have appeared healthy be f ore will now be

correctly id entifi ed as ne edi ng at ten tion .

Perform these disqualification checks in the order shown:

1. Wait 15 minutes for the next battery detection cycle. The warning may be

temporary.

2. Verify that the battery meets the m inimum AmpHour rating (XC1524: 30 Ah,

XC2524: 50 Ah, XC3012: 60 Ah, XC5012: 100 Ah)

3. Try adding a small DC load.

4. Replace the battery.

975-0187-01-01 3–5

Page 48

Operation

Charging B atteries

Before you sta rt to charge batteries read the “Important Safety Instructions” on

page v and follow all safety precautions when working with batteries.

To charge your batteries:

1. If possible, disconnect all loads from the battery, by opening a disconnect

switch, or by switching the loads off.

2. Ventilate the area around the batter y thoroughly. Review the charging

instructions supplied by the manufacturer of your batteries and take any steps

required.

3. Apply AC power to the XC Series by closing the AC breaker and/or applying

shorepower or turning the generator on. The indicator ligh ts will blink as an

initializati on sequence runs, last ing typically 10 seconds. After initialization the

charging indicator light illuminates.

During charging, the charging c urrent indicator lights show the total current

being delivered to the sele ct ed battery bank as well as any DC load applied.

4. Re-connect all loads to the bat tery, by closing a disconnec t switch, or by

switching the loads on.

The batteries can be in one of six differe nt stages:

Mode Remote Display

Bulk mode

Absorption mode

Rest mode (2-s tage charging)

Float mode (3-stage charging)

Equalize mode

Battery fault

3–6 975-0187-01-01

bUL

AbS

rdy

FLo

EqU

err

Page 49

Charging Batteries

After charging is complete, the XC Series enters into one of these modes:

Float mode When the ready indicator light illuminates, all batteries are fully

charged and rea dy for use. If you selec ted the 3-s tage cha rgi ng mode, the XC Series

is in float mode and will maintain the batteries’ charge.

Rest mode If you selected the 2-stage charging mod e, the ready indicator light

shows the charger is now in rest mode and is checking ba ttery voltage and elapsed

time since the la st charge cycle .

With either charging mode, the XC Series will begin a charging cycle 21 days after

the last cycle, or when battery voltage drops to below 12.5 V (12 V units) or 25 V

(24 V units) for 15 minutes.

975-0187-01-01 3–7

Page 50

Operation

Equalizing Fl oode d Ba tteries

About Equalizing

The XC Series equalizes only flooded lead-acid or lead-calcium batteries. It does

not equalize sealed lead-ac id batteries since they can be damaged by this process.

In the following conditi ons the remote display will show

not enter equalization mode :

• the battery type is set fo r Gel or AGM

• any battery is not fully charged (a ll three battery banks must be charged to float

or rest stage before equaliz a tion can be activated on any bank)

• there is an active fault on the battery you are trying to charge

Xantrex recommends tha t you run a nor mal char g e cycle on the batte ries be fore you

equalize the m.

WARNING: Explosion hazard

During equalization, the battery generates explosive gases. Follow all the battery safety

precautions listed in this guide. Ventilate the area ar ound the battery thoroughly and ensure

that th ere are no sources of flame or sparks in the vicinity

no

and the XC Seri es wil l

CAUTION: Risk of battery damage

The XC Series cannot automatically determine when to stop the equali zation of a battery.

You must monitor the battery specific gravity throughout equalization to determine the end

of the equalize cycle. The one hour time-out is intended as a safety feature to require the

user to continually re-activate it as necessary after checking ba tteries manually, but may not

be sufficiently short to prevent battery damage.

3–8 975-0187-01-01

Page 51

Equalizing Flooded Batteries

Performing An Equalization

Turn off or disconnect all DC loads on the battery during equalization. The voltage

applied to the battery during e qualization may be above the safe levels for some

loads.

To equal ize your batt eries:

1. Check the battery elec tr olyte level. If necessary, refill with distilled water only.

All the cells should have simil ar electrolyte levels. If the levels are widely

different, it will influence the relative concentration of acid, thereby affecting

the specific gravity measurements.

2. Verify that all banks are in either f loat or rest mode.

3. Press

4. Press

MODE and BANK at the same time.

BANK to select which bank you wish to equalize. The bank indicator light

will flash to show which bank has been select ed.

5. Press and hold

ON/STANDBY to put the XC Series into equalization mode.

You can cancel the equalization request by press ing ON/STANDBY once.

If the battery cannot be equalized, the display will show no.

Check that the battery is floode d and in floa t mode.

EQU

6. When the charger is in equalize mode, the display will show

.

7. Monitor the specif ic gravity of each cell of the battery during equalization with

a battery hydrometer.

The equalize cycle will terminate in one hour.

Check the specific gravi ty of each cell a nd repeat the equalization cycle until

they all meet the battery manufacturer’s specifications for specific gravity or

until the specific gravity stabilizes relative to each other for an hour.

8. The charger automatically exits equalization to float mode or rest mode after 1

hour. To manually exit equaliz ation mode early, press

MODE and BANK at the

same time and then press and hold ON/STANDBY.

You can cancel the manual exit request by pressing ON/STANDBY onc e.

9. When equalization has finished, check the battery electrolyte level. If

necessary, refill with distilled water only.

975-0187-01-01 3–9

Page 52

Operation

Transitioning the XC Series to On, Disabled or Off

There are two ways to turn the XC Series on:

• connect AC power at the source

• press

There are two ways to disable the XC Series:

WARNING: Shock hazard

The XC Series still has live voltage while disabl ed. Even when AC power is removed, if th e

XC Series is co nnecte d to a bat tery on bank 1, the uni t will take powe r from the battery. The

only time the XCSeries is de- energized completely is when both AC and DC are

disconnected.

• disconnect AC power at the source

• press

The XC Series continues to monitor the batteries, but will not charge them.

There is only one wa y to saf ely turn th e X C Series off:

• disconnect the AC power at the sourc e and disc onnect all DC batteries.

ON/STANDBY on the remote display if AC is still connected.

ON/STANDBY on the remote display.

This is the only state where the XC Series is completely discharged.

When the XC Series is disabled or off, the remote display is inactive.

3–10 975-0187-01-01

Page 53

Accessing Charger Information

Accessing Charger Information

The XC Series can give you a lot of inf ormation about the stat us of the charger and

the batteries.

Reading Remote Display and Onboard Status Indicator Lights

The remote display and onboard stat us panel show what is happening during the

charging proce ss and are also helpful in troubleshooting. Refer to Chapter 4,

“Trou bleshooting” for more information about int erpreting the remote display and

onboard status indicator lights.

The remote display is designed to report on the active status of the charger. While

the unit is char ging, the remote display rep orts only on the battery being charged at

that moment. It does not report the status of other batteries.

The Ready light on the onboard status indi cator panel only illuminate s when all

flo

connected banks have reached float (

stage charging. If one of the three batteries has been disqualified before it reaches

float/rest stage, while the others have r eached float (

(

rdy

) of 2-stage charging , the Ready light on the onboard sta tus indica tor panel will

not illuminate.

) of 3-stage charging or rest (

flo

) of 3-stage charging or rest

rdy

) of 2-

975-0187-01-01 3–11

Page 54

Operation

Table 3-1

Reading XC Series Status

Charger Status

Charging in bulk or absorption mode.

Remote display shows scrolling display of charging

state, batte ry voltage in volts and charging current in

amps.

Indicator lights indicate the charging current in % of

full ch arge . A t tr a n s it io n poi n ts w h en th e cu rr en t is

changing, two indicator lights may flash alternately,

then settle into the new charging current reading.

Equalizing.

Charging indicator light flashes once every four

seconds if bank 1 is be ing equa li zed, tw ice ever y four

seconds if bank 2 is being equa lized, and three times

every four seconds if bank 3 is being equalized.

Float mode of three stage charging or rest mode of

two stage ch arging.

All batteries have been fully charged.

A battery has been disqualif ied while in float mode of

three stage charging or rest mode of two stage

charging.

Remote

Display Onboard Status Indica t or Lights

BUL

or

Charging indicator light illuminates

ABS

EQU

FLo

Rdy

FLo or

rdy

Charging indicator light flashes

or

Ready indicator light illuminates

25% current indicator light flas hes

A battery has been disqual ified while in bulk or

dis

25% current indicator light flas hes

absorption mode.

Non-charger fault condition.

Any fault condition that prevents the char ger from

charging one or more bank s, but is not a charger

failure. Remote disp lay shows details of fault.

ERR

BAT

PoL

(example)

Fault indic ator light illuminates

3–12 975-0187-01-01

Page 55

Accessing Charger Information

Table 3-1

Charger Status

Battery too hot faul t

Battery too cold fau lt

Charger fault c ondition.

The charger is damaged, contact service.

Reading XC Series Status

Remote

Display Onboard Status Indicator Lights

ERR

HoT

ERR

CLD

ERR

CHF

Reporting While Charging or Equalizing

After configuration, the XC Series defaults to a scrolling display. As long as there

are no faults or errors to report, the remote will display the followin g information,

in order, for the bank presently being charged:

• Charging Stage

• Battery Voltage

• Charger Curren t

If there is a fault or warning related to one of the ba nks, the fault or wa rning

information will dis play in the scrolling display befor e the charging state for the

bank presently being charged. Charging for ba nks not in fault will continue (see

“Error Messages on Remote Display” on page 4–4). Charging for the bank in fault

will resume once the fault condi tion is cleared.

Fault indic ator light illuminated

100% current indicator light flashes

Fault indic ator light illuminated

10% current indicator light flas hes

Fault indic ator light flashes

975-0187-01-01 3–13

Page 56

Operation

Reporting While Battery Monitoring

The XC Series is considere d to be battery monitoring if it is experiencing a charger

level fault. If there is a charger leve l fault (affecting all banks), all charging will be

suspended until the charger fault is resolved (see “Error Messages on Rem ote

Display” on page 4–4).

The remote will display all of the fol lowing, in order:

• Highest level charger fault or warning (if present)

• Bank 1 Highest level bank fault or warning (i f present)

• Bank 1 Charging Sta ge

• Bank 1 Battery Voltage

• Bank 1 Charger Curre nt

• Bank 2 Highest level bank fault or warning (i f present)

• Bank 2 Charging Sta ge

• Bank 2 Battery Voltage

• Bank 2 Charger Curre nt

• Bank 3 Highest level bank fault or warning (i f present)

• Bank 3 Charging Sta ge

• Bank 3 Battery Voltage

• Bank 3 Charger Curre nt

Reporting While Disabled

If AC power ha s been disconnected or if you ha ve used the remote display to