Page 1

TS400 Sine Wave Inverter

Owner’s Guide

Page 2

Page 3

TS400 Sine Wave Inverter

Owner’s Guide

Page 4

$ERXW;DQWUH[

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup

power applications in both grid-connected and stand-alone systems. Xantrex products include inverters, battery

chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute

electrical power.

7UDGHPDUNV

TS400 Sine Wave Inverter is a trademark of Xantrex International. Xantrex is a registered trademark of Xantrex

International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used

herein for identification purposes only.

1RWLFHRI&RS\ULJKW

TS400 Sine Wave Inverter Owner’s Guide © July 2003 Xantrex International. All rights reserved.

'LVFODLPHU

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

'DWHDQG5HYLVLRQ

July 2003 Revision A

3DUW1XPEHU

975-0055-01-01

&RQWDFW,QIRUPDWLRQ

Telephone: 1-800-670-0707 (toll free in North America)

1-604-422-2777 (direct)

Fax: 1-604-420-2145

Email: CustomerService@xantrex.com

Web: www.xantrex.com

Page 5

About This Guide

Purpose

The TS400 Sine Wave Inverter Owner’s Guide contains information for

installing, operating, and troubleshooting the TS400 Sine Wave Inverter

(TS400).

Scope

This Guide provides safety guidelines, installation, operation,

troubleshooting, and warranty information for the TS400.

Basic information on battery types and sizes is provided in Appendix B,

“Battery Types and Sizes”. For comprehensive information about your

battery, refer to the battery manufactu rer’s guide.

Service information is not included as the unit does not contain user-

serviceable parts.

Audience

This Guide is intended for anyone who needs to install and operate the

TS400 Sine Wave Inverter. Installers should be certified technicians or

electricians.

Organization

The Owner’s Guide is organized into four chapters and two appendixes.

Chapter 1, “Introduction”, outlines the main performance and safety

features of the TS400. Reading this chapter will give you a clear

understanding of the inverter’s capabilities.

Chapter 2, “Installation”, provides detailed information for installing the

TS400.

975-0055-01-01 iii

Page 6

About This Guide

Chapter 3, “Operation”, provi des information ab out ope ra ti ng t h e TS400.

Details are provided on how to read the front panel indicators to monitor

the TS400.

Chapter 4, “Troubleshooting”, explains how to iden tify and solve

problems that can occur with the TS400.

Appendix A, “Specifications”, provides the electrical and physical

specifications of the TS400.

Appendix B, “Battery Types and Sizes”, provides information that will

help you to select, connect, and maintain batteries that are most

appropriate for your application.

“Warranty and Product Information”, contains the product warranty,

explains how to retur n a product f or servic e, and descr ibes how to pre pare

for a call to Xantrex Customer Service.

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions that could result in pers onal

injury or loss of life.

CAUTION

Cautions identif y condi tions or pra ct ices t hat c ould r esult in

damage to the TS400 Sine Wave Inverter or to other

equipment.

Note: Notes describe additional information which may add to

your understanding of how to use the TS400.

Important:

item that you must pay attention to.

These notes describe an important action item or an

iv 975-0055-01-01

Page 7

Acronyms and Terminology

AC Alternating current

DC Direct current

CSA Canadian Standards Association

FCC Federal Communications Commission

GFCI Ground fault circuit interrupter

UL Underwriters Laboratories Inc.

Hardwiring to make a permanent electrical connection

Related Information

You can find more information about Xantrex Technology Inc. as well as

its products and services at www.xantrex.com

About This Guide

975-0055-01-01 v

Page 8

vi

Page 9

Important Safety Instructions

WARNING

This Owner’s Guide contains important safety and operating

instructions.

Before using your TS400 Sine Wave Inverter, be sure to read,

understand, and save these safety instructions.

WARNING: Restrictions on Use

The TS400 Sine Wave Inverter shall not be used in connection

with life support systems or other medical equipment or

devices.

WARNING: Shock hazard

The TS400 has On/Standby mode only. It does not have an Off

mode, that is, DC power is permanently connected to the unit.

General Precautions

1. Before installing and using the inverter, read all appropriate sections

of this guide and any cautionary markings on the inverter and the

batteries.

2. Do not operate the inverter if it has received a sharp blow, been

dropped, or otherw ise damaged . If the unit i s damaged, s ee “Warranty

and Product Information” on page WA–1.

3. Do not dismantle the inverter; it contains no user-servi ceable parts.

Attempting to ser vice the unit yo urself c ould caus e elect rical s hock or

fire. Internal capacitors remain charged after all power is

disconnected. See “Warranty” on page WA–1 for instructions on

obtaining service.

975-0055-01-01 vii

Page 10

Important Safety Instructions

4. To reduce the risk of electrical shock, disconnect DC power from the

inverter before working on any circuits connected to the inverter.

Turning the On/Standby switch to Standby ( ) will not reduce this

risk.

5. Protect the inverter from rain, snow, spray, and water.

6. T o r edu ce th e ris k of overhe ating, ke ep the venti lati on ope nin gs cl ear,

and do not install the inverter in a com partment with limited airflow.

Precautions When Working With Batteries

WARNING: Explosion and Fire Hazard

1. To reduce the risk of battery explosion, follow all instructions

published by the battery manufacturer and the manufacturer of the

equipment in which the battery is installed.

2. Make sure the area around the battery is well ventilated.

3. Never smoke or allow a spark or flame near the engine or batteries.

4. Use caution to red uce the risk of dro ppi ng a metal tool on the ba tt er y.

It could spark or short circuit the battery or other electrical parts and

could cause an explosion.

Explosive Gas Precautions

1. Batteries generate explosive gases during normal operation. Be sure

you follow all relevant instructions exactly before installing or using

your inverter.

2. This equipment contains components which tend to produce arcs or

sparks. To prevent fire or explosion, do not install the inverter in

compartments containing batteries or flammable materials or in

locations that require igniti on-protec ted equi pment. Thi s inclu des any

space containing gasoline-powered machinery, fuel tanks, as well as

joints, fittings, or other connections between components of the fuel

system.

viii 975-0055-01-01

Page 11

FCC Information to the User

This Class B device complies with Part 15 of the FCC Rules and all

requirements of the Canadian Interference-Causing Equipment

Regulations. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must

accept any interference received , including interference that may c ause

undesired operation.

Important Safety Instructions

975-0055-01-01 ix

Page 12

x

Page 13

Contents

Important Safety Instructions

General Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

Precautions When Working With Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Explosive G as Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

FCC Information to the User - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -ix

1

Introduction

How TS400 Works - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Premium Power and Ease o f Use- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Comprehensive Protect ion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

TS400 Features- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–4

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–4

Back Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–5

Optional Ac cessory: Remote Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

Dimensions of Remote Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

Part number of Remote Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

2

Installation

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Preparing for Installati on - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Installation Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Materials List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Installation Tools and Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Installing the TS400 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

Step 1: Designing Your I nstallation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

Step 2: Mounting Your Inv erter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–10

Step 3: Conn ecting the Chassis Ground - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Step 4: Installing the Optional S400 Remote Switch - - - - - - - - - - - - - - - - - - - - - -2–12

Step 5: Getting Ready to Connect the DC Cables - - - - - - - - - - - - - - - - - - - - - - - -2–14

Step 6: Routing the DC Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15

Step 7: Conn ecting the DC Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–16

Step 8: Connecting Your Equipment to the GFCI Outlets - - - - - - - - - - - - - - - - - - -2–18

Step 9: Hardwiring the AC Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–19

Step 10: Performing Checks Prior to Initial Start-up - - - - - - - - - - - - - - - - - - - - - -2–22

Step 11: Testing Your Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–22

975-0055-01-01 xi

Page 14

Contents

3

Operation

Front Panel Features- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Operating the TS400 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Turning the TS400 On - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Turning the TS400 to Standby When Not in Use - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Using the Optional S400 Remote Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Recharging Your Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Recovering from Low Bat tery Voltage Shutdown - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Restarting or Operatin g Multiple Pi eces of Equip ment - - - - - - - - - - - - - - - - - - - - - 3–5

Monitoring the Operating Status- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Resetting A fter a Fault or Shutdown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

4

Troubleshooting

Troubleshooting Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

A

Specifications

Electrical Specificatio ns - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Physical Sp ecifications with Projections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Regulatory Approvals- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

Fan Cooling System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

B

Battery Types and Sizes

Battery Typ es - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–2

Automotive Starting Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Deep-Cycle Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Battery Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–3

Estimating Battery Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–4

Battery Sizing Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–4

Battery Sizing Worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–5

Using Multiple Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–6

Two Batteries Connected In Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–6

Two Separate Battery Banks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–6

Battery Tips - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–7

Warranty and Product Information

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - WA–1

Disclaimer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - WA–2

Product - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - WA–2

xii 975-0055-01-01

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - WA–1

Page 15

Contents

Exclusions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -WA –2

Warning: Lim itations On Use - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -WA–2

Return Material Authoriza tion Policy- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -WA–3

Return Proc edure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -WA–3

Out of Warranty Service - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -WA–3

Information About Your System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -WA–4

Index

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -IX–1

975-0055-01-01 xiii

Page 16

xiv

Page 17

Introduction

Congratulations on your purchase of the Xantrex TS400 Sine

Wave Inverter!

The TS400 has been designed to give you premium power,

ease of use, and outstanding reliability.

Please read this chapter to familiarize yourself with the main

performance and protection features of the TS400.

T o ensure quality customer service for your inverter, be sure to

keep your proof of purchase. Also, take a few minutes at this

time to complete the form, “Information About Your System”

on page WA–4.

Page 18

Introduction

How TS400 Works

TS400 is a sine wave i nverter wh ich conver ts 12 vo lts dir ect-curr ent (DC)

power from your battery to 120 volts alte rnating current (AC) power . This

AC power is the same as the electricity you get from your utility. In terms

of output, TS400 provides 400 watts of sine wave power for operating

your equipment.

Premium Power and Ease of Use

TS400 provides premium power for your portable power needs. The

inverter’s sine wave output provides clean power for small power tools,

test equipment, television monitors and battery chargers.

Superior features and rugged durability have been combined with ease of

use:

• 400 watt inverter with 800 watt surge

• Filtered sine wave output will not cause distortion on sensitive

electronics

• DSP control technology starts complex loads with ease

• Two GFCI outlets and hardwire AC connections

• Easy-to-read indicator lights on the front panel

• Optional S400 Remote Switch provides On/Standby control from a

convenient location

• Audible alarm for low battery voltage

• Automatic c ooling fan

1–2 975-0055-01-01

Page 19

Comprehensive Protection

TS400 is designed to meet UL 458 and CSA C22.2 No. 107.1 safety

standards and it is compliant with F CC Class B.

TS400 comes equipped with numerous protection features to guarantee

you safe and worry-free operation.

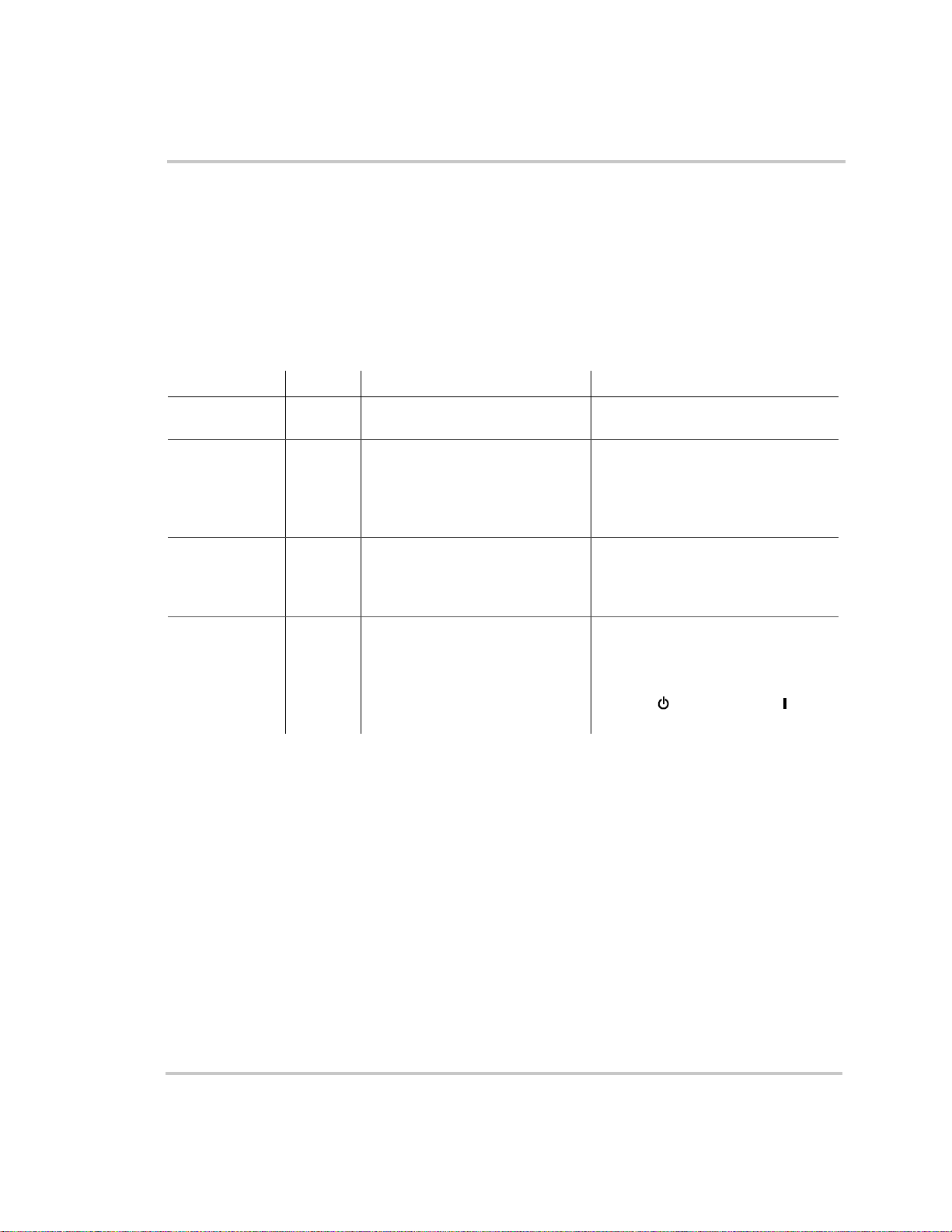

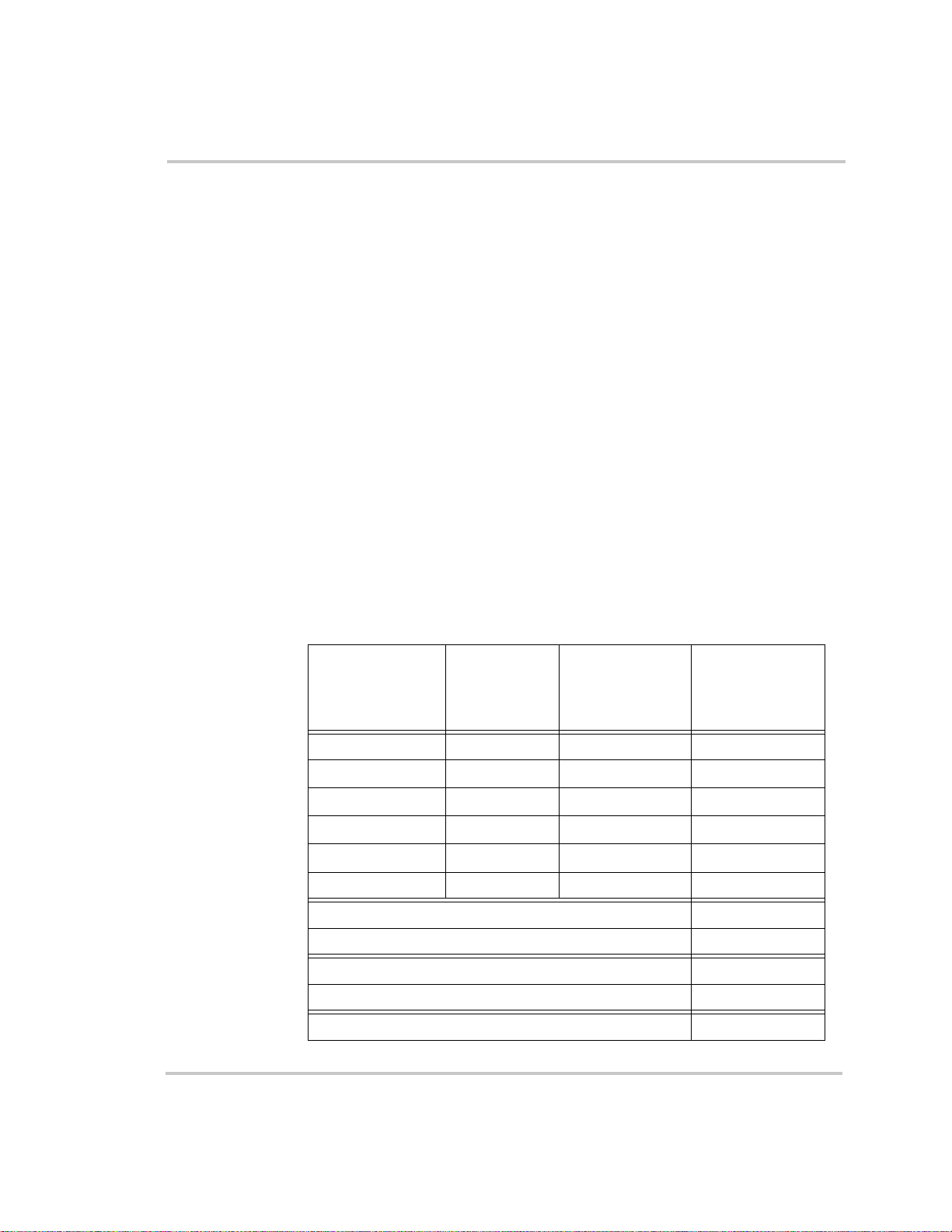

3URWHFWLRQIHDWXUH 7KLVSURWHFWLRQIHDWXUH«

Comprehensive Protection

Low voltage alarm and

shutdown

High voltage shutdown Protects the TS400 by disabling the AC output when the input

Over-temperature

shutdown

Overload protection Disables the AC output of the TS400 if the appliance connected to

Supplemental circuit

protection

Protects the battery from becoming completely discharged. The

Low Battery light and audible alarm indicate that input voltage is

low (10.7 volts). If the input voltage drops below 10.3 volts, the

TS400 shuts down automatically and the Inverter ON light turns

off. The TS400 recovers automatically when the input voltage

comes up to about 12.6 volts.

voltage rises to 15.3 volts or more. The AC output is enabled when

the input voltage drops to 14.5 volts.

Disables the AC output of the TS400 when the internal temperature

rises to unacceptable levels due to higher ambient temperature or

overloading. The TS400 recovers automatically when it cools

down.

the inverter exceeds the 400 watt rating of the inverter. The TS400

will have to be reset. (See “Resetting After a Fault or Shutdown” on

page 3–7.)

Trips and disables the AC output when a current in excess of 7.5

amps is drawn from the TS400. The supplemental circuit protector

can be reset to enable the unit to operate again after clearing the

overload condition. (See “Resetting After a Fault or Shutdown” on

page 3–7.)

Short circuit protection Disables the AC output of the TS400 when a short circuit is applied

on the AC output. Once the short circuit is cleared, the TS400 will

have to be reset. (See “Resetting After a Fault or Shutdown” on

page 3–7.)

Ground fault circuit

interrupter (GFCI)

975-0055-01-01 1–3

Trips and disables the output of the TS400 when a ground fault

current is detected. The output can be enabled again by resetting the

GFCI, once the ground fault is cleared. (See “Ground Fault” on

page 3–7.)

Page 20

Introduction

TS400 Features

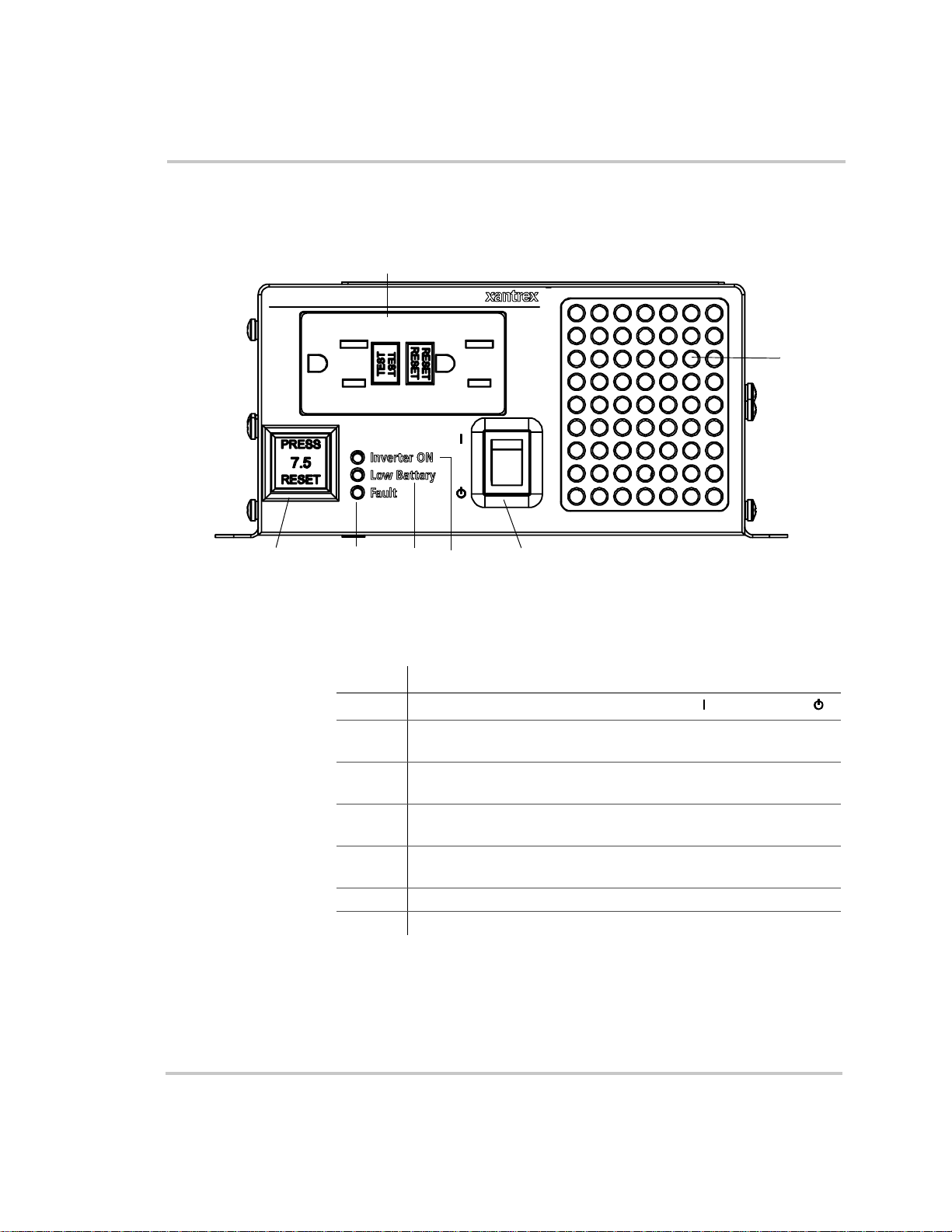

Front Panel

6

7

Figure 1-1

\

5

4

3

Front Panel of the TS400

Table 1-1

)HDWXUH 'HVFULSWLRQ

1

2 Inverter ON light illuminates when the TS400 is powering

3 Low Battery light illum inates when your battery voltage is lower

4 Fault light illuminates for fault conditions such as over

5 Supplemental Circuit Protection button trips if there is an over-

6 GFCI outl ets for connecting your equipment.

7 Ventilation openings provide air circulation for peak performance.

2

1

Front Panel Features

On/Standby Switch turns th e in ve rt er to O n ( )

equipment from the battery.

than 10.7 volts.

temperature, output overload, or battery over voltage.

current (over 7.5 amps) or a short circuit.

or to Standb y ().

1–4 975-0055-01-01

Page 21

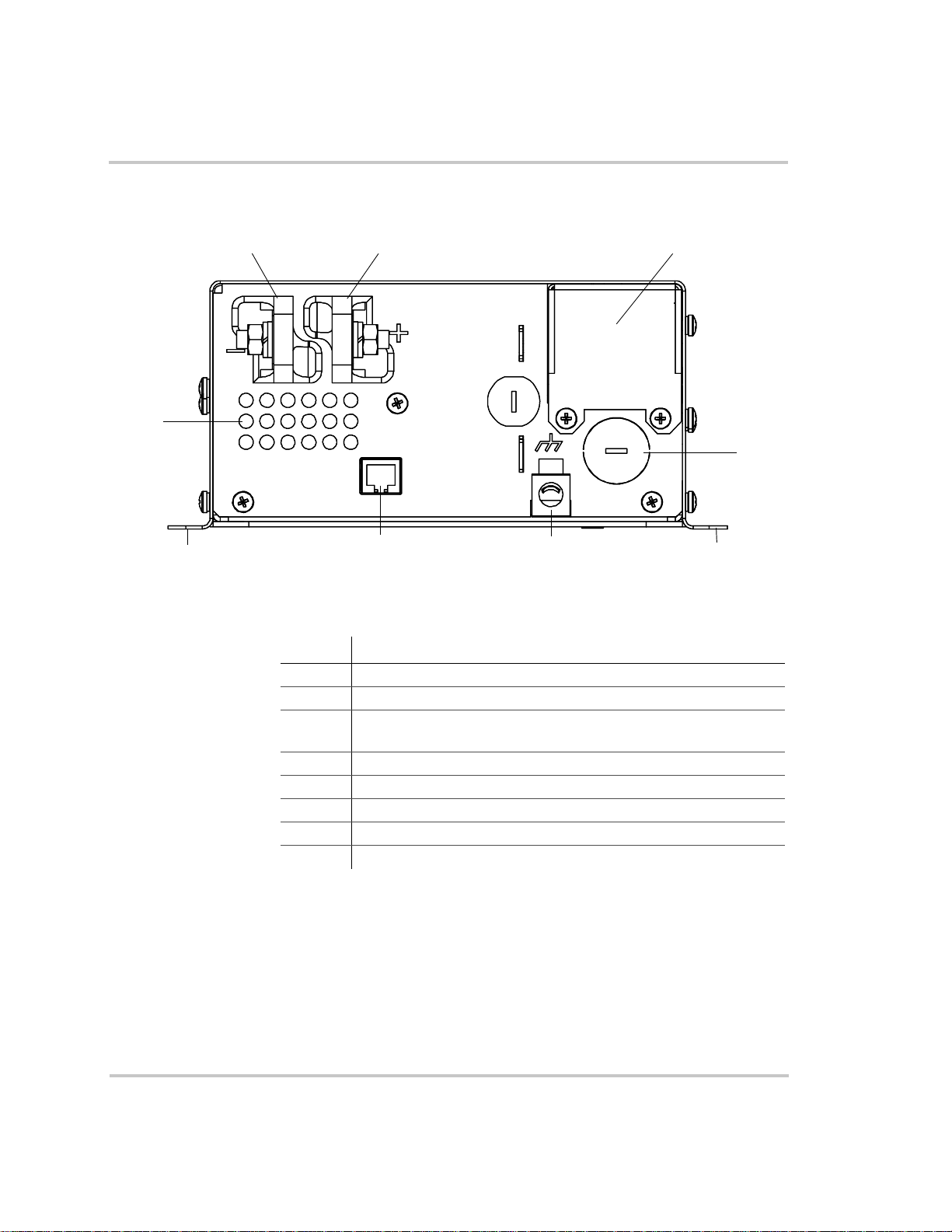

Back Panel

TS400 Features

8

Figure 1-2

12

7

Back Panel of the TS400

Table 1-2

)HDWXUH 'HVFULSWLRQ

1 DC terminal, negative

2 DC terminal, positive

3 Wiring box access panel (For a view with the panel removed, see

4 Knockout for AC output hardwiring

5 Chassis ground lug

6 Jack for optional remote switch

7 Mounting flanges

8 Ventilation openings provide air circulation.

6

Back Panel Features

“Completing the Hardwiring” on page 2–21.)

5

3

4

7

975-0055-01-01 1–5

Page 22

Introduction

Optional Accessory: Remote Switch

An optional remote switch can be plugged into the remote switch jack at

the back of the TS400. It lets you switch the TS400 from on to standby

from a convenient locat ion —up to 25 f ee t ( 7.5 m) a way from the inverter

(using the cable supplied with the switch).

Dimensions of Remote Switch

+HLJKW

:LGWK

'HSWK

&DEOHOHQJWK

Part number of Remote Switch

To purchase a remote switch, please contact Customer Service for a

referral to a distributor. Please provide the part number 808-2400. See

page ii for contact information.

Note: The remote switch jack at the back of the TS400 may not be

accessible once the inverter has been mounted.

If you intend to use the rem ote switch with an TS400 that has already

been installed, consult a qualified service technician before installing

and connecting the remote switch.

2.5 inches (63.5 mm)

2 inches (50.8 mm)

1.1 inches (28.3 mm)

25 feet (7.5 m)

1–6 975-0055-01-01

Page 23

Installation

Chapter 2, “Installation”, provides detailed information for

installing the TS400 and the optional S400 Remote Switch.

This chapter provides:

• a system diagram

• safety instructions and installation codes that must be

observed during installation

• a list of installation tools and materials

• detailed installation procedures

• chassis ground and DC cabling information

• procedures for hardwiring the AC output

• an illustration of inverter dimensions

CAUTION

Be sure to read all instructions before installing and operating

the TS400.

Page 24

Installation

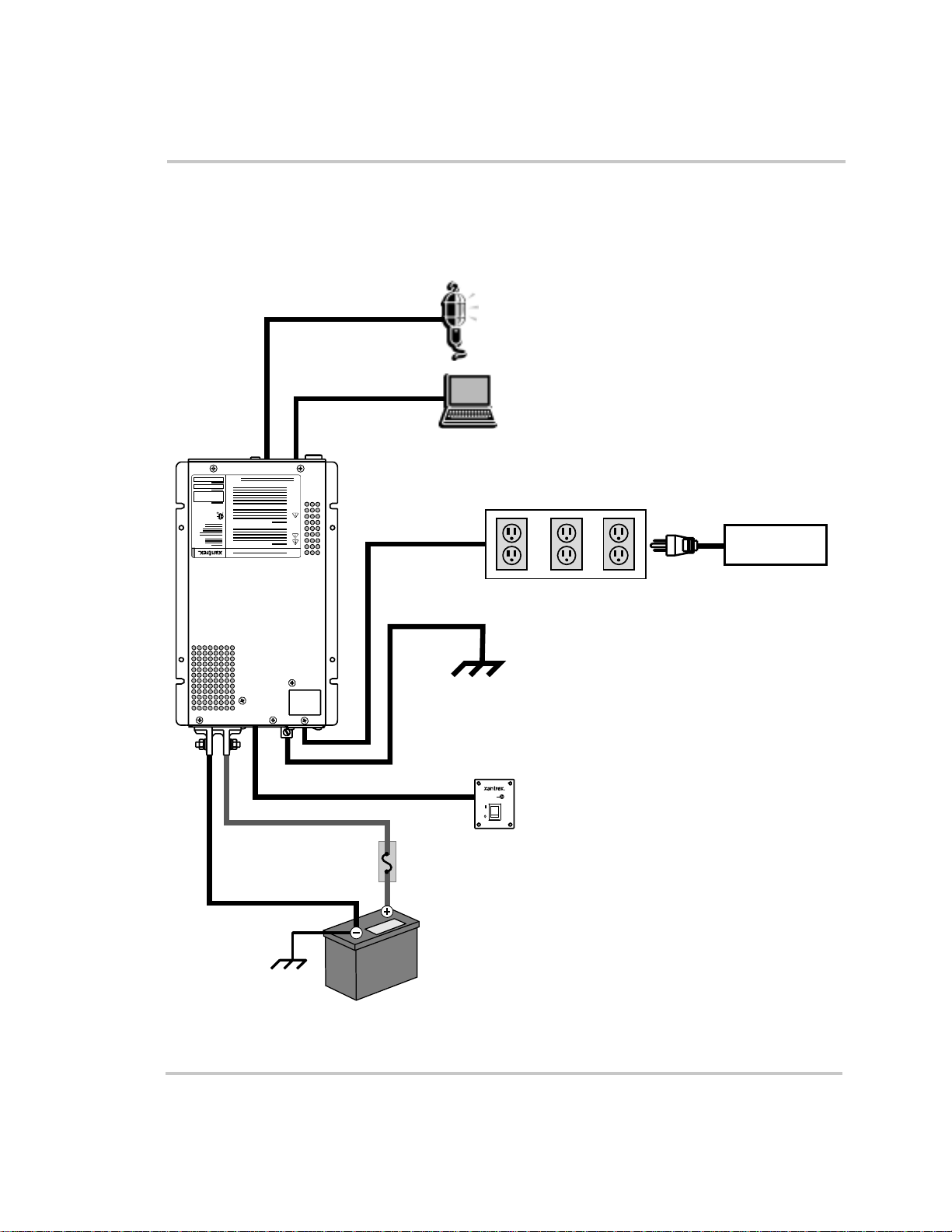

Introduction

The system diagram shown i n Fi gur e 2-1 is the basi c i nst al lation. Review

this diagram carefully be fore installin g the TS400.

GFCI OUTLET

GFCI OUTLET

ADDITIONAL

AC HARDWIRING

LOADS

INVERTER

DC FUSE AND DISCONNECT

Figure 2-1

DC CIRCUIT BREAKER

OR

System Diagram

BATTERY (S)

AC OUTLETS

S400 REMOTE

Inverter ON

SWITCH

(OPTIONAL)

TS400 Configuration

2–2 975-0055-01-01

Page 25

Preparing for Installation

Read this entire installation chapter so you can plan the installation from

beginning to end. Prior to beginning your installation, review the

“Important Safety Instruct i ons ” on page vii.

WARNING: Electrical shock and fire hazards

Xantrex recommends all wiring be done by quali fied personnel.

Disconnect all power sources to prevent accidental shock.

Disable and secure all disconnect devices and automatic

generator startin g devic es.

It is the inst aller ’s responsibility to ensure compliance with all

applicable installation codes and regulations.

WARNING: Fire hazard

To meet regulatory requirements, the TS400 must be mounted

on a flat horizontal surface with the front panel in the upright

position.

Preparing for Installation

Installation Codes

It is the inst aller ’s responsibility to determine which codes apply and to

ensure that all applicable installatio n requirements are met.

Applicable instal la ti on codes vary depending on the specific location and

application of the installation. Some examples are:

• The U.S. National Electrical Code (NEC)

• The Canadian Electrical Code (CEC)

• Canadian Standards Association (CSA) , and RV Industry Asso ciation

(RVIA) requirements for installation in RVs.

WARNING: Restrictions on use

The TS400 Sine Wave Inverter shall not be used in

connection with life support systems or other medical

equipment or devices.

975-0055-01-01 2–3

Page 26

Installation

Materials List

Your TS400 Sine Wave Inverter package includes:

• One TS400 Sine Wave Inverter

• TS400 Sine Wave Inverter Owner’s Guide

After you unpack your TS400, be sure to record the product information

in the form “Information About Your System” on page WA–4.

If any of these materials are missing or unsatisfactory, please contact

Customer Service.

Telephone 1-800-670-0707 (toll free in North America)

1-604-42 2-2777 (direct)

Fax 1-604-420-2145

Email CustomerService@xantrex.com

Web www.xantrex.com

Installation Tools and Materials

You will need the following tools and materials to install the TS400 and

the optional S400 Remote Switch:

Tools

To install the TS400, you need:

❐ Phillips screwdriver: #2

❐ Slot screwdrivers: 1/8 inch and 1/4 inch

❐ Wrench for DC terminals: 10 mm or adjustable

❐ Wire stripper

To install the optional S400 Remote Switch, you need:

❐ Power drill with 1/8-in ch bit

❐ Jigsaw (optional)

❐ Feed wire (optional)

Materials for TS400 and Optional S400 Remote Switch

To install the TS400 and optional S400 Remote Switch, you require:

❐ DC cables (See Table 2-1 on page 2–9.)

2–4 975-0055-01-01

Page 27

❐ Appropriately sized connectors. Two DC connectors suitable for ¼

inch (6 mm) that go on the DC input cable ter minals. The other cable

connectors will depend on your installation.

❐ Crimping tool for fastening lugs and terminals on DC cables (You

may find it more conveni ent to have th e crimp conn ectors at tached by

the company that sells you the cable.)

❐ DC fuse and Disconnect or DC circuit breaker (See page 2–9.)

❐ Four #10 hardware fasteners to mount the TS400

❐ Four #6 self-tapping screws to mount the S400 Remote Switch

Materials for AC output hardwiring

❐ Cable requirements:

• within the range of No. 14 to No. 18 AWG (minimum size)

• 3 conductors

• solid or stranded

❐ 1/2 inch cable clamp

Preparing for Installation

975-0055-01-01 2–5

Page 28

Installation

Installing the TS400

Overview

This chapter provides detailed information on installing the TS400. The

overall procedure is divided into 11 steps:

1. Designing your installation (page 2–6)

2. Mounting your inverter (page 2–10)

3. Connecting the chassis ground (page 2–11)

4. Installing the optional S400 Remote Switch

5. Getting ready to connect the DC cables (page 2–14)

6. Routing the DC cables (page 2–15)

7. Connecting the DC cables (page 2–16)

8. Connecting your equipment to the GFCI outlets (page 2–18)

9. Hardwiring the AC output (page 2–19)

10. Performing checks prior to initial start-up (page 2–22)

11. Testing your installation (page 2–22)

(page 2–12)

Step 1: Designing Your Installation

Before doing anything else, you need to determine how you are going to

use your TS400, and then design a power system that will give you

maximum performance. The more thorough your planning, the better

your power needs will be met. In particular, you will need to:

• Be aware of installation codes

• Choose an appropriate location

• Calculate your battery requirements and appropriate battery size

• Calculate the DC cable size

• Select the correct DC f use and Disconnect or th e DC circuit breaker

Installation Codes

See “Installation Codes” on page 2–3 for more information.

2–6 975-0055-01-01

Page 29

Choosing a Location

:

Installing the TS400

WARNING: Risk of fire or explosion

This equipment contai ns components t hat could pr oduce arcs or

sparks. To reduce the risk of fire or e xplosion, do not ins tall t his

equipment in compartments containing batteries or flammable

materials, or in locations that require igniti on-protected

equipment. This includes any space containing gasolinepowered machinery, fuel tanks, or joints, fittings, or other

connections between components of the fuel system.

WARNING: Fire hazard

Do not cover or obstruct the ventilation openings. Do not i nstall

this equipment in a compartment with limited airflow.

Overheating may result.

The inverter should only be installed in a location that meets the

following requirements:

Dry Choose a dry location. Do not allow water or other fluids

to drip or splash on the inverter. Do not expose to rain,

snow or splashing water.

Cool Normal air temperature should be between 32 °F (0 °C)

and 104 °F (40 °C) — the cooler the better within this

range.

Ventilated The inverter requires air circulation to maintain optimum

operating temperature and pr ovide bes t performance. If the

unit has inadequate ventilation, it may shut down due to

overheating. Allow as much space around the ventilation

openings as possible. Xantrex recommends that other

objects be at least 3 inches (76 mm) away from the

ventilation openings for best performance. The air vented

through the openings should also have a path to circulate

away from the inverter.

Safe Do not install the inverter in the same compartment as

batteries or in any compartment containing flammable

liquids like gasoline.

975-0055-01-01 2–7

Page 30

Installation

Battery Requirements

Close to

battery

compartment

Protected

from battery

acid and

gases

Orientation To meet regulatory requirements, the TS400 must be

Long DC cables must be very large (and expensive), so

they should be kept short (see Table 2-1 on page 2–9).

However, the unit should NOT be installed in the battery

compartment due to the possible presence of explosive

hydrogen gas from the batteries.

Never allow battery acid to drip on the inverter or its

wiring when filling the batteries or reading their specific

gravity. Do not mount the unit where it will be exposed to

gases produced by the batteries. These gases are corrosive

and prolonged exposure will damage the inverter.

mounted on a flat horizontal surface with the front panel in

the upright position.

CAUTION

The TS400 Sine Wave Inverter must only be connected to

batteries with a nominal output voltage of 12 volts. The TS400

Sine Wave Inverter will not operate from a 6 volt battery and

will be damaged if connected to a 24 volt battery.

The batteries th at you use strongly af fect t he perfor mance of the TS400. It

is important to connect the inverter to the correct size and type of battery.

See Appendix B, “Battery Types and Sizes” on page B–1 for more

information.

2–8 975-0055-01-01

Page 31

DC Cables

Installing the TS400

For the best load starting performance, the DC cables should be as short

and large as po ssible. See Table 2-1 for minimum recommended cable

size. Using a smaller cable may cause the inverter to shut down under

heavy load. A larger cable may be used.

Table 2-1

&DEOH/HQJWK%DWWHU\WR,QYHUWHU

HDFKFDEOH

0–10 feet (0–3 meters) No. 6

10–15 feet (3–4.5 meters) No. 4

15–30 feet (4.5–9 meters) No. 2

30–40 feet (9–12 meters) No. 0

Minimum Recommend ed DC Inpu t Cable (cop per) — AWG

DC Fuse and Disconnect or DC Circuit Breaker

If you are using a DC fuse and Disconnect, a maximum 80 amp Class T

fuse shall be used for the DC fuse. A fuse of lo wer r ating c an be used, but

it shall not be lower t han 60 amp Class T. The Disconnect shall be ra ted at

least 50 amps.

Additionally, a DC circuit breaker rated 50 amps can be used.

0LQLPXP5HFRPPHQGHG

&DEOH6L]H³$:*

975-0055-01-01 2–9

Page 32

Installation

Step 2: Mounting Your Inverter

Mount your inverter before you connect any wires or cables.

For your convenience, the inverter dimensions are provided in

Figure 2-9 on page 2–23.

WARNING: Fire hazard

To meet regulatory requirements, the TS400 must be mounted

on a flat horizontal surface with the front panel in the upright

position.

To mount your TS400:

1. Turn the On/Standby switch on the front panel of the inverter to

Standby ( ) position.

2. Select an appropriate mounting location and orientation.

See “Choosing a Location” on page 2–7.

3. Hold the inverter against the mounting surface, mark the position of

the mounting screws, and then remove the inverter.

OR

Use “Inverter Dimensio ns” on page 2–23 to mark the positio n of the

mounting screws.

You can also download a full-scale version of the mounting template

from www.xantrex.com

4. Pilot drill the four mounting holes.

5. Fasten the inverter to the mounting surface with four #10 hardware

fasteners.

2–10 975-0055-01-01

Page 33

Step 3: Connecting the Chassis Ground

The chassis ground lug is used to connect the chassis of the inverter to

your system’s chassis grounding point, as required by installation codes.

Use copper cable that is either bare or provi ded wit h green insulation. Do

not use the chassis ground lug for your AC output grounding wire.

To connect the chassis ground:

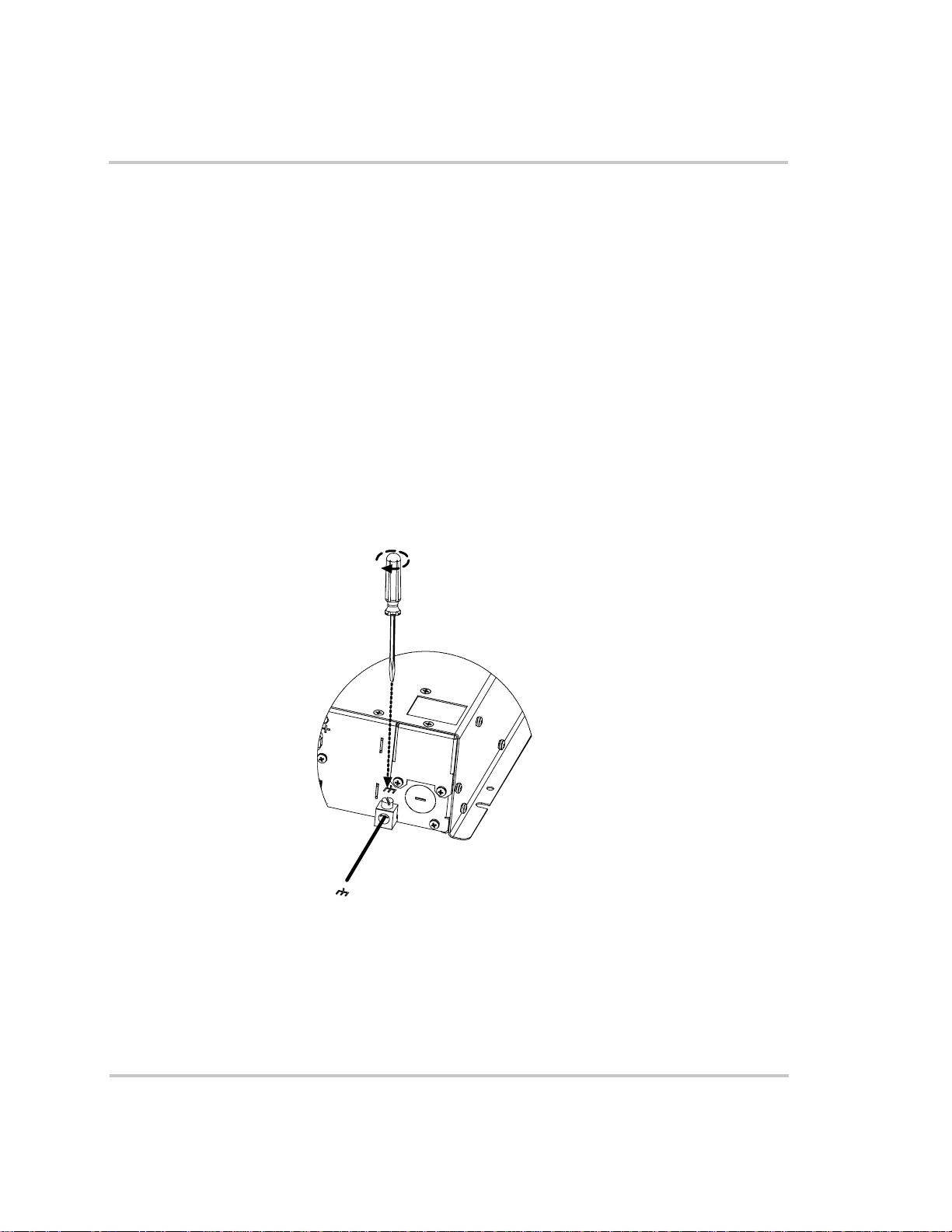

Refer to Figure 2-2.

1. Using the 1/4 inch slot screwdriver, loosen the screw on the chassis

ground lug.

2. Connect a No. 8 AWG copper cable between the inverter’s chassis

ground lug and the DC grounding point for your system.

In an RV or vehicle installation, this will usually be the vehicle

chassis or a dedicated chassis ground bus.

3. Tighten the screw to a torque of 6–7 lbf-in (0.68–0.79 Nm).

Installing the TS400

Figure 2-2

975-0055-01-01 2–11

Connecting the Chassis Ground

Page 34

Installation

Step 4: Installing the Optional S400 Remote Switch

WARNING: Shock hazard

Before making an opening in a wall, bulkhead or panel, ensure

there is no wiring or other obstruction w ithin the wall.

WARNING: Shock hazard

Ensure both the S400 Remote Switch and the TS400 are in

Standby ( ) mode before installing.

Installing the S400 Remote Switch (Xantrex product number 808-2400) is

optional. The TS400 operates normally without the remote switch.

The S400 Remote S witch is designed to be flush mounted on a wall,

bulkhead or panel. A 25 foot (7.5 meter) telephone cable is supplied with

the remote sw itch.

If you want to extend the cable, use a high quality, 4-wire telephone

extension cable with 6-position, 4-contact connectors. The maximum

recommended cable length is 50 feet (15 meters).

For your convenience, a full-scale mounting template is provided on

page 2–24.

Note: The S400 Remote Switch connects to a jack at the back of the

inverter. See “System Diagram” on page 2–2.

To install the remote switch:

1. Choose a location that is dr y, free from corrosive or explosive fumes,

and otherwise appropriate for installing an electronic device.

2. Using the template, pilot-drill the mounting holes. Cut an opening

about 2 inches x 1.2 inches (5 0 mm x 30 mm) and 1.4 inc hes (35 mm)

deep.

3. Route the telephone cable inside the wall and through the opening to

the inverter.

2–12 975-0055-01-01

Page 35

Installing the TS400

4. Connect one end of the telephone cable to the back of the inverter as

shown in Figure 2-3.

Figure 2-3

Connecting Cable to the TS400

5. Connect the other end of the telephone cable to the remote switch as

shown in Figure 2-4.

Figure 2-4

Connecting Cable to the S400 Remote Switch

6. Place the remote swit ch in the opening and secure it with the fou r #6

fasteners.

975-0055-01-01 2–13

Page 36

Installation

Step 5: Getting Ready to Connect the DC Cables

The DC cables should be as short as possible and large enough to handle

the required current, in accordance with the electrical codes or regulations

applicable to your installation. The minimum recommended DC cable

size is specifi ed i n Table 2-1 on page 2–9. For the recommended DC fuse

and Disconnect or DC circuit breaker, see page 2–9.

To prepare the DC cables:

Refer to Figure 2-5, “Connection Order for DC Cables” on page 2–16.

1. Cut the negative cable to the recomme nded leng th. (Se e Table 2-1 on

page 2–9 for DC cable size.) Strip off enough insulation so you can

install the terminal you will be using.

Xantrex recommends the use of crimp connectors such as a ring lug

type. The connector should be designed for a 6 mm or 1/4 inch stud

size to connect to the TS4 00 Sine Wave Inverter. If a crimp connector

is used, it should be crimped us ing the tool indicate d by the connect or

manufacturer.

2. Cut two lengths of positive cable. One cable (maximum 18 inches)

goes from the battery to the DC fuse and Disconnect or to the DC

circuit breaker. The other cable goes from the DC fuse and

Disconnect or to the DC circuit break er to the posit i ve DC termin al.

3. Attach the connectors to the ends of both cables. Make sure no stray

wire strands protrude from the terminals.

2–14 975-0055-01-01

Page 37

Step 6: Routing the DC Cables

WARNING: Fire and shock haza rd

Route the cables away from sharp edges which might damage

the insulation. Avoid sharp bends in the cable.

Guidelines for Routing the DC Cables

• Do not attempt to use the chassis in place of the battery negative

connection for grounding . The invert er requi res a reliable return path

directly to the battery.

• To reduce the chance of interference, keep the positive and negative

cables close together—ideally, tied together at regular intervals as

shown in Figure 2-5, “Connect ion Order for DC Cables” on page 2–

16.

• T o ensure maximum performanc e from the invert er , do not rou te your

DC cables through a DC distribution panel, battery isolator, or other

device that will cause additional voltage drops. The exception is the

DC fuse and Disconnect or the DC circuit breaker which is required

to protect the DC wiring.

Installing the TS400

975-0055-01-01 2–15

Page 38

Installation

Step 7: Connecting the DC Cables

8

Battery

Figure 2-5

7

6

3

5

Connection Order for DC Cables

2

9

4

Inverter

1

CAUTION: Reverse polarity

Before making the final DC connection, check cable polarity at

both the battery and the invert er. Positive (+) must be connected

to positive (+); negative (–) must be connected to negative (–).

Reversing the positive (+) and negative (–) battery cables will

damage the inverter and void your warranty.

WARNING: Fire hazard

Use only appropriately sized copper cable. Make sure all DC

connections are tightened to a torque of 2.2–2.6 lbf-ft

(3.0–3.5 Nm). Loose connections will overheat.

2–16 975-0055-01-01

Page 39

Installing the TS400

To connect the DC cables:

Connect the DC cables as shown in Figure 2-5, in the order shown by the

numbers.

1. Switch the On/Standby switch to the Standby ( ) position.

2. Route the DC cables from the battery bank to the inverter.

See “Step 6: Routing the DC Cables” on page 2–15.

3. Install a DC fuse and Disconnect or a DC circuit breaker in the

positive side of the circuit within 18 inches of the battery.

This protects your battery and wiring in case of accidental shorting.

(See “DC Fuse and Disconnect or DC Circuit Breaker” on page 2–9

for recommended fuse size and type.) Open the DC fuse and

Disconnect or turn off the DC circuit breaker.

4. Connect one connector on the POSITI VE (+) cable to the POSITIVE

DC terminal on the inverter. Tighten the nut to a torque of

2.2–2.6 lbf-ft (3.0–3.5 Nm).

5. Connect the other connector to the positive (+) terminal DC fuse and

Disconne ct or to the DC circuit breaker. Use a wrench to tighten the

connection according to the manufac tur er’s recommendations. Test

that the cable is secure.

6. Attach a short DC cable from the unconnecte d end of t he DC fuse and

Disconnect or DC circuit breaker. Tighten appropriately.

7. Observing polarity carefully, connect the other end of the fused cabl e

to the POSITIVE (+) terminal of the battery. Tighten this connection

to the battery manufacturer’s recommended torque.

8. Connect one connector on the NEGATIVE (–) cable to the

NEGATIVE (–) battery terminal. Tight en the conne ction acc ording to

the battery manufacturer’s recommended torque.

9. Check th at the polarity of the DC connections is correct: po sitive (+)

on the inverter is connected to the positive (+) on the battery, and

negative (–) is connected to the negative (–).

10. Connect the other connector of the NEGATIVE (–) cable onto the

NEGATIVE (–) terminal on the TS400 Sine Wave Inverter.

11. Use a wrench to tighten the nut to a torque of 2.2–2.6 lbf-ft

(3.0–3.5 Nm). Test that the cable is secure.

975-0055-01-01 2–17

Page 40

Installation

Step 8: Connecting Your Equipment to the GFCI Outlets

To connect your AC equipment to the GFCI outlets:

1. Turn the inverter’s On/Standby switch to Standby ( ).

2. Turn your AC equipment off.

3. Connect your AC equipment to the GFCI outlets in the front panel.

4. If you wish to connect more equipment, use a multiple-outlet

extension cord. Ensure that the total power drawn does not exceed

400 watts.

Note: Ensure that the Reset button on the GFCI outlets is not tripped.

Important:

inverter, Xantrex recommends that they be hardwired. See “Step 9:

Hardwiring the AC Output” on page 2–19.

If you have more permanent loads to connect to the

2–18 975-0055-01-01

Page 41

Step 9: Hardwiring the AC Output

If you wish to permanently connect additional AC outlets, Xantrex

recommends hardwiring the AC output connections.

WARNING: Fire, shock, and energy hazards

Make sure wiring is disconnected from all electrical sources

before handling. All wiring must be done in accordance with

local and national electrical wiring codes. Do not connect the

output leads of the inverter to any incoming AC source.

To hardwire the AC output connections:

1. Turn the On/Standby switch to Standby ( ).

2. Remove the knockout using a slot screwdriver as shown in

Figure 2-6. Do not leave the knockout inside the wiring box.

Installing the TS400

Figure 2-6

975-0055-01-01 2–19

Removing the Knockout

Page 42

Installation

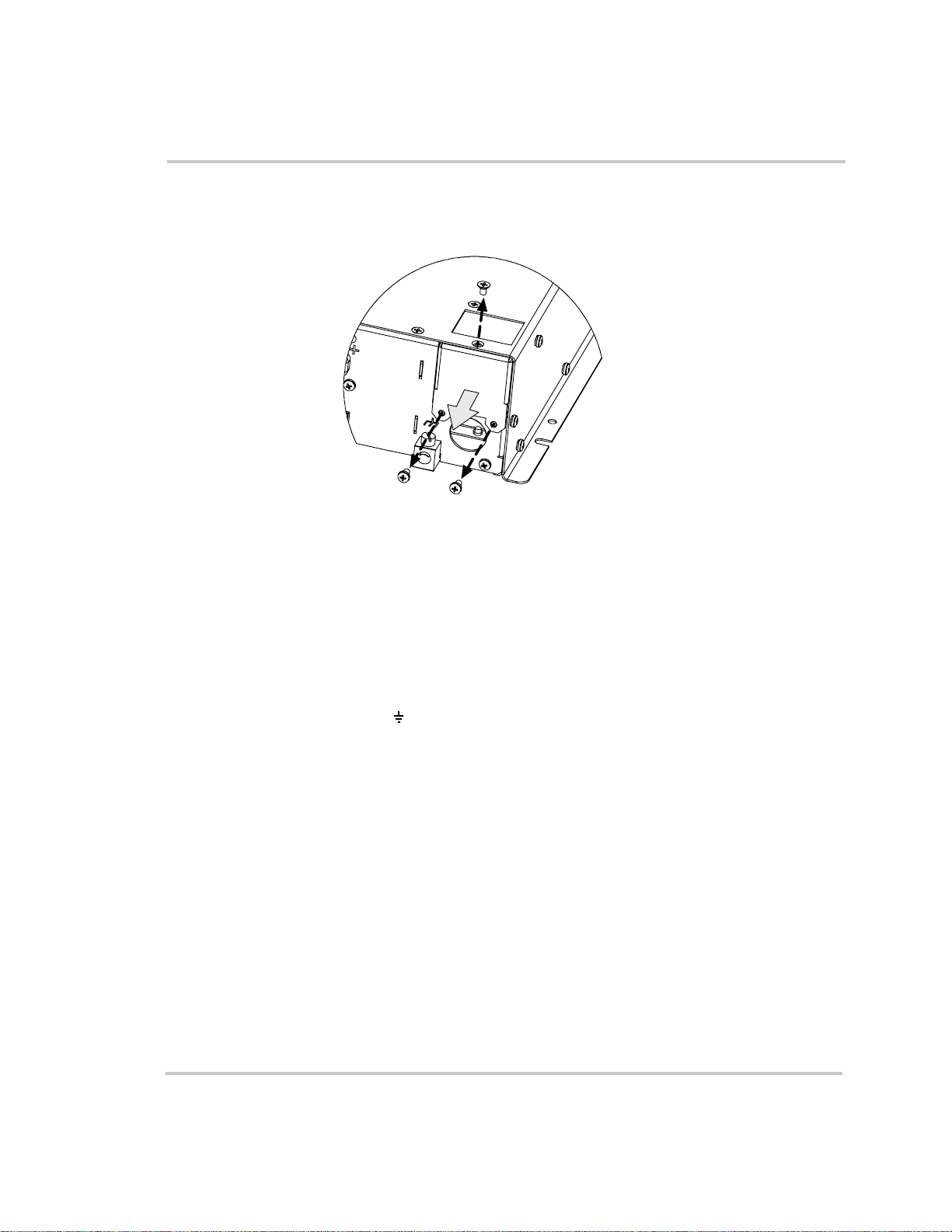

3. Locate the wiring box access panel, and remove the three screws to

access the wiring box as shown in Figure 2-7.

Figure 2-7

Removing the 3 Screws on the Wiring Box Access Panel

4. Remove the wiring box access panel from the unit.

5. Install a 1/2 inch cable clamp.

6. Locate the terminal block.

The three terminals are labelled as follows:

• L Line

• N Neutral

• Ground

7. Strip about 2 inches (50 mm) off the jacket of the AC output cable.

The AC output cable must be either solid or stranded, within the

range of No. 14 to No. 18 AWG, and have three conductors.

8. Strip approximately 3/8 inch (10 mm) off the insulation of the cable.

9. Run the AC cable through the cable clamp and into the wiring box.

10. Using the 1/8 inch slot screwdriver, loosen the wire attachment

screws on the terminals by five turns.

11. Insert and fasten the Ground wire into the corresponding terminal.

12. Insert the Line and Neutral wires into the corresponding terminals.

2–20 975-0055-01-01

Page 43

Installing the TS400

13. Tighten the wire attachment screws to a torque of 1.3–1.8 lbf-ft

(1.76–2.44 Nm) as shown in Figure 2-8. Leave some slack inside the

output wiring box.

14. Secure the cable clamp on the cable jacket.

15. Attach the wiring box access panel and tighten the three screws.

Figure 2-8

975-0055-01-01 2–21

Completing the Hardwiring

Page 44

Installation

Step 10: Performing Checks Prior to Initial Start-up

Before starting up your inverter, ensure these conditions are met:

❐ Chassis ground is properly installed

❐ On/Standby switch is in the Standby ( ) position on the TS400

❐ Positive (+) battery cable is connected to the positive (+) battery

terminal through the DC fuse and Disconnect or DC circuit breaker

❐ Negative (–) battery cable is connected to the negative (–) battery

terminal

❐ Battery voltage is within the proper range for this unit

(10.3–15.3 volts DC)

❐ DC Fuse is intact (not blown)

Step 11: Testing Your Installation

WARNING: Shock hazard

The On/Standby switch on the TS400 does not disconnect DC

power to the TS400.

When you are ready to tes t yo ur i nst allation and operate the TS400, close

the DC fuse and Disconnect or th e DC circuit breaker to supply DC power

to the TS400.

To test the TS400:

1. Turn the inverter’s On/Standby switch to the On ( ) position. If the

optional S400 Remote Switch is insta lled, turn the On/S tandby swit ch

on the remote switch to the On ( ) position.

The green Inverter ON indicator illuminates.

2. Plug an appliance of 400 watts or less into one of the GFCI outlets.

3. Turn the appliance on to verify that it operates.

4. If the appliance operates, your installation is successful.

5. If the red Fault light illuminates, see “Troubleshooting” on page 4–1.

2–22 975-0055-01-01

Page 45

Installing the TS400

T

5

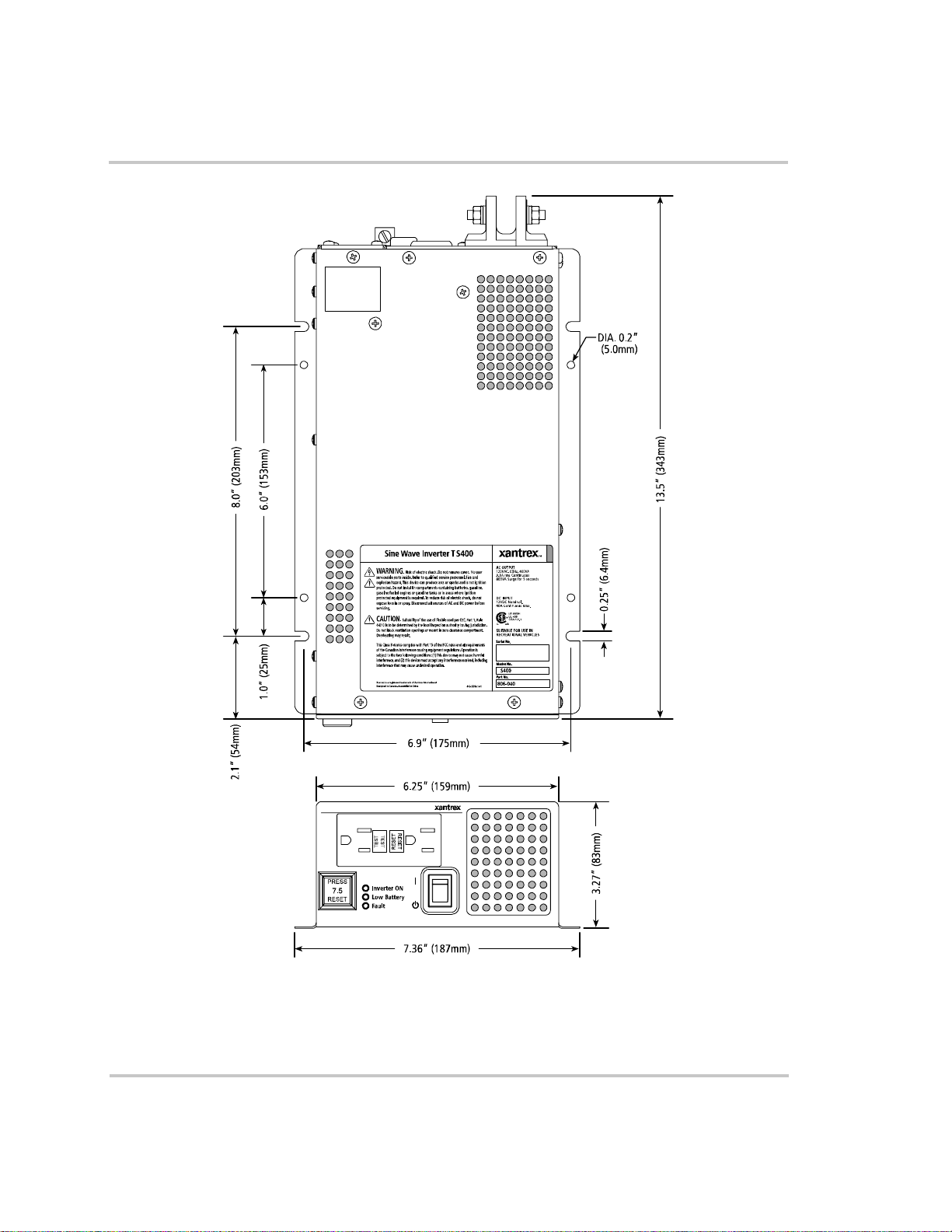

Figure 2-9

Inverter Dimensions

This drawing is not to scale. A full-scale mounting template is available at www.xantrex.com

975-0055-01-01 2–23

Page 46

Installation

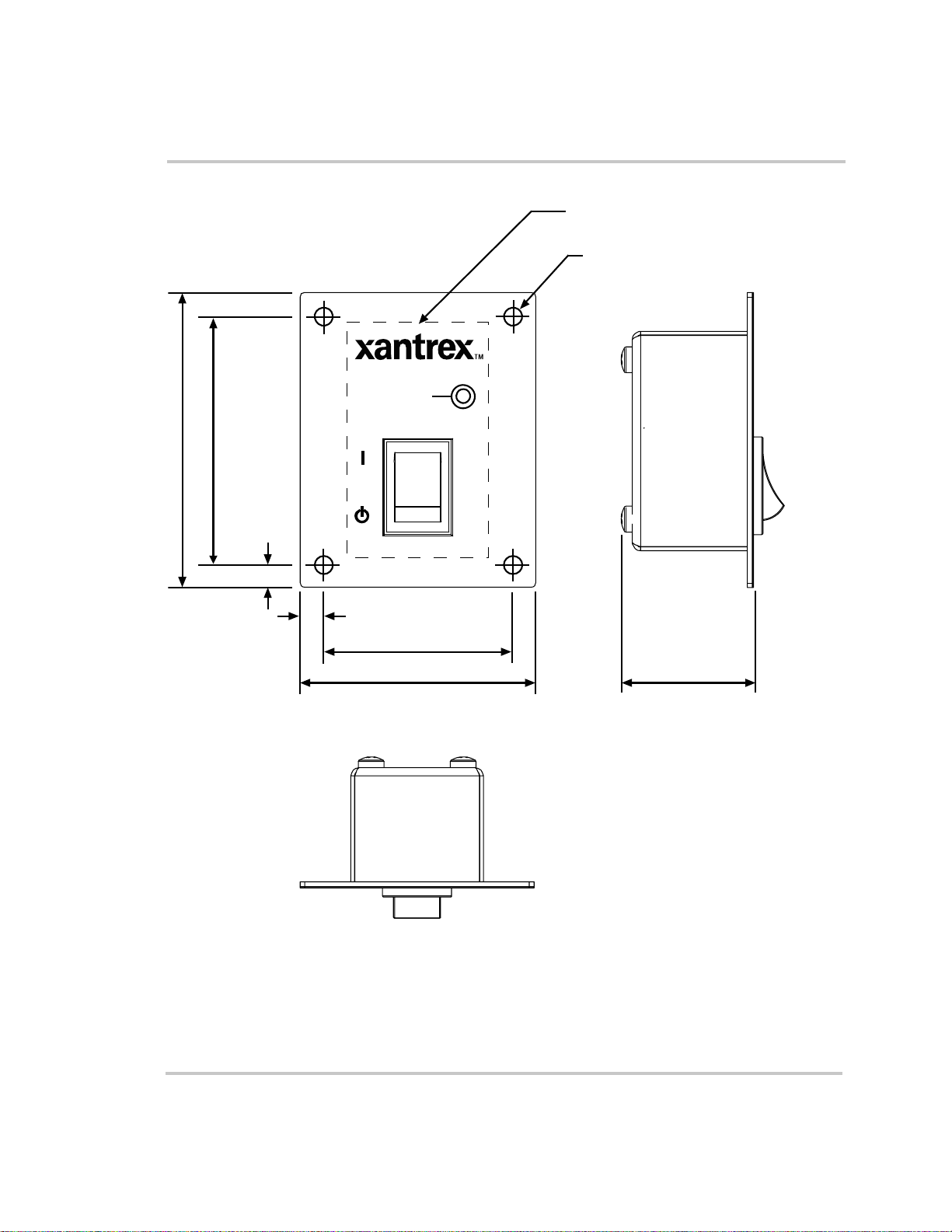

2.5" (63.5)

CUTOUT PANEL 2" X 1.2" (50.8 X 30.5)

(DASHED LINE)

DRILL Ø0.125 (1/8") HOLE

4 PLACES FOR #6/32 SELF

TAPPING SCREW

Inverter ON

2.1" (53.5)

0.2" TYP (5.0)

Figure 2-10

0.2" TYP (5.0)

1.6" (40.8)

2" (50.8)

1.1" (28.3)

S400 Remote Switch Mounting Template (Scale approximately 1:1)

2–24 975-0055-01-01

Page 47

Operation

Chapter 3, “Operation” explains how to use your TS400

effectively. This chapter explains how to turn the TS400 to

On

() or Standby ( ) from the front panel or from the optional

S400 Remote Switch, monitor the status of the TS400, and

reset the inverter.

CAUTION

Read this cha pter before operating the TS400 Sine Wave

Inverter.

WARNING: Restrictions on use

The TS400 Sine Wave Inverter shall not be used in connection

with life support systems or other medical equipment or

devices.

Page 48

Operation

Front Panel Features

Before you begin to operate the TS400, review the front panel features in

Figure 3-1.

For a detailed description of each of the different features, see “Front

Panel of the TS400” on page 1 –4 in the “Introduction” chapter.

6

7

Figure 3-1

\

5

4

3

Front Panel of the TS400

Table 3-1

)HDWXUH 'HVFULSWLRQ

1 On/Standby Switch

2 Inverter ON light

3 Low Battery light

4 Fault light

5 Supplemental Circuit Protection button

6 T wo GFCI outlets

7 Ventilation openin gs

2

1

Front Panel Features

3–2 975-0055-01-01

Page 49

Operating the TS400

Operating the TS400

WARNING: Shock hazard

The TS400 has On mode and Standby mode only. It does not

have an Off mode, that is, DC power is perm ane ntl y conn ect ed

to the unit.

On/Standby switch You can turn the TS400 to On () or to Standby ( ) using the On/S ta ndby

switch (see “Front Panel of the TS400” on page 3–2).

Optional remote

switch

Resetting the TS400 The On/Standby switch on the TS400 or the S400 Remote Switch is also

Turning the TS400 On

If you have installed the optional S400 Remote Switch, you can also use

the remote sw itch to turn the TS400 to On

“Using the Optional S4 00 Remote Switch” on page 3–4.

used to reset the TS400 after a Fault condition. See “Resetting After a

Fault or Shutdown” on page 3–7.

When the On/Sta ndby switch is turned to On (), the TS400 powers your

equipment using energy from the battery.

To turn the TS400 on:

1. Turn the On/Standby switch on the TS400 to the On

() or to Standby ( ). See

() position.

The Inverter ON light illuminates on the TS400.

AND

If you have installed the S400 Remote Switch, turn the S400 Remote

Switch to On

2. Operate your equipment.

().

Turning the TS400 to Standby When Not in Use

When you are not using the TS400 and want to conserve battery power,

turn the inverter’s On/Standby switch to the Standby ( ) position.

To turn the TS400 to standby:

1. Turn your equipment off.

2. Turn the On/Standby switch on the TS400 or the optional S400

Remote Sw itch to the Standby ( ) position.

The Inverter ON light turns off.

With the On/Standby switch in Standby ( ) position, the TS400 draws no

current fro m the battery.

975-0055-01-01 3–3

Page 50

Operation

If the On/Standby switch on the TS400 is in the On () position and the

optional S400 Remote Switch is in the Standby ( ) position (see

“Important” on page 3–4), the TS400 draws very little current (about

1 mA) from the battery.

Using the Optional S400 Remote Switch

The S400 Remote S witch performs the same function as the On/Standby

switch on the TS400.

Important: For the Remote Switch to function, the On/Standby switch

on the TS400 must be turned to the On

Purpose The S400 Remote Switch provi des On/St andby control of the TS400 from

a convenient location of up to 25 feet (7.5 meters) away using the

supplied telephone cable.

Cable length You can use a longer cable up to a maximum recommended length of 50

feet (15 meters). Xantrex recommends using a high quality 4-wire

telephone cable wth 6-position, 4-contact connectors.

() position.

Inverter ON

Figure 3-2

3–4 975-0055-01-01

S400 Remote Switch

Page 51

Recharging Your Batteries

Recharging Your Batteries

Low Battery light If the Low Battery light illuminates on the TS400 and you hear the low

battery alarm, your battery level is low (less than 10.7 volts). As long as

the Inverter ON light is illuminated on the TS400, the unit will continue

to supply inverter power to your equipment.

However, Xantrex highly recommends that you recharge your battery.

Turn off your equipment and recharge your battery. When the Low

Battery light an d th e audible alarm tur n off (at 12.6 v olt s), you can restart

your equipment. See “Restarting or Operating Multiple Pieces of

Equipment”.

Importance of

recharging

More information For more information about ba ttery char gers an d battery moni tors, see t he

Recovering from Low Battery Voltage Shutdown

Xantrex recommends that you recharge your batteries before they are

50% discharge d. This gi ves them a much long er life c ycle tha n rechar ging

them when they are almost completely discharged. See “Battery State of

Charge” on page B–8.

Xantrex web site at www.xantrex.com.

If the Low Battery light illuminates, you hear an alarm, and the Inverter

ON light on the front panel turns off when you are operating the unit, the

TS400 has shut down due to low battery voltage (10.3 volts). Output

power is interrupted.

To recover from a low battery voltage shutdown:

1. Turn off your equipment and recharge your battery. The alarm will

turn off when battery voltage reaches 11.6 volts.

2. When the Low Battery light t urns of f (12.6 vol ts) and the I nverter ON

light illuminates, you can restart your equipment.

Restarting or Operating Multiple Pieces of Equipment

The TS400 can handle several pieces of equipment simultaneously as

long as they do not draw more than 400 watts in total.

To restart or operate several pieces of equipment:

◆ T u rn eac h dev ic e on separa tely after the TS400 has started.

This action ensures that the TS400 does not have to deliver the

starting current for all the loads at on ce and will help to preven t an

overload shutdown.

975-0055-01-01 3–5

Page 52

Operation

Monitoring the Operating Status

The operating status of the TS400 is indicated by three ligh ts on th e fr ont

panel and an audible alarm. See Table 3-2.

For an illustration of the indicator lights on the front panel, see “Front

Panel of the TS400” on page 3 –2.

If none of the front panel lights are on, see “Troublesho oti ng Refe re nce”

on page 4–2.

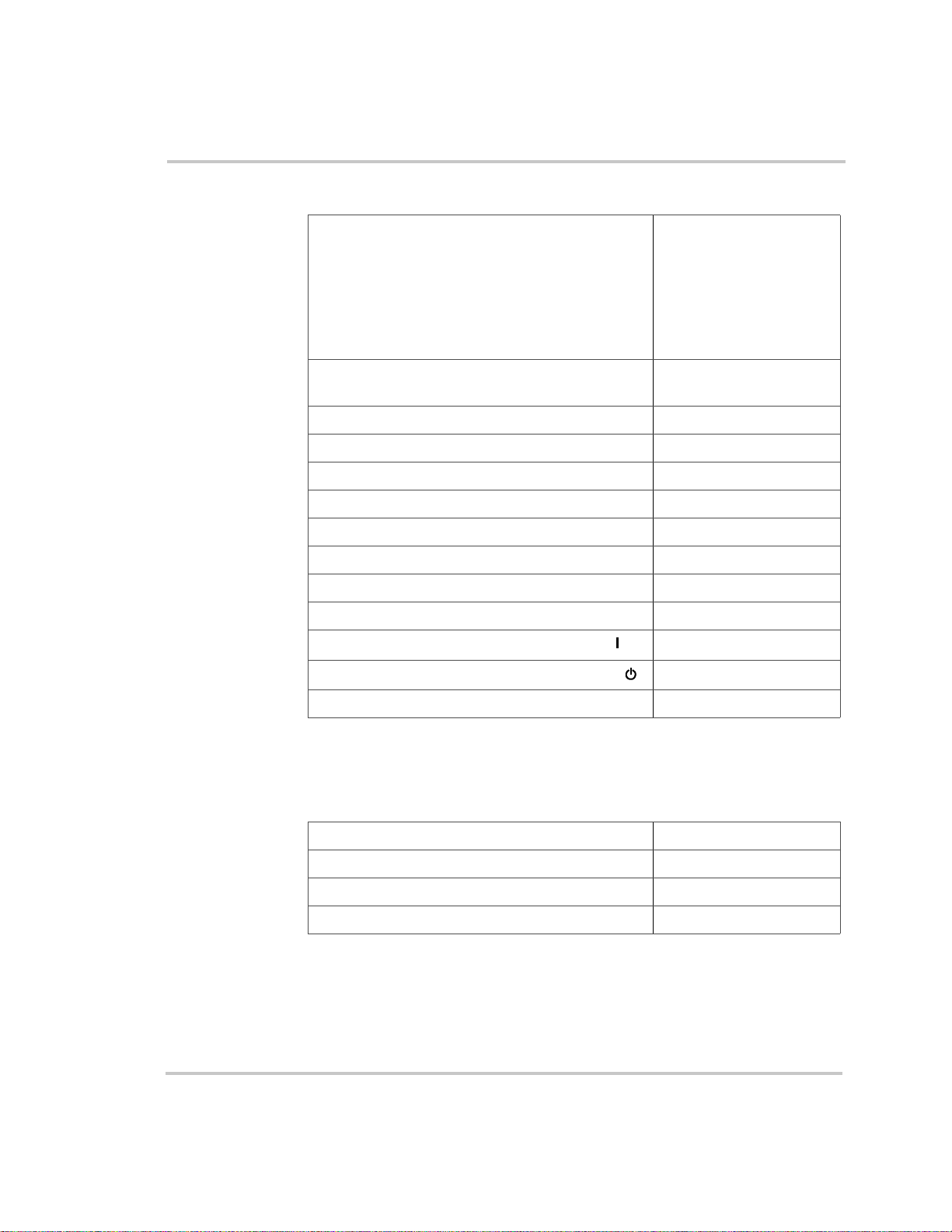

Table 3-2

/LJKW &RORU 6WDWXV $FWLRQ

Inverter ON Green When the TS400 is on, the Inverter

Low Battery &

Inverter ON

(with audible

alarm)

Low Battery

(with audible

alarm)

Fault Red The Fault light illuminates

Status of Indicator Lights and Alarm

ON light illuminates.

Y ellow &

Green

Yellow When only the Low Battery light

When the Low Battery and

Inverter ON lights illuminate, your

battery level is low. (The battery

voltage has dropped below 10.7

volts DC.)

illuminates, your battery level is

critically low. (The battery voltage

has dropped below 10.3 volts DC.)

whenever there is a battery overvoltage fault condition (exceeds

15.3 volts), output overload fault

condition or over-temperature

fault condition.

You can run your equipment using

energy from the battery.

You can run your equipment but your

battery level is low. Charge your

battery.

You cannot run equipment. Charge

your battery.

You cannot run equipment as the AC

output is disabled. Clear the fault

condition. Reset the TS400 by

turning the On/Standby switch to

Standby

() and then to On ( ).

3–6 975-0055-01-01

Page 53

Resetting After a Fault or Shutdown

This section provide s explanati ons and proced ures for reset ting the TS400

after a fault or shutdown.

If you are unable to resol ve the problem after referring to Table 3-3, refer

to the “Troubleshooting” section on page 4–2.

Resetting After a Fault or Shutdown

Table 3-3

)DXOW 6WDWXV $FWLRQ

Shutdown The TS400 needs to be reset. Turn the On/Standby switch on either the

Short Circuit If there is a short circuit, the

Ground Fault When a fault conditio n is

Resetting After a Fault or Shutdown

Supplemental Circuit

Protection button trips.

detected, the Reset button on

the GFCI outlet trips and

power to the appliance is

interrupted.

inverter’s front panel or the optional S400

Remote Switch to Standb y ( ) and then to

On ( ).

Remove the short circuit condition then press

the Supplemental Circuit Protection button.

Reset: To resume normal operation, determine

and correct the ground fault, then press the

Reset button.

Test: Press the Test button on the GFCI outlet

with the TS400 turned to On ( ). The Reset

button should trip. Press the Reset button to

reset the GFCI and continue with normal

operation. This test should be performed on a

monthly basis.

If the Reset button does not trip, the GFCI may

have failed. Contact yo ur dealer to h ave a

qualified service person examine the TS400.

Overload The TS400 is designed to

provide 400 watts con tinuously

and 800 watts surge capability

for five seconds. If the

connected equipment draws

more than the rated power, the

TS400 will shut down and the

red Fault light illuminates.

975-0055-01-01 3–7

Disconnect the equipment connected to the

inverter and then turn the On/Standby switch

on either the inverter’s front panel or the S400

Remote Switch to Standb y ( ) and then to

On ( ).

See also “Recharging Your Batteries” on

page 3–5.

Page 54

3–8

Page 55

Troubleshooting

The TS400 is designed for high reliability and has a number of

protection features for trouble-free operation. If, however, you

have any problems operating your inverter, refer to the

“Troubleshooting Reference” on page 4–3.

Read this troubleshooting chapter before calling your dealer or

Xantrex Customer Service. See page ii for contact

information.

If you cannot resolve the problem, record the information

asked for on the form, “Information About Your System” on

page WA–4. Providing this information to our Customer

Service Representatives will help them to assist you better.

Page 56

Troubleshooting

Troubleshooting Reference

WARNING: Electrical shock and fire hazard

Do not disassemble the TS400. It does not contain any user-

serviceable parts. Atte mpting to service the unit yourself coul d

result in electrical shock or fire.

This section provides you with troubleshooting tips to identify and solve

most problems that can occur with the TS400.

Before contacting your dealer or customer service, please refer to the

table, “Troubleshooting Reference”.

If the “Troubleshooting Reference” table does not help you resolve the

problem, contact your dealer or Xantrex customer service.

Figure 4-1

For a detailed description of the different features, see “TS400 Features”

on page 1–4.

4–2 975-0055-01-01

Front Panel

Page 57

Troubleshooting Reference

Table 4-1

3UREOHP 3RVVLEOH&DXVH 6ROXWLRQ

No output voltage. No

indicator lights are

illuminated.

No output voltage. Inverter

ON light is illuminated.

No output voltage. Fault light

is illuminated.

T r ou bleshoo ting Re feren ce

The switch is in Standby ( )

mode.

No input power to the

inverter.

DC fuse open (external)

Supplemental Circuit

Protection button has tripped.

GFCI has tripped.

Inverter may be overloaded.

Turn the On/Standby switch on the inverter

to On ( ).

Check the DC wiring to the inverter for

loose connections, frayed wiring or an open

DC Disconnect.

Have a qualified service technician check

and replace the fuse.

Disconnect all equipment to reduce the

overload. Check the AC wiring and reset

the Supplemental Circuit Protection button.

Clear the ground fault, and reset the GFCI

by pressing the Reset button on the GFCI.

Disconnect all equipment connected to the

inverter, and reset the inverter by turning

the On/Standby switch to Standby

then to On ( ).

() and

Battery voltage may be too

high.

Over temperature.

No output voltage. Low

Battery light is illuminated

and alarm is on.

975-0055-01-01 4–3

Battery voltage is too low.

Poor DC wiring.

The inverter will restart if the battery

voltage drops below 14.5 volts DC.

Allow the inverter to cool down. The

inverter will restart automatically.

Recharge the battery to more than 12.6

volts DC. The inverter will restart

automatically.

Turn the inverter to Standby

Disconnect the DC wiring. Use proper

wiring and ensure all connections are tight.

().

Page 58

Troubleshooting

Table 4-1

3UREOHP 3RVVLEOH&DXVH 6ROXWLRQ

Output voltage is present.

Inverter ON light and Low

Battery light are illuminated

and alarm is on.

Fan does not turn on. The internal components of

Fan runs all the time. The amount of power being

Troubleshooting Reference

Battery voltage is low. Disconnect all equipment. Charge the

the inverter are not warm.

consumed by the equipment

is high.

The ambient temperature is

high.

batteries.

No action. The fan will run automatically

when necessary to cool the internal

components of the inverter.

No action. The fan will run at lower speeds

and stop automatically when the internal

temperature of the inverter falls.

No action. The fan will run at lower speeds

and stop automatically when the ambient

temperature falls.

For more information on the “Fan Cooling

System”, refer to page A–3.

4–4 975-0055-01-01

Page 59

Specifications

Appendix A, “Specifications”, contains the electrical and

physical specifications for the TS400.

All specifications are subject to change without notice.

Page 60

Specifications

Electrical Specifications

Output power at 12 VDC input

• Continuous

1

400 VA

(0 °C to 40 °C), derated

linearly to 300 VA at

122 °F (50 °C)

, 32 °F to 104 °F

• Surge capacity for 5 seconds

Input voltage 12 VDC nominal

Output voltage 120 VAC RMS ± 3 VAC

Output fr equency 60 Hz ± 0.05 Hz

Output wave form Sine wave

Total harmonic dis tortion of output waveform <3%

High battery shutdown 15.3 ± 0.3 VD C

Low battery indication and audible alarm 10.7 ± 0.3 VDC

Low batte ry shutdown 10.3 ± 0.3 VD C

Maximum efficiency 88%

No load current draw with switch turned to On ( )

No load current draw with switch set to Standby

Supplemental circuit protector 7.5 AAC

1.

The term “watts” has been used throughout the guide to refer to output

power. More correctly, the actual unit of power used is “VA”.

800 VA

10.3 to 15.3 VDC

1.25 ADC Maximum

0 ADC

()

Physical Specifications with Projections

Length 13.5 inches (343 mm)

Width 7.36 inches (187 mm)

Height 3.27 inches (83 mm)

Weight 10 lb (4.54 kg)

A–2 975-0055-01-01

Page 61

Regulatory Approvals

CSA/NRTL approved to CSA C22.2 No. 107.1 and UL 458

FCC Class B

Fan Cooling System

A fan cools the internal heat-generating components of the inverter. The

fan begins to operate when the interna l temperatu re rises

fan increases with inter nal temperat ure.

The fan turns off if the internal temperature of the inverter drops

Regulatory Approvals

. The speed of the

.

975-0055-01-01 A–3

Page 62

A–4

Page 63

Battery Types and

Sizes

The batteries that you use strongly affect the performance of

the TS400. It is important to connect the inverter to the correct

size and type of battery.

The information in Appendix B will help you to select,

connect, and maintain batteries that are most appropriate for

your application.

Page 64

Battery Types and Sizes

Battery Types

Automotive Starting Batteries

The lead-acid battery you are most familiar with is probably the starting

battery in your vehicle. An automotive starting battery is designed to

deliver a large amount of current for a short period of time (so it can start

your engine). Only a small portion of the battery’s capacity is used when

starting the engine, and the spent capacity is quickly recharged by the

running engine.

The starting battery in your vehicle is not designed for repeated deepdischarge cycles where the battery is almost completely discharged and

then recharged. If a starting battery is used in this kind of deep discharge

service, it will wear out very rapidly.

Deep-Cycle Batteries

Deep-cycle batteries are designed for deep discharge service where they

will be repeatedl y dischar ged an d rechar ged . They are mark eted f or use in

recreational vehi cl es, boats, and elect r ic gol f c ar ts—so you may see them

referred to as RV batteries, marine batteries, or golf cart batteries.

For most applications of the TS400, Xantrex recommends that you use

one or more deep-cycle batteries that are separated from the vehicle’s

starting battery by a battery isolator.

A battery isolator is a solid-state electronic circuit that allows equipment

to be operated from an auxi liary ba ttery withou t danger of dischar ging t he

vehicle’s starting battery. During vehicle operation, the battery isolator

automatically directs the charge from the alternator to the battery

requiring the charge.

Battery iso lators are available at marine and RV dealers and most auto

parts stores.

B–2 975-0055-01-01

Page 65

Battery Size

Battery Size

CAUTION

The TS400 Sine Wave Inverter must only be connected to

batteries with a nominal output voltage of 12 volts. The TS400

Sine Wave Inverter will not operate from a 6 volt battery and

will be damaged if connected to a 24 volt battery.

Battery size or capacity is as important as the battery type fo r efficient

operation of your loads. Xantrex recommends that you purchase as much

battery capacity as you need.

A number of different standards are used to rate battery energy storage

capacity. Automotive and marine starting batteries are normally rated in

cranking amps. This is not a relevant rating for continuous loads like an

inverter. Deep-cycle batteries use a more suitable rating system, either

“amp-hours” (“Ah”) or “reserve capacity” in minutes.

Battery Reserve Capacity Battery rese rve capacity is a measure of

how long a battery can deliver a certain amount of current—usually 25

amps. For example, a battery with a reserve capacity of 180 minutes can

deliver 25 amps for 180 minutes before it is completely discharged.

Amp-hour (Ah) Capacity Amp-hour capacity is a measure of how

many amps a battery can deliver for a specified length of time—usually

20 hours. For example, a typical marine or RV battery rated for 100 Ah

can deliver 5 amps for 20 hours (5 A x 20 hours = 100 Ah).

This same battery can deliver a higher or lower current for less or more

time, limited approx imately b y the 100 Ah figure (for e xample, 50 A for 2

hours, or 200 A for 1/2 hour), but usually th e capaci ty figure given is on ly

accurate at the specified rate (20 hours).

To calculate the battery capacity you require, read “Estimating Battery

Requirements” on page B–4 and “Battery Sizing Example” on page B–4,

and then complete the “Battery Sizing Worksheet” on page B–5.

975-0055-01-01 B–3

Page 66

Battery Types and Sizes

Estimating Battery Requirements

To determine how much battery capacity you need:

1. Determine how many watts are consumed by each applia nce that you

will operate from the TS400. You can normally find the watt rating

labelled on the product. If only the current draw is given, multiply it

by 115 to get the power consumption in watts.

2. Estimate how many hours each appliance will be operating each day.

3. Calculate the daily watt-hours needed for each appliance.

4. Add the total number of watt-hours needed for all the equipment and

multiply it by the number of days between charges.

5. Divide the total watt-hours of AC load between charges by 10. This

gives the battery Ah used between charges.

6. Double the total Ah used between charges to get the recommended

battery size in Ah.

See the battery sizing example that follows.

Battery Sizing Example

This battery sizing ex ample illustrates a typical calculation, assum ing an

opportunity to charge the batteries every three days:

.

'DLO\ZDWWKRXUV

$3RZHU

&RQVXPSWLRQ

$SSOLDQFH

TV 100 W 4 hours 400 Wh

Fan 60 W 4 hours 240 Wh

3 lamps, 60 W each 180 W 4 hours 720 Wh

Laptop computer 60 W 4 hours 240 Wh

Small hand drill 300 W 1 hours 300 Wh

Other loads 100 W 3 hours 300 Wh

Total daily watt-hours of AC load 2200 Wh

x Number of days between charges 2

= Total watt-hours of AC load between charges 4400 Wh

Battery Ah used between charges (divide by 10) 440 Ah

Recommended Battery Bank Size in Ah (multiply by 2) 880 Ah

:DWWV

%2SHUDWLQJ

7LPHSHU'D\

+RXUV

QHHGHGIRUWKLV

DSSOLDQFH

$[%

B–4 975-0055-01-01

Page 67

This example illustrates how quickly your battery needs can escalate. To

reduce the required battery size, you can conserve energy by eliminating

or reducing the use of some loads or by recharging more frequently.

When sizing your battery, resist the temptation to skip the last step of this

calculation (multipl ying by 2). More capacity is better si nce you will have

more reser ve capacity, be better ab le to handle large loads and surge

loads, and your battery won’t be discharged as deeply. Battery life is

directly dependent on how deeply the battery is discharged. The deeper

the discharge, the shorter the batter y life.

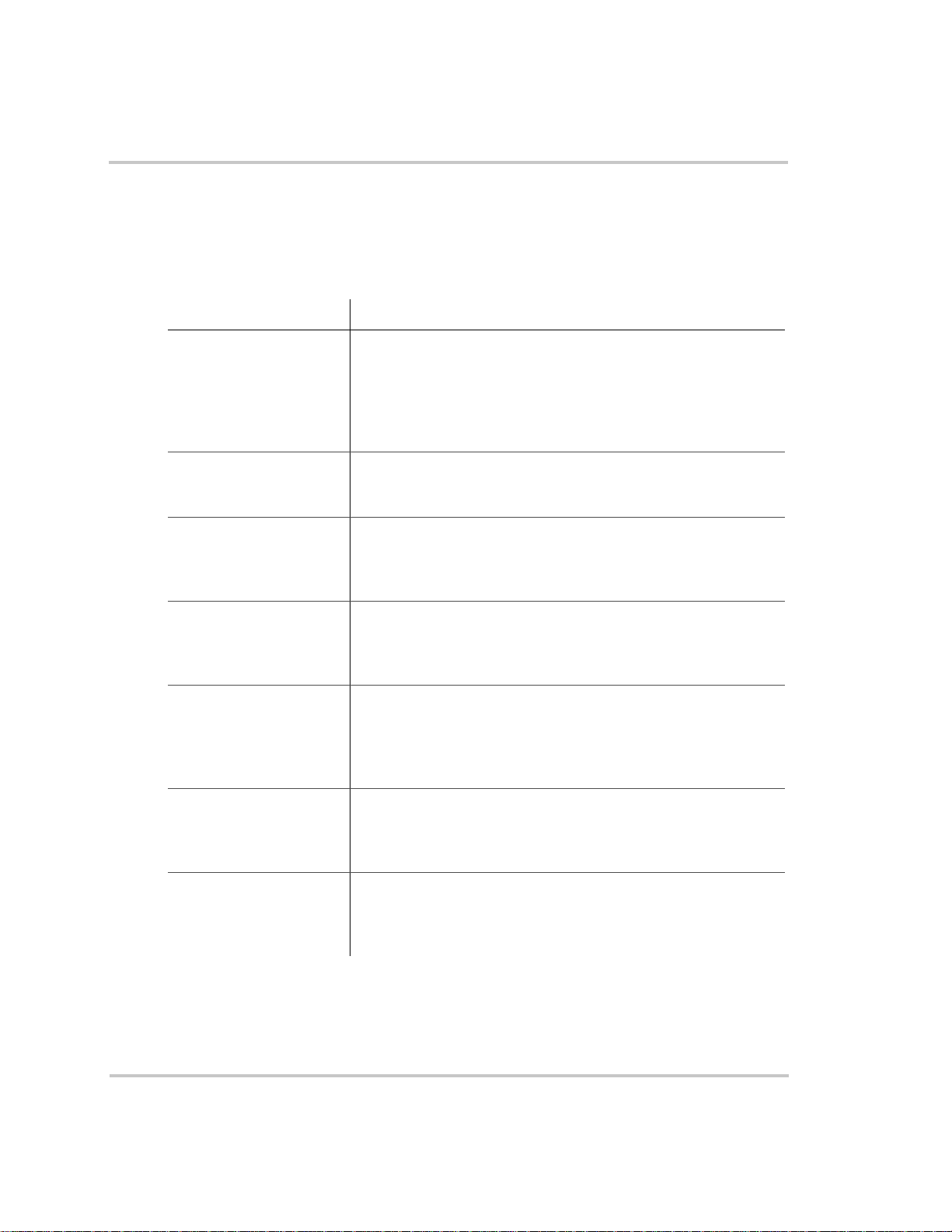

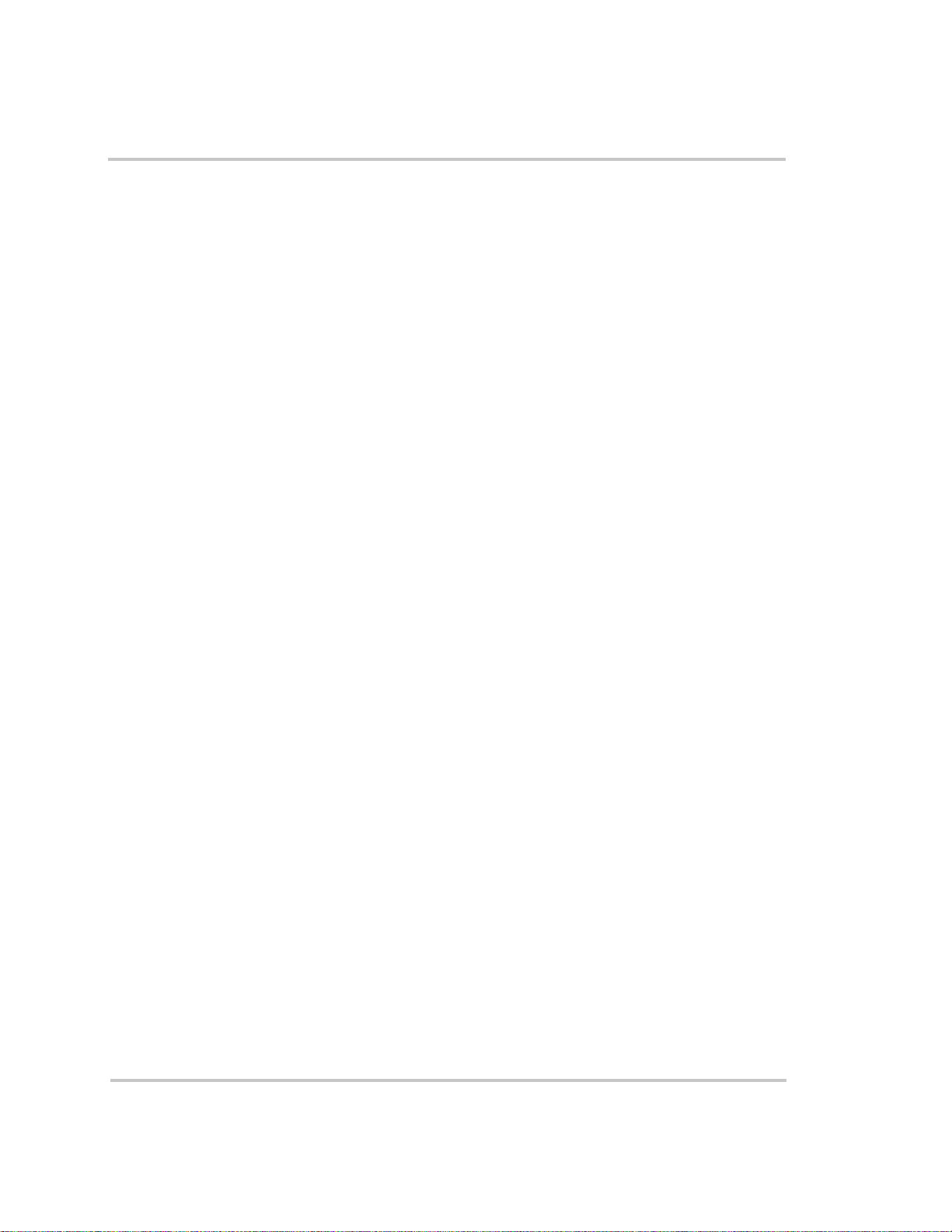

Battery Sizing Worksheet

Use the following worksheet to calculate your battery needs. To ensure

sufficient battery capacity, be generous when estimating the operating

time per day for each of the loads you will run.

$SSOLDQFH

Estimating Battery Requirements

'DLO\ZDWWKRXUV

$3RZHU

&RQVXPSWLRQ

:DWWV

W hours Wh

%2SHUDWLQJ

7LPHSHU'D\

+RXUV

QHHGHGIRUWKLV

DSSOLDQFH

$[%

W hour Wh

W hours Wh

W hours Wh

Whours Wh

Whours Wh

Total daily watt-hours of AC load Wh

x Number of days between charges

= Total watt-hours of AC load between charges Wh

Battery Ah used between charges (divide by 10) Ah

Recommended Battery Bank Size in Ah (multiply by 2) Ah

975-0055-01-01 B–5

Page 68

Battery Types and Sizes

Using Multiple Batteries

As your power requirements increase, you may need to use more than one

battery to obtain sufficient capacity. Read “Two Batteries Connected In

Parallel” on page B–6 and “Two Separat e Ba tt ery Banks” on page B–6 to

determine whether two batteries or two battery banks are more

appropriate for your applications.

Two Batteries Connected In Parallel

Two identical batteries can be connected positive (+) to positive (+) and

negative (–) to negative (–) in a parallel system. A parallel system doubles

capacity and maintains the voltage of a single battery.

CAUTION

Do not connect the following in parallel:

• batteries made by different manufacturers

• different types of batteries

• batteries that have different Ah ratings

Decreased battery life and improper charging will result.

Two Separate Battery Banks

If you need more than two batteries (or are using different makes or

models of batteries), Xantrex recommends that you install two separate

battery banks and a battery selector switch.

By installing a battery selector switch, you can select between the two

battery banks, use both banks in parallel, or disconnect both banks from

the load. Battery selector switches are available at marine and RV dealers.

B–6 975-0055-01-01

Page 69

Battery Tips

Battery Tips

WARNING: Explosion and fire hazard

Review “Precautions When Working With Batteries” on

page viii before you work wi t h th e batteries in you r s ystem.

Explosive/Corrosi ve Ga ses Lead-acid batteries may emit hydrogen

gases, oxygen, and sulfuric acid fumes when recharging. To reduce the

risk of explosion:

• Vent the battery compartment to prevent the accumulation of gases.

• Do not install electronic or electrical equipment in the battery

compartment.

• Do not smoke or use an open flame when working around batteries.

Temperature Sensitivity The capacity of lead-acid batteries is

temperature sensitive. Battery capac ity is rated at 77 ºF (25 ºC). At 0 ºF

(–20 ºC), the Ah capacity is about half the rated capacity. You should

consider temperature when designing your system.

• Low Temperatures If extremely low temperatures are expected

where the inverter is going to be located, you should consider a

heated equipment room. If the system is located in an unheated

space, an insulated battery enclosure is recommended.

• High Temperatures The batteries should also be protected from

high temperatures. These can be caused by high ambient

temperatures, solar heating of the battery enclosure, or heat

released by a nearby engine or generator. High battery

temperatures shorten battery life and therefore you should

ventilate the enclosure and use shade and insulation as

appropriate.

Discharged Batteries Do not leave batteries in a discharged state for

more than a day or two. They will unde rgo a chemical proces s (s ulf at io n )

that can permanently damage the battery. As well, batteries self-discharge

over a period of three to six months, and they should be recharged

periodically even if they are not being used.

Electrolyte Level If your batteries are no t the “maintenance-free” type,

check the electrolyte level at least once a month. Excessive fluid loss is a

sign of overcharging. Replenish the electrolyte using only distilled water.

Battery Connections Connections to battery posts must be made with

permanent connectors that provide a reliable, low-resistance connection.

Do not use alligator clips. Clean the connections regularly and prevent

corrosion by using a protective spray coating or Vaseline.

975-0055-01-01 B–7

Page 70

Battery Types and Sizes

Battery State of Charge You can measure battery state of charge with

a hydrometer or approximate state of charge with a voltmeter. Use a

digital voltmeter that can display tenths or hundredths of a volt when

measuring 10 to 30 volts. Make your measurements when the battery has