Page 1

OPERATION and MAINTENANCE

MANUAL

for

MODEL PV-20208

20 KW Grid-Tied

Photovoltaic Inverter

Document #151119

Revision B November 10, 2000

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS - THIS MANUAL CONTAINS IMPORTANT INSTRUC-

TIONS FOR TRACE TECHNOLOGIES MODEL PV-20208 GRID TIED PHOTOVOLTAIC

INVERTER THAT SHALL BE FOLLOWED DURING INSTALLATION AND MAINTENANCE

OF THE PV-20208.

Xantrex Technologies Inc./Trace Technologies Corp.

161-G SOUTH VASCO ROAD

Livermore, CA 94550

(925) 245-5400

Copyright 2000, Xantrex T echnologies Inc./T race Technologies Corp.

Page 2

T able of Contents

Section 1: Product Description

Introduction

Major Components

Interconnection Standards Compliance

Specifications

Equipment Symbol

Section 2: Safety

Safety Features

Isolation Procedure

Anti Island Protection

Section 3: Installation And Initial Turn-On

Isolation Transformer Requirements

T orque and Wire Gauge Specifications

Installation Instructions

Interconnection Wiring

Initial Turn On Procedure

Section 4: Operation

Description of System Operation

Operator Interface Panel (LED and LCD)

Example of Normal System Operation

Section 5: Troubleshooting

General

Fault Conditions and Troubleshooting

Fault Clearing

Fault Descriptons and Troubleshooting

Section 6: Preventative Maintenance

Isolation Procedure

Turn-On Procedure

Section 7: Drawings and Major Parts Lists

System Schematic, Grid Tied PV Inverter , PV-Series

Assembly Drawings And Major Parts Lists

Envelope Drawing, Grid Tied PV Inverter , PV-20208

UL Listing Document, April 25, 2000

UL Listing Card, September 8, 2000

Accessories

Page 3

SECTION 1

PRODUCT DESCRIPTION

INTRODUCTION

The Trace Technologies Model PV-20208 is a 20KW Grid Tied Photovoltaic Inverter. It utilizes advanced power electronics to allow interface of a photovoltaic array with a utility grid. The PV-20208 is

a highly integrated assembly, consisting of an inverter bridge and associated control electronics all on

a single board. The PV-20208 control software provides for complete overall system control with a

variety of protective and safety features.

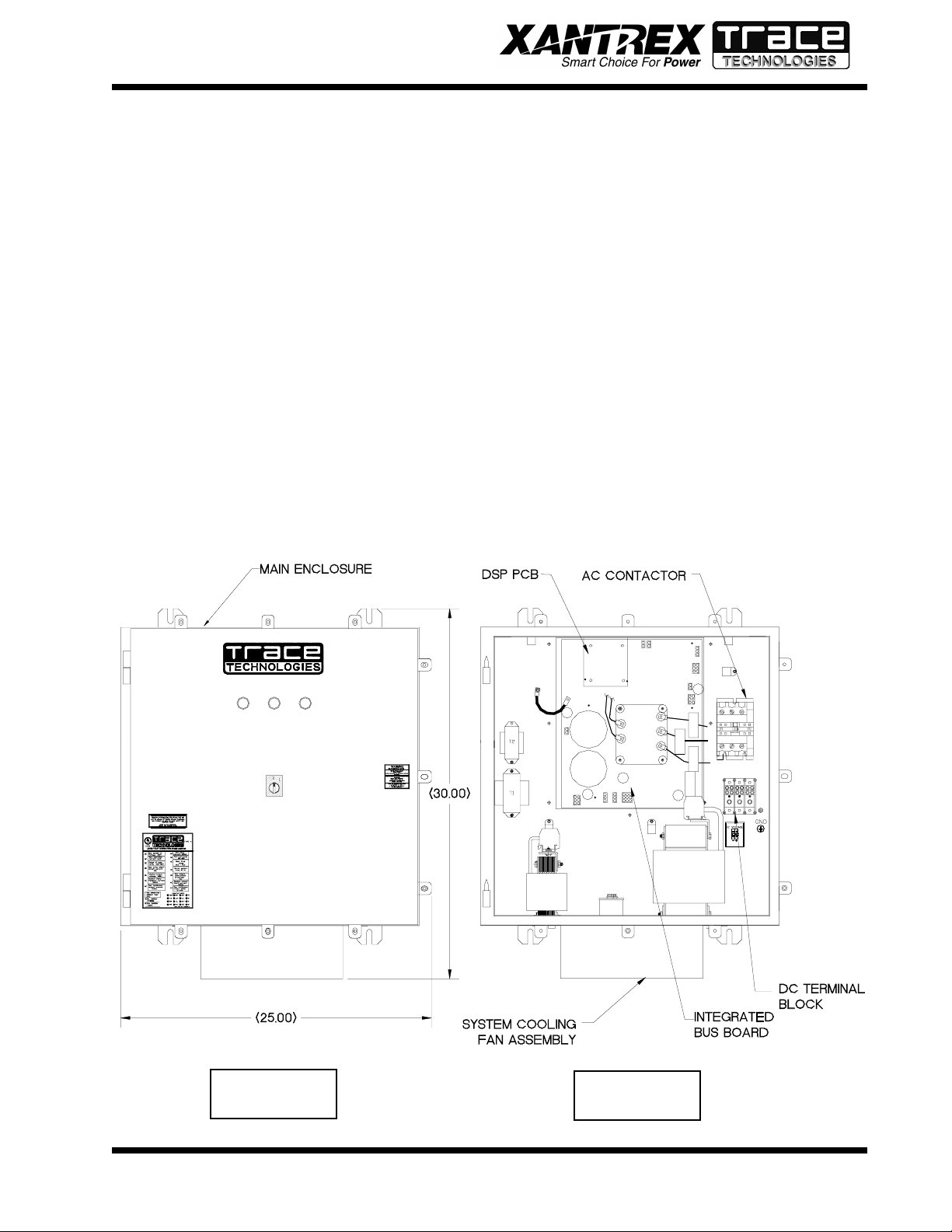

MAJOR COMPONENTS

The major components of the PV-20208 are identified in Drawing No. 151121.

Main Enclosure

The enclosure (shown in Figure 1-1) is NEMA-4 rated. The PV-20208 enclosure contains the Integrated Bus Board, output line filter (insuring that the PV-20208 line currents and voltages meet IEEE519 harmonic distortion requirements), control power transformers, and A/C contactor (PV-20208 A/

C output to the grid). Also found within the enclosure are the system protection devices (control power

circuit fuses). The front door of the enclosure contains the operator interface panel (three LED’s or

LCD and an on/off switch).

1-1

Figure 1-1

Figure 1-2

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 4

SECTION 1

PRODUCT DESCRIPTION

CAUTION

The fuses within the PV-20208 are intended for protecting the PV-20208 control circuitry only. They are not intended to provide protection for the PV array or external

cabling.

Integrated Bus Board

The PV-20208 design makes use of a fully integrated bus board as shown in Figure 1-2. The bus board

assembly is mounted to an aluminum extrusion heat sink, which mounts through an opening in the

back of the enclosure. The power electronics is comprised of a six pack of IGBT devices, mounted to

the heat sink. The bus board is mounted on top of the IGBT six pack device, and is supported through

a series of standoffs attached to the heat sink.

The bus board contains all of the necessary control functions to drive the (attached) switching transistors. The bus board contains the following functional circuits: D/C control power supplies (+5V, +/15V and four isolated +15V sources for the IGBT’s), A/C and D/C high voltage measurement, A/C and

ground current measurements, contactor and indicator controls, discrete input sensing (on/off switch),

and closed loop PWM modulators. The bus board contains a micro-controller chip to perform the lowlevel control functions associated with the collection of measurement and driving the pulse width

modulators.

A plug in DSP module controls the bus board. The DSP module is designed to the industry standard,

PC-104 specification, and is used to perform the majority of the calculations needed to control the bus

board. The most significant tasks are: control of PV-20208 electromechanical components and power

electronics converters, signal conditioning (digital filtering and transformations), and communication

with the operator interface panel and system sensors.

The PV array ties directly to the DC bus. The inverter controller manages the transfer of power between

the DC bus and the utility grid.

INTERCONNECTION STANDARDS COMPLIANCE

The PV-20208 has been tested and certified by Underwriters Laboratories to be in compliance with

UL1741 Static Inverters And Charge Controllers For Use In Photovoltaic Power Systems, as well

as IEEE-P929 Recommended Practice For Utility Interface Of Photovoltaic (PV) Systems.

IEEE-P929 provides guidance regarding equipment and functions necessary to ensure compatible operation of photovoltaic systems which are connected in parallel with the electric utility. UL1741 is the

test procedure performed by Underwriters Laboratory on the PV-20208 to verify it meets the recommendations of IEEE-P929. Refer to both documents for details of these recommendations and test

procedures.

1-2

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 5

SECTION 1

PRODUCT DESCRIPTION

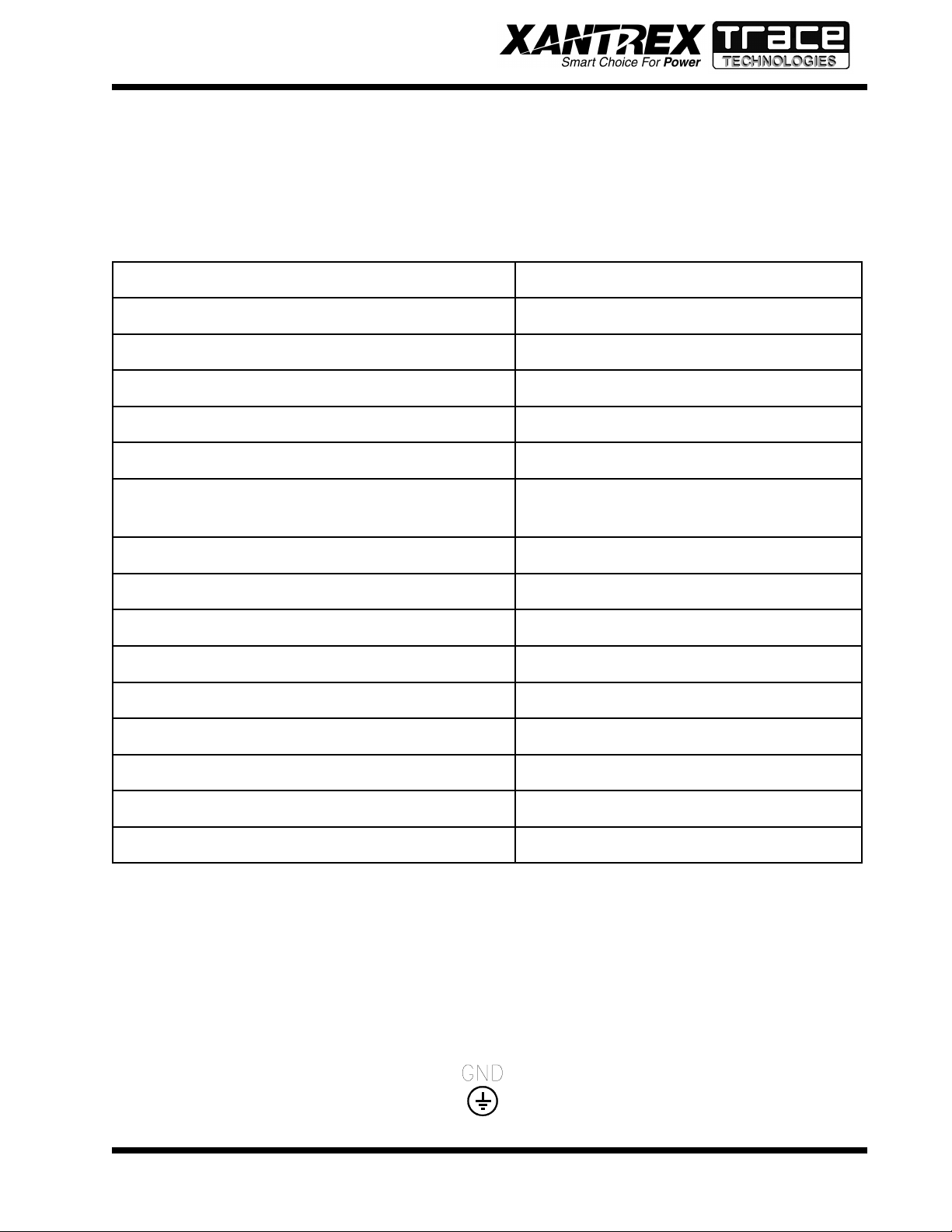

SPECIFICATIONS

The PV-20208 has been designed for photovoltaic power systems, which operate within the following

specifications. Application of the PV-20208 in a manner inconsistent with these specifications may

cause damage to the PV-20208 and other system components, and is a violation of the terms of the

warranty.

egatloVeniLCAlanimoN%01±,CAV802

tnerruCeniLCAmumixaM )egatlovenilwolta(SMRA86.16

ycneuqerFeniLlanimoNzH5.0±,zH06

daoLCAsuounitnoCCAv802@WK0.02

egnaRegatloVVPCDV006-033

tnerruCmumixaMVPCDA8.36

noitarugifnoCVP

dnuorglartuen

ralop-ibro,dednuorgevitagenraloponoM

erutarepmeTgnitarepO*C°05ot02-

erutarepmeTegarotSC°05ot04-

gnitaRerutarepmeTtneibmAmumixaMC°05

ytidimuHevitaleRgnisnednoc-noN,%59oT

noitavelEteef006,6evobadetareD

)sehcnini(snoisnemiD41X52X03

thgieW.sbl571.xorppA

epyTerusolcnE4AMEN

eliFgnitsiLLU653991E-eliF

*If ambient temperature is between -20 to 0° C, the unit must be powered up in standby for at least

one hour prior to going on-line.

EQUIPMENT SYMBOL

Chassis ground – Customer supplied system ground connection point. This symbol may be found near

a stud within the main enclosure. It is provided as a location to bond the electrical system equipment

ground.

1-3

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 6

SECTION 2

SAFETY

SAFETY FEATURES

WARNING

The PV-20208 enclosure contains exposed high voltage conductors. The enclosure

door should remain closed, except during maintenance or testing. These servicing

instructions are for use by qualified personnel only. To reduce the risk of electric

shock, do not perform any servicing other than that specified in the operating

instructions unless you are qualified to do so. Do not open the cabinet door if

extreme moisture is present (rain or heavy dew).

Front Panel Indicators

The PV-20208 incorporates three colored LED indicators, used to show the current operating state of

the inverter. The indicators have the following meanings:

• Red: Fault Mode - The inverter has sensed an abnormal condition. To reset the unit (clearing the

fault condition), cycle the on/off switch (see below).

• Amber: Sleep Mode – The inverter is waiting for sufficient PV voltage to start the inverter.

• Green: Operator Mode - The inverter is active and generating A/C current.

On/Off Switch

The PV-20208 incorporates a maintained position on/off switch located on the front door of the enclosure. Under normal conditions, the on/off switch in the on position. Turning the switch to the off

position will initiate a controlled shutdown of the PV-20208 and open the main contactor within the

unit. The PV-20208 is prevented from being restarted until the on/off switch is turned back to the on

position. Cycling the on/off switch will reset the PV-20208 and attempt to clear any system fault.

Main Enclosure Door

The front door of the PV-20208 main enclosure is pad lockable. It is recommended that the PV-20208

enclosure door be padlocked during normal operation.

WARNING

The PV-20208 does not incorporate a door interlock switch. Please make sure the

unit is powered down, and isolated from the utility grid and PV panels, prior to

opening the enclosure door. (Allow 5 minutes for any stored potentials to be discharged, prior to opening the unit). The front door of the PV-20208 main enclosure

is pad lockable. It is recommended that the PV-20208 enclosure door be padlocked

during normal operation.

Fault Reporting

Any fault conditions are reported to the operator interface. If the PV-20208 is equipped with LED’s,

the red LED will light and the green LED will flash the corresponding number of the fault. If the PV20208 is equipped with the LCD option, the LCD will display a text description of the fault. Refer to

Section 5, Troubleshooting, for detailed descriptions of system fault conditions.

PV Ground Fault Detection

The PV-20208 is equipped with ground fault detection circuitry and control. The single point of PV

2-1

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 7

SECTION 2

SAFETY

system ground must be routed through CT1 on the main control board (see section 3, installation and section 7, system schematic for further detail). Upon detection of 1.5 amps of ground

fault current, the PV-20208 executes an orderly shutdown, and annunciates a ground fault at the

operator interface. The PV-20208 will remain faulted until the ground fault is remedied and

cleared at the operator interface (see section 5, troubleshooting).

ISOLATION PROCEDURE

The following procedure should be followed to de-energize the PV-20208 for maintenance:

WARNING

The terminals of the PV input may be energized if the arrays are energized. In

addition, allow 5 minutes for all capacitors within the enclosure to discharge after

disconnecting the PV-20208 from AC and DC sources.

1. Turn the on/off switch to the off position.

2. Open the PV array disconnect switch (if present).

3. Open the AC interface disconnect (if present).

4. Open the isolation transformer circuit breaker.

5. Install lockout devices on the isolation transformer circuit breaker and PV disconnect switch (if

present).

ANTI ISLAND PROTECTION

A digital phase-shift-loop (PSL) circuit is implemented in the DSP inverter controller to prevent

“Islanding” of the PV-20208.

The DSP continuously makes minor adjustments to the power factor phase angle above and below

unity. In the event of a utility outage, these adjustments destabilize the feedback between the inverter

and the remaining load, resulting in an over/under frequency or voltage condition. The PV-20208

then performs an orderly shutdown. The fault condition will remain until the utility voltage and

frequency have returned to normal for 5 minutes.

This method has been extensively tested and proven to exceed the requirements of UL 1741.

2-2

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 8

SECTION 3

INSTALLATION AND INITIAL TURN-ON

ISOLATION TRANSFORMER REQUIREMENTS

The PV-20208 is required to have an isolation transformer wired between the inverter AC output and

the utility interconnection. Any standard dry-type isolation transformer is compatible with the PV20208 as long as the inverter side is rated for a minimum of 20KVA continuous duty.

WARNING

Check with the local utility of jurisdiction when selecting the winding configuration of the isolation transformer. Individual utilities may have unique requirements related to isolation transformer wiring. Some winding configurations may

keep the PV-20208 from detecting a loss of phase condition on the utility system

which may allow potentially lethal voltage to be present on the open phase wirings.

Inverter Side Isolation Transformer Requirements

The inverter side transformer windings may be configured either delta or WYE, and must be rated for

208 VAC. Trace Technologies recommends using a delta wound transformer to avoid installation mistakes. If a WYE wound transformer is used to interface with the PV-20208, and the PV array is

grounded, the neutral (X0) must be left floating. If the neutral is tied to ground, the inverter will not

function properly , and may be damaged.

Utility Side Isolation Transformer Requirements

The utility side isolation transformer windings may be configured either delta or WYE, and must be

rated for the utility voltage at the point of utility inter-connection. Check with the utility of jurisdiction

when selecting an isolation transformer configuration. If a WYE wound transformer is used to interface

with the utility , it is not necessary to connect the neutral (X0) to ground. The PV-20208 is a balanced,

three phase, current sourcing inverter, and only operates with the presence of a stable utility voltage.

Single phase grounded loads which may be present between the transformer and utility, will maintain

their existing ground reference at the utility distribution transformer . Grounding the neutral of a WYE

wound transformer may create an “open delta” condition, depending on the utility configuration. This

condition may keep the PV-20208 from detecting a loss of phase condition on the utility system,

which may allow potentially lethal voltage to be present on the open phase wiring.

Contact your Xantrex/Trace Technologies distributor if you have any questions regarding isolation

transformer requirements.

TORQUE AND WIRE GAUGE SPECIFICATIONS

The following torque specifications are to be used on all electrical interfaces made during installation

of the PV-20208.

T orque Table

3-1

eziStloBrokcolBlanimreTgnitteSeuqroT

1-6MmN9.5/.sblni25

23126tumwahS/zarreFmN6.31-3.2/sblni021-02

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 9

SECTION 3

INSTALLATION AND INITIAL TURN-ON

The following table shows acceptable wire gauges to be connected to the PV-20208 AC and DC

inputs.

Wire Gauge Table

noitanimreTGWAegnaReriW

)CA(rotcatnoC01#-3#

)CD(kcolBnoitubirtsiD41#-0/2

INSTALLATION INSTRUCTIONS

CAUTION

All wiring methods shall be in accordance with the National Electrical Code ANSI/

NFPA 70. All power conductors interfacing to the PV-20208 should be sized in

accordance with the National Electric Code ANSI/NFP A 70 and local codes. Large

gauge wire must have a minimum bend radius dependent upon the wire gauge

(refer to the National Electric Code, Article 373-6B). Take care to keep the wire

bundles away from any sharp edges which may damage wire insulation over time.

Trace Technologies recommends using No. 6 AWG, 105 degrees C, minimum,

copper wire for all connections with the PV-20208.

Ventilation Considerations

1. Maintain a minimum 6” clearance above and below the PV-20208 for proper cooling fan operation.

2. Maintain a minimum 1” clearance to the left and right of the PV-20208.

Installation

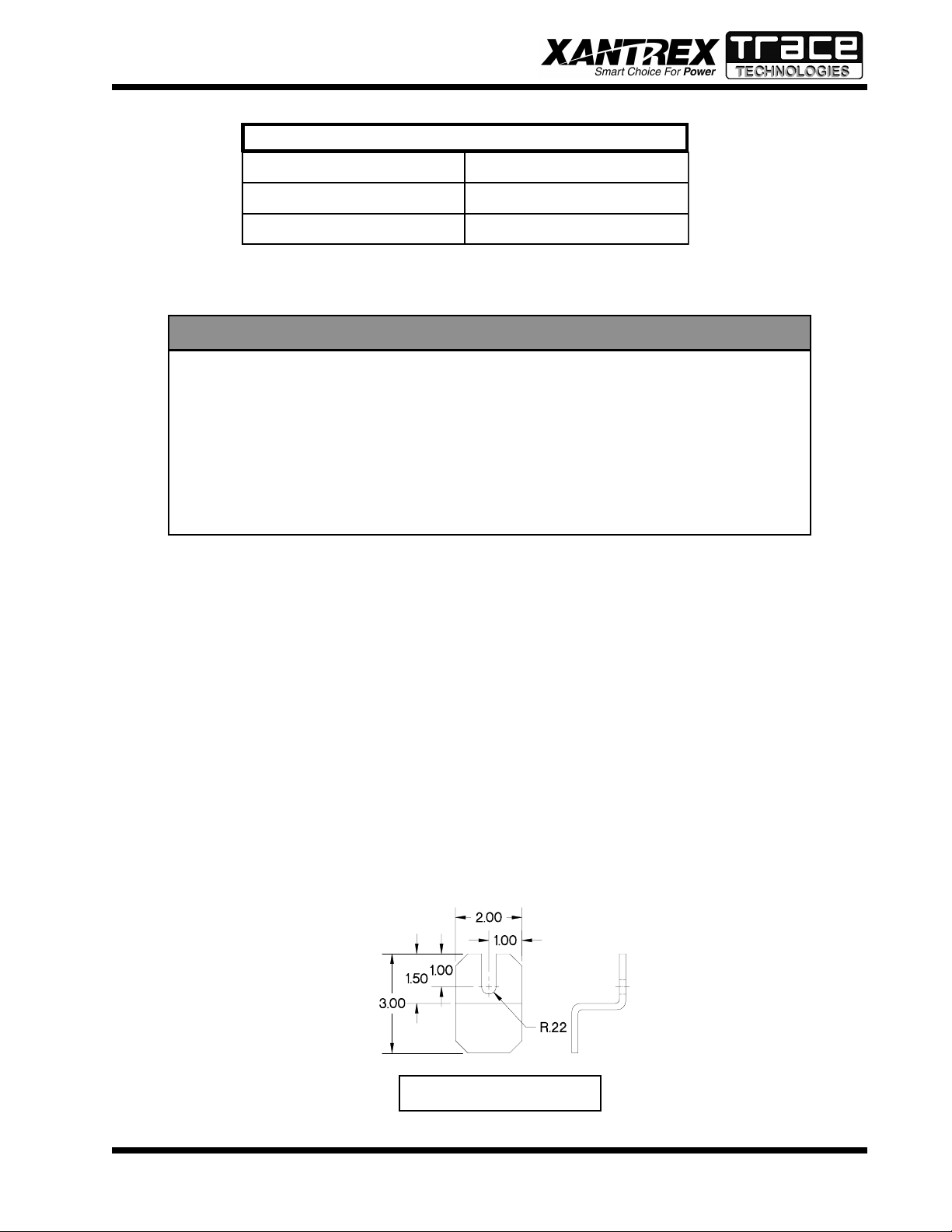

1. The unit must be mounted at least 3’ off the ground, and 12” above any horizontal surface.

2. Screw two 3/8” x 3-1/2” long lag bolts into existing studs in the wall (16-inch mounting center) at

lower mounting level on PV-20208. Lag bolts should be horizontally level with each other. Leave

a minimum of 1” of bolt protruding from the wall.

3. Place the PV-20208 bottom mounting ears, shown in Figure 3-1 and Figure 3-2 onto installed lag

bolts. (See following page.)

4. Hold the unit against wall and install upper lag bolts (3/8” x 3-1/2”). Tighten bolts firmly.

5. Tighten lower lag bolts while unit is held in place.

6. Install two 1-1/2” liquid tight connectors (included with the PV-20208) where shown in

Figure 3-3. (See following page.)

3-2

Figure 3-1

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 10

SECTION 3

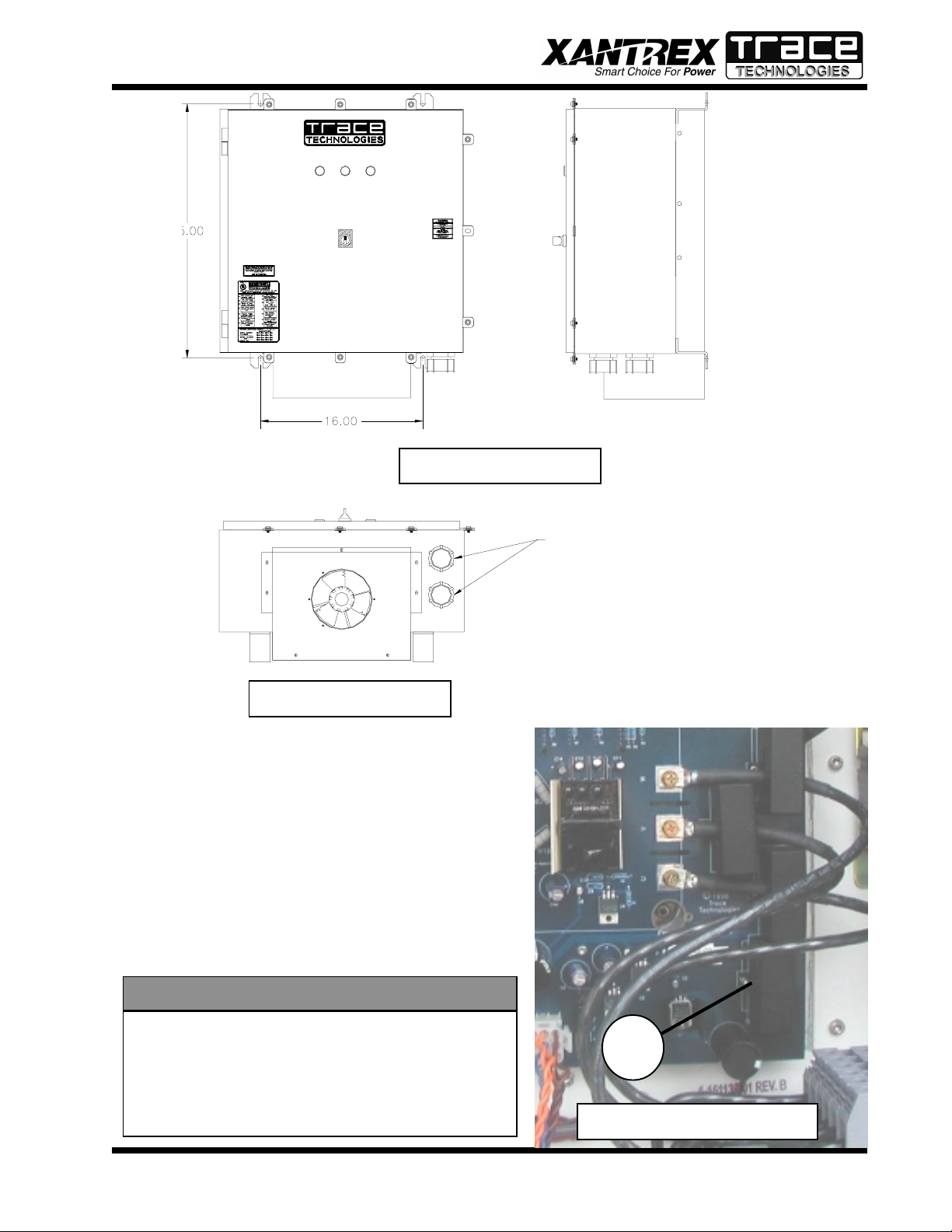

CT1

INSTALLATION AND INITIAL TURN-ON

Figure 3-2

Figure 3-3

Array Grounding and Ground Fault Detection

If grounding the PV array is required for monopolar or

bipolar arrays, jumper TB1-2 to a (PV-) cabinet ground

stud. If ground fault detection is required, route this

jumper through CT1 located on the lower right hand

corner of the control board (see the system schematic

for further detail). This must be the only point of PV

grounding for the PV-20208 and the ground fault

detection system to function properly .

LIQUID TIGHT CONNECTORS

CAUTION

The input and output circuits are isolated from

the enclosure, and that system grounding, if required by sections 690-41 and 690-42 of the National Electric Code, ANSI/NFPA 70, is the

responsibiliy of the installer.

3-3

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

CONTROL BOARD & CT1

DOCUMENT: 151119

Page 11

SECTION 3

INSTALLATION AND INITIAL TURN-ON

Phase-Sequencing

The PV-20208 is equipped with an automatic phasedetection control algorithm. This allows the utility

interface conductors to be connected in any sequence

convenient at the time of installation. Upon system

initialization at power-up, the PV-20208 determines

the phase sequence of the utility connection and

configures the modulator drivers accordingly .

INTERCONNECTION WIRING

CAUTION

To reduce the risk of fire, connect only to a circuit provided with 90 amperes maximum branch

circuit overcurrent protection in accordance with

the National Electrical Code, ANSI/NFPA 70.

The following wires for connecting the PV-20208 to external devices are not provided by Xantrex/Trace Tech-

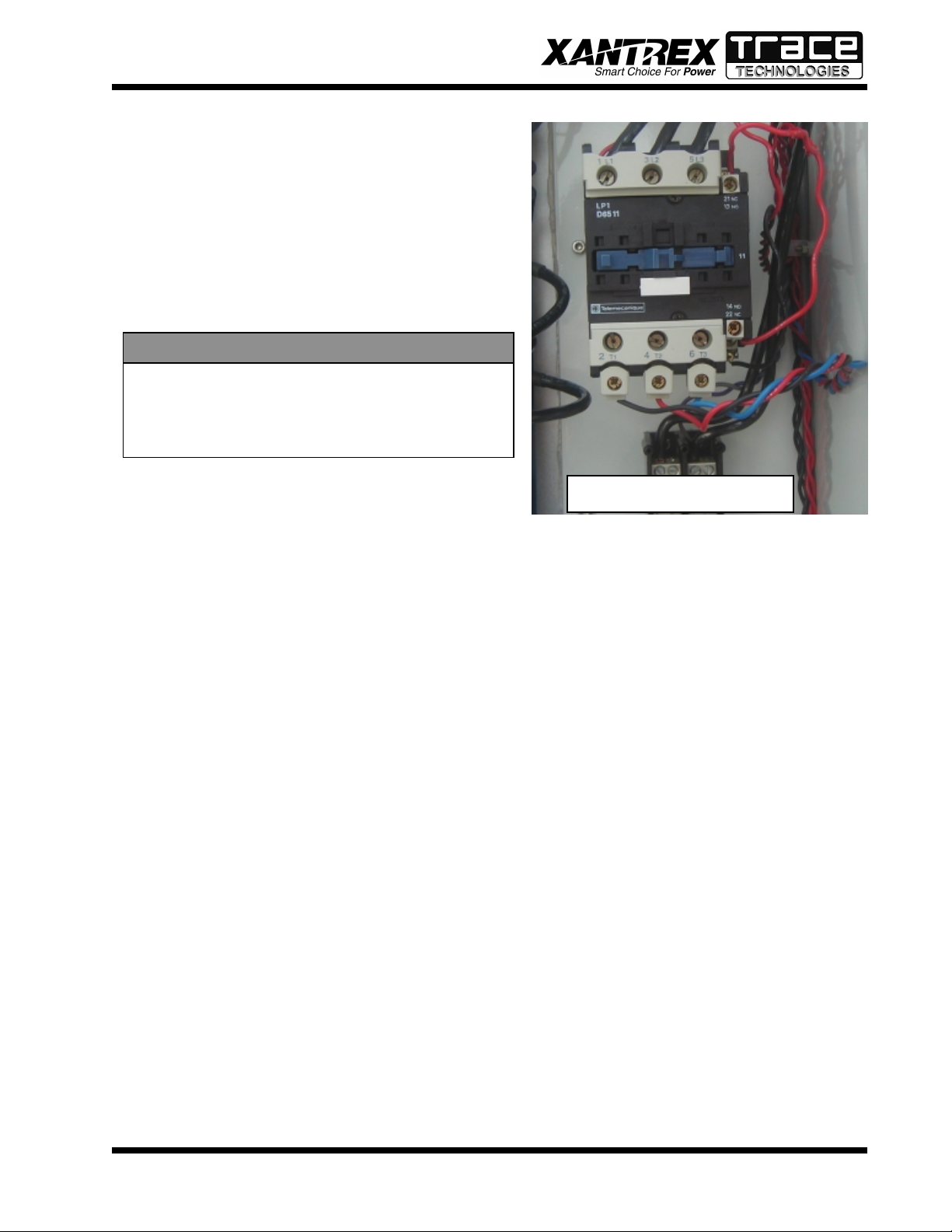

MAIN CONTACTOR

nologies: (See wiring diagram on the following page.)

• 3-Phase 208 VAC inverter output (main contactor, see picture) to terminals of the 208 VAC delta

side of isolation transformer. If the inverter side of the isolation transformer is configured

WYE and the PV array is grounded, the neutral must be left floating. Ground loops will

exist when the inverter starts switching, which will cause the inverter to shut down due to

phase over-currents and may result in damage to the PV-20208. Also, insure that this

neutral is not bonded to the isolation transformer frame.

• System ground to the isolation transformer chassis ground.

• Isolation transformer grid side terminals to line circuit breaker (or the AC disconnect switch if

present).

• PV frame ground to PV-20208 enclosure chassis ground stud.

• PV-20208 enclosure chassis ground stud to the electrical distribution system ground.

• PV+ to the inverter enclosure terminal block TB1-1.

• PV- to the inverter enclosure terminal block TB1-2.

Install all wires listed above. Refer to the system schematics in Section 7 for more detailed terminal

locations.

3-4

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 12

SECTION 3

INSTALLATION AND INITIAL TURN-ON

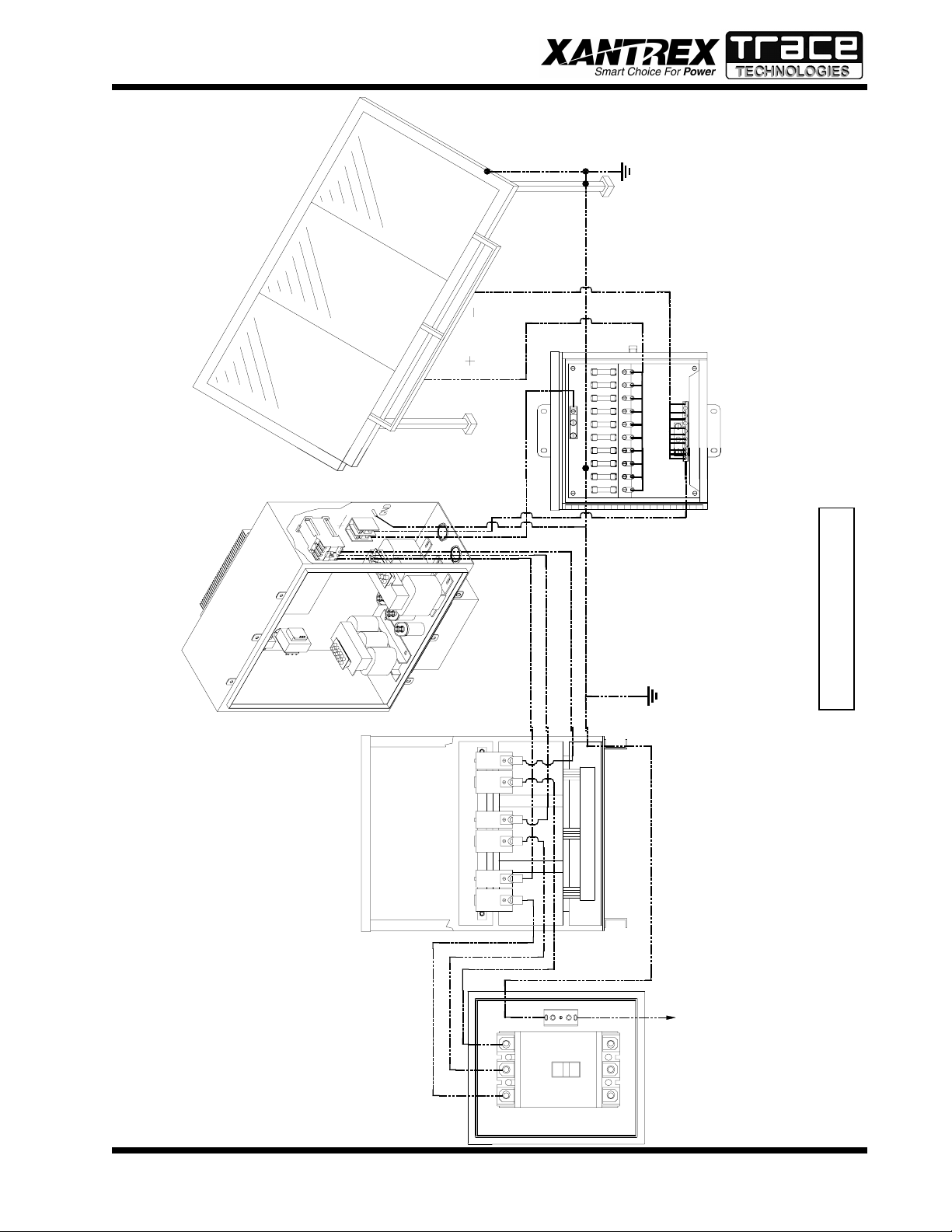

Frame

PV Array

Ground

Inverter

PV-20208

X1 H1 X2 H2 X3 H3

PV+

X0

Isolation

Transformer

PV-

(Optional)

Trace Combiner Box

Wiring Diagram

3-5

C

B

A

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

To Single Point Electrical

Distribution System Ground

Breaker

Line Circuit

DOCUMENT: 151119

Page 13

SECTION 3

INSTALLATION AND INITIAL TURN-ON

INITIAL TURN ON PROCEDURE

The following procedures are intended to verify correct installation and proper operation of the PV-

20208. These steps are to be followed sequentially. Do not continue if any of the steps or results are

unclear. Refer to Section 4 for a detailed description of system operation. Refer to Section 5 for fault

condition descriptions and troubleshooting. Refer to Section 7 for detailed system schematics.

Visual Inspection, Isolation Transformer

• Verify the isolation transformer circuit breaker is open.

• Remove the isolation transformer access panel.

• If the inverter side of the isolation transformer is configured WYE, the neutral must be left floating.

The transformer neutral must not be connected to the utility side neutral, the transformer chassis, or

ground.

• Verify the inverter 208 VAC conductors are connected to the isolation transformer.

• Verify the utility conductors are properly connected to the isolation transformer.

Visual Inspection, PV-20208

• Insure AC and DC disconnect are opened (if present).

• Insure PV array string disconnect switches are opened (if present).

• Open the door of the enclosure, and inspect.

• Verify all wire connections are tight.

• Inspect the cables between the terminal blocks and the matrix driver board. All wire harnesses

should be snap-locked into their respective PCB headers.

Visual Inspection, PV Array Wiring

• Verify the PV+, PV-, PV neutral (if array is bipolar), and PV

safety ground are isolated from each other. The PV safety

ground should be bonded to the enclosure ground stud. Refer to system schematic in Section 7.

• Verify all PV fuses are installed (if present).

• Verify PV string diodes are wired properly (if present).

• V erify proper PV voltage polarity at the PV string disconnect/

combiner boxes.

Initial Power

• Close the isolation transformer circuit breaker.

• Verify 208 VAC voltage across the AC disconnect.

• Close the AC disconnect (if present).

• With the DC disconnect switch opened (if present), close one

of the PV array string disconnect devices.

• Carefully measure VDC at the PV disconnect switch. The

value should be the same as at the PV array string disconnect

device. It should also be positive.

• Close the PV disconnect switch (if present).

• Carefully measure VDC across TB1-1 and TB1-2 (PV +/-)

terminal block. The value should be the same as at the PV

DC TERMINAL

3-6

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 14

SECTION 3

INSTALLATION AND INITIAL TURN-ON

array string disconnect device. It should also be positive.

• Carefully measure VDC across the matrix + and – busses. The value should be the same as at the

PV array string disconnect switch. It should also be positive.

• Open the PV disconnect switch. The matrix capacitor bank voltage should slowly degrade to near

zero over a 5-minute period.

• Open all PV string disconnect switches.

System Verification

• Ensure the on/off switch is enabled.

• Upon applying 208 VAC power to the PV-20208, observe the three LED indicator lights on the

front door. The LED’s should be switching on and off in a sequenced pattern. The LED’s may be

difficult to see depending on external light conditions. After approximately 15 seconds, the panel

should finish initialization

• Remedy any faults reported. If the fault indicator does not change, the fault condition is still present

(see Section 5). Cycling the on/off switch will reset the PV-20208 and attempt to clear any system

faults. Once all faults are cleared, the amber indicator light will come on indicating the PV-20208

is in standby .

• Close all PV array string disconnect switches (if present).

• Close the main PV disconnect switch (if present).

• If the PV voltage is above the PV Start Voltage setpoint, and the PV Start Time is exceeded, the PV-

20208 should transition to “Power Tracking” (see Section 4, Operation).

• Depending upon solar conditions, the PV-20208 may not operate at full power. If the PV array is

not experiencing full sun, the PV maximum power tracker will regulate the PV voltage to maintain

maximum PV power output. (See section 4 for further description of the peak power tracker).

• The PV-20208 is now fully operational.

Fine Tuning

• All PV-20208 operating parameters have been set at the factory , based upon prior experience with

various PV arrays. Parameters may be modified using an optional graphical user interface. Contact

your Xantrex/Trace Technologies distributor for further information.

• It is recommended that the PV-20208 be watched during W ake-Up and Sleep T est. If the PV-20208

cycles between operating and sleeping at either of these times, the operating setpoints may not be

set properly . (Refer to Section 4 for a detailed description of PV-20208 operating states). The PV20208 should not cycle if the setpoints are set properly.

3-7

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 15

SECTION 4

OPERATION

DESCRIPTION OF SYSTEM OPERATION

Overview

The PV-20208 is a fully automated grid-tied photovoltaic inverter. Manual interaction or control of the

inverter is necessary only in the event of a system fault. The following conditions govern PV-20208

operation:

• Stable utility voltage and frequency must be present for all states of operation.

• Fault states are automatic from any state of operation. A fault will cause the PV-20208 to immedi-

ately stop processing all power. The fault condition will be reported to the operator interface.

• The on/off switch, located on the front door of the PV-20208, must be switched to the on position

for all operating states.

• Cycling the on/off switch attempts to clear any system faults and return the PV-20208 to normal

operation.

Operating States

Control software governs the operation of the PV-20208. There are five main operating states. The

following descriptions depict the LED interface. Inverters configured with LCD displays will indicate

operating states on the display.

• Standby: The amber LED is illuminated. The PCU monitors the status of the PV array and utility

grid, waiting until the PV array voltage is sufficient to export power to the utility.

• Wake-Up: The amber LED is illuminated. Once the PV voltage is sufficient to export power to the

utility grid, the PV-20208 will wait 5 minutes before starting to insure the voltage is not transient in

nature. This keeps the system from cycling during unstable irradiance conditions.

• Power Tracking: The green LED will illuminate while the PV-20208 delivers power to the utility.

This is the standard operating state of the PV-20208. The PV-20208 maximum power tracker will

optimize power output from the PV array. If available PV power is above the maximum power

rating of the PV-20208, the inverter will current limit, which will cause the PV voltage to rise

above the array peak power voltage. The minimum operating voltage of the PV-20208 is 330 VDC.

The power tracker will not track voltage below this point, regardless of the actual peak power

voltage of the PV array.

• Sleep Test: The control system will begin a 5 minute sleep test. This normally indicates the PV

irradiance is declining as the sun sets. If the output power remains below 200 watts during the 5

minute sleep test, the system will transition to standby. The time delay allows the inverter to ride

through any temporary irradiance reductions.

• Fault: The PV-20208 has encountered a fault condition. When this happens, regardless of the PV-

20208 state-of-operation, the PV-20208 will stop processing all power and execute an orderly system shutdown. The red LED will illuminate while the yellow and green LED’s flash the fault code

(See section 5, Troubleshooting).

OPERATOR INTERFACE (LED and LCD)

NOTE

On early versions of the PV-20208, a push-pull Emergency Stop switch was used

instead of the on/off switch. It functioned in the same manner described for the on/

off switch.

4-1

Copyright 2000, Xantrex Technologies/Trace Technologies Corp.

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

DOCUMENT: 151119

Page 16

SECTION 4

OPERATION

The standard operator interface on the PV-20208 consists of 3 system status indicator LED’s and an

on/off switch. The LED’s indicate the following states of operation:

• Red LED: Indicates the system is faulted or the on/off switch is switched to the off position. The

inverter will not function while this LED is illuminated. Cycling the on/off switch will attempt to

clear the fault condition and allow the inverter to resume normal operation.

• Amber LED: Indicates the inverter is in standby, waiting for sufficient DC voltage to begin peak

power tracking. This LED will turn off once the PV-20208 begins producing power. In the event of

a fault condition, the amber LED will flash, indicating the beginning of the fault code sequence

(See section 5, Troubleshooting).

• Green LED: Indicates the inverter is on-line and outputting power. In the event of a fault, the green

LED will flash a sequence indicating the fault code (See section 5, Troubleshooting).

The on/off switch is used to enable or disable system operation. The on/off switch is also used to reset

the inverter and clear any system faults.

The PV-20208 may be equipped with an optional Liquid Crystal Display instead of the LED indicators.

The display consists of 4 text lines containing the following information:

• Line 1: System Goal State - This is the target state of the inverter.

• Line 2: System Status - The current operating state of the inverter.

• Line 3: Inverter Output Power or Fault Description - During normal operation, this line will

report the inverter real time output power. If the PV-20208 is faulted, this line will report a description of the fault condition.

• Line 4: PV Voltage - The DC voltage measured at the PV-20208 DC input terminals.

The following is a typical display of the LCD during the five operating states and an on/off switch.

Status: Power Track

Shutdown

Standby

Status: Power Track

Wake Up Test

Status: Power Track

Sleep Test

Sleep Test

Status: Power Track

Faulted

Fault Description

4-2

Wake Up

Status: Power Track

Power Tracking

Line kVA:

PV Volts:

Power Tracking

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies/Trace Technologies Corp.

Fault

Status: Power Track

Emergency Stop

Emergency Stop

DOCUMENT: 151119

Page 17

SECTION 4

OPERATION

EXAMPLE OF NORMAL SYSTEM OPERATION

Upon initial application of AC voltage, the LED’s located on the front door will sequentially flash for

approximately 15 seconds. Once the system has finished initializing, the PV-20208 will remain in

standby until adequate PV voltage is available (amber LED is lit). 5 minutes after the PV start voltage

has been reached, the PV-20208 will synchronize to the utility grid and begin peak power tracking the

PV array. The time delay protects the inverter from excessive on/off cycling.

The PV-20208 will continue to process power until the AC output power approaches the operating

losses of the inverter for a period of 5 minutes. The time delay protects the inverter from excessive on/

off cycling.

SYSTEM OPERATING PARAMETERS

The PV-20208 contains a number of system operating parameters which may be field adjusted using an

optional graphical user interface program available first quarter, 2001 (contact Xantrex/Trace Technologies for further information). All operating parameters have been set at the factory during system

test based upon prior experience with various PV arrays, or to be in compliance with UL1741. In

general, the factory default settings allow for stable and efficient operation of the PV-20208 connected

with any PV array configured for a 330-500 VDC peak power voltage point.

Below is a list of the PV-20208 operating parameters, showing valid ranges and the factory default

settings. Some field adjustable parameters are password protected and may only be changed by trained

service technicians. In particular are parameters relating to utility protection setpoints. These have been

set in the factory to the limits mandated by UL1741. Any changes to these setpoints should be agreed

upon by the local utility and the equipment owner. The ability to adjust the voltage and frequency

setpoints across the actual utility voltage and frequency has been provided as a simulation tool to verify

the PV-20208 accurately detects and responds to a utility excursion. This test should only be performed

by a trained service technician. It is possible to adjust the setpoints in a manner that will prevent the

PV-20208 from functioning.

retemaraPnoitpircseD

resU

elbatteS

noituloseR

egnaR

yrotcaF

tluafeD

gnitteS

drowssaP

detcetorP

tratS_V_VPegatloVpUekaWVP006-233V1.0083

sttaW_potS_VP

rewoP

tuptuOnwoDtuhSVP

0001-001W1.0002

tuptuOdednammoC

reP_I_xaM_TPP

fOtnecrePAsArewoP

001-0A1001*

rewoPdetaR

4-3

feR_V_TPP

roFegatloVVPgnitratS

rekcarTrewoPkaeP

006-233V1.0053

-continued-

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies/Trace Technologies Corp.

DOCUMENT: 151119

Page 18

SECTION 4

OPERATION

retemaraPnoitpircseD

resU

elbatteS

noituloseR

egnaR

yrotcaF

tluafeD

gnitteS

drowssaP

detcetorP

rekcarTrewoPkaeP

petS_V_TPP

petSnoitabretreP

0.01-0.0V1.05.1

egatloV

xaM_I_dnuorG

elbawollAmumixaM

tnerruCtluaFdnuorG

0.01-0.1A1.00.3

rebmuNlaireSrebmuNlaireSretrevnI9999-0000A/NteSyrotcaF*

xaM_qerF

niM_qerF

elbawollAmumixaM

ycneuqerFytilitU

elbawollAmuminiM

ycneuqerFytilitU

0.36-0.75zH1.05.06*

0.36-0.75zH1.05.95*

elbawollAmumixaM

yaleD_xaM_qerF

AoTesnopseRemiT

ycneuqerFhgiHytilitU

06-0elcyC13*

noisrucxE

elbawollAmumixaM

yaleD_niM_qerF

AoTesnopseRemiT

ycneuqerFwoLytilitU

06-0elcyC13*

noisrucxE

xaM_CAV

niM_CAV

egatloVytilitU

egatloVytilitU

elbawollAmumixaM

elbawollAmuminiM

6.942-4.661V1.05.022*

6.942-4.661V1.05.591*

elbawollAmumixaM

yaleD_xaM_CAV

AoTesnopseRemiT

egatloVhgiHytilitU

06-0elcyC15*

noisrucxE

elbawollAmumixaM

yaleD_niM_CAV

AoTesnopseRemiT

egatloVwoLytilitU

06-0elcyC15*

noisrucxE

4-4

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies/Trace Technologies Corp.

DOCUMENT: 151119

Page 19

SECTION 5

TROUBLESHOOTING

GENERAL

In the event of a fault, the PV-20208 will annunciate the condition at the operator interface. The PV20208 will execute an orderly shutdown and remain faulted until the fault is cleared (manually or automatically).

In general, the operator should respond to any PV-20208 fault as follows:

1. The source of the fault should be sought by referring to the following chart.

2. Rectify the fault condition and attempt to clear the fault by cycling the on/off switch.

3. If the problem cannot be corrected, contact your Xantrex/Trace Technologies distributor for assistance or service.

FAULT CONDITIONS AND TROUBLESHOOTING

Fault Code Annunciation

The PV-20208 will report faults by LED display blinking the amber and green LED’ s on the front door

of the inverter . If a fault is detected, the red LED will light continuously and the amber and green LED’ s

will blink the sequence of the fault. The amber LED will light once, indicating the beginning of the fault

code sequence (first count). The green LED will blink X number of times, indicating the remainder of

the fault count. For example: If the PV-20208 experiences a ground fault (fault #3), the yellow and

green LED will flash once then the green LED will flash twice again. This sequence will repeat until the

fault condition has been corrected and cleared.

5-1

LED Display

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex T echnologies Inc./Trace Technologies Corp.

LCD Display

DOCUMENT: 151119

Page 20

SECTION 5

TROUBLESHOOTING

LCD Fault Annunciation (Optional Equipment)

The LCD interface reports fault conditions on Line 2 and 3. The fault code number will follow a text

description. The fault description will remain displayed until the fault has been corrected and cleared.

Each fault is described below .

F AUL T DESCRIPTIONS

noitpircseDtluaFsehsalFDELforebmuN)DCL(edoCtluaF

tnerruCrevOMPI12000x0

erutarepmeTrevOMPI21000x0

tnerruCdnuorG30800x0

egatloVrevOVP/CDWS40400x0

ycneuqerFrednUeniLCA50040x0

ycneuqerFrevOeniLCA60080x0

woLegatloVeniLCA70010x0

hgiHegatloVeniLCA80020x0

egatloVrevOsuBCD90200x0

tluaFmetsySlanretnI010100x0

potSycnegremEenoNenoN

FAULT CLEARING

Once the cause of the fault condition has been corrected, the fault can be cleared with the on/off switch.

First turn the switch to the off position and then back to the on position in order to reset the inverter. If

a fault is sustained the inverter will not reset, and will continue to report the fault. Once the fault clears,

the red LED will turn off and the yellow LED will remain lit.

FAULT DESCRIPTIONS AND TROUBLESHOOTING

(1) IPM Over Current Fault (0x0002)

The IPM module has detected a short circuit/over current condition, or low supply voltage.

Possible causes:

• Short circuit in output AC line.

• Low supply voltage to IPM control circuit.

• Shorted isolation transformer.

5-2

Copyright 2000, Xantrex T echnologies Inc./Trace Technologies Corp.

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

DOCUMENT: 151119

Page 21

SECTION 5

TROUBLESHOOTING

(2) IPM Over Temp Fault (0x0001)

The IPM module has exceeded its maximum allowable temperature.

Possible causes:

• Clogged inlet filter .

• External cooling fan inoperable.

• Airflow on heat sink impeded due to accumulation of debris.

• Operation above rated ambient temperature for an extended period of time.

• Auxiliary contact block on contactor K1 inoperable. This is only possible if the fan does not operate

when the contactor closes. Carefully check voltage at the K1-N.O. aux. contact to the ground bus

when the contactor is closed. (See schematic in Section 7)

(3) Ground Current Fault (0x0080)

The earth safety ground current has exceeded the maximum-programmed value.

Possible causes:

• The negative wire from the PV array has been passed through CT1. Remove wire and connect to

TB1-2. Run wire from TB1-2, through CT1, and land at one of the chassis ground studs.

• Inspect the PV array for actual ground faults.

• The PV array has been grounded in more than one location. If the PV array is grounded through

CT1, it must not be grounded at any other location.

• CT1 defective: Contact your Xantrex/Trace Technologies distributor for assistance or service.

(4) SW PV/DC Over Voltage Fault (0x0040)

The PV voltage has exceeded the maximum programmed limit. This limit is set to 600 VDC during

system test.

Check the PV input voltage at the PV disconnect switch. If the voltage is below 600 VDC, restart the

PV-20208.

Possible causes:

• The PV array open circuit voltage exceeded 600 VDC.

• There is a problem with the PV voltage sense wiring (see system schematic in Section 7).

(5) AC Line Under Frequency Fault (0x0400)

The AC utility frequency fell below the minimum programmed limit. This limit is set to 59.5 Hz and the

system response time limit is set to 3 cycles to insure the PV-20208 disconnects from the utility within

the time allowed by UL1741.

Possible causes:

• The utility frequency fell below the allowable limit (59.5 Hz by default). V erify the utility frequency

is stable and within allowable operating limits.

• There is a problem with one or more of the AC sense wires (see system schematic in Section 7).

This fault is auto-resetting. The unit will automatically restart after line has stabilized within normal

limits for 5 minutes.

5-3

PV-20208 Photovoltaic Inverter

DOCUMENT: 151119

Operation and Maintenance Manual

Copyright 2000, Xantrex T echnologies Inc./Trace Technologies Corp.

Page 22

SECTION 5

TROUBLESHOOTING

(6) AC Line Over Frequency Fault (0x0800)

The AC frequency exceeded the maximum-programmed limit. This limit is set to 60.5 Hz and the system

response time limit is set to 3 cycles to insure the PV-20208 disconnects from the utility within the time

allowed by UL1741.

Possible causes:

• The utility frequency exceeded the allowable limit (60.5 Hz by default). V erify the utility frequency

is stable and within allowable operating limits.

• There is a problem with one or more of the AC sense wires (see system schematic in Section 7).

This fault is auto-resetting. The unit will automatically restart after line has stabilized within normal

limits for 5 minutes.

(7) AC Line Voltage Low Fault (0x0100)

The utility AC voltage fell below the minimum programmed limit. There are two levels of response to

low line voltage conditions. The first level of response is set to 195.5 VAC with a time delay of 5 cycles.

By default, the second level is set to 156 VAC with a time delay of 1 cycle, and is not field adjustable.

Possible causes:

• The utility voltage fell below the allowable limit (195.5 VAC by default). V erify the utility voltage is

stable and within allowable operating limits.

• There is a problem with one or more of the AC sense wires (see system schematic in Section 7).

This fault is auto-resetting. The unit will automatically restart after line has stabilized within normal

limits for 5 minutes.

(8) AC Line Voltage High Fault (0x0200)

The utility AC voltage exceeded the maximum-programmed limit. There are two levels of response to

high line voltage conditions. The first level of response is set to 220.5 VAC with a time delay of 5 cycles.

By default, the second level is set to 247.5 VAC with a time delay of 1 cycle, and is not field adjustable.

Possible causes:

• The utility voltage exceeded the allowable limit (220.5 VAC by default). V erify the utility voltage is

stable and within allowable operating limits.

• There is a problem with one or more of the AC sense wires (see system schematic in Section 7).

The fault is auto-resetting. The unit will automatically restart after line has stabilized within normal

limits for 5 minutes.

(9) DC Bus Over Voltage Fault - Hardware (0x0020)

The DC bus voltage has exceeded the maximum limit.

This is also the PV input voltage sense point. Check the PV input voltage at the PV disconnect switch.

If the voltage is below 600 VDC, cycle the on/off switch and restart the PV-20208.

5-4

PV-20208 Photovoltaic Inverter

DOCUMENT: 151119

Operation and Maintenance Manual

Copyright 2000, Xantrex T echnologies Inc./Trace Technologies Corp.

Page 23

SECTION 5

TROUBLESHOOTING

Possible causes:

• The PV array open circuit voltage exceeded 600 VDC.

• There is a problem with the PV voltage sense wiring (see system schematic in Section 7).

(10) Internal System Fault

There has been an internal system fault. Contact your Xantrex/Trace Technologies distributor.

Possible cause:

• There is a problem with the integrated bus board or DSP control board.

Emergency Stop Fault

The on/off switch, located on the front door of the enclosure is disabled. The contact block on the back

of the switch must be open for the PV-20208 to report this message.

If the switch is enabled and the red indicator light is still on, isolate the PV-20208 from external power,

then:

• Verify continuity across the switch contact block while the switch is turned to the on position.

• Verify continuity between P7-1 and P7-2 while the switch is enabled.

This message will display on the second line of the LCD display . It does not indicate a system fault if the

on/off switch is turned to the off position.

5-5

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex T echnologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 24

SECTION 6

PREVENTATIVE MAINTENANCE

Xantrex/Trace Technologies recommends that the following preventative maintenance be carried out

on the PV-20208:

Monthly intervals or as required:

Aluminum Extrusion Heatsink

Accumulation of dirt and debris on the aluminum extrusion heatsink and fan shroud will decrease the ability to transfer heat, which can cause the PV-20208 to shutdown on over-temperature alarms. Inspect the aluminum extrusion heatsink and fan shroud for accumulation of dirt.

Clean if debris is present.

Fan Operation

Verify proper operation of the heatsink cooling fan, located within the shroud below the enclosure. The fan operates when the K1 contactor is closed. Remove any debris from the fan and

finger guard.

Six month intervals:

Enclosure Seals

Inspect the enclosure door seal. If damaged, replace with equivalent closed cell foam gasket.

Call your Xantrex/Trace Technologies distributor for factory replacements or specifications.

Electrical Connections

Inspect the condition of all cables interfacing to the PV-20208. Inspect all wire crimps and

connections for damage caused from high temperature. Check for corrosion. Replace any damaged wires. Verify all mechanical connections are sufficiently tightened.

Enclosure

Access the enclosure and remove any accumulated dirt and debris. Vacuum enclosure whenever

dust or dirt is present.

ISOLATION PROCEDURE

The following procedure should be followed to de-energize the PV-20208 for maintenance:

WARNING

The terminals of the PV input may be energized if the arrays are energized. In

addition, allow 5 minutes for all capacitors within the enclosure to discharge after shutting down the PV-20208.

1. Turn the on/off switch to the off position.

2. Open the PV array disconnect switch (if present).

3. Open the AC disconnect (if present).

4. Open the isolation transformer circuit breaker.

5. Install lockout devices on the isolation transformer circuit breaker and PV disconnect switch.

6-1

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 25

SECTION 6

PREVENTATIVE MAINTENANCE

TURN-ON PROCEDURE

Refer to Section 3 for a detailed first-time turn on procedure.

1. Remove any lockout devices from the isolation transformer circuit breaker and PV disconnect

switch.

2. Close the isolation transformer circuit breaker.

3. Close the AC disconnect (if present).

4. Close the PV array disconnect switch (if present).

5. Turn the on/off switch to the on position.

After a 15 second initialization period and a 5 minute wake up period, the PV-20208 will automatically

begin power tracking, given the PV voltage is greater than the PV start voltage setpoint.

6-2

PV-20208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 26

SECTION 7

DRAWINGS AND PARTS LIST

150474 Rev F : Schematic, System, Grid Tied PV Inverter, PV-Series

151121 Rev B : Assembly, Main Enclosure, Control Components, 20 KVA, PV-20208

Table of Components

151120 Rev B : Envelope Drawing, Grid Tied Inverter, PV-20208

Underwriters Laboratories Listing Document, April 25, 2000

Underwriters Laboratories Listing Card, September 8, 2000

Accessories:

151258 - Combiner Box, 10 Pole, 600 VDC, Nema 3R

151260 - Combiner Box, 12 Pole, 600 VDC, Nema 3R

151179 - Transformer, 20 KVA, 3 Pole, 60 Hz, 208 Delta/208-120V

151180 - Transformer, 20 KVA, 3 Pole, 60 Hz, 208 Delta/480-277V

PV-20208 Photovoltaic Inverter

7-1 Operation and Maintenance Manual

Copyright 2000, Xantrex Technologies Inc./Trace Technologies Corp.

DOCUMENT: 151119

Page 27

Page 28

Page 29

Trace Technologies PV-20208

Photovoltaic Inverter

Major Parts List

Assembly Description: Main Enclosure, Control Components, PV-20208

Trace Technologies Assembly # 151121

Item # Qty Reference Designator Trace Technologies Part # Description

1 1 1-151139-01 Fab, Enclosure

2 1 1-150691-01 Heatsink, 339.88 X 387.35

3 1 1-151146-01 Fab, Fan Shroud

4 1 T1 1-150438-01 Transformer, 80VA

5 1 T2 1-150446-01 Transformer, 40VA

6 1 K1 1-150668-65 Contactor, 3P, 24VDC Coil, 65A

7 1 TB1-2 1-150410-01 Block, Power Distribution, Mini 2P

8 1 1-150714-01 Fan, 24VDC, 6", 240CFM, 53.3dB

9 1 L2 1-150671-01 Inductor, 1.0mH, 65Arms

10 3 CA, CB, CC 1-150403-01 Capacitor, NP, 2UF, 600VAC, 6%

11 1 L1 1-150665-01 Reactor, Line, 158uH, 65Arms

12 1 1-150378-02 Assy, PCB, DSP

13 2 1-151199-06 Conduit, Liquid Tight Connector, Zinc

151121 Sheet 2 of 2

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Trace Technologies Corporation

3547C South Higuera Street

San Luis Obispo, CA, USA 93401

Installation Instructions for Photovoltaic Combiner Box

Unit should be mounted in the vertical position using integral mounting tabs with

appropriate hardware (not included).

MODEL

NUMBER

CB-10H20-3R 600 20A 12.8A 101A

CB-10HD8-3R 600 8A 5A 64A

CB-12H20-3R 600 20A 12.8A 192A

CB-12H20-4 600 20A 12.8A 192A

MAX DC

VOLTAGE

MAX FUSE

SIZE

MAX SOURCE

Isc

MAX RATED

OUTPUT I

Wiring methods shall be in accordance with National Electrical Code, Article 310 and

690, ANSI/NFPA 70. Copper conductors only, 75°C.

Wiring requirements are as follows:

MODEL NUMBER SOURCE WIRE RANGE OUTPUT WIRE RANGE

CB-10H20-3R #14 to #8 #6 to #2

CB-10HD8-3R #14 to #8 #6 to #2

CB-12H20-3R #14 to #6 (2) #14 to (2) 1/0

CB-12H20-4 #14 to #6 (2) #14 to (2) 1/0

For Model numbers CB-10H20-3R and CB-10HD8-3R reference attached drawing for

appropriate output wire routing requirements.

Chassis ground may be accomplished using supplied ground screw in base of unit.

Recommended tightening torque (pound-inch):

#18 - #10 #8 #6 - #3 #2 #1/0

20 25 35 40 50

FIRE HAZARD-When wiring is complete, check all terminal screws for proper torque.

A SUITABLE DC RATED SYSTEM DISCONNECT SHALL BE USED IN

CONJUNCTION WITH THE INSTALLATION OF THIS EQUIPMENT.

Copyright Trace Technologies Document # D07200 Rev B. Sept. 27, 2000

Page 36

Copyright Trace Technologies Document # D07200 Rev B. Sept. 27, 2000

Page 37

Page 38

Loading...

Loading...