Xantrex GT 2.5-DE, GT 3.8-DE, GT 2.8-SP, GT 3.8-SP, GT 5.0-SP Owner Manual

GT 2.5-DE

GT 3.8-DE

GT 2.8-SP

GT 3.8-SP

GT 5.0-SP

Owner’s Manual

Xantrex Grid Tie

Solar Inverter

Xantrex Grid Tie Solar Inverter

Owner’s Manual

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products ranging from small mobile units to utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup power applications in both grid-connected and stand-alone systems. Xantrex products include inverters, battery chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute electrical power.

Trademarks

Xantrex Grid Tie Solar Inverter is a trademark of Xantrex International. Xantrex and Xanbus are registered trademarks of Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used herein for identification purposes only.

Notice of Copyright

Xantrex Grid Tie Solar Inverter Owner’s Manual © September 2007 Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a)MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b)ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

September 2007 Revision C

Part Number

975-0253-01-01

Product Numbers

864-0105 (GT2.8-SP-QC-230), 864-0104 (GT3.8-SP-QC-230), 864-1029 (GT5.0-SP-QC-230), 864-0106 (GT2.5- DE-QC-230), 864-0103 (GT3.8-DE-QC-230)

Contact Information

Telephone: +34 93 470 5330

Fax: |

+34 93 473 6093 |

Email: |

support.europe@xantrex.com |

Web: |

www.xantrex.com |

About This Manual

The purpose of this Owner’s Manual is to provide explanations and procedures for installing, operating, maintaining, and troubleshooting the Xantrex Grid Tie Solar Inverter™.

Scope

The manual provides safety guidelines, detailed planning and setup information. It provides procedures for installing the inverter and information about operating and troubleshooting the unit. It does not provide details about particular brands of photovoltaic (PV) panels. You need to consult individual PV manufacturers for this information.

Audience

The manual is intended for anyone who needs to install and operate the GT Inverter. Installers should be fully educated on the hazards of installing electrical equipment. Certified electricians or technicians are recommended.

Organization

This manual is organized into 6 chapters and an appendix.

Chapter 1, “Introduction”, contains information about the features and functions of the Xantrex Grid Tie Solar Inverter.

Chapter 2, “Installation”, provides information about planning for and installing the GT Inverter. It contains information to help you plan wire routes, ensure your PV array provides necessary power, and find a suitable location for installation.

Chapter 3, “Wiring the Inverter”, provides procedures for making DC and AC wiring connections for single and multiple inverter installations. This chapter also includes information about communications wiring and using GT-View monitoring software.

Chapter 4, “Starting the Inverter”, contains information on starting up the Xantrex Grid Tie Solar Inverter and performing a functional test.

Chapter 5, “Monitoring the Inverter”, contains information for understanding the LCD screens and the LED indicators.

Chapter 6, “Maintenance and Troubleshooting”, contains information about how to provide general maintenance for the Xantrex Grid Tie Solar Inverter. It also provides information about troubleshooting the unit.

Appendix A, “Specifications”, contains information about the electrical and environmental specifications of the Xantrex Grid Tie Solar Inverter.

975-0253-01-01 |

iii |

About This Manual

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions that could result in personal injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to the unit or other equipment.

Important: These notes describe things that are important for you to know, but not as serious as a caution or warning.

Abbreviations Used

GT |

Grid Tie |

ISC |

Short Circuit Current |

LCD |

Liquid Crystal Display |

|

|

LED |

Light Emitting Diode |

|

|

MPPT |

Maximum Power Point Tracking |

|

|

PMAX |

Maximum Output Power |

PNOM |

Nominal Output Power |

PC |

Personal Computer |

|

|

PV |

Photovoltaic |

|

|

STC |

Standard Test Condition |

|

|

Vac |

Volts AC |

|

|

Vdc |

Volts DC |

|

|

VMP |

Voltage at Maximum Power |

VOC |

Open Circuit Voltage |

UPV |

PV Array DC Voltage |

iv |

975-0253-01-01 |

About This Manual

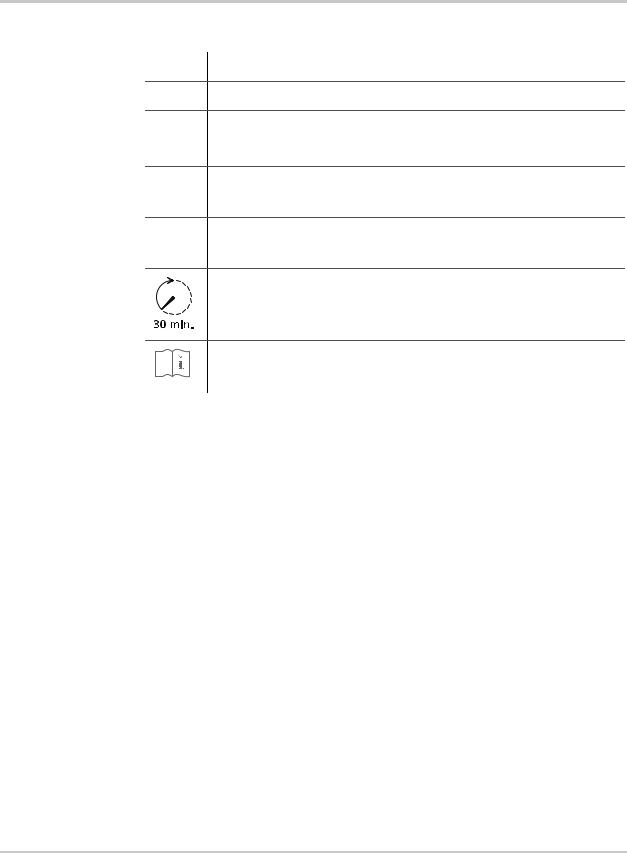

Symbols Used

Alternating Current (AC)

Direct Current (DC)

In this guide: Important information, warnings, or cautions.

On the product: Important information, warnings or cautions with further explanation in the product guide.

Caution, risk of electric shock.

Hot surface—risk of burns.

FOR AUTHORIZED SERVICE PERSONNEL: Before opening cover, disconnect DC and AC power and wait 30 minutes to allow internal voltages to reach safe levels.

NOTE: there are no user-serviceable parts inside.

Refer to the operating instructions.

Related Information

You can find more information about Xantrex Technology Inc. as well as its products and services at www.xantrex.com

975-0253-01-01 |

v |

vi

Important Safety Instructions

SAVE THESE INSTRUCTIONS—This manual contains important instructions that shall be followed during the installation and maintenance of the Xantrex Grid Tie Solar Inverter.

1.Before installing and using the GT Inverter, read all instructions and cautionary markings on the inverter and in all appropriate sections of this guide.

2.To reduce risk of fire hazard, do not cover or obstruct the heat sink.

3.Observe the clearance recommendations as described on page 2–12. Do not install the GT Inverter in a zero-clearance or non-ventilated compartment. Overheating may result.

4.Use only accessories recommended or sold by the manufacturer. Doing otherwise may result in a risk of fire, electric shock, or injury to persons.

5.To avoid a risk of fire and electric shock, make sure that existing wiring is in good condition and that wire is not undersized. Do not operate the GT Inverter with damaged or substandard wiring.

6.Do not operate the GT Inverter if it has received a sharp blow, been dropped, or otherwise damaged in any way. If the GT Inverter is damaged, see the Warranty section.

7.Do not disassemble the GT Inverter. It contains no user-serviceable parts. See Warranty for instructions on obtaining service. Attempting to service the GT Inverter yourself may result in a risk of electrical shock or fire and will void the factory warranty.

8.To reduce the risk of electrical shock, disconnect both AC and DC power from the GT Inverter before attempting any maintenance or cleaning or working on any circuits connected to the inverter. Turning off controls will not reduce this risk. Internal capacitors remain charged for up to 30 minutes after disconnecting all sources of power.

9.The GT Inverter must be provided with an equipment-grounding conductor connected to the AC ground.

975-0253-01-01 |

vii |

Safety

Regulatory Compliance

The GT Inverter is CE Marked for the following Directives and standards:

•Low Voltage Directive 73/23/EEC, per EN50178 “Electronic Equipment for Use in Power Installations”.

•EMC Directive 204/108/EC, per:

•EN61000-6-3 “Emission Standard for Residential, Commercial, and Light-Industrial Environments”

•EN61000-6-1 “Immunity for Residential, Commercial, and Light-Industrial Environments”

•EN61000-3-2 “Limits for Harmonic Current Emissions”

•EN61000-3-3 “Limitations of Voltage Fluctuations and Flicker”.

The GT Inverter is designed for utility interactive operation. It has complete on-board over-current, overtemperature and anti-islanding protection. It monitors voltage and frequency of the utility grid and automatically stops supplying power whenever conditions on the utility grid deviate from standard levels (see Specifications).

The GT Inverter is equipped with a high frequency transformer that assures galvanic isolation between the DC side and the utility power grid.

German models have an integrated ENS and comply with the VDE 0126 regulations for supplementary grid connection, especially to the “regulation for the supplementary grid feeding with photovoltaic electricity producing facilities to the low voltage power supply grid” issued by the VDEW.

Spanish models comply with Royal Decree 1663/2000 and with section 10 of Annex XI of Royal Decree 661/2007, regarding the connection of photovoltaic installations to the low tension network.

viii |

975-0253-01-01 |

Contents

Important Safety Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vii

Regulatory Compliance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

1 |

Introduction |

|

|

About the Xantrex Grid Tie Solar Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

- 1–2 |

|

Standard Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

1–3 |

2 |

Installation |

|

|

Installation Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–2 |

|

Single Inverter Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–2 |

|

Multiple Inverter Installations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–2 |

|

Planning the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–2 |

|

Inverter Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–4 |

|

PV Array Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–5 |

|

Grounding Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–7 |

|

Routing the Wires - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–8 |

|

Preparing for the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–9 |

|

Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–9 |

|

AC Circuit Breaker Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–9 |

|

AC and DC Disconnects - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–9 |

|

Mounting the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–10 |

|

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–10 |

|

Tools and Materials Needed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–11 |

|

Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–11 |

|

Installing the Mounting Bracket - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–12 |

|

Mounting the Inverter on the Bracket - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

2–16 |

3 |

Wiring the Inverter |

|

|

Connecting the DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

3–2 |

|

Equipment Needed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

3–3 |

|

DC Fuses (GT5.0-SP Model Only) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

3–3 |

|

Connecting the PV Array - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

3–4 |

|

Connecting Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

3–6 |

|

Connecting the AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

3–7 |

|

Making AC Connections for GT2.5-DE, GT3.8-DE, GT2.8-SP, GT3.8-SP Models - - - - - - - |

3–7 |

|

Making AC Connections for GT5.0-SP Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

3–9 |

|

Communications Wiring for Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

3–10 |

975-0253-01-01 |

ix |

Contents

Xanbus Network Technology - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–10 Guidelines for Routing the Network Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–12 Connecting Network Cable between Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–13 Communications Wiring for Monitoring a Single Inverter - - - - - - - - - - - - - - - - - - - - - - - -3–14

4 Starting the Inverter

Commissioning Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Disconnect Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

5 Monitoring the Inverter

Monitoring the Front Panel Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Front Panel Display Screens and What They Mean - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Startup Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Normal Operation Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Offline Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–7

Fault Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Special Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–11

Custom Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–11

Status Indicator Lights- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–12

6 Maintenance and Troubleshooting

Factors Affecting GT Inverter Performance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

PV Array Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

Other Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–3

Performing General Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–3

Identifying Error/Fault Conditions and Solutions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–4

A Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2 Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2 Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2 Islanding Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2 Adjustable Disconnect Settings (SP models only) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3 Output Power Versus Ambient Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4 Efficiency - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Environmental Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5 User Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5 Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Warranty and Return Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

WA–1 |

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

- IX–1 |

x |

975-0253-01-01 |

Figures

Figure 1-1 Basic System Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2 Figure 1-2 Main Features of the GT Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3 Figure 2-1 Installation Options Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3 Figure 2-2 GT Inverter mounting orientation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5 Figure 2-3 Installation Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10 Figure 2-4 GT Inverter Dimensions (GT5.0-SP shown) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11 Figure 2-5 Mounting Bracket and GT Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12 Figure 2-6 Examples of Mounting on a Pole or Rails - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14 Figure 2-7 Installing the Mounting Bracket using Plywood Support - - - - - - - - - - - - - - - - - - - - - 2–15 Figure 2-8 Proper Placement of the Inverter on the Mounting Bracket - - - - - - - - - - - - - - - - - - - 2–16 Figure 3-1 PV Quick Connect Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2 Figure 3-2 GT5.0-SP DC Fuse Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4 Figure 3-3 DC Connections for a Two-String PV Array - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5 Figure 3-4 Improper Multiple Inverter Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6 Figure 3-5 AC Connector (Female) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8 Figure 3-6 AC Connector Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8 Figure 3-7 GT5.0-SP AC Wiring Compartment and Terminal Block - - - - - - - - - - - - - - - - - - - - - 3–9 Figure 3-8 Network Layout (Communication Ports Cover Not Installed)- - - - - - - - - - - - - - - - - - 3–10 Figure 3-9 Network Terminator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11 Figure 3-10 Location of Xanbus RJ45 Ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11 Figure 3-11 Network Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11 Figure 3-12 Replacing the Communication Ports Cover - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–13 Figure 5-1 Front Panel LCD Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2 Figure 5-2 Location of Status Indicator Lights - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–12 Figure A-1 Output Power vs. Ambient Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–4 Figure A-2 Output Power vs. Ambient Temperature (GT5.0-SP) - - - - - - - - - - - - - - - - - - - - - - - -A–4

975-0253-01-01 |

xi |

xii

Tables

Table 2-1 MPPT Operational Window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6 Table 2-2 MPPT Operational Window (GT5.0-SP)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6 Table 2-3 Inverter Clearance Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12 Table 3-1 Recommended Fuses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3 Table 3-2 Network Components and Part Numbers- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12 Table 5-1 Startup Screens on GT Inverter Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - 5–3 Table 5-2 Startup Screens on GT5.0-SP Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4 Table 5-3 Normal Operation Default Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5 Table 5-4 Normal Operation Screens for All GT Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6 Table 5-5 Additional Normal Operation Screens for Each GT Inverter in a Multiple Unit System - 5–7 Table 5-6 Offline Mode Default Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–7 Table 5-7 Offline Mode Screens for All GT Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8 Table 5-8 Additional Offline Mode Screens for Each GT Inverter in a Multiple Unit System - - - - 5–8 Table 5-9 Fault Message Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9 Table 5-10 Additional Fault Mode Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10 Table 5-11 Special Message Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–11 Table 5-12 Status Indicator LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–12 Table 6-1 Troubleshooting the GT Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–4

975-0253-01-01 |

xiii |

xiv

1 Introduction

Chapter 1, “Introduction”, contains information about the features and functions of the Xantrex Grid Tie Solar Inverter.

Introduction

About the Xantrex Grid Tie Solar Inverter

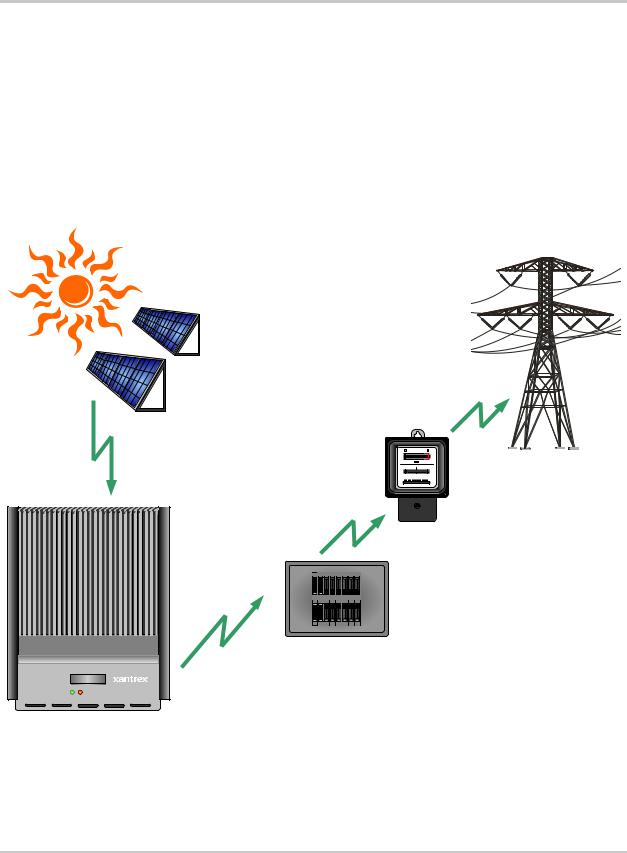

The Xantrex Grid Tie Solar Inverter (GT Inverter) is designed to convert solar electric (photovoltaic or PV) power into utility-grade electricity that can be used by the home or sold to the local power company.

Installing the GT Inverter consists of mounting it to the wall and connecting the DC input to a PV array and the AC output to the utility. See Figure 1-1 for a simple diagram of a typical installation.

In order to operate, the GT Inverter must have grid power available and connected. It will not provide backup power if the AC grid fails.

Photovoltaic (PV) Panels—

PV Array

Power routed to Utility Grid

Harvested solar energy

DC converted to AC

Grid Tie Solar Inverter

Xantrex GT Inverter

Figure 1-1 Basic System Overview

Main Utility

Service Panel

0 0 0 0 0 0 0 8 k Wh |

Utility Grid |

230 V 10( 60) A 50 Hz |

Utility Meter

1–2 |

975-0253-01-01 |

|

About the Xantrex Grid Tie Solar Inverter |

|

|

PV compatibility |

The GT Inverter is designed to take advantage of solar modules configured as high |

|

voltage PV string arrays—single crystalline, poly crystalline, or thin film—with a |

|

195 to 550 Vdc input voltage Maximum Power Point range (240 to 550 Vdc for |

|

the GT5.0-SP model). |

Maximum Power |

The GT Inverter uses Xantrex proprietary Maximum Power Point Tracking |

Point Tracking |

(MPPT) technology to harvest the maximum amount of energy from the solar |

(MPPT) |

array. MPPT learns your array’s specific characteristics, maximizing its output at |

|

all times. |

High efficiency |

The high-frequency, solid-state design of the GT Inverter is extremely efficient— |

|

up to 96%. |

Expandable |

Multiple GT Inverters may be networked together for increased net metering |

|

capacity or future system growth. |

Communications |

The GT Inverter uses the Xanbus® communications protocol, enabling it to |

protocol |

communicate with multiple units connected within the system. For more |

|

information, see “Xanbus Network Technology” on page 3–10. |

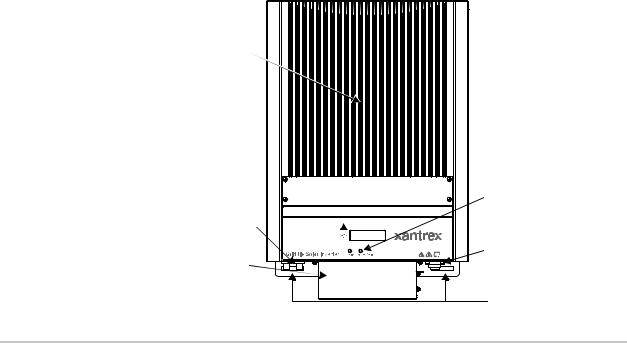

Standard Features

The GT Inverter has the following standard features:

•Sealed inverter (IP54) and external heat sink to protect power electronic components

•Quick-connect AC and DC connections

•Liquid Crystal Display (LCD) to provide easy-to-read system status and daily cumulative energy production information

•Two LED indicator lights to provide status and ground fault indication.

Heat sink

LCD

|

LED indicator lights |

DC quick-connects |

|

Communication |

AC connection |

|

|

ports cover |

|

|

Mounting slots (five) |

Figure 1-2 Main Features of the GT Inverter

975-0253-01-01 |

1–3 |

1–4

2 Installation

Chapter 2, “Installation”, provides information about planning for and installing the GT Inverter. It contains information to help you plan wire routes, ensure your PV array provides necessary power, and find a suitable location for installation.

The topics in this chapter are organized as follows:

•“Installation Options” on page 2–2

•“Planning the Installation” on page 2–2

•“Preparing for the Installation” on page 2–9

•“Mounting the Inverter” on page 2–10.

Installation

Installation Options

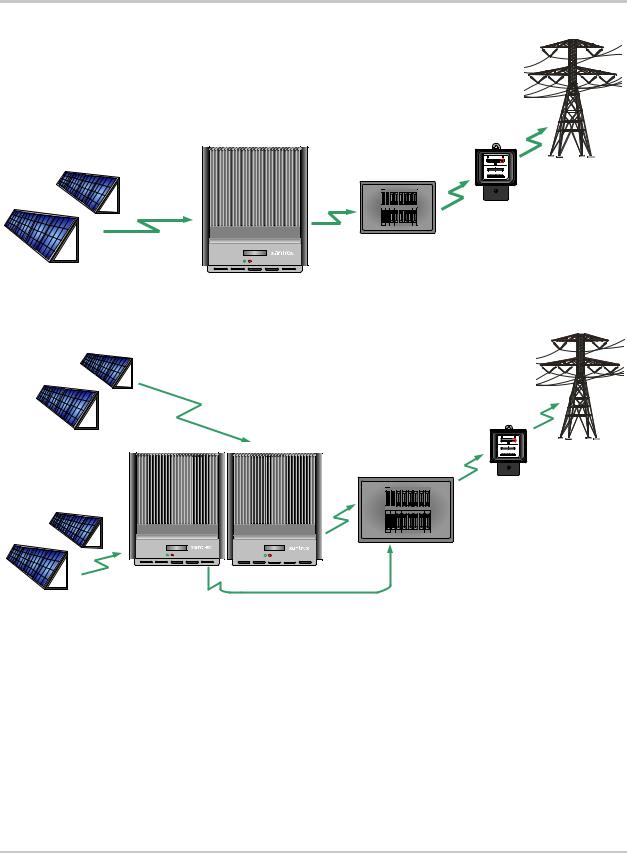

The GT Inverter may be installed as a single inverter for a single PV array of up to two PV strings (up to three PV strings for the GT5.0-SP model), or in a multiple inverter configuration for multiple PV arrays (see Figure 2-1 for diagrams of both options).

Single Inverter Installation

In this configuration, a single inverter collects the harvested solar energy and routes the power to the main utility service panel and the utility grid.

Multiple Inverter Installations

If multiple inverters are used, each inverter must be wired to an independent PV array. In this configuration, each inverter collects the harvested solar energy from a separate PV array and routes the power to the main utility service panel and the utility grid.

Communications between inverters is optional, but can be enabled by installing communications cabling to the inverter RJ45 ports. See “Connecting Network Cable between Inverters” on page 3–13.

Planning the Installation

The following issues need to be considered when planning for an installation using the GT Inverter. See the specified sections for more information.

•“Inverter Location” on page 2–4

•“PV Array Requirements” on page 2–5

•“Grounding Requirements” on page 2–7

•“Routing the Wires” on page 2–8.

Ensure that you have obtained all permits required by local authorities or utilities before commencing installation.

2–2 |

975-0253-01-01 |

Planning the Installation

Single Inverter Installation

Harvested solar energy

Photovoltaic (PV) Panels—

PV Array

Grid Tie Solar Inverter |

GT Inverter

Surplus power routed to Utility Grid

DC converted to AC |

0 |

0 |

0 |

0 |

0 |

0 8 |

Utility Grid |

0 |

|

Utility Meter |

Main Utility

Service Panel

PV Array #2 |

Multiple Inverter Installation |

|

|

Harvested solar energy |

Surplus power routed |

|

to Utility Grid |

0 |

0 |

0 |

0 |

0 |

0 |

0 8 |

Utility Grid |

|

|

|

|

|

|

|

Photovoltaic Panels—

Multiple PV Arrays

Grid Tie Solar Inverter |

Harvested GT Inverter #1

solar energy

PV Array #1

|

DC converted to AC |

|

Utility Meter |

Grid Tie Solar Inverter |

Main Utility |

GT Inverter #2 |

Service Panel |

|

|

DC converted to AC |

|

Figure 2-1 Installation Options Overview

975-0253-01-01 |

2–3 |

Installation

Inverter Location

WARNING: Burn hazard

Do not install in a location where people can accidentally come into contact with the front of the inverter. High temperatures can be present on the face of the inverter, causing a potential burn hazard.

In extreme conditions, the GT Inverter chassis can reach temperatures that can cause skin burns if accidentally touched. Ensure that the GT Inverter is located away from normal traffic areas.

Inverter failure due to improper installation will void the inverter warranty.

Consider the following when determining where to install the inverter.

Fire Safety |

• Do not install anywhere near combustible or flammable materials such |

|

as wooden cabinets and furniture, or stored fuels and solvents. |

Indoor/ |

• The GT Inverter can be mounted indoors or outdoors. When installed |

Outdoor |

outdoors, the GT Inverter must be mounted in a vertical orientation. |

|

• In outdoor installations the GT Inverter should be located away from |

|

lawn sprinklers and other sources of spray. |

Orientation |

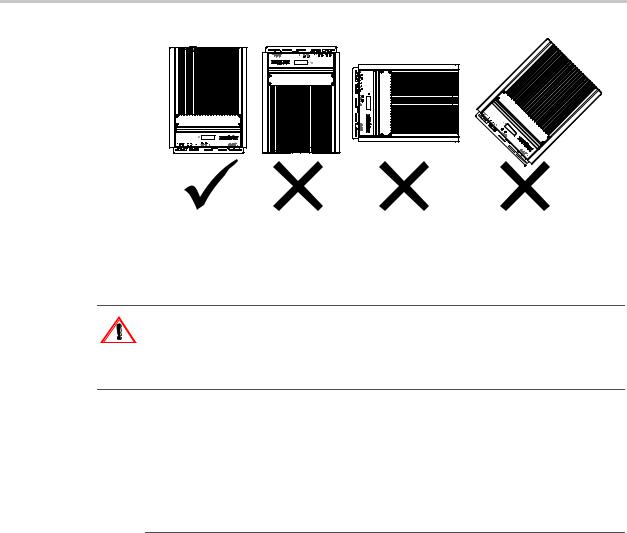

• The GT Inverter must be mounted vertically (with DC and AC |

|

connectors facing down) on a wall or pole. See Figure 2-2. |

Temperature |

• Ensure that the GT Inverter is mounted in a location where the |

|

ambient temperature range is -25 to 65 °C. |

|

• At extreme cold temperatures, the front panel LCD may not function |

|

normally. At higher temperatures, the unit may derate power. See |

|

“Environmental Specifications” on page A–5 and “Output Power vs. |

|

Ambient Temperature” on page A–4. |

Ground |

• Outdoors, the GT Inverter requires at least 100 cm of clearance |

Clearance |

between the bottom of the unit and the ground. This clearance helps |

|

prevent water from splashing onto the bottom of the unit. |

|

• Install the GT Inverter at a height at which the LCD is easily readable. |

Distance |

• To minimize copper losses, ensure that wire lengths between the PV |

|

array and the GT Inverter and between the inverter and the Main |

|

Utility Service Panel are kept to a minimum. |

|

• Maximum distances will depend on wire gauges used and PV array |

|

output voltages. |

Debris free |

• Excessive debris (such as dust, leaves, and cobwebs) can accumulate |

|

on the unit, interfering with wiring connections and ventilation. Do |

|

not install in a location where debris can accumulate (such as under a |

|

tree). |

2–4 |

975-0253-01-01 |

Planning the Installation

Figure 2-2 GT Inverter mounting orientation

PV Array Requirements

WARNING: Shock hazard

Whenever a PV array is exposed to sunlight, a shock hazard exists at the output wires or exposed terminals. To reduce the risk of shock during installation, cover the array with an opaque (dark) material before making any connections.

General Recommendations

It is important that the PV array is installed correctly to the manufacturer’s specifications and to local code requirements.

Equipment and Installation Recommendations

|

Important: The PV array should be free of shade. This requirement includes even |

|

|

small obstructions such as antennas, chimneys, and power lines. As well, be aware of |

|

|

potential obstructions from growing trees and neighboring buildings. A small amount of |

|

|

shade can have a disproportionately high impact on system performance. |

|

Equipment |

• All electrical equipment should be approved for the voltage and current |

|

recommendations |

ratings necessary for the application. |

|

|

• All wiring should be sized correctly to minimize voltage drop. |

|

|

• All exposed wires or conduits should be sunlight resistant. |

|

|

• All required overcurrent protections should be included in the system and |

|

|

accessible for maintenance. |

|

Installation |

• All electrical terminations should be fully tightened, secured, and strain |

|

recommendations |

relieved as appropriate. |

|

|

• All mounting equipment should be installed according to the manufacturer’s |

|

|

specifications. |

|

|

• All wires, conduit, exposed conductors and electrical boxes should be secured |

|

|

and supported according to code requirements. |

|

|

|

|

975-0253-01-01 |

2–5 |

Installation

Voltage and MPPT Requirements

MPPT operational |

The MPPT software maximizes the output energy of solar arrays as long as the |

||||

window |

operating voltage is within the MPPT operational window. Ensure that the PV |

||||

|

array used in the system operates within the MPPT operational window. |

||||

|

Effects of array voltages outside of the MPPT operational window are shown in |

||||

|

Table 2-1. |

|

|

|

|

|

Table 2-1 MPPT Operational Window |

|

|

||

|

Voltage |

|

Effect of Array Voltage |

|

Inverter Mode |

|

|

|

|||

|

|

|

|

|

|

|

< 195 Vdc |

|

Operating voltage shifts to 195 Vdc; the array is |

|

Low power |

|

|

|

not at its maximum power point |

|

|

|

195 to 550 Vdc |

|

Maximum harvest of solar energy |

|

MPPT window |

|

550 to 600 Vdc |

|

Reduced harvest of solar energy |

|

Power derating |

|

> 600 |

|

Inverter stops selling surplus energy and shuts |

|

Shutdown |

|

|

|

down. Higher voltage may damage the inverter. |

|

|

|

Table 2-2 MPPT Operational Window (GT5.0-SP) |

|

|

||

|

Voltage |

|

Effect of Array Voltage |

|

Inverter Mode |

|

|

|

|||

|

|

|

|

|

|

|

< 240 Vdc |

|

Operating voltage shifts to 240 Vdc; the array is |

|

Low power |

|

|

|

not at its maximum power point |

|

|

|

240 to 550 Vdc |

|

Maximum harvest of solar energy |

|

MPPT window |

|

550 to 580 Vdc |

|

Reduced harvest of solar energy |

|

Power derating |

|

> 580 |

|

Inverter stops selling surplus energy and shuts |

|

Shutdown |

|

|

|

down. Voltage above 600 Vdc may damage the |

|

|

|

|

|

inverter. |

|

|

Voltage |

The maximum power point voltage of a string connected to the GT Inverter should |

||||

requirements |

be a minimum of 195 Vdc (240 Vdc for GT5.0-SP). If it is less than 195/240 Vdc, |

||||

|

the inverter will continue to operate, but it will regulate the PV voltage to |

||||

|

195/240 V. Because the array will not be operating at its maximum power point, |

||||

|

this may result in lower than expected energy harvest. |

|

|

||

Maximum PV |

The solar array should be sized such that its maximum power output does not |

||||

Power |

exceed the limits of the MPPT operational window (195/240 to 550 Vdc). See |

||||

|

“Guidelines for Matching PV Array Size to Xantrex Grid Tie Solar Inverter |

||||

|

Input”. |

|

|

|

|

The array voltage should never exceed 600 VOC (open circuit voltage) under any thermal condition.

Likewise, ensure that the ISC (short circuit current) rating of the array at any temperature does not exceed the short circuit current rating of the inverter.

2–6 |

975-0253-01-01 |

Loading...

Loading...