Page 1

OPERATION and MAINTENANCE

MANUAL

for

MODEL PV-100208

100 kW Grid-Tied Photovoltaic Inverter

Document #151700

Revision B October 13, 2003

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS - THIS MANUAL CONTAINS IMPORTANT INSTRUCTIONS

FOR XANTREX TECHNOLOGY MODEL PV-100208 GRID TIED PHOTOVOLTAIC INVERTER

THAT SHALL BE FOLLOWED DURING INSTALLATION AND MAINTENANCE OF THE PV-

100208.

Xantrex Technology Inc.

161-G SOUTH VASCO ROAD

Livermore, CA 94550

(925) 245-5400

Copyright 2003, Xantrex Technology Inc.

Page 2

Table of Contents

Product Description ................................................ Section 1

Introduction ............................................................................. 1-1

Major Components ................................................................. 1-1

Control Components ............................................................... 1-2

Interconnection Standards Compliance .....................................1-3

Specifications .......................................................................... 1-4

Equipment Symbol ................................................................... 1-4

Safety ............................................................................. Section 2

Safety Features ........................................................................2-1

Isolation Procedure ..................................................................2-2

Installation And Initial Turn-On ....................... Section 3

Isolation Transformer Requirements .......................................... 3-1

Torque and Wire Gauge Specifications .....................................3-2

Installation Instructions ............................................................. 3-2

Interconnection Wiring .............................................................3-4

Initial Turn On Procedure .........................................................3-6

Operation ................................................................... Section 4

Description of System Operation ..............................................4-1

Operation Features .................................................................. 4-2

Operator Interface ................................................................... 4-3

Manual State Transitions .......................................................... 4-5

Automatic State Transitions ......................................................4-6

Auto-Restart Feature ............................................................... 4-7

Isolation Procedure ..................................................................4-7

Turn-On Procedure ................................................................. 4-7

Troubleshooting ....................................................... Section 5

General ................................................................................... 5-1

Alarms and Fault Conditions ....................................................5-1

Preventative Maintenance .................................. Section 6

Periodic Maintenance .............................................................. 6-1

Isolation Procedure ..................................................................6-2

Turn-On Procedure ................................................................. 6-2

Appendix ...................................................................... Section 7

Fault Codes .............................................................................7-1

Read/Write Parameter Menu.................................................... 7-1

Warranty and Certifications ...................................................... 7-4

Drawings List .......................................................................... 7-5

Page 3

SECTION 1

PRODUCT DESCRIPTION

INTRODUCTION

The Xantrex Technology Model PV-100208 is a current following grid tied photovoltaic inverter,

utilizing state-of-the-art IPM (Intelligent Power Module), insulated gate bi-polar transistors (IGBT’s)

and gate drive circuits to allow interface of a photovoltaic array with a utility grid. The PV-100208

consists of an inverter bridge, photovoltaic controller, and associated control electronics. The PV100208 control software provides for complete overall system control with a variety of protection and

safety features.

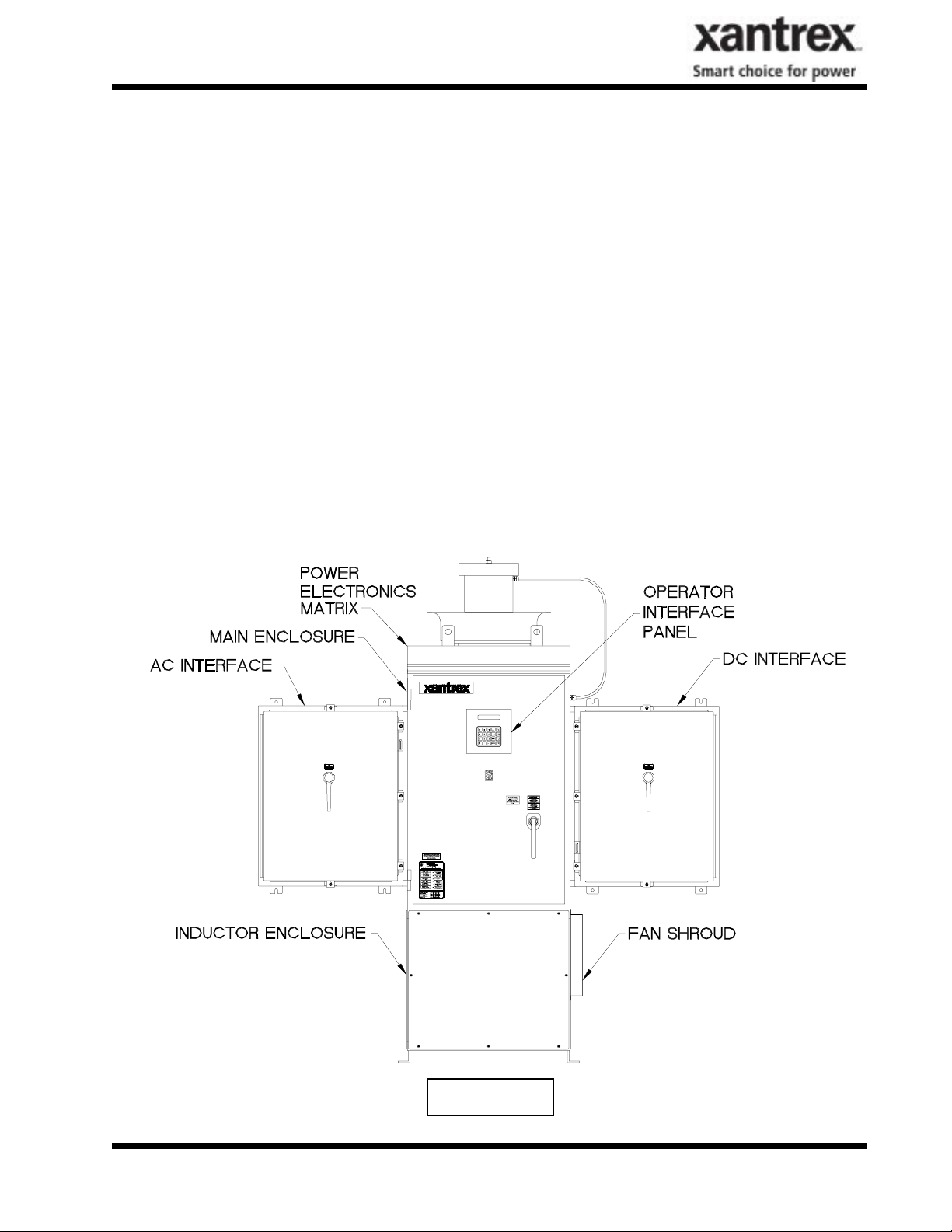

MAJOR COMPONENTS

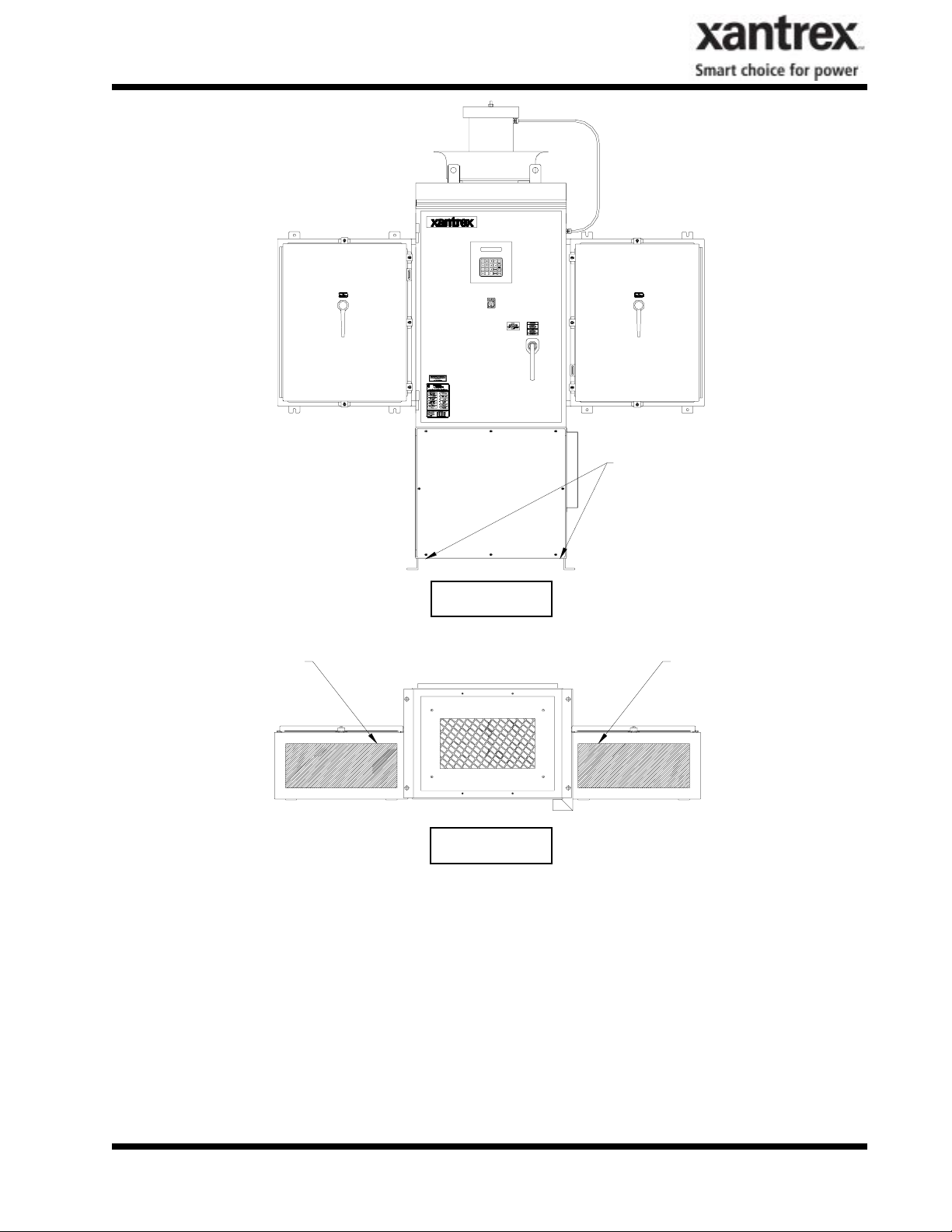

The major components of the PV-100208 are identified in Figure 1-1. Control components are identified in Figure 1-2. For specific control components see Drawing No. 151702 located in Section 7

(Appendix).

Main Enclosure

This enclosure is NEMA-3R rated. The PV-100208 main enclosure contains the power electronic inverter bridge, electrical and electromechanical control components, power supplies, system sensing

circuits, and the PV-100208 embedded control unit. Also found within the main enclosure are some of

the system protection devices (sense and control power fuses).

DOCUMENT: 151700

Figure 1-1

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

1-1

Page 4

SECTION 1

PRODUCT DESCRIPTION

AC Interface Enclosure

This enclosure is NEMA-3R rated. The AC Interface serves as the connection between the isolation

transformer/utility and the PV-100208. This enclosure is where the AC line fuses and AC disconnect

switch reside. For specific control components see Drawing No. 151703 in Section 7 (Appendix).

DC Interface Enclosure

This enclosure is NEMA-3R rated. The DC Interface serves as the connection interface between the PV

array and the PV-100208. This enclosure is where the DC disconnect switch and DC contactor reside.

For specific control components see Drawing No. 151704 in Section 7 (Appendix).

CAUTION

The fuses within the PV-100208 are intended for protecting the PV-100208 control

circuitry only. They are not intended to provide protection for the PV array or external

cabling.

Power Electronics Matrix

The power electronics converter is located at the top of the PV-100208 Main Enclosure. The matrix is

comprised of switching transistors (IGBTs), transistor gate drive electronics, a laminated power bus,

DC capacitor bank, and an aluminum extrusion heat sink with a cooling fan. The fan is located above

the matrix heatsink.

The PV array is tied logically to the matrix DC bus via the DC interface enclosure. The embedded

control unit manages the transfer of power between the DC bus and the utility grid.

Operator Interface

The operator interface is located on the front door of the PV-100208 main enclosure. It consists of an

On/Off switch and a keypad with liquid crystal display for control and monitoring purposes. All interface components are NEMA-3R rated. Refer to Section 4 for detailed operation instructions.

Inductor Enclosure

This enclosure is NEMA-3R rated. It contains the necessary filter components to insure the PV-100208

line currents and voltages meet IEEE-519 and UL1741 harmonic distortion requirements. Mounted on

the right side of the lower enclosure is an inductor fan to allow cooling of the line filter components

within. This enclosure also serves as the mounting base for the PV-100208 main enclosure.

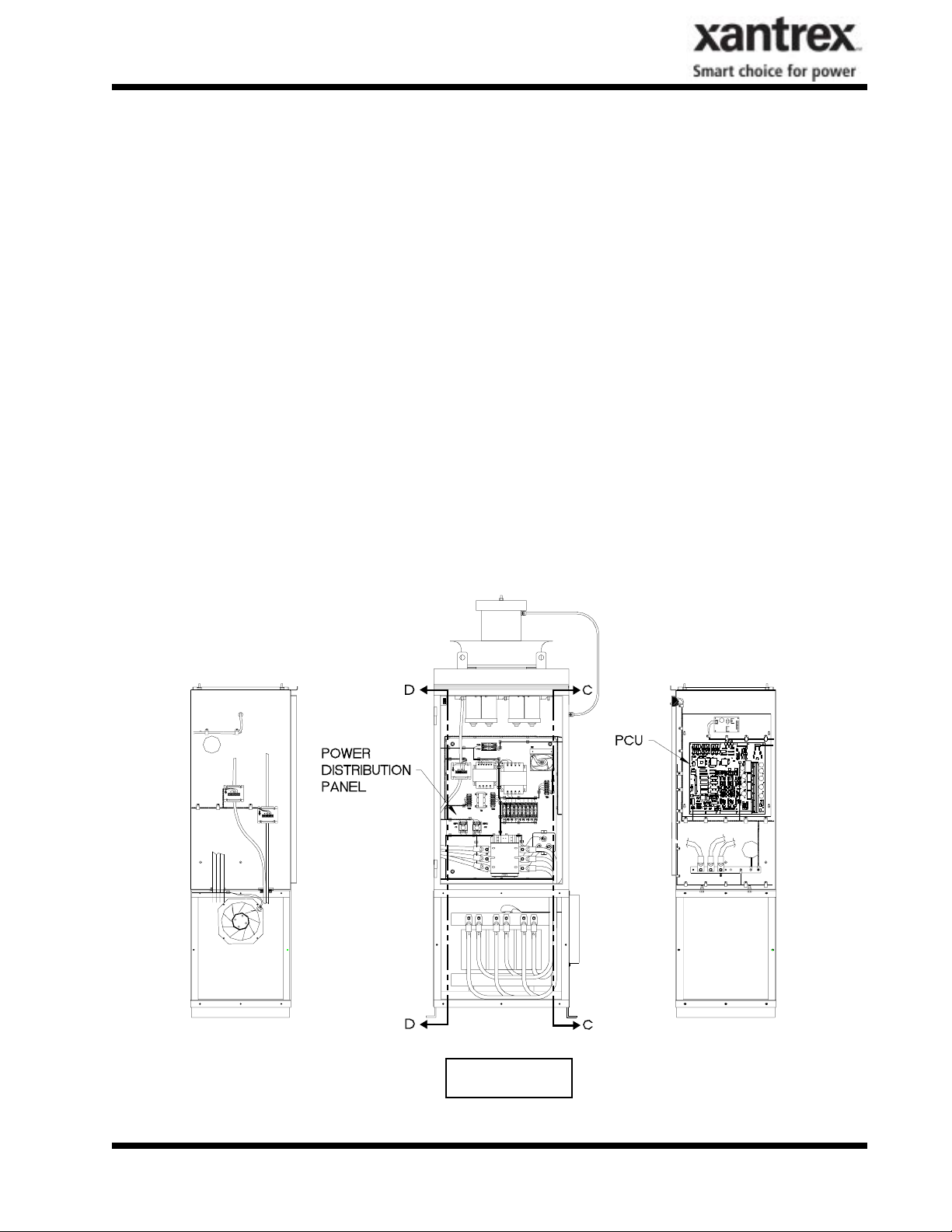

CONTROL COMPONENTS

The following assemblies are contained within the PV-100208 main enclosure as shown in Figure 1-2

(see Appendix in Section 7).

Power Distribution Panel

This panel contains many of the Electro-mechanical, protective, and control power components necessary to support the operation of the PV-100208.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

1-2

Page 5

SECTION 1

PRODUCT DESCRIPTION

Power Control Unit (PCU)

The PCU is a Digital Signal Processor (DSP) based control board that performs numerous control and

diagnostic functions associated with PV-100208 operation. Its most significant tasks are control of PV100208 electromechanical components and power electronics converters, signal conditioning for high

voltage signal inputs and communication with the operator interface panel and system sensors. The

PCU also contains the necessary DC power supplies to support its operation.

INTERCONNECTION STANDARDS COMPLIANCE

The PV-100208 has been tested and listed by Underwriters Laboratories to be in compliance with

UL1741 Static Inverters And Charge Controllers For Use In Photovoltaic Power Systems, as well

as IEEE-929-2000 Recommended Practice For Utility Interface Of Photovoltaic (PV) Systems.

IEEE-929-2000 provides guidance regarding equipment and functions necessary to ensure compatible

operation of photovoltaic systems which are connected in parallel with the electric utility. UL1741 is

the standard applied by Underwriters Laboratory to the PV-100208 to verify it meets the recommendations of IEEE-929-2000. Refer to both documents for details of these recommendations and test proce-

dures.

DOCUMENT: 151700

C-C

Figure 1-2

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

D-D

1-3

Page 6

SECTION 1

PRODUCT DESCRIPTION

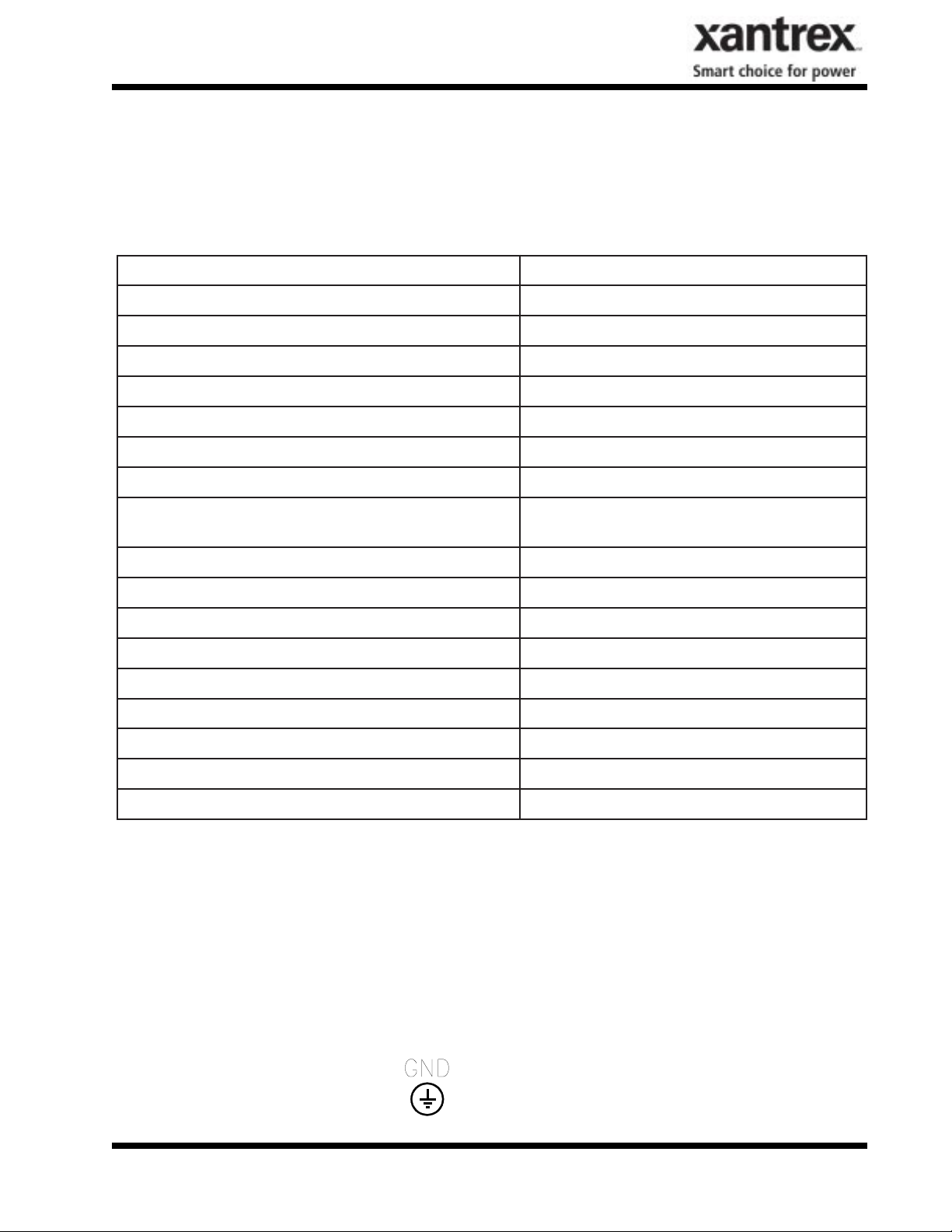

SPECIFICATIONS

The PV-100208 has been designed for photovoltaic power systems, which operate within the following

specifications. Application of the PV-100208 in a manner inconsistent with these specifications may

cause damage to the PV-100208 and other system components, and is a violation of the terms of the

warranty.

egatloVeniLCAlanimoN%21-%01+,CAV802

tnerruCeniLCAmumixaM )egatlovenilwolta(SMRA803

ycneuqerFeniLlanimoNzH7.0-5.0+,zH06

rewoPtuptuOCAsuounitnoC esahP3CAV802@Wk0.001

egatloVmumixaMVPCDV006

wodniWgnikcarTrewoPkaePCDV006-*033

egatloVgnikcarTrewoPkaePmuminiMVPCDV033

tnerruCmumixaMVPCDA913

noitarugifnoCVP dednuorgevitagenraloponoM

erutarepmeTgnitarepOC°05ot02-**

erutarepmeTegarotSC°05ot04-

gnitaRerutarepmeTtneibmAmumixaMC°05

ytidimuHevitaleRgnisnednoc-noN,%59oT

noitavelEteef006,6evobadetareD

)sehcnini(snoisnemiD02X5.67X38

thgieW.sbl0051.xorppA

epyTerusolcnER3AMEN

eliFgnitsiLLU653991E-eliF

*Dependent on actual AC line voltage. Refer to Section 4 for detail on the minimum power tracking

voltage.

**If ambient temperature is between -20 to 0° C, the unit must be powered up in standby for at least

one hour prior to going on-line.

EQUIPMENT SYMBOL

Chassis ground – Customer supplied system ground connection point. This symbol may be found near

a stud within the main enclosure. It is provided as a location to bond the electrical system equipment

ground.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

1-4

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

Page 7

SECTION 2

SAFETY

SAFETY FEATURES

WARNING

The PV-100208 enclosure contains exposed high voltage conductors. The enclosure

doors should remain locked, except during maintenance or testing. These servicing

instructions are for use by qualified personnel only. To reduce the risk of electric

shock, do not perform any servicing other than that specified in the operating

instructions unless you are qualified to do so. Do not open the cabinet doors if

extreme moisture is present (rain or heavy dew).

On/Off Switch

The PV-100208 incorporates a maintained position on/off switch located on the front door of the main

enclosure. Under normal conditions, the on/off switch is in the on position. Turning the switch to the

off position will initiate a controlled shutdown of the PV-100208 and open the A/C contactor within

the unit. The A/C contactor cannot be closed unless the switch is in the on position. The PV-100208 is

prevented from being restarted until the on/off switch is turned back to the on position. Cycling the on/

off switch will reset the PV-100208 and attempt to clear any system fault.

Main Enclosure Door Interlock Switch

The front door of the PV-100208 main enclosure is equipped with an interlock switch to preclude

operation in the event of the front door being opened. It is required that the PV-100208 main enclosure

door handle be padlocked during normal operation.

WARNING

The PV-100208 will immediately shutdown if the front door is opened during

operation. It is required that the PV-100208 main enclosure door handle be padlocked during normal operations. Please make sure the unit is powered down, and

isolated from the utility grid and PV panels, prior to opening the front door. Allow

5 minutes for any stored potentials to be discharged, prior to opening the unit.

Disconnect Switches

Both AC & DC switches are equipped with lockout hasps for personnel safety. The switch enclosure

door will not open while the PV-100208 is running. In addition, the switch handle and shaft provide a

door interlock. The door cannot be opened when the switch is in the “on” position. The PV disconnect

switch is equipped with an auxiliary contact block which enables the switch to be used as a load break

PV disconnect. In the event a disconnect switch is opened while the PV-100208 is processing power

from the PV array, the contact block will signal the PCU to stop processing power before the switch

opens.

Fault Reporting

Any fault conditions are reported to the operator interface. The LCD will display a text description of

the fault. Refer to Section 5, Troubleshooting, for detailed descriptions of system fault conditions.

PV Ground Fault Detection

The PV-100208 is equipped with ground fault detection circuitry (see section 3, installation and section 7, system schematic for further detail). Upon detection of 10 amps of ground fault current, the PV100208 executes an orderly shutdown, and annunciates a ground fault at the operator interface. The

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

2-1

Page 8

SECTION 2

SAFETY

PV-100208 will remain faulted until the ground fault is remedied and cleared at the operator interface

(see section 5, troubleshooting).

Over/Under Voltage and Frequency

The over/under frequency and voltage detection setpoints have been chosen to be in compliance with

IEEE-929 and UL1741.

noitidnoCtluaF

)lanimoNfo%(

%05<CAVCAV<401selcyC6

%05< %88<CAVCAV<401<381sdnoceS2

%88<CAV< %011CAV<381<822noitarepOlamroN

%731<CAV<%011582<CAV<822sdnoceS2

%731<CAV582< CAVselcyC2

7.0-detar<f3.95<fselcyC6

5.0+detar>f5.06>fselcyC6

egnaRegatloVemiTpirT

Anti Island Protection

A digital phase-shift-loop (PSL) circuit is implemented in the DSP inverter controller to prevent

“Islanding” of the PV-100208.

The DSP continuously makes minor adjustments to the power factor phase angle above and below

unity. In the event of a utility outage, these adjustments destabilize the feedback between the inverter

and the remaining load, resulting in an over/under frequency or voltage condition. The PV-100208

then performs an orderly shutdown. The fault condition will remain until the utility voltage and

frequency have returned to normal for 5 minutes.

This method has been extensively tested and proven to exceed the requirements of UL 1741.

ISOLATION PROCEDURE

The following procedure should be followed to de-energize the PV-100208 for maintenance:

WARNING

The terminals of the PV input may be energized if the arrays are energized. In

addition, allow 5 minutes for all capacitors within the enclosure to discharge after

disconnecting the PV-100208 from AC and DC sources.

1. Turn the on/off switch to the off position.

2. Open the PV array disconnect switch.

3. Open the AC interface disconnect switch.

4. Open the isolation transformer circuit breaker.

5. Install lockout devices on the isolation transformer circuit breaker and PV disconnect switch.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

2-2

Page 9

SECTION 3

INSTALLATION AND INITIAL TURN-ON

ISOLATION TRANSFORMER REQUIREMENTS

The PV-100208 UL1741 certification requires the 100 kVA WYE/WYE isolation transformer be wired

between the inverter AC output and the utility interconnection. This custom 100 kVA isolation transformer is included with any PV-100208 that requires UL1741 certification (see Appendix in Section 7

for transformer dimensions and specifications). If UL1741 and NEC690 is not a requirement of your

PV installation, you may use any standard dry-type isolation transformer as long as the inverter side is

rated for a minimum of 100 kVA, 208 VAC continuous duty. Contact Xantrex Technology if you have

any questions.

WARNING

Check with the local utility of jurisdiction when selecting the winding configuration of the isolation transformer. Individual utilities may have unique requirements related to isolation transformer wiring. Some winding configurations may

keep the PV-100208 from detecting a loss of phase condition on the utility system

which may allow potentially lethal voltage to be present on the open phase wirings.

WARNING

Xantrex Technology requires installing an isolation transformer between the PV100208 inverter and the point of utility interconnection. Failure to do so could

result in catastrophic damage to the PV-100208 as well as the utility distribution

system and will void the product warranty.

Inverter Side Isolation Transformer Requirements

The inverter side transformer windings may be configured either DELTA or WYE, and must be rated

for 208 VAC. If a WYE wound transformer is used to interface with the PV-100208, and the PV

array is grounded, the neutral (X0) must be left floating. If the neutral is tied to ground, the inverter

will suffer irreparable damage.

Utility Side Isolation Transformer Requirements

The utility side isolation transformer windings may be configured either DELTA or WYE, and must be

rated for the utility voltage at the point of utility inter-connection. Check with the utility of jurisdiction

when selecting an isolation transformer configuration. If a WYE wound transformer is used to interface

with the utility, it is not necessary to connect the neutral (X0) to ground. The PV-100208 is a balanced,

three phase, current sourcing inverter, and only operates with the presence of a stable utility voltage.

Single phase grounded loads which may be present between the transformer and utility, will maintain

their existing ground reference at the utility distribution transformer. Grounding the neutral of a WYE

wound transformer may create an “open delta” condition, depending on the utility configuration. This

condition may keep the PV-100208 from detecting a loss of phase condition on the utility system,

which may allow potentially lethal voltage to be present on the open phase wiring.

Contact your Xantrex Technology distributor if you have any questions regarding isolation transformer

requirements.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

3-1

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

Page 10

SECTION 3

INSTALLATION AND INITIAL TURN-ON

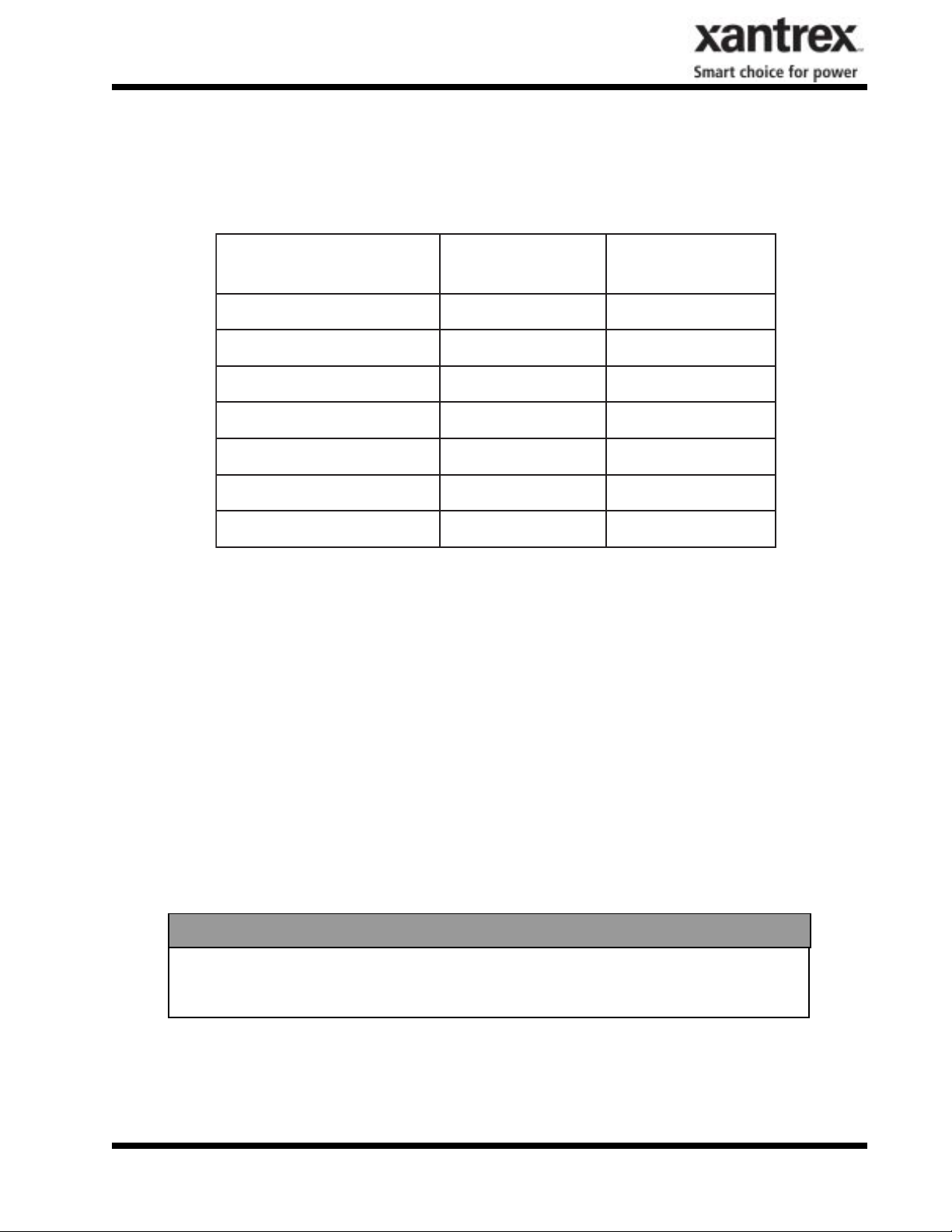

TORQUE AND WIRE GAUGE SPECIFICATIONS

The following torque specifications are to be used on all electrical interfaces made during installation

of the PV-100208.

Torque Table

eziStloBrokcolBlanimreTgnitteSeuqroT

)CA(tloB61-8/3mN2.82/.sblni052

,-CD,+CD(kcolBlanimreT

)lartueNCD&

mN1.13/sblni572

The following table shows acceptable wire gauges to be connected to the PV-100208 AC and DC

inputs.

Wire Gauge Table

noitanimreTGWAegnaReriW

)CA(hctiwStcennocsiD)nim(MCM052

-CD,+CD(kcolBlanimreT

)lartueNCD&

4#-MCM005

INSTALLATION INSTRUCTIONS

CAUTION

All wiring methods shall be in accordance with the National Electrical Code ANSI/

NFPA 70. All power conductors interfacing to the PV-100208 should be sized in

accordance with the National Electric Code ANSI/NFPA 70 and local codes. Large

gauge wire must have a minimum bend radius dependent upon the wire gauge

(refer to the National Electric Code, Article 373-6B). Take care to keep the wire

bundles away from any sharp edges which may damage wire insulation over time.

Xantrex Technology recommends using 250 MCM, 105 degrees C, minimum, copper wire for all connections to the PV-100208.

Ventilation Considerations

Maintain a minimum of 6” clearance in back and minimum of 12” in front and both sides of the PV100208 for proper cooling fan operation.

Installation

1. Move the PV-100208 into place. Lift the PV-100208 from beneath the lower enclosure with a

forklift as shown in Figure 3-1. (See following page.)

2. Anchor the lower enclosure feet to the floor with a 1/2” anchor bolts.

3. Install all conduits needed for cable entry in the shaded areas of both AC and DC interface enclosures as shown in Figure 3-2. (See following page).

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

3-2

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

Page 11

SECTION 3

INSTALLATION AND INITIAL TURN-ON

Lift Here

Figure 3-1

Cable Entry Area

Cable Entry Area

Figure 3-2

Array Grounding

NEC 690-41/42 requires the PV array to be earth grounded. The PV-100208 chassis is also bonded

to the PV safety ground terminal block. Refer to the system schematic in the appendix for further

wiring configuration.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

3-3

Page 12

SECTION 3

INSTALLATION AND INITIAL TURN-ON

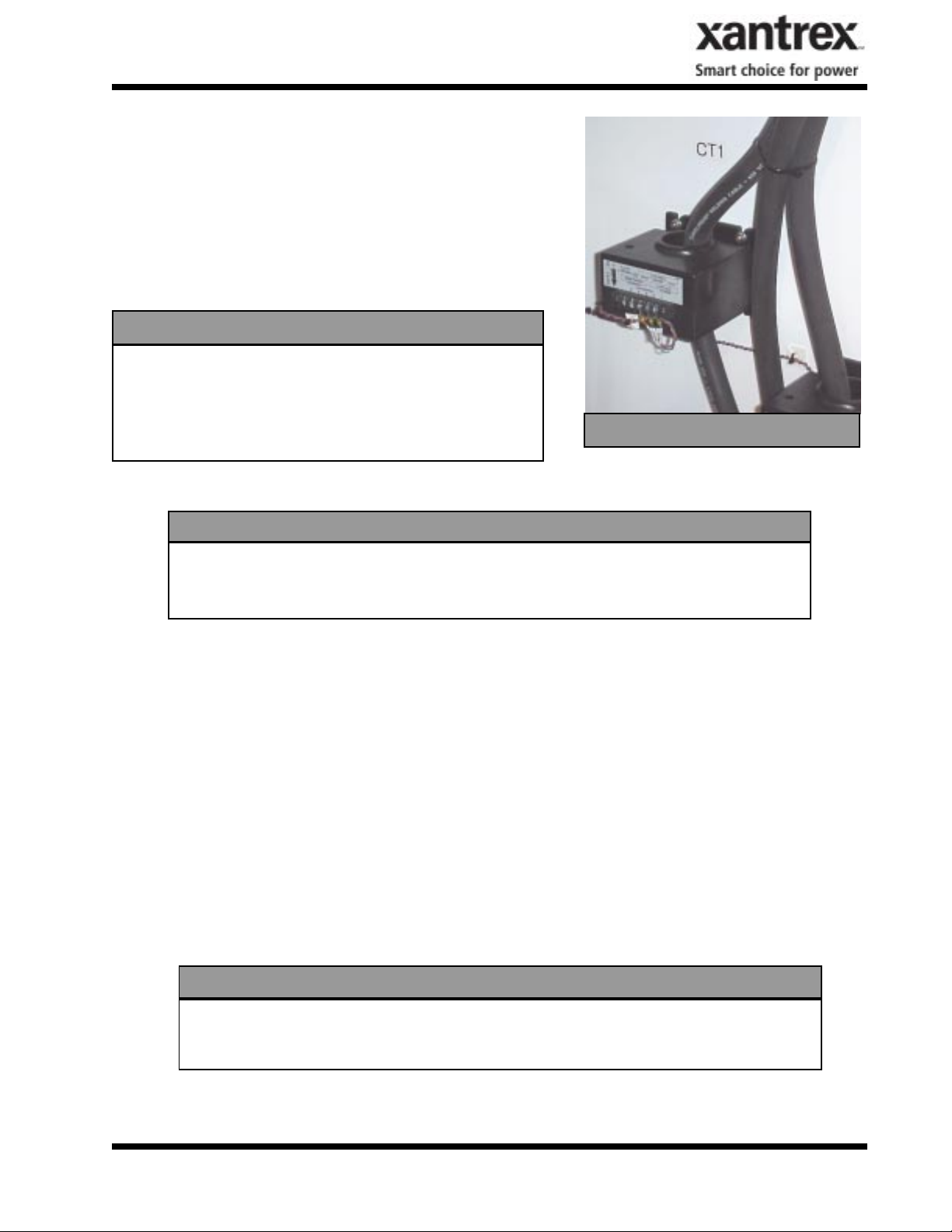

Ground Fault Detection

The PV-100208 is equipped with a ground fault detection

circuit and current transducer. This circuit is active when the

PV array is grounded as described in the previous section. In

the event of a greater than 10 amp ground fault, the PV100208 will execute an orderly shutdown and annunciates a

ground fault at the operator interface. The PV-100208 will

remain faulted until the ground fault is remedied and cleared

at the operator interface (see section 5, Troubleshooting).

CAUTION

The input and output circuits are isolated from the

enclosure and that system grounding, if required by

sections 690-41 and 690-42 of the National Electric

Code, ANSI/NFPA 70, is the responsibility of the installer.

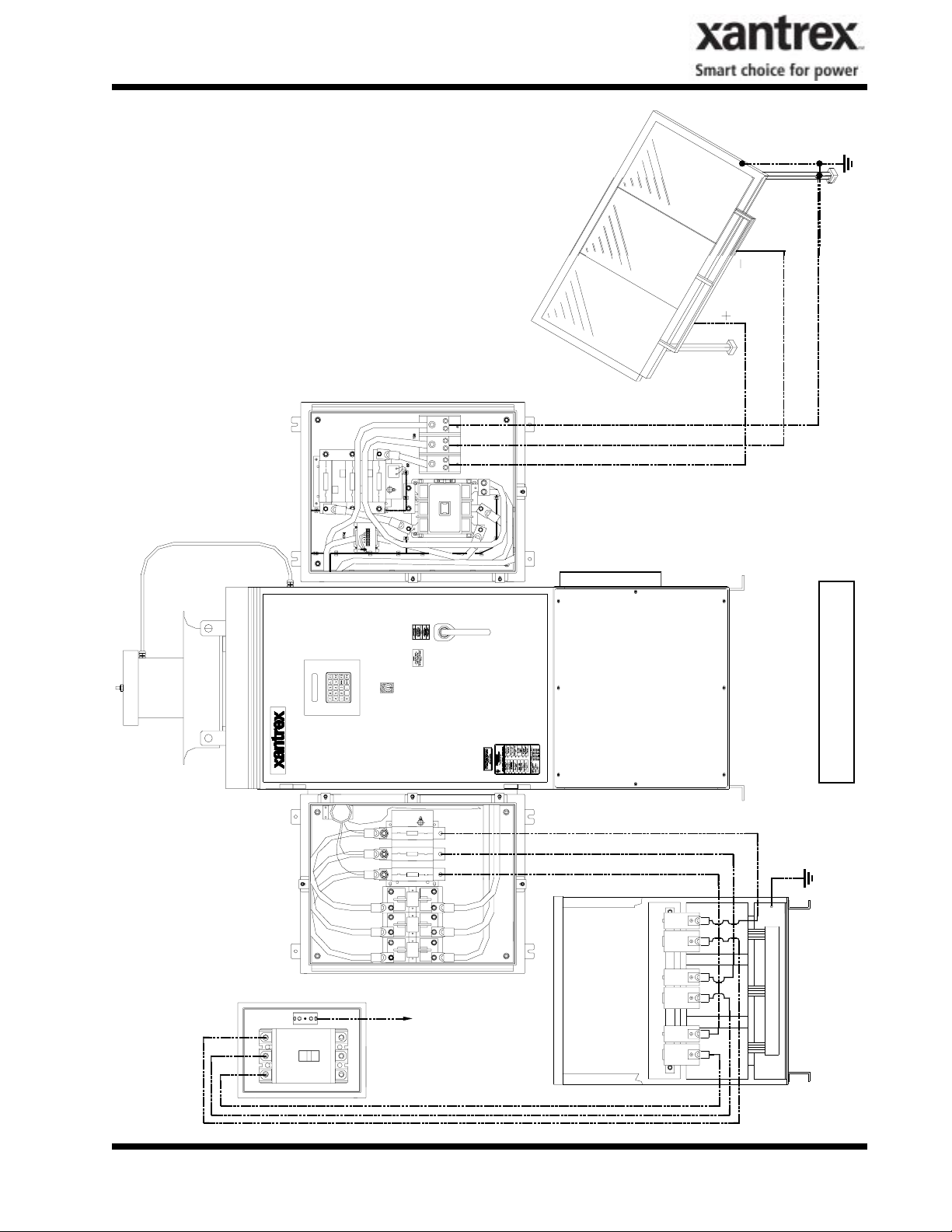

INTERCONNECTION WIRING

CT1

CAUTION

To reduce the risk of fire, connect only to a circuit provided with 450 amperes

maximum branch circuit overcurrent protection in accordance with the National

Electrical Code, ANSI/NFPA 70.

The following wires for connecting the PV-100208 to external devices are not provided by Xantrex

Technology: (See installation diagram on pages 3-5.)

• Connect 3-Phase 208 VAC inverter output (AC Disconnect switch) to terminals of the 208 VAC

inverter side of isolation transformer. If the inverter side of the isolation transformer is con-

figured WYE, the neutral must be left floating. If the inverter side neutral is tied to ground,

the inverter will not function properly. Also, insure that the neutral is not bonded to the

isolation transformer frame. Be sure to maintain proper phasing as shown in the system sche-

matic found in Section 7.

• Connect Isolation transformer grid side terminals 1, 2, and 3 to line circuit breaker. Be sure to

maintain proper phasing as shown in the system schematic found in Section 7.

• PV frame ground to ground terminal block (TB3).

• Connect PV+, PV-, and PV Safety ground to the DC interface enclosure’s designated termina-

tions. See Section 7 for further detail .

CAUTION

When connecting external AC wires to the PV-100208, positive phasing sequence

must be maintained throughout the installation process. Refer to the System

Schematic in Section 7 of this manual for proper phasing convention.

Install all wires listed above. Refer to the Appendix in Section 7 for layout of the AC and DC interface enclosures. Refer to the system schematic in Section 7 for more detailed terminal locations.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

3-4

Page 13

SECTION 3

INSTALLATION AND INITIAL TURN-ON

PV Array

Frame Ground

GND

PV-

PV+

Circuit

DOCUMENT: 151700

Breaker

AC Interface DC Interface

A B C

To Single Point

Electrical

Distribution

System Ground

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

H3 X3

X2H2

H1 X1

Inverter

PV-100208

3-5

Wiring Diagram

Gnd

Chassis

Isolation Transformer

Page 14

SECTION 3

INSTALLATION AND INITIAL TURN-ON

INITIAL TURN ON PROCEDURE

The following must be performed by an approved Technician:

The following procedures are intended to verify correct installation and proper operation of the PV-

100208. These steps are to be followed sequentially. Do not continue if any of the steps or results are

unclear. Refer to Section 4 for a detailed description of system operation. Refer to Section 5 for fault

condition descriptions and troubleshooting. Refer to Section 7 for detailed system schematics.

Visual Inspection, Isolation Transformer WYE/WYE

• Verify the isolation transformer circuit breaker is open.

• If a phase rotation meter is available, verify proper phase rotation at the line side of the isolation

transformer circuit breaker.

• Insure the neutral on the inverter side is left floating. If the inverter side neutral is tied to ground,

the inverter will not function properly. Also, insure that the neutral is not bonded to the

isolation transformer frame.

• Verify the inverter 208 VAC conductors are connected to the isolation transformer.

• If the wires are marked, verify they follow the sequence on the line side of the isolation transformer

and circuit breaker.

• Verify the utility conductors are properly connected to the isolation transformer.

Visual Inspection, PV-100208

• Insure AC and DC disconnect switches are opened.

• Remove the front cover from the inductor enclosure, open the door of the main enclosure, and

disconnect enclosures and inspect.

• Verify all wire connections are tight.

• Inspect the fiber optic cables between the PCU and the matrix driver boards. All fibers should be

snap-locked into their respective receivers/transmitters.

• Insure all connector jack screws on the PCU and matrix driver board are tight.

• Verify AC phase connections landed at the AC interface enclosure.

Visual Inspection, PV Array Wiring

• Verify the PV+, PV-, and PV safety ground are isolated from each other. The safety ground must not

be tied to PV-.

• Verify all PV fuses are installed.

Initial Power

• Turn the On/Off switch, located on the front door to Off.

• With the DC disconnect switch opened, close one of the PV array string disconnect switches.

• Carefully measure VDC across the PV +/- terminal block. The value should be the same as at the

PV array string disconnect switch. It should also be positive.

• Close the PV disconnect switch.

• Carefully measure VDC between the DC contactor negative (-) terminal and the DC switch positive

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

3-6

Page 15

SECTION 3

INSTALLATION AND INITIAL TURN-ON

(+) terminal. The value should be the same as at the PV array string disconnect switch. It should

also be positive.

• Open all PV string disconnect switches.

• Close the isolation transformer circuit breaker.

• Verify 208 VAC voltage across the AC disconnect switch. If a phase rotation meter is available,

verify proper phase rotation at the AC disconnect switch.

• Close the AC disconnect switch.

• Verify 208 VAC voltage across the AC line fuses F1-3.

System Verification

• Upon applying 208 VAC power to the PV-100208, observe the operator interface panel. After

approximately 15 seconds, the panel should finish initialization and will probably report a fault

condition.

• Remedy any faults reported. To clear a fault condition, press the <ENTER> key twice. If the fault

message does not change, the fault condition is still present. Most likely, any faults seen at this

point will be related to PV-100208 safety switches. To disable the door interlock switch with the

main enclosure door opened, pull the switch shaft out. It will lock in its ‘maintenance’ position.

Once all faults are cleared the system will read ‘Sleeping’ or ‘Keyswitch Disable’ depending on the

position of the On/Off switch. To re-enable interlock, push the shaft in and close the door.

• Scroll up the menu until ‘Enter Read Parameter:’ is displayed.

• Press <Enter>, then <19>. This is line voltage frequency being read by the PCU. It should read 60.0

+0.5, -0.7.

• Verify the On/Off switch is in the ‘Off’ position.

• Close the PV array string disconnect switches.

• Close the PV-100208 DC disconnect switch.

• Press <F2> on the operator interface panel. If the PV voltage is above the PV Start Voltage setpoint,

the second line should read ‘Waking Up’. Once the PV Start Time is exceeded, the PV-100208

should transition to ‘Power Tracking’.

• The power tracker was previously limited to 25% of PV-100208 rated power. Once the PV-100208

has stabilized operation (approximately 20 seconds), scroll through the main operator interface

panel menu. Verify all phase voltages and currents are closely balanced.

• Scroll to ‘Enter Read Parameter:’ Press <ENTER> then <17> <ENTER> to view ground fault

current value. This value should be equal to or very close to zero. Continue to monitor this value as

the PV-100208 is commanded to higher power levels.

• Enter the write parameter menu and increase the ‘I PPT Max %’ to 50. Exit the write parameter

menu and verify all operating values are proper.

• Continue to increment ‘I PPT Max %’ to 100. Depending upon solar conditions, the PV-100208

may not operate at full power. If the PV array is not experiencing full sun, the PV maximum power

tracker will regulate the PV voltage to maintain maximum PV power output. To determine if the

PV-100208 has reached it’s maximum power output, enter <20> at the ‘Enter Read Parameter:’ ‘0’

means the PV-100208 has not reached maximum power, contrarily, ‘1’ means the PV-100208 has

reached maximum power and executed the modified peak power tracker to limit output power.

• The PV-100208 is now fully operational.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

3-7

Page 16

SECTION 3

INSTALLATION AND INITIAL TURN-ON

Power Tracker Fine Tuning:

• All PV-100208 operating parameters have been set at the factory, based upon prior experience with

PV arrays.

• It is recommended that the PV-100208 be watched during Wake-Up and Sleep Test. If the PV-

100208 cycles between operating and sleeping at either of these times, the condition setpoints are

not set properly (refer to section 4 for detailed description of PV-100208 state transitions). The

PV100208 should not cycle if the setpoints are set properly.

NOTE

Some field adjustable parameters are password protected and may only be changed

by trained service technicians. In particular are parameters relating to utility

protection setpoints. These have been set in the factory to the limits mandated by

UL1741. Any changes to these setpoints should be agreed upon by the local utility

and the equipment owner.

NOTE

Visually inspect the exterior surfaces for any damage (nicks, chips, exposed base

metal and scratches) that may have occurred during shipment or installation.

Touch up or recoat using White NISSEN Feltip Paint Marker, or equivalent to

prevent rust or corrosion.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

3-8

Page 17

SECTION 4

OPERATION

DESCRIPTION OF SYSTEM OPERATION

Overview

The PV-100208 is a fully automated grid-tied photovoltaic inverter. Manual interaction or control of

the inverter is necessary only in the event of a system fault. The following conditions govern PV100208 operation:

• Stable utility voltage and frequency must be present for all states of operation.

• Fault states are automatic from any state of operation. A fault will cause the PV-100208 to imme-

diately stop processing all power. The fault condition will be reported to the operator interface.

• The on/off switch, located on the front door of the PV-100208, must be switched to the on position

for all operating states.

• Cycling the on/off switch attempts to clear any system faults and return the PV-100208 to normal

operation.

Operating States

A state machine implemented within the PCU control software governs the operation of the PV100208.

There are five steady-state operating states and numerous intermediate transition states. The intermediate transition states provide an orderly progression from one operating state to the next. The user has

the ability to manually transition the PV-100208 between operating states from the operator interface

keypad. Manual transitions are initiated by entering a ‘Goal State’, where the goal state is the desired

operating state. Given all applicable system parameters are within acceptable limits, and the request is

valid within the state machine, the PV-100208 will initiate the proper sequence of operations necessary

to progress to the requested goal state. Refer to Figure 4-3 for a description of valid state transitions.

• Shutdown: The line interface controller is idle. The PCU monitors the status of the PV array and

utility grid, waiting in standby until the PV array is available to produce power to the grid.

• Fault: The PV-100208 has encountered a fault condition. When this happens, regardless of the PV100208 state-of-operation, the PV-100208 will stop processing all power and execute an orderly

system shutdown. A description of the fault and fault code will appear on the operator interface

LCD. The Fault state may be cleared from the keypad once the cause of the fault has been corrected. See Section 5 for a complete description of all fault codes.

• Manual Current: This operating state is provided to evaluate the existing PV array V-I characteristics. The PV controller regulates a constant amount of PV current as commanded by the user from

the operator interface keypad, up to the PV current limit of the PV-100208. If the user commands

more PV current than is available, the DC bus voltage will drop below the minimum bus voltage

level and the PV-100208 will return to Sleeping mode.

• Matrix Test: This operating state is provided to verify proper operation of the matrix and associated control electronics. There is no power transfer between the PV and utility in this mode.

• Power Tracking: This is the standard operating state of the PV-100208. The PV-100208 maxi-

mum power tracker will demand maximum power from the PV array, given sufficient PV irradiance.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

4-1

Page 18

SECTION 4

OPERATION

The user should be aware of the following conditions governing PV-100208 state transitions:

• Utility power must be present for all states of operation.

• Fault states are automatic from any state of operation. A fault will cause the PV-100208 to

immediately stop processing all power. The fault condition will be reported to the operator

interface LCD.

• Most PV-100208 faults are latching and must be cleared at the operator interface keypad before

transitioning to another operating state.

• The On/Off switch, located on the front door of the PV-100208, must be in the On position for

all operating states except Matrix Test, in which case it must be in the Off position.

OPERATION FEATURES

Fixed Unity Power Factor Operation

The Xantrex PV Series grid tied inverters maintains unity power factor during operation. The control

software constantly senses utility voltage, and constructs the output current waveform to match the

utility voltage. The PV line of inverters is not capable of operation without the presence of normal

utility voltage, nor is it capable of varying the output power factor off unity.

Utility Voltage/Frequency Fault Automatic Reset

In the event of a utility voltage or frequency excursion outside of preset limits, the PV-100208 will stop

operation and annunciate a fault at the operator interface. Once the utility voltage has stabilized within

acceptable limits for a period of at least five minutes, the PV-100208 will automatically clear the fault

and resume normal operation. Voltage and frequency fault setpoints are detailed later in this section.

Active Island Detection

Much concern has been given to the possibility of an inverter causing a ‘utility island’ condition during

a utility power outage. An island condition is defined as grid tied inverter maintaining operation and

supporting a load that has been isolated from the utility power source. This requires the load to be

closely balanced to the output power of the inverter as well as having a resonant frequency close to

60Hz. Needless to say, this is an extremely remote possibility. To insure this condition does not occur,

the PV-100208 control software contains an active phase-shift-loop algorithm, which destabilizes a

balanced load, which may otherwise be capable of maintaining inverter operation in the absence of

utility voltage. This feature has been extensively tested and proven to exceed the safety requirements of

UL-1741 and IEEE-929-2000.

Ground Fault Detection

The PV-100208 is equipped with a ground fault detection circuit and current transducer. In the event of

a 10 amp ground fault, the PV-100208 will execute an orderly shutdown and annunciates a ground fault

at the operator interface. (See Section 5, Troubleshooting).

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

4-2

Page 19

SECTION 4

OPERATION

Current Imbalance Detection

In the event of phase-to-phase current imbalance of greater than 20% between phases, the inverter will

execute an orderly shutdown, and annunciate a fault at the operator interface. See Section 5, Troubleshooting, for further information on this fault condition.

DC Overvoltage Detection

In the event of DC voltage greater than 600Vdc, the PV-100208 will execute an orderly shutdown and

annunciate a fault to the operator interface. If DC voltage remains greater than 600Vdc, the PV-100208

may be irreparably damaged. See Section 5, troubleshooting for further information on this fault condition.

Peak Power Tracking

The PV-100208 control software employs an active PV peak power tracker designed to maintain maximum power output from the PV array at all times of operation. The peak power voltage point varies

primarily depending upon the temperature of the PV cells. The PV-100208 constantly seeks the optimum voltage and current operating points of the PV array to maintain maximum PV power output.

Upon PV wake-up, the power tracker will increase power while ramping PV array voltage to the PV

maximum power voltage reference setpoint (PPT V Ref). The change rate is governed by the power

point ramp time setpoint (PPT Ramp T). Once the PV voltage is ramped to the reference setpoint, the

PCU begins to adjust the commanded PV voltage around the reference setpoint, seeking maximum PV

power. The power tracker may only adjust the operating voltage +/- 20% of PPT V Ref. The PV

maximum power voltage step and update rate are user setable (PPT V Step and PPT Rate, respectively).

If available PV power is above the maximum allowable power level of the PV-100208, the power

tracker will increase voltage as needed to maintain output power below rated maximum.

The minimum operating voltage of the PV-100208 is 330 VDC. The power tracker will not track

voltage below this point, regardless of the reference voltage setpoint.

Automatic Sleep Test

Toward the end of every solar day, the PV-100208 automatically determines when to stop producing

power dependent upon the output power of the inverter. As the net output power of the PV-100208

nears zero, a timer is started to allow the inverter to ride through any brief irradiance reductions.

OPERATOR INTERFACE

The operator interface display consists of two main menu levels: The read parameter menu and the

write parameter menu. The read parameter menu consists of all system parameters, the date and time.

These can be viewed any time the PV-100208 has control power.

The write parameter menu consists of a goal state sub-menu, and all system write parameters. The write

parameter menu is password protected and may only be changed by trained service technicians. In

particular are parameters relating to utility protection setpoints. These have been set in the factory to

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

4-3

Page 20

SECTION 4

OPERATION

the limits mandated by UL1741. Any changes to these setpoints should be agreed upon by the local

utility and the equipment owner. The ability to adjust the voltage and frequency setpoints with respect

to the actual utility voltage and frequency has been provided as a simulation tool to verify the PV100208 accurately detects and responds to a utility excursion. This test should only be performed by a

trained service technician. It is possible to adjust the setpoints in a manner that will prevent the PV100208 from functioning.

Upon system power up, the operator interface LCD will display the system operating state on the first

line. The second line will display the date and time. This is the standard display.

Refer to Section 7, Appendix for a complete description of all system read/write parameters.

NOTE

The operator interface display will reset itself to the standard display if there is no

input for 30 seconds.

Read

Parameter

Menu

Standard

Display

Password

Figure 4-1

Operator Interface Flow Chart

Password

Write

Parameter

Menu

Enter

Goal State

Set Date/T ime

Change

Parameters

Figure 4-2

Operator Interface Keypad

Viewing Read/Write Parameters Values

To display any parameter, use the /\ or \/ keys on the operator interface keypad to scroll through the

read/write parameters. The \/ key will scroll downward through the menu and the /\ key will scroll

upward. Upon reaching the end of the menu, it will roll-over to the beginning.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

4-4

Page 21

SECTION 4

OPERATION

Write parameter values are password protected; however, they may be viewed in the read parameter

menu without entering a password. From the standard display press the /\ key. The display will read

‘Enter Parameter ID:’. Enter the desired write parameter ID, then press the ‘Enter’.

Refer to Section 7: Appendix, for a table of all read/write parameters and their descriptions.

Changing Write Parameter Values

From the standard display or anywhere in the read parameter menu, you may access the write parameter menu by pressing the <MENU> key. This will ask for a password. Enter the password and press

the <ENTER> button. Use the /\ or \/ key on the operator interface keypad to scroll through the write

parameters. To change the displayed parameter, press the <ENTER> button. Enter the desired value

and press <ENTER>. If the value entered is outside the acceptable range for the parameter, the original

value will remain. To leave the write parameter menu press the <MENU> button repeatedly until the

standard display shows on the LCD.

Refer to Section 7: Appendix, for a table of all read/write parameters and their descriptions.

Commanding Goal State Changes

From the standard display press the <MENU> key. This will ask for a password. Enter the password

and press the <ENTER> button. The LCD will prompt ‘Change Goal State?’. Press <ENTER> again.

The goal state menu will show on the LCD. Scroll through the goal state menu with the /\ or \/ keys

until the desired goal state is reached. Press <ENTER>. The LCD will prompt: ‘Press F4 to Confirm’.

Press <F4> and the PV-100208 will transition to this goal state. If the goal state requested violates the

conditions of the state machine, the PV-100208 will remain in the previous state of operation.

Setting the Date and Time

From the standard display enter the write parameter menu (see previous). From the ‘Change Goal

State?’ prompt, scroll up with the /\ key until date/time parameter is reached. Press the enter key. The

date/time will be replaced with an underscore. Enter the proper date/time in a six digit format. For

example: The date is entered month-day-year: April 28, 2002 is entered 042802 <ENTER>. The time

is entered in military hours-minutes-seconds: 4:30 pm is entered 163000 <ENTER>. If the date/time is

entered incorrectly the original value will remain. Press <MENU> to return to the standard display.

MANUAL STATE TRANSITIONS

Refer to previous sections on commanding PV-100208 goal states.

• Sleeping → Matrix Test → Sleeping:

Turn the On/Off switch to the Off position. Command the PV-100208 to Matrix Test. Once the user

has completed the test, command the PV-100208 to Sleeping. If the On/Off switch is turned to On

while the PV-100208 is in the Matrix Test state, the PV-100208 will transition to Sleeping.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

4-5

Page 22

SECTION 4

OPERATION

Figure 4-3

PV-100208 State Machine

• Power Tracking→ Manual Current→ Power Tracking or Sleeping:

Verify the PV manual current parameter (I Manual %) is set to the desired percent of rated. Command the PV-100208 to Manual Current mode from the operator interface keypad. While in the

manual current mode, the user may change the PV manual current parameter. However, the user

may demand greater current than the capacity of the PV array. If this causes the PV voltage to drop

below the minimum operating voltage (300 Vdc), the PV-100208 will transition to Sleeping.

To exit the Manual Current mode the user must manually command the PV-100208 to either Power

Tracking or Sleeping.

AUTOMATIC STATE TRANSITIONS

• Sleeping → Power Tracking → Sleeping:

The On/Off switch must be turned to the On position. Once the PV voltage exceeds the PV voltage

start setpoint (PV V Start) the PV-100208 will start a wake-up timer (PV T Start). If the PV voltage

remains above the PV start voltage setpoint for the duration of the wake-up timer, the PV-100208

will transition to Power Tracking.

If the PV power drops below the PV power stop setpoint (PV P Stop) the PV-100208 will start a PV

sleep timer (PV T Stop). If the PV voltage and power remain below their respective setpoints for

the duration of the sleep timer, the PV-100208 will transition to Sleeping

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

4-6

Page 23

SECTION 4

OPERATION

• Any State → Fault:

If the PV-100208 encounters a fault, regardless of operating state, it will transition to the Fault

state. The PV-100208 will remain in this state until the fault condition has been remedied and

cleared via the front panel.

A description of the fault will show on the first line of the operator interface LCD. The second line

of the LCD will read ‘Clear Fault?’. To clear a fault press <ENTER>. The PV-100208 will transition to Sleeping. If the fault does not clear, the fault condition has not been corrected. If the ‘Clear

Fault?’ message is not shown on the second line of the LCD, scroll through the read parameter

menu with the /\ or \/ keys until the message appears.

AUTO-RESTART FEATURE

In the event of a utility voltage or frequency surge or sag, which causes the inverter to shut down, the

PV-100208 will automatically transition to a fault condition. Once the utility recovers for a period of

five minutes, the PV-100208 will automatically clear the fault, then resume normal operation.

ISOLATION PROCEDURE

The following procedure should be followed to de-energize the PV-100208 for maintenance:

1. Turn the On/Off switch to the Off position.

2. Open the PV array disconnect switches.

3. Open the AC disconnect switch.

4. Open the isolation transformer circuit breaker.

5. Install lockout devices on the isolation transformer circuit breaker and PV disconnect switch.

WARNING

The terminals of the disconnect switches may be energized if the arrays are energized. In addition, allow 5 minutes for all capacitors within the main enclosure to

discharge after disconnecting the PV-100208 from AC and DC sources.

TURN-ON PROCEDURE

Refer to Section 3 for a detailed first-time turn on procedure.

1. Remove any lockout devices from the isolation transformer circuit breaker and PV disconnect

switch.

2. Close the isolation transformer circuit breaker.

3. Close the AC disconnect switch.

4. Close PV array disconnect switches.

5. Turn the On/Off switch to the On position.

After a 15 second initialization period, the PV-100208 will automatically transition to ‘Waking Up’,

given the PV voltage is greater than the PV V Start setpoint.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

4-7

Page 24

SECTION 5

TROUBLESHOOTING

GENERAL

In the event of a fault, the PV-100208 will annunciate the condition at the operator interface. The PV100208 will execute an orderly shutdown and remain faulted until the fault is cleared (manually or

automatically).

In general, the operator should respond to any PV-100208 fault as follows:

1. The source of the fault should be sought by referring to the following chart.

2. Rectify the fault condition and attempt to clear the fault by cycling the on/off switch.

3. If the problem cannot be corrected, note and write down the fault code and description, then contact

your Xantrex Technology distributor for assistance or service.

ALARM AND FAULT CONDITIONS

WARNING

Lethal energy may be stored within each matrix assembly. Use extreme caution

when troubleshooting. After disconnect all sources of power, wait at least 5 minutes

for internal capacitors to discharge.

(H) - Fault triggered by hardware.

(S) - Fault triggered by software.

0000 - No Faults

No fault conditions are detected.

002C - Matrix Over-Temperature (S)

The temperature of the matrix aluminum heat sink exceeded 85°C.

Possible causes:

• External cooling fan inoperable

• Air flow on heat sink impeded due to accumulation of debris

• Operation above rated ambient temperature for an extended period of time

002E - State Machine Failure (S)

Software has encountered an undefined state.

Attempt to clear the fault by either cycling control power or pressing the black reset button in the lower

left corner of the PCU. If the fault is sustained, replacement or service of the PCU will be necessary.

002F – Parameter Out Of Date (S)

Software has determined that the system variables within the operator interface panel do not match the

ones in the PCU. Generally this fault may be cleared and normal operation resumed.

0031 - Ground Current Fault (S)

The earth safety ground current has exceeded the maximum programmed value (Max Gnd Flt I).

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

5-1

Page 25

SECTION 5

TROUBLESHOOTING

Possible causes:

• Inspect the PV array for ground faults.

• CT3 defective: Troubleshoot the ground fault CT3, located on the power distribution panel of the

main enclosure (see system schematic drawing in Section 7), using the procedures described in fault

YY27.

0032 - PV Overvoltage (S)

The PV voltage has exceeded the maximum programmed limit (PV Max Volt).

Check the PV input voltage at the PV disconnect switch. If the voltage is below 600 VDC, clear the

alarm and restart the PV-100208.

0040 - In Programming Mode (S)

System is in reload PROM mode.

0042 - Bad Memory (S)

The static memory test failed upon system initialization. This fault is generally transient in nature.

Attempt to clear the fault by either cycling control power or pressing the black reset button in the lower

left corner of the PCU. If the fault is sustained, replacement or service of the PCU will be necessary.

0045 – Line Matrix Failure to Turn On (S)

0046 – Line Matrix Failure to Turn Off (S)

Software was not able turn on or turn off the indicated switching matrix.

Attempt to clear the fault by either cycling control power or pressing the black reset button in the lower

left corner of the PCU. If the fault is sustained, replacement or service of the PCU will be necessary.

0061 – Line AC Frequency Too Low (S)

The AC line frequency fell below the allowable limit.

This fault is self-clearing. Once the utility frequency has recovered within the acceptable operating

range, the PV-100208 will automatically clear this fault and resume normal operation after 5 minutes. If

the fault will not clear, verify the adjustable setpoint is below the actual utility frequency. If the fault is

sustained, contact your Xantrex Technology distributor for assistance or service.

0062 - Line AC Frequency Too High (S)

The AC frequency exceeded the allowable limit.

This fault is self-clearing. Once the utility frequency has recovered within the acceptable operating

range, the PV-100208 will automatically clear this fault and resume normal operation after 5 minutes. If

the fault will not clear, verify the adjustable setpoint is above the actual utility frequency. If the fault is

sustained, contact your Xantrex Technology distributor for assistance or service.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

5-2

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

Page 26

SECTION 5

TROUBLESHOOTING

0063 - AC Voltage Too Low (S)

The AC Inverter voltage fell below the minimum programmed limit (Min AC Volt).

This problem was caused by the utility. Clear the fault and restart the PV-100208.

Possible causes:

• High momentary load which forces the inverter to current limit

• Fuses F1, F2, F3, F4, F5 or F6 blown

• SSR-1 inoperable

• Contactor K1 inoperable

• Utility voltage fell below the allowable limit.

This fault is self-clearing. Once the utility voltage has recovered within the acceptable operating range,

the PV-100208 will automatically clear this fault and resume normal operation after 5 minutes. If the

fault will not clear, verify the adjustable setpoint is below the actual utility voltage. If the fault is sustained, contact your Xantrex Technology distributor for assistance or service.

0064 - AC Voltage Too High (S)

The inverter controller voltage exceeded the maximum-programmed limit (Max AC Volt).

Possible causes:

• SSR-1 inoperable

• Contactor K1 inoperable

• Utility voltage exceeded the allowable limit.

This fault is self-clearing. Once the utility voltage has recovered within the acceptable operating range,

the PV-100208 will automatically clear this fault and resume normal operation after 5 minutes. If the

fault will not clear, verify the adjustable setpoint is above the actual utility voltage. If the fault is sustained, contact your Xantrex Technology distributor for assistance or service.

012A - Interrupt Time-Out (S)

The PCU was not able to service the interrupt for approximately 1 second.

Attempt to clear the fault and restart the PV-100208 by pressing the black reset button on the lower left

corner of the PCU. If the fault is sustained, replacement or service of the PCU will be necessary.

0230 – Door Interlock Switch Open (H)

The door interlock lock switch located in the inside upper left corner of the main enclosure door is open.

If the switch is closed and the fault still registers on the front panel, isolate the PV-100208 from external

power, then:

• Verify continuity across the switch contact block while the switch is closed.

• Verify continuity between PCU-J2-5 and PCU-J3-3.

0430 - PV Auxiliary Switch Open (H)

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

5-3

Page 27

SECTION 5

TROUBLESHOOTING

The dry contact auxiliary switch mounted to the PV disconnect switch has been toggled. The auxiliary switch should be opened when the PV disc switch is open. If the fault will not clear when the PV

disconnect switch is closed:

• Isolate PV-100208 from utility power.

• Close PV disc switch and check continuity between PCU J3-3 and PCU J2-7. If there is no continu-

ity, inspect wiring between the PCU and the auxiliary switch (see page 3 of the system schematic for

further detail).

XX25 - Line Gate Drive Fault (S)

One of the IGBT gate drive boards signaled the PCU that there was a fault. The particular device at

which the fault was detected is indicated by the first two digits of the fault code, as follows:

XX: 01 = Phase A+ 02 = Phase A-

04 = Phase B+ 08 = Phase B-

10 = Phase C+ 20 = Phase CIf more than one phase faults simultaneously, the error code will contain the summation of phase fault

values. For example, if phase A+ and B+ fault simultaneously, the error will read 0525.

Make sure the fiber optics for the device and matrix in question are properly connected to the driver

board. Similarly, make sure the fiber is properly connected at the PCU.

Clear the fault and restart the PV-100208. If the fault is sustained, contact your Xantrex Technology

distributor for assistance or service.

YY27 - Line Over-Current Fault (S)

Current in one phase of the matrix has exceeded the allowable limit. The faulted phase is indicated by the

first two digits of the fault code, as follows:

YY: 01 = Phase A

02 = Phase B

04 = Phase C

If more than one phase faults simultaneously, the error code will contain the summation of phase fault

values. For example, if phase A and C fault simultaneously, the error will read 0527.

Possible causes:

• AC system wiring short: Inspect the AC power system for short circuits.

• PCU Power Supply is defective: Verify +/-15Vdc sources, referenced to analog ground, on the

PCU. There are labeled test points on the PCU circuit board. Note: There are two isolated +15Vdc

power supplies labeled +15Vdc and +15Vdc Drv. The +15Vdc Drv power supply provides power

for the matrix driver boards only.

• Faulty CT wiring: Verify the wiring between the PCU power supply and the CT is properly con-

nected and undamaged. Refer to page 3 of the system schematic in Section 7.

• CT defective: Locate the current transducer for the matrix and phase in question (see control com-

ponents drawing in Section 7). With a digital multi-meter measure the voltage from CT pins 1, 2, and

3 to chassis ground. Pins 1 and 3 should read approximately +15 and -15Vdc respectively. These

voltages are sourced directly from the PCU. Pin 2 should read less than 20mV when no current is

passing through the CT window. If Pin 2 reads greater than 20mV, and the supply voltages are on

Pins 1 and 3 are correct, the CT may be damaged.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

5-4

Page 28

SECTION 5

TROUBLESHOOTING

Clear the fault and restart the PCU. If the fault is sustained contact your Xantrex Technology distributor

for assistance or service.

0828 – PV Over-Current Fault (S)

Current through the PV CT has exceeded the allowable limit.

Possible causes:

• PV system wiring short: Inspect the PV power system for short circuits.

• PCU Power Supply is defective: Verify +/-15Vdc sources, referenced to analog ground, on the

PCU. There are labeled test points on the PCU circuit board. Note: There are two isolated +15Vdc

power supplies labeled +15Vdc and +15Vdc Drv. The +15Vdc Drv power supply provides power

for the matrix driver boards only.

• Faulty CT wiring: Verify the wiring between the PCU and the CT is properly connected and undam-

aged. Refer to the system schematic in Section 7.

• CT defective: Locate the current transducer for the PV leg in question (see control components

drawing in Section 7). With a digital multi-meter measure the voltage from CT pins 1, 2, and 3 to

chassis ground. Pins 1 and 3 should read approximately +15 and -15Vdc respectively. These voltages are sourced directly from the PCU. Pin 2 should read less than 20mV when no current is

passing through the CT window. If Pin 2 reads greater than 20mV, and the supply voltages are on

Pins 1 and 3 are correct, the CT may be damaged

Clear the fault and restart the PCU. If the fault is sustained contact your Xantrex Technology distributor

for assistance or service.

8021 - DC Bus Voltage High (H)

The DC Bus voltage has exceeded the maximum allowable limit.

This fault is generally transient in nature. Clear the fault and attempt to restart the PV-100208.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

5-5

Page 29

SECTION 6

PREVENTATIVE MAINTENANCE

PERIODIC MAINTENANCE

Xantrex Technology recommends that the following preventative maintenance be carried out on the

PV-100208:

Monthly intervals or as required:

NOTE

Visually inspect the exterior surfaces for any damage (nicks, chips, exposed base

metal and scratches). Touch up or recoat using White NISSEN Feltip Paint Marker,

or equivalent to prevent rust or corrosion.

Aluminum Extrusion Heatsink

Accumulation of dirt and debris on the aluminum extrusion heatsink and fan will decrease the

ability to transfer heat, which can cause the PV-100208 to shutdown on over-temperature alarms.

Inspect the aluminum extrusion heatsink and fan for accumulation of dirt and debris. Clean if

debris is present.

Fan Operation

Verify proper operation of the heatsink cooling fan, located above the matrix heatsink. The fan

operates when the K1 contactor is closed. Remove any debris from the fan.

Internal Circulation Fan:

Verify the internal circulation fan is operating whenever there is utility power applied to the

PV-100208.

Inductor Enclosure Cooling Fan:

Verify this fan operates whenever the PV-100208 is processing power.

Six month intervals:

(See Isolation Procedure located on page 6-2, and perform prior to the following)

Enclosure Seals

Inspect the enclosure access panel seal. If damaged, replace with equivalent closed cell foam

gasket. Call your Xantrex Technology distributor for factory replacements or specifications.

Electrical Connections

Inspect the condition of all wiring within the PV-100208. Inspect all wire crimps and connections for damage caused from high temperature. Check for corrosion. Replace any damaged

wires. Verify all mechanical connections are sufficiently tightened. Verify all conduction surfaces are clean and free of corrosion.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

6-1

Page 30

SECTION 6

PREVENTATIVE MAINTENANCE

Mechanical electrical connections will loosen over time. This is caused primarily by thermal

cycling during normal operation. As connections loosen, electrical impedance will increase at

the connection, eventually leading to fire and component damage. It is critical to check all

electrical connections every six months.

Inductor Enclosure

Access the inductor enclosure and remove any accumulated dirt and debris. Vacuum enclosure

whenever dust or dirt is present.

ISOLATION PROCEDURE

The following procedure should be followed to de-energize the PV-100208 for maintenance:

WARNING

The terminals of the PV input may be energized if the arrays are energized. In

addition, allow 5 minutes for all capacitors within the enclosure to discharge after shutting down the PV-100208.

1. Turn the on/off switch to the off position.

2. Open the PV array disconnect switch.

3. Open the AC interface disconnect switch.

4. Open the isolation transformer circuit breaker.

5. Install lockout devices on the isolation transformer circuit breaker and PV disconnect switch.

TURN-ON PROCEDURE

Refer to Section 3 for a detailed first-time turn on procedure.

1. Remove any lockout devices from the isolation transformer circuit breaker and PV disconnect

switch.

2. Close the isolation transformer circuit breaker.

3. Close the AC interface disconnect switch.

4. Close the PV array disconnect switch.

5. Turn the on/off switch to the on position.

After a 15 second initialization period and a 5 minute wake up period, the PV-100208 will automatically begin power tracking, given the PV voltage is greater than the PV start voltage setpoint.

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

6-2

Page 31

SECTION 7

APPENDIX

FAULTS CODES

Refer to section 5 for detailed fault code descriptions.

H - Fault(s) triggered by hardware

S - Fault(s) triggered by software

rorrE

edoC

)s(ecruoStluaFS/H

0000stluaFoN

C200erutarepmeT-revOxirtaM)S(

E200eruliaFenihcaMetatS)S(

F200etaDfotuOretemaraPerawtfoS)S(

1300tluaFtnerruCdnuorG)S(

2300egatloV-revOVP)S(

0400edoMgnimmargorPnI)S(

2400yromeMdaB)S(

5400nOnruToteruliaFlortnoCxirtaMeniL)S(

6400ffOnruToteruliaFlortnoCxirtaMeniL)S(

1600woLooTycneuqerFeniL)S(

READ/WRITE PARAMETER MENU

Read-Only Parameters

rorrE

edoC

2600hgiHooTycneuqerFeniL)S(

3600woLooTegatloVeniL)S(

4600hgiHooTegatloVeniL)S(

A210tuO-emiTtpurretnI)S(

0320kcolretnIrooD)H(

0340kcolBtcatnoCyrailixuAVP)H(

52XXevirDetaGxirtaMeniL)S(

72YYtnerruC-revOxirtaMeniL)S(

8280tnerruC-revOVP)S(

1208hgiHooTegatloVsuBCD)H(

)s(ecruoStluaFS/H

sretemaraPDIepyTstinUstimiLataDtluafeDsnoitpircseD

etatS

DOCUMENT: 151700

gnitarepOtnerruC

1daeRA/NA/NA/N

etatSlaoGmetsyS2daeRA/NA/NA/N

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

:setatStnerruC

gnizilitinI-0

delbasiD-yeK-1

gnipeelS-2

gnitratS-3

gnikcarT-rewoP-4

tnerruClaunaM-5

tseTxirtaM-6

detluaF-7

:setatSlaoG

nwoDtuhS-0

gnikcarT-rewoP-1

tnerruClaunaM-2

tseTxirtaM-3

7-1

Page 32

SECTION 7

APPENDIX

edoCtluaF3daeRA/NA/NA/NevobAsedoCtluaFeeS

etatSretrevnI4daeRA/NA/NA/N

sretemaraPDIepyTstinUstimiLataDtluafeDsnoitpircseD

:setatSretrevnI

nwoDtuhS-0

ybdnatS-1

gnitratS-2

gnitteS-niaM-3

eniL-nO-4

egatloVB-AeniL5daeRsmrVA/NA/NegatloVeniLoteniL

egatloVC-BeniL6daeRsmrVA/NA/NegatloVeniLoteniL

egatloVA-CeniL7daeRsmrVA/NA/NegatloVeniLoteniL

tnerruCAeniL8daeRsmrAA/NA/N

tnerruCBeniL9daeRsmrAA/NA/N

tnerruCCeniL01daeRsmrAA/NA/N

rewoPlaeRretrevnI11daeRAVkA/NA/N

xirtaMretrevnI

erutarepmeT

21daeRC°A/NA/N

etatSVP31daeRA/NA/NA/N

egatloVVP41daeRCDVA/NA/N

tnerruCVP51daeRCDAA/NA/N

rewoPVP61daeRWkA/NA/N

tnerruCtluaFdnuorG71daeRsmrAA/NA/N

:setatSVP

nwoDtuhS-0

peelS-1

puekaW-2

enilnO-3

tseT-peelS-4

DOCUMENT: 151700

ffO/nOrewoPkaeP81daeRA/NA/NA/N

ycneuqerFretrevnI91daeRzHA/NA/N

retrevnImumixaM

rewoP

02daeRAVkA/NA/N

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

nO-0

ffO-1

rewoPeniLmumixaM

UCPybdedroceR

7-2

Page 33

SECTION 7

APPENDIX

sretemaraPDIepyTstinUstimiLataDtluafeDsnoitpircseD

rewoPVPmumixaM12daeRWkA/N1:1

retrevnImumixaM

)Aesahp(tnerruC

22daeRsmrAA/N1:1

rewoPeniLmumixaM

UCPybdedroceR

tnerruCeniLmumixaM

UCPybdedroceR

tnerruCVPmumixaM

VPdednammoC

tnerruC

32daeRCDAA/N1:1

ebotelbaliavA

VPehtybdednammoC

rekcarTrewoP

egatloVCAmumixaM23etirWstloV922<V<091922

egatloVCAmuminiM33etirWstloV022<V<381381

CAmumixaM

ycneuqerF

CAmuminiM

ycneuqerF

43etirWzH

53etirWzH

5.06

5.06

tnioptestluaf

tnioptestluaf

<zH<3.95

<zH<3.95

5.06

3.95

tnioptestluaf

tnioptestluaf

egatloVCAmumixaM

egatloVCAmuminiM

ycneuqerFCAmumixaM

ycneuqerFCAmuminiM

dnuorGmumixaM

tpurretnItluaF

63etirWspmA02<I<101

feRVTPP73etirWstloV006<V<003004

tratSVVP83etirWstloV006<V<003044

tratSTVP93etirWceS0021<T<0003

potSTVP04etirWceS0021<T<002

potSPVP14etirWWk

<Wk<2.0

0.01

tnerructluafdnuorG

tnioptes

rekcarTrewoPkaeP

egatloVecnerefeR

-ekawrekcartrewopVP

egatlovpu

VProfyaledemiT

pu-ekaw

peelsVProfyaledemiT

tset

0.1

remittsetpeels

nigebottnioprewopVP

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

7-3

Page 34

SECTION 7

APPENDIX

sretemaraPDIepyTstinUstimiLataDtluafeDsnoitpircseD

%xaMTPPI24etirW% 001<%<0001

%launaMI34etirW% 001<%<052

elbanETPP44etirWA/N1ro01

etaRTPP54etirWceS0.01<T<1.05.0etaretadpurekcartrewoP

petSVTPP64etirWstloV0.01<V<00.1

WARRANTY AND CERTIFICATION

Xantrex Inverter Warranty Registration

elbawollamumixamfotnecreP

tnerrucedomrekcartrewopVP

elbawollamumixamfotnecreP

tnerrucedomlaunamVP

fI.fforonorekcartrewopsnruT

lliwrekcartrewopehtffo

ecnereferehttaegatlovetaluger

.tnioptes

ffO=0

nO=1

fopetsnoitabrutrepegatloV

rekcartrewop

Underwriters Laboratories Compliance Of Standard UL1741

DRAWINGS LIST

151667 : Schematic, System, Grid Tied PV Inverter, PV-100208

151701 : Envelope Drawing, Grid Tied Inverter, PV-100208

151702 : Enclosure, Main, Control Components, PV-100208

151703 : Enclosure, AC Interface, PV-100208

151704 : Enclosure, DC Interface, PV-100208

151708 : Transformer, 100 kVA, 3-Pole, 60 Hz, 98% Efficient, 208Y/120 or 480Y/277

DOCUMENT: 151700

PV-100208 Photovoltaic Inverter

Operation and Maintenance Manual

Copyright 2003, Xantrex Technology Inc.

7-4

Page 35

Xantrex Technology, Inc.

Distributed Power Markets

161G South Vasco Road

Livermore, CA 94550 USA

Phone +1 925.245.5400

Fax +1 925.245.1022

XANTREX PV SERIES LIMITED WARRANTY AND REGISTRATION

Xantrex Technology warrants all equipment supplied to Customer under this purchase

order against defects in workmanship and material for a period of (12) twelve months

from delivery, provided that the equipment has been operated and maintained in

accordance with the service manual provided with the equipment. Should Customer

give Xantrex written notice of any such defects within the warranty period, and

Xantrex’s inspection confirms the existence of such defects, Xantrex shall correct the

defects, either by repair or replacement, at its sole option.

For wall-mounted products (generally, below 30 kW in rating), defective products must

be returned to Xantrex or it Authorized Service Center in the original or equivalent

packaging. The cost of transportation and insurance on items returned for service is at

the Customer’s expense. Return transportation and insurance expense shall be borne by

Xantrex.

For floor mounted inverter products (generally, 30 kW in rating and above), warranty

repairs or replacements are performed at the installation site. Xantrex’s material, labor,

freight and travel/living expenses associated with such repair or replacement shall be

borne by Xantrex.

In either case, Customer’s labor and travel/living expense shall be borne by Customer.

Xantrex will assume no expense, liability or responsibility for repairs made by or for

Customer without written authority from Xantrex. Xantrex shall not be responsible for

any consequential, incidental or similar damages.

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Project Name ______________________

Customer PO # ______________________

Inverter Serial # ______________________

Delivery Date ______________________

Xantrex Authorized Signature: Customer Authorized Signature:

________________________ ________________________

________________________ ________________________

Date Date

Page 36

Page 37

D

Page 38

D

Page 39

Page 40

Page 41

Xantrex Technology Inc. PV-100208

Item #

Qty

Reference Designator

Xantrex Technology Part #

Description

Upper Enclosure

23

1

TB1

1-111238-01

Block, Terminal, Ground Bus

Lower Enclosure

27

1

TH-SW

1-151530-02

Thermostat, Disk, Snap, 157 to 169C

Qty

Reference Designator

Xantrex Technology Part #

Enclosure Door (Not Shown)

30

2-1-150326-01

Contact Block, NC

Photovoltaic Inverter

Major Parts List

Assembly Description: Main Enclosure, Control Components, PV-100208

Xantrex Technology Assembly # 151702

1 1 - 1-151572-01 Fab, Enclosure, Upper, 1 Bay, PV100208

2 1 - 1-151198-02 PCU Board

3 1 - 1-150209-01 Assy, Matrix