Page 1

PROwatt™ 600

Inverter

Owner’s Guide

Page 2

PROwatt 600 Inverter

Owner’s Guide

Page 3

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power

electronics and controls with products from 50 watt mobile units to 1 MW utilityscale systems for wind, solar, batteries, fuel cells, microturbines, and backup

power applications in both grid-connected and stand-alone systems. Xantrex

products include inverters, battery chargers, programmable power supplies, and

variable speed drives that convert, supply, control, clean, and distribute electrical

power.

Trademarks

PROwatt is a trademark of Xantrex International. Xantrex is a registered

trademark of Xantrex Technology Inc.

Other trademarks, registered trademarks, and product names are the property of

their respective owners and are used herein for identification purposes only.

Notice of Copyright

PROwatt 600 Owner’s Guide © January 2001 Xantrex International. All rights

reserved.

Disclaimer

While every precaution has been taken to ensure the accuracy of the contents of

this guide, Xantrex International assumes no responsibility for errors or

omissions. Note as well that specifications and product functionality may change

without notice.

Date and Revision

January 2001, Revision 1

Part Number

445-0115-01-01

Contact Information

Web: www.xantrex.com

Email: support.prowatt@xantrex.com

Phone: 1-800-670-0707

Fax: 1-800-994-7828

Page 4

About This Guide

Purpose

The PROwatt 600 Owner’s Guide contains information that

enables individuals to install, operate, and troubleshoot the

PROwatt 600 Inverter.

Scope

The guide provides safety guidelines, detailed information

for designing an installation, procedures for installing the

inverter, as well as operating and troubleshooting

information. It does not provide details about particular

brands of batteries. You need to consult individual battery

manufacturers for this information.

Audience

The guide is intended for anyone who needs to install and

operate the PROwatt™ 600 Inverter.

Page 5

About This Guide

Organization

This guide has four chapters and four appendixes.

Chapter 1, “Introduction”, outlines the main performance and

safety features of the PROwatt 600 Inverter. Reading this

chapter will give you a clear understanding of the inverter’s

capabilities.

Chapter 2, “Installation”, outlines the inverter’s main

physical features. This information will give you a good

orientation to the product before you install it. The chapter

then goes on to explain how to plan and complete an effective

installation.

Chapter 3, “Operation”, provides information about turning

on and operating the inverter. Details are provided about how

to read the front panel indicators to monitor the system. The

chapter also provides information about battery charging and

routine maintenance.

Chapter 4, “Troubleshooting”, explains how to identify and

solve problems that can occur with the inverter.

Appendix A, “Specifications”, provides the electrical and

physical specifications.

Appendix B, “Battery Types and Sizes”, provides

background information about battery types as well as

information that will allow you to calculate the size and

number of batteries your system requires.

Appendix C, “Alternators and Charging Systems”, describes

charging system components and explains how to design a

charging system for your installation.

Appendix D,“Product and System Information” , contains the

product’s warranty, explains how to return a product for

service, and describes how to prepare for a call to Xantrex

Customer Service.

iv

Page 6

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions that could result in

personal injury or loss of life and appear in this

form.

CAUTION

Cautions identify conditions or practices that could

result in damage to the PROwatt unit or to other

equipment.

About This Guide

Note

:

Notes describe additional information which may

add to your understanding of how to use the inverter.

Related Information

You can find more information about Xantrex

Technology Inc. as well as its products and services at

www.xantrex.com

v

Page 7

vi

Page 8

Important Safety Information

WARNING

Before installing and using your PROwatt

Inverter, read and save these safety instructions.

General Precautions

1. Before installing and using the inverter, read all

appropriate sections of this guide and any cautionary

markings on the inverter and the batteries.

2. Do not operate the inverter if it has received a sharp

blow, been dropped, or otherwise damaged. If the unit is

damaged, see “Warranty” on page 42 and “Return

Material Authorization Policy” on page 43.

3. Do not dismantle the inverter; it contains no user

serviceable parts. Attempting to service the unit yourself

could cause electrical shock or fire.

remain charged after all power is disconnected.

page 43 for instructions on obtaining service.

™

600

Internal capacitors

See

4. To reduce the risk of electrical shock, disconnect both

AC and DC power from the inverter before working on

any circuits connected to the inverter. Turning off the

front panel On/Off will not reduce this risk.

5. Protect the inverter from rain, snow, spray, and bilge

water.

6. To reduce the risk of overheating or fire, keep the

ventilation openings clear, and do not install the inverter

in a zero-clearance compartment.

vii

Page 9

Explosive Gas Precautions

Explosive Gas Precautions

1. Batteries generate explosive gases during normal

operation. Be sure you follow all relevant instructions

exactly before installing or using your inverter.

2. This equipment contains components which tend to

produce arcs or sparks. To prevent fire or explosion, do

not install the inverter in compartments containing

batteries or flammable materials or in locations that

require ignition-protected equipment. This includes any

space containing gasoline-powered machinery, fuel

tanks, as well as joints, fittings, or other connections

between components of the fuel system.

Precautions When Working With Batteries

1. Follow all instructions published by the battery

manufacturer and the manufacturer of the equipment in

which the battery is installed.

2. Make sure the area around the battery is well ventilated.

3. Never smoke or allow a spark or flame near the engine or

battery.

4. Use caution to reduce the risk of dropping a metal tool on

the battery. It could spark or short circuit the battery or

other electrical parts and could cause an explosion.

5. Remove metal items like rings, bracelets, and watches

when working with lead-acid batteries. These batteries

produce a short-circuit current high enough to weld a ring

or the like to metal, and thus cause a severe burn.

6. If you need to remove a battery, always remove the

positive terminal from the battery first. Make sure all

accessories are off so you don’t cause an arc.

viii

Page 10

Precautions For Using Rechargeable Appliances

Precautions For Using Rechargeable

Appliances

Most battery-operated equipment uses a separate charger or

transformer that is plugged into an AC receptacle and

produces a low voltage output. If the label on the AC adapter

or charger states that the adapter or charger produces a low

voltage AC or DC output (less than 30 volts), the PROwatt

can power this charger or adapter safely.

Some rechargers for small nickel-cadmium batteries can be

damaged if connected to the PROwatt 600 Inverter. Do not

use the following with the PROwatt 600 Inverter:

• Small battery-operated appliances like flashlights, razors,

and night lights that can be plugged directly into an AC

receptacle to recharge

• Chargers for battery packs used in hand power tools.

These chargers display a warning label stating that

dangerous voltages are present at the battery terminals

AC Wiring Warning

Do not connect the PROwatt 600 Inverter to AC distribution

wiring.

The PROwatt is designed to be connected directly to standard

electrical and electronic equipment. Do not connect it to

household or recreational vehicle AC distribution wiring. Do

not connect it to any AC load circuit in which the neutral

conductor is connected to ground (earth) or to the negative of

the DC (battery) source. Doing so will destroy the unit.

ix

Page 11

x

Page 12

Contents

General Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

Explosive Gas Precautions - - - - - - - - - - - - - - - - - - - - - - - - - viii

Precautions When Working With Batteries - - - - - - - - - - - - - - viii

Precautions For Using Rechargeable Appliances - - - - - - - - - - - ix

AC Wiring Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ix

1Introduction

Quality Power and Ease of Use - - - - - - - - - - - - - - - - - - - - - - - - 2

Comprehensive Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

2 Installation

AC Wiring Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Safety Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

PROwatt 600 Materials- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Front Panel (AC End) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Back Panel (DC End) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Installation Tools and Materials - - - - - - - - - - - - - - - - - - - - - - - - 6

Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Planning Your Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Calculating Battery Requirements - - - - - - - - - - - - - - - - - - - - - 7

Choosing a Charging System - - - - - - - - - - - - - - - - - - - - - - - - 7

Choosing a Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Mounting the Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

xi

Page 13

Contents

Connecting the Chassis Ground - - - - - - - - - - - - - - - - - - - - - - - - 9

Grounding Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Connecting DC Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Cabling Guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Cabling Procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

3Operation

Turning the Inverter On and Off- - - - - - - - - - - - - - - - - - - - - - - 16

Operating Several Loads at Once - - - - - - - - - - - - - - - - - - - - - - 16

Turning the Inverter Off Between Charges- - - - - - - - - - - - - - - - 16

Reading the Front Panel Indicators - - - - - - - - - - - - - - - - - - - - - 17

Green POWER LED - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Red FAULT LED - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Operating Limits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Power Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Input Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Inverter Loads- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Problem Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Trouble Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Battery Charging Frequency - - - - - - - - - - - - - - - - - - - - - - - - - 20

Routine Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

4 Troubleshooting

Common Problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Buzz in Audio Equipment - - - - - - - - - - - - - - - - - - - - - - - - - 22

Television Reception - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Troubleshooting Reference - - - - - - - - - - - - - - - - - - - - - - - - - - 23

A

Specifications

Electrical Performance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

Physical - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

B

Battery Types and Sizes

Battery Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

xii

Page 14

Automotive Starting Batteries - - - - - - - - - - - - - - - - - - - - - - - 28

Deep-Cycle Lead-Acid Batteries - - - - - - - - - - - - - - - - - - - - - 29

Battery Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Estimating Battery Requirements - - - - - - - - - - - - - - - - - - - - - - 31

Battery Sizing Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Battery Sizing Worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

Two Batteries Connected In Parallel- - - - - - - - - - - - - - - - - - - - 34

Battery Tips - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

C

Alternators and Charging Systems

Charging System Requirements - - - - - - - - - - - - - - - - - - - - - - - 38

Charging With an Engine Alternator - - - - - - - - - - - - - - - - - - - - 38

Using Your Vehicle’s Standard Engine Alternator - - - - - - - - - 38

Using an Alternator Controller - - - - - - - - - - - - - - - - - - - - - - 39

Contents

Using a High-Output Alternator - - - - - - - - - - - - - - - - - - - - - 39

Charging From AC Power- - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Charging From Alternative Energy Sources - - - - - - - - - - - - - - - 40

D

Product and System Information

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Return Material Authorization Policy - - - - - - - - - - - - - - - - - - - 43

Return Material Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Information About Your System - - - - - - - - - - - - - - - - - - - - - - 45

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

xiii

Page 15

xiv

Page 16

1

Introduction

Congratulations on your purchase of the

PROwatt™ 600 Inverter! As part of the

PROwatt Inverter family, the PROwatt 600

has been designed to give you quality power,

ease of use, and outstanding reliability.

Please take a few moments to read this

chapter to familiarize yourself with the

PROwatt 600’s main performance and

protection features.

Page 17

Quality Power and Ease of Use

Quality Power and Ease of Use

The PROwatt 600 Inverter is a professional-quality, midrange inverter designed to handle a variety of household and

commercial applications including large screen TVs, VCRs,

computer systems, bread makers, blenders, fans, and small

power tools.

Superior features and rugged durability have been combined

with extreme ease of use:

• The unit is compact, light weight, and easy to install.

• The easy-to-read indicators on the front panel.

• Low standby battery demand means you don’t have to

worry about draining your battery if you leave the

inverter on for a few days. When the inverter is on but is

not powering any loads, the draw on the battery is less

than 300mA.

Comprehensive Protection

The PROwatt 600 Inverter comes equipped with numerous

protection features to guarantee you safe and worry-free

operation:

Low battery alarm

discharged to 10.7V or lower.

Automatic low voltage shutdown feature

from becoming completely discharged if the battery voltage

drops below 10V.

High voltage shutdown feature

input voltage rises to 15V or more.

Over temperature shutdown feature

the temperature rises above an acceptable level.

Alerts you if the battery has become

Protects the inverter if the

Protects the battery

Turns the inverter off if

2

Page 18

2

Installation

Chapter 2 explains how to install the

PROwatt 600 Inverter.

Installing the PROwatt 600 is

straightforward. Here’s a summary of the

five main steps:

• Plan the installation.

• Choose a location.

• Mount the inverter.

• Connect the chassis ground.

• Connect the DC cables.

Remember: the better your planning, the

better the performance you will receive from

the PROwatt 600 Inverter.

3

Page 19

AC Wiring Warning

AC Wiring Warning

WARNING

Do not connect the PROwatt 600 Inverter to AC

distribution wiring.

The PROwatt is designed to be connected directly to standard

electrical and electronic equipment. Do not connect it to

household or recreational vehicle AC distribution wiring. Do

not connect it to any AC load circuit in which the neutral

conductor is connected to ground (earth) or to the negative of

the DC (battery) source. Doing so will destroy the unit.

Safety Instructions

Before you install the PROwatt 600:

• Review the “Important Safety Information” on page vii.

• Read and follow all Warnings and Cautions in this

chapter.

PROwatt 600 Materials

Your PROwatt 600 Inverter package includes:

• 1 PROwatt 600 Inverter

• 1 Owner’s Guide

If either of these items is missing or is unsatisfactory in any

way, please contact Xantrex Customer Service:

Phone:

Fax:

Email:

1-800-670-0707

1-800-994-7828

support.prowatt@xantrex.com

As soon as you unpack your inverter, be sure to record the

product information asked for on page 45. Then take a minute

to familiarize yourself with the front and back panel features.

4

Page 20

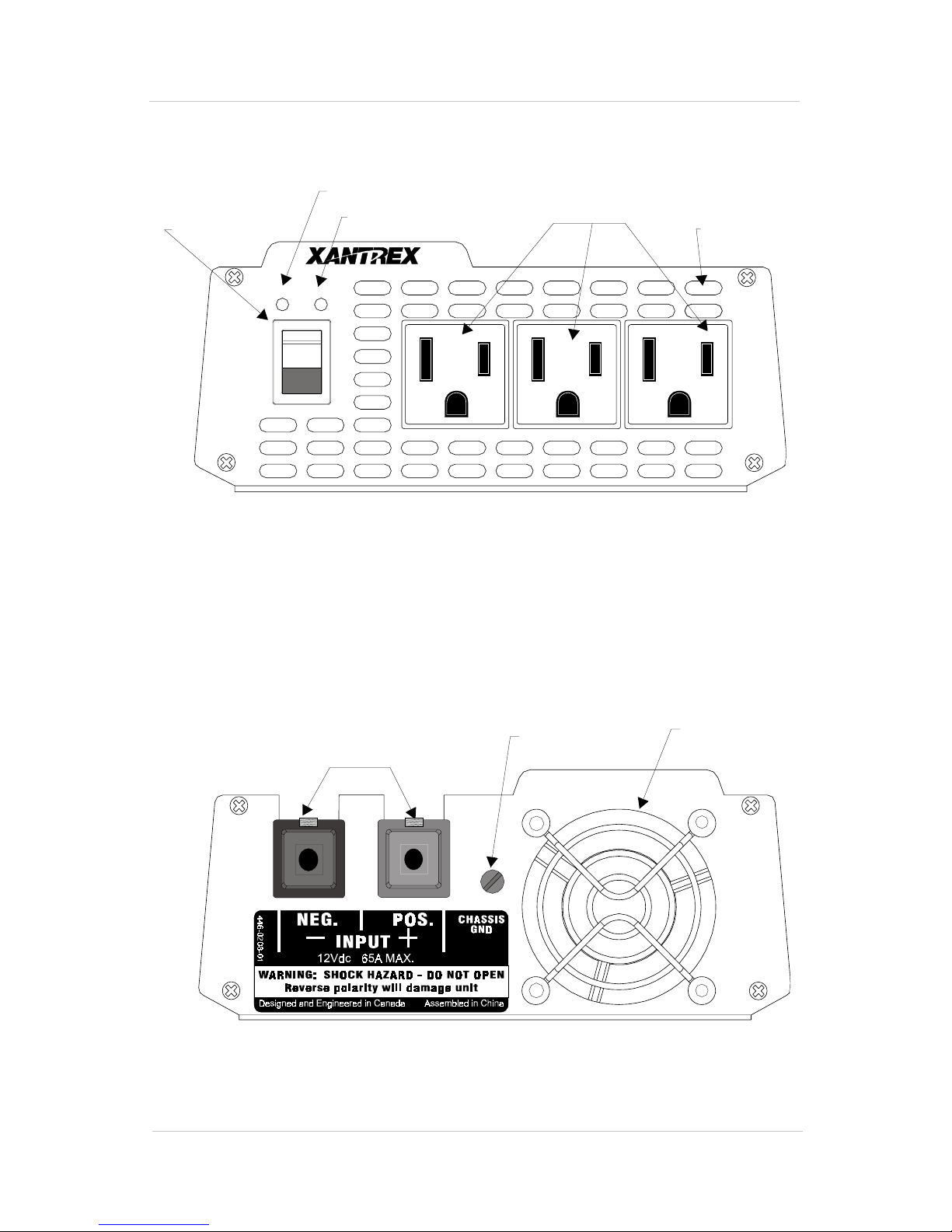

Front Panel (AC End)

Front Panel (AC End)

POWER LED

On/Off Switch

POWER

ON

OFF

FAULT LED

FAULT

Figure 1 Front Panel (AC End)

AC Power Receptacles

Ventilation

Openings

OUTPUT

115Vac

60Hz

Back Panel (DC End)

Negative and Positive

DC Cabling Terminals

Figure 2 Back Panel (DC End)

Chassis Ground

Screw

Ventilation

Openings

5

Page 21

Installation Tools and Materials

Installation Tools and Materials

Tools

❐

Wire stripper

❐

Slot head screwdriver

❐

Wrench(es) for DC terminals

❐

Drill

Materials

❐

4 corrosion-resistant fasteners sized #10 or larger for

mounting the inverter

❐

Copper DC cable sized appropriately for your installation

❐

Lugs and terminals for the DC cables as well as

appropriate tools (e.g. crimping tool). (You may find it

convenient to have the crimp connectors attached by the

company that sells you the cable.)

❐

DC fuse(s) Bussman ANL-80 or a Gould type A3T80

Class T fuse with fuse holder

❐

Appropriately sized copper cable for the chassis ground

❐

Battery isolator

❐

Alternator controller*

❐

High-output alternator*

* Consult Appendix B and Appendix C to determine whether

you need these components.

6

Page 22

Planning Your Installation

Before doing anything else, you need to determine how you

will be using your PROwatt 600 and on the basis of that,

design a power system that will give the best performance.

The more thorough your planning, the better your power

needs will be met. In particular, you need to:

• Calculate your battery requirements

• Choose an effective charging system

Calculating Battery Requirements

Battery type and size strongly affect performance of the

PROwatt 600. Therefore, you must identify the type of loads

your inverter will be powering. Once you know how much

power you will be using, you can determine how much

battery capacity you need. Xantrex recommends that you

purchase as much battery capacity as possible.

Planning Your Installation

Consult Appendix B “Battery Types and Sizes” on page 27

for a detailed explanation of how to determine the appropriate

number and size of batteries for your installation.

CAUTION

The PROwatt 600 must only be connected to a

battery that has a nominal output of 12 volts. It will

not operate when connected to a 6 volt battery and

will be damaged if connected to a 24 volt battery.

Choosing a Charging System

Your charging system must be appropriate for your inverter

installation. This will ensure that power is available when

you need it and that your batteries remain in top condition.

Inadequate charging will degrade system performance, and

the wrong type of charger will reduce battery life.

Consult Appendix C “Alternators and Charging Systems” on

page 37 for information that will explain how to design an

effective charging system.

7

Page 23

Choosing a Location

Choosing a Location

WARNING

The PROwatt 600 contains components that tend to

produce arcs or sparks. To prevent fire or explosion,

do not install the PROwatt in compartments

containing batteries or flammable materials or in

locations that require ignition-protected equipment.

WARNING

To reduce the risk of fire, do not cover or obstruct the

ventilation openings. Do not install the PROwatt 600

in a zero-clearance compartment. Overheating may

result.

The PROwatt 600 Inverter should only be installed in a

location that meets these requirements:

Dry

Cool

Ven ti lat ed

Safe

Close to

battery

Protected

from battery

gases

Do not allow water or other liquids to drop or splash

on the PROwatt 600.

Ambient air temperature should be between 32º F

and 105º F (0º C and 40º C)—the cooler the better

within this range.

Leave at least 2 inches (5 cm) clearance around the

PROwatt 600 for air flow. Ensure that ventilation

openings at the front and rear are not obstructed.

Do not install the inverter in the same compartment

as batteries or in any compartment capable of storing

flammable liquids like gasoline.

DC cables must be shorter than 4 feet (1.2 m) each.

Longer AC wires are preferable to longer DC wires.

Do not mount the inverter where it will be exposed to

battery gases. These are very corrosive, and

prolonged exposure will damage the inverter.

8

Page 24

Mounting the Inverter

To mount the PROwatt 600 Inverter:

1. Turn off the inverter’s On/Off switch.

2. Select an appropriate mounting location and orientation.

The PROwatt must be oriented in one of these two ways:

• Horizontally on a vertical surface. (The ventilation

openings must not point up or down.)

• On or under a horizontal surface

3. Mark the positions of the four mounting screws, and

pilot-drill the mounting holes.

4. Fasten the inverter using corrosion-resistant hardware

sized #10 or larger.

Mounting the Inverter

Connecting the Chassis Ground

WARNING: Electrical Shock Hazard

Never operate the PROwatt 600 without

connecting the chassis to ground. Electrical shock

hazard could result.

This inverter does not provide isolation between

the DC and AC circuits. Therefore the AC line and

neutral are both “hot” relative to battery negative.

The ground pins of the AC output receptacles are

connected to the battery negative as is the chassis

of the inverter.

The PROwatt 600 has a screw terminal labeled

GND

used to connect the inverter’s chassis to the ground. To

connect the chassis to ground, follow the guidelines below.

on the rear panel as shown in Figure 1. This is to be

CHASSIS

9

Page 25

Connecting DC Cables

Grounding Locations

The chassis ground terminal must be connected to a

grounding point, which varies depending on where you

install the PROwatt 600. Follow the guidelines that

correspond to your type of installation.

Vehicle

Connect the

CHASSIS GND

chassis using 8 AWG copper wire (preferably with green/

yellow insulation).

Marine

Connect the

CHASSIS GND

grounding bus or the engine’s negative bus using 6 AWG

copper wire that has insulation rated at 90º C.

Fixed Location

CHASSIS GND

(residential, for example). Connect the

screw to your system’s DC grounding point

using 6 AWG wire. The system’s grounding point will

usually be the AC service entrance grounding point or a

separate ground rod. For a solar PV (photovoltaic)

installation, this is usually the same ground rod used to

ground the PV array.

Connecting DC Cables

screw to the vehicle’s

screw to the boat’s DC

Proper cables and wiring are essential to effective operation

of the PROwatt 600. Because the PROwatt 600 has a low

voltage, high current input, low-resistance wiring between

the battery and the inverter is essential to deliver the

maximum amount of usable energy to your load.

Cabling Guidelines

Deviating from these guidelines will cause excessive voltage

drop or melting of the cable and/or connectors. The inverter

may also shut down or fail to operate some loads.

• Make sure each cable between the inverter and the

battery is no longer than 4 feet (1.2 m).

• Use 4 AWG copper (90º C insulation rating).

10

Page 26

• Do not use aluminum. It has about 1/3 more resistance

than copper cable of the same size, and it is difficult to

make good, low-resistance connections to aluminum.

Cabling Procedure

Follow the procedure given below and consult Figure 3 and

Figure 4 for details that are specific to your installation.

ISO L AT OR

GROUND TO

VEHICLE

CHASSIS

Connecting DC Cables

FROM ALTERNATO R

OR CHARGER

TO DC

LOADS

PROwatt

FUSE O R

CIRCUIT

BREAKER

GROUND TO

VEHICLE

CHASSIS

600

DEEP-CYCLE

FUSE OR

CIRCUIT

BREAKER

AUXILIARY

BATTERY

Figure 3 Installation for Normal Loads

VEHICLE

STARTING

BATTERY

TO VEHICLE

GROUND TO

VEHICLE

CHASSIS

11

Page 27

Connecting DC Cables

FRO M A LTE RNATOR

OR CHARGER

IS OLATO R

TO DC

LOADS

FUSE OR

CIRCUIT

BREA KER

PROwatt

DEEP-CYCLE

DEEP-CYCLE

FUSE OR

CIRCUIT

BREAKER

AUXILIARY

BATTERY

AUXILIARY

BATTERY

GROUND TO

VEHICLE

CHASSIS

600

GROUND TO

VEHICLE

CHASSIS

VEHICLE

STARTING

BATTERY

TO VEHICLE

GROUND TO

VEHICLE

CHASSIS

Figure 4 Installation for Heavy Loads

Cabling Procedure

To connect the DC cables:

1. Cut the cables to the correct length.

2. Strip the appropriate amount of insulation from one end

of each cable and attach the connectors that will join the

cables to the battery, battery isolator switch, or fuse

block. The connectors you use must create a permanent,

low-resistance connection.

12

Page 28

Connecting DC Cables

If you are using crimp connectors, use the tool

recommended by the terminal manufacturer. Make sure

no stray wires protrude from the terminal. (You can also

have the crimp connectors attached by the company that

sells you the cable.)

3. Strip about 1/2 inch (1.25cm) from the ends of the cables

that will be connected to the inverter.

4. Install a fuse and fuse holder in the cable that will be used

for the positive side of the DC circuit. The fuse must be

as close to the battery as possible, must be rated for DC

circuits, rated 80A max, and have a short-circuit interrupt

rating that exceeds the short-circuit current available

from the battery.

Xantrex recommends a Bussman ANL-80 fuse or a

Gould type A3T80 Class T fuse, or equivalent for

installations requiring a “code fuse”.

5. Insert the stripped ends of the cables into the cabling

terminals on the rear of the inverter and tighten the

screws securely. The red terminal is positive (+); the

black terminal is negative (–). See Figure 2.

6. Attach the connector on the negative cable to the

negative battery terminal. Make a secure connection.

Loose connectors cause excessive voltage drop and may

cause overheated wires and melted insulation.

CAUTION: Reverse Polarity

Power connections to the PROwatt 600 must be

positive to positive and negative to negative.

A reverse polarity connection (positive to negative)

will blow a fuse in the inverter and may cause

permanent damage. Your warranty does not cover

damage caused by a reverse polarity connection.

13

Page 29

Connecting DC Cables

7. Before proceeding, make sure that the cable you have just

installed connects the negative terminal of the inverter to

the negative terminal of the battery.

8. Connect the cable from the positive (red) terminal of the

PROwatt 600 to the positive terminal of the battery.

This is the last cable connection. A spark is normal when

you make it.

9. If you have installed a battery selector switch, use it to

select one of the batteries.

WARNING: Explosion or Fire

Do not complete the next step if flammable fumes

are present. Explosion or fire may result.

Thoroughly ventilate the battery compartment

before making this connection.

10. Turn on the inverter’s On/Off switch.

11. Check the inverter’s front panel. The

should be on. If it is not, or if the

POWER

FAULT

indicator is on,

check your battery and the connections to the inverter.

indicator

14

Page 30

3

Operation

Chapter 3

PROwatt 600 Inverter efficiently.

Specifically, this chapter:

• Explains how to turn the inverter on

• Describes operating limits

• Provides information about routine

maintenance

• Discusses optimal battery charging

frequency

tells you how to operate the

15

Page 31

Turning the Inverter On and Off

Turning the Inverter On and Off

The On/Off switch on the front panel turns the control circuit

in the PROwatt 600 on and off.

To turn the inverter on or off:

• Turn the On/Off switch or off.

CAUTION

The inverter’s On/Off switch does not disconnect

power from the PROwatt.

When the switch is Off, the inverter draws no current from

the battery.

Operating Several Loads at Once

If you are going to operate several loads from the

PROwatt 600, turn them on separately after you have turned

the inverter on. This will ensure that the inverter does not

have to deliver the starting current for all the loads at once.

Turning the Inverter Off Between Charges

When the switch is on but no power is being supplied to a

load, the inverter draws less than 300 mA from the battery.

This is a low current draw. It would take more than a week to

discharge a 100 Ah battery at this current, so you don’t have

to worry about excessive drain on your battery if you leave

the inverter switched on for a few days.

If you are not planning to recharge your battery within a week

or so, turn the inverter off.

16

Page 32

Reading the Front Panel Indicators

Reading the Front Panel Indicators

Green POWER LED

The

POWER

power and the inverter is switched On.

Red FAULT LED

The

FAULT

Condition Cause / Action

Over Temperature

Shutdown

LED is on when the inverter is connected to DC

LED comes on for one of the following reasons:

The PROwatt 600 has overheated and shut

down. The inverter may have overheated

because it was operated at power levels

above its 600W continuous output rating or

because it was installed in a location that

does not allow it to dissipate heat properly.

Turn the inverter off and then back on after

it has cooled down.

Note:

any loads, and leave the switch on to keep

the fan running.

To cool the inverter quickly, remove

Overload Shutdown A severe overload has caused the

PROwatt 600 to shut down.

Turn it off for 4–5 seconds, correct the fault

condition, and turn it back on. Do not turn

the inverter on again unless you have

corrected the fault condition (removed the

load or unplugged it).

Low Voltage

Shutdown

High Voltage

Shutdown

The supply voltage (battery) has dropped

below 10 V.

The supply voltage (battery) has exceeded

15 V.

See “Troubleshooting Reference” on page 23 for further

details about the

FAULT

LED.

17

Page 33

Operating Limits

Operating Limits

Power Output

The PROwatt 600 Inverter will deliver 600W or 5A

continuously. This wattage rating applies to resistive loads

such as incandescent lights while the current rating applies to

reactive loads such as motors.

Input Voltage

The input voltage limits are shown in the following table.

Operating

Condition Voltage Range Comment

Normal 10 V–15 V

Peak Performance 12 V–14 V

Low Voltage Alarm At or below 10.7 V The audible low battery alarm sounds

Low Voltage Shut

Down

High Voltage Shut

Down

FAULT

and

Less than 10 V The inverter shuts down to protect the

battery from being over-discharged.

It will not restart unless the input

voltage exceeds 10 V and the unit is

manually reset. You manually reset

the unit by turning it off for 4–5

seconds and then turning it back on.

At or above 15 V The inverter shuts down to protect

itself from excessive input voltage.

FAULT

The

Note:

incorporates over-voltage protection,

it can still be damaged if input

voltage exceeds 16 V.

indicator comes on.

indicator comes on.

Although the PROwatt 600

18

The unit will not restart unless the

input voltage is less than 15 V and the

unit is manually reset. You manually

reset the unit by turning it off for 4–5

seconds and then turning it back on.

Page 34

Inverter Loads

The PROwatt 600 will operate most AC loads within its

power rating (600 watts / 5 amps). However, some appliances

and equipment may be difficult to operate, and other

appliances may actually be damaged if you try to operate

them with the PROwatt 600. Please read “Problem Loads”

and “Trouble Loads” carefully.

Problem Loads

Som e indu ction m otors used in freezers, pum ps, an d other

motor-operated equipm ent need high surge currents to start.

The PROwatt 600 may not be able to start some of these

m otors even though their rated current draw is w ithin the

PR O w att’s lim its. The P R O w att 600 w ill norm ally start

single-phase induction motors rated at 1/4 horsepower or less.

Inverter Loads

Trouble Loads

Some appliances, including the types listed below, may be

damaged if they are connected to the PROwatt 600:

• Electronics that modulate RF (radio frequency) signals

on the AC line will not work and may be damaged.

• Speed controllers found in some fans, kitchen appliances,

and other loads may be damaged.

• Some rechargers for small nickel-cadmium batteries can

be damaged if connected to the PROwatt 600. See

“Precautions For Using Rechargeable Appliances” on

page ix for further details.

CAUTION

Some equipment may be damaged by the

PROwatt 600’s quasi-square wave output.

If you are unsure about powering any device with the

PROwatt 600, contact the manufacturer of the device.

19

Page 35

Battery Charging Frequency

Battery Charging Frequency

When possible, recharge your batteries when they are about

50% discharged or earlier. This will give you a much longer

battery cycle life than recharging when the batteries are

almost completely discharged.

Routine Maintenance

Minimal maintenance is required to keep your PROwatt 600

operating properly. Periodically you should:

• Clean the exterior of the unit with a damp cloth to

prevent the accumulation of dust and dirt

• Tighten the screws on the DC input terminals

20

Page 36

4

Troubleshooting

Chapter 4

most problems that can occur with the

PROwatt 600 Inverter.

If a problem occurs, please review this

chapter before contacting Xantrex Customer

Service.

If you cannot solve a problem and need to

contact Xantrex, record the information that

is asked for in

System” on page 4545

Customer Service Representatives give you

better service.

will help you identify the source of

“Information About Your

. This will help our

21

Page 37

Common Problems

Common Problems

WARNING

Do not dismantle the PROwatt 600 Inverter. It does

not contain any user-serviceable parts. Attempting

to service the unit yourself could result in an

electrical shock or burn.

Buzz in Audio Equipment

Some inexpensive stereo systems emit a buzzing noise from

their loudspeakers when operated from the PROwatt 600.

This occurs because the power supply in the audio system

does not adequately filter the modified sine wave produced

by the PROwatt. The only solution is to use a sound system

that has a higher quality power supply.

Television Reception

When the PROwatt 600 is operating, it can interfere with

television reception on some channels. If interference occurs,

try the following:

1. Make sure the chassis ground screw on the rear of the

PROwatt is solidly connected to the ground system of

your vehicle, boat, or home.

2. Make sure that the television antenna provides an

adequate (“snow-free”) signal and that you are using

good quality cable between the antenna and the

television.

3. Keep the cables between the battery and the PROwatt as

short as possible and twist them together with two to

three twists per foot. (This minimizes radiated

interference from the cables.)

4. Move the television as far away from the PROwatt as

possible.

5. Do not operate high power loads with the PROwatt while

the television is on.

22

Page 38

Troubleshooting Reference

Troubleshooting Reference

Problem Possible Cause Solution

Low output voltage

(96 Vac–104 Vac)

Load runs for a few

seconds and then

FAULT

indicator lights.

No output voltage, alarm

sounding, and

FAULT

indicator on.

No output voltage;

neither indicator on.

You are using a

voltmeter that cannot

Use a true RMS reading

voltmeter.

accurately read the

RMS voltage of a

modified sine wave.

Overload Reduce the load.

Low input voltage Recharge battery; check

connections and cable.

The inverter is off.

No power to the

inverter.

Inverter fuse open.

Turn the inverter on.

Check wiring to inverter.

Have a qualified technician

check and replace the fuse

if necessary.

Reverse DC polarity.

Have a service technician

check and replace the fuse,

making sure to observe

correct polarity.

No output voltage and

FAULT

indicator is on.

Low battery alarm stays

on; load ran for short

time.

No output voltage;

FAULT

indicator on;

load exceeds 600 W/5 A

output. Unit hot to touch.

No output voltage and

FAULT

indicator is on.

High input voltage. Make sure the PROwatt is

connected to a 12 V battery.

Check voltage regulation of

the charging system.

Poor DC wiring; poor

battery condition.

Use proper cable and make

solid connections. Install a

new battery.

Thermal shutdown. Allow the unit to cool off.

Reduce the load if

continuous operation is

required.

Improve ventilation. Make

sure ventilation openings

are not obstructed. Reduce

ambient temperature.

Short circuit.

Check AC wiring for short

circuit.

Very high power load.

Remove the load.

23

Page 39

24

Page 40

A

Specifications

Appendix A contains electrical and physical

specifications for the PROwatt 600 Inverter.

25

Page 41

Electrical Performance

Electrical Performance

Output power at 20º C ambient

and 12 Vdc input:

• Continuous power

• Surge power

Output voltage 115 Vac RMS ±10%

Output waveform Modified sine wave (quasi-

Output frequency 60 Hz ±4 Hz

Input voltage 10 Vdc–15 Vdc

Low battery alarm Audible, 10.7 V

Low battery shutdown 10 V

600 W

1200 W

square wave)

High battery shutdown 15 V

Optimum efficiency 90%

No load current draw ≤0.3 A

Physical

Length 11” (28 cm)

Width 6.25” (16 cm)

Height 2.5” (6.5 cm)

Weight 4.1lb. (2 kg)

Specifications are subject to change without notice.

26

Page 42

B

Battery Types

and Sizes

The batteries you use strongly affect the

performance of the PROwatt 600 Inverter. It

is important to connect the inverter to the

correct size and type of battery.

The information in Appendix B will help

you select, connect, and maintain batteries

that are most appropriate for your

application.

27

Page 43

Battery Types

Battery Types

Automotive Starting Batteries

Purpose

The lead-acid battery you are most familiar with is probably

the starting battery in your automobile. An automotive

starting battery is designed to deliver a large amount of

current for a short period of time (so it can start your engine).

Only a small portion of the battery’s capacity is used to start

the engine, and it is quickly recharged by the running engine.

This type of battery is not designed for repeated cycles where

the battery is almost completely discharged and then

recharged. If it is used in this kind of deep discharge service,

it will wear out rapidly.

Light Loads

If your installation uses relatively low power loads (that is,

power consumption of 300 W or less) and relatively short

operating times before recharging (one hour or less), you can

connect the PROwatt 600 directly to the vehicle starting

battery. See Figure 5.

28

GROUND TO

VEHICLE

CHAS SIS

VEHICLE

STARTING

BATTERY

FROM

ALTERNATOR

PROwatt

GROUND TO

VEHICLE

CHAS SIS

600

FUSE OR

CIRCUIT

BREA KER

Figure 5 Battery Connection for Light Loads

Page 44

Deep-Cycle Lead-Acid Batteries

Purpose

Deep-cycle lead-acid batteries are designed for deep

discharge service where they will be repeatedly discharged

and recharged. They are marketed for use in recreational

vehicles, boats, and electric golf carts—so you may see them

referred to as RV batteries, marine batteries, or golf cart

batteries.

Average and Heavier Loads

For most applications of the PROwatt 600 Inverter, Xantrex

recommends that you use one or more deep-cycle batteries

that are separated from the vehicle’s starting battery by a

battery isolator.

A battery isolator is a solid-state electronic circuit that allows

equipment to be operated from an auxiliary battery without

danger of discharging the vehicle’s starting battery. During

vehicle operation, the battery isolator automatically directs

the charge from the alternator to the battery requiring the

charge. Figure 6 shows a battery isolator.

Battery Size

Battery isolators are available at marine and RV dealers and

most auto parts stores.

Battery Size

CAUTION

The PROwatt 600 must only be connected to

batteries with a nominal output voltage of 12 volts.

The PROwatt 600 will not operate from a 6 volt

battery and will be damaged if connected to a 24

volt battery.

Importance of Battery Size

Battery size or capacity is as important as the battery type

you use.

29

Page 45

Battery Size

Battery Capacity Standards

A number of different standards are used to rate battery

energy storage capacity. Automotive and marine starting

batteries are normally rated in cranking amps. This is not a

relevant rating for continuous loads like an inverter. Deepcycle batteries use a more suitable rating system, either

“amp-hours” (“Ah”) or “reserve capacity” in minutes.

Battery Reserve Capacity

Battery reserve capacity is a

measure of how long a battery can deliver a certain amount of

current—usually 25 amps. For example, a battery with a

reserve capacity of 180 minutes can deliver 25 amps for 180

minutes before it is completely discharged.

Amp-hour (Ah) Capacity

Amp-hour capacity is a measure

of how many amps a battery can deliver for a specified length

of time—usually 20 hours. For example, a typical marine or

RV battery rated for 100Ah can deliver 5 amps for 20 hours

(5 A x 20 hours = 100 Ah).

Actual Battery Capacity

Actual battery capacity decreases

as discharge current increases. A battery rated at 100Ah

which can deliver 5 A for 20 hours may deliver 20 A for only

4 hours, resulting in an actual capacity of 80 Ah. For this

reason, it is difficult to compare rated Ah capacity with

battery reserve capacity. For example, a battery with a reserve

capacity of 180 minutes has the following calculated Ah

capacity:

180 minutes

However its actual Ah rating will be closer to 100 because it

is rated at the discharge current required to get 20 hours of

operation (about 5 A).

To calculate the battery capacity you require, read

“Estimating Battery Requirements” on page 31 and “Battery

Sizing Example” on page 32, and then complete the “Battery

Sizing Worksheet” on page 33.

30

60 = 3 hours x 25 A = 75 Ah

÷

Page 46

Estimating Battery Requirements

Estimating Battery Requirements

To determine the battery capacity you require:

1. Determine how many watts are consumed by each

appliance that you will be operating from the

PROwatt 600. You can normally find this on a label on

the product. If only the current draw is given, multiply it

by 115 to get the power consumption in watts.

2. Estimate how many hours each appliance will be

operating each day.

3. Calculate the daily watt-hours needed for each appliance.

4. Add the total number of watt-hours needed for all the

appliances and multiply it by the number of days between

charges.

5. Divide the total watt-hours of AC load between charges

by 10. This gives the battery Ah used between charges.

6. Double the total Ah used between charges to get the

recommended battery size in Ah.

See the battery sizing example that follows.

31

Page 47

Battery Sizing Example

Battery Sizing Example

This example illustrates a typical calculation, assuming an

opportunity to charge the batteries every three days.

Daily watt-hours

needed for this

(A) Power

Appliance

TV & VCR 115 W 3 hours 345 Wh

Sewing machine 150 W 1 hour 150 Wh

Bread maker 600 W 1 1/2 hour 900 Wh

Blender 300 W 15 min = 1/4 hour 75 Wh

Consumption

Total Daily watt-hours of AC load 1470 Wh

(B) Operating

Time per Day

appliance

(= A x B)

x Number of Days between charges 3

= Total watt-hours of AC load between charges 4410 Wh

Battery Ah used between charges (divide by 10) 441 Ah

Recommended Battery Bank Size in Ah (multiply by 2) 882 Ah

This example illustrates how quickly your battery needs can

escalate. To reduce the required battery size, you can

conserve energy by eliminating or reducing the use of some

loads or re-charge more frequently.

When sizing your battery, resist the temptation to skip the last

step of this calculation (multiplying by 2). More capacity is

better since you will have more reserve capacity, be better

able to handle large loads and surge loads, and your battery

won't be discharged as deeply. Battery life is directly

dependent on how deeply the battery is discharged. The

deeper the discharge, the shorter the battery life.

32

Page 48

Battery Sizing Worksheet

Use the following worksheet to calculate your battery needs.

To ensure sufficient battery capacity, be generous when

estimating the operating time per day for each of the loads

you will run.

(A)

Appliance

Power

Consumption

Operating Time

per day

W hours Wh

W hours Wh

W hours Wh

(B)

Battery Sizing Worksheet

Daily watt-

hours needed

for this

appliance

(= A x B)

W hours Wh

W hours Wh

W hours Wh

W hours Wh

W hours Wh

Total Daily watt-hours of AC load Wh

x Number of Days between charges

= Total watt-hours of AC load between charges Wh

Battery Ah used between charges (divide by 10) Ah

Recommended Battery Bank Size in Ah (multiply by 2) Ah

As your power requirements increase, you may need to use

more than one battery to obtain sufficient capacity. Read

“Two Batteries Connected In Parallel” to determine whether

two batteries are appropriate for the applications you intend

to power.

33

Page 49

Two Batteries Connected In Parallel

Two Batteries Connected In Parallel

Two identical batteries can be connected positive (+) to

positive (+) and negative (–) to negative (–) in a parallel

system. A parallel system doubles capacity and maintains the

voltage of a single battery. Figure 6 shows two batteries

connected in parallel.

CAUTION

Do not make a parallel connection between

batteries made by different manufacturers,

different types of batteries, or batteries that have

different Ah ratings. Decreased battery life and

improper charging will result.

Do not connect an old battery to a new one.

TO DC

LOADS

FUSE OR

CIRCUIT

BREAKE R

PROwatt

DEEP-CYCLE

AUXILIARY

DEEP-CYCLE

AUXILIARY

FUSE OR

CIRCUIT

BREAKER

BATTERY

BATTERY

GROUND TO

VEHICLE

CHASSIS

600

IS OL ATO R

GROUND TO

VEHICLE

CHASSIS

FROM ALTERN ATOR

OR CHARGER

VEHICLE

STARTING

BATTERY

TO VEH ICLE

GROUND TO

VEHICLE

CHASSIS

Figure 6 Two Batteries Connected in Parallel

34

Page 50

Battery Tips

Battery Tips

WARNING

Review “Precautions When Working With

Batteries” on page viii before you work with the

batteries in your system.

Explosive/Corrosive Gases

Lead-acid batteries may emit

hydrogen, oxygen, and sulfuric acid fumes when recharging.

To reduce the risk of explosion:

• Vent the battery compartment to prevent the

accumulation of gases.

• Do not install electronic or electrical equipment in the

battery compartment.

• Do not smoke or use an open flame when working

around batteries.

Temperature Sensitivity

The capacity of lead-acid batteries

is temperature sensitive. Battery capacity is rated at 77º F

(25º C). At 0º F (–20º C), the Ah capacity is about half the

rated capacity. Temperature should be considered when you

design your system.

Low Temperatures

If extremely low temperatures are

expected where the inverter is going to be located, you should

consider a heated equipment room. If the system is located in

an unheated space, an insulated battery enclosure is

recommended.

High Temperatures

from high temperatures. These can be caused by high

ambient temperatures, solar heating of the battery enclosure,

or heat released by a nearby engine or generator. High battery

temperature results in short battery life and should be avoided

by ventilating the enclosure and reducing the external heat

source by shading and insulation.

The batteries should also be protected

35

Page 51

Battery Tips

Discharged Batteries

Do not leave batteries in a discharged

state for more than a day or two. They will undergo a

chemical process (sulfation) that can permanently damage the

battery. As well, batteries self-discharge over a period of

three to six months, so they should be recharged periodically

even if they are not being used.

Electrolyte Level

If your batteries are not the “maintenancefree” type, check the electrolyte level at least once a month.

Excessive fluid loss is a sign of overcharging. Replenish the

electrolyte using distilled water only.

Battery Connections

Connections to battery posts must be

made with permanent connectors that provide a reliable, lowresistance connection. Do not use alligator clips. Clean the

connections regularly and prevent corrosion by using a

protective spray coating or vaseline.

Battery State of Charge

You can measure battery state of

charge with a hydrometer or, more easily, with a voltmeter.

Use a digital voltmeter than can display tenths or hundredths

of a volt when measuring 10 to 30 volts. Make your

measurements when the battery has not been charged or

discharged for several hours. For a deep-cycle battery at

77º F (25º C), use the following table:

36

Battery Voltage State of Charge

12.7–13.0 100%

12.5–12.6 80%

12.3–12.4 60%

12.1–12.2 40%

11.9–12.0 20%

Page 52

C

Alternators and

Charging

Systems

A good charging system is important for the

health of your batteries. Poor recharging

methods can quickly damage them.

Appendix C provides guidelines for

recharging batteries from an alternator, from

AC power, and from alternate energy

sources.

37

Page 53

Charging System Requirements

Charging System Requirements

Your charging system should be capable of delivering a

charging current equal to 10–25% of the amp-hour capacity

of your battery. For example, if you have a 200 Ah battery,

the charging system should be able to deliver 50 amps. The

charging system must also be able to charge each 12 volt

battery up to approximately 14.4 V and then drop back to a

“float” voltage of 13.5–14 V (or shut off).

CAUTION

Never operate the PROwatt 600 directly from an

alternator. To work properly the PROwatt must be

connected to a battery or a well-regulated, highcurrent DC power supply.

Charging With an Engine Alternator

The following information will let you determine whether

your vehicle’s standard alternator will be adequate by itself,

whether you should install an alternator controller, or whether

you need a high-output alternator.

Using Your Vehicle’s Standard Engine Alternator

A typical engine alternator (12 volts) may not be able to meet

these requirements if your system uses large capacity

batteries. Alternators are typically rated for the current they

can deliver when they are cold. In use, alternators heat up,

and their output current capability drops by as much as 25%.

Therefore, standard alternators with ratings of 40–105 A will

only deliver a maximum of 30–80 A in actual use and will

deliver even less as battery voltage rises. Many alternators

cannot produce more than 13.6 V when they are hot. As a

result, a standard alternator may not be able to charge a large

battery quickly and completely.

Two solutions are to install an alternator controller or to

install a high-output alternator.

38

Page 54

Using an Alternator Controller

If your regular alternator is inadequate by itself, you can

install an alternator controller that will bypass the voltage

regulator and boost the alternator’s output voltage during

charging. This will increase the alternator’s charging rate at

higher battery voltages and ensure more rapid and complete

charging. Alternator controllers are available from marine

product dealers.

Using a High-Output Alternator

Heavy-duty alternators rated from 100–140A can replace

standard alternators and produce the higher current and

voltage required to charge multiple battery systems. They are

available from RV and marine dealers as well as auto parts

suppliers.

Charging From AC Power

Charging From AC Power

When recharging from AC power, use a good quality marine

battery charger or RV converter that meets the requirements

outlined in “Charging System Requirements” on page 38. For

information about battery chargers manufactured by Xantrex,

see the Xantrex web site at

Do not use chargers intended for occasional recharging of

automotive starting batteries. These chargers are not intended

for continuous use.

www.xantrex.com

39

Page 55

Charging From Alternative Energy Sources

Charging From Alternative Energy Sources

Your batteries can also be recharged from alternative energy

sources such as solar panels, wind, or hydro systems. Make

sure you use the appropriate battery charge controller for

your particular energy source.

CAUTION

Never operate the PROwatt 600 Inverter directly from

an energy source such as a solar panel. The PROw att

must be connected to a battery or a well-regulated, highcurrent DC power supply to work properly.

40

Page 56

D

Product and

System

Information

Appendix D contains the warranty for your

PROwatt 600 Inverter as well as instructions

for returning the product for servicing.

Appendix D also has a place where you can

record information about your system in case

you need to contact Customer Service.

41

Page 57

Warranty

Warranty

What does this warranty cover?

Xantrex manufactures its

products from parts and components that are new or

equivalent to new, in accordance with industry-standard

practices. This warranty covers any defects in workmanship

or materials.

How long does the coverage last?

This warranty lasts for

twelve months from the date of purchase. Implied warranties

of merchantability and fitness for a particular purpose are

limited to twelve months from the date of purchase. Some

jurisdictions do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.

What does this warranty not cover?

This warranty will not

apply where the product has been misused, neglected,

improperly installed, physically damaged or altered, either

internally or externally, or damaged from improper use or use

in an unsuitable environment. Xantrex does not warrant

uninterrupted operation of its products. Xantrex shall not be

liable for damages, whether direct, incidental, special, or

consequential, or economic loss even though caused by the

negligence or fault of Xantrex. Some jurisdictions do not

allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion

may not apply to you.

What will Xantrex do?

replace the defective product free of charge. Xantrex will, at

its own option, use new and/or reconditioned parts made by

various manufacturers in performing warranty repair and

building replacement products. If Xantrex repairs or replaces

a product, its warranty term is not extended. Xantrex owns all

parts removed from repaired products.

How do you get service?

proof of purchase must be provided and the product must not

be disassembled or modified without prior authorization by

Xantrex. If your product requires warranty service, please

return it to the place of purchase along with a copy of your

42

Xantrex will, at its option, repair or

To qualify for the warranty, dated

Page 58

Return Material Authorization Policy

dated proof of purchase. If you are unable to contact your

merchant, or the merchant is unable to provide service,

contact Xantrex directly at:

Phone:

Fax:

Email:

1-800-670-0707

1-800-994-7828

support.prowatt@xantrex.com

Return Material Authorization Policy

You must obtain a Return Material Authorization (RMA)

number from Xantrex before returning a product directly to

Xantrex. Products returned without an RMA number or

shipped collect will be refused. When you contact Xantrex to

obtain service, be prepared to supply the serial number of

your product and its date of purchase as well as information

about the installation and use of the unit. Record this

information in “Information About Your System” on page 45

of this guide.

Return Material Procedure

If you are returning a product from the USA or Canada,

follow this procedure:

1. Obtain an RMA number and a shipping address from

Xantrex.

2. Package the unit safely, preferably using the original box

and packing materials. Include the following:

• The RMA number

• A copy of your dated proof of purchase

• A return address where the repaired unit can be shipped

• A contact telephone number

• A brief description of the problem

3. Ship the unit freight prepaid to the address provided in

step 1. Collect shipments will be refused.

43

Page 59

Return Material Procedure

How do other laws apply?

This warranty gives you specific

legal rights, and you may also have other rights which vary

from jurisdiction to jurisdiction.

For our Canadian customers:

When used herein “implied

warranties of merchantability and fitness for a particular

purpose” includes all warranties and conditions, express or

implied, statutory or otherwise, including without limitation

implied warranties and conditions of merchantability and

fitness for a particular purpose.

44

Page 60

Information About Your System

Information About Your System

As soon as you open your PROwatt 600 Inverter package,

record the following information and be sure to keep your

proof of purchase.

❐

Model Number

(on top of unit)

❐

Serial Number

(on bottom of unit)

❐

Purchased From

❐

Purchase Date

If you need to contact Customer Service, please record the

following details before calling. This information will help

our representatives give you better service.

________________________

________________________

________________________

________________________

❐

Type of installation (e.g.

RV, boat, home)

❐

Length of time inverter has

been installed

❐

Battery size

❐

Battery type (e.g. flooded,

sealed gel cell, AGM)

❐

DC wiring size and length

❐

Alarm sounding?

❐

Description of indicators

❐

Appliances operating when

problem occurred

❐

Description of problem

__________________________________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________________________________

45

Page 61

46

Page 62

Index

A

AC wiring, warning about ix, 4

alarm, low battery

alternator controller

described

installing

alternator, high-output

amp-hour (Ah) capacity

appliances

battery-operated

blender

bread maker

possible damage to

power consumption

rechargeable

TV

audio equipment, buzz in

39

2

2

39

2

ix

2, 18,

ix

23

6

39

6,

30

19

33

22

B

batteries

amp-hour capacity

and temperature extremes

automotive starting

charging frequency

connecting 2 in parallel

connections for low power loads

deep-cycle lead-acid

30

28,

20

29

30

34

35

28

depth of discharge

discharged

electrolyte level

explosive gases

golf cart

marine

nickel-cadmium

parallel connection illustrated

reserve capacity

routine maintenance

RV

29

temperature sensitivity

battery chargers

recommended types

battery connections

battery isolator

component

using

battery packs

battery reserve capacity

battery selector switch

battery size

estimating example

estimating requirements

estimating worksheet

battery state of charge

blender

bread maker

29

2

29

29

2

36

6

ix

viii

36

ix

30

36

32

20

39

14

32

36

30

33

35

7, 29,

34

31

47

Page 63

Index

C

cables. See DC cables.

charging

from AC power

from alternative energy sources

with engine alternator

charging frequency for batteries

charging system requirements

charging systems, designing

CHASSIS GND

chassis ground

for fixed location

for marine installation

for vehicles

guidelines for connecting

computer systems

Customer Service

email

fax number

phone number

preparing to call

4,

43

10

4,

9

43

4,

39

2

45

10

43

38

10

7,

9

38

38

20

40

F

FAULT indicator 14, 17, 23

freezers

fuses

installing

make and size

replacing

19

13

23

6

G

gases

battery, venting

explosive

ground. See chassis ground.

viii, 14, 35

8

H

high voltage shutdown 2

high-output alternator

described

installing

mention

39

39

6

D

DC cables

correct polarity

fuses in

guidelines for selecting

procedure for connecting

recommended size and length

depth of discharge (DOD)

13

13

E

electrolyte level 36

explosive gases

48

viii, 14, 35

10

32

11

10

I

indicators

FAULT

how to read

POWER

input voltage

installation

materials

overview of steps

planning

tools

inverter

input voltage

loads

manual reset

14, 17,

14,

6

19

18

6

7

17

17

18

18

23

3

Page 64

Index

mounting location 8, 9

mounting orientation

operating several loads

power output

problem loads

proof of purchase

serial number

trouble loads

turning off

turning on

16

16

18

43

19

19

42

L

loads

average and heavy

light

28

operating several at once

possible damage to

problem

reactive

resistive

trouble

low battery alarm

low voltage shutdown

18

19

19

18

2, 18,

29

19

16

23

5

23

2

illustrated

9

16

using

output voltage low

over temperature shutdown

overload

P

polarity, maintaining correct 13, 23

16

POWER indicator

power output

power tools

product information, recording

proof of purchase

pumps

19

18

2

14,

42,

17

45

4

R

reserve capacity 30

Return Material Authorization number

43

returning products

23

2

how to package

policy

procedure

43

43

43

M

manual reset 18

motors

mounting orientation

18

induction

19

N

nickel-cadmium batteries ix

O

On/Off switch

S

safety information vii, 4

serial number

9

servicing

no user-serviceable parts

shutdown

high voltage

low voltage

over temperature

specifications

electrical

physical

26

26

43

2

vii, 22

2

2

49

Page 65

Index

starting batteries 30

state of charge

36

T

television reception 22

televisions

temperature

ideal ambient temperature

over temperature shutdown

troubleshooting

buzz in audio equipment

common problems

reference table

television reception

2

21

22

23

22

V

22

8

17

VCR 2

ventilation

ventilation openings

8,

35

vii, 8, 9, 23

W

warranty

and damage caused by reverse

polarity

obtaining service

period of coverage

terms and conditions

wiring. See DC cables.

13

42

42

42

X

Xantrex

email

fax number

phone number

4,

43

4,

43

4,

43

50

Page 66

PROwatt™ 600

Inverter

Made in China445-0115-01-01

Tel: 1-800-670-0707

Fax: 1-800-994-7828

Email: support.prowatt@xanrex.com

Web: www.xantrex.com

Loading...

Loading...