Page 1

i4.40

Xantrex

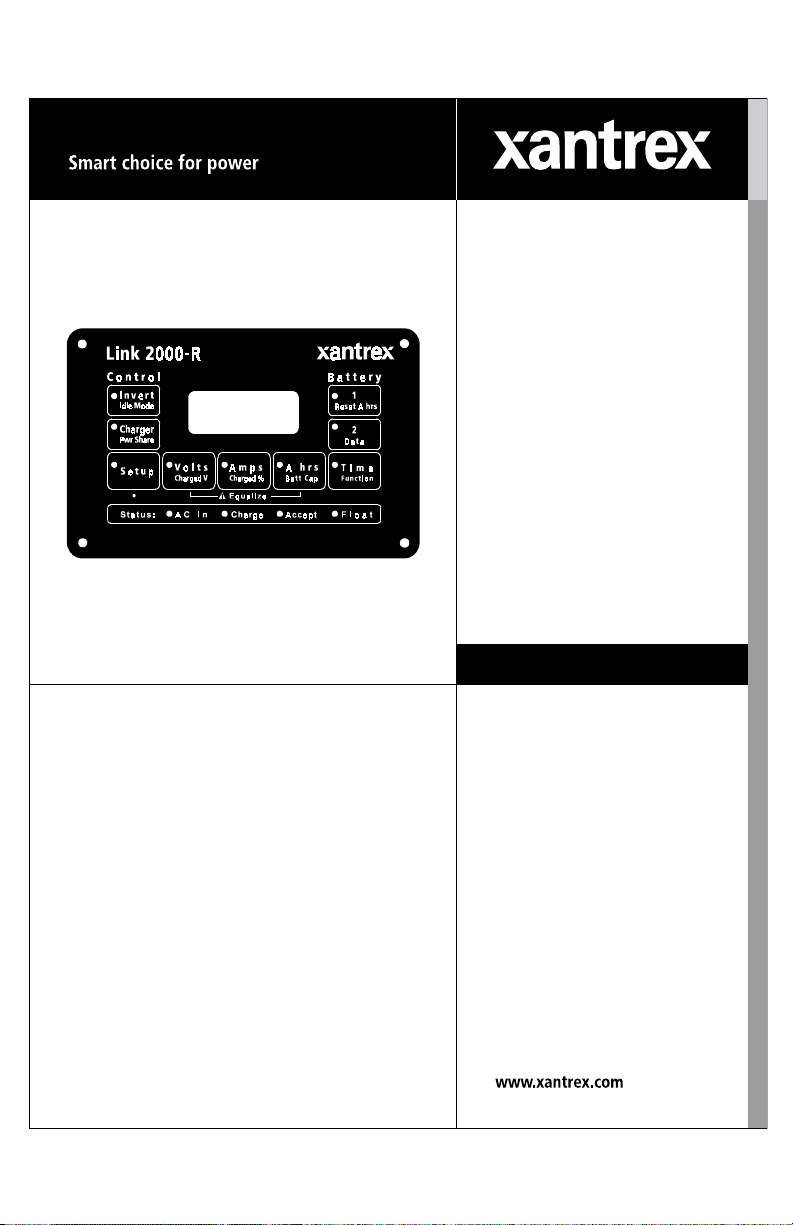

Link 2000-R

Regulator Option

Link 2000-R

Owner's Manual

Page 2

TABLE OF CONTENTS

Front Panel and Status Lights 3

How the LINK 2000-R Charges 4–5

Equalizing Cautions! 6

Special Setup for the LINK 2000-R 7

Required Reading 8

Wiring Instructions 9–15

Standby Regulators 15

Warranty 16

Troubleshooting Flow Chart 18

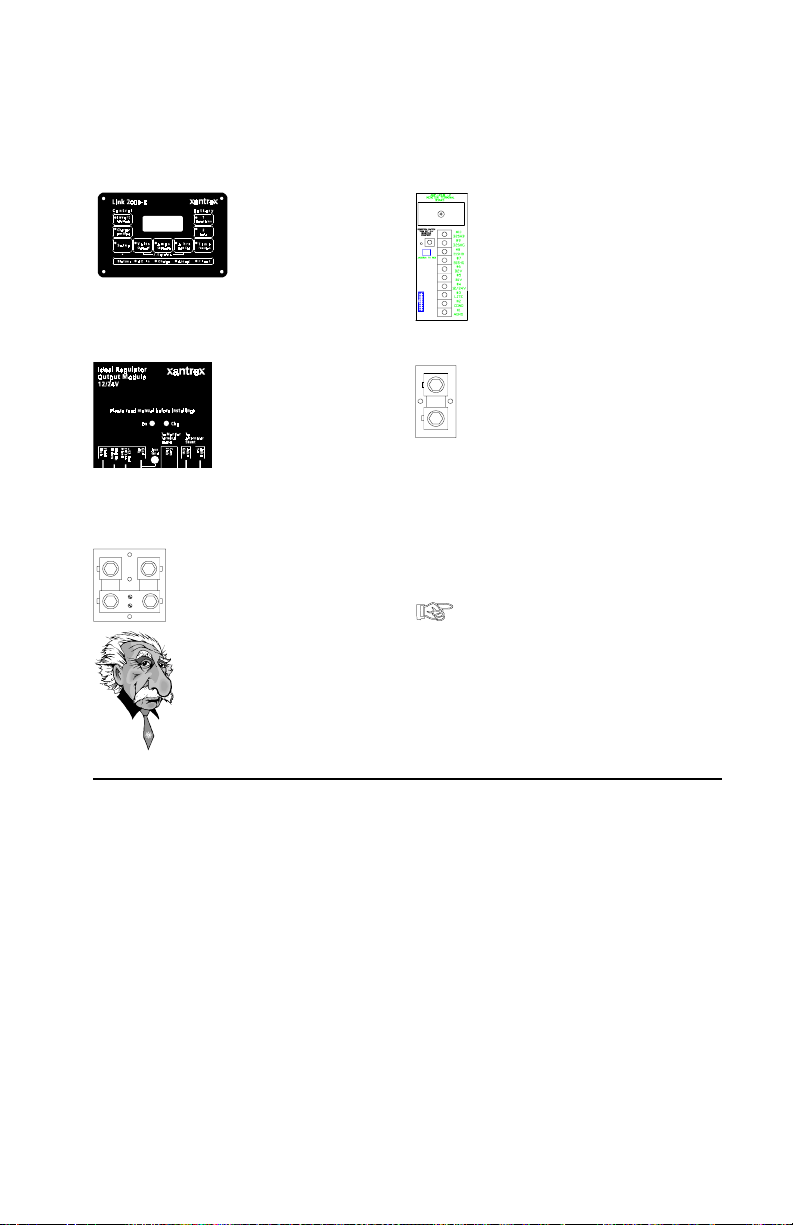

Wiring Diagram 19

The Helping Hand is used to draw your attention to very important sections of this

manual or to indicate items of special interest. Please read these sections carefully.

s

THIS DOCUMENT APPLIES TO LINK 2000-R SERIAL NUMBER 5000 AND ABOVE.

INSTALLERS! THIS DOCUMENT IS IMPORTANT FOR

OPERATION. PLEASE LEAVE IT WITH THE OWNER!

The LINK 2000-R is an integrated battery monitor, inverter/charger

controller, and advanced alternator regulator. This manual pertains

only to the installation, wiring, and testing of the alternator regulator

portion of the system. All other features and functions concerning

monitor operation and Freedom Inverter/Charger operation are

described in the LINK 2000 Owner's Manual (Part number 445-0198-

01-01). You

2000-R.

Notice of Copyright

Xantrex Link 2000-R Battery Monitor © November 2002 Xantrex International. All rights reserved. Xantrex is a registered

trademark of Xantrex International.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR

OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE

OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision: November 2002, Revision 1

Part Number: 445-0197-01-01

Contact Information Web: www.xantrex.com Email: CustomerService@xantrex.com

Phone: 1 800 670 0707 (toll free in North America) 1 604 422 2777 (direct) Fax: 1 604 420 2145

SUPPLEMENT TO THE LINK 2000 OWNER'S MANUAL

must be familiar with that manual before using the LINK

For use only with externally regulated

12- or 24-volt "P" Field type alternators.

See "Required Reading," page 8.

2

Page 3

FRONT PANEL AND STATUS LIGHTS

The front panel operation of the LINK 2000-R is exactly the same as described in the

LINK 2000 owner's manual, with the exceptions noted below.

i4.40

Status lights indicate which cycle the regulator

(and/or the charger) is in. The AC light will be

OFF if there is no external AC input.

Selecting TIME when the alternator regulator

is operating displays the alternator output

current. The current is displayed with an "

preceding the value.

FRONT PANEL SWITCHES

The operation of the front panel is the same as the LINK 2000 with the exception of the

TIME switch. When the alternator regulator is on (REG ON energized) and TIME is

selected, the alternator output current is displayed. It is preceded with the character "

For example, an alternator output current of 100 amps would be displayed as AI00.

AA

A".

AA

STATUS LIGHTS

The status lights on the front of LINK 2000-R use LEDs (light-emitting diodes) to indicate

which cycle the alternator regulator is in during charging. The meaning of the lights is the

same as described in the LINK 2000 installation manual. The only difference is that when

there is no external AC power available, and

indicate the charge cycle for the alternator regulator. If external AC power is available, the

charger is turned

the cycle of both the charger and the alternator regulator.

AC IN: Green LED on when AC is present.

CHARGE: Red LED on when charger/alternator is in bulk CHARGE Cycle.

ACCEPT: Orange LED on when charger/alternator is in ACCEPTANCE Cycle.

FLOAT: Green LED on when charger/alternator is in FLOAT Cycle.

ON, and the alternator is also charging the battery, the status lights indicate

Flashes Red LED when charger/alternator is in EQUALIZE Cycle.

the regulator is turned on, the status lights

A"

3

Page 4

HOW THE LINK 2000-R CHARGES

See page 18 of LINK 2000 manual for details of the Ideal Charge Curve.

The LINK 2000-R uses the Ideal Regulator Output Module to control the alternator

to conform to the Ideal Charge Curve’s four defining cycles; Charge, Acceptance, Float,

and Equalize. The following discusses details of each of the cycles.

NOTES: 1) Terminal references for the Ideal Regulator Output Module.

CYCLE

STATUS

LIGHT

RED

LED ON

2) Voltage values given are for 70 °F and liquid lead-acid batteries.

TURNING THE REGULATOR ON

The regulator is turned on by supplying 12 V or 24 V to the REG ON (brown

wire) terminal.

It must have power only when the engine is running. See page 13.

DELAY START-UP

Behavior: No output on the Field terminal (blue wire).

Two-second delay allows time for the engine to start.

RAMPING UP

Behavior: Output of alternator increases over a 20-second period.

Ramping up the alternator output avoids shock-loading the belts with full

alternator output. The output on the FIELD terminal is increased over a 20-second

period until the alternator current limit (default value 100 A) is reached. The Charge

Cycle now begins. If the acceptance voltage is reached before the current limit,

the Acceptance Cycle begins.

CHARGE CYCLE

Behavior: Alternator current at maximum and battery voltage increasing.

The Charge Cycle ensures fast charging without alternator overload. The

alternator current limit will not be exceeded. The FIELD output is varied to hold

the alternator at its current limit until the acceptance voltage is reached. When the

acceptance voltage has been attained by either battery, the Acceptance Cycle begins.

ACCEPTANCE CYCLE

Behavior: Battery amps falling, voltage at 14.4 V for 12 V systems, 28.8 for

24 V. (Voltage depends on battery type and ambient temperature settings.)

The Acceptance Cycle guarantees thorough charging by continuing to charge

the battery until the charging current becomes a small percentage of battery

ORANGE

LED ON

capacity (2% default). The alternator output is varied to maintain the battery at

the acceptance voltage. During the Acceptance Cycle the alternator current limit

will not be exceeded even if a heavy load is placed on the system.

When the batteries have reached the acceptance voltage and the current is

below 2%, the Acceptance Hold Cycle begins. If the Acceptance Cycle has lasted

3.5 hours, the Float Cycle begins, even if the charged parameters have not been

met. If the voltage of either battery falls below the acceptance voltage for more

than two minutes, the Charge Cycle starts again.

4

Page 5

ORANGE

LED ON

GREEN

LED ON

ACCEPTANCE HOLD CYCLE

Behavior: Voltage at 14.4 V (28.8 V for 24 V), battery amps below 2%.

The Acceptance Hold Cycle ensures that the battery has accepted as much

charge as it can. During the Acceptance Hold Cycle the charged voltage is

maintained and charging current is monitored. Both the charged voltage and the

charged current % must continue to be satisfied for 10 minutes for the Acceptance

Hold Cycle to end. The Acceptance Hold Cycle is also terminated after 20

minutes from its beginning even if the battery current has not stayed below the

charged current for the entire time.

If the voltage of the batteries falls below the charged voltage for more than two

minutes, the Charge Cycle starts again.

FLOAT CYCLE

Behavior: Battery amps below 2%, voltage constant at 13.5 V (27 V FOR

24 V). (Voltage depends on battery type and ambient temperature setting.)

During the Float Cycle the float voltage is maintained. The alternator will

supply up to its current limit to maintain the float voltage and supply DC loads.

RESTARTING THE CHARGE CYCLE

MANUALLY: The Ramp Up Cycle may be manually restarted by turning off

the REG ON terminal and turning it back on again. This will require you to turn

off the key switch supplying REG ON or shutting off and restarting the engine

if REG ON is supplied by an oil pressure switch.

AUTOMATICALLY: The Charge Cycle is automatically restarted if the

voltage of the battery being charged drops 0.2 V (0.4 V for 24 V) below the float

voltage (0.3 V when charging with the inverter/charger) for more than two minutes.

RED

LED

FLASH

EQUALIZE CYCLE

Behavior: Battery amps constant at 4%, voltage is rising to a maximum

of 16.0 V when charging with the alternator and 16.3 V when charging with

the inverter/charger. (Limited to acceptance voltage for gelled batteries.)

To start the Equalize Cycle press the SETUP BUTTON for five seconds until

the LED begins to flash. Now press both the VOLTS and the A hrs BUTTON

simultaneously. Hold them both down for five seconds until the red CHARGE

LED begins to flash and the “E” in the display goes out. To terminate the Equalize

Cycle and force the system into the float cycle, repeat the same procedure. The

cycle automatically terminates 3.5 hours after initiation, or when the current drops

to 2% of capacity at 16.0 V. (Equalize terminated in eight hours if using the

inverter/charger.)

The Equalize Cycle is a controlled overcharge to remove lead sulfate that is

not removed during normal charging. Liquid batteries should be equalized about

every 30 days when in deep cycling service.

5

Page 6

EQUALIZING CAUTIONS!

Turn off sensitive electronics before equalizing.

Equalizing causes the battery to gas. You should check the battery electrolyte

before and after equalization. Do not over-fill before equalization as the electrolyte may

expand and cause it to flow over the tops. You should be present during this type of

charging. Hydrogen and oxygen gas is generated during equalization. Make sure

there is adequate ventilation.

Batteries should not be equalized every charge/discharge cycle. Normally, the

battery is cycled between 50% charged and the 85% to 95% charged level reached by

the normal Charge and Acceptance Cycle. Every 30 days, though, the batteries should

be equalized to regain full capacity and extend life.

To equalize, first go through a complete Charge and Acceptance Cycle. Check the

electrolyte level, but do not overfill. Re-check and top off the electrolyte

Remember, equalizing is constant current charging with a small regulated

current that permits a higher maximum voltage. The goal is to use a small current

and gradually let the battery rise to its maximum voltage.

EQUALIZING GELLED BATTERIES

Gelled batteries are not normally equalized. However, if the battery has been

severely discharged, the voltage of the battery may easily reach the acceptance level

with a very small current. In fact, the current may be less than the 2% required to terminate the Acceptance Cycle. This can cause the system to believe that the battery is full

and switch to the Float Cycle. Equalization may be the only way to get the battery to

accept a charge. Be sure that the battery TYPE # is set to #1 or #2 before using this

cycle on gelled batteries.

voltage but the cycle lasts for 3.5 hours. (Eight hours if using the Freedom charger.)

Please consult your battery manufacturer regarding the appropriateness of this cycle

for their batteries.

The equalization voltage is limited to the acceptance

after equalizing.

6

Page 7

SPECIAL SETUP FOR LINK 2000-R

The following is a list of special setups that may be necessary to tailor the LINK 2000-R to

your system. Please see pages 10–14 of the LINK 2000 Owner's Manual for details on

how to use the FUNC mode.

F10 - ALTERNATOR CURRENT LIMIT

DEFAULT = 100 RANGE = OFF, 30–220 AMPS STEP = 10 A

This function is only used with the Link 2000-R (Alternator Regulator Model). It sets

a safety current limit for the alternator. This limits the maximum amount of current that the

alternator can deliver which in turn reduces heat and wear on belts and bearings. This value

is reset to 100 amps in the event of a reset to factory default values.

CAUTION: OFF defeats this safety feature and the alternator will be run at

full output until the Acceptance Voltage is reached. You can also use this feature

to troubleshoot the alternator current measuring/limiting feature.

F11 - BATTERY #2 USED FOR CONTROL

DEFAULT ON = BATTERY #2 USED FOR CONTROL

OFF = BATTERY #2 IS NOT USED FOR CONTROL

This function is used to defeat Battery #2 as a part of the charger and alternator

regulator control functions of the Link 2000-R. This is necessary for systems that have

both 12 V and 24 V batteries. Battery #1 must be the battery that is used by the Freedom

Inverter (or charged by the alternator when controlled by the Link 2000-R). You may also

wish to use this function if the main house battery (Bank #1) is substantially larger than

a separate engine battery (Bank #2) that is also monitored by the Link 2000-R. This will

prevent the Link 2000-R from making a premature transition to float based on the smaller

engine battery meeting the charged parameters substantially before the house battery.

NOTE: Function F11 is not changed in a reset to factory default values. If you

wish to change this function you must use the setup routine to change it.

7

Page 8

REQUIRED READING

1) Read the REQUIRED READING section of the LINK 2000 owner's manual.

2) All wiring to the terminal board should be #16 AWG (#14 may be used).

The same 8 wire twisted pair cable recommended in the LINK 2000 manual may

3)

be used for the LINK 2000-R. The wiring diagram is color coded to this cable.

CAUTION! YOU MUST READ THIS SECTION!

4) The LINK 2000-R Ideal Regulator Output Module is designed to replace external "P"

type regulators. If your alternator is internally regulated, modification will be necessary. The

LINK 2000-R is

regulation by switching in the negative supply to the field. This includes most Japanese and

internally regulated alternators. If these alternators are to be converted to external regulation

you must disconnect the internal regulator and the diode trio in the alternator. This

should be performed by a qualified alternator shop. The warranty does not cover the

alternator, batteries, or any other devices, or equipment in the system.

improperly converted alternator may cause damaging high voltages. Please be sure

to check the regulation voltage during initial operation to verify that the LINK 2000-R

is in control of the system.

5) The LINK 2000-R is designed to regulate alternators up to 230 amps, provided that

the field current does not exceed 10 amps total. It can also regulate two alternators in parallel,

charging the same battery, if they are the same size with a combined total capacity of less

than 230 amps, and combined field current less than 10 amps. If the alternators are on

different engines you must install a normally open oil pressure switch, or a relay activated

by the key switch, in series with the field of each alternator to avoid supplying field current

to an alternator whose engine is not running.

not designed to regulate N-type alternators; that is, alternators that require

An

6) The alternator shunt is in series with the alternator output and carries the full alternator

current. The brass portions of the shunt are at +12 V (24 V) potential and should therefore

be protected from accidental contact to grounded objects or battery negative.

If a small alternator is being replaced by a high output alternator you must increase

7)

the size of the alternator wiring. Use the table below to find the appropriate wire size. The

total length of both the positive and negative runs must be measured.

ALTERNATOR MAXIMUM OUTPUT CABLE SIZE (AWG)

10 FT OR LESS 11 TO 20 FT

35 A #8 #8

60 A #6 #4

75 A #6 #4

100 A #4 #2

130 A #4 #1

170 A #2 #1/0

200 A #1 #2/0

8) Battery temperature should never exceed 120 °F. We recommend a 110 °F limit.

8

Page 9

WIRING INSTRUCTIONS

Refer to the wiring diagram while using these instructions.

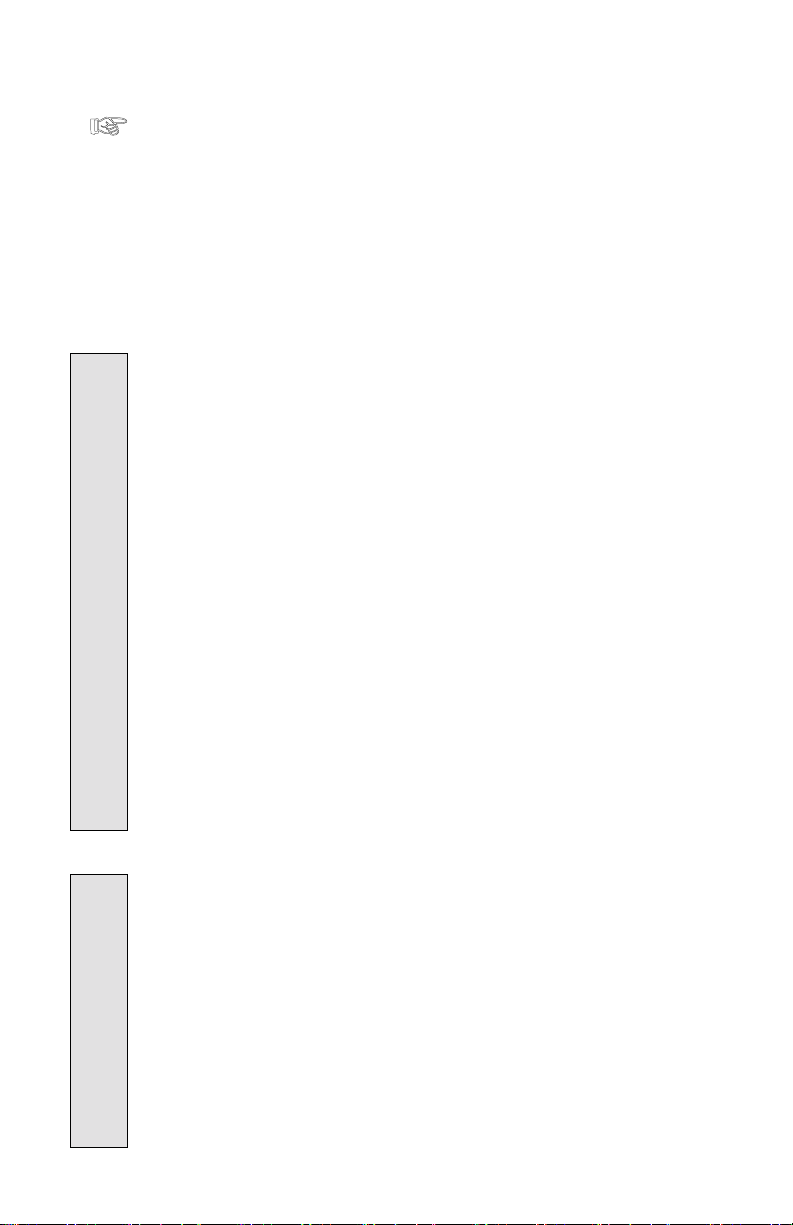

There are several components to LINK 2000-R METERS:

4) The Monitor Terminal Board: The

wiring for battery monitoring terminates

here. The ribbon cable from the meter

plugs into this board. It also has a RJ-45

jack on it for the Ideal Regulator Module.

5) The Alternator Shunt: Single 500 A,

50 mV shunt used to measure current

flowing out of the alternator.

These two cords are not interchangeable.

i4.40

1) The LINK 2000-R

Meter: Contains the micro-

processor and display. The

actual regulation program is

in the meter. It is terminated

with a ribbon cable. It also has

a RJ-11 jack for the remote

cord to the inverter/charger.

2) The Ideal Regulator

Output Module: Supplied

with a harness that connects

to the alternator. There is

also a RJ-45 jack and plugs

for the alternator shunt wiring

and red and green indicator

lights used for troubleshooting.

3) The Battery Shunt: Dual

500 A, 50 mV shunt used to

measure current flowing in or

out of the batteries.

6) Four Conductor Remote Cord: This 25' long

phone cord connects the LINK to the inverter/charger.

This is the smaller of the two cords.

7) Eight Conductor Data Cord: This 25' long cord

connects the Monitor Terminal Board to the Ideal

Regulator Output Module. This is the larger of the

two cords.

Our Customer Service Manager says, "Be a genius—ensure a

successful installation by following our wire-by-wire instructions

and please do the two progress checks and the final startup test."

Be sure the battery shunt is installed before proceeding.

MONITOR BOARD INSTALLATION & WIRING

MOUNTING THE MONITOR TERMINAL BOARD

The Monitor Terminal board should be secured behind or adjacent to the meter. It

should be accessible and easy to see during hookup. The meter comes standard with an

18" ribbon cable.

Wiring is simplified by using our custom multiple conductor twisted pair cable

available from your dealer. See LINK 2000 manual. If you supply your own cable we

recommend 16 AWG. Larger wire is okay but not necessary. Do not use larger than #14

AWG, as it will make terminating the wires difficult. Use twisted pairs where specified. Use

the same color scheme as on the schematic to facilitate troubleshooting if required.

Begin hooking up from the bottom (terminal #1 ) of the terminal strip toward

the top.

9

Page 10

TERMINAL #1

BLACK WIRE (AGND) is the Analog Ground. It is the reference for all

measurements. It must be connected on the BSHG (Grounded) side of the battery shunt.

The BSHG side of the shunt is the side

opposite of the negative battery terminals. It must

have a good connection to one of the two #10 screws on the top of the battery shunt.

Do not connect anything else to this terminal.

TERMINAL #2 is not used.

TERMINAL #3

WHITE WIRE (LITE) turns on the monitor backlighting. It may be supplied from

a switch that controls other instrument lighting or it may be connected to TERMINAL #4

if you wish the lighting to be on all the time. Set at the default value the backlighting consumes

about 8 mA (0.008 A). If left on all the time it would use less than 0.2 Ah per day.

TERMINAL #4 <<Consider the options for this wire>>

RED WIRE (12 / 24 V) is the +12 V / 24 V power to supply the meter. The wiring

diagram shows two options. The

preferred option is to jumper together TERMINALS

#4 and TERMINAL #5 as shown. Wired this way, the meter cannot accidentally be

de-powered. It has the disadvantage of always consuming a little bit of power from the

#1 Battery. The meter consumes about 28 mA (0.028 A). If left on all the time it would use

about 0.7 Ah per day.

If the system is left on for long periods (long enough to significantly discharge the

battery) with no charging sources available, then you should consider the option shown with

the dotted line. In this case the TERMINAL #4 RED WIRE is

not jumped to the

TERMINAL #5 BLUE WIRE but supplied from the common of the battery switch. (Be

sure to install the 2 A fuse as near the battery switch as possible.) Then, whichever battery

is selected by the battery switch is the battery that supplies the power for the meter.

Caution: With this option, if the battery switch is turned off, the meter is de-powered

and this resets amp hours to zero. Therefore the battery switch should never be turned off

except when leaving the system for a long period of time. When the system is returned to

service you must resynchronize the meter by fully charging the battery.

Another option for the TERMINAL #4 RED WIRE is to install a separate on/off

switch in it before it connects to the terminal board. Just remember to turn off the meter

when leaving the system unattended. (Amp hours will be reset to zero when the unit is

repowered.)

TERMINAL #5 <<See TERMINAL #4 above for options>>

BLUE WIRE (B1V) supplies Battery #1 voltage to the Link 2000-R for sensing.

It should be supplied directly from Battery #1 positive. Be sure to install the 2-amp fuse

shown in the drawing as near the battery as possible.

TERMINAL #6 <<if one battery to be monitored, jumper TERMINAL #5 & #6>>

VIOLET WIRE (B2V) supplies Battery #2 voltage to the Link 2000-R for sensing.

It should be supplied directly from Battery #2 positive. Be sure to install the 2-amp fuse

shown in the drawing.

10

Page 11

PROGRESS CHECK #1

The wires hooked up so far allow you to check the voltage monitoring functions. Install

the fuse that supplies TERMINAL #4 - Red Wire (+12 V / +24 V) and carefully plug

the ribbon cable into the Monitor Terminal Board, note the connector index key

and be sure the pins are lined up correctly.

From now on you may de-power the meter by unplugging the ribbon cable.

If you remove the fuse that supplies TERMINAL #4 - RED WIRE with the ribbon

cable plugged in, you must be careful when reinstalling it. It must be a deliberate

action. If the power to the meter is turned on and off in less than five-second intervals

it can cause the microprocessor to interrupt its initialization process. De-powering

and re-powering by using the ribbon cable avoids this problem.

Check each of the battery voltages. It is best to have a separate, accurate digital

voltmeter to compare the voltages shown on the Link 2000-R against the actual battery

voltage. They should be within a few hundredths of a volt. If they are not, check your

voltage sense lead fuses and fuse holders.

proceeding. If you have questions, call your dealer or Xantrex Technology Inc.

Unplug the ribbon cable before proceeding, or remove the fuses in the wires to

terminals #4, 5, & 6 before continuing.

<<The next four wires are for the dual battery shunt sense leads.>>

See "Required Reading" in the LINK 2000 installation manual regarding the special

care required in the installation of the shunt and its wiring.

TERMINAL #7 - Jumper to TERMINAL #9 for single bank current measurement.

GREEN WIRE (B1SHG) which is connected to the SMALL SCREW ON THE

GROUND SIDE, OR LOAD SIDE, of the Battery #1 shunt (B1SHG). This wire must be

located exactly as described to ensure accuracy of current measurements. This GREEN

WIRE AND ORANGE WIRE attached to Terminal #8 should be a twisted pair.

Any problems must be resolved before

TERMINAL #8 - Jumper to TERMINAL #10 for single bank current measurement.

ORANGE WIRE (B1SHB) is connected to the SMALL SCREW ON THE

BATTERY SIDE of the battery #1 shunt (B1SHB). This wire should be located exactly

as described to ensure accuracy in current measurements.

NOTE: If only one current input is used, jumper terminals #7 & #9 together

and terminals #8 & #10 together. This hookup will display the same current

information for both the Battery #1 and #2 selection.

TERMINAL #9

BROWN WIRE (B2SHG) is connected to the SMALL SCREW ON THE

GROUNDED, OR LOAD SIDE, of the battery #2 shunt (B2SHG). The TERMINAL #10

YELLOW WIRE and TERMINAL #9 BROWN WIRE should be a twisted pair.

11

Page 12

TERMINAL #10

YELLOW WIRE (B2SHB), is connected to the SMALL SCREW ON THE

BATTERY SIDE of the Battery #2 shunt (B2SHB). The TERMINAL #10 YELLOW

WIRE and TERMINAL #9 BROWN WIRE should be a twisted pair.

PROGRESS CHECK #2

Now it is time to check the battery current function. Plug the meter's ribbon cable into the

Monitor Terminal Board and/or insert the fuses. Turn off all DC loads and charging sources.

With everything off select Battery #1 or #2 Amps—the LINK 2000-R should read 0.0,

-0.0, or no more than -0.1 A. (The meter uses less than 0.1 A.) If there is a larger current

draw it normally means that not all the DC loads are turned off. There may be an alarm

system, a clock, or other instrumentation that is left on all the time intentionally. That is

okay as long as you find each load and decide that it is an acceptable continuous current

draw. Once your base-line current is known, remember it. If you cannot always turn off loads

and reach the same number of amps you should find out why. Turn on various loads and

make sure there is a minus sign in front of the display which indicates discharge. If the

number has no minus sign and there are no charging sources on, it means that the battery

shunt sense leads are reversed. If you have a problem call your dealer or Xantrex

Technology Inc. The wiring is now complete and the battery monitoring functions of the

meter now are fully operational.

The battery monitoring and inverter/charger functions of the LINK 2000-R may be

operated independently of the alternator regulator functions. Simply unplug the 8 conductor

data cord (described in the next section) between the Monitor Terminal Board and the Ideal

Regulator Output Module to disable the regulator. The alternator will freewheel harmlessly.

IDEAL REGULATOR OUTPUT MODULE WIRING

MOUNTING THE OUTPUT MODULE

The Ideal Regulator Output Module may be located anywhere convenient to the

alternator that is not subject to salt or fresh water spray. The components in this module

have been coated to resist corrosion but are not immune to, nor warranted against, abuse.

This module has on it the FET (field effect transistor) that actually does the work of

supplying power to the alternator field. While the reliability of this module is very high

it also does all of the real work. The system has been designed with on-site repairability

in mind, a spare Output Module or a standby regulator should be considered for longdistance cruising.

The harness that is supplied with this module is a standard alternator harness. It

is keyed so that it cannot be improperly plugged into the module. The colors mentioned

below correspond to the color code of the wiring harness. There is also a 25-foot 8

conductor data cord supplied to interconnect the Monitor Terminal Board and the Ideal

Regulator Output Module. The following discusses each of the wires connected to the

Ideal Regulator Output Module beginning from the left side of the module.

12

Page 13

FIELD WIRE TERMINAL

BLUE WIRE is connected to the FIELD TERMINAL on the back of the alternator

and supplies alternator field current. The gray insulated plug connector may be plugged

directly into standard small case high output alternators. (NOTE: The white wire that is

stubbed out of the gray plug is for electronic tachometers and has no function related to

alternator regulation.) If the plug will not fit into the alternator it may be cut off and the blue

wire may be terminated with an insulated spade terminal or other appropriate connection

for the alternator field terminal on the alternator. (The RED LED, on the Ideal Regulator

Output Module, labeled CHG indicates field voltage is present on this BLUE WIRE. The

RED LED glows more brightly as the alternator output increases.)

CAUTION: The gray plug will fit into the typical DELCO internally regulated

alternator but the internal regulator must first be disabled. DO NOT attempt to use the

Link 2000-R with an internally regulated alternator without modifying it to use

external regulation! See #4 on page 8.

REG ON TERMINAL

BROWN WIRE supplies the voltage that turns on the Ideal Regulator Output

Module. It should be connected to a normally open oil pressure switch, or some other

switch (such as an ignition switch or relay), that is hot (+12 V / 24 V)

when the engine is

running and off when the engine is off. If the system has a battery isolator, or separate

engine starting battery, the BROWN WIRE should be supplied from a stable 12 V / 24 V

source. This wire must not be connected to the oil pressure sensor for the oil pressure

gauge or to the oil pressure switch for the alarm system. A separate

NORMALLY OPEN

oil pressure switch should be used. When this wire is energized the GREEN LED labeled

ON is lit.

The GREEN LED must be OFF when the engine is off! If the regulator is left

continuously ON it may destroy the Ideal Regulator Output Module, damage the

alternator, discharge the battery, and cause system failure.

+12 V/24 V TERMINAL

RED WIRE is the +12 V / 24 V supply. It is shown connected to the alternator

side of the alternator shunt (ASHA). Connecting it here ensures a stable voltage with little

voltage drop to supply the alternator field power. The 10-amp fuse shown should be

installed to protect the wiring.

If an isolator is in the system, the +12 V / 24 V (Red wire) must connect to the

battery side of the isolator.

GND (GROUND) TERMINAL

BLACK WIRE wire is power ground. It is connected to the alternator ground.

ASHB TERMINAL (alternator shunt battery side)

GREEN WIRE must be terminated on the small screw on the battery side of

the alternator shunt. This wire must be connected exactly as shown. Since this wire is

at battery voltage it should be protected with a 2-amp fuse

at the shunt as shown;

install the fuse after the wiring is connected. No other wires should be connected here.

13

Page 14

ASHA TERMINAL (alternator shunt alternator side)

YELLOW WIRE must be terminated on the small screw on the alternator side of

the alternator shunt. This wire should be connected exactly as described to ensure proper

operation. Since this wire is at battery voltage it should be protected with a 2-amp fuse

the shunt as shown; install the fuse after the wiring is connected. No other wires should be

connected here.

FINAL TEST AND ENGINE STARTUP

Do this test with the engine OFF!

If you cannot pass this test do not start the engine!

This is the final checkout. Plug the 8 conductor data cord (the larger of the two

phone cords) into the Monitor Terminal Board and the Regulator Output Module. Check

the battery amps—you should see the same low number as in PROGRESS CHECK #2.

The green ON LED on the Ideal Regulator Output Module must be off.

Now we want to simulate the engine running, so turn on the regulator by turning the

key switch to the ON position, or if normally open oil pressure switch is used, jumper

together its two terminals.

terminal while the engine is off. The GREEN ON LED should be ON. The red Charge Cycle

Status light on the Link 2000-R front panel should also be ON. The RED CHG LED on

the Output Module, which indicates that field voltage is being supplied, should gradually

increase in brightness during the next 30 seconds. Also check the TIME function

which should display "a000" indicating the alternator output current is zero.

To verify that current is actually flowing into the alternator field use the LINK

2000-R to check the number of amps flowing from whichever battery has been selected

by the main battery switch. You should see -3 to -5 amps of current flowing. This current

is being supplied to the alternator field, and perhaps, to other instrumentation that is also

turned on with the key switch if you are not using an oil pressure switch.

To verify that it is the alternator field consuming the current, turn off the power

to the REG ON terminal and disconnect the FIELD wire from the alternator field. Repeat

the test. The current should now be about 2 to 4 amps less than it was. This test assures

you that the regulator is supplying the field current.

Another easy way to test if the field is energized is to check the magnetism of the

rotor by touching the end of the alternator shaft with a steel screwdriver. Do it with the

regulator turned on (wait 20 seconds for ramp-up cycle) and with it turned off—there

should be a noticeable difference. If you cannot pass this test see the troubleshooting

flow chart. If you still need help, call your dealer or Xantrex Technology Inc.

For this test only we want to supply voltage to the REG ON

at

14

Page 15

Neither the GREEN or the RED LED should be ON when the engine

is off! If the RED LED is ON, and the green LED (labeled "ON") is OFF, it is an

indication that the FET is shorted or the field is connected to some other source.

DO NOT OPERATE THE SYSTEM UNTIL THIS IS RESOLVED!

It is now time to start up the engine and see how everything works. For this test

make sure the battery charger or any other charging sources are turned off.

Partially discharge the batteries (remove at least 20% of the capacity—it may take a few

hours at a relativity high discharge rate). Start the engine and watch the battery voltage to

see that it raises to and levels off at about 14.4 (28.8) volts in the Acceptance Cycle. With

the default values, when the battery current falls to about 4 amps (2% of the battery capacity)

the regulator will shift into the Float Cycle and maintain the batteries at the Float voltage.

Also check the alternator current by pressing the TIME button and using a milliVolt meter

to measure the voltage drop across the alternator shunt and comparing it to the reading on

the LINK 2000-R. The milliVolt reading multiplied by ten should about equal the LINK

2000-R alternator current reading. The alternator current measurement is inherently less

accurate than the battery current measurement—you may see up to

+ 3 amps error.

STANDBY REGULATORS

Part of our power system design philosophy is to consider spares and backup

systems before they are needed. We have designed the Ideal Regulator with this in

mind. The Ideal Regulator Output Module wiring harness is compatible with standard P-

Field external regulators. Simply carry a spare regulator that is plug compatible and

just unplug the Output Module and plug in your standby regulator. You may use a simple,

adjustable, constant voltage regulator or we would suggest that you consider the Xantrex

Incharge Regulator, which provides three-stage charging, plug compatibility, and is fully

adjustable.

Install and test your standby regulator or any other spares you might carry

before cruising!

15

Page 16

LIMITED WARRANTY

What does this warranty cover?

This Limited Warranty is provided by Xantrex Technology, Inc. (“Xantrex”) and covers defects in workmanship and materials in your

Xantrex Link 2000-R. This warranty lasts for a Warranty Period of 12 months from the date of purchase at point of sale to you, the

original end user customer.

This Limited Warranty is transferable to subsequent owners but only for the unexpired portion of the Warranty Period.

What will Xantrex do?

Xantrex will, at its option, repair or replace the defective product free of charge, provided that you notify Xantrex of the product defect

within the Warranty Period, and provided that Xantrex through inspection establishes the existence of such a defect and that it is covered

by this Limited Warranty.

Xantrex will, at its option, use new and/or reconditioned parts in performing warranty repair and building replacement products. Xantrex

reserves the right to use parts or products of original or improved design in the repair or replacement. If Xantrex repairs or replaces a

product, its warranty continues for the remaining portion of the original Warranty Period or 90 days from the date of the return shipment

to the customer, whichever is greater. All replaced products and all parts removed from repaired products become the property of Xantrex.

Xantrex covers both parts and labor necessary to repair the product, and return shipment to the customer via a Xantrex-selected nonexpedited surface freight within the contiguous United States and Canada. Alaska and Hawaii are excluded. Contact Xantrex Customer

Service for details on freight policy for return shipments outside of the contiguous United States and Canada.

How do you get service?

If your product requires troubleshooting or warranty service, contact your merchant. If you are unable to contact your merchant, or the

merchant is unable to provide service, contact Xantrex directly at:

Phone: 1 800 670 0707 (toll free in North America) 1 604 422 2777 (direct)

Fax: 1 604 420 2145

Email: CustomerService@xantrex.com

Direct returns may be performed according to the Xantrex Return Material Authorization Policy described in your product manual. For

some products, Xantrex maintains a network of regional Authorized Service Centers. Call Xantrex or check our Web site to see if your

product can be repaired at one of these facilities.

In any warranty claim, dated proof of purchase must accompany the product and the product must not have been disassembled or modified

without prior written authorization by Xantrex.

Proof of purchase may be in any one of the following forms:

• The dated purchase receipt from the original purchase of the product at point of sale to the end user, or

• The dated dealer invoice or purchase receipt showing original equipment manufacturer (OEM) status, or

• The dated invoice or purchase receipt showing the product exchanged under warranty

What does this warranty not cover?

This Limited Warranty does not cover normal wear and tear of the product or costs related to the removal, installation, or troubleshooting

of the customer’s electrical systems. This warranty does not apply to and Xantrex will not be responsible for any defect in or damage to:

a) the product if it has been misused, neglected, improperly installed, physically damaged or altered, either internally or externally,

or damaged from improper use or use in an unsuitable environment;

b) the product if it has been subjected to fire, water, generalized corrosion, biological infestations, or input voltage that creates

operating conditions beyond the maximum or minimum limits listed in the Xantrex product specifications including high input

voltage from generators and lightning strikes;

c) the product if repairs have been done to it other than by Xantrex or its authorized service centers (hereafter “ASCs”);

d) the product if it is used as a component part of a product expressly warranted by another manufacturer;

e) the product if its original identification (trade-mark, serial number) markings have been defaced, altered, or removed.

Disclaimer

Product

THIS LIMITED WARRANTY IS THE SOLE AND EXCLUSIVE WARRANTY PROVIDED BY XANTREX IN CONNECTION WITH

YOUR XANTREX PRODUCT AND IS, WHERE PERMITTED BY LAW, IN LIEU OF ALL OTHER WARRANTIES, CONDITIONS,

GUARANTEES, REPRESENTATIONS, OBLIGATIONS AND LIABILITIES, EXPRESS OR IMPLIED, STATUTORY OR OTHERWISE

IN CONNECTION WITH THE PRODUCT, HOWEVER ARISING (WHETHER BY CONTRACT, TORT, NEGLIGENCE, PRINCIPLES

OF MANUFACTURER’S LIABILITY, OPERATION OF LAW, CONDUCT, STATEMENT OR OTHERWISE), INCLUDING WITHOUT

RESTRICTION ANY IMPLIED WARRANTY OR CONDITION OF QUALITY, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE TO

THE EXTENT REQUIRED UNDER APPLICABLE LAW TO APPLY TO THE PRODUCT SHALL BE LIMITED IN DURATION TO

THE PERIOD STIPULATED UNDER THIS LIMITED WARRANTY.

IN NO EVENT WILL XANTREX BE LIABLE FOR ANY SPECIAL, DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, LOSSES, COSTS OR EXPENSES HOWEVER ARISING WHETHER IN CONTRACT OR TORT INCLUDING WITHOUT

RESTRICTION ANY ECONOMIC LOSSES OF ANY KIND, ANY LOSS OR DAMAGE TO PROPERTY, ANY PERSONAL INJURY, ANY

DAMAGE OR INJURY ARISING FROM OR AS A RESULT OF MISUSE OR ABUSE, OR THE INCORRECT INSTALLATION, INTEGRATION OR OPERATION OF THE PRODUCT.

Exclusions

If this product is a consumer product, federal law does not allow an exclusion of implied warranties. To the extent you are entitled to

implied warranties under federal law, to the extent permitted by applicable law they are limited to the duration of this Limited Warranty.

Some states and provinces do not allow limitations or exclusions on implied warranties or on the duration of an implied warranty or on the

limitation or exclusion of incidental or consequential damages, so the above limitation(s) or exclusion(s) may not apply to you. This

Limited Warranty gives you specific legal rights. You may have other rights which may vary from state to state or province to province.

16

Page 17

Warning: Limitations On Use

Please refer to your product user manual for limitations on uses of the product. Specifically, please note that the Link 2000-R is not

intended for use in connection with life support systems and Xantrex makes no warranty or representation in connection with any use of

the product for such purposes.

Return Material Authorization Policy

Before returning a product directly to Xantrex you must obtain a Return Material Authorization (RMA) number and the correct factory

“Ship To” address. Products must also be shipped prepaid. Product shipments will be refused and returned at your expense if they are

unauthorized, returned without an RMA number clearly marked on the outside of the shipping box, if they are shipped collect, or if they are

shipped to the wrong location.

When you contact Xantrex to obtain service, please have your instruction manual ready for reference and be prepared to supply:

• The serial number of your product

• Information about the installation and use of the unit

• Information about the failure and/or reason for the return

• A copy of your dated proof of purchase

Return Procedure

1. Package the unit safely, preferably using the original box and packing materials. Please ensure that your product is shipped fully insured

in the original packaging or equivalent. This warranty will not apply where the product is damaged due to improper packaging.

2. Include the following:

• The RMA number supplied by Xantrex Technology Inc clearly marked on the outside of the box.

• A return address where the unit can be shipped. Post office boxes are not acceptable.

• A contact telephone number where you can be reached during work hours

• A brief description of the problem

3. Ship the unit prepaid to the address provided by your Xantrex customer service representative.

If you are returning a product from outside of the USA or Canada

In addition to the above, you MUST include return freight funds and are fully responsible for all documents, duties, tariffs, and deposits.

If you are returning a product to a Xantrex Authorized Service Center (ASC)

A Xantrex return material authorization (RMA) number is not required. However, you must contact the ASC prior to returning the product

or presenting the unit to verify any return procedures that may apply to that particular facility.

17

Page 18

18

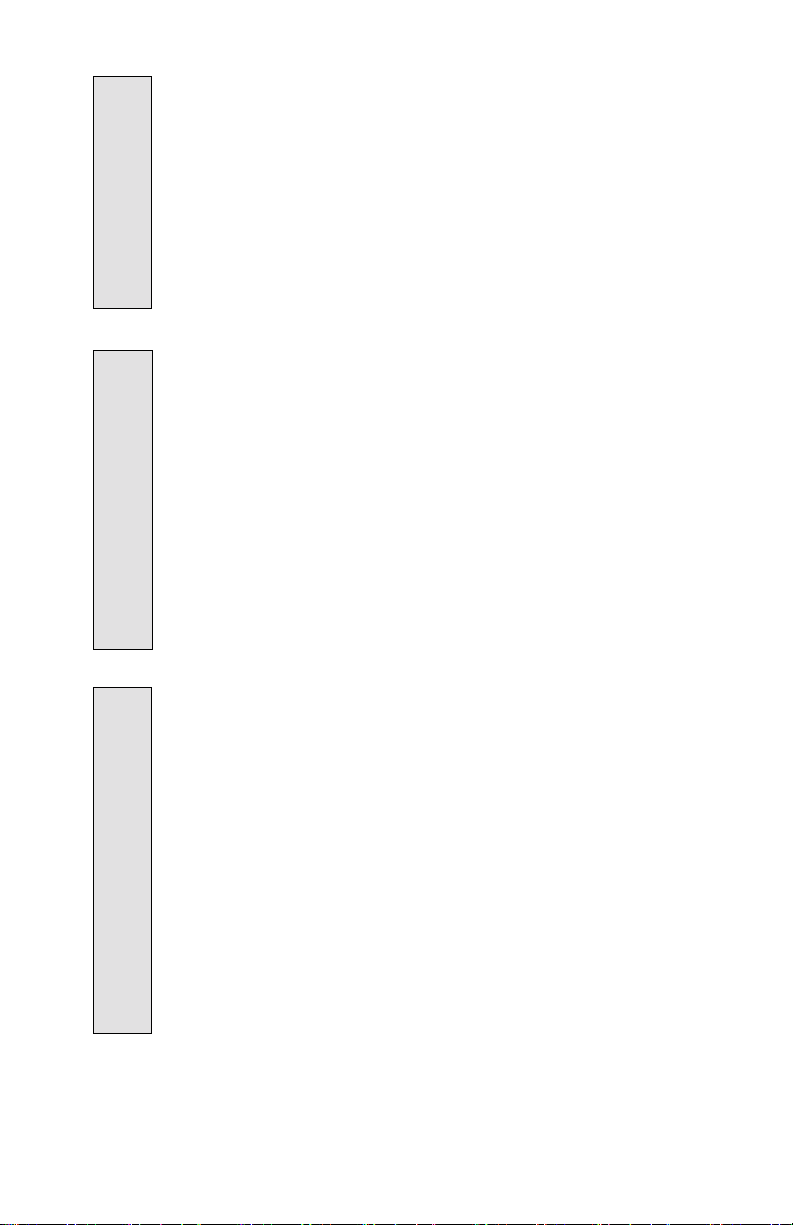

Regulator Troubleshooting Flow Chart

Most regulation problems can be solved with the following flow chart

Terminals #1 through #10 are on the Monitor Terminal Board.

Check

alternatorbelts, field

wire,alternator

ground, & field gnd.

Is the wiring harness

YES

from the Output

Module pluged in

Is there 12V between

YES

black & red wires, if

supplying red wire

Problem in ribbon

cable or meter. Try re-

YES

If not OK call us.

correctly

not check fuse

plugging cable

YES

Should be 10 to 12V.

Check for voltage at

the alternator end of

the blue field wire.

Output Module is

bad. Replace it.

Use this flow chart to assist in troubleshooting if

you encounter unexpected results during installa-

tion, start up, and operation of your new LINK

YES

2000-R

Voltage OK, problem

in alternator. If not

OK, problem in wire

or connections.

Alternator shunt sense

leads reversed and

current > 100.

Reverse sense leads.

Disconnect the

brown REG ON

wire, is the RED

LED still lit?

NO

The problem is in

the alternator or the

external wiring.

HIGH VOLTAGE

HIGH VOLTAGE,

REGULATOR NOT

IN CONTROL.

With engine off

LIT

make sure the

Green LED REG

ON is not lit.

NOT LIT

Is the Red CHG LED

YES

Output Module lit?

NO

Be sure set up correct

for your battery

system. Is Bat#2

defeated? See manual.

Check battery voltage

sense leads. Do

progress test #1.

If alternator was

converted from

internal reg. was

diode trio removed?

NO OUTPUT

Do final progress

& startup test

described on page 14

FAIL TEST

Is the green ON LED

located on the

Output Module lit?

NO

Is there 12V between

the black wire and

the brown wire REG

ON?

NO

Is the oil pressure

switch jumpered or

the key turned on?

YES

Check circuit

supplying the switch

(fuse & wire).

If voltage is OK

problem is with

Monitor Terminal

board, replace it.

OK

alternator current

Is the Red CHG

YES

LED on the Output

Is the Charge Cycle

status light lit on the

front panel of the

Is phone cord between

Monitor Board and

plugged in correctly?

Is there about 5V

between term #1 and

the test point shown

on the Monitor TB?

Is there about 5V

between term #1 and

YES

the test point shown?

If there is no voltage

the problem is in the

No or variable

Module lit?

NO

meter?

NO

Output Module

NO

NO

phone cord or

connections.

Wires referred to by color are in the wiring harness for the Ideal Regulator Output Module

Page 19

19

Page 20

T

Xantrex Technology Inc.

Toll free 1 800 670 0707

Direct 1 604 422 2777

Fax 1 604 420 2145

CustomerService@xantrex.com

www.xantrex.com

445-0197-01-01Rev. 1 Printed in the U.S.A.

Loading...

Loading...