Page 1

Xantrex

™

Heavy Duty Inverter•Charger 1012

with Ignition Protection

Installation Guide

Page 2

About Xantrex

Xantrex Technology develops, manufactures, and markets leading advanced power electronic and control products

for the Distributed, Mobile, and Programmable Power markets. The company’s enabling technology converts raw

electrical power from any central, distributed, or backup power source into high-quality power required by electronic

and electrical equipment.

Trademarks

Xantrex is a registered trademark of Xantrex International. © 2002 Xantrex International. All rights reserved.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used

herein for identification purposes only.

Notice of Copyright

Xantrex™ Heavy Duty Inverter•Charger 1012 with Ignition Protection Installation Guide © May 2002 Xantrex

International.

Disclaimer

Xantrex manufactures its products from parts and components that are new or equivalent to new, in accordance with

industry-standard practices.

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR

OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE

OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

May 2002, Revision 1

Part number

445-0173-01-01 Rev 1

Contact information

Telephone: 1-800-670-0707 (toll free in North America)

1-604-420-1585 (outside North America)

Fax: 1-800-994-7828 (toll free in North America)

1-604-420-1591 (outside North America)

Email: CustomerService@xantrex.com

Web: www.xantrex.com

Page 3

Contents

Important Safety Instructions

Explosive Gas Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Precautions When Working With Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

FCC Information to the User - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ix

1 Installation Planning

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

AC Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Shorepower - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Disconnect and Over-Current Protection Device - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Distribution panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–4

AC wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

AC Output Neutral Bonding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

DC Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

DC Cabling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

DC Disconnects and Over-Current Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–7

Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Locating the Inverter•Charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

2 Installing the IP1012

About the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Materials List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Tools and Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Installing the IP1012 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Mounting the Inverter•Charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Connecting the AC Input Flexible Cord - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Wiring considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–5

AC Input Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–5

Connecting the AC Output Flexible Cord - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Connecting the DC Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

DC Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Connecting the Battery Temperature Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Mounting Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Mounting to the Negative Battery Terminal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Mounting to the Side of the Battery Case - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Mounting the Remote Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Page 4

Contents

Starting the Inverter•Charger- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

Testing the Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

3 Battery Types and Sizes

Battery Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–1

Automotive Starting Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–1

Deep-Cycle Lead-Acid Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Battery Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Estimating Battery Requirements- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Battery Sizing Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Battery Sizing Worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Using Multiple Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Two Batteries Connected In Parallel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Two Separate Battery Banks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Battery Tips - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Index–1

iv

Page 5

Figures

Figure 1-1 Typical IP1012 installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Figure 2-1 Mounting holes on base - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Figure 2-2 Mounting the IP1012- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Figure 2-3 Bracket mounting option - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–5

Figure 2-4 AC input terminal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Figure 2-5 Making the AC input connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Figure 2-6 Connection order for DC cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Figure 2-7 Connection at DC terminal of the IP1012 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Figure 2-8 Connection at the battery - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Figure 2-9 DC Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Figure 2-10 BTS on Negative Battery Terminal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Figure 2-11 BTS Attached to Battery Case- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Figure 2-12 Connecting the battery temperature sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Figure 2-13 Remote switch dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Figure 2-14 Final mounting of the remote switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

Figure 3-1 Configuration for Normal Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Figure 3-2 Configuration for Heavy Loads- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

445-0173-01-01 Rev 1 v

Page 6

vi 45-0173-01-01 Rev 1

Page 7

Important Safety Instructions

WARNING

This section contains important safety and operating

instructions as prescribed by UL and CSA standards for

inverter•chargers used in residential, RV, and other

applications. Read and keep this Installation Guide for future

reference.

1. Before using the inverter•charger, read all instructions and cautionary

markings on the charger, the batteries, and all appropriate sections of this

guide.

2. While this unit is sealed, Xantrex does not recommend that it be

continuously exposed to rain, snow, spray, or bilge water. Do not install the

charger in a zero-clearance or small-clearance compartment. It may reduce

the usable power range.

3. Use only attachments recommended or sold by the manufacturer. Doing

otherwise may result in a risk of fire, electric shock, or injury to persons.

4. The inverter•charger is designed to be permanently connected to your AC

and DC electrical systems. Xantrex recommends that all wiring be done by

a certified technician or electrician to ensure adherence to the local and

national electrical codes applicable in your application.

5. To avoid a risk of fire and electric shock, make sure that existing wiring is

in good condition and that wire is not undersized. Do not operate the

inverter•charger with damaged or substandard wiring.

6. Do not operate the inverter•charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. If the unit is damaged, see the

Warranty section in Appendix B, “Product and System Information” in the

Operation Guide.

vii

Page 8

Important Safety Instructions

7. Do not disassemble the inverter•charger. See Appendix D, “Product

and System Information” in the Operation Guide for instructions on

obtaining service. Attempting to service the unit yourself may result

in a risk of electrical shock or fire. Internal capacitors remain charged

after all power is disconnected.

8. To reduce the risk of electrical shock, disconnect both AC and DC

power from the inverter•charger before attempting any maintenance

or cleaning or working on any circuits connected to the unit. Turning

off controls will not reduce this risk.

9. The inverter•charger must be provided with an equipment-grounding

conductor connected to the AC input ground.

Explosive Gas Precautions

1. Working in the vicinity of lead-acid batteries is dangerous. Batteries

generate explosive gases during normal operation. Therefore you

must read this guide and follow the instructions exactly before

installing or using your inverter•charger.

2. The IP1012 has been approved as Ignition Protected. It may be

installed in areas containing gasoline tanks and fittings which require

Ignition Protected equipment. Xantrex recommends, nevertheless,

that it is safest not to install electrical equipment in these areas.

3. To reduce the risk of battery explosion, follow these instructions and

those published by the battery manufacturer and the manufacturer of

the equipment in which the battery is installed.

Precautions When Working With Batteries

1. Have someone within range of your voice or close enough to come to

your aid when you work near a lead-acid battery.

2. Have plenty of fresh water and soap nearby in case battery acid

contacts skin, clothing, or eyes.

3. Wear complete eye protection and clothing protection. Avoid

touching your eyes while working near batteries.

4. If battery acid contacts skin or clothing, wash immediately with soap

and water. If acid enters your eye, immediately flood it with running

cold water for at least twenty minutes and get medical attention

immediately.

viii 445-0173-01-01 Rev 1

Page 9

FCC Information to the User

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential environment.

This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction guide,

may cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning equipment off and on, the

user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Important Safety Instructions

445-0173-01-01 Rev 1 ix

Page 10

x 445-0173-01-01 Rev 1

Page 11

1

Installation Planning

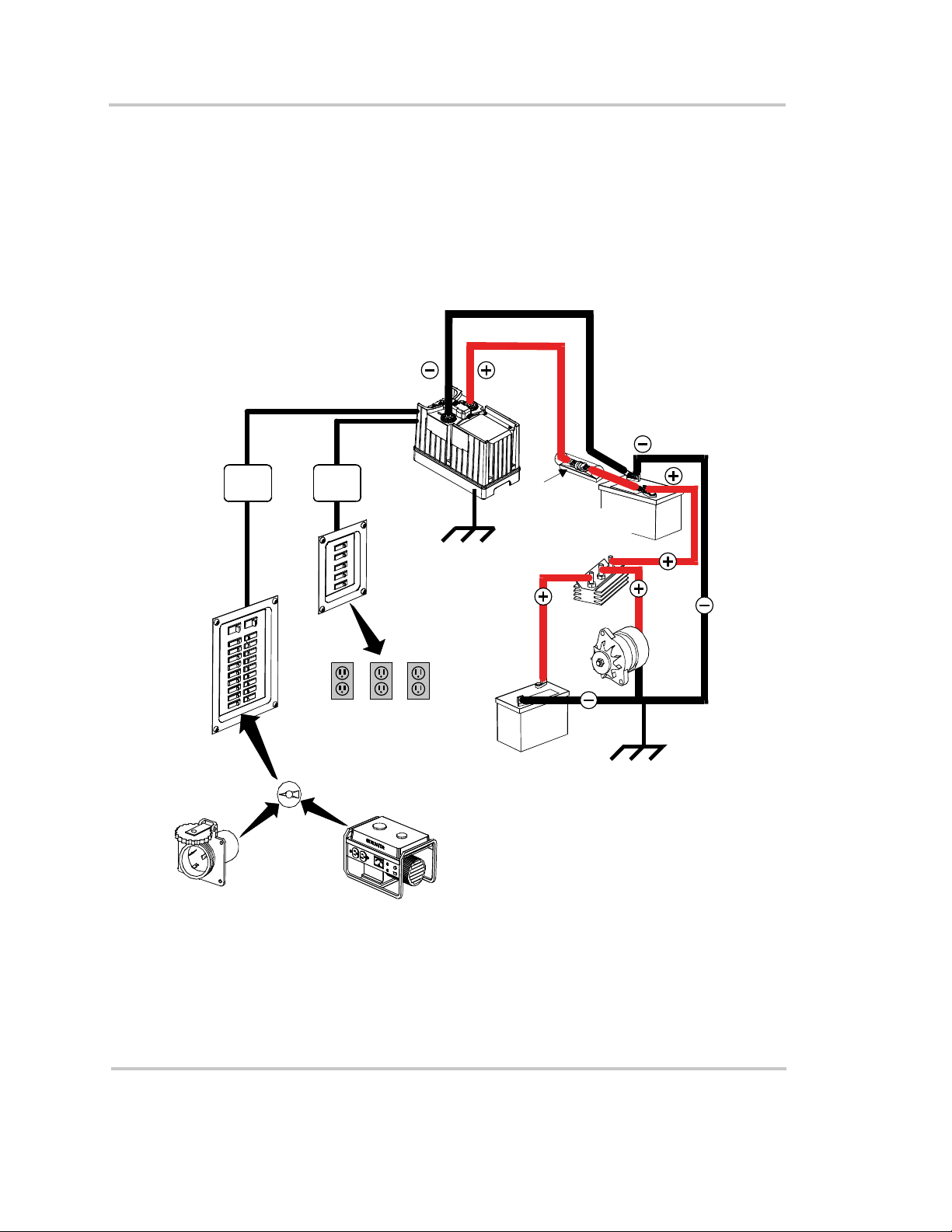

Chapter 1 provides information to help you plan for a

suitable installation for the IP1012. The chapter provides a

system diagram showing the components of an installation,

and provides information about each component. It also

discusses other installation considerations such as neutral to

ground bonding and the physical location of the unit.

Page 12

Installation Planning

Introduction

All types of inverter•charger installations, residential or mobile, share

common components. This chapter describes each component.

The system shown in Figure 1-1 is a basic installation. If your

requirements are more complex than this, Xantrex recommends that you

consult a qualified installer or electrician.

DC Input/Output

AC Input

AC Output

JUNCTION

BOX

Main AC Panel

Shorepower

JUNCTION

BOX

Chassis ground

AC Subpanel with

GFCI

AC Loads

Generator

DC fuse or

circuit breaker

Vehicle start

battery

12 Volt

deep cycle battery

Battery

isolator

Chassis ground

Figure 1-1 Typical IP1012 installation

1–2 445-0173-01-01 Rev 1

Page 13

AC Components

Shorepower

A source of 120 volt, 60 Hz alternating current

JUNCTION

JUNCTION

BOX

BOX

Note: Throughout this manual, the term “shorepower” refers to AC input

power from a utility grid, high-quality generator, or other source.

Disconnect and Over-Current Protection Device

To meet UL 458, and electrical code requirements, the inverter•charger

AC inputs and outputs must be provided with over-current protection

(such as a circuit breaker or fuse) and a disconnect device on both the AC

input and output:

is needed to provide energy for charging

batteries and to pass through to AC loads. This

source could be the utility grid (power

company) or an AC generator. Multiple sources

of good-quality shorepower can be used

Introduction

AC Input The circuit breaker or fuse used to

JUNCTION

JUNCTION

BOX

BOX

protect the

IP1012 Inverter•Charger must be

rated no more than 15 amps and must be

approved for use on 120 VAC branch circuits.

This circuit breaker or fuse is often in the

shorepower source. If the shorepower rating is

more than 15 amps, you need to add an

additional 15 amp breaker or fuse at the

junction box or electrical panel to which the IP1012 AC input is wired.

The wire used between the breaker and the inverter•charger input must be

sized to match the circuit breaker, in accordance with the electrical codes

or regulations applicable to your installation.

AC Output The circuit breaker or fuse

must be rated at no more than 15 amps and must

JUNCTION

JUNCTION

BOX

BOX

be approved for use on 120 VAC branch

circuits. The wire used between the

inverter•charger and the AC output breaker

must be sized to match the AC output circuit

breaker’s rating (#14 AWG or larger). The wire

from the AC output breaker to your loads must

be matched to the rating of the AC output

breakers.

445-0173-01-01 Rev 1 1–3

Page 14

Installation Planning

GFCI requirements Installations in recreational vehicles may require

GFCI protection of branch circuits connected to the AC output of the

inverter•charger. In addition, electrical codes require GFCI protection of

certain receptacles in residential installations.

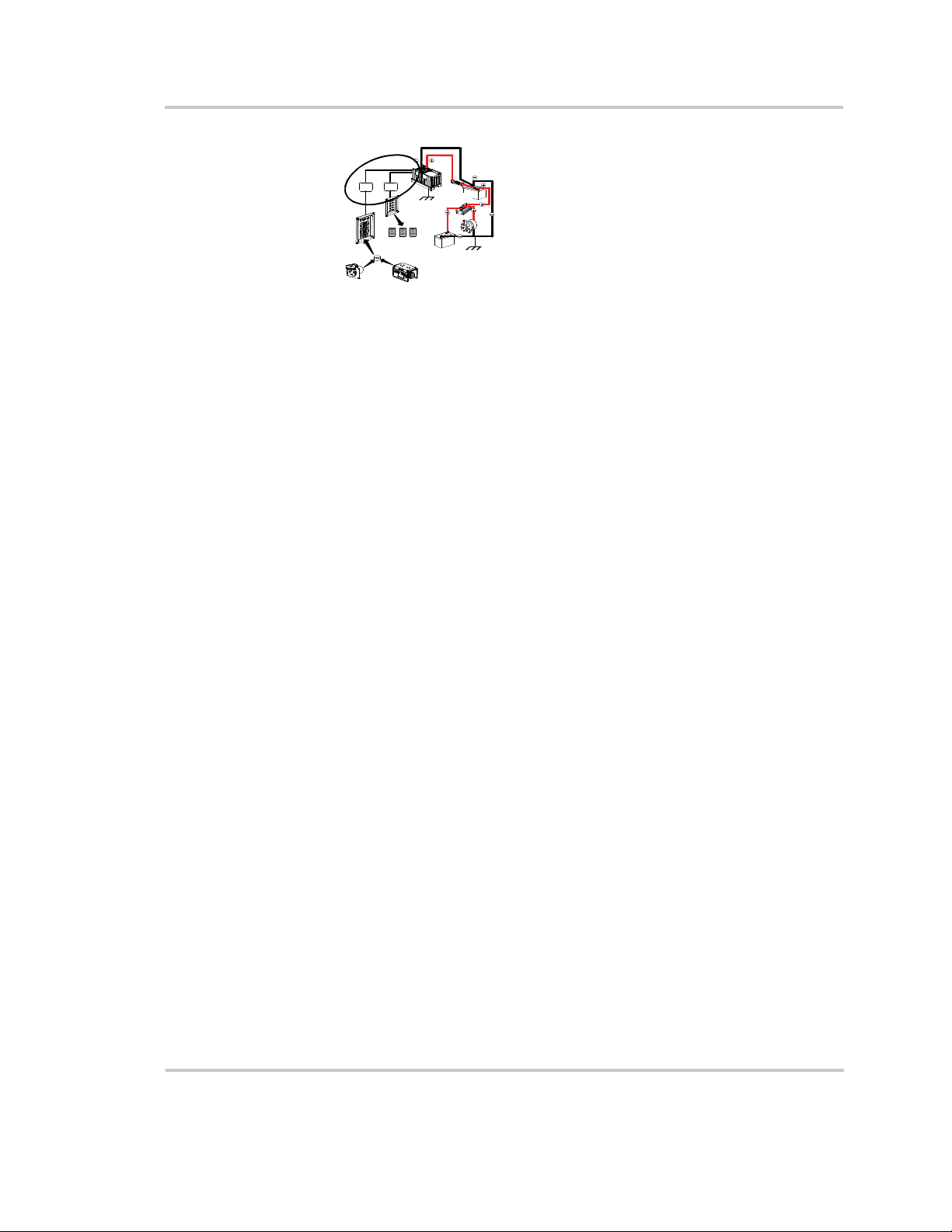

Tes te d G F CI s Compliance with UL standards requires that Xantrex

test and recommend specific GFCIs. Xantrex has tested the GFCIprotected 15 amp receptacles listed in Table 1-1 and found that they

function properly when connected to the AC output of the

Table 1-1 Tested GFCI Models

Manufacturer Model number

Pass &Seymour / Legrand 1591-WCN

Leviton 6598W

Bryant GFR82FTI

Hubbell GF5252GYA

Yatai Switch YT15-G

IP1012.

Disconnect Devices: Each system requires a method of disconnecting

the AC circuits. If the over-current protection device is a circuit breaker, it

will also serve as the disconnect. If fuses are used, separate AC

disconnect switches are needed ahead of the fuses.

Distribution panels

Most systems incorporate distribution centers

both ahead of the inverter•charger and between

JUNCTION

JUNCTION

BOX

BOX

the inverter•charger and the loads (the AC load

panel). A source panel includes a main circuit

breaker, which serves as over-current protection

and as a disconnect for the AC shorepower

supply line. Additional circuit breakers serve

individual circuits, one of which serves the

inverter•charger. The AC load panel can

incorporate both the main 15 amp breaker or

fuse with disconnect if the AC output cable is directly wired into the

panel.

Note: The IP1012 is designed to be connected only to single phase

wiring circuits (line, neutral, and ground)

1–4 445-0173-01-01 Rev 1

Page 15

Introduction

AC wiring

Definition AC wiring includes all the wires and connectors

between the AC source and the inverter•charger

JUNCTION

JUNCTION

BOX

BOX

and all wiring between the inverter•charger and

the AC panels, circuit breakers, and loads.

Size and type The type and size of the wiring varies with the installation and load. For

marine and some RV applications, flexible multiple-strand wire is

required. For residential installations, solid armored cable is often used.

Local installation codes may specify solid or stranded, overall size of the

conductors, and type and temperature rating of the insulation around the

wire. Xantrex recommends stranded wire for high-vibration

environments.

Size and AC

breaker rating

AC wiring must be sized to match the current rating of the AC breakers

you provide on the input and output AC circuits in accordance with the

electrical codes or regulations applicable to your installation. Xantrex

recommends a breaker size of 15 amps, and minimum wire size of

14 AWG.

Other codes and regulations may be applicable to your installation.

AC Output Neutral Bonding

Bonding system The IP1012 provides an non-defeatable system that automatically

connects the neutral conductor of the inverter AC output circuit to safety

ground (“bonding” it) during inverter operation, and disconnects it (“unbonding” it) when the inverter•charger is connected to AC shorepower.

This system is designed to conform to installation codes that require

single-phase AC sources such as inverters and generators to have their

neutral conductors tied to ground in the same way that the neutral

conductor from the utility is tied to ground.

Transfer relay These same codes specify that the neutral can only be connected to

ground in one place at any one time. Any AC source feeding the IP1012 is

required to have its neutral already connected to ground. Therefore, to

keep from connecting the neutral to ground in a second place, the transfer

relay breaks its own neutral ground connection when connected to

shorepower.

445-0173-01-01 Rev 1 1–5

Page 16

Installation Planning

Suitability This automatic neutral-to-ground bonding system is suited for

installations in which the AC shorepower source is known to have a

bonded neutral. This will be the case in most situations: in a utility feed

after the AC source panel, at a shorepower hook-up, or a generator with a

bonded neutral.

Neutral conductor The neutral conductor of the inverter•charger’s AC output circuit is

automatically connected to the chassis ground during inverter operation.

When AC utility power is present and the inverter•charger is in charge

mode, this connection is not present, so that the utility neutral is only

connected to ground at your source panel. This conforms to National

Electrical Code requirements that separately derived AC sources (such as

inverters and generators) have their neutral conductors tied to ground in

the same way that the neutral conductor from the utility is tied to ground

at the AC source panel.

DC Components

DC Cabling

DC cabling includes all the cables and

connectors between the batteries, the DC

JUNCTION

JUNCTION

BOX

BOX

number indicates a larger cable. Wire size is usually marked on the cables

for sizes this large.

disconnect and over-current protection device,

and the inverter•charger. All installations

require multi-strand insulated cables as well as

disconnect and over-current devices. DC cable

sizes are indicated by AWG notation or MCM

notation. Under the AWG standard, a larger

gauge number indicates a smaller wire

diameter. Under the MCM standard, a larger

Xantrex offers a DC cable kit (808-0795) containing two six-foot lengths

of DC cables designed for the IP1012. If you require cables of a different

length see Table 1-2 for minimum DC cable size and maximum fuse size

for the IP1012. The DC cables must be copper and must be rated

75 °C minimum. For some applications you may require higher

temperature wires.

Table 1-2 Required DC Cable and Fuse Size

DC Cable Length Cable Size Fuse Amps

Less than 6 feet 2/0 AWG or larger 300A class T

Between 6 and 10 feet 4/0 AWG or larger 300A class T

1–6 445-0173-01-01 Rev 1

Page 17

DC Disconnects and Over-Current Devices

The DC circuit from the battery to the inverter•charger

must be equipped with a disconnect and over-current

JUNCTION

JUNCTION

BOX

BOX

device. This usually consists of a circuit breaker, a

“fused-disconnect,” or a separate fuse and DC

disconnect. Do not confuse AC circuit breakers with

DC circuit breakers. They are not interchangeable.

The rating of the fuse or breaker must be matched to

the size of cables used in accordance with the

applicable installation codes. The breaker or

disconnect and fuse should be located as close as

possible to the battery, in the positive cable. Applicable codes may limit how far

the protection can be from the battery.

Batteries

Every IP1012 system requires a 12 volt, flooded lead-acid deep-cycle battery or

group of batteries to provide the DC current that the inverter•charger converts to

AC.

Chapter 3 provides more information about battery configurations for normal

and heavy loads.

Locating the Inverter•Charger

Note: The IP1012 does not charge GEL or AGM batteries. It only uses

12-volt flooded, lead-acid battery banks.

Locating the Inverter•Charger

The inverter•charger should only be installed in locations meeting the following

requirements:

Sheltered While the unit is sealed, Xantrex does not recommend

that fluids or water should be allowed to continuously

drip or splash on the unit.

Cool Normal air temperature should be between 32°F and

77°F (0°C and 40°C)—the cooler the better.

Ventilated Allow at least 4 inches (10 cm) of clearance all around

the unit. The more clearance for ventilation around the

unit, the better the performance.

445-0173-01-01 Rev 1 1–7

Page 18

Installation Planning

Safe The unit is ignition protected and can be stored in the

same area containing gasoline tanks and fittings which

require ignition protected equipment. Xantrex

recommends, nevertheless, it is safest not to install

electrical equipment in these areas, if possible.

Close to batteries Avoid excessive cable lengths (which reduce input and

output power due to wire resistance). Use the

recommended cable lengths and sizes.

Protected from

battery acid and

gases

Close to AC

junction box

Never allow battery acid to drip on the

inverter•charger or its wiring when reading specific

gravity or filling the battery. Also, do not mount the

unit where it will be exposed to gases produced by the

batteries. These gases are very corrosive, and

prolonged exposure will damage the inverter•charger.

Avoid excessive cable lengths and use the

recommended wire length and sizes. Undersized or

unnecessarily long cables may affect charging

accuracy.

1–8 445-0173-01-01 Rev 1

Page 19

2

Chapter 2 lists the tools and materials you need to install the IP1012.

The chapter also suggests methods for mounting the unit, and provides

procedures to install and test the system.

Important: The installer is responsible for meeting all electric

codes for installing an inverter•charger.

Installing the IP1012

Page 20

Installing the IP1012

About the Installation

Before beginning your installation:

• Read the entire chapter before you begin the installation.

• Assemble all tools and materials you require for the installation.

• Review all the safety instructions on page vii.

Materials List

Contents The following materials should be in the shipping box:

❐ Inverter•Charger

❐ Battery terminal covers (1 red, 1 black)

❐ Ground lug (with mounting screw and washer)

❐ Remote switch (with mounting screws)

❐ Battery temperature sensor

❐ AC input and output cables

❐ Battery terminal nuts, lock washers and flat washer

❐ M8x20 mounting bolts, washers, and lock washers

❐ Installation Guide

❐ Operation Guide

Optional You may purchase an optional DC Cable Kit (808-0795) or a DC Cable

and Mounting kit (808-0796) from Xantrex.

Recording

information

After unpacking the unit and checking the material list, record the serial

number of the IP1012 and other purchase information in Appendix B of

the Operation Guide. If you need to call Xantrex Customer Service, you

will be asked for this information.

Tools and Materials

You need the following tools and materials to install the inverter•charger,

remote switch, and battery temperature sensor:

❐ Wire stripper

❐ #2 Phillips screwdriver

❐ Needle-nose pliers

❐ 1 slot screwdriver

❐ Wrench for DC terminals (

2–2 445-0173-01-01 Rev 1

9/16 inch or 14 mm or adjustable)

Page 21

❐ Wire connectors or crimp connectors for AC wire and appropriate

tools

❐ Two strain-relief clamps for AC cables

❐ DC battery or welding cables, 2 x6 feet of 2/0 or 2 x 10 feet of 4/0 if

you have not purchased the optional kit.

❐ 4 x 2/0 or 4 x 4/0 lugs if you have not purchased the DC cable kit

OR

❐ 6 x 2/0 or 6 x 4/0 lugs for using a fused disconnect

❐ Crimping tools, if necessary

❐ AC and DC disconnects and over-current protective devices

❐ AC output GFCI

❐ Copper wire for grounding

Installing the IP1012

Overview

Installing the IP1012

There are six main steps in the installation of the IP1012:

1. Mounting the inverter•charger

2. Connecting the AC input flexible cord

3. Connecting the AC output flexible cord

4. Grounding the DC ground

5. Connecting the battery temperature sensor.

6. Mounting and connecting the remote switch

Mounting the Inverter•Charger

Requirements To meet regulatory requirements the IP1012 must be mounted securely so

that the bottom surface is horizontal. You can meet this requirement by

securing the unit to a platform or custom bracket from the underside of

the unit. Then the platform or bracket must be firmly secured to the floor

or wall.

Optional Xantrex offers a bracket designed specifically for the IP1012, part number

808-0272. You may contact Customer Service for details. The bracket is

shown in Figure 2-3.

Floor mounting Figure 2-1 shows the position and distance between the mounting holes

on the base of the unit.

445-0173-01-01 Rev 1 2–3

Page 22

Installing the IP1012

152 mm (6”)

Figure 2-1 Mounting holes on base

To floor mount the IP1012:

1. Place the unit on a flat mounting surface with the holes drilled

according to Figure 2-1.

2. Mount each corner as shown in Figure 2-2.

3. Torque bolts to 5.6 to 6.2 ft-lbs.

4. Secure the mounting surface to the floor.

Inverter•charger

Mounting surface

Flat washer

Lock washer

M8 bolt

Figure 2-2 Mounting the IP1012

2–4 445-0173-01-01 Rev 1

Page 23

Installing the IP1012

Bracket mounting You may also mount the IP1012 in a custom bracket, then secure it to the

floor or wall. Figure 2-3 shows the Xantrex mounting bracket.

Figure 2-3 Bracket mounting option

Connecting the AC Input Flexible Cord

WARNING: Fire, Shock, and Energy Hazards

Make sure wiring is disconnected from all electrical sources

before handling. All wiring must be done in accordance with

local and national electrical wiring codes. Do not connect the

output terminals of the inverter•charger to any incoming AC

source.

Wiring considerations

Connectors Connect AC wires to shorepower with twist-on wire connectors or crimp-

on splice connectors according to the type of installation:

• For installations subject to vibration, use crimp-on connectors.

• For installations in locations not subject to vibration, twist-on wire

connectors may be used instead of crimp-on connectors.

Stripping insulation The amount of insulation you strip off individual wires will be specified

by the connector manufacturer and is different for different types of

connectors.

AC Input Connections

To make the AC input connections:

1. Strip about two inches off the jacket from the AC cord (15 ft/4.5 m)

with the female connector and separate the three wires.Strip

insulation from each of the wires according to the guidelines given by

the connector manufacturer.

2. Feed the wire into a junction box, electrical panel or other source.

445-0173-01-01 Rev 1 2–5

Page 24

Installing the IP1012

1

3. Secure with a strain relief clamp.

4. Connect wires as follows:

• the IP1012 green wire to the shorepower green or bare copper ground

wire to the appropriate ground screw inside the junction box or

electrical panel as per local electrical codes.

• the IP1012 white wire to the shorepower white wire (neutral)

connection or to the neutral bus in the case of an electrical breaker

panel.

• the IP1012 black to the shorepower black (hot) feed, or directly to a

breaker.

5. Plug the AC input cord into the unit as shown in Figure 2-5. You must

line up the small slot on the connector with the equivalent key on the

input IP1012 as shown in Figure 2-4. Rotate the connector back and

forth to align them, then insert fully.

Figure 2-4 AC input terminal

6. Turn the collar of the connector clockwise about 1/2 turn until you

feel it lock in place. Test that it is firmly seated and cannot be pulled

out.

l

2

as shown in “2”

Figure 2-5 Making the AC input connection

2–6 445-0173-01-01 Rev 1

Page 25

Connecting the AC Output Flexible Cord

To make the AC output wiring connections:

1. Strip about two inches of the jacket from the end of the AC cord

(15 ft/4.5 m) with the male connector and separate the three wires.

Strip insulation from each of the wires according to the guidelines

given by the connector manufacturer.

2. Feed the wires into a knock-out with a strain relief in an AC load

panel or junction box through a 15 amp circuit breaker and GFCI.

3. Tighten the strain relief.

4. Connect the black wire (line) to the breaker, white to the AC load

neutral wire or neutral terminal strip, the green wire to the AC load

ground wire green or bare copper, and/or the ground screw according

to your local electrical code.

5. Connect the AC output connector in a similar fashion to the AC input

as shown in Figure 2-5. The connector slots and key must line up

before the connector can be inserted.

Connecting the DC Cables

Installing the IP1012

CAUTION: Reverse Polarity

Before making the final DC connection, check cable polarity at

both the battery and the inverter•charger. Positive must be

connected to positive; negative must be connected to negative.

Reversing the positive and negative battery cables will damage

the inverter•charger and void your warranty. This type of

damage is easily detected.

WARNING: Fire Hazard

Use only copper wire rated 75 °C minimum. Some applications

may require a higher temperature rated wire. Make sure all DC

connections are tight to a torque of 12-15 ft-lbs (16–20 Nm).

Loose connections will overheat and may cause fire.

Preparation If you are not using the DC cable kit, your DC cables should be as short as

possible and large enough to handle the required current, in accordance

with the electrical codes or regulations applicable to your installation.

Table 1-2 on page 1–6 specifies the minimum DC cable size and

maximum fuse size for the IP1012.

To prepare the DC cables:

1. Cut the negative cable to a six-foot length with enough insulation

stripped off so you can install the terminal you will be using.

445-0173-01-01 Rev 1 2–7

Page 26

Installing the IP1012

The DC terminals are designed to fit up to 500 MCM crimp-on ring

(lug) terminals or box connectors which have a 3/8 inch hole.

2. Cut two lengths of positive cable; one length to go from the battery to

the DC breaker or fuse with disconnect; the other to go from the DC

breaker to the IP1012 terminal.

3. Attach the connectors to the ends of the cables.

4

3

Fuse and

disconnect

or D

C Breaker

2

5

1

Figure 2-6 Connection order for DC cables

Figure 2-6 shows the connection order for the DC cables.

To connect the DC cables:

1. Route the DC cables from the battery bank to the inverter•charger but

don’t connect them yet.

Do not route your DC cables through an electrical distribution panel,

battery isolator, or other device that will cause additional voltage

drops.

2. Install a fuse and disconnect or DC breaker in an approved enclosure,

according to your local electrical code, between the inverter•charger

and the battery (2 in Figure 2-6) and secure the enclosure.

Fuses and breakers must be installed in the positive side of the DC

circuit, as close as possible to the battery, but not in the battery

enclosure. This protects your battery and wiring in case of accidental

shorting. (See Table 1-2 on page 1–6 for required fuse size.)

3. Attach one connector on the positive cable to the positive DC

terminal on the IP1012 as shown in Figure 2-7, and then attach the

other connector to the POSITIVE (+) terminal DC breaker or fused

disconnect. (1 in Figure 2-6)

2–8 445-0173-01-01 Rev 1

Page 27

3/8 “ nut

Lock washer

Installing the IP1012

DC cable assembly

Flat washer

Figure 2-7 Connection at DC terminal of the IP1012

4. Use a wrench to tighten all connections to a torque of 12 to 15 ftpounds (16 to 20 Nm). Test that the cable is secure.

5. Attach the red terminal cover to the IP1012 by laying it over the

positive terminal and pressing it firmly until it “snaps” into place.

6. Attach a short DC cable from the unconnected end of the DC breaker

(2 in Figure 2-6). Tighten appropriately.

7. Observing polarity carefully, attach the other end of the short cable to

the POSITIVE (+) terminal of the battery (3 in Figure 2-6). Figure 2-

8 shows the details of the connection. Tighten this connection to the

battery manufacturer’s recommended torque.

445-0173-01-01 Rev 1 2–9

Page 28

Installing the IP1012

3/8 in nut

Lockwasher

Flat washer

DC cable

assemby

Figure 2-8 Connection at the battery

8. Connect one connector on the negative cable to the negative terminal

Torque to battery

manufacturer’s instructions

on the battery and tighten (4 in Figure 2-6). Before proceeding, check

that cable polarity is correct, and then connect the other end of the

cable to the NEGATIVE (–) terminal on the IP1012 (5 in Figure 2-6).

This is the last cable connection. Sparking is normal when it is made.

Use a wrench to tighten to a torque of 12–15 foot-pounds (16–20Nm).

Test that the cable is secure.

DC Grounding

Installation

guidelines

9. Attach the black DC terminal cover to the negative terminal.

The supplied Chassis Ground lug, to be installed on the base of the

inverter•charger in one of three locations, is used to connect the chassis of

the inverter•charger to your system’s DC grounding point as required by

regulations for some installations.

Install the grounding wire along with its “wire protector” inserted and

bent around the lug as shown in Figure 2-9.

Use copper wire that is either bare or provided with green insulation. Do

not use the DC Ground Lug for your AC grounding.

2–10 445-0173-01-01 Rev 1

Page 29

Installing the IP1012

wire protector

Figure 2-9 DC Grounding

Guidelines Follow the guidelines below that correspond to your type of installation.

These guidelines assume you are using the code-compliant DC supply

cable and fuse sizes indicated in this guide. If you are using different

sizes, refer to the applicable code for DC grounding details.

Recreational Vehicle Use 8 AWG copper wire and connect it between

the Chassis Ground lug and the vehicle’s DC grounding point (usually the

vehicle chassis or a dedicated DC ground bus).

Residential Use 4 AWG wire and connect it between the Chassis

Ground lug and your system’s DC grounding point. This will usually be

the AC service entrance grounding point or a separate ground rod.

Connecting the Battery Temperature Sensor

WARNING Energy and Explosion Hazard

Review the Important Safety Instructions on page vii

Mounting Options

You can mount the battery temperature sensor (BTS) in one of two ways:

• On the negative battery terminal. This allows the internal battery

temperature to be sensed and provides the most accurate results.

• To the side of the battery using the self-adhesive backing. This also

provides good results in most situations

445-0173-01-01 Rev 1 2–11

Page 30

Installing the IP1012

Mounting to the Negative Battery Terminal

Note: In this procedure, you must install the DC cable on the battery

terminal first. Then the sensor is installed on top of the DC cable. This

sequence is required to provide the best connection to the battery and to

thereby ensure correct performance of the sensor.

To mount the sensor on the negative battery terminal

1. Decide which battery is to be monitored.

When all battery banks are located in the same compartment, select

the battery that requires the most frequent charging (in an RV or other

applications, this is usually the “house” battery). Where a battery is

located in a separate compartment from other batteries, and where

temperatures are constantly high (as in an engine room), it is a good

idea to monitor this battery to keep it from being overcharged as a

result of its constant high temperature. In this situation, the cooler

battery bank will be slightly undercharged since it will be at a lower

temperature than the battery being monitored, but this practice of

monitoring the warmer battery will prolong the warmer battery’s life.

2. Switch off all devices operating from the battery, then allow

approximately 10 minutes for any explosive gasses to dissipate.

3. Open the battery switch, if present, to disconnect the battery.

4. Remove the nut that secures the existing negative DC wire to the

battery.

5. Move or reorient the existing negative DC wire so there is a flat

surface on which to seat the battery temperature sensor mounting

plate. You may need to bend the ring terminal and/or wires downward

to allow the sensor to seat on the top surface of the upper ring

terminal.

6. Mount the sensor directly on top of the negative DC wire terminal, as

shown in Figure 2-10, and tighten the terminal nut firmly.

2–12 445-0173-01-01 Rev 1

Page 31

Installing the IP1012

Figure 2-10 BTS on Negative

Battery Terminal

7. Check that the sensor and all wires are fastened securely.

8. Turn the battery switch on again (if you opened it in step 3).

9. Route the sensor cable to the inverter•charger and attach cable as

shown in Figure 2-12. You may need to use needle-nose pliers to

grasp the collar and turn it. Secure the cable along its length.

Mounting to the Side of the Battery Case

To mount the sensor on the battery case

1. Select the battery to be monitored (see step 1 in the preceding

procedure).

2. Select a side suitable for attaching the sensor.

The surface where the sensor is to be mounted must be flat and free

from reinforcing ribs or other raised features. As well, this surface

must be in direct internal contact with battery electrolyte, so do not

install the sensor on a side near the top of the battery or on the

battery’s top surface.

445-0173-01-01 Rev 1 2–13

Page 32

Installing the IP1012

3. Clean the selected area thoroughly to remove any oil or grease that

could prevent the sensor from adhering to the battery case, and allow

the battery case to dry thoroughly.

4. Peel the protective backing from the self-adhesive strip on the rear of

the sensor.

5. Press the sensor firmly against the clean side of the battery to fix it in

place as shown in Figure 2-11.

Adhesive backing allows

for easy mounting on side

of battery.

Figure 2-11 BTS Attached to Battery Case

6. Route the sensor cable to the inverter•charger and plug it into the BTS

connector as shown in Figure 2-12. You may need to use needle-nose

pliers to grasp the collar and turn counter clockwise.

7. Secure the cable along its length.

1

2

Figure 2-12 Connecting the battery temperature sensor

Mounting the Remote Switch

Before mounting Flush-mounting the remote switch on a wall, bulkhead or panel requires

an opening approximately 1.25 in x 2.0 in as shown in Figure 2-13. You

need about 1½ inches of free space behind the mounting surface to

accommodate the depth of the switch and wire. Be sure there is no wiring

or other obstructions within the wall before you cut the opening.

2–14 445-0173-01-01 Rev 1

Page 33

Installing the IP1012

The remote switch communication cable is 15 feet long (4.5) meters.

Check to see that the communication cable will reach to the mounting

location from the inverter

1.25 in (32 mm)

2.0 in (50 mm)

•charger.

Drill size 1/16”(1.5 mm)

All 4 holes

Figure 2-13 Remote switch dimensions

To mount the display panel:

1. Choose a location that is dry, out of direct sunlight, free from

corrosive or explosive fumes, and otherwise appropriate for mounting

an electronic device.

2. Pilot-drill the mounting holes and cut out the hole in which the panel

will be inserted.

3. Route the communications cable to the inverter•charger and connect

to the inverter•charger.

4. Place the panel in the opening and secure it with appropriate

fasteners.

445-0173-01-01 Rev 1 2–15

Page 34

Installing the IP1012

Figure 2-14 Final mounting of the remote switch

Starting the Inverter•Charger

Starting Start the IP1012 by turning it on at the remote switch. If you are

connected to shorepower the AC light illuminates steadily after an initial

startup of 30 seconds.

If you have disconnected shorepower the Battery Power light should

illuminate steadily.

Checking

installation

If shorepower is connected and the Shore Power light does not illuminate,

check that all breakers and GFCIs are reset and fuses are not blown.

Check all input and output wiring connections.

If the Battery Power light does not illuminate, check that

• all DC connections are torqued to the correct specification and that

none are loose

• the remote switch cable is properly connected

• the DC disconnect or fused disconnect is closed

• there is no reverse polarity.

If all connections are correctly made and the unit still fails to start, contact

Xantrex Customer Service at the number provided at the front of this

guide.

Testing the Installation

Purpose The purpose of testing the installation, even if it appears to be working as

expected, is to help check that the DC connections are tight and that there

are no voltage drops across the connections. Loose connections increase

the risk of fire and degrade the performance of the inverter

•charger

Tools You will require a digital voltmeter with a minimum resolution of

0.001 VDC(1mV).

Cable size The tests are based on the cable lengths and size supplied in Table 1-2 on

page 1–6.

2–16 445-0173-01-01 Rev 1

Page 35

Testing the Installation

Tests There are two tests which may be performed. The first measures the

voltage difference between battery and the IP1012. The second test

measures the voltage drop on individual cable connections.

To measure voltage difference between the battery and the IP1012:

1. Remove the terminal covers from the IP1012.

1. Ensure the AC output breaker and the GFCI are reset.

2. Plug in and operate a hand-held hair dryer or other 1000 to 1500 watt

load.

3. With the digital voltmeter leads placed directly on the battery studs,

measure the voltage at the battery between the positive and negative

terminals (3 and 4) while the load is operating.

4

3

F

us

e

d

a

is

n

co

d

o

r D

nn

e

C

ct

B

2

re

a

ke

r

5

1

4. Check the DC voltage on the IP1012 studs (1 and 5) while the load is

operating.

5. Calculate the difference between the readings. The voltage difference

should be as follows:

Load size

1000–1500

watts

Voltage drop

with fuse

less than 0.35

VDC

Voltage drop

without fuse

less than 0.2 VDC

6. If the voltage difference is greater than shown in the table, shut the

system down and re-check the tightness of all connections.

To measure the individual connection voltage drop:

1. Place one voltmeter test lead on the battery cable lug and the other on

the stud (or terminal) to which it is connected. Check to see that the

voltage drop (with full load test current) is less than 0.003 mV

(3 mV).

2. Perform this voltage check between all stud and lug connections

including the fuse (or DC disconnect) terminals and battery cable

lugs.

Customer Service If tightening the connections does not result in the desired test results,

record the readings and call Xantrex Customer Service.

445-0173-01-01 Rev 1 2–17

Page 36

2–18 445-0173-01-01 Rev 1

Page 37

3

The batteries you use strongly affect the performance of the IP1012. It is

important to connect the inverter to the correct size and type of battery.

The information in Chapter 3 will help you select, connect, and

maintain batteries that are most appropriate for your application.

Battery Types and

Sizes

Page 38

Battery Types and Sizes

Battery Types

Automotive Starting Batteries

The lead-acid battery you are most familiar with is probably the starting

battery in your automobile. An automotive starting battery is designed to

deliver a large amount of current for a short period of time (so it can start

your engine). Only a small portion of the battery’s capacity is used when

starting the engine, and it is quickly recharged by the running engine.

This type of battery is not designed for repeated cycles where the battery

is almost completely discharged and then recharged. If it is used in this

kind of deep discharge service, it will wear out very rapidly.

Deep-Cycle Lead-Acid Batteries

Deep-cycle lead-acid batteries are designed for deep discharge service

where they will be repeatedly discharged and recharged. They are

marketed for use in recreational vehicles, boats, and electric golf carts—

so you may see them referred to as RV batteries, marine batteries, or golf

cart batteries.

For most applications of the IP1012, Xantrex recommends that you use

one or more deep-cycle batteries that are separated from the vehicle’s

starting battery by a battery isolator.

A battery isolator is a solid-state electronic circuit that allows equipment

to be operated from an auxiliary battery without danger of discharging the

vehicle’s starting battery. During vehicle operation, the battery isolator

automatically directs the charge from the alternator to the battery

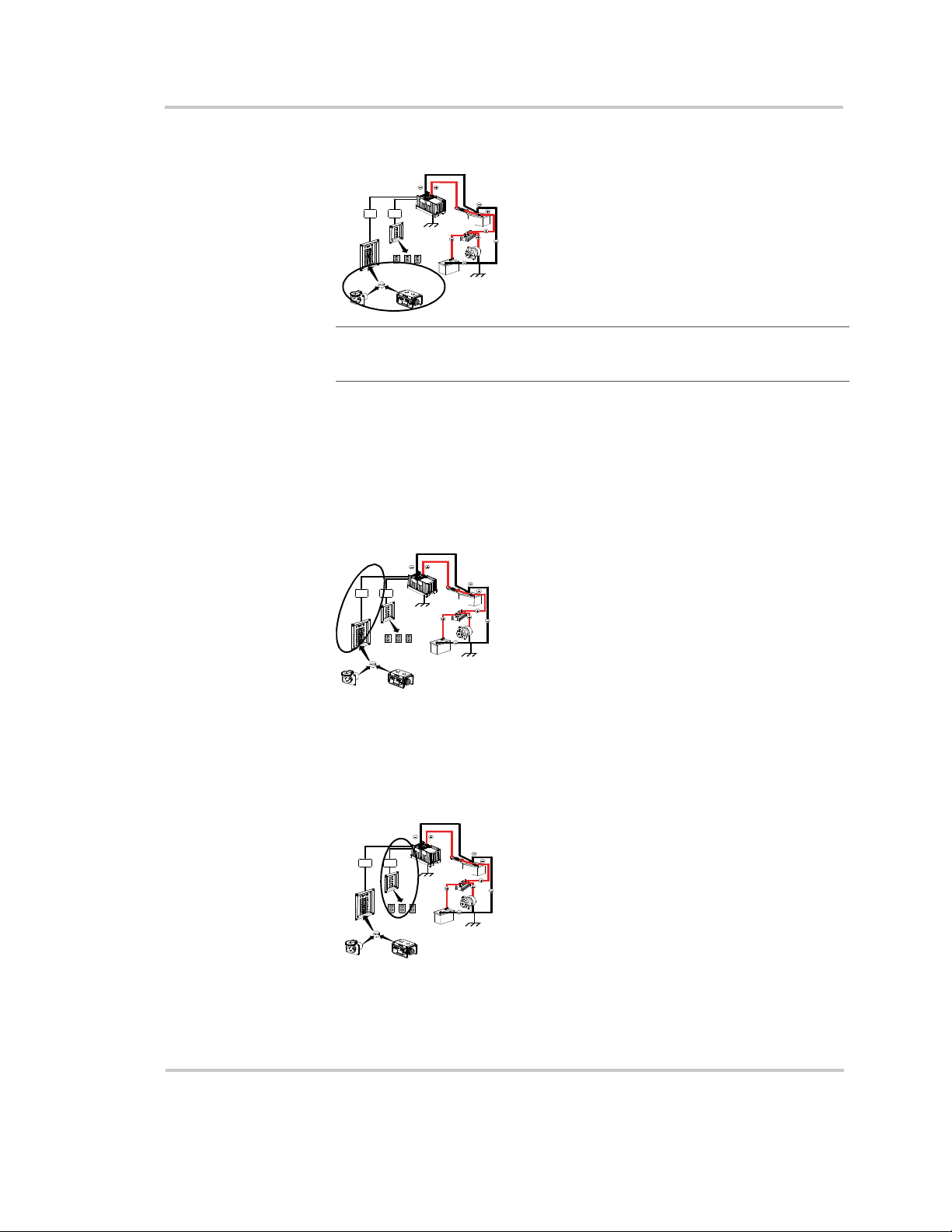

requiring the charge. Figure 3-1 and Figure 3-2 show a battery isolator in

configurations for normal and heavy-duty loads.

Battery isolators are available at marine and RV dealers and most auto

parts stores.

Battery Size

CAUTION

The IP1012 must only be connected to batteries with a nominal

output voltage of 12 volts. The IP1012 will not operate from a 6

volt battery and may be damaged if connected to a 24 volt

battery.

Importance Battery size or capacity is as important as the battery type for efficient

operation of your loads. Xantrex recommends that you purchase as much

battery capacity as possible.

3–2 445-0173-01-01 Rev 1

Page 39

Estimating Battery Requirements

Battery Capacity

Standards

A number of different standards are used to rate battery energy storage

capacity. Automotive and marine starting batteries are normally rated in

cranking amps. This is not a relevant rating for continuous loads like an

inverter. Deep-cycle batteries use a more suitable rating system, either

“amp-hours” (“Ah”) or “reserve capacity” in minutes.

Battery Reserve Capacity Battery reserve capacity is a measure of

how long a battery can deliver a certain amount of current—usually 25

amps. For example, a battery with a reserve capacity of 180 minutes can

deliver 25 amps for 180 minutes before it is completely discharged.

Amp-hour (Ah) Capacity Amp-hour capacity is a measure of how

many amps a battery can deliver for a specified length of time—usually

20 hours. For example, a typical marine or RV battery rated for 100 Ah

can deliver 5 amps for 20 hours (5 A x 20 hours = 100 Ah).

This same battery can deliver a higher or lower current for less or more

time, limited approximately by the 100 Ah figure (for example, 50 A for 2

hours, or 200 A for 1/2 hour), but usually the capacity figure given is only

accurate at the specified rate (20 hours).

To calculate the battery capacity you require, read “Estimating Battery

Requirements” on page 3–3 and “Battery Sizing Example” on page 3–4,

and then complete the “Battery Sizing Worksheet” on page 3–5.

Estimating Battery Requirements

To determine how much battery capacity you need:

1. Determine how many watts are consumed by each appliance that you

will operate from the IP1012. You can normally find this on a label on

the product. If only the current draw is given, multiply it by 115 to get

the power consumption in watts.

2. Estimate how many hours each appliance will be operating each day.

3. Calculate the daily watt-hours needed for each appliance.

4. Add the total number of watt-hours needed for all the appliances and

multiply it by the number of days between charges.

5. Divide the total watt-hours of AC load between charges by 10. This

gives the battery Ah used between charges.

6. Double the total Ah used between charges to get the recommended

battery size in Ah.

See the battery sizing example that follows.

445-0173-01-01 Rev 1 3–3

Page 40

Battery Types and Sizes

Battery Sizing Example

This battery sizing example illustrates a typical calculation, assuming an

opportunity to charge the batteries every three days.

Appliance

TV & VCR 115 W 3 hours 345 Wh

Microwave oven 1500 W 15 min = 1/4

3 lamps, 60 W

each

Coffee maker 750 W 15 min = 1/4

Coffee grinder 100 W 1 min = 1/60

Hair dryer 1500 W 6 min = 1/10

Sewing machine 150 W 30 min = 1/2

Washing machine 1500 W 30 min = 1/2

Steam iron 700 W 6 min = 1/10

Total daily watt-hours of AC load 2674.20 Wh

x Number of days between charges 3

= Total watt-hours of AC load between charges 8022.60 Wh

Battery Ah used between charges (divide by 10) 802.70 Ah

Recommended Battery Bank Size in Ah (multiply by 2)1600 Ah

Daily watthours needed

for this

(A) Power

Consumption

(B) Operating

Time per Day

appliance

(= A x B)

375 Wh

hour

180 W 4 hours 720 Wh

187.50 Wh

hour

1.70 Wh

hour

150 Wh

hour

75 Wh

hour

750 Wh

hour

70 Wh

hour

This example illustrates how quickly your battery needs can escalate. To

reduce the required battery size, you can conserve energy by eliminating

or reducing the use of some loads or by re-charging more frequently.

When sizing your battery, resist the temptation to skip the last step of this

calculation (multiplying by 2). More capacity is better since you will have

more reserve capacity, be better able to handle large loads and surge loads,

and your battery won't be discharged as deeply. Battery life is directly

3–4 445-0173-01-01 Rev 1

Page 41

dependent on how deeply the battery is discharged. The deeper the

discharge, the shorter the battery life.

Battery Sizing Worksheet

Use the following worksheet to calculate your battery needs. To ensure

sufficient battery capacity, be generous when estimating the operating

time per day for each of the loads you will run.

Appliance

Using Multiple Batteries

Daily watt-

hours needed

(A)

Power

Consumption

(B)

Operating Time

per day

for this

appliance

(= A x B)

W hours Wh

W hours Wh

W hours Wh

W hours Wh

W hours Wh

Total daily watt-hours of AC load Wh

x Number of days between charges

= Total watt-hours of AC load between charges Wh

Battery Ah used between charges (divide by 10) Ah

Recommended Battery Bank Size in Ah (multiply by 2)Ah

Using Multiple Batteries

As your power requirements increase, you may need to use more than one

battery to obtain sufficient capacity. Read “Two Batteries Connected In

Parallel” and “Two Separate Battery Banks” to determine whether two

batteries or two battery banks are more appropriate for your applications.

W hours Wh

W hours Wh

W hours Wh

445-0173-01-01 Rev 1 3–5

Page 42

Battery Types and Sizes

Two Batteries Connected In Parallel

Two identical batteries can be connected positive (+) to positive (+) and

negative (–) to negative (–) in a parallel system. A parallel system doubles

capacity and maintains the voltage of a single battery.

Figure 3-2 shows batteries connected in parallel. Figure 3-1 shows a

battery configuration suitable for normal loads; Figure 3-2 shows a

configuration that is recommended for heavy loads.

In these configurations, the IP1012 will charge any batteries connected to

it, but will not charge batteries through the battery isolator. The vehicle

starting batteries in the configuration shown in the figures will only be

charged by the alternator.

The deep cycle batteries can, however, be charged from the IP1012 and

the alternator. The batteries could be subject to a high charging current.

CAUTION

Do not connect the following in parallel: batteries made by

different manufacturers, different types of batteries, batteries

that have different Ah ratings. Decreased battery life and

improper charging will result.

ISOLATOR

GROUND TO

VEHICLE

CHASSIS

ODC

OADS

FUSEOR

CIRCUIT

BREAKER

T

L

FUSE OR

CIRCUIT

BREAKER

DEEP-CYCLE

AUXILIARY

BATTERY

Figure 3-1 Configuration for Normal Loads

FROM ALTERNATOR

OR CHARGER

VEHICLE

STARTING

BATTERY

TO VEHICLE

GROUND TO

VEHICLE

CHASSIS

3–6 445-0173-01-01 Rev 1

Page 43

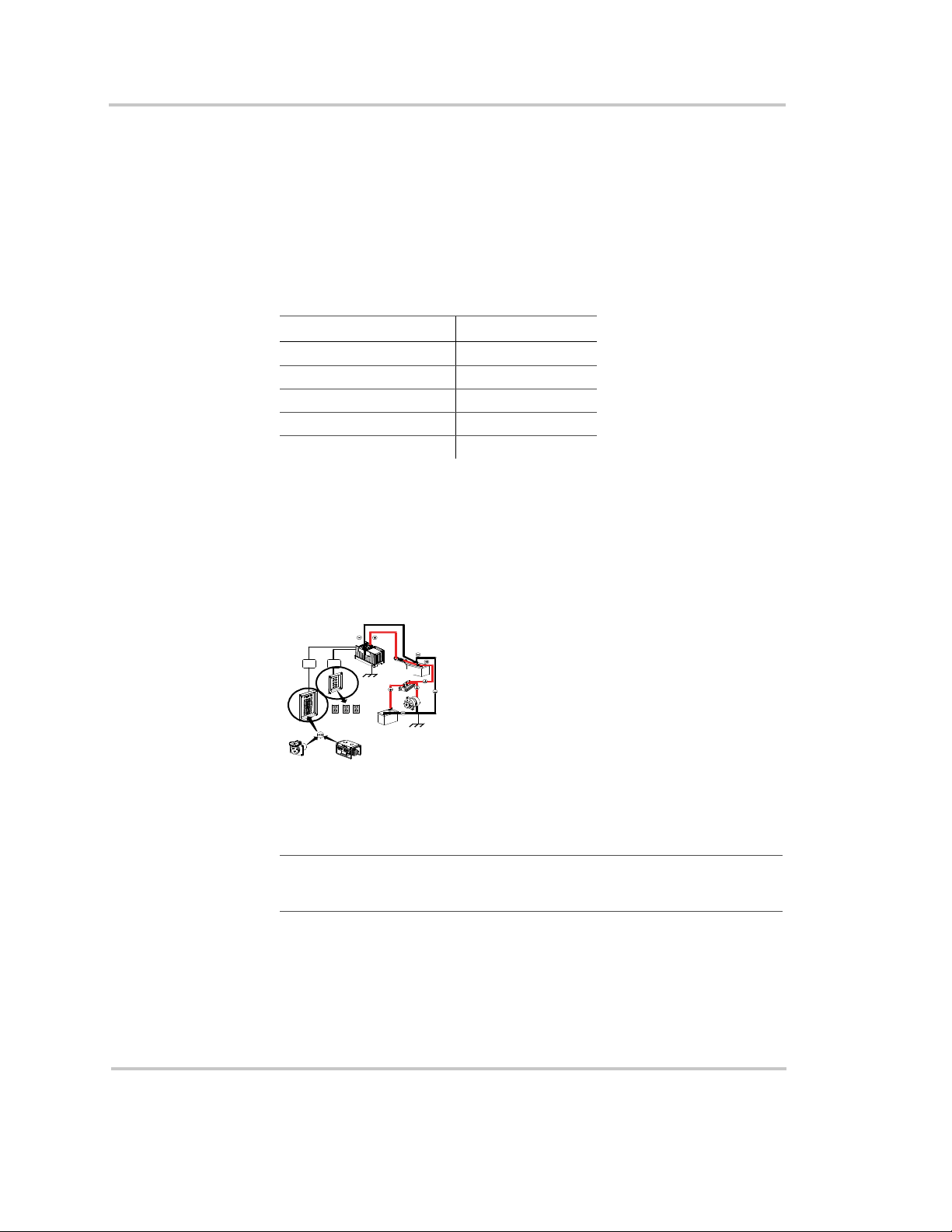

Two Separate Battery Banks

If you need more than two batteries (or are using different makes or

models of batteries), Xantrex recommends that you install two separate

battery banks and a battery selector switch.

Figure 3-2 shows two separate battery banks and a battery selector switch.

This configuration is recommended for heavy-duty applications.

Battery Tips

Battery Selector

Switch

By installing a battery selector switch, you can select between the two

battery banks, use both banks in parallel, or disconnect both banks from

the load. Battery selector switches are available at marine and RV dealers.

DEEP-CYCLE

BATTERY

DEEP-CYCL E

BATTERY

TO VEHI CLE

GROUND TO

VEHICLE

CHASSIS

GROUND TO

VEHICLE

CHASSIS

TO DC

LOADS

FROMALTERNATOR

OR CHARGER

ALL

1

OFF 2

BATTERY

SELECTOR

SWITCH

FUSE OR

CIRCUIT

BREAKER

BATTERYISOLATOR

DEEP-CYCLE

BATTERY

DEEP-CYCLE

BATTERY

FUSE OR

CIRCUIT

BREAKER

BATTERY

SELECTOR

SWITCH

ALL

OFF 2

VEHICLE

STARTING

BATTERY

FUSE OR

CIRC UIT

BREAKER

FUSE OR

CIRCUIT

BREAKER

1

BOTH

Figure 3-2 Configuration for Heavy Loads

Battery Tips

WARNING

Review the “Important Safety Instructions” before working

with the batteries in your system.

Explosive/Corrosive Gases Lead-acid batteries may emit hydrogen,

oxygen, and sulfuric acid fumes when recharging. To reduce the risk of

explosion:

445-0173-01-01 Rev 1 3–7

Page 44

Battery Types and Sizes

• Vent the battery compartment to prevent the accumulation of gases.

• Do not install electronic or electrical equipment which is not ignition

protected in the battery compartment.

• Do not smoke or use an open flame when working around batteries.

Temperature Sensitivity The capacity of lead-acid batteries is

temperature sensitive. Battery capacity is rated at 77º F (25º C). At 0º F

(–20º C), the Ah capacity is about half the rated capacity. You should

consider temperature when designing your system.

• Low Temperatures If extremely low temperatures are expected

where the inverter is going to be located, you should consider a

heated equipment room. If the system is located in an unheated

space, an insulated battery enclosure is recommended.

• High Temperatures The batteries should also be protected from

high temperatures. They can be caused by high ambient

temperatures, solar heating of the battery enclosure, or heat released

by a nearby engine or generator. High battery temperatures shorten

battery life and therefore you should ventilate the enclosure and use

shade and insulation as appropriate.

Discharged Batteries Do not leave batteries in a discharged state for

more than a day or two. They will undergo a chemical process (sulfation)

that can permanently damage the battery. As well, batteries self-discharge

over a period of three to six months, so they should be recharged

periodically even if they are not being used.

Electrolyte Level If your batteries are not the “maintenance-free” type,

check the electrolyte level at least once a month. Excessive fluid loss is a

sign of overcharging. Replenish the electrolyte using distilled water only.

Battery Connections Connections to battery posts must be made with

permanent connectors that provide a reliable, low-resistance connection.

Do not use alligator clips. Clean the connections regularly and prevent

corrosion by using a protective spray coating or vaseline.

3–8 445-0173-01-01 Rev 1

Page 45

Battery Tips

Battery State of Charge You can measure battery state of charge with

a hydrometer or, more easily, with a voltmeter. Use a digital voltmeter

than can display tenths or hundredths of a volt when measuring 10 to 30

volts. Make your measurements when the battery has not been charged or

discharged for several hours. For a deep-cycle battery at 77º F (25º C), use

the following table:

Battery Voltage State of Charge

12.7–13.0 100%

12.5–12.6 80%

12.3–12.4 60%

12.1–12.2 40%

11.9–12.0 20%

445-0173-01-01 Rev 1 3–9

Page 46

3–10 445-0173-01-01 Rev 1

Page 47

Index

A

AC circuit breaker 1–3

AC disconnect devices

AC distribution panel

AC fuses

AC input considerations

AC input cord, connecting

AC output considerations

AC output cord, connecting

AC output neutral bonding

AC wiring

Ah. See amp-hour capacity.

amp-hour (Ah) capacity

automotive starting marine

1–3

1–5

1–4

1–4

1–3

2–5

1–3

2–7

1–6

3–3

3–1

B

batteries

connecting in parallel

deep-cycle

discharged

first aid when working with

parallel connection illustrated

precautions when working with

temperature sensitivity

batteries, use of multiple

battery banks, separate

battery care tips

battery connections, maintaining

battery isolator, using

battery reserve capacity

battery selector switch

battery size

estimating example

estimating worksheet

battery state of charge, measuring

1–7

3–8

3–7

3–5

viii

3–8

3–5

3–6

3–2

3–2

3–7

3–3

3–5

3–6

viii

3–8

3–8

battery temperature sensor

attaching to battery terminal

attaching to side of battery

battery temperature sensor, installing

battery, automotive

bracket mounting

breaker ratings for AC wiring

BTS. See battery temperature sensor.

3–1

2–5

2–12

2–13

1–5

C

cable lengths, DC 1–6, 2–7

cable sizes, DC

chassis ground lug

circuit breakers, AC

connectors, recommended types

1–6

2–10, 2–11

1–3

2–5

D

DC cable lengths 1–6

DC cable sizes

DC cables, connecting

DC disconnect device

DC fuse sizes

DC grounding

recreational vehicle

residential

DC over-current device

deep-cycle battery

deep-cycle lead-acid battery, about

depth of discharge (DOD)

diagram, system

distribution panel, AC

1–6

2–7

1–7

1–6

2–11

2–11

1–7

1–7

3–2

3–4

1–2

1–4

E

electrolyte level, checking 3–8

2–11

Page 48

Index

F

FCC information to the user ix

first aid

floor mounting

fuse sizes

AC

DC

1–viii

2–4

1–3

1–6

G

gases, reducing risk of explosive 3–7

GFCI requirements

GFCIs, tested

ground wire sizes

groundwire, installing

1–4

1–4

2–11

2–10

I

ignition protection, safety implications 1–8

installation, testing

installation, tools and materials

inverter•charger

locating for installation

2–16

2–2

1–7

M

materials list 2–2

mounting template, diagram

mounting, considerations

multiple batteries

3–5

2–4

2–3

S

safety instructions vii–viii

shorepower, defined

single-phase wiring circuit

system diagram

system test after installation

1–3

1–4

1–2

2–16

T

temperature sensor 2–11

testing installation

transfer relay

2–16

1–5

V

ventilation, importance of 3–7

N

neutral bonding system, purpose of 1–5

neutral conductor

1–6

O

output cord, connecting 2–7

P

polarity, avoiding reverse 2–7

R

recreational vehicles, DC grounding 2–11

remote switch, enabling with

reserve capacity

reserve capacity in batteries

residential installations, DC grounding

reverse polarity, danger of

Index–2

3–2

2–16

3–2

2–11

2–7

Loading...

Loading...