Page 1

This Manual is Bookmarked

Operating Instructions — Parts Manual

Disc, Belt, and Combination Disc/Belt Sanders

Models: 4200A, 4300A, 4400A

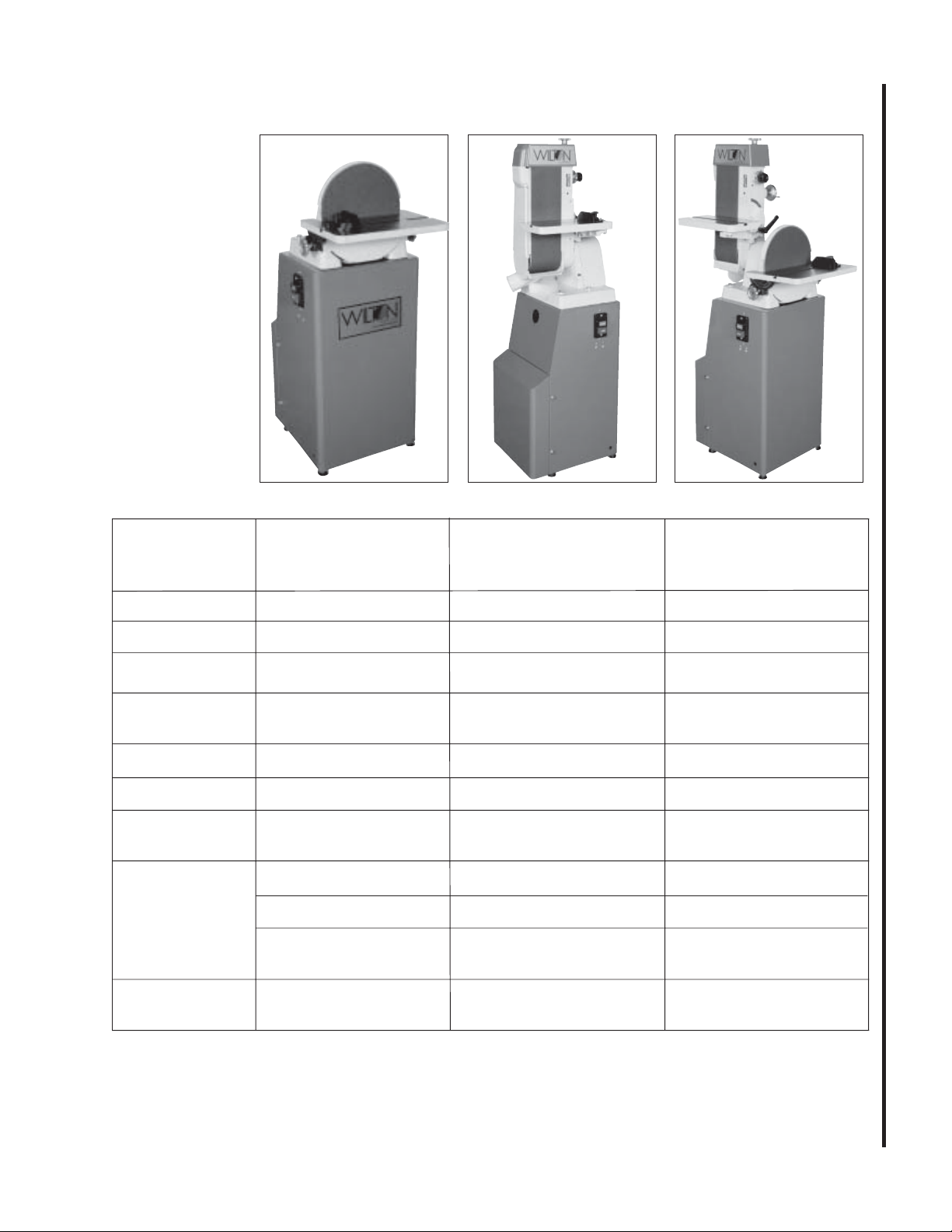

4200A Disc/Belt Sander 4300A 6 Inch Belt Sander 4400A 12 Inch Disc Sander

WHM TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. 5511365

Ph.: 800-274-6848 Revision E2 10/04

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

This manual has been prepared for the owner and operators of a Wilton Sander. Its purpose, aside from

machine operation, is to promote safety using accepted operating and maintenance procedures. To obtain

maximum life and efficiency from your Sander and to aid in using it safely, please read this manual thoroughly

and follow instructions carefully.

Warranty and Service

WMH Tool Group warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Repair Stations located throughout the United States can provide quick service or information.

In most cases, a WMH Tool Group Repair Station can assist in authorizing repair work, obtaining parts, or

perform routine or major maintenance repair on your Wilton product.

For the name of an Authorized Repair Station in your area, please call 1-888-594-5866, or visit our web site at

www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group is consistently adding new products to the line. For complete, up-to-date

product information, check with your local WMH Tool Group distributor, or visit our web site at

www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that its products meet high quality and durability standards and

warrants to the original retail consumer/purchaser of our products that each product be free from defects in

materials and workmanship as follows: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS

SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, repair or alterations outside our facilities, or to a lack

of maintenance.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP BE LIABLE

FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL, CONTINGENT, SPECIAL,

OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage prepaid, to

an Authorized Repair Station designated by our office. Proof of purchase date and an explanation of the

complaint must accompany the merchandise. If our inspection discloses a defect, we will either repair or

replace the product at our discretion, or refund the purchase price if we cannot readily and quickly provide a

repair or replacement. We will return the repaired product or replacement at WMH Tool Group’s expense, but

if it is determined there is no defect, or that the defect resulted from causes not within the scope of WMH Tool

Group’s warranty, then the user must bear the cost of storing and returning the product. This warranty gives

you specific legal rights; you may also have other rights, which vary from state to state.

WMH Tool Group sells through distributors only. Members of the WMH Tool Group reserve the right to effect

at any time, without prior notice, alterations to parts, fittings and accessory equipment, which they may deem

necessary for any reason whatsoever.

Page 3

Table of Contents

Cover Page ......................................................................................................................................... 1

Warranty..............................................................................................................................................2

Table of Contents ................................................................................................................................3

Machine and Manual Overview ............................................................................................................4

General Specifications......................................................................................................................... 5

Warnings .............................................................................................................................................6

Operating Instructions ..........................................................................................................................8

Maintenance ......................................................................................................................................10

Setup and Installation ........................................................................................................................ 13

Troubleshooting .................................................................................................................................18

Wiring Diagrams ................................................................................................................................19

Replacement Parts ............................................................................................................................ 20

Accessories ....................................................................................................................................... 28

3

Page 4

Machine and Manual Overview

Wilton Abrasive Finishing Machines are available in three

different configurations: disc, belt, and combination disc

and belt. Each configuration is a rugged, heavy-duty

machine designed for maximum high production work in

an industrial environment.

The speed of stock removal and the quality of finish

achieved is determined largely by the aggressiveness of

the abrasive disc or belt mounted on the machine. With

very aggressive grits, these machines are typically considered grinding machines. With very fine grits, these

machines are typically considered sanding machines.

Whatever you call them, and however you use them, the

instructions in this manual will help you use them safely

and productively.

You will note there are several types of electrical systems available for these machines. All of these systems

are equally effective in providing power to the grinding

mechanism -- however, local codes and the type of environment in which the machine is used will often be a

factor in your choice of system.

Instructions in this manual assume that you are using

one of the Model 4200A series Belt and Disc machines.

If you have a disc only, or belt only machine, you can

bypass those instructions which do not apply to you.

4

Page 5

General Specifications

Table size

Table tilt

Miter gauge groove

Disc diameter

Disc Speed

Platen size

Belt size

Belt speed

Dimensions

(depth, W, H)

Dimensions w/platen

vertical (depth,W, H)

Dimensions w/platen

horizontal

(depth, W, H)

Motor options

Weight

Disc Sander

12x16 3/8 in. (254x416mm)

45° down, 20° up

3/8x3/4 in. (9.5x19mm)

12 in. (305mm)

1960 RPM

29x17x42 3/4 in.

(1070x725x4250mm)

Model 4400A 1 ph. 1.5HP

115/230V

Model 4401A 3 ph. 1.5HP

230V/460V

Model 4403A 3 ph. 1.5HP

230/460V (connected 460)

full JIC, 110V at the switch

unassembled

164 lbs. (74 kg.)

Belt Sander

7 3/8x14 3/4 in. (187x355mm)

45° down, 20° up

3/8x3/4 in. (9.5x19mm)

6 1/4x14 3/4 in. (159x375mm)

6x48 in. (152x1214mm)

2850 SFM

19x16x57 1/2 in.

(475x400x1437mm)

25 1/2x16x43 in.

(637x400x1075mm)

Model 4300A 1 ph. 1.5HP

115/230V

Model 4301A 3 ph. 1.5HP

230V/460V

Model 4303A 3 ph. 1.5HP 230/

460V (connected 460) full JIC,

110V at the switch

211 lbs. (96 kg.)

Disc/Belt Sander

Disc:12x16 3/8 in. (254x416mm)

Belt: 7 3/8x14 3/4 in.

(187x355mm)

(both) 45° down, 20° up

(both) 3/8x3/4 in. (9.5x19mm)

12 in. (305mm)

1960 RPM

6 1/4x14 3/4 in. (159x375mm)

6x48 in. (152x1214mm)

2850 SFM

19x16x57 1/2 in.

(475x400x1437mm)

25 1/2x16x43 in.

(637x400x1075mm)

Model 4200A 1 ph. 1.5HP

115/220V

Model 4202A 3 ph. 1.5HP

230V/460V

Model 4204A 3 ph. 1.5HP 230/

460V (connected 460) full JIC,

110V at the switch

250 lbs. (113 kg.)

5

Page 6

General Machinery Cautions

- Misuse of this machine can cause serious injury.

- For safety, the machine must be set up, used and

serviced properly.

- Read, understand and follow the instructions in the

operator’s and parts manual which was shipped with

your machine.

When setting up the machine:

- Always avoid using the machine in damp or poorly

lighted work areas.

- Always be sure the machine is securely anchored to the

floor.

- Always keep the machine guards in place.

- Always put the start switch in the “OFF” position before

plugging in the machine.

You — the stationary power tool user — hold the key to safety.

Read and follow these simple rules for best results and full benefits from your machine. Used properly, Wilton’s

machinery is among the best in design and safety. However, any machine used improperly can be rendered inefficient

and unsafe. It is absolutely mandatory that those who use our products be properly trained in how to use them correctly.

They should read and understand the Operators and Parts Manual as well as all labels affixed to the machine. Failure

in following all of these warnings can cause serious injuries.

When using the machine:

- Never operate the machine with safety guards missing.

- Always wear safety glasses with side shields (See ANSI

Z87.1)

- Never wear loose clothing or jewelry.

- Never overreach — you may slip and fall into the

machine.

- Never leave the machine running while unattended.

- Always shut the machine off when not in use.

When servicing the machine:

- Always unplug the machine from the electrical power

while servicing.

- Always follow the instructions in the operators and parts

manual when changing accessory tools or parts.

- Never modify the machine without consulting Wilton

Corporation.

General Machinery Warnings

1. Always wear protective eye wear when operating machinery. Eye wear shall be impact resistant, protective safety

glasses with side shields which comply with ANSI Z87.1

specifications. Use of eye wear which does not comply

with ANSI Z87.1 specifications could result in severe injury

from the breakage of the eye protection.

2. Wear proper apparel. No loose clothing or jewelry which

can get caught in moving parts. Rubber soled, nonslip,

footwear is recommended for best footing.

3. Do not overreach. Failure to maintain a proper working

position can cause you to fall into the machine or cause

6

your clothing to get caught — pulling you into the machine.

4. Keep the guards in place and in proper working order.

Do not operate the machine with the guards removed.

5. Avoid dangerous working environments. Do not use stationary machine tools in wet or damp locations. Keep work

areas clean and well lit.

6. Special electrical precautions should be taken when

working on flammable materials.

7. Avoid accidental starts by being sure that the start switch

is in the “OFF” position before plugging in the machine.

8. Never leave the machine running while unattended. The

machine shall be shut off whenever it is not being used.

9. Disconnect the electrical power before servicing, whenever changing accessories or when general maintenance

is done on the machine.

10. Maintain all machine tools with care. Follow all maintenance instructions for lubricating and the changing of accessories. No attempt shall be made to modify or have

makeshift repairs done to the machine. This not only voids

the warranty but also renders the machine unsafe.

10. The machinery must be anchored to the floor.

11. Secure your work. Use clamps or a vise to hold your

work, when practical. It is safer than using your hands and

it frees both hands to operate the machine.

12. Never brush chips away while the machine is in operation.

13. Keep work area clean. Cluttered areas invite accidents.

14. Remove adjusting keys and wrenches before turning

the machine on.

15. Use the right tool. Don’t force a tool or attachment to do

a job it was not designed for.

16. Use only recommended accessories and follow manufacturers instructions pertaining to them.

17. Keep hands in sight and clear of all moving parts and

cutting surfaces.

18. All visitors should be kept at a safe distance from the

work area. Make your workshop completely safe by using

padlocks, master switches, or by removing starter keys.

19. Know the tool you are using — its application, limitations, and potential hazards.

Page 7

General Electrical Cautions

This machine should be grounded in accordance with the

National Electrical Code and local codes and ordinances.

The work should be done by a qualified electrician. The

machine should be grounded to protect the user from electrical shock.

Wire Sizes

Caution: For circuits that are a great distance from the electrical service box, the wire size must be increased in order

to deliver ample voltage to the motor. To minimize power

losses and to prevent motor overheating and burnout, the

use of wire sizes for branch circuits or electrical extension

cords according to the following table is recommended:

Conductor length

0-50 feet

50-100 feet

Over 100 feet

AWG (American Wire Gauge) number

240 volt lines 120 volt lines

No. 14

No. 14

No. 12

Safety Requirements for Abrasive

Sanding Machines

Abrasive sanding can be hazardous to operators and bystanders. Sanding sparks, chips and dust particles thrown

off by the sanding disc can cause serious injury if contacted or inhaled. To avoid such injuries you must comply

with the following safety requirements:

1. Always wear protective eyewear when operating machinery. Eye wear shall be impact resistant, safety glasses with

side shields which comply with ANSI Z87.1. Use of eye

wear which does not comply with ANSI Z87.1 specifications could result in severe injury from the breakage of the

eye protection.

2. Wear leather safety gloves, arm guards, leather aprons

and safety shoes.

3. A dust collection system is recommended, The operator

should also wear a dust mask at all times.

4. Additional precautions may be necessary for sanding

materials which are flammable or have other hazardous

properties. You should always consult the manufacturer of

such materials for instructions on sanding and handling.

5. Do not force or jam the workpiece into the sanding disc.

6. Before sanding, always allow the motor to come up to

operating speed, then check the sanding disc for wobble,

runout, or any unbalanced condition. If the disc is not operating accurately and smoothly, immediately stop the motor

and make repairs before attempting any sanding operations.

No. 14

No. 12

No. 8

7. Abrasive discs must be stored in a controlled environment area. Relative humidity should be 35% to 50% and

the temperature should be between 60o and 80o Fahrenheit. Failure to do so could cause premature disc failure.

8. Examine the face of the sanding disc carefully. Excessive sanding that wears down to the backing material can

tear the disc. Never use a disc which shows backing, nicks

or cuts on the surface or edge or damage due to creasing

or poor handling.

9. When installing a new disc, be certain the disc is accurately centered on the drive wheel. Failure to do so could

cause a serious unbalanced condition.

10. Always present the workpiece to the wheel while resting the workpiece firmly on the table. Failure to do so could

result in damage to the workpiece or throwing of the

workpiece off the wheel.

11. Safety shoes which comply with ANSI Z41.1 should be

worn.

12. Personal hearing protection such as ear plugs or ear

muffs should be used to protect against the effect of noise

exposure.

7

Figure A Figure B

Figure C

Figure D

Page 8

Operating Instructions

These sanders can be used to remove stock from a

wide variety of machinable materials. Different materials

require different grit types and grades to achieve the desired stock removal rate and surface finish. Please consult

with your abrasive materials supplier for specific recommendations on the correct grit material and grade required

for your specific needs.

When removing stock from soft materials (wood, plastic, etc.) these machines are typically called "sanders."

When removing stock from hard materials (cast iron, steel,

etc.) they are referred to as "grinders". The word "sander"

is used, more-or-less consistently, throughout this manual.

It refers to the machines and not the type of abrasive finishing being performed.

Before operating your sander, please read the basic

instructions on safe machine usage on the preceding two

pages.

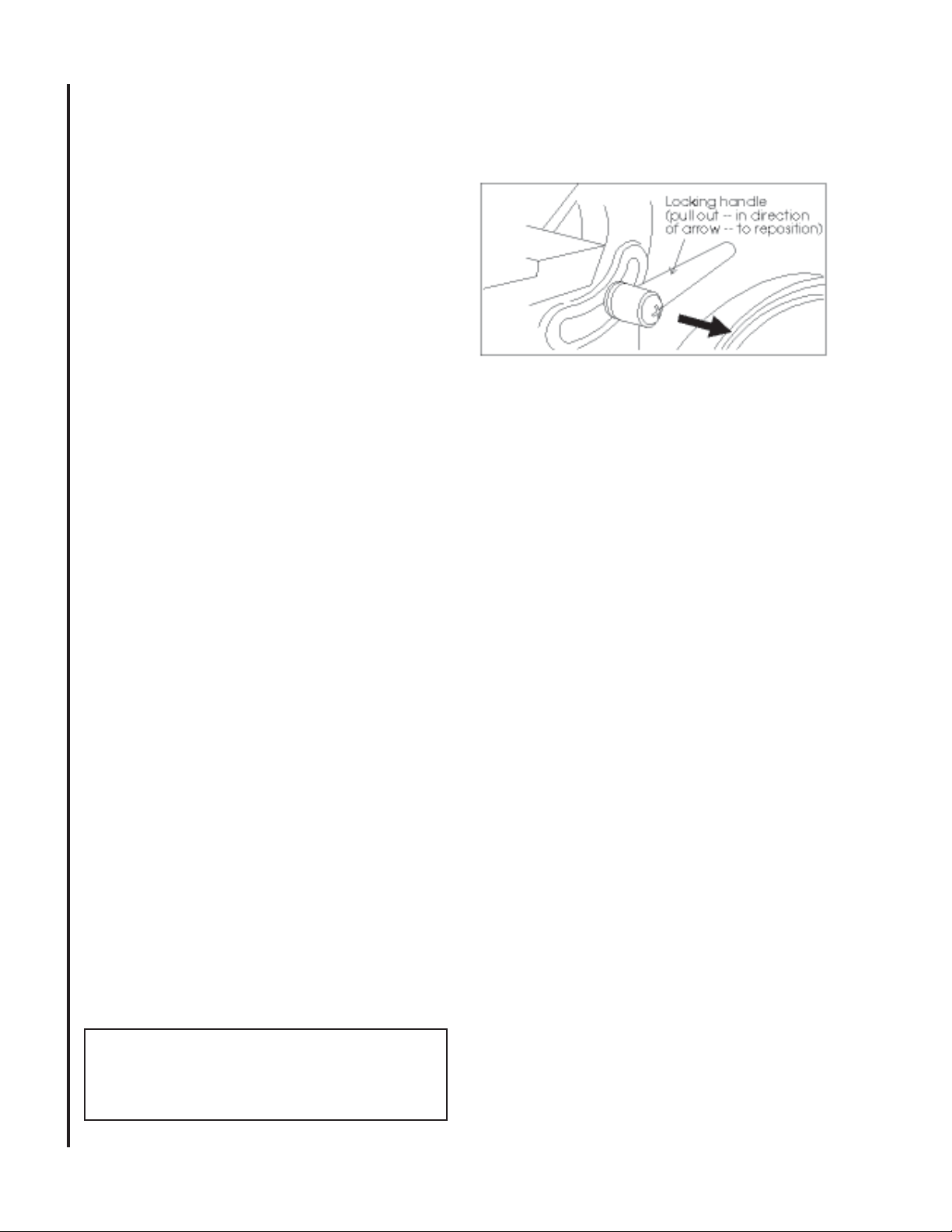

Figure 1: Locking handle for belt table

Using the Indexing Lock Handle

The lock handle is spring loaded and can be reposi-

tioned on its shaft to permit easy locking and unlocking.

Belt Sander

The sanding belt must be in good condition, at proper

tension, and tracking correctly, before doing any sanding,

grinding or other abrasive machining operations. Refer to

the section on Track Mechanism Maintenance if you have

any problems with belt tension or tracking.

To Reposition the Handle:

1. Pull outward against its spring.

2. Rotate the handle to the position you require.

3. Release the handle and its spring will return it to the

correct operating position.

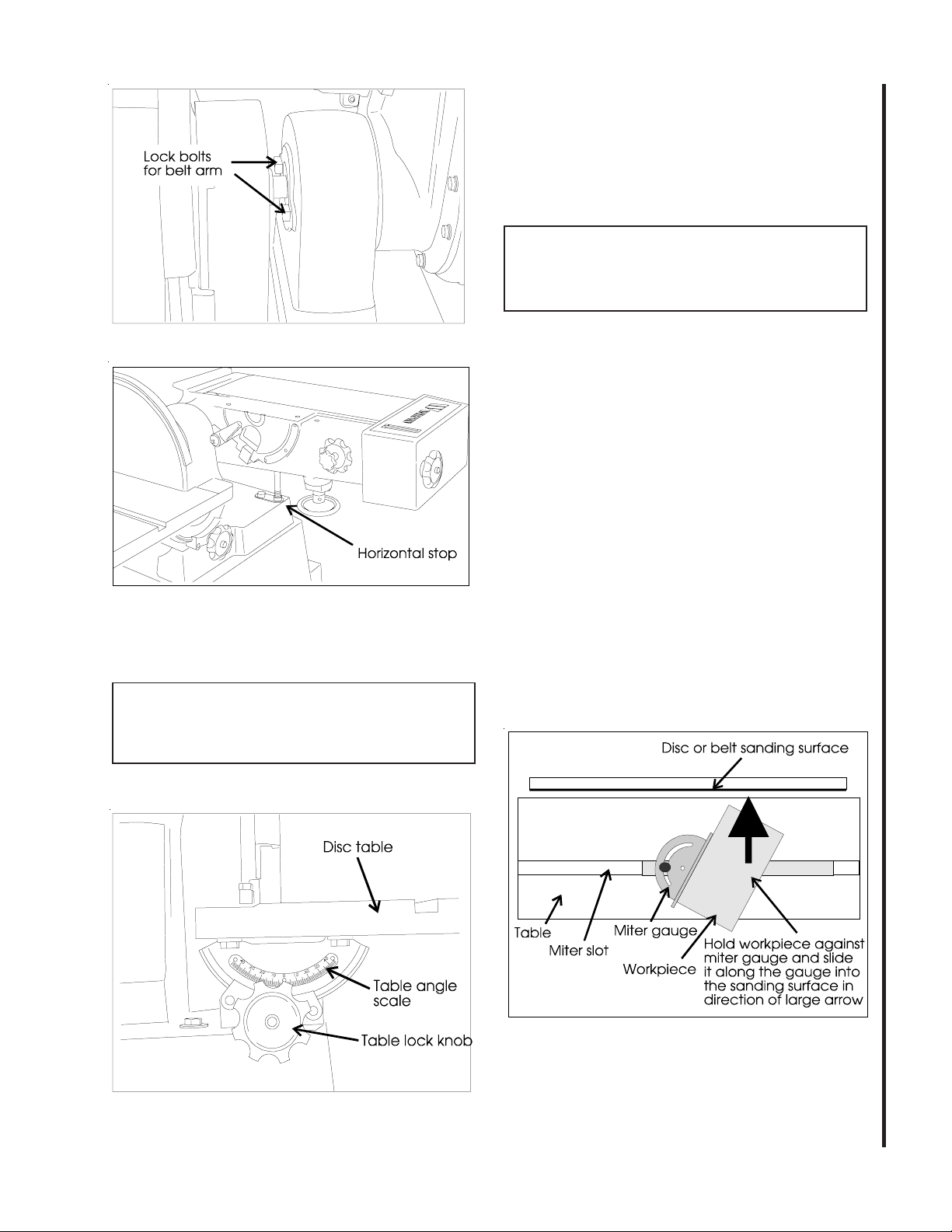

Adjusting the Belt Sander Arm

Adjusting the Belt Sander Table

You can tilt the table in a range between 20o upward

and 45o downward. A single locking handle on the side of

the table is used to lock and unlock the table to permit

adjustment.

There are two positive lock stop positions: at 90o (that

is, at a right angle to the platen) and at 45o downward (essentially 90o + 45o or 135o total to the platen.)

To Tilt the Belt Sander Table:

1. Unlock the locking handle on the side of the table.

2. Using the pointer and scale, set the angle to any re-

8

quired angle between 20o upward and 45o downward.

3. Lock the lock handle.

To Tilt the Table to Exactly 45o:

1. Flip out the stop bracket (see Figure 20).

2. Unlock the locking handle.

3. Move the table until it contacts the stop bracket.

4. Lock the table lock handle.

CAUTION: NEVER ADJUST THE TABLE ANGLE

WHILE THE SANDER IS RUNNING. ALWAYS TURN

THE MOTOR OFF BEFORE ADJUSTING THE TABLE

ANGLE.

The arm which holds the sanding belt can be positioned at a full vertical position, a full horizontal position, or

at any angle in between which is convenient to the type of

sanding you are doing.

A positive stop mechanism is used to permit quick

adjustment to the vertical or horizontal positions.

To Adjust to Vertical:

1. Unlock both of the lock bolts. These are located under

the arbor cover.

2. Move the arm to vertical until it contacts its stop.

3. Tighten both of the lock bolts, and replace arbor cover.

To Adjust to Horizontal:

1. Unlock both of the lock bolts.

2. Move the arm to horizontal until it contacts its stop. (See

Figure 3.)

3. Tighten both of the lock bolts and replace arbor cover.

To Adjust the Arm to Any Angle Between

Vertical and Horizontal:

1. Unlock both of the lock bolts.

2. Use a machinist's protractor and level to set the arm to

the required angle.

3. Tighten both of the lock bolts and replace arbor cover.

Page 9

Adjusting the Disc Sander Table

1. Unlock the two locking knobs underneath the table at

each end. (See Figure 4.)

2. Using the pointer and scale, set the angle to any required angle between 20o upward and 45o downward.

3. Lock the two locking knobs underneath the table.

CAUTION: NEVER ADJUST THE TABLE ANGLE

WHILE THE SANDER IS RUNNING. ALWAYS TURN

THE MOTOR OFF BEFORE ADJUSTING THE TABLE

ANGLE.

Figure 2: Lock bolts for belt arm

Figure 3: Arm at horizontal -- note that the table is removed.

The table may be removed or left in position, and may also

be set to any angle to allow horizontal sanding of various

angles.

CAUTION: NEVER ADJUST THE ARM ANGLE

WHILE THE SANDER IS RUNNING. ALWAYS TURN

OFF THE MOTOR BEFORE ADJUSTING THE ARM

ANGLE.

Use of the Miter Gauge

The miter gauge can be used on either the disc or

belt surfaces to sand accurate angles on workpieces. When

using the gauge, alone, you sand a single angle. However,

by tilting the table and using the miter gauge in combination with the table tilt, it is possible to sand compound

angles, as well.

When grinding a compound angle you should always check the accuracy of your setup by sanding a piece

of scrap material before doing any finish sanding on the

actual workpiece.

1. Set the angle you wish to sand using the scale on the

miter gauge.

2. Tighten the miter gauge securely so the miter reference

surface will not move while you are sanding.

3. Place the workpiece against the miter reference surface

and slide it along the reference surface and into the sanding disc or belt. The basic method is shown in Figure 5,

below.

Figure 4: Disc sander table adjustment

9

Figure 5: Use of the miter system

Page 10

10

Maintenance

Belt Replacement

1. Disconnect the power to the machine to prevent accidental start-ups. If the machine is plugged into an outlet,

unplug it. If the machine is hardwired to a branch circuit

with a junction box, remove the fuse or trip the circuit breaker

to the branch.

2. Remove the lock knob and top cover (See Figure 6).

3. Remove the side guard and table.

4. Release the belt tension by turning the tension handle

in a counterclockwise direction (See Figure 7). If the handle

is difficult to turn, perform Track Mechanism Maintenance

according to the instructions following this section.

5. Remove the belt.

6. Check the drums and platen for scoring or signs of

wear which might require service or replacement.

7. Check the height of the platen with a straight edge. If it

is not 1/32 in. above the drums, adjust it according to the

instructions in Platen Replacement or Adjustment in the

Machine Setup section of this manual.

8. Check the drums for looseness which might cause

tracking problems. Correct any loose condition by tightening or replacing any parts as required.

9. Slip the new belt onto the drums and platen.

10. Adjust the tension handle clockwise until the belt is flat

against the platen and there is no curling or buckling of the

belt in the middle.

11. Turn the drums by hand to see if the belt tracks moreor-less true. JUST BECAUSE THE OLD BELT TRACKED

CORRECTLY DOES NOT MEAN THE NEW BELT WILL.

Always check the tracking when replacing a belt.

12. To adjust the tracking:

12.1. Plug the machine back into the outlet or

reestablish power in the branch.

12.2. Loosen the tracking lock knob.

12.3. Jog the motor on and off as necessary to

observe the tracking, and turn the tracking knob as

necessary to make the belt track in the center of the

platen and drums. Turn the tracking knob clockwise to

move the belt toward the right and counterclockwise to

move the belt toward the left.

12.4. When the belt seems to be tracking correctly, turn

the motor on and leave it running while fine tuning the

tracking.

12.5. Lock the tracking lock knob.

12.6. When the lock knob is secure, turn the power

off and disconnect the machine from the outlet or

branch as in Step 1, above.

13. Replace the table, side guard, top cover and lock

knob by reversing steps 3 and 2, above.

14. If you have not already done so, reconnect the power

to the machine and return it to service.

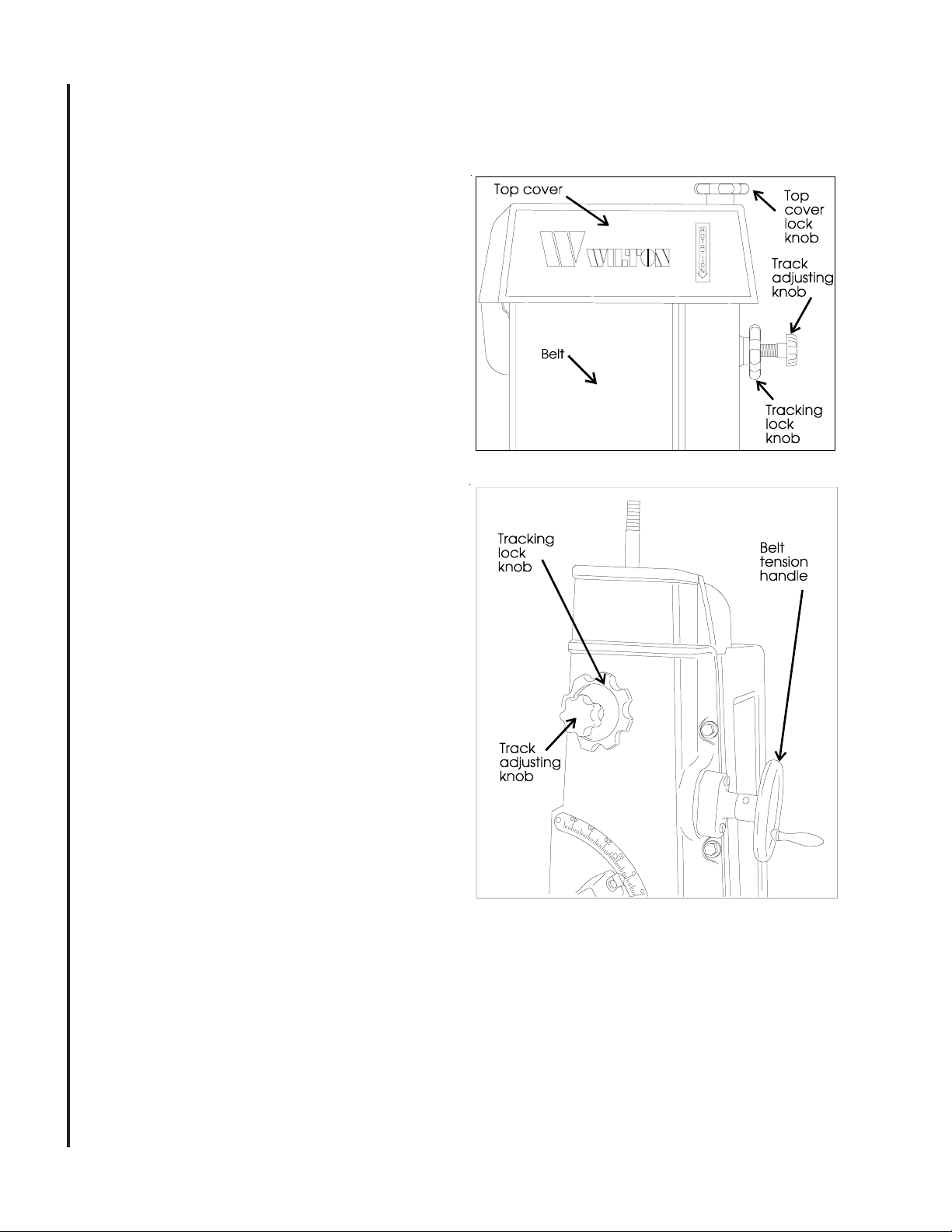

Figure 6: Top cover components

Figure 7: Belt adjustment components (Note top cover

removed for removal and replacement of belt.)

Page 11

Track Mechanism Maintenance

While the use of a dust collection system can extend

service intervals, an accumulation of dust will almost certainly require periodic cleaning of the tracking mechanism.

The more continuous the use of the machine, the more

frequently this maintenance should be performed.

As mentioned in the preceding section, the need for

required maintenance is often indicated by difficulty in adjusting the tension/tracking mechanism.

Maintenance:

1. With the belt removed according to the instructions in

Belt Replacement, pull out the upper tracking system and

clean away all built up material in the upper part of the

bracket casting.

2. Take the two keys off of the idler pin bracket, wipe off, and

re-grease.

3. Reverse the above steps to make the machine ready for

reinstallation of the belt according to the Belt Replacement

instructions.

Installing Abrasive Discs

1. Disconnect the power to the machine to prevent accidental start-ups.

2. Peel off the old abrasive disc.

3. Clean the drive disc surface using naptha or a similar

nonflammable solvent that will dry film-free.

4. Pull the protective backing half off the new abrasive disc.

5. Position the new disc carefully so it is centered accurately on the drive disc. (See Figure 8.)

6. When accurately centered, remove the rest of the protective backing and press the abrasive disc firmly against the

drive disc so complete adhesive contact is made.

7. Reconnect the power to the machine.

Replacing the V-Belt.

1. Disconnect the power to the machine to prevent accidental start-ups.

2. Remove the belt guard (Figure 9) and disc table

3. Remove the table tilt lock knob (Figure 10).

Figure 9: Removing belt guard

Figure 8: Installing new abrasive disc

11

Figure 10: Disc table lock knob

3. Loosen the four motor bolts so the motor can slide on

its plate.

4. Remove the belt from the motor pulley.

5. Remove three of the base mounting bolts, then loosen

the fourth bolt slightly. This allows you to rotate the machine on the machine base (See Figure 11).

Page 12

12

Figure 11: Rotating the machine casting to remove the disc

guard bolts

6. Remove the two bolts, underneath the machine casting,

that secure the disc guard to the casting (See Figure 11).

Figure 13: Removing the guard and drive disc, together.

6. Slide the disc and its guard off of the machine, together

(See Figure 13).

7. The V-belt can now be removed from the drive arbor.

8. Install the new belt on the top pulley.

9. Slide the disc and guard back into position.

10. Reinstall the disc guard bolts underneath the table.

11. Position the drive disc so that it is no more than 1/16

inch away from the table, then tighten BOTH of the set

screws by inserting the hex wrench through the hole in the

disc guard casting.

12. Rotate the machine back onto its base and secure it

with all four mounting bolts.

13. Install the belt over the bottom pulley.

14. Tension the belt so that when pressed, in the middle of

its travel, it has no more than one belt's width of movement

-- then tighten the four motor bolts.

15. Observe the alignment of the motor pulley and arbor

pulley. If necessary, correct their alignment by shifting the

motor slightly on its mount (which involves loosening and

retightening the mounting bolts and checking tension) or

by shifting the pulley slightly on the motor shaft (which involves loosening the motor pulley set screw and sliding

the pulley into alignment) or by moving the arbor pulley

slightly on its shaft (See Figure 14).

16. When the pulleys are accurately aligned, reinstall the

belt guard.

17. Reestablish electrical power to the machine.

Figure 12: Locating the set screws that secure the disc to

the arbor

5. Through the hole in the disc guard casting, locate and

remove the TWO set screws that secure the drive disc to

the arbor. One set screw clamps on the arbor key and the

other clamps on the arbor shaft, itself. Be sure you loosen

both of them.

Page 13

Figure 14: Loosening pulley set screws to allow the

adjustment of pulley on arbor shaft.

Machine Setup

Basic Setup

1. Position the machine where it will be located on the

shop floor. When positioning the machine, consider the

type of work which will be done on it so you allow sufficient

room not only for the workpieces, but also for service to the

machine.

2. Open the door in the base of the machine and, using the

holes in the base as a template, mark the floor for the

position of the hold-down bolts.

3. Move the machine to expose the hold-down bolt marks

and install anchors for the hold-down bolts.

4. Put the machine back over the hold-down anchors and

bolt the machine securely to the shop floor. THIS MUST BE

DONE FOR SAFE OPERATION OF THE MACHINE.

5. Establish an electrical service connection to the machine. This will vary according to the model purchased. ALL

ELECTRICAL CONNECTIONS SHOULD BE MADE BY A

QUALIFIED ELECTRICIAN WHO IS FAMILIAR WITH YOUR

STATE AND LOCAL CODES. Many models of these machines make use of high voltages which pose a significant

risk of serious injury or DEATH if proper knowledge and

precautions are not used. Electrical instructions are included in the Electrical section of these Machine Setup

instructions.

6. Machines with belts are shipped with the belts in slack

condition. During the electrical hookup phase of machine

setup, the belt will have to be tightened and checked for

tracking. See the Belt Replacement section for instructions

on this procedure.

13

Page 14

Disc Table Angle Adjustment

1. Disconnect the power to the machine to prevent accidental start-ups.

2. Loosen the table locking knobs on either end of the

table.

3. Using a machinist's square against the table and disc,

set the table at exactly 90o to the disc (See Figure 15).

4. Tighten the table locking knobs.

5. Check the pointer. If it is not exactly on the zero mark,

loosen the pointer attaching screw, adjust the pointer, and

retighten the screw.

6. Reconnect the power to the machine.

Figure 16: Using an adjustable square to set the table

parallelism.

14

Figure 15: Using a square to check the disc table scale.

Disc Table Miter Parallelism Adjustment

1. Disconnect the power to the machine to prevent accidental start-ups.

2. Set the table angle to zero.

3. Place a scale or adjustable machinist's square against

either the left or right edge of the disc face and measure the

distance to the miter slot edge (See Figure 16).

4. Move the measuring device to the opposite edge of the

disc and measure the distance to the miter slot.

5. Adjust the table by loosening the four attachment screws

under the table, then move the table until the distance between the miter slot and the disc is equal on both sides

(See Figure 17).

6. Tighten the four attachment screws.

7. Reconnect the electrical power to the machine.

Figure 17: Table attachment screws -- loosen to adjust

miter groove parallelism.

Disc Table Gap Adjustment

1. Using a scale, check the gap between the edge of the

table and the face of the disc. It should be very close to 3/32

inch. If it is much more or less than that distance, adjust it

as follows:

2. Disconnect the electrical power to the machine.

3. Using the access hole on the top of the disc guard,

locate and loosen the two set screws that secure the disc

to the shaft.

4. Slide the disc in or out along its shaft until the table-todisc gap is 3/32 inch (See Figure 18).

5. Tighten both set screws.

6. Reconnect the electrical power to the machine.

Figure 18: Table-todisc gap

measurement.

Page 15

Belt Table Miter Slot Parallelism Adjustment

1. Disconnect the power to the machine to prevent accidental start-ups.

2. Set the table angle to zero.

3. Place a scale or adjustable machinist's square against

either the left or right edge of the belt or platen and measure the distance to the miter slot edge (See Figure 19).

4. Move the measuring device to the opposite edge of the

belt or platen and measure the distance to the miter slot.

5. Adjust the table by loosening the three attachment screws

under the table, then move the table until the distance between the miter slot and belt or platen is equal on both

sides.

6. Tighten the three attachment screws.

7. Reconnect the electrical power to the machine.

Belt Table Angle Adjustment

1. Loosen the table locking handle and tilt the table

upward to about 15

2. Flip out the stop bracket (See Figure 21).

3. Lower the table until its adjusting screw touches

the stop bracket.

4. Place a machinist's square against the table and

belt or platen.

5. If adjustment is required, turn the adjusting screw

(Figure 20) until the table is exactly square to the platen.

6. Check the pointer. If it is not on 0o, loosen the

pointer screw and adjust the pointer until it is on 0

7. Tighten the pointer screw.

8. Loosen the table lock handle and tilt the table until

its stop contacts the 45

9. Using a machinist's protractor set on 135o (90o +

45o) adjust the screw until the table and platen are in

correct adjustment. DO NOT reset the pointer after

this operation.

o

.

o

stop position.

o

.

Figure 19: Using an adjustable square to check and

set miter slot parallelism on the belt table.

Figure 20: Location of adjustment (socket head)

screws and pointer attachment screw for table angle

adjustment.

Figure 21: Locations of stop lugs and stop

bracket for zero and 45

o

table positions.

15

Page 16

Adjusting or Replacing the Platen

Electrical

1. Disconnect the electrical power to the machine to prevent accidental start-ups.

2. Remove the top cover, side guard and belt as outlined in

Belt Replacement.

3. Remove the table by unscrewing the locking handling

and lifting the complete table assembly, from the machine.

4. If you are replacing the platen, remove the three screws

that hold it to its mount -- then install the new platen and

replace the mounting screws finger tight.

5. If you are only adjusting the platen, loosen the three

mounting screws to allow adjustment.

6. Using a straight edge as shown in Figure 22, adjust the

platen height until it is 1/32 inch higher than the crown of

both the drive and idler drums.

7. Tighten the platen adjustment screws.

8. Reinstall the table and belt.

9. Check and adjust, if necessary, the tracking of the belt

according to instructions in Belt replacement.

10. Reinstall the guards and covers.

11. Check and adjust the table angles and miter slot

squareness, according to table adjustment instructions in

this manual.

12. Reconnect the electrical power to the machine.

Caution: Wilton sanders are available in a wide variety of electrical configurations to meet the needs of the

purchaser with respect to power available and compliance

with electrical codes. Each machine is tested at the factory

for operation before shipment and the power cord is tagged

with the power requirements for the machine, as shipped.

HOWEVER, before attempting any electrical hookup, you

should be certain:

1. The electrical characteristics of the service branch match

the requirements of the motor.

2. The service branch is equipped with wires of the required gauge or size.

3. The branch circuit intended for the machine is protected

with a time delay fuse or circuit breaker with a rated amperage just slightly greater than the full load current of the

motor.

MOTOR AMPERAGE full load current

Phase Voltage Amperage

111520

1 220 10

3 220 5.2

3 440 2.6

16

CAUTION: All electrical service work on your

Wilton sander should be performed by a qualified,

licensed electrician who is familiar with all safe standard electrical installation practices and all applicable electrical codes. This includes local electrical codes which may affect the connection and operation of the Wilton sander in your specific manufacturing operation.

Figure 22: Method for adjusting height of platen above drive

and idler drums.

Page 17

Single Phase Electrical Hookup

Three Phase Electrical Hookup

When connecting your machine to single phase

power, you may be connecting to either 115 or 230 volts,

depending upon the motor type provided. Local codes may,

or may not, permit the use of a plug type of connection for

your machine. Where a plug connection is permitted, the

following installation practices must be followed:

1. The plug used must be a grounding type of plug. That is,

on a 115 volt single phase connection, the plug must be a

three-prong plug with two flat, parallel blades for the power

wires and a single rounded or U-shaped prong for the

ground connection. On 230 volt single phase connections,

the lug must be a three prong plug with two flat blades in

tandem to carry the current, and a third round or U-shaped

prong for the ground connection.

2. The service branch to which the plug is connected must

be a branch with a separate ground wire so the grounding

prong of the plug can be connected to ground effectively.

Note: Local electrical codes in many jurisdictions

DO NOT ALLOW THE USE OF PLUG TYPE CONNECTIONS

FOR SINGLE PHASE POWER WHEN THE MACHINE IS USED

IN A COMMERCIAL OR INDUSTRIAL ESTABLISHMENT.

In these cases you must connect your machine to

the service branch using a hardwired junction box connection.

Motor Rotation

The motor should be turning counterclockwise, the

belt sander should be moving downward, and the disc

sander should be turning clockwise. These motors are

wired at the factory for correct rotation.

1. Be certain the power to the branch you are connecting is

off and locked out, so power cannot be reestablished accidentally.

2. Connect the ground wires. These wires will be either

green, or green with a white stripe.

3. Connect the remaining three cable wires to the three

power wires in the service branch.

4. Reestablish the power to the branch.

Motor Rotation

The motor should be turning counterclockwise,

the belt sander should be moving downward and the disc

sander should be turning clockwise. If this is the case, the

machine can be considered wired correctly. If the motor is

not turning in the correct direction, take the following corrective action:

1. Disconnect power in the branch again and be certain it

cannot be accidentally turned on while you correct the wiring.

2. Reverse ANY TWO of the power wires to the machine.

3. Reestablish the power to the machine.

4. Turn the machine on. The motor should now be turning

in the correct direction.

Voltage Conversion

Single phase machines are pre-wired for 115V or

230V per customer request. If it becomes necessary to

change the voltage, remove the back cover from the base

and place the machine on its side. Remove the terminal

cover from the motor. Rewire the motor according to the

motor connection diagram, (Figure 32 or, Figure 33).

Different electrical plugs are required depending on which

voltage you select. This completes the voltage conversion

process.

Circuit Protection

Where the service branch is protected with a fuse or

circuit breaker that has too high a value to offer protection to

the motor supplied, a fuse or circuit breaker box should be

used at the point where the machine connection is made

and the time delay fuse or circuit breaker should be a value

just slightly higher than the maximum load current draw.

Voltage Conversion

Three phase machines are pre-wired for 230V or

460V per customer request. If it becomes necessary to

change the voltage, remove the back cover from the base

and place the machine on its side. Remove the terminal

cover from the motor. Rewire the motor according to the

motor connection diagram, Figure 32 or, Figure 33). This

completes the voltage conversion process

Circuit Protection

Where the service branch is protected with a fuse or

circuit breaker that has too high a value to offer protection to

the motor supplied, a fuse or circuit breaker box should be

used at the point where the machine connection is made

and the time delay fuse or circuit breaker should be a value

just slightly higher than the maximum load current draw.

17

Page 18

Troubleshooting

Fault

Motor will not run

Motor stalls easily

Abrasive belt or disc slows

down although motor keeps

running at working speed

Probable cause

1. Motor is defective

2. Voltage is too low

3. Switch is defective

4. Branch circuit fuse is blown or

the circuit breaker is tripped

5. Branch is shut down for service

6. Open circuit in the wiring

1. Low voltage.

2. Fuse is blown (three phase

motors only.)

3. Improper wiring.

1. Belt is slipping 1. Replace the belt.

Suggested remedy

1. Replace the motor.

2. Check the power supply for the proper

voltage.

3. Replace the switch.

4. Determine the reason for the blown fuse

or tripped circuit breaker -- then replace

the fuse or reset the breaker.

5. Check all personnel and machines on

the branch to be certain someone has

not shut down the branch for service. DO

NOT replace the fuse or reset the breaker

unless you are certain no personnel are

working on the machines, wires or con

trols in the circuit.

6. Inspect all the wire connections for loose

or open connections.

1. Check for proper voltage at the motor

-- correct as necessary.

2. Replace the blown fuse.

3. Check for proper connections.

18

Poor tracking

Unsteady belt 1. Slack in the abrasive belt. 1. Adjust the belt tension.

Short belt life

CAUTION: For all of the electrical faults and corrections in the above table Wilton recommends the use of a qualified

and licensed electrician for all circuit tracing, diagnosis and repair.

1. Tracking is out of adjustment.

2. Too much belt tension.

3. Not enough belt tension.

4. Belt is jointed improperly.

5. Lack of crown on the drive roller.

6. Worn bearings.

1. Excessive pressure applied while

grinding.

2. Working on only one side of the belt

or only in one area of the disc.

3. Incorrect abrasive material or grit

size.

1. Adjust the belt tracking.

2. Loosen the tension until the belt is just

taut.

3. Tighten the tension until the belt is more

taut.

4. Check the belt for an irregular seam or

shape.

5. Remove the belt and put a straight edge

along the drive roller. There should be a

slight crown (high spot toward the middle

of the roller.) If the crown has worn away,

replace the roller.

6. Check all the bearings for excessive heat

or loose shafts. Replace if necessary.

1. Allow the belt to do the cutting. Excessive

pressure only dulls the grit and removes it

from the cloth.

2. Use all the surface areas of the abrasive

cloth.

3. Check with your abrasives supplier for rec

ommendations on the type and coarse

ness of the abrasive required for the

workpieces you are sanding or grinding.

Page 19

Electrical Schematics

JIC Packages

Figures 25 and 26, below: Wiring diagrams for 230 and 460 VAC with controller with warning light.

Figure 27 and 28, below: Wiring diagrams for 230 and 460 VAC with push button switch.

19

Page 20

Electrical Schematics

Standard 1 phase and 3 phase machines

Figure 30: Schematic diagram for single phase motor. Figure 31: Schematic diagram for 3-phase motor.

Figure 32: Motor connection diagram for 1-phase motor.

Figure 33: Motor connection diagram for 3-phase motor.

20

Replacement Parts

This section provides exploded view illustrations that show the replacement parts for the Model 4400A, 4300A,

4200A Disc, Belt, and Combination Disc/Belt Sanders. Also provided are parts listings that provide part number

and description. Item numbers shown on the illustration relate to the item numbers in the facing parts listing.

Order replacement parts from:

WMH Tool Group

2420 Vantage Drive

Elgin, Illinois 60123

Phone: 800-274-6848

www.wmhtoolgroup.com

Identify the replacement part by the part number shown in the parts listing. Be sure to include the model

number and serial number of your machine when ordering replacement parts to assure that you will receive the

correct part.

Page 21

Exploded View – Model 4200A Belt and Disc Sander

Assembly

21

Page 22

22

Parts Listing – Model 4200A Belt and Disc Sander Assembly

Ref # Part No. Description Qty.

1 5508427 Bracket 1

2 5511833 Square Nut, M10 1

3 50510801 Spring 1

4 5051091 Sleeve 1

5 5051131 Collar 1

6 5508431 Shaft with Collar 1

7 5051151 Cap 1

8 TS-2361051 Lock Washer, M5 2

9 TS-1513051 SHFS, M5 x 25 2

10 5051721 Hand Wheel 1

11 5511818 FH Screw, M5 x 6 4

12 TS-1550071 Flat Washer, M10 2

13 5508432 Tilting Table 1

14 5508450 Hand Knob 4

15 5508429 Belt Adj. Knob, M10 1

16 5511824 Drive Screw, M2 x 5 5

17 5508437 Stop Lock 1

18 5511828 Groove Pin, M5 x 45 1

19 5051351 Tilting Scale 1

20 TS-1523011 SHSS, M6 x 6 2

21 5511827 Groove Pin, M4 x 8 2

22 5051331 Segment 1

23 5511725 4200 Arbor Pulley 1

24 TS-1504061 SHCS, M8 x 30 4

25 TS-2361081 Lock Washer, M8 4

26 5508433 Trunnion 1

27 TS-1550061 Flat Washer, M8 9

28 TS-2361081 Lock Washer, M8 9

29 TS-1490041 Hex Cap Screw, M8 x 25 3

30 5508435 Stud, M10 1

31 TS-1550071 Flat Washer, M10 4

32 5508436 Acorn Nut and Handle 1

33 TS-2361061 Lock Washer, M6 3

34 TS-1482031 Hex Cap Screw, M6 x 16 3

35 5508439 Preload Bushing, M54 1

36 BB-6205ZZ Ball Bearing, 6205ZZ 1

37 5508438 Bearing Housing 1

38 TS-2210951 Hex Cap Screw, M10 x 140 2

39 5051421 Key, 5 x 5 x 70 1

40 5508441 Drive Shaft 1

41 5051451 Key, 5 x 5 x 35 1

42 4200A-042 Key, 5 x 5 x 55 1

43 BB-6204ZZ Ball Bearing, 6204ZZ 1

44 5051471 Retaining Ring, S20 1

45 VB-A59 V-Belt, A59 1

46 TS-2245081 SHFS, M5 x 8 4

47 5508444 Belt Guard Assembly 1

48 4200A-048 Warning Label 1

49 TS-1540071 Hex Nut, Full, M10 5

50 5508446 Stop Pin 1

51 5508447 Base 1

52 TS-2210801 Hex Cap Screw, M10 x 80 4

53 5515292 Flat Washer, M10 8

54 TS-2361101 Lock Washer, M10 6

55 5051841 Garnet Belt 1

Ref # Part No. Description Qty.

56 5508455 Deflector Plate 1

57 TS-2361051 Lock Washer, M5 2

58 TS-1513021 SHFS, M5 x 12 2

59 5508454 Drive Drum Guard 1

60 5508456 Dust Deflector 1

61 TS-2361101 Lock Washer, M10 3

62 TS-1491021 Hex Cap Screw, M10 x 20 3

63 5508457 Platen 1

64 TS-1514011 SHFS, M6 x 12 2

65 5051601A Side Guard 1

66 TS-1540231 Hex Nut, M24 1

67 9058121 Lock Washer, Ext., M24 1

68 5051981 Spacer 1

69 5051971A Drive Drum 1

70 5508458 Clamp Ring 1

71 4200A-071 Spacer 1

72 5051031 Tension Lever Pin 1

73 5051021 Belt Tension Lever 1

74 BB-6202ZZ Ball Bearing, 6202ZZ 2

75 5508461 Idler Drum Shaft with 1

Lock Nut 1

76 TS-2342121 Hex Nut, Nylon Lock M12 2

77 5508460 Bearing Lock Nut 1

78 5051591A Idler Drum Guard 1

79 5508462 Stud 3

80 5508463 Clamp Bar 2

81 5052121 Bottom Guard 1

82 TS-2361061 Lock Washer, M6 4

83 5052061B Idler Drum Spacer 2

84 5508459 Idler Pin Bracket 1

85 TS-0367061 Roll Pin, 1/4" x 1-1/4" 2

86 5052001 Block 2

87 5052061A Idler Drum 2

88 5508434 Pointer 1

89 5508451 Clamp with Pins 2

90 4200A-090 Roll Pin, M6 x 45 4

91 5508453 Disc Guard 1

92 TS-2239551 SHCS, M10 x 55 2

93 5051741 Pointer 1

94 TS-1523031 SHSS, M6 x 10 2

95 5051641 Disc, Aluminum 1

96 5051631 Garnet Disc 1

97 5051681 Trunnion 2

98 TS-1490041 Hex Cap Screw, M8 x 25 4

99 5508449 Table 1

100 5051701 Tilting Table Scale 1

101 5052271 Deluxe Miter Gauge 1

102 TS-1550071 Flat Washer, M10 2

103 TS-1482032 Hex Cap Screw, M6 x 17 4

104 4200A-104 Label, Name 1

105 4200A-105 Label, Direction 2

106 TS-1482081 Hex Cap Screw, M6 x 40 2

107 TS-1540041 Hex Nut, Full, M6 2

108 TS-1523021 SHFS, M6 x 8 1

109 4200A-109 Label, Warning 1

110 TS-152704 Allen Wrench, 4mm 1

Page 23

Exploded View – Model 4300A Belt Sander Assembly

23

Page 24

Parts Listing – Model 4300A Belt Sander

24

Ref # Part No. Description Qty.

1 5508427 Bracket 1

2 5511833 Square Nut, M10 1

3 5051081 Spring 1

4 5051091 Sleeve 1

5 5051131 Collar 1

6 5508431 Shaft with Collar 1

7 5051151 Cap 1

8 TS-2361051 Lock Washer, M5 2

9 TS-1513051 SHFS, M5 x 25 2

10 5051721 Hand Wheel 1

11 5511818 Flat Head Screw, M5 x 6 4

12 TS-1550071 Flat Washer, M10 1

13 5508432 Tilting Table 1

14 5508450 Hand Knob 2

15 5508429 Belt Adj. Knob, M10 1

16 5511824 Drive Screw, M2 x 5 3

17 5508437 Stop Lock 1

18 5511828 Groove Pin, M5 x 45 1

19 5051351 Tilting Scale 1

20 TS-1523011 SHSS, M6 x 6 2

21 5511827 Groove Pin, M4 x 8 2

22 5051331 Segment 1

23 5511725 4200 Arbor Pulley 1

24 TS-1504061 SHCS, M8 x 30 4

25 TS-2361081 Lock Washer, M8 4

26 5508433 Trunnion 1

27 TS-1550061 Flat Washer, M8 3

28 TS-2361081 Lock Washer, M8 3

29 TS-1490041 Hex Cap Screw, M8 x 25 3

30 5508435 Stud, M10 1

31 TS-1550071 Flat Washer, M10 4

32 5508436 Acorn Nut and Handle 1

33 TS-2361061 Lock Washer, M6 3

34 TS-1482033 Hex Cap Screw, M6 x 18 3

35 5508439 Reload Bushing, M54 1

36 BB-6205ZZ Ball Bearing, 6205ZZ 1

37 5508438 Bearing Housing 1

38 TS-2210951 Hex Cap Screw, M10 x 140 2

39 5051421 Key, 5 x 5 x 70 1

40 5508442 Drive Shaft 1

41 5051451 Key, 5 x 5 x 35 1

42 TS-1482034 Hex Cap Screw, M6 x 19 4

43 BB-6204ZZ Ball Bearing, 6204ZZ 1

44 5051471 Retaining Ring, S20 1

45 VB-A59 V-Belt, A59 1

46 TS-2245081 SHFS, M5 x 8 4

47 5508445 Belt Guard Assembly 1

48 4200A-048 Label, Warning 1

49 TS-1540071 Hex Nut, Full, M10 5

50 5508446 Stop Pin 1

51 5508448 Base 1

Ref # Part No. Description Qty.

52 TS-2210801 Hex Cap Screw, M10 x 80 4

53 TS-1550071 Flat Washer, M10 8

54 TS-2361101 Lock Washer, M10 6

55 5051841 Garnet Belt 1

56 5508455 Deflector Plate 1

57 TS-2361051 Lock Washer, M5 2

58 TS-1513021 SHFS, M5 x 12 2

59 5508454 Drive Drum Guard 1

60 5508456 Dust Deflector 1

61 TS-2361101 Lock Washer, M10 3

62 TS-1491021 Hex Cap Screw, M10 x 20 3

63 5508457 Platen 1

64 TS-1514011 SHFS, M6 x 12 2

65 5051601A Side Guard 1

66 TS-1540231 Hex Nut, M24 1

67 9058121 Lock Washer, Ext., M24 1

68 5051981 Spacer 1

69 5051971A Drive Drum 1

70 5508458 Clamp Ring 1

71 4200A-077 Idler Drum Shaft 1

72 5051031 Tension Lever Pin 1

73 5051021 Belt Tension Lever 1

74 BB-6202ZZ Ball Brearing, 6202ZZ 2

75 5508461 Idler Drum Shaft with 1

Lock Nut

76 TS-2342121 Hex Nut, Nylon Lock, M12 2

77 5508460 Bearing Lock Nut 1

78 5051591A Idler Drum Guard 1

79 5508462 Stud 1

80 5508463 Clamp Bar 2

81 5052121 Bottom Guard 1

82 TS-2361061 Lock Washer, M6 4

83 5052061B Idler Drum Spacer 2

84 5508459 Idler Pin Bracket 1

85 TS-0367061 Roll Pin, 1/4" x 1-1/4" 2

86 5052001 Block 2

87 5052061A Idler Drum 2

88 5508434 Pointer 1

89 5052271 Deluxe Miter Gauge 1

90 4300A-090 Label, Name 1

91 4200A-105 Label, Direction 1

92 TS-1482081 Hex Cap Screw, M6 x 40 2

93 TS-1540041 Hex Nut,Full, M6 2

94 4300A-094 Label, Warning 1

95 TS-152704 Allen Wrench, 4mm 1

Page 25

Exploded View – Model 4400A Disc Sander Assembly

25

Page 26

26

Parts Listing – Model 4400A Disc Sander Assembly

Ref # Part No. Description Qty.

1 5508427 Bracket 1

2 TS-1523011 SHSS, M6 x 6 2

3 5511725 4200 Arbor Pulley 1

4 TS-1504061 SHCS, M8 x 30 4

5 TS-2361081 Lock Washer, M8 4

6 5508443 Drive Shaft 1

7 5051451 Key, 5 x 5 x 35 1

8 4200A-042 Key, 5 x 5 x 55 1

9 BB-6204ZZ Ball Bearing, 6204ZZ 1

10 5051471 Retaining Ring, S20 1

11 VB-A59 V-Belt, A59 1

12 5511818 Pan Head Screw, M5 x 6 4

13 5508444 Belt Guard Assembly 1

14 BB-6205ZZ Ball Bearing, 6205ZZ 1

15 5508439 Locking Bushing 1

16 TS-1550061 Flat Washer, M8 1

17 TS-1490031 Hex Cap Screw, M8 x 20 1

18 4400A-018 Glue Bushing 1

19 4200A-105 Label, Direction 1

20 4400A-020 Label, Warning 1

21 4400A-021 Label, Warning 1

22 TS-1540071 Hex Nut, Full, M10 4

23 TS-2210801 Hex Cap Screw, M10 x 80 4

24 TS-1550071 Flat Washer, M10 8

25 5508447 Base 1

26 TS-1550071 Flat Washer, M10 2

27 TS-2361101 Lock Washer, M10 4

28 5508450 Hand Knob 2

29 5508451 Clamp with Pins 2

30 4200A-090 Roll Pin, M6 x 45 4

31 5508462 Stud 2

32 5508453 Disc Guard 1

33 TS-2361101 Lock Washer, M10 2

34 TS-2239551 SHCS, M10 x 55 2

35 5051741 Pointer 1

36 TS-1523021 SHFS, M6 x 8 1

37 TS-1523031 SHSS, M6 x 10 2

38 5051641 Disc, Aluminum 1

39 5051631 Garnet Disc 1

40 5508449 Table 1

41 5051681 Trunnion 2

42 TS-2361081 Lock Washer, M8 4

43 TS-1490041 Hex Cap Screw, M8 x 25 4

44 5051701 Tilting Table Scale 1

45 5511824 Drive Screw, M2 x 5 2

46 5052271 Deluxe Miter Gauge 1

Page 27

Exploded View - Base Assembly (All Models)

Ref # Part No. Description Qty.

301 5511743 Enclosure 1

302 TS-1540081 Hex Nut, M12 4

303 5511745 Adjustable Mount 4

304 5511729 Large Cover 1

305 5052431 Motor Mounting Plate 1

306 TS-1490031 HHCS, M8 x 20 7

307 TS-1550061 Flat Washer, M8 7

308 TS-1540061 Hex Nut, M8 7

309 5514650 1.5 HP 115/230V 1 Ph. 1

309 5514651 1.5 HP 115/230V 1 Ph. 1

310 TS-1550061 Flat Washer, M8 4

311 TS-1490011 HHCS, M8 x 12 4

312 TS-2361081 Lock Washer, M8 7

313 9133081 Power Cord 1

314 5514703 Switch Box 1

315 5511753 Tapping Bolt w/ Washer 2

316 5511754 Bushing 1

317 9139391 Switch 1

318 TS-2361081 Lock Washer, M8 4

319 TS-2360121 Flat Washer, M12 4

Ref # Part No. Description Qty.

320 4200A-B320 Cover 1

321 4200A-B321 Pan Head Bolt w/ Flange 3

322 TS-1540041 Hex Nut, M6 3

323 TS-1540031 Hex Nut, M5 2

324 TS-0733203 Lock Washer, Ext., #10 2

325 4200A-B325 Pan Head Screw, M5 x 8 2

326 TS-2284082 Pan Head Screw, M4 x 8 2

327 TS-2361041 Lock Washer, M4 4

328 4200A-B328 Label, Name 1

329 TS-1533052 Pan Head Screw, M5 x 16 1

330 4200A-B330 Cord Clamp 1

331 TS-1540031 Hex Nut, M5 1

332 4200A-B332 Wiring Nut 3

333 TS-1550021 Flat Washer, M4 6

334 4200A-B334 Label, Voltage 1

335 4200A-B335 Switch Cover 1

27

Page 28

Dust Collection System (Optional)

Installation

Transport the shipping container to the installation site.

Unpack the dust collection system and check for

damage. Contact the carrier if damage is found. Open

the installation kit (refer to Optional Accessories in

the parts listing for installation kits). Install the cover

and debris collection drawer if removed. Slip a hose

clamp over the 3-inch vacuum hose. Slip the hose on

the inlet duct. Move the clamp over the duct to secure

the hose.

Repeat the procedure to connect the hose to the outlet

duct on the grinding machine.

Electrical Connection

Refer to the Dust Collection System Wiring Diagram

for wiring information. Connection to electrical power

should be made by a qualified electrician. Observe local

electrical codes when connecting the machine.

Operation

The dust collection system motor is started by setting

the toggle switch on the motor to the ON position. Set

the switch to OFF to shut down the dust collection

system.

Filter

Check for accumulation of debris. Replace the filter at

intervals that you determine are appropriate for your

shop environment and machine utilization.

Drawer Seal

Check the drawer seal periodically and replace if

damaged or missing. Keep the seal in good condition

to help maintain collection system efficiency.

ON/OFF switch on

motor at rear of dust

collection system

Removable cover –

remove for interior

cleaning/access to

impeller

Second Inlet

Duct on this side

28

Maintenance

WARNING:

· MAKE SURE YOU DISCONNECT THE ELECTRI-

CAL POWER TO THE DUST COLLECTION SYSTEM BEFORE PERFORMING MAINTENANCE.

FAILURE TO DO SO MAY RESULT IN INJURY

TO THE OPERATOR AND/OR MAINTENANCE

PERSONNEL.

· DO NOT OPERATE THE DUST COLLECTION

SYSTEM WITH THE COVER REMOVED. INJURY

TO FINGERS AND HANDS FROM THE FAN

BLADES, AND INGESTION OF LOOSE FITTING

CLOTHING INTO THE AIR INLET WITH

RESULTANT INJURY IS ALSO POSSIBLE.

Cleaning

Periodically dispose of accumulated chips and debris

from the chip drawer. Use a brush to loosen debris from

internal surfaces. Use a vacuum cleaner to clean up

the loosened debris.

Outlet filter at rear

removes fine debris

from outlet air stream

Inlet Duct – Connect

3 inch hose - secure

with clamp

Figure 1: Dust Collector Assembled View

Chip Drawer Pull to Open

Page 29

Disassembly

Disassembly of the dust collection system is only

required to replace the motor or the fan components.

The motor switch, if failed, can be replaced without

removal of the motor.

1. Remove the chip drawer (2) and cover (4) from the

base (1).

2. Remove the filter cover (5) and filter (6). Replace

the filter if required.

3. Remove five nuts (10) and lock washers (11) from

the studs at the rear of the base (1).

4. Remove four nuts (12) and lock washers (13) from

the screws (14). Remove the screws (14) from inside

the fan housings. Separate the motor support panel

(9) (with fan and motor still attached) from the base

(1).

5. Remove five nuts (17), lock washers (18) and the

screws (19) that secure the fan housings together.

6. Using a flat bladed tool, separate the outer fan

housing (16) from the inner fan housing (24).

7. Using an Allen wrench, loosen the set screw (22).

Remove the fan (21) from the shaft of the motor

(25). Remove the key (23) from the motor shaft.

8. Use a flat-bladed screwdriver to hold the flat head

screws (28) (in inner fan housing). Remove four nuts

(26) and lock washers (27) from the flat head screws

(28) in the motor mounting lugs.

Assembly

Assembly is the reverse of disassembly. Observe the

following during assembly:

1. Assemble the motor (25) and inner fan housing (24)

on the rear panel; make sure the fan duct is facing

downward.

2. Make sure the guard strap (20) is installed in the

recesses in the fan duct.

3. Mate the fan housings (16 and 24). Turn the fan

(21) by hand to check for rubbing. Adjust the fan as

required.

4. Use a spare screw or a Phillips screwdriver to align

the screw holes in the outer fan housing (16), spacer

(15), and in the internal panel of the base (1).

5. With the screw holes aligned, install the support

panel (9) on the five studs at the rear of the base

(1).

6. Connect the electrical power and check the operation of the dust collection system.

29

Page 30

Exploded View – Model 5511885 Dust Collection System

15 14

16

21

22

26

24

28

19

20

12

13

18

17

11

10

9

23

27

25

30

REAR VIEW

5

6

7

8

4

1

2

FRONT VIEW

3

Page 31

Parts Listing – Model 5511885 Dust Collection System

Ref. Part

No. Number Description Qty

1 5514731 Base 1

2 5514732 Drawer, Chip 1

3 5514733 Seal, Tape *AR

4 5514734 Cover 1

5 5514735 Cover, Filter 1

6 5514779 Filter 1

7 5514736 Panel, Rear Foam 1

8 5514737 Panel, Side Foam 2

9 5514738 Panel, Motor Support 1

10 5514739 Nut, Hex 5

11 5514740 Washer, Lock 5

12 5514741 Nut, Hex 4

13 5514742 Washer, Lock 4

14 5514743 Screw, Hex Head 4

15 5514744 Spacer 1

16 5514745 Housing, Outer Fan 1

17 5514746 Nut, Hex 5

18 5514747 Washer, Lock 5

Ref. Part

No. Number Description Qty

19 5514748 Screw, Hex Head 5

20 5514749 Strap, Guard 1

21 5514750 Fan 1

22 5514751 Screw, Set 1

23 5514752 Key 1

24 5514753 Housing, Inner Fan 1

25 5514754 Motor 1

26 5514755 Screw, Hex Head 4

27 5514756 Seal, Tape *AR

28 5514757 Switch, Motor 1

Connection Kits:

Refer to Wilton catalog for appropriate connection

kit for your grinding machine, or contact Wilton for

assistance.

Wiring Information - Dust Collection System

31

Page 32

WMH Tool Group

2420 Vantage Drive

Elgin, Illinois 60123

Phone: 800-274-6848

www.wmhtoolgroup.com

Loading...

Loading...