WIKA 851.02.100 User Manual [en, de, fr]

Operating Instructions

Betriebsanleitung

Mode d’emploi

Differential pressure gauges Model 702.01.100, 702.02.100,

702.03.100 and 851.02.100 per directive 94/9/EC (ATEX)

Differenzdruckmessgeräte Typ 702.01.100, 702.02.100, 702.03.100

und 851.02.100 nach Richtlinie 94/9/EG (ATEX)

Manomètres pour pression différentielle Type 702.01.100,

702.02.100, 702.03.100 et 851.02.100 selon directive 94/9/EG (ATEX)

II 2 GD c

su

Model 702.01.100 per ATEX

st

Model 702.02/03.100 per ATEX

sv

GB

D

F

Model 851.02.100 per ATEX

GB

Operating instructions Model 702.01.100, 702.02.100,

702.03.100 and 851.02.100 per ATEX Page 1-14

Betriebsanleitung Typ 702.01.100, 702.02.100,

D

702.03.100 und 851.02.100 nach ATEX Seite 15-26

Mode d’emploi Type 702.01.100, 702.02.100,

F

702.03.100 et 851.02.100 selon ATEX Page 27-35

2 WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

11242370 06/2007 GB/D/F

Contents

Contents

Contents

1. Safety instructions 4

2. Description and operating principle 4

3. Technical data and intended use 5

4. Requirements for use in potentially explosive

atmospheres 5

5. Installation instructions 6

6. Measuring assembly 7

7. Commissioning 8

8. Optional extras / accessories 9

9. Maintenance and servicing / cleaning 11

10. Repairs 11

11. Disposal 11

Enclosure 1: Declaration of conformity

for Model 702.01.100 su 12

Enclosure 2: Declaration of conformity

for Models 702.02.100 / 702.03.100 st 13

GB

Enclosure 3: Declaration of conformity

for Model 851.02.100 sv 14

11242370 06/2007 GB/D/F

3WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

1. Safety instructions / 2. Description and operating principle

1. Safety instructions

!

GB

Caution

The appropriate national safety regulations (i.e. VDE 0100 /

EN 60 079-14 / EN 837-2) must be observed when installing,

commissioning and operating these instruments.

T Do not work on gauge while under voltage (applies to

Model 702.02/03.100 and 851.02.100)

T Serious injuries and/or damage can occur should the appropriate

regulations not be observed

T Only appropriately qualified personnel should work on these

instruments

T The effective maximum surface temperature does not depend on

these gauges themselves, but mainly on the respective medium

temperature! For maximum permissible medium temperatures,

see the table on page 6.

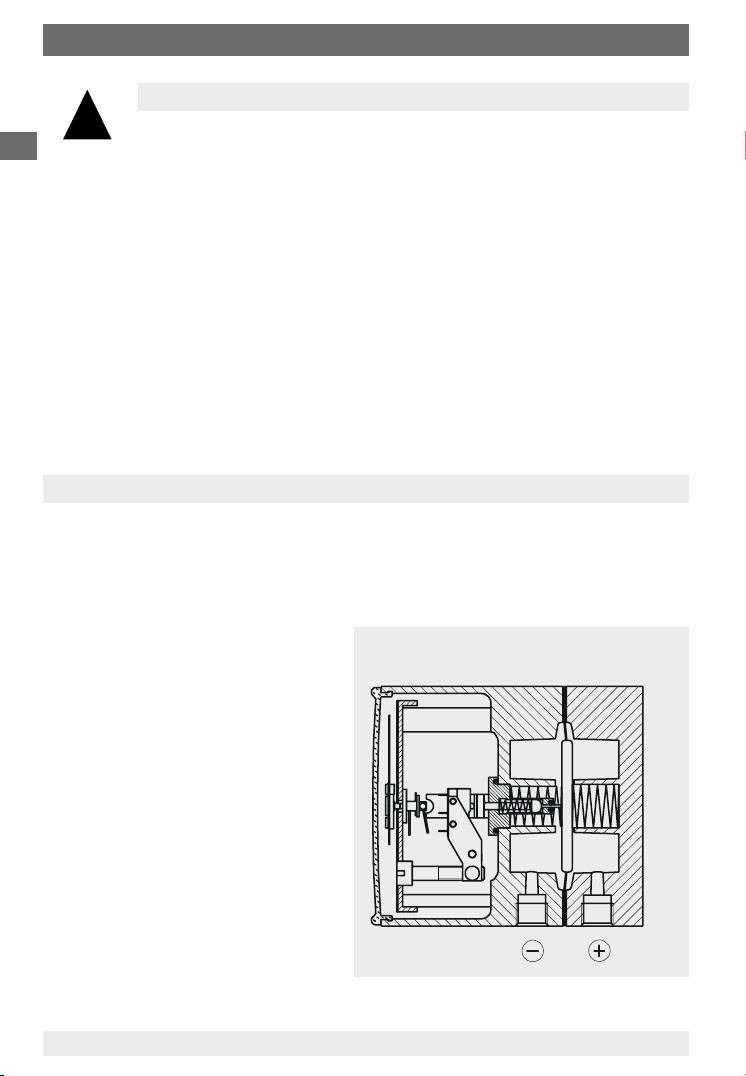

2. Description and operating principle

The j and i measuring medium chambers are separated by an elastic diaphragm. The differential pressure causes an axial movement (measured travel) in

the diaphragm against the measuring range spring. The measured travel is

proportional to the differential pressure and is transmitted, "pressure sealed"

and with minimal friction, via a connecting rod; for:

T su to the movement

T st to the movement

and in addition to the plungers

on the microswitches

T sv to the plungers

on the microswitches

For further information on gauge

construction

T su see data sheet

PM 07.15

T st see data sheet

PM 07.16 or PM 07.19

T sv see data sheet

PM 07.17

4 WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

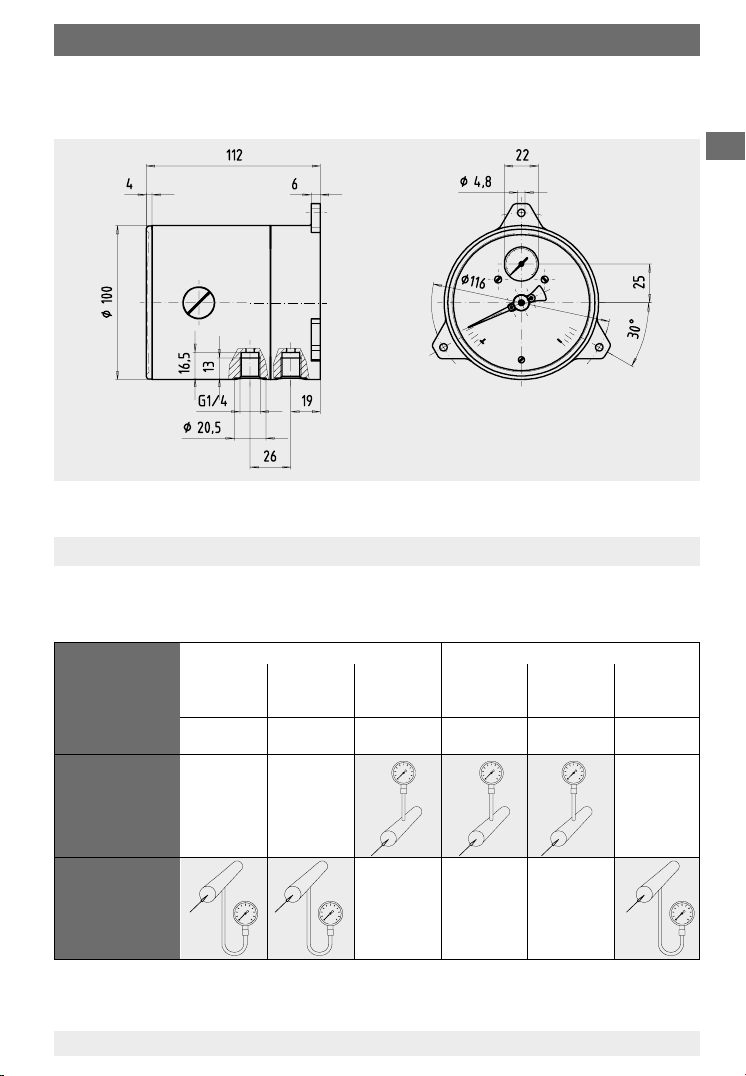

Illustration for example st

2122740.01

11242370 06/2007 GB/D/F

3. Technical data and intended use / 4. Requirements for use ...

3. Technical data and intended use

Static pressure: 25 bar

Overpressure safety (either side): up to 25 bar max.

Operating temperature Ambient -10 … +70 °C

Observe restrictions for use in potentially explosive atmospheres

(see section 4)

Pressure connection: 2 × G ¼ female

IP Ingress protection: IP 54 (EN 60 529 / IEC 529)

Permissible vibration levels at the mounting point

T As a matter of principle the instruments should only be mounted in locations

without a vibration load.

T Isolation from a mounting point exposed to vibration can be achieved, for

example, by mounting the pressure gauge to a solid wall and a flexible

capillary connecting the measuring point to the pressure gauge (see

section 5).

T The following limits must not be exceeded:

Frequency range < 150 Hz

Acceleration < 0.7 g (7 m/s

Electrical contact

(applies to Model 702.02/03.100 and 851.02.100)

Adjustable range: from 10 % to 100 % of span

Switching point adjustment: from the outside by means of setpoint screw(s)

Contact hysterisis: max. 5 % of full-scale value

Medium +90 °C maximum

2

)

GB

4. Requirements for use in potentially explosive

!

Note

11242370 06/2007 GB/D/F

The built-in Reed contacts (applies to Model 702.02/03.100 and

851.02.100) do not possess their own ignition source. For the

purposes of intrinsic safety they are 'simple apparatus' as defined

in EN 50 020.

When supplied from a tested and certified intrinsically safe circuit

(associated apparatus), these switches may be used in potentially

explosive atmospheres up to category 2 without having to take any

further measures.

atmospheres

5WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

4. Requirements for use ... / 5. Installation instructions

Operating temperature for all Models

Ambient (for use in potentially explosive atmospheres): -10 ... +60 °C

GB

Medium: The permissible medium temperature does not only depend on

the instrument design, but also on the ignition temperature of the

surrounding explosive atmosphere. Both aspects have to be

taken into account.

For permissible maximum medium temperatures see table

Attention! With gaseous substances the temperature may increase as a result

of the compression temperature. In such cases, either the rate of change of the

pressure must be slowed down or the permissible medium temperature must be

reduced.

Permissible medium temperature

Temperature class of Permissible maximum medium

the ambient atmosphere temperature (in the pressure system)

(ignition temperature)

T 6 ( > 85 °C) +70 °C

T 5 ( > 100 °C) +85 °C

all other temperature classes +90 °C

5. Installation instructions

Installation of the differential pressure gauge should follow the installation

recommendations for pressure gauges according to EN 837-2 /7.

T The maximum permissible medium / ambient temperature must not be

exceeded

T Prior to the installation of the pressure gauge, the pipes should be thoroughly

cleaned by tapping, blowing or rinsing

T The pressure gauges must be protected against contamination and high

temperature fluctuations!

T The pressure gauges should be installed and operated so as to avoid

exposure to vibration (see also section 3: Permissible vibration levels at the

mounting point).

6 WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

11242370 06/2007 GB/D/F

5. Installation instructions / 6. Measuring assembly

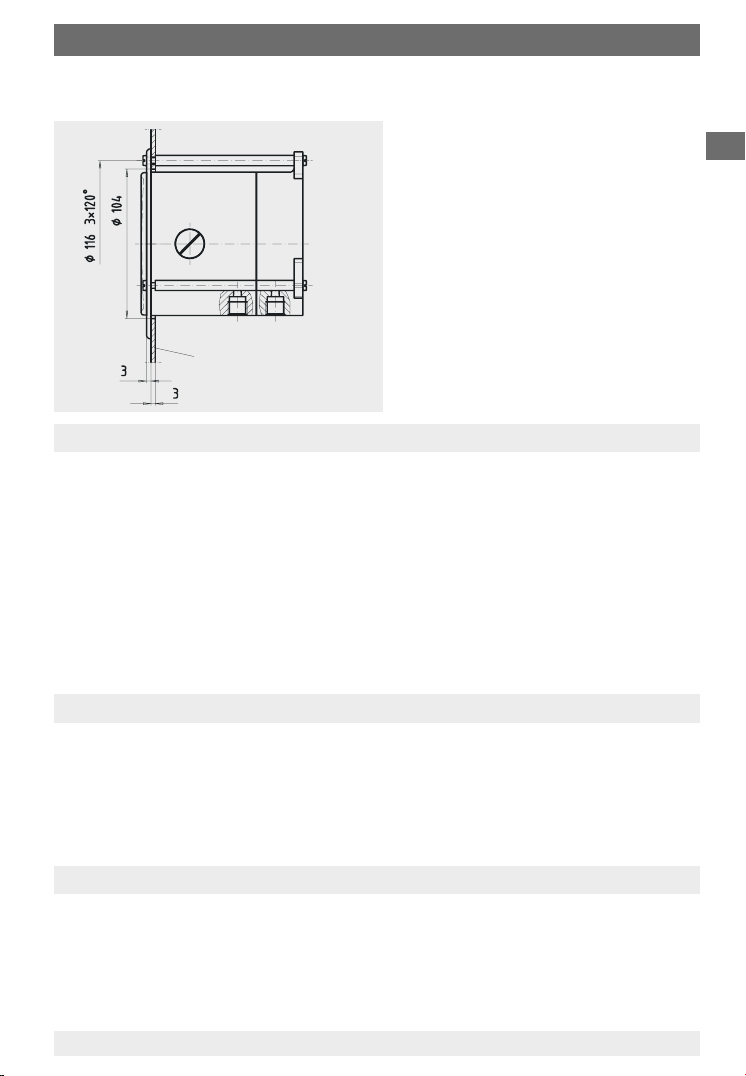

Wall mounting

Installation using the three integral, cast mounting brackets

6. Measuring assembly

Proven measuring assemblies for various types of media. Recommended

set-up for pressure measurement instruments are shown below.

GB

2123541.01

Contents of

tail pipe

Typically

Pressure

instrument

higher

than tapping

point

Pressure

instrument

lower

than tapping

point

11242370 06/2007 GB/D/F

Liquid media Gaseous media

Liquid Liquid with Vapour Gas only Wet gas Liquid gas

vapour only condensate

Condensate Boiling liquid LPG Dry air Moist air Steam

Flue gas

7WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

7. Commissioning

7. Commissioning

7.1 Mounting of the pressure connection

GB

Pressure entries identified j and

During the commissioning process, pressure peaks must be avoided absolutely.

Open the shut-off valves slowly.

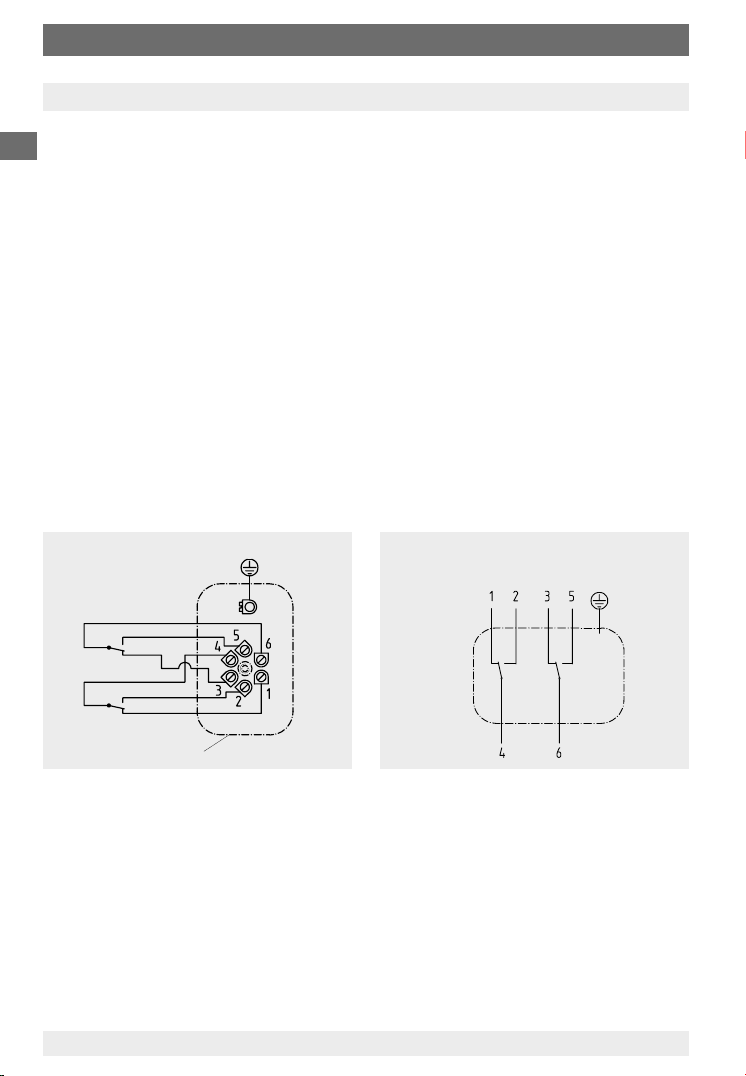

7.2 Wiring details

(applies to Model 702.02/03.100 and 851.02.100)

T The electrical connections should be made by qualified electricians

T Connection details and switch functions are given on the instrument rating

plate. Connection terminals (1 ... 6) and the ground terminal are appropriately

marked.

T The mains connection lines to be provided must be suitable for maximum

instrument power consumption and comply with IEC 227 or IEC 245

T The instruments must be included in the equipotential bonding of the plant

Connection details

ij

high pressure

i

low pressure

Connection is via a

terminal box or L-plug

per DIN 43 651

850.33 2nd contact

850.3 1st contact

Terminal box

Connection is via a

cable gland and cable

2162679.01

850.3

1nd contact

850.33

2st contact

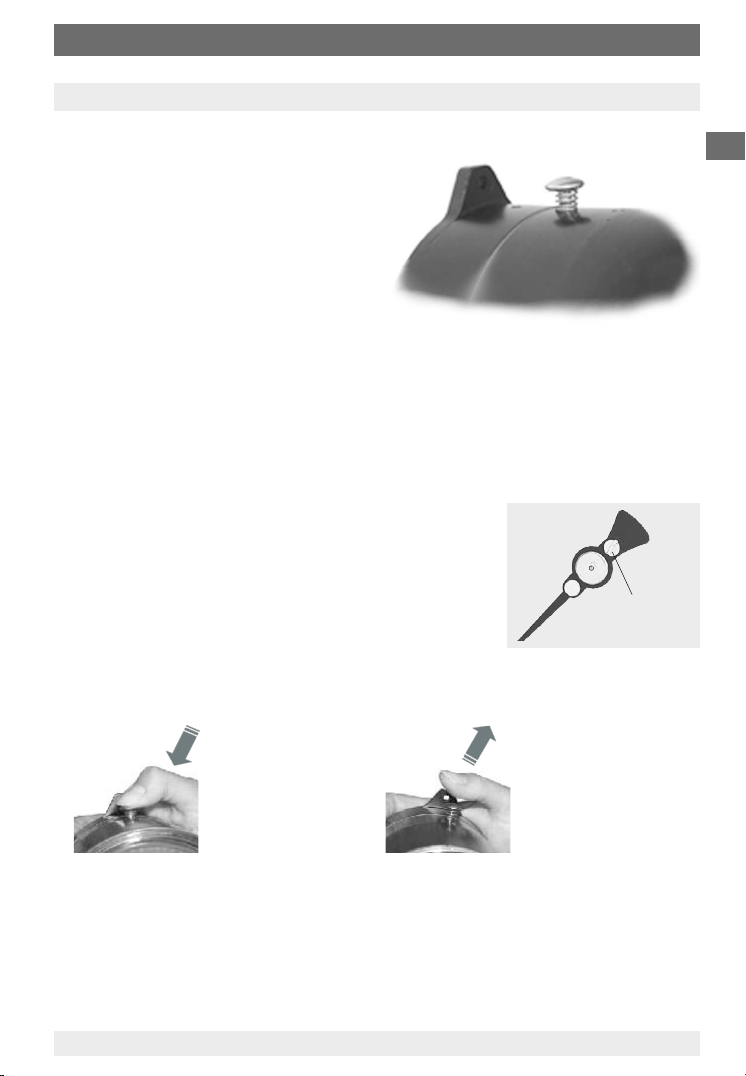

Setting the switch point

The switch points are set by means of the setpoint screws, accessible from the

front. The 270 p° assistant scale indicates the current setpoint.

For contact re-adjustment, lever the window out of the case via the recess in its

circumference. The desired switch point can be set by turning the setpoint

screw.

Afterwards press the window back into the case.

8 WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

2162679.0X

11242370 06/2007 GB/D/F

8. Optional extras / accessories

8. Optional extras / accessories

8.1 Integrated pressure equalising valve

The zero point check during operation

is enabled by pushing the valve

button.

The measuring medium flows

from the higher pressure side to the

opposite side and the differential

pressure drops to zero.

st and sv:

When the valve button is pushed, the differential pressure pointer must move

into the range of the zero point tolerance bar. If it does, the instrument is

functioning correctly. In the case of possible deviations beyond the tolerance

bar, a zero point correction can be made via a standard integrated adjustment

pointer.

To do this, the snap-fit window must be lifted

off using a screw driver at the impression/recess

in the circumference.

The zero point is corrected by turning the slotted

screw on the adjustment pointer.

Afterwards the window must be snap-fitted back

Slotted

screw

onto the case. The differential pressure is indicated

once more, as soon as the valve button is released.

GB

11242370 06/2007 GB/D/F

Valve button,

pushed

Differential pressure

is zero

Released

Differential pressure

is measured again

9WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

8. Optional extras / accessories

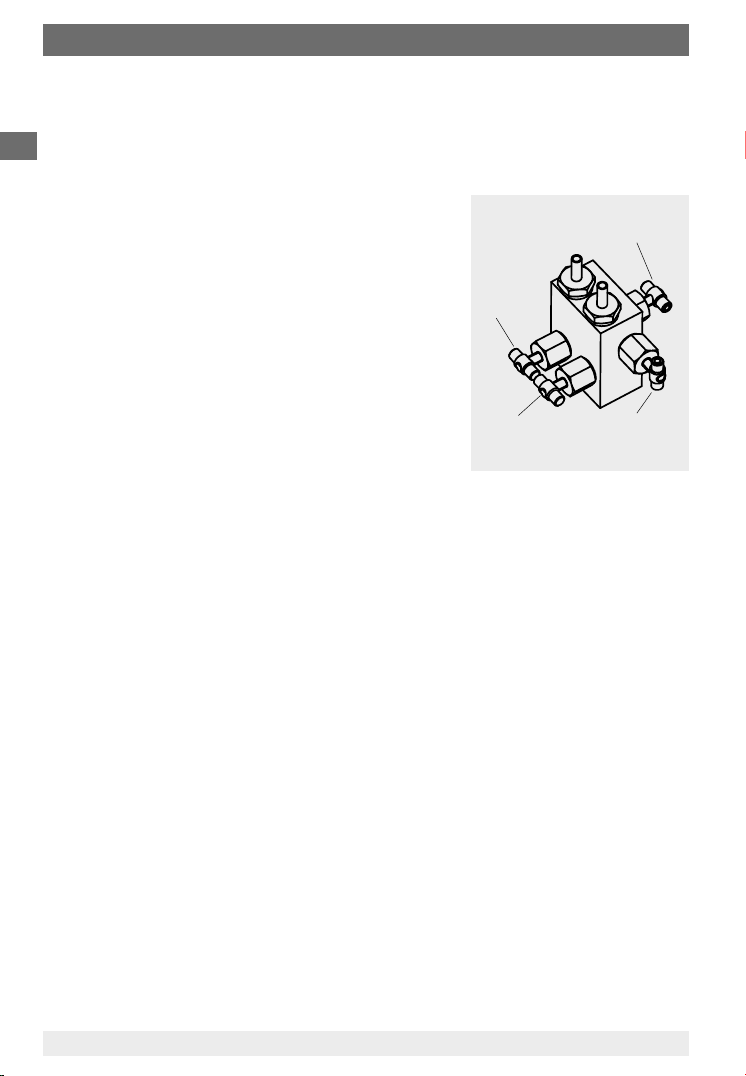

8.2 Four-way valve manifold

T Shut off j - and i process line for disassembling and testing of

GB

measuring instrument without interrupting the process that is running.

Protect the instrument against inadmissible

overpressure loading, such as, for example,

in the case of pressure tests and undefined

operating conditions (also temporary shut

down).

Gauge valve,

T Pressure equalising for zero point check

during normal operation as well as equali-

high pressure

j

side

sation of the pressures at high pressure and

low pressure side during start-up and operation

(with opened pressure equalising valve).

T Process line air bleeding for liquid measuring

media and purging the process line for

removing impurities.

Gauge valve,

low pressure

side

8.2.1 Handling instructions

T Work sequence to start measuring

1. Open pressure equalising valve (middle valve)

2. Open shut-off valve of the negative-pressure media chamber (i right

valve) and the positive-pressure media chamber (j left valve)

3. Close pressure equalising valve

T Operating sequence for air bleeding/purging of piping

1. start: Open shut-off valve of the negative-pressure (i) and positive-

pressure (j) media chamber

Open pressure equalising valve and valve for purging or air bleeding

2. end: Close pressure equalising valve and valve for purging or air bleeding

T Procedure at the end of the measuring operation

(also for partial system shut-down)

1. Open pressure equalising valve

2. Close shut-off valve of the negative-pressure (i) and positive-pressure

(j) media chamber

T Task list for removing the transmitter during normal operation

1. Open pressure equalising valve

2. Close shut-off valve of the negative-pressure (i) and positive-pressure

(j) media chamber

3. Open valve for purging or air bleeding

Pressure

equalising valve

Valve for

i

purging or

air bleeding

10 WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

11242370 06/2007 GB/D/F

8. Optional extras / accessories ... 11. Disposal

8.3 Front flange for panel mounting

2123649.0X

Panel cut-out

Panel

9. Maintenance and servicing / cleaning

The instruments require no maintenance or servicing and will give very long

service when handled and operated properly.

The indicator and switching function should be checked once or twice every

12 months. The instrument must be disconnected from the process to check

with a pressure testing device.

The instruments should be cleaned with a damp cloth, moistened with soap

solution. It must be ensured that all the parts are dry before the power is

switched on again.

The residual pressure medium in dismounted pressure gauges may be

hazardous or toxic. This should be considered when handling and storing the

removed pressure gauges.

GB

10. Repairs

Repairs should only be carried out by the manufacturer or appropriately trained

personnel.

For further details see the data sheet for the respective basic gauge (PM 07.15,

PM 07.16, PM 07.17 or PM 07.19).

11. Disposal

Dispose of instrument components and packaging materials in accordance with

the respective waste treatment and disposal regulations of the region or country

to which the instrument is supplied.

11242370 06/2007 GB/D/F

11WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch per ATEX

Loading...

Loading...