Whirlpool AGB 539/WP, AGB 561/WP, AGB 546/WP, AGB 554/WP, AGB 612/WP INSTRUCTION FOR USE

...Page 1

039_03

Instructions for installation,

use and maintenance

01/2006

BARBECUES

LAVA STONE

AGB 612/WP · AGB 613/WP

AGB 471/WP · AGB 472/WP

AGB 539/WP · AGB 546/WP

AGB 554/WP · AGB 561/WP

Page 2

039_03 - Barbecues lava stone

2

CHARACTERISTICS

Supplied by:

Date:

Customer Service:

FAX

e-mail

Page 3

Models and dimensions page 4

Data of appliances 8

Technical data 8-9

Operating instructions 10

Construction, equipment installed

and safety devices 10

Assembly 10

Location 10

Legal and technical requisites 10

Installation 10

Installation procedure 10

Gas venting 10

Commissioning the appliance 11

Before commissioning the appliance 11

Start-up 11

Testing the power rating 11

Checking input pressure 11

Checking power rating using

the volumetric method 11

Checking power rating when using LP gas 11

Checking the pilot light 11

Checking the primary air 11

Checking the functions 12

Note for the installer page 12

Running the appliance on other types of gas12

Replacing the main burner nozzle 12

Replacing the pilot burner nozzle 12

Adjusting the low flame 12

Maintenance 13

Replacing parts 13

Ignition plung 13

Gas tap 13

Thermocouple 13

Using the appliance 14

First time use of the plate 14

Ignition 14

Turning the pilot burner on 14

Turning the main burner on and adjusting

the temperature 14

Turning the appliance off 14

Turning the appliance off during

normal operation 14

Turning the appliance off

in an emergency 14

What to do if something goes wrong or if

not using the appliance for a long time 14

Taking care of the appliance -

frequency of maintenance 14

Warning 15

INDEX

039_03 - Barbecues lava stone

3

Page 4

039_03 - Barbecues lava stone

4

C

G

T

Deep fat tray

Gas connection (3/4”)

Data plate

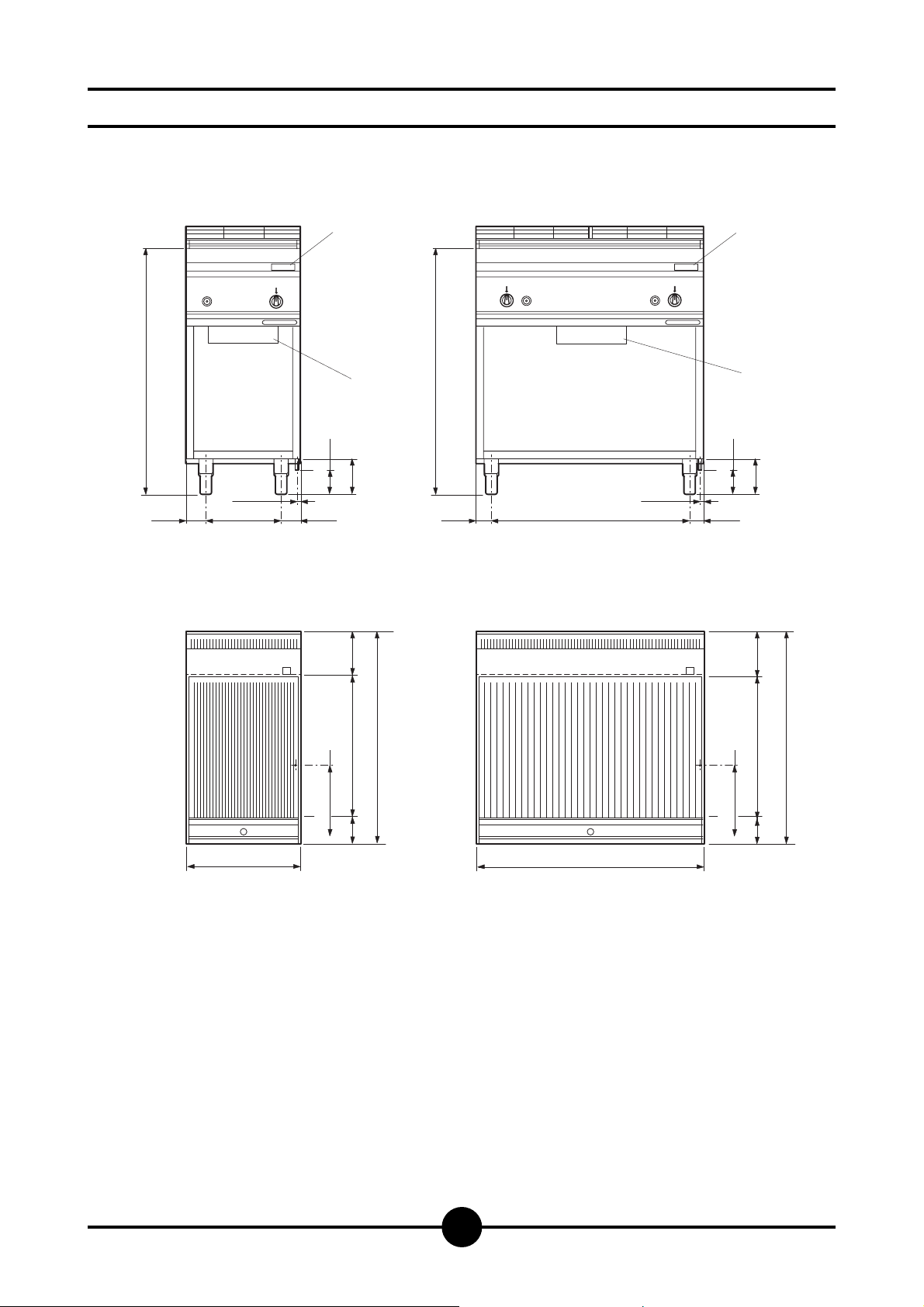

AGB 471/WP

AGB 472/WP

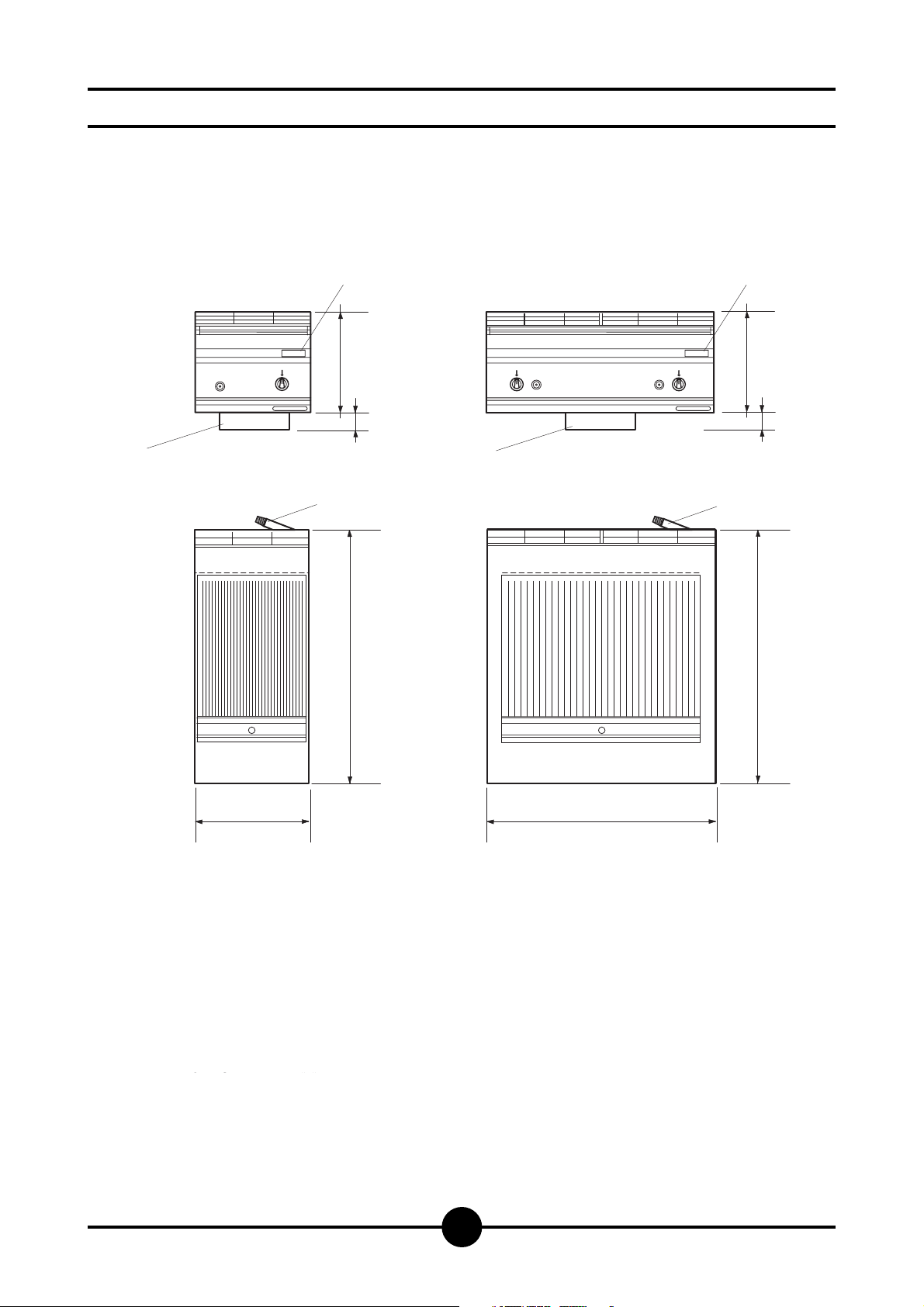

Models and dimensions

T T

270

36

C

C

G

900

400 800

270

36

G

900

C

G

T

Cassetto raccogliolio

Allacciamento gas (3/4")

Targhetta caratteristiche

Page 5

039_03 - Barbecues lava stone

5

G

T

Gas connection (1/2”)

Data plate

AGB 554/WP AGB 561/WP

Models and dimensions

875

21

55 55

290

G

±2

100

T

C

875

T

C

G

55

±2

100

140

100

140

100

55

21

695

700

555

G

±2

280

50

400

G

Allacciamento gas (1/2")

T

Targhetta caratteristiche

800

G

±2

280

555

50

700

Page 6

039_03 - Barbecues lava stone

6

G

T

Gas connection (1/2”)

Data plate

AGB 612/WP AGB 613/WP

Models and dimensions

TT

G

400

13.5

30

655

G

13.5

30

800

Page 7

039_03 - Barbecues lava stone

7

G

T

Gas connection (1/2”)

Data plate

AGB 539/WP AGB 546/WP

Models and dimensions

T

GG

13.5

30

700

T

13.5

30

700

400

800

Page 8

039_03 - Barbecues lava stone

8

2 - CHARACTERISTICS OF THE APPLIANCES

3 - TECHNICAL DATA

These appliances are used for professional purposes.

Installation, repair and use must be carried out by expert personnel.

The instructions contained in this manual apply to our barbe-

cues lava stone in the II2H3+ category (see table on page 9).

Model

AGB 612/WP

AGB 613/WP

AGB 539/WP

AGB 546/WP

AGB 554/WP

AGB 561/WP

AGB 471/WP

AGB 472/WP

Version

Gas lava stone grill

Gas lava stone grill - 2 cooking zones

Gas lava stone grill

Gas lava stone grill - 2 cooking zones

Gas lava stone grill

Gas lava stone grill - 2 cooking zones

Gas lava stone grill

Gas lava stone grill - 2 cooking zones

Dim.: LxWxH

400 x 650 x 300

800 x 650 x 300

400 x 700 x 300

800 x 700 x 300

400 x 700 x 875

800 x 700 x 875

400 x 900 x 270

800 x 900 x 270

N.

51BQ2911

51BQ2911

51BQ2911

51BQ2911

51BQ2911

51BQ2911

51BQ2911

51BQ2911

The data plate is located on the front of the appliance and on

the control panel. It contains all necessary reference data such

as the name of the manufacturer, input pressure, gas type setting, etc.

CAT/KAT GAS/GAZ G30 G31 G20 G25

II2H3B/P P mbar 30 30 20 -

II2H3+ P mbar 30 37 20--

II2H3+ P mbar 28 37 20 -

0051

TIPO/TYPE

MOD.

ART.

N.

N.

Qn kW

MOD.

V AC kW Hz

L’APPARECCHIO DEVE ESSERE ALLACCIATO CONFORMEMENTE ALLE LEGGI IN VIGORE E

INSTALLATO IN UN LOCALE BEN AERATO. LEGGERE I MANUALI DI ISTRUZIONI PRIMA

DELL'INSTALLAZIONE E DELL'UTILIZZAZIONE DELL'APPARECCHIO. L'APPARECCHIO DEVE

ESSERE INSTALLATO DA PERSONALE QUALIFICATO.

m3/h

II2ELL3B/P P mbar 50 50 20 20

II2E+3+ P mbar 28 37 20 25

II2H3B/P P mbar 50 50 20 -

I2E P mbar - - 20 -

II2H3+ P mbar 28 37 20 -

I3B/P P mbar 30 30

I3+ P mbar 28 37

Predisposto a gas: - Gas preset: - Prevu pour gaz:

Eingestelt für Gas: - Preparado para gas: -

25II2L3B/P P mbar 30 30

--II2H3B/P P mbar 30 30

--

--

Geschuckt voor:

SE FI DK CZ SK SI

IT CH PT

ES IE GB GR

NL

DE

FR BE

AT CH

LU

EE LV LT

EE LV LT

NO MT CY IS HU

CY

MADE IN ITALY

G30/G31 30/37 mbar

G20 20 mbar

Page 9

039_03 - Barbecues lava stone

9

3 - TECHNICAL DATA

Primary air distance “A”

Methane gas G20

Liquid gas G30/G31

TABLE 1

Category

Construction type

Air necessary for combustion

Nominal thermal power

Minimum thermal power

Connection pressure

Methane gas 2H

Liquid gas 3+

Gas connection values

Methane gas 2H

Liquid gas 3+

Nozzles Ø 1/100 mm

Main burner

G20

G30/G31

(HuB = 9.45 kWh/m

3

) m3/h

(HuB = 12.87 kWh/kg) kg/h

Nominal capacity

Low flame

Nominal capacity

-

G20

G30/31

20 mbar

28/37 mbar

II2H3+

A

m

3

/h

kW

kW

No. of nozzles, pilot burner

G20

G30/G31

20

40

0.952

0.704

220

Adjustable

145

-

35

20

20

40

1.905

1.409

2 x 220

Adjustable

2 x 145

-

2 x 35

2 x 20

AGB 612/WP - AGB 539/WP

AGB 554/WP - AGB 471/WP

14

9

4

AGB 613/WP - AGB 546/WP

AGB 561/WP - AGB 472/WP

28

18

8

Model

Page 10

039_03 - Barbecues lava stone

10

Construction, equipment installed

and safety devices

Robust steel frame, with 4 legs (adjustable in height).

18/10 chrome-nickel steel outer panelling.

The appliance is also fitted with a stainless steel fat

tray. The lava stone is heated by tubular chromiumplated steel burners, built to withtand thermomechanical stress.

The pilot burner has adjustable injectors.

The combustion chamber and flues are made of electro-galvanised steel sheeting.

The temperature is set using the safety taps provided.

It goes from low (minimum) to high (maximum) through

a range of easily selectable intermediate levels.

Our grid are available either with a fish or meat surface.

Models AGB 613/WP - AGB 546/WP - AGB 561/WP AGB 472/WP have two separate grilling areas on the

plate. Each area has its own temperature controls.

ASSEMBLY

Location

The appliance should be installed in a well ventilated

room, and it is necessary under a range hood.

The appliance can be installed on its own or alongside

other equipment.

If the appliance is to be installed near inflammable

walls, a minimum distance of 200 mm. around the sides

and back should be allowed.

If this is impossible, take proper steps to ensure the installation is safe, such as fitting tiles or heat-reflecting

material to the walls.

Before connecting up the appliance to the gas supply,

check on the data plate that the appliance is fitted for

the type of gas available.

If not, consult paragraph “Running the appliance on

other types of gas”, page 12.

Legal and technical requisites

During assembly, the following legal and technical requisites should be adhered to:

- relevant national legislation;

- local building and fire safety regulations;

- worksheet “Technical rules for installing gas”;

- worksheet “Technical rules for LP gas”;

- worksheet “Gas installations in industrial kitchens”;

- industrial injury legislation;

- local Gas Board regulations;

- current CEI regulations.

INSTALLATION

Assembly, installation and maintenance, i.e.: assembly,

connecting the gas supply, checking power rating,

transforming or adapting the appliance to run on other types

of gas, and commissioning, must all be done by contractors authorised by the local Gas Board in accordance with local and national legislation.

Before doing anything else, seek advice from your Gas

Board.

Installation procedure

To level the appliance correctly, adjust the height of the

four legs.

The R 1/2” gas off-take for models AGB 612/WP AGB 539/WP - AGB 554/WP - AGB 613/WP AGB 546/WP - AGB 561/WP and R 3/4” for models

AGB 471/WP - AGB 472/WP on the appliance can either

be permanently fixed to the If flexible hose is used, it

must be in stainless steel and to current regulations.

After completing connection, check for leaks using a

special leak-detector spray.

Gas venting

These appliances are A construction type, thus no gas

venting is required.

For advice on ventilating the premises where the appliance is installed, observe current regulations.

OPERATING INSTRUCTIONS

Page 11

039_03 - Barbecues lava stone

11

Before commissioning the appliance

Before commissioning the appliance, remove the protective wrapping.

Thoroughly clean the work-surface and the outside of

the appliance using lukewarm water and detergent.

With a damp cloth eliminate all traces of the rust-proofing applied in the workshop then dry with a clean cloth.

Start-up

Before starting the appliance up, check that its specifications (category and type of gas used) match those of

the family and group of the gas available locally.

If not, adapt the appliance to the gas family or group required (see paragraph “Running the appliance on other

types of gas”, page 12).

To start the appliance up, see the instructions for regular use.

Testing the power rating

Use the specific nozzles for the nominal capacity on the

appliance.

Capacity can be of two types:

- nominal, as given on the data plate;

- minimum.

These nozzles are shown in “TECHNICAL DATA” table 1.

The following are the operating pressure tolerances to obtain the nominal power according to the agreed nozzles:

- from 15 to 22.5 mbar for gases of the second family;

- from 25 to 45 mbar for gases of the third family

(propane).

The appliance will not work outside the above pressure

thresholds.

To adjust the capacity to its minimum value, use the data in “TECHNICAL DATA” tables 1.

If you wish to check the nominal capacity further, you

may do so using a gas meter according to the so-called

”volumetric method”.

It is normally enough, however, simply to check that the

nozzles are functioning correctly.

Checking input pressure (Fig. 3)

Input pressure should be measured using a gauge (e.g.

a gooseneck pipe, min. resolution 0.1 mbar).

Remove screw (22) from the pressure socket and connect it to the tube on the gauge; after measuring, the

screw should be retightened absolutely airtight (22).

Checking power rating using the

volumetric method

Using a gas meter and a chronometer, you can read the

volume of gas output per time unit.

The correct volume will be the value of “E” expressed in

litres per hour (It/hr) or litres per minute (It/min).

The following formula is used to calculate the value of “E”:

Capacity should only be measured when the appliance

is at a standstill.

The heat value can be obtained from your local Gas

Board.

To obtain the nominal and minimum capacities in relation to the nominal pressure, consult the “TECHNICAL

DATA” table.

WARNING

It is not possible to adjust nominal capacity in advance.

Checking power rating when using

LP gas

Check that the type of nozzles used match manufacturer's specifications.

Check that the output pressure regulator installed collaterally to the plant conforms to the specifications laid

down in paragraph "Testing the power rating".

Checking the pilot light (fig.5)

When correctly adjusted, the pilot light flame will completely surround the thermocouple and will not flicker; if

not, adjust the screw (12) for regulation of the pilot

burner.

Checking the primary air

The grid can be adjusted. Air volume flow is correct

when there is sufficient protection against the flame rising when the burner is cold or light-back when it is hot.

Capacity

Heat value

E =

COMMISSIONING THE APPLIANCE

3

17

16

18

21

22

20

Page 12

039_03 - Barbecues lava stone

12

Checking the functions

- Start the appliance in accordance with the

instructions;

- Check the gas tubes for leaks;

- Check that the flame on the main burner lights

properly and is correctly formed, even on low;

- Check that the pilot light is correctly regulated;

- Draw up a servicing and maintenance contract.

- Check that the pilot light is correctly regulated;

- Draw up a servicing and maintenance contract.

Note for the installer

- Explain and demonstrate to the user how the ma-

chine works according to the instructions, and hand

him this manual.

- Remind the user that any structural alterations to the

room housing the appliance may affect the combustion air supply. Once the alterations have been completed, the appliance and its functions should be

thoroughly checked.

Running the appliance on other types

of gas

When changing to another type of gas, e.g. from natural

to LP, or to another gas group, consult the “TECHNICAL

DATA” table to determine the correct nozzles to use.

The nozzles for the main burners for different types of

gas, marked in 100ths of mm, are in a case supplied

with the appliance.

When the appliance has been transformed or adapted,

recheck its functions as described in paragraph

"Checking the functions".

Replacing the main burner nozzle

To change nozzle (30), pull out the fat tray and loosen

the fixing screws holding the control panel in place.

Remove the panel. Unscrew the nozzle from the nozzle

holder with an adjustable spanner; replace with a new

nozzle (see “TECHNICAL DATA” table).

To make changing the nozzle easier, loosen screw (39)

to push the air adjustment sleeve back.

After fitting the nozzle, reset primary air distance “A”

(see “TECHNICAL DATA” table).

Replacing the pilot burner nozzle

(Fig. 5)

To get at the pilot burner, slide out the fat tray and remove the control panel (as previously described).

The pilot burner can be regulated by unscrewing the cap

(11) and turning the screw (12) with a screwdriver.

Tightening the screw reduces the capacity and loosening

the screw increases it. To change to another type of gas,

replace the nozzle on burner (36) according to the type

of gas used, by loosening hose (35) (see “TECHNICAL

DATA” table).

Adjusting the low flame (Fig. 3)

Referring to the “TECHNICAL DATA” table, set the low

flame screw (20) as follows:

- if the appliance is to run on LP gas, tighten the low

flame screw as far as it will go;

- if the appliance is to run on natural gas, turn the low flame

screw while simultaneously adjusting the primary air;

- read off the setting in It/min which corresponds to the

heat value (calculated by the “Volumetric Method”);

- start the appliance up according to the instructions;

- after allowing the appliance to run for 45 mins., turn the

knob to low and set minimum gas flow by turning screw

(20) (to the right = gas flow decreases; to the left = gas

flow increases).

On models AGB 613/WP - AGB 546/WP - AGB 561/WP AGB 472/WP each burner must be adjusted separately.

2

40

30

39

2928

Page 13

039_03 - Barbecues lava stone

13

MAINTENANCE

The following maintenance programme should be carried out at least once a year:

- Check that all the safety and setting devices are

working properly;

- Check that the burners are working properly with regard to:

● ignition

● combustion safety;

- Check the functions of the appliance as described in

paragraph "Checking the functions".

If the main burner needs cleaning, proceed as follows:

a) remove the control knobs and the fat tray; unscrew

the fixing screws and remove the control panel;

b) unscrew hose clamp (28 - fig.2) to disconnect the

gas vent connector from the nozzle holder;

c) remove the cooking grid and the charcoal grill (lava stone) support.

The main burner can now be removed for cleaning.

Take care when cleaning the flame apertures.

Make sure you use a prong with the right diameter.

When reassembling the burner, make sure the back

slots properly into the combustion chamber.

- Check the gas venting path (make sure the gas is

correctly evacuated).

REPLACING PARTS

All parts must be replaced by authorised technicians only!

To replace the following parts, first remove the control

knobs, slide out the fat tray and remove the control panel (after unscrewing its fixing screws).

Ignition plug (Fig. 5)

The spark plug (16) can be removed after opening the

flame support by unscrewing the fastening screws (19).

Disconnect the starter cable and insert a new spark plug.

Gas tap (Fig. 3)

Loosen the gas piping and thermocouple hoses (17

and 16), then loosen the screws fixing the gas supply

(21) to the gas ramp and insert a new tap.

Thermocouple (Figs. 3 & 5)

Loosen the screw couplings fastening the thermocouple to

the gas tap (fig. 3/17) and pilot burner (fig. 5/19); insert the

new part.

After replacing the parts, fit the control panel and its

parts back in the right order.

WARNING

Every time a replacement involving gas input parts

is made, recheck all functions and test for leakage.

5

11

131412

17

16

19

Page 14

FIRST-TIME USE OF THE GRID

Important!

Before using the appliance for the first time, thoroughly clean the grid with lukewarm water and detergent,

using a soft cloth to eliminate all trace of the rustproofing applied in the workshop. Dry with a clean

cloth.

IGNITION

Turning the pilot burner on (Fig. 4)

Press knob (4) and turn it to the left .

Keep the knob pressed down while repeatedly pressing

piezo ignition button (6) until you can see through aperture

(10) on the control panel that the flame has caught. Keep

the knob pressed down for another 15-20 seconds; if the

flame goes out after the knob is released, start again.

Turning the main burner on and

adjusting the temperature (Fig. 4)

To light the main burner, turn the knob to the right until it is

on ‘high’ , or else continue until it reaches low ; the

heating capacity must be set between these two positions.

TURNING THE APPLIANCE OFF

Turning the appliance off during

normal operation

To turn the main burner off only, simply turn the knob

to ; this way only the pilot burner will stay on.

To turn the appliance off completely, turn the knob to ●;

this will turn the pilot burner off as well.

Turning the appliance off in an

emergency

In an emergency turn off the gas supply.

What to do if something goes wrong or if

not using the appliance for a long time

If the appliance is not to be used for a long time, or if it

breaks down or works incorrectly, close the tap to the gas

mains located outside the appliance.

If anything goes wrong, call the aftersales department.

WARNING

The height of the grid in relation to the flame may be

adjusted during cooking. To do this, grip both handles

11 and raise or lower them simultaneously (fig. 4) according to the position required, finally fitting them into one of the notches in the respective grooves.

TAKING CARE OF THE APPLIANCE

FREQUENCY OF MAINTENANCE

After using the grid, clean its surface while it is still quite

warm. Use emery paper or steel wool.

The fat tray should be emptied and cleaned daily after

use.

Giving the appliance a thorough clean every day (after

turning it off) will keep it in perfect working order and make

it last longer.

All steel parts should be cleaned with water and a detergent, using a damp cloth; do not use abrasive substances

or corroding detergents. Do not use steel wool anywhere

but on the grilling plate since this might cause rust.

For the same reason, avoid touching the appliance with

anything made of iron.

Do not clean any parts of the appliance other than the

grilling plate with emery or sandpaper. If absolutely necessary, you may use powdered pumice stone.

If the appliance is extremely dirty, use a synthetic sponge

such as Scotchbrite.

After cleaning the appliance, rinse with clean water and

dry with a clean cloth.

All maintenance work must be carried out by qualified

personnel only.

Have the appliance checked at least once a year; we

strongly recommend that you stipulate a servicing and

maintenance contract with your supplier.

USING THE APPLIANCE

039_03 - Barbecues lava stone

14

4

Page 15

WHIRLPOOL EUROPE srl

V.le Guido Borghi, 27

I – 21025 Comerio – VA

WARNING

THE MANUFACTURER CANNOT BE HELD RESPONSIBLE

FOR ANY INACCURACIES IN THIS BOOKLET DUE

TO COPYING OR PRINTING ERRORS.

DUE TO ITS POLICY OF CONTINUAL PRODUCT IMPROVEMENT,

THE MANUFACTURER RESERVES THE RIGHT

TO MAKE ANY CHANGES DEEMED NECESSARY.

THE MANUFACTURER CANNOT BE HELD RESPONSIBLE

IF THE INSTRUCTIONS CONTAINED IN THIS MANUAL

ARE NOT OBSERVED.

THIS DOCUMENTATION IS ONLY INTENDED

FOR QUALIFIED TECHNICIANS WHO ARE AWARE

OF THE RESPECTIVE SAFETY REGULATIONS.

Loading...

Loading...