Page 1

FR

PT

ADN 240

ADN 241

TRADITIONAL

SERIES

ABBATTITORI e SURGELATORI

RAPIDI di TEMPERATURA

BLAST CHILLER AND FREEZERS

SCHNELLKÜHLER CHOCKFROSTER

CELLULES DE REFRIGERATION RAPIDE ET

CONGELATION

ABATIDORES – CONGELADORES RAPIDOS DE

TEMPERATURA

IT

GB

DE

ES

ES

Page 2

FR

IT

Il costruttore si riserva il diritto di modificare senza preavviso le caratteristiche delle apparecchiature presentate in

questa pubblicazione.

GB

The manufacturer reserves the right to modify the appliances presented in this publication without notice.

Le fabricant se réserve le droit de modifier sans préavis les caractéristiques des appareil présentés dans cette

publication.

DE

Der Hersteller behält sich das Recht vor, die in dieser Broschüre vorgelegten Geräte ohne Voranzeige zuändern.

ES

El constructor se reserva el derecho de modificar sin previo aviso las características de los equipos presentados

en esta publicación.

PT

O fabricante reserva-se o direito de modificar sem aviso prévio as características dos aparelhos apresentados

nesta publicação.

Page 3

ENGLISH

1. INDEX

1. INDEX............................................................................................................................................1

2. ANALYTICAL INDEX.....................................................................................................................2

3. REGULATIONS AND GENERAL INSTRUCTIONS........................................................................3

3.1. General information..............................................................................................................3

3.2. Warranty..............................................................................................................................3

3.3. Replacement of Parts...........................................................................................................3

3.4. Description of the Appliance.................................................................................................4

3.5. Features Plate......................................................................................................................5

4. SAFETY.........................................................................................................................................5

4.1. Safety Devices.....................................................................................................................6

5. USE AND FUNCTIONING..............................................................................................................7

5.1. Description of the Functioning Cycles...................................................................................7

5.2. Description of the Controls...................................................................................................8

5.3. Functionality.........................................................................................................................9

5.4. Recommendations for Use.................................................................................................11

6. CLEANING AND MAINTENANCE................................................................................................12

6.1. Recommendations for Cleaning and Maintenance..............................................................12

6.2. Routine Maintenance..........................................................................................................12

6.3. Extraordinary maintenance.................................................................................................12

7. TROUBLESHOOTING.................................................................................................................14

7.1. Faults Display.....................................................................................................................15

8. INSTALLATION............................................................................................................................15

8.1. Packaging And Unpacking..................................................................................................15

8.2. Installation..........................................................................................................................16

8.3. Electric Power Supply Connection......................................................................................17

8.4. Inspection...........................................................................................................................17

9. DISPOSAL OF THE APPLIANCE.................................................................................................18

10. REFRIGERANT TECHNICAL CARD............................................................................................18

ATTACHMENTS................................................................................................................................. I

GB

1

Page 4

ENGLISH

2. ANALYTICAL INDEX

GB

B

Blast chilling Cycle; 11

C

Cleaning the condenser; 13

Cleaning the evaporator; 12

D

Defrosting; 7

Description of the Appliance; 4

Description of the Controls; 8

Disposal of the Appliance; 18

Door micro switch; 6

E

Electric Power Supply Connection; 17

Evaporator Fan Micro switch; 6

F

FAULTS; 14

Faults Display; 15

Features Plate; 5

G

General information; 3

H

High condensation temperature alarm; 6

I

Inspection; 17

Installation; 16

P

Packaging; 15

Preservation; 7

Prolonged Inactivity; 11

Protective Fuses; 6

R

Recommendations for Cleaning and Maintenance;

12

Recommendations for normal use; 11

Recommendations for Use; 10

REFRIGERANT TECHNICAL CARD; 18

Replacement of Parts; 3

Replacing the fuses; 13

Routine Maintenance; 12

S

SAFETY; 5

Safety Devices; 6

Shock freezing Cycle; 12

T

Temperature Blast Chilling; 7

Temperature Blast Chilling (+90 à+3°C); 9

Temperature Shock Freezing; 7

Temperature Shock Freezing (+90 à-18°C); 10

Time Blast Chilling; 7

Time Blast Chilling (+90 à+3°C); 9

Time Shock Freezing; 7

Time Shock Freezing (+90 à-18°C); 10

U

Unpacking; 15

W

Warranty; 3

2

Page 5

3. REGULATIONS AND GENERAL INSTRUCTIONS

3.1. General information

This manual has been designed by the

manufacturer to provide the necessary information

to those who are authorised to interact with the

appliance.

The persons receiving the information must read it

carefully and apply it strictly.

Reading the information contained in this

document will allow the user to prevent risks to

personal health and safety.

Keep this manual for the entire operating life of

the equipment in a place which is well-known and

easily accessible, so that it is always available

when its consultation becomes necessary.

3.2. Warranty

The warranty of the equipment and the

components we produce has duration of 1 (one)

year from the date of delivery and translates into

the supply, free of charge, of parts that we

consider to be faulty.

These faults must, however, be independent from

incorrect use of the product in compliance with the

indications stated in the manual.

3.3. Replacement of Parts

Particular symbols have been used to highlight

some parts of the text that are very important or to

indicate some important specifications. Their

meanings are given below: Caution - Warning

! Indicates important information regarding

safety. Behave appropriately so as not to risk

the health and safety of persons or cause

damage.

Important

iIndicates particularly important technical

information that must not be ignored.

Fees deriving from labour, journeys and transport

are excluded from the warranty.

The materials replaced under warranty are our

property and must therefore be returned under the

responsibility and expense of the customer.

ENGLISH

GB

! Activate all envisioned safety devices before

carrying out any replacement intervention.

iIn particular, deactivate the electrical power

supply using the differential isolating switch.

Only use original spare parts to replace worn

components.

iAll responsibility is declined for injury to

persons or damage to components deriving from

the use of non-original spare parts and

interventions which could modify the safety

requisites, without authorisation of the

manufacturer.

3

Page 6

GB

1 2

A

ENGLISH

3.4. Description of the Appliance

The Blast chiller-Shock freezer, from now on

defined as appliance, has been designed and built

to cool and/or freeze foodstuffs in the professional

catering ambit.

1) condensation area: it is positioned in the

lower part and is characterised by the

presence of the condensing unit.

2) electric area: it is positioned in the lower

part of the appliance and contains the

control and power supply components as

well as electric wiring.

3) evaporation area: it is situated inside the

refrigerated compartment in the rear and

is characterised by the evaporating unit.

4) storage area: it is situated inside the

refrigerated compartment and is destined

for the cooling and/or freezing of

foodstuffs.

The lower part is also distinguished by a control

panel (A) that allows access to the electric parts;

there is a vertically-opening door in the front,

which closes the refrigerated compartment

hermetically.

Depending on requirements, the appliance is

produced in several versions.

4 TRAY BLAST CHILLER-SHOCK FREEZER

Model suitable to contain 4 trays with

blast chilling capacity of 15 kg and 8 kg in

shock freezing.

5 TRAY BLAST CHILLER-SHOCK FREEZER

Model suitable to contain 5 trays with

blast chilling capacity of 15 kg and 9 kg in

shock freezing.

3 - 4

4

Page 7

2 3 6

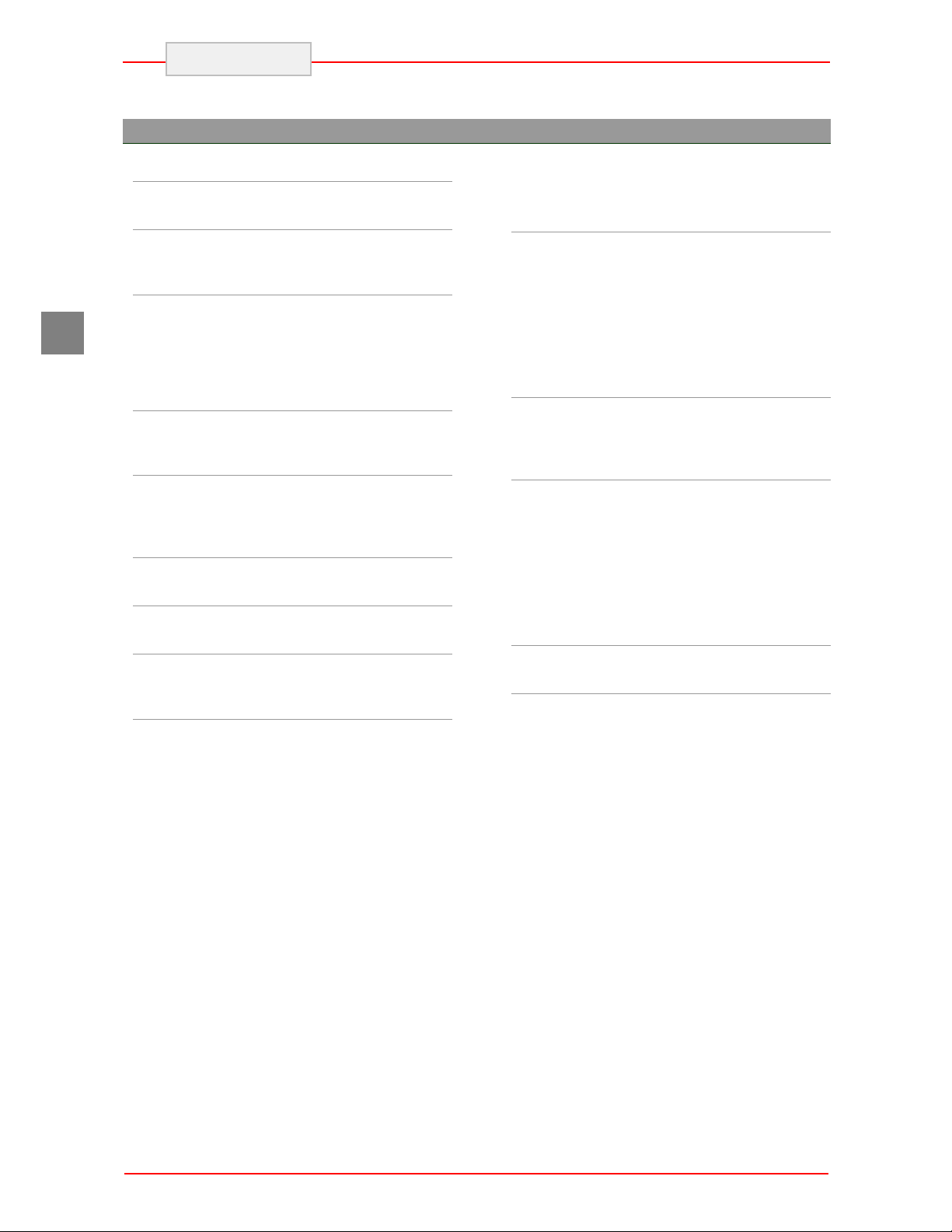

3.5. Features Plate

The identification plate shown is applied directly

onto the appliance. It states the references and all

indications indispensable for working in safety.

1) Appliance code

2) Description of the appliance

3) Serial number

4) Power supply voltage and frequency

5) Electrical absorption

6) Climatic class

7) Type and Amount of refrigerant gas

8) WEEE symbol

ENGLISH

1

GB

4. SAFETY

iIt is recommended to carefully read the

instructions and warnings contained in this

manual before using the appliance. The

information contained in the manual is

fundamental for the safety of use and for machine

maintenance.

! Keep this manual carefully so that it can be

consulted when necessary.

i The electric plant has been designed in

compliance with the IEC EN 60335-2-24

Standard.

, Specific adhesives highlight the presence of

mains voltage in the proximity of areas (however

protected) with risks of an electrical nature.

! Before the connection, ensure the presence of

an omnipolar switch with minimum contacts

opening equal to 3 mm in the mains power supply

upstream from the appliance (requested for

appliances supplied without plug to connect to the

fixed plant).

In the design and construction phase, the

manufacturer has paid particular attention to the

aspects that can cause risks to safety and health

of persons that interact with the appliance.

Carefully read the instructions stated in the

manual supplied and those applied directly to the

machine, and particularly respect those regarding

safety.

Do not tamper or eliminate the installed safety

devices. Failure to comply with this requisite can

lead to serious risks for personal health and

safety.

It is recommended to simulate some test

manoeuvres in order to identify the controls, in

particular those relative to switch-on and switchoff and their main functions.

The appliance is only destined for the use for

which it has been designed; any other use must

be considered improper.

iThe manufacturer declines all liability for any

damage to objects or injury to persons owing to

improper or incorrect use.

5

Page 8

ENGLISH

GB

i All maintenance interventions that require

precise technical skill or particular ability must be

performed exclusively by qualified staff.

! When using the appliance, never obstruct the

air inlet when the appliance is on, so as not to

compromise its performance and safety.

4.1. Safety Devices

During the running of appliance, some control

devices may activate and govern the correct

running of the machine. In other cases, they may

deactivate parts or the whole machine, to put the

appliance in safe conditions. Main controls are

described below.

Door micro switch

If the door is opened, the

magnetic switch placed on the control board

opens and, during blast-chilling or shock-freezing,

evaporator fans go off and a warning message

appears on the display at the same time. This

condition may also be determined when the door

is not perfectly aligned to or near the control

board: in this case with machine in STOP phase,

cycle start-up is prevented, apart from start-up of

the defrosting cycle.

Protective Fuses

Some protection fuses in the general power

supply line are activated in case of overload.

! Never stretch the power cable.

In order to guarantee hygiene and protect the

foodstuffs from contamination, the elements that

come into direct or indirect contact with the

foodstuffs must be cleaned very well along with

the surrounding areas. These operations must

only be performed using detergents that can be

used with foodstuffs, avoiding inflammable

products or those that contain substances that are

harmful to personal health.

In the case of prolonged inactivity, as well as

disconnecting all the supply lines, it is necessary

to accurately clean all internal and external parts

of the appliance.

High condensation temperature alarm

In the event of room

conditions or functional failures, which cause the

condenser to exceed the maximum temperature

value, an alarm is triggered and stops the

machine running. The machine can be run when

an acceptable temperature value is reset.

Evaporator Fan Micro switch

If the deflector is opened to

inspect the evaporator or fans this micro switch

positioned on the evaporator deflector deactivates

machine functioning. Closure of the deflector with

the successive disappearance of the alarm on the

display, restores normal machine functioning.

6

Page 9

5. USE AND FUNCTIONING

5.1. Description of the Functioning Cycles

The following are brief descriptions and types of

operating cycles.

Temperature Blast Chilling

This cycle allows a reduction in temperature in the

product core from +90°C to +3°C as quickly as

possible and within a MAX time of 90 minutes.

The cycle ends when the value +3°C, read by the

needle probe, is reached.

Time Blast Chilling

This cycle allows a reduction in temperature in the

product core from +90°C to +3°C during the set

time: we remind you that it is advisable to run

some previous testing temperature cycles in order

to determine the necessary time for a correct

product blast chilling process. Do not forget that

acquired times have to be considered valid for

exclusive use of the same type of product and in

the same quantities per cycle.

Temperature Shock Freezing

This cycle allows a reduction in temperature in the

product core from +90°C to -18°C in the quickest

time possible and within a MAX time equal to 270

minutes. The cycle ends when the value -18°C,

read by the needle probe, is reached.

Time Shock Freezing

This cycle allows a reduction in temperature in the

product core from +90°C to -18°C during the set

time: we remind you that it is advisable to run

ENGLISH

some previous testing temperature cycles in order

to determine the necessary time for a correct

product blast chilling process. Do not forget that

acquired times have to be considered valid for

exclusive use of the same type of product and in

the same quantities per cycle.

Preservation

At the end of each cycle as described above,

either temperature or time cycle, the preservation

cycle will be started automatically, with no time

limit. The freezer temperature will refer to last

cycle, just concluded:

Ø + 3°C for blast chilling

Ø -25°C for shock-freezing

Warning: use of this cycle is recommended only

for short periods prior to storage of the product in

a storage unit or in case of emergency, so as to

avoid such a limited use of a machine with such

high potential.

Defrosting

The frost forming on the evaporator following the

deposit of humidity from the product can

jeopardise the correct functioning of the

appliance. A defrosting cycle must be carried out

to restore full functionality.

Defrosting is performed by forced ventilation using

the evaporator fan. The cycle can be performed

with the door open or closed and can also be

interrupted at any time.

GB

7

Page 10

GB

S6 S5 S4 S3 S2

ENGLISH

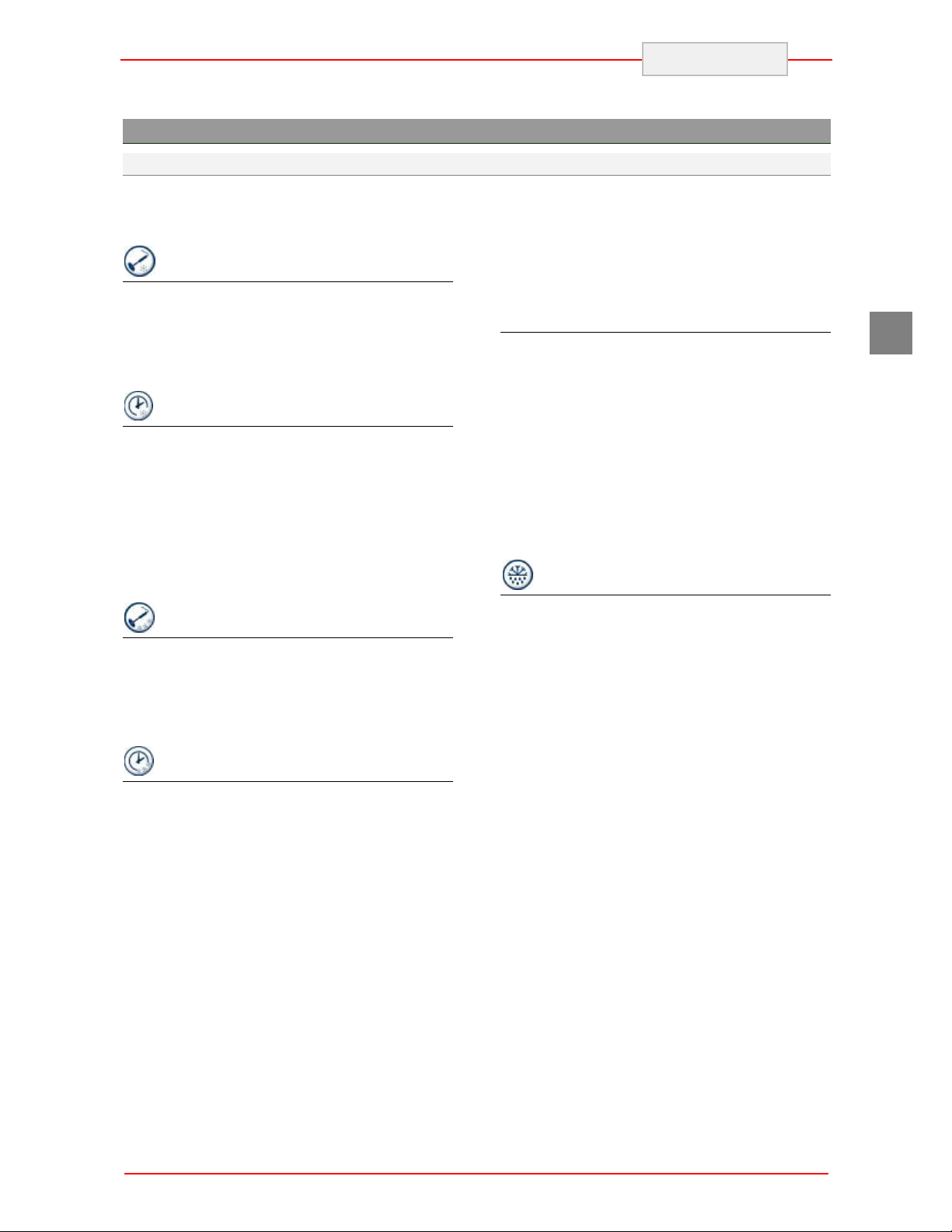

5.2. Description of the Controls

Below is a brief description of the functions carried

out by the keys on the control panel.

Temperature Blast chilling Key

By pressing the key with the machine at a

standstill, it allows to select a temperature blast

chilling cycle (+90°Cà+3°C).

Cycle start key

Once a cycle has been selected, press this button

to start the cycle.

If it is pressed during functioning the appliance

stops; the setting of the previous cycle selected

remains, which can be started immediately.

By pressing this button for at least 5 seconds the

machine passes to the stand-by mode. Repeat

the procedure to reactivate the board.

DEFROST key

When the machine is off a manual defrosting

cycle can be started.

If the key is pressed again, the defrosting in

progress can be stopped.

Display (DY1): symbols description

Time Blast chilling Key

By pressing the key with the machine at a

standstill, it allows to select a time blast chilling

cycle.

Time Blast chilling Key

By pressing the key with the machine at a

standstill allows to select a temperature shock

freezing cycle (+90°Cà-18°C).

Time Shock freezing Key

By pressing the key with the machine at a

standstill, it allows to select a time shock freezing

cycle.

Time increase and decrease keys

When the time blast chilling and/or shock freezing

mode is selected, these buttons allow to set the

cycle duration.

S1

Ø S1 : shock-freezing cycle on

Ø S2 : blast-chilling cycle on

Ø S3 : preserving cycle on

Ø S4 : temperature cycle on (referred to S1 or

S2)

Ø S5 : time cycle on (referred to S1 or S2)

Ø S6 : power supply on – always on even with

machine in stand-by

8

Page 11

2

5.3. Functionality

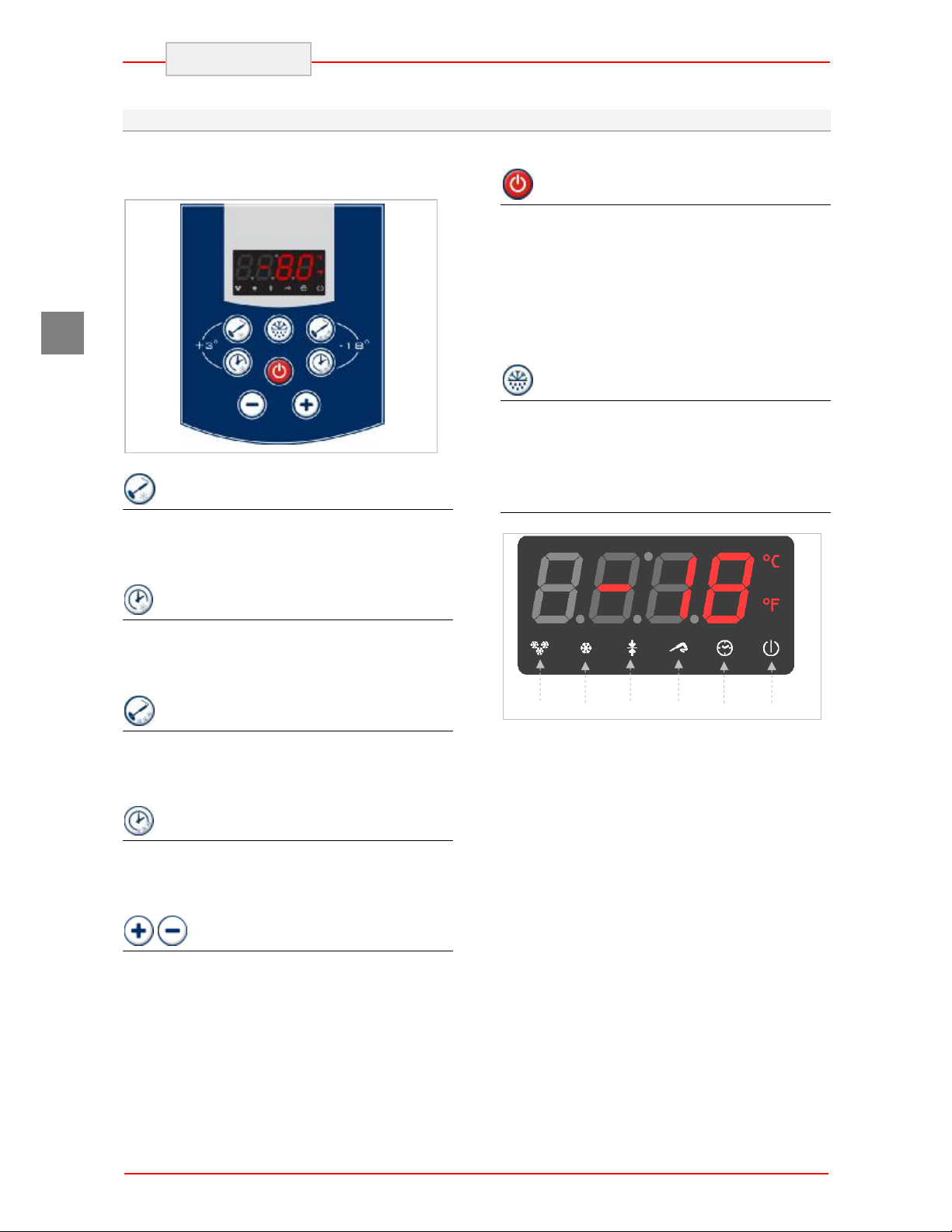

Temperature Blast Chilling (+90 à+3°C)

1

ENGLISH

Time Blast Chilling (+90 à+3°C)

Select blast chilling by pressing key until S2

and S4 LEDs light up.

v Insert the needle probe into the product.

v Start the cycle by pressing the key.

As soon as the needle probe detects the

temperature of +3°C the blast chilling time is

completed and a preserving cycle is automatically

started: the message on the display,

an intermittent sound for 5 seconds and switch-on

of LED S3 confirm the correct conclusion of the

cycle.

The appearance of the alternating

1

2

Select blast chilling by pressing key until S2

and S5 LEDs light up.

v Set the required blast chilling time using

keys and .

v Start the cycle by pressing the key.

This information appears on the display:

2

3

At the end of the set time, the blast

chilling cycle is concluded and the preserving

cycle is automatically started: the display of

“END”, an intermitting 5-seconds sound and LED

S3 that goes on confirm the correct conclusion of

the cycle.

GB

and messages on the display,

indicates the end of the cycle beyond the

maximum time equal to 90 minutes. Press to

detect the effective time taken.

The visualisation of on the display,

alternated to time value 00.00, means that, at the

end of the MAX. time of 90 minutes, the cycle was

not yet concluded. Wait for “END/OUT” messages

to alternately appear on the display; then, press

to show the effective time taken.

Press to conclude the preservation cycle.

Press to conclude the preservation cycle.

9

Page 12

3 2 2 1

2

ENGLISH

GB

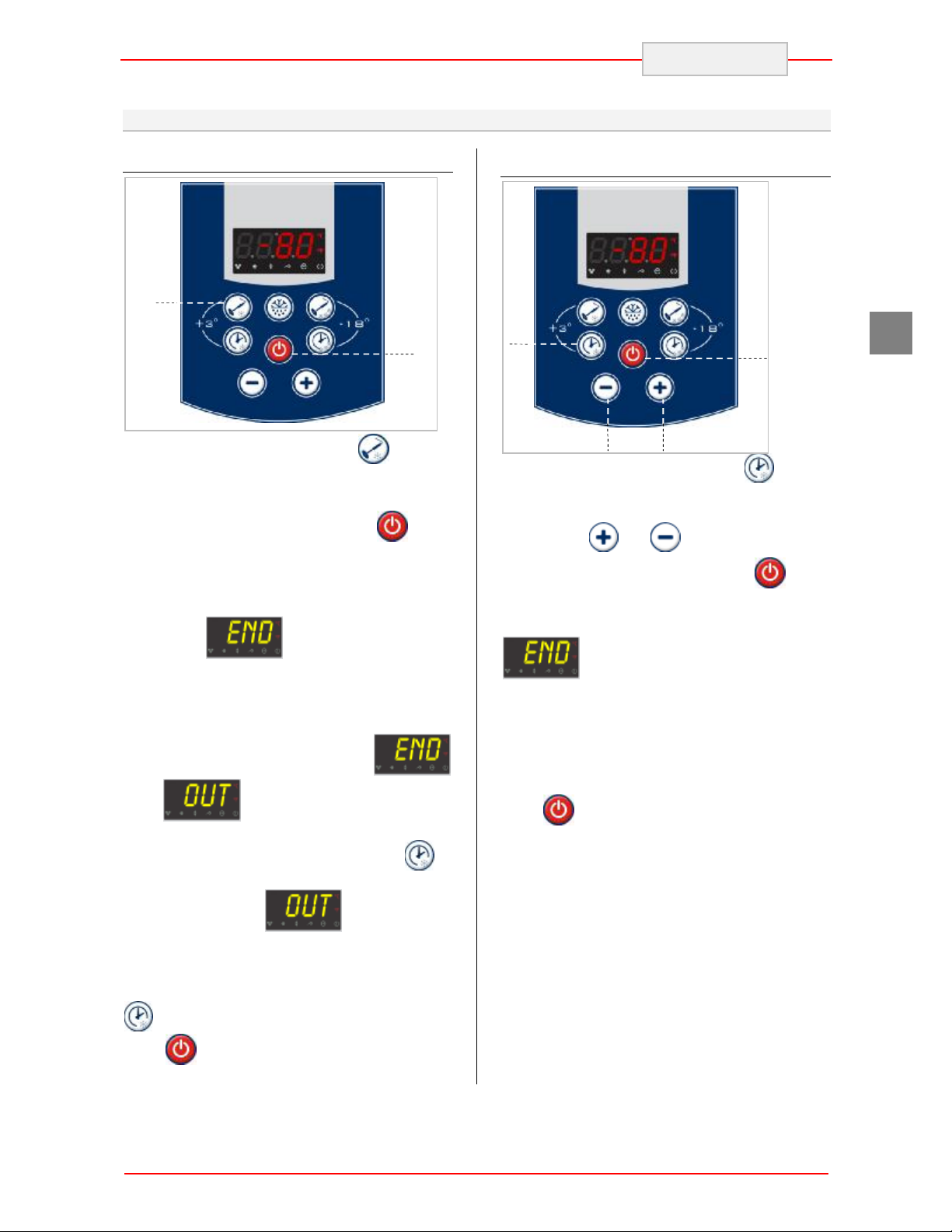

Temperature Shock Freezing (+90 à-18°C)

v Select shock freezing by pressing the

key until S1 and S4 LEDs light up.

v Insert the needle probe into the product.

v Start the cycle by pressing key

This information appears on the display:

Time Shock Freezing (+90 à-18°C)

1

v Select blast chilling by pressing key

until S1 and S5 LEDs light up.

v Set the required shock freezing time using

keys and .

v Start the cycle by pressing the key.

As soon as the needle probe detects

the temperature of -18°C, the shock-freezing time

is completed and a preserving cycle is

automatically started: the display of “END”, an

intermitting 5-seconds sound and LED S3 that

goes on confirm the correct conclusion of the

cycle.

The alternate

visualisation of “END/OUT” on the display shows

that the cycle is completed past the MAX time of

270 minutes. Press to detect the effective

time taken.

The display of “OUT” on the display,

alternated to time value 00.00, means that, at the

end of the MAX. time of 270 minutes, the cycle

was not yet concluded. Wait for “END/OUT”

messages to alternately appear on the display;

then, press to show the effective time taken.

Press to conclude the preservation cycle.

At the end of the set time, the shock

freezing time is concluded and the preserving

cycle is automatically started: the display of

“END”, an intermitting 5-seconds sound and LED

S3 that goes on confirm the correct conclusion of

the cycle.

Press to conclude the preservation cycle.

Defrosting

v Make sure the machine is in STOP mode.

v Press key for defrosting.

The "DEF" message on the display

indicates a defrosting cycle is in progress.

Defrosting is performed by forced ventilation using

the evaporating fans; the cycle may be performed

with the door open or closed and be interrupted at

any time by pressing the key.

10

Page 13

5.4. Recommendations for Use

Prolonged Inactivity

If the appliance remains inactive for a long period,

proceed as follows:

1. Use the automatic isolating switch to

deactivate connection to the main electrical

line.

2. Clean the appliance and surrounding areas

thoroughly;

3. Spread a thin layer of cooking oil onto the

stainless steel surfaces;

4. Carry out all maintenance operations;

5. Leave the doors ajar to prevent the formation

of mould and/or unpleasant odours.

Recommendations for normal use

In order to ensure correct use of the appliance, it

is good practice to apply the following

recommendations:

!Do not obstruct the zone in front of the

condensing unit in order to favour heat disposal

from the condenser to a maximum.

Always keep the front of the condenser clean.

áDo not insert foodstuffs that are well above

the temperature of 65°C. As well as initially

overloading the machine it can make protections

intervene that prolong temperature descent times.

If possible, a brief external period is useful to

lower the temperature to acceptable values.

Check the planarity of the appliance rest surface.

i Do not stack the materials to be preserved

in contact with the internal walls, so blocking the

circulation of air, which guarantees uniformity of

the internal temperature of the refrigerated

compartment.

i There must be a sufficient space between

the basins and trays used in order to guarantee a

sufficient flow of cold air on the entire product.

Therefore avoid the following positions of trays

and/or basins stated below.

i Never obstruct the inlet of the evaporator

fans.

i Products that are more difficult to chill

because of their composition and size should be

placed in the centre.

ENGLISH

GB

Limit the number of times and the duration of time

the doors are opened.

! Blast chilling data refer to standard products

(low fat content) with a thickness below 50 mm;

therefore avoid overlaying products or the

insertion of pieces with a much higher thickness.

This would, in fact, lead to an extension of blast

chilling times. Always distribute the product well

on the trays or basins or in the case of thick

pieces decrease the amount to blast chill.

iAfter blast chilling/shock freezing the

product, it can be stored in a preservation cabinet

after having been duly protected. A tag should be

applied describing the contents of the product,

blast chilling/shock freezing date and expiry date.

When the product has been blast chilled it must

be preserved at a constant temperature of +2°C ,

while if it has been shock frozen it must be

preserved at a constant temperature of -20°C.

i The chiller should be used for storage for

short periods only.

! To prevent bacterial contamination or

contamination of any other biological nature,

the needle probe must be disinfected after

use.

! To extract the product that has undergone blast

chilling or shock freezing, always wear gloves to

protect the hands, as "burns" may occur from the

cold.

i Blast chilling Cycle

With this operating modality the chiller keeps the

temperature of the refrigerating compartment

close to zero during the entire chilling process in

11

Page 14

ENGLISH

GB

order to ensure a gradual drop in the temperature

of the product to +3°C. In this way, ice crystals do

not form on the surface of the product. This blast

chilling method should be used preferably for

products that are not packed and whose

physical/organoleptic characteristics could be

damaged by the formation of superficial ice (e.g.

fish).

i Shock freezing Cycle

With this blast chilling modality the blast chiller

maintains the temperature at a negative value

below -18°C which is the end temperature of

shock freezing. For shock freezing to be

successful and fast, food should be in small

pieces, especially if it has a high fat content. The

largest pieces should be placed in central trays. If

it takes longer than standard time to shock freeze

and the sizes cannot be reduced, decrease the

quantity and precool the chiller compartment by

starting an empty shock freezing cycle before

shock freezing the product.

6. CLEANING AND MAINTENANCE

6.1. Recommendations for Cleaning and Maintenance

particular, deactivate the electrical power supply

! Activate all envisioned safety devices before

carrying out any maintenance interventions. In

6.2. Routine Maintenance

Routine maintenance consists of daily cleaning of

all the parts which can come into contact with

foodstuffs and the periodic maintenance of the

burners, nozzles and draining pipes.

Correct maintenance allows the user to maximise

performance levels and operating life and

constantly maintain safety requirements.

Do not spray the appliance with direct jets of

water or using high pressure appliances.

Do not use iron wool, brushes or scrapers to clean

the stainless steel as ferrous particles could be

deposited which, on oxidising, could lead to rust.

6.3. Extraordinary maintenance

Have the following operations carried out

periodically by specialised staff:

Ø Check the perfect sealing of the door

gaskets and replace them if necessary.

Ø Check that the electric connections have

not loosened.

Ø Check the efficiency of the heating

element resistance

Ø Check functioning of the board and

probes.

Ø Check the efficiency of the electrical

system.

Ø Clean the evaporator.

Ø Clean the condenser.

Cleaning the evaporator

Clean the evaporator periodically.

using the automatic isolating switch.

To remove hardened residues, use wooden or

plastic spatulas or abrasive rubber pads.

During long periods of inactivity, spread a

protective layer on all stainless steel surfaces by

wiping them with a cloth soaked in Vaseline oil

and airing the rooms periodically.

! Do not use products which contain substances

which are harmful and dangerous for personal

health (solvents, petrol etc.).

At the end of the day it is advisable to clean:

Ø the cooling compartment

Ø the appliance.

! As the fins of the evaporator are very sharp,

always wear protective gloves for the next

phases. Only a brush must be used for cleaning:

do not use jets of liquid or sharp instruments.

To access the evaporator proceed as follows:

1. Open the door (A) of the appliance.

2. Loosen the two screws (B) on the right of the

deflector.

3. Remove the runners (C):

4. Turn the deflector (D) to the left

12

Page 15

C B

A B

2. Remove the lower panel (B) from the

technical compartment: to do this, remove

the screw fasteners (C).

3. It is now possible to clean the finned part

of the condenser (D) using suitable tools

and protection devices.

4. After cleaning, close the control panel and

fix it with the screws removed beforehand.

ENGLISH

GB

C

B

A

D

Cleaning the condenser

Clean the condenser periodically.

! As the fins of the condenser are very sharp,

always wear protective gloves for the next

phases. Use protective masks and glasses in the

presence of dust.

i Whenever the condenser has a deposit of

dust in correspondence with the fins, this can be

removed using a suction device or with a brush

applied, using a vertical movement along the

direction of the fins.

C

D

E

Replacing the fuses

C

i The fuses are in the lower part of the

technical compartment (E). To access these, open

the control panel using the same method listed for

the access and cleaning of the condenser.

! No other instruments must be used, which may

deform the fins and therefore the efficiency of the

appliance.

To clean, proceed as follows:

1. Open the door (A) of the appliance.

13

Page 16

ENGLISH

7. TROUBLESHOOTING

The information shown below aims to help with

the identification and correction of any anomalies

and malfunctions which could occur during use.

Some of these problems can be resolved by the

Problem Causes Solutions

user. For the others, precise skill is required and

they must therefore only be carried out by

qualified staff.

Check the power supply cable.

GB

The refrigerator unit does not start

The refrigerator unit functions

continuously, cooling insufficiently

The refrigerator unit does not stop

Presence of ice inside the

evaporator

Appliance noise Persistent vibrations

No voltage

Check the correct connection of the

Other causes

Room too hot Air the environment

Dirty condenser clean the condenser

Insufficient door sealing check the gaskets

Insufficient quantity of

refrigerant gas

Condenser fan at a standstill

Evaporator fan standstill

Probe faulty

Circuit board fault

@ If the problem persists,

contact the after-sales centre.

@ Contact the after-sales

@ Contact the after-sales

@ Contact the after-sales

@ Contact the after-sales

@ Contact the after-sales

Carry out a defrosting cycle possibly

Check fuses.

appliance.

centre.

centre.

centre.

centre.

centre.

with the door open.

@ If the problem persists,

contact the after-sales centre.

check there is no contact between

the appliance and other objects

inside or outside

14

Page 17

FRAGILE

DO NOT EXPOSE

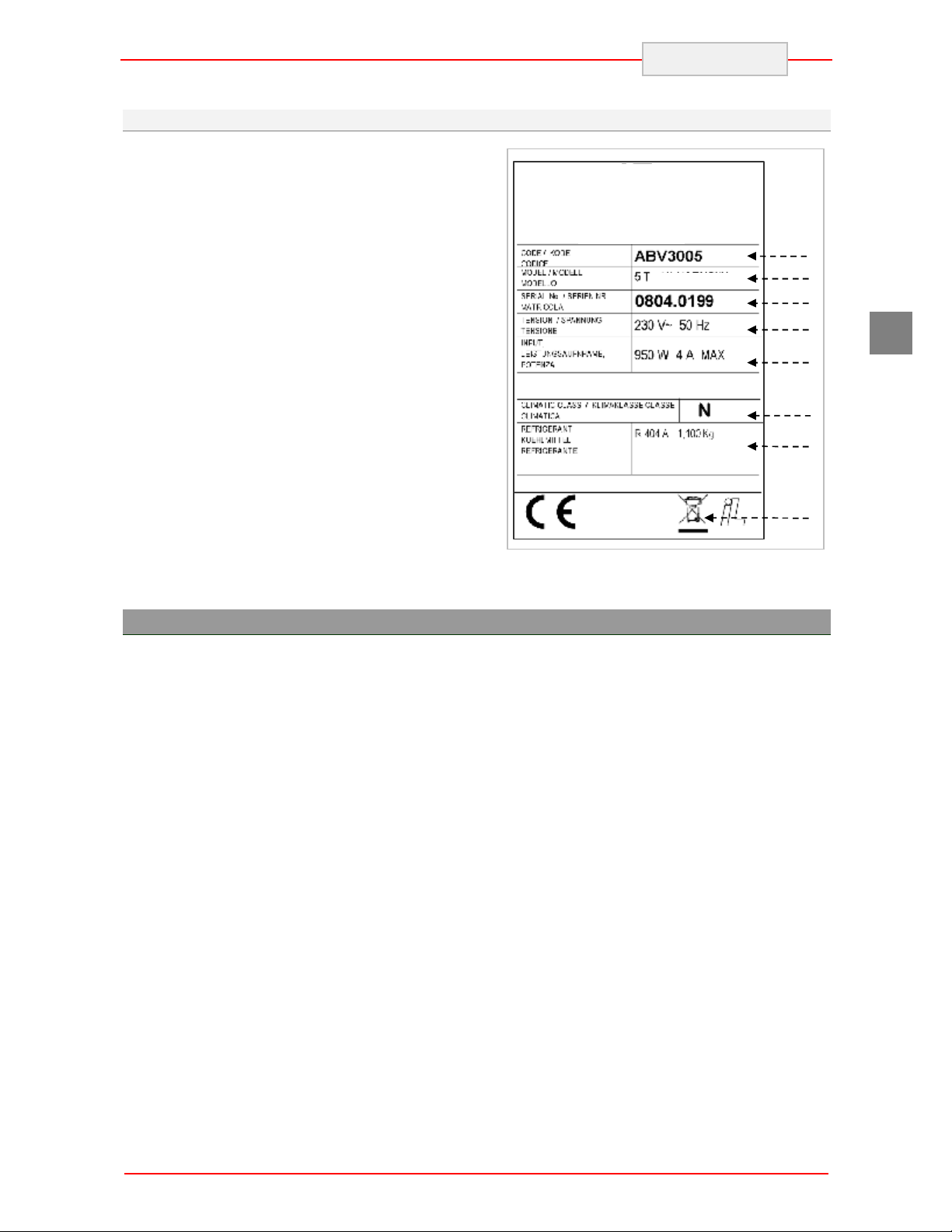

7.1. Faults Display

Problem Causes Solutions

"E0" flashes on the display and

the buzzer emits an intermittent

noise

(compartment probe error)

"E2" flashes on the display and

the buzzer emits an intermittent

noise

(condenser probe error)

"E3" flashes on the display and

the buzzer emits an intermittent

noise

(needle probe error)

Ø The type of probe is

incorrect.

Ø The probe is faulty.

Ø The probe – circuit board

connection is incorrect.

Ø The temperature detected

by the probe is out of the

limits accepted by the

compartment probe in use

ENGLISH

@ Contact the after-sales

centre.

Ø Check that the compartment

probe is the PTC type.

Ø Check the integrity of the

compartment probe.

Ø Check correctness of the

instrument - probe connection.

Ø Check that the temperature in

proximity of the compartment

probe is not out of the accepted

limits

GB

"dFL" flashes on the display and

the buzzer emits an intermittent

noise

"Ht" flashes on the display and

the buzzer emits an intermittent

sound

(high condensation

temperature alarm)

The evaporator fan deflector

has been opened.

The condenser temperature

has exceeded the set limit.

8. INSTALLATION

8.1. Packaging And Unpacking

Handle and install the appliance respecting the

information provided by the manufacturer, shown

directly on the packaging, on the appliance and in

this manual.

The lifting and transportation system of the

packaged product envisions the use of a fork-lift

truck or a pallet stacker. When using these,

particular attention must be paid to balancing the

weight in order to prevent the risk of overturning

(avoid excessive tilting!).

Close the evaporator fan deflector.

@ If the problem persists,

contact the after-sales centre.

Ø Air the environment.

Ø Clean the condenser

Ø Check that the fans function

correctly.

@ If the problem persists,

contact the after-sales centre

The packaging is made of cardboard and the

pallet of wood. A series of symbols is printed on

the cardboard packaging which highlights, in

accordance with international standards, the

provisions to which the appliances are subjected

during loading, unloading, transport and storage.

! ATTENTION: When inserting the lifting device,

pay attention to the power supply cable and the

position of the feet.

15

TOP

HANDLE

WITH CARE

TO HUMIDITY

Page 18

ENGLISH

GB

On delivery, check that the packaging is intact and

has not undergone any damage during

transportation.

The transportation company must be notified of

any damage immediately.

The appliance must be unpacked as soon as

possible to check that it is intact and undamaged.

Do not cut the cardboard with sharp tools so as

not to damage to the steel panels underneath.

Pull the cardboard packaging upwards.

After having unpacked the appliance, check that

the features correspond to those requested in the

order;

8.2. Installation

All the installation phases must be considered,

from the moment of creation of the general plan.

The installation area must be equipped with all

power supply and production residue drainage

connections and must be suitably lit and respect

current laws regarding hygiene and sanitary

requirements.

Contact the dealer immediately if there are any

anomalies.

! Packaging elements (nylon bags, polystyrene

foam, staples …) must not be left within reach of

children.

Remove the protective PVC film from the internal

and external walls, avoiding the use of metal

tools.

i Connect and leave for a certain period of

time (at least 2 hours) before checking

functioning. During transport it is probable that the

compressor lubricant oil has entered the

refrigerant circuit blocking the capillary: as a

consequence the appliance will function for a

certain period of time without producing cold until

the oil has returned to the compressor.

iThe performance of the appliance is

guaranteed with a room temperature of 32°C. A

higher temperature can compromise its

performance and, in more serious cases, cause

the appliance’s protections to start up.

Therefore, consider the most critical room

conditions that can be reached in that position

before making a choice.

Level the appliance by acting on the individual

feet.

! This appliance can only be installed and

operate in rooms which are permanently

ventilated, in order to guarantee correct operation.

! ATTENTION: the appliance requires the

minimum functioning spaces, as shown in the

attachments.

The defrosting water and the water that forms at

the bottom of the refrigerating compartment

during operation or during periodical internal

cleaning must be drained through a prearranged

hose with a minimum diameter 3/4” connected to

the hose at the bottom of the chiller.

A drain trap should also be guaranteed. The drain

must be in compliance with Standards in force.

16

Page 19

8.3. Electric Power Supply Connection

Connection must be carried out by authorised and

qualified staff, respecting the current laws

regarding the subject and using appropriate

prescribed material.

i Before connecting the appliance to the

electric mains, check that the voltage and the

frequency correspond to the data stated on the

registration plate applied on the rear of the

appliance.

iThe appliance is supplied with an operating

voltage of 230V 1+N~ 50 50Hz. On request, it is

8.4. Inspection

The appliance is delivered in conditions such that

it can be started-up by the user.

This functionality is guaranteed by passing the

tests (electric inspection - functional inspection,

appearance inspection) and relative certification

through the specific attachments.

At least the following should be checked after

installation:

Ø Check the electric connections.

ENGLISH

possible to have appliances with different

voltages.

! Before connection, ensure the presence of a

relevant differential switch with adequate power in

the mains power supply, upstream from the

appliance, in order to protect the appliance from

overloads or short circuits

Ø Check the functionality and efficiency of

drains.

Ø Check that there are no tools or materials

left in the appliance that could jeopardise

its functionality or even damage the

machine.

Ø Have the appliance perform at least one

complete chill blasting/shock freezing

cycle

GB

17

Page 20

GB

ENGLISH

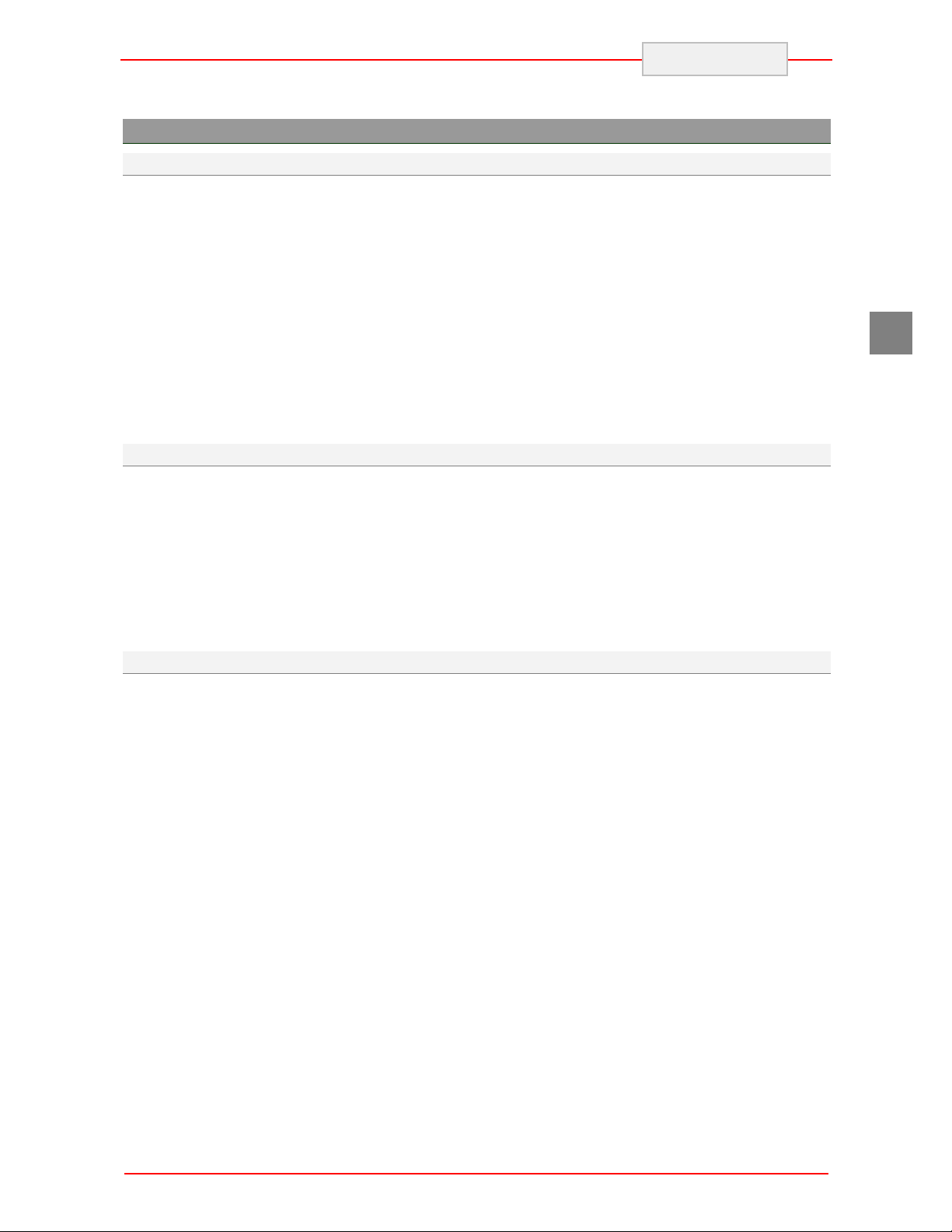

9. DISPOSAL OF THE APPLIANCE

iThis appliance is marked in compliance with

the 2002/96/EC European Directive, WASTE

ELECTRICAL AND ELECTRONIC EQUIPMENT

(WEEE).

! By assuring that this product is disposed of

correctly, the user contributes to preventing the

potential negative consequences on the

environment and health.

indicates that this product must not be treated as

domestic waste but must be taken to suitable

collection points for the recycling of electric and

electronic appliances.

Dispose of it following local regulations regarding

waste disposal.

For further information regarding the treatment,

recovery and recycling of this product, contact the

relevant local office, the domestic waste collection

service or the shop where the product was

purchased.

The symbol found on the

product or on the accompanying documentation

10. REFRIGERANT TECHNICAL CARD

The refrigerant used in the machine is R404a

fluid. Below find the components of the fluid:

PENTAFLUOROETHANE (HFC R125)

44%

ETHANE 1,1,1 – TRIFLUORO (HFC R143A)

52%

ETHANE 1,1,1,2 TETRAFLUORO (HFC

R134A) 4%

IDENTIFICATION OF DANGERS

The rapid evaporation of the liquid can cause

freezing. The inhalation of high concentrations

of vapour can cause irregular heartbeat, short term

narcotic effects (including vertigo, headache and

mental confusion), fainting and death.

· Effects to the eyes: Freezing or cold burns

caused by contact with the liquid.

· Effects on the skin: Freezing or cold burns

caused by contact with the liquid.

· Effects of ingestion. Ingestion is not

considered a means of exposure

FIRST AID

Eyes: In the case of contact, wash the eye well

using a large amount of water for at least 15

minutes. Consult a doctor.

Effects on the skin: Wash with water for at least 15

minutes after excessive contact. If necessary, cure

freezing by gently warming the area in question.

Consult a doctor in the case of irritation.

Ingestion: Ingestion is not considered a means of

exposure.

Inhalation: If large concentrations are inhaled, go

into the open air. Keep the person calm. If the

person cannot breath, perform artificial respiration. If

respiration is difficult, apply oxygen. Consult a

doctor.

18

Page 21

ALLEGATI

ANNEXES

ANLAGEN

ANNEXEX

ANEXOS

I

Page 22

II

Page 23

SCHEDA ALLACCIAMENTI

- CONNECTION CARD

–

ANSCHLUSSSCHEMA

ß

~

3T

700

34060

75

320

455

325

130 70480

FICHE DES RACCORDEMENTS- FICHA DE ENLACES

20

850

900

150

100

60 60664

150

784

190

140

890

940

Scarico acqua

Water Drain

Vidage Eau

ß

Wasserabfluss

Evacuacion Agua

700

Allacciamento Elettrico230V

Electric Connection1+N ~

Branchement Electrique50 Hz

~

Elektroanschluss

Conexiòn elètrica

1445

III

Page 24

SCHEDA ALLACCIAMENTI

- CONNECTION CARD

–

ANSCHLUSSSCHEMA

~

5T

800

75

370

455

130 70550

41060

FICHE DES RACCORDEMENTS- FICHA DE ENLACES

900

950

150

100

60 60664

150

784

190

140

940

990

Scarico acqua

Water Drain

Vidage Eau

ß

Wasserabfluss

Evacuacion Agua

ß

Allacciamento Elettrico230V

Electric Connection1+N ~

Branchement Electrique50 Hz

~

Elektroanschluss

Conexiòn elètrica

1545

IV

Page 25

SCHEDA ALLACCIAMENTI

- CONNECTION CARD

–

ANSCHLUSSSCHEMA

745

745

FICHE DES RACCORDEMENTS- FICHA DE ENLACES

800 784

900

100

700 784

100

850

V

Page 26

Temperatura di funzionamento -

ouvertes

condensa

[°C]

[°C]

FAMILY NAMEFAMILY NAMEFAMILY NAME

IT GB FR

CHILLERS/FREEZERS

DescrizioneDescriptionDescription

•

á

min/max

Produttività per ciclo - kgProductivity per Cycle - kg.Productivité par cycle - kg.

q

Ciclo Positivo (+90° +3°)Positive Cycle (+90° +3°)Positive Cycle (+90° +3°)

Ciclo Negativo (+90° -18°)Negative Cycle (+90° -18°)Negative Cycle (+90° -18°)

Dimensioni EsterneExternal DimensionDimensions Externes

LarghezzaWidthLargeur

Profondità / con porta apertaDepth / with open doors

AltezzaHeightHauteur

Dimensioni InterneInternal DimensionDimensions Internes

LarghezzaWidthLargeur

ProfonditàDepthProfondeur

AltezzaHeightHauteur

Incernieramento PortaDoor hingesCharnières de porte

Numero e tipo di porteN° and type of doorsNombre et type de portes

Tipo di griglieTrays typeType de plateaux

Capacita di carico - Teglie

H=65 mm

SbrinamentoDefrostDégivrages

ß

Tipo di sbrinamentoType of defrostTipe de dégivrages

Evaporazione acqua di

CompressoreCompressor powerPuissance du compresseur

Temperatura di evaporazione -

Potenza - HPPower HPPuissance - HP

Potenza Frigorifera - [watt]Refrigerant Power [watt]Puissance frigorifique - [watt]

RefrigeranteRefrigerantRéfrigérant

Fluido RefrigeranteTypeFluide réfrigérant

Quantita di refrigerante - [gr]Refrigerant quantity [gr]Quantité de réfrigérant - [gr]

Potenza assorbita [watt]Total Power [watt]Puissance [watt]

~

Tensione di AlimentazioneSupply VoltageTension d'alimentation

Operating Temperature

Max Load Capacity - Trays

H=65 - N°

Evaporation of defrost waterÉvaporation condensats

T° Evaporation [°C]

Température de

fonctionnement - min/max °C -

Profondeur / avec portes

Capacité de chargement plateaux h 65 mm

Température d'évaporation -

S I M P L Y

3T 1/1

-18°C / +90°C-18°C / +90°C

1215

89

784784

700 / 1445

850 900 - ( 950 NF Version)

664664

340410

320390

Right SideRight Side

1, Full1, Full

GN 1/1

34

Manual

Air defrost

ManualManual

-25-25

1/25/8

790890

R404aR404a

9001100

800850

230V 50Hz 1+N~230V 50Hz 1+N~

5T 1/1

800 / 1545

GN 1/1,

600x400

Manual

Air defrost

Potenza Sonora - dBANoise Level - dbANiveau sonore - dBA

U

Peso netto - [kg]Net weight [kg]Poids net - [kg]

=

l

= Di Serie ¨=Opzionalel= Standard ¨=Option

l

= De Sèrie ¨=Option

5458

VI

Page 27

Temperatura de

Temperatura de

abierta

aberta

Ensambladura con bisagras de

la Puerta

condensación

condensado

(C°)

(C°)

(gr)

FAMILY NAMEFAMILY NAMEFAMILY NAME

DE ES PT

CHILLERS/FREEZERS

ModelleDescripciónDescrição

•

Temperaturbereich

á

min/max °C

ProduktivitätProductividad por ciclo – kgProdutividade por ciclo – kg

q

Positiver Zyklus (+90° +3°)Ciclo Positivo (+90° +3°)Ciclo Positivo (+90° +3°)

Negativer Zyklus (+90° -18°)Ciclo Negativo (+90° -18°)Ciclo Negativo (+90° -18°)

Außenabmessungen - mmDimensiones ExterioresDimensões Exteriores

BreiteAnchoLargura

Tiefe/mit geöffneter Tür

HöheAltoAltura

AbmessungenDimensiones InterioresDimensões Interiores

BreiteAnchoLargura

TiefeProfundidadProfundidade

HöheAltoAltura

Türanschlag

Anzahl und Art der TürenNúmero y tipo de puertasNúmero e tipo de portas

EinschubgrößeTipo de rejillasTipo de tabuleiros

Max. Bestückungskapazität

-Höhe der Schalen: 65 mm

AbtauDescongelaciónDescongelação

ß

typologieTipo de descongelaciónTipo de descongelação

Abtauart

KompressorCompresorCompressor

Verdampfungstemperatur [°C]

Kompressorleistung - HPPotencia – HPPotência – HP

Kälteleistung [Watt]Potencia Frogorífica – (watt)Potência Frogorífica – (watt)

KältemittelRefrigeranteRefrigerante

Kältemittel TypFluido Refrigerante Fluido Refrigerante

Kühlmittelmenge - [gr]Cantidad de refrigerante – (gr)

Anschlusswert [watt]Potencia absorbida (watt)Potência absorvida (watt)

~

NetzspannungTensión de alimentaciónTensão de alimentação

funcionamiento – mín./máx.

Profundidad / con puerta

Capacidad de carga – Fuentes

de 65 mm de alto

Evaporación del agua de

Temperatura de evaporación –

funcionamiento – mín./máx.

Profundidade / com porta

Charneiras da porta

Capacidade de carga –

Tabuleiros H = 65 mm

Evaporação da agua de

Temperatura de evaporação –

Quantidade de refrigerante –

S I M P L Y

3T 1/1

5T 1/1

-18°C / +90°C-18°C / +90°C

1215

89

784784

700 / 1445

800 / 1545

850 900 - ( 950 NF Version)

664664

340410

320390

Right SideRight Side

1, Full1, Full

GN 1/1

GN 1/1,

600x400

34

Manual

Air defrost

Manual

Air defrost

ManualManual

-25-25

1/25/8

790890

R404aR404a

9001100

800850

230V 50Hz 1+N~230V 50Hz 1+N~

Geräuschpegel - dBAPotencia Sonora – dBAPotência Sonora – dBA

U

Nettogewicht - [kg]Peso neto – (kg)Peso liquido – (kg)

=

l

= Standard ¨=Option

l

= De Serie ¨= Opcional

l= De Série ¨= Opcional

VII

5458

Page 28

Code 33813

–

Revision 01

SCHEMA ELETTRICO

- ELECTRIC DIAGRAM – SCHALTBILD

SCHÉMA ÈLECTRIQUE - ESQUEMA ELÉCTRICO

RPFP CP

1512A

121413

11

MLML MLML

16

RL2

5

6

RL1

3

4

MPME

191718

MN

RST

TRANSFOMER

12A

1

2

F1

M2

M

M2

M3 M3

1~

M

1~

VE VC C

M

1~

M4

M1

M1

M1

MN

22 0V 5 0Hz ~

AC C M X18F B

In= 3A LR A=1 8A

23 0V/ 50Hz 2 5W

230 V 1~ 50Hz

ø5 x 20 10A "T"

3T 5T

ALIMENTAZIONE

AC C M PT1 4LA

230 V 1~ 50Hz

C = COMPRESS ORE

CAVO L=3 000 C/SPINA SCHUKO

F1 = FUSIBILE

A4E 315 -AC 08 -09

230 V/ 50 Hz + C ON D 3 µ F

M4Q 04 5-E A0 1-01

23 0V/5 0Hz 1 0 W / m

220 V 5 0Hz ~

A4 E250 -AL 06 -09

In =2. 8A L RA= 16A

230 V /5 0H z + CO ND 3 µ F

VC = VENTILATORE CONDENSATORE

VE = VENTILA TORE EVAPORATORE

RST = RESISTENZA STIPITE

MP = MICRO PORTA

KTY 83-12 1

PTC KTY 81-1 21 99 0 Ohm @25°C

PTC KTY 81-1 21 99 0 Ohm @25°C

RP = SON DA C ELLA

FP = SONDA SPILLONE

ME = MICRO VENTILATO RE EVAPORATORE

CP = SON DA C ONDE NSAT ORE

L

N

VIII

Page 29

NOTE

IX

Page 30

NOTE

X

Page 31

XI

Page 32

XII

Page 33

FR

IT

A TERMINI DI LEGGE È RISERVATA LA PROPRIETÀ DI QUESTO MANUALE CON DIVIETO DI

RIPRODURLO E/O DISTRIBUIRLO IN QUALSIASI FORMA SENZA NOSTRA AUTORIZZAZIONE

GB

IN COMPLIANCE WITH THE LAW IN FORCE,IT IS PROHIBITED TO REPRODUCE AND/OR

DISTRIBUTE THIS MANUAL IN ANY WAY WITHOUT THE AUTHROISATION OF THE PROPRIETOR

AUX TERMES DE LA LOI, LA PROPRIETE DE CETTE NOTICE EST RESERVEE. IL EST DONC

INTERDIT DE LA REPRODUIRE ET/OU DE LA DISTRIBUER SOUS QUELQUE FORME QUE CE SOIT

SANS NOTRE AUTORISATION.

DE

LAUT GESETZLICHER VORSCHRIFT STEHT DIESES HANDBUCH UNTER

EIGENTUMSVORBEHALT UND DARF AUS DIESEM GRUND NICHT OHNE UNSERE GENEHMIGUNG

VERVIELFACHT U/O IN JEDER FORM AN DRITTE WEITERGEGEBEN WERDEN

ES

DE ACUERDO CON LOS TÉRMINOS DE LA LEY ESTÁ RESERVADA LA PROPIEDAD DE ESTE

MANUAL CON EXPRESA PROHIBICIÓN DE REPRODUCIRLO Y /O DISTRIBUIRLO EN CUALQUIER

FORMA SIN NUESTRA AUTORIZACIÓN

Page 34

3 5 0 7 9 R e v i s i o n 00

Loading...

Loading...