Page 1

PROPAQ

Patient Monitors Menu

®

100-Series*Monitors

Calibration/Maintenance Manual

M-Series Hardware, Softwar e Versions 7/8

This manual (810-0334-XX) applies only to 100-Series Monitors with serial numbers beginning with an “M” (such as

ME00204, or MB00223), and to printers with serial numbers beginning with MCO. If your printer’s serial number begins

with TCO, and your monitor’s serial number begins with TB, use Service Manual 810-0012-XX; if your monitor’s serial

number begins with TE, use Service Manual 810-0257-XX.

*IMPORTANT SERIAL NUMBER INFORMATION

Page 2

Copyright ©1993 by Protocol Systems, Inc. All rights reserved. No part of this document

may be duplicated in any form without the written permission of Protocol Systems, Inc.

GSA Listing # V797P-3165J

NSN Listings:

Model 102/LCD: 6515-01-3156196

Model 104/LCD: 6515-01-3156198

Model 106/LCD: 6515-01-3156197

Model 102/EL: 6515-01-3627449

Model 104/EL: 6515-01-3627451

Model 106/EL: 6515-01-3627447

Expansion Module with Printer: 6515-01-3159814

Oximeter (SpO2): 6515-01-3631219

Protocol® and Propaq® are registered trademarks of Protocol Systems, Inc.

Protocol Systems, Inc. is protected under various patents and patents pending.

NELLCOR® and DURASENSOR® are registered trademarks, and C-LOCK™ and

OXISENSOR™ are trademarks of Nellcor, Incorporated. Nellcor is protected under U.S.

patents 4,621,643, 4,653,498, 4,700,708, 4,770,179, 4,802,486, 4,869,254, 4,928,692, and

4,934,372.

HP and Hewlett-Packard are registered trademarks of Hewlett-Packard Company.

Protocol Systems, Inc.

8500 S. W. Creekside Place

Beaverton, OR 97005 USA

(503) 526-8500

Customer Service: (800) 289-2500

Facsimile: (503) 526-4300

Technical Service: (800) 289-2501

Part Number: 810-0334-01Rev. A

First Printing: 4/94

Printed in the U.S.A.

Page 3

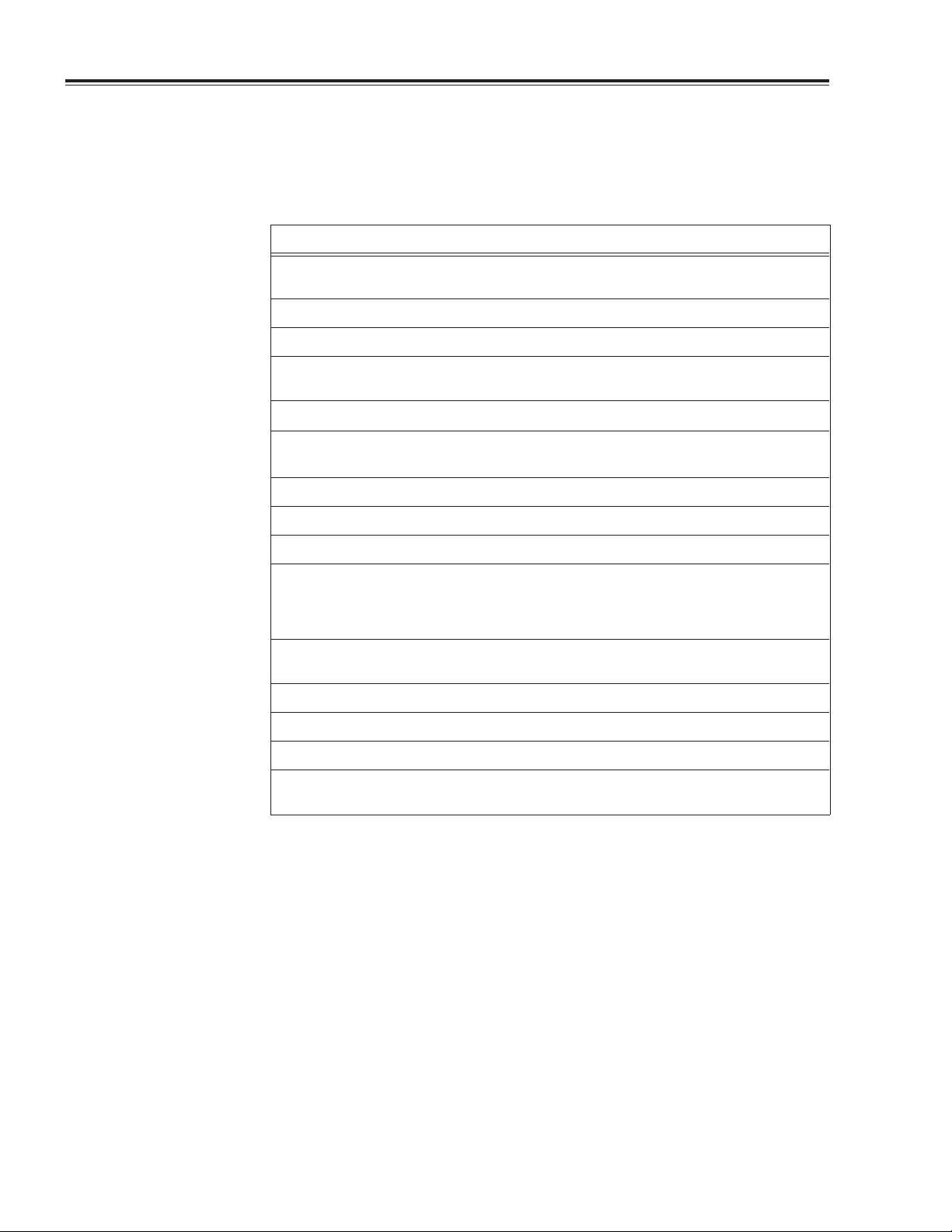

Service Manual Update/Change Information

A-Series Hardware

Service Manual Update

Introduction

The following table identifies important information about this update.

Item Information

This update/change has part number 810-0698-00 Rev. A

This update/change affects/covers information

in manual(s) with Protocol part number(s)

This update/change affects/covers Propaq monitors with “A” serial number prefix

The information in this update/change is provided because of

For more information contact Protocol Systems, Inc. Technical Support at:

810-0334-01

New revision of hardware in Propaq monitor

prompted new serial number prefix “A” which

requires update/change to service information already published for existing Propaq

monitors.

800 289 2501 or 503 526 8500. See the

Service Manual for other access information.

The Flexible Monitoring Company

1 of 4

Page 4

Copyright 1995 by Protocol Systems, Inc. All rights reserved. No part of this document may be

duplicated in any form without the written permission of Protocol Systems, Inc.

Propaq

, Acuity

, and Protocol

are registered trademarks of Protocol Systems, Inc.

Protocol Systems, Inc.

Technical Service Dept.

8500 SW Creekside Pl.

Beaverton, Oregon 97008-7107

In the United States: 800.289.2501

Worldwide: 503.526.8500

Facsimile: 503.526.4910

Worldwide e-mail: solutions@protocol.com

World Wide Web access: http://www.protocol.com/service

Page 5

Overview

In 1994, Protocol Systems introduced the “International” series of Propaq monitors designated

with the serial number prefix “A.” This hardware reduces electromagnetic emissions, improves

susceptibility to electro-magnetic interference (EMI), and incorporates other features implemented

in the latest version of Propaq software, including the End-tidal CO

these changes, this Service Manual update was produced to inform you of the effects, if any, the

changes had upon current service manuals.

The information in this update/change is applicable only to the Propaq Service Manual part number 810-0334-01. It does not affect any other service document.

For board layouts, schematics, and assembly drawing changes effected with the release of A series

hardware, contact Protocol Systems for information.

Overview of Changes to Sections

monitoring option. Due to

2

Section Affected Description

Section 1 None

Section 2 None

Section 3 None

Section 4 None

Section 5 None

Section 6 None

Section 7 None

Section 8 Additional part numbers. Contact Protocol

Technical Support.

Appendices None

There are no other changes to the document identified above.

Protocol Systems, Inc. 3 of 4

Page 6

###

4 of 4 Service Manual Update

Page 7

Propaq 100-Series Monitors Safety Summary

Safety

Summary

CAUTION

WARNING

The general safety information in this summary is for both operating and

servicing personnel. Specific warnings and cautions will be found

throughout the Operator’s Guide and other manuals where they apply. Such

specific warnings and cautions may not appear here in this summary.

CAUTION statements in the documentation identify conditions or practices

that could result in damage to the equipment or other property.

WARNING statements in the documentation identify conditions or practices

that could result in personal injury.

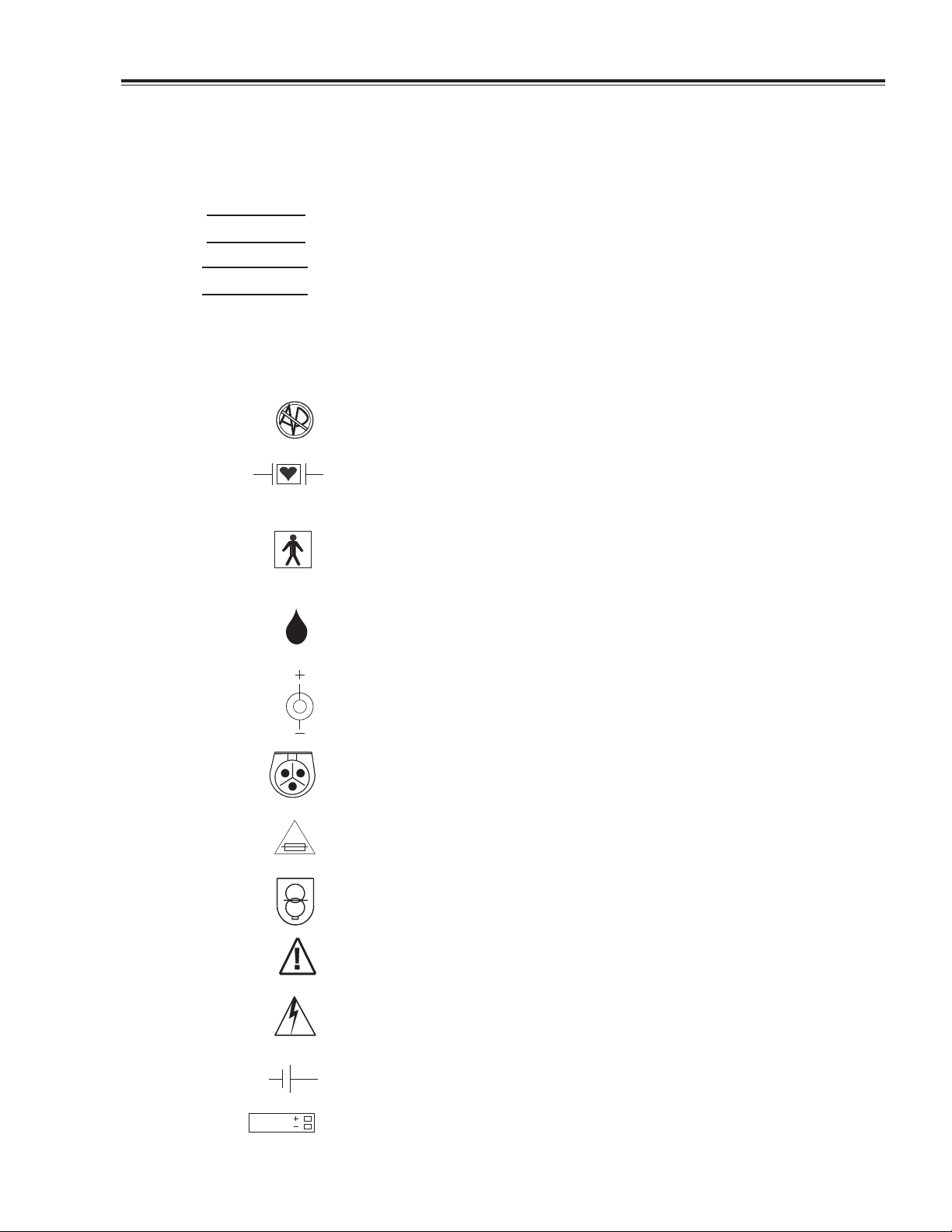

Symbols The following symbols may appear in the documentation, and on labels on

the Propaq monitors.

DANGER: Risk of explosion when used in the presence of flammable

anesthetics. (This is on older versions only.)

Type CF, Isolated patient connections comply with the allowable risk

(leakage) current limits for direct cardiac application and are protected

against the effects of defibrillation.

Type BF, Isolated accessible and applied parts comply with the allowable

risk (leakage) current limits for noncardiac body applications, protecting the

patient and operator from risk of electric shock.

Protected against water dripping vertically. (Protection Classification IPX1

per IEC Publication 529.)

IPX1

DC power input connector for applications not requiring a “high output”

power adapter.

DC power input connector for applications requiring a “high output” power

adapter.

For continued fire protection, use only the specified fuse.

Internal power transformer meets requirements of a short-circuit-proof

safety-isolating power transformer (symbol is located on ac power adapter).

Caution: Refer to User’s Guide and accompanying documentation.

Caution: Refer servicing to qualified service personnel. (For products

certified by Underwriters Laboratories.)

Battery.

Positioning of battery.

Calibration/Maintenance Manual 810-0334-01 i

Page 8

Safety Summary Propaq 100-Series Monitors

Direct current.

Alternating current.

For indoor use only.

Important Safety

Considerations

Place the product in a location where it cannot harm the patient should it fall

from a shelf or other mount.

Do not autoclave this product.

Inspect the power adapter cord periodically for fraying or other damage, and

replace the adapter as needed. (The power adapter is not a serviceable part;

however, the detachable power cord used with the Universal Power Adapter

is replaceable). Do not operate the apparatus from mains power with a

damaged power adapter cord or plug.

Frequent electrical and visual checks should be made on cables and

electrode wires. Broken or frayed electrode wires, or loose snap-fittings may

cause interference or loss of signal. Particular attention should be paid to the

point at which the wire enters the snap-fittings, since flexure will eventually

cause breakage of strands at this point.

Avoid electrosurgery burns at monitoring sites by ensuring proper

connection of the electrosurgery return circuit. If the electrosurgery return

electrode is improperly connected, the other patient-connected monitoring

electrodes and transducers (particularly ECG electrodes and temperature

probes) will serve as return paths for the high-frequency energy. This is

especially true for older electrosurgery units which have the return circuit

deliberately earth-grounded. For improved safety, never deliberately ground

the return circuit of an isolated-output electrosurgery unit. If necessary,

operate the monitor on battery power only to prevent a return to earth

ground through the monitor.

To assure operator safety during defibrillation, keep the discharge paddles

away from ECG and other electrodes, as well as other conductive parts in

contact with the patient. During defibrillation, always avoid contact with any

accessories, such as cables and sensors, connected to the Propaq’s left side

panel. For additional safety precautions, refer to the defibrillator operator’s

manual.

To ensure patient safety, the conductive parts of the ECG electrodes

(including associated connectors) and other patient-applied parts should not

contact other conductive parts, including earth ground, at any time.

Do not operate this product in the presence of flammable anesthetics.

Explosion can result. This product must only be operated in strict

conformance with local fire prevention regulations.

ii 810-0334-01 Calibration/Maintenance Manual

Page 9

Propaq 100-Series Monitors Safety Summary

NOTE

Within certain governmental jurisdictions, all interconnected

accessory equipment must be labeled by an approved testing

laboratory. After interconnection with accessory equipment, risk

(leakage) current and grounding requirements m ust be maintained.

To ensure patient safety, use only accessories recommended or supplied by

Protocol Systems, Inc. For a list of those accessories, see the Protocol

Products and Accessories book (PN 810-0409-00) that accompanies the

Users Guide.

Do not autoclave accessories unless the manufacturer’s instructions clearly

approve it. Many accessories can be severely damaged by autoclaving.

To ensure conformance to risk (leakage) current requirements when

operating from an ac mains power source, use only a Protocol Systems’

503-0002, 503-0053, or 503-0054 power adapter.

Pour limiter le courant de fuite conformément aux exigences lorsque

l’appareil est branché au secteur, utiliser seulement un bloc d’alimentation

de la série 503-0002 503-0053, 503-0054.

A product that has been dropped or severely abused should be checked by

qualified service personnel to verify proper operation and acceptable risk

(leakage) current values.

While under warranty, the Propaq should be serviced only by Protocol

Systems’ service personnel. Service documentation is available from

Protocol Systems, Inc. to aid the biomedical engineer during post-warranty

period service.

Component replacement and internal adjustments must be made by qualified

service personnel only.

Calibration/Maintenance Manual 810-0334-01 iii

Page 10

Section 1 General Information

Available Documentation................................................................................................1-1

About This Manual .........................................................................................................1-1

Product Description......................................................................................................... 1-2

Limited Warranty.............................................................................................................1-3

History of Manuals By Monitor Serial Numbers.........................................................1-3

Section 2 Installation and Service

Introduction......................................................................................................................2-1

Unpacking/ Repacking .................................................................................................... 2-1

Warranty Service ............................................................................................................. 2-1

Repair and Upgrade Support.......................................................................................... 2-2

Recommended Service.................................................................................................... 2-3

Service Intervals..........................................................................................................2-3

Table of Contents

Functional Verification....................................................................................................2-4

Self Test .......................................................................................................................2-4

The Service Menus ..................................................................................................... 2-4

Equipment Required....................................................................................................2-6

Procedure .....................................................................................................................2-6

Power System..............................................................................................................2-7

Button Tests .................................................................................................................2-8

Display .........................................................................................................................2-8

ECG Channel & Alarm Indicators ............................................................................ 2-9

P1, P2......................................................................................................................... 2-11

CUFF Channel...........................................................................................................2-12

Temperature................................................................................................................ 2-13

Battery Capacity Test................................................................................................2-14

Checks..............................................................................................................2-14

SpO

2

Printer Tests ...............................................................................................................2-16

(section continued on next page)

Calibration/Maintenance Manual 810-0334-01 v

Page 11

Table of Contents Propaq 100-Series Monitors

Section 2 Installation and Service (Cont)

CO2Functional Verification.....................................................................................2-18

Determine Local Barometric Pressure ................................................................ 2-18

Determine Partial Pressure of Test Gas Source................................................. 2-19

Functional Verification Procedure ....................................................................... 2-21

Patient Isolation Safety Checks ...............................................................................2-23

Patient Leakage (Risk) Current Test................................................................... 2-23

Dielectric Strength (Hi-Pot) Test......................................................................... 2-23

Section 3 Calibration

Introduction...................................................................................................................... 3-1

Equipment Required ................................................................................................... 3-1

The Service Menus ......................................................................................................... 3-3

Accessing Functions ................................................................................................... 3-3

Calibration Procedure...................................................................................................... 3-4

Setup ............................................................................................................................ 3-5

Recharger Board..............................................................................................................3-5

Main Board.................................................................................................................. 3-9

Setup........................................................................................................................ 3-9

Power Supplies ....................................................................................................... 3-9

P1, P2................................................................................................................... 3-14

Delayed Analog/Defib Sync................................................................................. 3-15

CUFF Channel...................................................................................................... 3-16

Temperature ...........................................................................................................3-18

SpO

Calibration ........................................................................................................... 3-19

2

MSP Board (CO

) Calibration ..................................................................................... 3-19

2

Functional Verification..................................................................................................3-20

vi 810-0334-01 Calibration/Maintenance Manual

Page 12

Propaq 100-Series Monitors Table of Contents

Section 4 Troubleshooting

Introduction......................................................................................................................4-1

Screen Messages.............................................................................................................. 4-1

Equipment Alerts and Caution Messages.................................................................. 4-1

ECG Messages ............................................................................................................4-1

Invasive Pressure Messages........................................................................................ 4-2

Cuff Messages............................................................................................................. 4-3

Temperature Messages................................................................................................4-4

Messages............................................................................................................4-5

SpO

2

Printer Messages ......................................................................................................... 4-5

Messages .............................................................................................................4-5

CO

2

Fatal Error Codes............................................................................................................ 4-7

Section 5 Replacement Procedures

Introduction......................................................................................................................5-1

System Software.......................................................................................................... 5-1

Safety Tests..................................................................................................................5-1

Opening the Monitor.......................................................................................................5-2

Closing the Monitor........................................................................................................ 5-3

Replacing the Battery Pack ...........................................................................................5-3

Replacing the Dual Battery Pack................................................................................... 5-4

Dual Battery in Expansion Module........................................................................... 5-5

Dual Battery in SpO

Module ...................................................................................5-6

2

Replacing the Lithium Battery.......................................................................................5-6

Replacing Fuses...............................................................................................................5-7

Replacing the Air Filter.................................................................................................. 5-8

Replacing Air Tubing......................................................................................................5-9

Replacing Cables............................................................................................................. 5-9

Replacing System Software.......................................................................................... 5-10

Servicing Cuff Fittings.................................................................................................. 5-10

(section continued on next page)

Calibration/Maintenance Manual 810-0334-01 vii

Page 13

Table of Contents Propaq 100-Series Monitors

Section 5 Replacement Procedures (Cont)

Replacing the Main Board.......................................................................................... 5-12

Removing Main Board............................................................................................. 5-12

Installing Main Board............................................................................................... 5-14

Replacing EL Front Panel Components...................................................................... 5-15

Replacing the Recharger Board ...................................................................................5-16

Removing Recharger Board.....................................................................................5-16

Installing Recharger Board.......................................................................................5-17

Replacing the Pump...................................................................................................... 5-18

Removing Pump........................................................................................................5-18

Installing Pump ......................................................................................................... 5-18

Replacing the Side Panels............................................................................................ 5-19

Removing Side Panels.............................................................................................. 5-19

Installing Side Panels ............................................................................................... 5-19

Separating Expansion Module From Monitor ............................................................ 5-21

Attaching Expansion Module...................................................................................... 5-22

Opening Expansion Module.........................................................................................5-23

Closing Expansion Module .......................................................................................... 5-24

Replacing the Printer .................................................................................................... 5-25

Removing Printer...................................................................................................... 5-25

Installing Printer........................................................................................................5-26

Replacing Expansion Module Front Panel.................................................................. 5-27

Removing Expansion Module Front Panel............................................................. 5-27

Installing Expansion Module Front Panel............................................................... 5-27

Replacing Expansion Module Button Board and Buttons......................................... 5-28

Removing Button Board and Buttons..................................................................... 5-28

Installing Button Board and Buttons....................................................................... 5-28

Separating SpO

Module From Monitor..................................................................... 5-29

2

Attaching the SpO2Module......................................................................................... 5-30

Opening the SpO

Closing the SpO

Module........................................................................................... 5-30

2

Module ............................................................................................ 5-31

2

viii 810-0334-01 Calibration/Maintenance Manual

Page 14

Propaq 100-Series Monitors Table of Contents

Section 5 Replacement Procedures (Cont)

Replacing the SpO2Circuit Boards............................................................................. 5-31

Removing SpO

Installing the SpO

Circuit Boards............................................................................... 5-32

2

Circuit Boards.......................................................................... 5-32

2

Replacing the CO2/SpO2Circuit Boards.....................................................................5-33

Removing the CO

Installing the CO

/SpO2Circuit Boards................................................................5-33

2

/SpO2Circuit Boards.................................................................. 5-34

2

Replacing Side Panels...................................................................................................5-34

Section 6 Theory of Operation

Introduction......................................................................................................................6-1

Propaq Monitor....................................................................................................................6-3

System Description.......................................................................................................... 6-3

Monitoring Electronics................................................................................................ 6-3

NIBP Pneumatics ........................................................................................................6-4

Power Electronics........................................................................................................6-4

Functional Description .................................................................................................... 6-5

Power Distribution ......................................................................................................6-5

Cabling Diagrams........................................................................................................6-5

Expansion Module and Printer .........................................................................................6-6

System Description.......................................................................................................... 6-6

Overview...................................................................................................................... 6-6

Print Head....................................................................................................................6-6

Functional Description .................................................................................................... 6-6

Pulse Oximetry Option (SpO

)........................................................................................... 6-8

2

System Description.......................................................................................................... 6-8

Overview...................................................................................................................... 6-8

Oxygen Transducers....................................................................................................6-9

Functional Description .................................................................................................. 6-10

(section continued on next page)

Calibration/Maintenance Manual 810-0334-01 ix

Page 15

Table of Contents Propaq 100-Series Monitors

Section 6 Theory of Operation (Cont)

Capnography (CO2) System ............................................................................................. 6-15

System Description ....................................................................................................... 6-15

Overview....................................................................................................................6-15

Functional Description.................................................................................................. 6-16

Mainstream Board..................................................................................................... 6-16

Non Isolated Circuitry.......................................................................................... 6-16

Isolated Circuitry .................................................................................................. 6-16

IPC Expansion........................................................................................................... 6-17

Power Distribution System.......................................................................................6-17

Mainstream CO

Sensor........................................................................................... 6-18

2

Section 7 Diagrams

Section 8 Replaceable Parts

Introduction...................................................................................................................... 8-1

Appendix A Buildable Test Equipment

Appendix B Dynatech/Nevada Patient Simulator Modification

Appendix C Software Revision History

x 810-0334-01 Calibration/Maintenance Manual

Page 16

List of Illustrations

Fig. 2-1. The Service Menus, Version 7............................................................................................2-4

Fig. 2-2. The Service Menus, Version 8............................................................................................2-5

Fig. 2-3. Cuff Calibration Kit Attachments ..................................................................................... 2-12

Fig. 2-4. SpO2 Waveform Shape......................................................................................................2-15

Fig. 2-5. Printer Test Printout...........................................................................................................2-17

Fig. 3-1. The Service Menus, Version 7............................................................................................3-3

Fig. 3-2. The Service Menus, Version 8............................................................................................3-4

Fig. 3-3. Locations of P1, P4, and P6, Recharger Board ................................................................. 3-6

Fig. 3-4. Recharger Board Test Points and Adjustments .................................................................. 3-7

Fig. 3-5. Main Board Test Points and Adjustments........................................................................3-10

Fig. 3-6. Defib Sync/Analog Output Connector..............................................................................3-15

Fig. 5-1. Opening the Propaq: Screws and Transducer Tubing........................................................5-2

Fig. 5-2. Battery Pack Compartment.................................................................................................. 5-4

Fig. 5-3. Fuse Locations .....................................................................................................................5-7

Fig. 5-4. Location of Air Filter ..........................................................................................................5-8

Fig. 5-5. Location of System Software PROMS and Lithium Battery..........................................5-10

Fig. 5-6. Replacing Cuff Hose Fittings............................................................................................ 5-11

Fig. 5-7. Disassembling the Metal Cuff Fitting ..............................................................................5-11

Fig. 5-8. Main Board Screws, Connectors and Cables................................................................... 5-13

Fig. 5-9. Recharger Board Screws, Connectors & Cables..............................................................5-16

Fig. 5-10. Proper Pump Orientation ..................................................................................................5-18

Fig. 5-11. Expansion Module Securing Screws................................................................................ 5-21

Fig. 5-12. Disconnecting Monitor From Expansion Module/Battery Pack.....................................5-22

Fig. 5-13. Disconnecting Battery from Expansion Module ............................................................. 5-23

Fig. 5-14. Expansion Module Rear Panel Gasket Channels and O-Ring Gaskets .........................5-25

Fig. 5-15. Installing Printer Main Board Into Expansion Module .................................................. 5-26

Fig. 5-16. Expansion Module Front Panel (Rear View)...................................................................5-29

Fig. 5-17. Securing Tabs .................................................................................................................... 5-30

(continued on next page)

Calibration/Maintenance Manual 810-0334-01 xi

Page 17

List of Illustrations Propaq 100-Series Monitors

Fig. 6-1. Printer Functional Block Diagram...................................................................................... 6-7

Fig. 6-2. SpO2 System Block Diagram............................................................................................. 6-9

Fig. 6-3. SpO2 Oxygen Transducer (NELLCOR)........................................................................... 6-10

Fig. 6-4. SpO2 Board Functional Block Diagram ...........................................................................6-11

Fig. 6-5. MiniSOOM Timing (Normal Run Mode)........................................................................ 6-12

Fig. 6-6. MiniSOOM Timing (Calibration Mode).......................................................................... 6-13

Fig. 6-7. Information Flow Between Expansion Module............................................................... 6-16

Fig. 6-8. Capnography Functional Block Diagram......................................................................... 6-17

Fig. 6-9. CO2 Sensor Components.................................................................................................. 6-18

Fig. 7-1. Cable Location Diagram (EL Display) .............................................................................. 7-3

Fig. 7-2. Cable Location Diagram (LCD Display)........................................................................... 7-4

Fig. 7-3. Main Board to Recharger Board Cable.............................................................................. 7-5

Fig. 7-4. AAMI ECG to Main Board Cable..................................................................................... 7-5

Fig. 7-5. HP ECG to Main Board Cable........................................................................................... 7-5

Fig. 7-6. 6-Pin P1/P2 to Main Board Cable...................................................................................... 7-6

Fig. 7-7. HP P1/P2 to Main Board Cable ......................................................................................... 7-6

Fig. 7-8. T1/T2 to Main Board Cable ............................................................................................... 7-7

Fig. 7-9. Analog and Speaker Output to Main Board Cable.......................................................... 7-7

Fig. 7-10. RS423 to Main Board Cable.............................................................................................. 7-8

Fig. 7-11. Recharger Board to Battery Cable/Expansion Connector................................................. 7-8

Fig. 7-12. Battery Compartment Temperature Sensor Cable............................................................. 7-8

Fig. 7-13. External Power Connector to Recharger Board Cable ..................................................... 7-9

Fig. 7-14. Expansion Connector Cable ............................................................................................... 7-9

Fig. 7-15. EL Backlight panel to Recharger Bd Cable...................................................................... 7-9

Fig. 7-16. LED to Main Board Cable................................................................................................. 7-9

Fig. 7-17. LEDs and Switch to Recharger Board Cable.................................................................. 7-10

Fig. 7-18. SpO2 Speaker Cables ....................................................................................................... 7-10

Fig. 7-19. Pump Cable ........................................................................................................................7-11

Fig. 7-20. SCP Board to Rear Chassis Expansion Connector Cable ...............................................7-11

Fig. 7-21. Expansion Module Battery to Printer Cable ....................................................................7-11

Fig. 7-22. SCP Board to Printer Main Board Cable........................................................................ 7-12

Fig. 7-23. Printer Main Board to Key Board Cable ........................................................................ 7-12

Fig. 7-24. Printer Main Board to Rear Chassis Expansion Connector Cable ................................7-12

Fig. 7-25. Mini SOOM Brd to Sub D Oximeter Sensor Cable ...................................................... 7-13

Fig. 7-26. Main Board to LCD Recharger Board Cable.................................................................. 7-13

xii 810-0334-01 Calibration/Maintenance Manual

Page 18

Propaq 100-Series Monitors List of Illustrations

The following are block diagrams, printed on 11 x 17 pages at the back of Section 7

Fig. 7-27. System Level Block Diagram

Fig. 7-28. Isolated Patient Circuits Block Diagram

Fig. 7-29. Non-Isolated Circuits Block Diagram

Fig. 7-30. Displays Block Diagram

Fig. 7-31. EL Recharger and Power Supplies/Distribution Block Diagram

Fig. 7-32. LCD Recharger Block Diagram

The following are assembly diagrams, printed on 11 x 17 pages at the back of Section 7

Fig. 7-33. SpO2for Propaq, 824-0204-XX, sheet 1 of 2

Fig. 7-34. SpO

for Propaq, 824-0204-XX, sheet 2 of 2

2

Fig. 7-35. EL Display Panel, 824-0208-XX, sheet 2 of 9

Fig. 7-36. LCD Display Panel, 824-0208-XX, sheet 3 of 9

Fig. 7-37. SpO

Fig. 7-38. SpO

Fig. 7-39. SpO

Fig. 7-40. SpO

Fig. 7-41. Printerless SpO

/CO2Option W/Printer, 824-0208-XX, sheet 4 of 9

2

/CO2Option Without Printer, 824-0208-XX, sheet 5 of 9

2

Option W/Printer, 824-0208-XX, sheet 6 of 9

2

/CO2Option W/Printer, 824-0208-XX, sheet 7 of 9

2

/CO2Option, 824-0208-XX, sheet 8 of 9

2

Fig. 7-42. Main Board EL PCB 2nd Level Details, 824-0211-01, sheet 4 of 4

Fig. 7-43. Main Board LCD PCB 2nd Level Details, 824-0218-00, sheet 4 of 4

Fig. 7-44. EL Front Panel, 824-0226-00, sheet 1 of 2

Fig. 7-45. EL Front Panel, 824-0226-00, sheet 2 of 2

Fig. 7-46. Rear Chassis, 824-0230-00, sheet 3 of 5

Fig. 7-47. Rear Chassis, 824-0230-00, sheet 4 of 5

Fig. 7-48. Rear Chassis, 824-0230-00, sheet 5 of 5

Fig. A-1. Electromedics 37°C Temperature Simulator Schematic................................................... A-2

Fig. A-2. Power Supply Adapter Cables Schematic .........................................................................A-2

Fig. A-3. Battery Substitution Plugs Schematic................................................................................A-3

Fig. A-4. Temperature Sensor Substitution Plug Schematic............................................................. A-3

Fig. A-5. RS-423 Loopback Test Fixture ..........................................................................................A-4

Fig. B-1. Modified Invasive Pressure Model 215A Cable................................................................B-2

Fig. B-2. Model 215A Top PCB Modification ..................................................................................B-2

Calibration/Maintenance Manual 810-0334-01 xiii

Page 19

List of Tables

Table 1-1. Propaq 100-Series Monitors Configurations .................................................... 1-3

Table 2-1. Recommended Service Intervals/Procedures .................................................... 2-3

Table 2-2. Equipment Required for Functional Verification ............................................. 2-6

Table 2-3. Local Uncorrected Barometric Pressure

as a Function of Altitude................................................................................. 2-19

Table 2-4. Possible Sources of CO

Table 2-5. Electrical Connections for

Patient Leakage (Risk) Current Safety Tests ................................................. 2-23

Table 2-6. Summary of Connection Points and

High-Voltage Test Potentials............................................................................2-24

Table 3-1. Recommended Calibration Intervals ................................................................. 3-1

Table 3-2. Equipment Required—Calibration and Functional Verification...................... 3-2

Table 3-3. Isolated Power Supply Voltage Checks...........................................................3-11

Table 3-4. Non-Isolated Power Supply Voltage Checks.................................................. 3-12

Table 3-5. Isolated Power Supply Ripple Checks ........................................................... 3-12

Table 3-6. Non-Isolated Power Supply Ripple Checks ................................................... 3-13

Table 6-1 Schematic, Board, Assembly, Drawing and Service Kit Part Numbers

by Board Type.................................................................................................... 6-2

List of Cabling, Block, and Assembly Diagrams............................................ 7-1

Table 7-1. Location of Cables and Connectors (EL Display) .......................................... 7-3

Table 7-2. Location of Cables and Connectors (LCD Display) ....................................... 7-4

Table 8-1. Service Parts, “MX”Serial Number Applicability............................................8-2

Verification Test Errors ......................................... 2-22

2

Table B-1. Modified Dynatech/Nevada Model 215A Cable Wiring.................................B-1

Table C-1. Software Revisions.............................................................................................C-1

xiv 810-0334-01 Calibration/Maintenance Manual

Page 20

Section 1

General Information

A vailable

Documentation

The Calibration/Maintenance Manual contains information for the

service technician to service Propaq monitors at the replaceable module

level. Replaceable modules are items that can be easily replaced without

desoldering circuit board components.

Servicing to the component level requires the Schematics & Drawings

Set, and the appropriate option section for SpO

options.

− For detailed circuit descriptions, bills of materials, mechanical

assembly drawings, and schematics of the monitor main board,

interconnect board, and recharger board, see the Schematics &

Drawings Set (orderable separately as 810-0334-10).

− Similar information on the Printer, Oximeter, and Capnograph is

found in the appropriate option section of the Schematics &

Drawings Set:

Service manuals contain service information for the biomedical electronic

technician (BMET or CBET). Only factory-trained technicians should

service the Propaq series monitors.

NOTE

,CO2andPropaqPrinter

2

This manual does not include operating instructions or

information. Refer to the appropriate user's guide.

About This

Manual

Calibration/Maintenance Manual 810-0334-01 1-1

The Calibration/Maintenance Manual contains eight sections and three

appendices, as described below.

•

Section 1 General InformationThis section contains information

about how to use the manuals, and a description of the Propaq series

monitors, optional Expansion Module with printer, SpO

option.

CO

2

•

Section 2 Installation and ServiceThis section contains instructions

on how to unpack and repack the monitor for shipping. Servicing

interval recommendations are provided for developing preventive

maintenance schedules. A functional verification procedure allows

option, and

2

Page 21

Section 1—General Information Propaq 100-Series Monitors

checking the performance and safety features of the monitor without

opening the case.

•

Section 3 Calibration—This section lists all tools and test equipment

needed to perform a complete calibration procedure. A description of

the Service Menu functions is provided. The calibration procedure

allows you to calibrate the Propaq to factory specifications.

•

Section 4 Troubleshooting—This section contains descriptions of

screen messages and software error codes for use in troubleshooting.

•

Section 5 Replacement Procedures—This section contains information

and step-by-step instructions on making modular repairs to the Propaq,

and shows you how to remove and replace serviceable modules.

•

Section 6 Theory of Operation—This section describes the Propaq’s

circuitry at the system and functional-block levels only.

Detailed circuit operation descriptions for each of the monitor’s circuit

boards and specific options are contained in the Schematics & Drawings

Set and appropriate option section, as noted on the previous page.

•

Section 7 Diagrams—This section contains block diagrams and cabling

drawings.

•

Section 8 Replaceable Parts—This section lists serviceable mechanical

and electrical parts (generally in kit form) for the Propaq series

monitors, the printer, the pulse oximeter, and the capnography option.

•

Appendix A Buildable Test Equipment—This section provides

descriptions and schematics for test equipment that you can build for

servicing the Propaq.

•

Appendix B Dynatech/Nevada Patient Simulator Modification—This

section shows you how to modify Dynatech/Nevada models 213A,

215A, and 217A Patient Simulators for use with the Propaq series

monitors. This section is especially important if you simultaneously

connect both the ECG and invasive blood pressure channels of this

patient simulator to the Propaq.

•

Appendix C Software Revision History—This section lists the

software revisions for the Propaq.

Product

Description

The Propaq series is a product line of lightweight, ultra-portable patient

monitors applicable to a wide variety of health care services. These

monitors measure and display a patient’s vital signs, including ECG,

non-invasive blood pressure, invasive blood pressure, temperature,

oxygen saturation derived by pulse oximetry (with SpO

mainstream carbon-dioxide monitoring (w ith CO

Option). Propaq

2

Option) and

2

configurations vary depending on the model. Table 1-1 lists the monitors

and their configurations available at the printing of this manual.

1-2 810-0334-01 Calibration/Maintenance Manual

Page 22

Propaq 100-Series Monitors Section 1—General Information

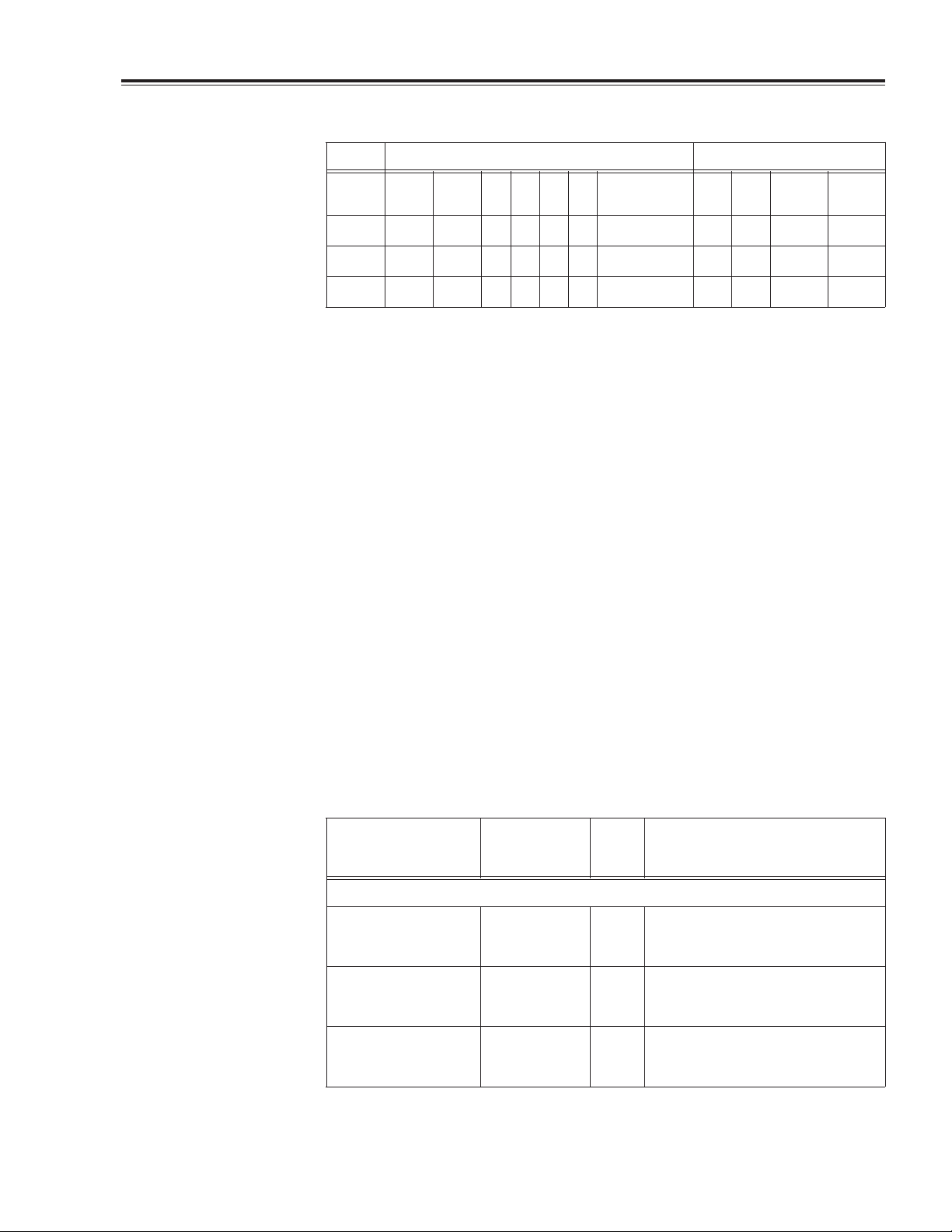

Table 1-1. Propaq 100-Series Monitors Configurations

Standard Features Options

Analog Out/

Model ECG Cuff P1 P2 T1 T2

Defib Sync SpO

2CO2

PrinterHPConn.

Limited

W arranty

History of

Manuals By

Monitor Serial

Numbers

102

104

106

♥♥ ♥♥ ♥ ♥♥♥ ♥

♥♥♥ ♥♥ ♥ ♥♥♥ ♥

♥♥♥♥♥ ♥ ♥♥♥ ♥

All models of monitor may be ordered with the optional Hewlett-Packard

patient connector side panel.

The Propaq Expansion Module allows SpO

and CO2monitoring to be

2

added to any Propaq monitor. The Expansion Module with Printer (EMP)

includes a high-resolution, dot-matrix printer for documenting patient

vital signs.

The Propaq 100-Series Monitors are sold by Protocol Systems, Inc.

under the w arranties set forth in the warranty statement supplied with

each product. Additional copies of the w arranty statement can be

obtained from Protocol Systems, Inc.

Propaq manuals are updated with each new monitor design, and history

information is provided (as deemed appropriate) for earlier monitors. In

some cases, an early manual is re-released with an updated part number;

in other cases, a new manual is released. The following table lists the

releases of Propaq manuals, and cross-references the serial numbers of

the monitor and printer (and the software version number) to which the

manual applies.

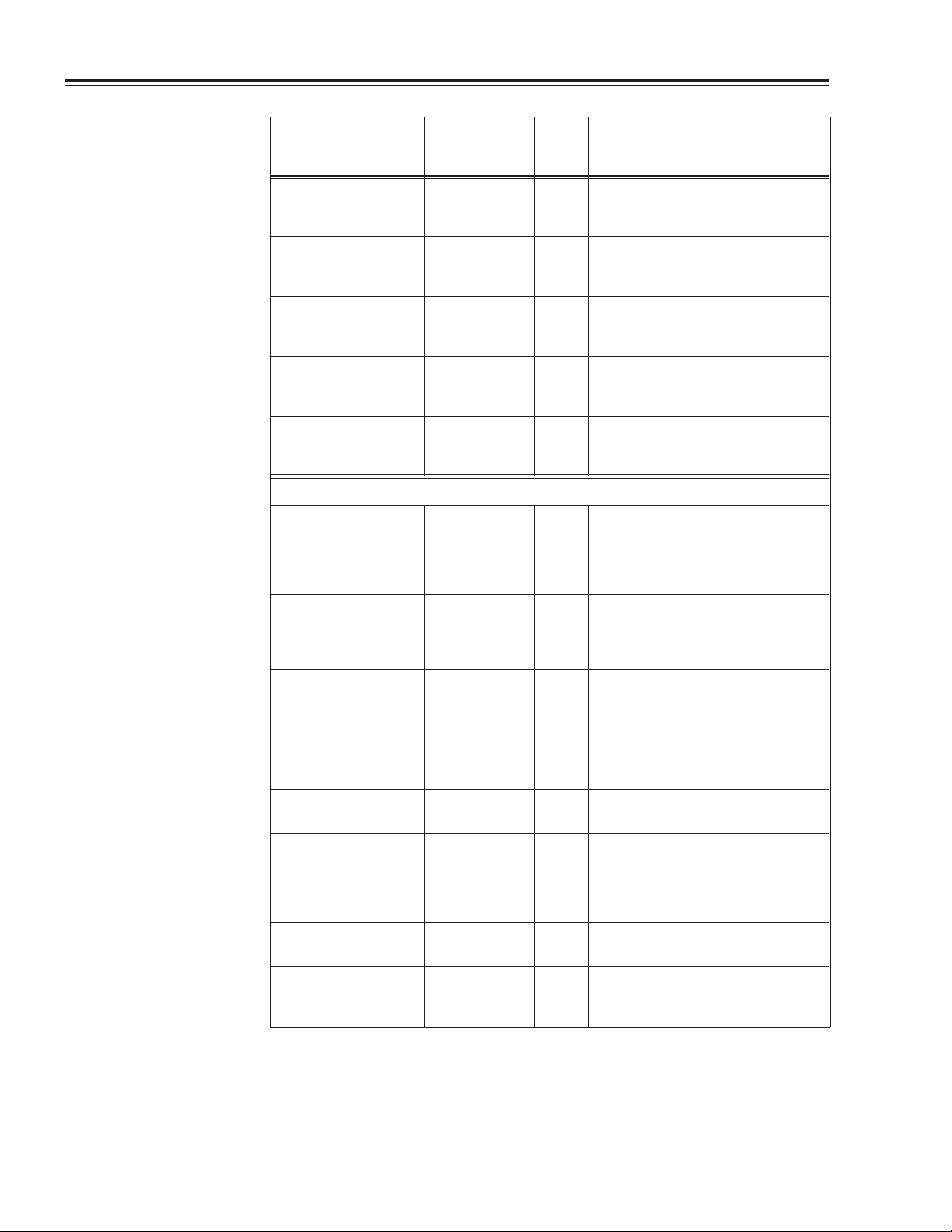

Monitor/Printer

Serial Number &

Software Version

TBXXXXX

(Printer TCOxxxx)

Software V.6

TEXXXXX

(Printer TCOxxxx)

Software V.6

MXXXXXX

(Printer MCOxxx)

Software V.7

Calibration/Maintenance Manual 810-0334-01 1-3

Issue/

Revision/

Part Number

SERVICE DOCUMENTATION

Rev A

810-0012-01

Rev A

810-0257-00

Rev A

810-0334-00

Issue

Date Comments

Technical Reference Guide

2/92 Technical Reference Guide

10/92 Service Manual Version 7

software

Page 23

Section 1—General Information Propaq 100-Series Monitors

Monitor/Printer

Serial Number &

Software Version

MXXXXXX

(Printer MCOxxx)

Software V.7/8

MXXXXXX

(Printer MCOxxx)

Software V.7/8

MXXXXXX

(Printer MCOxxx)

Software V.7/8

MXXXXXX

(Printer MCOxxx)

Software V.7/8

MXXXXXX

(Printer MCOxxx)

Software V.7/8

TXXX

(Version 3.x)

TXXX

(Printer TCOxxx)

Issue/

Revision/

Part Number

Rev A

Issue

Date Comments

9/93 Calibration/Maintenance

810-0334-01

Rev A

9/93 Schematics & Drawings Set

810-0334-10

Rev A

9/93 Printer Section of 810-0334-01

810-0334-30

Rev A

9/93 SpO

810-0334-20

Rev A

9/93 CO

810-0334-40

USERS DOCUMENTATION

Rev A

4/89 Original Release (Users Guide)

810-0035-00

Rev A

8/89 Original Release (Printer

810-0085-00

Manual, adds Capnograph and

Version 8 software

Section of 810-0334-01

2

section of 810-0334-01

2

Operators Guide)

TXXX

(Version 4.x)

TXXX

(Version 5.x)

TXXX

(Version 6.x)

TXXXX

(Version 6.x)

TXXXX

(Version 6.x)

TXXXX

(Version 6.2)

MXXXX

(Version 7.x)

MXXXXXX

(Printer MCOxxx)

(Version 8.0)

Revs A,B,C

810-0035-01

Rev A

810-0140-00

Rev A

810-0035-02

Rev A

810-0203-00

Rev A

810-0250-00

Rev B

810-0324-00

Rev B

810-0331-00

Rev A

810-0408-00

10/89,

12/89,

4/90

Updates for software 4.xx.xxx,

misc. correction and update

data, and international

certification

9/90 Updates for software 5.xx.xxx,

adding SpO

2

6/91 Updates for software 6.0,

includes printer operator’s

guide, and SpO

.AddsEL

2

option.

8/91 Hewlett-Packard Connector

update, supplements 810-0035-02

10/91 Pulse oximetry update,

supplements 810-0035-02

6/92 Software 6.2 update,

supplements 810-0035-02

6/92 Software 7.0 update,

supplements 810-0035-02

4/93 Software version 8.0. Original

release of User’s Guide. English

language

1-4 810-0334-01 Calibration/Maintenance Manual

Page 24

Section 2

Installation and Service

Introduction This section provides the information for unpacking, initial setup and

checkout of the Propaq 100-series monitors. Information is provided for

developing a preventive maintenance schedule.

When the monitor is first unpacked and before it is placed in service, the

functional verification and safety checks provided in this section should be

performed.

Unpacking/

Repacking

W arranty

Service

Use the following guidelines when unpacking the monitor from its shipping

carton.

1. Before unpacking the monitor, check the shipping carton for damage.

2. If damage is apparent, it is a good idea to stop unpacking the carton and

contact the shipping company for further instructions. If the carton is

intact, unpack the Propaq.

3. With the Propaq out of its carton, check to see that all the items listed on

the Packing Slip (provided with shipment) are in the shipping carton.

4. If an item is missing, first recheck the carton, then check with your

receiving department. If necessary, contact Protocol Systems, Inc. at the

address and phone number shown in Repair and Upgrade Support.

The shipping carton and packing material should be saved for

repacking the monitor in case it needs to be sent to a repair center

or back to Protocol Systems for service.

If during the warranty period, the Propaq requires service, DO NOT

ATTEMPT TO SERVICE IT YOURSELF. For fast, convenient service from

Protocol Systems, follow the procedure below.

Calibration/Maintenance Manual 810-0334-01 2-1

Page 25

Section 2—Installation and Service Propaq 100-Series Monitors

Repair and

Upgrade

Support

For repair and upgrade information, contact:

Technical Services Dept.

Protocol Systems, Inc.

8500 S. W. Creekside Place

Beaverton, OR 97005-7107 U.S.A.

or call Protocol Systems, Inc. in the U.S.A. at (800) 289-2500.

Technical Services toll-free number: (800) 289-2501.

For world-wide facsimile communications, call (503) 526-4200.

If calling from outside the United States, call (503) 526-8500.

When calling Protocol for service information or to order service parts,

please have the following information ready:

•

model number (102, 104, or 106 from front of monitor),

•

serial number (from back of instrument),

•

software version (from startup screen)

•

attached options, if any (such as printer or SpO2option)

•

a full description of the problem or service needed

•

your complete return shipping address

•

your purchase order number (for non-warranty repairs, all upgrades

and parts orders)

•

a contact name and phone number for any further questions.

Model and serial numbers are printed on the label located on the rear of the

monitor and options. The software version number is displayed each time

the monitor is powered on.

If you are returning a Propaq for service:

•

The Technical Service representative will give you a Return Material

Authorization (RMA ) number and tell you w here and how to ship the

monitor for service. Without the RMA number, Protocol cannot accept

the monitor for service.

•

Package the monitor in its original shipping carton using the original

packing material. The material and carton w ere specifically designed

for the monitor’s safety during shipment.

•

Clearly address the box and ship it to the address provided by

Protocol’s Technical Service representative. Be sure to write the RMA

number on the outside of the shipping carton, and on any included

correspondence.

For the location of your nearest Protocol Systems authorized repair center,

or for information on all Protocol Systems products, contact Protocol

Systems, Inc.

2-2 810-0334-01 Calibration/Maintenance Manual

Page 26

Propaq 100-Series Monitors Section 2—Installation and Service

Recommended

Service

The Calibration/Maintenance Manual provides instructions and information

for technicians to repair the Propaq at the replaceable module level.

Replaceable modules include circuit boards, large hardware items, such as

the air pump, check valve, chassis parts, and other parts easily replaced

without desoldering of surface-mount components and other small hardware.

Module-level repair allows monitor repair in minimal time and for a

nominal price for the replaceable module.

Because of the specialized equipment and knowledge required to

manufacture and repair the Propaq, Protocol Systems, Inc. recommends that

only Protocol’s authorized repair facilities provide component-level repair. If

repair by other than Protocol’s authorized repair facilities is required, such a

facility must have the necessary equipment to service and repair surface

mount technology (SMT) electronics as well as the specialized equipment to

service Propaq monitors. The Schematics & Drawings Set (orderable as

810-0334-10) and appropriate option section (SpO

PN 810-0334-30, or CO

PN 810-0334-40) provides schematics, parts lists,

2

PN 810-0334-20, Printer

2

etc. helpful in component-level servicing. Contact Protocol Systems, Inc. for

more information.

Service Intervals Table 2-1 lists recommended service intervals and procedures that should be

considered in order to keep the monitor in good operating condition.

Table 2-1. Recommended Service Intervals/Procedures

Interval/Condition Perform

Semi-annually Complete Functional Verification and

Safety Check (Section 2).

Minimum every three years Replace lithium battery. Replace battery

pack. Replace air filter.

Monitor is dropped, in an accident, or

suspected rough handling.

Suspected malfunction with all or part

of functions.

Monitor fails Functional Verification. Repair followed by Functional

Module has been replaced and monitor

fails Functional Verification.

Every 5,000 hours of operation or

whenever screen becomes difficult to

view

Complete Functional Verification and

Safety Check (Section 2).

Functional Verification (Section 2) of

suspected function(s).

Verification (Section 2), and Calibration

as required (Section 3).

Repair followed by Functional

Verification (Section 2), and Calibration

as required (Section 3).

Replace LCD backlight (LCD monitors

only)

Calibration/Maintenance Manual 810-0334-01 2-3

Page 27

Section 2—Installation and Service Propaq 100-Series Monitors

Functional

V erification

The functional verification procedures verify proper operation of the

monitor, oximeter, and printer. This procedure should be performed at

intervals or conditions listed in Table 2-1.

Self Test Many functions, such as alarms, waveform and scale sizing, and printer

control, are software operations. Since system software is automatically

checked during the monitor’s power-up self-test, all software functions work

normally if no error messages appear during the power-up sequence. (Some

error messages indicate hardware failures.)

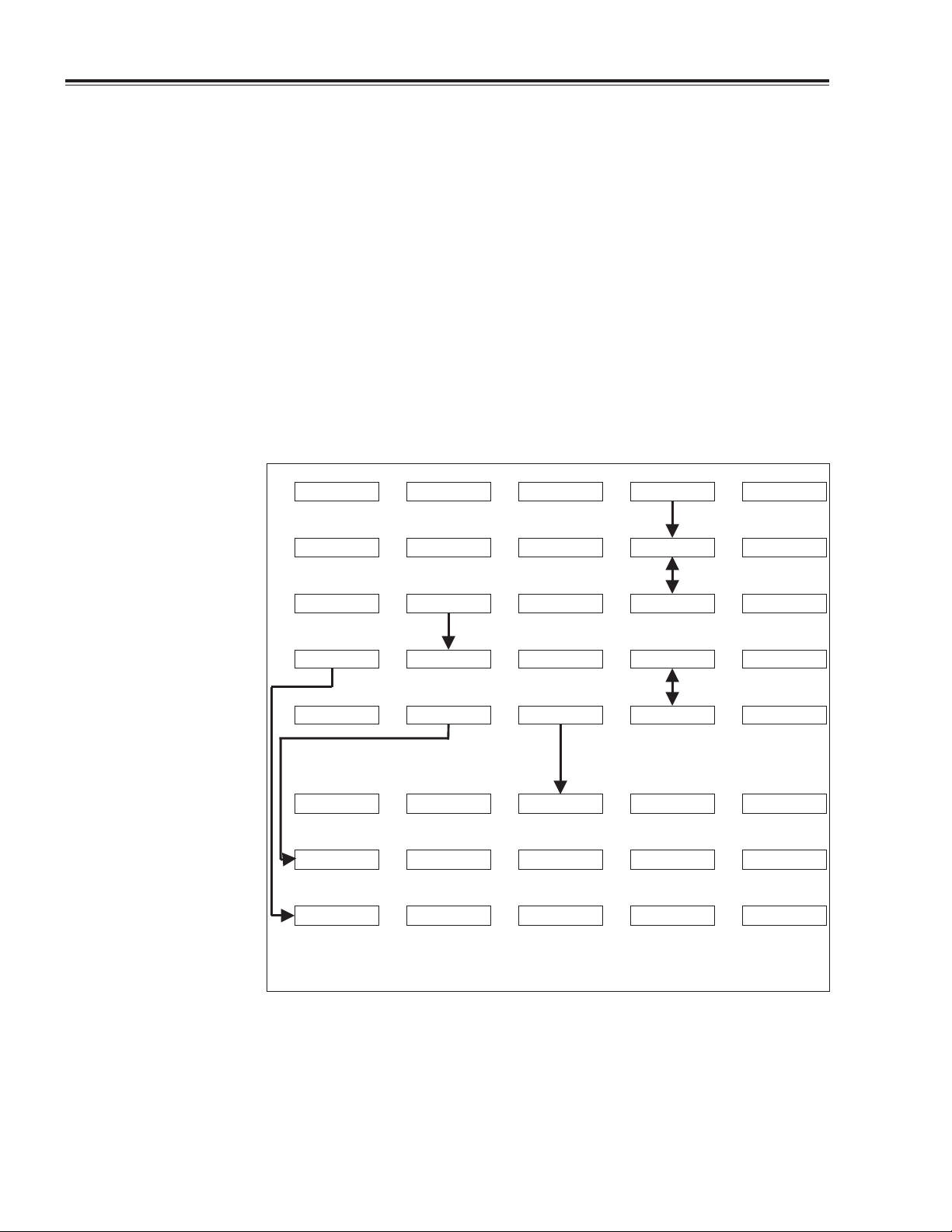

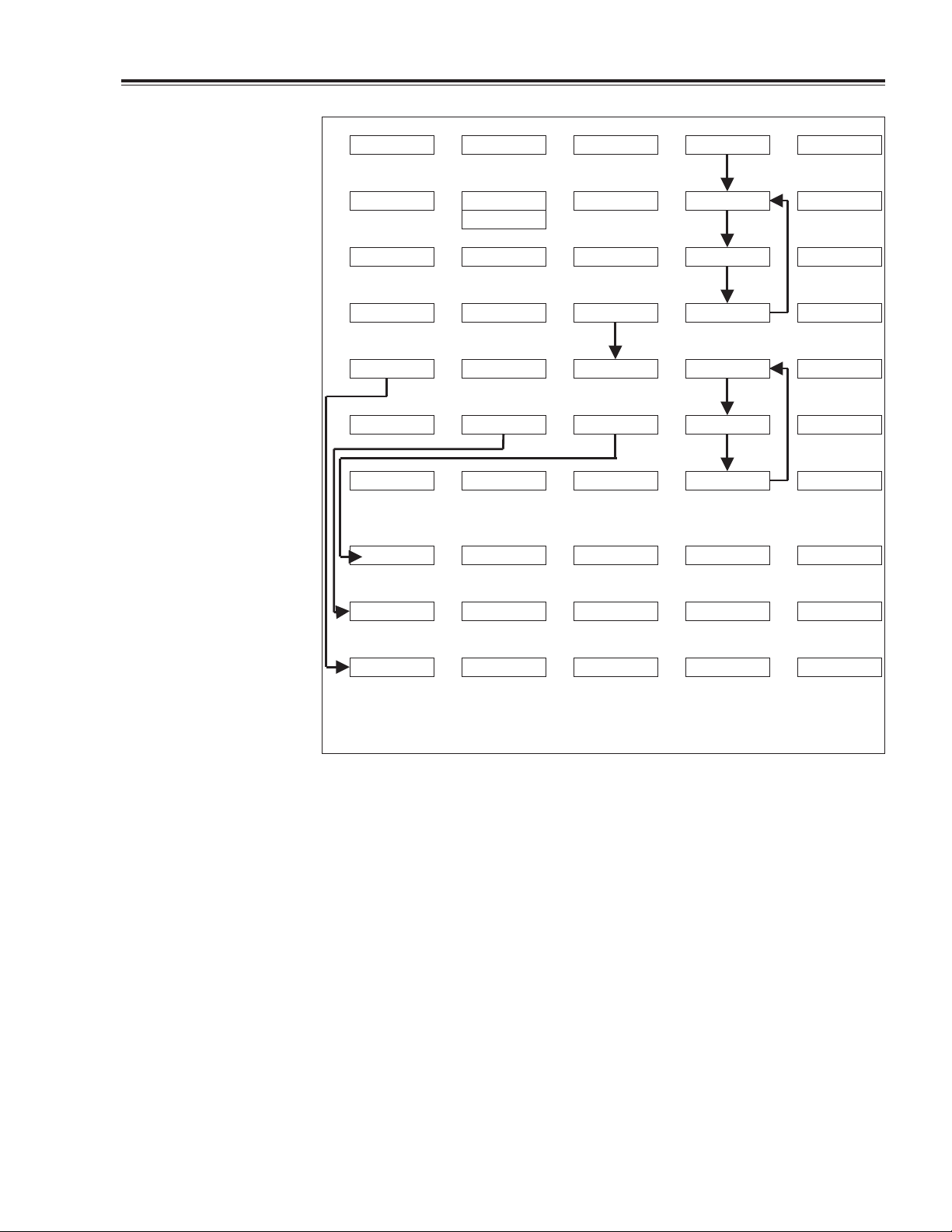

The Service Menus Service Menus are provided to facilitate functional verification. The Service

Menus (Figure 2-1) contain several functions for testing and verifying the

Cuff channel, display, invasive pressure channel (models 104 and 106 only),

and printer. During the functional verification procedure, the Service Menu

functions will be accessed to perform necessary tests.

SENSORS FREEZESYSTEMDISPLAYALARMS

PRINTER MAIN MENUMORENET OFFPROGRAM

INSERV MAIN MENUMORETIME/DAYSERVICE

CUFF TST MAIN MENUMORESPO2 TEST

LOOP TEST MAIN MENUOUT TEST

CYCLE MAIN MENUBORDERCOLUMN 2COLUMN 1

PUMP TST MAIN MENUCUFF CALAUTO PMP

a

IBP TEST applicable only for Propaq 104, 106.

b

SPO2 TEST intended for factory use with SpO2 option.

c

NET TEST applicable only for Network option.

IBP TEST

PIXL TST

a

Fig. 2-1. The Service Menus, Version 7

b

c

MAIN MENUMORENET TEST

VERSION 7.x

2-4 810-0334-01 Calibration/Maintenance Manual

Page 28

Propaq 100-Series Monitors Section 2—Installation and Service

SENSORS FREEZESYSTEMDISPLAYALARMS

d

SNAPSHOT

INSERV MAIN MENUMORETIME/DAYPROGRAM

CHANGE MAIN MENUMORESERVICENEXT

CUFF TST MAIN MENUMORESPO2 TEST

TEMP TEST MAIN MENUMORENET TEST

CO2 TEST

LOOP TEST MAIN MENUOUT TEST

CYCLE MAIN MENUBORDERCOLUMN 2COLUMN 1

e

IBP TEST

PIXL TST

d

a

MAIN MENUMORENET OFFPRINTER

b

c

MAIN MENUMORE

PUMP TST MAIN MENUCUFF CALAUTO PMP

a

IBP TEST applicable only for Propaq 104, 106.

b

SPO2 TEST intended for factory use with SpO2 option.

c

NET TEST applicable only for Network option.

d

Depends on option installed.

e

Applicable only for CO2option.

Fig. 2-2. The Service Menus, Version 8

VERSION 8.x

Menu functions are accessed by pressing one or a series of buttons below

menu labels on the monitor display. Button presses to access any function in

the Propaq are shown in this manual with the > character separating the

names of the buttons to be pressed. For example, SENSORS > ECG >

LEAD means starting from the Main Menu, press the SENSORS button,

then the ECG button, and finally the LEAD button.

The Service Menu is activated by pressing from the Main Menu (Version

7.x software) SYSTEM > MORE > SERVICE, or (Version 8.x software)

SYSTEM > MORE > MORE > SERVICE.

NOTE

In the following procedures, where Version 8.x button presses differ

from Version 7.x button presses, both versions are given. Otherwise,

button presses are the same for both versions.

Calibration/Maintenance Manual 810-0334-01 2-5

Page 29

Section 2—Installation and Service Propaq 100-Series Monitors

Equipment Required Table 2-2 lists all the equipment needed to perform a functional verification.

Some equipment can be manufactured. See Appendix A for information on

manufacturable test equipment.

Table 2-2. Equipment Required for Functional Verification

Equipment Description

Mercury-column Manometer with Bulb (400 mmHg), Baumanometer 14-383 wall

mount Manometer or equivalent

50 MHz Triggered Sweep Oscilloscope, Tektronix 2225 or equivalent

Variable DC Power Supply, 0-36 V, 3A, VIZ WP-715A or equivalent

Patient Simulators, Dynatech/Nevada 213A, 215A, or 217A with Temperature and

EGG Cable/Leads

Electromedics 37° C Temperature Sensor Simulator (See Appendix A)

IBP Simulator, 5 µV/mmHg/volt, Fogg Systems BP48C, BP28, or MDE Datasim

6000 with IBP cables

Adult Cuff Kit, Protocol PN 008-0006-XX

Protocol Cuff Calibration Kit, Protocol PN 008-0012-XX

Power Supply Adapter Cables (See Appendix A)

Propaq AC Power Adapter

North American, 120 V, 60 Hz, Protocol PN 503-0002-00

International, 220-240 V, 50-60 Hz, Protocol PN 503-0002-20

Japanese, 100 V, 50-60 Hz, Protocol PN 503-0002-30

Safety Analyzer, Dynatech/Nevada (formerly Neurodyne-Dempsey), 431F-1D or

equivalent

Rod-L Model M100AVS5 High-Voltage Potential Tester, or equivalent

NELLCOR Pocket Tester, PT-2500

Test gas source: dry 4% to 10%* CO

Tw o rubber test tube stoppers, with 1/8" to 1/4" vent holes opened through (for

CO

tests)

2

*Gas may be between 4 and 10%, but exact CO2concentration must be certified within

±0.01%. See procedure later in this section for determining partial pressure.

, balance air (with flow meter)

2

Procedure NOTE

If the monitor has been stored for longer than one month

without the monitor connected to the ac adapter (for

recharging), the battery voltage should be checked. The battery

may need to be replaced if it cannot hold a charge.

The functional verification must be done only when the monitor is fully

assembled. Equipment required to perform this procedure is shown in Table

2-2. Most items not commercially available can be made according to the

information in Appendix A.

2-6 810-0334-01 Calibration/Maintenance Manual

Page 30

Propaq 100-Series Monitors Section 2—Installation and Service

NOTE

If you plan to use a Dynatech/Nevada model 213A, 215A, or 217A

Patient Simulator to simultaneously simulate ECG and invasive

blood pressure, see Appendix B for important information.

If the monitor did not pass the functional verification, or when it is time to

do a routine calibration, see the Calibration Procedure in Section 3.

Functional verification and safety checks must always be done after monitor

disassembly or calibration, or whenever there is a question about the safety

of the patient functions.

NOTE

Before starting the verification procedures, charge the battery

for at least 8 hours with the monitor turned off. (Charge for 12

hours if a Printer or SpO

module is attached.)

2

Power System The following steps check the integrity of the power system.

1. If the ac power adapter is not plugged in, plug it into an ac socket

with the correct voltage and connect it to the monitor’s right side panel

dc power connector.

2. Check that the green

BATTERY CHARGING indicator lights.

3. Disconnect the power adapter from the monitor. Check that the

BATTERY CHARGING indicator turns off.

CAUTION

In the next steps, carefully check for the proper polarity of the

connection between the power supply and the monitor. If voltage

is applied with the wrong polarity, it will blow an internal fuse

(F1 on the Recharger board). Refer to the diagram on the

monitor’s right side panel for proper polarity.

4. Turn on the dc power supply and set it for 15 V

5. Using the power supply adapter cable (constructed as shown in

Appendix A), connect the power supply to the monitor’s dc input

connector on the right side panel.

6. Check that the

BATTERY CHARGING LED indicator lights.

7. Check that the current draw from the supply is less than 650 mA.

NOTE

Initial charge current can be as high as 880 mA. However, as the

battery charges, the current will decrease. A fully charged battery

draws less than 100 mA. You should notice the current draw slowly

drop the longer the dc supply is connected to the monitor.

±0.5 V.

8. Turn off the power supply.

9. Disconnect the supply from the monitor.

Calibration/Maintenance Manual 810-0334-01 2-7

Page 31

Section 2—Installation and Service Propaq 100-Series Monitors

Button Tests The following steps check the operation of the buttons.

1. Turn on the monitor.

2. Make sure that no error messages appear and the monitor correctly

powers up.

3. With the Main Menu displayed

a. press one of the buttons

b. check that the menu changed

c. press the MAIN MENU button

d. repeat steps 3a through 3c until all buttons have been checked.

4. Make sure that the Main Menu is displayed when you are done.

Display The following steps check the display.

1. Press MAIN MENU.

2. For Version 8.x software, press SYSTEM > MORE > MORE >

SERVICE > MORE > PIXL TST > CYCLE to start the display tests

(usually starts at COLUMN1).

For Version 7.x software, press SYSTEM > MORE > SERVICE >

MORE > PIXL TST > CYCLE.

3. Check that all pixels in the activated columns are turned on.

4. Press the left button to advance to the next test, COLUMN2.

5. Check that all pixels in the activated columns are turned on.

6. Press the left button to advance to the next test, BORDER.

7. Check that all pixels around the perimeter of the display are turned off.

8. Press any but the left button to stop the tests.

9. Press MAIN MENU.

10 .Press SYSTEM > MORE > TIME/DAY and check that the displayed

time of day and date are correct. If they are not, correct them using the

NEXT and UP or DOWN buttons and set them with the ENTER

button.

The clock should be accurate to ±2 seconds per day or ±1 minute

per month. If the clock does not meet these specifications, complete

the calibration of the Clock/Calendar listed in Section 3.

2-8 810-0334-01 Calibration/Maintenance Manual

Page 32

Propaq 100-Series Monitors Section 2Installation and Service

ECG Channel &

Alarm Indicators

The following steps check the ECG channel and the alarm indicator drivers.

1. Connect the ECG channel to the patient simulator.

2. Set the simulator as follows:

normal sinus rhythm

80 beats per minute (bpm)

1 mV amplitude

3. Set the monitor as follows (from the Main Menu, press the keys

indicated in parentheses):

Lead II (SENSORS > ECG > LEAD)

1 mV ECG size (SENSORS > ECG > SIZE)

25 mm/Sec sweep speed (SENSORS > ECG > mm/SEC)

ALL ALARMS OFF (ALARMS > ALL ALRM)

Version 7.x- Tone to LOW (DISPLAY > MORE > TONE)

Version 8.x- Tone to LOW (SENSORS > ECG > MORE > TONE)

4. Check that a normal sinus rhythm ECG waveform is displayed with a

peak-to-peak height equal to that of the reference pulse at the left side

of the display (18

±2 pixels high, after subtracting 1 pixel from the

total for trace thickness). There should be a soft beep tone with each

QRS event.

NOTE

The patient simulator recommended in Table 2-2 provides a 1mV

output at Lead II. Other simulators may provide 1 mV at different

leads. If you use a simulator other than the one recommended,

check the simulator's specifications.

5. From the Main Menu, press (V7.x) DISPLAY > MORE > TONE, or

(V8.x) SENSORS > ECG > MORE > TONE.

6. Check that the tone turned off.

7. Press TONE twice more and check for high and medium tones.

This affects only the heart beat tone. Alarm tones are not affected.

Turn the tone off for the remainder of the functional verification.

8. Press MAIN MENU.

9. Check that the monitor's heart rate display is 80 ±4 bpm.

10. Remove one ECG lead wire.

Calibration/Maintenance Manual 810-0334-01 2-9

Page 33

Section 2—Installation and Service Propaq 100-Series Monitors

11. Check that an equipment alarm occurs. The LEAD FAIL message

should accurately indicate the removed lead.

12. Disconnect one of the two remaining leads.

13. Check that an equipment alarm occurs with a

LEAD FAIL MULTIPLE

message.

14. Reconnect all leads.

15. Press MAIN MENU.

16. Check that the

ALARM(S) OFF light is on.

17. Press ALARMS > STAT SET to automatically set heart rate alarm

limits.

18. Set the simulator heart rate outside a heart rate alarm limit.

19. Check that an alarm violation occurs with the tone and

ALARM light

on.

NOTE

The alarm tone may be set to high, med or low through DISPLAY

> MORE > MORE > NEXT (press until “alarm tone volume”

function appears) > CHANGE.

20. Press ALL ALRM to turn off alarms.

21. Check that the tone turns off.

22. Press MAIN MENU.

23. Adjust the simulator heart rate to 80 bpm.

24. Set the simulator for PACED RHYTHMS, NON-FUNCTION.

25. If pacer indicator is not on, press SENSORS > ECG > MORE >

PACER to turn on the pacer indicator.

A dashed line between the heart rate numeric and waveform

windows indicates the pacer indicator is on.

26. Check that a dashed vertical line is displayed on the ECG waveform

each time a pacer pulse occurs.

27. Check that the heart rate numeric is displayed as three horizontal

dashed lines.

28. Press MAIN MENU.

2-10 810-0334-01 Calibration/Maintenance Manual

Page 34

Propaq 100-Series Monitors Section 2—Installation and Service

P1, P2 The following steps verify the operation of one invasive pressure channel

(P1). Repeat the steps for checking P2 of a Propaq 106. If you are verifying

a Propaq 102, skip this part of the procedure.

NOTE

Check that the P1 and P2 waveforms are turned on in the wave

select window.

CAUTION

Many blood pressure simulators are not intended to be used as

a calibration standard. The simulator you use should have an

accuracy of at least 1%. Check your simulator’s specifications.

NOTE

If you are using the D ynatech/Nevada model 213A, 215A, or 217A

patient simulator, do not simultaneously monitor ECG and invasive

blood pressure (IBP) unless the modification to the simulator is

performed as described in Appendix B. If you do not wish to modify

your sim ulator, use ECG and IBP independently.

1. Disconnect the ECG cable from the monitor.

(Disconnecting an active channel initiates an equipment alarm.)

2. Press the DISABLE button to remove the alarm screen.

3 .Plug the pressure simulator into the monitor’s P1 connector (use the

P2 connector if verifying P2).

4. Set the simulator to 0 mmHg.

5. Check that P1 NOT ZEROED (or P2 NOT ZEROED) is displayed in

the blood pressure numerics window.

(The pressure scale does not appear until the pressure channel has

been zeroed.)

6. Zero the pressure channel by pressing SENSORS > INV PRS >

MORE > ZERO P1 (Press MORE twice to access ZERO P2).

7. Check that P1 ZEROED (or P2 ZEROED) is displayed.

8. Check that the mean pressure numeric is 0 mmHg ±2 mmHg.

9. Set the pressure simulator to 200 mmHg.

10. Check that the mean pressure numeric is 200 mmHg ±2 mmHg.

11. Set the pressure simulator to 0 mmHg.

12 .Press MORE > RESCALE.

13. Check that the displayed pressure waveform noise is no larger than 6

pixels p-p, after subtracting 1 pixel from the total for trace thickness.

14. Press MAIN MENU.

Calibration/Maintenance Manual 810-0334-01 2-11

Page 35

Section 2—Installation and Service Propaq 100-Series Monitors

CUFF Channel NOTE

In the following steps, the monitor’s displayed pressure must be

checked against a calibrated mercury-column manometer.

1. Connect the cuff, manometer with bulb, and the monitor together with

the Cuff Calibration Kit. See Figure 2-3.

2. Wrap the adult cuff around a cylindrical object about the size of an

adult’s arm.

3. Press SYSTEM > MORE > (V8.x press MORE again) SERVICE >

CUFF TST > CUFF CAL.

The Propaq pneumatic components now prevent cuff air from

flowing through the vent port to the atmosphere for a ten-minute

period. If steps 4 through 9 take longer than ten minutes, simply

press CUFF CAL again.

4. Close the valve on the bulb and squeeze the bulb to inflate the cuff to

250 mmHg as shown on the mercury-column manometer.

5. Check that the reading on the monitor’s display is 250±4 mmHg.

6. Reduce the pressure to 100 mmHg and check that the displayed

pressure is 100±2mmHg.

Fig. 2-3. Cuff Calibration Kit Attachments