Page 1

Service Manual

Operator Manual

Cardio Menu

PneumoCheck™

Spirometer Model # 61000,

Printer Charger #’s 76100 & 76106

Part 610132

Welch Allyn Medical Division

4341 State Street Road

P.O. Box 220

Skaneateles Falls, NY 13153-0220

Copyright 1997

Page 2

.oNtraP.veRegnahCfonoitpircseD#NCEetaDdevorppA

231016D noitamrofnIgnitoohselbuorTedulcniotnwardeRdnadesiveR 09563-579tcOerbmetteS.R

231016E 2noitceSnitseThcneBregrahC/retnirPdeddA 52324-500.voNorreLnarF

DRAWINGS AND/OR ILLUSTRATIONS AND/OR PART NUMBERS CONTAINED IN THIS DOCUMENT

ARE FOR REFERENCE PURPOSES ONLY! FOR CURRENT REVISIONS CALL WELCH ALLYN.

Service Manual 610132 Rev. E Pneumocheck Handle and Printer/Charger 1

Page 3

2 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 4

Contents

General Information........................................................................................................... 5

1.1 Handheld Spirometer ................................................................................................................6

1.2 Printer .........................................................................................................................................8

Service ...............................................................................................................................11

2.1 Bench Test Of Pneumocheck.................................................................................................12

2.2 Bench Test of Printer Charger................................................................................................17

2.3 Required Tools and Equipment .............................................................................................21

2.4 Test and Adjustment Procedures ...........................................................................................22

Theory of Operation ..........................................................................................................23

3.1 Spirometer Circuit Description ..............................................................................................24

3.2 Spirometer - Printer Circuit Description ...............................................................................30

3.3 Messages.................................................................................................................................33

Troubleshooting................................................................................................................37

4.1 PneumoCheck Handle Technical Troubleshooting ............................................................. 40

4.2 Customer Service Questions and Answers.........................................................................43

Disassembly and Repair...................................................................................................49

5.1 Pneumocheck Handle Disassembly Procedures ................................................................ 50

5.2 Pneumocheck Printer/Charger Disassembly Procedures ................................................. 56

Pneumocheck Handle and Printer/Charger Spare Parts ...............................................65

List of Drawings and A Specs ..........................................................................................67

Service Manual 610132 Rev. E Pneumocheck Handle and Printer/Charger 3

Page 5

Help Information:

• All service and repairs must be performed by authorized Welch Allyn personnel or

agents, using Welch Allyn replacement parts. Failure to do so will invalidate the

product warranty.

• If you have any questions about servicing the 61000 Pneumocheck or the 76100 or

76105 Printer Chargers, please call or write Welch Allyn:

Attn: Product Service Department

Welch Allyn, Inc.

4341 State Street Road

Skaneateles Falls, NY 13153-0220

U.S.A.

Telephone: 800-535-6663

Fax: 315-685-4653

• Troubleshooting assistance is contained in Section 4 of this manual.

• Please read and understand the PneumoCheck and Printer/Charger Operating

Instructions PN 610140-3.

4 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 6

Section 1 - General Information

1.1 Basic Description - Handheld Spirometer

1.2 Basic Description - Printer

General Information

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 5

Page 7

Section 1 - General Information

1.1 Handheld Spirometer

Refer to Owners Guide

P/N 610140-3

The handheld spirometer is a small, battery operated

device incorporating a laminar flow sensing pneumatic

liquid crystal display, and electronic circuitry in an

injection molded case.

The front panel of the handheld spirometer includes the

eight character, alphanumeric display, two push-button

keys labeled TEST and DATA, an ON/OFF slide switch

and a battery charge indicator light. The flow sensor is

housed in the top portion of the device and is removable

for cleaning and sterilization. The mouth piece is at one

end of the flow sensor and fits disposable cups or

disposable cardboard tubes. There are two electrical

contacts on each side to the spirometers batteries. On

one side of the spirometer is a DC jack for battery

charging in case the operator chooses not to purchase

the optional printer base.

The main function of the handheld spirometer is to

gather data from two kinds of spirometry maneuvers by

patients: the FVC maneuver and the MVV maneuver.

The TEST key is used to select and perform the desired

test. It is normally pressed when the spirometer is

displaying the word SELECT. It can also be pressed

during a maneuver or during the results display to

prematurely quit a test and begin another.

The DATA key is used to continue whenever the device

pauses to display some information. When the word

SELECT is being displayed, the DATA key can be used

to show the results of the test that is currently stored in

memory.

The general flow of usage of the device starts with the

selection of a test. The operator then waits for an

audible beep, indicating that it is ready to acquire data

from the maneuver. The patient puts the mouth piece to

his mouth and performs the maneuver. Upon

completion indicated by another audible beep, there is

a brief delay while the results are calculated then the

result messages are displayed. This completes the

loop, and the machine goes back to SELECT and waits

for another keypress.

6 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

6 Pneumocheck Handle and Printer/Charger

Page 8

Section 1 - General Information

When not in use, the handheld spirometer sits-in the

cradle of the printer base (or it is connected to an outlet

via a DC power adapter,) and the battery is charged.

The battery indicator light remains on whenever a

source of charge current is present. The spirometer

becomes operational when it is lifted from the printer

base or disconnected from the DC adapter. The

spirometer is functional only while disconnected from

the charger or printer base and the ON/OFF switch is

ON. The word SELECT appears on the display and the

device waits for a keypress from the operator.

When the word SELECT is on the display, you can do

one to the following:

1. Press the test key which will start the sequence

for doing an FVC test, and MVV test, or a

calibration of the spirometer.

2. Press the DATA key which will display the test

values of the best test of a test is currently

stored in the spirometer’s memory.

3. Put the spirometer back into the printer cradle

which will start the sequence for transmitting

any test data in the spirometer’s memory to the

printer’s memory, and then resume charging

the battery.

4. Connect the spirometer to the DC power

adapter, which will resume charging the battery.

5. Turn the unit off using the ON/OFF slide switch.

A more detailed description of the operation of the

spirometer is contained in the Operator’s Manual.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 7

Page 9

Section 1 - General Information

1.2 Printer

The printer base consists of a receptacle to hold the

spirometer, a battery charging circuit, a high speed

thermal line printer, and associated microprocessor a

power circuitry, all housed in an injection molded case.

The front panel of the printer includes 2 indicator lights,

and 3 push button keys marked STOP, FEED, and

PRINT. Also on the front panel are 5 numeric rotary

switches: 2 digits for AGE, and 3 digits for HEIGHT.

The are also 2 slide switches for selecting SEX and

RACE.

There is a set of 4 option switches located on the

underside of the unit.

The main function of the printer base is to print reports

of spirometry tests performed by the handheld

spirometer, and to charge the spirometer’s battery.

The general flow of usage is as follows:

When the spirometer is placed in the cradle of the base,

it immediately begins sending data to the printer base

during which time the message SENDING appears on

the panel of the printer base. Once the data transfer is

complete, the printer base gives a compound beep and

continues to charge. The READY light on the printer

base turns on solidly, indicating that there is a test

stored in its memory. The operator then sets the patient

demographic switches for the patient, then presses the

PRINT key to print the report.

There are two indicator lights on the front panel of the

printer base. One is labeled POWER and is on

whenever the unit is plugged into a powered outlet. The

other light is labeled READY, in the memory of the

printer base. When the device is receiving data from

the spirometer, this light flashes. Once the transfer is

complete and test is in memory, the light remains on.

8 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 10

Section 1 - General Information

The READY light is also used to indicate an error

condition. Errors are numbered from one to three.

When an error occurs, an alarm sounds and the

READY light flashes in groups of 1, 2, or 3 flashes (at a

rate of times per second), corresponding to the error

that was detected. A one second pause occurs between

these flashes. This continues until the error condition

has been cleared.

The PRINT key is used to print a report. If there is no

report to be printed and the PRINT key is pressed, a

short chirp will sound and no report is printed.

The FEED key is used to feed paper out of the printer.

The paper is fed as long as the key is held down. The

key is not operable while a report is being printed or

while the data is being transferred from the spirometer.

The STOP key aborts the current task (report printing or

data transfer) and returns to the wait state of the base.

It is also used to clear the machine of any error

condition that it might be in. It does not clear the printer

base’s memory.

The demographic switches are used to indicate the

patient’s age, height, sex, and race. The AGE switch

consists of two digits, each of which can range from 0 to

9. The range of valid values depends on the normal

being used.

The HEIGHT switches operate in the same manner as

the AGE switch, except that it has three digits. Either

inches or centimeters can be used for the height. As

was the case for AGE the range of valid values depend

on the normal being used.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 9

Page 11

Section 1 - General Information

If the value for either age or height fails outside of valid

range, then the normal values are not calculated or

printed on the report.

The SEX switch is a slide switch. The up position

indicates the patient is a female, while the down

position indicates that the patient is male.

The RACE switch is also a slide switch. The up position

indicates race group 1 and the down position indicates

race group 2. Race group 1 is used if the patient is

Black, Oriental, East Indian, or Pakistani. Race group 2

is used for all other races.

There are four option switches located on the underside

of the printer base. The switches are dip switches that

can be in either the ON or OFF position. These switches

can be changed while the printer base is on. The

options specify certain aspects of the report printing.

They are:

1. OFF

2. OFF Knudson, 1983

1. ON

2. OFF Knudson, 1976

1. OFF

2. ON Morris, Crapo et al

1. ON

2. ON European

3. OFF: Short report form

3. ON: Long report form

4. OFF: Flow/Volume plot

4. ON: Volume/Time plot

These options are discussed in further detail in the

Operator’s Manual.

10 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 12

Section 2 - Service

2.1 Bench Test of Pneumocheck

2,2 Bench Test of Printer/Charger

2.3 Required Tools and Equipment

2.4 Test and Adjustment Procedures

Service

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 11

Page 13

Section 2 - Service

2.1 BENCH TEST OF

PNEUMOCHECK

SECTION A

1 Remove pneumotach if necessary.

Caution: Adequate ESD protection

must be worn at all times when

working on the Pneumocheck,

handle or printer/charger.

2 Obtain a good set of batteries and insert in

pneumocheck.

3 Replace pneumotach. Turn pneumocheck on. If

unit powers up continue testing (steps 3 &

beyond). If unit doesn’t power up, take apart.

Refer to troubleshooting guide.

4 Put into data mode (hold down white button,

turn unit on and release white button).

5 Observe LCD; all segments should be on.

6 Depress and release ‘test’ button. Unit should

step through a self diagnostic.

Testing > ROM OK > RAM OK > EEPRM OK>

ASLEEP

In ‘ASLEEP’ mode, the unit will stop and await

further instruction.

If unit stops before sleep mode, there is a

failure. Refer to troubleshooting guide.

7 Depress & release test button: ON reading

should be displayed. It should read

between 30 and 80. Continue testing whether

on reading is in range or not.

Calibration of this circuit will be covered in

SEC B, STEP 6.

8 Depress & release test button: Unit should give

BAT reading. This should be 815 +/- 1%

(807-823). Even if number is outside of range,

continue on to steps 9-12. Refer to

troubleshooting guide to diagnose after

completing step 12.

12 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 14

Section 2 - Service

9 Depress & release test button: Ambient

temperature should be displayed.

20 degrees C = 68 degrees F

22 degrees C = 72 degrees F

24 degrees C = 75 degrees F

25 degrees C = 77 degrees F

27 degrees C = 81 degrees F

30 degrees C = 86 degrees F

If unit displays a reading outside ambient

temperature range, complete steps 10 thru 12.

Then, refer to troubleshooting guide. If unit

displays a reading of 390-400 degrees F,

check battery voltages. If battery voltage is

low, replace battery and repeat steps 4 thru

12.

10 Depress & release test button: Unit should

read FO = 55. This is a software coefficient.

11 Depress & release test button: Unit should

display a flashing ‘BAT OK’ message.

12 Depress & release test button: Unit should

display ‘DO DCV’ message.

13 Turn unit off. Depress test button and turn unit

on, release test button. Unit should read:

‘Test Mode’ >VER.3.5 >clear > select. The

latest software is VER 3.5: If unit reads VER

3.2, the software must be changed. The

PROM is part no 610102-535. It goes into

position U4 of the LCD digital PC board.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 13

Page 15

Section 2 - Service

Disassemble Unit:

SECTION B

Wear ESD wrist strap when performing the

following operations.

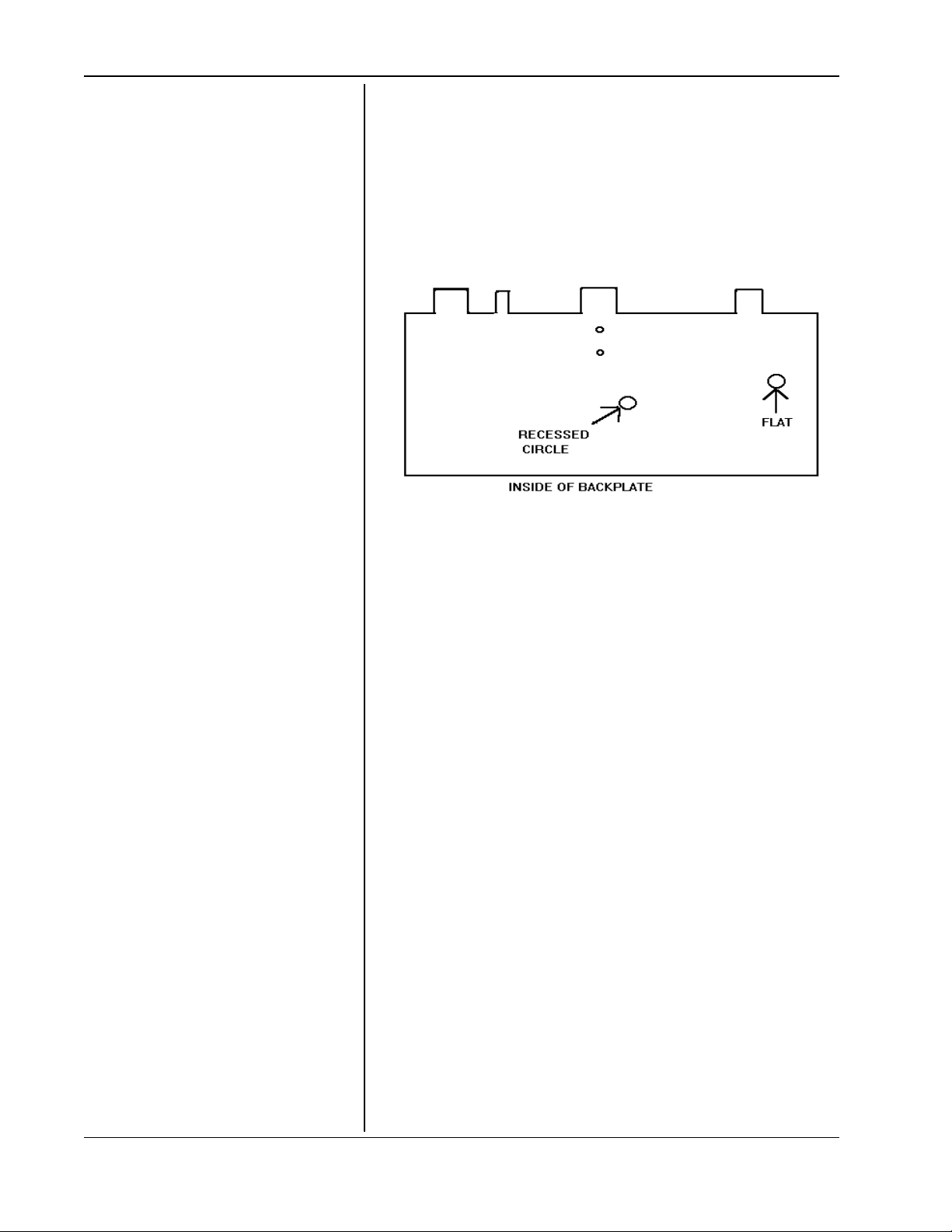

1 Observe backplate; notice what must be

present:

If there is a raised surface where the ‘flat’

should be and/or if there is no recessed circle,

replace backplate (610015-503).Remove

battery holder before discarding old

backplate.

NOTE:Observe back of LCD board. If back of

LCD board does not have a metal bar, you

must replace this board.

2 Apply a moderate amount of force to the side

of each battery contact. Contact should hold

firm. If it does not, take battery contact off and

clean any dried epoxy off of metal conducting

surface on PC board.

Obtain a new battery contact (610067-1) and

solder to PC board, noting proper

positioning.

Before soldering, screw contact onto PC board

with appropriate hardware.

Lastly, tighten to specifications (approx. 12-16

in/oz.) or until moderately firm. Take note that

black fiber washer is not destroyed. Perform

this step whether epoxy was adequate or

contact had to be soldered.

14 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 16

Section 2 - Service

3 If required, change Red LED to orange

(230015-6).

4 If necessary, change software. You must

remove digital board from front plate to do

this. PROM is location U4 on digital board.

5 If necessary, reverse side contacts. To do this,

remove the two metal contacts from the black

plastic piece. Reverse the plastic piece so that

metal contacts will be raised outside of plastic

surface of main frame. Do this for each side.

6 Calibrate the transducer circuit: to get to ON

reading, see steps 4-7 section A. If ON

reading was in spec.(see step 7, section A),

set to 50 or as close as you can get (within

5 cts.), using R33 (pot at bottom of PC board).

Apply 58.8 DPA (60 mm of water with

manometer) to transducer via long hose.

Adjust R36 (pot just above R33) to 844 +/- 5

cts. Return to ODPA, reading should be 50 +/5 cts. Readjust if necessary.

If the transducer reading is outside of the 30-80

range, measure the transducer output ofpins 2 and 4

of the transducer. They are the two white wires

coming from the transducer. You should see no more

than approx. 300 micro volts (.3mv). If this is the

case, readjust ON reading to spec. as per sec. B,

step 6.

If you see more than 300 mcvolts (.3mv), replace

transducer.

If you cannot build pressure in transducer,

diaphragm is torn, replace transducer.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 15

Page 17

Section 2 - Service

Once transducer is replaced, calibrate according to

Section B, step 6.

Once transducer is calibrated, re-assemble unit.

7 With unit assembled and good batteries in,

without the pneumotach (top piece), insert

into working printer charger. With a DC

ammeter, measure current between the top

of each battery. You should see approx. 11 ma

recharge current.

If reading is outside of 10-12 ma, refer to

troubleshooting guide.

8 If reading is good, assemble pneumotach onto

handle. Obtain final test form.

Step through, test in ‘DATA’ mode as per

Section A, steps 4-12 .

Observe ‘ON’ reading . As you do this and

write down in appropriate place on form.

Continue to move forward until you see DO

DCV.

At this point throw switch on test printer to RXTX OK

position. This puts a short circuit between the RX and

TX communication lines. Insert handle. The following

messages should appear:

DCV SEEN > RXTX OK > CHARGE > screen blank.

If they do, remove handle, the message DO DCV

should re-appear. Return switch on test printer to RX

fail position.

These tests are taken from spec. A01943 Rev.F.

Get ready to calibrate w/3.0 liter syringe according to

spec. A01945 Rev.D.

16 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 18

Section 2 - Service

1. ESD protection is required whenever working with the

pneumocheck printer .

2. Apply power to the unit. It should beep twice and the

“power LED” will light. The “data” light should not be

lit.

3. Note and record “dip” switch settings if customer

owned. These switches will have to be returned to

these positions when testing is complete.

4. Check printer well to make sure there is no foam pad.

If there is one, it must be removed. Make sure printer

is powered down. Remove pad by walking and rolling

back pad from ends. Move slowly as to not tear the

pad if possible. Continue until pad is removed. Clean

remaining adhesive with an adhesive remover solution.

Try to avoid scratching the printer well plastic piece.

2.2 Bench Test of the

Pneumocheck Printer/charger

5. Complete the following tests: A .

With a DVM set on the 200VDC range, measure 14vdc

across contacts as shown below that are marked with

an (**).

14 vdc

** ##

gnd

## **

B. Check voltage between ground contact in printer

well and pin 8 of the J2 connector. The J2 connector is

the longer of the two groups of pins in front of the

printhead. Pin 1 is at the left end of the longer group,

counting left to right. The voltage should be between

4.75 and 5.75 vdc.

C. Check voltage between ground contact in printer

well and pin 1 of the J2 connector. The voltage should

be 24vdc +/- .5 volts.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 17

Page 19

Section 2 - Service

D. Install a paper roll if one is not installed. Measure the

dc voltage between the ground contact in printer well

and pin 3 of the J1 connector . The J1 connector is the

smaller of the two groups of pins in front of the

printhead. Pin 1 is on the left, counting left to right.

The voltage should be 3.00 vdc or less.

6. Making sure the red capped lever at right of printhead

is pushed all the way toward the back of the printer,

hold down the feed button. The paper should advance

steadily forward.

7. Hold down feed button, then press and release the

stop button. The paper should automatically feed in

the reverse direction. Release the feed button. Paper

will stop feeding.

8. Push the print button. The unit should beep,

indicating that it has no data. The data light should

remain unlit.

9. Download data into printer by placing spirometer

handle, in on state, with data in it, into the printer well.

The data light should flash repeatedly for several

seconds. After this, the data light should be lit.

10.Make sure all dip switches on bottom of printer are

set to the “off” position. On top of printer, set the

following: Age: 36; Height: 159; Race: 2; Sex: F .

Depress and release the print button to obtain a

printout. The printout should agree with the settings.

Also, the standard printed should be Knudson 1976

(dip switches 1 and 2 in off position), short form (dip

switch 3 in off position), and the flow over volume graph

(dip switch 4 in off position).

18 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 20

Section 2 - Service

1 1.Set dip switches on bottom of printer to “on” position.

On top of printer, set the following: Age: 59; Height:

96; Race: 1; Sex: M.

Depress and release the print button to obtain a

printout. Observe printout. The printout should agree

with the settings. Also, the standard should be Euro

CCS (dip switches 1 and 2 in on position), the long

form, which is a questionnaire (dip switch 3 in on

position), and the volume over time graph (dip switch

4 in on position).

12.Return dip switches to position they were when unit

came in from customer. If unit is a loaner , or a new unit

being returned to stock, set all dip switches to off

position.

13.Hold down the print button and press/release the stop

button. Release the print button. A test printout should

print. At right side of top line, check the version of

software. It should be V3.2. If it is V3.1, it needs to be

changed. The “PROM” that controls this is in position

U5 on the main

pcboard. Replace existing Prom with

part number 610102-506. This Prom is software

version V3.2.

14.Perform agency tests on printer. These include the

ground continuity test and the leakage current test. If

the main pcboard, transformer or line filter was

replaced, perform the hypot test. Observe standards.

They are:

Ground continuity test: .2 ohm maximum

resistance with 10 amperes of current flow through the

earth ground line from the wall plug to a distant metal

point on the unit, probably the transformer screw

opposite where the ground wire is connected;

Leakage current test: 100 microamps or less

from any dead metal part on printer to earth ground,

with the printer ungrounded and powered up.

Hypot test: 1200 vac across the hot and neutral

(tied together) and earth ground for one second without

breakdown (voltage reduction).

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 19

Page 21

Section 2 - Service

15.This concludes the printer bench test. Make sure there

is an ample supply of paper in printer. When loading

paper, feed about 2-3 inches, put leading edge of

paper through paper cutter envelope before putting

paper cutter in place. Any questions call Welch Allyn

Technical Service at 800-535-6663, Technical

Support.

20 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 22

Section 2 - Service

Required Tools:

1. Compression ring tool - Welch Allyn tool

number T8608

2. Snap ring pliers (external) VACO #22

3. #1 Phillips head screwdriver

4. 1/4 inch flat head screwdriver

5. 3/32" Hex Key

Required Test Equipment

1. Merriam M131 Manometer with C34259

mount kit or Welch Allyn Pressure

Applicator Box.

2.3 Tools and Test

Equipment Listing

2. Pressure Source - Welch Allyn number

T9161

3. 0-7VDC Power supply with 100 mA current

limit

4. 0-14VDC Power Supply

5. 0-50mADC ammeter

6. 0-14VDC voltmeter

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 21

Page 23

Section 2 - Service

2.4 TEST AND

ADJUSTMENTS

PNEUMOCHECK HANDLE

A set of specification drawings have been included in

Section 7 with reference made to them here. The

following tests should be done before the unit is

returned to the customer.

1 Calibrate and test the handle per specification

drawing A01945. “Calibrating with Welch Allyn

Spirometer.

2. Perform all tests on specification drawing

A01951, “Dynamic Waveform Testing”

For troubleshooting use, specification drawing

A01943 has been included for testing at the

PC Board Level.

PNEUMOCHECK PRINTER/

CHARGER

22 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

1. Perform Dielectric Strength Test per:

A00167- UL/CSA Models

A00178- IEC Models

2. Perform Leakage Current Test per A00171

3. Perform Grounding Continuity Test per:

A00172 - UL/CSA

A02242 - IEC

4. Perform all tests listed on A01958, “Base Final

Testing”

For troubleshooting use, specification drawing

A01946 has been included for testing at the PC

Board Level.

Page 24

Section 3 - Theory of Operation

3.1 Spirometer Circuit Description

3.2 Spirometer - Printer Circuit Description

3.3 Messages

Theory of Operation

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 23

Page 25

Section 3 - Theory of Operation

3.1 Spirometer Circuit Description

General

The handheld spirometer’s electronics are contained on

two boards, designated the “Digital Board” and the

“Analog Board”. The analog board contains the power

control circuitry, as well as the analog signal amplifiers.

The digital board contains the digital circuitry, as well as

the front panel components.

The spirometer is designed to minimize power

consumption by having four separate operational

states:

a. OFF When SW1 is off only the battery charge

circuit is enabled. Only diode leakage

current flows.

b. ASLEEP In this state SW1 is on and Vcc is

present but the processor is not running. The

switched analog power is off.

In this state:

i. CR1 is not oscillating

ii. RB is oscillating (100Khz)

iii. All port bits are tri-state except for P6

which has all bits low

iv. The data and address bus is passive

v. The RAM is disabled (U5 pin 26 is low)

vi. TP6 is low

Normally in this state, since the LCD controller is

running, there will be something on the display. The

software can, however, intentionally blank the display.

c. AWAKE In this state the digital circuitry is

operating, but the analog power is off. This

state is entered when the processor has some

work to do.

24 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 26

Section 3 - Theory of Operation

In this state:

i. VA+ and VA- are not present

ii. U12 and U13 are not powered

iii. U8 i s not operating

iv . CR1 is oscillating (8Mhz)

v . The CPU clock (pin 22 of U4) is running

(2Mhz)

In normal operation this state will terminate and

return to the sleep state as soon as the p ro ce ss or

has nothing to do, such as while it is waiting for a

keypress.

d. FULL ON In this state all of the circuitry is turned

on. The charge pump may or may not

be operating.

If everything is correct the power consumption in the

four states should be:

State 1: OFF: Less that 0.1ma, typ 0.001ma

State 2: ASLEEP: Less than 2.5ma, typ 1.6 ma

State 3: AWAKE: Less than 16ma, typ 10ma

State 4: FULL ON: Less than 35ma, typ 25ma

NOTE: That achieving these levels is both a hardware

and a software function. Malfunctioning software can

raise the power to as much as 5ma in State 2 and 70ma

in State 4.

The maintenance mode of the spirometer allows it to be

placed in each state for testing purposes.

2. Power Consumption

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 25

Page 27

Section 3 - Theory of Operation

3. Spirometer Power

Circuit Description

The battery charge is supplied by U14 which is a voltage

regulator wired as a 12ma current source. D6 and D7

provide reverse polarity protection.

Transistor T1 is the source for the current used in the

spirometer if it is turned on while plugged into the

printer. Its output voltage is regulated by the zener D13

to a voltage which will reverse bias D18 while at the

same time insuring that the voltage reaching U8 does

not exceed its design limit of 10v. This means that the

tested voltage at TP1 must lie between 7.7 and 9.6v

with 14-20v applied to the DC jack.

R22 and R23 divide the zener voltage to provide the

sense voltage so that the processor can tell when DC is

applied. This voltage should be between 4.20 and 4.85

volts with DC applied to the charging jack. This sense

voltage is taken to pin 35 of the CPU and pin 1 of the U1.

The raw power for the spirometer comes from either the

battery via D18, or if DC is supplied, via T1. It goes

through the ON/OFF switch SW1 to the 5v regulator

119. U9 also supplies the low battery warning if Vcc

comes out of regulation. This will occur when the

battery voltage drops below about 6.3 volts.

Power for the analog sampling circuitry is taken directly

from the battery so that it is impossible to test patients

while powering the unit from the DC jack. T5 and T6

form a software controlled switch to turn analog power

on only while actually needed and thus conserve

battery power. This voltage will be on when CPU pin 2

is high. The voltage at the collector of T6 will be 6 to 10

volts when on, and can be easily tested at pin 1 or U1.

This switched analog voltage is inverted by U8, which

should have a visible charge pump oscillating at eight

kilohertz across C18. It will develop at least -6 volts

across C20.

The switched analog voltage and its inversion are

regulated by U7, T3, and T4 to provide +/- 4 volts VA+

and VA-. R18 and R19 divide Vcc to provide a guide

voltage. U7A and T3 use this voltage to give VA+. U7B

and T4 invert VA+ to provide a matching VA-.

26 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 28

Section 3 - Theory of Operation

TP2 and TP3 should measure +/- 3.90 to 4.10 volts. These

voltages power the pressure transducer as well a U10 to

U11.

The switched analog voltage is also, regulated by U15B

and T2 to give an isolated 5v +/- 0.10 volts at TP6. This

voltage powers the A/D and U12. Under the assumption

that both devices will never be used at the same instant,

this power is also used to supply U13 on units with a

610117-501 pressure transducers. Units with a

6010116-501 use Vcc.

Since the reference voltage from the A/D and the

reference voltage of the transducer are both derived

from Vcc, any variations in Vcc are ratiometrically

canceled out.

U10 and U11 are powered by VA+ and VA- because

they must deal with negative voltages. However, since

VA+ is less than Vcc, they cannot swing the full voltage

range of the A/D. Therefore, U15, the first amplifier

stage, is powered by V+.

When pressure sensing, VA+ and VA- must be on. The

output of the transducer is a small differential signal

(0.45 to 0.9 mv/cm H2O) on a common mode signal of

about -1 volts.

U10 forms a differential amplifier with adjustable gain.

U11B removes the common mode voltage, provides an

appropriate level shift, and provides a further gain of 5x.

The output of U11B is frequency limited to a few

hundred hertz by C25.

The bais voltage is supplied by a software charge

pump. When appropriate software is running 0-1 Khz

pulse train from pin 16 of the CPU charges C2 to 0-2

volts (TP4). U11A buffers this voltage and uses it to

offset U11B.

4. Spirometer Analog

Circuit Description

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 27

Page 29

Section 3 - Theory of Operation

The output of U11B (TP5) depends upon the particular

transducer, the charge pump and the adjustment of R33

and R36. The nominal output is 0.125 volt with no

pressure applied and 2.10 volts with a pressure

corresponding to 12 L/S of airflow (approximately 6cm

H2O). With no pressure and no charge pump pulse train

TP5 will be in the neighborhood of 1 volt.

U15A provides the final stage of amplification (2x). D9

clamps its input to prevent latch up when the output of

U11B goes negative.

With VA on, the charge pump operating and R33 and

R36 adjusted. U15A drives the A/D channel 0 with 0.5

- 4.5 volts as the airflow in the sensor ranges from 0 to

14 L/S.

5. Spirometer Digital

Circuit Description

The CPU, U2, has an address and data bus which

connects it to a 32K RAM U4, and 8K RAM, U5. Control

for these is performed by U3.

D1 and C4 provide a power-on reset. Residual power is

quickly discharged through SW1 and R3 to ensure that

reset occurs every time the power is cycled.

The A/D, EEPROM and LCD controller (U6) are serial

devices connected to the CPU ports.

The “TEST” key is connected directly to a CPU interrupt

input. The other interrupt input is shared by the “DATA”

key and the DC sense line from the power supply.

In order to allow both positive and negative transitions

of DC input to cause interrupts. U1B can be used to

invert the DC sense signal under software control. U1A

forms a latch which can be forced high or low by

software. R2 keeps it latched which can be forced high

or low by the software. R2 keeps latched high or low

when the CPU goes to sleep and the P4,4 goes to the

tri-state condition.

28 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 30

Section 3 - Theory of Operation

First, there is a signal from pin 5 of U9 which will go low

if Vcc comes out of regulation. This will occur if the

battery voltage falls below about 6.3 volts, depending

on the load.

In normal operation Vcc coming out of regulation will be

detected as soon as a key is pressed and the CPU

wakes up again. No detection is made while the unit is

waiting for a key press because the CPU is ASLEEP.

Another situation which can occur is that the battery is

failing but Vcc has not yet come out of regulation. This

condition is determined by software control of T7,

which, when ON, couples VA+ into A/D converter

channel 1. This allows VA+ to be compared to Vref =

Vcc, from which it is possible to detect a failing battery.

This case is only detected when the spirometer enters

the “STEADY” phase at the start of a test. This

condition occurs when the battery voltage falls below

about 6.2 volts.

6. Low Battery Detection

Note that the latter form of low battery condition is

“temporary”, because when it is detected the “LOW

BAT” warning is given and analog power is turned back

off again. If Vcc is still good the “LOW BAT” message

goes away again after several seconds and the unit

returns to “SELECT”.

A unit in this condition cannot perform further tests, but

it can retain, review, and transmit an existing test.

Due to the sharp decay rate of NI-CAD batteries, this

interim state will exist for only a short time. Before long,

Vcc will come out of regulation and the “LOW BAT”

condition will become permanent.

The operation of the low battery detection can be tested

in maintenance mode by varying the voltage applied to

the battery terminals while operating the unit.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 29

Page 31

Section 3 - Theory of Operation

3.2 Spirometer - Printer

Circuit Description

1. Digital Circuit Desription

This board is based on the Mitsubishi 50734 processor

which has an integral stepping motor driver, a UART

and a four channel 8 bit A/D converter. This makes the

digital circuitry very simple.

The printer mechanism has the thermal head driver

internal to it, so the interface to the processor is simple

and direct. The head temperature must be monitored

by the processor so that the head pulse width can be

controlled to produce a consistent end image at any

temperature. In this circuit the head thermistor is

balanced against an adjustable resistor which allows us

to trim each unit for variations in the head and

thermistor without trimming the timing constants within

the software. The software is designed to prevent

driving the head when the thermistor reading is out of

range. By using other analog channels for “Head-up”

and “Papersense” we avoid the need for logic level

converters on these lines.

The printer mechanism prints 256 dots per line in four

distinct banks of 64 dots. The signals DST1 through

DST4 select the bank. The data for each bank is loaded

serially from the processor using the CLK, DIN, and

LATCH signals. The ENABLE signal protects the

element heaters during CPU reset cycles.

In order to achieve maximum printing speed, the

printing actually occurs while the paper is moving

smoothly. Thus the printed horizontal lines are actually

less diagonal.

The UDS 5707 serves to buffer the paper drive motor

signals. D12 clamps the inductive surges. A port bit is

used to disable the motor drivers when they are not

being used. CPU pin 22 must be high to enable the

motor. On newer boards this buffer is an SN 75437

(P/N 761181-501), and performs the same function.

The front panel is a simple matrix of switch closures

isolated with doides. The options DIP switch is handled

in the same way.

30 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 32

Section 3 - Theory of Operation

The two inverters connected to the CPU pin 23

functions as a latch which powers up in the low state but

which can be forced to a latched high state by software.

It is used to provide a reliable mechanism by which the

software can distinguish between power-up reset and a

reset caused by the front panel reset key.

The three inverters connected to CPU pin 20 provide

enough drive to illuminate the front panel “ready” LED

directly.

The alarm device is an electromagnetic transducer. It

requires a transistor to drive it. D1 clamps inductive

surges.

Communication with the spirometer is handled by

protected direct UART connections. The signals are

standard asynchronous ASCII at 4800 baud, however,

the levels are CMOS logic levels, not RS232 level.

The printer power supply provides 24 volts at 3 amps

peak. 5 volts at 200ma, and 14 volts at 100ma.

The 24 volts output is regulated with a switching power

regulator while the 5 and 14 volt supplies utilitize linear

regulators. The present design incorporates a

transformer that allows a primary voltage of either 90 to

132 vac or 200 to 275 vac.

The switching regulator IC has a maximum allowable

supply voltage of 50 volts. The minimum output voltage

for the 24 volt supply that will ensure proper printer

operation and print contrast is 22 volts. Using a

transformer with a nominal 25 volt secondary and a full

wave bridge rectifier result in a voltage range of 27 volts

to 43 volts at the regulator when the input voltage varies

through the specified range.

The switching oscillator frequency is determined C17

and R32 which were selected to provide a 20Kh rate.

2. Printer Power Supply

Circuit Description

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 31

Page 33

Section 3 - Theory of Operation

The 24 volt output is fed into a divider network made up

of R27 and R28. The output of the divider network is

then fed into the error amplifier, ERR1. The 5 volt

reference voltage is reduced through a divider made up

of R37, R38, and R39 to 2 volts, and also fed into ERR1.

The difference voltage is then used to correct the 24 volt

output voltage.

The output current is limited to 2.5A by comparing the

voltage across R29 and to the 0.5 volt output of the

reference divider network.

A soft start circuit made up of C18, R31, and R38

causes the regulator to wait about 50 clock cycles

before the transistor control pulse width is increased to

its normal duration.

32 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 34

Section 3 - Theory of Operation

3.3 Messages

The following is a tabulation of the various messages

that may be displayed by the spirometer and/or printer

by the printer:

Indicates that this test has a greater FVC+FEV1 than

the one currently in memory. It will replace the stored

test.

Indicates that this test is close to but not better than, the

currently stored best test.

Indicates that this test has a lower FVC or FEV1 by at

least 5%, and will not replace the existing best test. To

correct this, inhale more fully before blowing, and blast

out harder at the start.

The effort was good. (A “good” test is one with no

identifiable faults.)

The patient coughed during the maneuver or flow was

interrupted, or uneven. To correct this, the patient

should refrain from coughing.

Quality Messages

NEW BEST

MATCH

NO MATCH

GOOD FVC

COUGH

5% or 0.1 liters of exhalation occurs before the back

extrapolation point. (ATS specification.) To correct this

the patient should blast out harder at the beginning of

the maneuver.

The flow stopped abruptly. To correct this. The patient

should keep blowing longer.

Low flow effort. To correct this, the patient should blast

out harder.

The maneuver was less the 3 seconds long. To correct

this, the patient should inhale more deeply and blow

out longer. If this message is displayed during an MVV

maneuver, the maneuver was less than 6 seconds long,

and the patient should continue longer.

The effort was good.

BAD. START

BAD.STOP

WEAK TRY

TOO.SHORT

GOOD MVV

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 33

Page 35

Section 3 - Theory of Operation

GOOD CAL

CF=XXX

RETRY.CAL

Each of the 3 calibration maneuvers was within 1/2% of

the average. The existing calibration factor will be

replaced with the cal factor from this calibration.

Shows calibration value after a successful calibration

was completed. The value is now the new calibration

value replacing the old one that was previously stored

in memory.

One or more of the calibration maneuvers exceeded

the average by more that 1/2%. The existing calibration

factor is not updated.

Test Values

FVC x.xxx In Liters

FEV1 x.xxx In Liters

RATIO xx % FEV1/FVC

Status Messages

CLEAR

TEST.MODE

SEND FVC

MMEF x.xxx In liters per second

PEF x.xxx In liters per second

MVV xxx In liters per minute

RATE xxx In liters per minute

TIME xx.x In seconds

Appears when the power is recycled, indicating that the

memory is cleared.

Appears briefly when entering the test mode of the

device.

Indicates that the spirometer is transmitting an FVC test

to the printer base.

SEND MVV

34 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Indicates that the spirometer is transmitting an MVV

test to the printer base.

Page 36

Section 3 - Theory of Operation

Indicates that the device has begun charging the

spirometer batteries.

Asks the operator or patient to hold the spirometer

steady (with no movement) while it references the

machine to zero flow in order to establish a baseline for

future data.

Indicates that the spirometer is in the process of

readjusting the nominal charge pump value for zero

flow.

Appears briefly while the spirometer calculating the

results of a test.

Appears when the operator pushes the TEST key from

the ready position. If the operator does not push the

TEST key again within 2 seconds, the spirometer will

conclude that an MVV test is desired, and will begin the

MVV sequence.

CHARGE

STEADY

RETRIM

BUSY

FVC

Appears if the operator presses the TEST key again

within 2 seconds, the spirometer will conclude that an

MVV test is desired, and will begin the MVV sequence.

Appears if the operator presses the TEST key

immediately after the MVV message is displayed.

Once this message is displayed, if the operator does

not press the TEST key again within 2 seconds, the

spirometer will conclude that a calibration is desired,

and will begin the calibration sequence.

If the operator presses the TEST key immediately after

the CAL message, the spirometer will go back to

READY.

Asks the patient to perform the nth FVC maneuver.

Tests are numbered, so that you can see which test you

are on.

Asks the patient to perform the nth MVV maneuver.

MVV

CAL

DO FVC n

DO MVV n

Asks the patient to perform the nth calibration

maneuver.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 35

DO CAL n

Page 37

Section 3 - Theory of Operation

Exception Messages

FLOW LIM

VOL LIM

TOO SOON

TX FAIL

NO DATA A

NO DATA B

NO DATA C

NO DATA D

The flow during a maneuver has exceeded the flow

sensor’s capacity of 14 liters/second (minimum).

The volume during a maneuver has exceeded the

spirometers capacity of liters (minimum).

Flow was present as a sampling started.

Transmission failure.

Maneuver was interrupted, such as by the press of a

key or the detection of a low battery.

FVC or MVV timed out - the maneuver did not start

within 13 seconds after the beep.

FVC terminated normally, but on analysis, no

exhalation was found.

The FVC maneuver appeared too short and/or

fragmented; possibly coughing with no blow.

NO DATA E

NO DATA F

NO DATA G

Problem and Error Messages

LOW BATT

TEMP LIM

The MVV did not have enough breaths to analyze.

During the MVV, the breaths were too inconsistent or

uneven.

Maneuver analysis routine failed: unable to analyze the

data.

The battery is too low to continue and requires

recharging.

The temperature range of the spirometer has been

exceeded. The acceptable operating range is between

59 and 105

o

F. The spirometer must be allowed to

return to an acceptable temperature range before

continuing.

36 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 38

Section 3 - Theory of Operation

The device cannot trim the baseline out. This is usually

due to an abrupt thermal change. The machine must

be allowed to return to an acceptable temperature

range before proceeding.

Encountering either the TEMP LIM or TRIM LIM

messages during normal operation may indicate a

possible hardware failure.

The spirometer failed to see a stable baseline value

within 30 seconds.

Bus error.

EEPROM check sum error. (This will occur once upon

first use of a new machine).

TRIM LIM

UNSTEADY

ERROR 0

ERROR 1

Out of memory.

Opcode error--another form of bus error.

Interrupt timing error.

EEPROM failure.

Spurious interrupt.

Error numbers greater that these indicate an

unexpected event in the program. In general, error

messages are probably caused by a hardware failure.

ERROR 2

ERROR 3

ERROR 4

ERROR 5

ERROR 6

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 37

Page 39

38 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 40

Section 4 - Troubleshooting

T roubleshooting

4.1 Technical Troubleshooting

4.2 Customer Service Questions and Answers

Service Manual 610132 Rev. E Pneumocheck Handle and Printer/Charger 39

Page 41

Section 4 - Troubleshooting

4.1 PneumoCheck Handle Technical Troubleshooting

(Most frequent problems at top)

tnialpmoCesuaCnoitcAevitcerroC

ydaetsnusdaeR.1recudsnartevitcefeD)ArecudsnartecalpeR)A

sdaeR.2 'BATADON' recudsnartevitcefeD)ArecudsnartecalpeR)A

)liafxT(timsnarttonseoD.3noitisoptcatnocedisgnorW)A.stcatnocnoitisopeR)A

sdaeR.4 'TABWOL' seirettabdeliaF)Aseirettabecalper/tseT)A

Model Number: 61001

rotaluger667evitcefeD)Brotaluger667ecalpeR)B

eriwrecudsnartnekorB)CsnoitcenocerotseR)C

eriwrecudsnartnekorB)BsnoitcennocerotseR)B

stcatnocytriD)BstcatnocnaelC)B

eldnahnieriwnekorB)CsnoitcennocerotseR)C

stcatnoc/yrettabdedorroC)BsmetidedorrocecalpeR)B

tnenopmocevitcefeD)C

6PTtaegatlovon

purewoptonlliW.5

)ezigrene(egatlovyrettabwoL)Aseirettabecalper/tseT)A

stcatnocyrettabdedorroC)BsmetidedorrocecalpeR)B

hcatomuenPdedorroc/ytriD)C

stcatnoc

81DdeliaF)D81DecalpeR)D

hctiwSffO/nOdeliaF)EhctiwSffO/nOecalpeR)E

5rorresdaeR.6egatlovyrettabwoL)A

rotcennoc1JtatniojredlosdloC)B

draoblatigid

elbacnobbirdeliaF)CelbacnobbirecalpeR)C

rossecorPnotniojredlosdloC)D rossecorPnotniojredloserotseR)D

CDA21UdeliaF)ECDA21UecalpeR)E

.21Uro,81D,8UecalpeR)C

.stniojredlosdlocrofkcehC

stniojerotseR

.stcatnocytridnaelC)C

stcatnocdedorrocecalpeR

.yrettabegrahceR)A

yrettabevitcefedecalpeR

tniojredloserotseR)B

52rorresdaeR.7erawtfosdlO)AerawtfoswenotedargpU)A

rosnes.pmetdeliaF)Brosnes.pmetecalpeR)B

.pmettneibmahgiH)C

nwod

tinuloocdnamoorreloocotevoM)C

40 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 42

Section 4 -Troubleshooting

PneumoCheck Handle Technical Troubleshooting

tnialpmoCesuaCnoitcAevitcerroC

Model Number: 61001

sdaeR.8 'MILPMET'

)erawtfosweN(

rorresdaeR.9 '1' MORPE31UdeliaF)AMORPE31UecalpeR)A

rorresdaeR.01 53 morpdeliaF)AmorpdemmargorpecalpeR)A

tuostnemgeS.11DCLnOelytsdlO)A

sdaeR.21 'LACYRTER' recudsnartdeliaF)ArecudsnartecalpeR)A

gnidaernoelbatsnU.31

etarbilactonlliW

tsetegrahcersliaF.41retnirpnidetaestontinU)AeldnahtaeserdnaevomeR)A

egatlovysioN)A

7DevitcefeD)C7DecalpeR)C

rosnes.pmetdeliaF)Arosnes.pmetecalpeR)A

)s(tcatnocDCLytriD)B)s(tcatnocDCLnaelC)B

hcatomuenPdeliaF)BhcatomuenpecalpeR)B

esoheceiphtuomesooL)CesohnethgiT)C

)4-ro/dna4+(

redlosrosroticapacdeliaF)BsnoitcennocerotserkcehC)B

81DevitcefeD)B81DecalpeR)B

latigidBCPlatigidecalpeR)A

draob

,51C,41C,21CsroticapackcehC)A

02C,91C

41UevitcefeD)D713ML41UecalpeR)D

Service Manual 610132 Rev. E Pneumocheck Handle and Printer/Charger 41

Page 43

Section 4 -Troubleshooting

PneumoCheck Printer T roubleshooting

(Most frequent problems at top)

melborPesuaCnoitcAevitcerroC

esufnwolB.1)s(esufnepo,egruseniL)A)s(esufecalpeR)A

Model(s): 76101

egatlovgnihctiwS.7UdetrohS)B

1-990167,rotaluger

roticapac71CdetrohS)C

)v05fu2.2(

repapecnavdatonseoD.2noitcesrotomdaehtnirpdeliaF)AdaehtnirpecalpeR)A

elbacnobbir1JevitcefeD)B1JecalperroriapeR)B

ylppusv42+woL)C

revird6UdeliaF)Drevird6UecalpeR)D

)ezigrene(purewoptonlliW.3)s(esufnepO)A)s(esufecalpeR)A

rotaluger7UdeliaF)Brotaluger7UecalpeR)B

4PtaeriwnopmircesooL)C

rotcennoc

tuotnirpetelpmocnirodaB.4580167NPdaehtnirpdeliaF)AdaehtnirpecalpeR)A

elbacnobbir2JdeliaF)Belbacnobbir2JecalpeR)B

tatniojredlos1VdloC)C

rossecorp

rotaluger7UecalpeR)B

roticapac71CecalpeR)C

detaicossarehtoro/dna7UecalpeR)C

trapdeliaf

4PtaeriwpmirceR)C

tniojredlosriapeR)C

rossecorp1UdeliaF)Drossecorp1UecalpeR)D

putratsnolangis"peeB"oN.54U,3U,1UtatniojdaB)AtniojredlosdlocriapeR)A

605-201016morp5UdeliaF)Bmorp5UecalpeR)B

daehtnirpdetrohS)CdaehtnirpecalpeR)C

latsyrc1RCdeliaF)Dlatsyrc1RCecalpeR)D

/egareporptnirptonseoD.6

tamrofthgieh

/ecarreporptnirptonseoD.7

tamrofxes

snoitporeporptnirptonseoD.8

)1ws(tamrof

draob

draob

sedoiddetaicossa

hctiwsyratornoedoiddeliaF)B

bcplortnocnotniojredlosdloC)AtniojredlosriapeR)A

bcplortnocnoedoiddeliaF)BedoiddeliafecalpeR)B

ro1wstatniojredlosdloC)A

edoiddetaicossaro1wsdeliaF)Bedoiddetaicossaro1wsecalpeR)B

hctiwsyratornotniojredlosdloC)A

tniojredlosriapeR)A

edoiddeliafecalpeR)B

)s(tniojredlosdlocriapeR)A

42 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 44

Section 4 -Troubleshooting

Solutions

4.2 Customer Service

Questions and Answers

Reading On LCD

Make sure they are not attempting to calibrate while

the handle is in the printer well.

Make sure they realize there is a CALIBRATION

CHECK and a RECALIBRATION. When performing

calibration, 3 liter syringe must be operated smoothly

and evenly with consistent speed. Refer to pages

32, 33, 34, & 35 of operating instructions for the

calibration instruction.

The American Thoracic Society recommends

checking accurancy of calibration daily.

If documentation of the calibration check is required,

insert the handle in the printer well and push print

after a cal check had been completed. (Note: They

cannot get a printout of the recalibration).

The pneumotach screen should be inspected daily

and cleaned when necessary.

Calibration

Cleaning & Sterilizing

We recommend cleaning and sterilizing the

pneumotach assembly every 50 maneuvers. They

can be steam autoclaved, ethylene oxide, soaked or

boiled.

Regardless of sterilization method, pneumotach

must be completely dry before reusing. A wet or

damp pneumotach inaccurate results. Four days air

drying time is required, or 10 minutes with a hair

dryer on high.

Handle must come back for repair.

The handle must come back for checking and repair.

Turn the unit off, then on again. It may reset itself. If

not, it is a hadware problem-handle must come back

for service.

Display Blank (Or Fading)

Erroneous Results

Error 5

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 43

Page 45

Section 4 -Troubleshooting

Error 23

Error 25 Or Temp. Lim

Infrequently customer complains of Error 23. Have

them turn handle off/on to see if it will reset-perhaps

leave for a couple minutes and try again. In talking

the Tech. Rep., they have not been able to duplicate

problem inhouse. Customer must return both

handle and printer for service.

This is a temperature problem.

Is the office extra warm (cold) today?

Is the unit sitting in direct sun, near heat register,

etc.?

Advise to put the handle on the desk for a minute

before attempting a test - it should be OK.

If the error message continues and creates a problem

they may return handle for new software update (3.5)

It was also discovered Error 25 could indicate low

battery. Change batteries.

Forced Vital Capacity

Getting the Wrong Graph

Green Data Light on Printer

The amount of air that can be exhaled during a rapid

forced exhalation. (1 long, hard blast)

Have them check the bottom of the printer, “flip” the

4th switch the opposite way, and see it that corrects

the situation.

This indicator light will be lit as long as there is

information on the printer.

If they want to clear the printer entirely, it must be

unplugged.

If the customer has entered incorrect data in the

height or age, and the patient data is still in the

printer, all they need to do is insert correct info and

push print.

44 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 46

Section 4 -Troubleshooting

Are batteries within warranty? Check battery voltage

should be 3.5 volts.

Are the printer & handle power lights (orange) on?

Put in charger overnight, try again. Has it been in the

printer charger?

If error 5 appears after unit has been in printer for

more than 3 hours, let unit cool down. If error 5 goes

away, there is a hardware failure, unit must be

returned.

Make sure the contacts in the pneumocheck

assembly are making good contact with the batteries.

Clean contacts.

If necessary, return handle & printer for checking.

The largest column of air inhaled and/or exhaled over

a timed period. This maneuver imitates rapid

breathing.

Low Batt Message

Maximum V oluntary

Ventilation

The maneuver did not start within 20 seconds after

the “beep”.

Have them try again, watching the display carefully.

If a problem, return handle.

The problem is due to the information the user

entered into the printer:

The AGE of the individual is outside the limits built into

the predicted values (for Knudson 3, the limits are age 5

to 83 for males and 87 for females). These can be found

on Pages 54 through 58 of the operating instructions.

Pages 52 & 53 of the operating instructions gives the

formula for calculating predicted values manually .

Or the HEIGHTis entered wrong. You can use either

inches or centimeters, and in using inches the “O” must

go in the first space. Example: Patient is 5 foot 6 inches

tall. Info entered into machine: 066

No DATA B

No % Or Norms on Printout

Page 54 in Operating Instructions

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 45

Page 47

Section 4 -Troubleshooting

No % Or Norms on Printout

Page 54 in Operating Instructions

cont’d

No Power to Printer

No Print on Printout

Paper Replacement

Pneumocheck handle is in test mode-you will

received no % norms in the print-Turn on w/out

buttons depressed. Remove handle-turn unit off turn

handle on into normal mode.

They may have blown a fuse.

Make sure the paper is inserted correctly.

If cannot be corrected, printer must be returned for

service.

Remove printer cover.

Feed any remaining paper through printer. DO NOT

PULL PAPER BACKWARDS THROUGH THE

PRINGER.

Save black plastic spindle.

The printer does not store

more than one patients Data

The printer saves only the

best test.

Put red lever all the way forward.

Place new roll of paper in the printer well. The paper

feeds forward from the bottom of the roll.

Insert edge of paper under the gray rubber pinch

roller until paper exits top of printer.

Push red lever as far back as possible.

Press FEED button to feed paper through.

Replace printer cover.

If the doctor wants a printout of all the tests on a

patient, they have to run a test, print it out, then turn

off the Pneumocheck and start over again as a new

test.

THE PNEUMOCHECK HANDLE SHOULD BE LEFT

IN THE OFF POSITION TO KEEP THE BATTERY

FULLY CHARGED AT ALL TIMES. THE PRINTER

SHOULD BE LEFT PLUGGED IN.

46 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 48

Section 4 -Troubleshooting

On the bottom right hand corner of the printer, there

are 4 little dip switches.

1 & 2 control the predicted

3 indicates long or short form

4 indicates volume/time or flow/volume graph.

Refer to page 24 of operating instructions.

When the machines leave the factory, they are set

with all the switches in the off position, i.e., they are

set for the Knudson 83 predicted values, short form,

and flow/volume graph.

The norms that are selected, together with the

version of software in the machine print out on each

tape. This is located just below the actual values.

Example: NORMS: KNUDSON 1983 (VS35P31)

(The “S” means handle, “P” means printer)

Printer Options

The message “Retrim” in itself is no problem. They

MUST let the unit work thru this step. If they turn it

off, they will only get retrim the next time they go to do

a test. The retrim mode lasts 45 seconds to 1 minute,

then it will advance to “do FVC”. (Sometimes I have

found it necessary to have the customer get the

instrument into “retrim” mode and time with a watch.

It may seem like an eternity, but actually will be

within the 1 minute range).

Retrim only means the instrument is trying to

establish the baseline. It will not go into this mode

each time they want to do a procedure.

If retrim occurs regularly, or if it will not advance after

the 1 minute, handle must be returned for service.

The Welch Allyn PnuemoCheck complies with

American Thoracic Society

OSHA

UL

CSA

IEC

Retrim

Standards Compliance

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 47

Page 49

Section 4 -Troubleshooting

T rim.Lim

TX Fail (Transmission Fails)

Handle cannot trim the baseline. May be due to an

abrupt thermal change or weak battery.

If not, may be hardware failure. If so, turn handle off/on.

If unit does not clear, return for service.

Broken or bent contact in handle or printer? Push

paper feed button - Does paper feed through

machine.

If not: Is there paper in the machine?

Is paper tension lever (red, near paper roll) pushed

back all the way? Make sure that paper is properly

fed. There could be a paper jam.

To clear: Depress STOP & FEED buttons

simultaniously. Release STOP button. This will feed

paper backwards. Release FEED button. This should

clear the jam. Depress FEED button - paper should

flow through OK.

Printer does not advance paper and/or unit grinds

or strains when the feed button is depressed.

As a “last ditch” effort, unplug the printer ar the back

and plug it in again - this should reset the machine.

Unsteady

48 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

While in the “steady” mode, was the handle moved?

If not, problem could be a bad tranducer - handle

must be returned for repair.

Page 50

Section 5 - Disassembly and Repair

Disassembly and Repair

5.1 Pneumocheck Handle

5.2 Pneumocheck Printer/Charger

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 49

Page 51

Section 5 - Disassembly and Repair

5.1 PNEUMOCHECK

HANDLE DISASSEMBLY

PROCEDURES

ITEM NUMBERS REFERENCED ON DRAWING

610135 (SPIROMETER ASSEMBLY)

This section describes how to remove the following

subassemblies and major components:

A. MOUTH PIECE ASSEMBLY (Item 3)

B. PNEUMOTACH ASSEMBLY (Item 18)

C. REAR BASE ASSEMBLY (Item 2)

D. ELECTRONIC COMPONENT

ASSEMBLY (Item 6)

E. FRONT HOUSING ASSEMBLY (Item

21)

F. BATTERY CONTACTS (P/N 610067)

G. PRESSURE TRANSDUCER

ASSEMBLY (P/N 610116-502)

NOTE: All work must be done at a grounded work

station by grounded personnel.

A. Removing the MOUTH PIECE ASSEMBLY

(Item 3)

1. Remove the MOUTH PIECE

ASSEMBLY by pulling it straight off

the PNEUMOTACHASSEMBLY (Item

18).

Reassembly is the reverse of disassembly.

B. Removing the PNEUMOTACH ASSEMBLY

(Item 18)

1. Loosen the two studs (item 19) at the

bottom of the body with a coin or

screwdriver.

2. Remove the PNEUMOTACH

ASSEMBLY.

NOTE: The MOUTH PIECE ASSEMBLY (item

3) is not part of the PNEUMOTACH ASSEMBLY.

The MOUTH PIECE ASSEMBLY may be removed

as instructed in Part A.

50 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 52

Section 5 - Disassembly and Repair

Reassembly is the reverse of disassembly.

NOTE: Torque the studs (item 19) to 5 - 8 in. lbs.

C. Removing the REAR BASE ASSEMBLY (item

2)

1. Remove the PNEUMOTACH

ASSEMBLY (item 18) as instructed in

Part B.

2. Remove the two pressure port gaskets

(item 11), the two retaining rings (item

14), and the compression ring (item 12).

3. Peel off the LABEL (item 1) affixed to

the REAR BASE ASSEMBLY (item 2).

NOTE: This label must be removed to reveal

two screws holding the REAR BASE ASSEMBLY to

the rest of the assembly. Once this label is removed it

cannot be reused. Always affix a new label after

repair.

4. Remove the two screws (item 10) from

the REAR BASE ASSEMBLY.

5. Remove the REAR BASE ASSEMBLY.

NOTE: The BATTERY HOLDER (item 15) is

not part of the REAR BASE ASSEMBLY. If the REAR

BASE ASSEMBLY is being replaced, use the old

BATTERY COMPARTMENT (if reusable) with the

new REAR BASE ASSEMBLY.

Reassembly is the reverse of disassembly.

Torque item 17 to 5 - 6.25 in. lbs.

Torque item 10 to 5.8 - 7.25 in. lbs.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 51

Page 53

Section 5 - Disassembly and Repair

D. Removing the ELECTRONIC COMPONENT

ASSEMBLY (item 6)

NOTE: The ELECTRONIC COMPONENT

ASSEMBLY consists of two P.C. boards (see parts

drawing), the analog assembly and the digital

assembly. These P.C. boards are a matched set,

and must always be replaced as a matched set.

1. Remove the PNEUMOTACH

ASSEMBLY (item 18) as instructed in

Part B.

2. Remove the REAR BASE ASSEMBLY

(item 2) as instructed in Part C, Steps 2

- 5.

3 Note the routing of the rubber hose.

The rubber hose must be routed the

same way during reassembly with no

kinks or pinches.

4. Remove the two screws (item 5)

securing the analog assembly to the

standoffs (item 7).

5. Slide the charging contacts (which are

wired to the analog assembly) out of

their slots in the FRONT HOUSING

ASSEMBLY (item 21).

6. Remove the four standoffs (item 7) and

the single screw (item 20) that secure

the digital assembly to the FRONT

HOUSING ASSEMBLY (item 21).

7. Remove the two stud assemblies (items

9 and 22) and the top and bottom

insulating paper (items 8 and 9

respectively).

NOTE: If a new stud assembly is needed, make

one by assembling item 22 onto item 19 and

tightening 18 - 20 in. lbs.

52 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

52 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 54

Section 5 - Disassembly and Repair

8. Remove the ELECTRONIC

COMPONENT ASSEMBLY.

NOTES:

Torque items 20 and 7 to 5 - 6.25 in. lbs.

Torque item 5 to 1.1 to 1.3 in. lbs.

Reassembly is the reverse of disassembly.

E. Removing the FRONT HOUSING ASSEMBLY

(item 21)

1. Remove the PNEUMOTACH

ASSEMBLY (item 18) as instructed in

Part B.

2. Remove the REAR BASE ASSEMBLY

(item 2) as instructed in Step C, Steps 1

- 5.

3. Remove the ELECTRONIC

COMPONENT ASSEMBLY (item 18) as

instructed in Part D.

4. Remove the FRONT HOUSING

ASSEMBLY.

NOTE: If the FRONT HOUSING ASSEMBLY is

being replaced, copy the serial number from the old

assembly onto the blank label of the new assembly.

Reassembly is the reverse of disassembly.

F. Removing the BATTERY CONTACTS (P/N

610067)

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 53

Service Manual 610132 Rev. E

Page 55

Section 5 - Disassembly and Repair

NOTE: These instructions apply only to

assemblies where the BATTERY CONTACTS are

glued to the P. C. Board. Also, anytime old

BATTERY CONTACTS are removed, the new

BATTERY CONTACTS must be soldered onto the

P. C. Board.

1. Remove the PNEUMOTACH

ASSEMBLY (item 18) instructed in Part

B.

2. Remove the REAR BASE ASSEMBLY

(item 2) as instructed in Part C, Steps 2

- 5.

3. Remove the ELECTRONIC

COMPONENT ASSEMBLY (item 6) as

instructed in Part D,Steps 3 - 8.

4. Remove the 0-80 X .187 screw (P/N

106100-10), the 0-80 hex nut (P/N

106109-1) and the flat washer, (P/N

106103-3) holding the battery contact to

the analog P. C. Board.

5. Remove the BATTERY CONTACT.

Reassembly is the reverse of disassembly

NOTE: Remove residual epoxy and clean the

BATTERY CONTACTS and the P. C.

Board pads with a degreaser before assembly.

Solder the new BATTERY CONTACTS (P/N 610067-

1) onto the P. C. Board.

Torque to bolts to 13 - 16 in. oz.

G. Removing the PRESSURE

TRANSDUCER ASSEMBLY (P/N

610116-502).

54 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 56

Section 5 - Disassembly and Repair

1. Remove the PNEUMOTACH ASSEMBLY

(item 18) as instructed in Part B.

2. Remove the REAR BASE ASSEMBLY

(item 2) as instructed in Part C, Steps 2

- 5.

3. Remove the ELECTRONIC

COMPONENT ASSEMBLY (item 6) as

instructed in Part D, Steps 3 - 8.

4. Remove the solder and the PRESSURE

TRANSDUCER ASSEMBLY from the P.

C. Board

Reassembly is the reverse of disassembly

NOTE: See drawing No 610051 for a view of

how to resolder a PRESSURE TRANSDUCER

ASSEMBLY to the P. C. Board.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 55

Page 57

Section 5 - Disassembly and Repair

5.2 PNEUMOCHECK

PRINTER/CHARGER

DISASSEMBLY

PROCEDURES

ITEM NUMBERS REFERENCED ON DRAWING

761168 (DOMESTIC EXPLODED VIEW MODEL

76101)

ITEM NUMBERS REFERENCED ON DRAWING

761170 (INTERNATIONAL EXPLODED VIEW 220V

MODELS 76102, 76104, 76106)

These procedures describe how to remove the

following subassemblies and major components:

A. TOP PANEL ASSEMBLY (Item 1)

B. CONTROL P. C. BOARD ASSEMBLY (Item

10)

C. SPRING CONTACTS (Item 13)

D. MAIN P.C. BOARD ASSEMBLY (Item 14)

E. THERMAL PRINTER (Item 11)

F. TRANSFORMER ASSEMBLY (Item 8)

G. RFI FILTER (Item 7)

H. FUSES (Item 29)

I. BASE HOUSING ASSEMBLY (Item 19)

J. ROTARY SWITCH ASSEMBLY (Item 38)

Before doing any work:

1. All work must be done at grounded work

stations by grounded personnel.

2. Remove the PRINTER COVER.

3. Reverse feed the paper out of the THERMAL

PRINTER (item 11) by pressing the STOP

button, pressing the FEED button, and then

releasing the STOP button (in that order).

56 Pneumocheck Handle and Printer/Charger Service Manual 610132 Rev. E

Page 58

Section 5 - Disassembly and Repair

4. Remove the AC line cord from the AC outlet

and from the back of the PRINTER/

CHARGER.

5. Remove the PAPER ROLL (item 4) and the

SPINDLE (item 5).

6. Refer to the parts drawing when following

procedures. There are two drawings for this

purpose: onefor U.S.A. and Japan., and one

for the U.K. Australia, and Europe.

A. Removing the TOP PANEL ASSEMBLY (Item

1)

1. Remove the seven phillips drive screws

(6-item 18 and 1-item 19), securing the

TOP PANEL ASSEMBLY to the BASE

HOUSING ASSEMBLY (item 17).

2. Carefully lift the TOP PANEL

ASSEMBLY high enough so that the flat

ribbon cable can bereached and unplug

it from the CONTROL P.C. BOARD

ASSEMBLY (item 10).

NOTE: Be careful not to damage the SPRING

CONTACTS (item 13) when lifting the

TOP PANEL ASSEMBLY.

3. Unplug the remaining flat ribbon cable

connector for the TOP PANEL

ASSEMBLY.

4. Remove the TOP PANEL ASSEMBLY.

Reassembly is the reverse of disassembly.

NOTES: The ribbon cable is plugged in properly

when the RED wire of the connector to the

CONTROL P. C. BOARD ASSEMBLY (item 10) is to

the LEFT when facing the front of the PRINTER/

CHARGER.

Service Manual 610132 Rev. E Pneumocheck Handle Printer/Charger 57