Page 1

Welch Allyn Connex® Vital Signs

Monitor 6000 Series™

Service manual

Page 2

© 2011 Welch Allyn. All rights are reserved. To support the intended use of the product described in this publication, the

purchaser of the product is permitted to copy this publication, for internal distribution only, from the media provided by Welch

Allyn. No other use, reproduction, or distribution of this publication, or any part of it, is permitted without written permission from

Welch Allyn. Welch Allyn assumes no responsibility for any injury to anyone, or for any illegal or improper use of the product, that

may result from failure to use this product in accordance with the instructions, cautions, warnings, or statement of intended use

published in this manual.

SureTemp, Welch Allyn , Connex, and SureBP are registered trademarks of Welch Allyn.

Vital Signs Monitor 6000 Series is a trademark of Welch Allyn.

LNCS, SpHb, and Rainbow are trademarks of, and SET, LNOP, and Masimo are registered trademarks of, Masimo Corporation.

Possession or purchase of a Masimo SpO2- or Masimo SpHb-equipped device does not convey any express or implied license to

use the device with unauthorized sensors or cables which would, alone or in combination with this device, fall within the scope of

one or more of the patents relating to this device.

Nellcor and OxiMax are registered trademarks of Nellcor Puritan Bennett Inc.

Braun and ThermoScan are registered trademarks of Braun GmbH.

Software in this product is Copyright 2011 Welch Allyn or its vendors. All rights are reserved. The software is protected by United

States of America copyright laws and international treaty provisions applicable worldwide. Under such laws, the licensee is

entitled to use the copy of the software incorporated with this instrument as intended in the operation of the product in which it is

embedded. The software may not be copied, decompiled, reverse-engineered, disassembled, or otherwise reduced to humanperceivable form. This is not a sale of the software or any copy of the software; all right, title, and ownership of the software

remain with Welch Allyn or its vendors.

For information about any Welch Allyn product, call Welch Allyn Technical Support:

USA

+1 800 535 6663

+1 315 685 4560

Canada

European Call Center

Germany

Malaysia

Singapore

United Kingdom

103730 (CD)

Material Number 408102, Ver. B

Japan

Spain

+1 800 561 8797

+353 46 90 67790

+49 695 098 5132

+81 42 703 6084

+603 7875 3341

+65 6419 8100

+34 917 499 357

+44 207 365 6780

Welch Allyn, Inc.

4341 State Street Road

Skaneateles Falls, NY 13153-0220 USA

www.welchallyn.com

Australia

Latin America

Netherlands

South Africa

Sweden

103500 (printed copy)

Material Number 717129, 80016618 Ver. B

China

France

Italy

+61 2 9638 3000

+86 21 6327 9631

+33 155 69 58 49

+39 026 968 2425

+1 305 669 9003

+31 202 061 360

+27 11 777 7555

+46 85 853 6551

Regulatory Affairs Representative

Welch Allyn Limited

Navan Business Park

Dublin Road

Navan, County Meath

Republic of Ireland

Page 3

Contents

Symbols ................................................................................................... 1

Safety ....................................................................................................... 3

iii

Documentation symbols .................................................................................................................. 1

Power symbols .................................................................................................................................. 1

Connectivity symbols ........................................................................................................................ 2

Miscellaneous symbols ................................................................................................................... 2

Warnings and cautions .................................................................................................................... 3

General safety considerations ........................................................................................................ 4

Electrostatic discharge (ESD) ......................................................................................................... 4

Overview .................................................................................................. 5

Purpose and scope ........................................................................................................................... 5

Technical support services ............................................................................................................. 5

Recommended service intervals .................................................................................................... 9

The Welch Allyn Service Tool ......................................................................................................... 9

Battery performance ...................................................................................................................... 11

Controls, indicators, and connectors ................................................... 13

Service menu ......................................................................................... 17

Access the Service screens ......................................................................................................... 17

General tab ....................................................................................................................................... 17

Self-tests tab .................................................................................................................................... 19

Logs tab ............................................................................................................................................ 20

Device tab ........................................................................................................................................ 20

Licensing tab .................................................................................................................................... 21

Power-up sequence ............................................................................... 23

Troubleshooting .................................................................................... 25

Symptoms and solutions ................................................................................................................ 25

Technical alarm messages ........................................................................................................... 34

Disassembly and repair ........................................................................ 47

Required tools and equipment ...................................................................................................... 48

Power down the monitor ............................................................................................................... 48

Remove the battery ......................................................................................................................... 48

Remove the rear housing ............................................................................................................... 49

Disassemble the rear housing ...................................................................................................... 52

Disassemble the main chassis ..................................................................................................... 58

Page 4

iv

Contents Welch Allyn Connex® Vital Signs Monitor 6000 Series™

Functional verification and calibration ................................................ 81

Functional verification tests .......................................................................................................... 81

Electrical safety testing ......................................................................... 93

Ground stud connector .................................................................................................................. 93

Options, upgrades, and licenses .......................................................... 95

Available options, upgrades, and licenses ................................................................................. 96

Install options .................................................................................................................................. 97

Masimo Hemoglobin (SpHb) upgrade ......................................................................................... 99

Configure options .......................................................................................................................... 100

Field replaceable units ........................................................................ 101

Rear housing .................................................................................................................................. 101

Bottom housing ............................................................................................................................. 105

Top housing .................................................................................................................................... 107

Side panels ..................................................................................................................................... 109

Front housing and mid section .................................................................................................... 109

Miscellaneous parts ..................................................................................................................... 112

Service tools .................................................................................................................................. 113

Options ............................................................................................................................................ 113

Licenses .......................................................................................................................................... 116

Partners in Care service and support agreements ................................................................. 116

Service and repair training .......................................................................................................... 116

Appendices .......................................................................................... 117

Decontamination and cleaning requirements .......................................................................... 117

Identifying the monitor and subsystems ................................................................................... 119

Factory defaults ............................................................................................................................. 122

Disassembly and repair reference ............................................................................................. 129

Interconnect diagram ................................................................................................................... 137

Page 5

Symbols

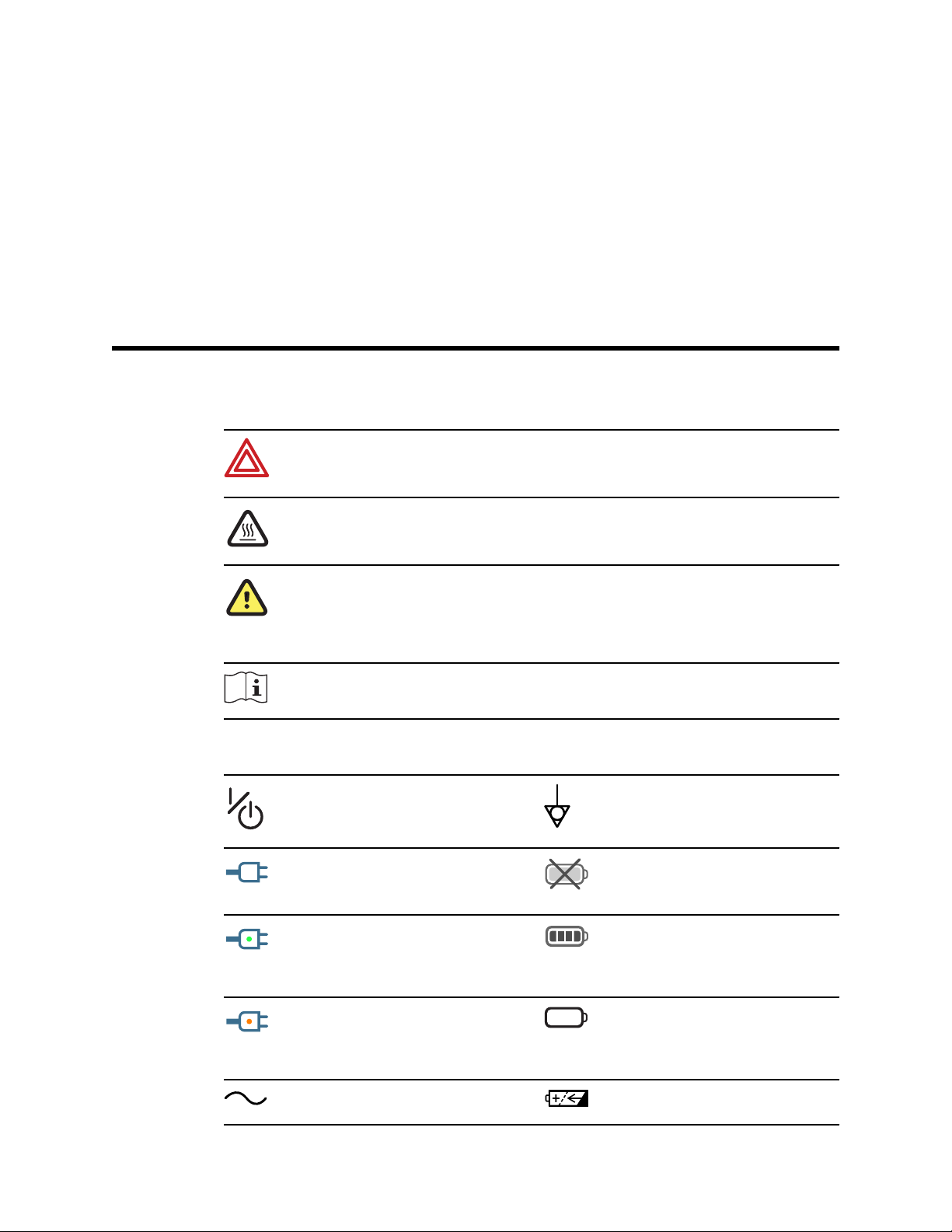

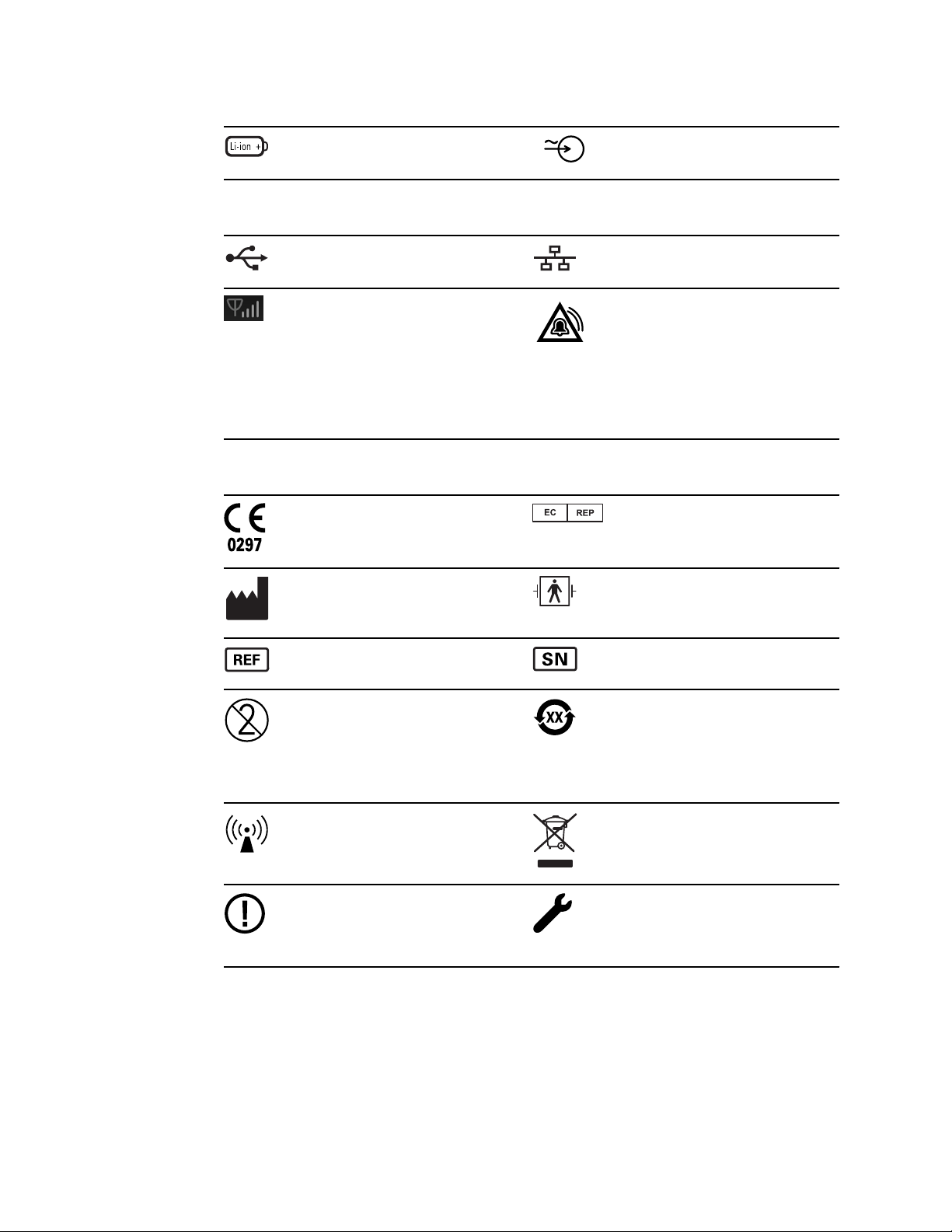

Documentation symbols

1

WARNING The warning statements in this manual

identify conditions or practices that could lead to

illness, injury, or death.

Power symbols

WARNING Hot surface. Do not touch.

Caution The caution statements in this manual

identify conditions or practices that could result in

damage to the equipment or other property, or loss of

data. This definition applies to both yellow and black

and white symbols.

Consult operating instructions.

Power on/standby Equipotential terminal

(on display) Monitor is

plugged into Alternating

Current power

(on the monitor, green

indicator) Alternating Current

power present, battery fully

charged

Battery absent or faulty

Battery charge level

(on the monitor, amber

indicator) Alternating Current

power present, battery is

charging

Alternating Current (AC) Rechargeable battery

Battery cover

Page 6

Symbols Welch Allyn Connex® Vital Signs Monitor 6000 Series™

2

Li-ion battery AC input power

Connectivity symbols

USB Ethernet (RJ45)

Wireless signal strength

• Best (4 bars)

• Good (3 bars)

• Fair (2 bars)

• Weak (1 bar)

• No signal (no bars)

• No connection (blank)

Miscellaneous symbols

Meets essential requirements

of European Medical Device

Directive 93/42/EEC

Manufacturer Defibrillation-proof Type BF

Reorder number Serial number

Do not reuse China RoHS markings for

Nurse call

European Community

Representative

applied parts

control of pollution caused by

electronic information

products. XX indicates

Environmentally Friendly Use

Period in years.

Nonionizing electromagnetic

radiation

Restrictions for use of

wireless device in Europe.

European communities class 2

radio equipment.

Recycle the product separate

from other disposables

Call for maintenance

Page 7

Safety

3

All users of the monitor must read and understand all safety information presented in this manual

before using or repairing the monitor.

United States federal law restricts this device to sale, distribution, or use by or on the order of a

licensed medical practitioner.

Warnings and cautions

WARNING Safety risk. Make frequent electrical and visual checks on cables,

sensors, and electrode wires. All cables, sensors, and electrode wires must be

inspected and properly maintained and in proper working order to allow the

equipment to function properly and to protect patients.

WARNING Safety risk. Place the monitor and accessories in locations where

they cannot harm the patient should they fall from a shelf or mount.

WARNING Fire and explosion hazard. Do not operate the monitor in the presence

of a flammable anesthetic mixture with air, oxygen, or nitrous oxide; in oxygenenriched environments; or in any other potentially explosive environment.

WARNING Inaccurate measurement risk. Dust and particle ingress can affect the

accuracy of blood pressure measurements. Use the monitor in clean environments

to ensure measurement accuracy. If you notice dust or lint build-up on the monitor’s

vent openings, have the monitor inspected and cleaned by a qualified service

technician.

Caution To ensure that the monitor meets its performance specifications, store

and use the monitor in an environment that maintains the specified temperature and

humidity ranges.

Caution The monitor may not function properly if dropped or damaged. Protect it

from severe impact and shock. Do not use the monitor if you notice any signs of

damage.

Caution Do not connect more than one patient to a monitor or connect more than

one monitor to a patient.

Caution Do not operate the monitor in the presence of magnetic resonance

imaging (MRI) or hyperbaric chambers.

Caution Do not autoclave the monitor. Autoclave accessories only if the

manufacturer’s instructions clearly approve it.

Page 8

4

Safety Welch Allyn Connex® Vital Signs Monitor 6000 Series™

General safety considerations

• If the monitor detects an unrecoverable problem, it displays an error message. For more

information see “Troubleshooting.”

• To ensure patient safety, use only accessories recommended or supplied by Welch Allyn. (See

the accessories list in the device’s directions for use). Always use accessories according to

your facility’s standards and according to the manufacturer’s recommendations and

instructions. Always follow the manufacturer’s directions for use.

• Welch Allyn recommends that only Welch Allyn service personnel or an authorized repair

center perform warranty service. Performing unauthorized service on a device that is within

warranty may void the warranty.

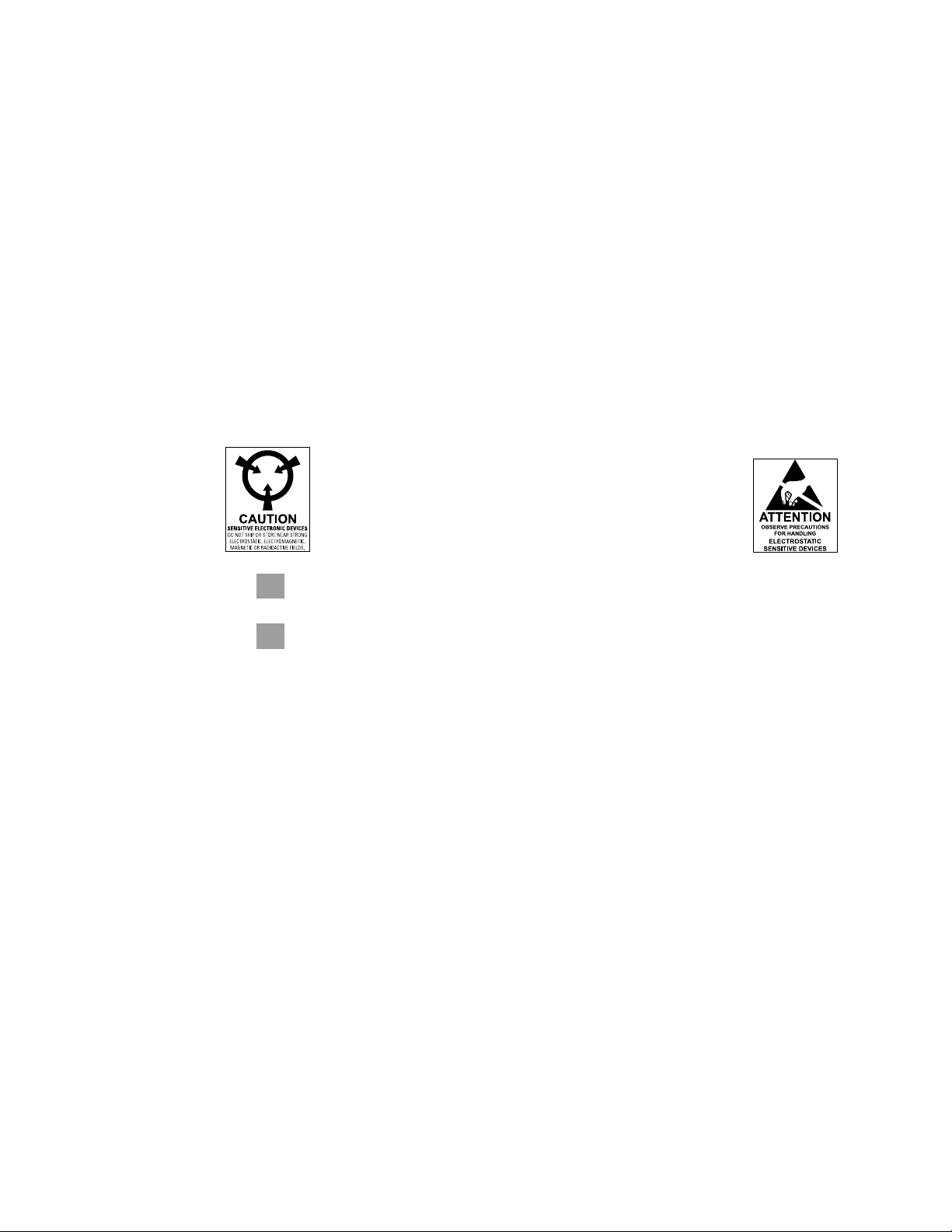

Electrostatic discharge (ESD)

Caution Electrostatic discharge (ESD) can damage or destroy electronic

components. Handle static-sensitive components only at static-safe workstation.

Caution Assume that all electrical and electronic components of the monitor are

static-sensitive.

Electrostatic discharge is a sudden current flowing from a charged object to another object or to

ground. Electrostatic charges can accumulate on common items such as foam drinking cups,

cellophane tape, synthetic clothing, untreated foam packaging material, and untreated plastic bags

and work folders, to name only a few.

Electronic components and assemblies, if not properly protected against ESD, can be permanently

damaged or destroyed when near or in contact with electrostatically charged objects. When you

handle components or assemblies that are not in protective bags and you are not sure whether

they are static-sensitive, assume that they are static-sensitive and handle them accordingly.

• Perform all service procedures in a static-protected environment. Always use techniques and

equipment designed to protect personnel and equipment from electrostatic discharge.

• Remove static-sensitive components and assemblies from their static-shielding bags only at

static-safe workstations—a properly grounded table and grounded floor mat—and only when

you are wearing a grounded wrist strap (with a resistor of at least 1 megohm in series) or other

grounding device.

• Use only grounded tools when inserting, adjusting, or removing static-sensitive components

and assemblies.

• Remove or insert static-sensitive components and assemblies only with monitor power turned

off.

• Insert and seal static-sensitive components and assemblies into their original static-shielding

bags before removing them from static-protected areas.

• Always test your ground strap, bench mat, conductive work surface, and ground cord before

removing components and assemblies from their protective bags and before beginning any

disassembly or assembly procedures.

Page 9

Overview

Purpose and scope

This service manual is a reference for periodic preventive maintenance and corrective service

procedures for the Welch Allyn Connex Vital Signs Monitor 6000 Series. It is intended for use only

by trained and qualified service personnel.

Corrective service is supported to the level of field-replaceable units. These include circuit-board

assemblies and some subassemblies, case parts, and other parts.

5

Find instructions for functional testing and performance verification in the Welch Allyn Service

Tool help files.

This manual applies only to this device. For servicing of any other vital signs monitor, see the

service manual for the specific device.

Service work not described in this manual must be performed by qualified service personnel at the

factory or at an authorized Welch Allyn service center.

Related documents

When using this manual, refer to the following:

• Welch Allyn Connex Vital Signs Monitor 6000 Series Directions for use (part number 103501)

• Welch Allyn Service Tool CD (part number 103521)

• Welch Allyn Service Tool Install guide (part number 103820)

• Welch Allyn Braun PRO 4000 Service Manual (part number 701627)

• Welch Allyn 9600 Plus Calibration Tester Directions for use (part number 701754)

• Welch Allyn website: www.welchallyn.com

Caution No component-level repair of circuit boards and subassemblies is

supported. Use only the repair procedures described in this manual.

WARNING When performing a service procedure, follow the instructions exactly

as presented in this manual. Failure to do so could damage the monitor, invalidate

the product warranty, and lead to serious personal injury.

Technical support services

Welch Allyn offers the following technical support services:

• Telephone support

Page 10

Overview Welch Allyn Connex® Vital Signs Monitor 6000 Series™

6

• Loaner equipment

• Service agreements

• Service training

• Replacement service parts

• Product service

For information on any of these services, call the Welch Allyn Service Center nearest you.

Service loaners

For warranty or non-warranty repairs not covered under a support agreement, loaners are

available for a nominal charge, subject to availability. Payment is required prior to shipment for all

loaners not covered under a support agreement. The loaner fee can be found on the Welch Allyn

loaner price list.

Welch Allyn Service Centers that provide repair service for this product can, on request, loan a

device for use while the device is being repaired. Loaned devices are provided free of charge for

products repaired while under a support agreement that includes a free loaner provision.

Loaner equipment for the individual component modules is not available.

Service options

Partners in Care service agreements

While product warranties provide basic assurance of Welch Allyn hardware quality, they may not

include the full range of services and support you need. Welch Allyn offers premium service and

support through our Partners in Care program. Whether you service your own devices and require

a minimum of support or rely on us to service your device, Welch Allyn provides a program that will

meet your needs. For more information visit our web site at www.welchallyn.com or call your sales

representative.

Warranty service

All repairs on products under warranty must be performed or approved by Welch Allyn. Refer all

warranty service to Welch Allyn Product Service or another authorized Welch Allyn Service

Center. Obtain a Return Material Authorization (RMA) number for all returns to Welch Allyn

Product Service.

Caution Unauthorized repairs will void the product warranty.

Non-warranty service

Welch Allyn product service and authorized service centers support non-warranty repairs. Contact

any Welch Allyn regional service center for pricing and service options.

Welch Allyn offers modular repair parts for sale to support non-warranty service. This service must

be performed only by qualified end-user biomedical/clinical engineers using this service manual.

Service training is available from Welch Allyn for biomedical/clinical engineers. For information, go

to www.welchallyn.com/support/technical/monitoring_suppt_training.htm.

Page 11

Service manual Overview 7

Repairs

A Welch Allyn Service Center must perform all repairs on products under warranty, unless you

have purchased a Welch Allyn support agreement allowing you to service the device while under

warranty.

Caution Unauthorized repairs will void the product warranty.

Qualified service personnel or a Welch Allyn Service Center should repair products out of

warranty.

If you are advised to return a product to Welch Allyn for repair or routine maintenance, schedule

the repair with the service center nearest you.

Welch Allyn Technical Support

If you have a problem with the device that you cannot resolve, call the Welch Allyn Technical

Support Center nearest you for assistance. A representative will assist you in troubleshooting the

problem and will make every effort to solve the problem over the phone, avoiding a potential

unnecessary return.

If your product requires warranty, extended warranty, or non-warranty repair service, a Welch

Allyn Technical Support representative will record all necessary information to issue an RMA

number. The support representative will provide you with the address of the Welch Allyn Service

Center to send your device to.

An RMA number must be obtained prior to any return. Be sure to note this number on the outside of

your shipping box and include a copy of the RMA in the box.

Returns without an RMA number will not be accepted for delivery.

Technical support is available during local business hours.

Returning products

When returning a product to Welch Allyn for service, ensure that you have the following

information:

• Product name, model number, and serial number. This information may be found on the

product and serial number labels on the bottom of the device.

• A complete return shipping address.

• A contact name and phone number.

• Any special shipping instructions.

• A purchase-order number or credit-card number if the product is not covered by a warranty.

• A full description of the problem or service request.

1. Contact Welch Allyn and request an RMA number.

Page 12

8

Overview Welch Allyn Connex® Vital Signs Monitor 6000 Series™

Note Welch Allyn does not accept returned products without an RMA.

2. Ship the device to Welch Allyn, observing these packing guidelines:

a. Remove from the package the battery, all hoses, connectors, cables, sensors, power

cords, and other ancillary products and equipment, except those items that might be

associated with the problem.

Recommendations for returning the Lithium Ion battery

• Use ground transportation to return batteries.

• If returning multiple batteries, package each battery individually.

• Do not consolidate multiple batteries in a single package.

• Use packaging provided by Welch Allyn or the battery manufacturer.

• Do not pack a defective battery in checked or carry-on baggage if traveling by air.

Packaging

• If you return the battery with the device, remove the battery, seal the battery in an

antistatic plastic bag, and place the battery in the position reserved for the battery in

the original shipping carton near the device.

• If you return the battery separately, package the battery in the replacement battery’s

plastic bag and shipping box.

If the original shipping carton or replacement battery shipping box is unavailable, consult

the manufacturer website for information regarding shipping lithium ion batteries:

www.nexergy.com/lithium-shipping.htm

WARNING Safety risk. Do not ship any battery that has been

physically damaged or shows signs of leakage unless you

receive specific instructions which meet the requirements for

the shipment of Lithium batteries. Dispose of damaged or

leaking batteries in an environmentally safe manner consistent

with local regulations.

Note In the United States, the applicable regulations can be found in

the Code of Federal Regulations (CFR). Refer to 49 CFR 173.185

for shipping lithium batteries by air or ground. Use 49 CFR

172.102 sections 29, 188, 189, A54, A55, A100, A101, A103, and

A104 to find the special provisions for shipping lithium

batteries.

b. Clean the device.

Note To ensure safe receipt of your device by the service center and

to expedite processing and return of the device to you,

thoroughly clean all residues from the device before

you ship it to Welch Allyn. For decontamination and

cleaning requirements, see “Decontamination and cleaning” in

the appendices.

If a returned device is found to be contaminated with bodily

fluids, it will be returned at the owner’s expense. United States

federal regulations prohibit the processing of any device

contaminated with blood-borne pathogens. Welch Allyn

thoroughly cleans all returned devices on receipt, but any

device that cannot be adequately cleaned cannot be repaired.

Page 13

Service manual Overview 9

c. Put the device, enclosed in a plastic bag with a packing list, into the original shipping

carton with the original packing materials or into another appropriate shipping carton.

d. Write the Welch Allyn RMA number with the Welch Allyn address on the outside of the

shipping carton.

Recommended service intervals

To confirm that the device is functioning within the design specifications, perform periodic service

using the Welch Allyn Service Tool, Gold edition, as indicated in the following table.

Component Service interval Service procedure

Monitor Annually Functional verification

NIBP module Annually Functional verification and calibration

if necessary

SpO2 module Annually Functional verification

SpHb parameter Annually Functional verification

SureTemp Plus Semi-annually Functional verification

Braun ThermoScan PRO

4000

Printer module Annually Functional verification

Battery 300 charge cycles Replace battery

Perform a complete functional verification of the device whenever any of the following conditions

exist:

• The device has been dropped or otherwise damaged

• The device is malfunctioning

• The case has been opened

• A part has been replaced

For details on performing the functional verification, see the section on functional verification.

Maintenance

For device maintenance information, see “Maintenance and service” in the device’s directions for

use. Covered topics include the following:

• Replacing the printer paper

• Inspecting and cleaning the device and accessories

• Changing the battery

Annually Functional verification

The Welch Allyn Service Tool

The Welch Allyn Service Tool is available in the following editions:

• Silver: Accompanies your device.

Page 14

10

Overview Welch Allyn Connex® Vital Signs Monitor 6000 Series™

• Gold: Required to perform complete functional verification and calibration. This edition

requires an additional license. For more information about acquiring this license, contact

Welch Allyn.

Note To qualify for the Gold license, you must attend the Welch Allyn

technical training course or complete online training for the device.

Clinicians and technical service personnel can use the service tool to manage and maintain

supported Welch Allyn products. You can use the service tool to do the following:

• Review device information. When connected to the device, the service tool lists installed

modules, installed firmware and hardware versions, warranty and repair information, status,

and usage history.

• Receive notifications when periodic maintenance is needed. The service tool can

help you manage and maintain your entire inventory of supported Welch Allyn products.

Through the remote service function, the service tool can connect to Welch Allyn Customer

Service. With this functionality you can automatically receive firmware updates and feature

upgrades for your supported products, including software upgrades for the service tool.

• Install updates and upgrades. The service tool can read the firmware version for each

module and check for available updates or upgrades.

• Create a work list. The work list provides information about service actions—referred to as

work orders—that are waiting for you to perform on your maintained devices. Work orders

may include periodic calibrations, upgrades, or license installations.

• Schedule periodic maintenance. You can use the service tool to set the service interval

for each maintained device.

• View and save logs. You can download and save log files from the device for analysis to

help diagnose and identify reported issues.

• Create user accounts. Administrators can create user accounts and set permission levels

to control access to the features, allowing one group to perform administrative tasks and

another to perform service tasks. Restricting access prevents the service tool from being used

to make unauthorized changes on a connected device.

• Perform functional verification. You can use the service tool to test each component of

the system to ensure that its performance meets design specifications. Functional verification

is required to meet the periodic maintenance requirements. This feature is not supported for

all products and requires the service tool Gold edition for each supported product.

• Perform calibration verification. The service tool can check any system requiring

calibration and, if necessary, calibrate the device to match the design specifications.

Calibration verification is required to meet the periodic maintenance requirements. This

feature is not supported for all products and requires the service tool, Gold edition, for each

supported product.

• Recover devices. In the rare case where a device can no longer boot because of corrupted

firmware, the service tool can connect the device to Welch Allyn Technical Support to

reinstall the firmware.

• Extensible. The device accepts new plug-ins to support future Welch Allyn products.

Some of these features are enabled for any user (Silver edition). Others require special user

account privileges or a Welch Allyn service contract (Gold edition). If you require gold-level

support for a Welch Allyn product, please contact Welch Allyn technical support.

Page 15

Service manual Overview 11

Battery performance

About the battery

The device uses a rechargeable lithium ion smart battery. Internal circuitry enables the battery to

report its condition to the device. The device displays the battery status via the LED power

indicator, icons on the screen, and status messages appearing in the Device Status area of the

display. Battery information may be collected using the service tool.

New batteries are shipped from the manufacturer with a 30 percent charge to extend shelf life.

When installing a new battery in the device, you must plug the device into AC power to wake up

the battery. If the AC power is not applied to the device, the new battery will appear discharged.

The Device Status area displays a low-battery status message when 30 minutes of power remain

and again when 5 minutes remain.

You can expect new, fully charged batteries to have enough power for the following:

• Six-cell batteries provide approximately 26 patient exams.

• Nine-cell batteries provide approximately 47 patient exams.

Note A patient exam includes NIBP, temperature, and SpO2 measurements at the rate of

The number of exams per charge decrease with the battery age.

Depending on the age of the battery, a 6-cell battery takes 3 hours and a 9-cell battery takes 4

hours to fully charge at room temperature.

Both batteries have a lifetime of 300 charge cycles or more, where a charge cycle is equal to fully

charged to discharged to fully charged at room temperature.

Battery charging is provided by the device’s internal power supply.

For a complete list of battery specifications, see the device’s directions for use.

Best practices

The following practices help to extend the life of the battery and the device.

• Remove the battery when storing the device.

• Replace batteries that trigger a low battery status message when fully charged.

• Do not use damaged or leaking batteries.

• Store batteries with a 30 to 50 percent charge.

• Store batteries within the temperature range indicated for each period:

one patient every 10 minutes with a 2 minute display timeout setting with a new

battery, conducted at room temperature (72.5 °F ±4.5 °F; 22.5 °C ±2.5 °C).

WARNING Safety risk. When handling and storing Lithium batteries: Avoid

mechanical or electrical abuse. Batteries may explode or cause burns, if

disassembled, crushed or exposed to fire or high temperatures. Do not short or

install with incorrect polarity.

○

For storage less than 30 days: Maintain temperature at –4 °F and 122 °F (–20 °C and 50 °C).

○

For storage between 30 days and 90 days: Maintain temperature at –4 °F and 104 °F (–20

°C and 40 °C).

Page 16

12

Overview Welch Allyn Connex® Vital Signs Monitor 6000 Series™

○

For storage more than 90 days up to 2 years: Maintain temperature at –4 °F and 95 °F (–20

°C and 35 °C).

• Recycle batteries where ever possible. In the United States call 1-800-8-BATTERY for

information about recycling your Lithium Ion battery or go to the RBRC website at

www.rbrc.org for additional information.

• When recycling is not an option dispose of batteries in an environmentally safe manner

consistent with local regulations.

Factors affecting battery operating time

The following settings and conditions affect the battery operating time.

• The display brightness setting

• The display power-saver setting

• The device power-down setting

• Frequency and duration of alarms and alerts

• Amount of motion artifact during NIBP measurements

• Radio searching for an access point

Page 17

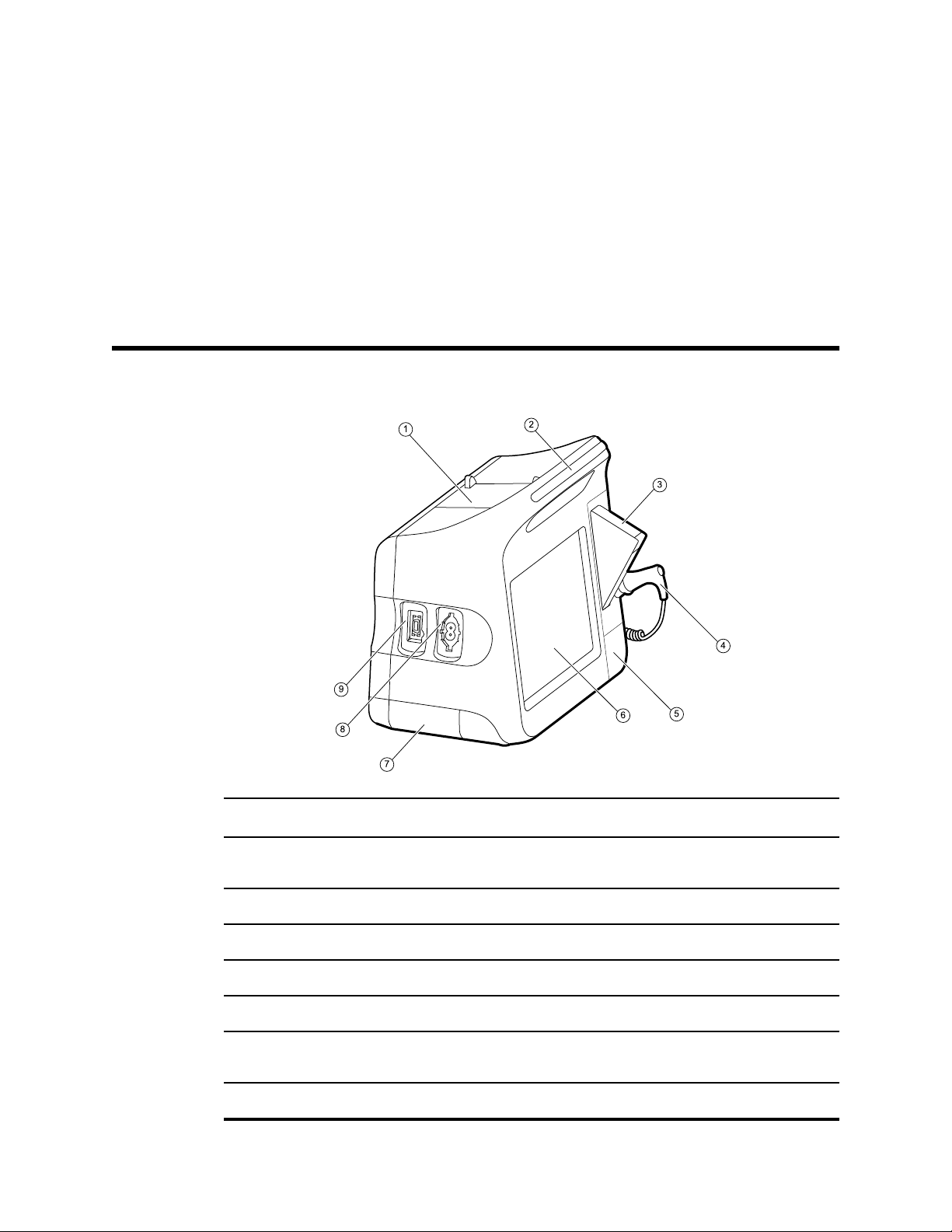

Controls, indicators, and connectors

Note Your model might not contain all of these features.

13

No. Feature Description

1 Printer Optional. Printer provides a printout of patient and device

information.

2 Light bar Provides a visual alarm with red and amber LEDs.

3 Thermometry Optional. Temperature probe cover box.

4 Thermometry Optional. Temperature probe.

5 Thermometry (connector behind cover) Secures the probe connection to the device.

6 LCD screen 1024 x 600 pixels color touchscreen provides a graphical

user interface.

7 Battery compartment (behind cover) Houses the Li-ion battery.

Page 18

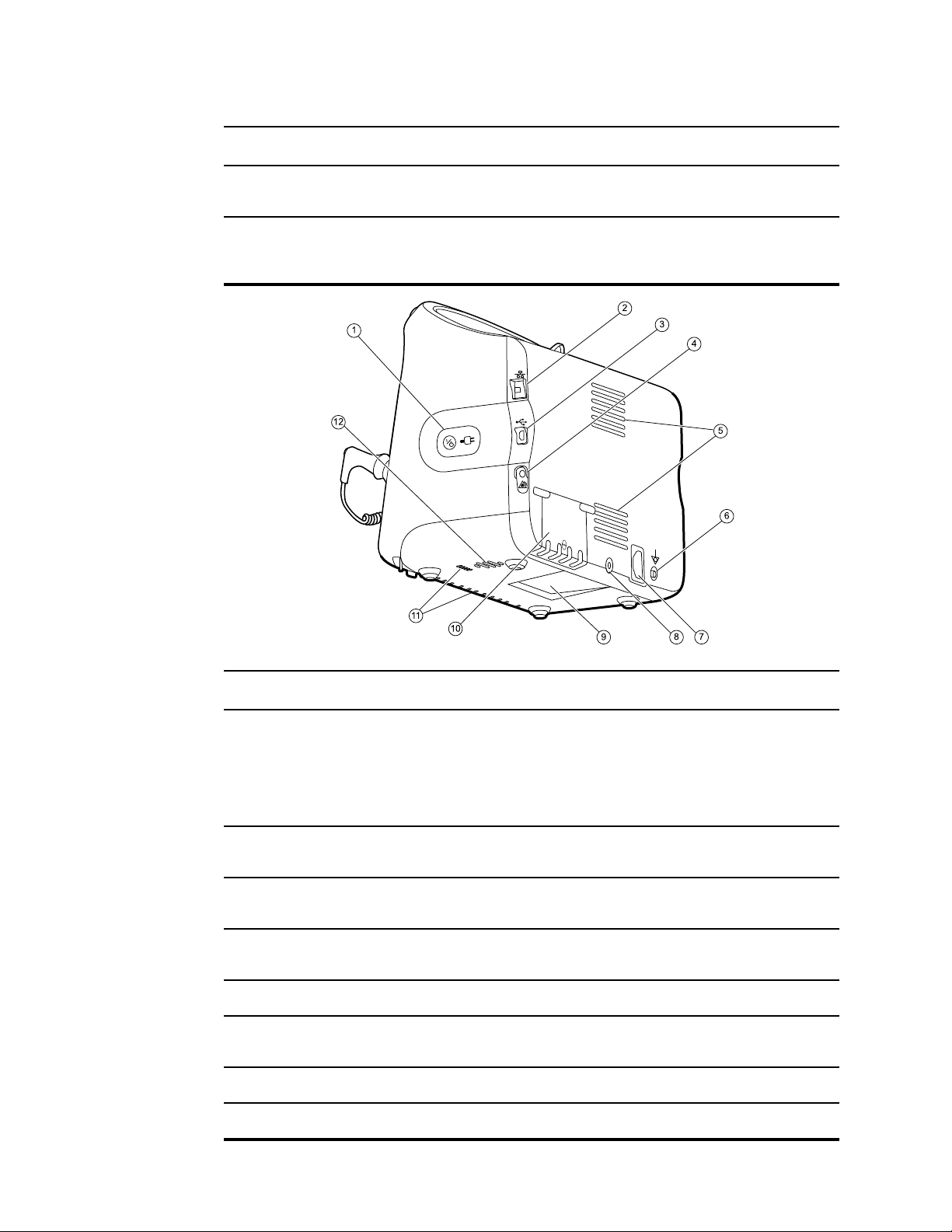

Controls, indicators, and connectors Welch Allyn Connex® Vital Signs Monitor 6000 Series™

14

No. Feature Description

8 Blood pressure Self-contained module for easy replacement. Supports

dual-lumen or single-lumen hoses.

9 Pulse oximetry Optional Nellcor (SpO2) or Masimo Rainbow SET (SpO2 or

combined SpO2/SpHb) in a self-contained module for easy

replacement.

No. Feature Description

1 Power switch and LED Power-on/Standby switch.

The LED indicates the charging status when connected to

AC power:

• Green: The battery is charged.

• Amber: The battery is charging.

2 Ethernet RJ45 Provides a hardwired connection to the computer

network.

3 USB client Provides a connection to an external computer for testing

and software upgrades.

4 Nurse call Optional. Provides a connection to the hospital nurse call

system. (Not available on the 6300 model.)

5 Fan exhaust

6 Ground lug (equipotential terminal) Provided for electrical safety testing and as a means for

connection of a potential equalization conductor.

7 Power connection Provides an external AC power connection.

8 Mobile stand mounting hardware Secures the mounting plate to the device.

Page 19

Service manual Controls, indicators, and connectors 15

No. Feature Description

9 Recess for mounting plate Secures the device when mounted on the mobile stand or

wall.

10 USB connector door Provides access to host USB connections for optional

accessories.

11 Fan intake

12 Speaker Provides tones. A piezo beeper inside the device provides

backup.

Page 20

Controls, indicators, and connectors Welch Allyn Connex® Vital Signs Monitor 6000 Series™

16

Page 21

Service menu

Access the Service screens

1. From the Home tab, touch the Settings tab.

2. Touch the Advanced tab.

3. Enter 6345 as the access code and touch OK.

4. Touch the Service tab.

17

5. Perform service tasks by making selections or touching other tabs.

6. When you are done, touch Exit.

General tab

The General screen appears.

Note Service tasks and how to do them are detailed in this section.

The Home tab appears.

Restore factory default settings

1. Go to the Service screens as described in “Access the Service screens.”

2. Touch the General tab.

Page 22

Service menu Welch Allyn Connex® Vital Signs Monitor 6000 Series™

18

3. Restore factory default settings:

• To restore radio settings to factory default values, touch Radio settings.

• To restore all current settings to factory default values, touch All settings.

A confirmation dialog appears and the device reboots.

4. Touch OK.

The factory default settings are restored.

Save the device configuration to a drive

You can save the device configuration to a USB flash drive. You can use the saved configuration to

restore this device’s configuration or to copy this device’s configuration to other devices.

Note Not all flash drives are supported.

1. Connect a flash drive to the USB port.

2. Go to the Service screens as described in “Access the Service screens.”

3. Touch the General tab.

4. Touch Save to USB.

A confirmation dialog displays.

5. Touch OK.

The device configuration is saved to the USB flash drive and the device reboots.

Load a monitor configuration

You can load a configuration from a USB flash drive to the monitor.

Note Not all flash drives are supported.

Note If your configuration includes radio parameters, make sure the radio is enabled. The

radio must be enabled before you can import radio parameters.

1. Connect a flash drive to the USB port.

2. Go to the Service screens as described in “Access the Service screens.”

3. Touch the General tab.

4. Touch Configure from USB.

A confirmation dialog displays.

5. Touch OK.

The configuration from the USB flash drive overwrites the configuration on the monitor.

Enter an asset tag

You can enter an alpha-numeric identifier in the data field to serve as an asset tag for device

identification.

1. Go to the Service screens as described in “Access the Service screens.”

2. Touch the General tab.

Page 23

Service manual Service menu 19

3. Touch and enter up to 20 characters.

4. Touch OK.

Note If the device language changes, the asset tag remains unchanged.

Self-tests tab

Perform a self-test

This tab calibrates the touchscreen, if needed.

1. Go to the Service screens as described in “Access the Service screens.”

2. Touch the Self-tests tab.

3. Touch Start.

a. Touch the location indicated by the device. The device checks the current calibration. If

the location coordinates and touched location match, a Calibration Confirmation dialog

displays. Touch OK to finish.

b. If the locations do not match, a calibration failure dialog displays. Touch Calibrate, and

then touch the screen as indicated. When calibration is complete, a Calibration

Confirmation dialog displays. Touch OK to finish.

Page 24

Service menu Welch Allyn Connex® Vital Signs Monitor 6000 Series™

20

Logs tab

View an error or event log

1. Go to the Service screens as described in “Access the Service screens.”

2. Touch the Logs tab.

3. View a log report.

• To view an error log, select Error.

• To view an event log, select Event.

Device tab

View device and module information

1. Go to the Service screens as described in “Access the Service screens.”

2. Touch the Device tab.

Page 25

Service manual Service menu 21

Device and module information appears for you to view.

Licensing tab

View device licenses

1. Go to the Service screens as described in “Access the Service screens.”

2. Touch the Licensing tab.

A list of available licenses appears. Checks indicate installed licenses.

Page 26

Service menu Welch Allyn Connex® Vital Signs Monitor 6000 Series™

22

Page 27

Power-up sequence

The system performs a power-on self test (POST) each time the device is powered on. During

power up, the system performs a comprehensive self test of the software. If software testing is

successful, the system then tests internal hardware. If all tests are successful, the system

completes power up and the Home screen appears.

To perform the POST:

1. Disconnect any patient cables connected to the system.

2. Insert a fully charged battery into the system.

3. Upon each power up, confirm the following:

a. The light bar flashes red then amber.

b. The Welch Allyn startup screen appears.

c. A beep sounds, followed by two chimes.

23

Note If no chimes sound, replace the speaker as specified in

“Remove the speaker.”

d. The product line logo appears at the bottom of the screen.

e. If a printer is installed, the paper advances slightly.

f. The Home screen appears.

WARNING Equipment failure risk. The system includes a fan that circulates air

through the device. If the fan does not run when you power up the device, remove it

from use and inform qualified service personnel immediately. Do not use the system

until the problem is corrected.

If the internal self-check is successful, the system shows its normal functions with all values blank

and the system is ready for operation. If the self-check fails, an error message appears in the

system status area at the top of the screen. If a fault that could adversely affect the product is

detected, the system enters a safe mode and stops monitoring patients. The system remains in

safe mode until it is turned off by pressing the Power button or until it shuts down automatically

after a period of inactivity.

If a system error is detected, the system becomes inactive until you press or until the system

shuts down automatically. The system displays a system fault message that contains a wrench

icon( ) and a system fault code to aid service and engineers in diagnosing the problem.

While in safe mode, the red LED bar and the piezo buzzer cycle on and off.

Page 28

Power-up sequence Welch Allyn Connex® Vital Signs Monitor 6000 Series™

24

Page 29

Troubleshooting

This section provides the following tables to help troubleshoot the device.

• Symptoms and solutions: These tables list symptoms you might observe, list possible

causes, and suggest actions that may eliminate the problem.

• Technical alarm messages: These tables list messages generated by the device software

when a problem is detected. The tables explain possible causes and suggest actions that can

resolve the problem.

25

These tables can help you diagnose and fix a problem. They do not replace basic troubleshooting

skills. You must still trace the source of the problem to the board or module level to decide the best

course of action. Welch Allyn does not support component-level repair to the board or module. For

available replacement parts, see “Field Replaceable Units.”

WARNING Do not perform troubleshooting on a device that is emitting smoke or

exhibits other signs of excessive overheating. Disconnect the device from AC

power and call Welch Allyn Technical Support immediately.

Caution Replace parts, components, or accessories only with parts supplied or

approved by Welch Allyn. The use of any other parts can lead to inferior device

performance and will void the product warranty.

Symptoms and solutions

Power

Symptom Possible cause Suggested action

The device does not power up A new battery was installed Connect AC power to wake up

the battery.

The AC power is disconnected Connect AC power.

The power cord is defective Replace the power cord.

The battery is discharged Charge the battery.

The power button is defective Replace the right side panel

and power button.

Page 30

Troubleshooting Welch Allyn Connex® Vital Signs Monitor 6000 Series™

26

Symptom Possible cause Suggested action

An internal connection is faulty Check the power-flex cable

connection at J6 on the main

board.

Check the AC power harness

connections from the IEC

connector to the power

supply.

Check the power harness

from the power supply J2 to

J30 on the main board.

Check the battery power

harness from J2 on the

battery connector board to

J29 on the main board.

The power supply is defective Check the output voltage on

the power supply. The voltage

should be 15 V ± 0.45V DC. If it

is not, replace the power

supply.

Display

The battery doesn’t charge or

run time is low

The battery is defective Charge the battery for 5 hours.

If the battery icon on the

display still shows an empty

battery symbol, replace the

battery.

The main board is defective Replace the main board.

The battery is defective Charge the battery for 5 hours.

If the battery icon on the

display still shows an empty

battery symbol, replace the

battery.

The battery connector board is defective Check the battery connector

board for an open short or

broken connector and replace

if necessary.

The battery has reached the end of its useful

life

Use the service tool to check

cycle count. If the cycle count

exceeds 300, replace the

battery.

Symptom Possible cause Suggested action

The touchscreen does not

respond

Software error Reboot the device. Press and

hold the power button until

the device shuts down.

Page 31

Service manual Troubleshooting 27

Symptom Possible cause Suggested action

Note

The touchscreen is out of calibration Recalibrate the screen. In

Advanced Settings, touch the

Any

configuration

settings not

saved as

default will

be lost. Press

the power

button to

restart.

Service tab and then touch

the Self Tests tab.

The touchscreen lock is activated Slide the lock bar to unlock.

Touch the Settings tab,

touch the Device tab, and

then touch Start. Uncheck

Allow display lock

timeout.

An internal connection is faulty Check the connection at J48

on the main board with

display flex cable.

A display flex cable is broken Replace the touchscreen and

display assembly.

The display is blank when the

power is on

The main board has a faulty touchscreen

controller

The device is in Power-Saver mode Wake the display by touching

The device powered down after a period of

inactivity

Replace the main board.

the screen or the Power

button.

Turn on the device by

pressing the Power button.

In Advanced Settings, touch

the General tab and then

touch the Display tab. Set

Device powers down

after to the desired interval.

An internal connection is faulty Check the display harness

A cable is damaged Replace the cable.

The LCD display is dim The brightness setting is too low Increase the brightness

connections at the display

and J19 on the main board.

Replace the cable if damaged.

setting. Touch the Settings

tab and then touch the

Device tab. Set Display

Page 32

Troubleshooting Welch Allyn Connex® Vital Signs Monitor 6000 Series™

28

Symptom Possible cause Suggested action

brightness to the desired

level.

User interface

Symptom Possible cause Suggested action

Unable to access advanced

settings or enter the advanced

settings code

Communication

Symptom Possible cause Suggested action

Cannot communicate through

the USB client connection

The LCD display has reached the end of its

useful life

Patient monitoring is active or being

simulated

The parameter alarm is on Dismiss the alarm.

Intervals are turned on

The communications board does not receive

power

Replace the LCD display.

Discontinue patient

monitoring or stop the

simulation.

Stop intervals.

Check the voltage from J49 on

the main board for +5.0, ±0.5V

DC. Replace the main board if

necessary.

USB accessories do not

communicate with the monitor

The USB client is defective Test the connection by

connecting a PC running the

service tool. Verify that the

service tool is configured

properly on the PC to

communicate with the device.

See the service tool help files.

Replace the power cable to

the communications board.

The accessory is defective Replace with a known good

accessory.

The communications board is not receiving

power

One or more USB host connections are

defective

Check the voltage from J49 on

the main board for +5.0, ±0.5V

DC. Replace the main board if

necessary.

Test the connection with a

USB thumb drive. If no power

or enumeration is present,

such as an LED on a thumb

drive, replace the

communications board.

Page 33

Service manual Troubleshooting 29

Symptom Possible cause Suggested action

The device does not

communicate via Ethernet with

the computer network

The radio does not connect to

the network

A USB connection from the communications

board to the main board is faulty

The device is not configured properly Check the settings with your

The communications board is not receiving

power

The Ethernet connection from the main

board is faulty

The device is out of range of the access

point

The device is not configured properly Check the settings with your

The antenna is defective Check the antenna cable and

Verify that the USB cables are

connected correctly.

Replace the USB cables.

network administrator.

Check the voltage from J49 on

the main board for +5.0, ±0.5V

DC. Replace the main board if

necessary.

Test the internal Ethernet

cable. Replace if necessary.

Check the network status

screen’s RSSI value.

network administrator.

antenna connection. Replace

the cable and antenna if

necessary.

Alarm

The communications board is not receiving

power

Check the voltage from J49 on

the main board for +5.0, ±0.5V

DC. Replace the main board if

necessary.

Symptom Possible cause Suggested action

The light bar does not turn on No alarm was triggered Verify that the light bar

flashes when the monitor

starts.

Verify that the alarm is

triggered by a visual indicator

in the message status area

and an audio alarm occurs.

There is a faulty connection Check the light-bar harness

and connections at the light

bar and J46 on the main

board. Replace the defective

cable if necessary.

The light-bar board is defective Apply +3.3V to pin 1 of the

harness and ground to pin 2.

Verify that the amber LEDs

illuminate. Connect the

ground to pin 3. Verify that the

Page 34

Troubleshooting Welch Allyn Connex® Vital Signs Monitor 6000 Series™

30

Symptom Possible cause Suggested action

red LEDs illuminate. If one or

both do not illuminate, replace

the LED light bar.

The main board is defective Verify that there are +3.3V at

pin 1 of J46 on the main board.

No audible alarm occurs No alarm was triggered Verify that the alarm is

triggered by visual indicator in

message status area, and

light bar. Listen for audible

sounds on start up.

The alarm audio is set to off

Touch the Alarms tab and

then touch the General tab.

Select Alarm Audio on.

In the Advanced menu, touch

the General tab and then

touch the Alarms tab.

Uncheck Allow user to

turn off general audio.

The alarm audio is set too low

Touch the Alarms tab and

then touch the General tab.

Set Volume to the desired

level.

In the Advanced menu, touch

the General tab and then

touch the Alarms tab. Set

Minimum alarm

volume to the desired level.

There is a faulty connection Check the speaker harness

and connections at the

speaker and J12 on the main

board. Replace the defective

cable if needed.

NIBP

The speaker is defective Replace the speaker.

The main board is defective Test speaker output using an

oscilloscope on J12.

Symptom Possible cause Suggested action

The NIBP frame on the display

is blank

The USB cable is defective Replace the USB cable.

The NIBP module is not connected Check the internal USB

connection.

The NIBP module is not functional Replace the NIBP module.

Page 35

Service manual Troubleshooting 31

Symptom Possible cause Suggested action

SpO2

SpHb

If no NIBP error is logged, the main board

may be defective

Check the error logs for NIBP

errors. Replace the main

board if necessary.

Symptom Possible cause Suggested action

The SpO2 frame on the display

is blank

The USB cable is defective Replace the USB cable.

The SpO2 module is not connected Check the internal USB

connection.

The SpO2 module is not functional Replace the SpO2 module.

If no SpO2 error is logged, the main board

may be defective

Check the error logs for SpO2

errors. Replace the main

board if necessary.

Symptom Possible cause Suggested action

The SpHb frame on the display

is blank

Weight scale

Symptom Possible cause Suggested action

Weight does not appear in

manual parameter frame.

The UI license is not installed Purchase a license and install

the license using the service

tool.

The Monitor profile is not selected Change the profile to Monitor.

The wrong sensor is connected Use a sensor that supports

the SpHb parameter.

The sensor and/or cable expired Replace sensor and/or cable.

The Masimo SpO2 module does not have the

SpHb parameter enabled

The weight was not selected in advanced

settings

Purchase the parameter and

install using the service tool.

Select weight in the

Advanced settings

(Settings> Advanced;

enter 6345 and touch

OK>Parameters>Manual.)

Note: You can select only

four manual parameters.

Page 36

32

Troubleshooting Welch Allyn Connex® Vital Signs Monitor 6000 Series™

Symptom Possible cause Suggested action

The weight scale is not licensed Purchase a license and install

the license using the service

tool.

The weight scale is not connected Check cables and

connections. Use the service

tool to test connectivity.

Replace cables.

The weight scale is not configured Consult the scale directions

for use.

Temperature

Symptom Possible cause Suggested action

The temperature frame on the

display is blank

The USB cable is defective Replace the USB cable.

The temperature module is not connected Check the internal USB

The temperature module is not functional Replace the temperature

If no temperature error is logged, the main

board may be defective

Braun ThermoScan PRO 4000 thermometer

Symptom Possible cause Suggested action

The thermometer batteries

don’t charge

The dock LED is green, but the

battery is low or depleted

The rechargeable battery pack no longer

takes a charge

Primary AA batteries are installed in the

thermometer

Primary AA batteries are installed in the

thermometer

connection.

module.

Check the error logs for

temperature errors. Replace

the main board if necessary.

Replace the rechargeable

battery pack.

Replace the batteries with a

rechargeable battery pack.

Replace the batteries with a

rechargeable battery pack.

The dock is defective Replace the dock.

Note For additional troubleshooting tips for the thermometer, see the manufacturer’s

product documentation.

Page 37

Service manual Troubleshooting 33

Manual parameters

Symptom Possible cause Suggested action

Printer

The manual parameter frame

does not appear on the Home

tab, or the Patients manual tab

is blank.

BMI is not displayed. The BMI parameter is not selected Select the BMI parameter

No manual parameters are selected in

Advanced settings

Height or weight was changed Adjusting the height or weight

Weight scale not connected BMI is available only from a

Select the desired manual

parameters in Advanced

settings (Settings>

Advanced; enter 6345 and

touch OK>Parameters>

Manual).

Note: You can select only

four manual parameters.

parameters in the advanced

settings.

clears BMI.

weight scale with height.

Symptom Possible cause Suggested action

The printer does not print The reactive side of the thermal paper does

not face the print head

Reverse the printer paper.

The thermal paper is wet Clean and dry the inside of the

printer housing and replace

the printer paper.

The USB cable is defective Replace the USB cable.

The printer module is not connected Check the internal USB and

power harness connection.

The printer does not have power Check J17 on the main board.

For more information, see

“Interconnect diagram.”

The printer module does not function Replace the printer module.

The power harness is defective Test the power harness.

Replace if necessary.

If no printer error is logged, the main board

may be defective

Check the error logs for

printer errors. Replace the

main board if necessary.

Page 38

34

Troubleshooting Welch Allyn Connex® Vital Signs Monitor 6000 Series™

Bar code reader

Symptom Possible cause Suggested action

Errors

The bar code reader powers on

but does not transfer data

No license is installed Purchase a license and

install the license using

the service tool.

The bar-code reader is not programmed to use

USB Com Port Emulation mode

Refer to the

manufacturer's

documentation to program

the bar code reader to

USB COM Port Emulation

mode.

Symptom Possible cause Suggested action

#000000001 An internal software error Power down and restart. If the

error persists, call Welch Allyn

#000000002 An unclassified hardware error

#000000003 Graphics RAM POST

#000000004 System RAM POST

#000000005 Watchdog POST

Technical Support for service.

#000000006 FLASH initiation failed

#000000007 A display system error

#000000008 A real-time clock error

#000000009 An audio system error

#000000010 An Ethernet system error

#000000011 The touchscreen controller failed

#000000012 Five or more SMBUS errors over a 1-minute period

occurred

#000000013 The communications module or main board failed

#000000014 Main board USB hub failure

Technical alarm messages

This section presents tables of technical alarm and information messages to help you troubleshoot

issues on the device. For information about physiological, dialog, or informational messages, see

the device’s directions for use.

Page 39

Service manual Troubleshooting 35

When the device detects certain events, a message appears in the Device Status area at the top of

the screen. Message types include the following:

• Information messages appear on a blue background.

• Low- or medium-priority alarms appear on an amber background.

• High-priority alarms appear on a red background.

Technical alarm messages are low priority unless noted in the Message column.

You can dismiss a message by touching the message on the screen, or, for some messages, you

can wait for the message to time out.

To use these tables, locate the message that displays on the device in the left column of the table.

The remainder of the row explains possible causes and suggests actions that can resolve the

issue.

If you cannot resolve the issue, use the service tool to read the error log files or use the service

tool to perform a functional test1 on the module reporting the message.

NIBP messages

Message Possible cause Suggested action

Alarm

NIBP air leak; check cuff and

tubing connections.

NIBP not functional. Call for

service.

Unable to determine NIBP;

check connections; limit patient

movement.

Unable to determine NIBP;

check connections and tubing.

The NIBP module has an air leak Check the cuff and tubing

connections.

If no external leaks are found,

replace the NIBP module.

A calibration error occurred Review the error log to

determine the specific error.

Calibrate the NIBP system

using the service tool.

Internal errors or messaging errors occurred Review the error log.

The ambient temperature is out of range Use the monitor in the

specified temperature range.

Pressure exceeded the maximum limit for

this patient mode

The NIBP tubing has a kink Check the connections and

Check connections; limit

patient movement.

Clear the alarm and retry

NIBP.

tubing for kinks.

Clear the alarm and retry

NIBP.

Incorrect NIBP cuff size; check

patient type.

1

Requires the service tool, Gold edition.

A neonate cuff is in use with the monitor in

adult or pediatric mode

Check the patient type.

Clear the alarm and retry

NIBP.

Page 40

Troubleshooting Welch Allyn Connex® Vital Signs Monitor 6000 Series™

36

Message Possible cause Suggested action

Inflation too quick; check NIBP

cuff and tubing connections.

Unable to determine NIBP;

check inflation settings.

Information

User cancelled NIBP reading. Blood pressure reading cancelled by user

Tube type does not match

device configuration.

(NIBP measurement is

available)

NIBP inflation was too quick Check the connections and

Target pressure was too low Check inflation settings and

Too many attempts Change the inflation setting.

The tube type connected to the monitor does

not match the NIBP configuration.

tubing for kinks.

Clear the alarm and retry

NIBP.

change as necessary.

Clear the alarm and retry

NIBP.

Change the inflation setting.

Touch OK to dismiss.

Touch NIBP Start button to

dismiss and restart the NIBP

reading.

Touch OK to dismiss.

Configure the NIBP advanced

settings to match the tube

type, patient type, and

algorithm.

Excessive patient movement The NIBP reading was deemed not precise

SpO2 and SpHb messages

Message Possible cause Suggested action

Alarm

SpO2 not functional. Call for

service.

The single lumen switch on the NIBP

connection is stuck

A sensor is defective Replace the SpO2 sensor with

An internal error occurred Update host software to

Use a small screw driver to

press the switch in and

release until the spring

returns the switch to the duallumen position.

Touch OK to dismiss.

Limit patient movement and

restart the NIBP

measurement.

a known good sensor.

1.50.02 or later

Review the error log. Replace

the SpO2 module if necessary.

Page 41

Service manual Troubleshooting 37

Message Possible cause Suggested action

Attach SpO2 sensor to monitor. The sensor was not detected Check the sensor connection.

Replace the sensor.

Replace the SpO2 sensor. The SpO2 sensor is faulty or expired Replace the SpO2 sensor.

No SpO2 sensor is connected Connect the SpO2 sensor.

The cable is faulty or expired Replace the cable.

Searching for pulse signal.

(High-priority alarm)

Low SpO2 signal quality. Check

sensor.

Low SpHb signal quality. Check

sensor.

Low perfusion. Check sensor. Poor sensor placement on the patient Remove the sensor from the

SpO2 mode only. Check sensor

or cable.

SpO2 sensor expires in... The SpO2 sensor will expire soon Replace the SpO2 sensor.

The SpO2 sensor is not attached to the

patient’s finger

Poor sensor placement on the patient. Remove the sensor from the

Poor sensor placement on the patient Remove the sensor from the

The sensor is operating as an SpO2-only

sensor because it failed to calibrate properly

Touch the alarm icon or the

SpO2 frame to dismiss the

alarm.

Set the SpO2 Alarm limits to

off.

Reattach the SpO2 sensor to

the patients finger.

patient and reapply.

patient and reapply.

patient and reapply.

Reattach the cable to the

monitor.

Remove the sensor from the

patient and reapply.

Replace the SpO2 cable. The SpO2 cable is not functioning properly

or is expired

Expired sensor. The sensor is expired Replace the sensor.

Expired cable. The cable is expired Replace the cable.

Information

Excessive patient movement. The SpO2 reading was deemed not precise

Replace the SpO2 cable.

Touch OK to dismiss.

Limit patient movement and

continue the SpO2

measurement.

Page 42

Troubleshooting Welch Allyn Connex® Vital Signs Monitor 6000 Series™

38

Temperature messages

Message Possible cause Suggested action

Alarm

Connect temperature probe. No probe is connected Connect a temperature probe

and retry.

The probe is faulty Replace the temperature

probe.

The temperature module returned a connect

probe message

Insert correct color-coded

probe well.

Replace temperature probe. The probe is faulty Replace the temperature

Temperature not functional. Call

for service.

Retry temperature

measurement.

Note

This message

often

accompanies

other

temperature

messages.

The probe well is missing Insert a temperature probe

An internal error occurred Review the error log.

The USB cable is disconnected Check the USB cable.

The battery is depleted or missing (Braun

ThermoScan PRO 4000 thermometer only)

A probe heater or data error occurred Retry the temperature

User settings require adjustment Adjust the user settings and

Connect a temperature probe

and try again. If a probe is

already connected, replace

the probe. If the problem

persists, replace the

temperature module

well.

probe.

Replace the temperature

module.

Replace the batteries.

measurement. If the problem

persists, replace the probe.

retry.

Temperature time limit

exceeded.

Information

Tissue contact lost. Lost tissue contact while attempting to

The direct mode timed out Return the temperature probe

acquire temperature reading or acquired

reading was performed with limited tissue

contact

to the probe well and retry

measurement.

Touch OK to dismiss the

message. Start a new

temperature reading.

Page 43

Service manual Troubleshooting 39

Weight scale messages

Message Possible cause Suggested action

Weight scale not functional.

Call for service.

Printer messages

Message Possible cause Suggested action

Alarm

Low battery; plug into outlet. The monitor’s battery voltage is too low to

Printer door is open; close to

continue

Out of paper. The paper is not properly loaded Align the paper with the print

The weight scale is not operating properly Check the scale.

Use the service tool to check

connectivity with adapter.

Replace cables.

Replace adapter.

Connect the monitor to AC

support printing

The printer door is open Close the printer door.

power to recharge the

battery.

head.

The paper sensor does not detect paper Replace the paper.

Check the paper sensor.

Printer too hot; wait to retry

printing.

Printer not functional. Call for

service.

Information

Printing records. Printing records Allows the user to cancel

The print head overheated Wait for the print head to cool

down.

The printer motor is broken Replace the printer.

The detection switch malfunctioned Replace the printer.

A hardware failure occurred in the power

supply

The printer does not identify itself correctly Check the jumper setting at J8

The printer does not enumerate Replace the printer.

The printer door is ajar Close the printer door.

Check printer voltage.

on the printer board. Replace

the printer if necessary.

printing if desired.

Page 44

Troubleshooting Welch Allyn Connex® Vital Signs Monitor 6000 Series™

40

Message Possible cause Suggested action

Note

Printing report; please wait.

The number of

records

requested

appears in the

message and

counts down

during printing.

The Automatic print on interval

control is enabled

Communications module messages

Message Possible cause Suggested action

Communications module did not

power on properly. Power down

the device. (High-priority alarm)

The communications board is not connected

properly to the main board

Wait for printing to complete.

Change the interval

configuration to disable

Automatic print on

interval.

Check the USB connection at

J4. Check the Power

connection at J50. Check the

voltage from J49 on the main

board for +5.0 ±0.5V DC.

Replace the main board if

necessary.

Radio messages

Message Possible cause Suggested action

Alarm

Radio not functional. Call for

service.

Radio error. Power down and

restart.

The communications board malfunctioned Replace the communications

board.

A hardware failure occurred Replace the radio.

The radio has the wrong software Update the radio software.

The monitor and the radio failed to establish

communication with each other

Power down and restart the

monitor.

If the problem persists, check

the following:

• The USB and power

connections from the

main board to the

communications board.

• The connection from the

radio board to the

communications board.

Page 45

Service manual Troubleshooting 41

Message Possible cause Suggested action

• Monitor and radio

software compatibility.

Replace the radio if

necessary.

Unable to establish network

communications. Radio out of

network range.

Unable to establish network

communications. Call for

service.

Radio Software upgrade failed. The connection with the host was broken Re-establish the connection

Information

Radio software upgrade in

progress. Do not shut down.

Radio card rebooting; please

wait.

The radio is no longer communicating with

the access point

Unable to get an IP address from the DHCP

server

The radio was not provisioned correctly Reset radio to factory defaults

Hardware error Replace the radio.

Radio software is being written to radio Do not interrupt the upgrade

The radio is restarting as part of the

software upgrade

Verify that the monitor is

within the radio coverage

area. Verify that the radio is

correctly configured to the

network. If this message

appears intermittently, check

the RSSI value.

Verify that a DHCP sever is

available on the network. The

monitor requires an IP

address from a DHCP server.

and try again.